Collagen-based dura and preparation method thereof

A dura mater and collagen technology, applied in the field of collagen-based dura mater and its preparation, can solve the problems of difficult practical application requirements of dura mater substitutes, loss of collagen biological activity, unfriendly production process, etc., to achieve easy formation of large-scale industries Chain, sufficient source, low price effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

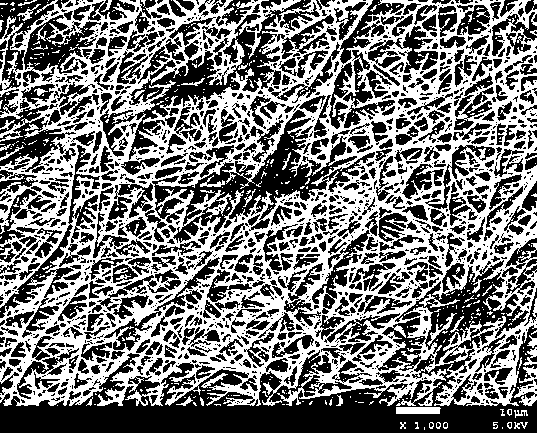

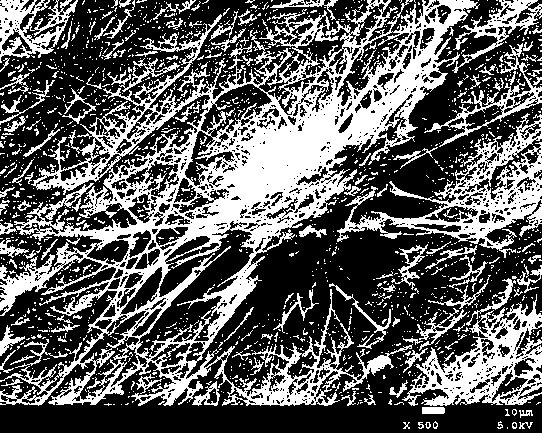

[0044] (1) Preparation of collagen homogeneous electrospinning solution: firstly, NaH2PO4 with a mass fraction of 0.1%wt was dissolved in 1-allyl-3-methylimidazolium benzoate ([BMIM][Ac] ), to obtain the ionic liquid composite solvent system, gradually dissolve bovine hide type I collagen in the ionic liquid composite solvent system at 4°C, initially add 1% of the mass percentage of the ionic liquid composite solvent system, and then add bovine hide Type I collagen, until the mass percentage of cowhide type I collagen in the ionic liquid composite solvent system is 5%, ultrasonic defoaming at 25°C until completely free of bubbles;

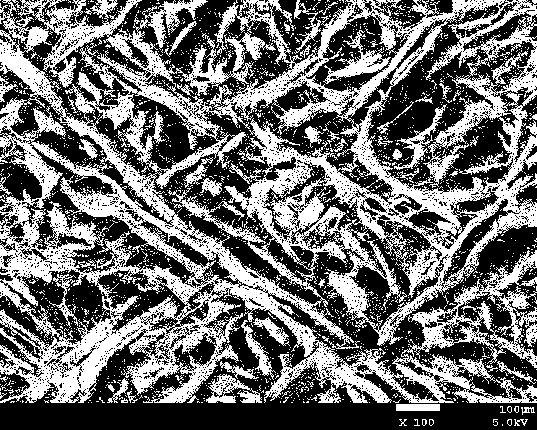

[0045] (2) Preparation of conductive decellularized porcine dermis substrate: split fresh ecological pigskin into thin slices with a thickness of 0.5-1.0 mm, and ultrasonically treat them with peracetic acid with a mass concentration of 3.0% for 1 h to inactivate the virus. Immediately afterwards, 50,000 units of trypsin with an activity mass conce...

Embodiment 2

[0051] (1) Preparation of collagen homogeneous electrospinning solution: first, dissolve NaHSO4 with a mass fraction of 0.5%wt in 1-ethyl-3-methylimidazolium glycinate ([EMIM][Gly]) at room temperature 25°C to obtain Ionic liquid composite solvent system, gradually dissolve pigskin type I collagen in the ionic liquid composite solvent system at 10°C, initially add 3% of the mass percentage of the ionic liquid composite solvent system, and then add pigskin I in turn after it is fully dissolved Collagen type I, until the mass percentage content of pigskin type I collagen in the ionic liquid composite solvent system is 10%, ultrasonic defoaming at 25°C until completely free of bubbles;

[0052] (2) Preparation of conductive decellularized porcine dermis substrate: the decellularized porcine dermis used was obtained in Example 1, and the composition was 0.9%wt sodium chloride (NaCl), 0.01Mol / L phosphate buffer solution ( PBS), the volume ratio NaCl: PBS is 5:5 electrolyte buffer...

Embodiment 3

[0058] (1) Preparation of collagen homogeneous electrospinning solution: firstly, NaHCO3 with a mass fraction of 1%wt was dissolved in 1-allyl-3-methylimidazole benzoate ([Amim][Ba] ), to obtain the ionic liquid composite solvent system, gradually dissolve bovine Achilles tendon type I collagen in the ionic liquid composite solvent system at 20°C, initially add 5% of the mass percentage of the ionic liquid composite solvent system, and then sequentially Add bovine Achilles tendon type I collagen until the mass percentage of bovine Achilles tendon type I collagen in the ionic liquid composite solvent system is 15%, and stand at 25°C for defoaming until completely free of bubbles;

[0059] (2) Preparation of conductive decellularized porcine dermis substrate: the decellularized porcine dermis used was obtained from Example 1, and the composition was 0.9%wt sodium chloride (NaCl), 0.01Mol / L phosphate buffer solution ( PBS), the volume ratio of NaCl: PBS is 9:1 electrolyte buffer ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Aperture | aaaaa | aaaaa |

| Aperture | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com