Semi-solid composite connecting forming process for preparing compound structures parts

A semi-solid forming and composite structure technology, applied in the field of advanced connection, can solve the problems of long processing route and high production cost, and achieve the effect of reducing energy consumption, improving product quality and expanding application fields

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

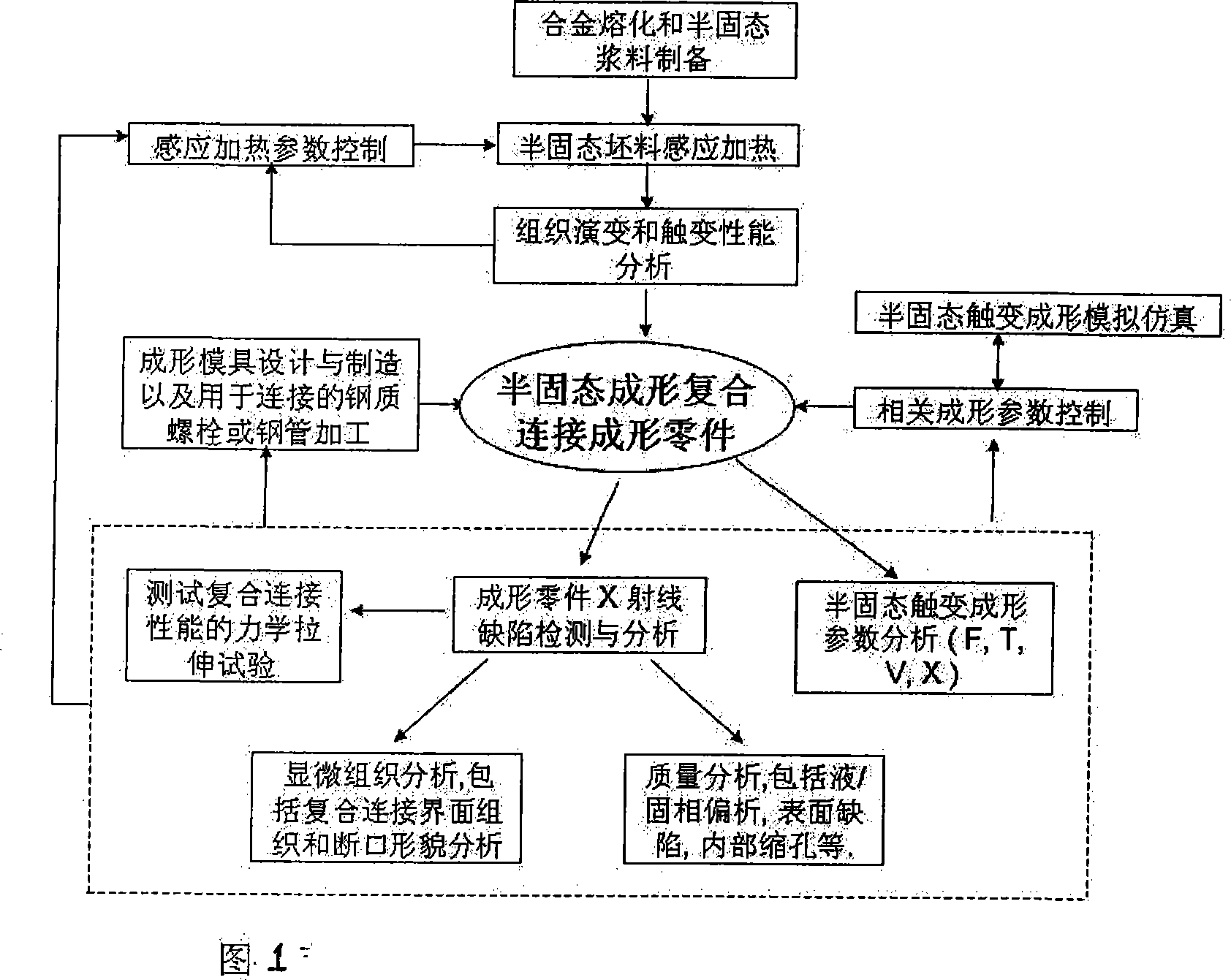

Method used

Image

Examples

Embodiment 1

[0026] Example 1: A semi-solid thixotropic forging-extrusion forming method was used to prepare composite structural parts connected by A356 aluminum alloy and steel bolts.

[0027] From Duralcan company (Duralcan company) purchase diameter is the A356 aluminum alloy rod stock that φ 76mm has semi-solid structure characteristic. After distance cutting, the billet is firstly heated rapidly and uniformly to the semi-solid temperature: 580°C with an induction heating furnace. Design the die for semi-solid thixotropic forging and extrusion forming A356 aluminum alloy parent parts, and process the position for placing steel connecting bolts in the die of the die. Process the functional parts for connection---steel connection bolts, and place them in the mold before semi-solid forming. The heated semi-solid billet is quickly put into the concave mold of the forming mold with a clamp (the mold preheating temperature is set to 200° C.). The forming speed of the press is adjusted to ...

Embodiment 2

[0028] Example 2: A composite structural part connected by MMC material (SiC particle reinforced A356 aluminum alloy) and steel bolts was prepared using a semi-solid thixotropic forging extrusion method.

[0029] The MMC material (SiC particle reinforced A356 aluminum alloy composite material) with a diameter of φ76 mm and semi-solid structure characteristics was purchased from Duralcan company (Duralcan company). After distance cutting, the billet is firstly heated rapidly and evenly to the semi-solid temperature: 578°C with an induction heating furnace. Design the mold for semi-solid thixotropic forging and extrusion forming MMC material matrix parts, and process the position for placing steel connecting bolts in the die of the mold. Process the functional parts for connection---steel connection bolts, and place them in the mold before semi-solid forming. The heated semi-solid billet is quickly put into the concave mold of the forming mold with a clamp (the mold preheating ...

Embodiment 3

[0030] Example 3: A semi-solid thixotropic forging and extrusion forming method was used to prepare a composite structural part in which an AZ91 magnesium alloy and a steel pipe were connected.

[0031] From Duralcan company (Duralcan company) purchase diameter is the AZ91 magnesium alloy bar stock that φ 76mm has semi-solid structure characteristic. After distance cutting, the billet is firstly heated quickly and uniformly to the semi-solid temperature: 583°C with an induction heating furnace, and argon is used as a protective gas during the heating process. Design the mold for semi-solid thixotropic forging and extrusion forming AZ91 magnesium alloy parent parts, and process the position for connecting steel pipes in the die of the mold. The functional part for connection - steel pipe is processed and placed in the mold before semi-solid forming. The heated semi-solid billet is quickly put into the concave mold of the forming mold with a clamp (the mold preheating temperatu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com