Starch-base tableware and manufacturing method thereof

A technology for basic meals and starch, applied in the directions of table utensils, home utensils, applications, etc., can solve the problems of not revealing the starch modification method, unable to achieve starch plasticization, unable to achieve biodegradation, etc., to avoid product surface pollution, inhibit Evaporation and hydrolysis of H2O and the effect of overcoming the regeneration phenomenon

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

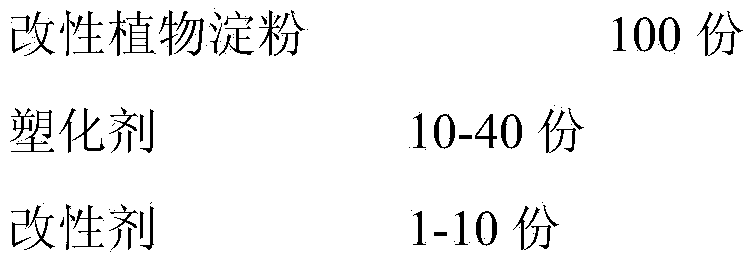

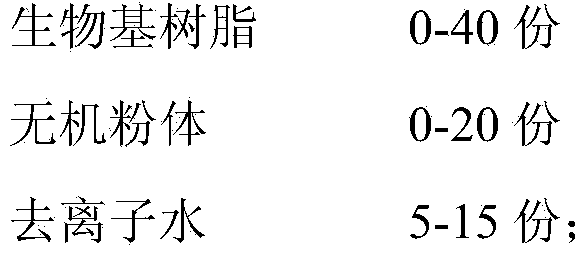

[0036] A starch-based tableware, comprising the following raw materials in parts by weight:

[0037]

[0038] Among them: the modified vegetable starch is obtained by grinding corn starch into 300 meshes, then adding 5 parts of surfactant and mixing, the mixing temperature is 20°C, and the mixing time is 8 minutes. The surfactant is JL produced by Nanjing Jinlaiwang Plastic Technology Co., Ltd. -G.

[0039] The preparation method of the starch-based tableware is as follows: mixing modified vegetable starch, plasticizer, deionized water, modifier and inorganic powder, and then adding bio-based resin to mix and mix, the mixing temperature is 60°C, and the time is for 20 minutes, and then cooled to 40°C to release the 24-hour wake-up material in a natural state, and then granulate through a reciprocating single-screw.

[0040] in:

[0041] The raw material of plasticizer and preparation method thereof are:

[0042]

[0043] Put the above-mentioned raw materials into the ...

Embodiment 2

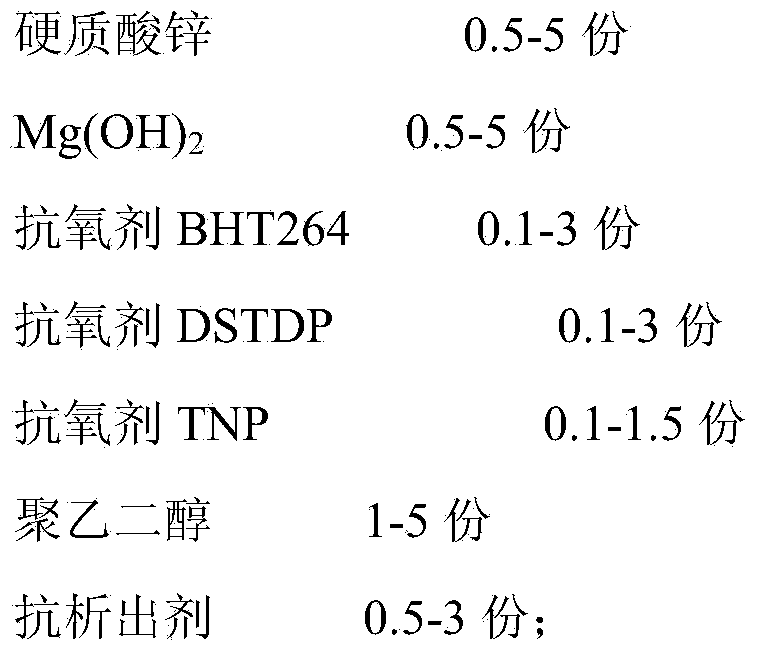

[0052] A starch-based tableware, comprising the following raw materials in parts by weight:

[0053]

[0054]

[0055] Among them: the modified vegetable starch is obtained by grinding corn starch into 500 mesh, then adding 5 parts of surfactant and mixing, the mixing temperature is 90°C, and the mixing time is 5 minutes. The surfactant is JL produced by Nanjing Jinlaiwang Plastic Technology Co., Ltd. -G FX -P.

[0056] The preparation method of the starch-based tableware is as follows: mixing modified plant starch, plasticizer, deionized water, modifier and inorganic powder, and then adding bio-based resin to mix and mix, the mixing temperature is 90°C, and the time is 10 minutes, and then by cooling to room temperature, release the 48-hour wake-up material in the natural state, and then granulate through a reciprocating single-screw.

[0057] in:

[0058] The raw material of plasticizer and preparation method thereof are:

[0059]

[0060] Put the above-mentioned...

Embodiment 3

[0069] A starch-based tableware, comprising the following raw materials in parts by weight:

[0070]

[0071] Among them: modified vegetable starch is obtained by grinding corn starch into 400 meshes, then adding 4 parts of surfactant and mixing, the mixing temperature is 0°C, and the mixing time is 10 minutes. The surfactant is JL produced by Nanjing Jinlaiwang Plastic Technology Co., Ltd. -GO2F.

[0072] The preparation method of the starch-based tableware is as follows: mixing modified vegetable starch, plasticizer, deionized water, modifier and inorganic powder, and then adding bio-based resin to mix and mix, the mixing temperature is 60°C, and the time is for 20 minutes, and then cooled to 40°C to release the 24-hour wake-up material in a natural state, and then granulate through a reciprocating single-screw.

[0073] The raw material of plasticizer and preparation method thereof are:

[0074] Glycerol 50 parts

[0075] Diethylene glycol butyl ether acetate 50 parts...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com