Overflow dyeing machine

An overflow dyeing machine and dyeing tank technology, which is applied in the field of overflow dyeing machines, can solve the problems of uneven fabric coloring, unbalanced main pump liquid supply, and unstable speed, so as to prevent fabric surface pollution, prevent nozzle clogging, The effect of improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

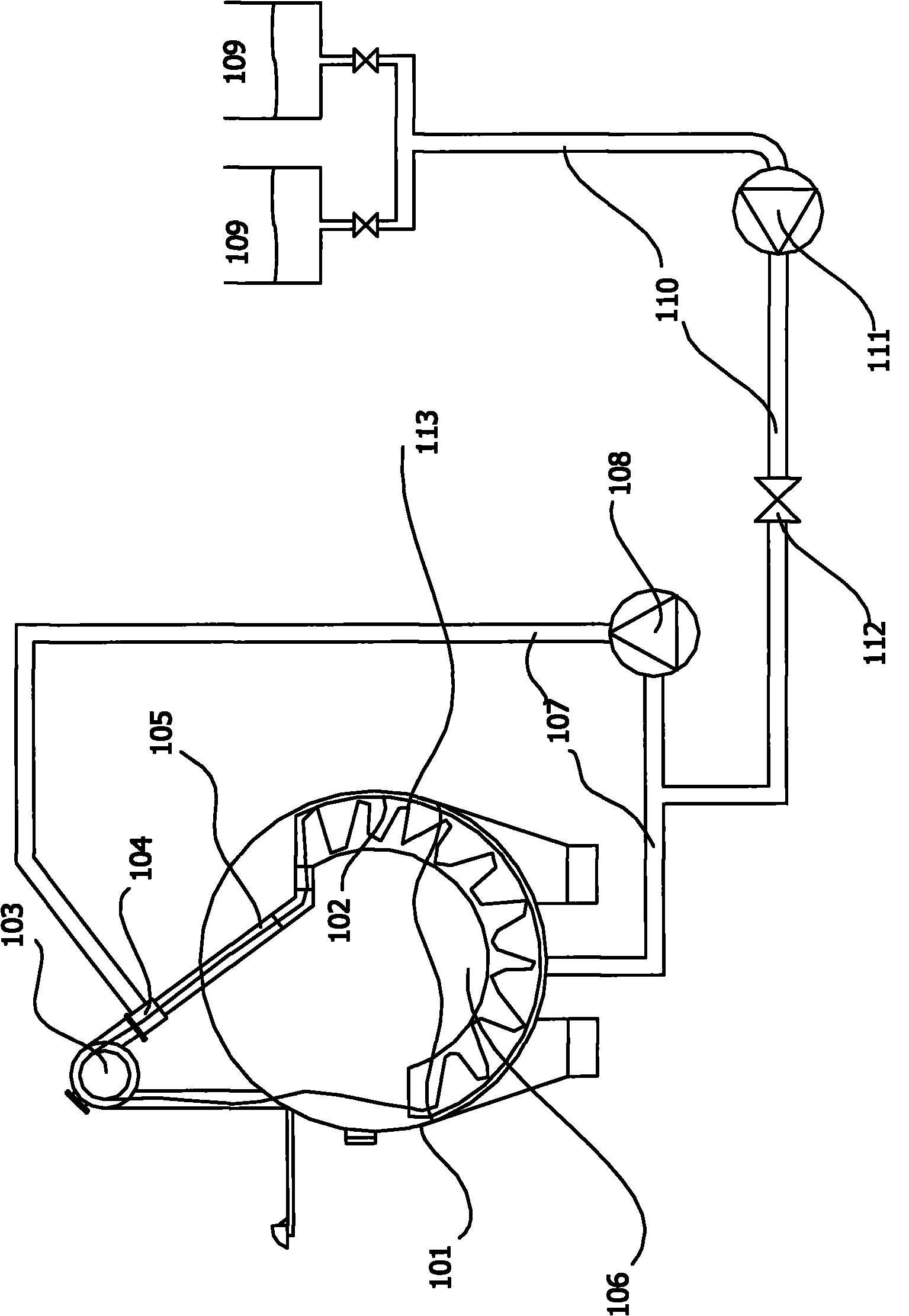

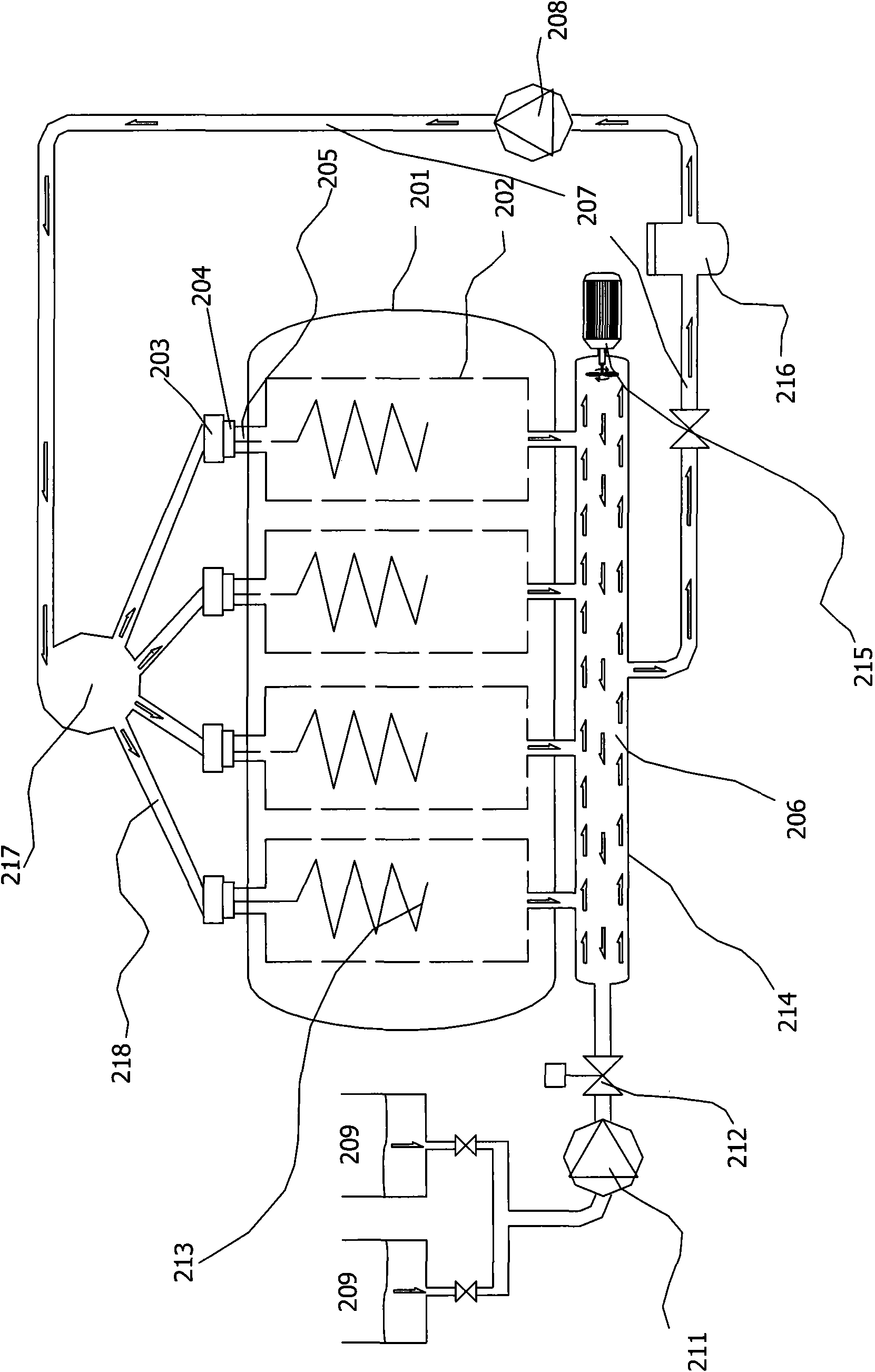

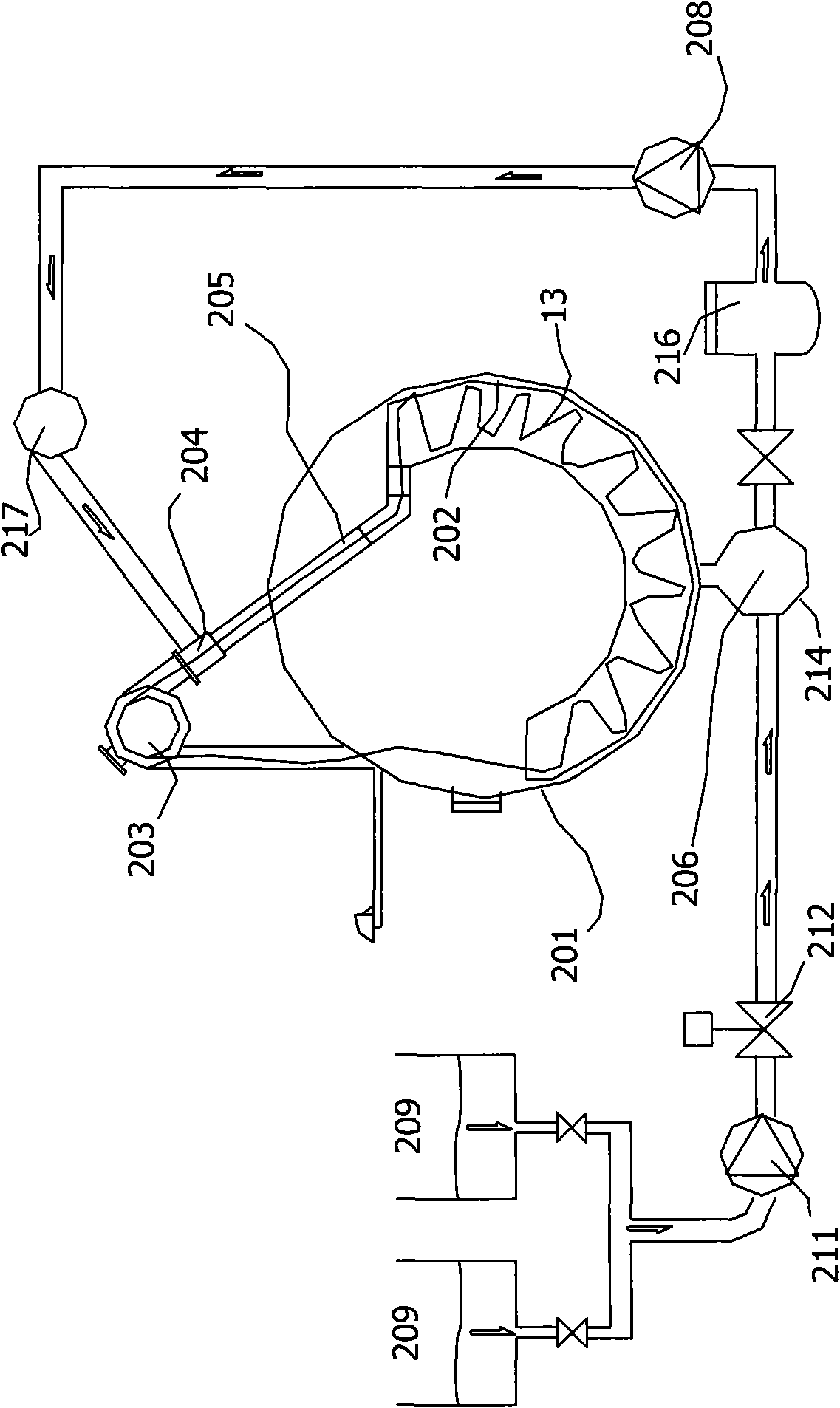

[0020] figure 2 It is a schematic diagram of the overall structure of the overflow dyeing machine of the present invention, image 3 for the invention figure 2 Schematic diagram of the lateral structure. Such as figure 2 and combine image 3 As shown, a kind of overflow dyeing machine provided by the present invention includes a main body 201, a dyeing tank 202 is arranged inside the main body 201, a cloth lifting wheel 203 is arranged outside the main body 201, and a nozzle 204 is arranged above the main body 201, The outlet of the dye tank 202 is connected with the inlet of the nozzle 204 through a circulation pipe 207; the outlet of the chemical material tank 209 is connected with the circulation pipe 207; on the circulation pipe 207, a liquid storage tank 214 is also provided, and the liquid storage tank 214 communicates with the dyeing tank 202, the outlet of the liquid storage tank 214 and the circulation pipeline 207 of the inlet of the nozzle 204 are connected w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com