Rectangular glass substrate and method for preparing the same

一种玻璃基板、制造方法的技术,应用在制造工具、半导体/固态器件制造、适用于磨削工件边缘的机床等方向,能够解决缺损、配线短路等问题,达到抑制制造成品率的降低、抑制表面污染的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

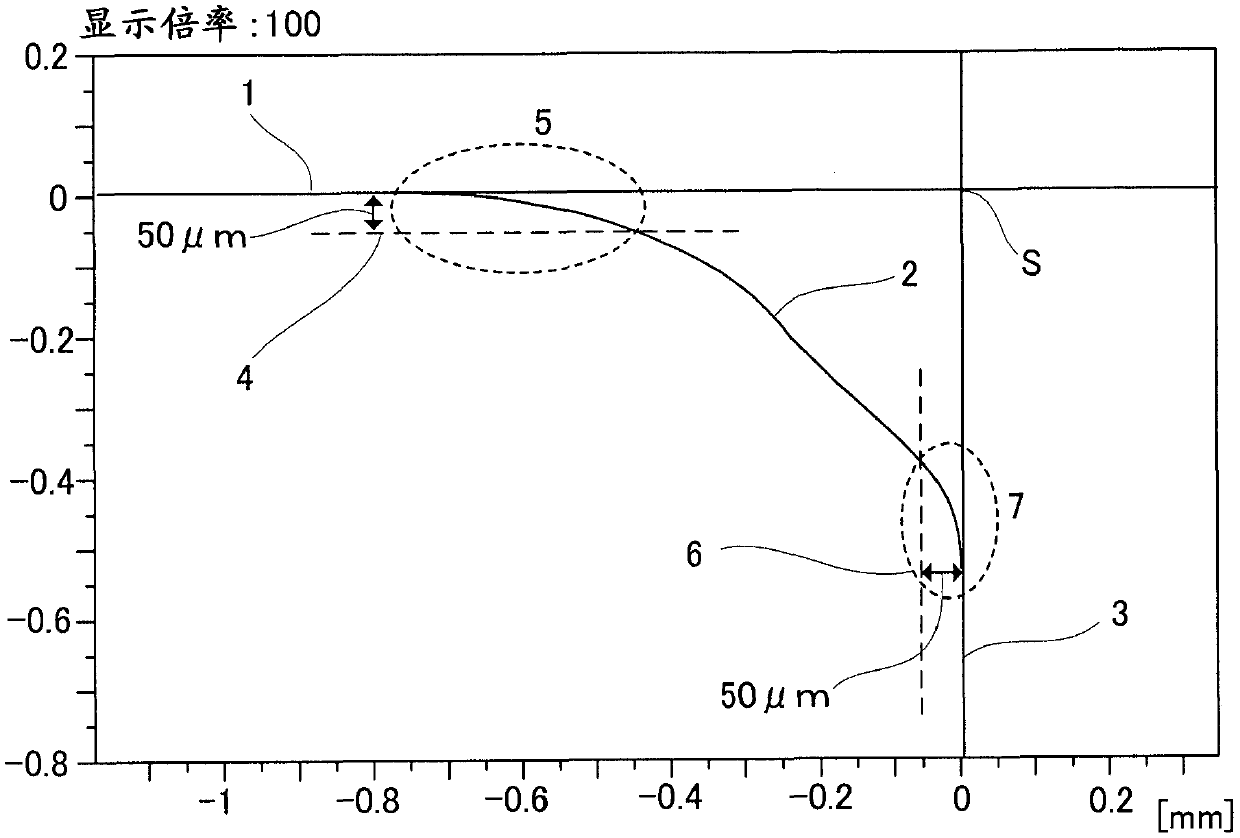

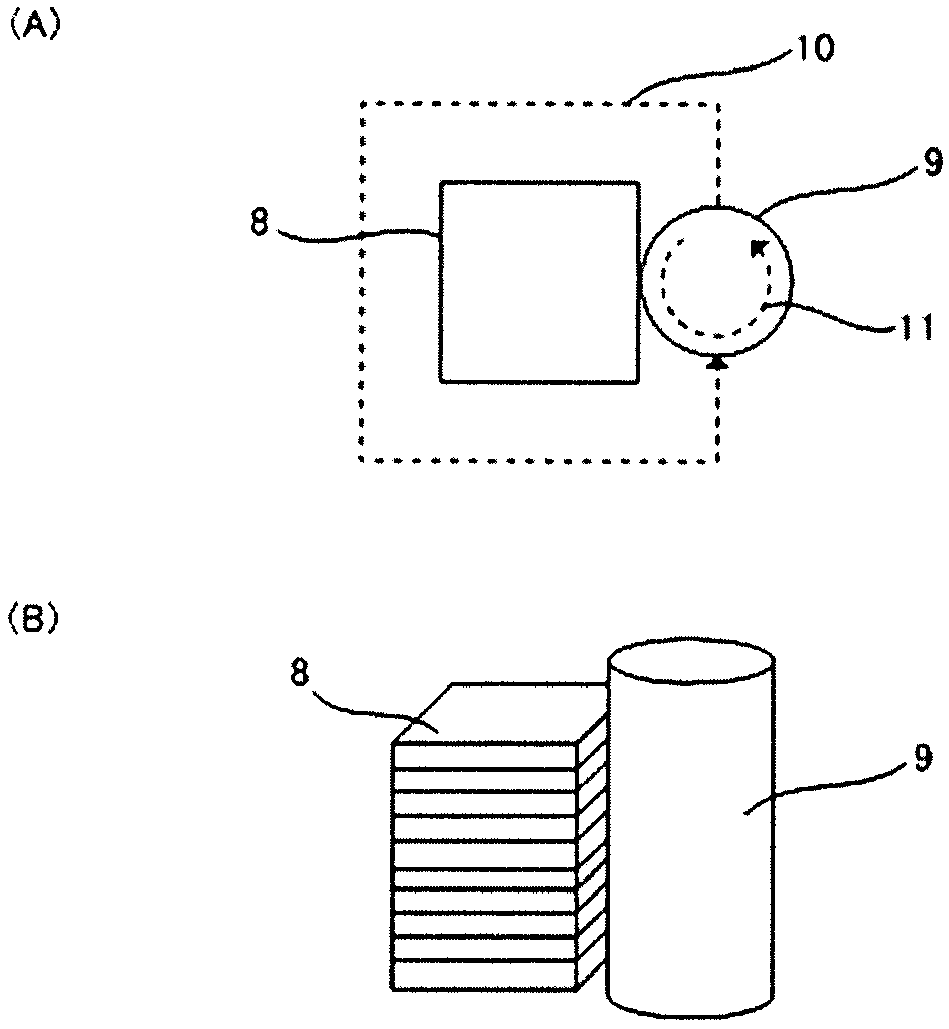

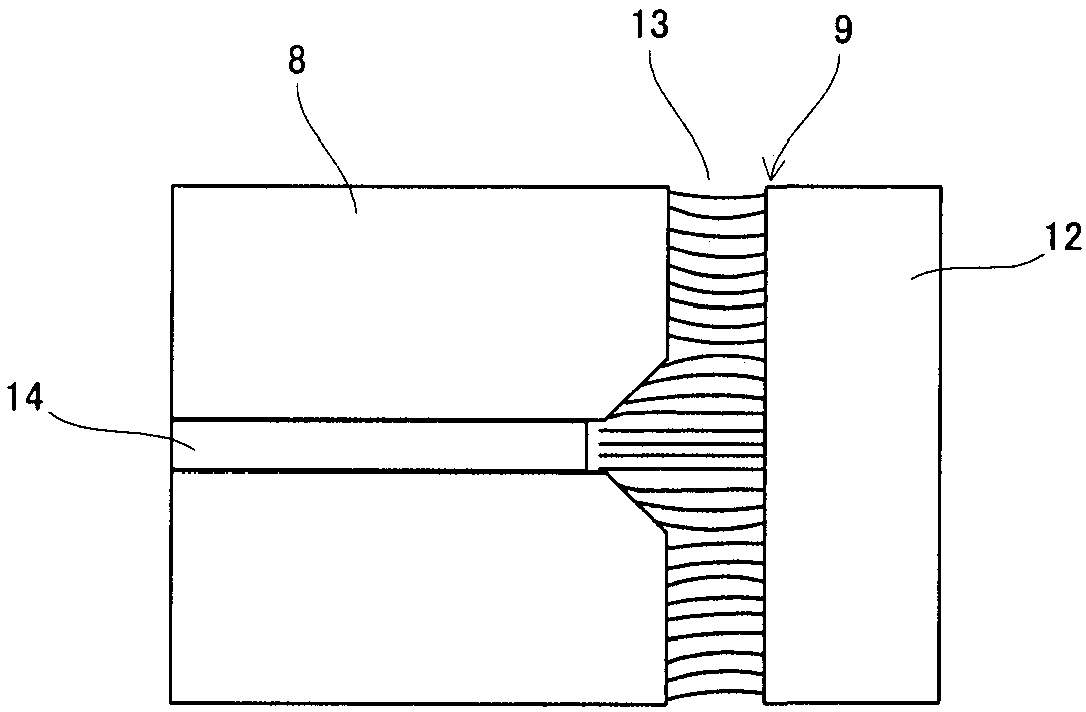

[0088] 100 raw material substrates of cut square synthetic quartz glass with an outer dimension of 152 mm were prepared, the front and back sides were ground, and then side and chamfered surfaces were ground with a diamond wheel (800 mesh). Next, use a brush with a wire diameter of 60 μm, a base diameter of 200 mm, a length of 150 cm, a hair body length of 20 mm, and a density of 3 hairs / mm 2 A nylon brush and a cerium oxide-based abrasive (A-10, manufactured by Showa Denko Co., Ltd.) were used to perform side mirror-finishing on one side surface for 5 minutes on a total of 4 surfaces to form a side surface and a chamfered surface shape. Specifically, 100 glass substrates were stacked at a stacking interval of 500 μm (8.3 times the wire diameter of the bristles of the brush), and the bristles were arranged so as to touch the sides of the substrates at a depth of about 8 mm from the bristles of the bristles. For the brush, the brush was rotated at a rotational speed of 1000 rpm...

Embodiment 2

[0097] In the same manner as in Example 1, 100 raw material substrates of cut square synthetic quartz glass with an outer dimension of 152 mm were prepared, and after grinding, side and chamfered surface grinding, a brush made of nylon with a wire diameter of 60 μm was used. Brushes and cerium oxide-based abrasives were used on a total of four surfaces to perform side mirror-finishing for one side surface for 5 minutes, thereby forming a side surface and a chamfered surface shape. At this time, the stacking interval of the rectangular synthetic quartz glass substrates was 200 μm (3.3 times the wire diameter of the bristles of the brush).

[0098] At the time when the mirror-finishing of the side surface was completed, the plate thickness was about 6.45 mm. Random 10 sheets were selected from 100 sheets in the same manner as in Example 1, and the shape of the chamfered surface and its vicinity was measured. As a result, the first curved surface from the surface to the position ...

Embodiment 3

[0105] In the same manner as in Example 1, 100 raw material substrates of cut square synthetic quartz glass with an outer dimension of 152 mm were prepared, and after grinding, side and chamfered surface grinding, a brush made of nylon with a wire diameter of 60 μm was used. Brushes and cerium oxide-based abrasives were used on a total of four surfaces to perform side mirror-finishing for one side surface for 5 minutes, thereby forming a side surface and a chamfered surface shape. At this time, the stacking interval of the rectangular synthetic quartz glass substrates was 200 μm (3.3 times the wire diameter of the bristles of the brush).

[0106] Then, a fixed plate with a diameter of 300 mm covered with a polishing cloth was brought into contact with the side surface to perform polishing. Paste the hard polyurethane liner on the fixed plate, make the rotation speed 70rpm, and make the grinding pressure 150gf / cm 2 , and polished using cerium oxide (A-10, manufactured by Showa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com