Hexagonal boron nitride substrate provided with single atomic layer step and preparation method and application thereof

A technology of hexagonal boron nitride and single atomic layer, which is applied in chemical instruments and methods, coatings, gaseous chemical plating, etc., can solve the problem of lack of hBN substrate pretreatment and achieve the effect of avoiding pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

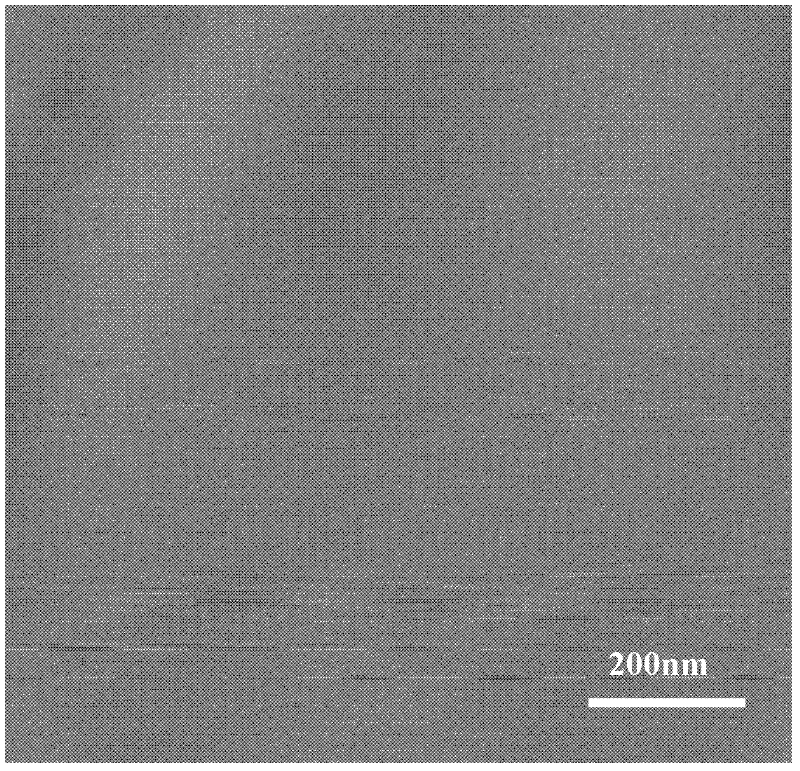

[0027] The first step: using single crystal hBN flakes as raw materials, on SiO 2 / Si substrates were mechanically exfoliated to obtain hBN sheets with fresh cleavage planes, such as figure 1 As shown, its surface is very flat without any steps.

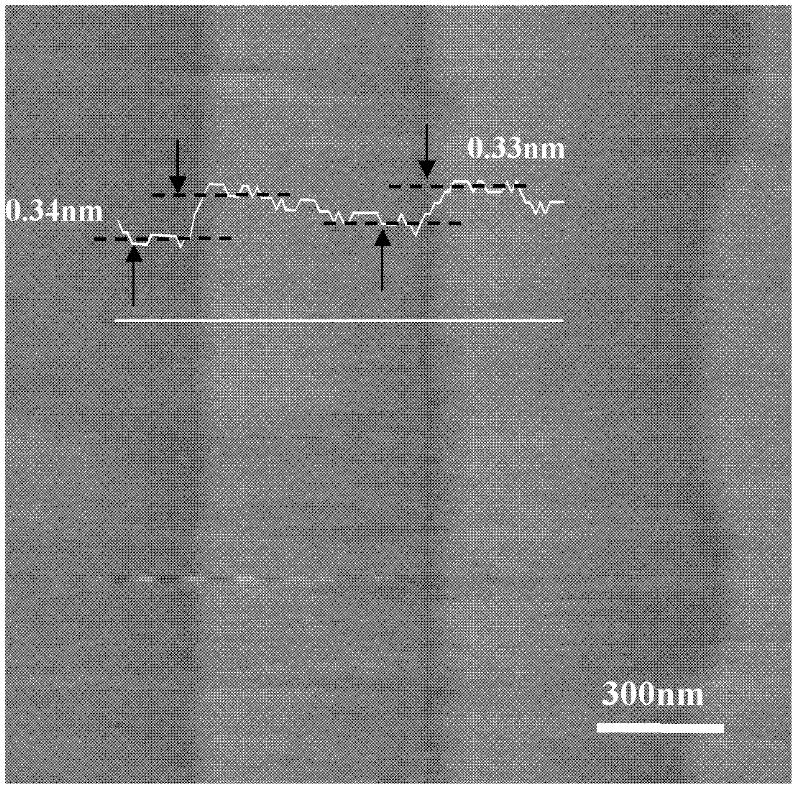

[0028] The second step: the hBN / SiO obtained in the first step 2 The substrate is put into a tube furnace, and the hydrogen-argon gas mixture (H 2 : Ar=1:3, volume ratio), be warming up to 1200 ℃ with the heating rate of 20 ℃ / min, constant temperature 10min, then cool with furnace, obtain like this figure 2 The height analysis shows that the height of the single atomic layer steps is 0.34nm and 0.33nm, which is a single BN atomic layer step, and the distance between the steps is about 500nm.

Embodiment 2

[0030] The first step: take the single crystal hBN block as the substrate, and remove the surface layer of hBN by mechanical stripping.

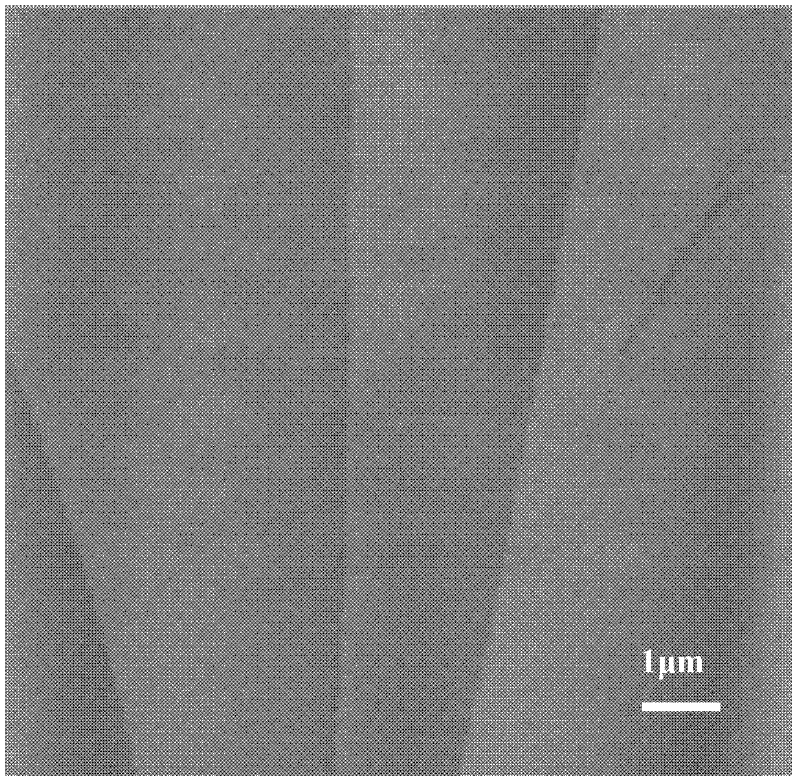

[0031] The second step: the substrate is put into the tube furnace, and the mixed gas of hydrogen and argon (H 2 : Ar=1:6, volume ratio), with a heating rate of 20°C / min, it is heated up to 1100°C, kept at a constant temperature for 50min, and then cooled with the furnace, so that the steps of the monoatomic layer height are obtained, such as image 3 shown. The spacing between the steps is 1-5 microns.

Embodiment 3

[0033] The first step: the hBN grown by CVD method is used as the substrate, and the hBN surface layer is removed by mechanical stripping. The process of preparing hBN by CVD method is as follows: use borazine as the BN source, argon as the carrier gas, and grow the hBN film at 1000 °C on the metal Ni as the substrate under the pressure of 5 Pa for half an hour, and transfer the hBN film to SiO 2 / Si substrate.

[0034] The second step: the substrate is put into the tube furnace, and the mixed gas of hydrogen and argon (H 2 : Ar=1:9, volume ratio), with a heating rate of 20°C / min, it is heated up to 1000°C, kept at a constant temperature for 300min, and finally cooled with the furnace, so that the steps of the monoatomic layer height are obtained, such as Figure 4 shown. The analysis result of the step height is 0.35nm, which is a single BN atomic step, and the interval between the steps is 2-5 microns.

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com