Device and method for carrying out laser machining on light guide board inside glass

An internal processing, light guide plate technology, applied in glass forming, light guide, glass production, etc., can solve problems such as poor environmental adaptability, and achieve the effect of not easy to wear, widely used, and high light transmittance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

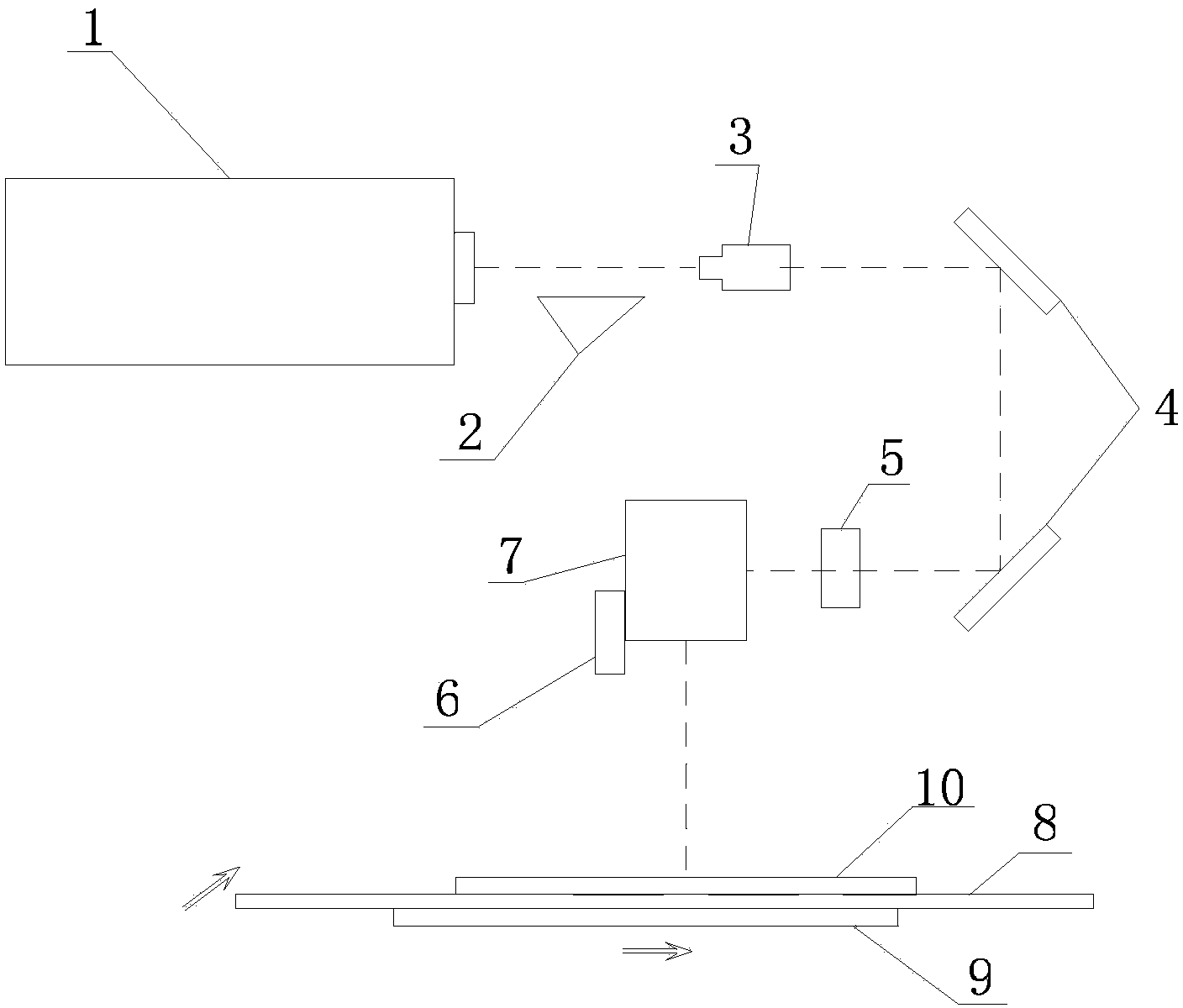

[0017] Such as figure 1 As shown, the device for laser processing the light guide plate inside the glass includes a laser 1 and a loading platform 8. The laser 1 is a high-frequency short-pulse laser with a laser wavelength of 266nm-1064nm, a pulse width of 1ps-200ns, and a frequency of 10KHz-2MHz. , the optical path at the output end of the laser 1 is sequentially provided with an optical gate 2, a beam expander mirror 3, a 45-degree total reflection mirror group 4, a beam shaping unit 5, and a scanning galvanometer 7, and the 45-degree total reflection mirror group 4 includes the first total reflection mirror and the second total reflection mirror, the uniform optical path of the reflection surface of the first total reflection mirror and the second total reflection mirror is 45°, and the CCD system 6 is composed of a 1 to 4 times variable magnification lens and a 500W pixel CCD for focus recognition And automatic alignment; the beam shaping unit 5 is composed of a multi-foc...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com