Acrylic coating composition with enganced oil resistance and water resistance, and preparation thereof

A composition, acrylic technology, used in antifouling/underwater coatings, biocide-containing paints, coatings, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

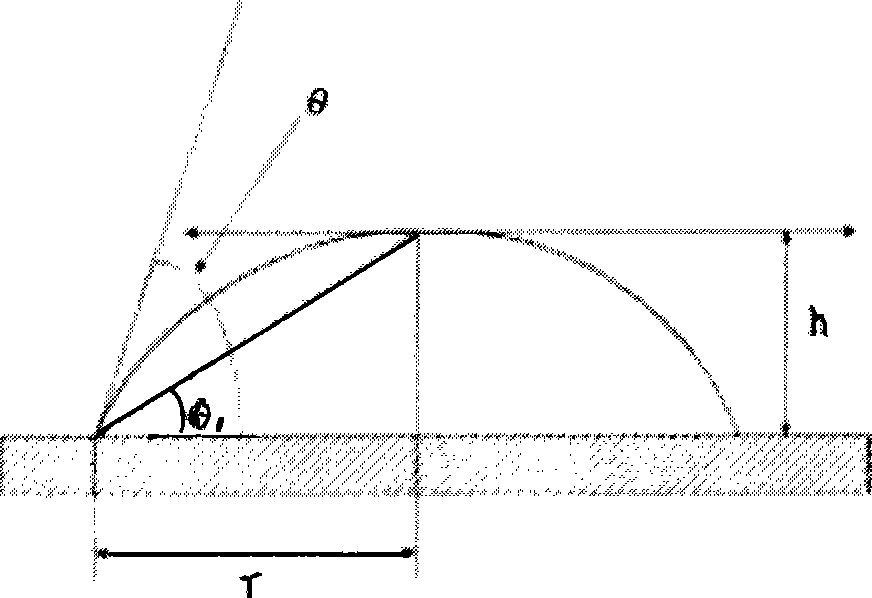

Image

Examples

Embodiment 1

[0043] Embodiment 1: the acrylic wall paint that has added fluorocarbon surfactant

[0044] (I) Preparation

[0045] Prepare the acrylic wall paint of the present invention according to the following steps, and the formula is shown in Table 1 below.

[0046] 1. Weigh water according to the recipe.

[0047]2. Slowly add a certain amount of hexanediol and thickener Natrosol250HBR under low-speed stirring at 500rpm until the thickener is completely dissolved.

[0048] 3. Keep stirring at low speed, add antifoaming agents Tego Foamex 800 and Orontan 1124, and continue stirring for 10 minutes. Then put in heavy calcium and titanium dioxide, turn to 2000rpm high-speed stirring, until dispersed to a fineness of less than 50μm.

[0049] 4. Switch to 500-600rpm low-speed stirring, add film-forming aid Texanol and fluorocarbon dispersant FSO-100, stir evenly, then add Primal AC-261 resin, covering polymer Ropaque-E, dispersant Triton X-405 , thickener Acrysol RM-220NPR and water, ...

Embodiment 2

[0067] Embodiment 2: Added the propylene of fluorocarbon surfactant, polytetrafluoroethylene micropowder and poly(ethylene glycol ether) dispersant acid wall paint

[0068] (I) preparation

[0069] Prepare the acrylic wall paint of the present invention according to the following steps, and the formula is shown in Table 4 below.

[0070] 1. Weigh water according to the formula.

[0071] 2. Slowly add a certain amount of hexanediol and thickener Natrosol250HBR under low-speed stirring at 500rpm until the thickener is completely dissolved.

[0072] 3. Keep stirring at low speed, add antifoaming agents Tego Foamex 800, Orontan 124, Tergitol 6 and Tergitol 10, and continue stirring for 10 minutes. Then put in heavy calcium, titanium dioxide and PTFE micropowder, and switch to 2000rpm high-speed stirring until the fineness is less than 50μm.

[0073] 4. Turn to 500-600rpm low-speed stirring, add film-forming aid Texanol, stir evenly, then add Primal AC-261 resin, covering po...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com