Assembly method of annular fuel element

A fuel element and assembly method technology, applied in the direction of manufacturing reactors, reactors, reducing greenhouse gases, etc., to achieve the effects of reducing assembly resistance, improving assembly efficiency and accuracy, and avoiding collisions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The assembling method of an annular fuel element according to the present invention will be further described below with reference to the drawings and specific embodiments.

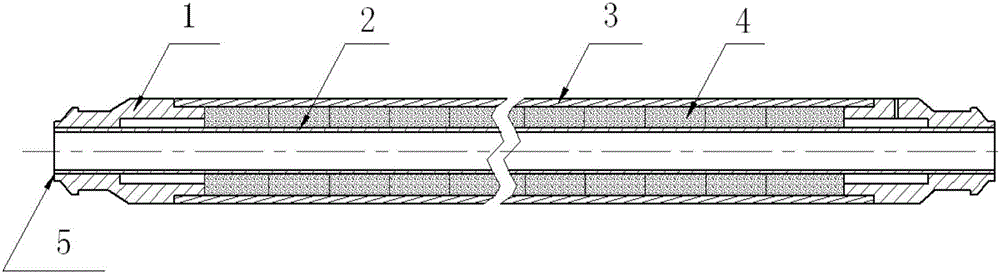

[0025] Such as figure 1 As shown, the annular fuel element of the present invention comprises upper and lower end plugs 1, an inner cladding tube 2 and an outer cladding tube 3, and an annular pellet ( 4).

[0026] The assembly method of the above-mentioned annular fuel element, it comprises the following steps:

[0027] a) Take the cleaned inner cladding tube 2, outer cladding tube 3, guide head 6 and core block 4 and place them horizontally on the operating table;

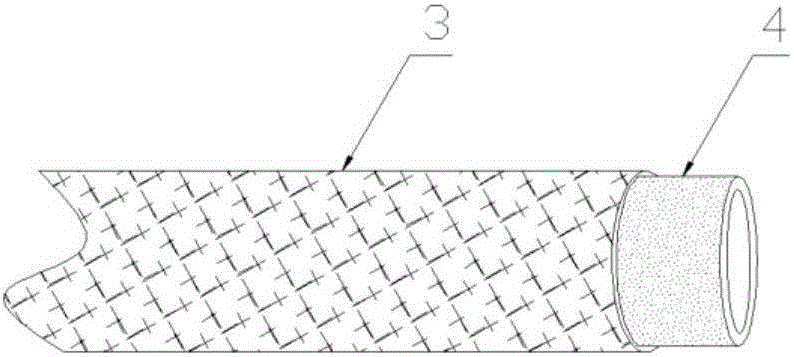

[0028] b) if image 3 As shown, the annular pellets 4 are packed into the outer cladding tube 3 one by one;

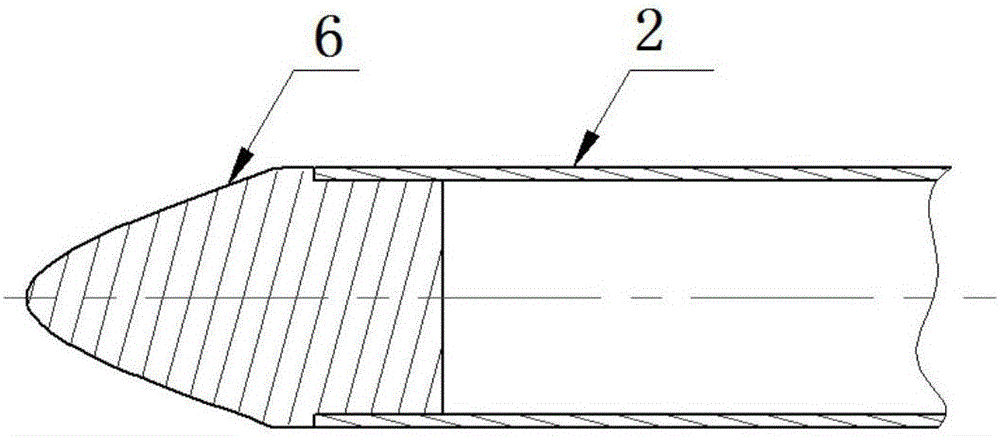

[0029] c) if figure 2 As shown, the guide head 6 is packed into one end of the inner cladding tube 2;

[0030] d) if Figure 4 As shown, one end of the inner cladding tube 2 equipped with the guide head 6 is loaded int...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com