Patents

Literature

146results about How to "Ease of assembly" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

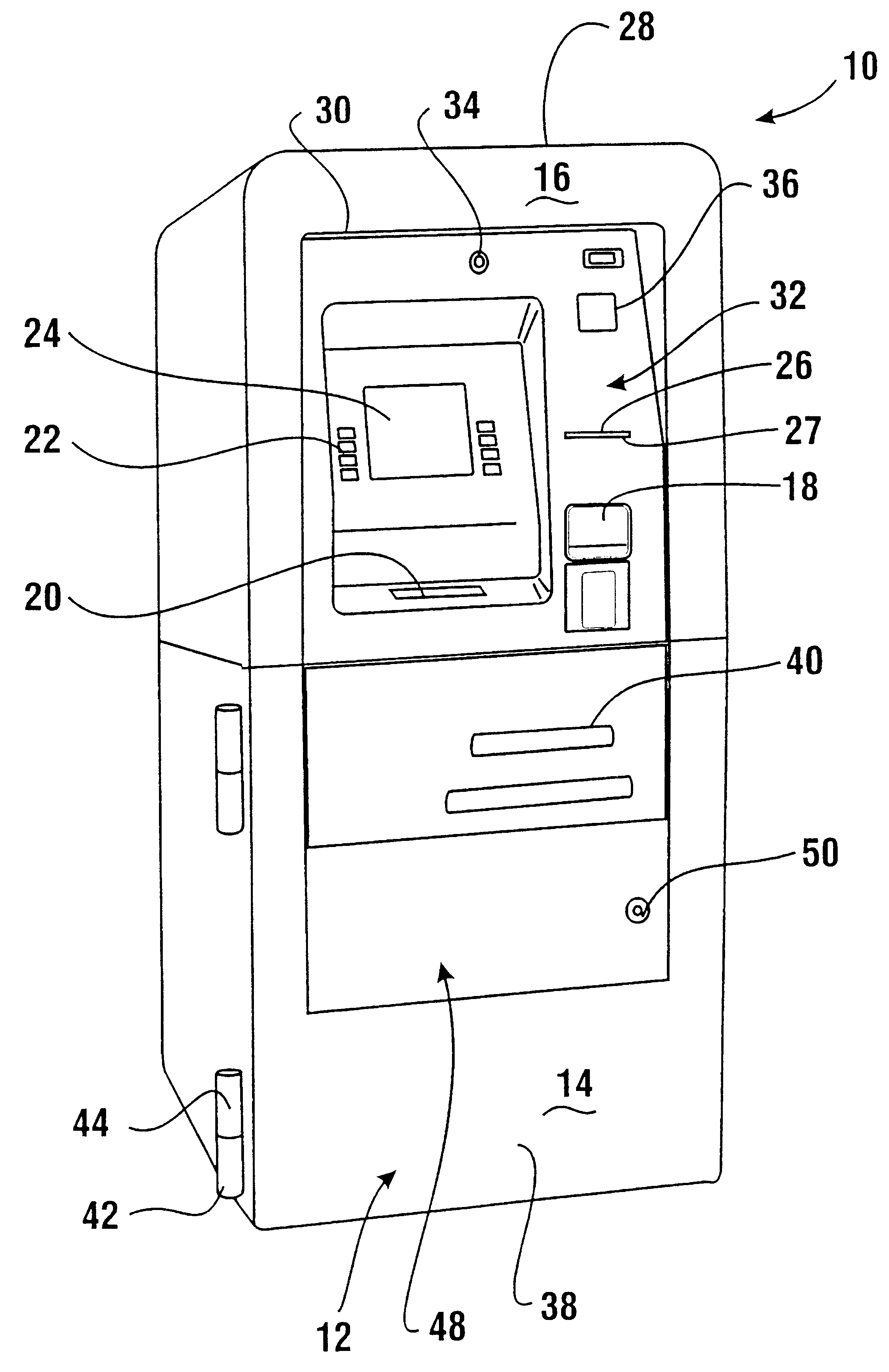

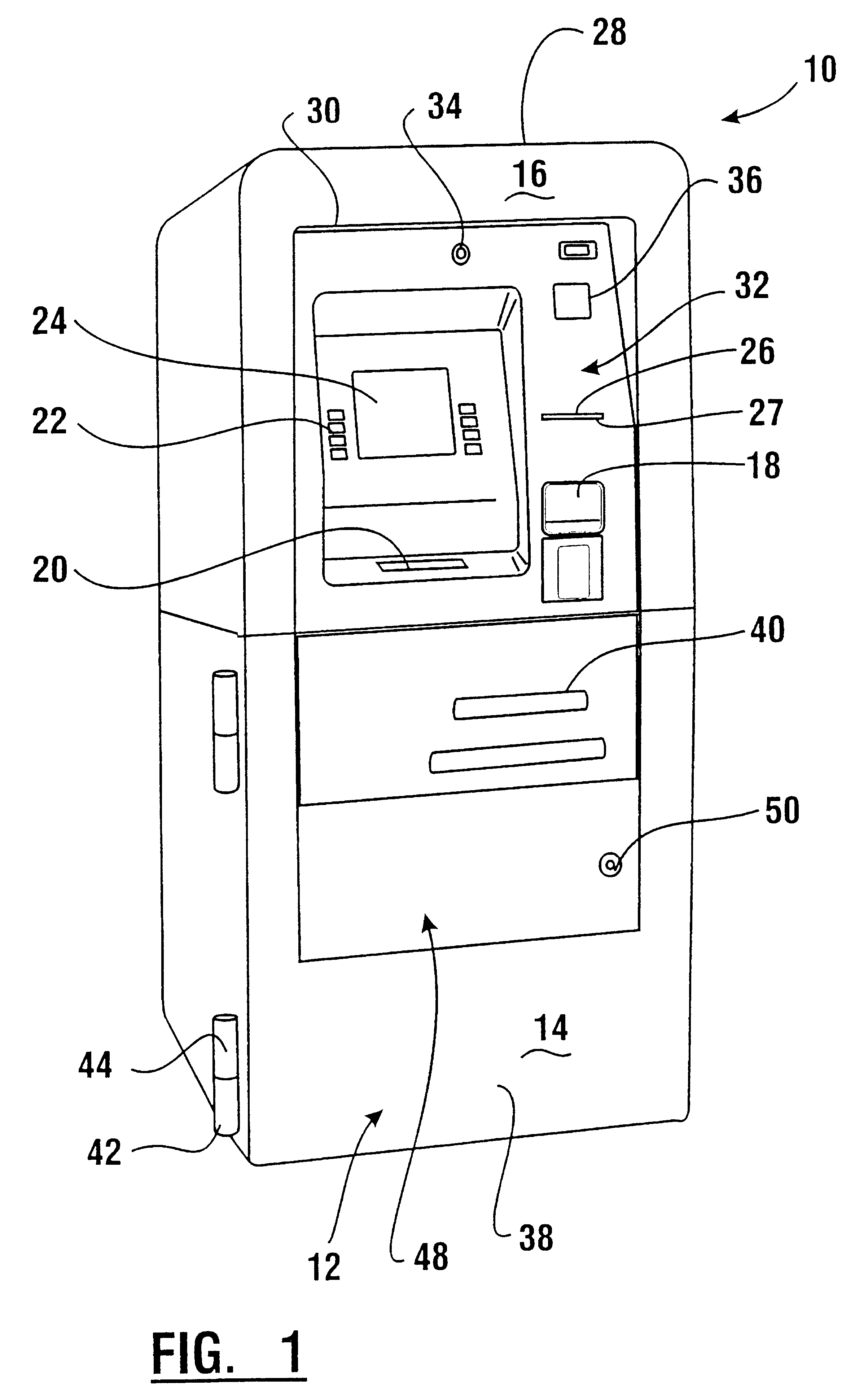

Automated banking machine enclosure

InactiveUS6527172B1Ease of assemblyBroaden accessComplete banking machinesFinanceComputer caseBiomedical engineering

An automated banking machine includes a chest portion (14). Transaction function devices such as an input device (18) and a display screen (24) are supported on the chest portion. A generally one-piece polymer body (28) is operatively engaged relative to the chest portion and extends in generally surrounding relation of the input device and display screen. The body includes at least one opening (30) such that the display screen is visible and the input device is accessible through the body.

Owner:DIEBOLD NIXDORF

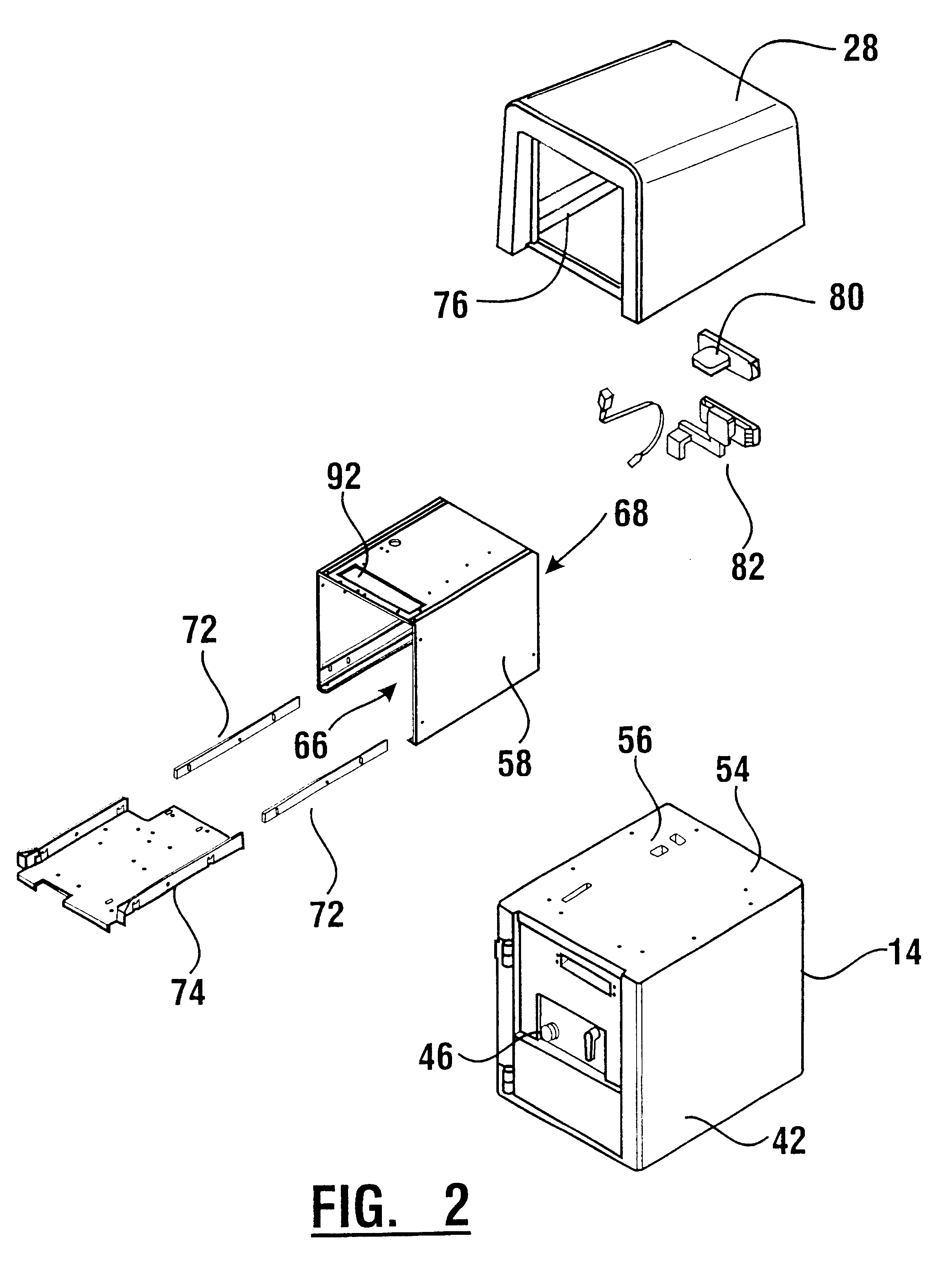

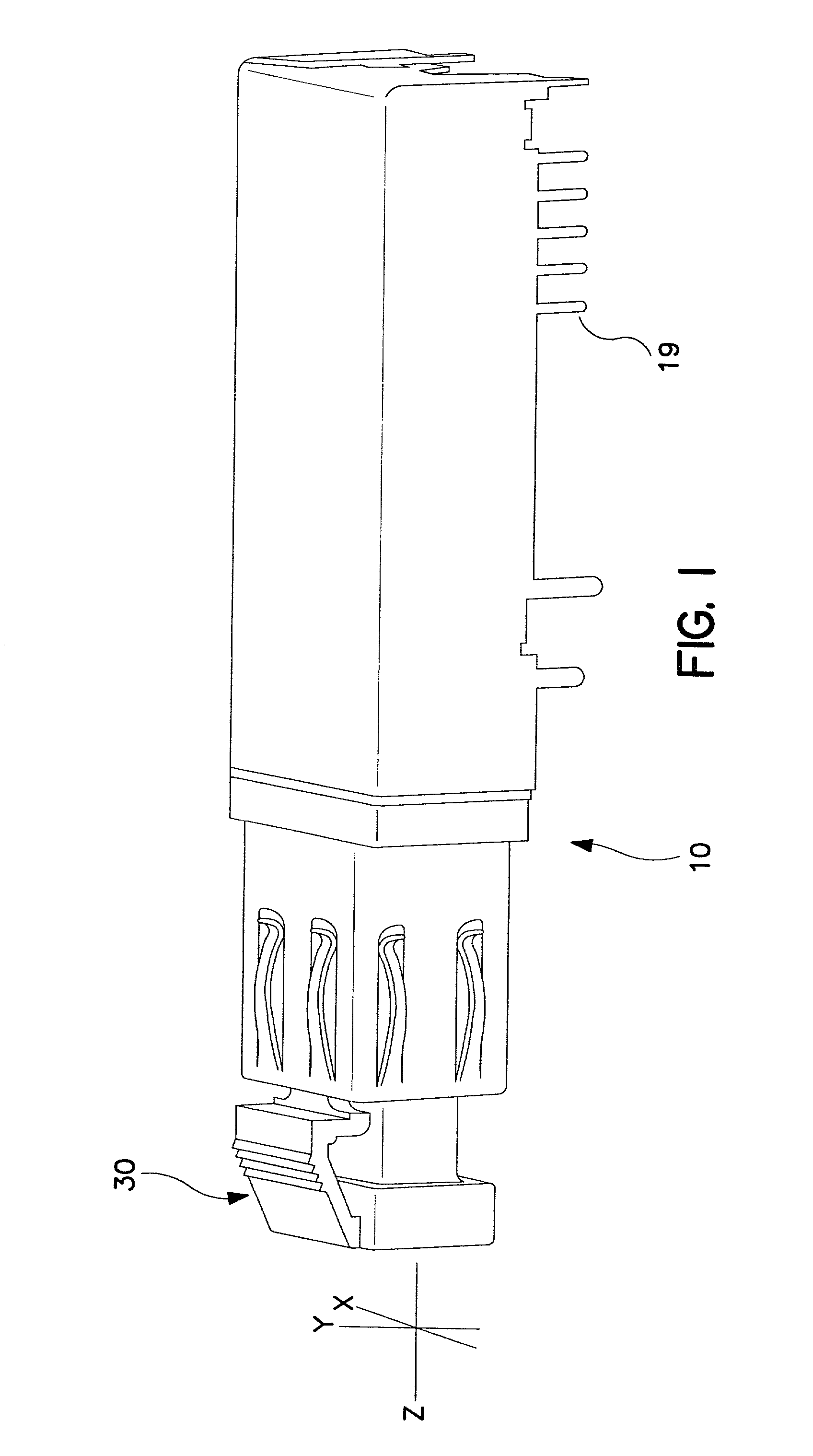

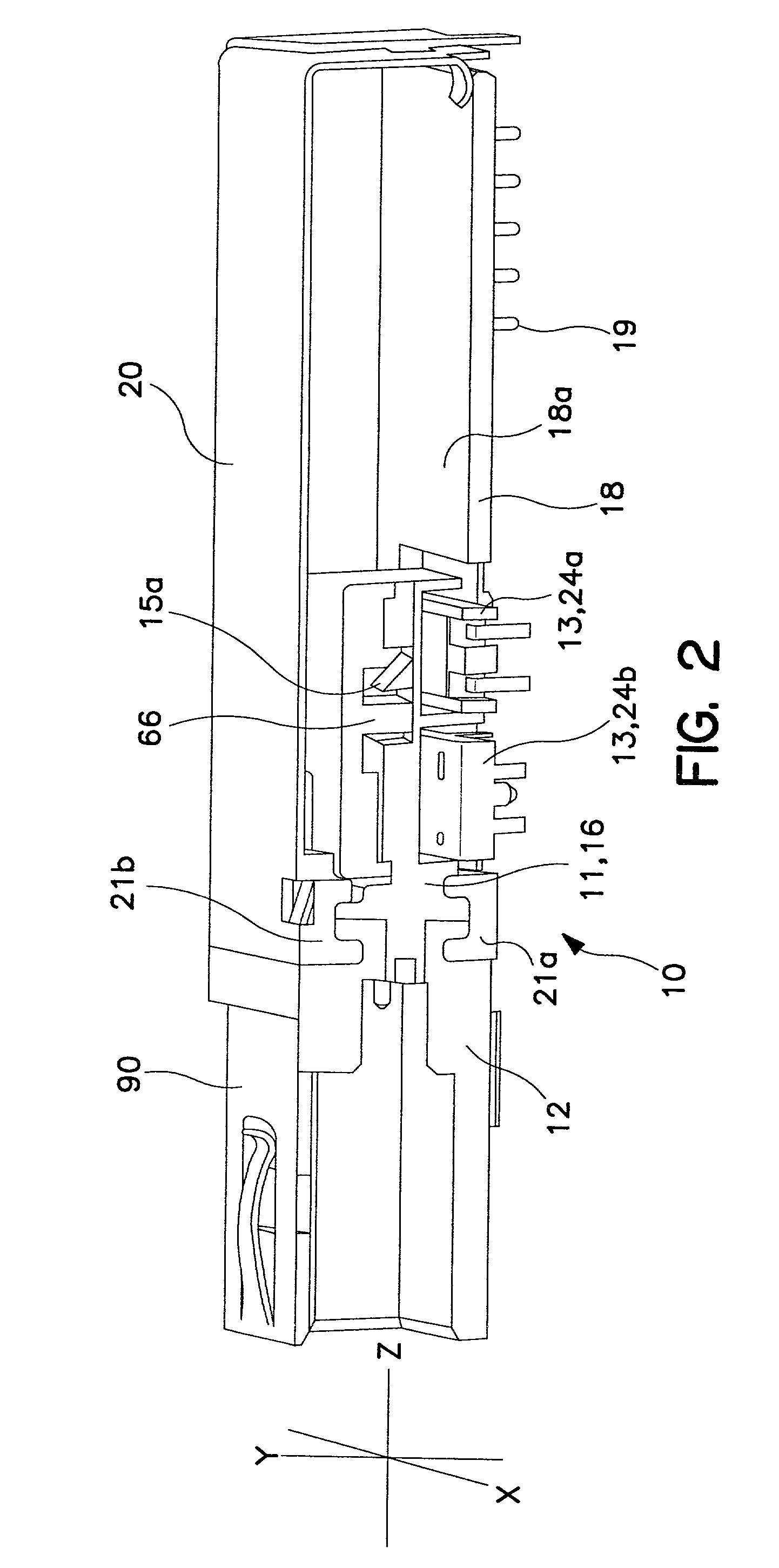

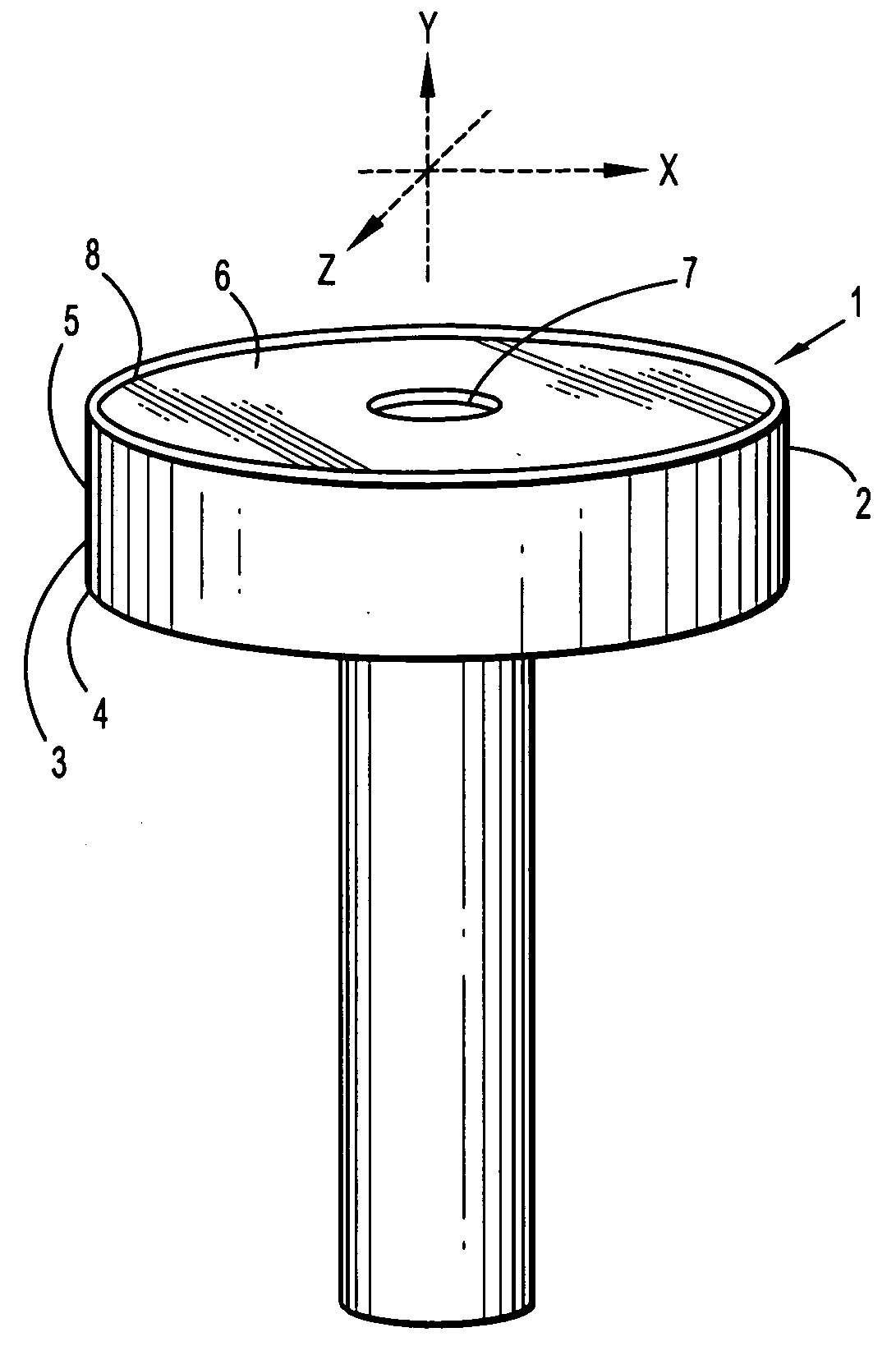

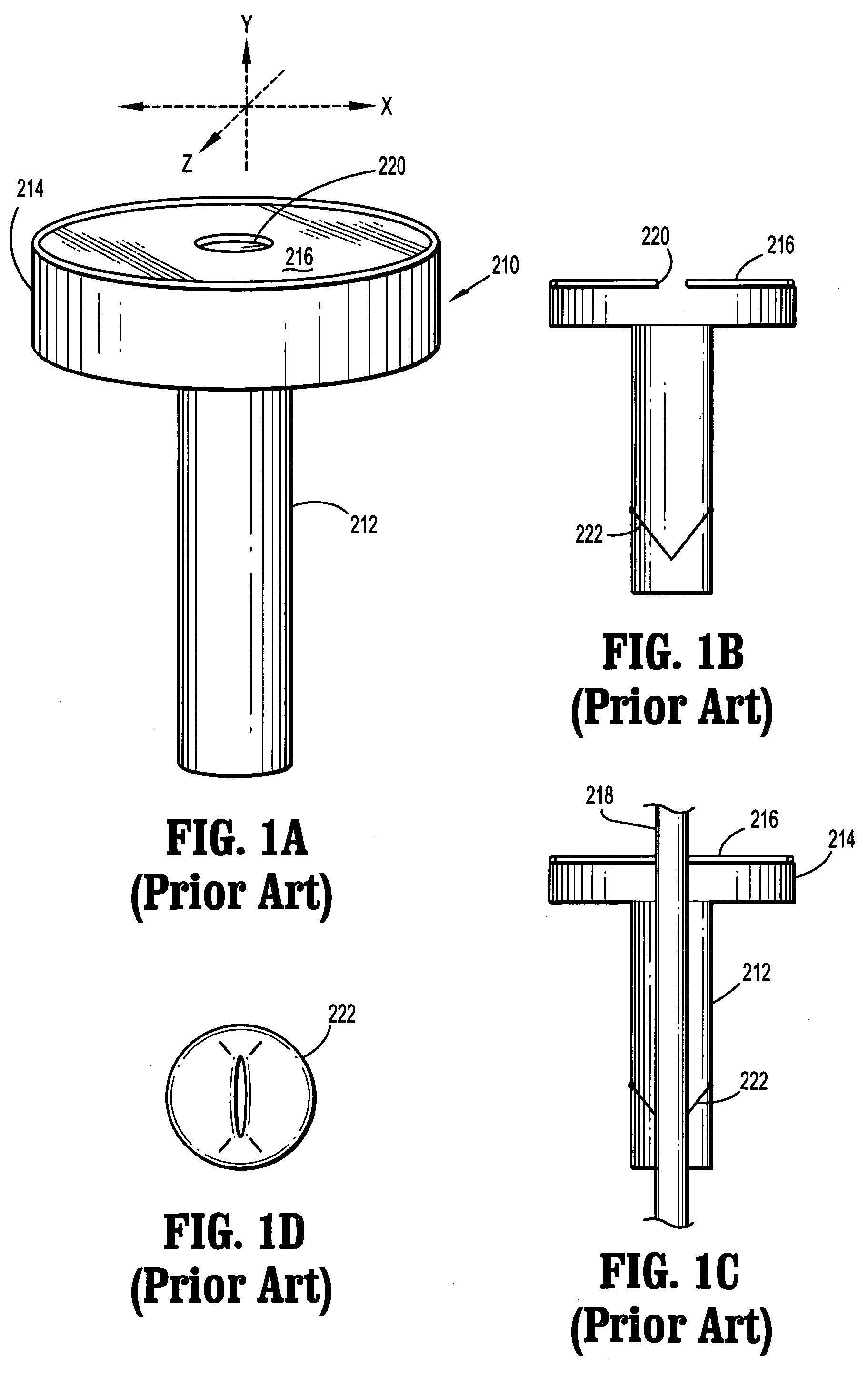

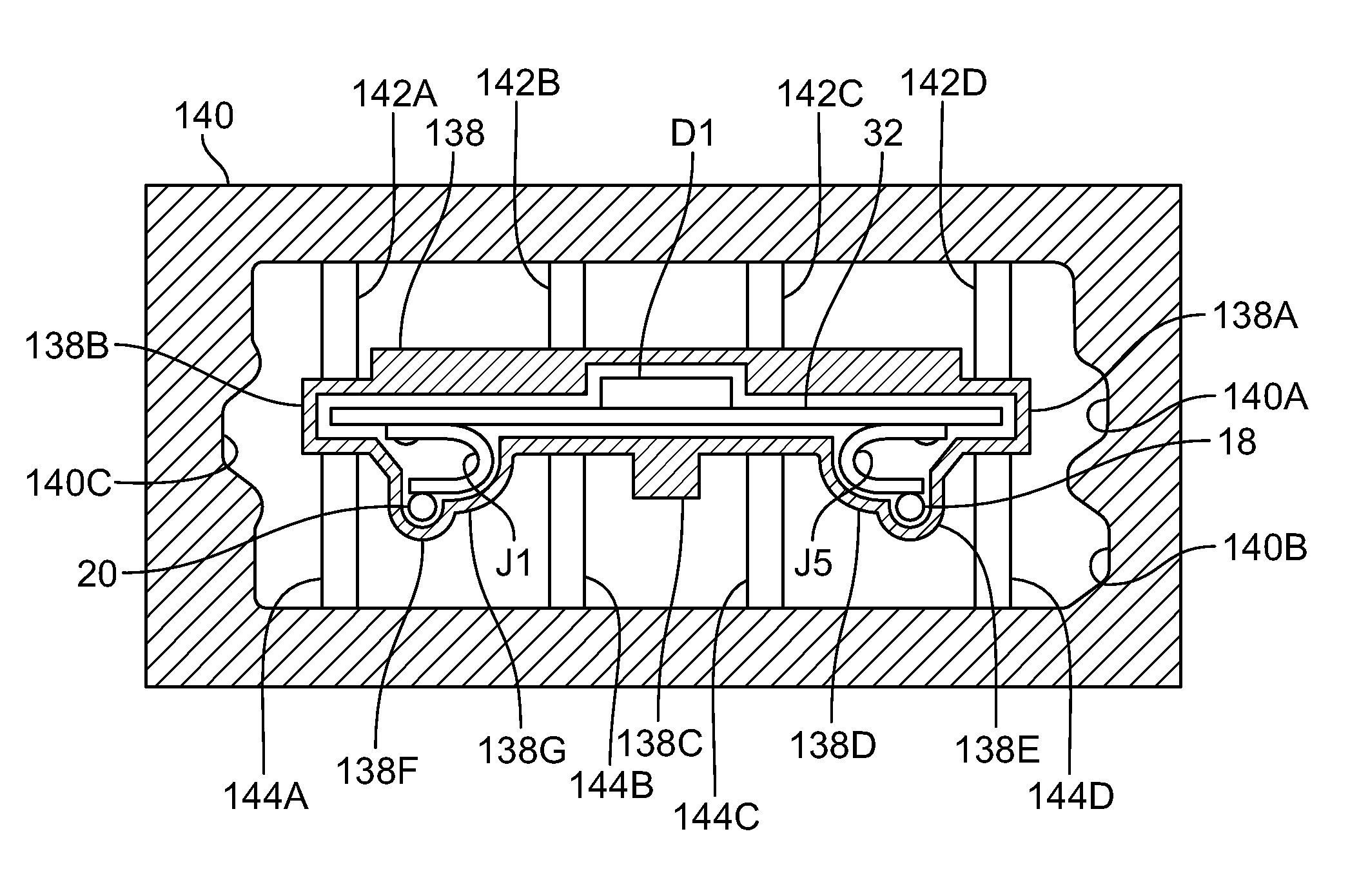

Optoelectric module for multi-fiber arrays

InactiveUS20030138219A1Increase spacingIncrease space required along x-axisCoupling light guidesFiberFiber array

An optoelectric module adapted to cooperate with a multi-fiber array by displacing a plurality of OEDs from the fiber array at least along the z,y-axes or a combination thereof while maintaining their alignment along either the x-axis of the fiber array, the module comprising: (a) a connector interface adapted to interconnect with a multi-fiber assembly having an x,y array of fibers; (b) a plurality of OEDs for converting between optical and electrical signals; and (c) optical paths wherein each optical path has a first end adapted for optically coupling with a corresponding fiber in an x,y array of fibers and a second end for optically coupling with a corresponding OED, wherein the distance between the second ends of at least two optical paths is greater than the distance between their corresponding first ends and wherein the distance across the second ends along the x-axis is no greater than the distance across the first ends along the x-axis.

Owner:TE CONNECTIVITY CORP

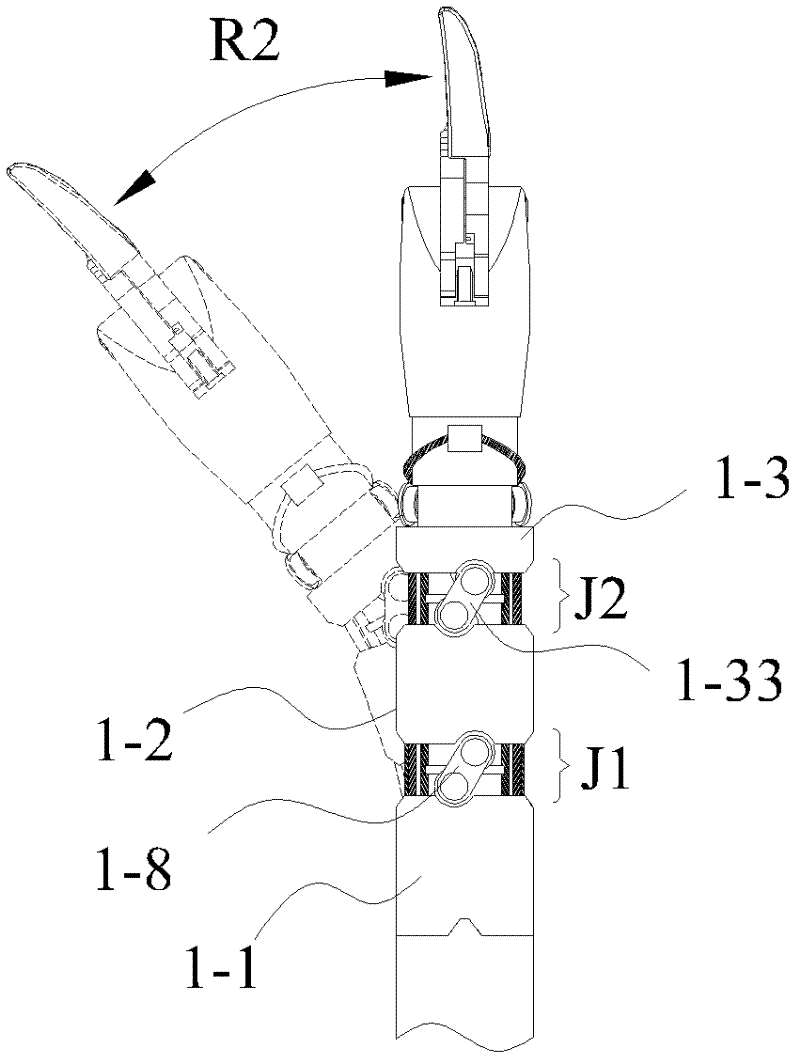

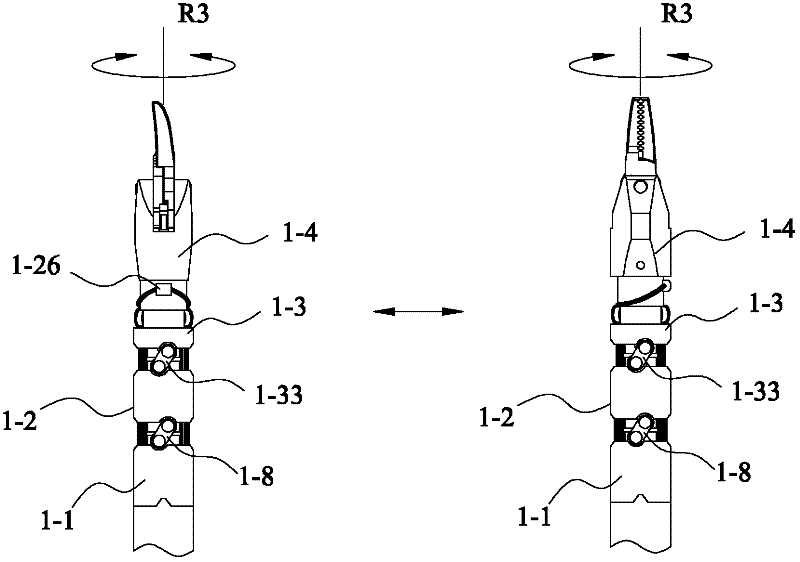

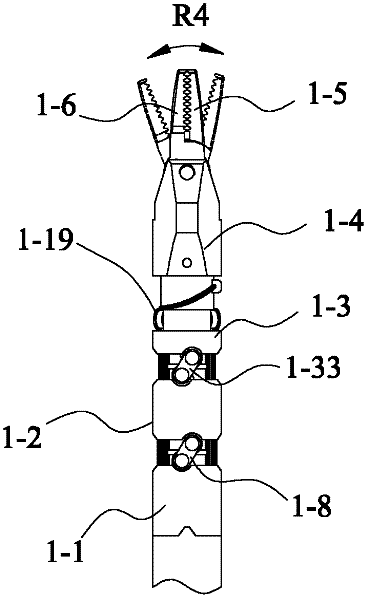

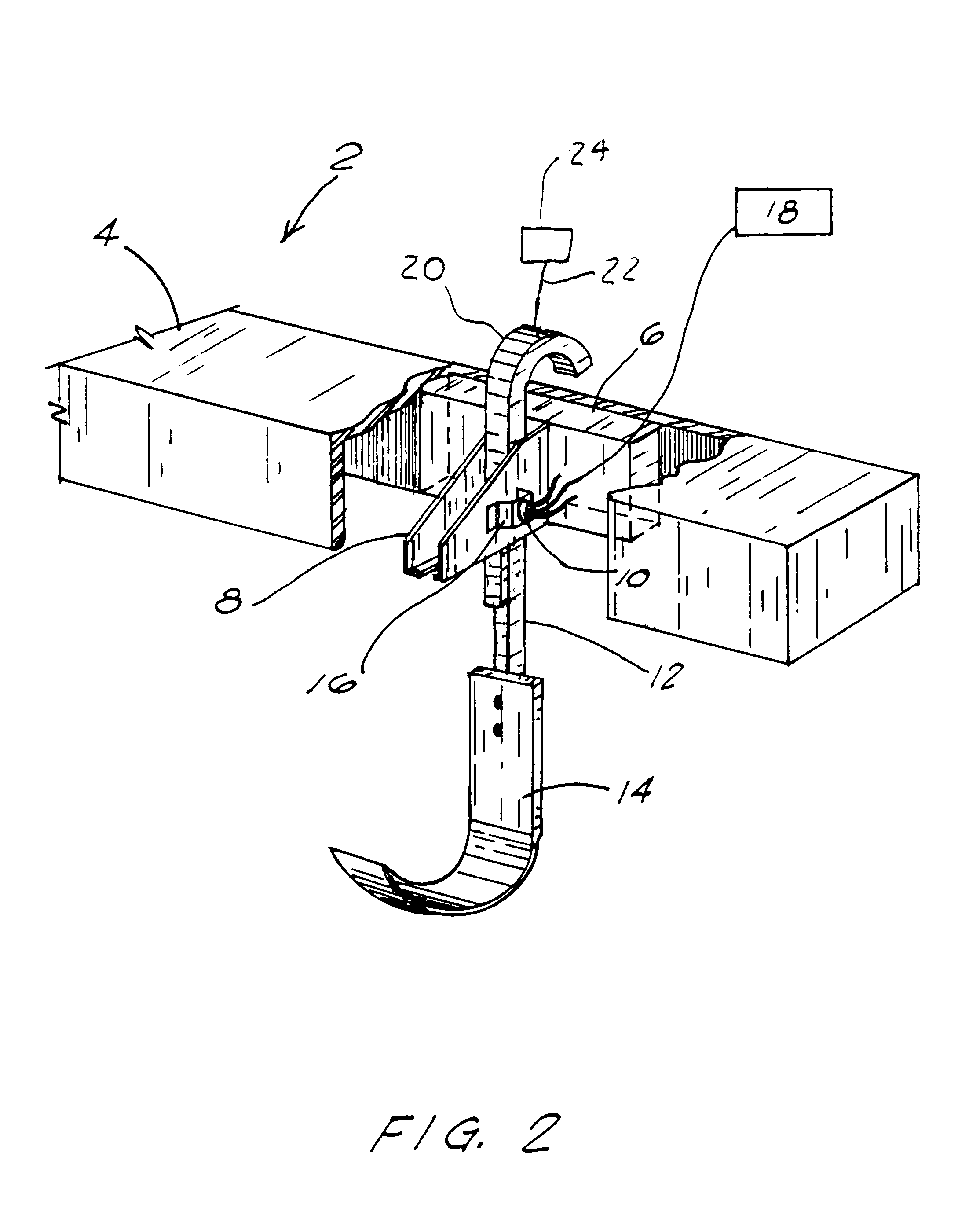

Micro instrument terminal based on module joint and used for minimally invasive surgery robot

ActiveCN102488554AFlexible to completeThe total length of the closed-loop transmission remains unchangedDiagnosticsSurgical robotsSurgical departmentTarsal Joint

The invention discloses a micro instrument terminal based on module joints and used for a minimally invasive surgery robot. The micro instrument terminal comprises a rotary module of a first four-bar mechanism consisting of a module top end part, a module bottom end part, a lower support and first left and right connection pieces, and a rotary module of a second four-bar mechanism consisting of amodule top end part, a rotary connection shaft, an upper support and second left and right connection pieces; two ends of a first steel wire rope are connected with the top surfaces of the module topend parts, and the other two ends of the first steel wire rope are sequentially connected with a first rotary actuating device through the module bottom end part; two ends of a second steel wire ropeare connected with a rotary connecting shaft, and the other two ends of the second steel wire rope are sequentially connected with the first rotary actuating device through the module top end parts and the module bottom end part; and the upper part of the rotary connecting shaft is inserted into the central hole of a rotary rod and is in clearance and running fit with the rotary rod, and the rotary rod is connected with a surgery apparatus. Complex surgery can be more flexibly completed by adopting the device.

Owner:SHANDONG WEIGAO SURGICAL ROBOT CO LTD

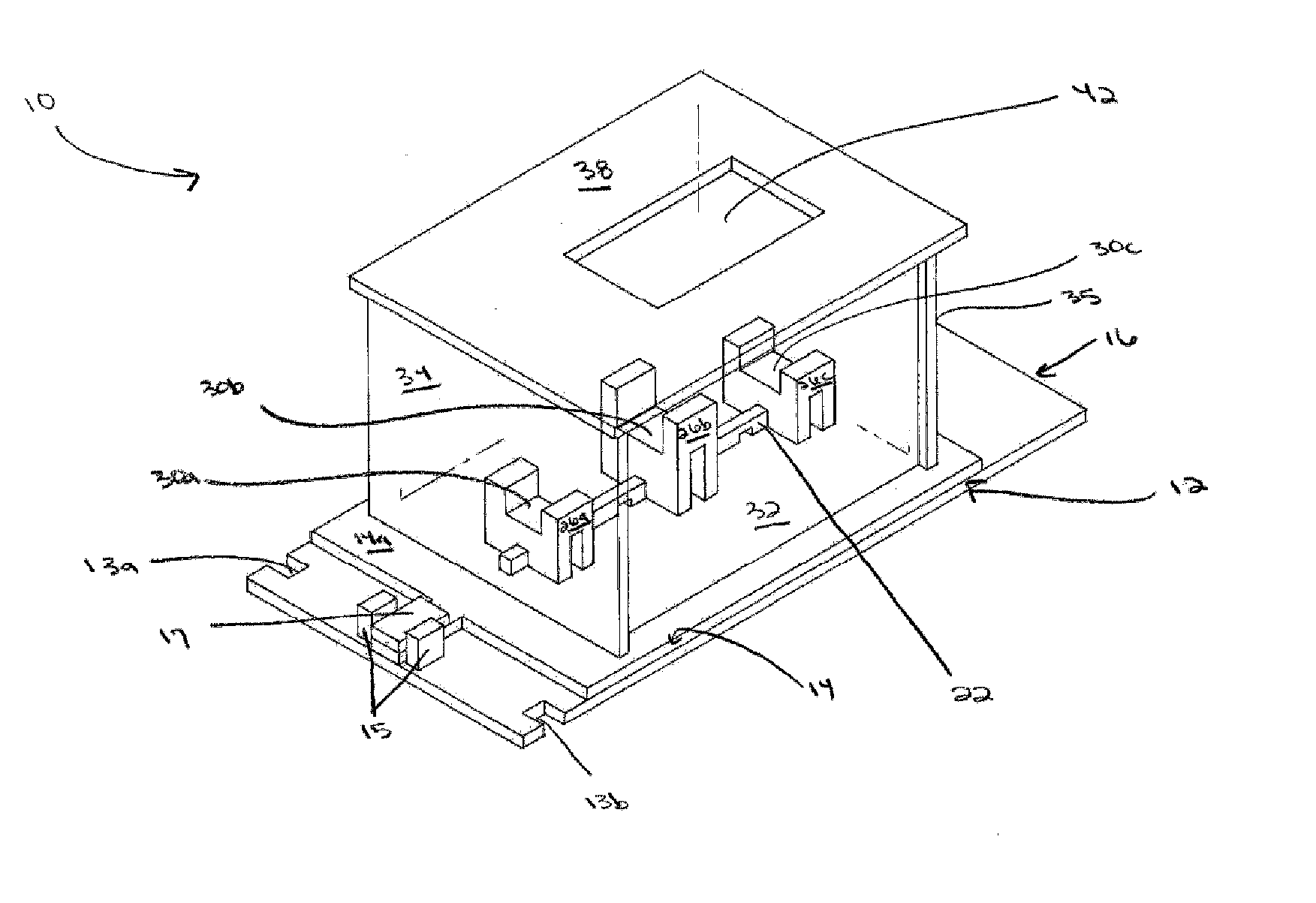

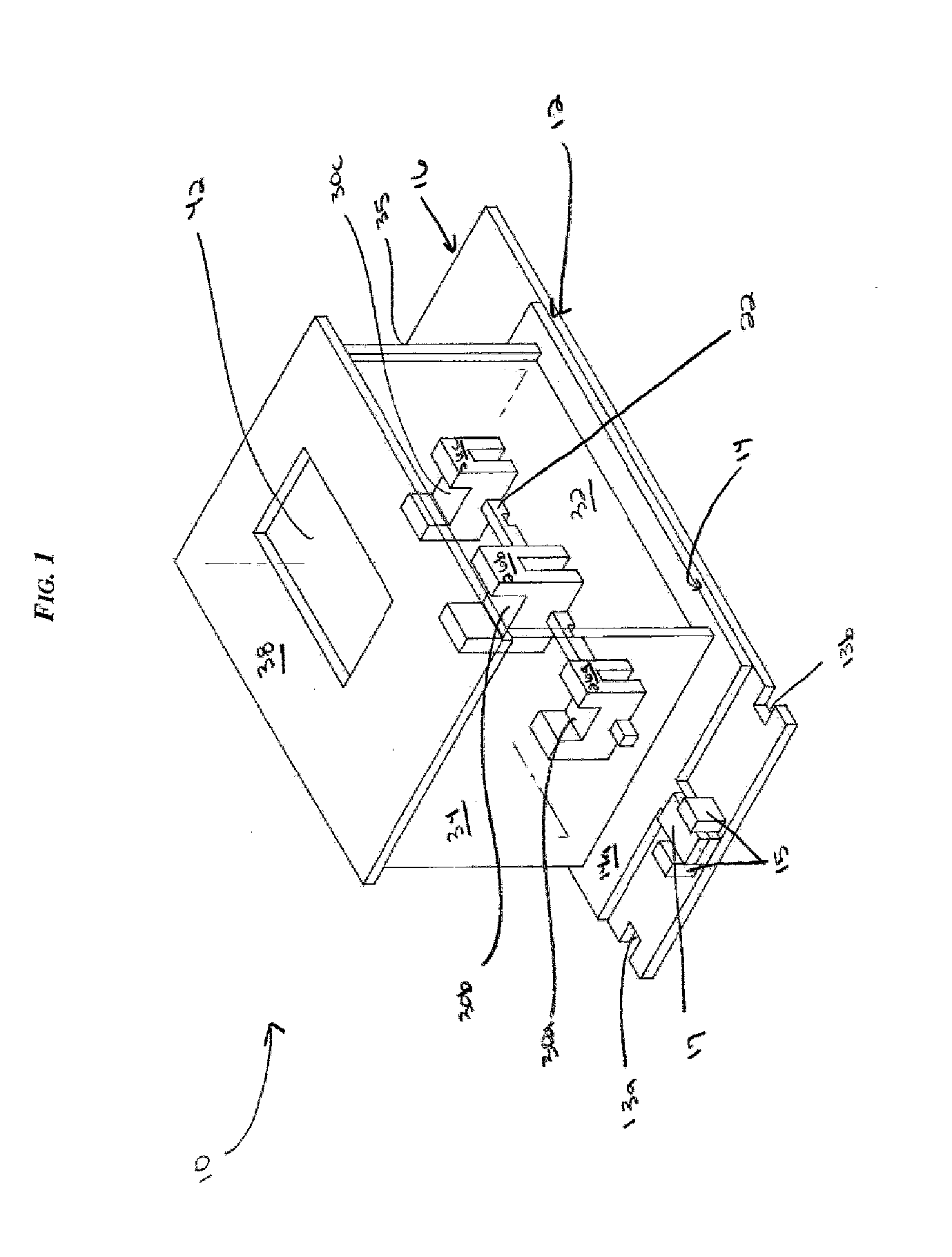

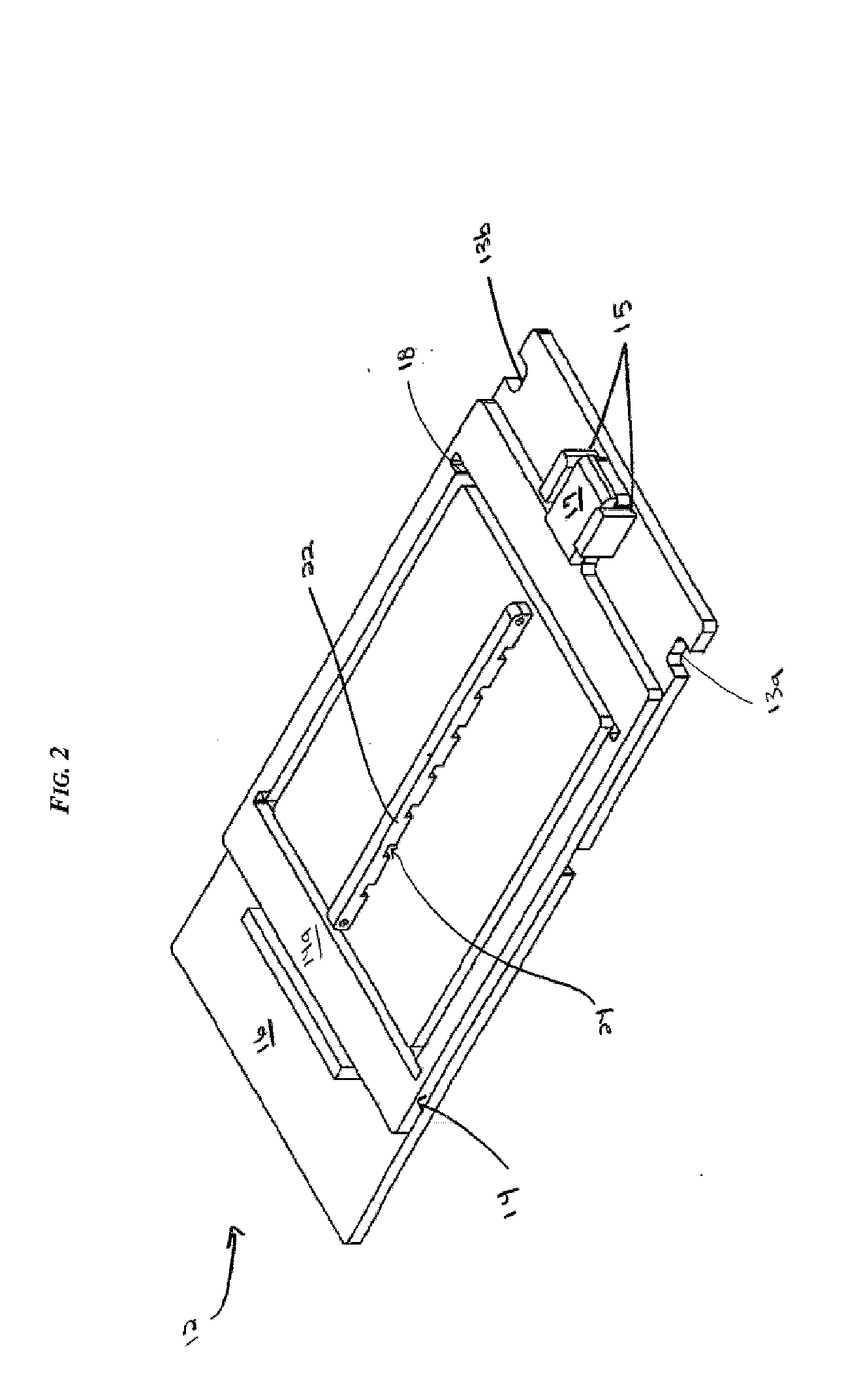

Spine simulator system

InactiveUS20060275741A1Assembled and and cleaned and transported with easeEase of assemblyEducational modelsSpinal operationAnterior approach

Various exemplary simulator systems are provided for use in simulating surgical procedures. The exemplary simulator systems can be adapted to simulate spinal surgery procedures involving, for example, an anterior approach, a posterior approach, or a minimally invasive approach. The simulator is generally in the form of a box that serves a representation of a body cavity.

Owner:DEPUY SPINE INC (US)

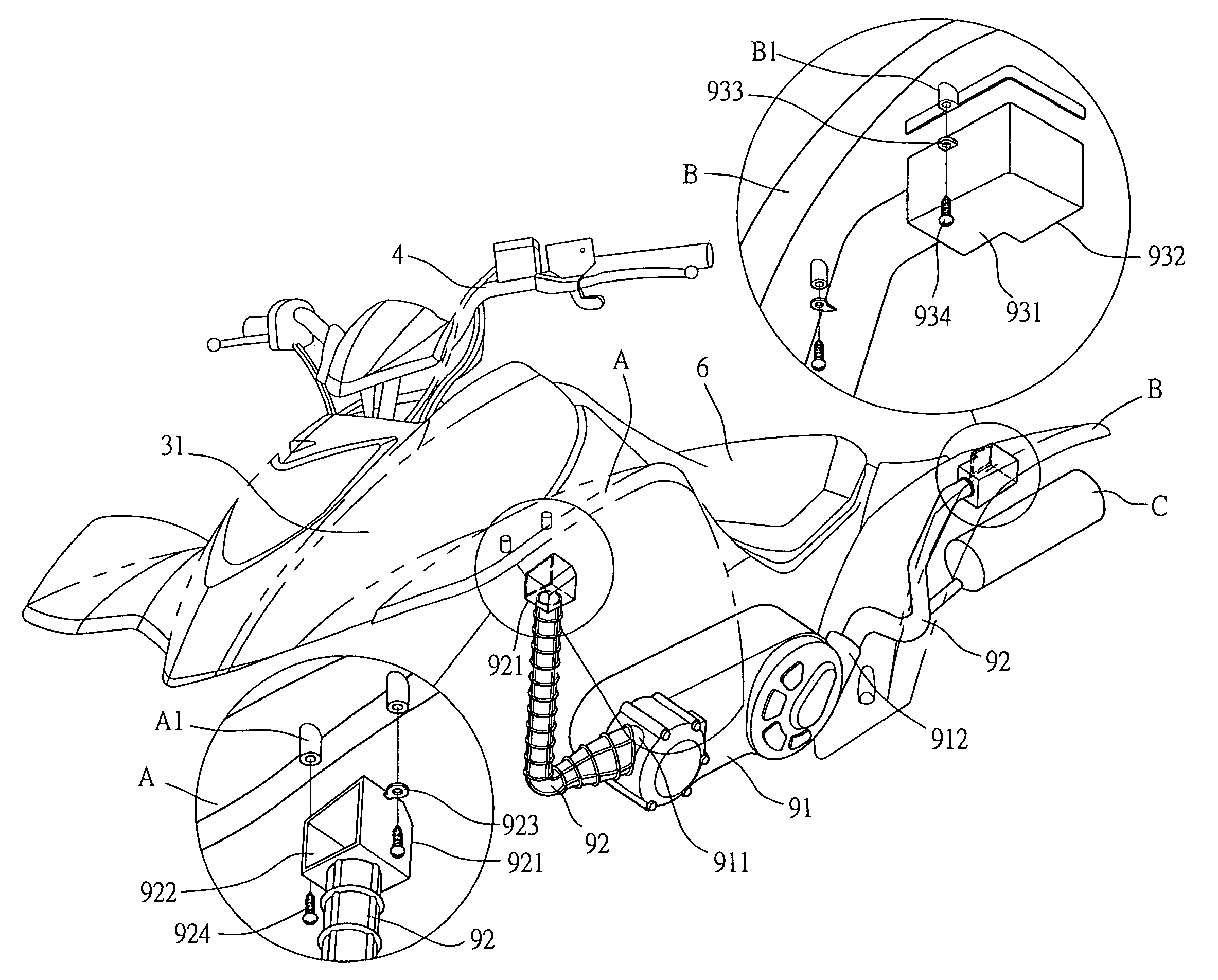

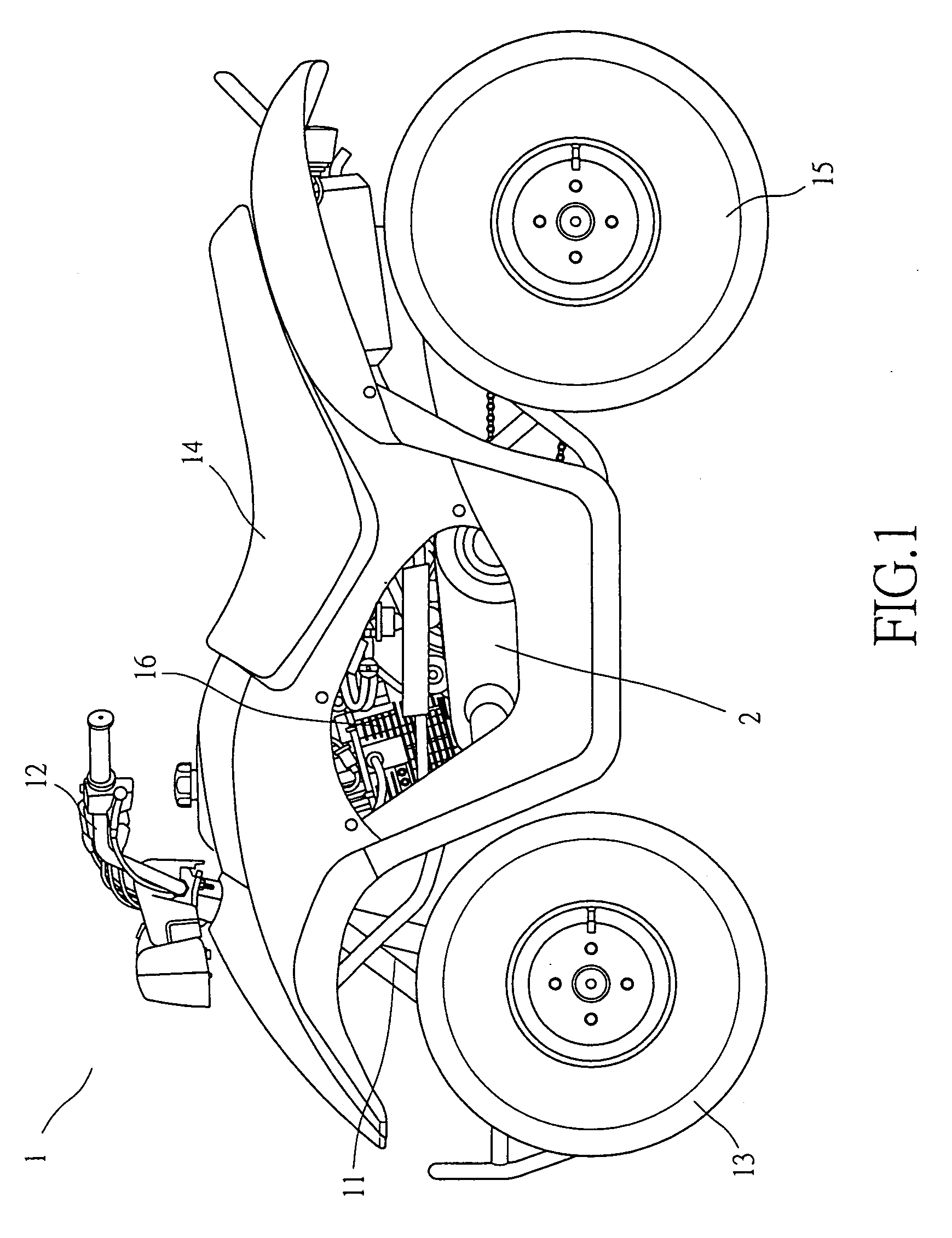

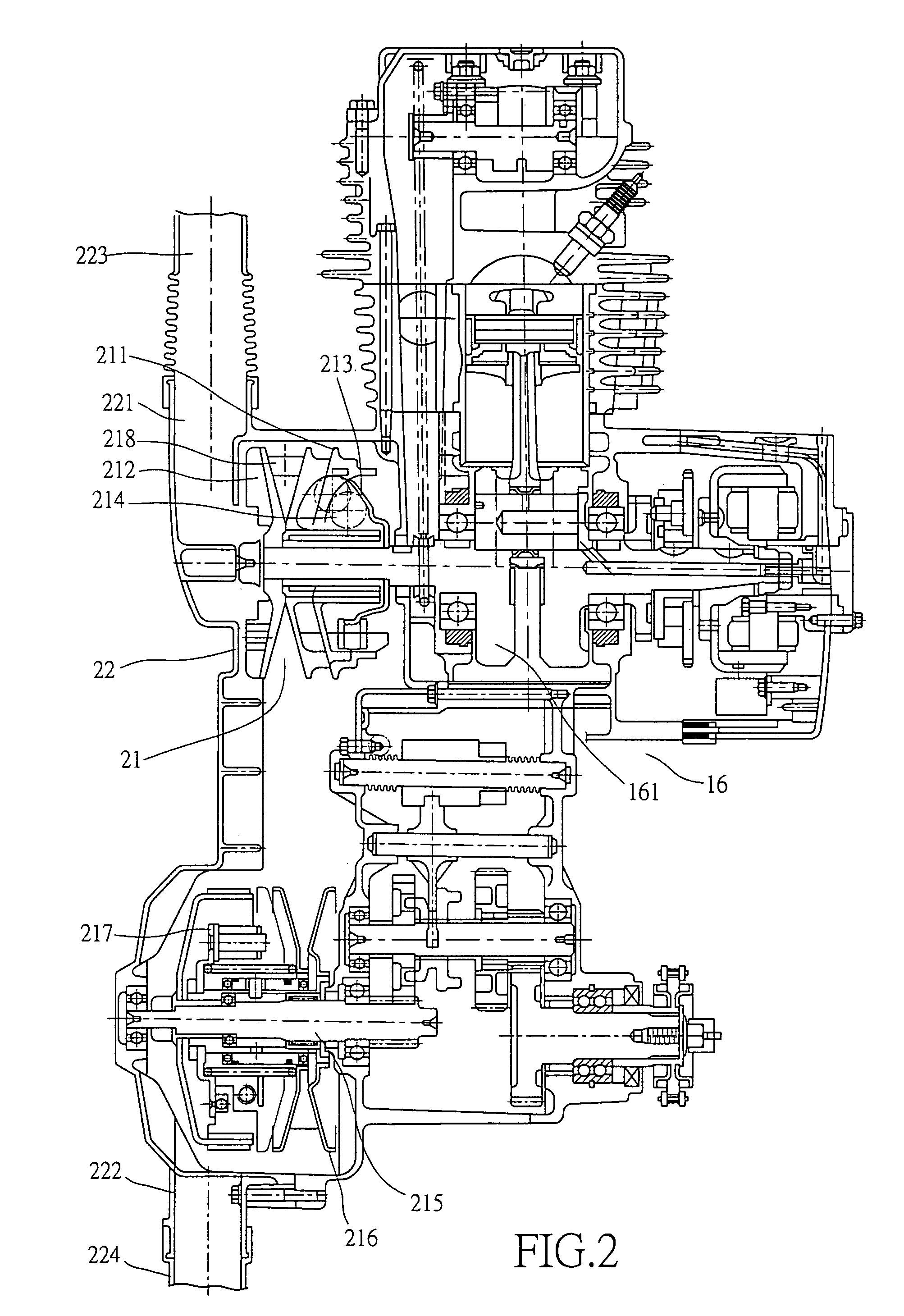

Cooling structure for a continuous variation transmission system of an all-terrain vehicle

InactiveUS6938676B2Optimize cooling structureReduce difficultyCyclesAir-treating devicesExhaust pipeTransmission system

The present invention concerns a cooling structure for a continuous variation transmission system of an all-terrain vehicle. Primarily speaking, it has an inlet conduit attached to the air inlet of the gearbox, with said inlet conduit extending in front of the engine until it reaches the below of the front mud guard, and an inlet box attached to the inlet conduit. An exhaust conduit is also being attached to the exhaust of the gearbox, with said exhaust pipe extending to the rear of the engine until it reaches the below of the rear mud guard, and an exhaust box is attached to the exhaust conduit. Both the inlet box and the exhaust box are placed above the tail of the engine exhaust conduit, and situated on the outer surface of the chassis. The inlet and exhaust box design prevents dust, dirt and water from entering the gearbox. Furthermore, the conduits are installed on the outer surface of the chassis to enable ease of assembly and maintenance, and to reduce the difficulty of installing other components.

Owner:KYMCO

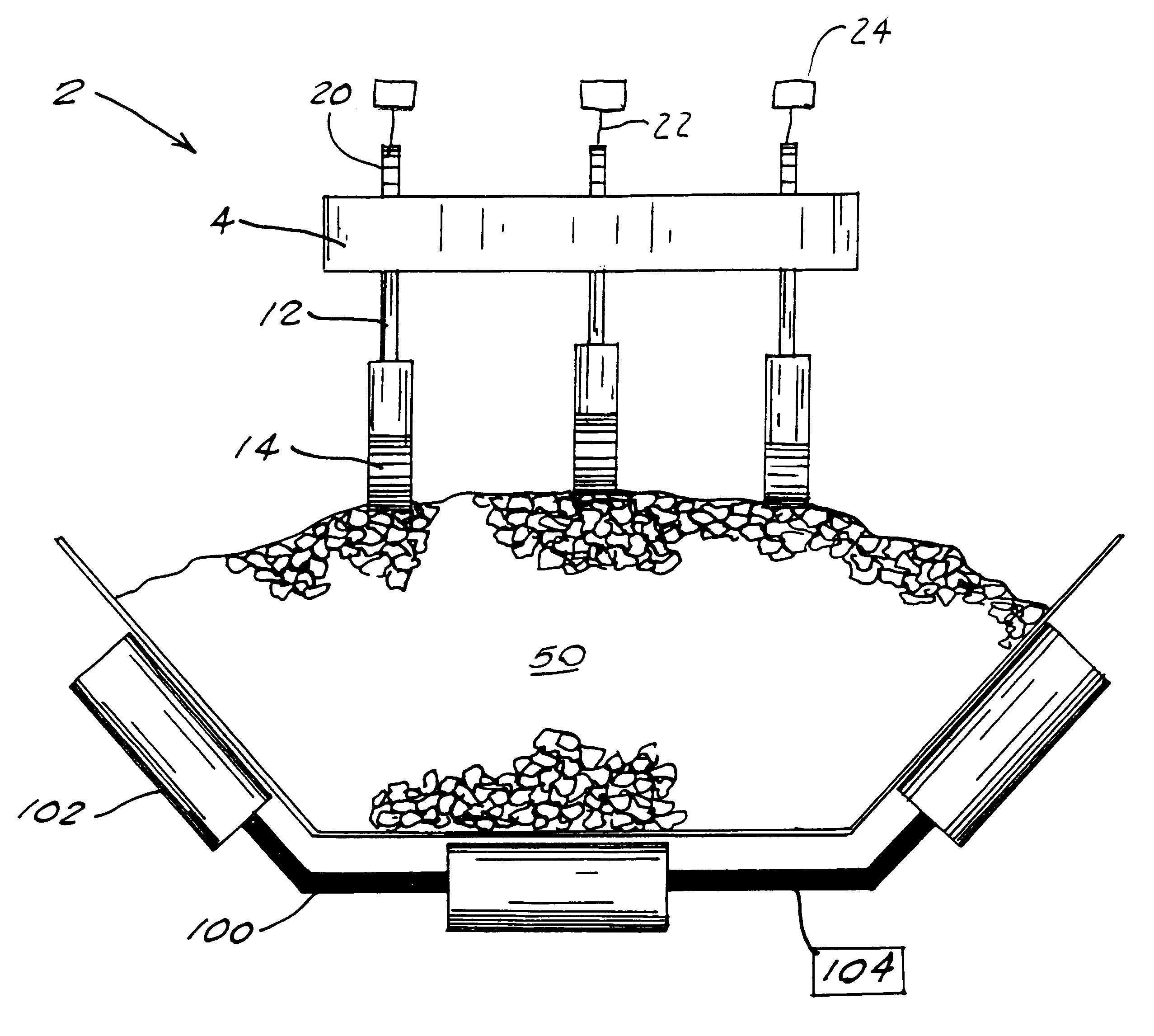

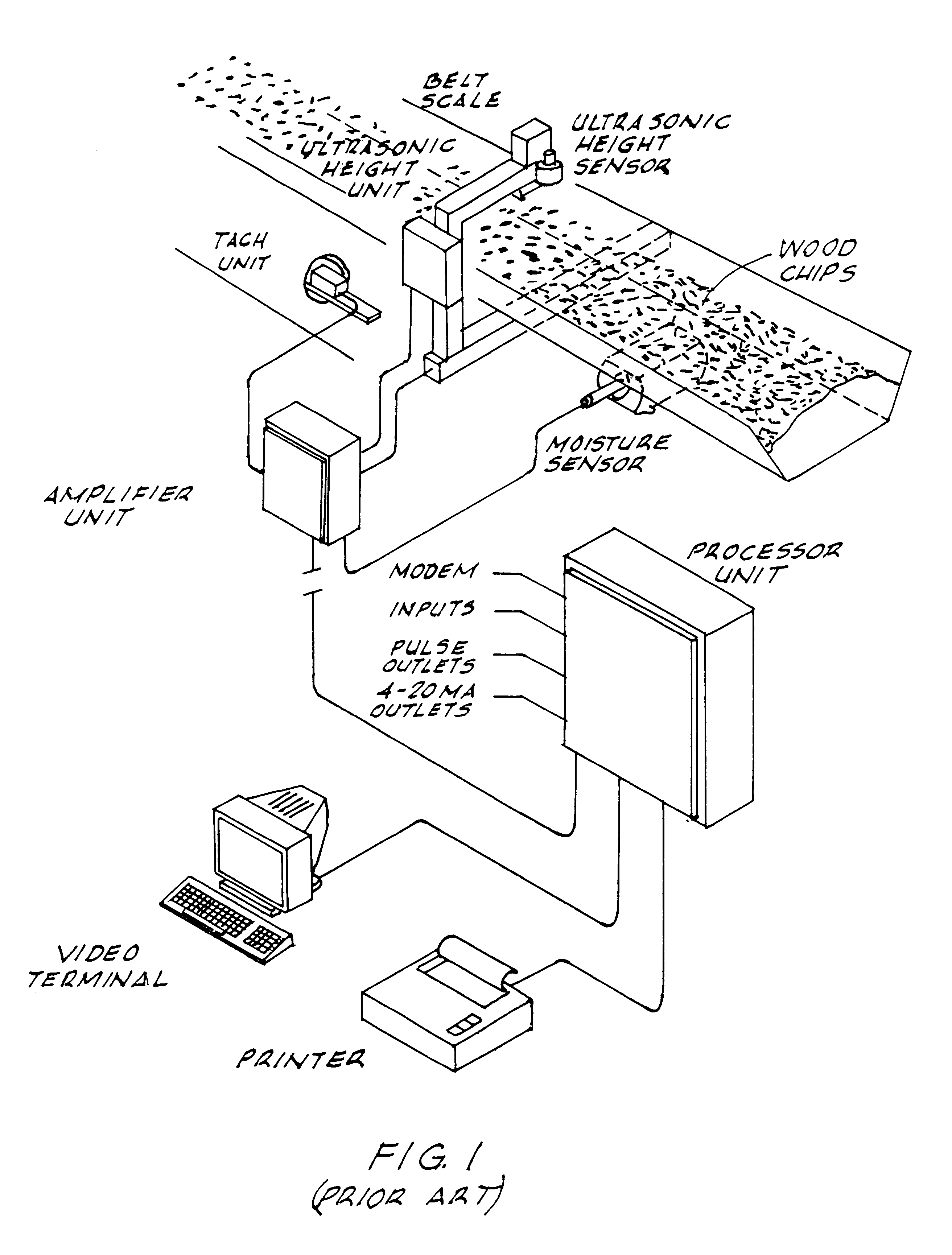

Height measurement apparatus for determining the volume/density of wood chips on a conveyor

InactiveUS6211470B1Volume/density can be accuratelyEase of assemblyControl devices for conveyorsLiquid transferring devicesMeasurement deviceEngineering

This invention relates to a height measurement apparatus for determining volume / density of wood chips on a conveyor. Such structures of this type, generally, employ the use of contacts that ride on top of the pile of wood chips in order to more accurately measure the volume and density of the wood chips.

Owner:MEADWESTVACO CORP

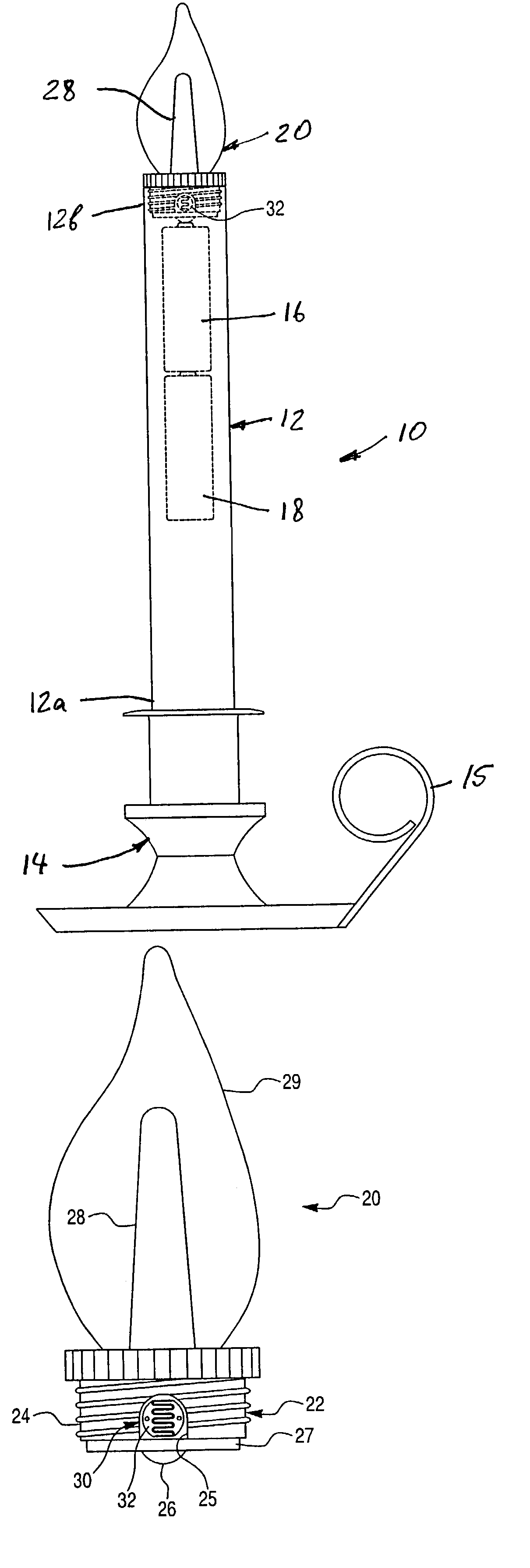

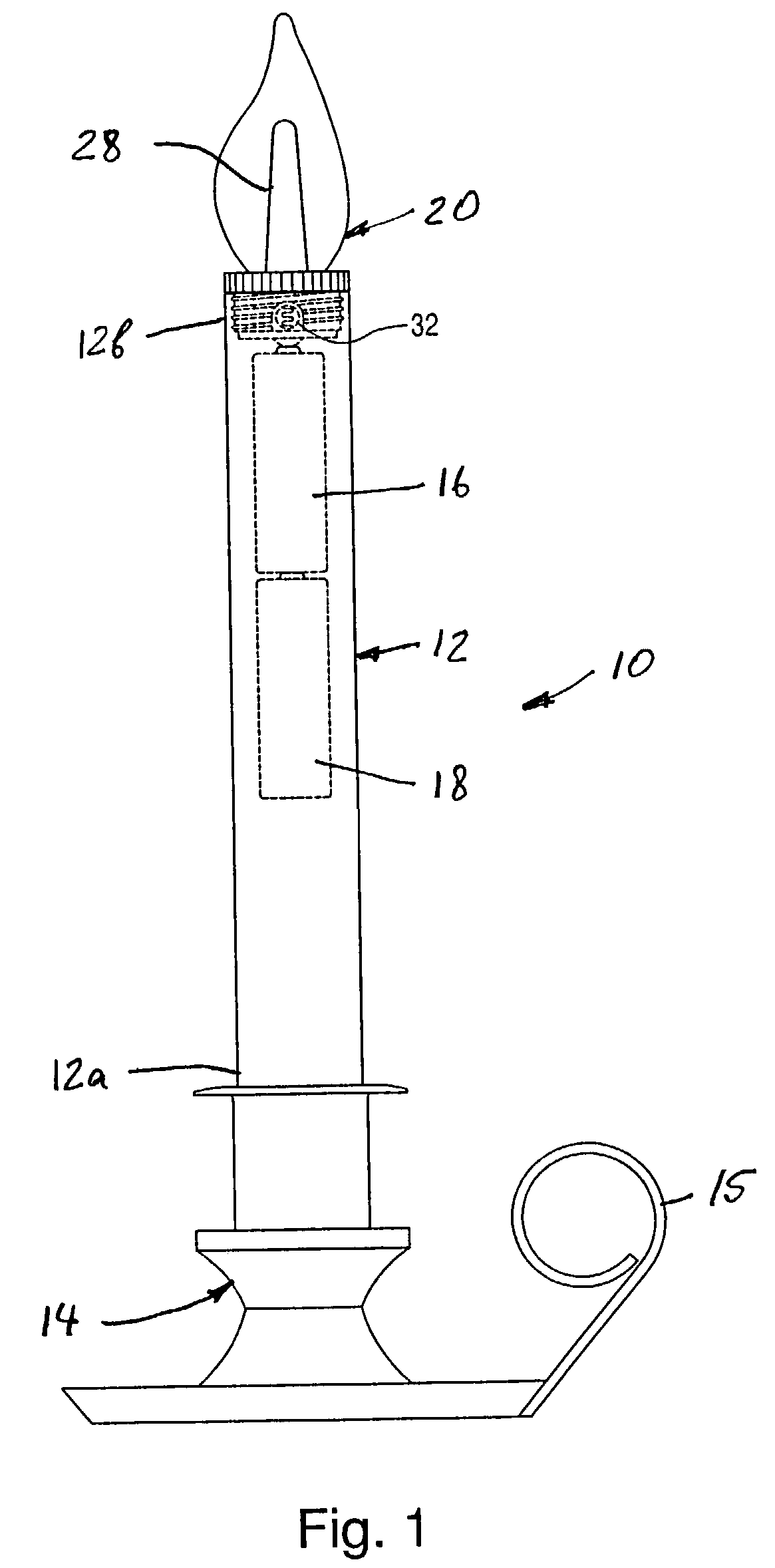

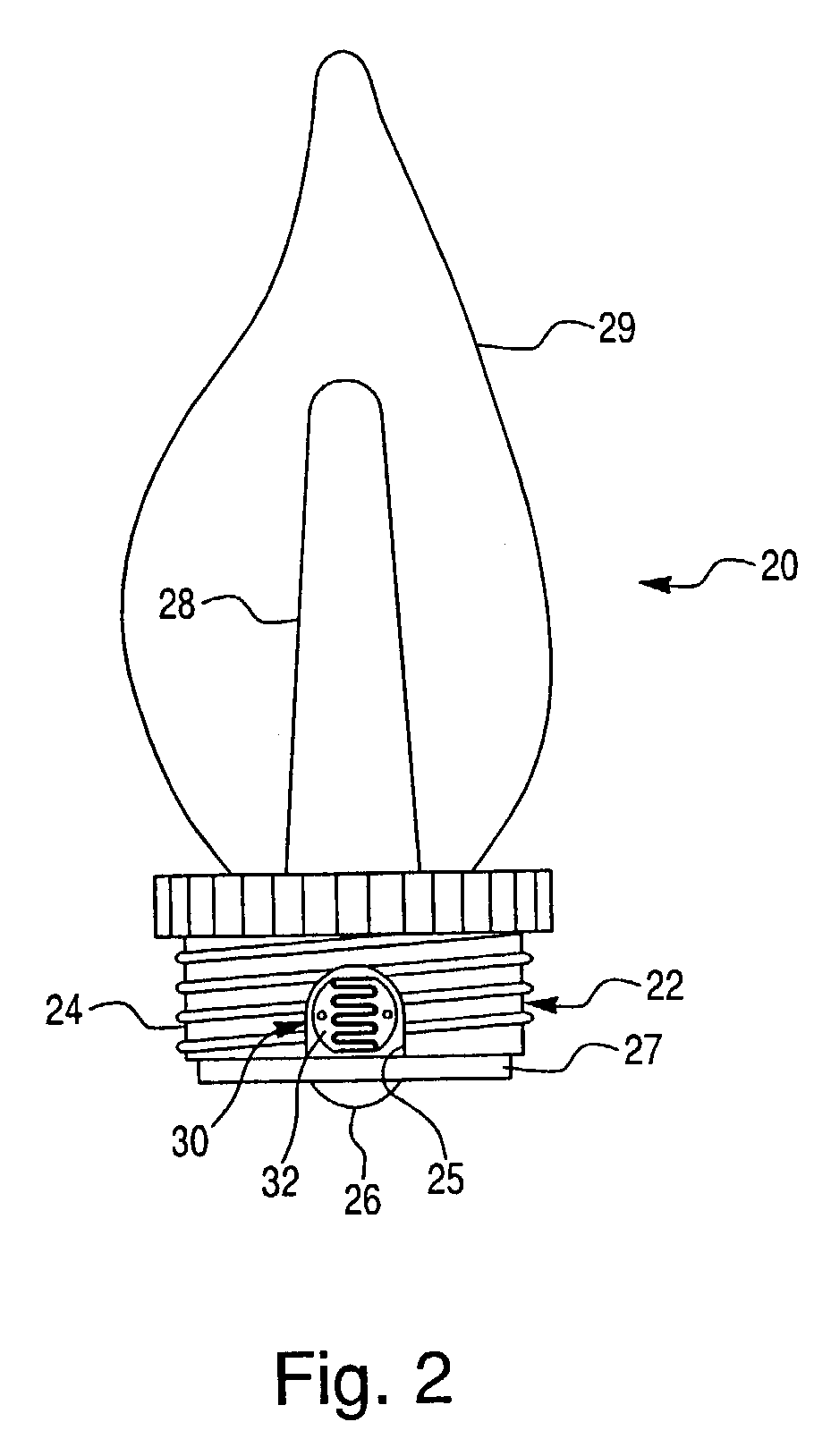

Electrical candle lamp

InactiveUS6981786B2Easy to assembleEasy to replaceCandle holdersPoint-like light sourceElectricityCandelabrum

The electrical candle lamp comprises a translucent candlestick member having a lower end and an upper end, a support member provided at the lower end of the candlestick member, and a light emitting assembly secured to the upper end of the candlestick member. The light emitting assembly includes a base portion, a light emitting device mounted to the base portion and an electronic control unit for controlling operation of the light emitting device. The electronic control unit includes an ambient light sensor provided for automatically turning the light emitting device on if ambient light level is below a predetermined level and for turning the light emitting device off if ambient light level is above the predetermined level. The ambient light sensor protrudes through an opening formed in an outer surface of the base portion of the light emitting assembly and is exposed to ambient light.

Owner:INT MARKETING

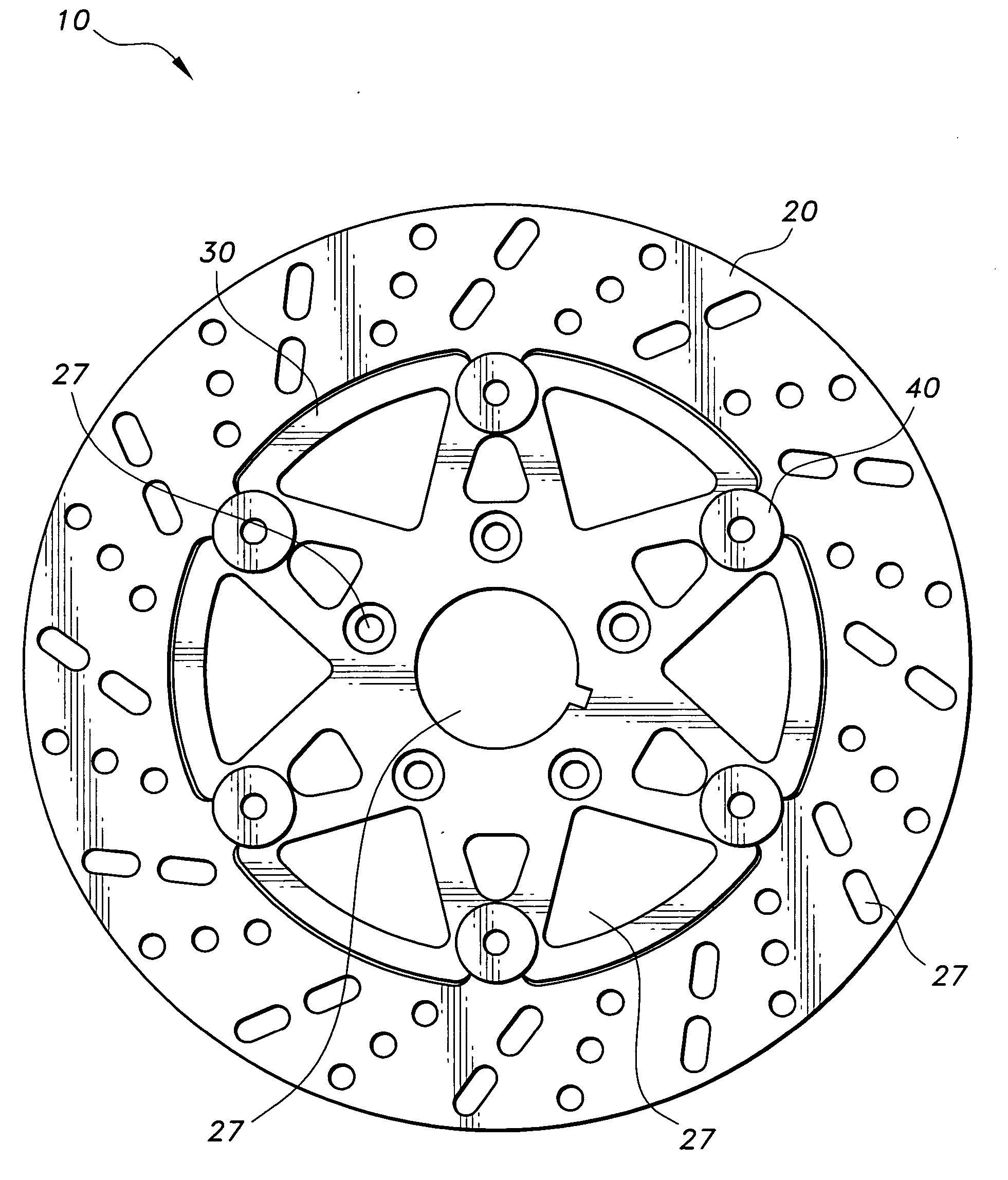

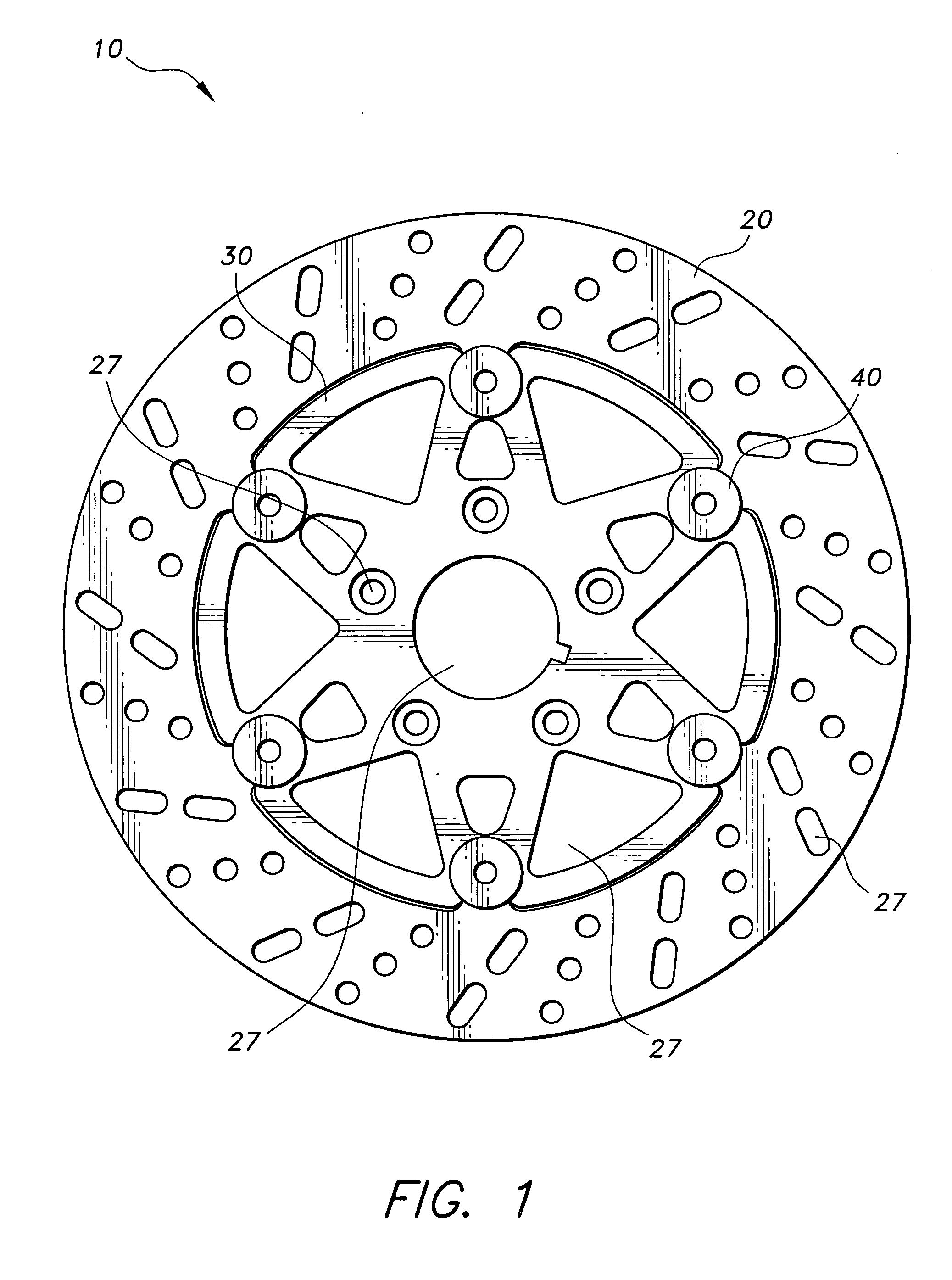

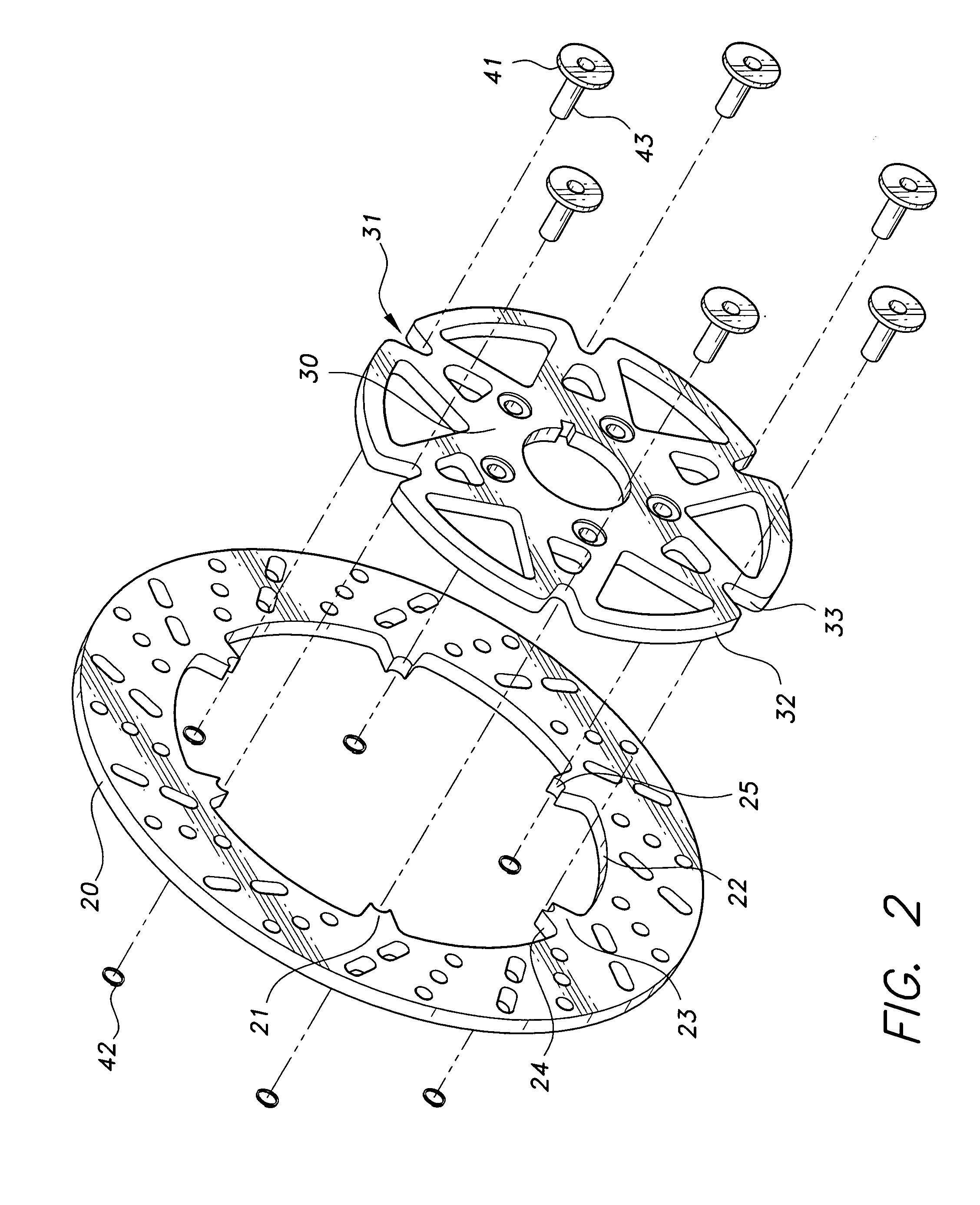

Floating brake rotor assembly with non-load bearing pins

ActiveUS20050082125A1Ease of assemblyEasy to replaceBraking element arrangementsBraking discsEngineeringMechanical engineering

The floating brake rotor assembly with non-load bearing pins includes a brake rotor and hub that are coplanar and are interconnected by pin and spring assemblies such that the pins do not bear rotational torque being transferred between the brake rotor and hub. The rotor has tooth-like protruding members along its inner edge that mate with recessess along the outer edge of the hub. When aligned, each protruding member and corresponding recess forms an aperture through which a pin is positioned, and allows for transfer of rotational torque without applying load force to the pin.

Owner:GEHRS JEFFREY W

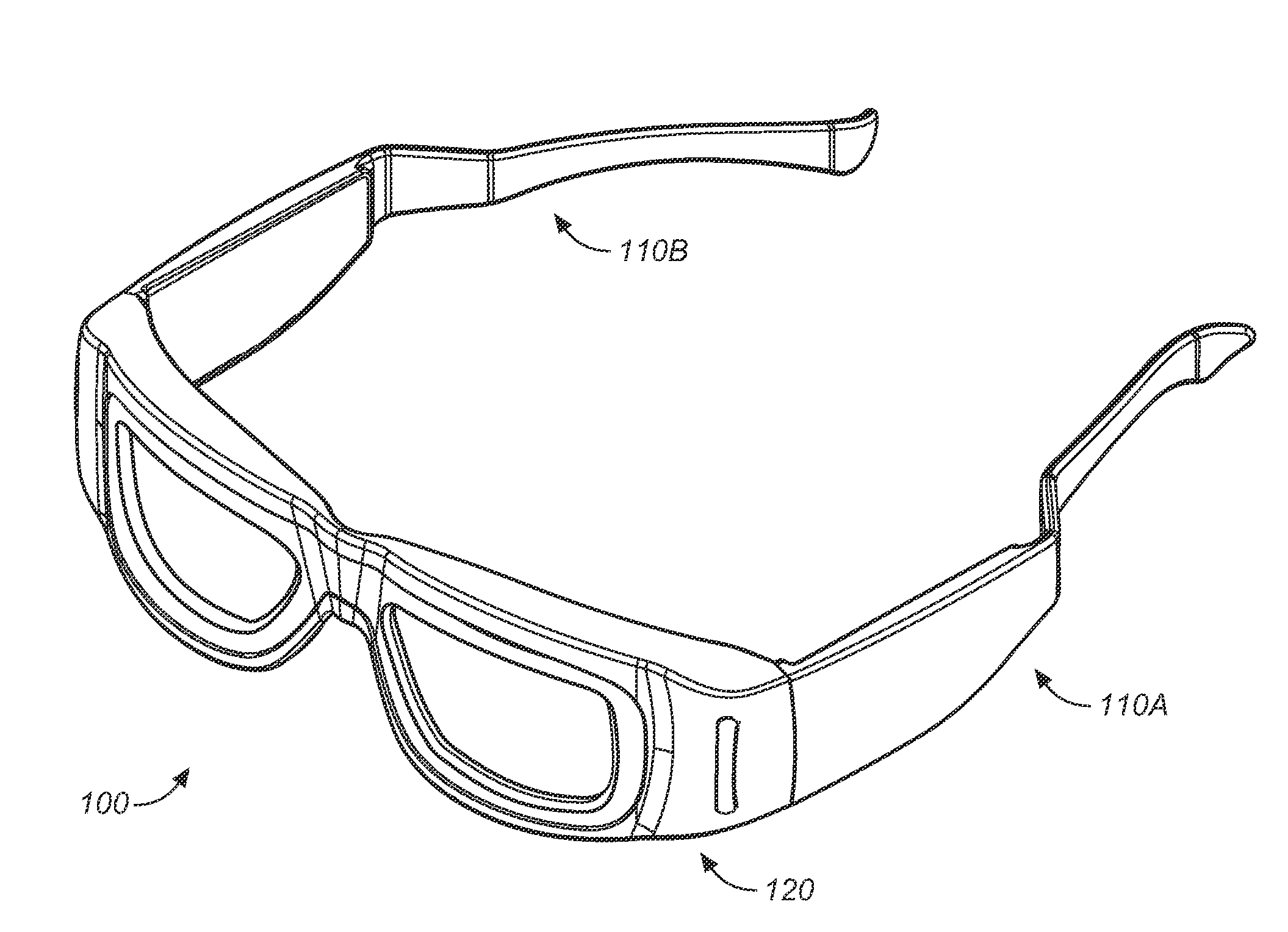

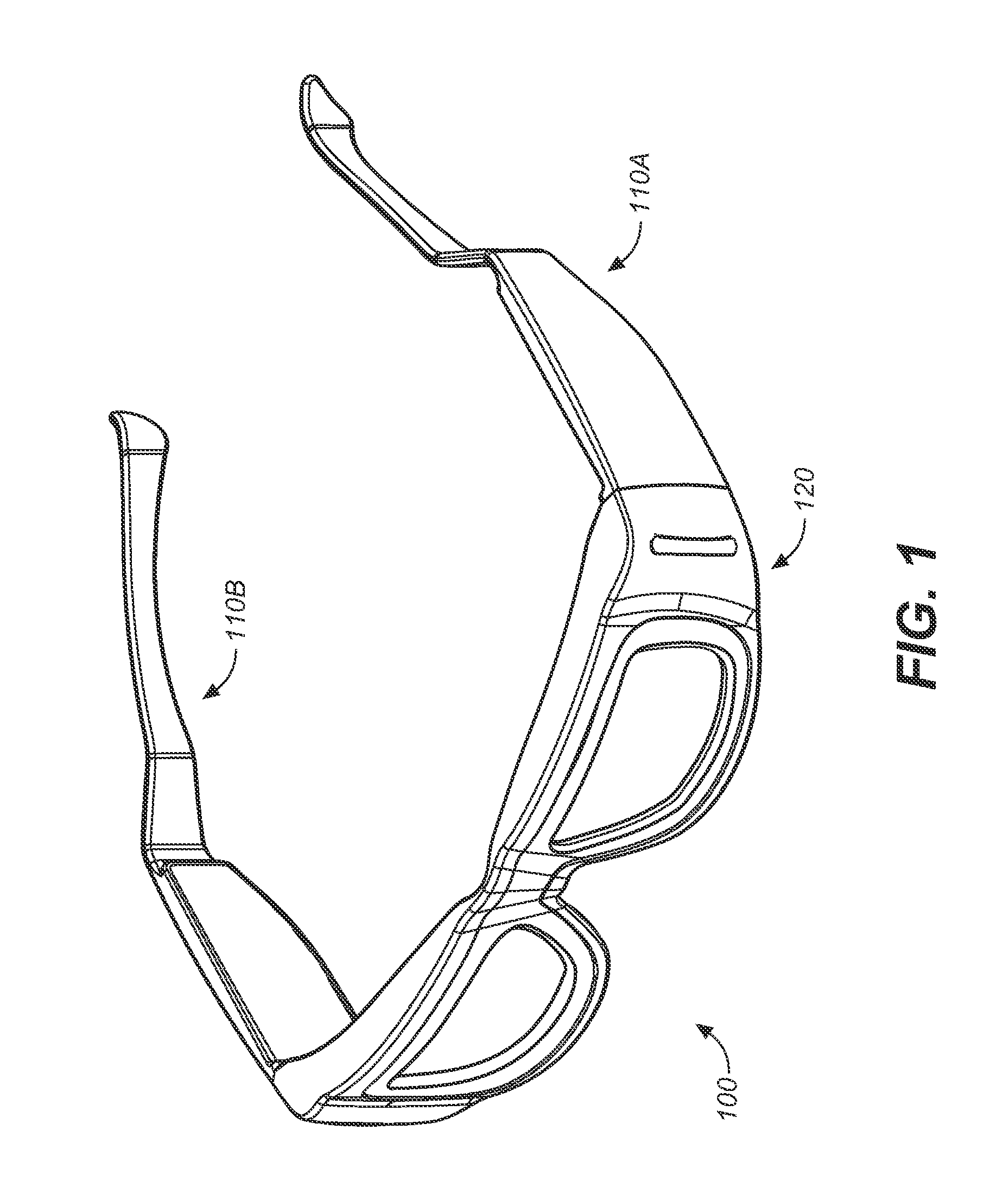

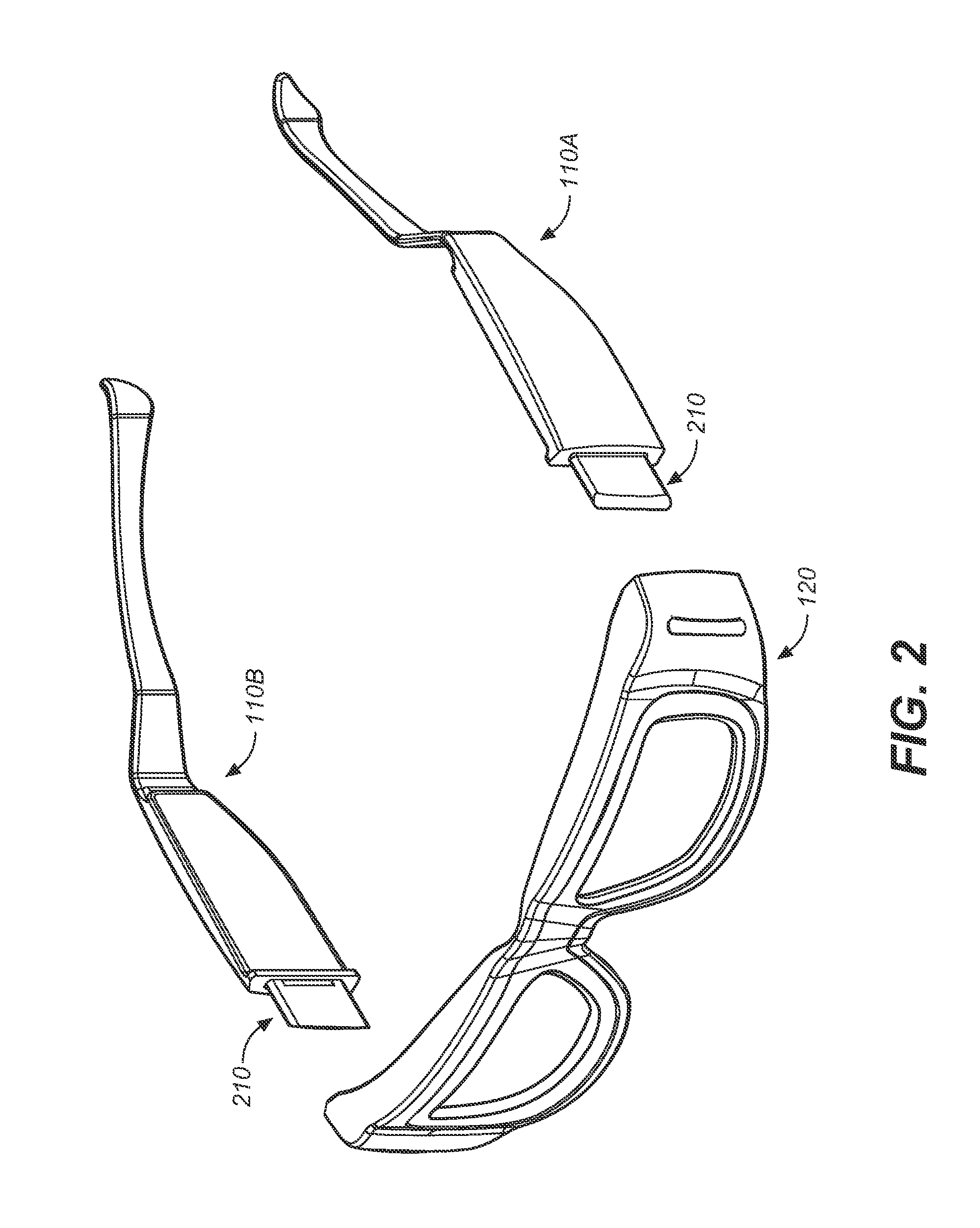

Eyeglasses for personal and commercial use including reuse in 3D theater and other repeated operations

ActiveUS20120224260A1Reduce reflectionImprove cleanabilityNon-optical adjunctsOptical filtersCamera lensOperational costs

3D glasses including features for an enhanced viewing experience with lower production and operating costs for theaters. Keyed lenses and removable temples facilitate assembly and field repairs. Specific angles of lens placement and the provision of specific anti-reflective areas on the frames enhance the quality of the optical path content being viewed. RFID and radio chips increase accountability and collection of use statistics. Smooth areas enhance cleaning and lower the time and material costs for between use cleanings.

Owner:DOLBY LAB LICENSING CORP

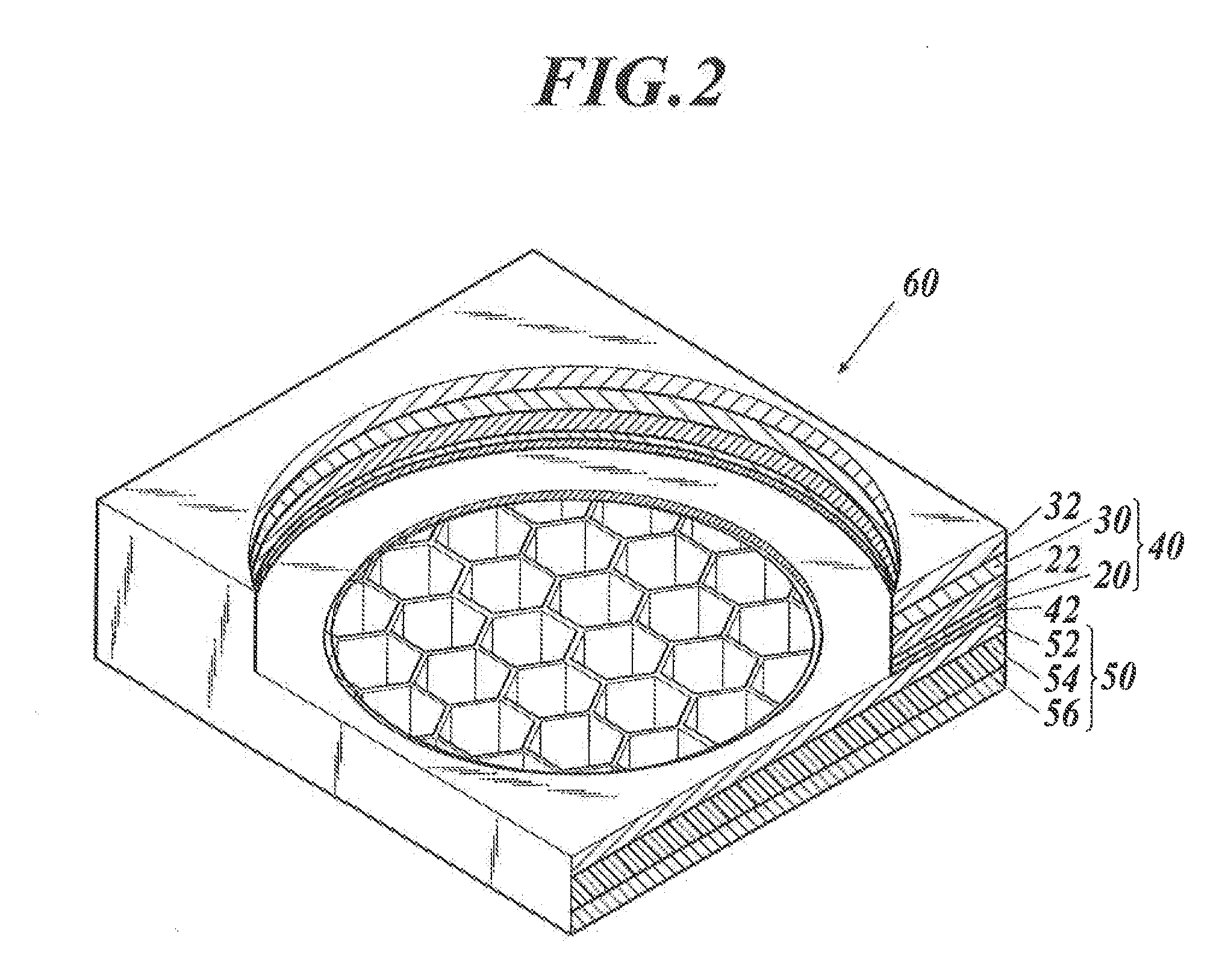

Surgical access port sealing assembly

InactiveUS20080125716A1Promote sportsReduce stress concentrationCannulasInfusion syringesStress concentrationEngineering

A surgical system assembly (1) includes a resilient seal (6) having a central opening (7) therein and being fixedly mounted to a housing (2); and a non-elastic, flexible member (9) joining the housing (2) to a rigid or semi-rigid cannula (14) or tube that is positioned at least partially through tissue, percutaneously, during a surgical procedure. Flexing of the non-elastic, flexible member (9) facilitates movement of the housing (2) and thus the resilient seal (6) relative to the cannula (14) in order to allow the seal (6) to move with an instrument or object protruding therethrough in sealing engagement as a means of reducing stress concentrations that tend to promote overstretching or “cat-eyeing” of the seal's central opening (7).

Owner:CRUZ LAWRENCE

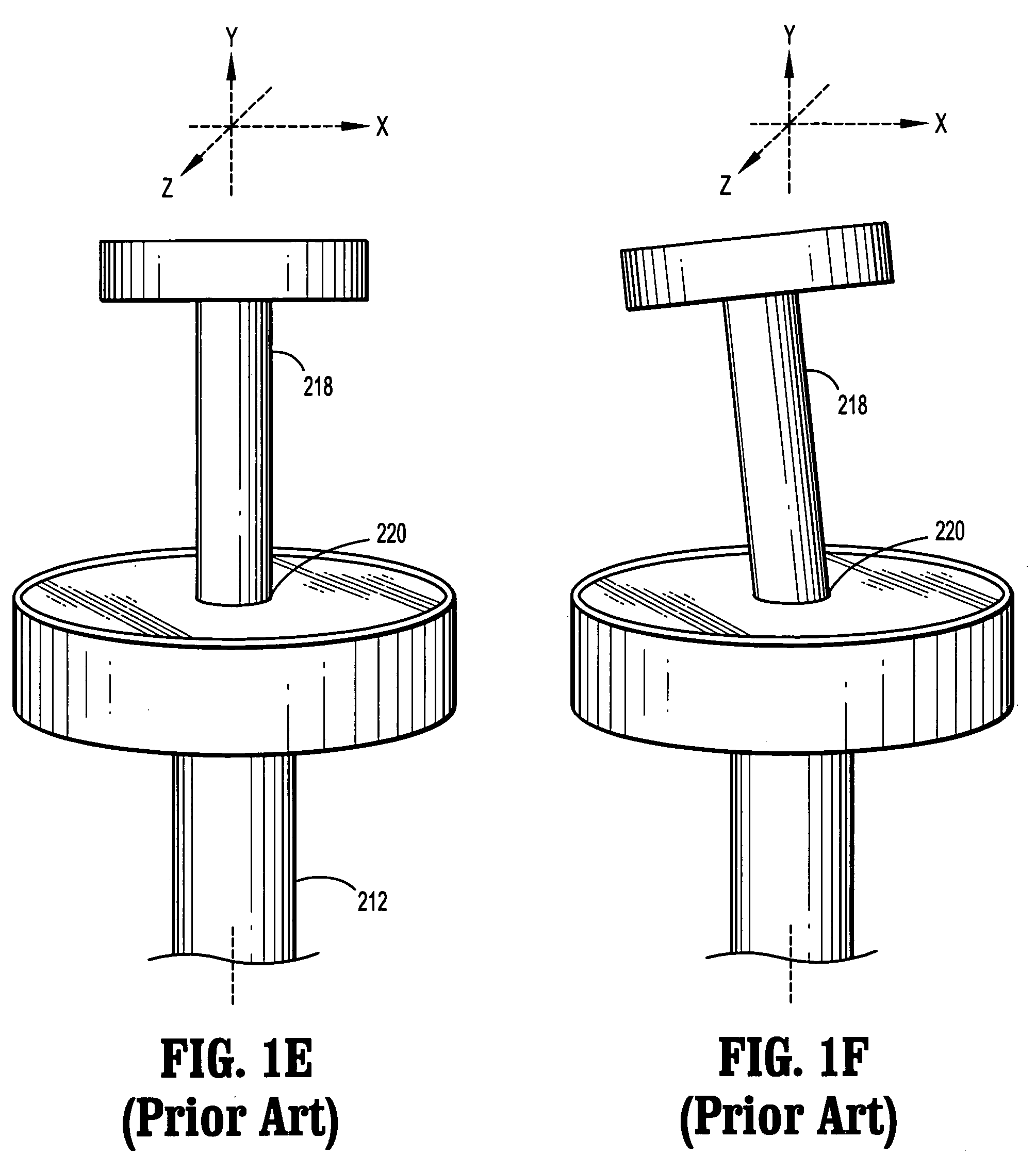

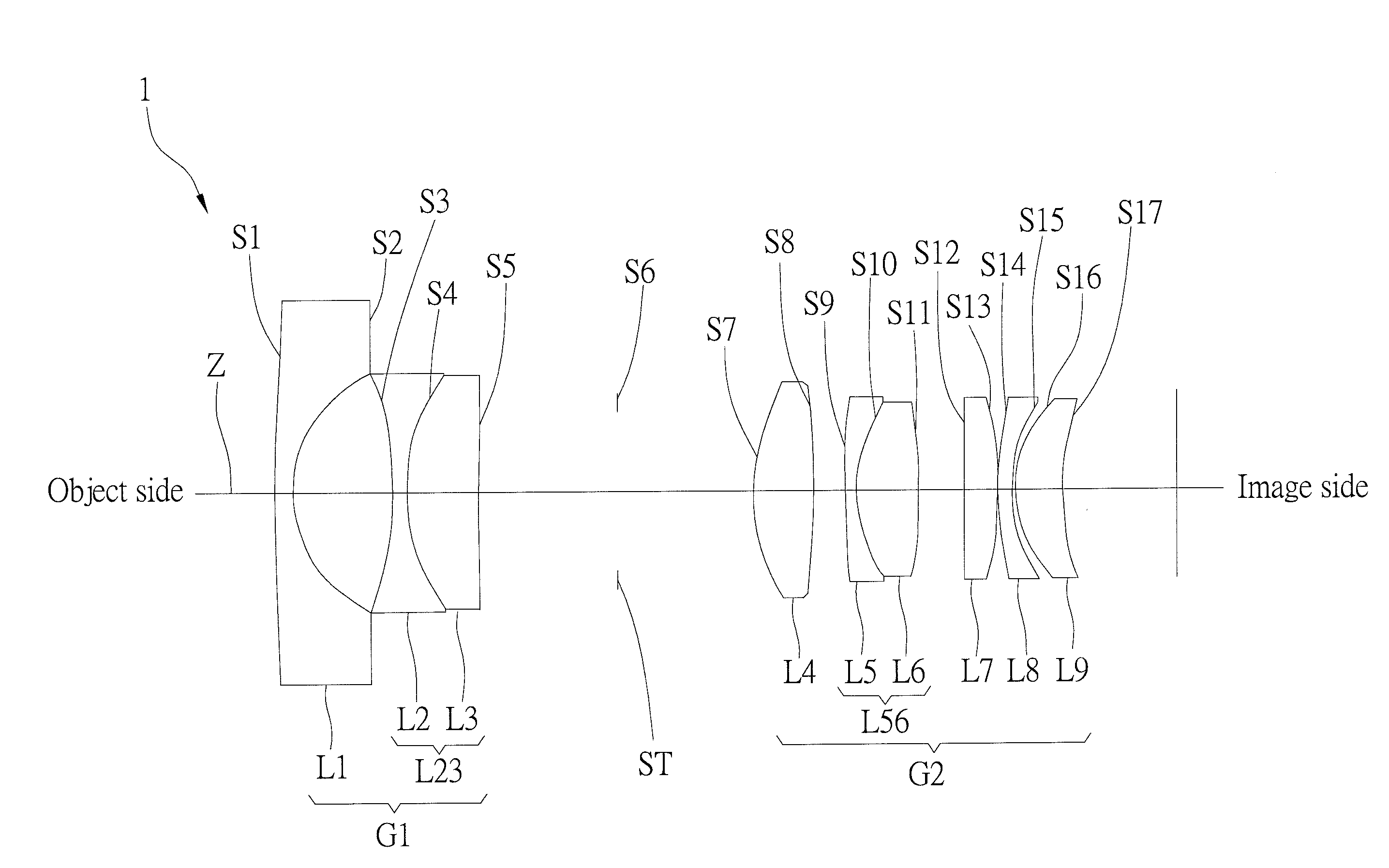

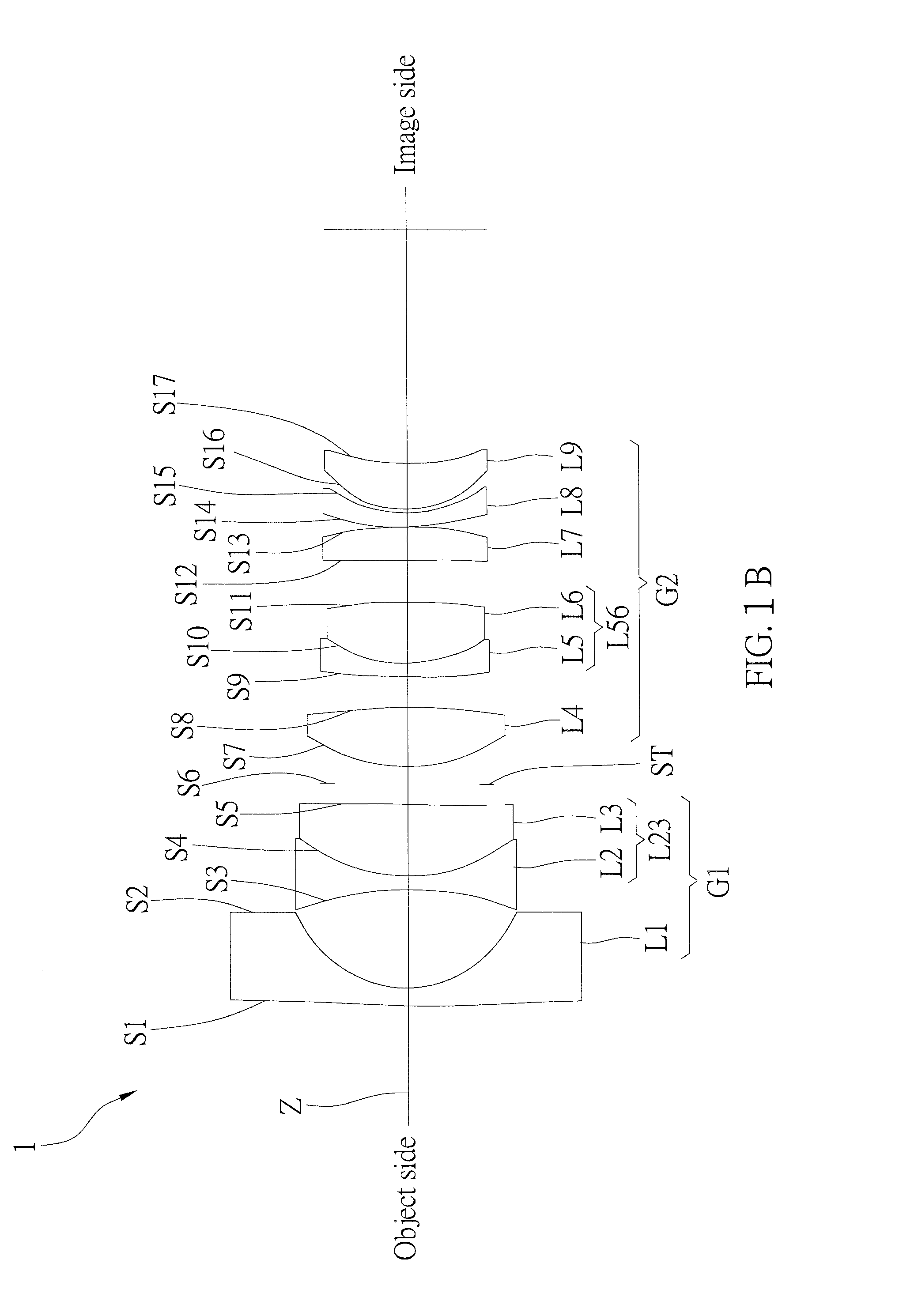

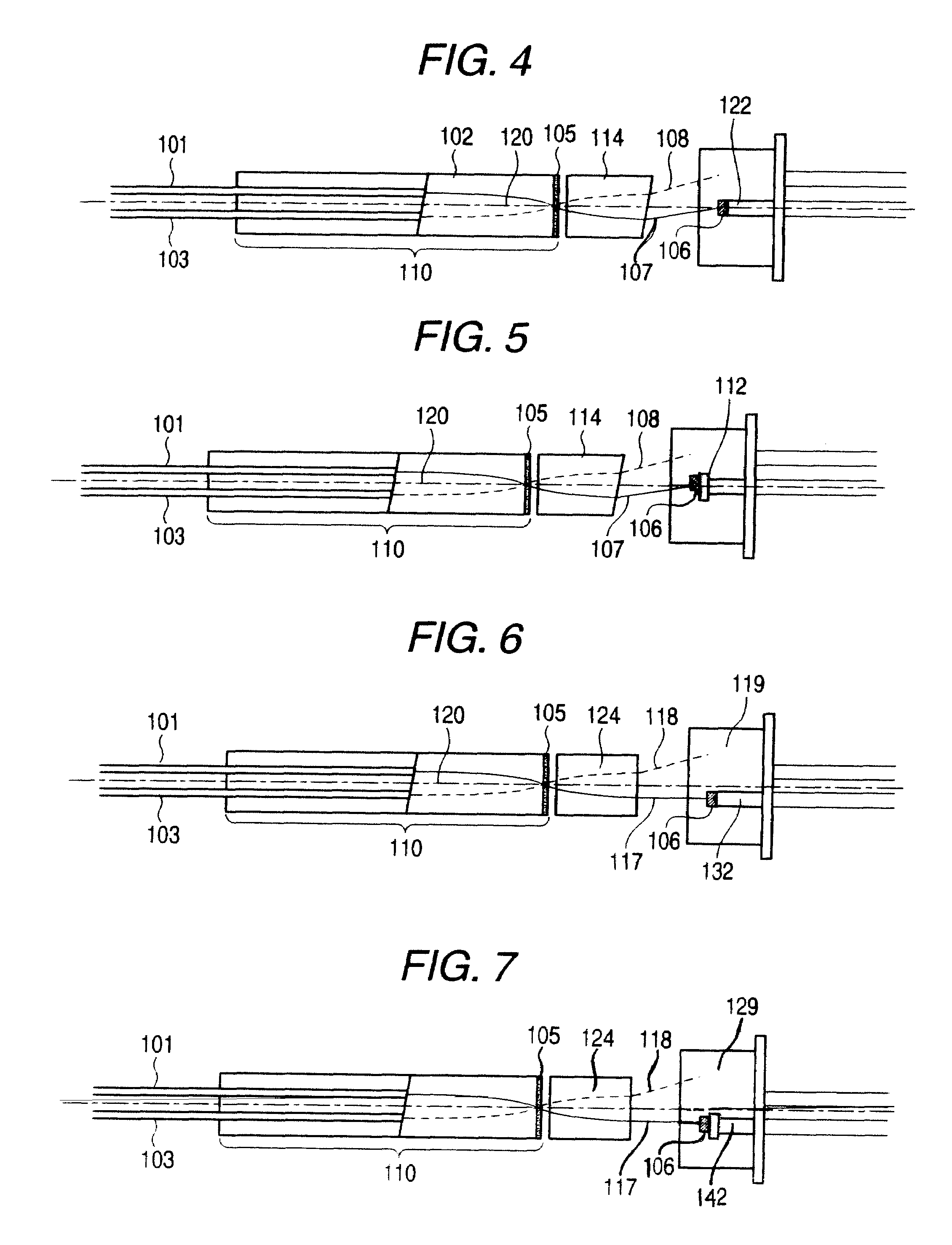

Zoom lens

A zoom lens includes, in order from an object side to an image side, a first lens group, an aperture, and a second lens group. The first lens group has negative refractive power, and is composed of a negative first lens, a negative second lens, and a positive third lens. The third lens and the second lens are adhered together to form a negative doublet. The second lens group has positive refractive power, and is composed of a positive fourth lens, a negative fifth lens, a positive sixth lens, a positive seventh lens, a negative eighth lens, and a positive ninth lens. The sixth lens and the fifth lens are adhered together to form a negative doublet. In addition, the first lens group can be moved between the object side and the aperture, while the second lens group can be moved between the aperture and the image side.

Owner:CALIN TECH

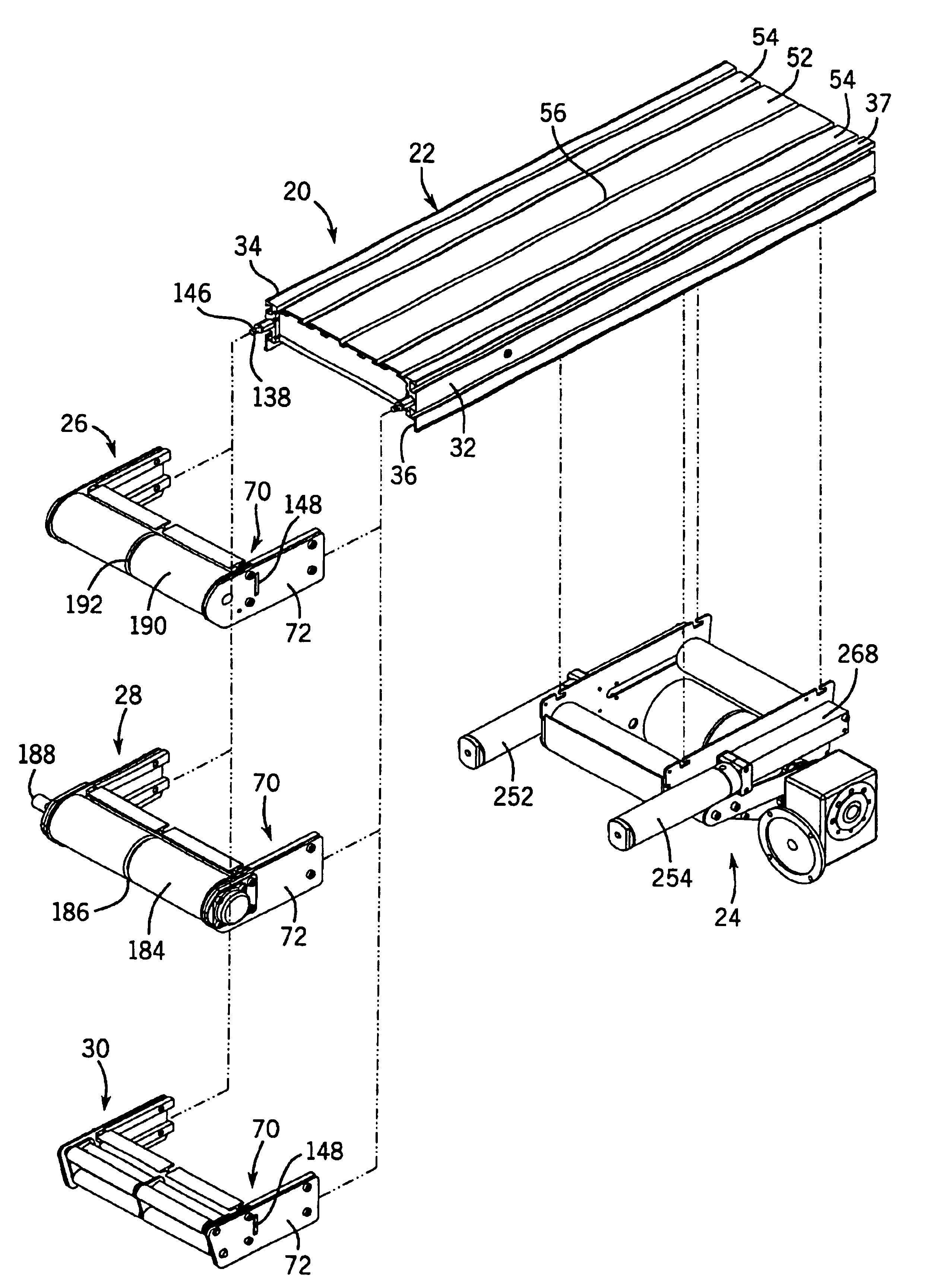

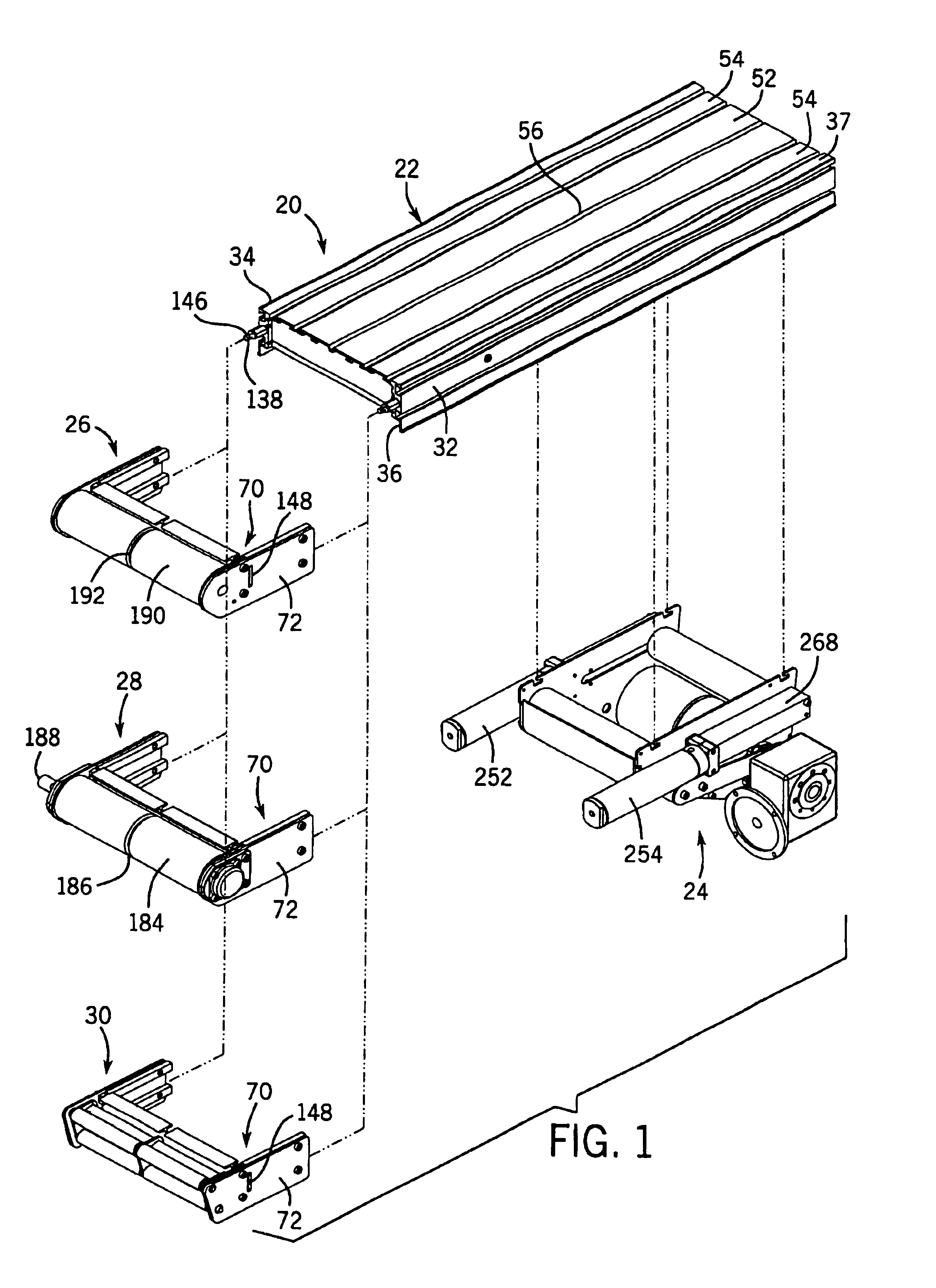

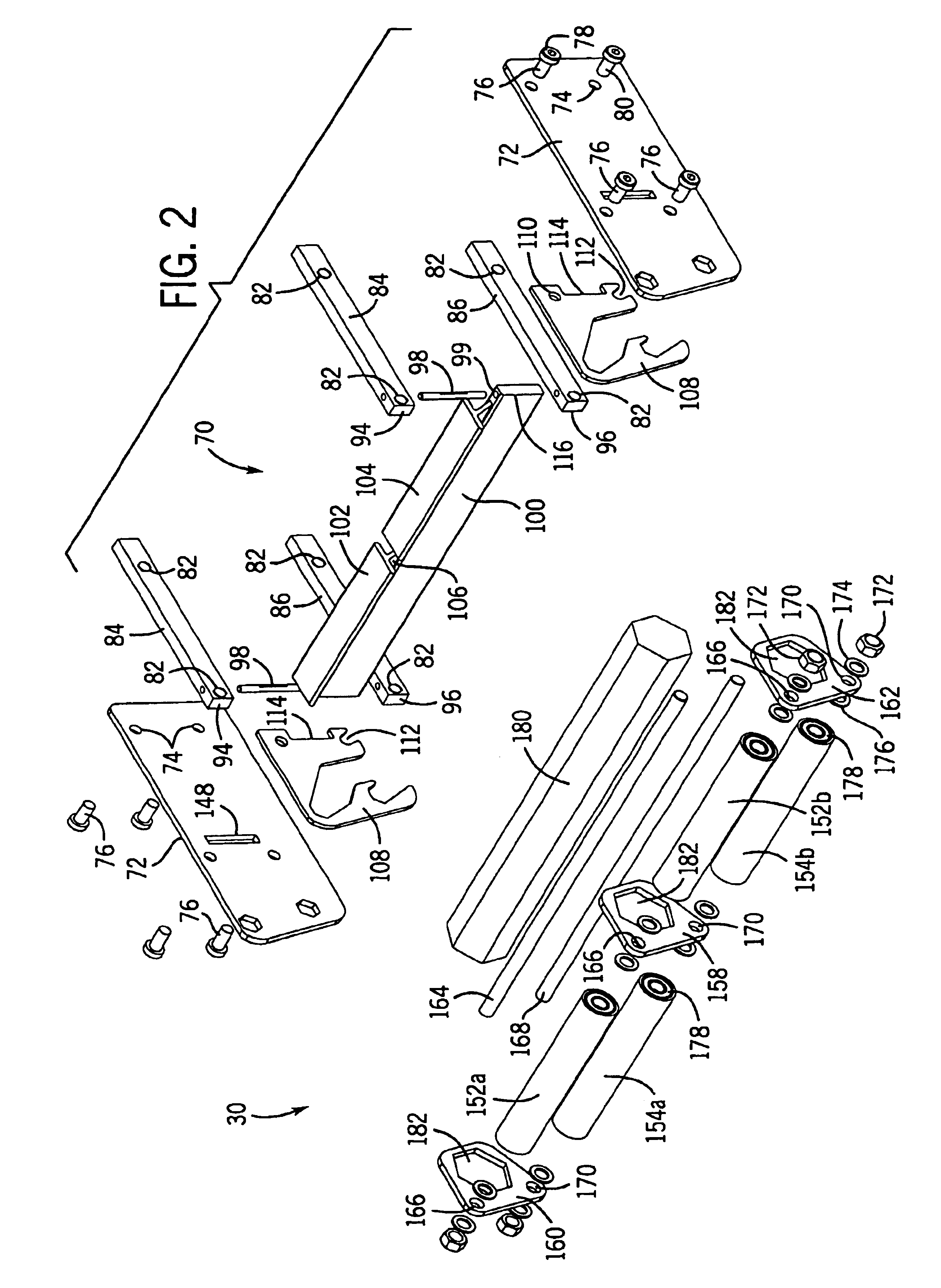

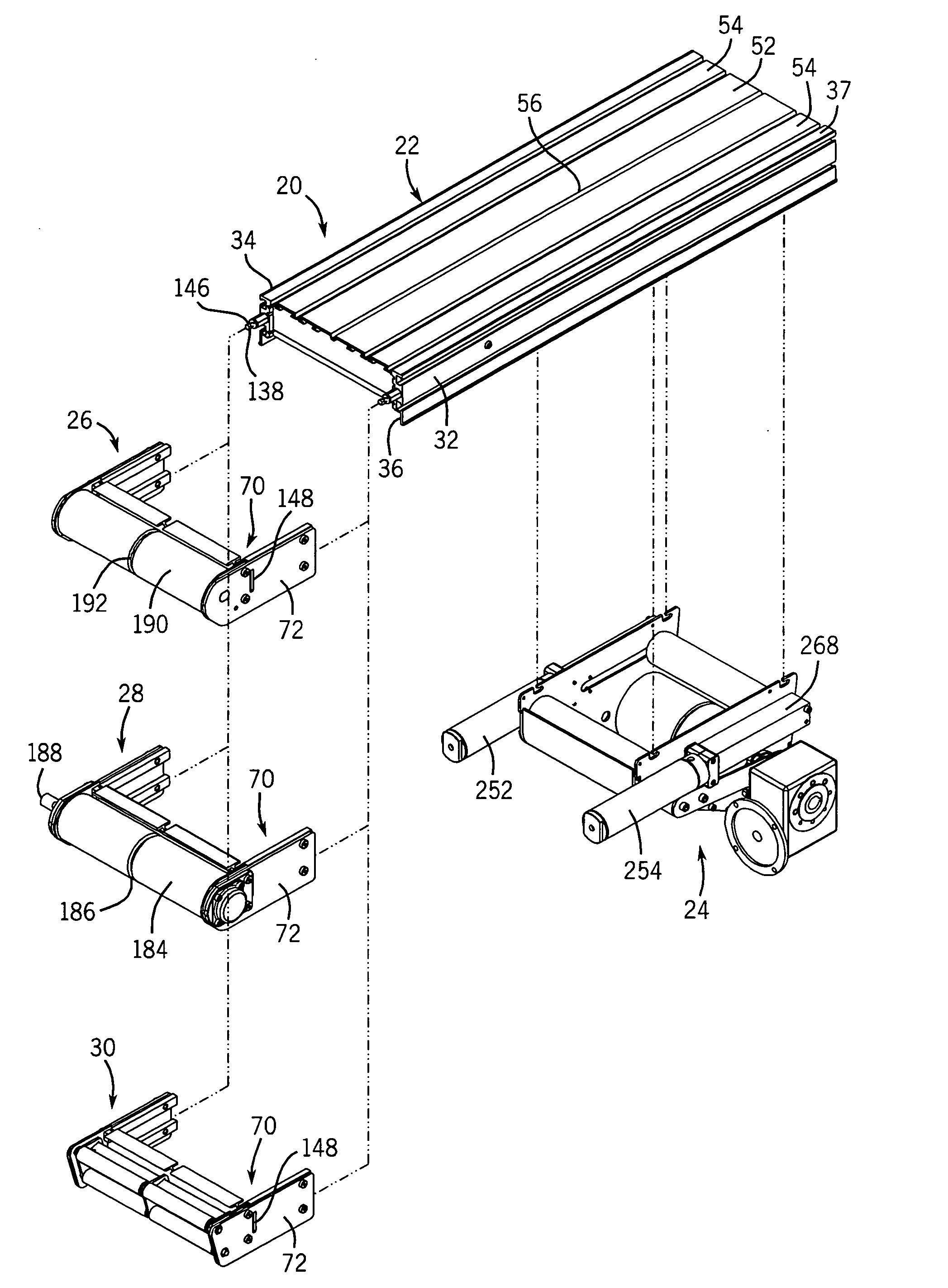

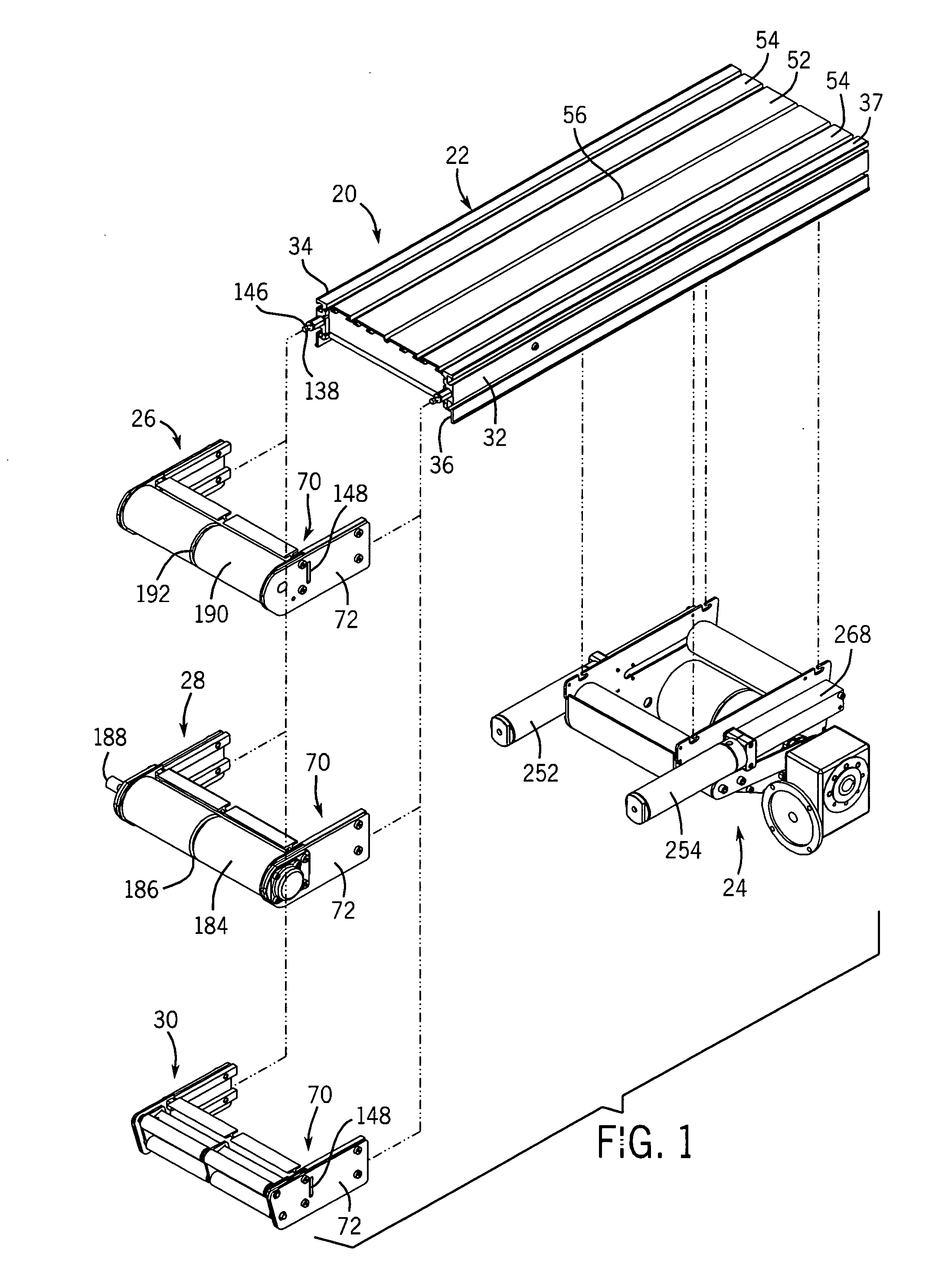

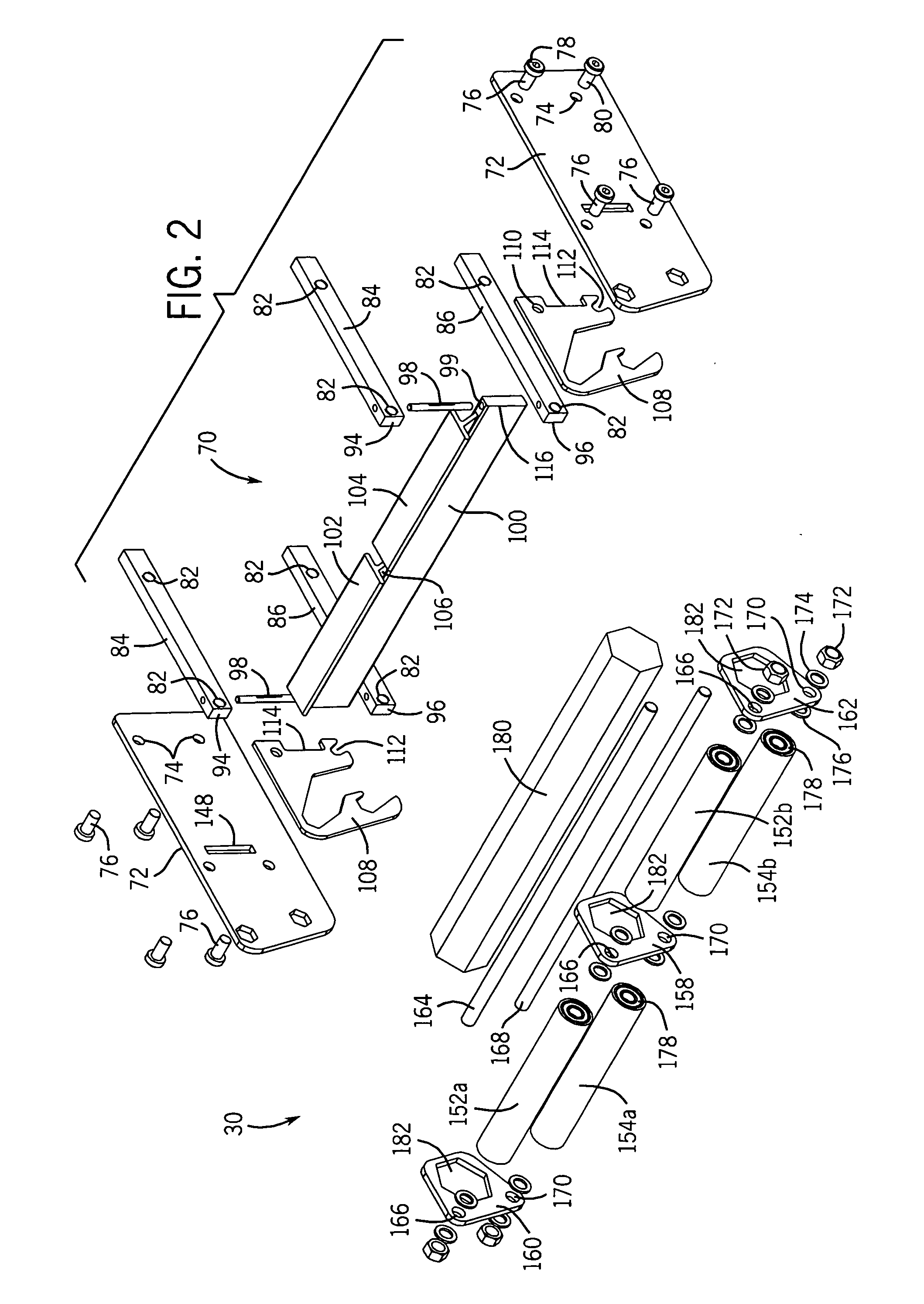

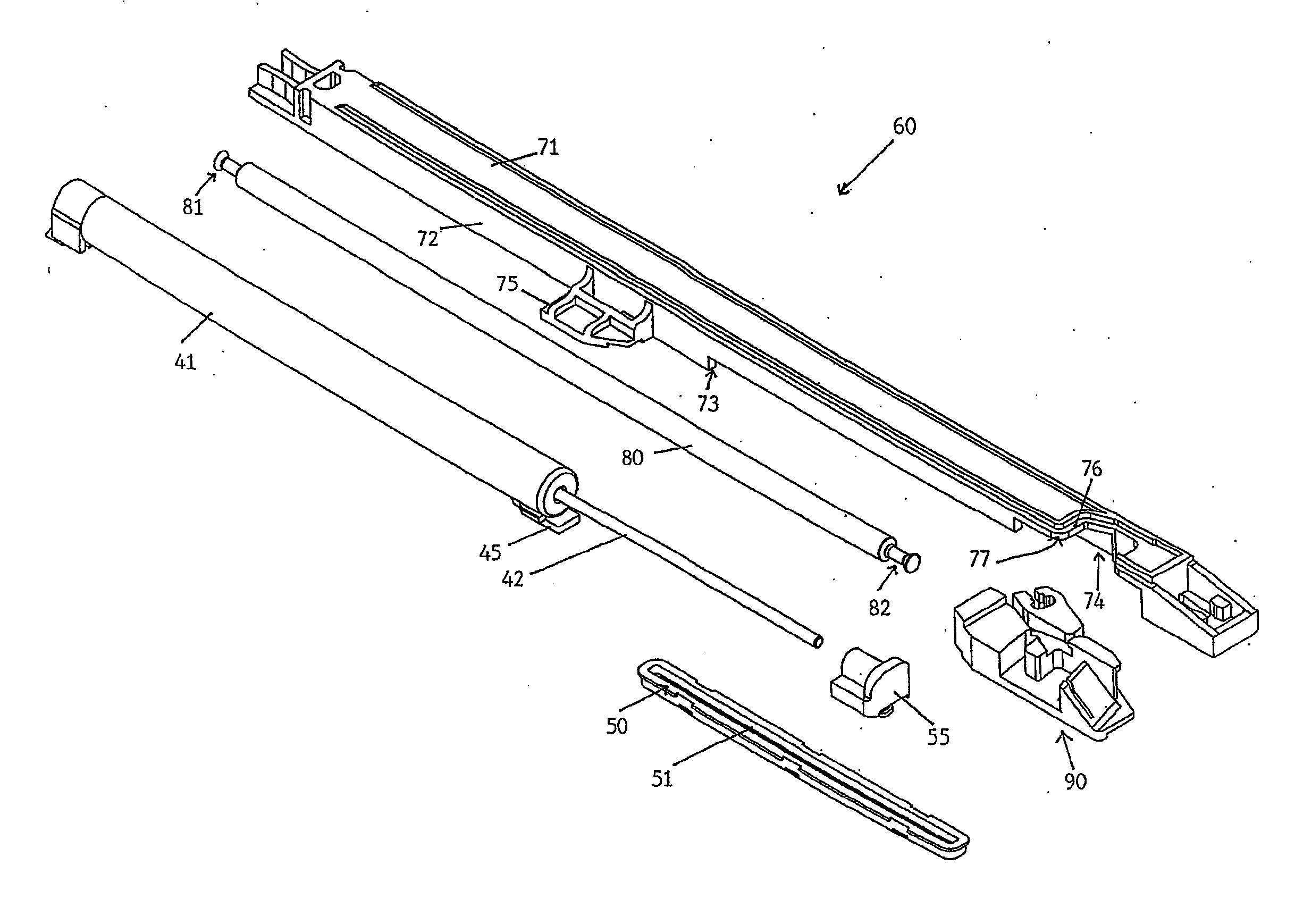

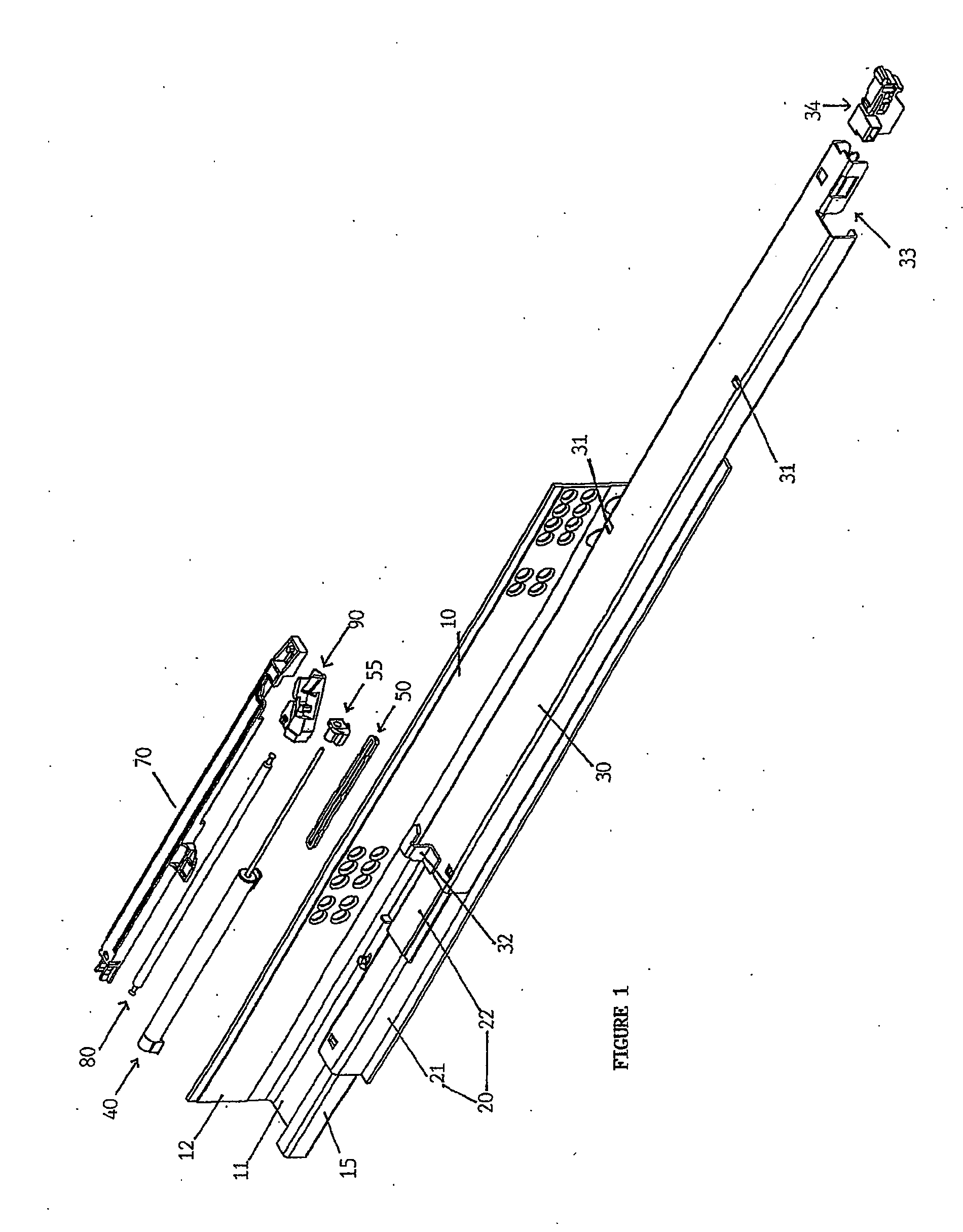

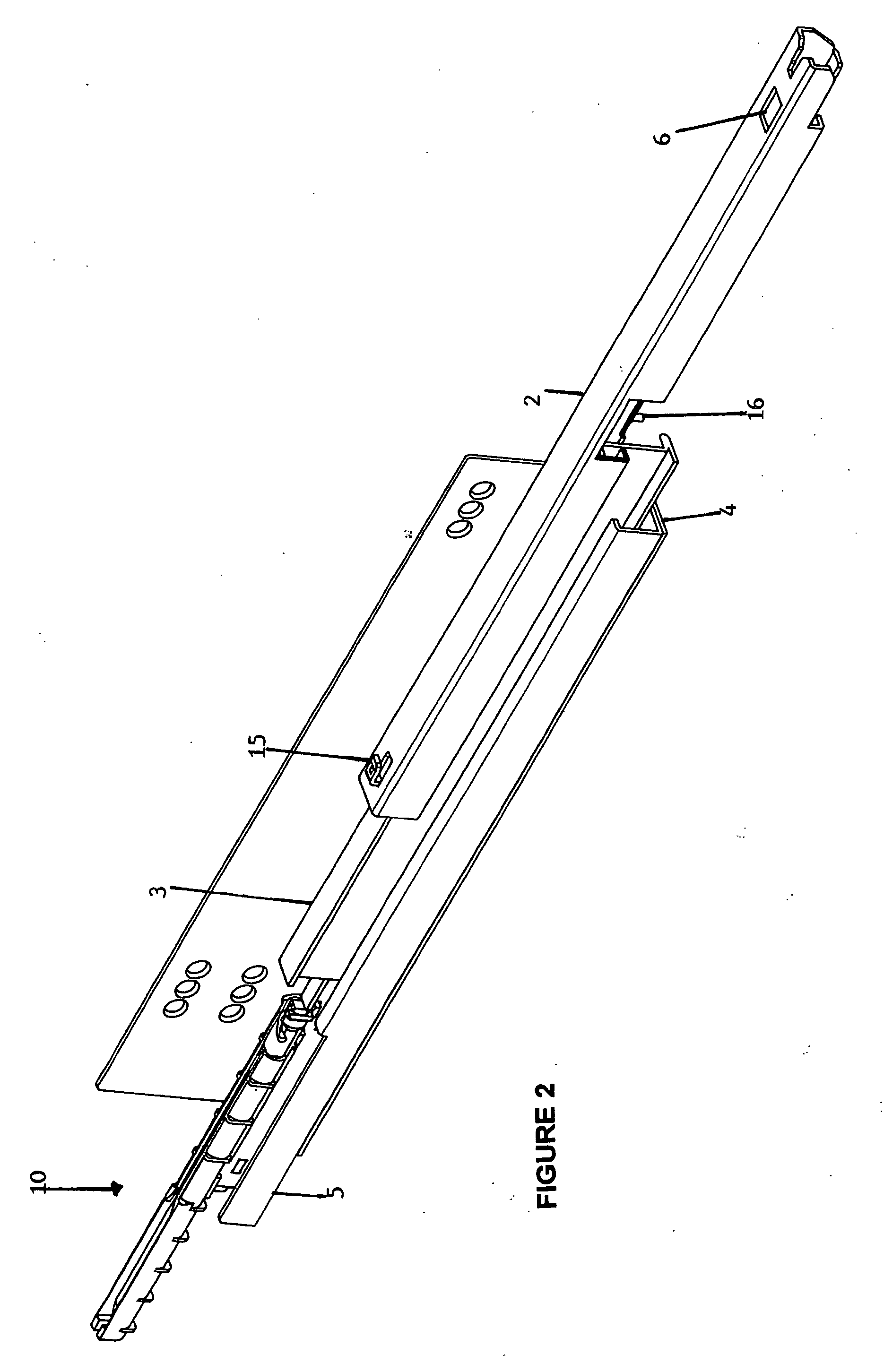

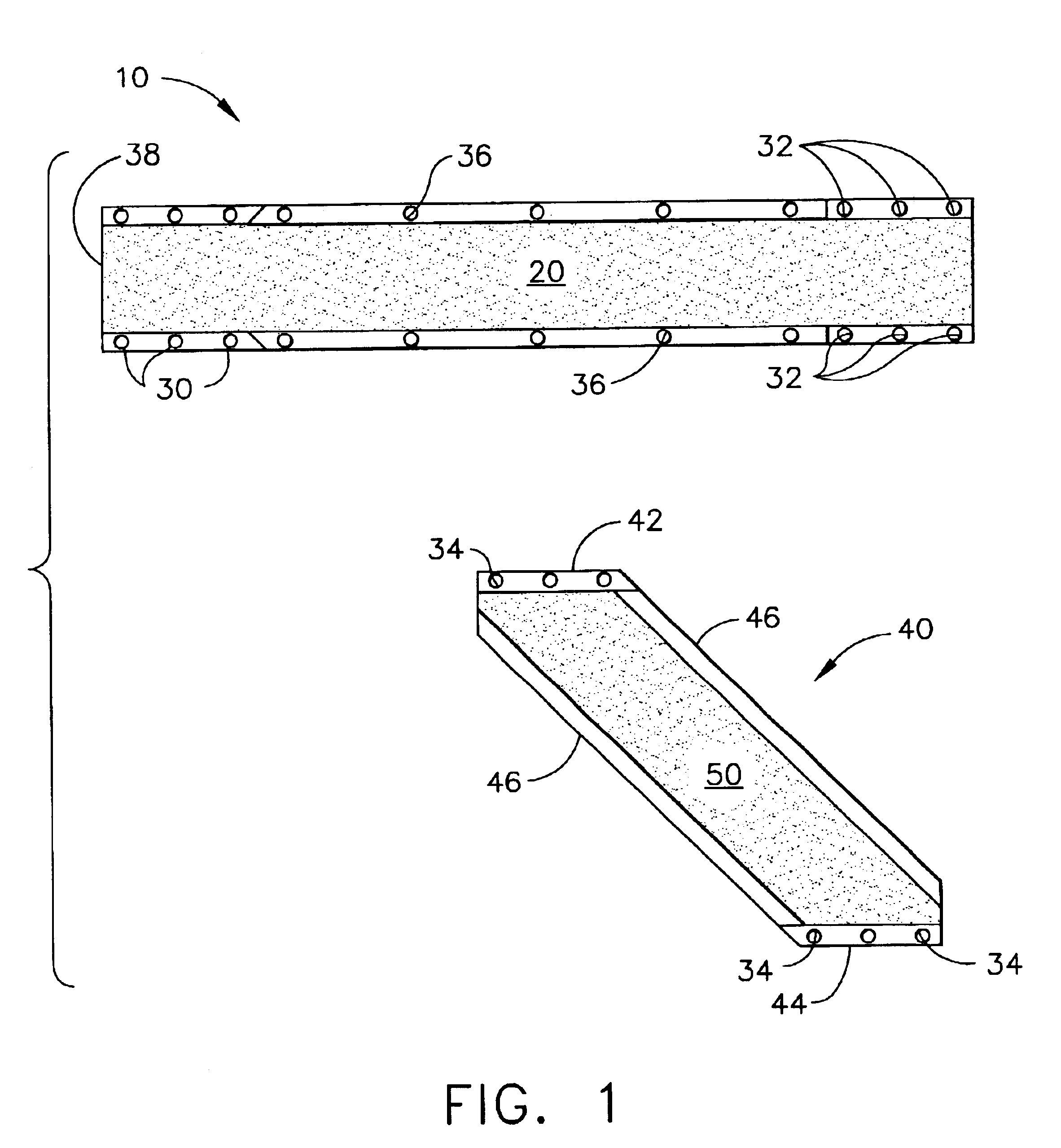

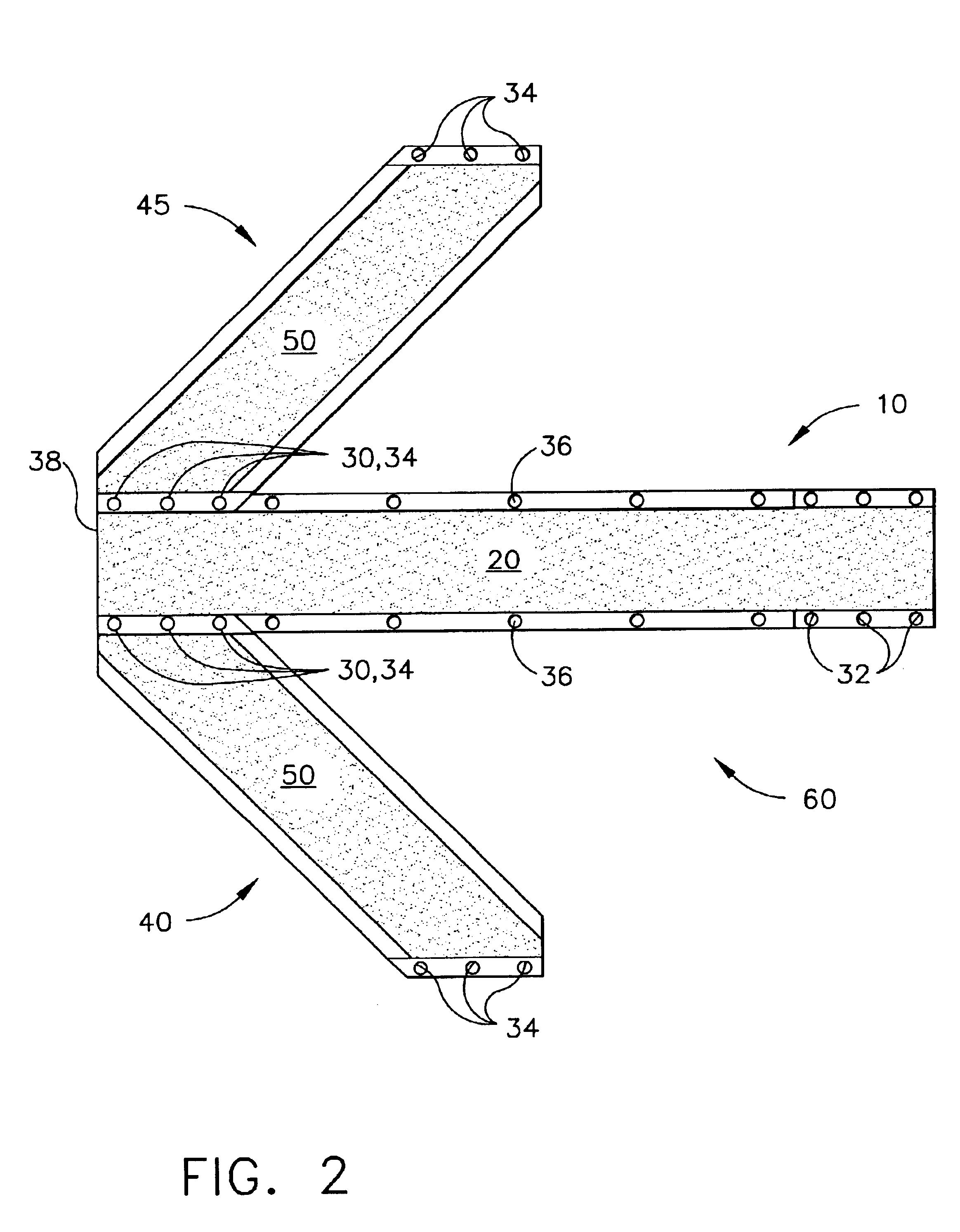

Endless belt conveyor frame

InactiveUS6871737B2Ease of assemblyManufacturing EaseConveyorsSupporting framesEngineeringConveyor belt

A conveyor construction that includes a conveyor frame assembly formed from a pair of spaced side frame members interconnected with each other by spaced cross members. The upper bed of the conveyor frame assembly is formed from individual bed plate strips attached to each of the cross members. The width of the conveyor frame assembly can be modified by the proper selection of the number of bed plate strips. The conveyor frame assembly includes a separate tensioning assembly and tracking adjustment assembly. The tracking adjustment assembly is adjusted separate from the tensioning assembly such that additional tension applied to the conveyor belt does not affect the previously selected tracking adjustment. The conveyor construction includes a center drive unit having only a single drive roller, a guide roller and a tensioning roller. The tensioning roller position is controlled by a pair of spaced tensioning cylinder.

Owner:DORNER MFG. CORP.

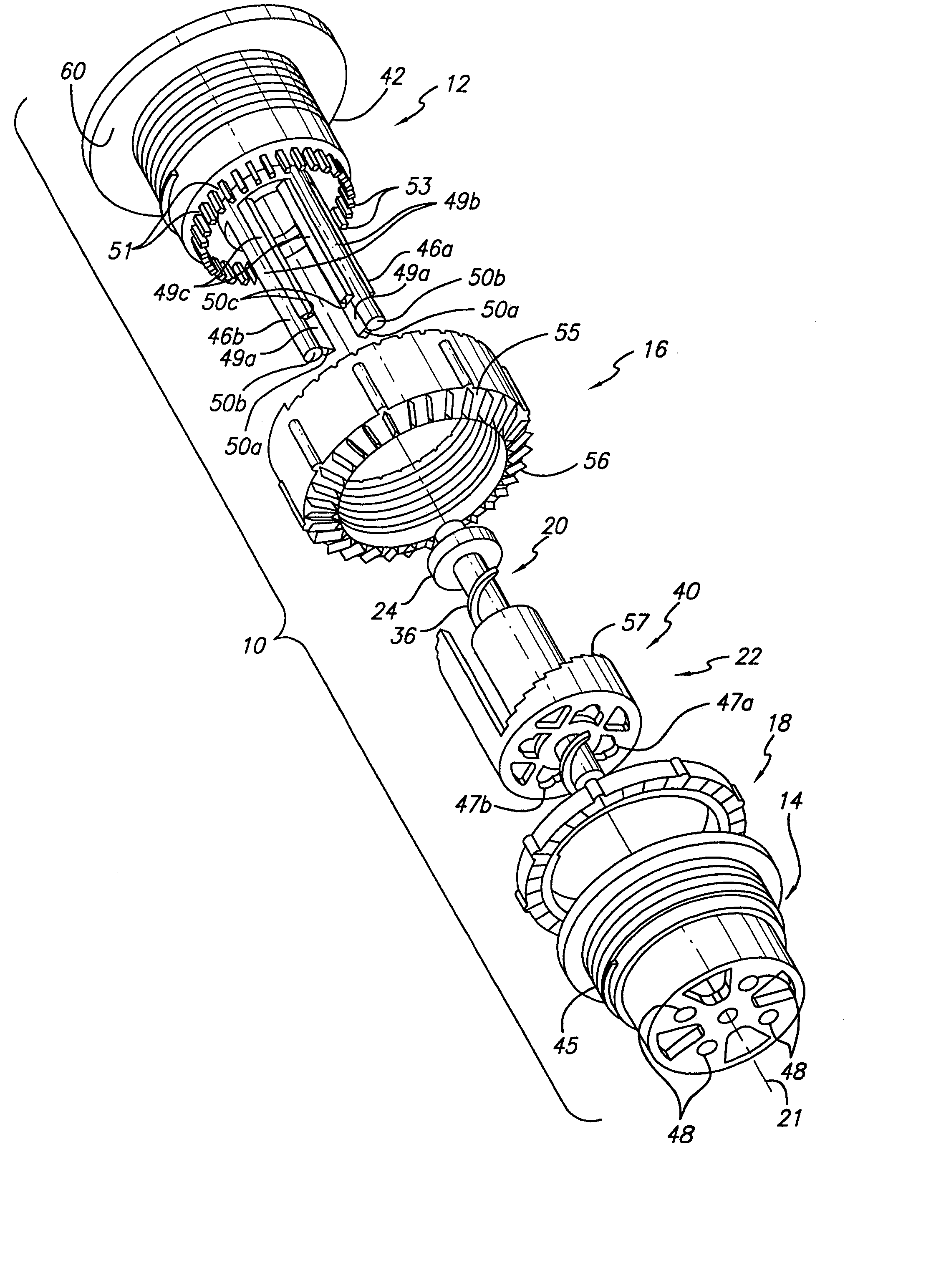

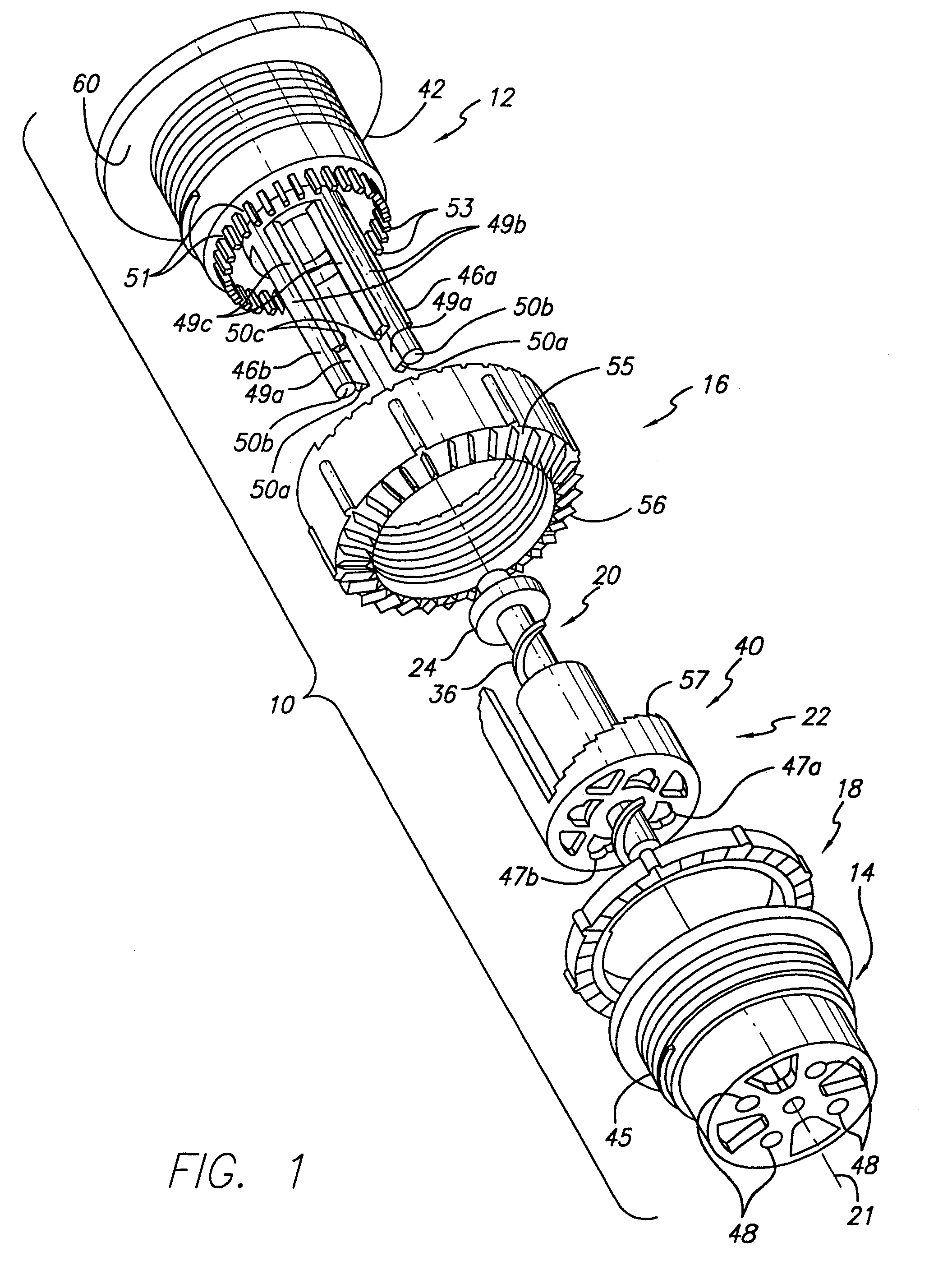

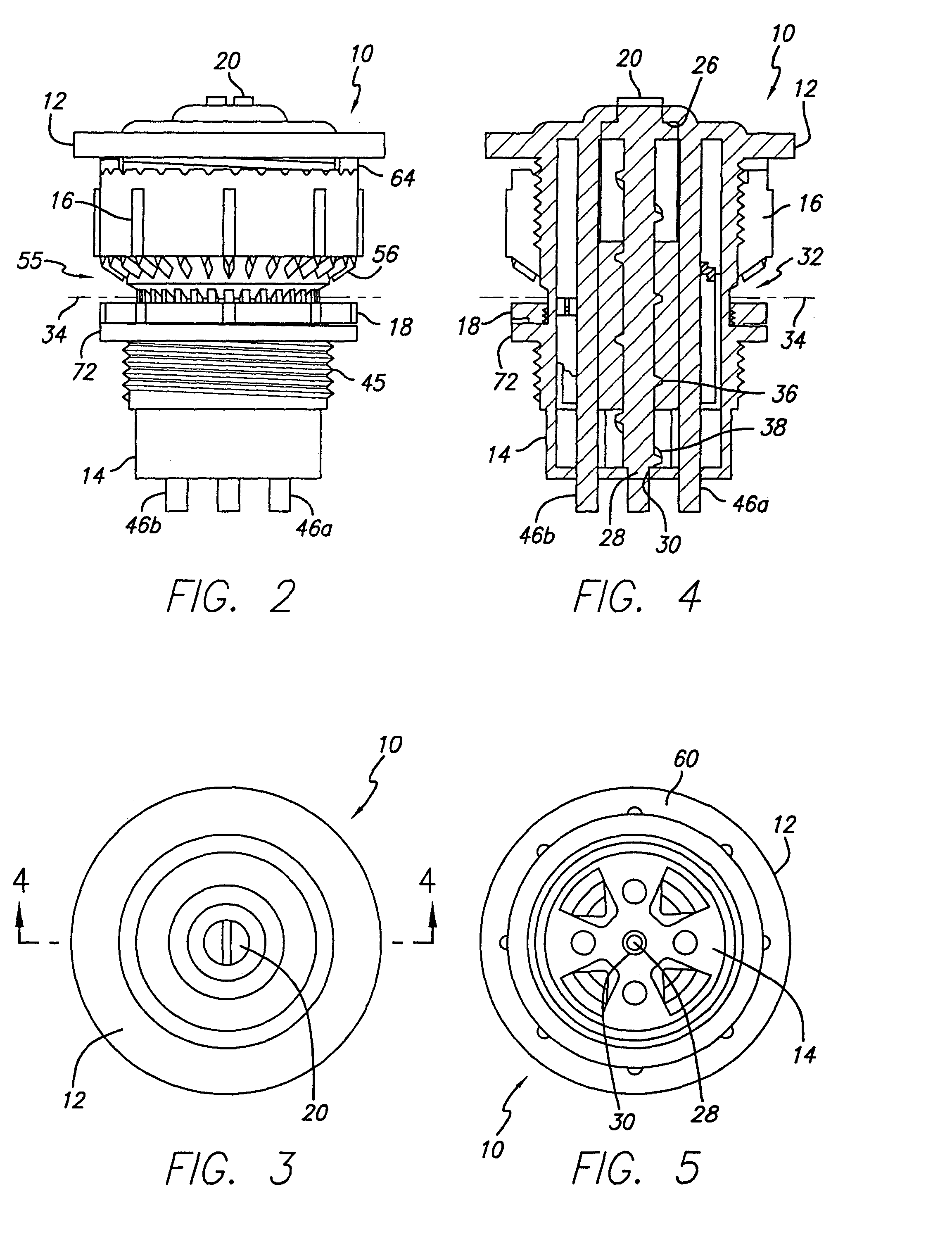

Flow volume adjustment device for irrigation sprinkler heads

The adjustable arc spray nozzle allows adjustment of the spray arc, the radius, and flow of the water spray provided by the nozzle. The nozzle includes a top member, a base member, and a discharge orifice defined therebetween. A rotatable external upper collar controls the radius of the pattern, an internal helix member controls the arc of the spray pattern, and an internal flow adjustment screw and an optional rotatable external lower collar control the flow of the nozzle.

Owner:CORDUA PAUL M

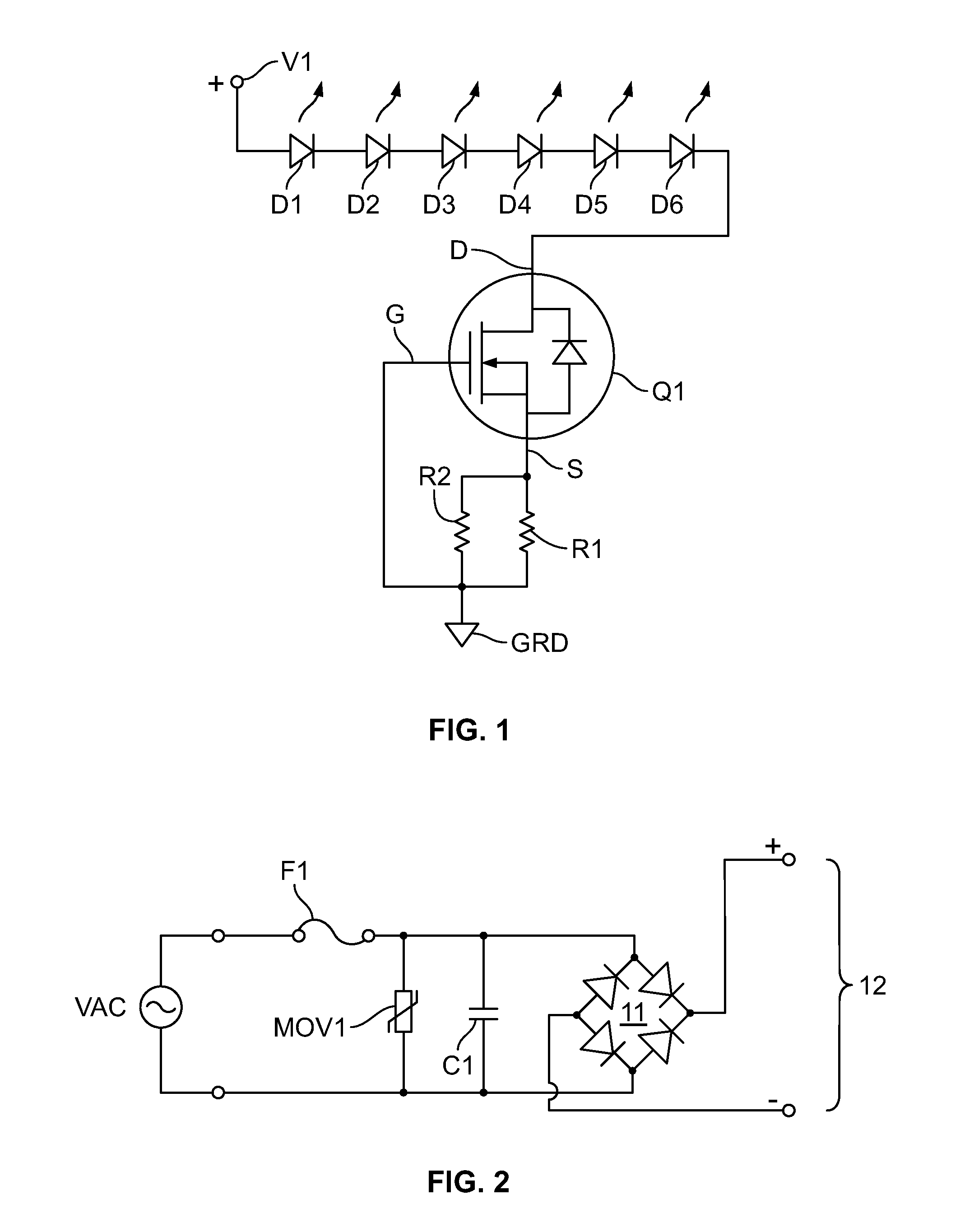

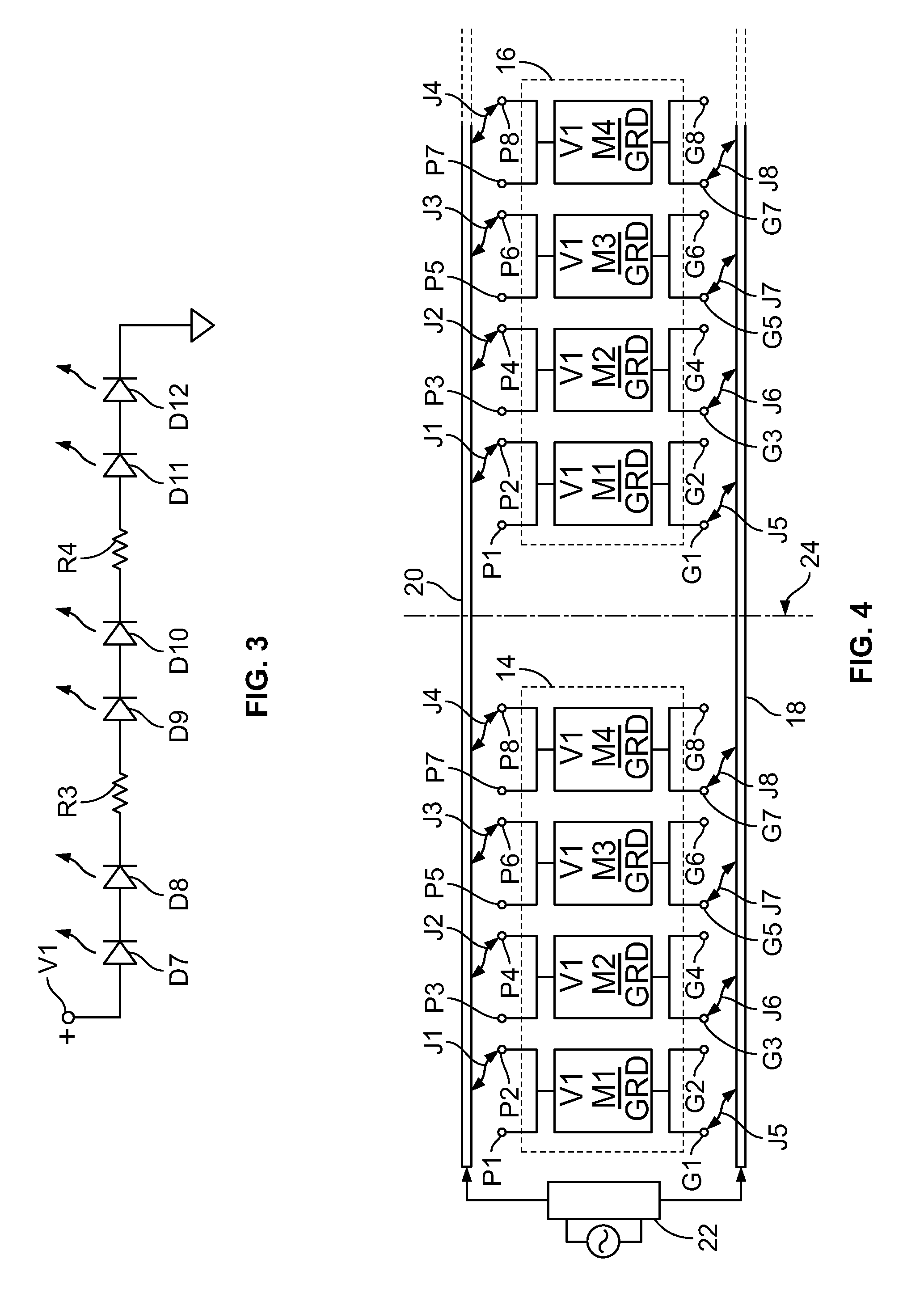

Light Strip and Method for Making a Light Strip

ActiveUS20160138768A1Ease of assemblyManufacturing EaseLighting support devicesPoint-like light sourceElectrical conductorEngineering

A light strip has a flexible enclosure extruded around a pair of conductors. The enclosure contains a lighting assembly with one or more flexible substrates that are each populated with a plurality of light circuits. The substrates are spaced from the pair of conductors. The lighting assembly has a plurality of connecting devices for electrically coupling the lighting assembly to the pair of conductors

Owner:MAG LED INC

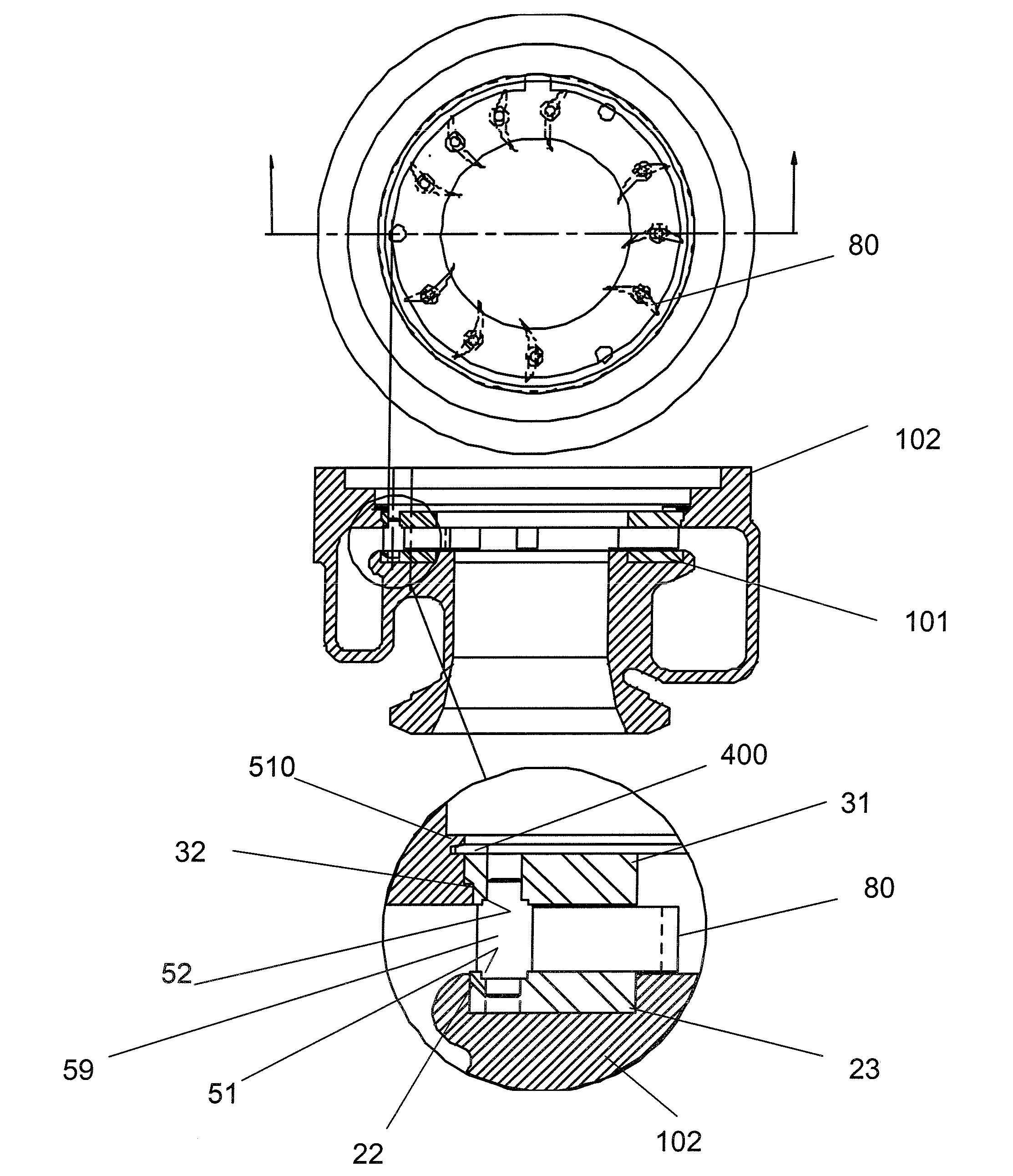

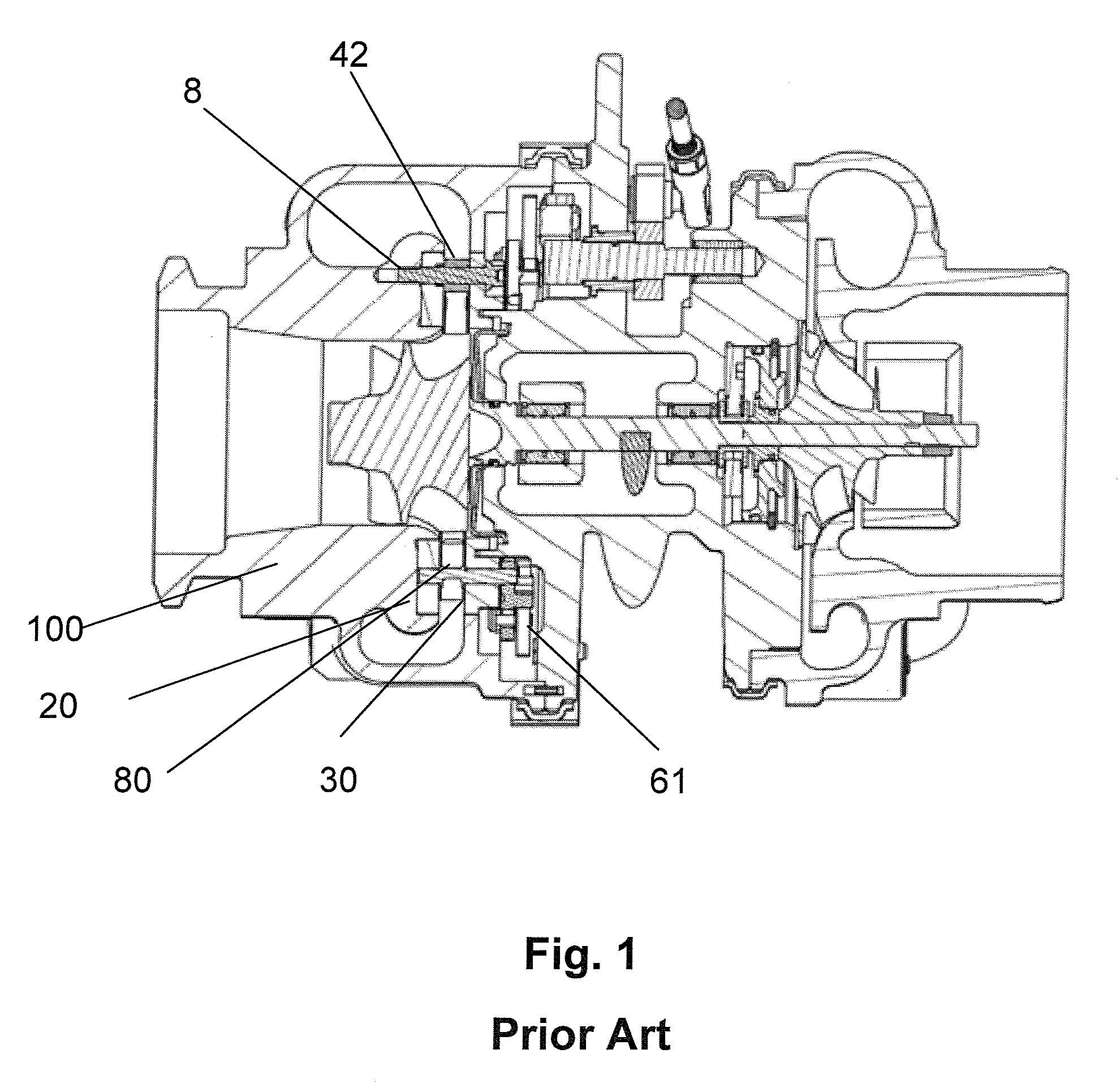

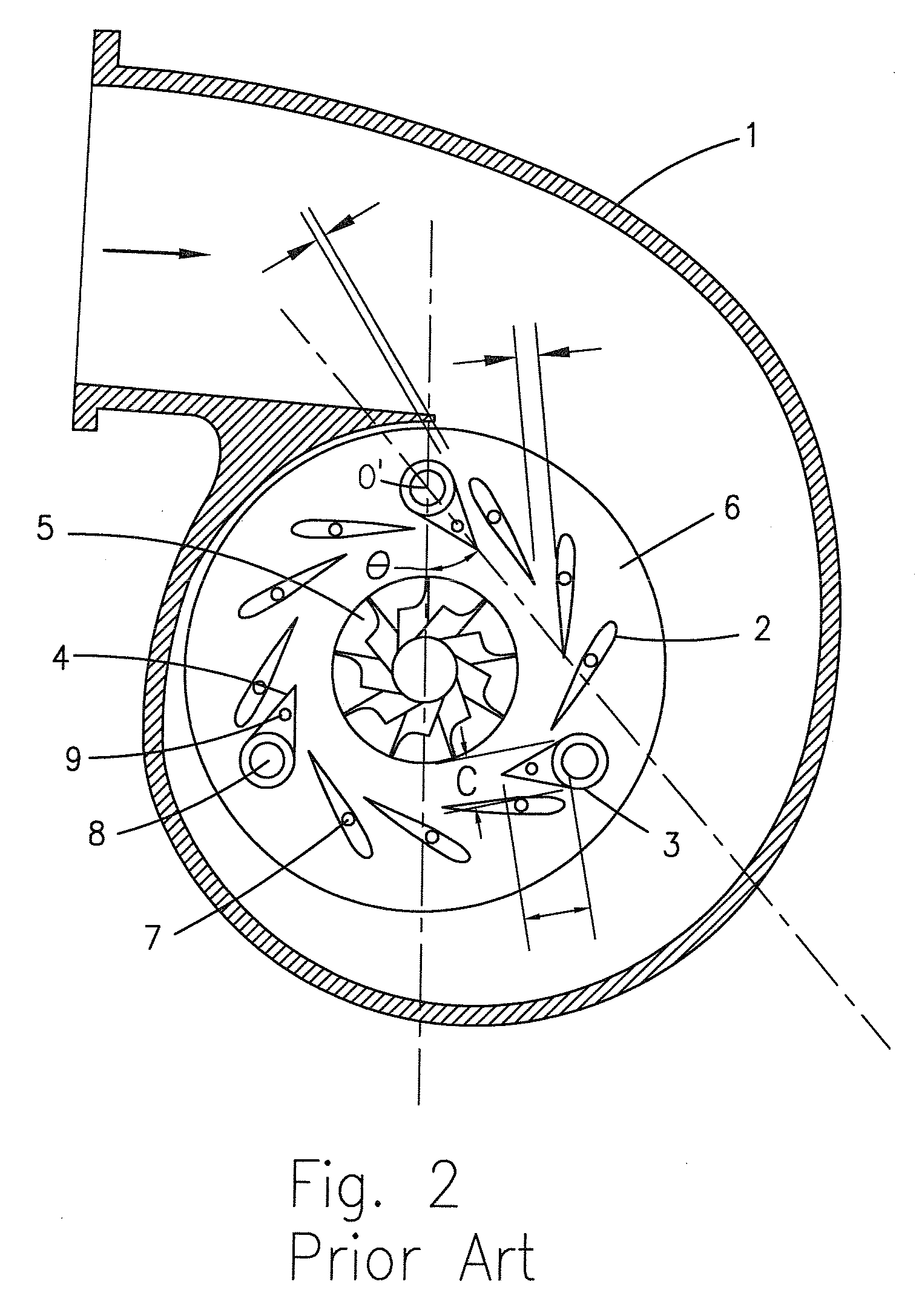

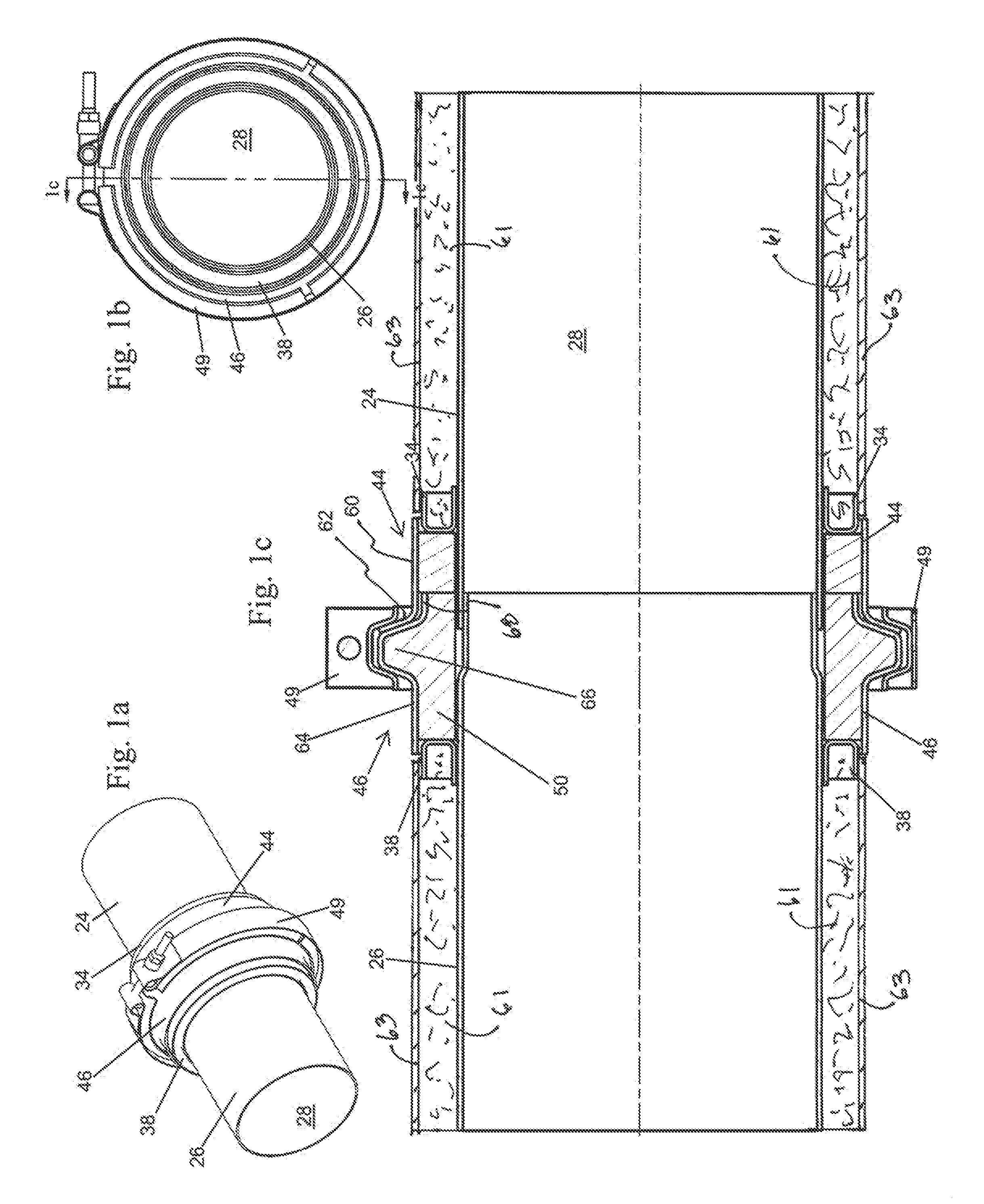

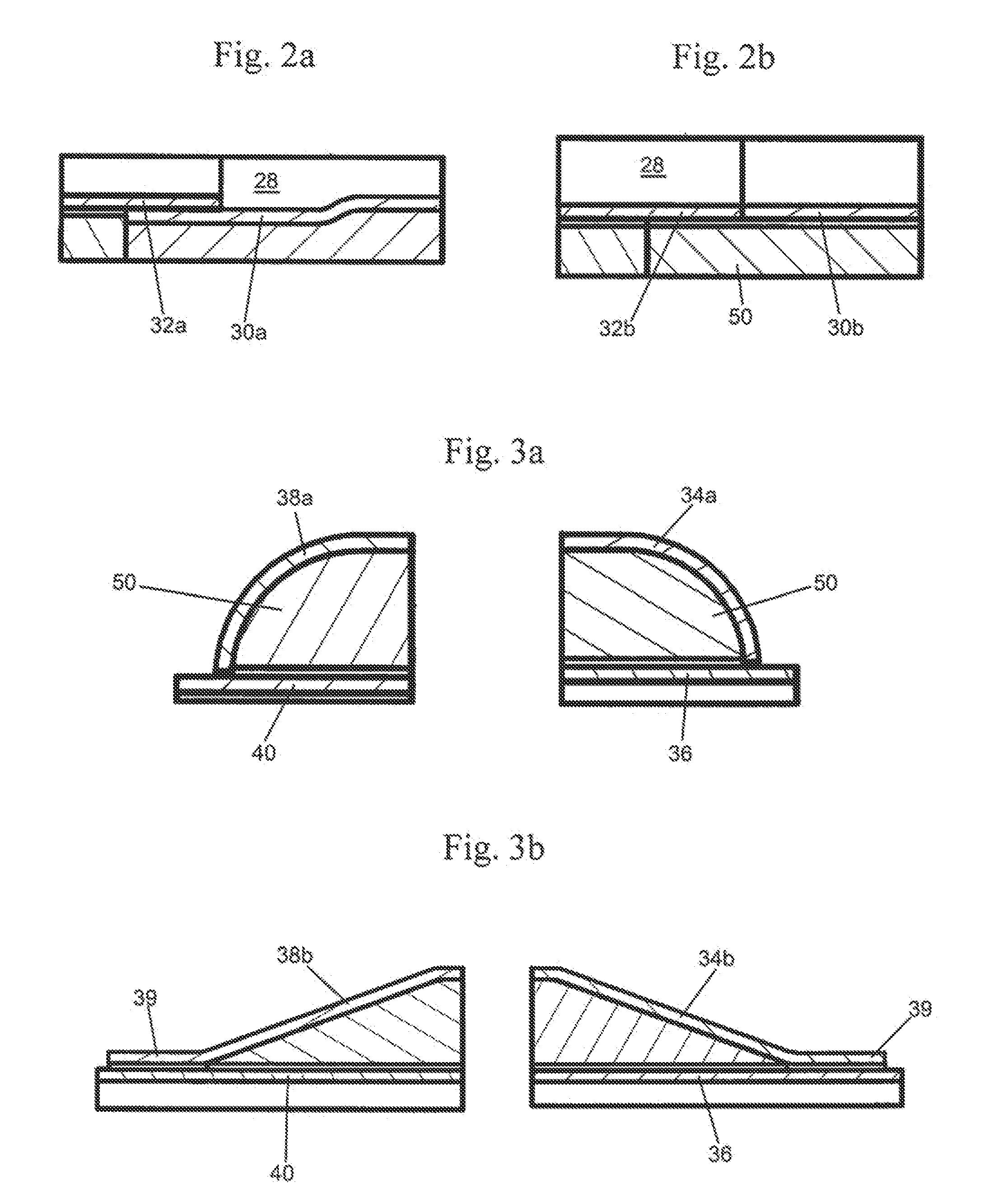

Variable geometry turbocharger, vane ring assembly with retaining member

ActiveUS20090022580A1Effective maintenanceEase of assemblyWind motor controlPump componentsRetaining ringVariable-geometry turbocharger

A vane ring assembly which includes a lower vane ring (23), an upper vane ring (31), one or more guide vanes (80) positioned at least partially between the vane rings, and a plurality of spacers (49, 50 or 59) positioned between the lower and upper vane rings (23, 31) for maintaining a distance between the lower and upper vane rings, the vane ring assembly being retained in a turbine housing (102) by a retaining ring (400) which is located in a groove (510) in the turbine housing.

Owner:BORG WARNER INC

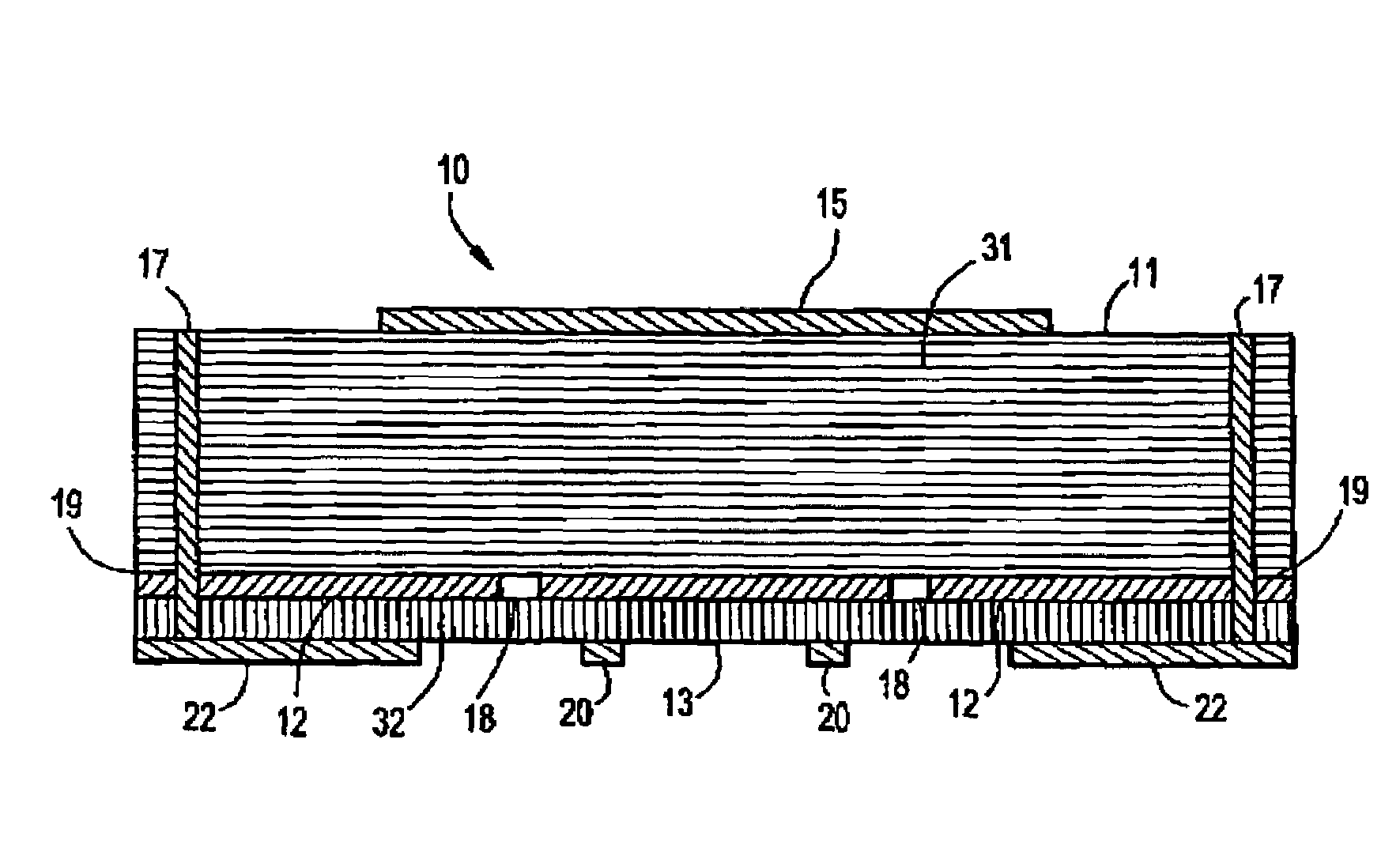

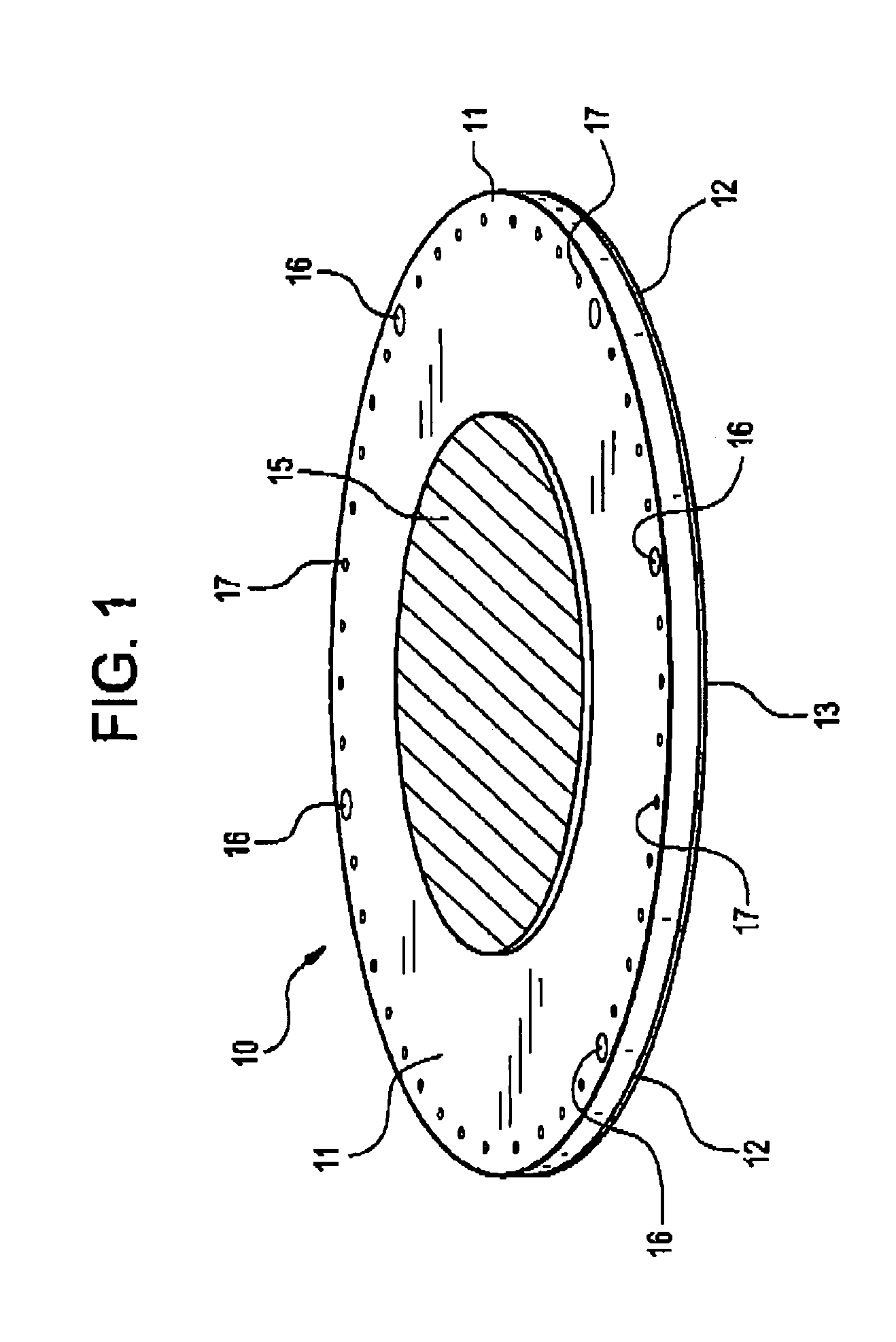

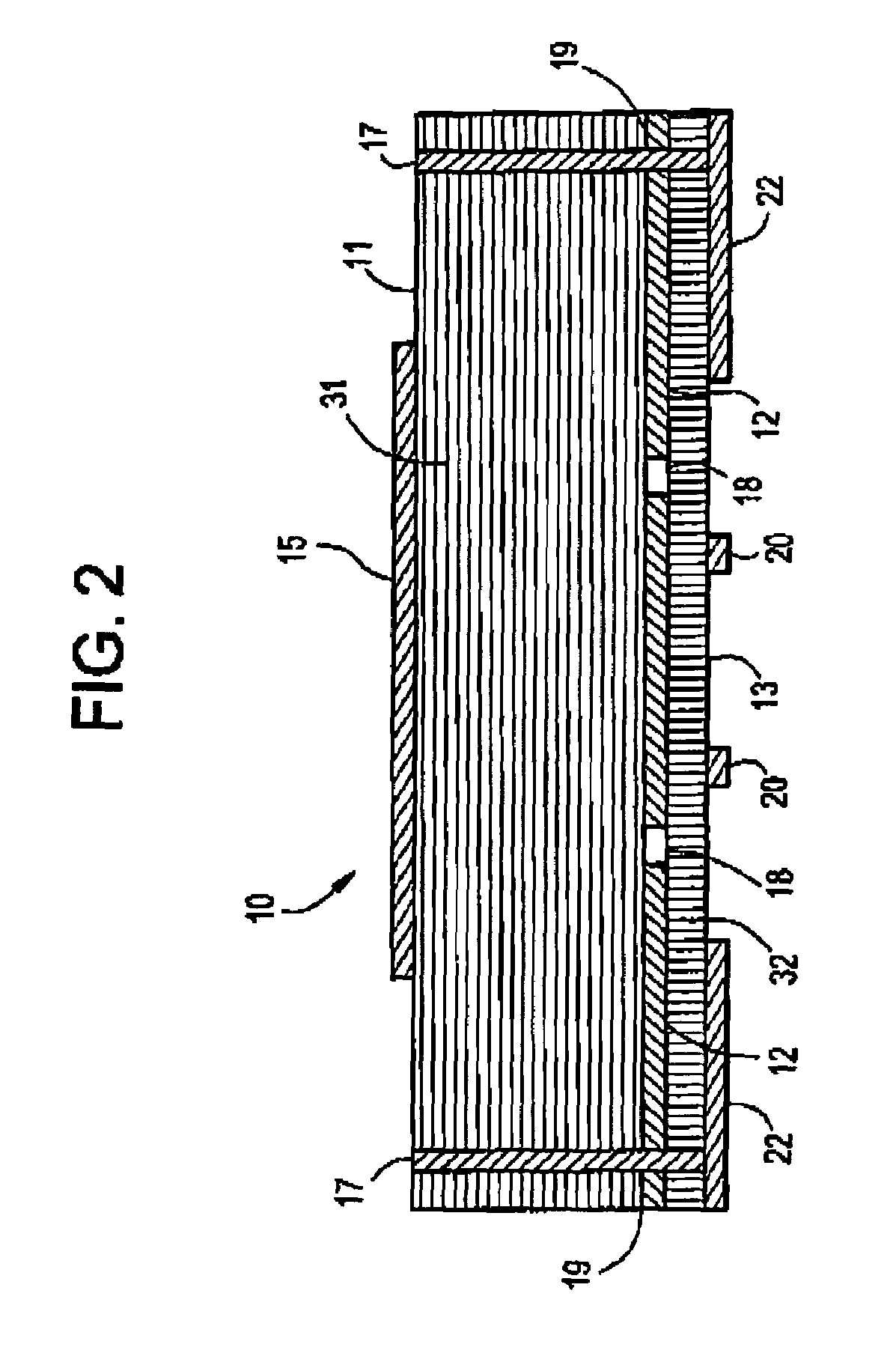

Broadband aperture coupled GNSS microstrip patch antenna

ActiveUS7429952B2Improved multipath mitigationEase of assemblySimultaneous aerial operationsRadiating elements structural formsMicrostrip patch antennaDielectric

A multilayer antenna structure configured to receive Global Navigation Satellite System (GNSS) and augmentation signals. The antenna includes a microstrip patch radiation element disposed at a top layer and a ground plane forming a first interior layer, the ground plane including at least two coupling apertures, and the ground plane isolated from said radiation element by a low loss dielectric. The antenna structure also includes a bottom layer, the bottom layer is isolated from the ground plane by another dielectric; at least two feed lines operably connected to a hybrid coupler disposed on the bottom layer; and an active circuit on the bottom layer, a first port of said active circuit operably connected to the hybrid coupler.

Owner:HEMISPHERE GNSS

Endless belt conveyor frame and tensioning device including center drive construction

InactiveUS20050145465A1Ease of assemblyManufacturing EaseConveyorsSupporting framesEngineeringBelt conveyor

A conveyor construction that includes a conveyor frame assembly formed from a pair of spaced side frame members interconnected with each other by spaced cross members. The upper bed of the conveyor frame assembly is formed from individual bed plate strips attached to each of the cross members. The width of the conveyor frame assembly can be modified by the proper selection of the number of bed plate strips. The conveyor frame assembly includes a separate tensioning assembly and tracking adjustment assembly. The tracking adjustment assembly is adjusted separate from the tensioning assembly such that additional tension applied to the conveyor belt does not affect the previously selected tracking adjustment. The conveyor construction includes a center drive unit having only a single drive roller, a guide roller and a tensioning roller. The tensioning roller position is controlled by a pair of spaced tensioning cylinder.

Owner:DORNER MFG. CORP.

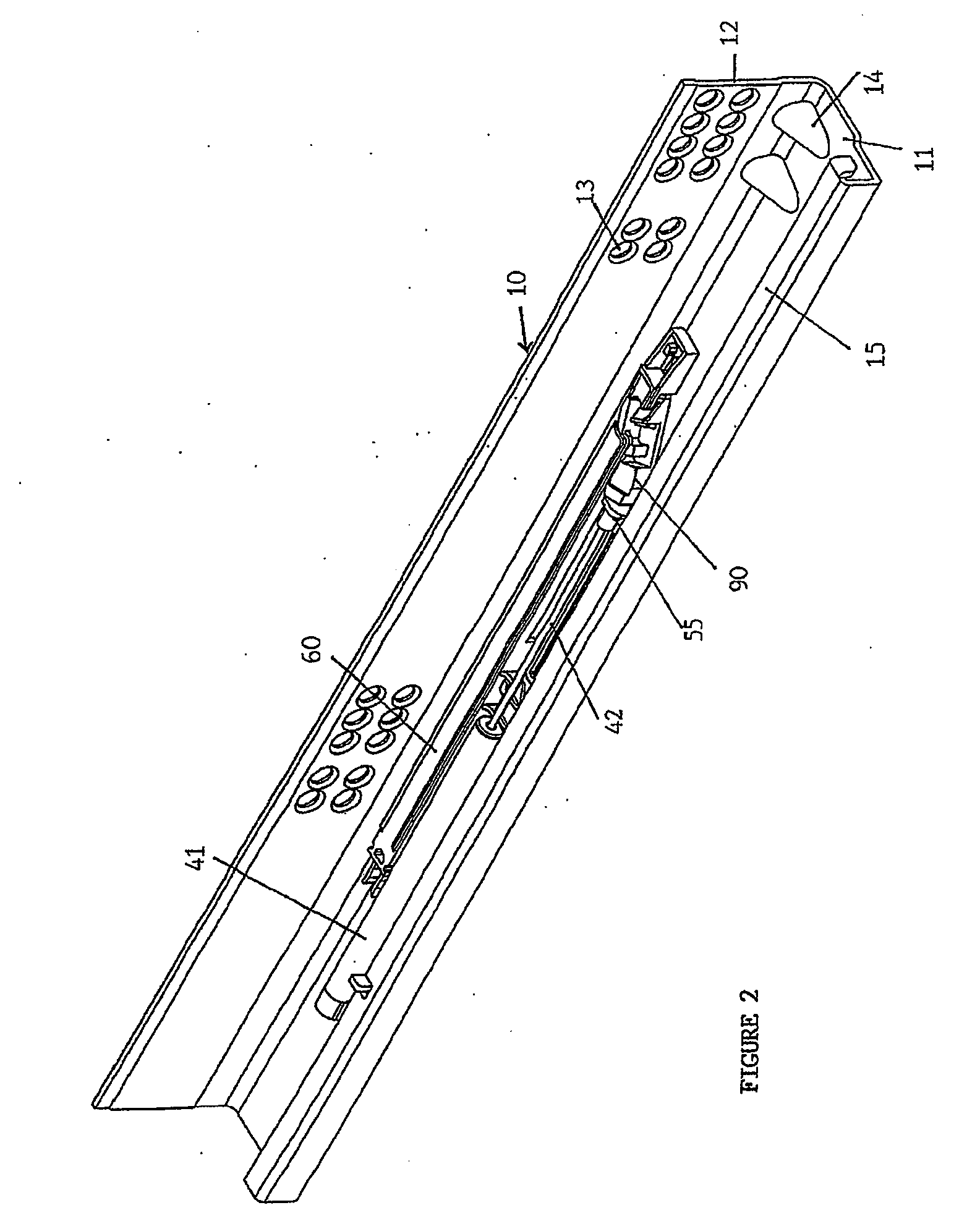

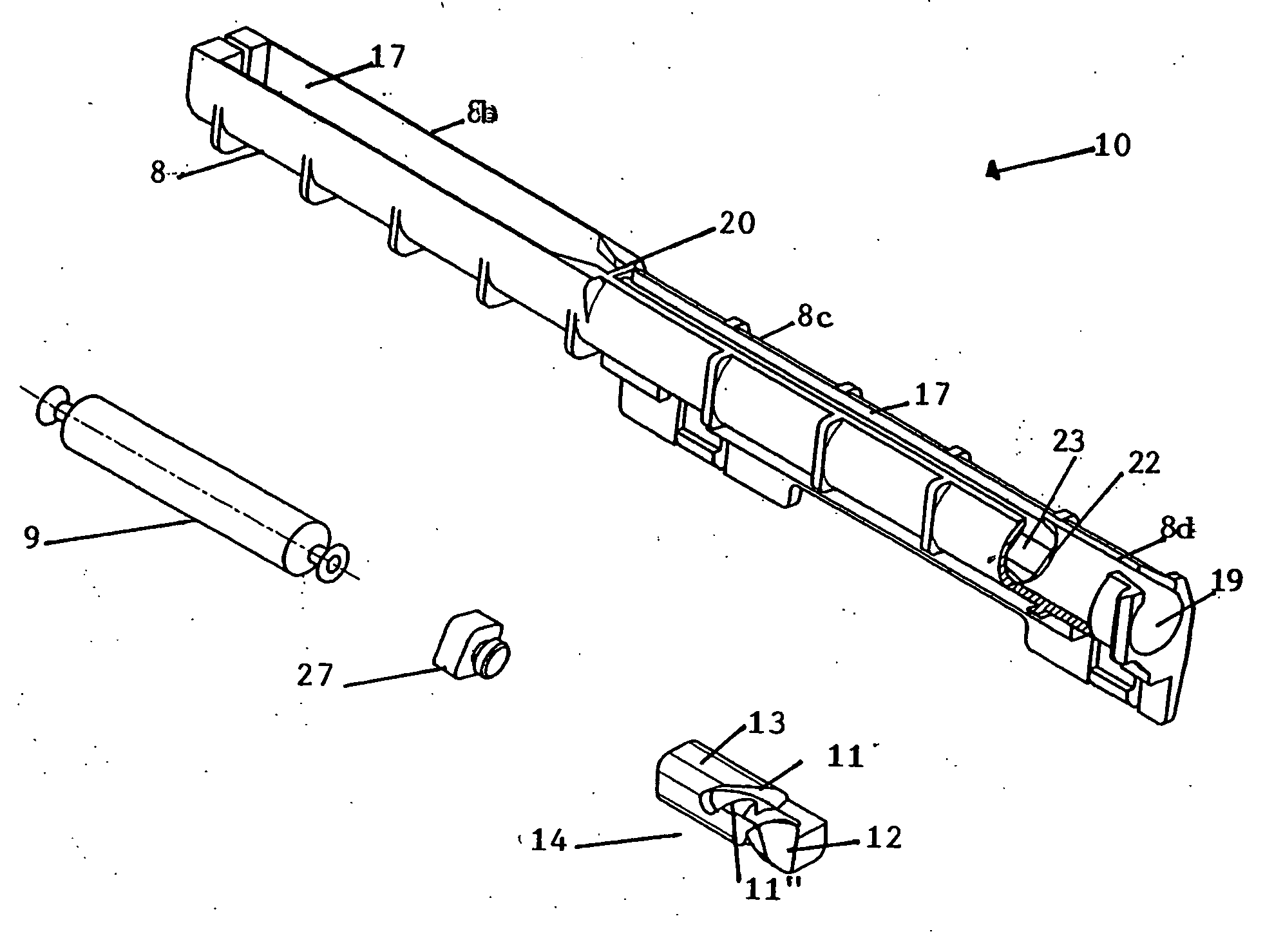

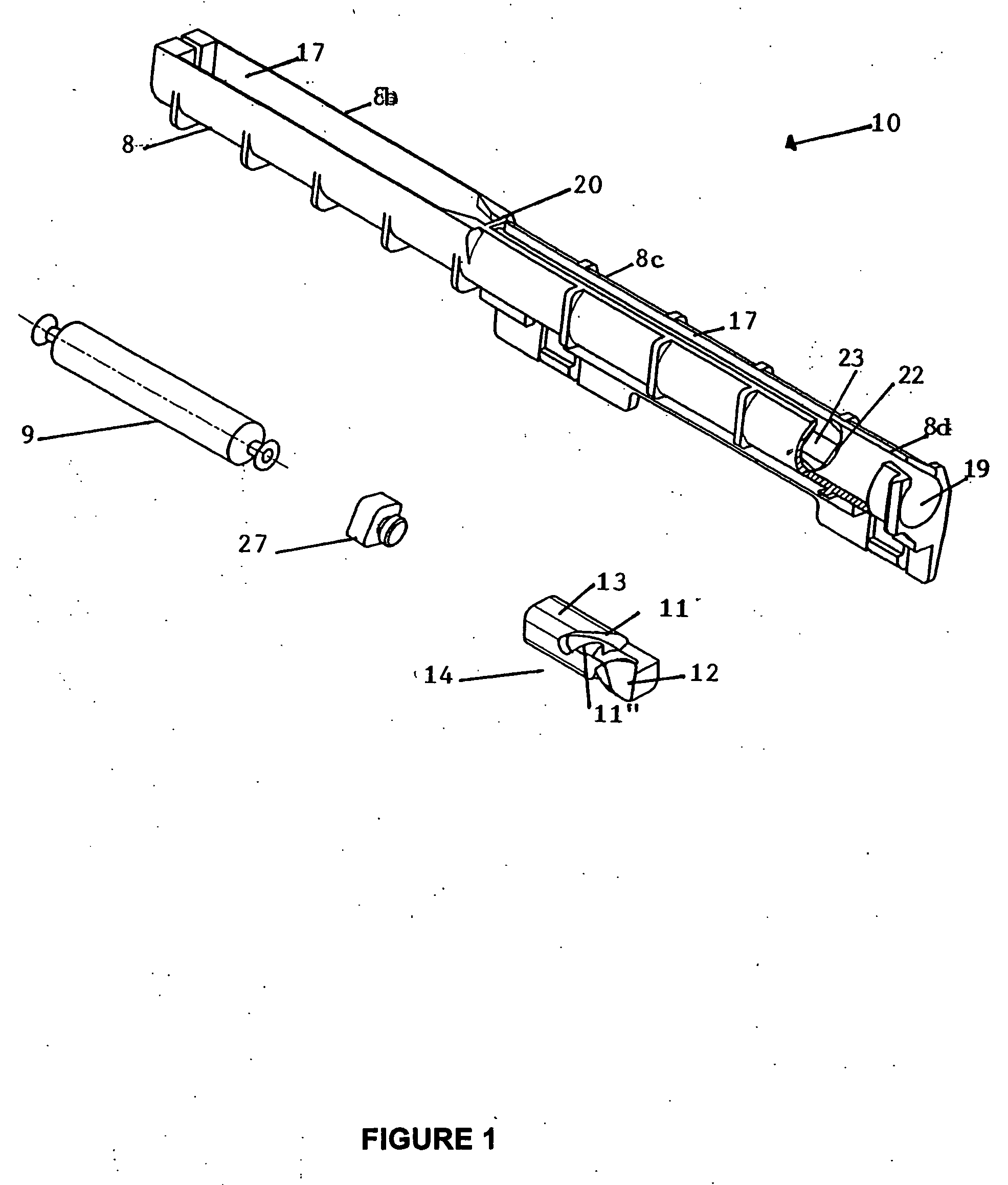

Drawer guide rail system

InactiveUS20130076219A1Robust designEliminate failure problemsDrawersFittingLinear motionDriver/operator

A guide rail system for slidably opening and closing a drawer within an enclosure is disclosed. The system comprises a mounting bracket for fixing the system to the enclosure, the mounting bracket having a fixed rail for receiving an intermediate rail capable of sliding back and forth on the fixed rail, and a pull out rail operatively attached to the drawer and capable of sliding back and forth on the intermediate rail. A resiliently compressible damping device, channel guide with sliding member and a closing device are disposed along the mounting bracket. The pull out rail has a guiding pin on its bottom surface. The sliding member is adapted to travel along the channel guide and locate an end of the damping device that can be pushed inwardly to provide damping. The closing device comprises a housing, a resilient means, and a driver pivotally mounted with the housing and operatively connected to the resilient means. The driver is pivotable between a first locked position and a second linearly moveable position, and includes an angular slot for receiving the guiding pin and an abutment projection contactable with the sliding member. During a closing action, the pull out rail is caused to slide in a drawer-closing direction. When the guiding pin reaches and engages with the angular slot, the action of the guiding pin within the angular slot causes the driver to be pivoted from its first position to its second position where the abutment projection engages with the sliding member. Thereafter, linear movement of the driver urges the sliding member to correspondingly travel along the channel guide against the resilience of the damping device, resulting in deceleration of the closing motion.

Owner:HARN MARKETING

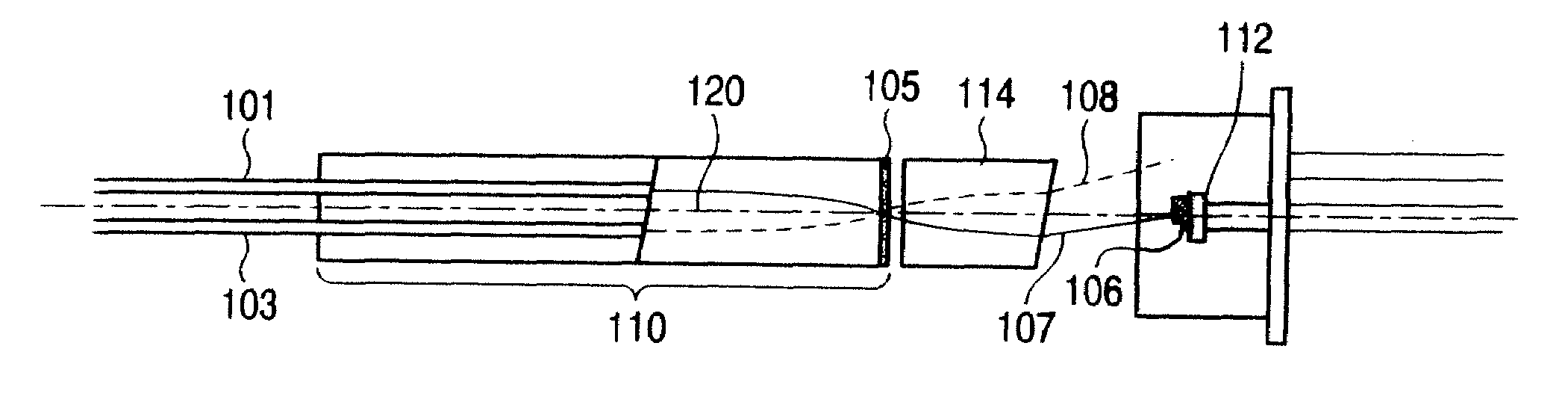

Optical tap module

In an optical tap module, a first lens, a focusing lens, and a photodiode are arranged such that a center axis of a cylindrical case housing the first lens, the focusing lens, and the photodiode is substantially located on the same line. When light propagates through a second optical fiber and is emitted from an end surface facing the first lens so as to be incident on an optical filter, and light transmitted the optical filter is converged by the focusing lens, the photodiode and a chip mounting support are arranged such that a focal point of light is located spatially distant from the surfaces of the photodiode and the chip mounting support.

Owner:GOFOTON HLDG

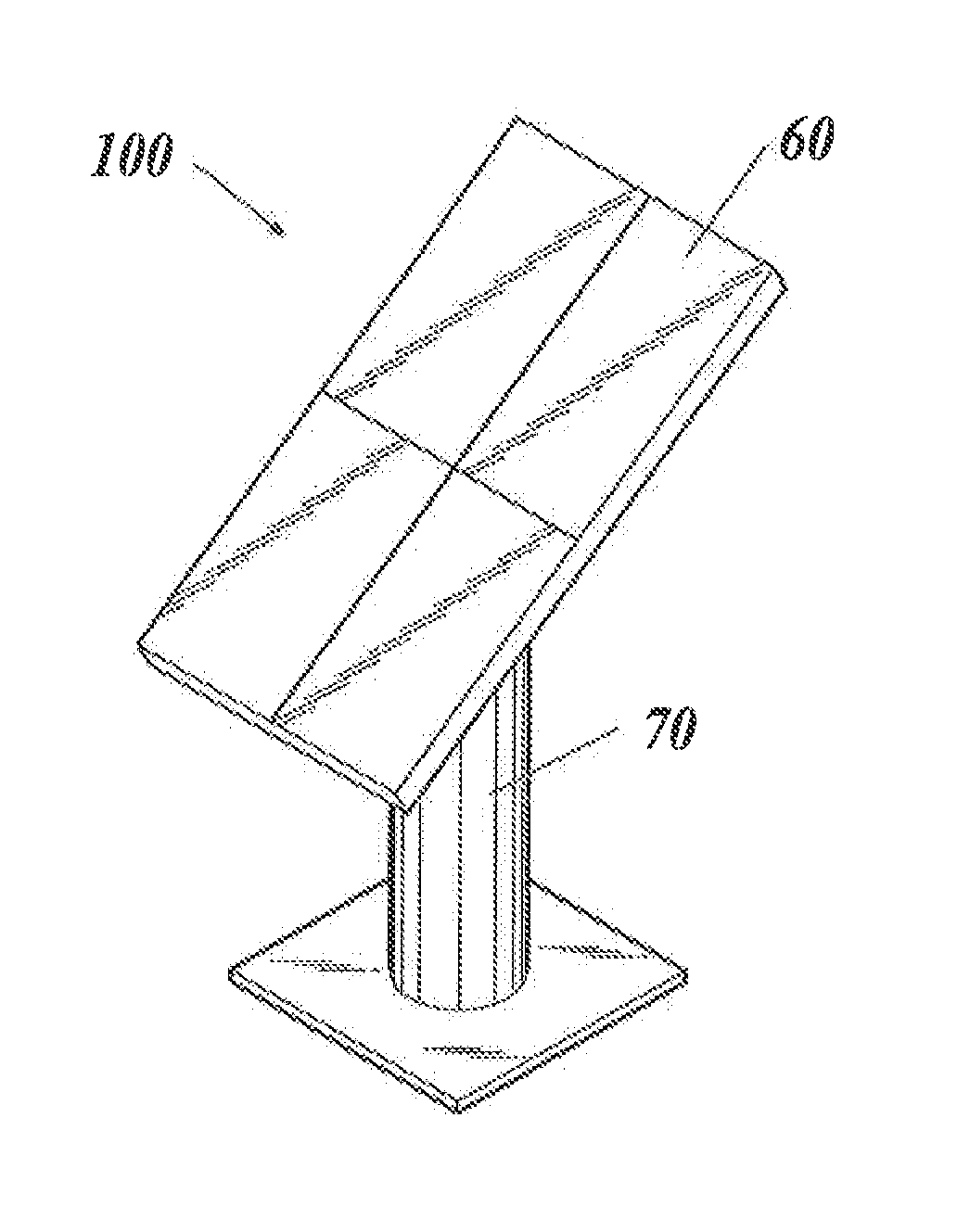

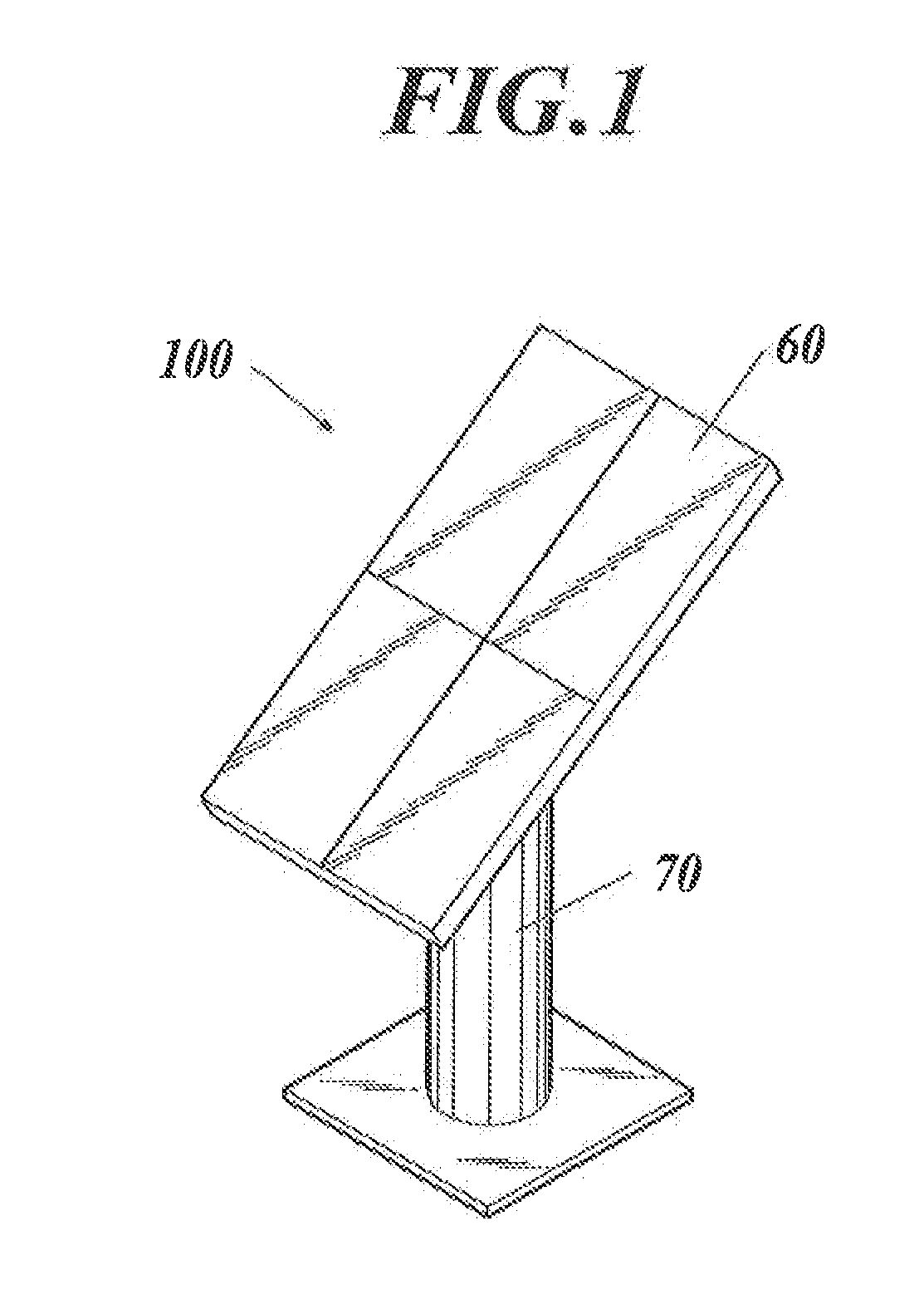

Reflective panel for solar power generation

InactiveUS20130114155A1Ease of assemblyEasy maintenanceSolar heating energyMirrorsEngineeringSolar power

A reflector for solar thermal power generation includes a light collecting mirror attached to a self-supporting base material. The light collecting mirror includes at least: a flexible supporting body; and a light / heat reflective layer provided on at least one side of the supporting body. The self-supporting base material has any one of configurations A and B below: A: the base material includes a pair of metallic plates and an intermediate layer provided between the metallic plates, the intermediate layer being a layer having a hollow structure or a layer composed of a resin material; and B: the base material is composed of a resin material layer having a hollow structure.

Owner:KONICA MINOLTA OPTO

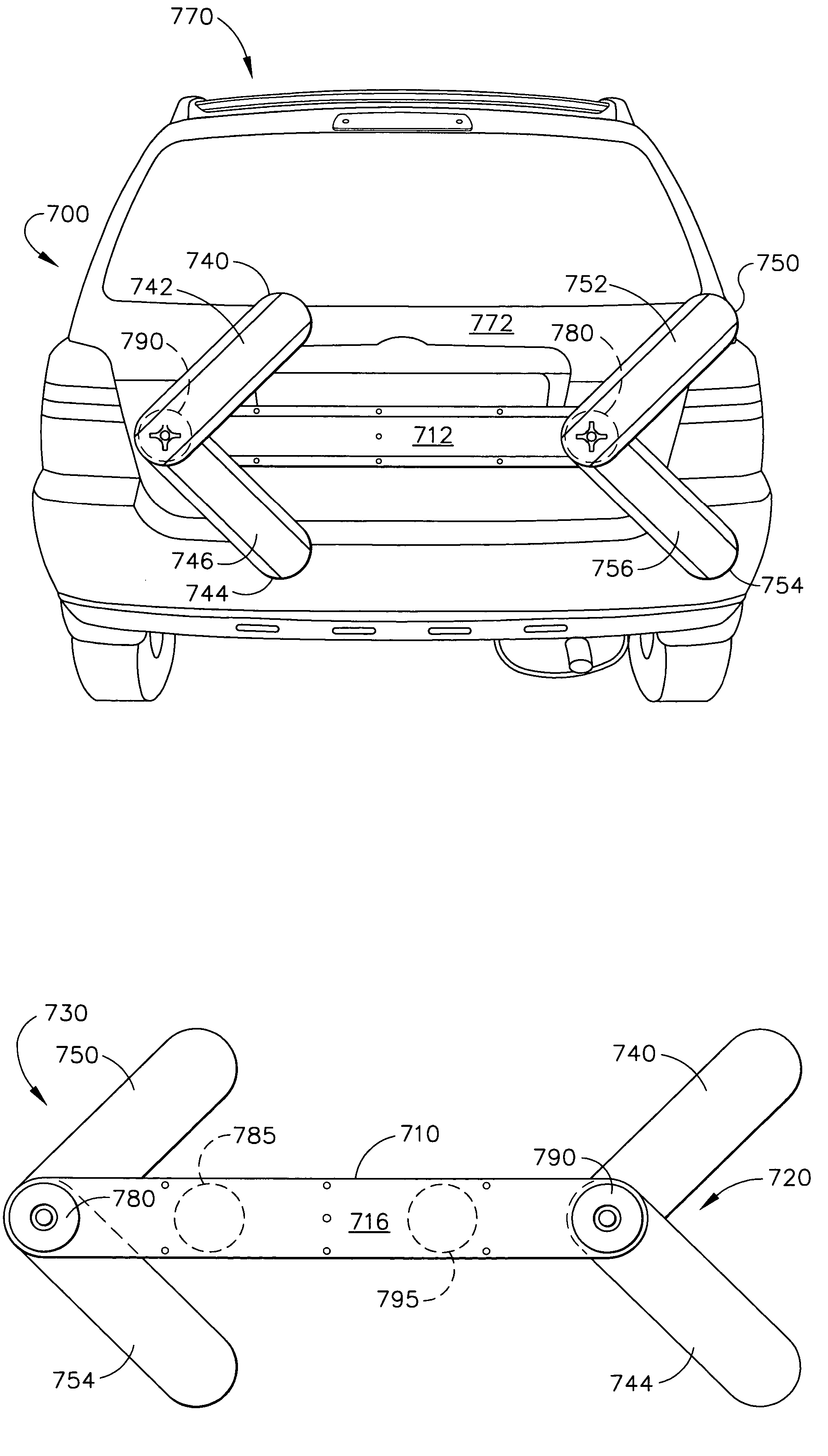

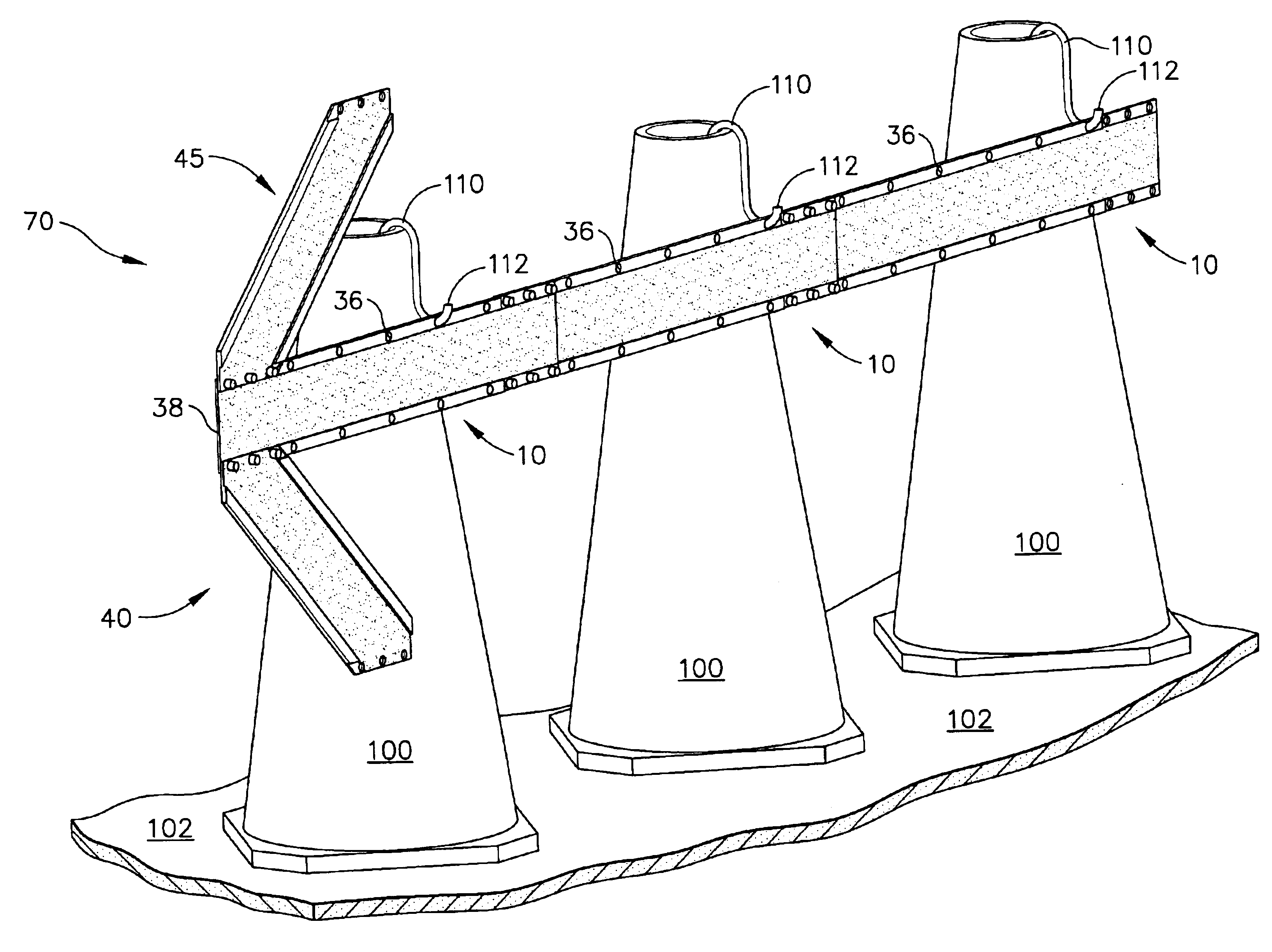

Reflective arrowhead traffic sign apparatus with magnetic mounting

InactiveUS7370602B2Easy to assembleEasy to mountPortable emergency signal deviceTraffic signalsEngineeringStructural engineering

A highly reflective arrowhead traffic sign is provided which exhibits an arrow shape to “aim” traffic away from a lane. A horizontal longitudinal member has at least one pair of arrow-shaped “wings” that extend beyond the outer boundary of the horizontal member. The wing sets can be attached to the horizontal member by use of locating holes and mating pins, or they can be pivotally mounted on the horizontal member. The arrow wings can be shaped into a configuration that points to the left or to the right, or simultaneously point to both the left and right, thereby indicating to traffic that a lane is closed, and that traffic must go either left or right to avoid the closed lane. The signs can be mounted in different ways, using hooks with suction cups or traffic cones, or using built-in magnets.

Owner:ZACAABEL

Insulated Tube Joint Connection

InactiveUS20150226368A1Reduce constructionDurability ease of easeSleeve/socket jointsFlanged jointsEngineeringMechanical engineering

Owner:NELSON GLOBAL PROD +1

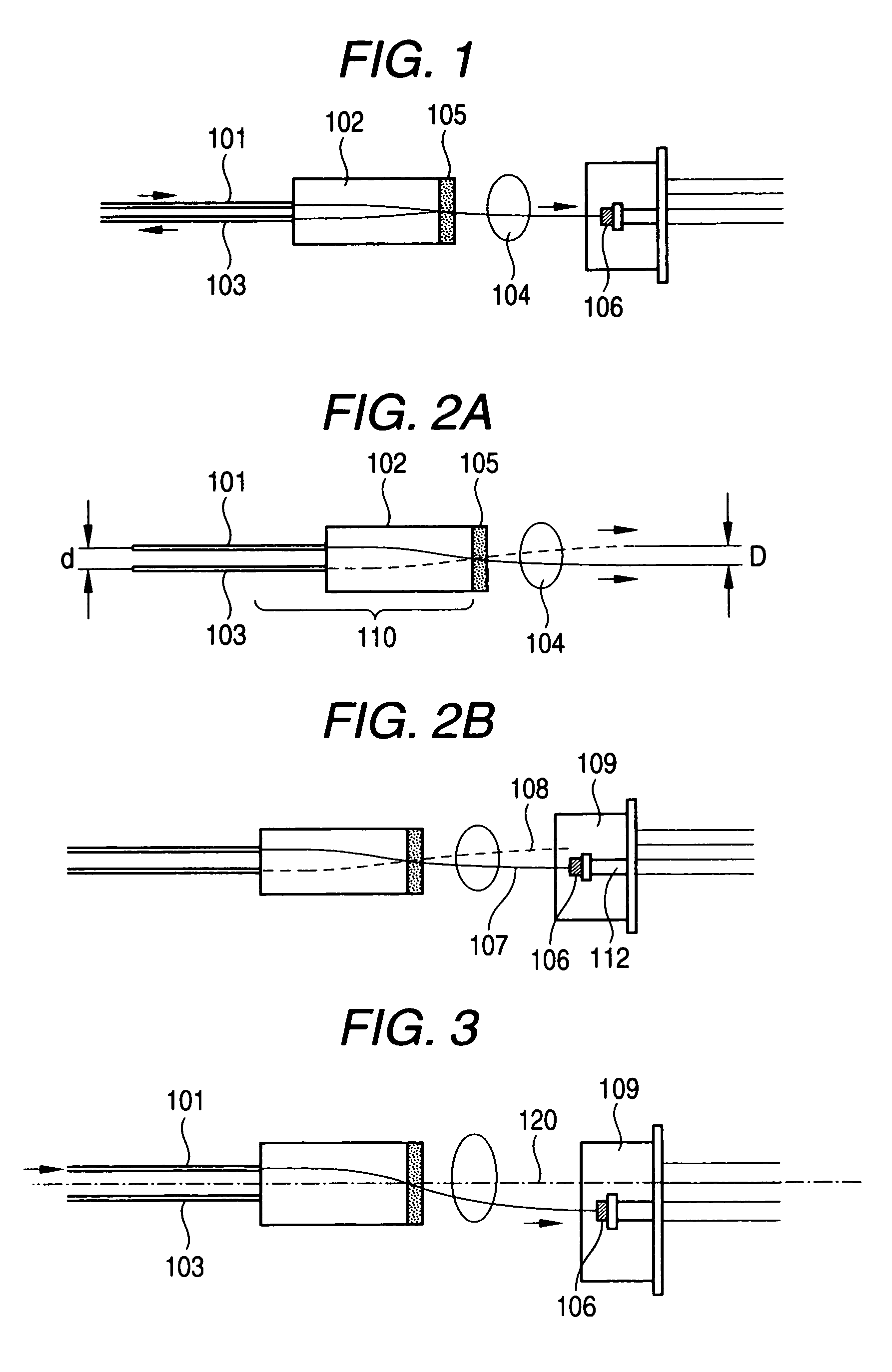

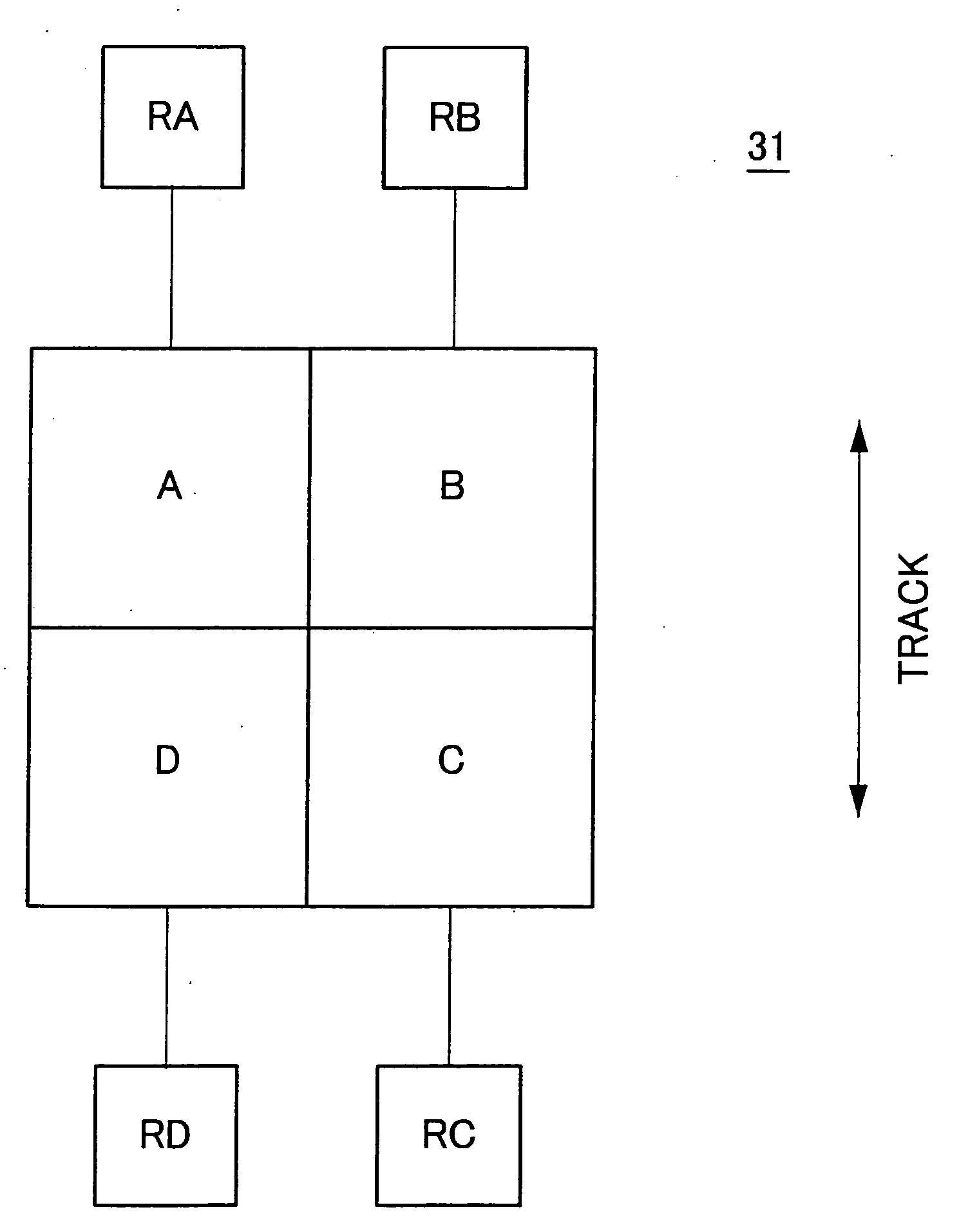

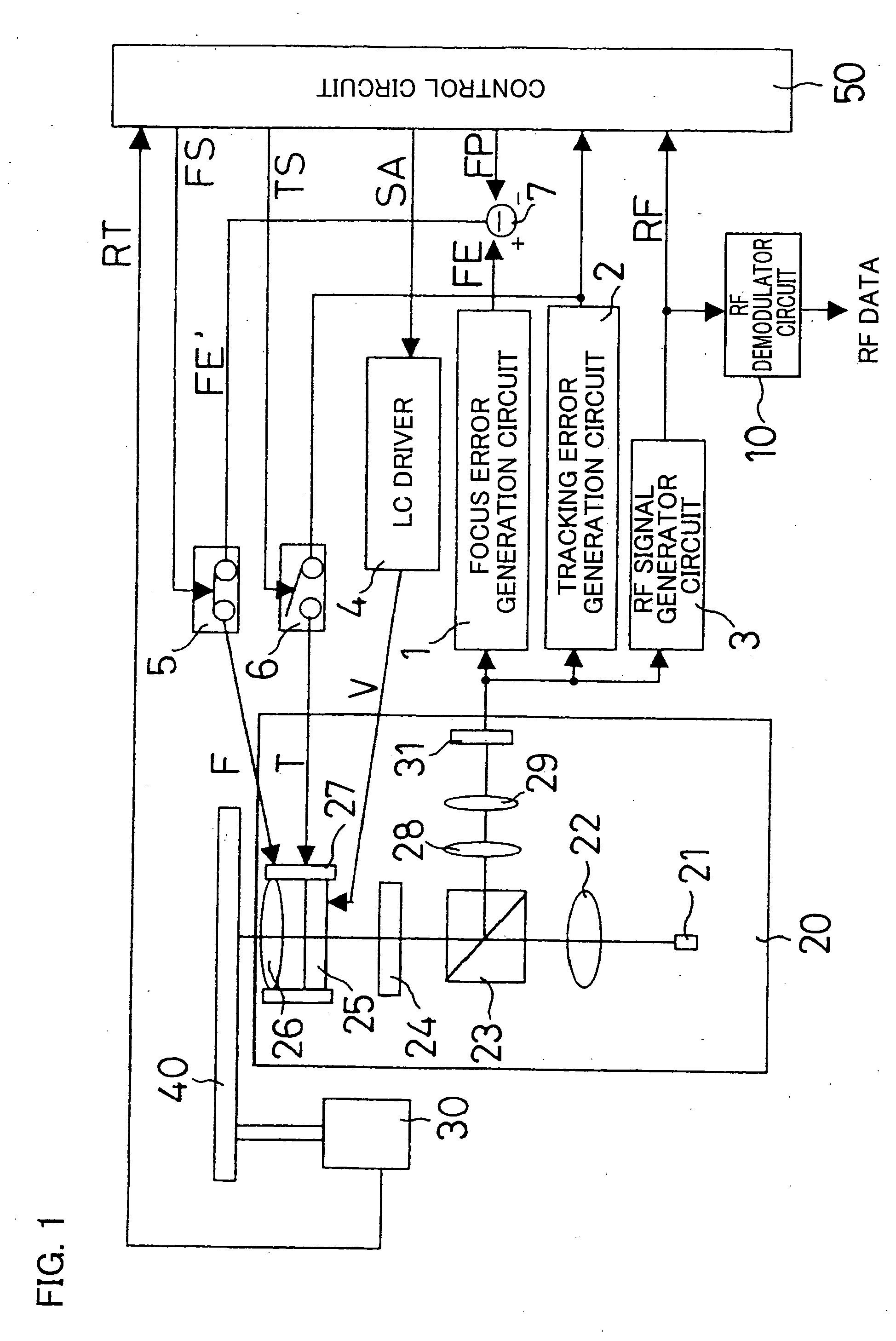

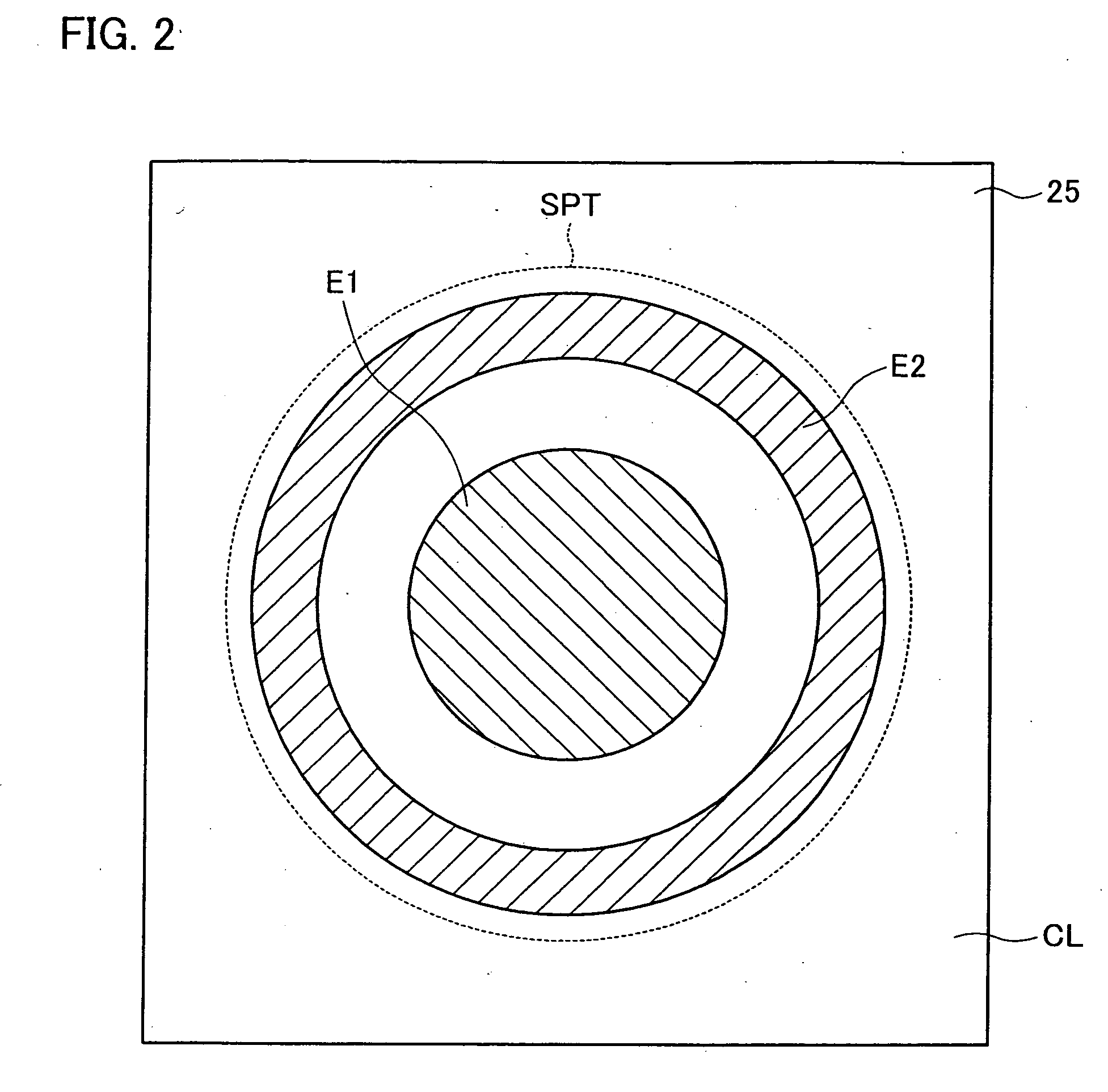

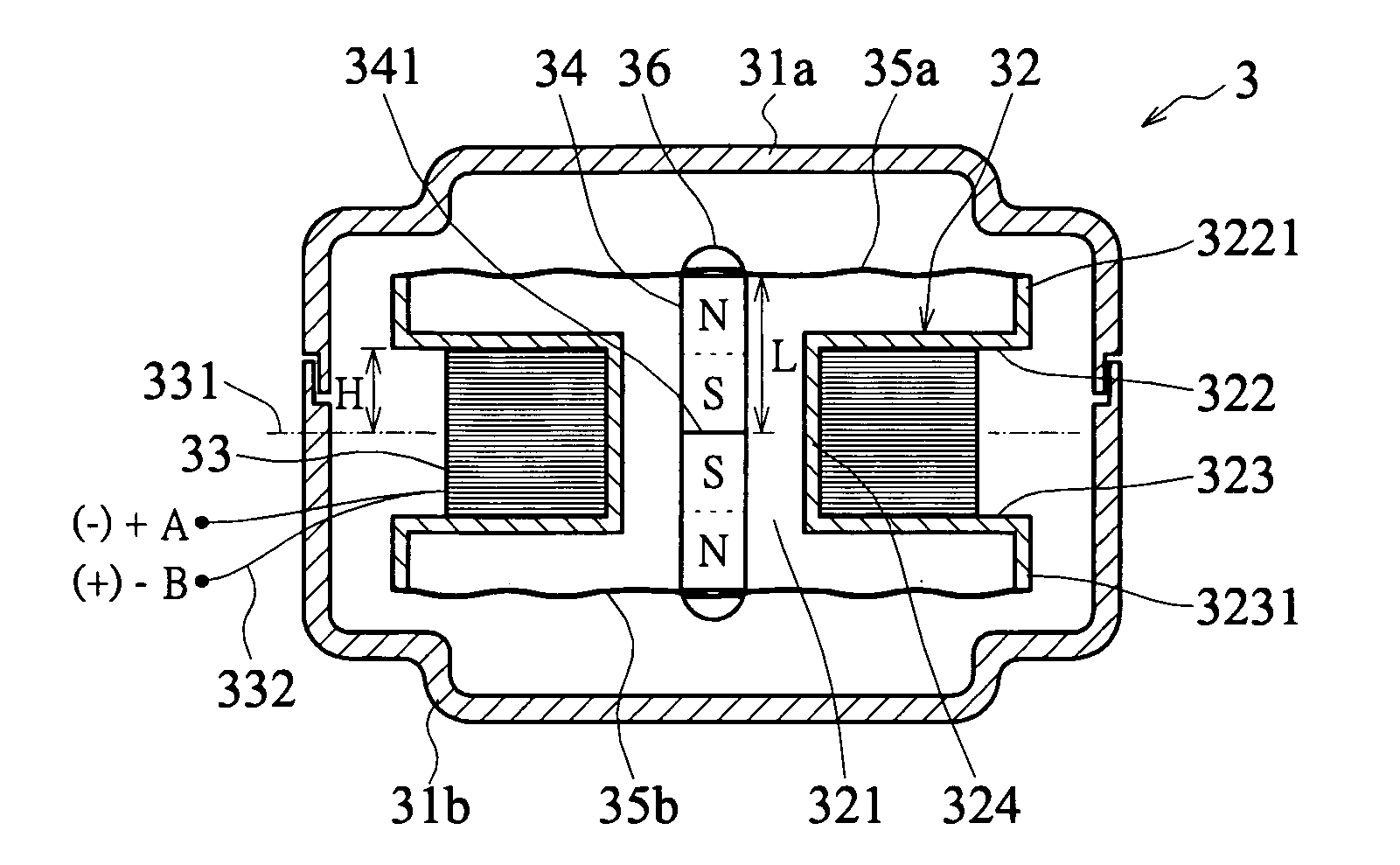

Optical pickup spherical aberration compensating method, optical pickup sherical aberration focus offset compensating method, and optical pickup device

InactiveUS20060062098A1Corrected quickly and accuratelyMaximising amplitudeRecord information storageOptical beam guiding meansOptical pickupLight beam

An optical pickup (20) projects a read beam onto an optical disc (40) as an optical storage medium which is driven to rotate by a spindle motor (30) and receives its reflection. A laser beam from a laser producing element (21) passes through a liquid crystal panel (25) and guided to an objective lens (26). The panel (25) is provided to correct spherical aberration caused by an irregular thickness of a transparent substrate of the optical disc (40). A control circuit (50) changes a spherical aberration correction signal SA to carry out sampling more than once, covering a range of the output of an optical sensor (31) where the output shows large changes. The circuit (50) determines the position of a peak of an approximation curve through calculation and designates that position as the magnitude of correction. Thus, the optical pickup (20) can quickly and accurately detect the magnitude of the correction of the spherical aberration caused by an irregular thickness of the optical disc (40).

Owner:SHARP KK

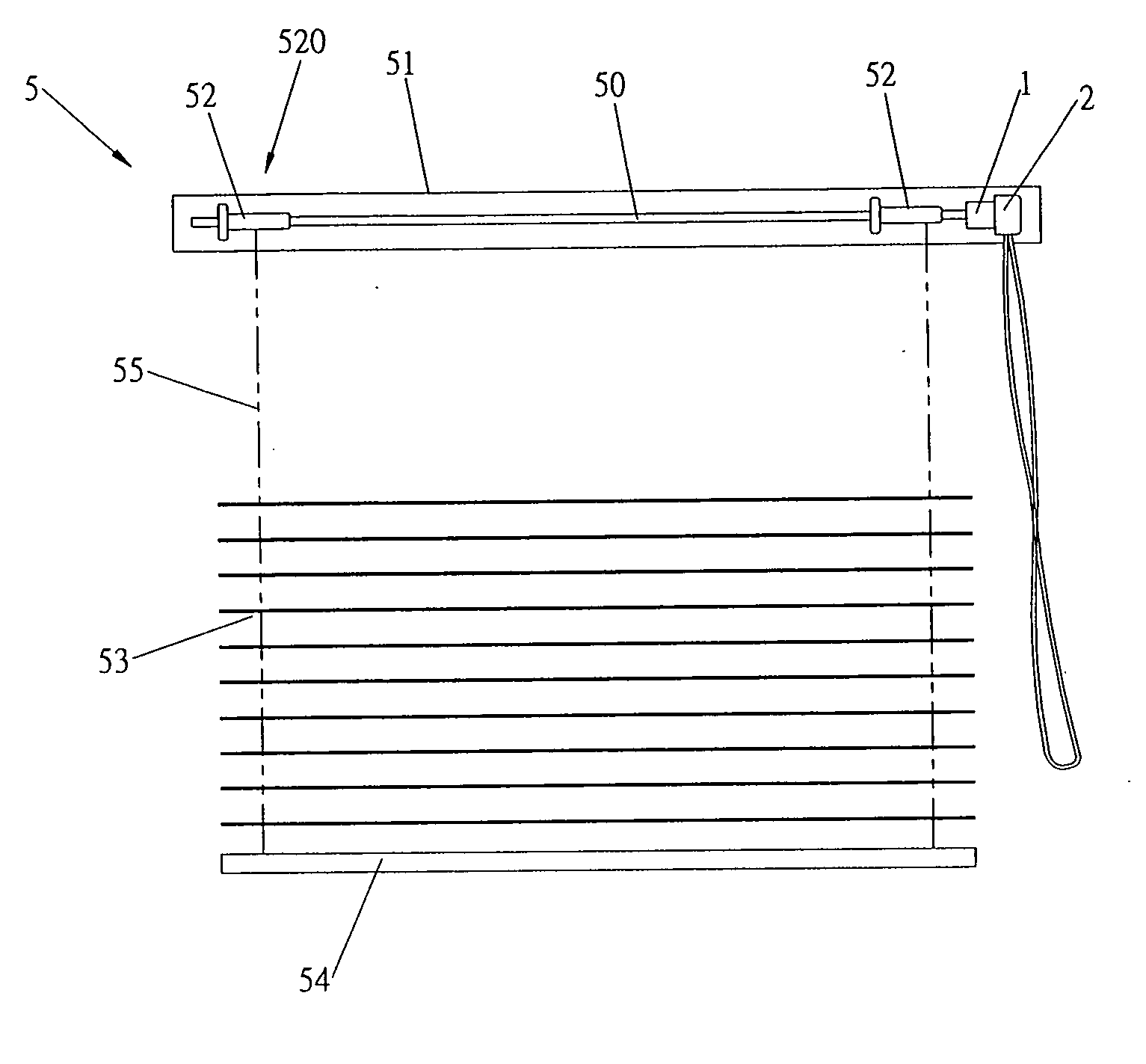

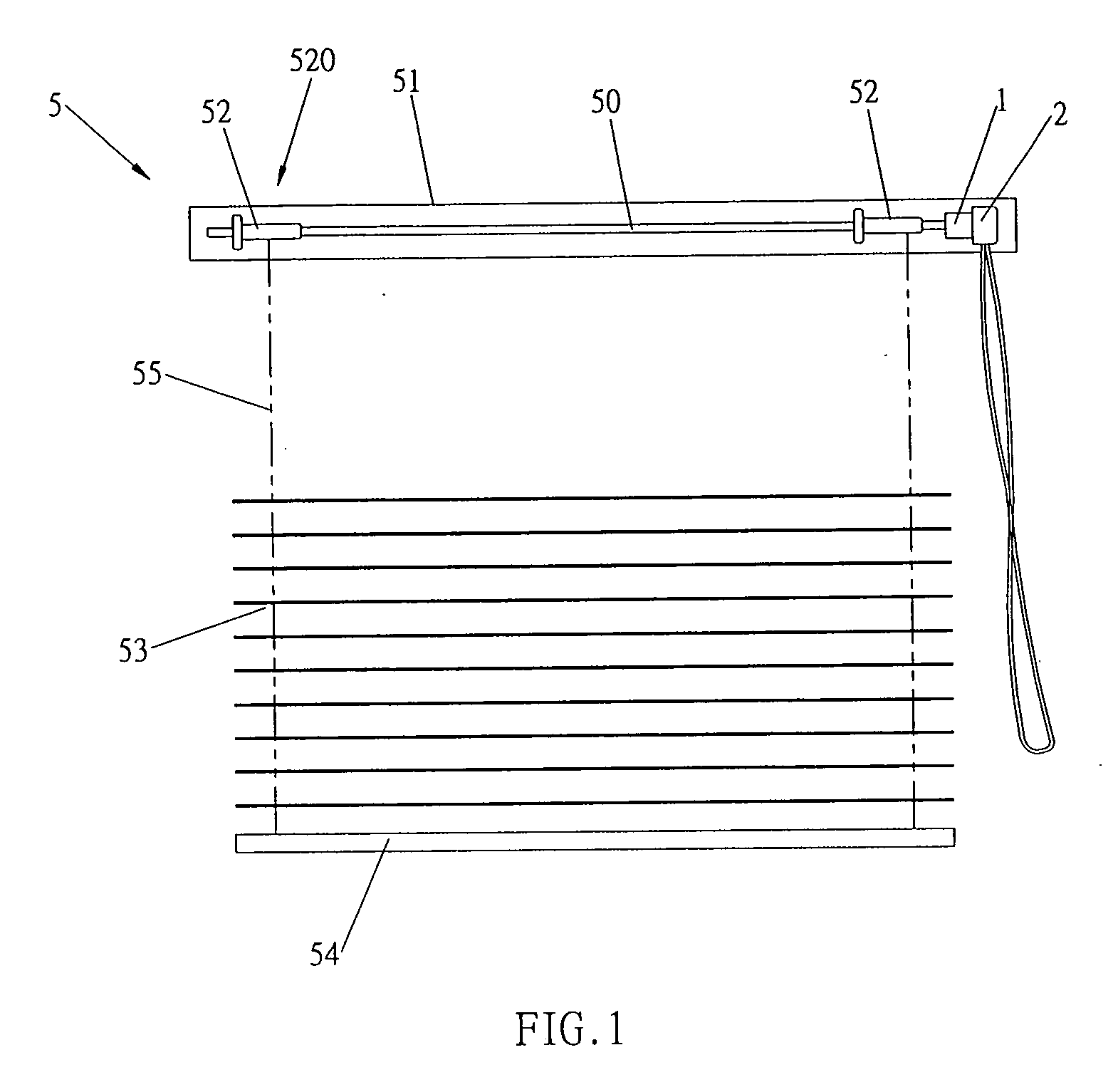

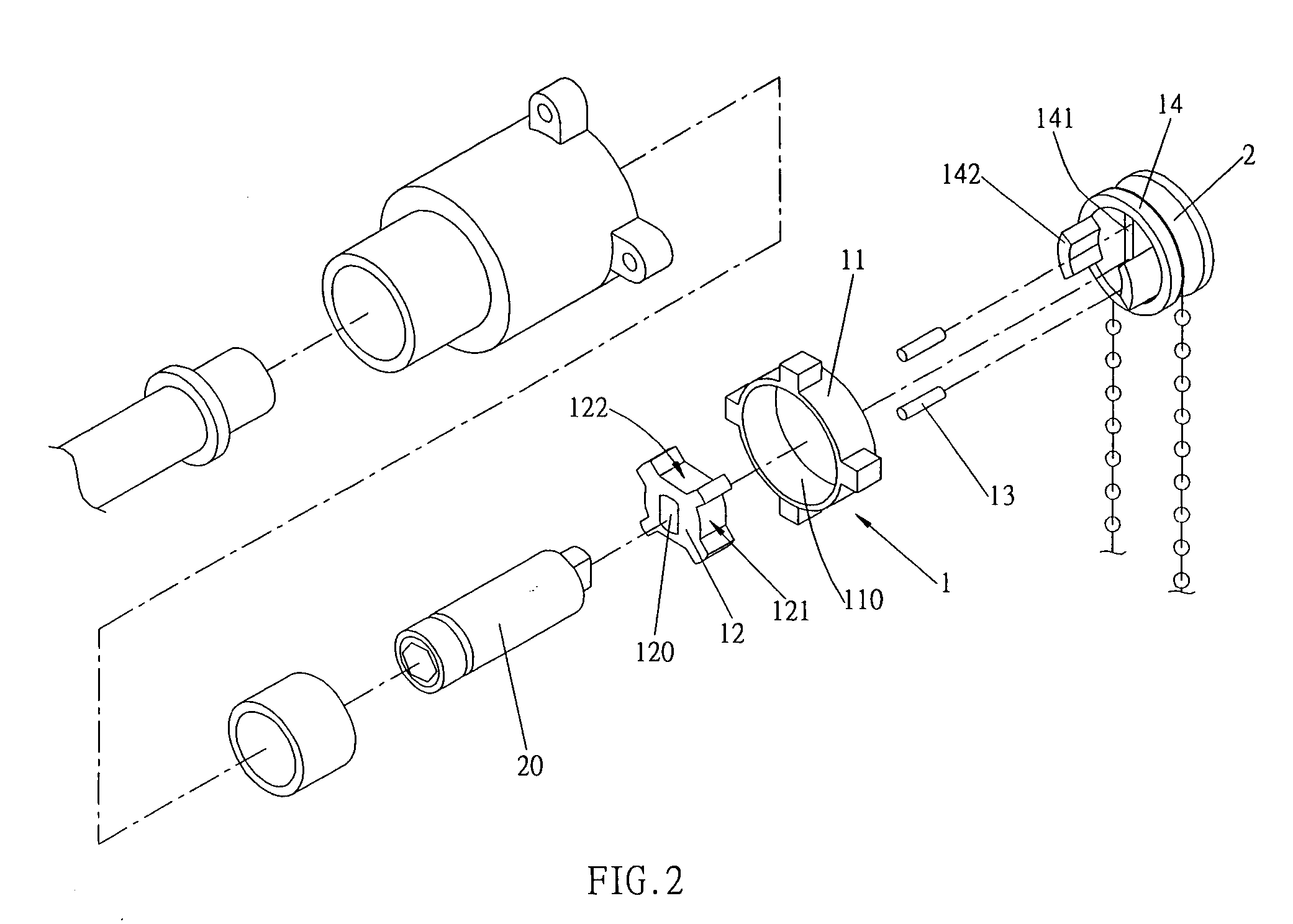

Brake mechanism for curtain linkage system

InactiveUS20060037720A1Efficient implementationOptimization mechanismLight protection screensEngineeringLinkage concept

A brake mechanism for curtain linkage system, which provides an improved mechanism for application in a curtain set such that when curtain slats are subjected to external forces that produce a counterforce, the counterforce is utilized to achieve a reverse braking effect. The brake mechanism can outwardly transmit motive power inputted to a drive unit to a connected linkage shaft. More specifically, the brake mechanism comprises a shield-shaped rotor disposed interior of a circular box. A confining ring is configured on a periphery of the circular box, and a rolling pin is configured between an inner circumference of the confining ring and a rotor, and the rolling pin functions to effectuate a shearing effect. Relative motion of the rolling pin and the rotor realizes a reverse braking effect in the confining ring, and which successfully achieves functionality of the brake mechanism of the present invention.

Owner:HUANG SHIEN TE

Closing device

InactiveUS20060279186A1Avoid Positional DistortionStrong and more rigidDrawersFittingEngineeringMechanical engineering

Owner:HARN MARKETING

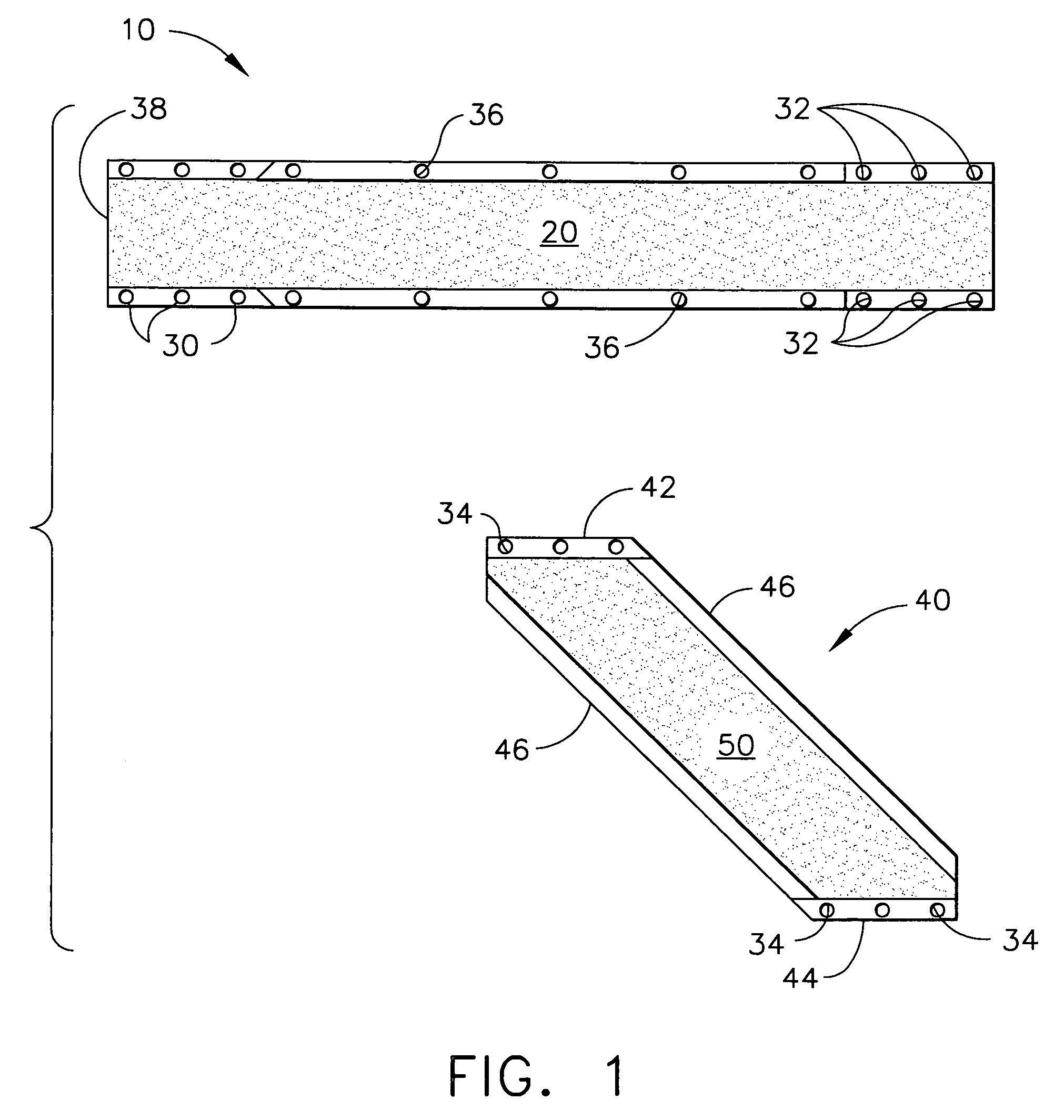

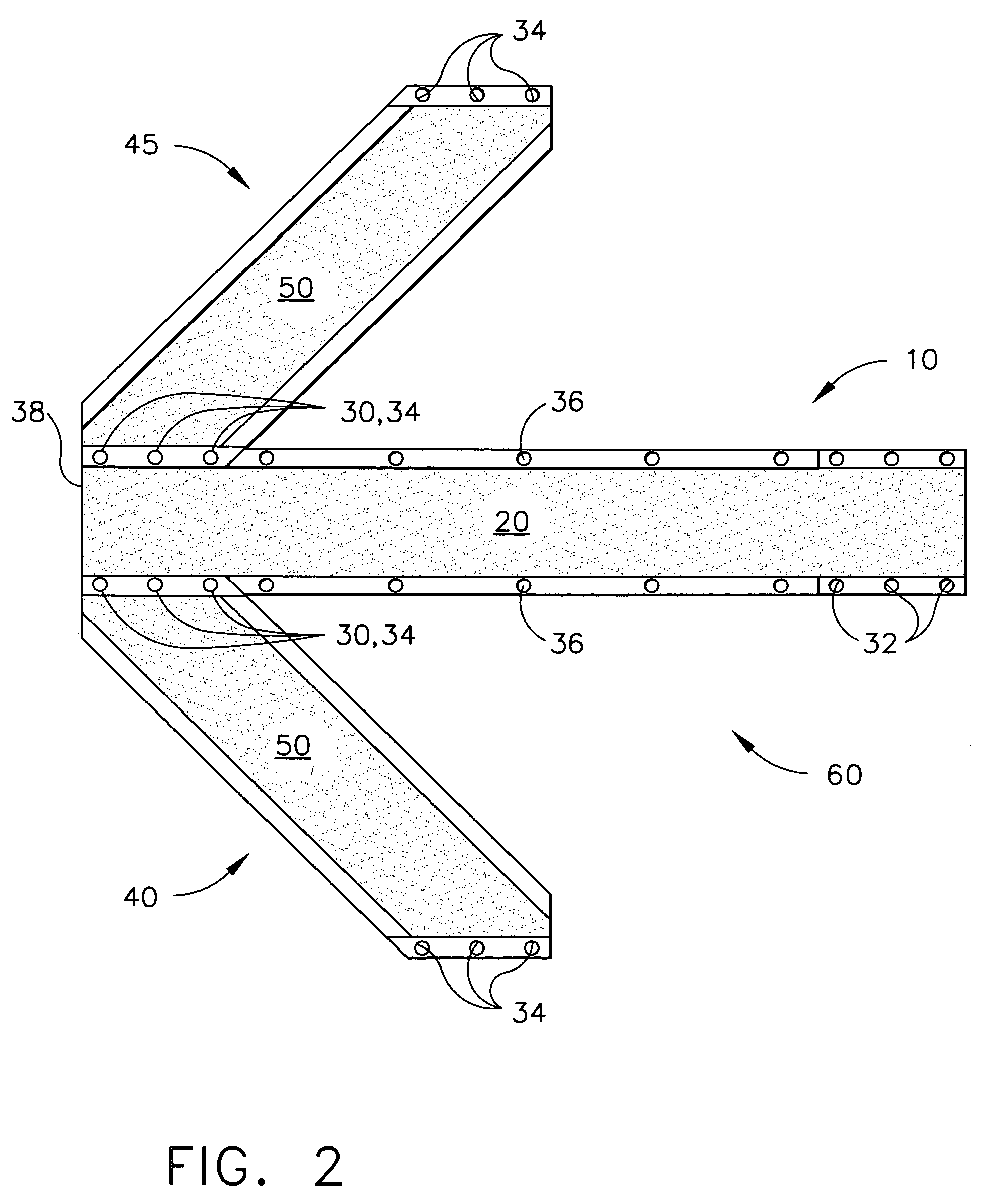

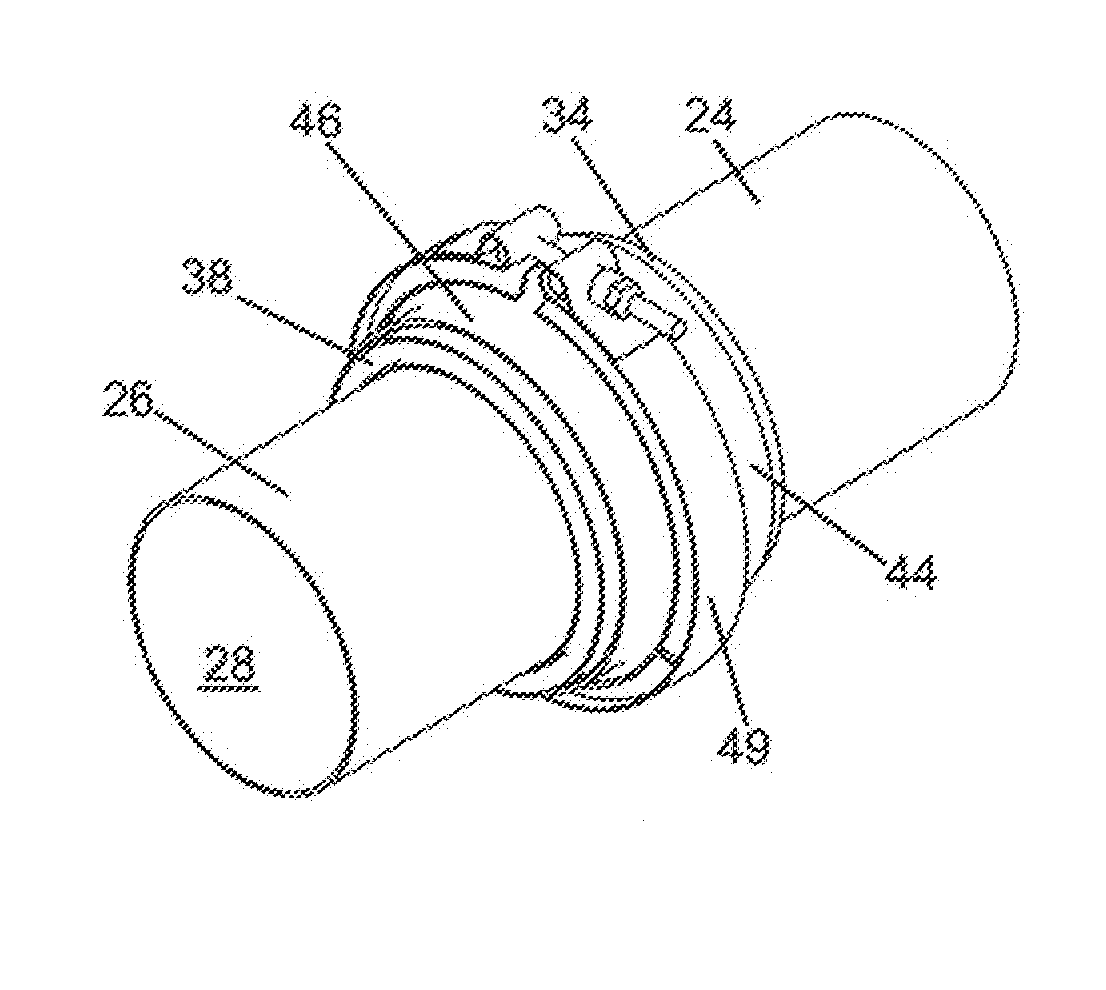

Reflective arrowhead traffic sign apparatus

InactiveUS6948446B2Easy to assembleEase of assemblyPortable emergency signal deviceTraffic signalsEngineeringStructural engineering

A highly reflective arrowhead traffic sign is provided which exhibits an arrow shape to “aim” traffic to one side or the other along a roadway. A horizontal longitudinal member has at least one pair of arrow-shaped “wings” that extend beyond the outer boundary of the horizontal member. The wing sets can be attached to the horizontal member by use of locating holes and mating pins, or they can be pivotally mounted on the horizontal member. The arrow wings can be shaped into a configuration that points to the left or to the right, or they can be placed on both ends of the horizontal member and simultaneously point to both the left and right, thereby indicating to traffic that a lane is closed, and that traffic must go either left or right to avoid the closed lane.

Owner:ZACAABEL

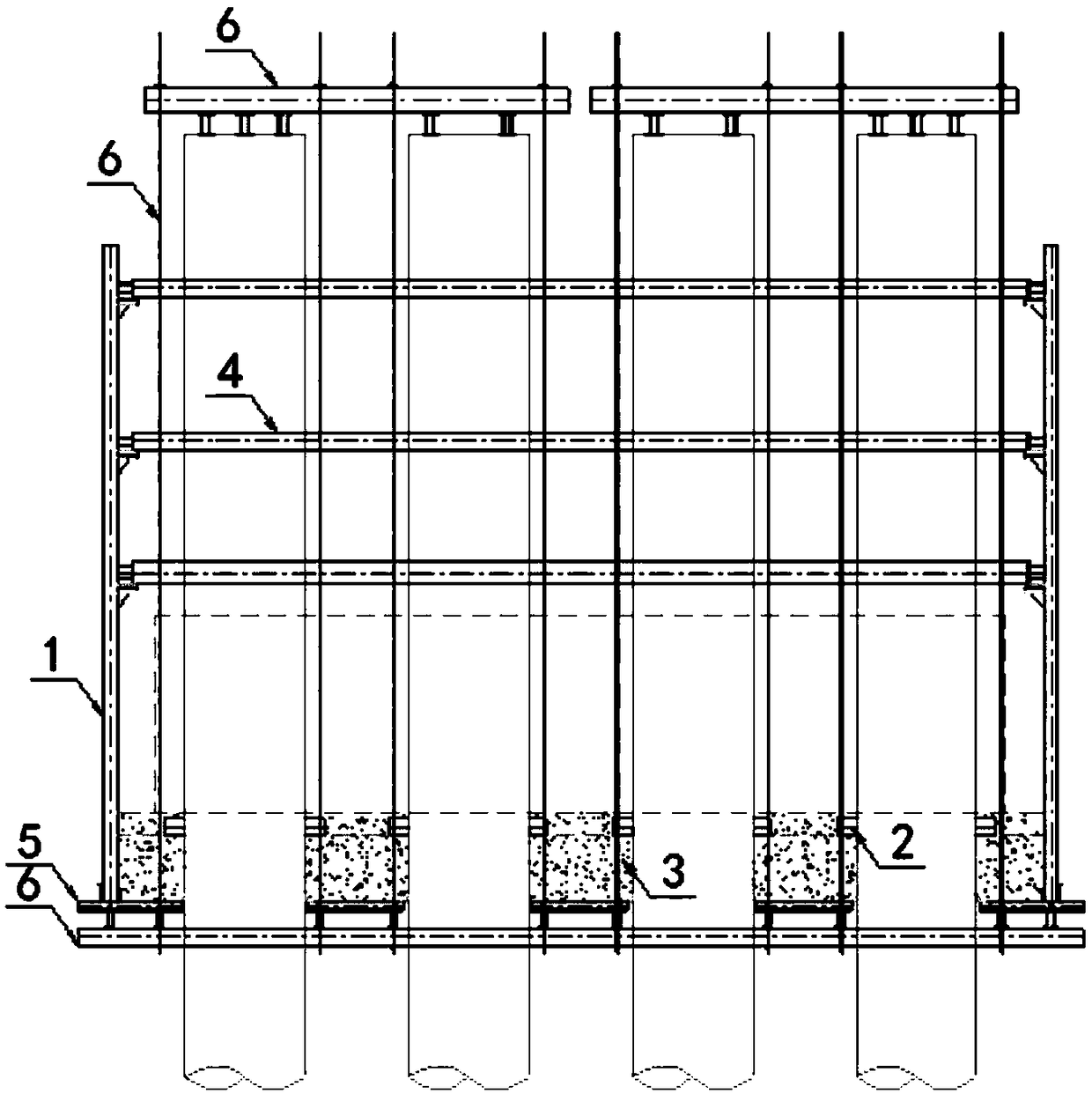

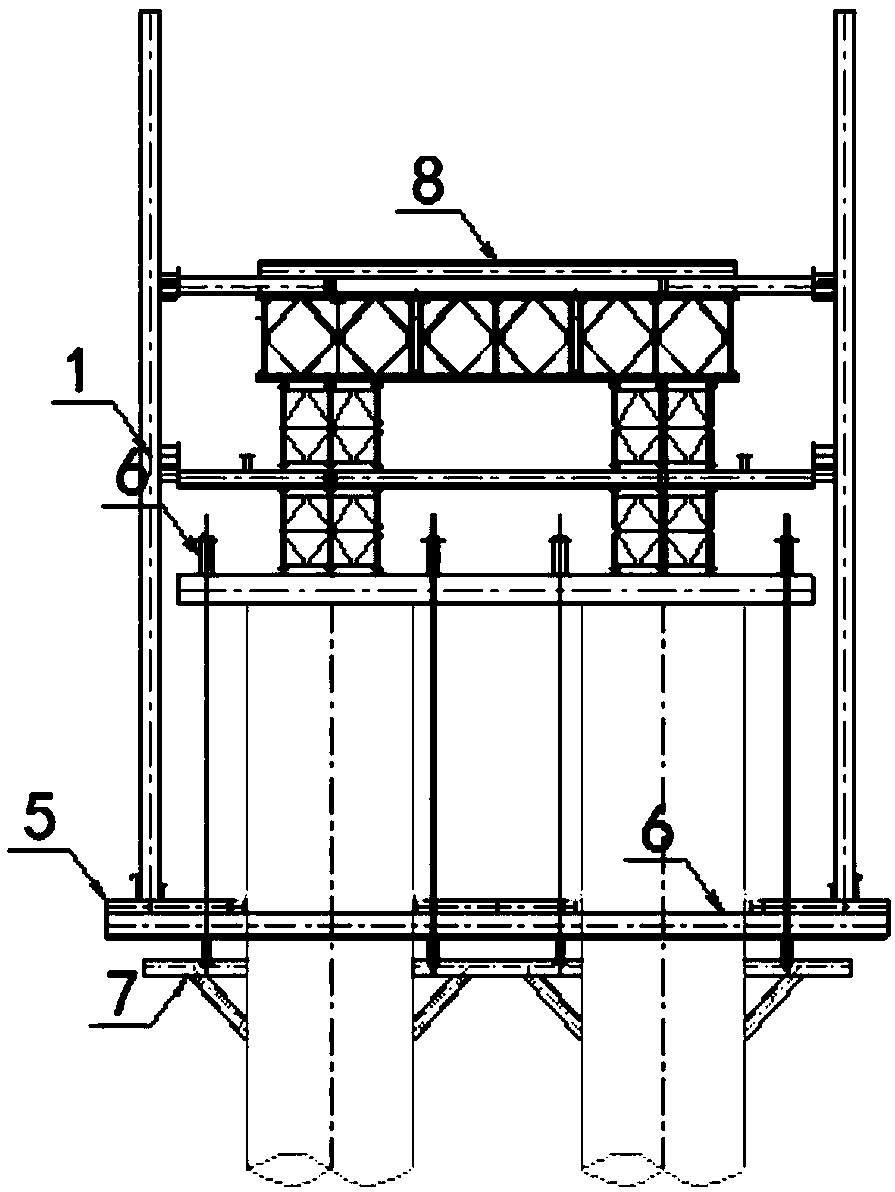

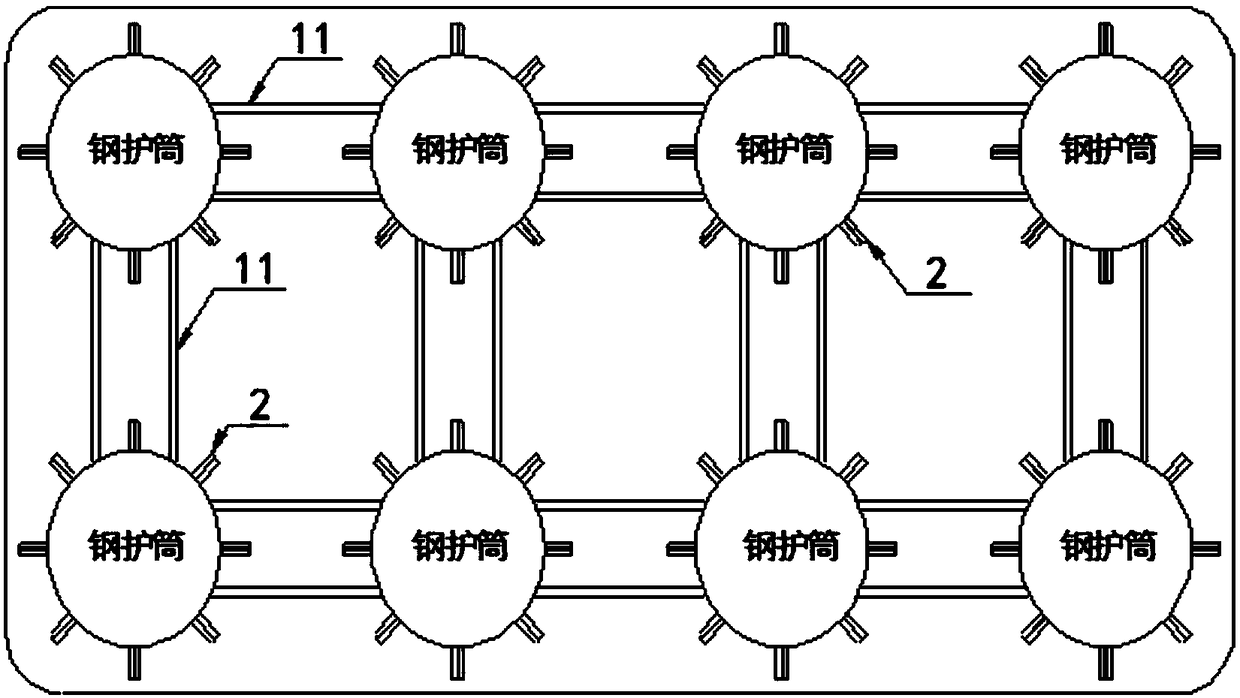

Construction method of deep water high pile bearing platform steel hanging box cofferdam

The invention discloses a construction method of a deep water high pile bearing platform steel hanging box cofferdam. The construction method comprises the following steps: 1) design of a steel hanging box cofferdam: Larson steel plate piles are adopted as wall plates of the steel hanging box cofferdam; 2) assembly and placement of the steel hanging box cofferdam: the steel hanging box cofferdam adopts high assembly and overall placement technologies; 3) bottom cover concrete construction: a bottom cover construction process is performed twice; after primary bottom covering, water in the steelhanging box cofferdam is extracted to a bottom cover surface; and then, the secondary bottom cover concrete casting is performed; and 4) disassembly of the steel hanging box cofferdam: after a bearing platform and part of underwater piers are constructed, the water is injected in the steel hanging box cofferdam to reach balanced inner and outer water levels; and the steel hanging box cofferdam isdisassembled. In the construction method, through the Larson steel plate piles as the wall plates of the steel hanging box cofferdam and twice bottom cover construction process, the construction progress can be accelerated, the economical cost is saved, and the engineering quality is guaranteed.

Owner:CHINA RAILWAY 23RD BUREAU GRP NO 1 ENG

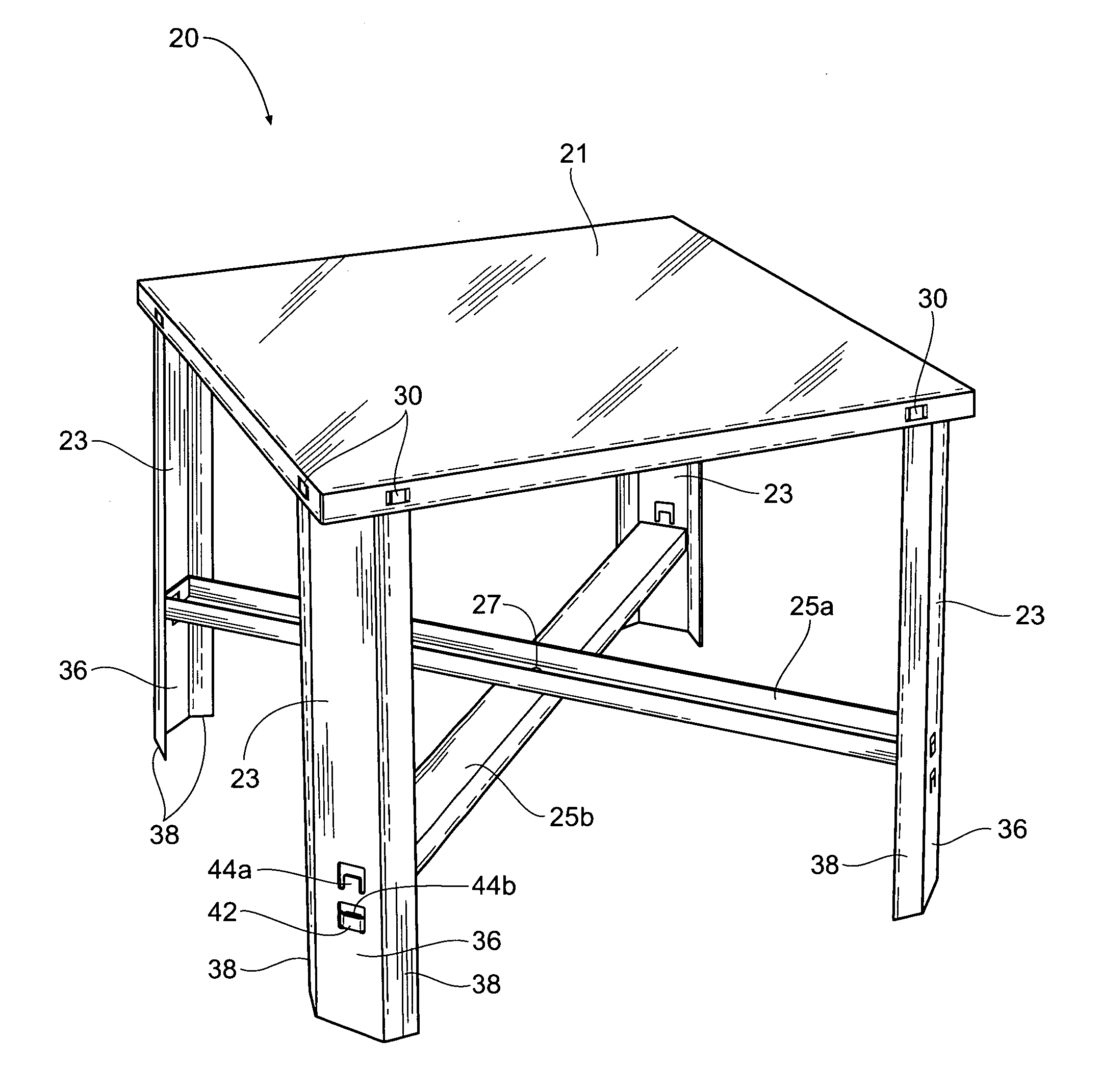

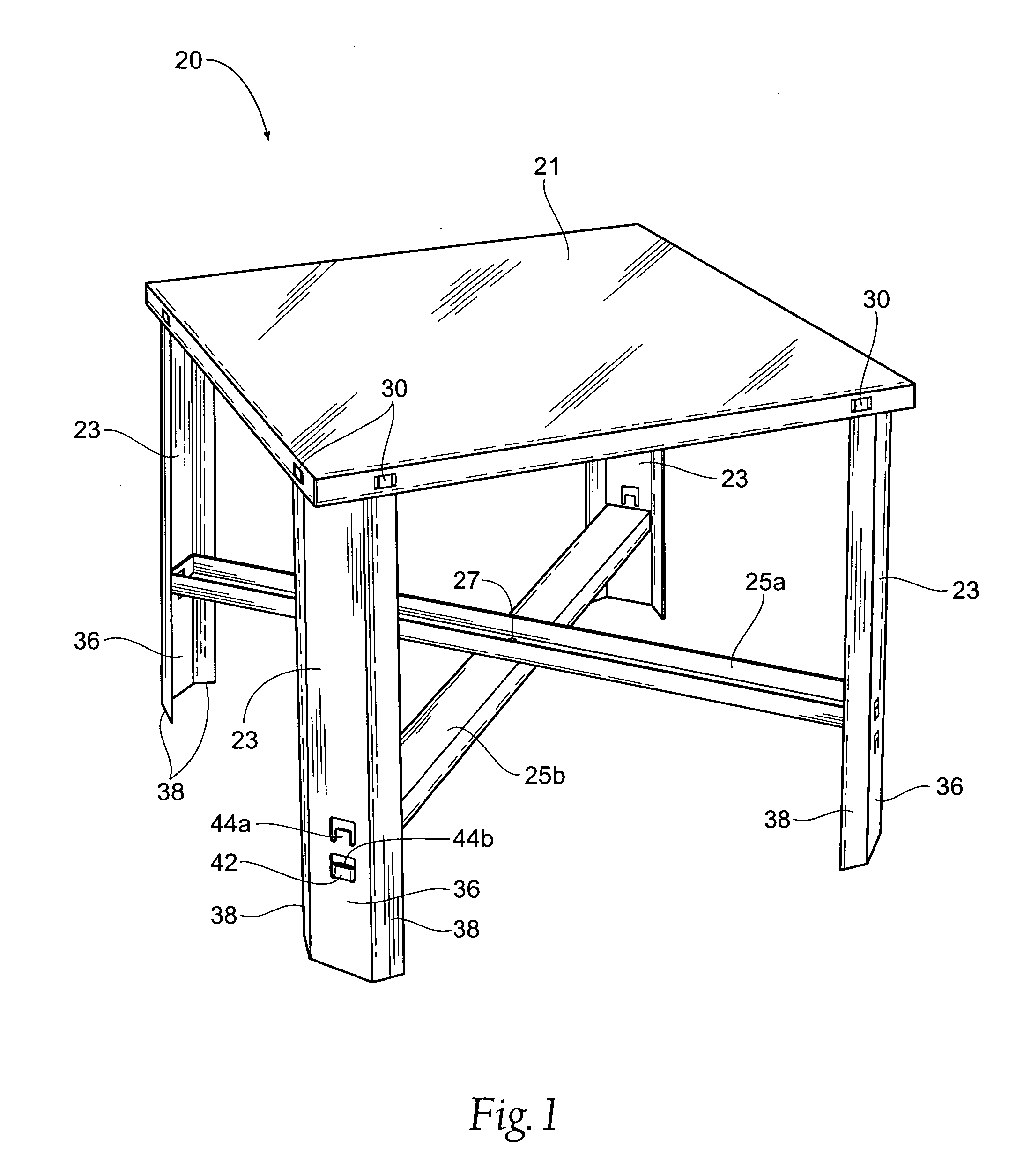

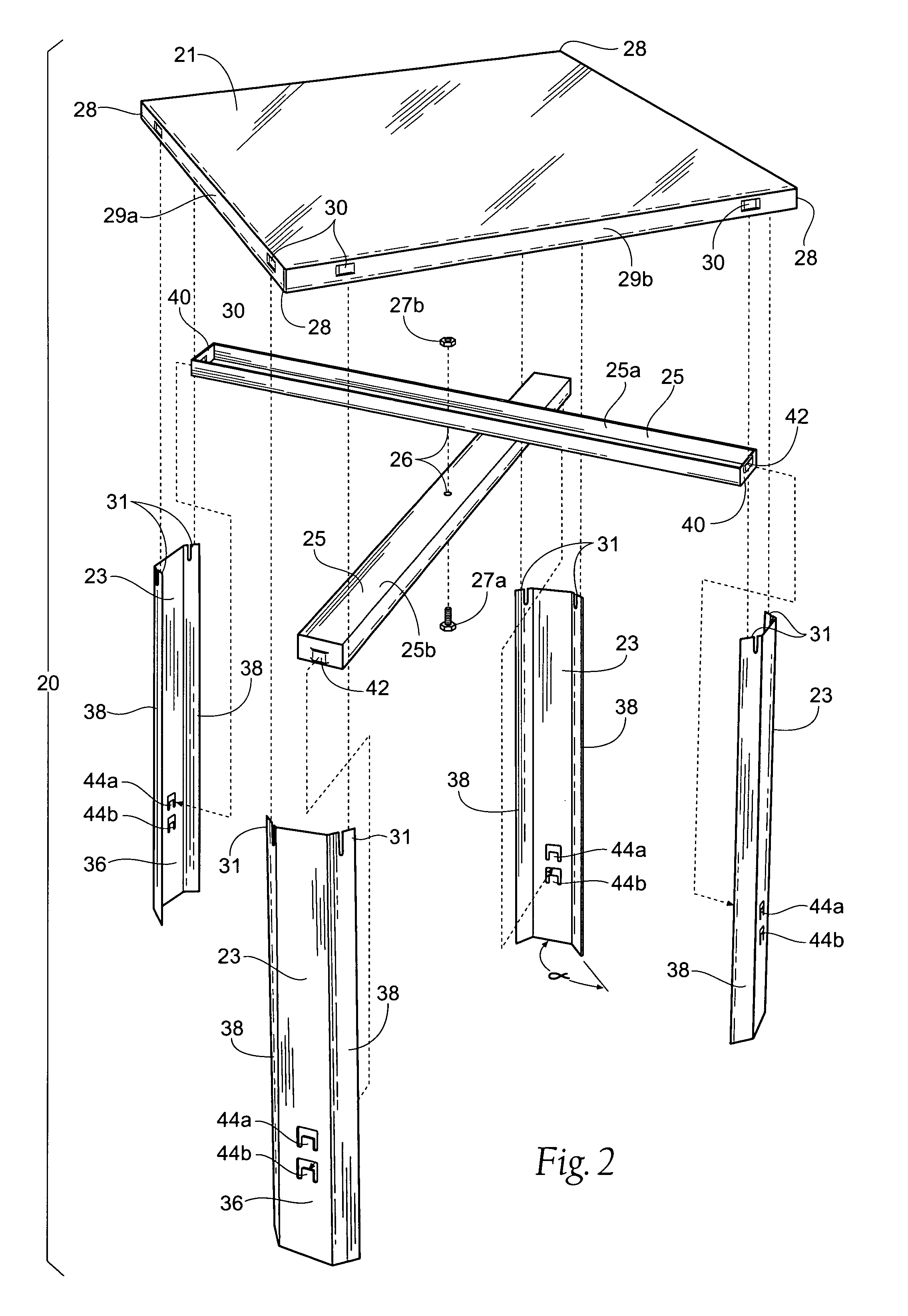

Water heater stand and assembly therof

ActiveUS20100269738A1Ease in breakdownEase of assemblyFoldable tablesStands/trestlesCruciformEngineering

The novel stand described and claimed herein has been found to be suitable for elevated support of water heaters and similar objects. A preferred embodiment of the stand may comprise a planar, rectangular tabletop formed and stamped from sheet-like material, and is being further formed with downwardly bent marginal side flanges. The tabletop is preferably supported by two pairs of oppositely disposed leg members, which are also stamped from sheet-like material. Each leg member is formed with a longitudinally extending flat central portion and oppositely positioned coextensive angularly bent flange portions. The surface of each leg flange mates with an adjacent facing surface of a respective surface of a respective one of the downwardly depending tabletop flanges. The stand further includes a cruciform arrangement of overlapping crossbars, of which opposite end thereof include means for detachable securement to an oppositely disposed one of said pair of leg members.

Owner:C & S MFG

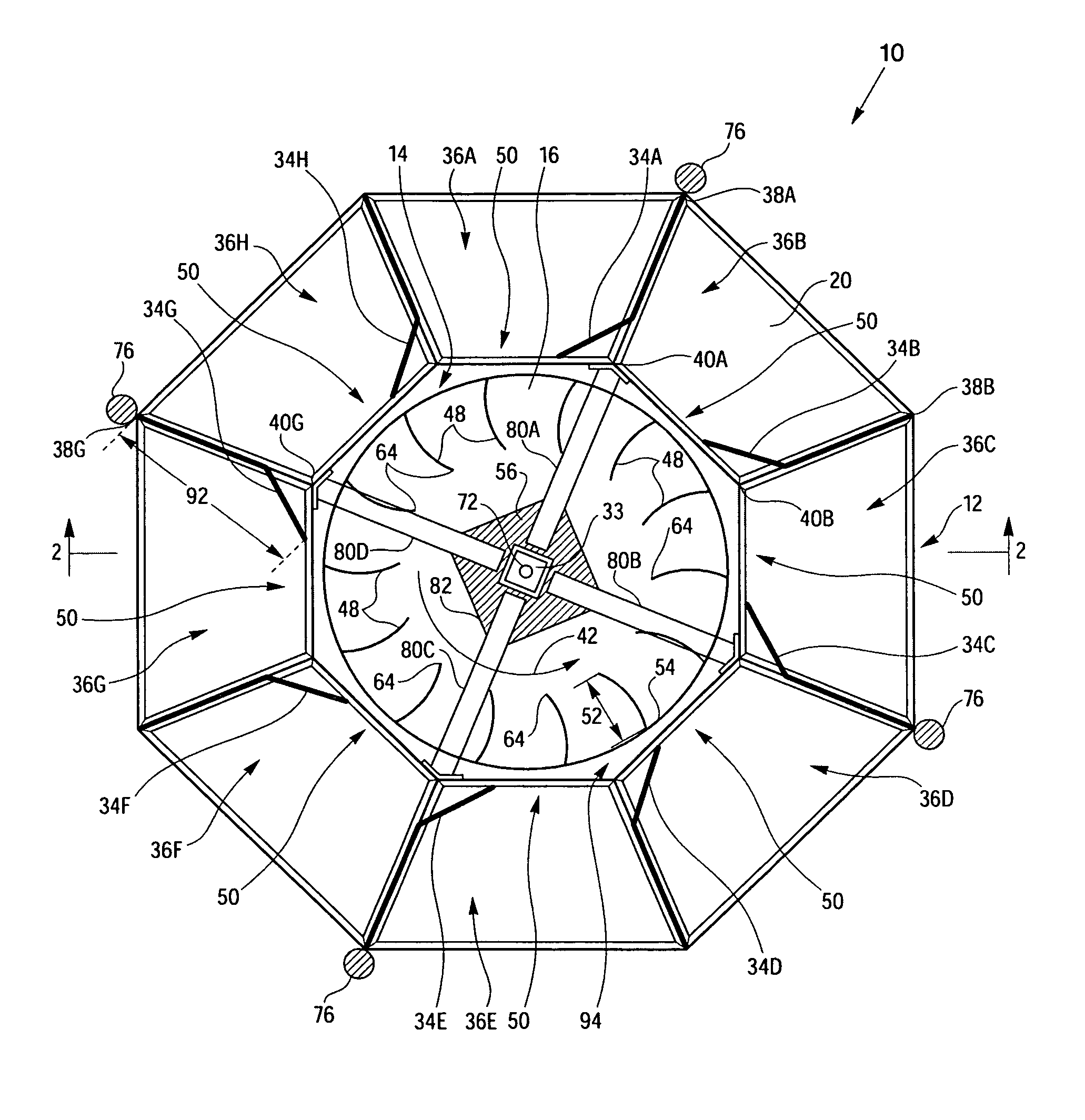

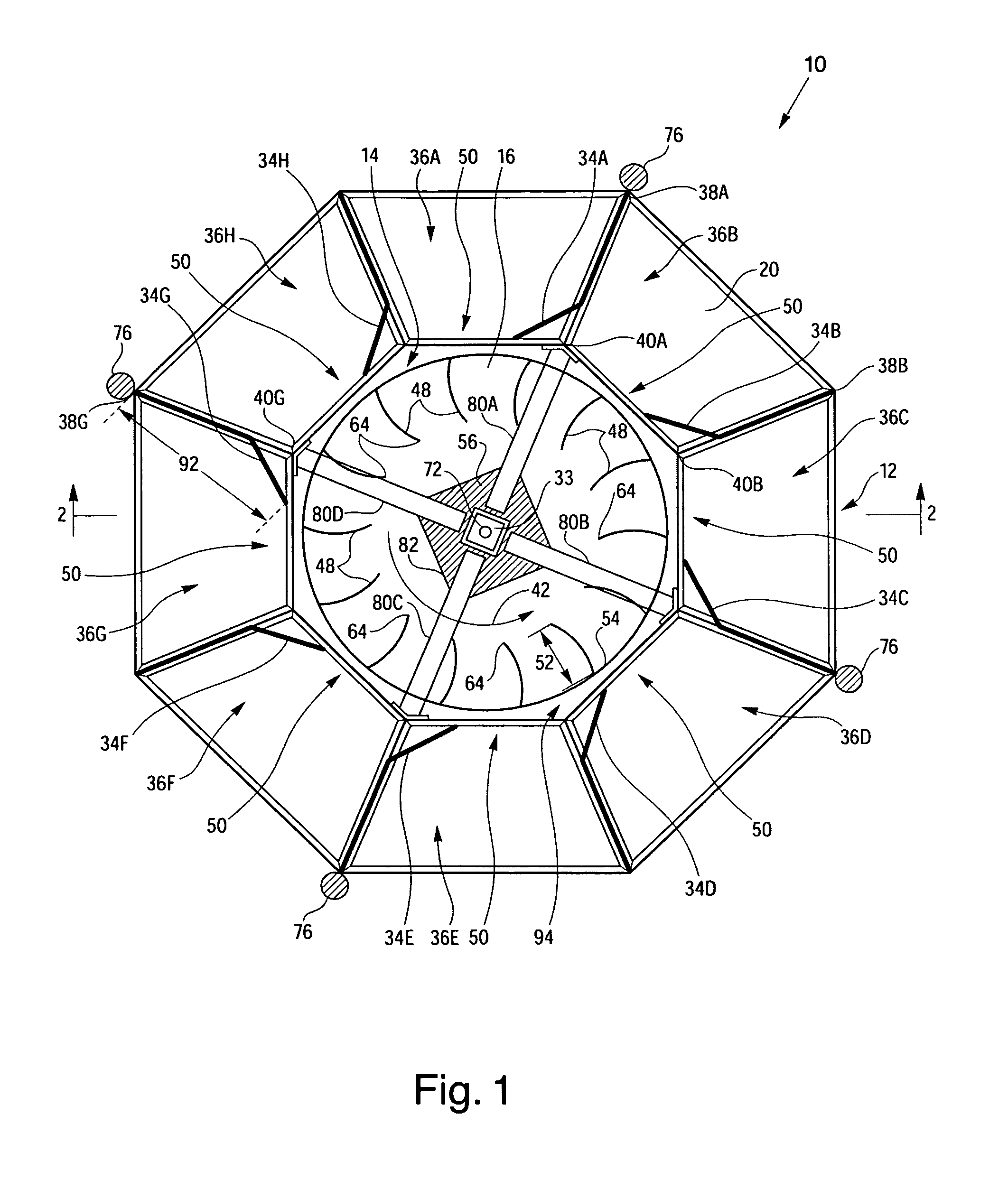

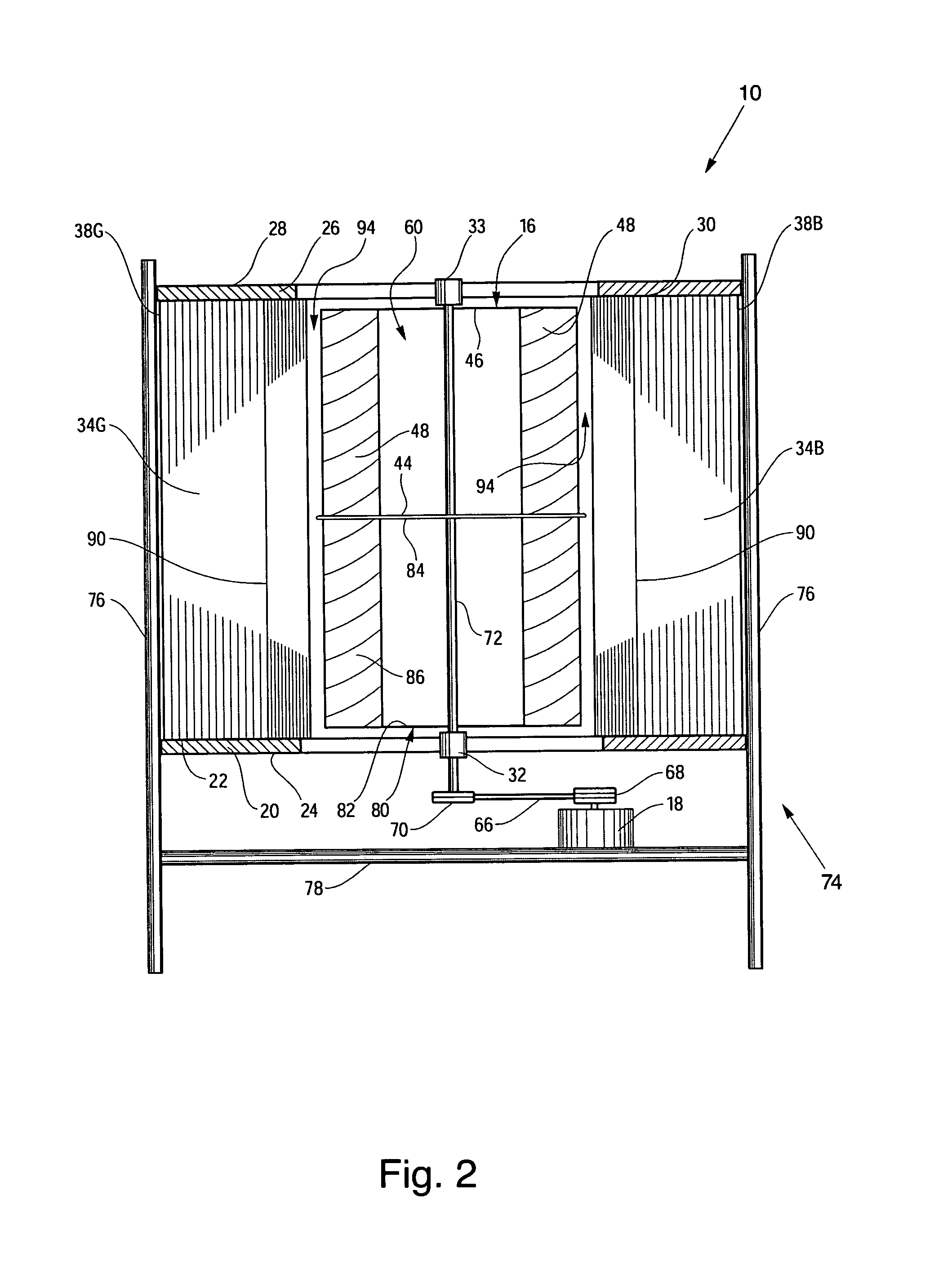

Open-flow vertical wind generator

InactiveUS8591171B1High strengthReduce weightWind motor controlRenewable energy generationTurbineWind force

The generator (10) includes an essentially cylindrical stator assembly (12) defining a central turbine void (14) in which a wind turbine (16) rotates to power an electrical generator (18). The wind turbine (16) includes vanes (48) having a width (52) less than 25 percent of a diameter (58) of the turbine (16). The turbine (16) defines an open void (60) between the vanes (48) for unrestricted passage of air through the wind turbine (16). Non-planar stators (34A-34H) extend between a base and an upper truss (20, 26) to strengthen the stator assembly (12) and to direct air exiting directional ducts (36A-36H) to move in a first rotational direction (42) within the turbine void (14). A plurality of geodesic truss segments (96A-96H) form the base and upper trusses (20, 26) to produce a strong, light-weight wind generator (10) that is easily assembled on-site.

Owner:MAYNARD MARK

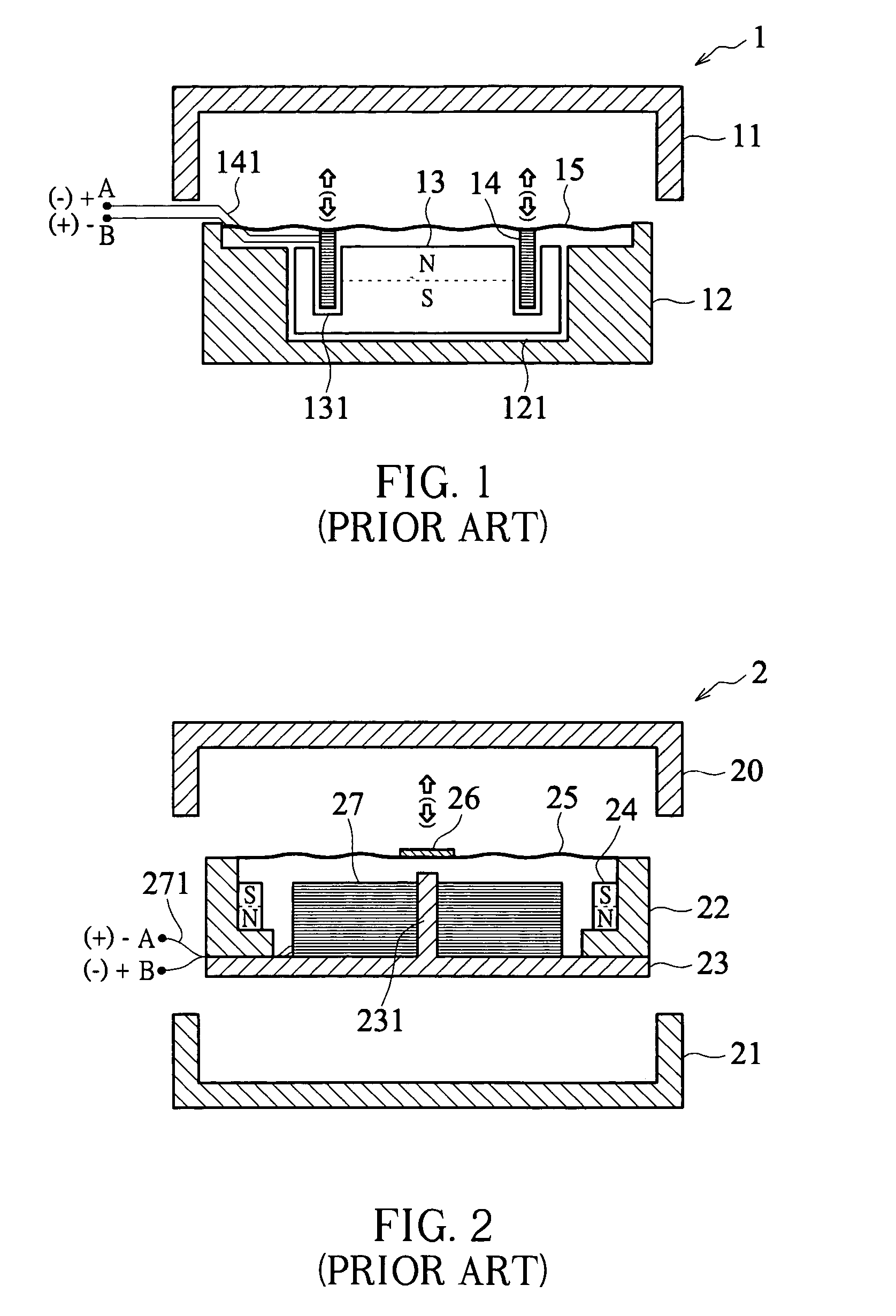

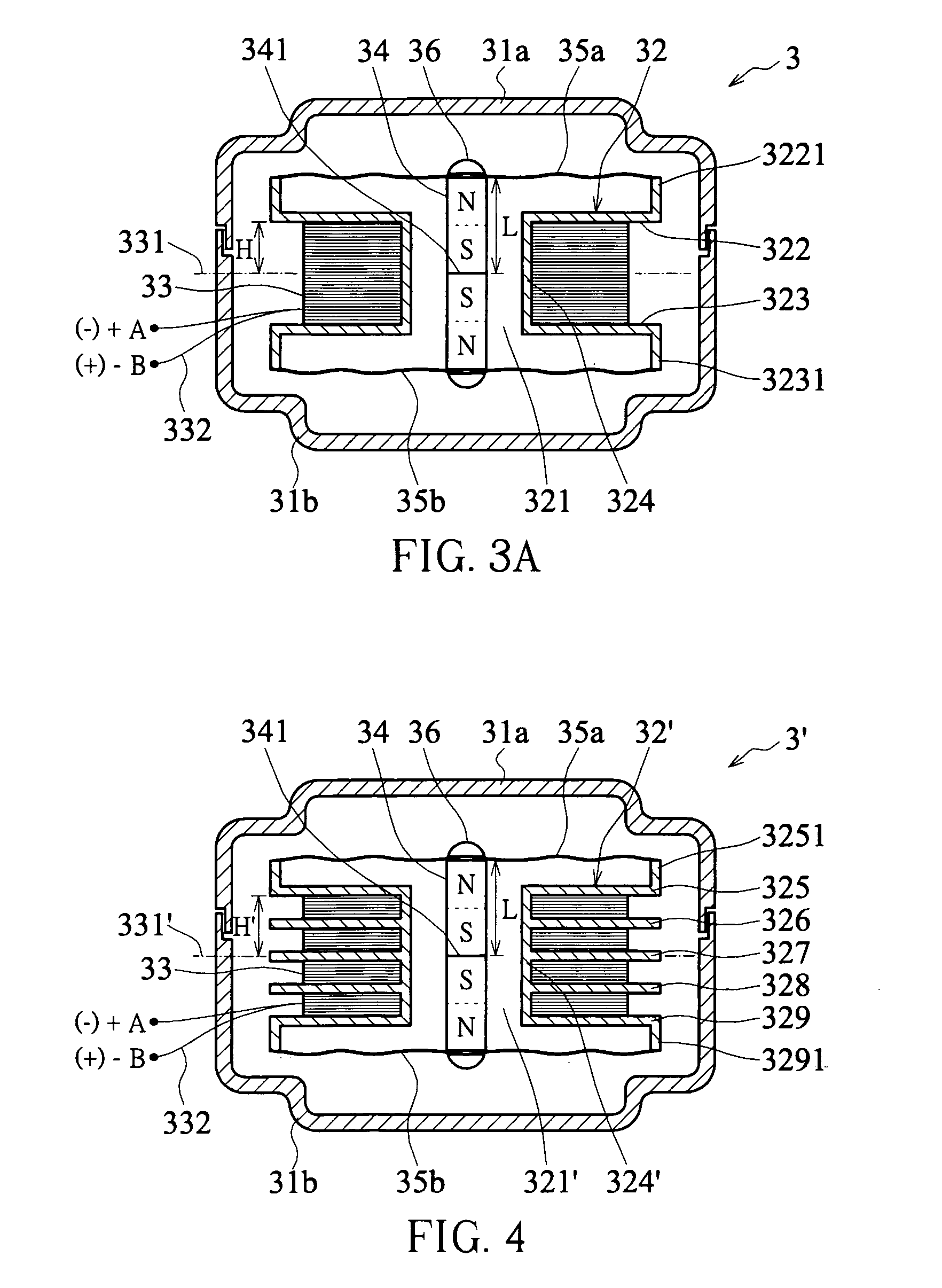

Structure of speaker

InactiveUS20050123166A1Manufacturing EaseEase of assemblyPlane diaphragmsFrequency/directions obtaining arrangementsBobbinLoudspeaker

A structure of speaker is disclosed. The disclosed speaker structure includes at least a bobbin, a coil, a membrane, and a magnetic assembly. The coil is wound around the side surface of the bobbin, and the membrane is disposed at end of the bobbin. Besides, the magnetic assembly is suspended in a through hole of the bobbin and have one end adhered to the membrane.

Owner:DELTA ELECTRONICS INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com