Patents

Literature

36results about How to "Optimize cooling structure" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

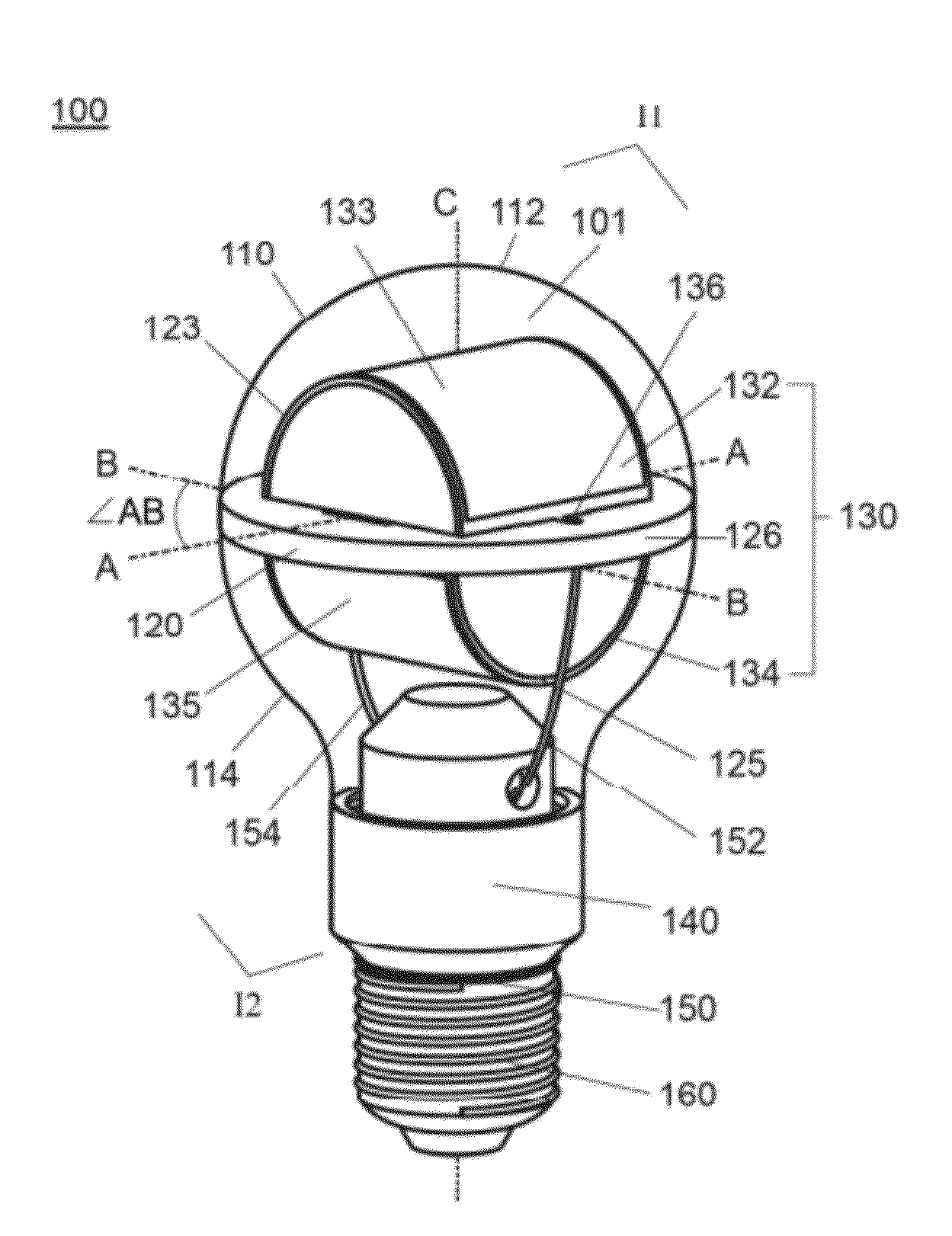

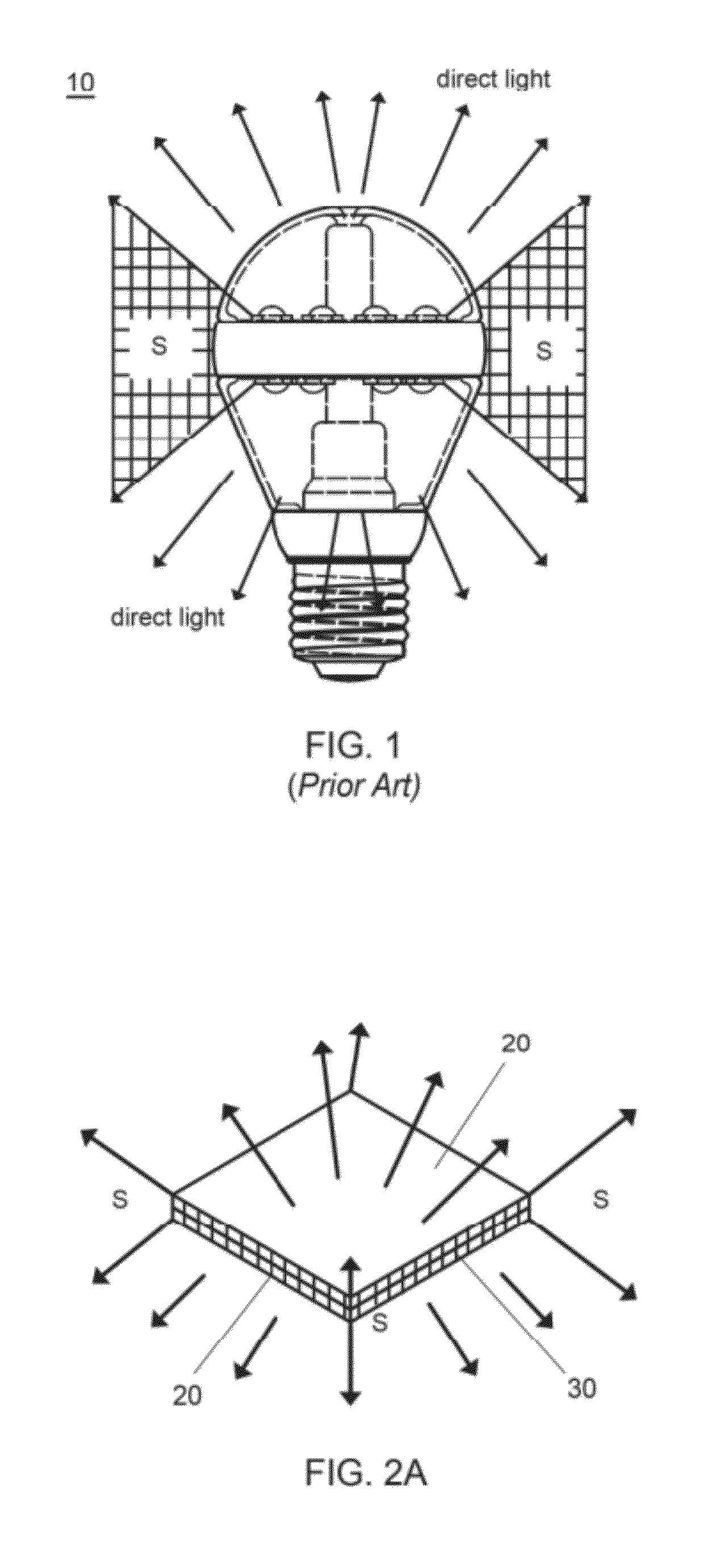

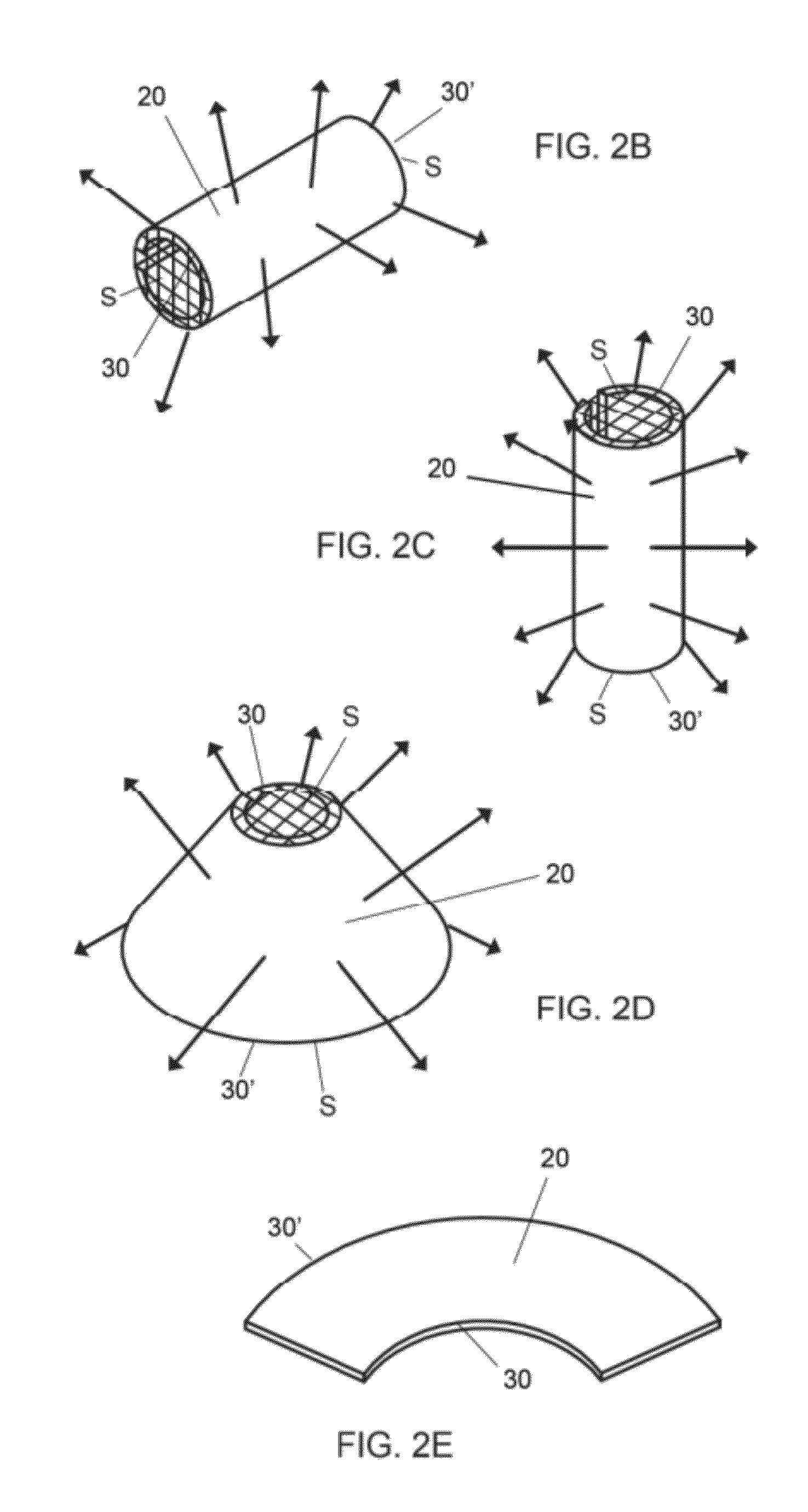

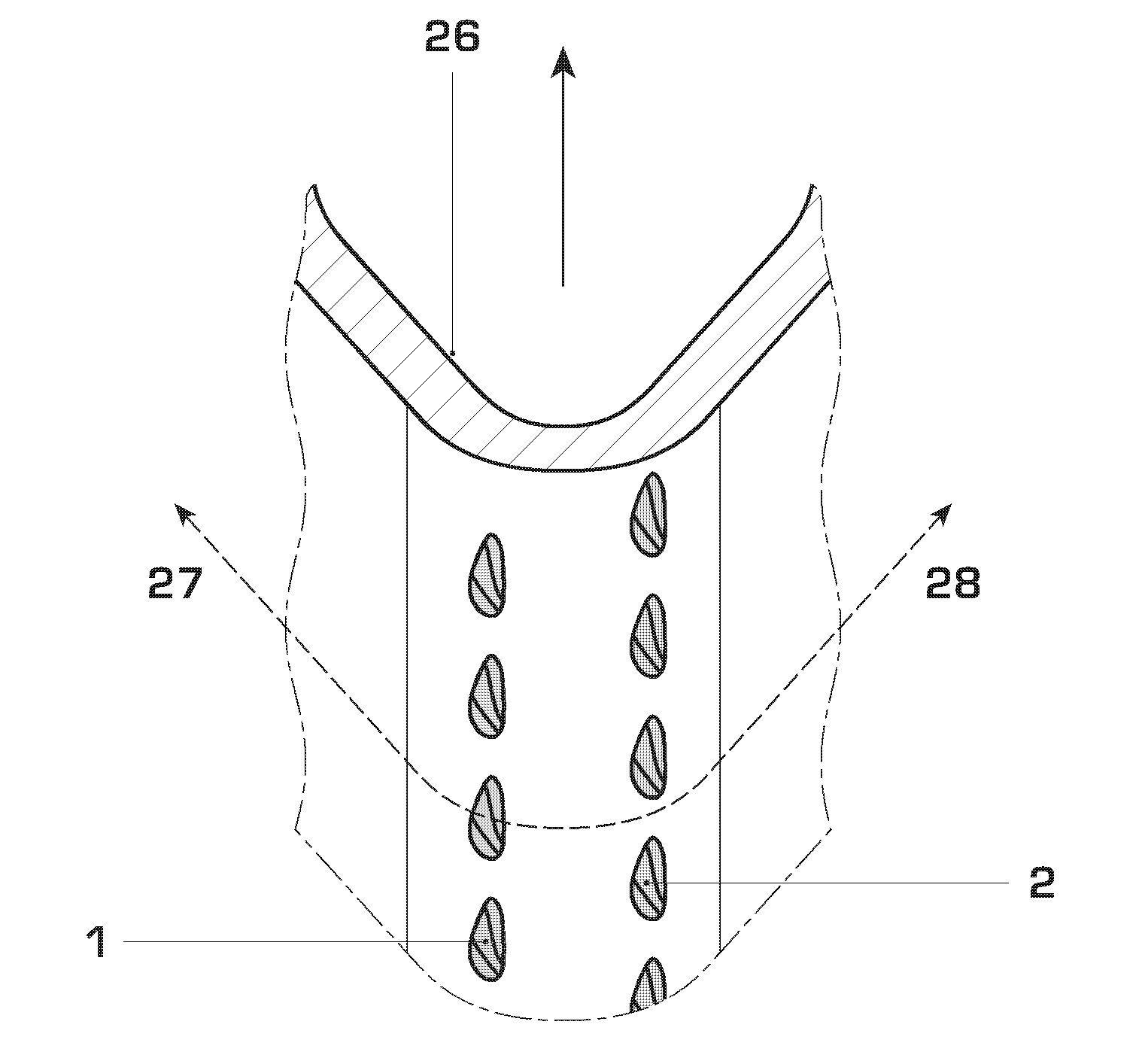

LED light bulb having an LED light engine with illuminated curved surfaces

InactiveUS8227962B1Convenient lightingObtain goodPoint-like light sourceElectric discharge tubesEngineeringLED lamp

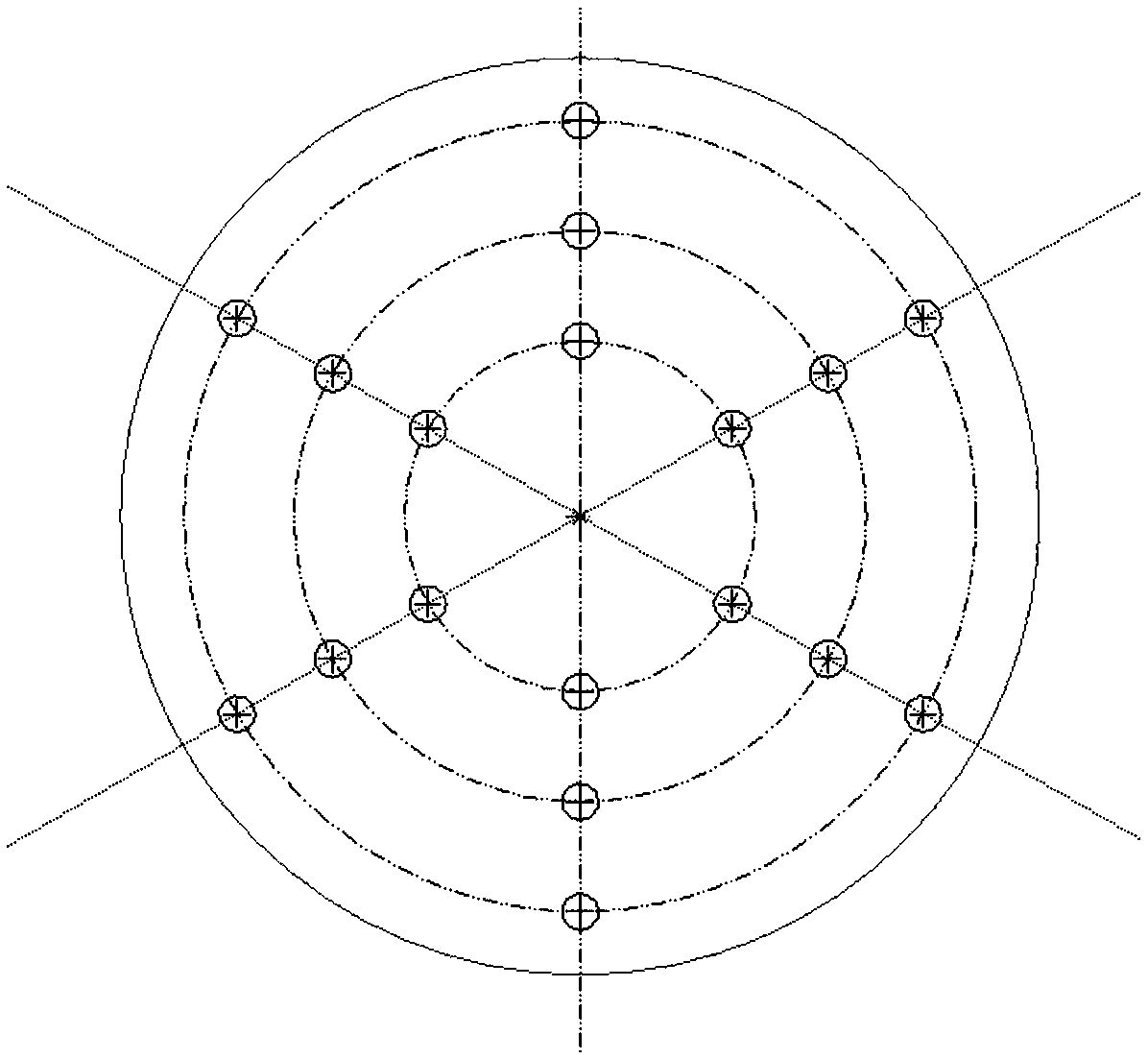

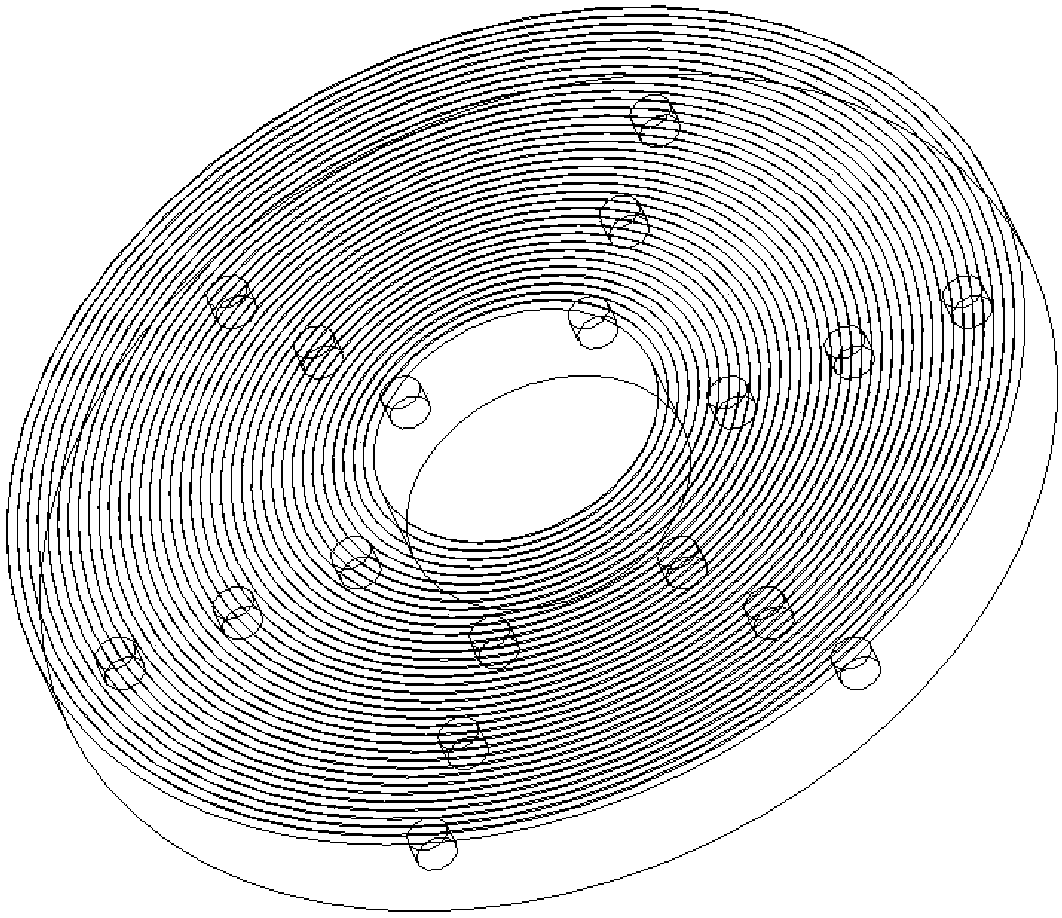

The present invention relates to an LED light bulb utilizing LED light sheets with illuminated curved surfaces and can be used as a replacement bulb. The LED light bulb comprises an LED light engine having first and second LED modules with first and second illuminated curved surfaces facing toward different illumination zones I1, I2 respectively and attached to a thermally conducive support block with an increased curved surface area for heat dissipation. Said first and second illuminated curved surfaces are curved about first and second axes A, B respectively and are arranged to be offset from each other with said axes A and B substantially perpendicular to each other such that an improved illumination with direct lights shone to at least six different sides of the light bulb and subsequently a substantially spherical illumination of dispersed lights may be obtained along with an enhanced cooling of the light bulb.

Owner:SU ALLEN HUI LONG

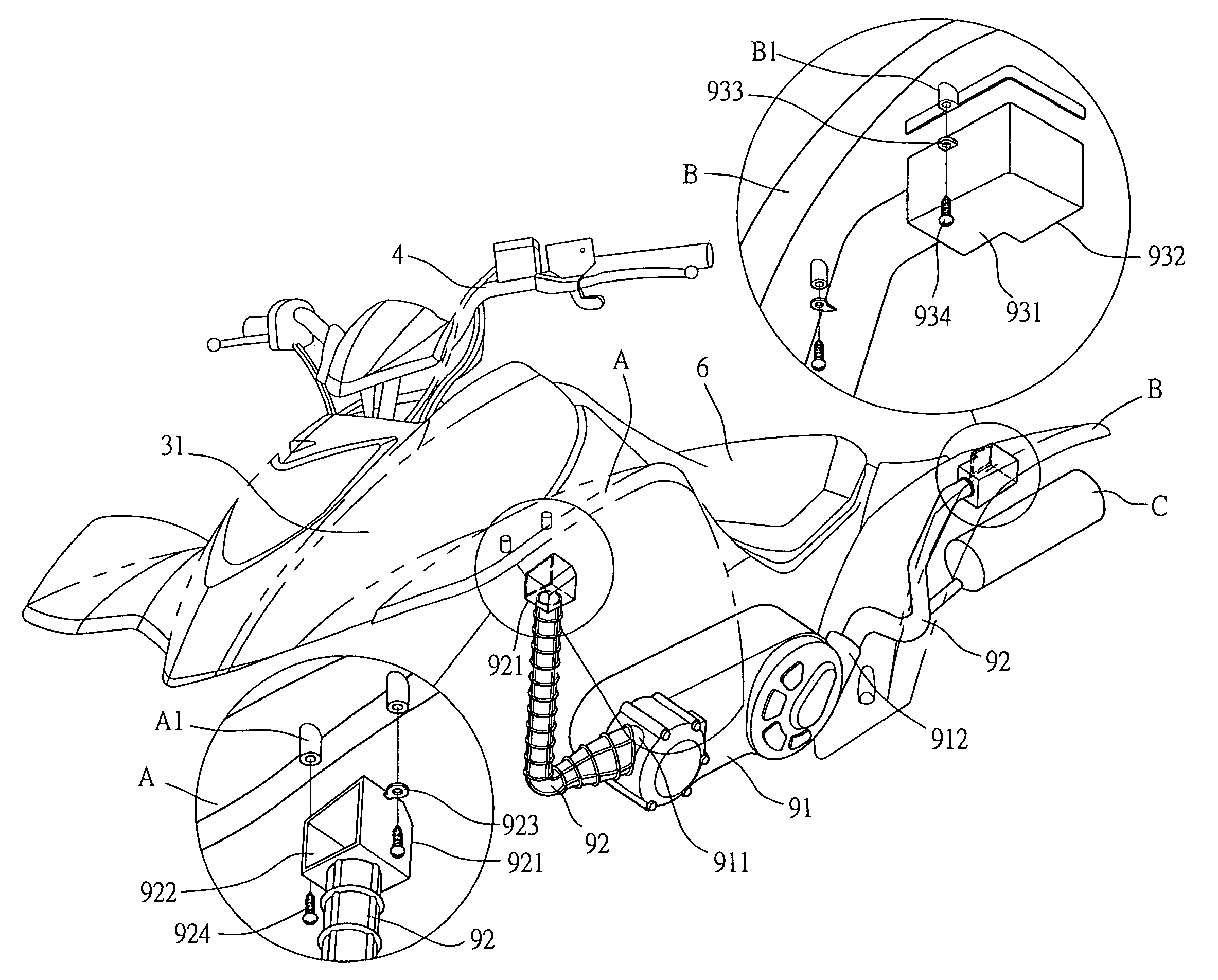

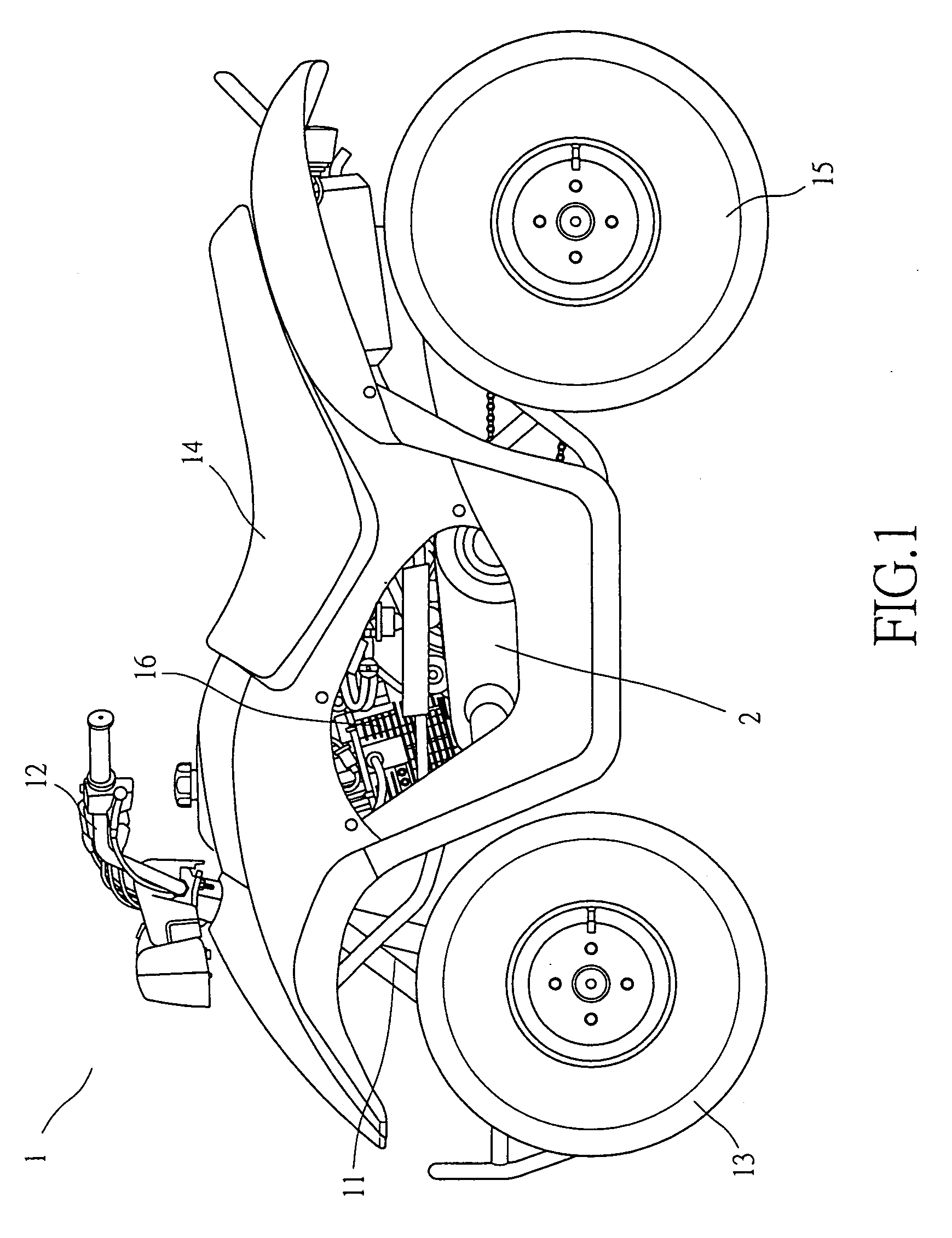

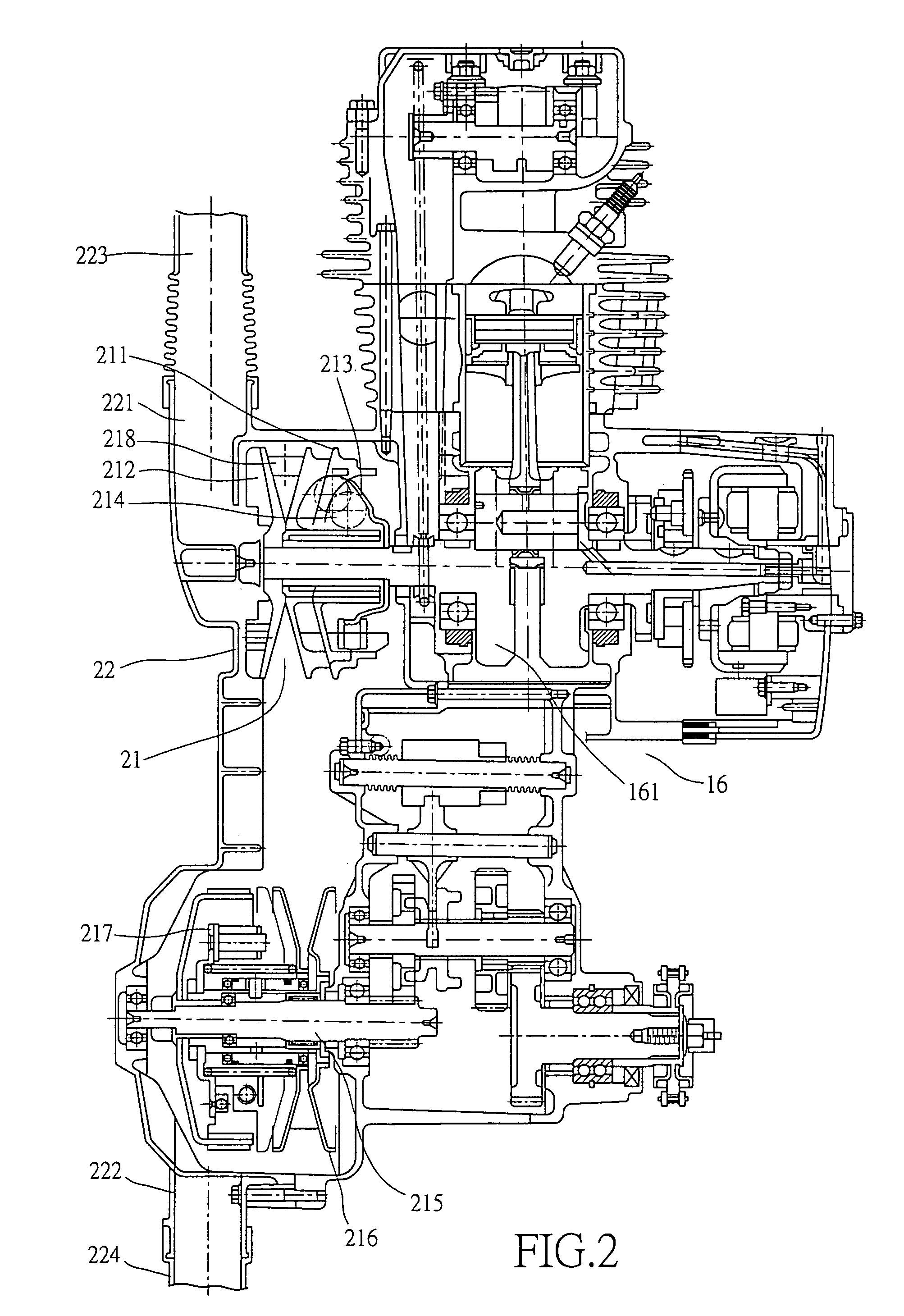

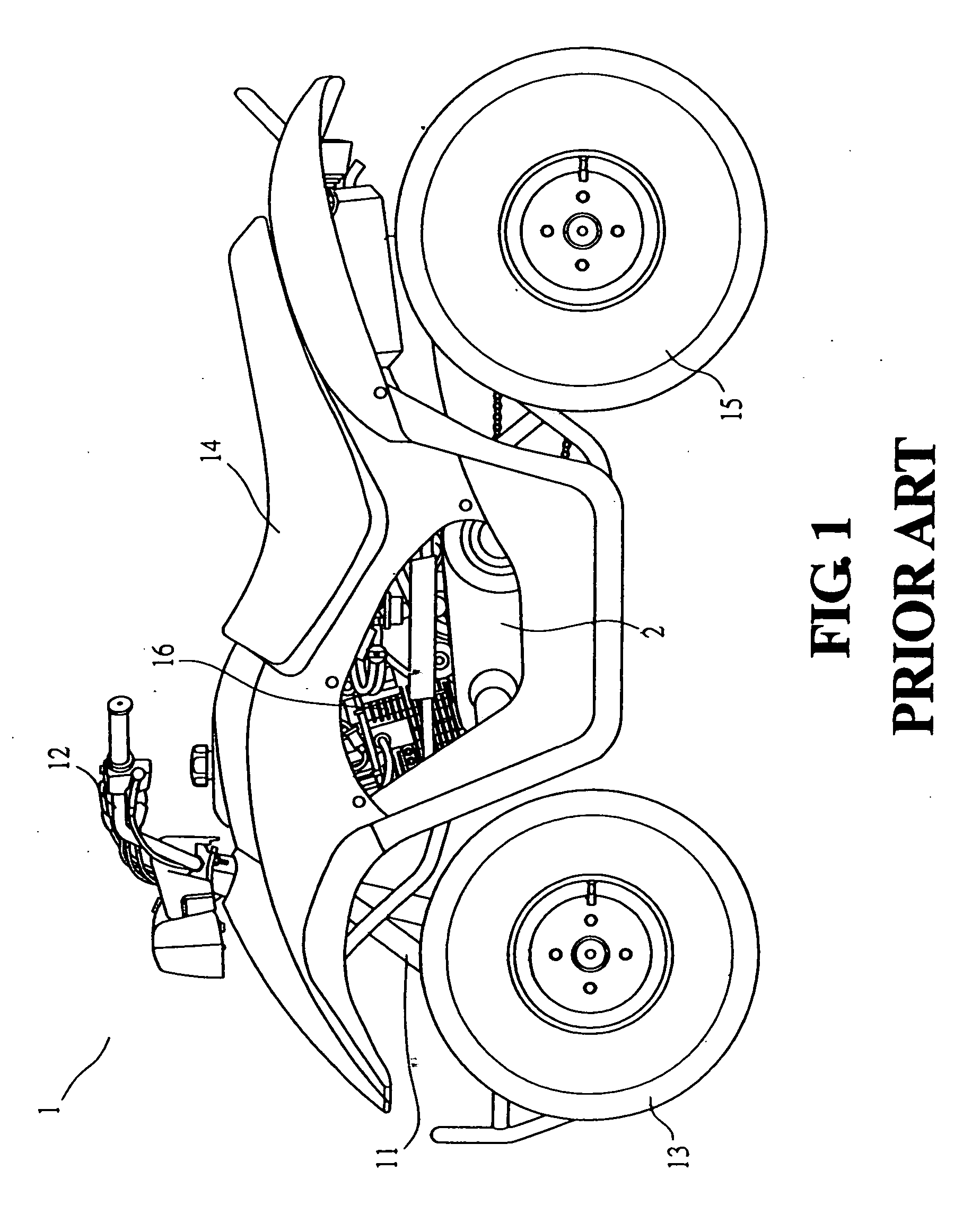

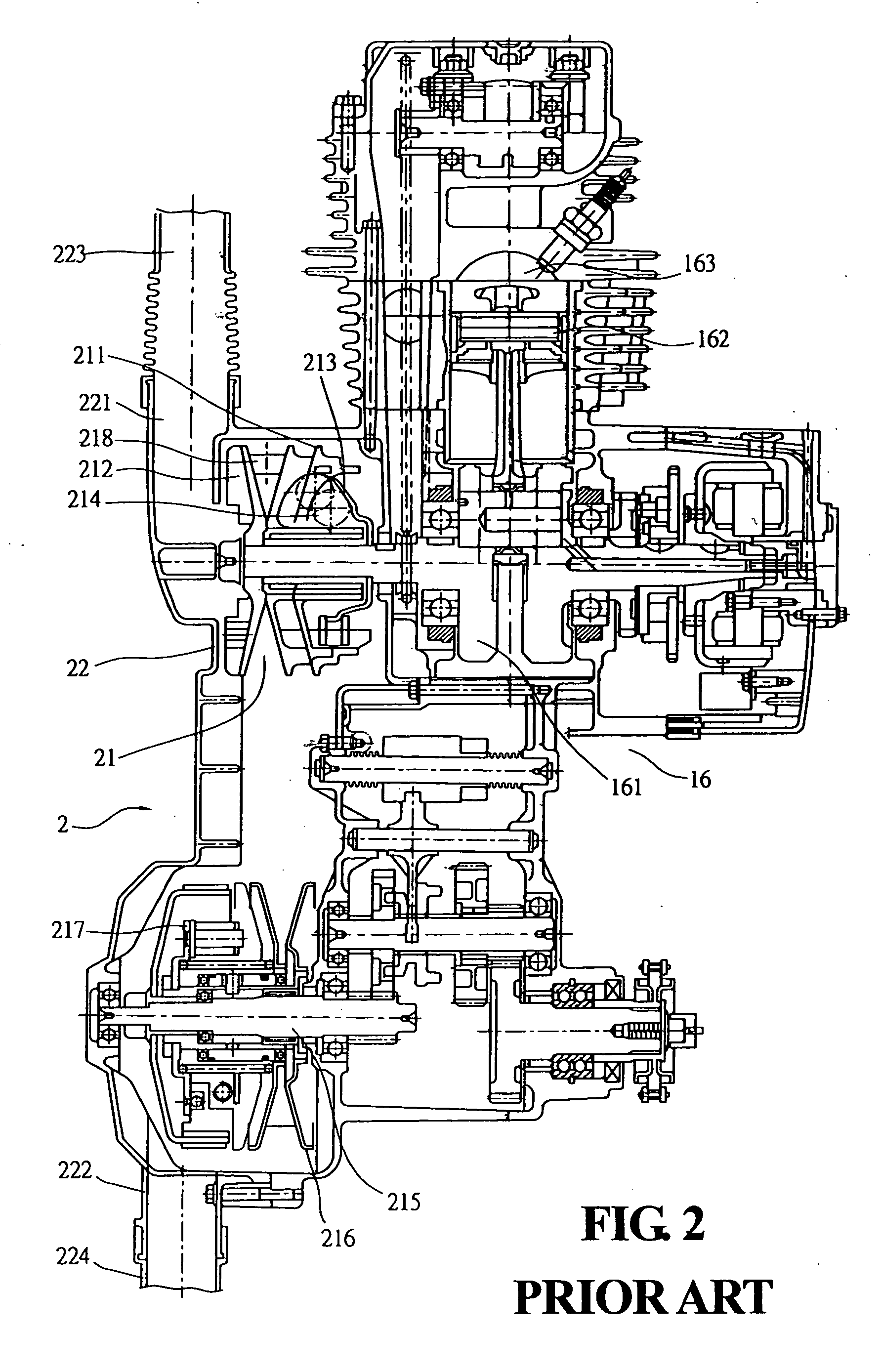

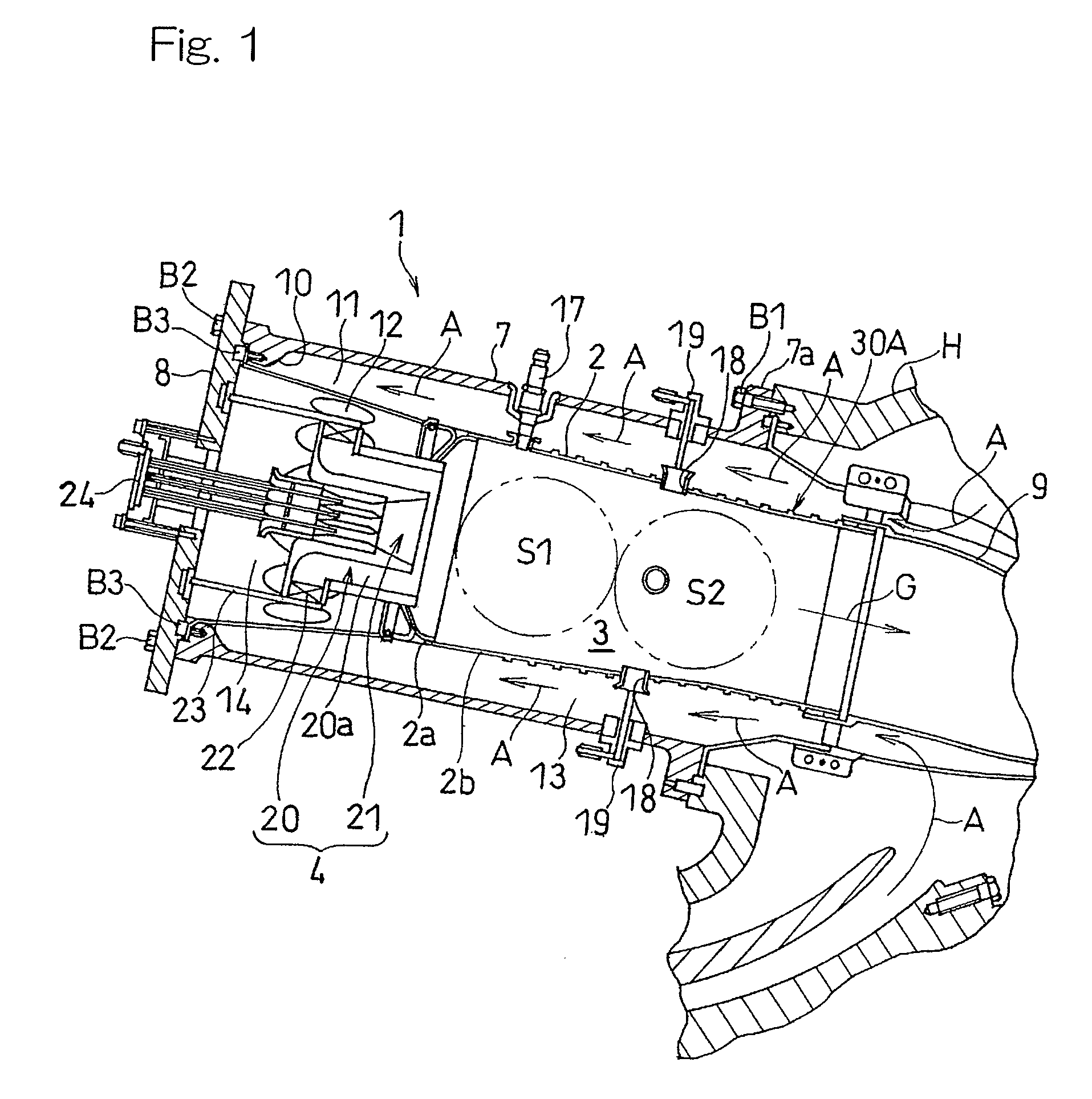

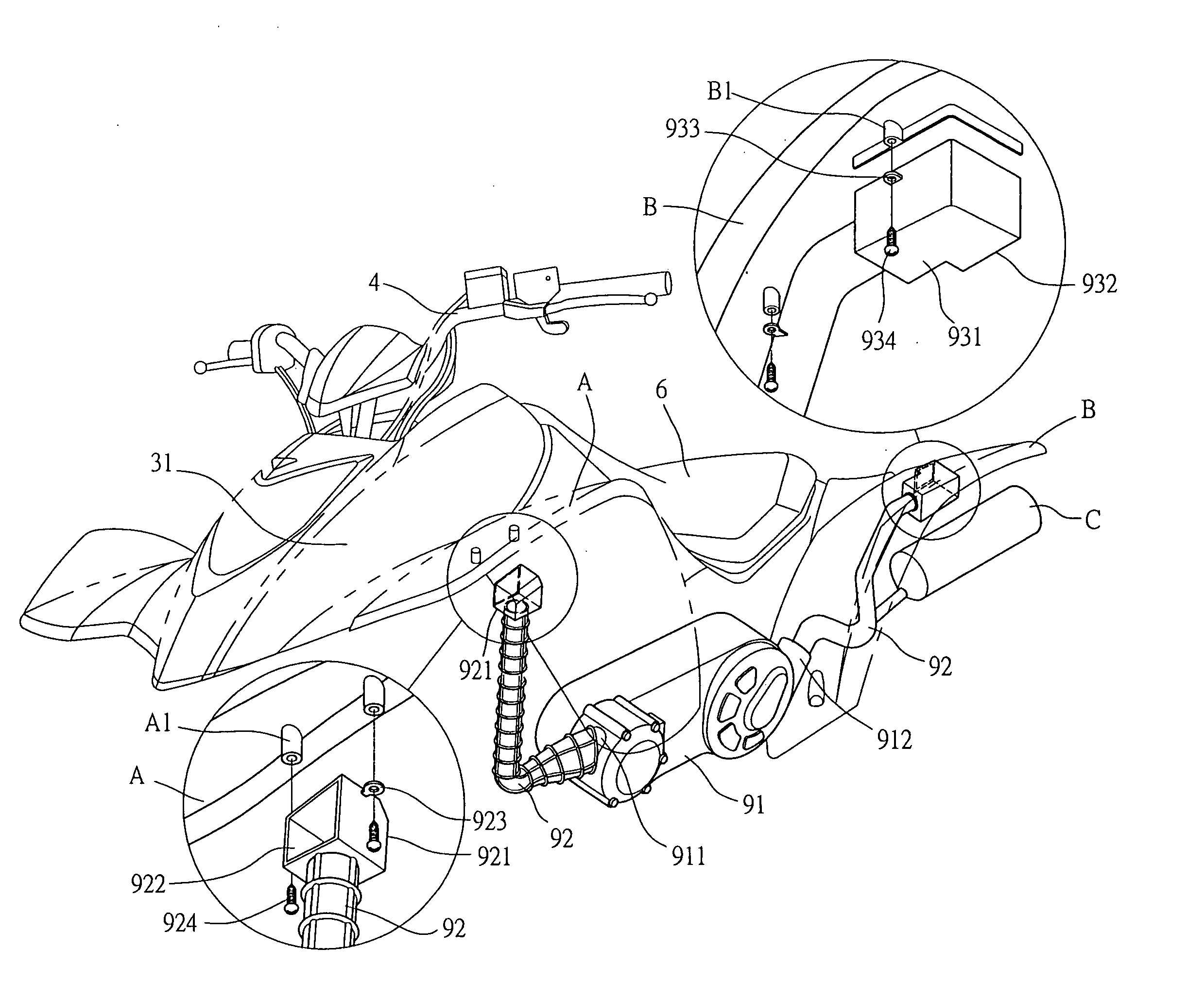

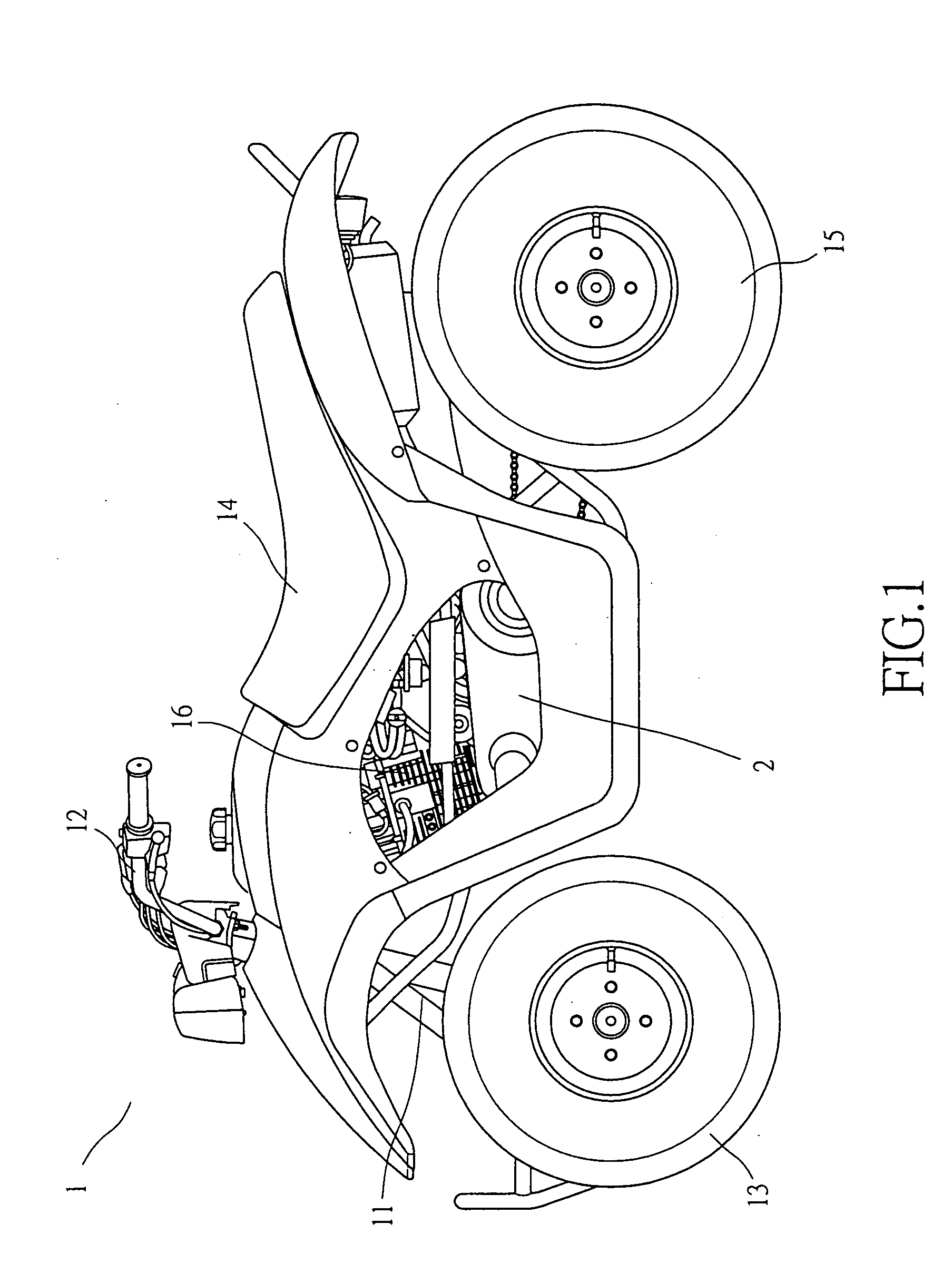

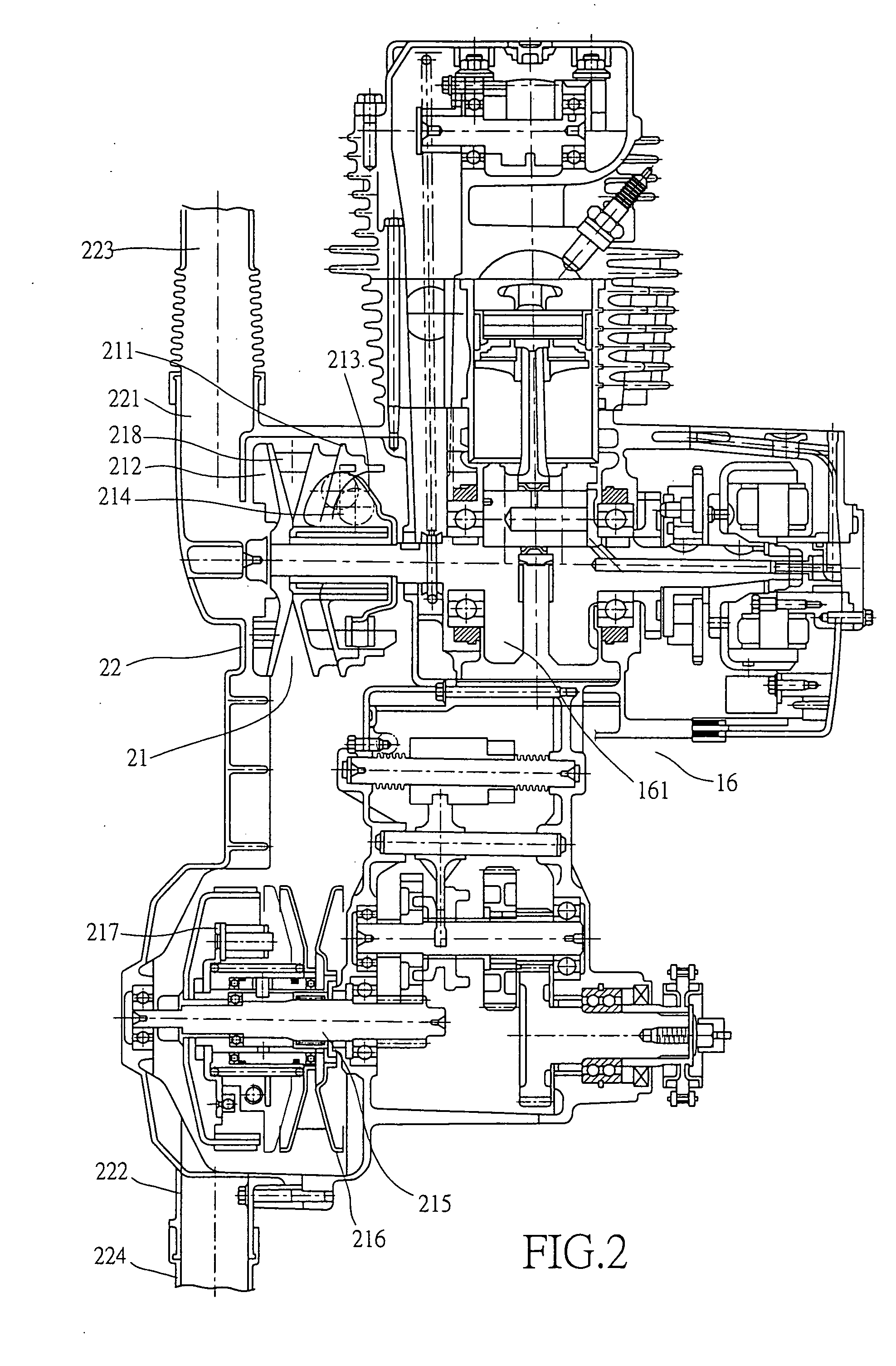

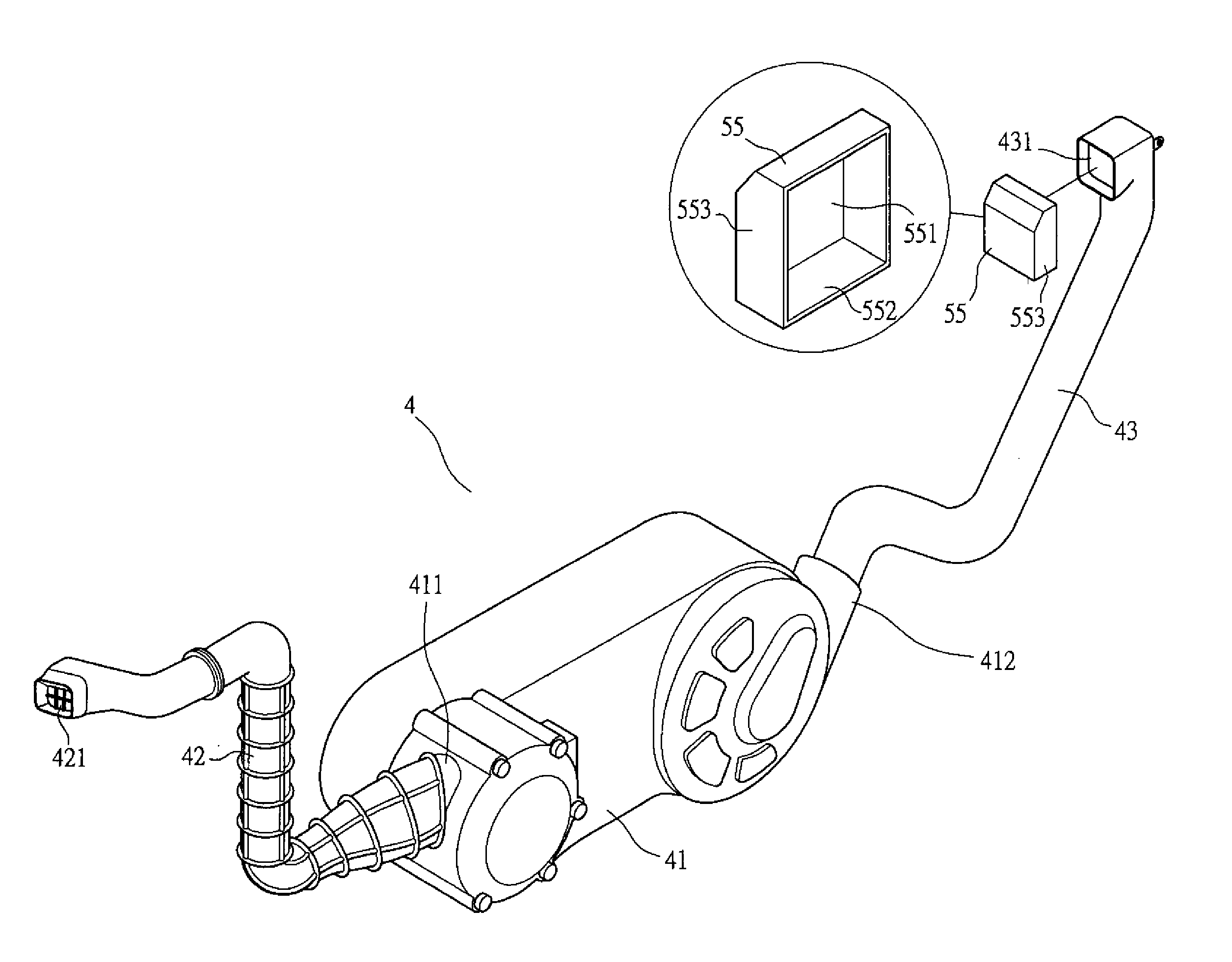

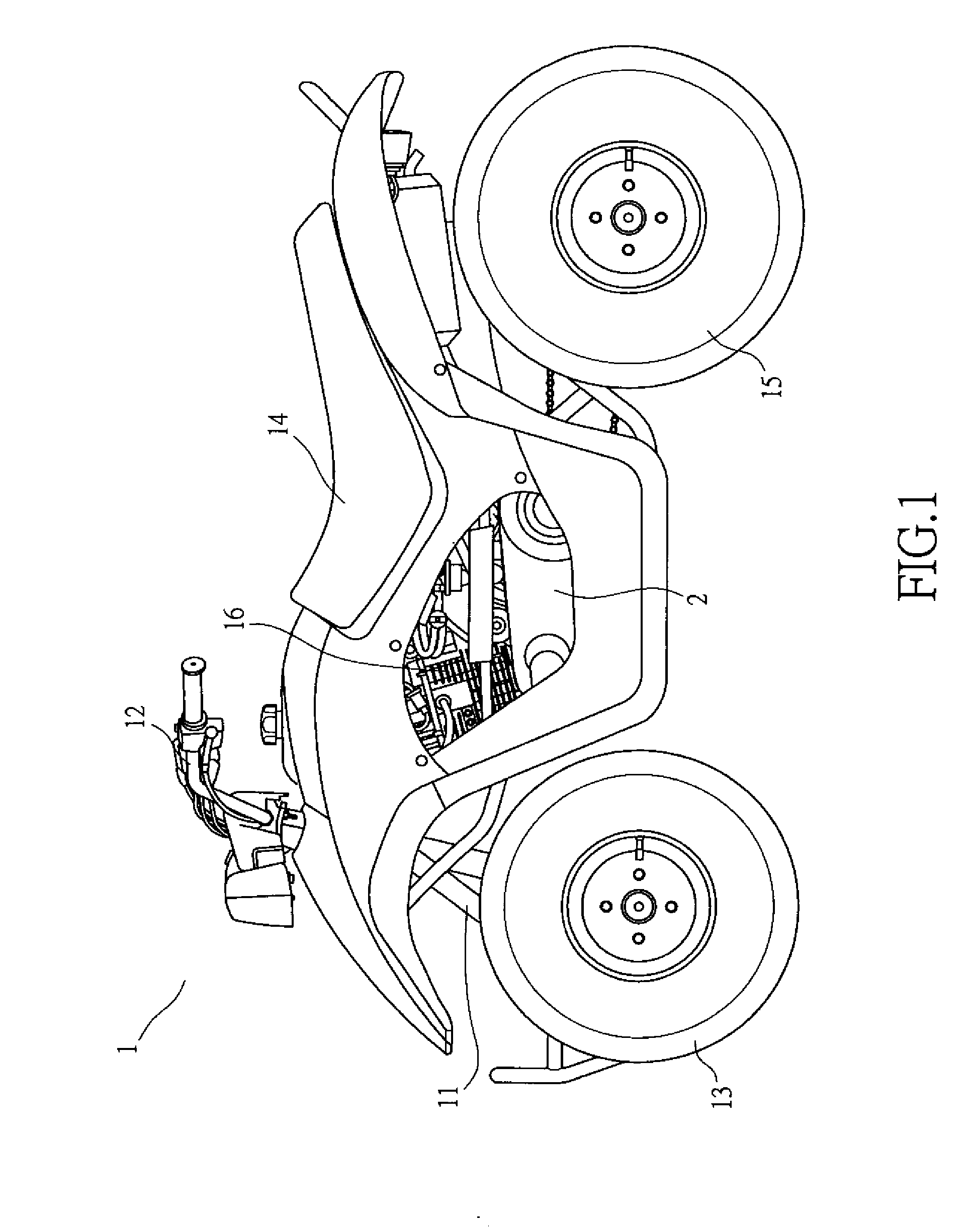

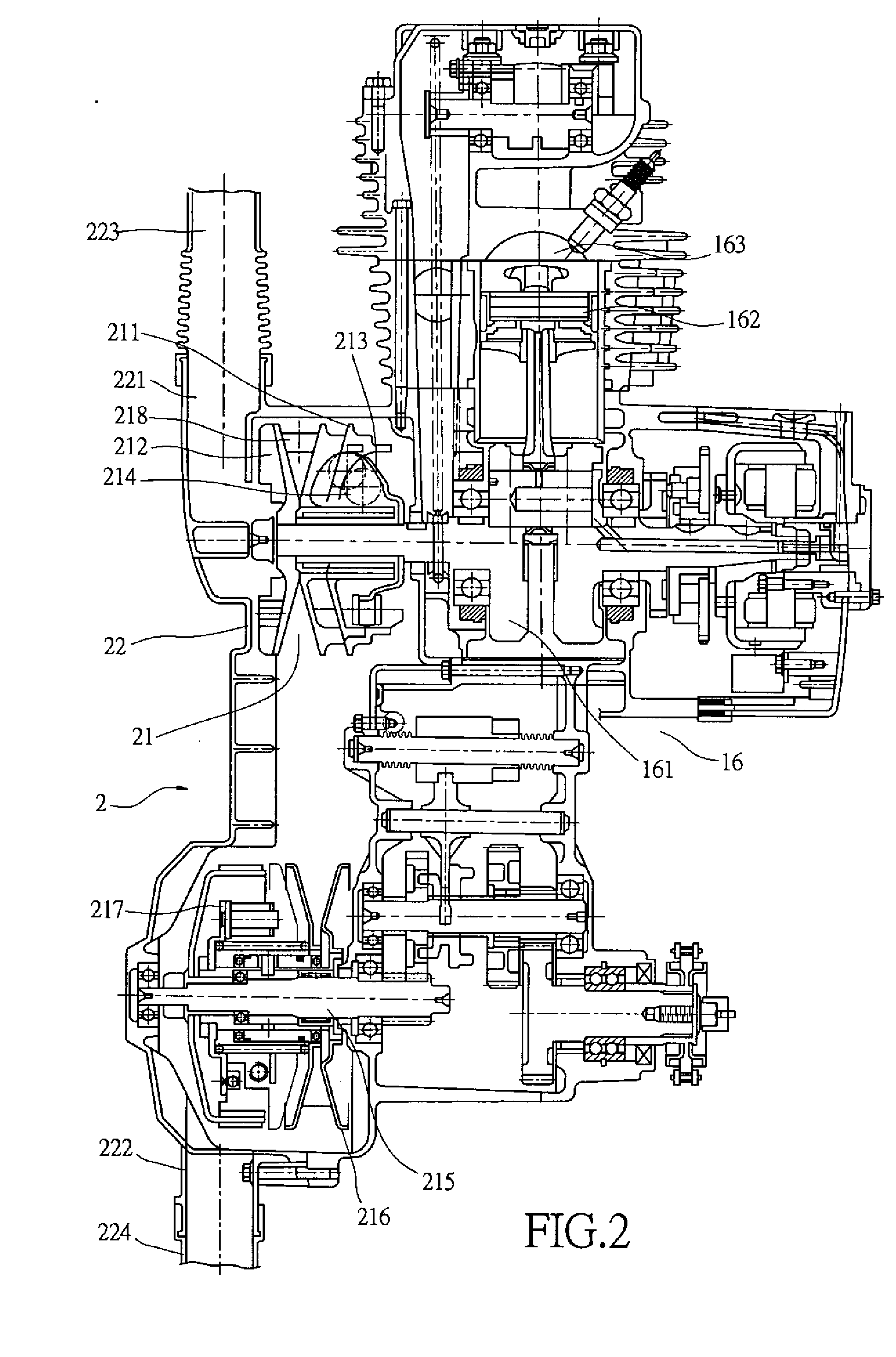

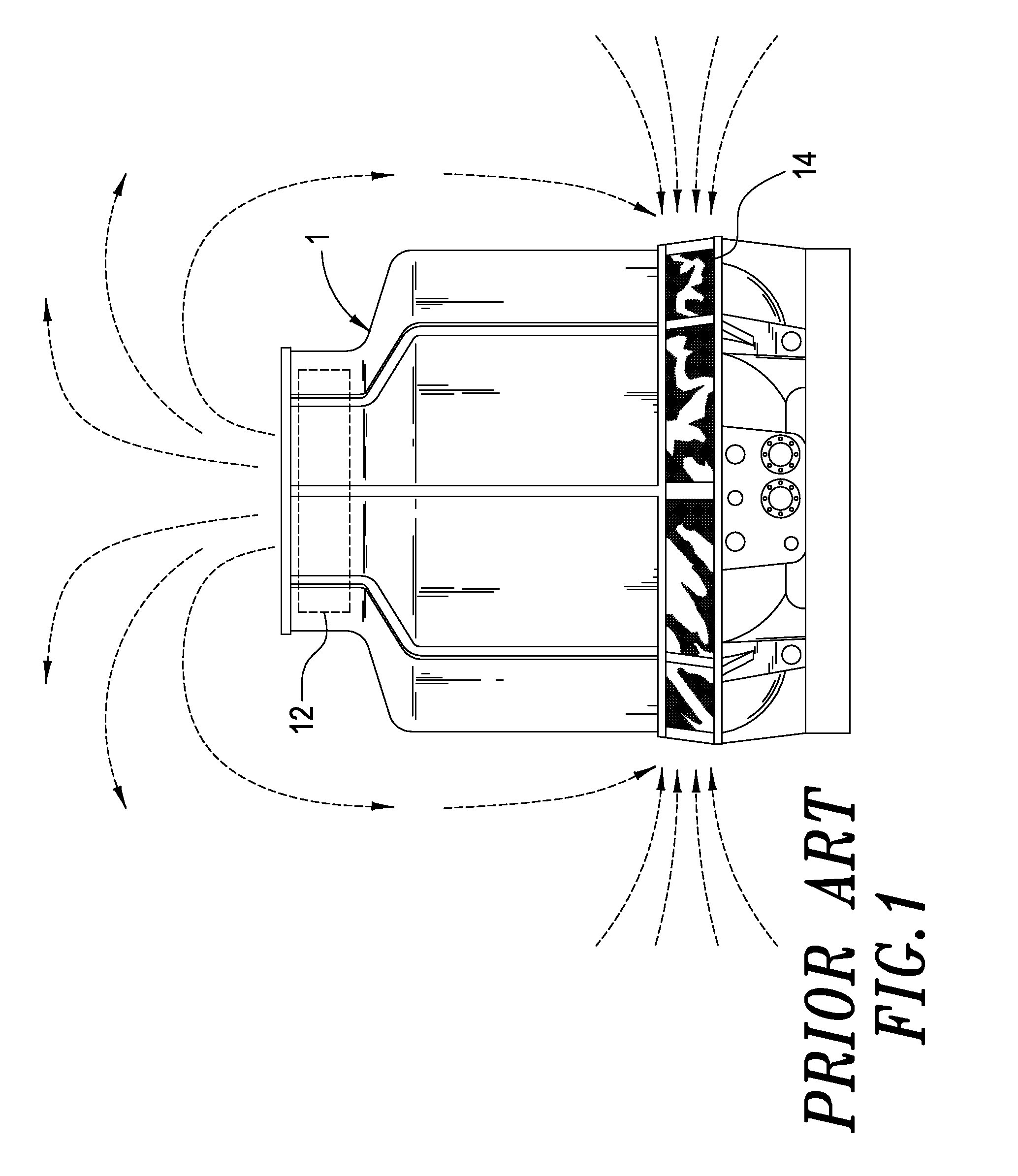

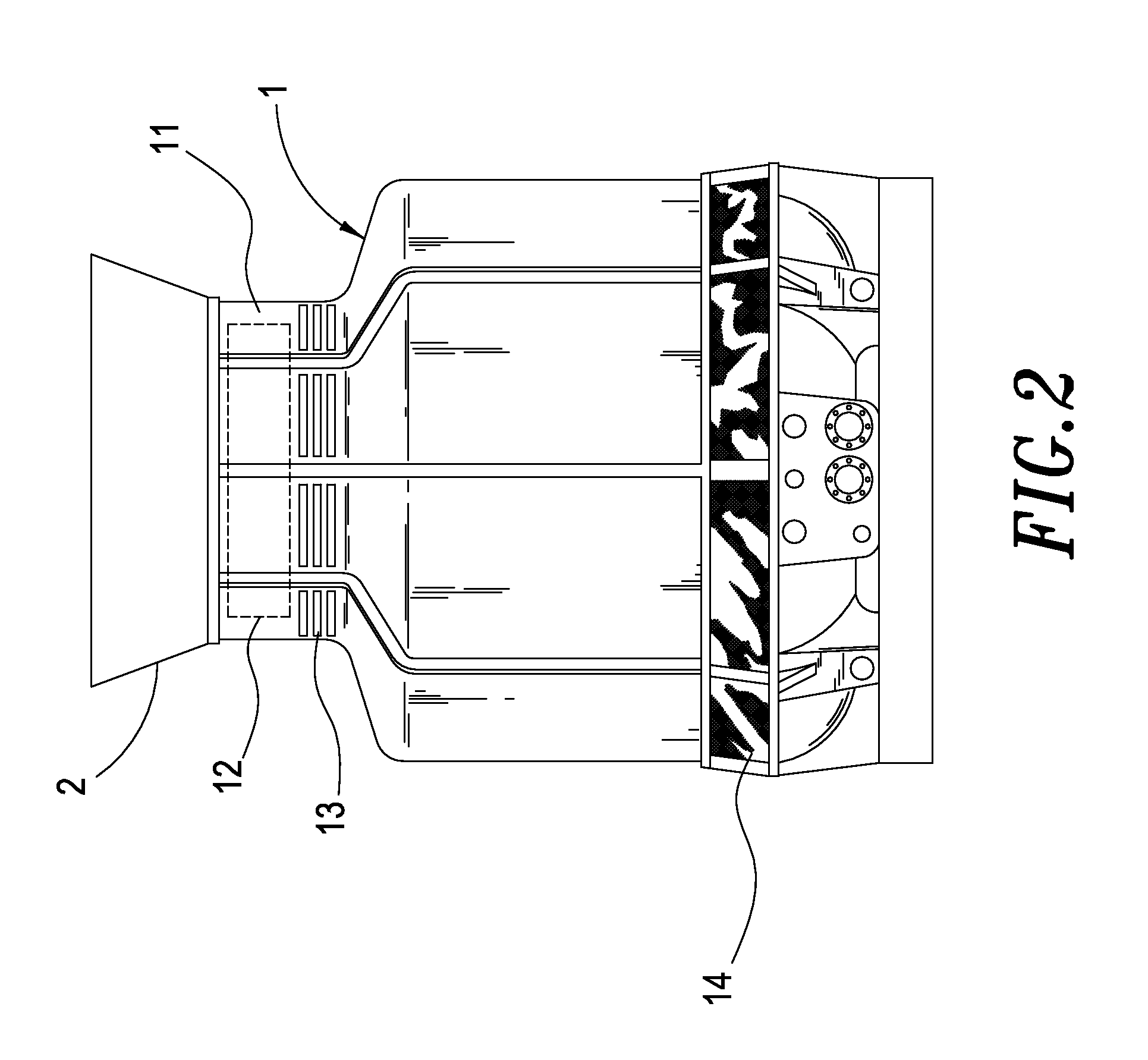

Cooling structure for a continuous variation transmission system of an all-terrain vehicle

InactiveUS6938676B2Optimize cooling structureReduce difficultyCyclesAir-treating devicesExhaust pipeTransmission system

The present invention concerns a cooling structure for a continuous variation transmission system of an all-terrain vehicle. Primarily speaking, it has an inlet conduit attached to the air inlet of the gearbox, with said inlet conduit extending in front of the engine until it reaches the below of the front mud guard, and an inlet box attached to the inlet conduit. An exhaust conduit is also being attached to the exhaust of the gearbox, with said exhaust pipe extending to the rear of the engine until it reaches the below of the rear mud guard, and an exhaust box is attached to the exhaust conduit. Both the inlet box and the exhaust box are placed above the tail of the engine exhaust conduit, and situated on the outer surface of the chassis. The inlet and exhaust box design prevents dust, dirt and water from entering the gearbox. Furthermore, the conduits are installed on the outer surface of the chassis to enable ease of assembly and maintenance, and to reduce the difficulty of installing other components.

Owner:KYMCO

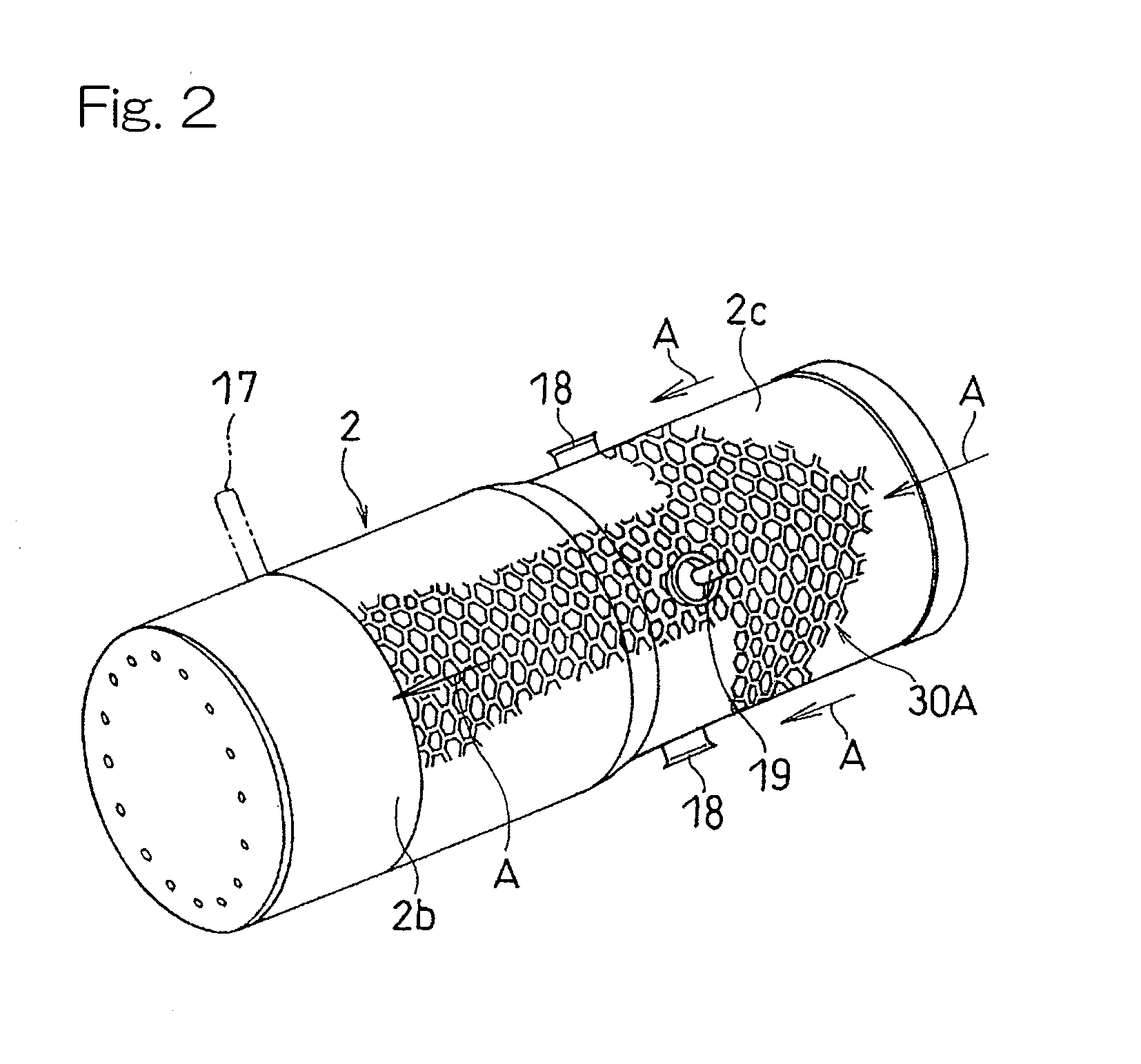

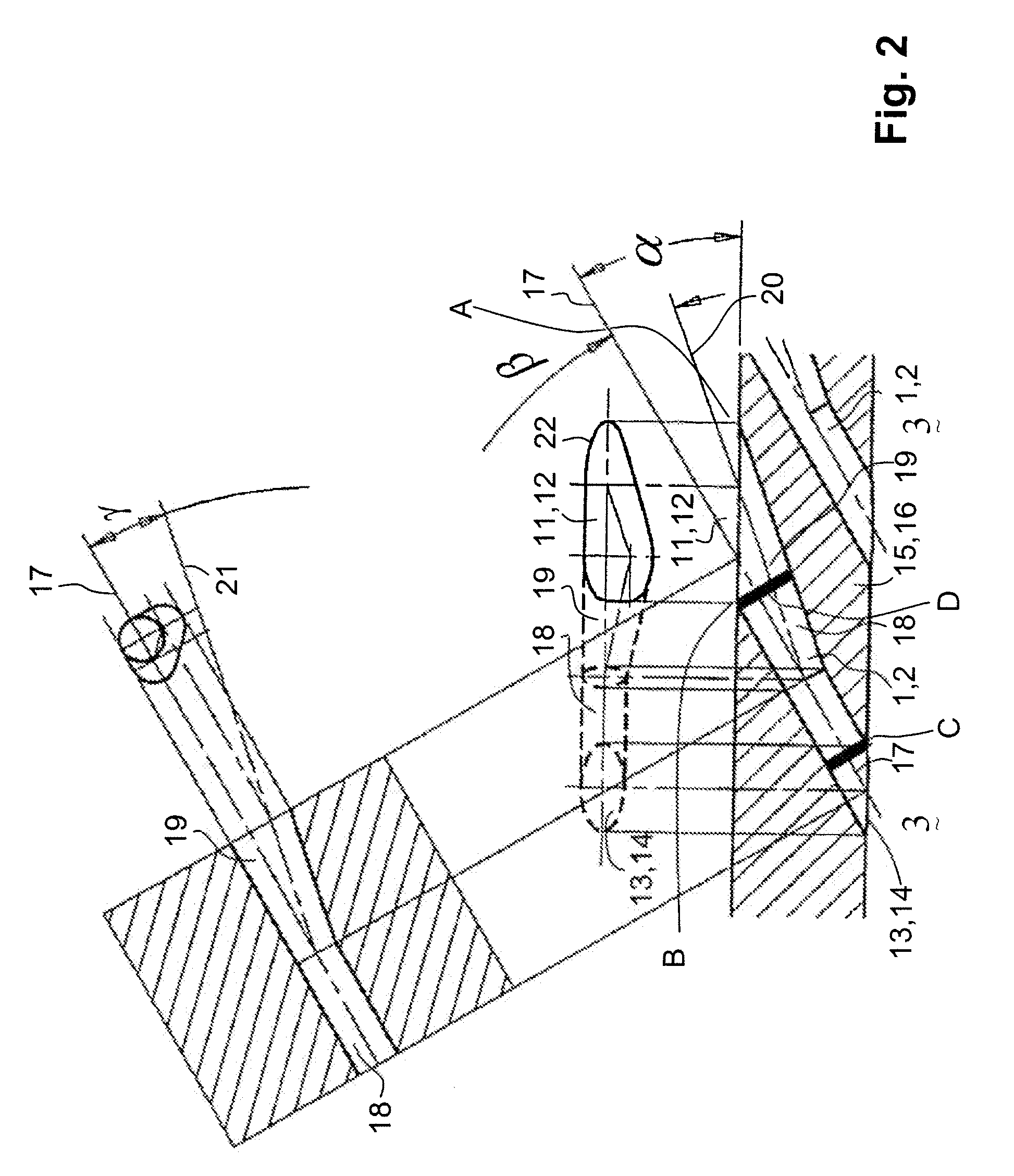

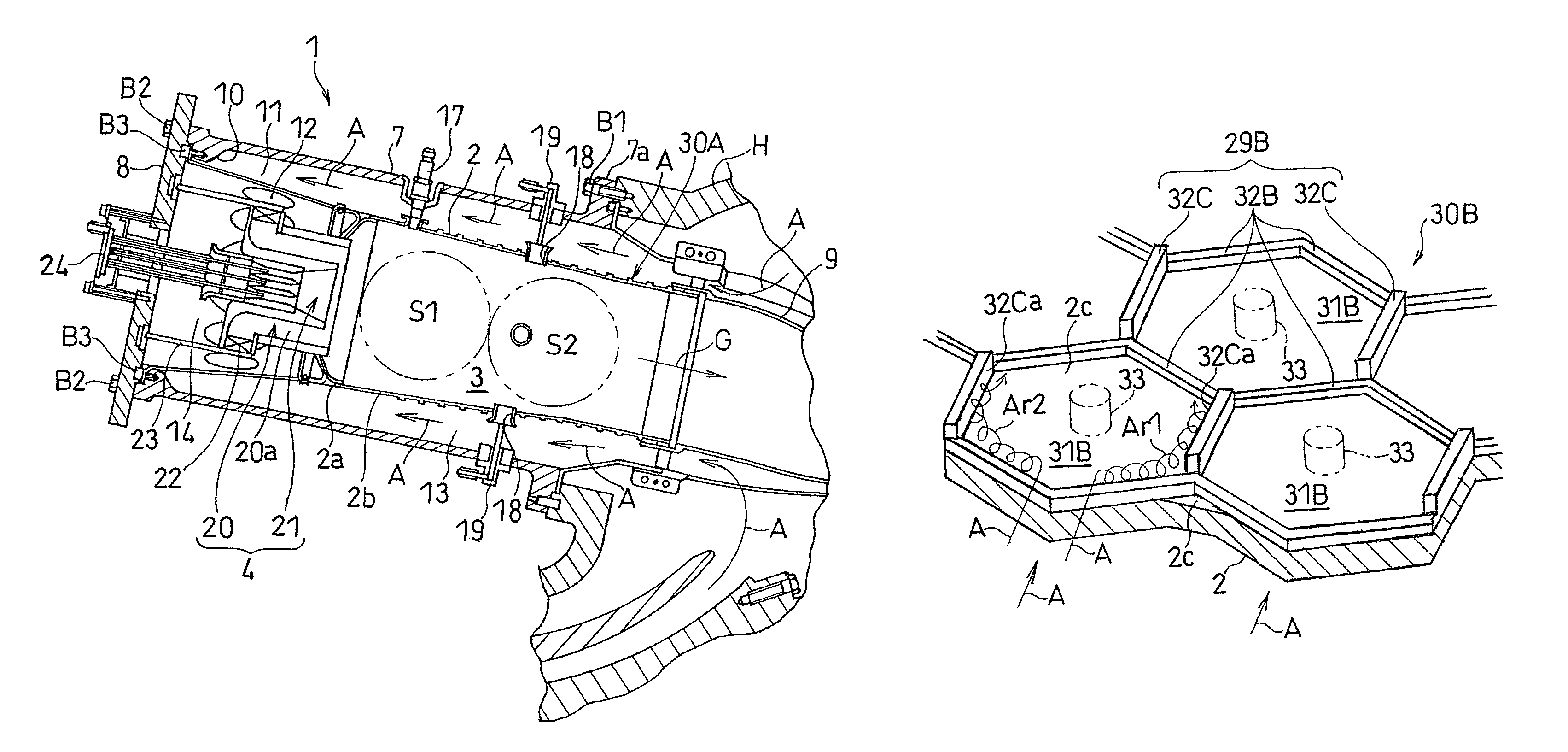

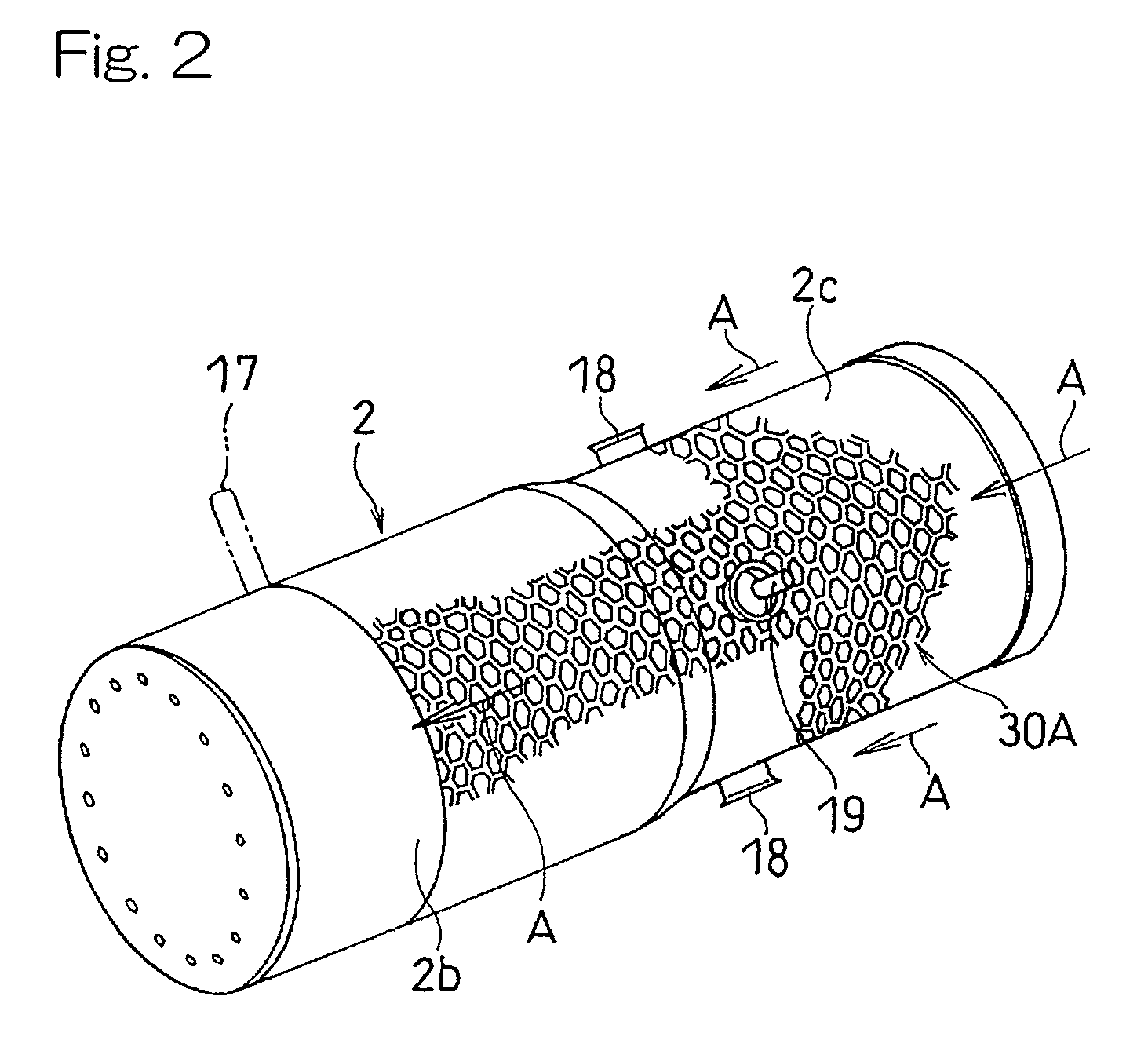

Cooling structure for gas turbine combustor

InactiveUS20110016869A1Increase the heat transfer surface areaImprove cooling effectContinuous combustion chamberEngine fuctionsCombustion chamberCombustor

To provide a gas turbine combustor having an improved cooling structure effective to efficiently suppress a possible occurrence of buckling in the combustion liner while exhibiting a convection cooling effect to the combustion liner, the gas turbine combustor includes a combustion liner having a combustion chamber defined therein and an outer peripheral surface forming a path of a compressed air, and a heat transfer enhancement structure provided on the outer peripheral surface of the combustion liner. The heat transfer enhancement structure referred to above is of a honeycomb construction defined by ribs protruding outwardly from the outer surface of the combustion liner. The honeycomb construction may be of a geometry in which hexagonal shapes, rhombic shapes, parallelogrammic shapes, bent rectangular shapes or triangular shapes are deployed next to each other.

Owner:KAWASAKI HEAVY IND LTD

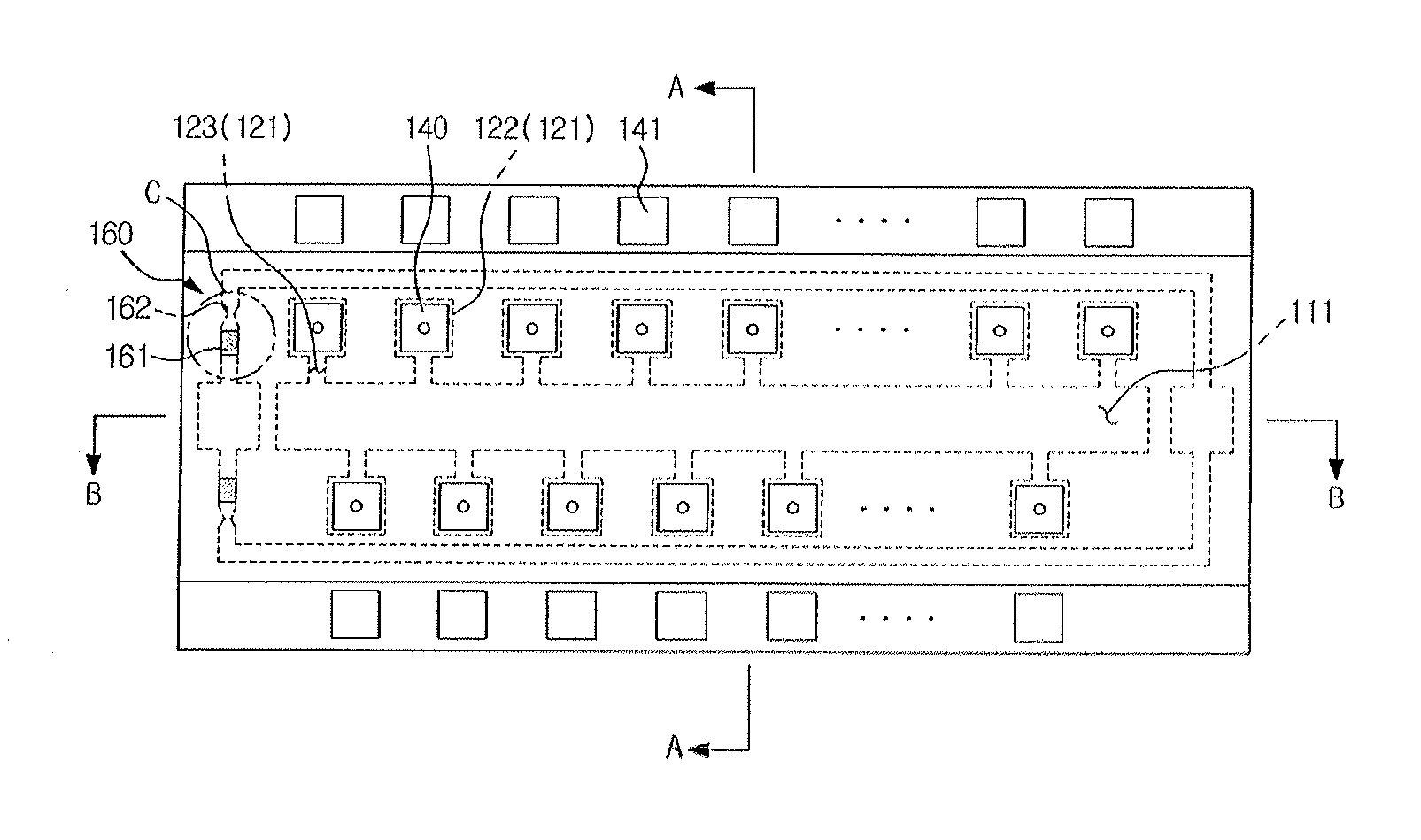

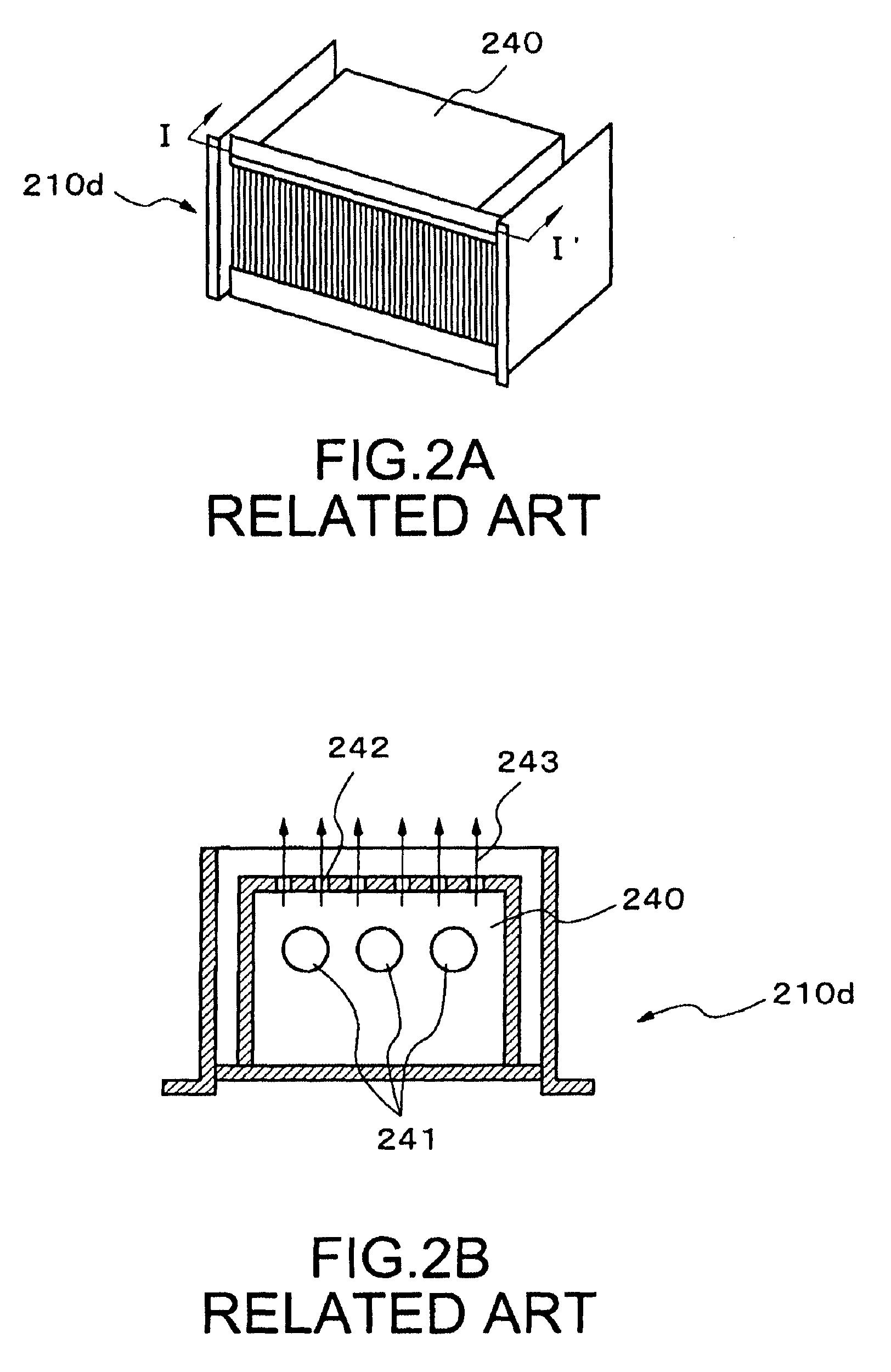

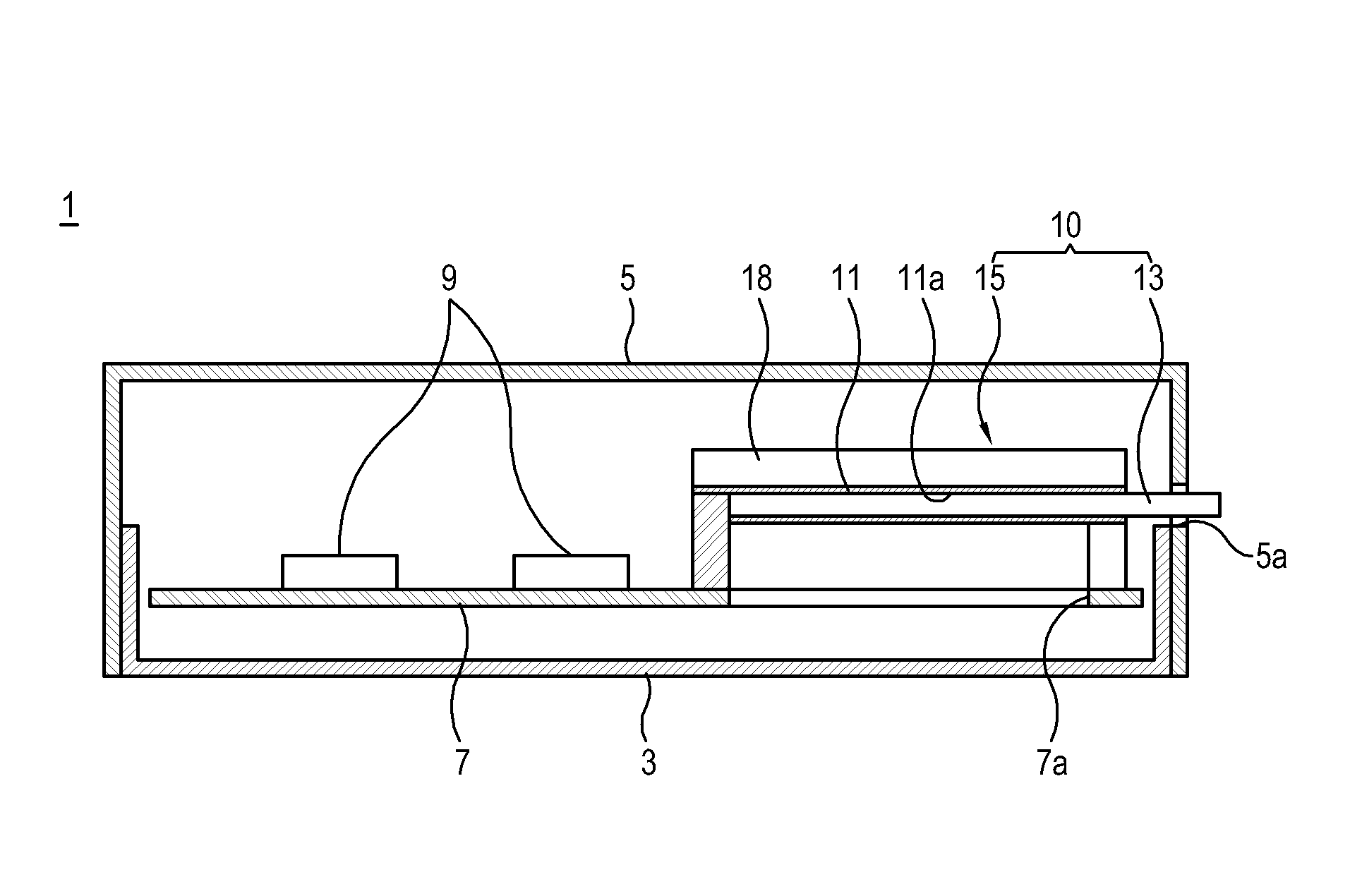

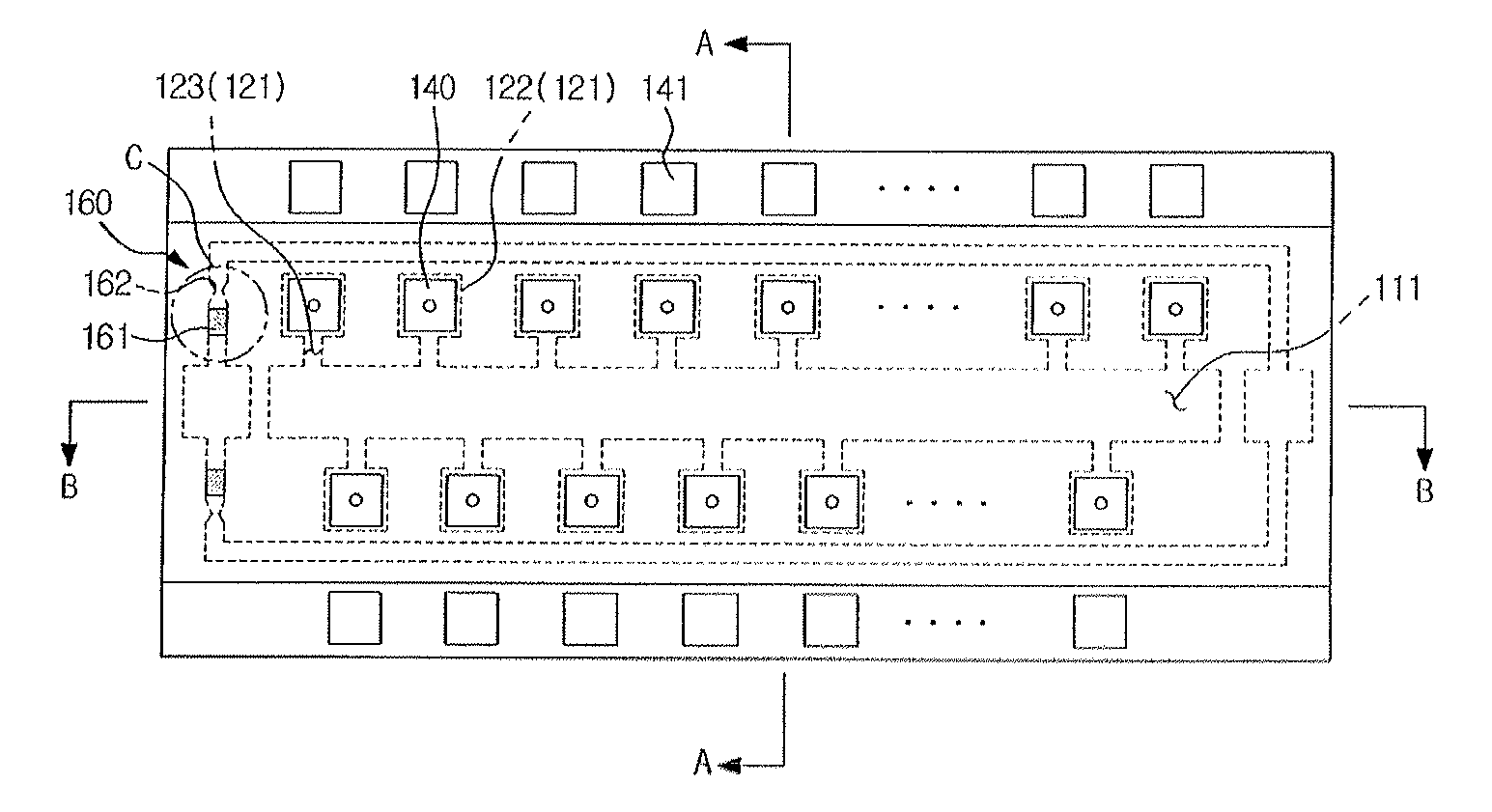

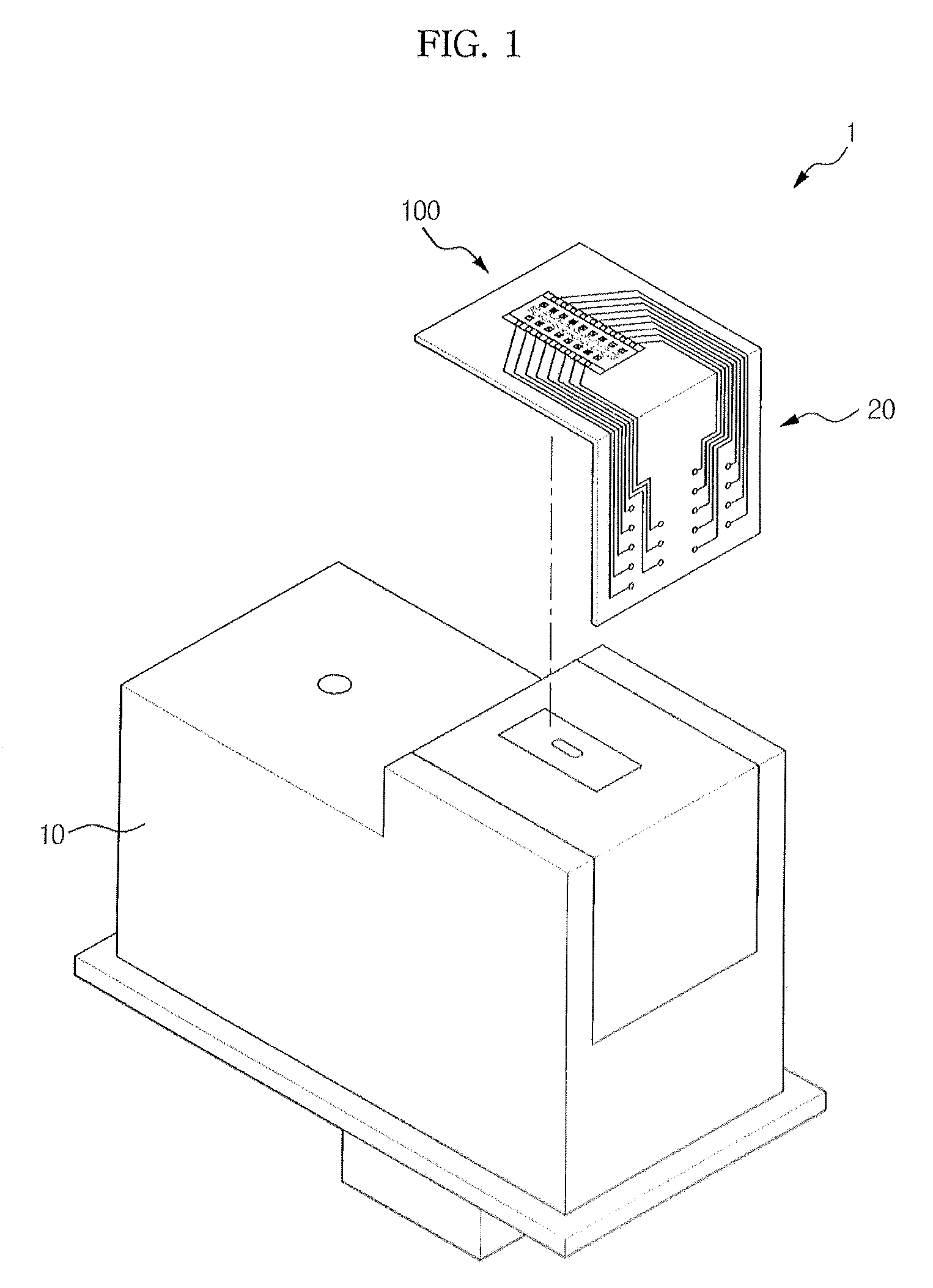

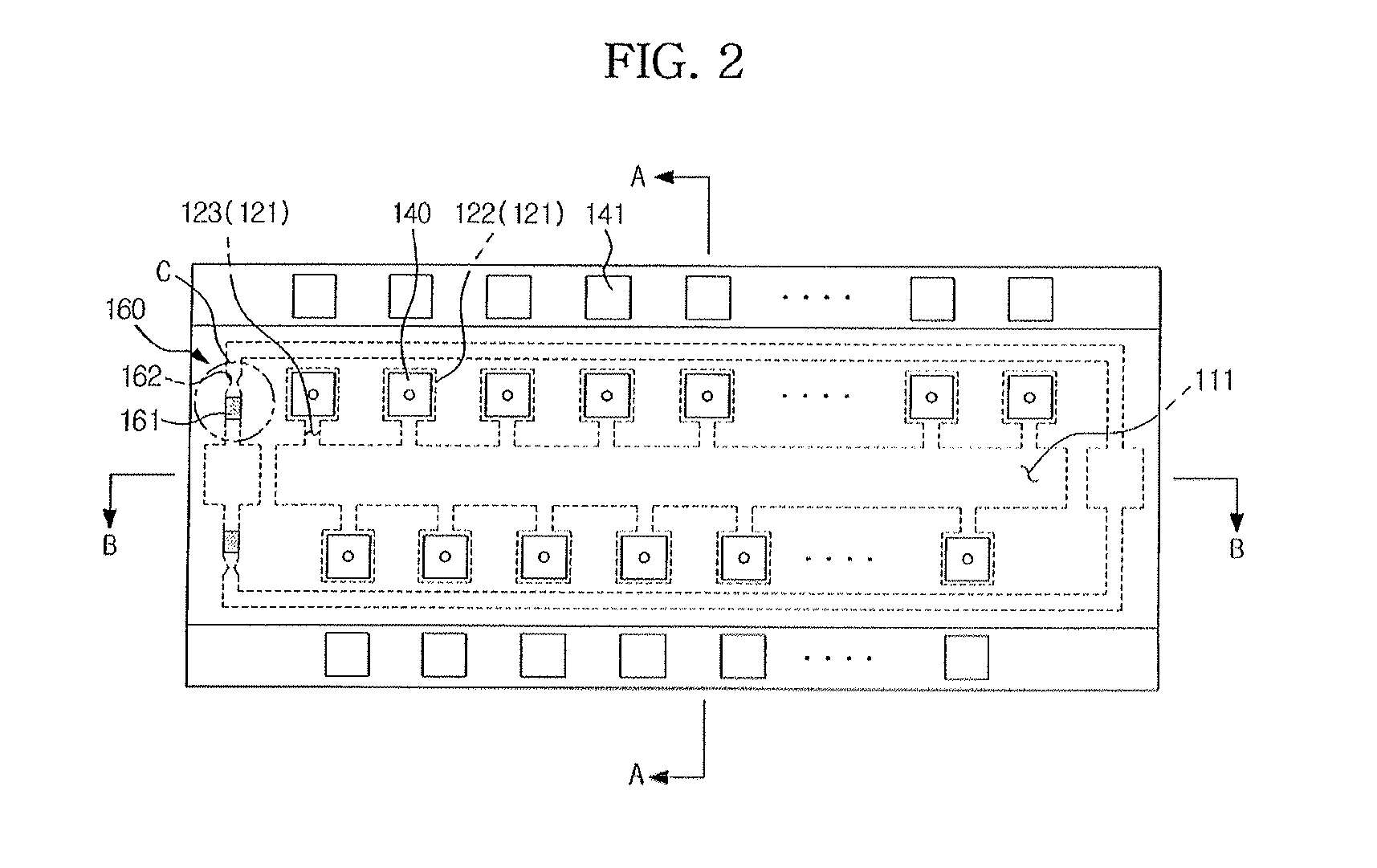

Head chip for ink jet type image forming apparatus

InactiveUS20100013887A1Avoid overall overheatingOptimize cooling structureOther printing apparatusEngineeringRefrigerant

A head chip for an ink jet type image forming apparatus with an improved cooling structure is disclosed. The head chip includes a plurality of nozzles to eject ink, a plurality of heaters for ink ejection to apply heat to ink so that the ink is ejected through the plurality of nozzles, and a cooling channel to circulate a refrigerant around the plurality of heaters for ink ejection.

Owner:HEWLETT PACKARD DEV CO LP

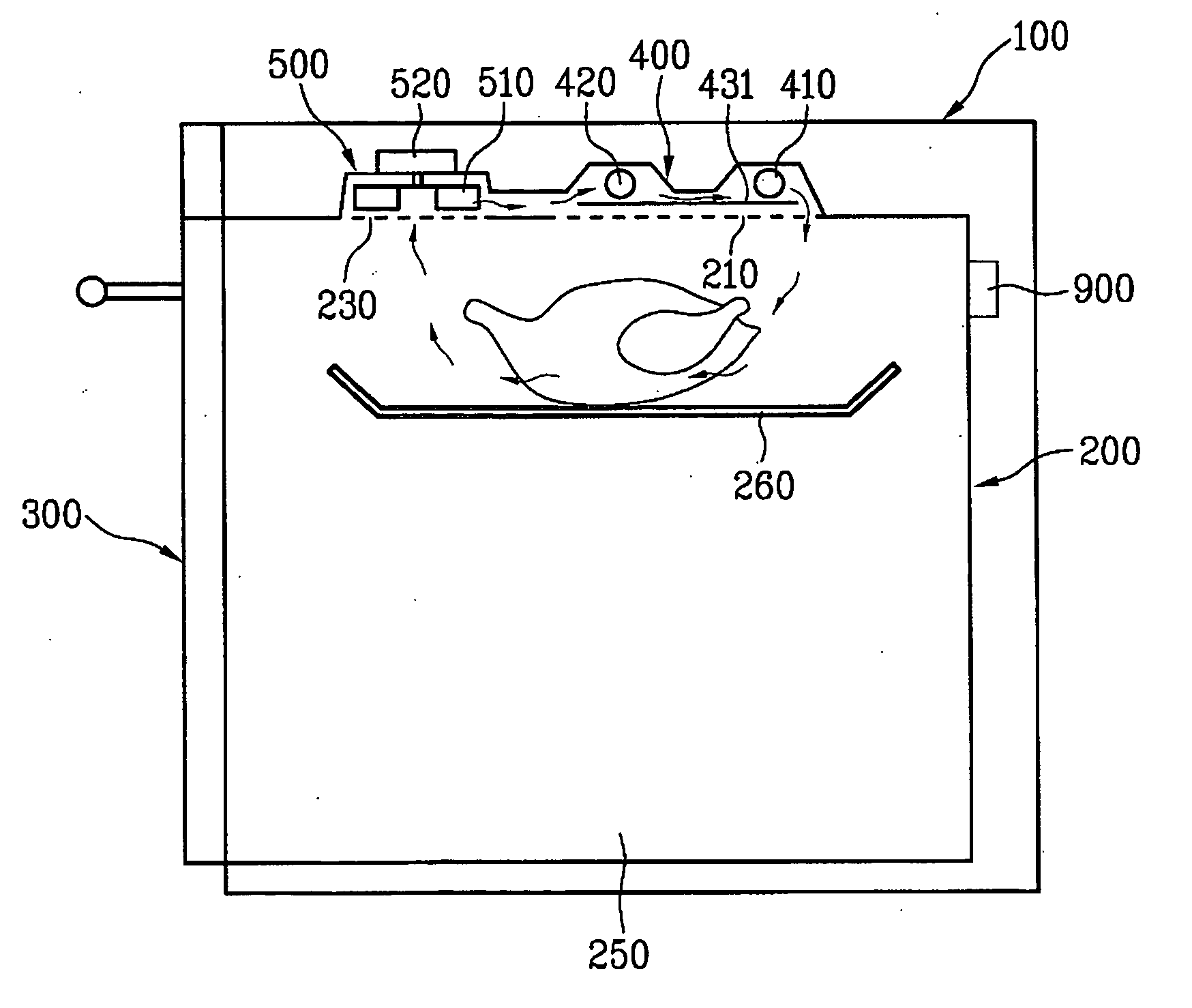

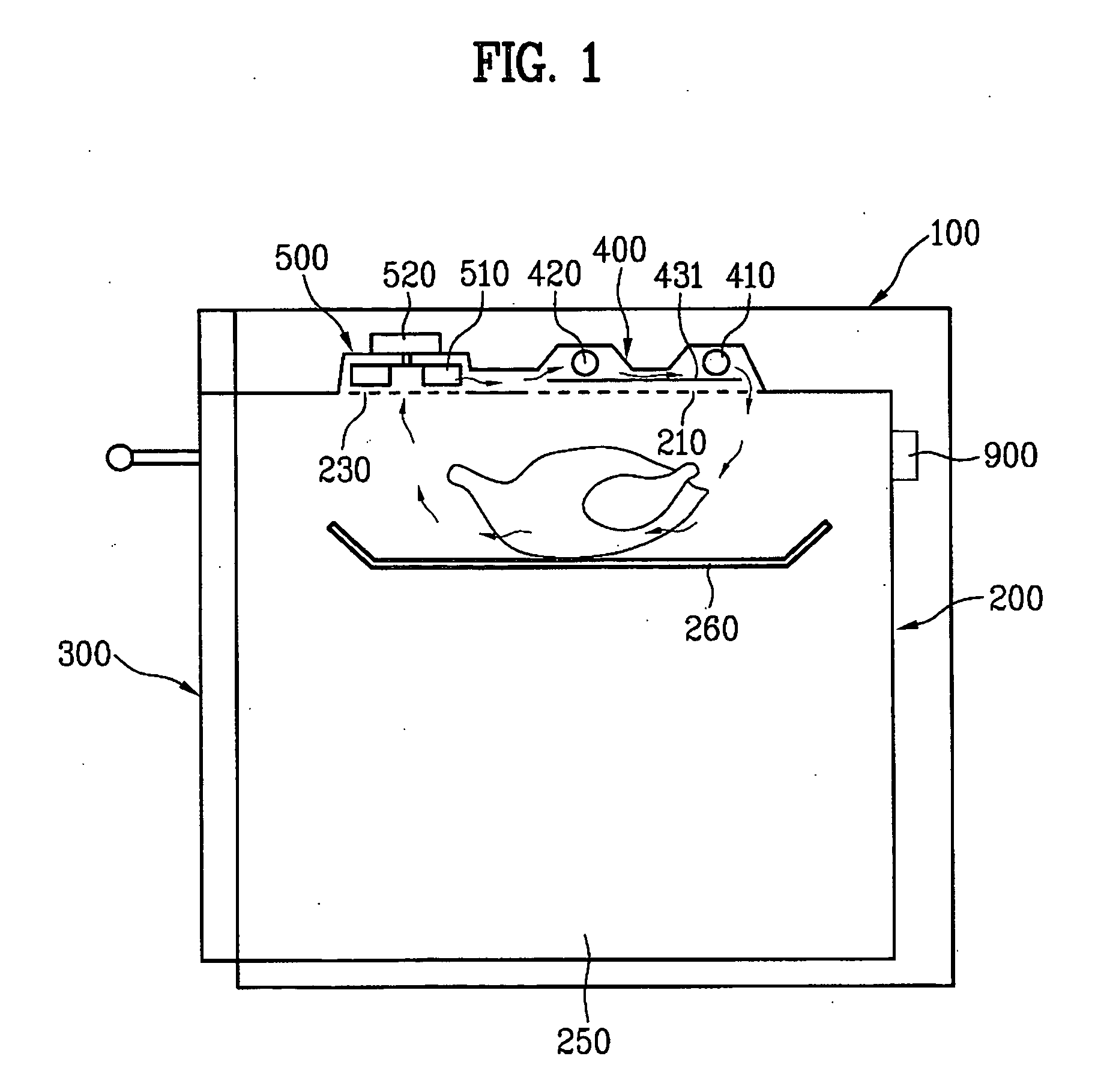

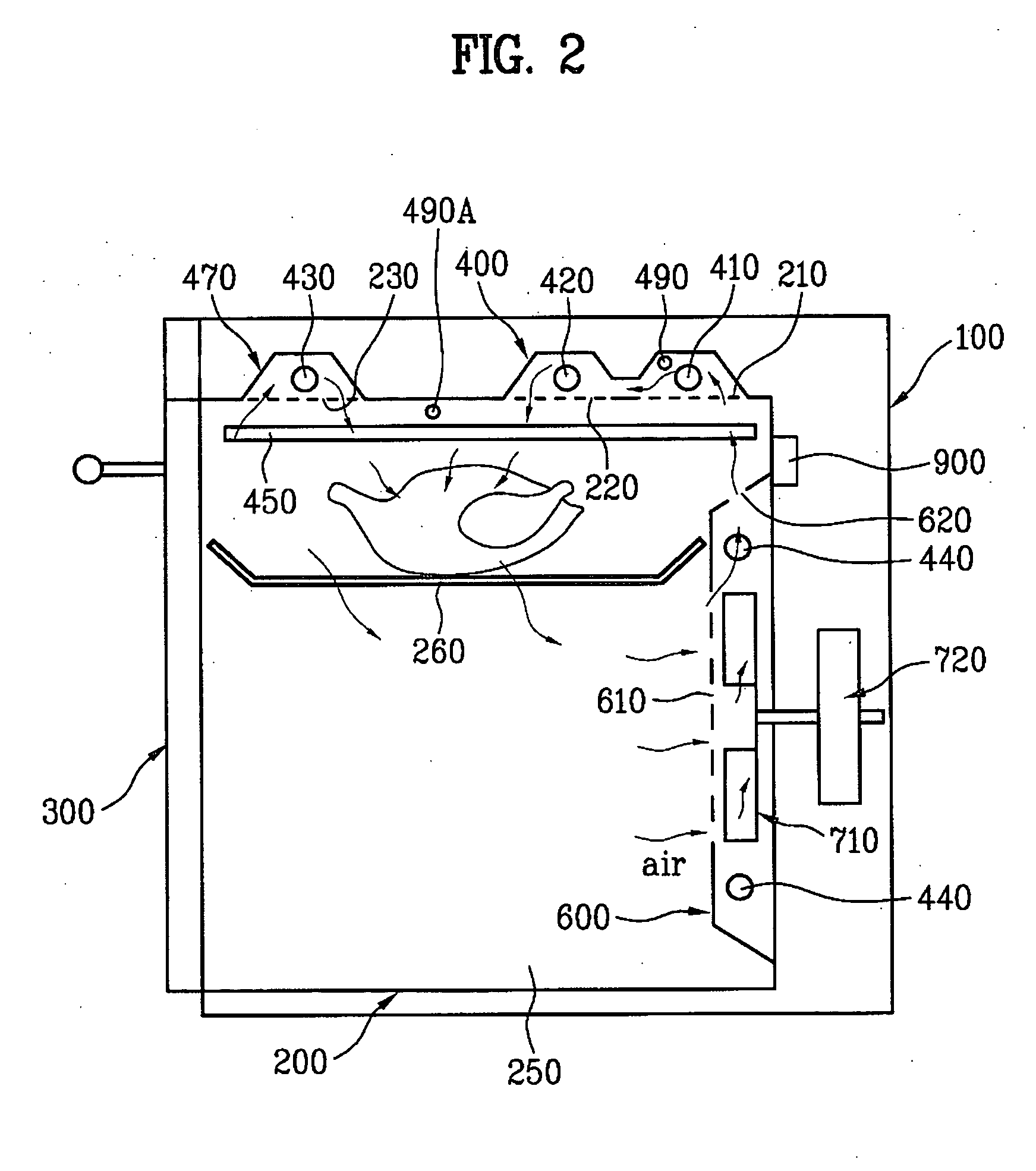

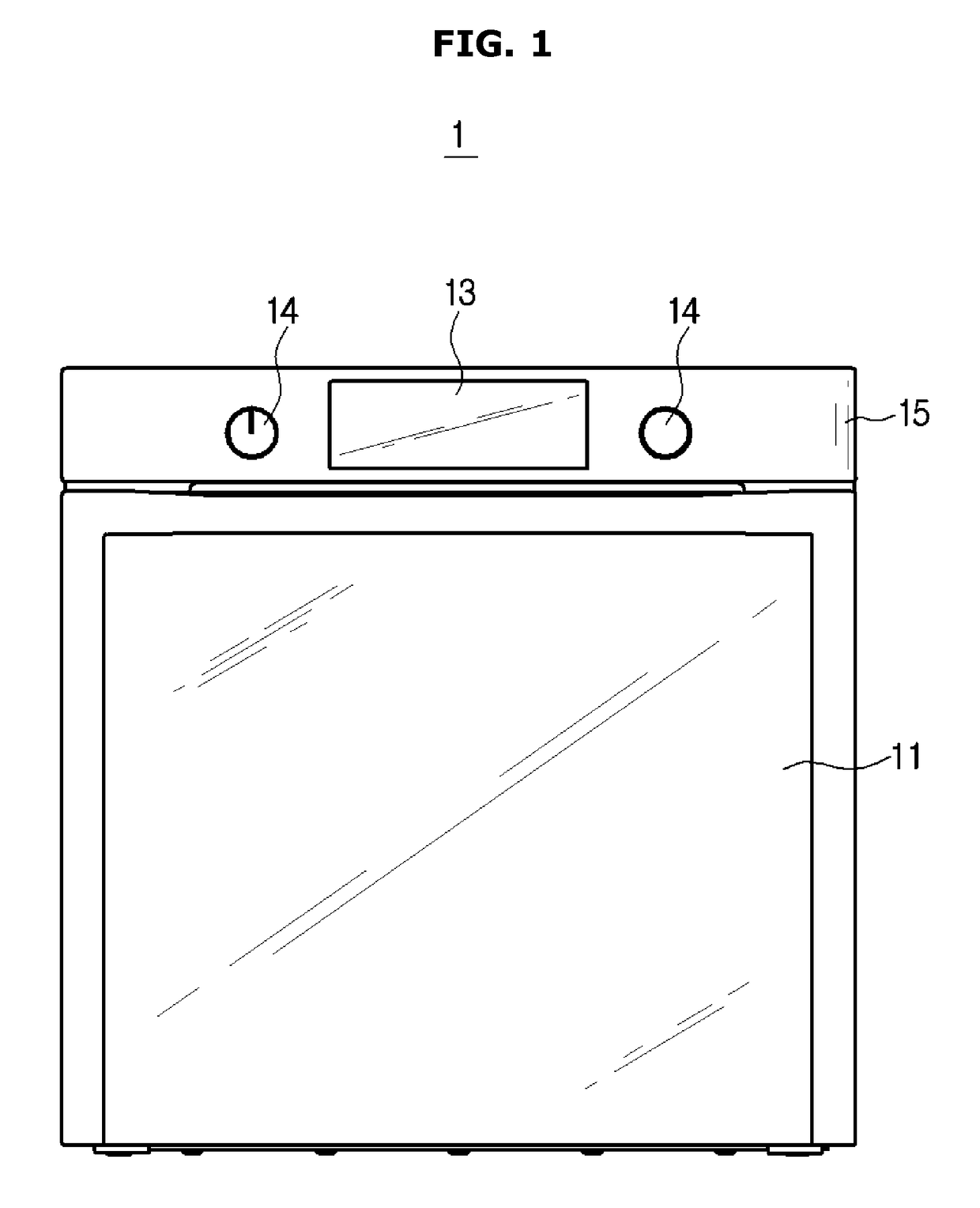

Electric oven

ActiveUS20060186108A1Simple structureAvoid componentsDomestic stoves or rangesDoors for stoves/rangesProcess engineeringAuxiliary heating

Owner:LG ELECTRONICS INC

Cooling structure for a continuous variation transmission system of an all-terrain vehicle

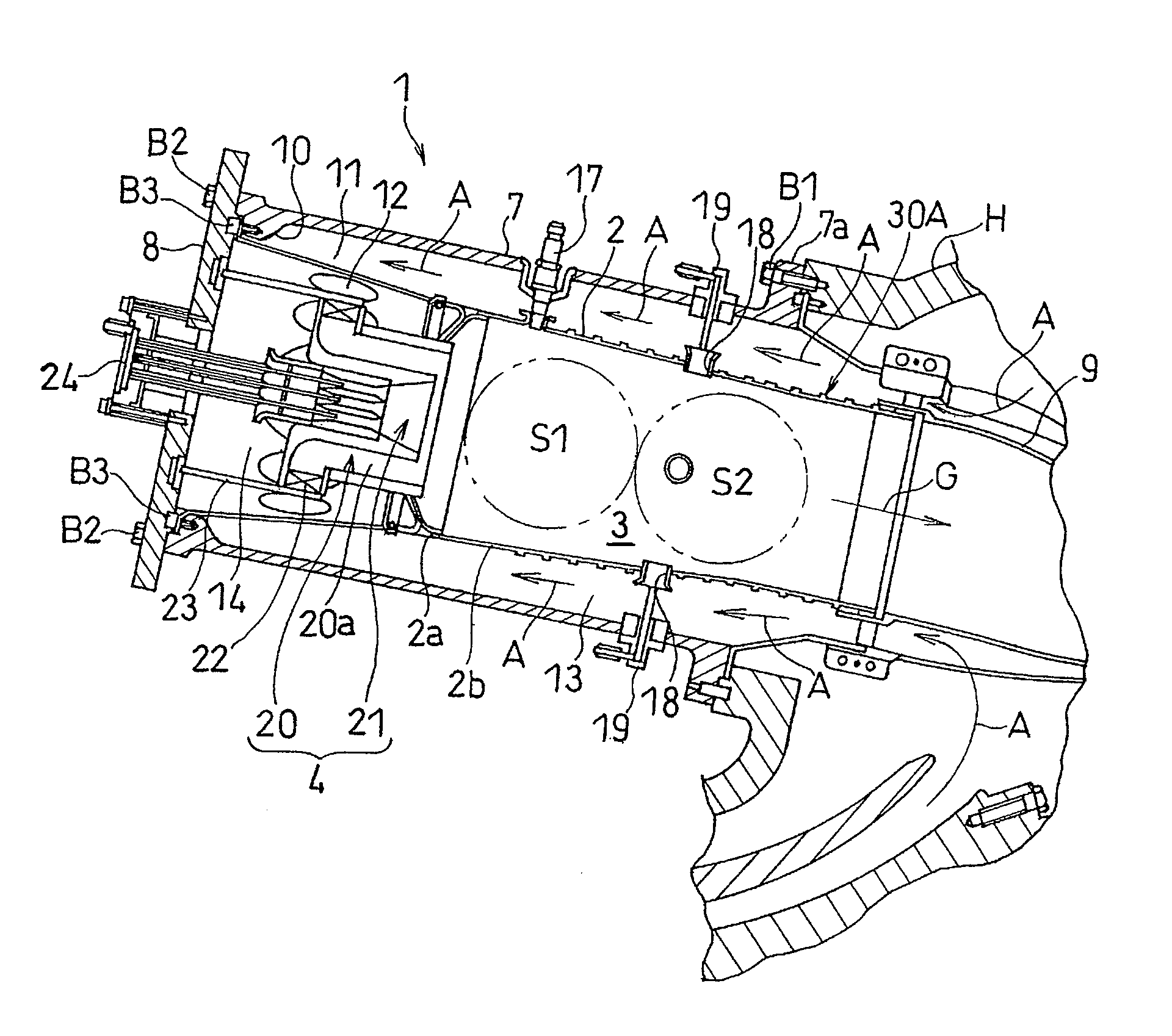

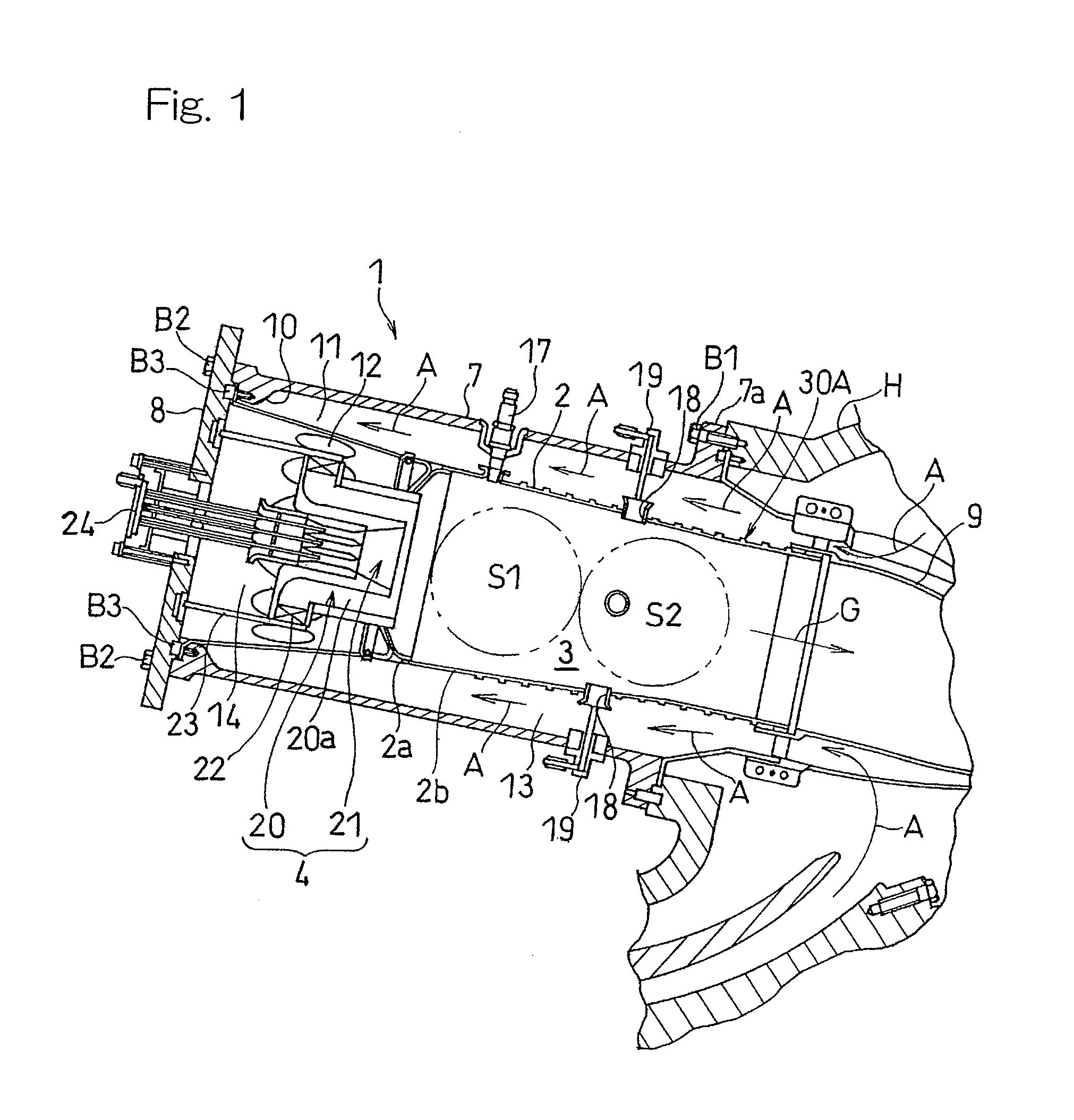

InactiveUS20070215404A1Optimize cooling structureCyclesCycle equipmentsTransmission systemHeat spreader

A cooling structure for a continuous variation transmission system of an all-terrain vehicle which includes a radiator mounted at a front end of the vehicle and under a front body cover, a hood enclosing the radiator, a gearbox having an inlet and an outlet, the inlet being connected with an inlet conduit for drawing outside cool air into the gearbox, the outlet being connected with an exhaust conduit for discharging hot air from the gearbox, wherein the inlet conduit has an inlet end mounted between the hood and the front body cover and shielded by the hood and the front body cover, whereby the cooling structure can effectively prevent water, dirt and dust from entering the gearbox and are simple in construction and easy to assemble and maintain.

Owner:KYMCO

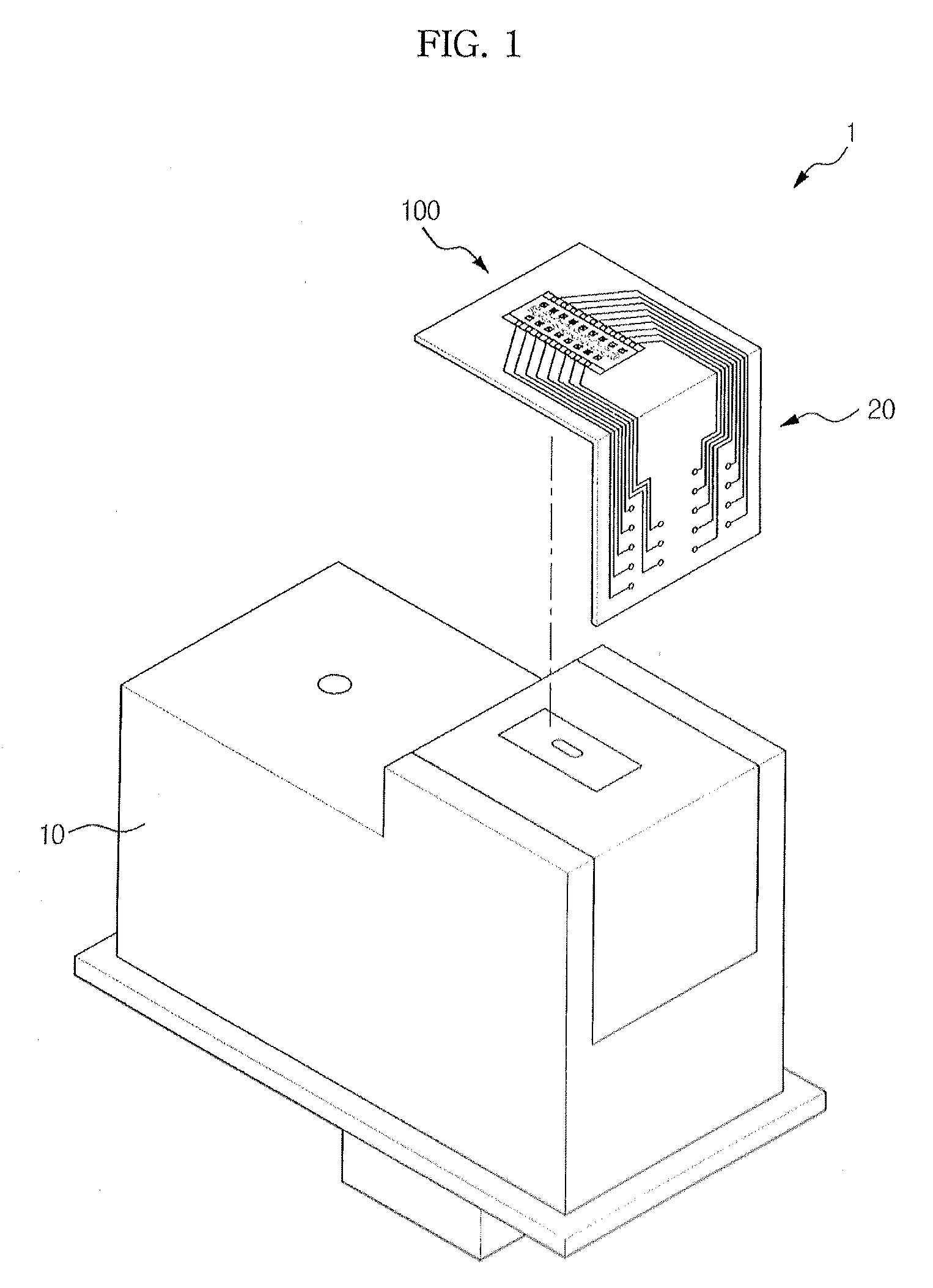

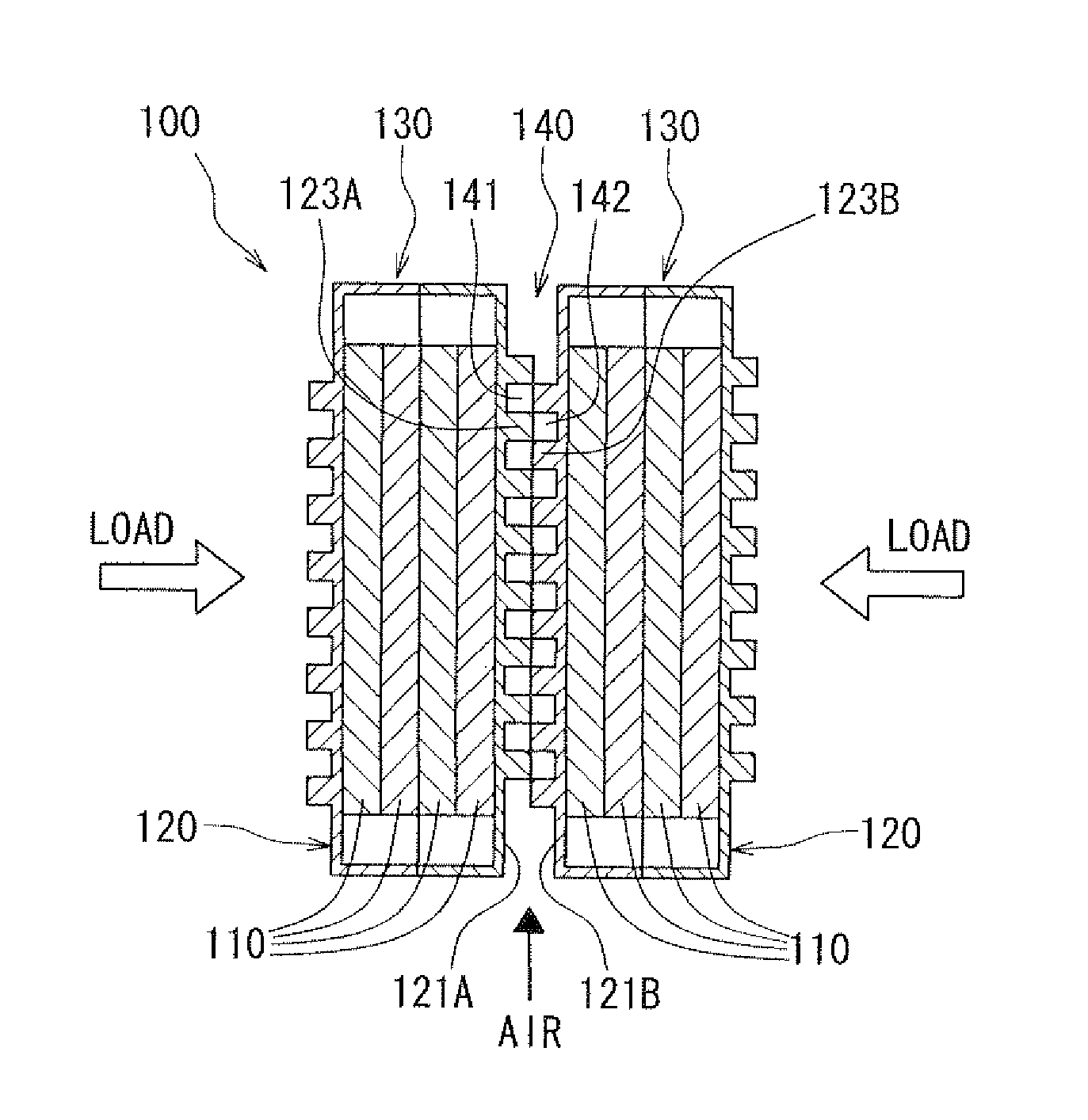

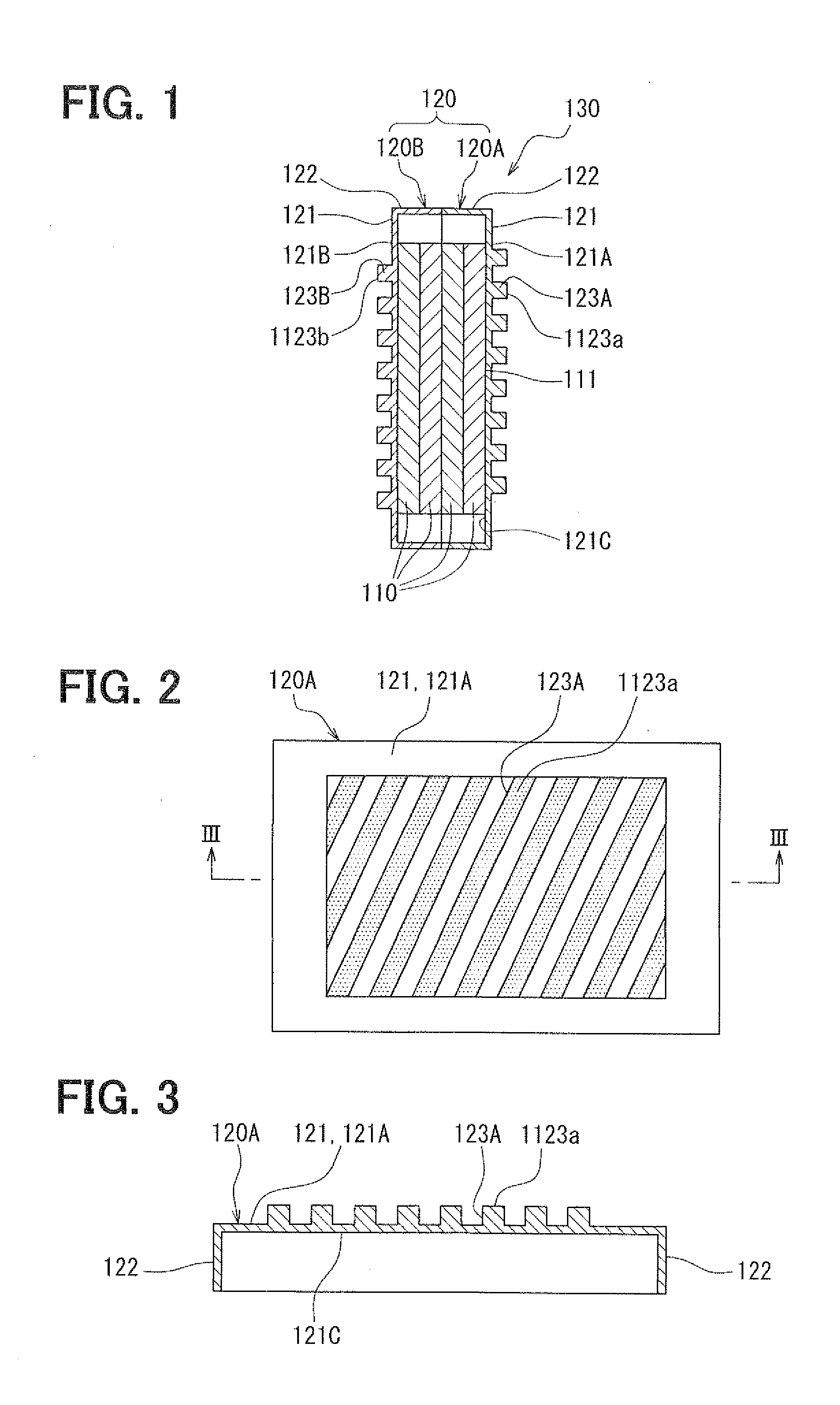

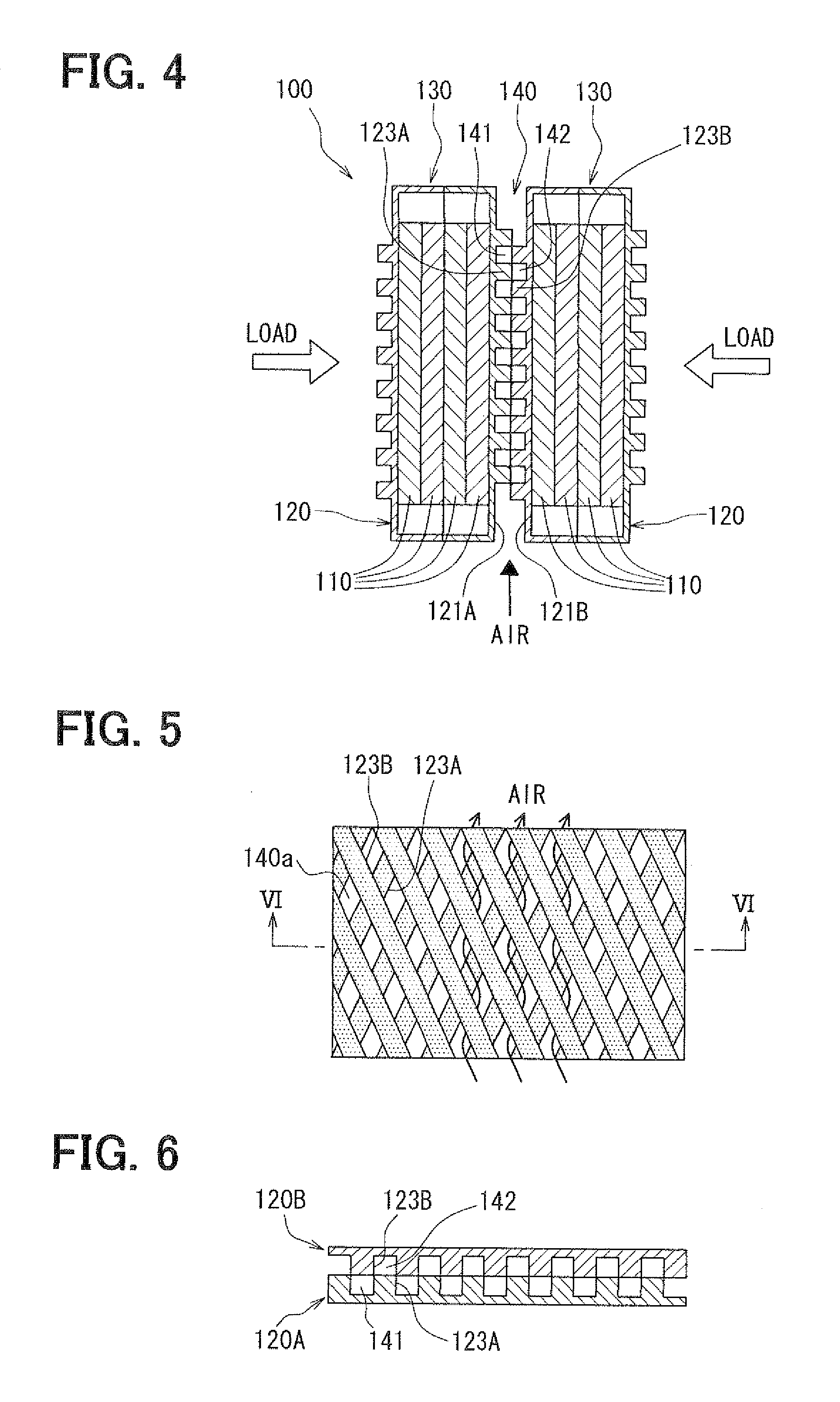

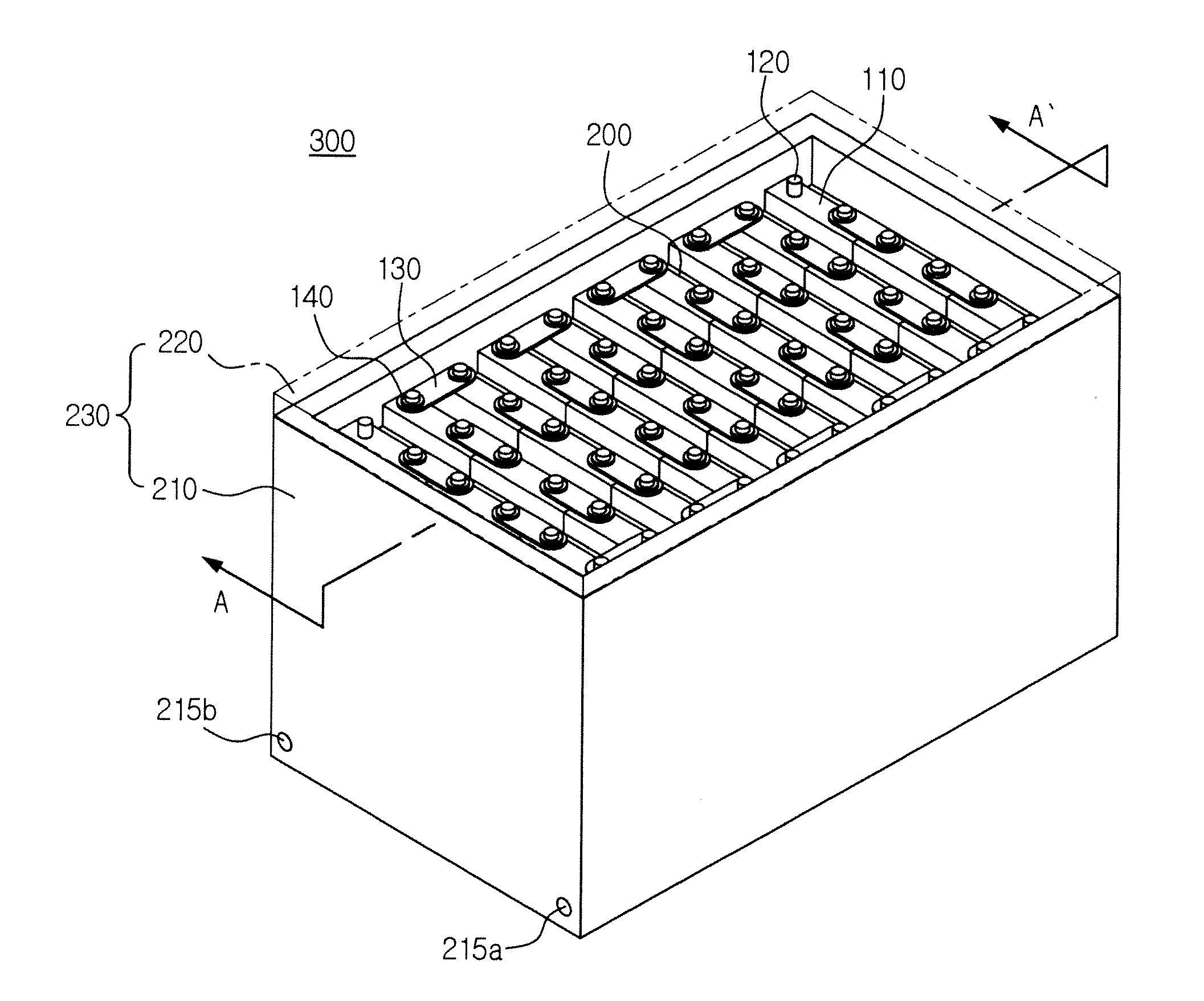

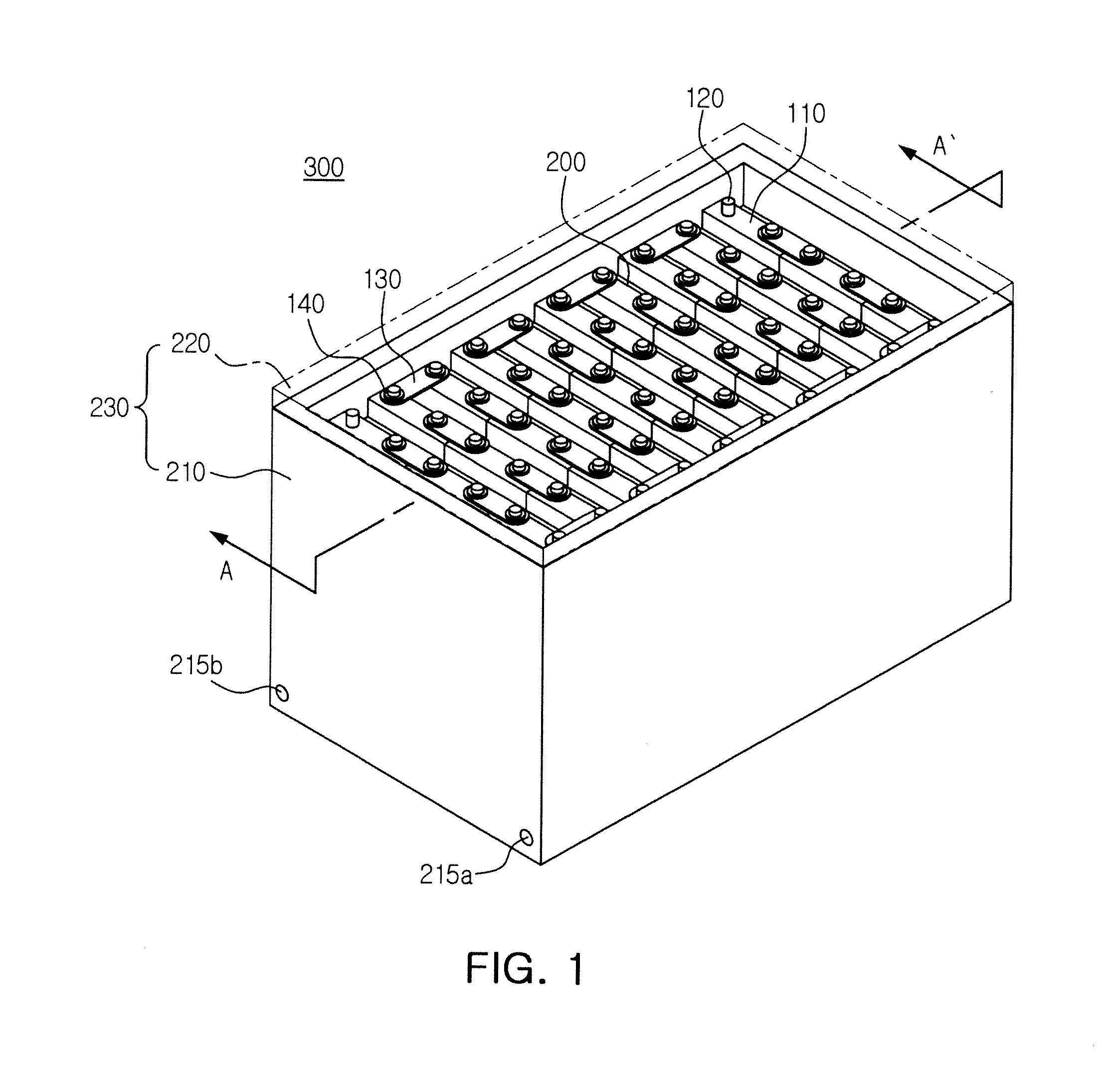

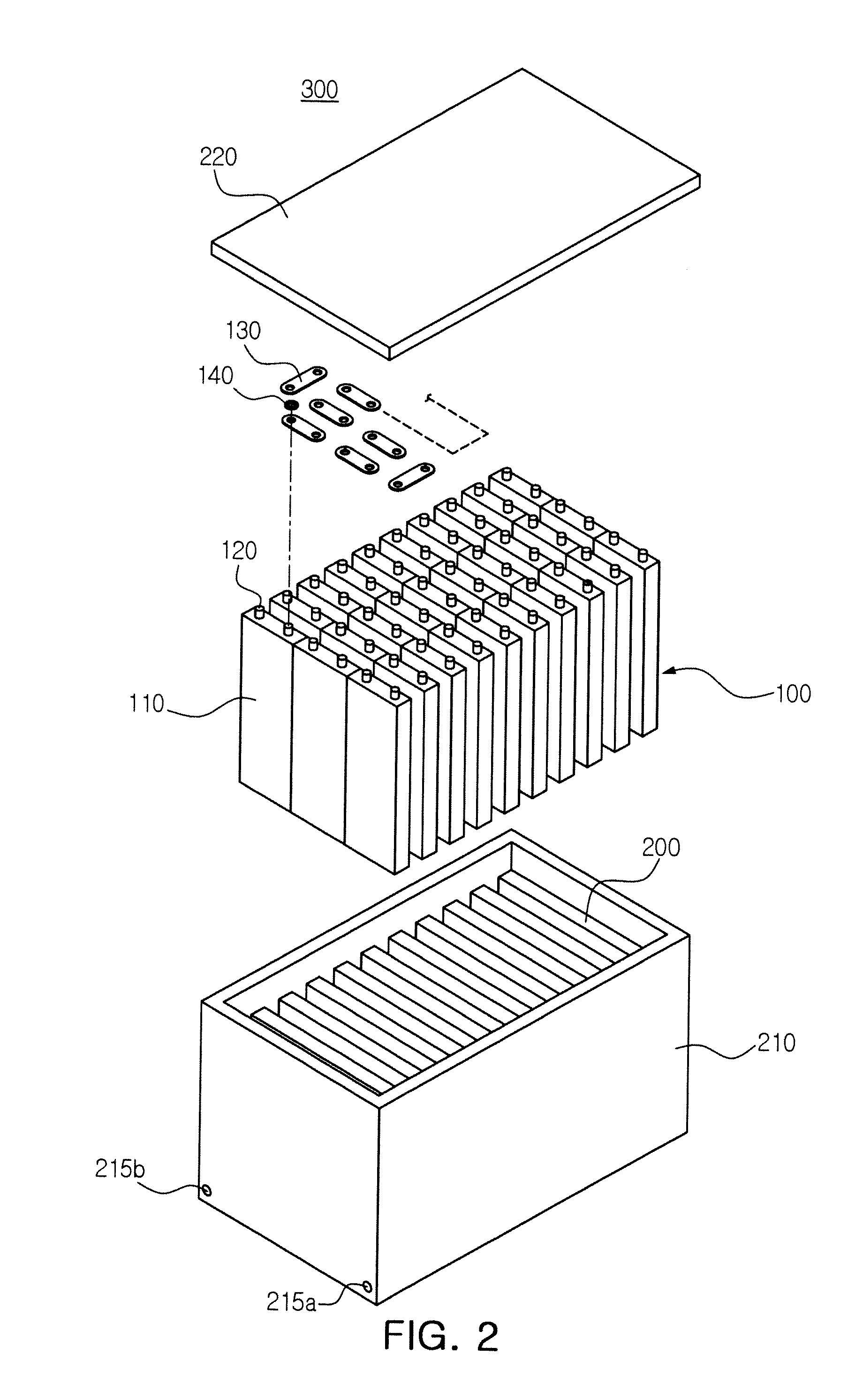

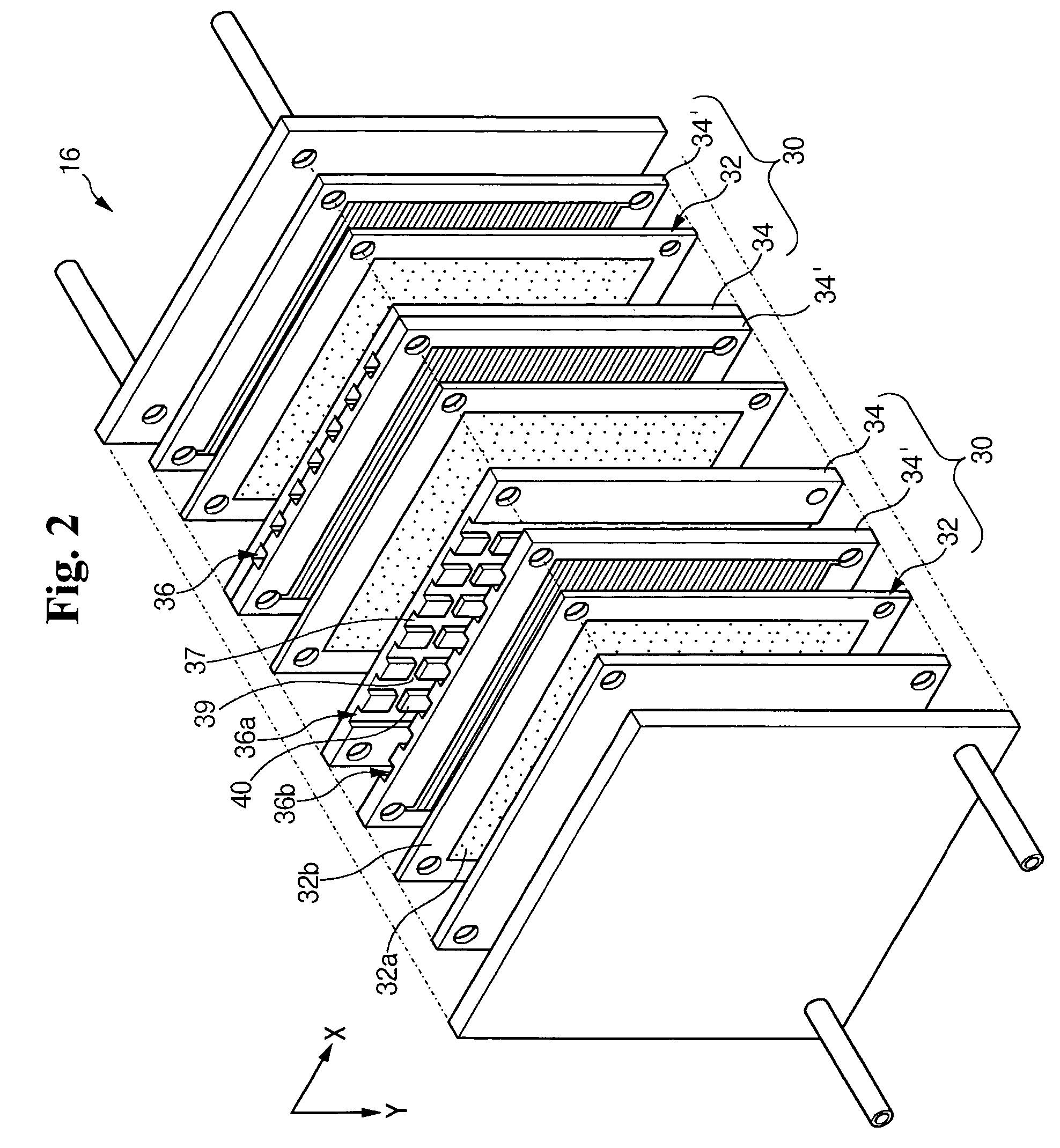

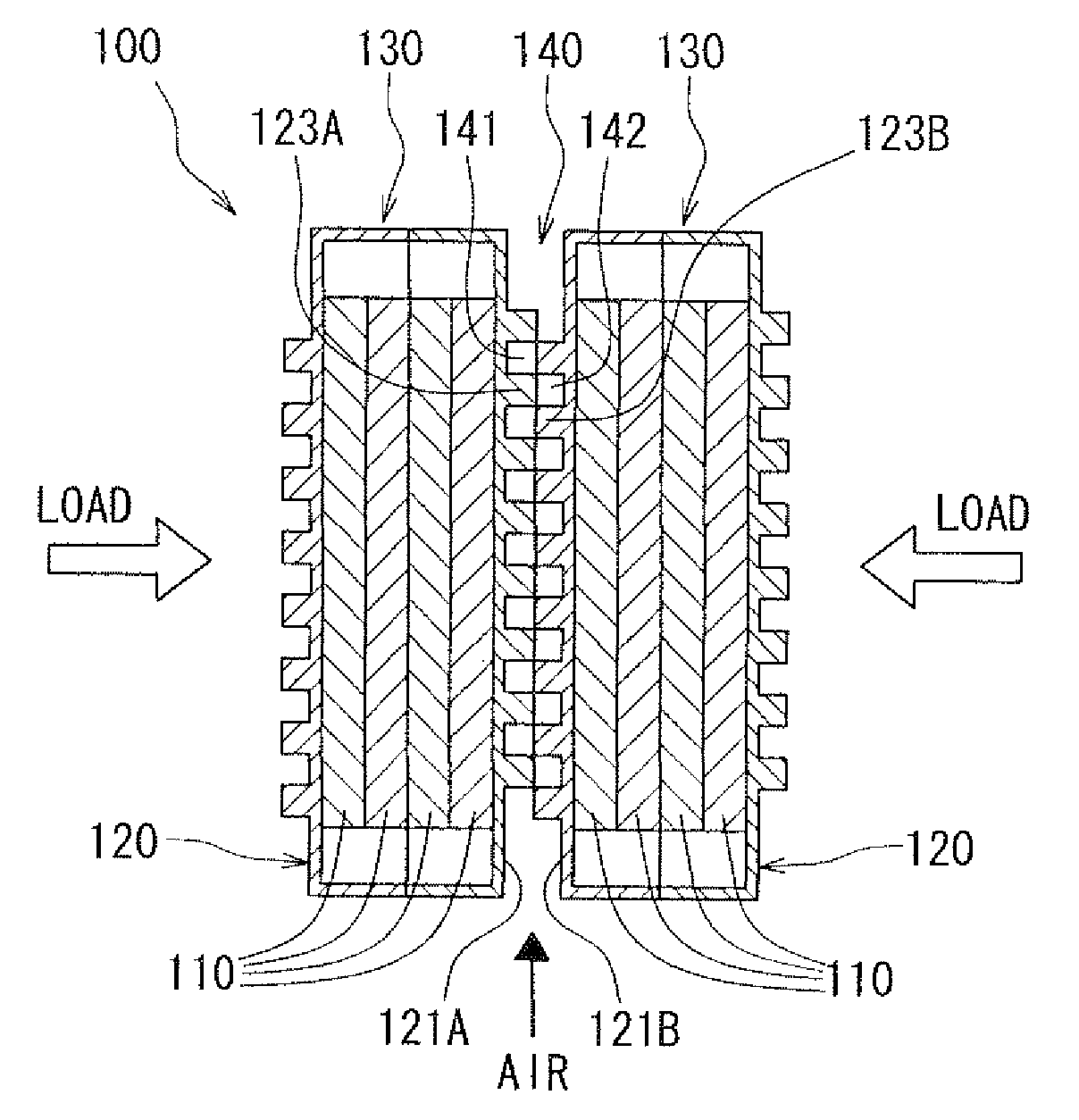

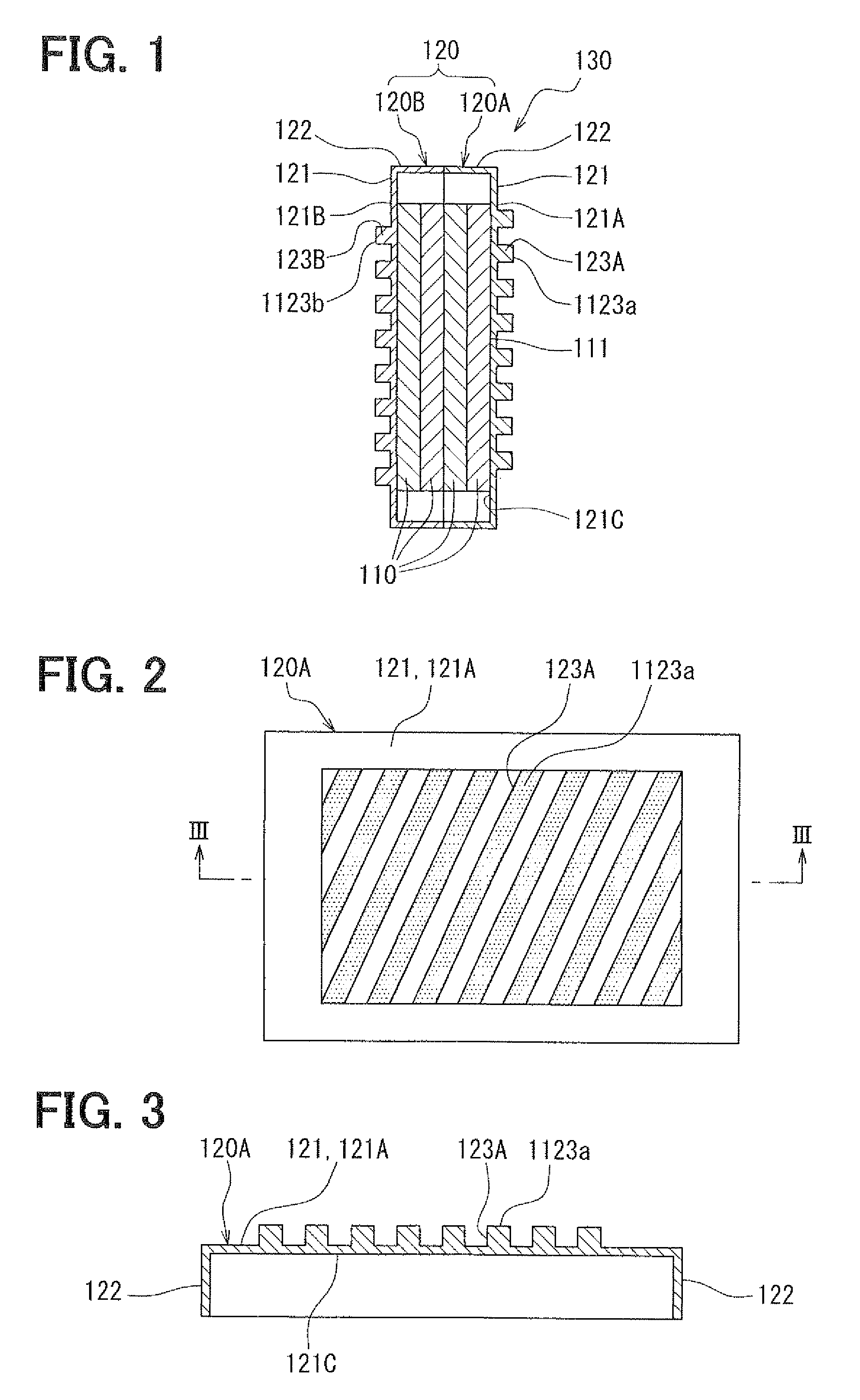

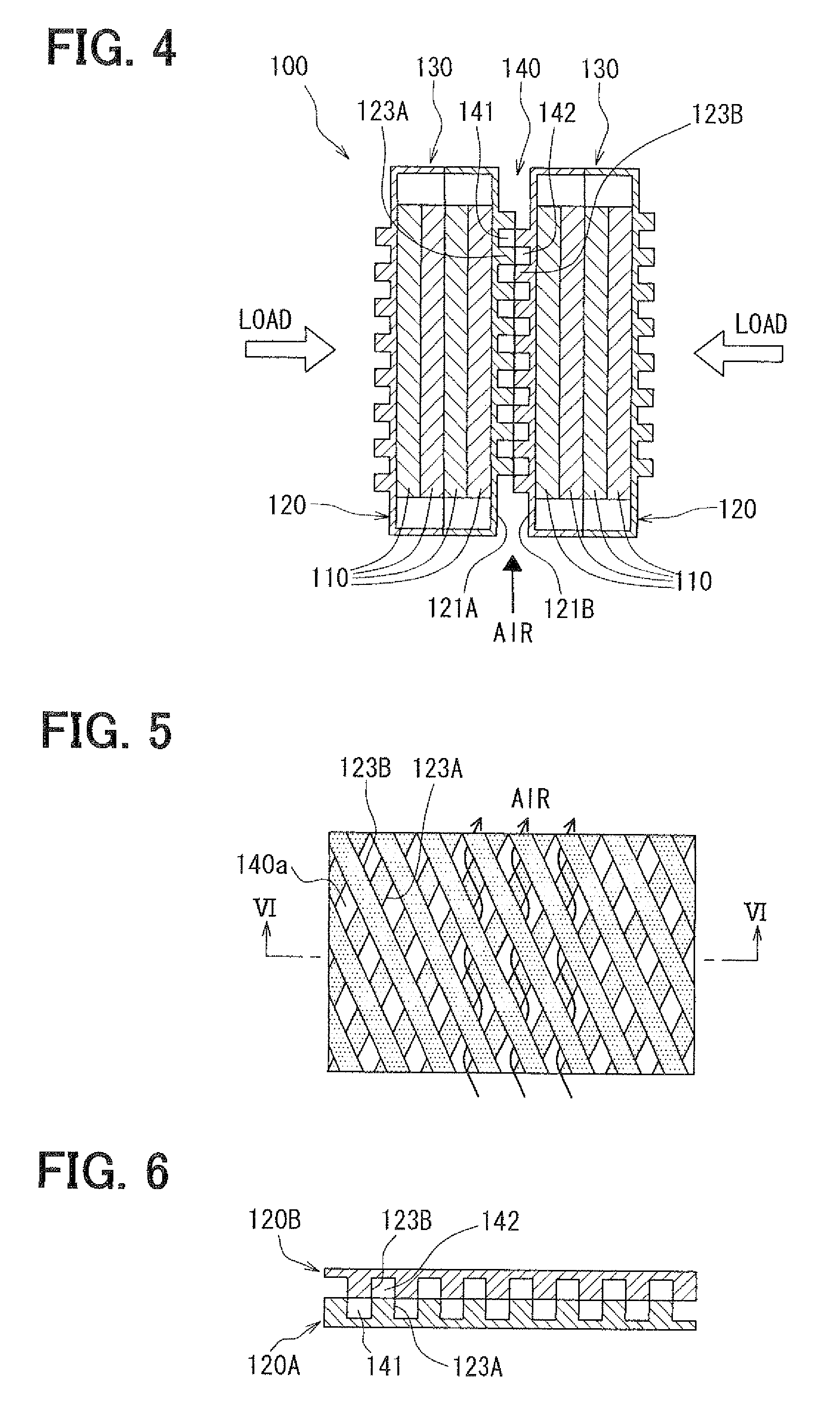

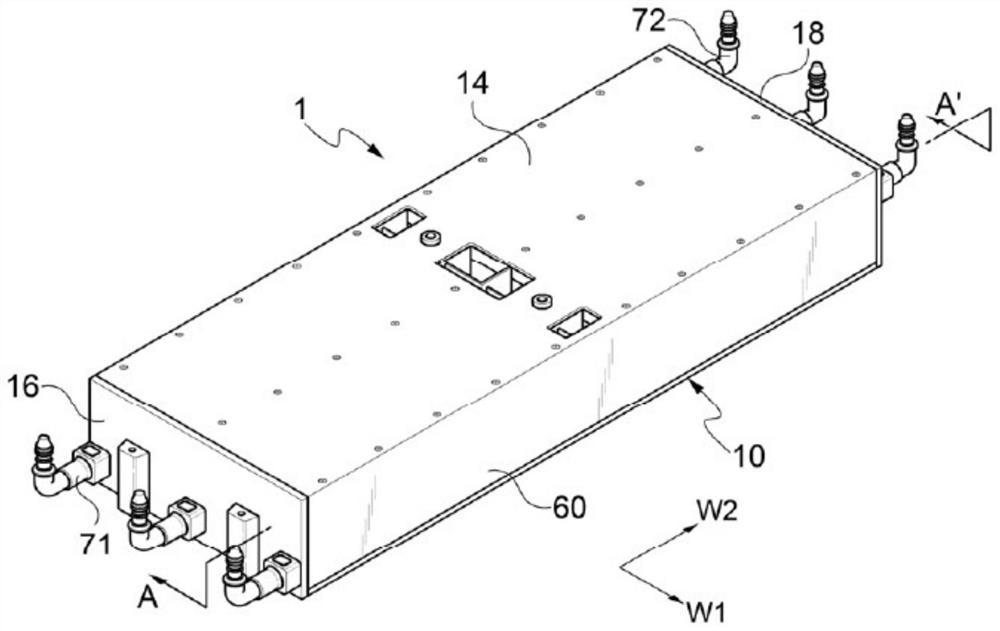

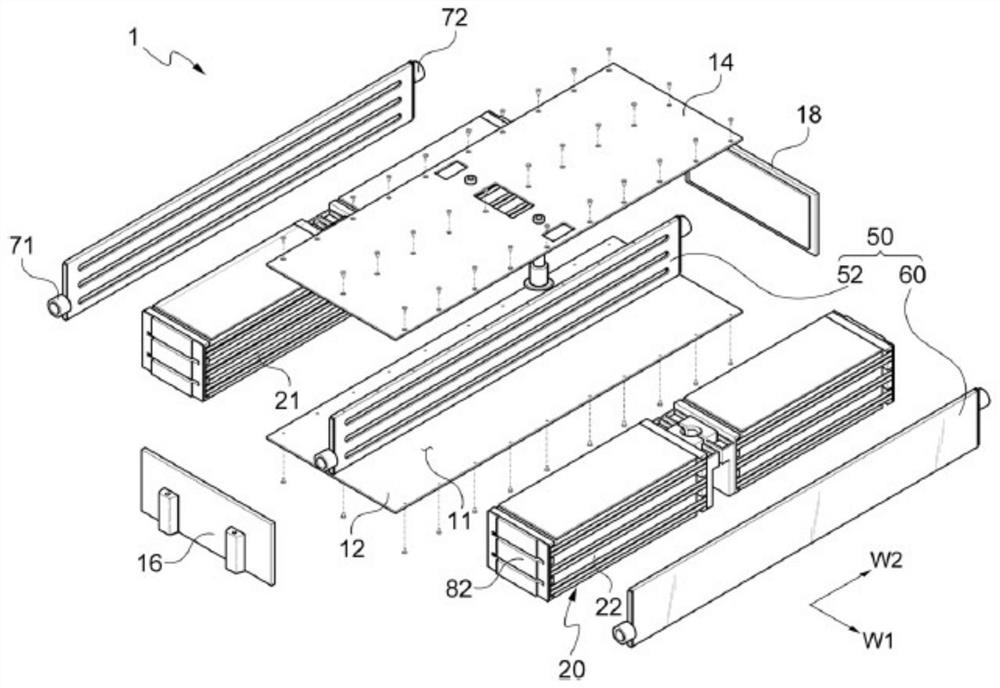

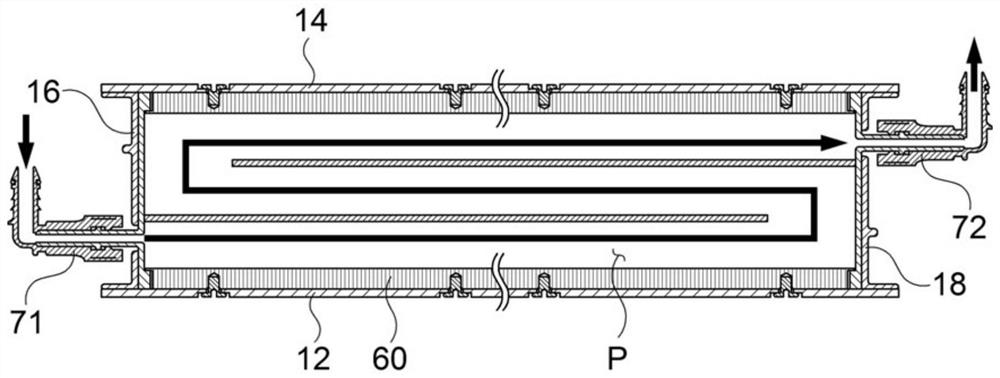

Battery pack with cooling passage

ActiveUS20120070711A1Effectively and evenly cooledIncrease in heat transfer coefficientCell temperature controlCells cooling/heatingCooling channelBattery cell

A battery pack includes battery modules each having a battery cell and a battery case housing the battery cell therein. The battery modules are stacked in a stacking direction so that a cooling passage for allowing a cooling medium to flow is defined between opposed surfaces of adjacent battery cases. One of the opposed surfaces has first ribs projecting toward the other of the opposed surfaces and extending parallel to each other along the one. The other of the opposed surfaces has second ribs projecting toward the one of the opposed surfaces and extending parallel to each other along the other. In the cooling passage, the first ribs and the second ribs intersect each other and end portions of the first ribs and end portions of the second ribs are in contact with each other in the stacking direction.

Owner:DENSO CORP

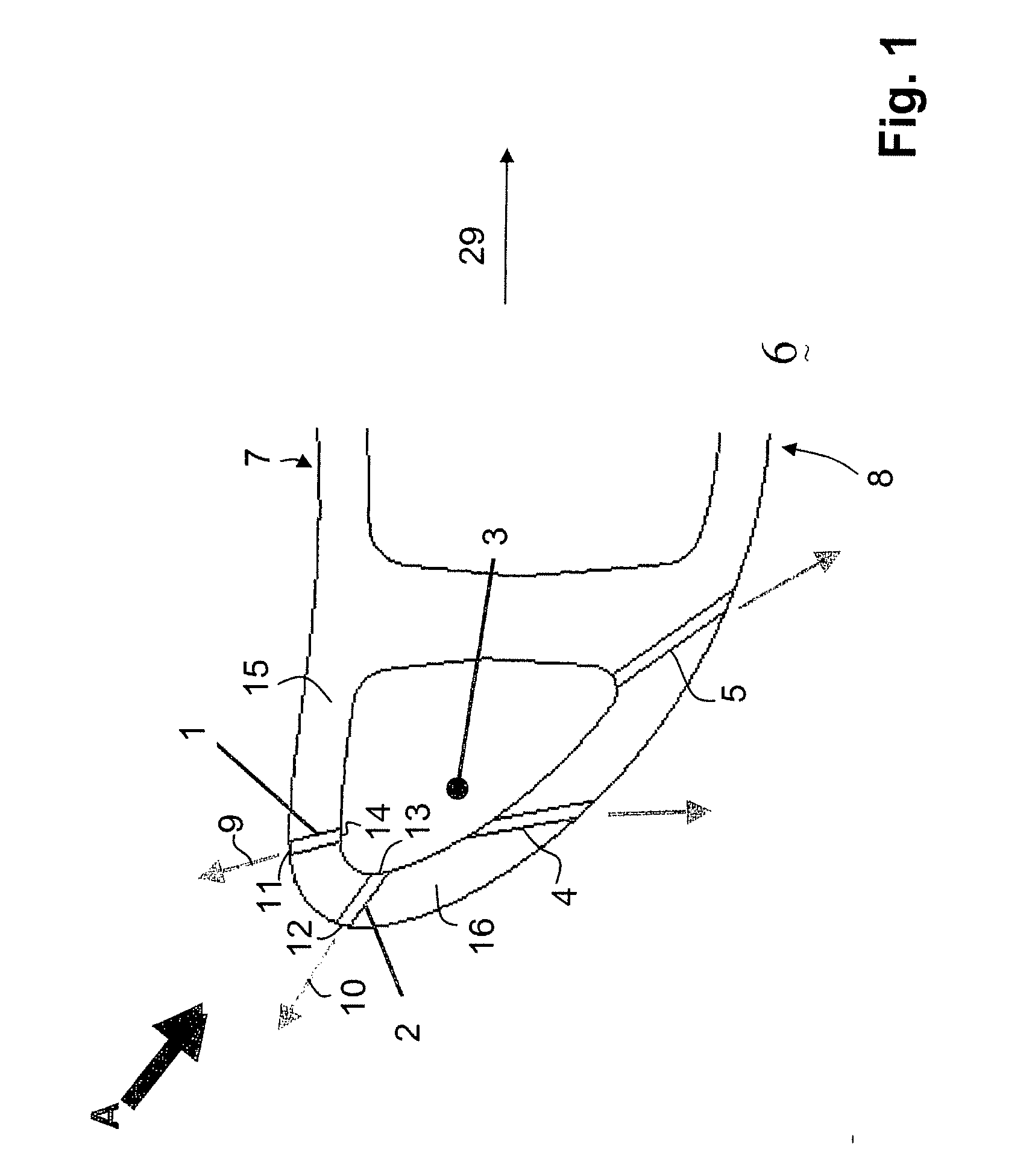

Gas Turbine Airfoil With Leading Edge Cooling

ActiveUS20080095622A1Optimize cooling structureEngine manufactureBlade accessoriesTrailing edgeGas turbines

A gas turbine airfoil (1) includes a pressure sidewall (15) and a suction sidewall (16), extending from a root to a tip and from a leading edge region to a trailing edge and having at least one cooling passage between the pressure sidewall (15) and the suction sidewall (16) for cooling air to pass through and cool the airfoil from within. One or several of the cooling passages (3) extend along the leading edge of the airfoil (1) and several film cooling holes (1,2) extend from the internal cooling passages (3) along the leading edge region to the outer surface of the leading edge region. The film cooling holes (1,2) each have a shape that is diffused in a radial outward direction of the leading edge of the airfoil (1) at least over a part of the length of the film cooling hole (1,2). Improved cooling in the leading edge region can be achieved because the cooling holes (1, 2) have a principal axis (17), and the shape is asymmetrically diffused in that it is diffused in the radial outward direction from the principal axis (17) along a forward inclination axis (20), and it is additionally diffused in a second lateral direction from the principal axis (17) along a lateral inclination axis (21).

Owner:GENERAL ELECTRIC TECH GMBH

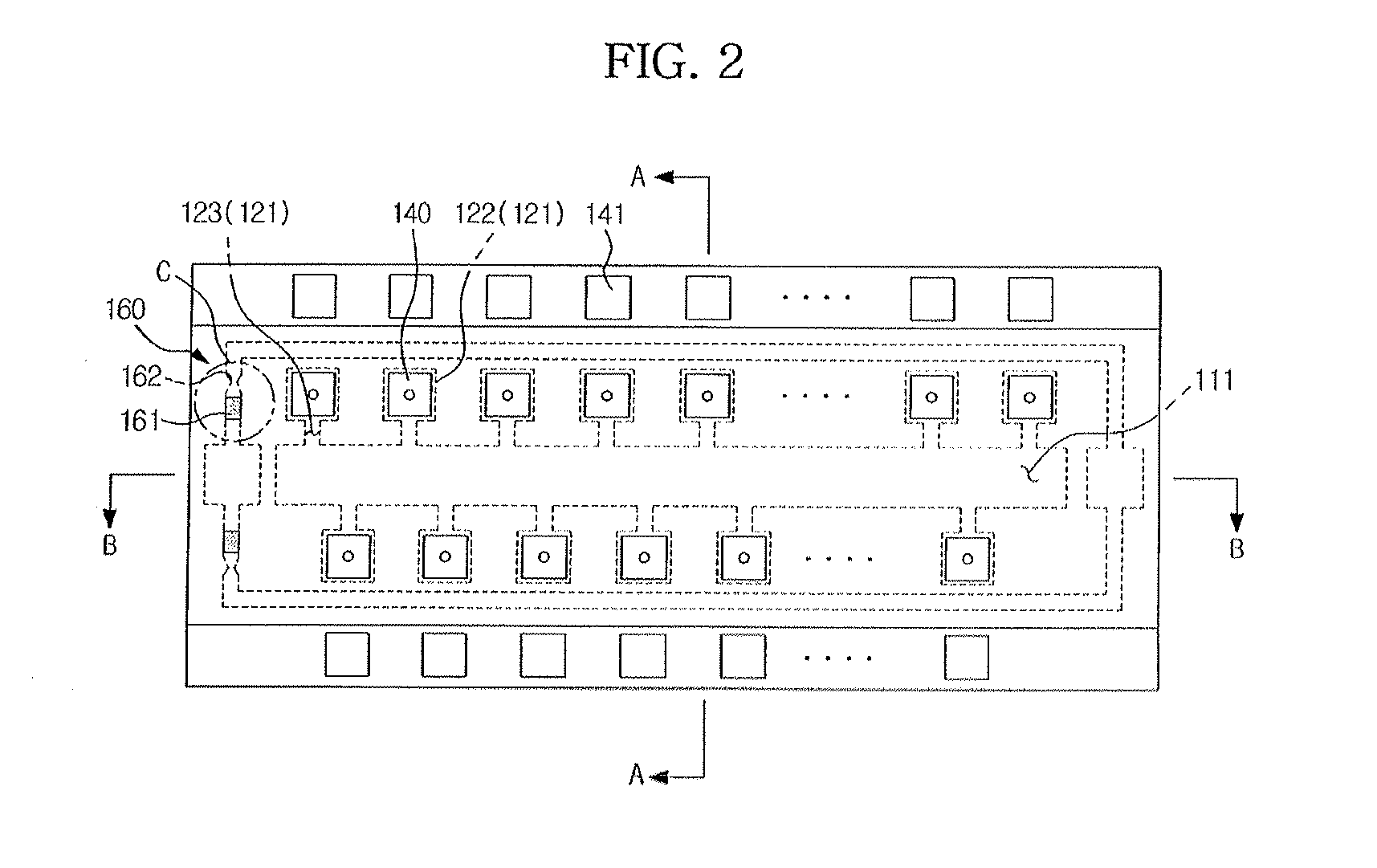

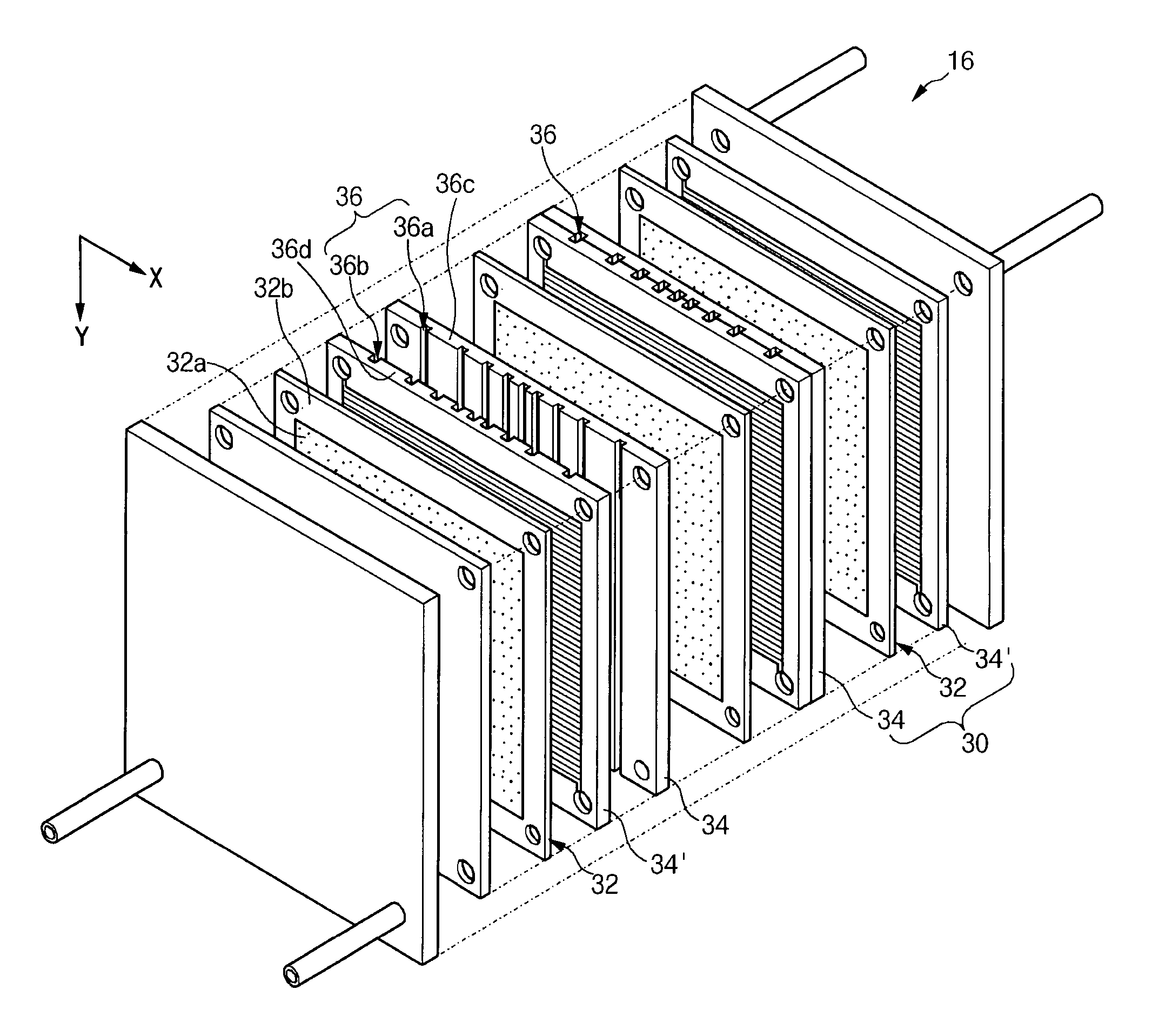

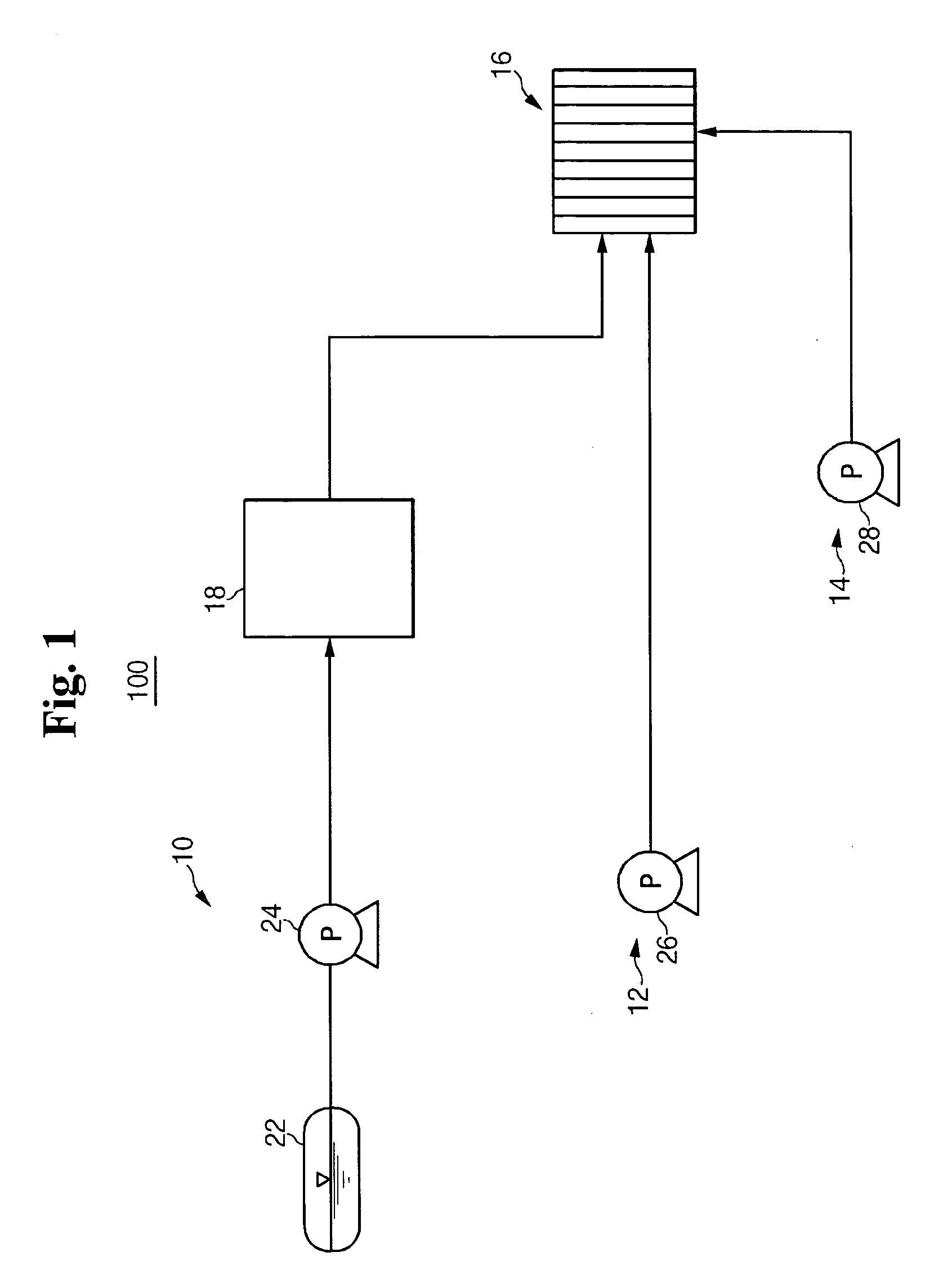

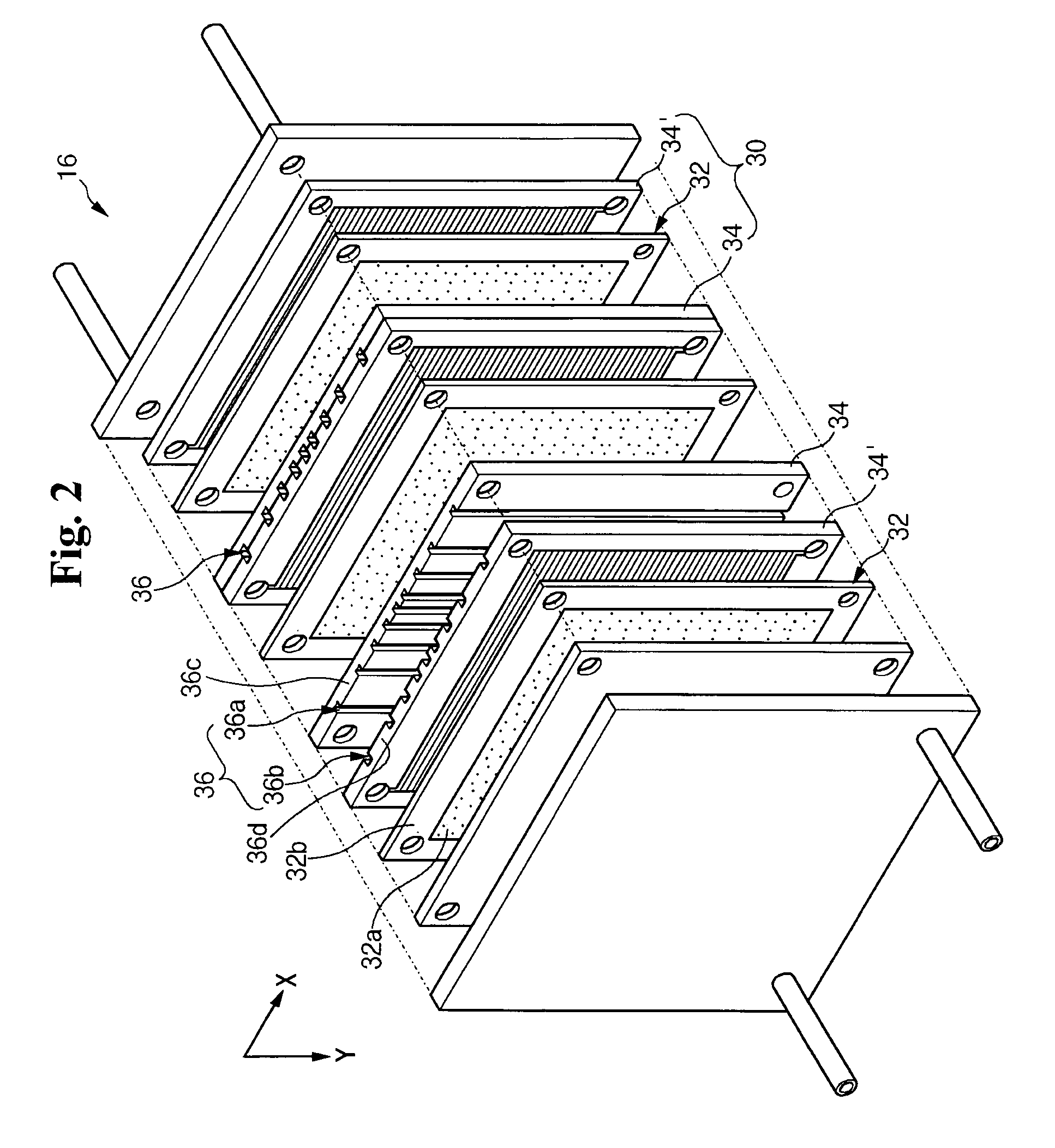

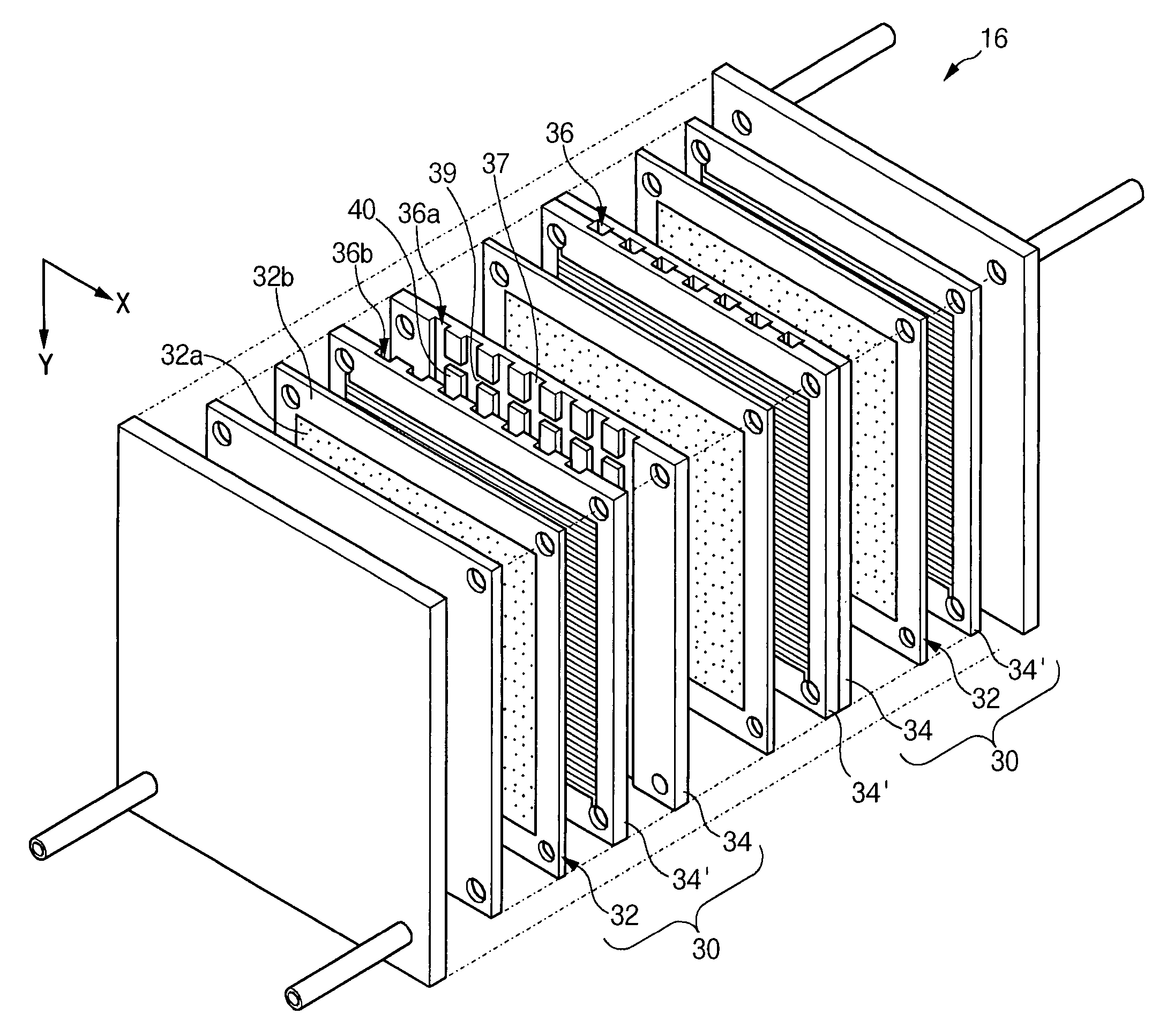

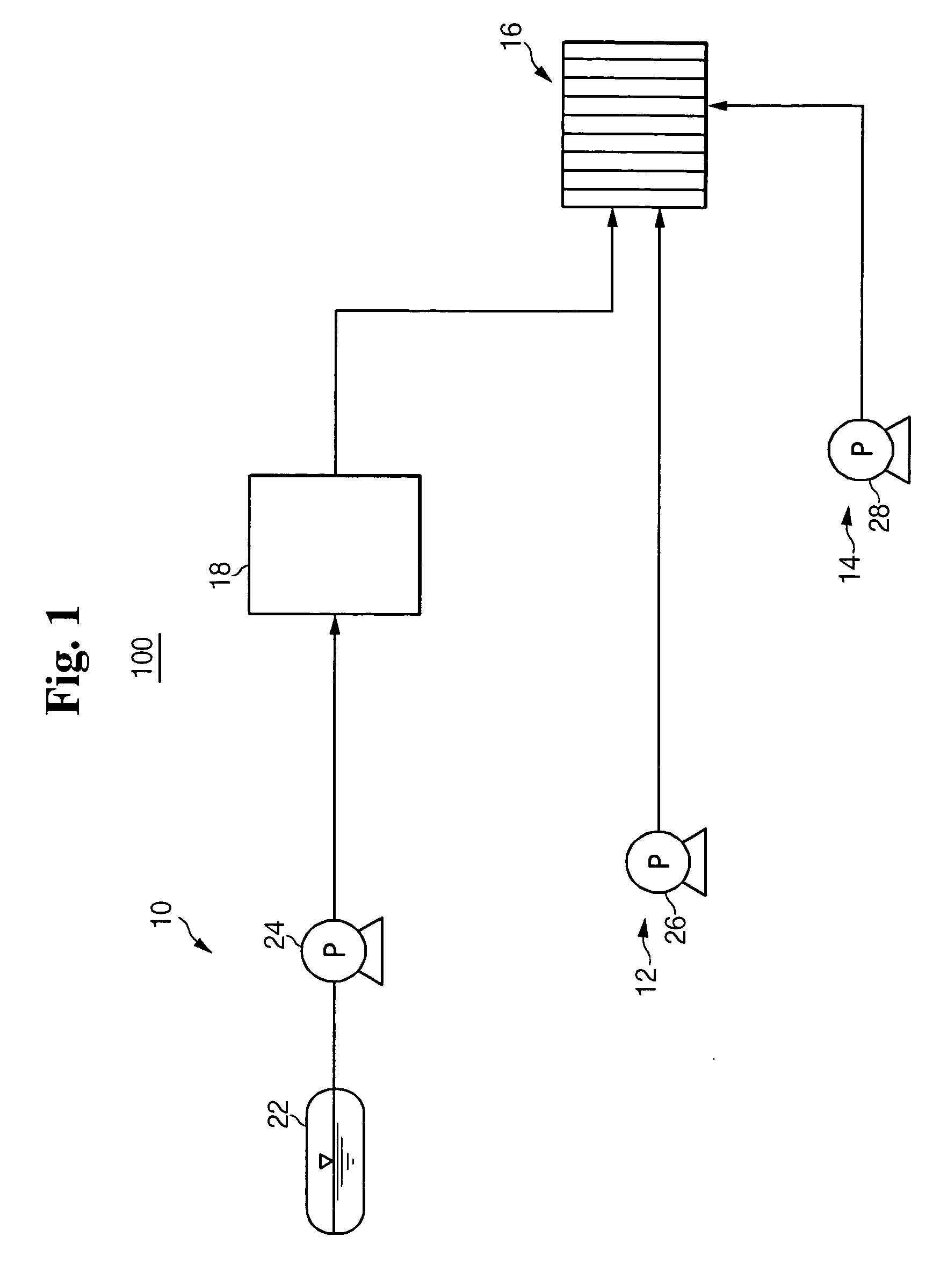

Fuel cell stack having improved cooling structure

InactiveUS20060046117A1Improve cooling efficiencyImprove performanceFuel cell heat exchangeFuel cells groupingElectricityElectrochemical response

A fuel cell stack that includes at least one electricity generator generating electric energy through an electrochemical reaction between hydrogen and oxygen and a cooling system are provided. The electricity generator includes a membrane-electrode assembly, separators on both sides of the membrane-electrode assembly, and cooling channels placed approximately parallel to a first direction of the membrane-electrode assembly, where a coolant flows through the cooling channels, and where the cooling channels have different distribution densities in a direction perpendicular to the first direction of the membrane-electrode assembly.

Owner:SAMSUNG SDI CO LTD

Cooling structure for gas turbine combustor

InactiveUS8220273B2Optimize cooling structureEfficiently suppress a possible occurrence of bucklingContinuous combustion chamberEngine fuctionsCombustion chamberCombustor

A gas turbine combustor having an improved cooling structure effective to efficiently suppress a possible occurrence of buckling in the combustion liner while exhibiting a convection cooling effect to the combustion liner, the gas turbine combustor includes a combustion liner having a combustion chamber defined therein and an outer peripheral surface forming a path of a compressed air, and a heat transfer enhancement structure provided on the outer peripheral surface of the combustion liner. The heat transfer enhancement structure referred to above is of a honeycomb construction defined by ribs protruding outwardly from the outer surface of the combustion liner. The honeycomb construction may be of a geometry in which hexagonal shapes, rhombic shapes, parallelogrammic shapes, bent rectangular shapes or triangular shapes are deployed next to each other.

Owner:KAWASAKI HEAVY IND LTD

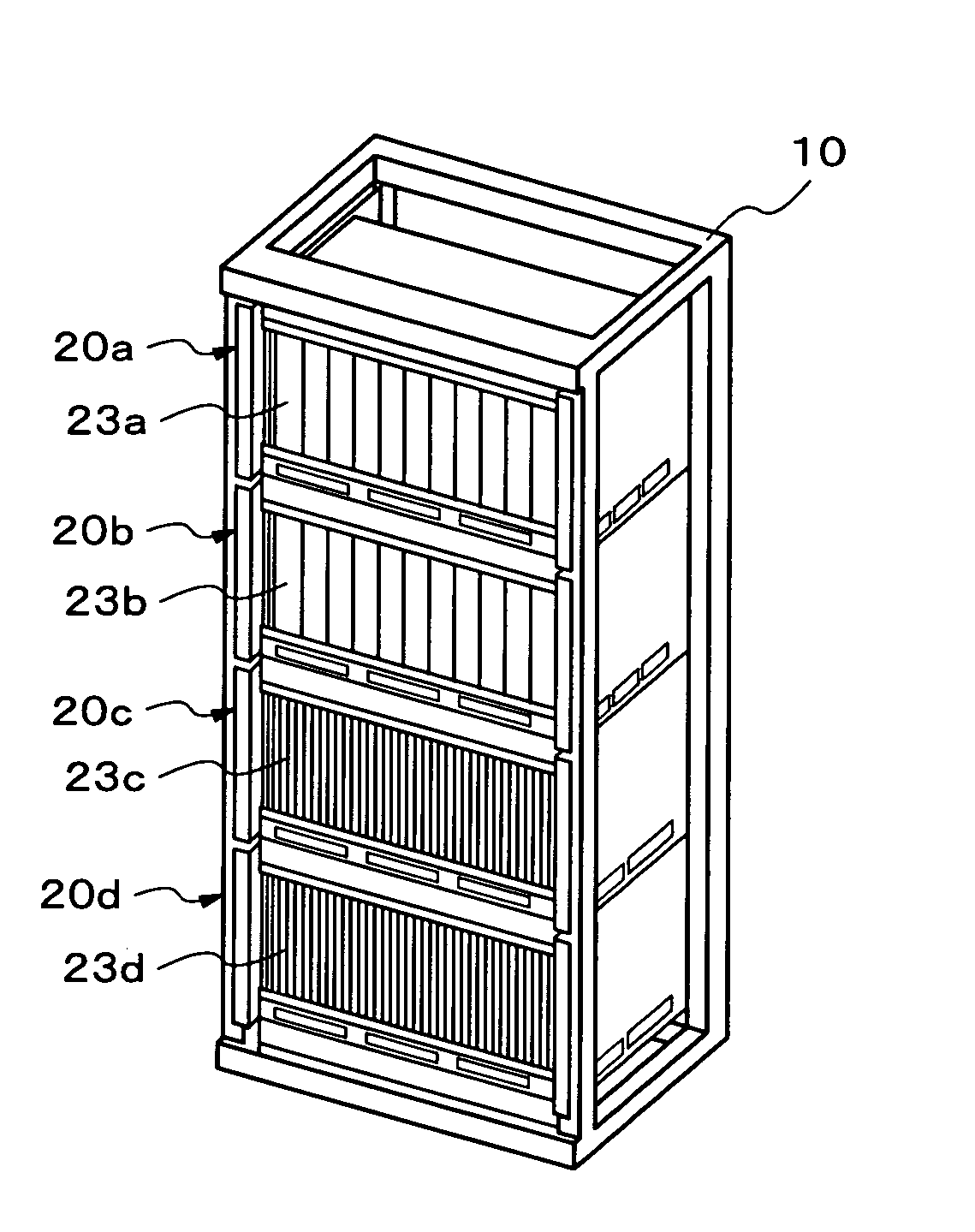

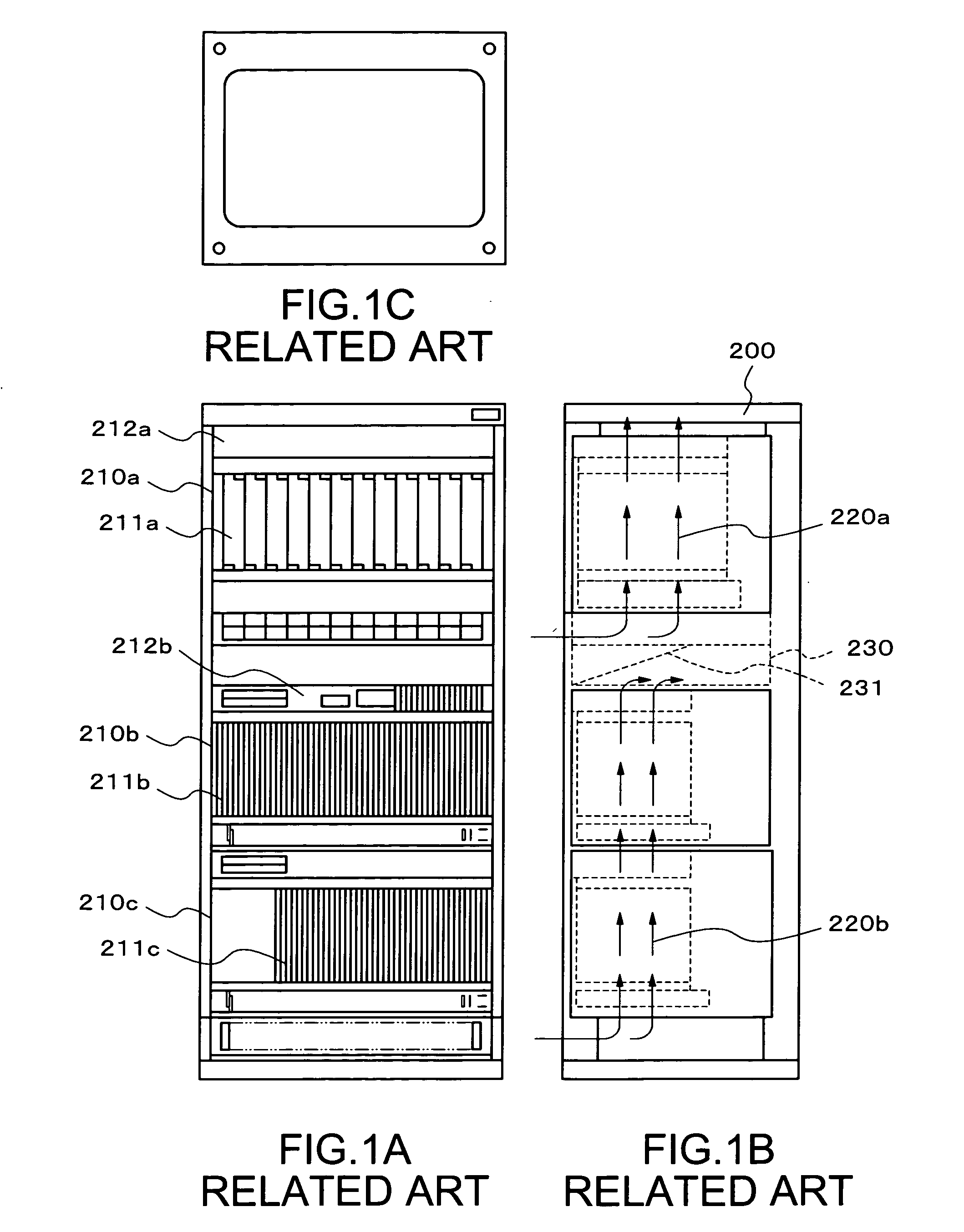

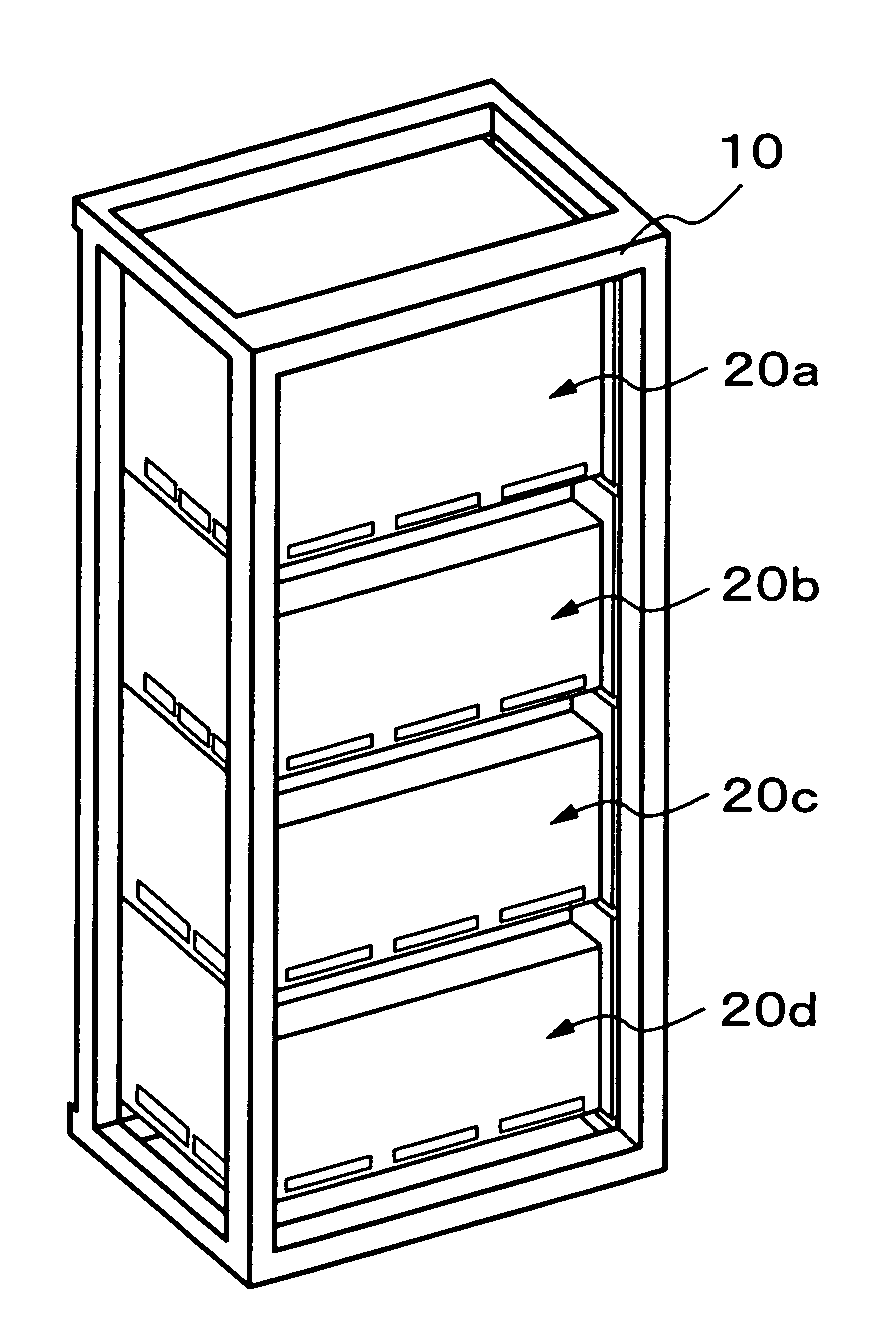

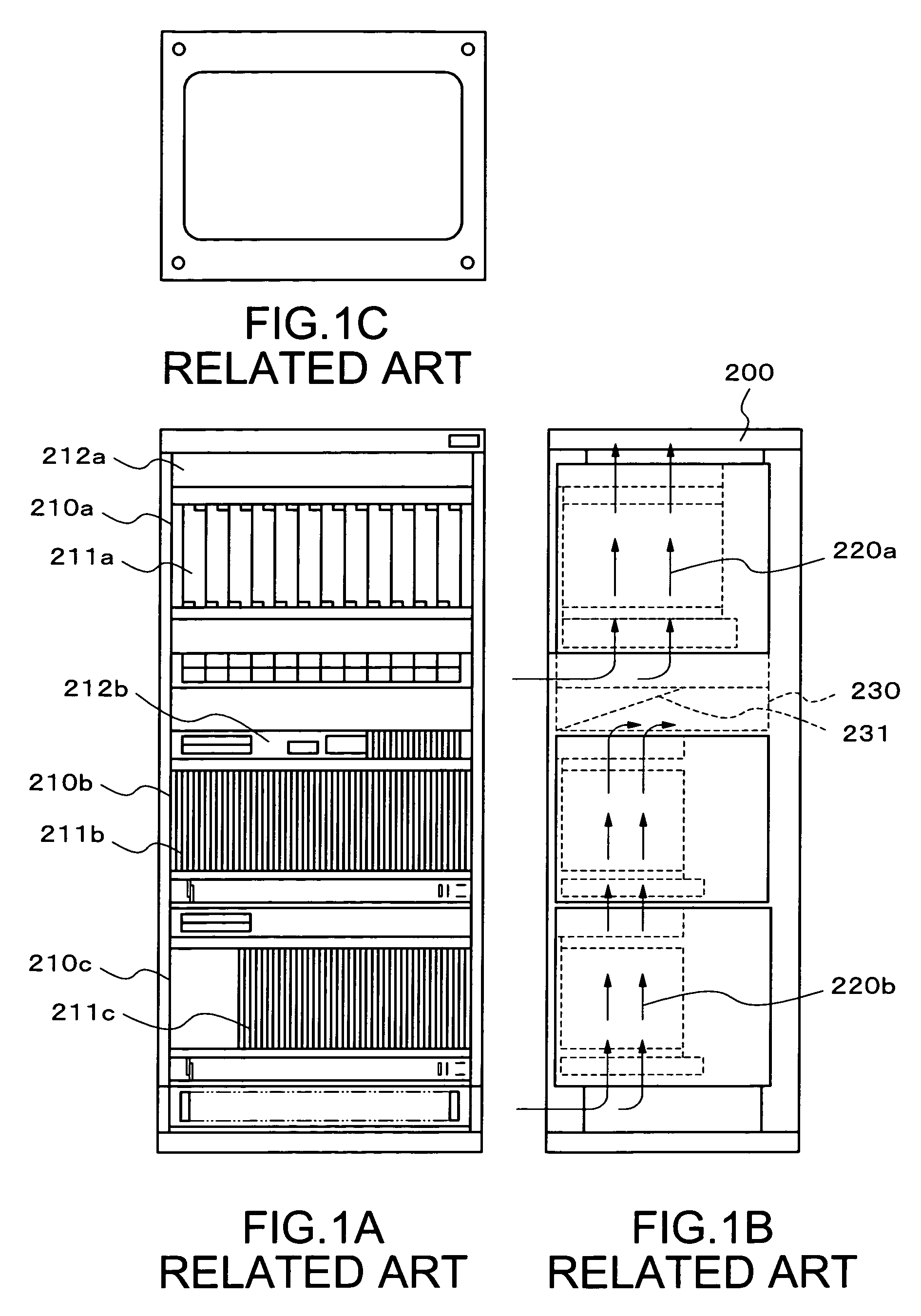

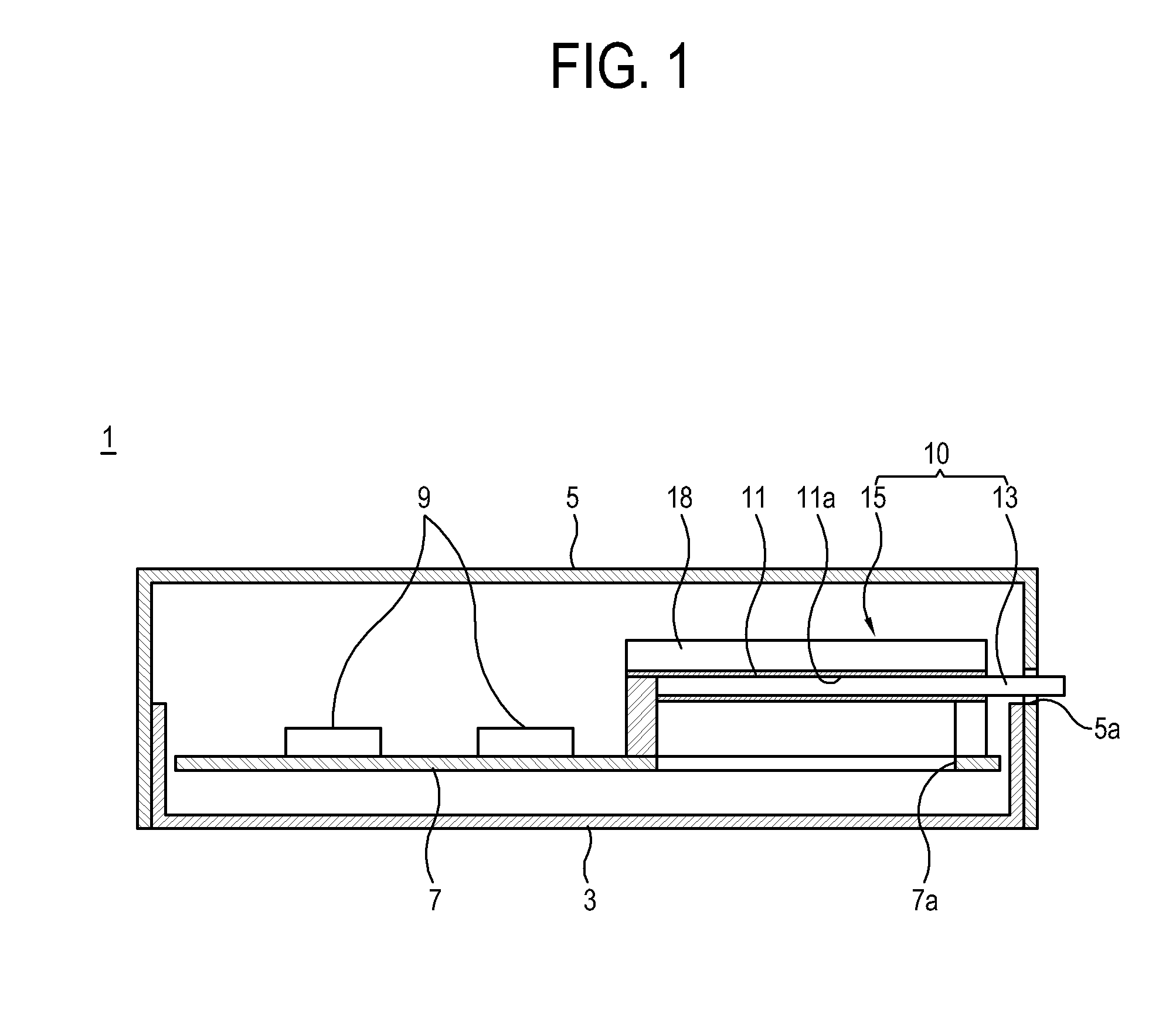

Electronic apparatus, fan unit, and subrack

InactiveUS20060223433A1Improve accommodationOptimize cooling structureDigital data processing detailsCooling/ventilation/heating modificationsEngineeringElectronic equipment

Owner:NEC CORP

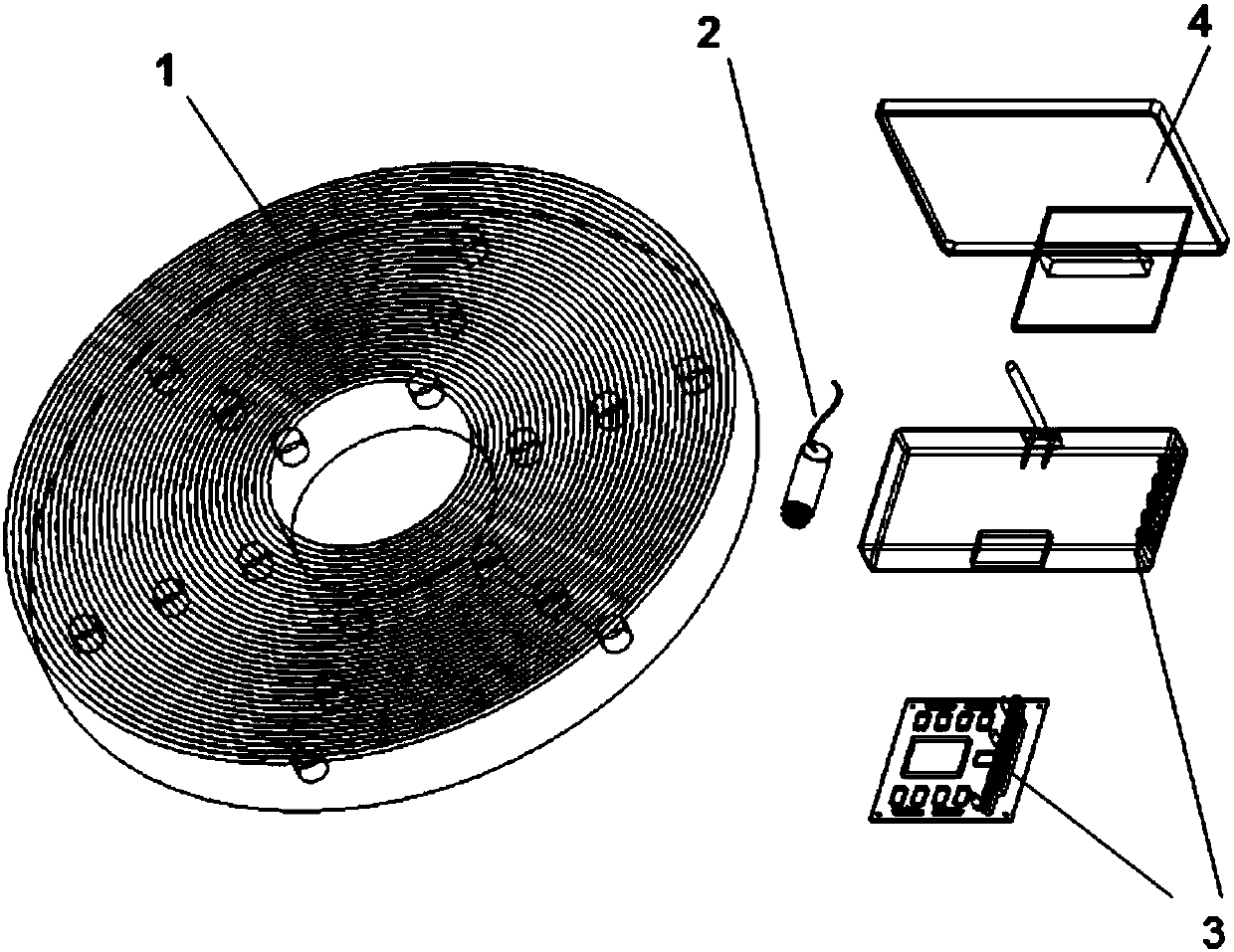

Energy storage module

InactiveUS20120040227A1Improve stabilityExtend the lifespanMultiple fixed capacitorsCell temperature controlWater flowStorage cell

There is provided an energy storage module including, a plurality of energy storage units having electrodes connected in series or in parallel, one or more cooling plates provided to alternate with the energy storage units, each having a flow path through which cooling water flows, so as to cool the energy storage units, and a housing surrounding the energy storage units and the cooling plates and including an inlet and an outlet through which the cooling water is drawn and discharged to thereby provide the cooling water to the cooling plates.

Owner:SAMSUNG ELECTRO MECHANICS CO LTD

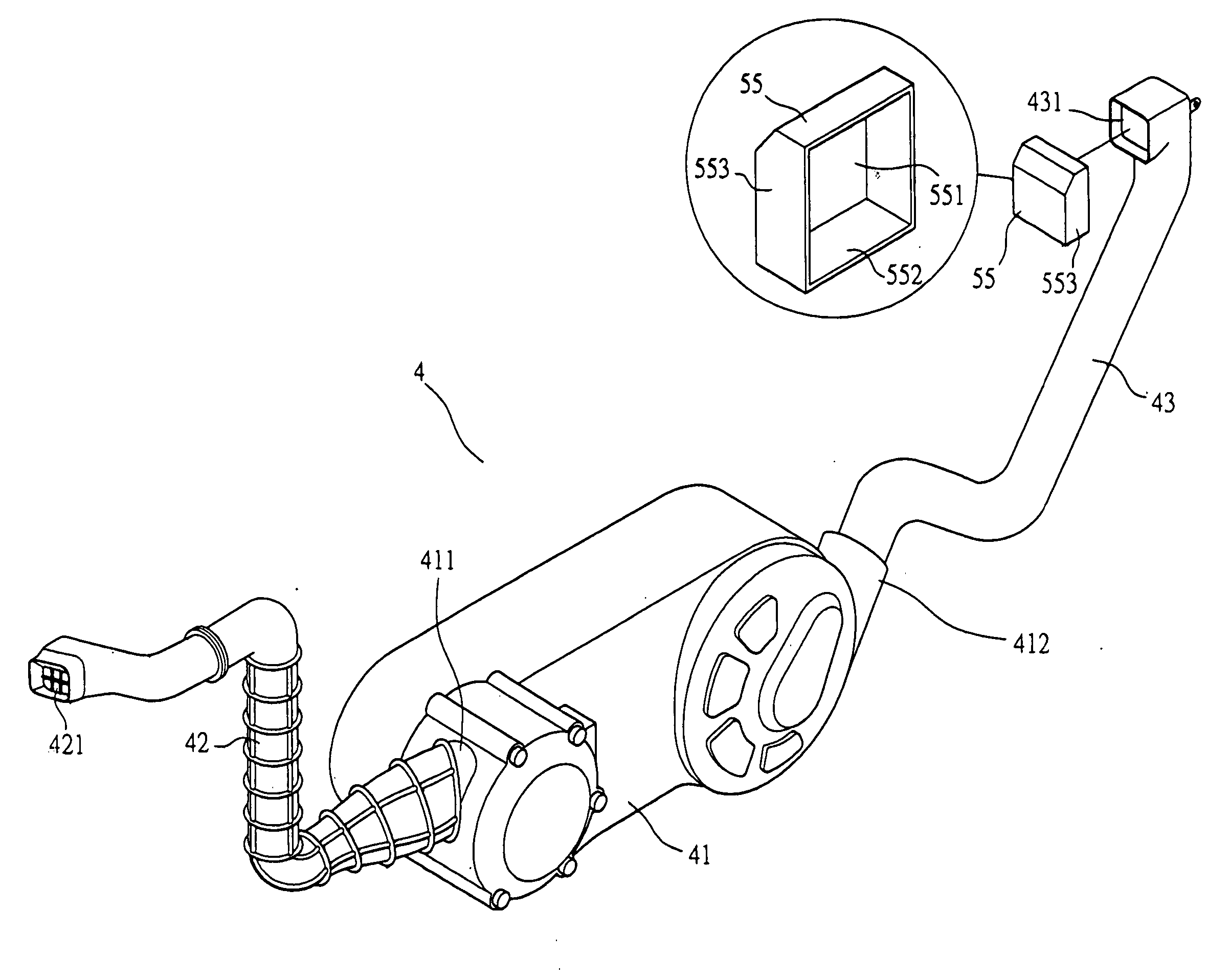

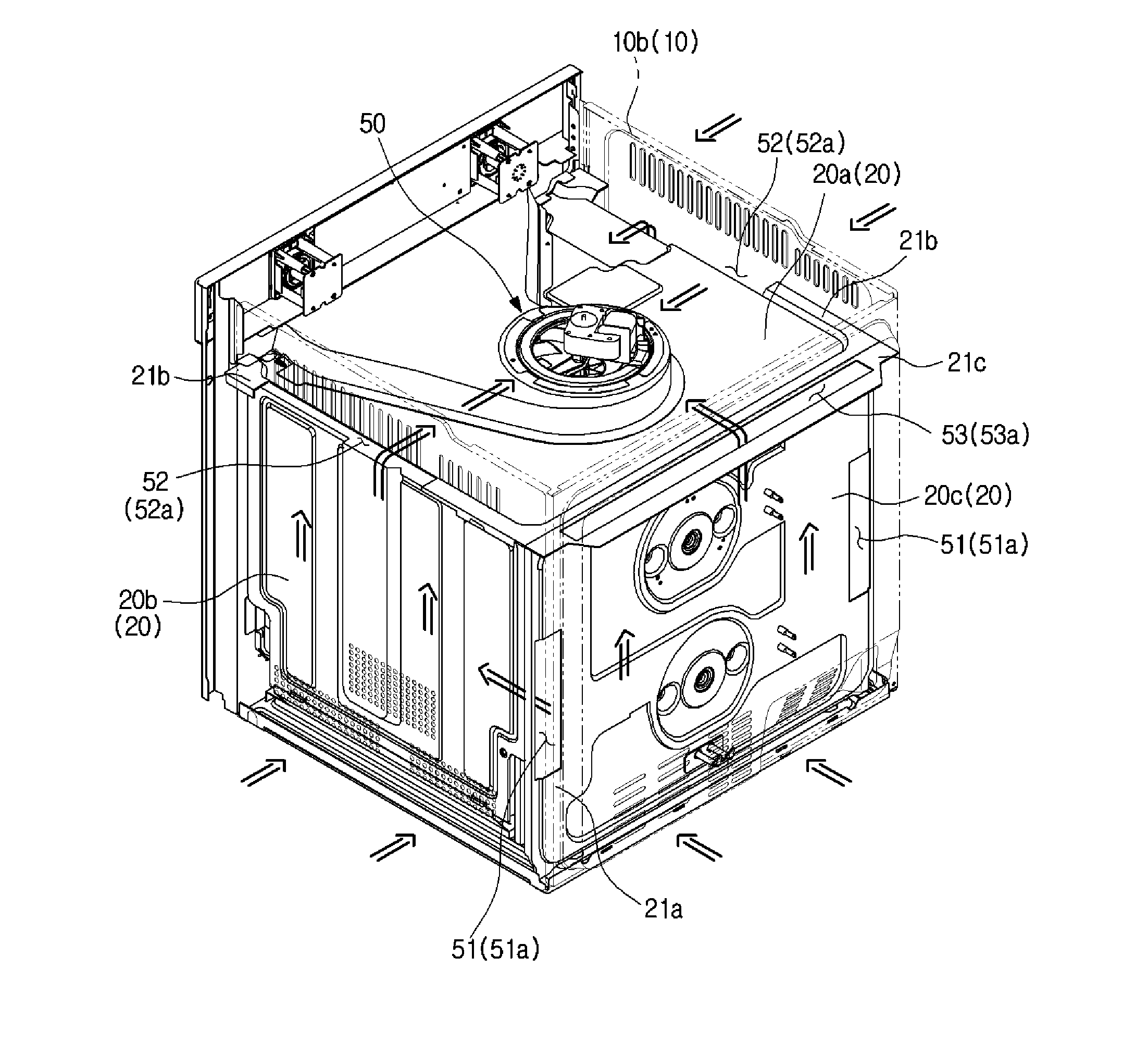

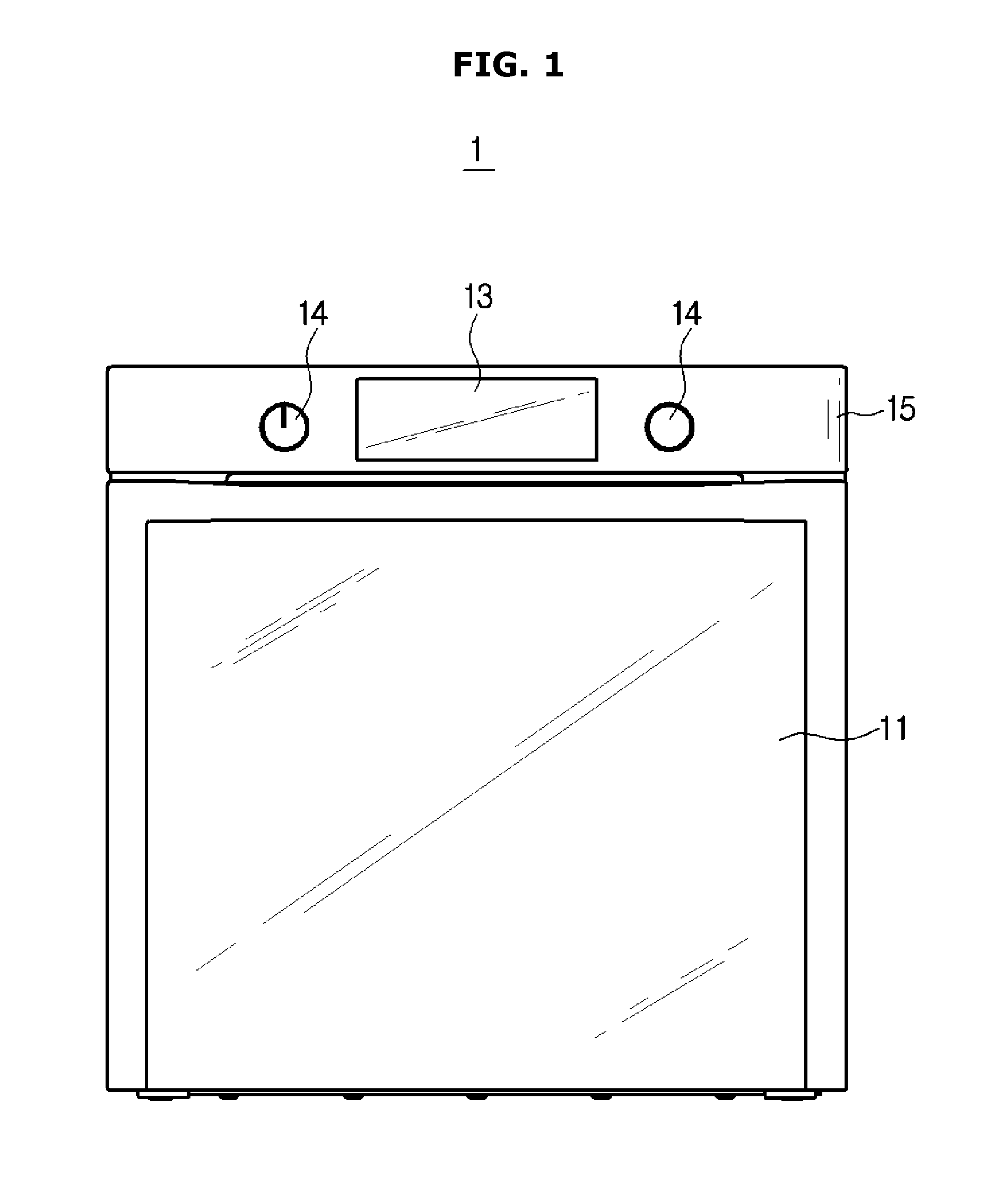

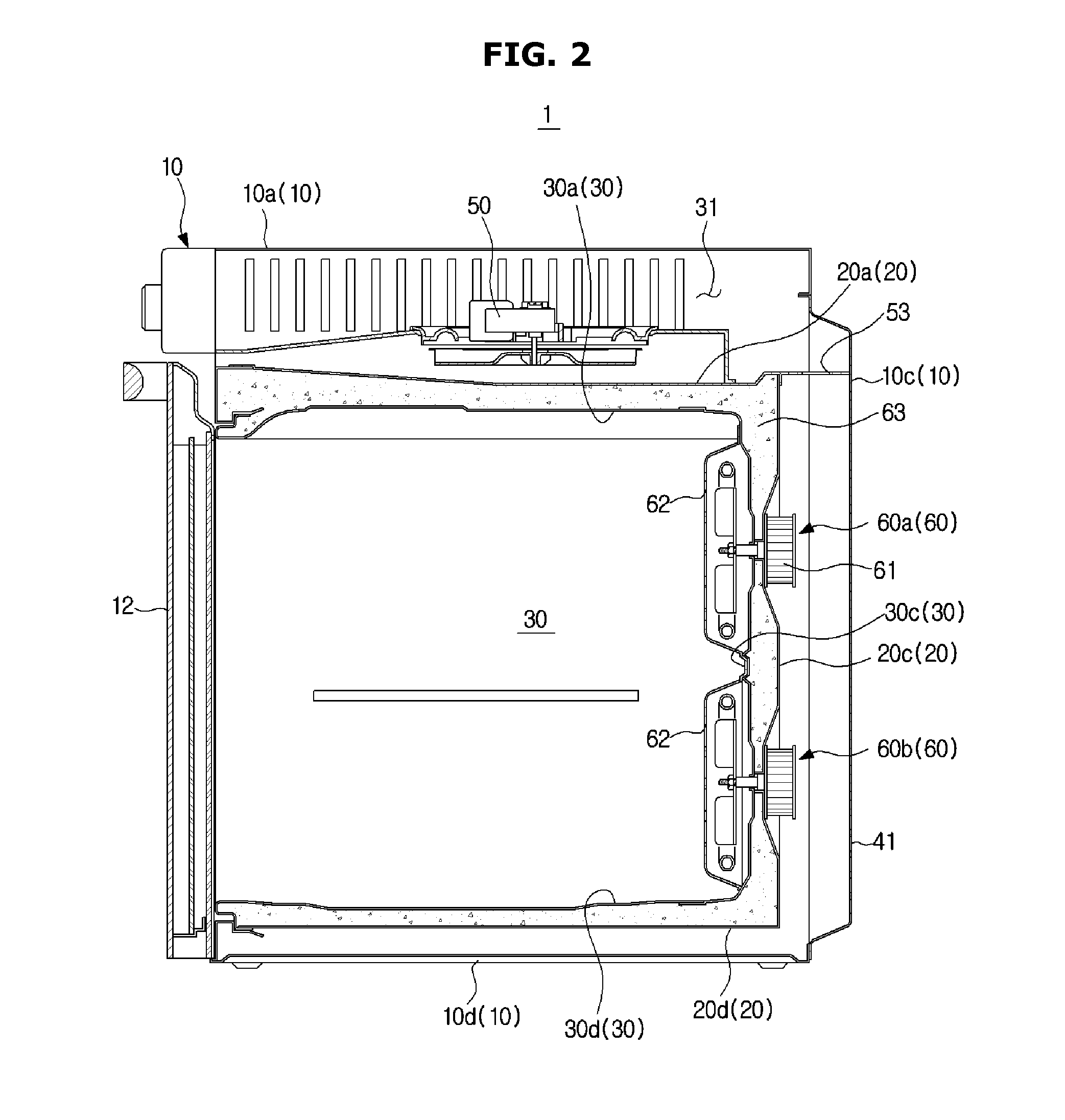

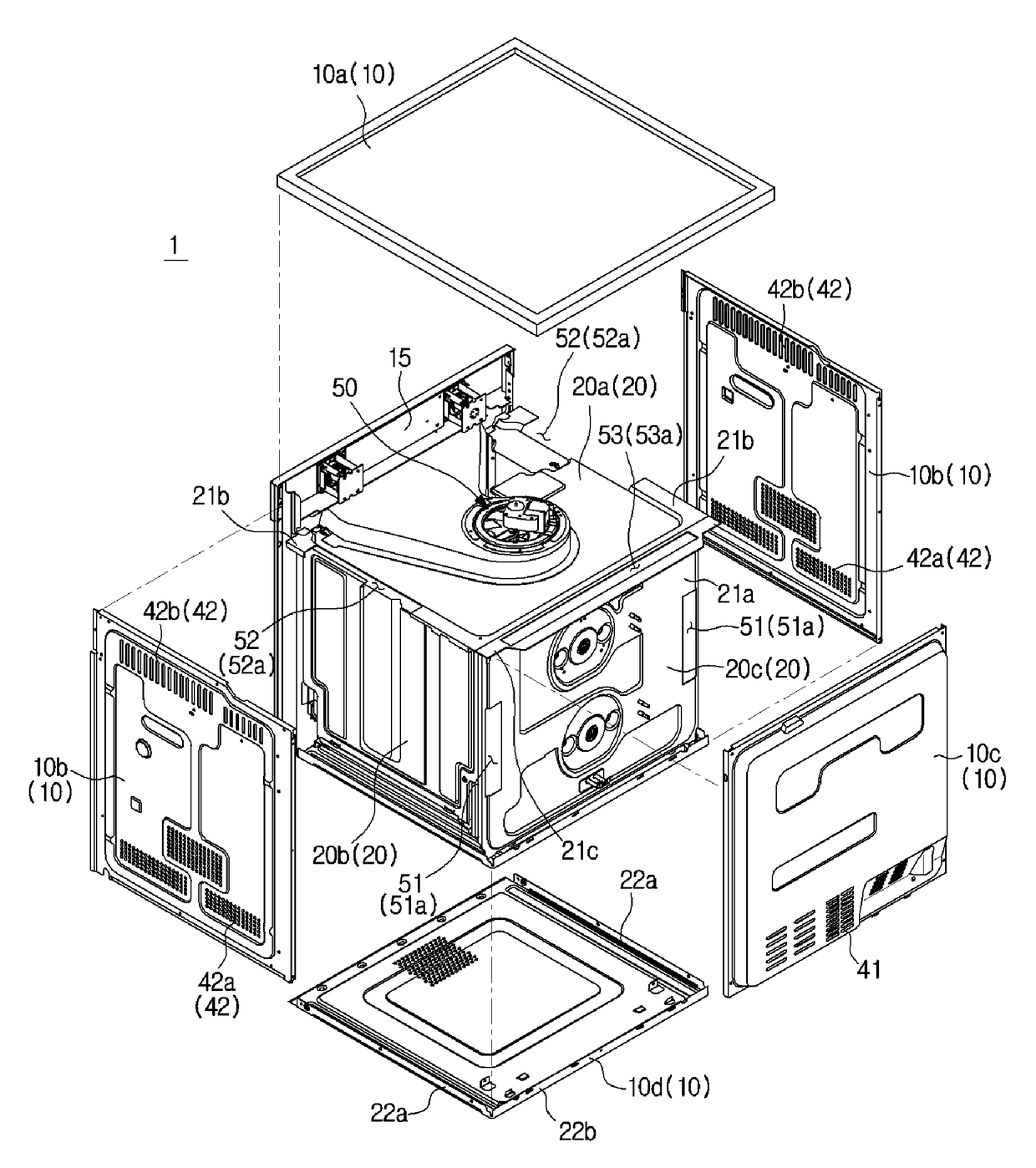

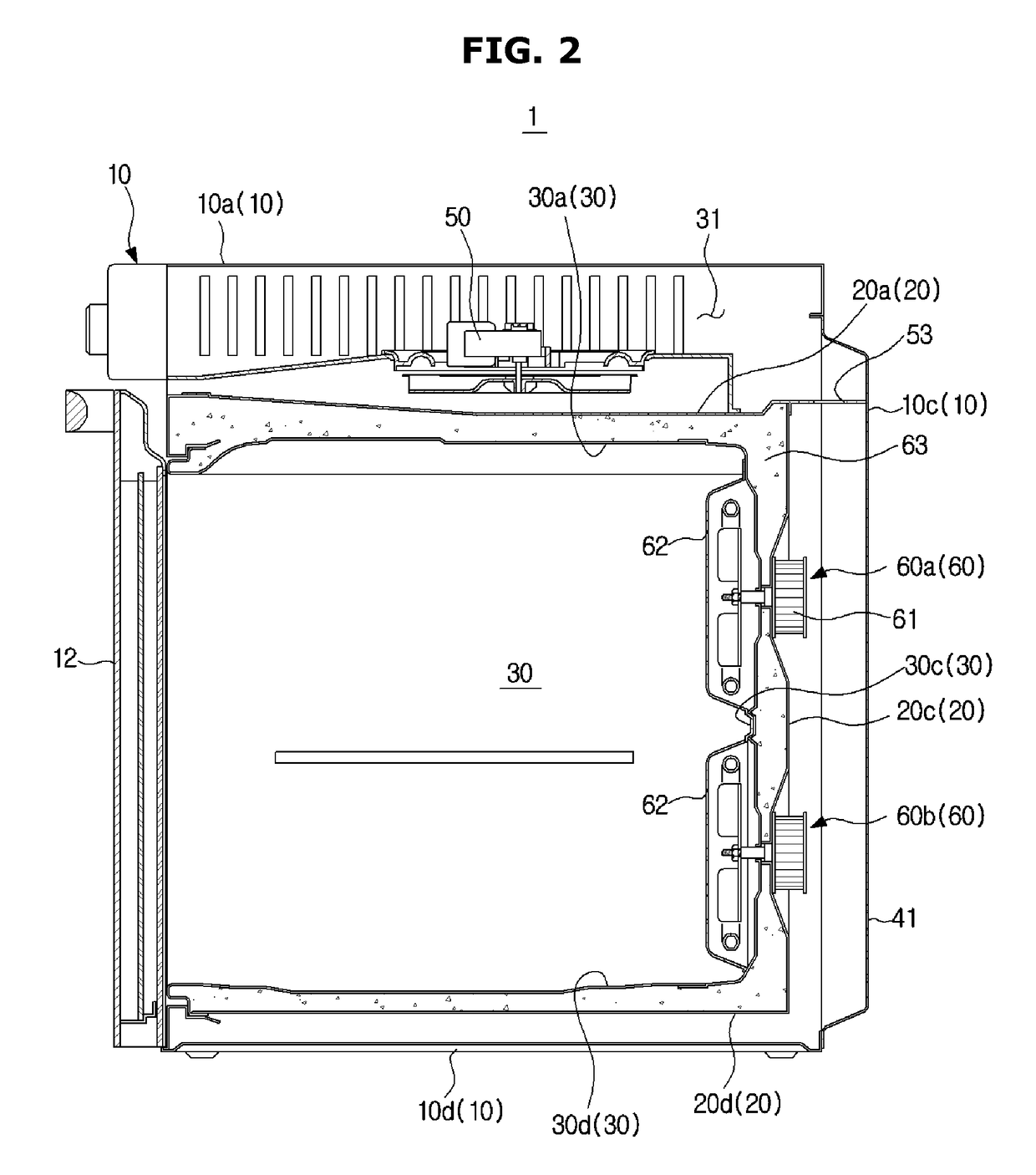

Oven

ActiveUS20160025352A1Increase in sizeOptimize cooling structureStoves/ranges foundationsDomestic stoves or rangesEngineeringBackplane

Owner:SAMSUNG ELECTRONICS CO LTD

Cooling structure for a continuous variation transmission system of an all-terrain vehicle

InactiveUS20050133194A1Optimize cooling structureReduce difficultyCyclesAir-treating devicesExhaust pipeTransmission system

The present invention concerns a cooling structure for a continuous variation transmission system of an all-terrain vehicle. Primarily speaking, it has an inlet conduit attached to the air inlet of the gearbox, with said inlet conduit extending in front of the engine until it reaches the below of the front mud guard, and an inlet box attached to the inlet conduit. An exhaust conduit is also being attached to the exhaust of the gearbox, with said exhaust pipe extending to the rear of the engine until it reaches the below of the rear mud guard, and an exhaust box is attached to the exhaust conduit. Both the inlet box and the exhaust box are placed above the tail of the engine exhaust conduit, and situated on the outer surface of the chassis. The inlet and exhaust box design prevents dust, dirt and water from entering the gearbox. Furthermore, the conduits are installed on the outer surface of the chassis to enable ease of assembly and maintenance, and to reduce the difficulty of installing other components.

Owner:KYMCO

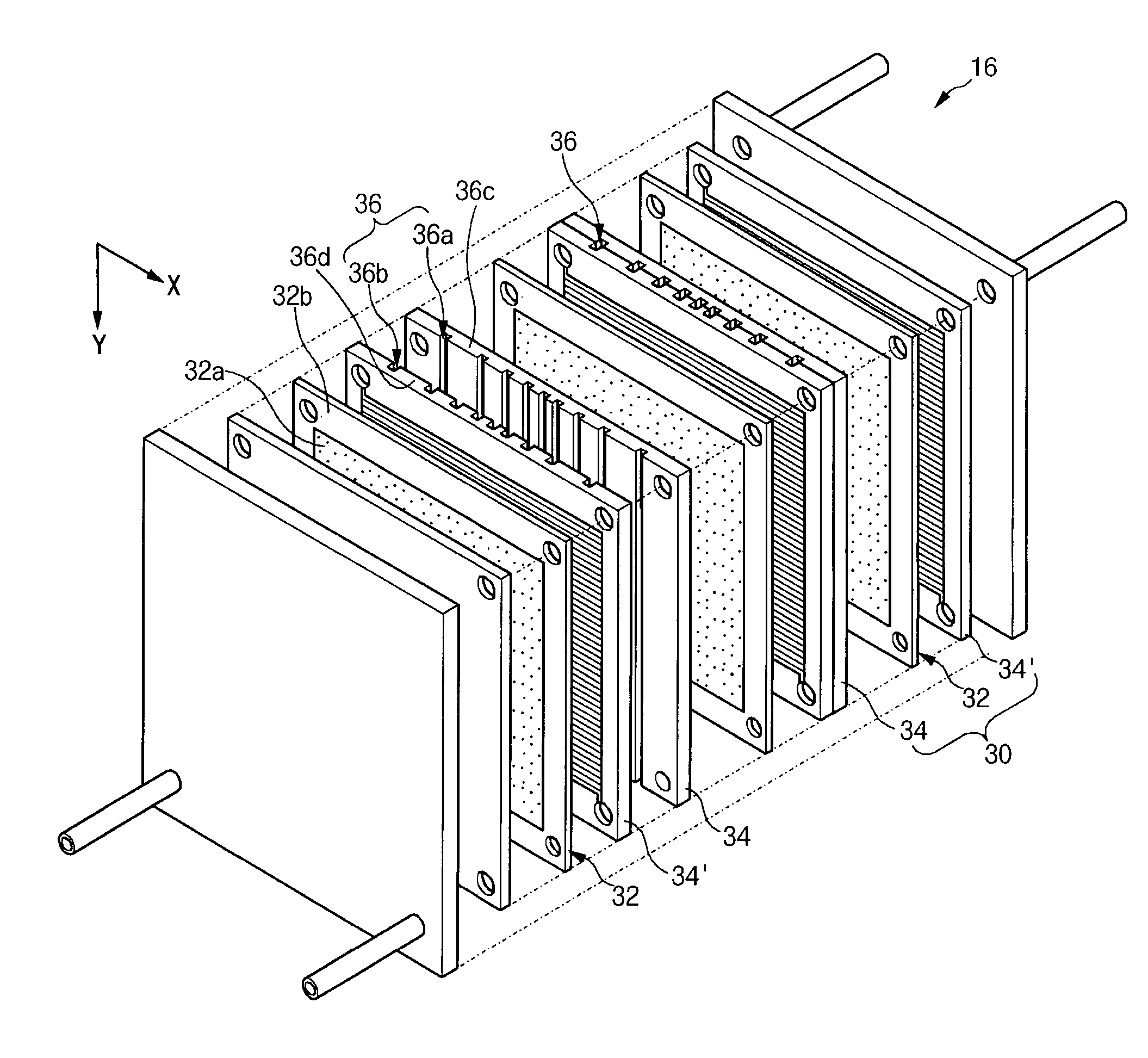

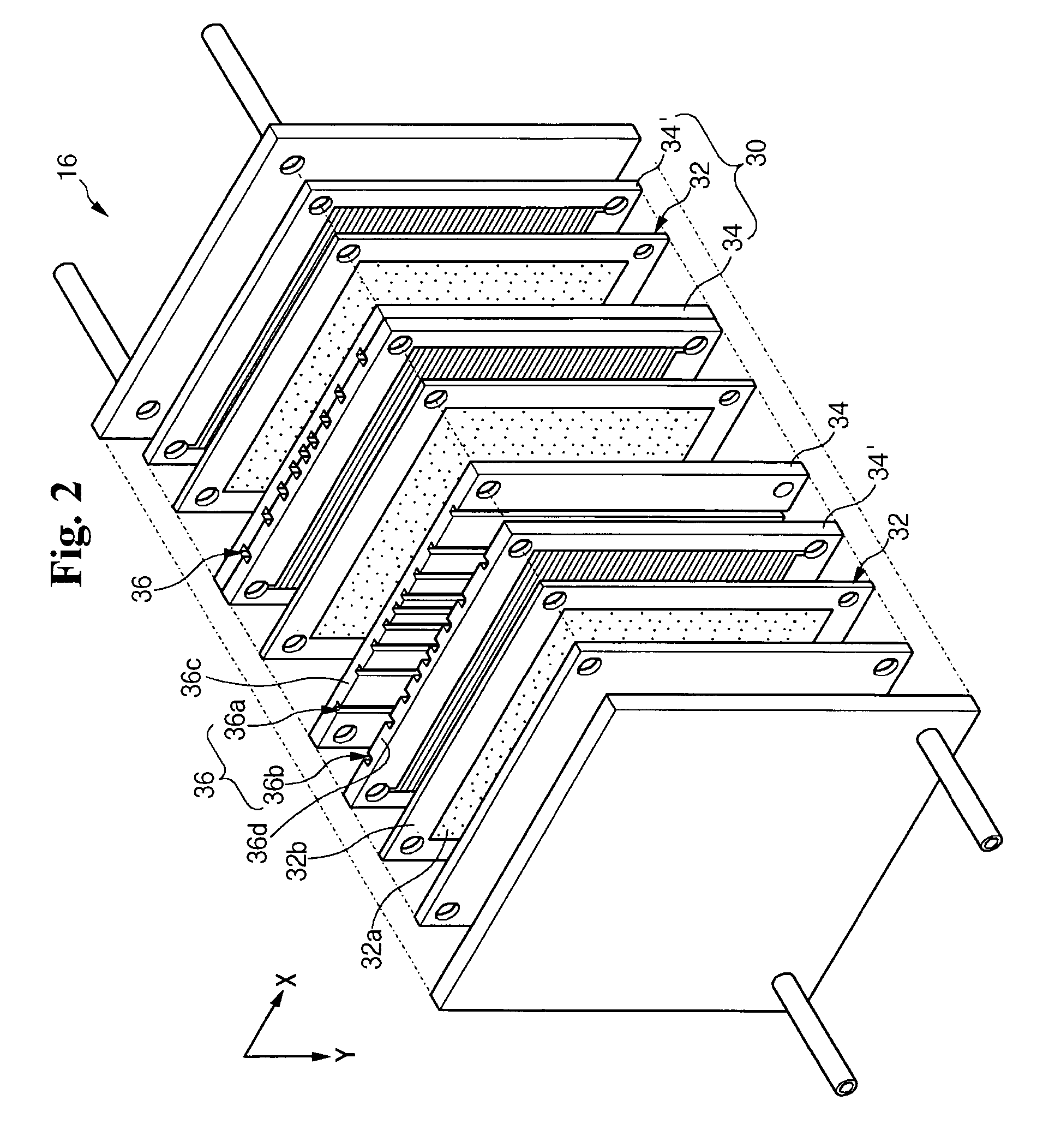

Fuel cell stack having improved cooling structure

InactiveUS20060046118A1Improve cooling efficiencyOptimize cooling structureFuel cell heat exchangeFuel cells groupingElectrochemical responseChannel coupling

A cooling system for a fuel cell stack is provided. The fuel cell stack includes electricity generators generating electric energy through an electrochemical reaction between hydrogen and oxygen, and separators between the electricity generators. It may also contain cooling plates between the electricity generators. Cooling channels including main channels and branch channels coupling the main channels together are formed in the separators or the cooling plates. The intersection of the main and branch cooling channels forms grid-shaped areas with pillars in between that are rectangular, triangular, circular, shaped like a parallelogram, or formed in a combination of these shapes. The cooling channels increase the contact area between the coolant and the separators or the cooling plates and therefore the cooling efficiency of a stack.

Owner:SAMSUNG SDI CO LTD

Oven

ActiveUS10066839B2Increase in sizeOptimize cooling structureStoves/ranges foundationsDomestic stoves or rangesEngineeringWaste management

Owner:SAMSUNG ELECTRONICS CO LTD

Cooling structure for a continuous variation transmission system of an all-terrain vehicle

InactiveUS20080264707A1Optimize cooling structureCyclesCycle equipmentsTransmission systemHeat spreader

A cooling structure for a continuous variation transmission system of an all-terrain vehicle which includes a radiator mounted at a front end of the vehicle and under a front body cover, a hood enclosing the radiator, a gearbox having an inlet and an outlet, the inlet being connected with an inlet conduit for drawing outside cool air into the gearbox, the outlet being connected with an exhaust conduit for discharging hot air from the gearbox, wherein the inlet conduit has an inlet end mounted between the hood and the front body cover and shielded by the hood and the front body cover, whereby the cooling structure can effectively prevent water, dirt and dust from entering the gearbox and are simple in construction and easy to assemble and maintain.

Owner:KYMCO

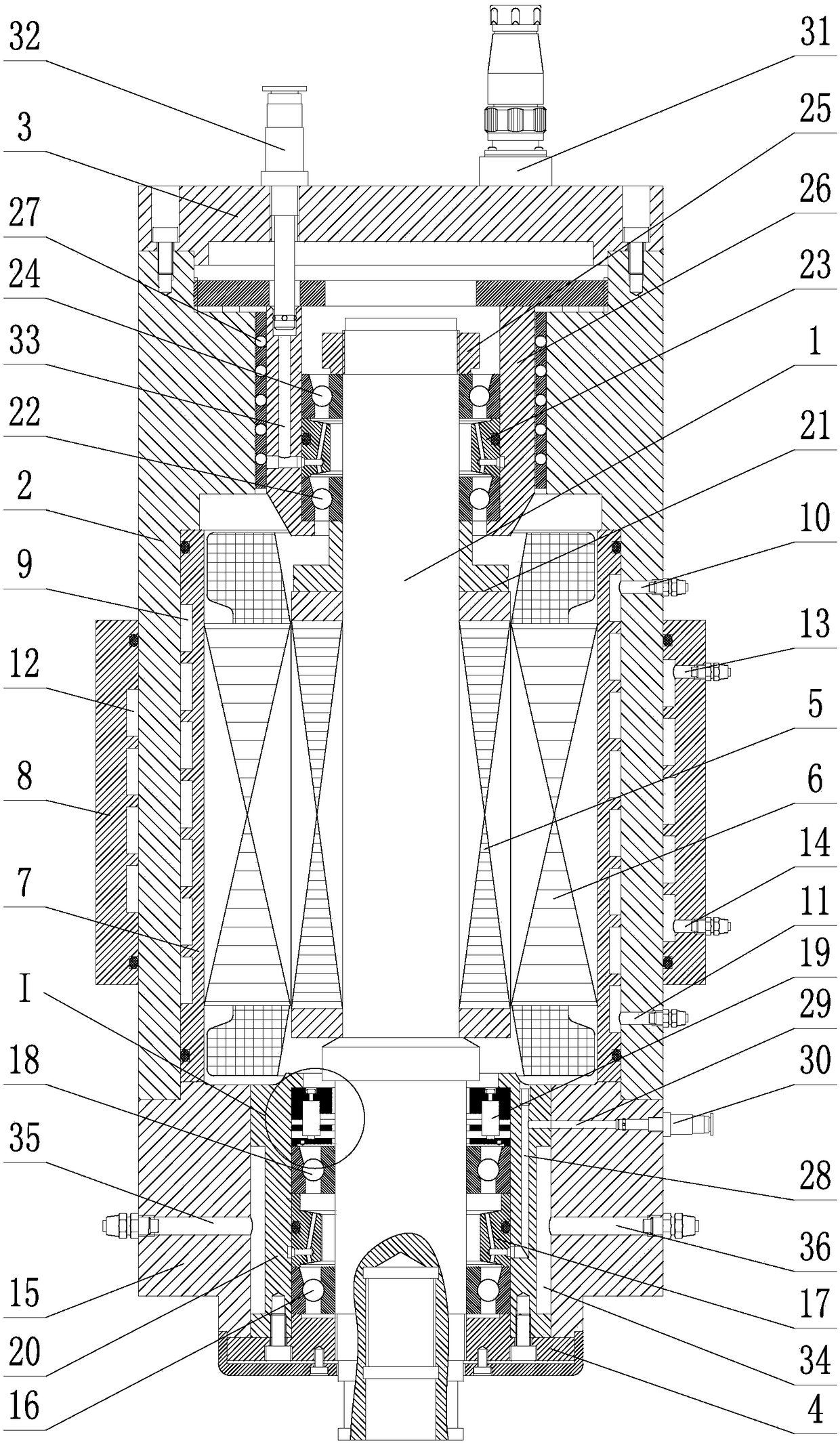

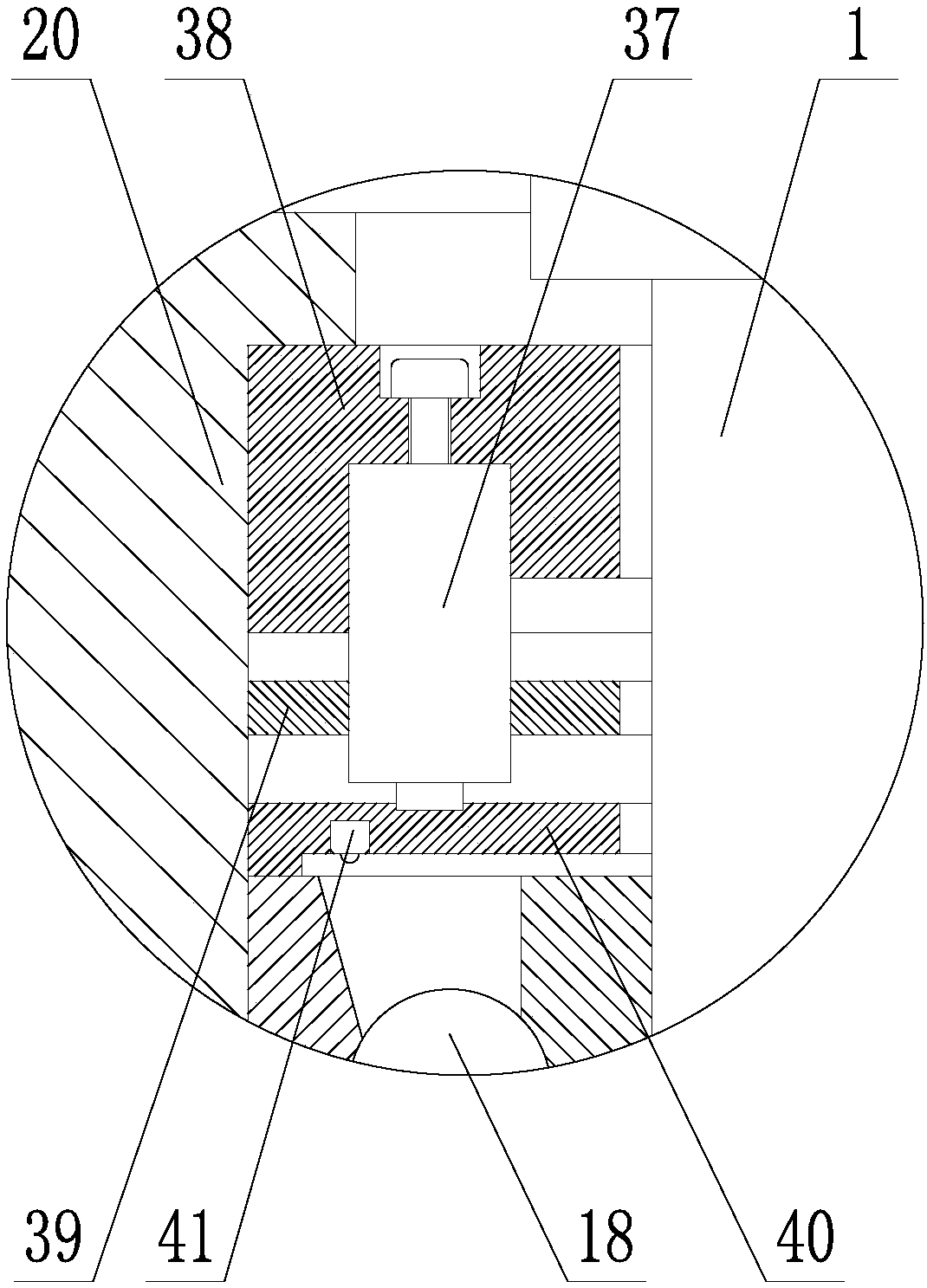

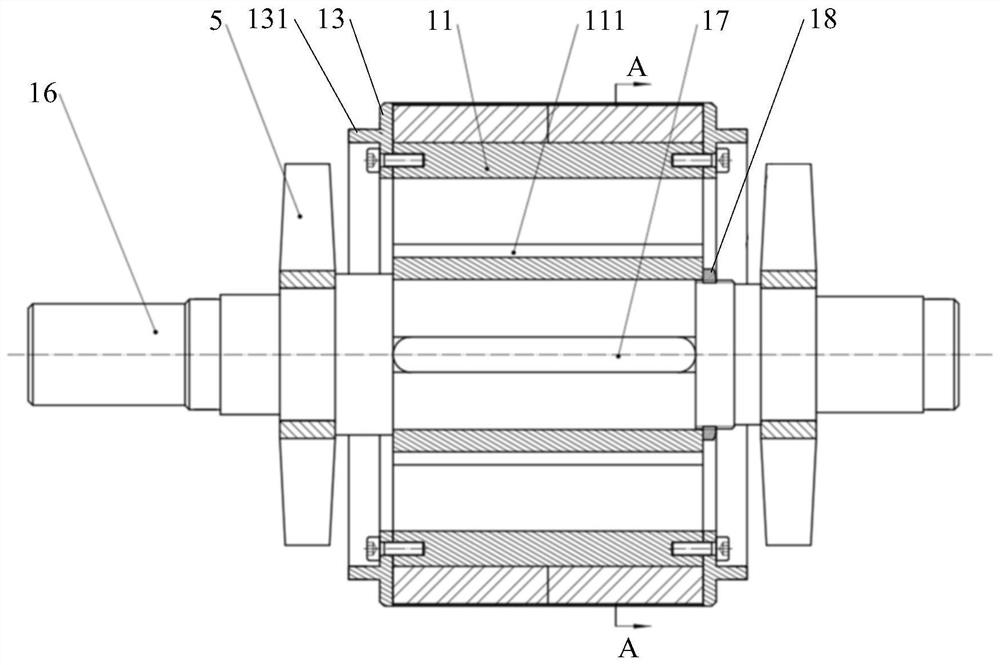

Numerical control grinding machine motorized spindle capable of automatically adjusting bearing pretightening force

PendingCN108247535AGuaranteed support accuracyReduce temperature riseGrinding machine componentsElectricityControl signal

The invention discloses a numerical control grinding machine motorized spindle capable of automatically adjusting bearing pretightening force. Specific to loss heating of a stator and a rotor of a motorized spindle, a dual water cold structure is designed; through two layers of cooling water sets at inside and outside of the shell body, the high-efficient radiation of a rotor is realized, the influence of the heating high temperature of the stator and the rotor on the spindle and the bearing is reduced; specific to the friction heating of the bearing itself, an outer bearing ring fixing sleeveis designed to be a cooling water sleeve structure; the high-efficient radiation of the bearing is realized through the bearing outer ring fixing sleeve with water cooling function, and then the bearing is efficiently lubricated to reduce the thermal deformation of the bearing; however, the cooling and lubricating effects can be reduced under the condition of higher rotate speed, thus the bearingmust be applied with proper pretightening force to counteract the thermal deformation; firstly, the bearing temperature is monitored in real time through a temperature sensor of an automatic bearingpretightening force adjusting mechanism, and the monitored bearing temperature data is fed back to a grinding machine numerical control system, and a control signal is output through the grinding machine numerical control system; thus elongation of a piezoelectric ceramic pillar is changed to generate proper pretightening force of the bearing.

Owner:SHENYANG JIANZHU UNIVERSITY +1

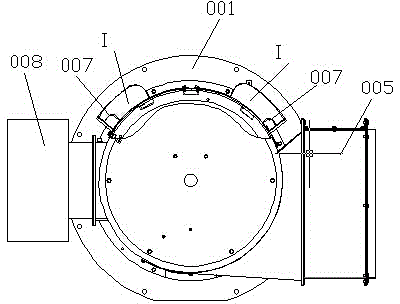

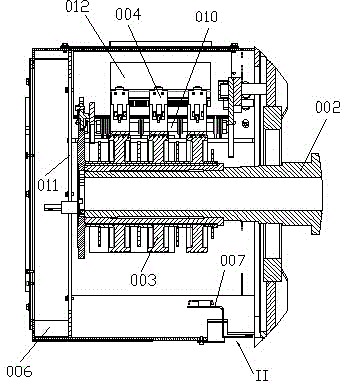

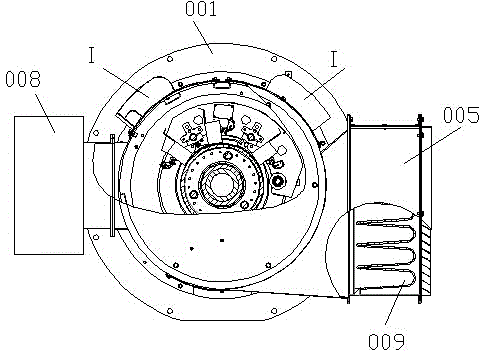

Multi-air path-structure collector ring ventilating and cooling device of doubly-fed wind generator

InactiveCN104578598AOptimize cooling structureCool evenlyCooling/ventillation arrangementEngineeringCentrifugal fan

The invention discloses a multi-air path-structure collector ring ventilating and cooling device of a doubly-fed wind generator, relates to equipment for ventilating and cooling a doubly-fed wind generator collector ring and removing carbon powder. The multi-air path-structure collector ring ventilating and cooling device comprises a cylindrical hood, wherein at least one group of symmetrical air inlets are formed in the side wall of the upper end of the hood; an air inlet is formed in the bottom of the hood; a circular arc-shaped bent deflector plate is arranged inside each air inlet to divide each air inlet into two air paths; positions of deflector plates in the air inlets in the upper end of the hood are correspondingly regulated according to the number of carbon brushes and the arrangement way of the carbon brushes; the deflector plate in the air inlet in the bottom of the hood guides one air path into the end surface of a centrifugal fan, and vertically guides the other air path to the top end of the hood. The multi-air path-structure collector ring ventilating and cooling device reduces the fault probability effectively, improves the running reliability of the doubly-fed wind generator, and reduces the maintenance cost of the generator.

Owner:宜兴华永电机有限公司

Self-tensioning modular panels

InactiveUS20170191262A1Reducing evaporation lossReduce energy lossPhotovoltaic supportsSolar heating energyFall protectionModularity

An innovative, low-density, highly-insulating modular panel for use in many applications and industries. The panel has a frame that may be preformed or bent and may be made of rigid or flexible material, and a panel covering comprising at least one pocket of thin, low-density shade fabric that has the capability of sufficiently stretching to surround the frame when the pocket is pulled onto it. The pocket may be then secured, along any previously open end where the frame was inserted, by various fastening devices. The panel covering pocket may have additional features added, as described herein. The panel is durable and cost-effective, and has good solar-control and insulating qualities. It is also a windbreak panel, a noise-reduction panel, an impact protection panel, a water-resistant panel, a fall protection panel, and a pollution-control panel. Two or more panels can be joined to create a structure-protecting panel assembly or system.

Owner:FORBIS JACK R +1

Copper plate polishing temperature on-line detection device

PendingCN107621312AQuick responseImprove timelinessThermometer detailsRadiation pyrometryWireless transmissionCopper

The present invention discloses a copper plate polishing temperature on-line detection device which comprises a copper plate, temperature sensors, a wireless data acquisition system and a display screen. The temperature sensors are distributed on the copper plate to measure the temperatures of different positions at the copper plate. The display screen displays the temperatures of different positions at the copper plate. The real-time online monitoring of the temperature of the copper plate in a processing process can be carried out, the copper plate surface temperature in a large size copperplate polishing process is accurately measured, the distribution law of the copper plate surface temperature is obtained, the device has an important meaning for controlling copper polishing surface shape precision and improving surface shape precision of a thin-plate part, and a cooling structure is optimized by the distribution law. The wireless data acquisition system comprises an acquisition module, a wireless transmission module and a wireless signal receiving module, and the copper plate polishing processing is not affected by the setting of the detection device by using wireless transmission.

Owner:HUAQIAO UNIVERSITY

Electronic apparatus, fan unit, and subrack

InactiveUS8292705B2Optimize cooling structureImprove accommodationDigital data processing detailsMechanical energy handlingEngineeringElectronic equipment

Owner:NEC CORP

Battery pack with cooling passage

ActiveUS9166262B2Optimize cooling structureEffectively and evenly cooledCell temperature controlCells cooling/heatingEngineeringCooling channel

A battery pack includes battery modules each having a battery cell and a battery case housing the battery cell therein. The battery modules are stacked in a stacking direction so that a cooling passage for allowing a cooling medium to flow is defined between opposed surfaces of adjacent battery cases. One of the opposed surfaces has first ribs projecting toward the other of the opposed surfaces and extending parallel to each other along the one. The other of the opposed surfaces has second ribs projecting toward the one of the opposed surfaces and extending parallel to each other along the other. In the cooling passage, the first ribs and the second ribs intersect each other and end portions of the first ribs and end portions of the second ribs are in contact with each other in the stacking direction.

Owner:DENSO CORP

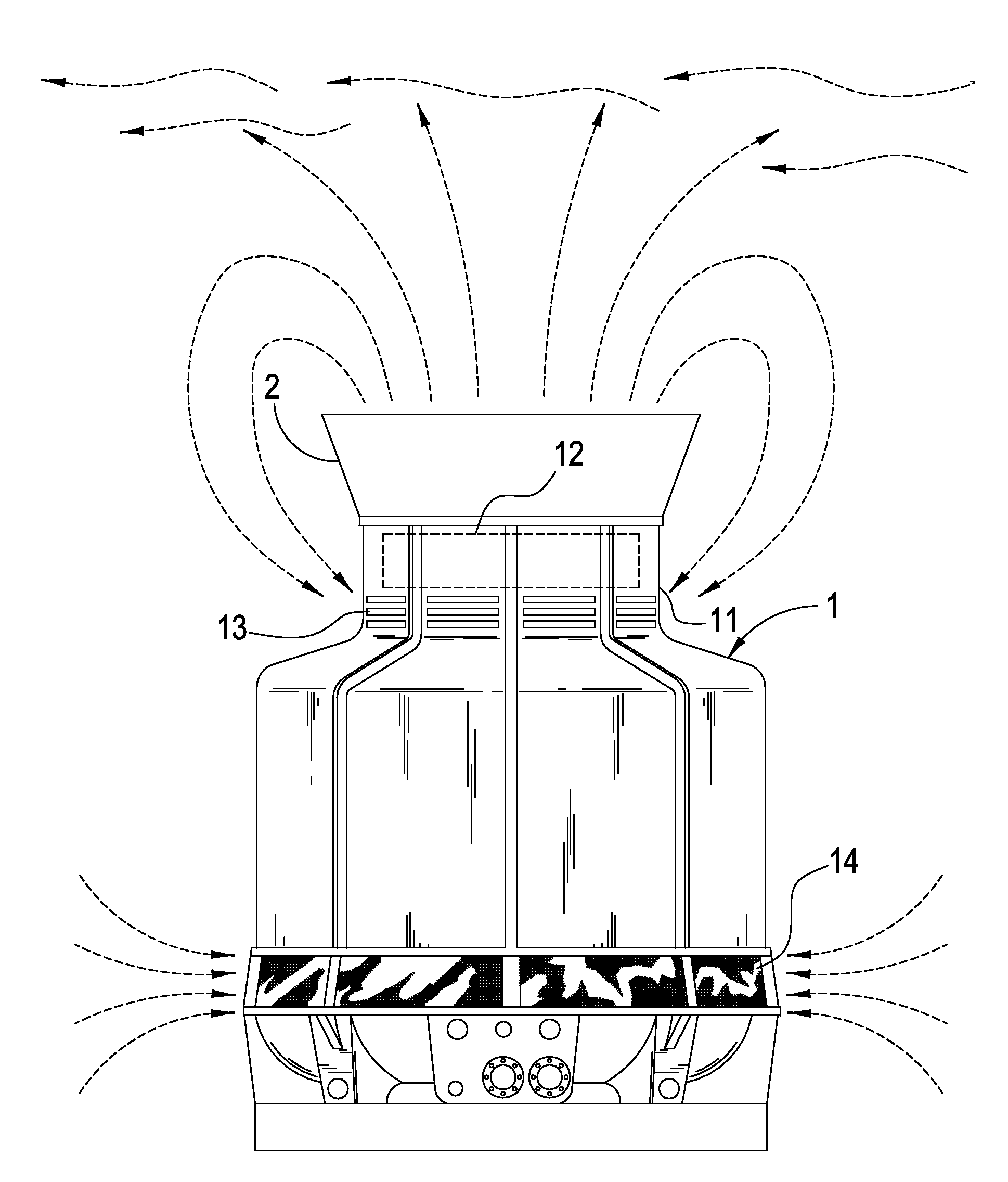

Set-top box and display apparatus having discrete-type card portion, and card portion-mounting methods thereof

InactiveUS20160119668A1Improve approachEasy maintenanceTelevision system detailsAnalogue secracy/subscription systemsComputer scienceSet top box

Disclosed are a set-top box and display apparatus having a discrete-type card portion and card portion-mounting methods thereof, in which the card portion with a card such as a cable card for descrambling a scrambled signal is readily detached and attached from the outside. The set-top box includes: a signal receiver configured to receive a scrambled signal; a card portion configured to include a card slot portion to which a cable card for descrambling the received scrambled signal is mountable; a substrate configured to include the signal receiver and electrically connect with the card portion; and a housing configured to support and surround the substrate, the housing including a first opening formed on a surface parallel with the substrate, and the card slot portion of the card portion being disposed to face the substrate with the first opening of the housing therebetween.

Owner:SAMSUNG ELECTRONICS CO LTD

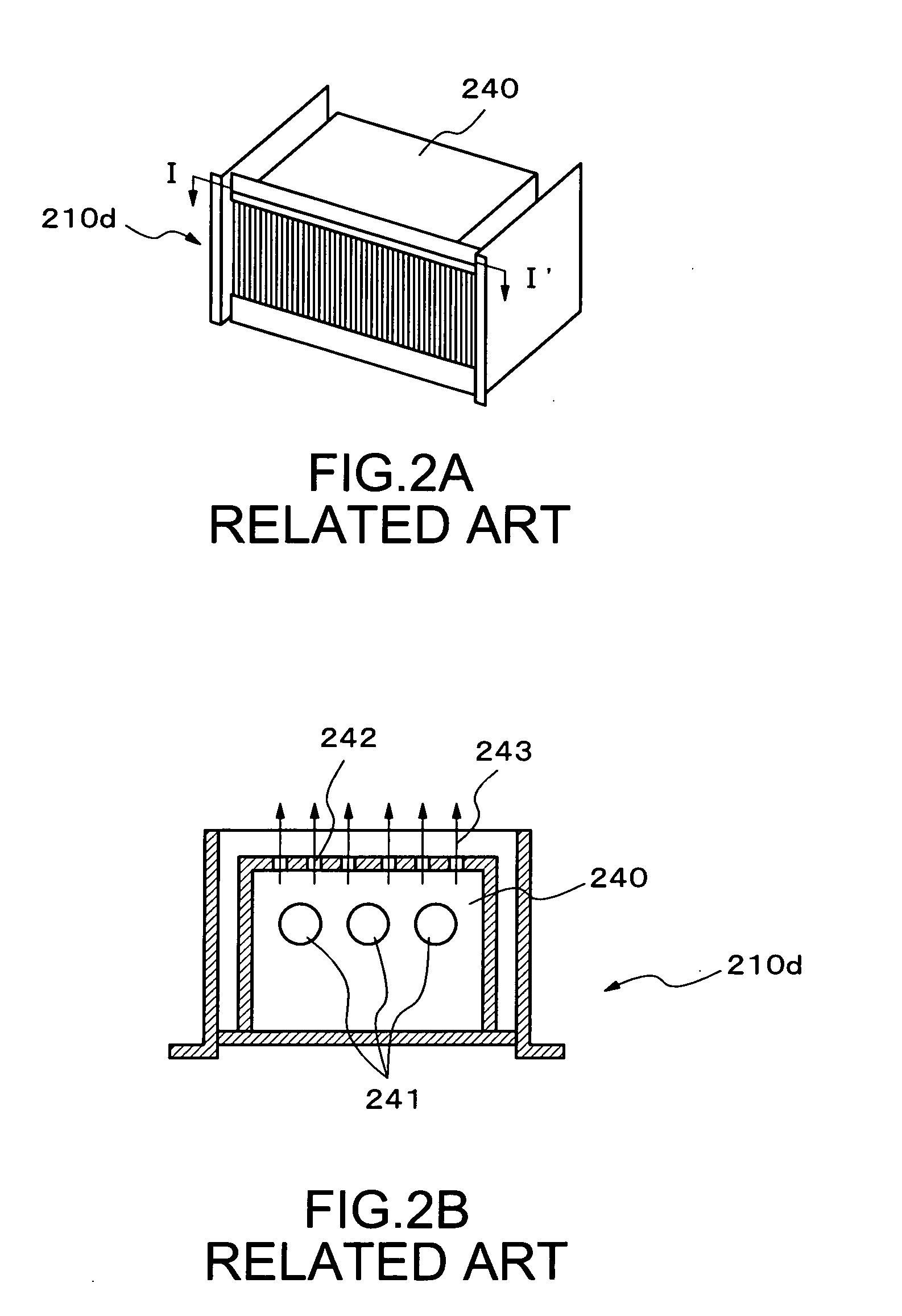

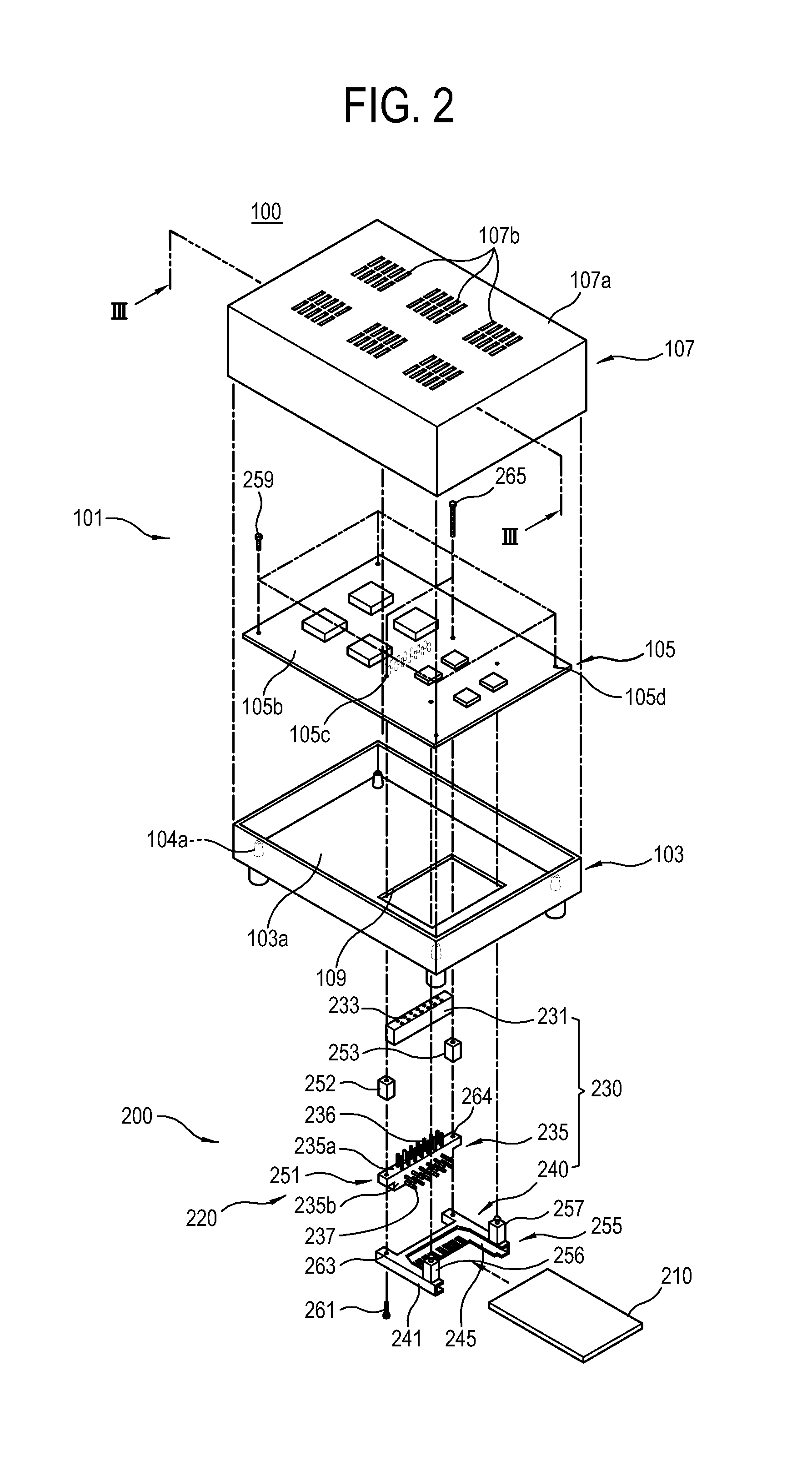

Structure of cooling tower

InactiveUS20090321968A1Simple structureImprove efficiencyCarburetting airUsing liquid separation agentCold airCooling tower

An improved structure of cooling tower includes a fan housing with a fan disposed therein, induction openings distributed on the fan housing and located below the fan, and a diffuser stack disposed at one end surface of the fan housing. In operation, cold air is drawn into the cooling tower by the fan through inlet openings of the cooling tower so as to exchange heat with the condensing water within a water chiller. When warm and wet air is drawn out of the cooling tower and the warm and wet air outside the cooling tower is induced in through the induction openings and then is drawn out, circulation reflux of warm and wet air, which tends to occur in conventional cooling towers, can be avoided and therefore increase the efficiency of the water chiller.

Owner:NAT TAIPEI UNIV OF TECH

Head chip for ink jet type image forming apparatus

InactiveUS8500232B2Optimize cooling structureAvoid overall overheatingOther printing apparatusEngineeringRefrigerant

Owner:HEWLETT PACKARD DEV CO LP

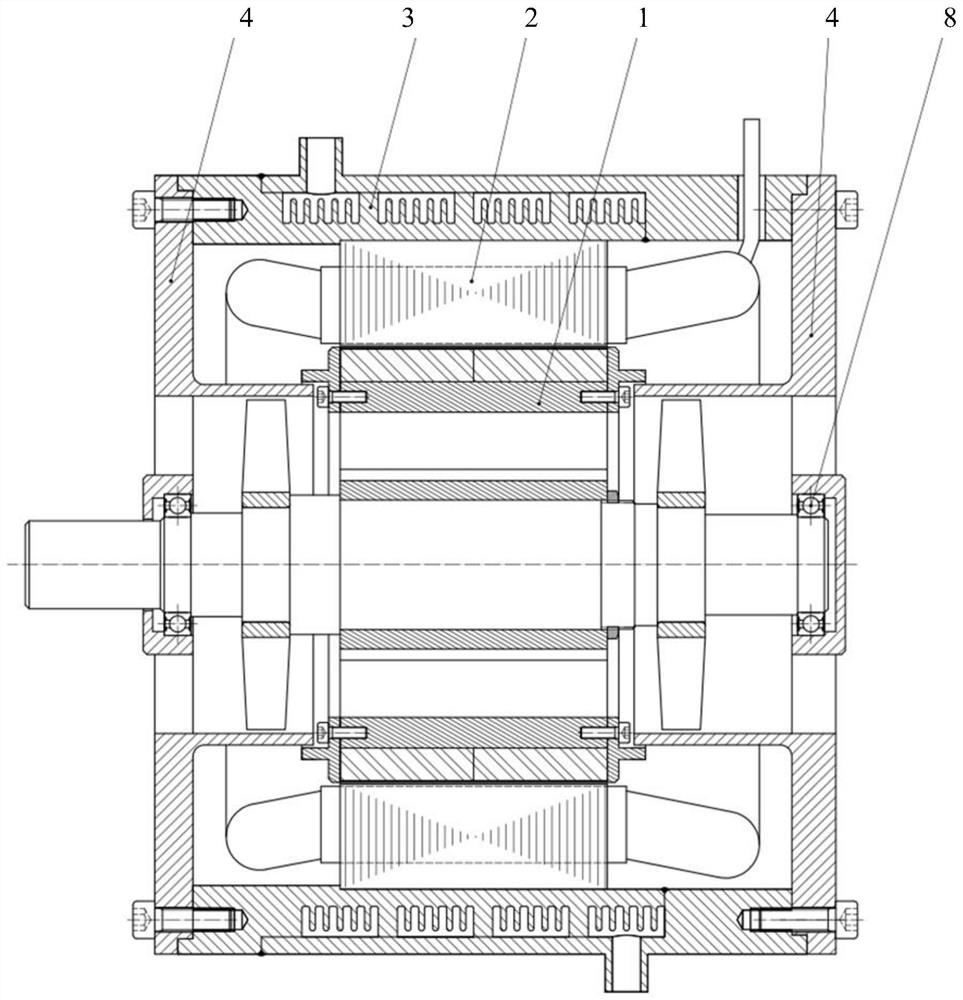

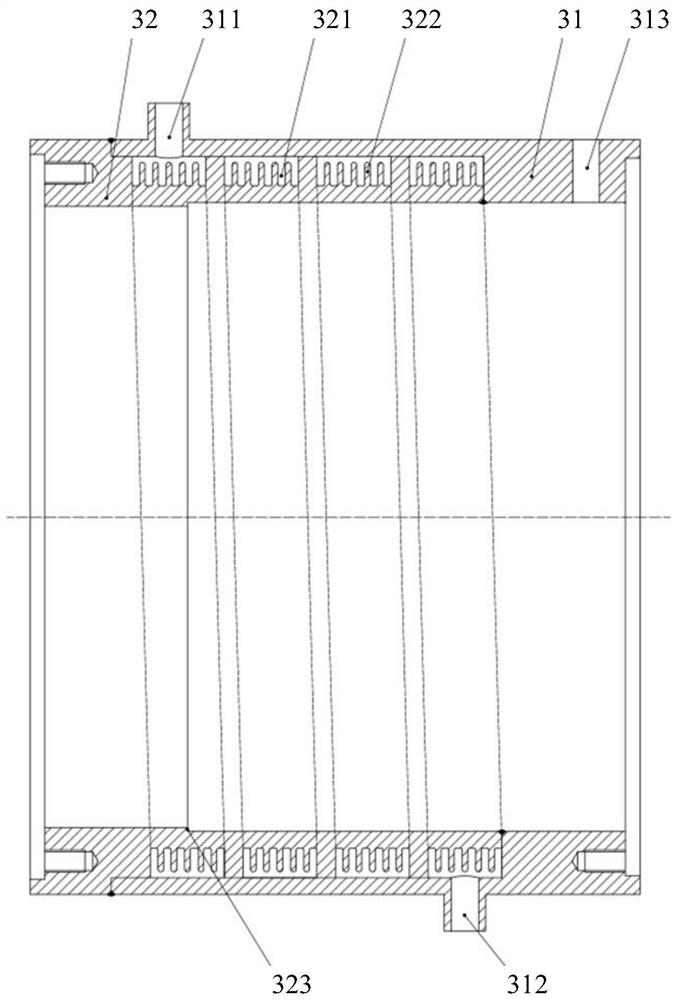

Motor with cooling structure

InactiveCN112117858AAdd cooling structureOptimize cooling structureMagnetic circuit rotating partsMagnetic circuit stationary partsElectric machineCooling effect

The invention discloses a motor with a cooling structure, which comprises a rotor, a stator, a casing and two end covers respectively arranged at two ends of the casing. The structure further comprises a cooling channel arranged in the side wall of the casing, and the casing is provided with a medium inlet and a medium outlet which are respectively communicated with the cooling channel; an axial fan is fixedly connected with the rotor, wherein the rotor is provided with an axial air duct, and the two end covers are respectively provided with a ventilation opening. According to the motor, a stator cooling structure is formed through the cooling channel to realize stator cooling; a rotor cooling structure is formed through the cooperation of the axial flow fan, the axial channel and the ventilation opening, and therfore the cooling of the rotor is realized; in other words, the overall cooling of the motor is realized through the combination of the stator cooling structure and the rotor cooling structure. Compared with the prior art, the motor disclosed in the invention is advantageous in that the stator cooling structure is added, and the rotor cooling structure is improved, so thatthe overall cooling effect of the motor is good, and the cooling efficiency is high.

Owner:卧龙电气(上海)中央研究院有限公司 +2

Fuel cell stack having improved cooling structure

InactiveUS7879504B2Improve efficiencyImprove performanceFuel cell heat exchangeFuel cells groupingElectrochemical responseElectricity

Owner:SAMSUNG SDI CO LTD

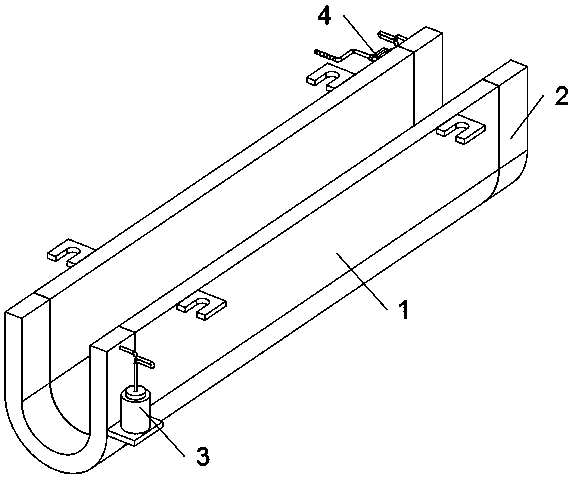

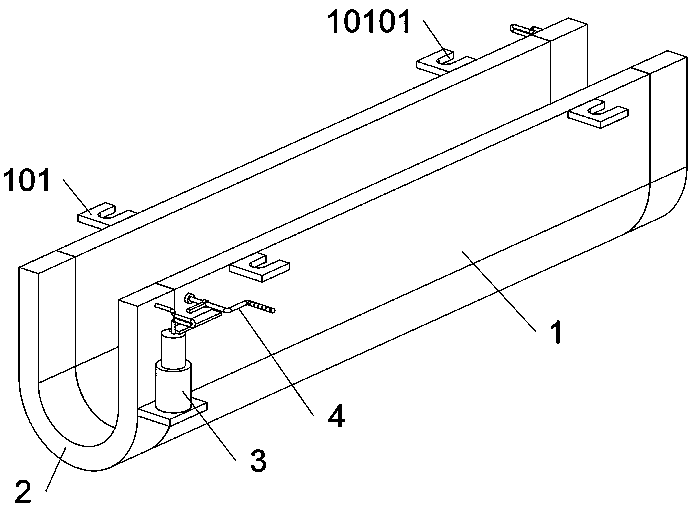

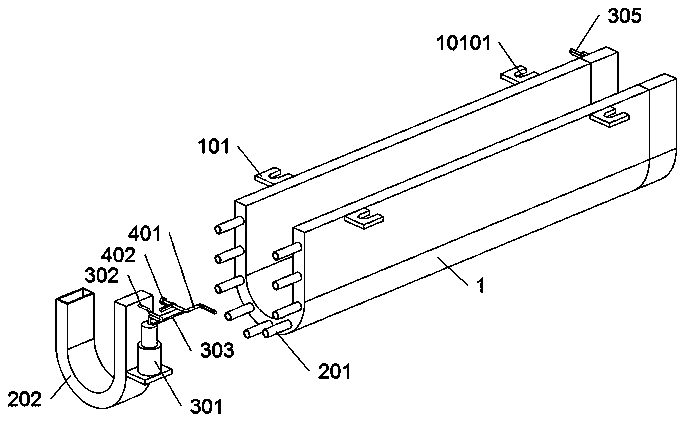

Molten aluminum chute with balanced temperature gradient

PendingCN111380360AExchangeImprove cooling uniformityCharge manipulationHandling discharged materialThermodynamicsGas cylinder

The invention provides a molten aluminum chute with balanced temperature gradient, and relates to the field of cast-rolled aluminum. The problems that cooling pipes are not uniformly distributed enough, cooling is one-sided and the efficiency is low, cooling gas in the cooling pipes is locally heated in the cooling process, and flowing and mixing of the gas cannot be realized in the cooling process, and the chute can be disassembled and taken out only by completely disassembling a plurality of fixing bolts during disassembly, maintenance or replacement are solved; the molten aluminum chute with balanced temperature gradient comprises a chute main body, and a cooling structure is mounted on the chute main body. Due to the fact that the initial state of an elastic gas cylinder is an extension state, and the initial state of the gas cylinder is a compression state, and when the elastic gas cylinder is extruded, the cooling gas in a connecting base and the cooling pipes is in a motion mixing state, so that the cooling efficiency can be improved; due to the fact that the length of a poke rod is larger than the distance between a rocker arm and a stress plate, when the rocker arm is continuously rotated, the elastic gas cylinder is in a continuous extrusion state at the moment, and gas exchange in the cooling pipes is achieved.

Owner:贵州莹月帆铝制品有限公司

Battery Module

PendingCN112582727AOptimize cooling structureAvoid overall overheatingBattery isolationSecondary cellsThermodynamicsEngineering

The present invention provides a battery module including: a pair of battery groups in which a plurality of battery cells are stacked; a first heat exchanger disposed between the pair of battery groups to perform heat exchange with first stacked surfaces of the pair of battery groups; and a pair of second heat exchangers disposed outside the pair of battery groups to perform heat exchange with second stacked surfaces which are sides opposite to the first stacked surfaces.

Owner:SK ON CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com