Molten aluminum chute with balanced temperature gradient

A temperature gradient and chute technology, applied in the field of cast-rolled aluminum, can solve the problems of low cooling efficiency, cumbersome disassembly, and uneven distribution of cooling pipes, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

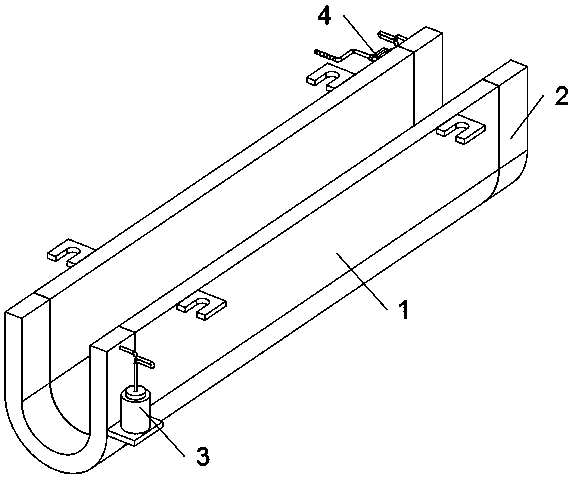

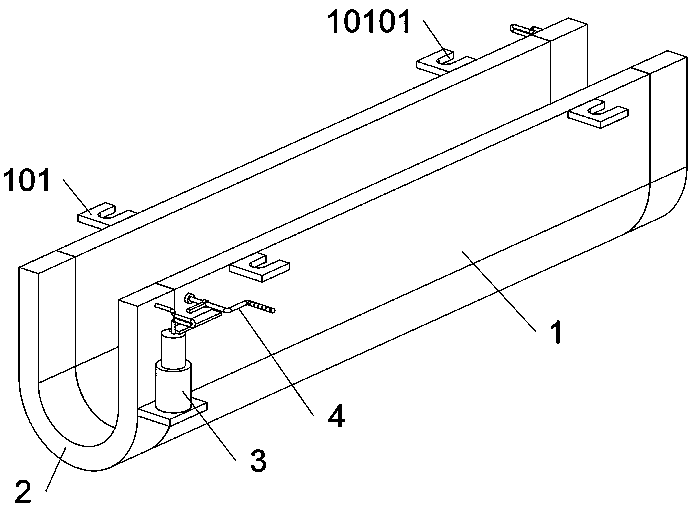

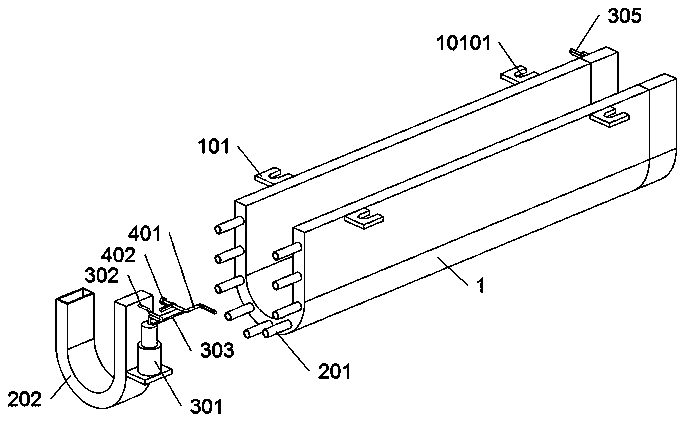

[0027] as attached figure 1 to the attached Figure 5 shown:

[0028] The present invention provides an aluminum liquid chute with balanced temperature gradient, comprising a chute main body 1; a cooling structure 2 is installed on the chute main body 1, a ventilation structure 3 is installed on the cooling structure 2, and a driving structure is also installed on the chute main body 1 4.

[0029] refer to as Figure 4 , the chute main body 1 has a U-shaped structure, and four fixing seats 101 are installed on the chute main body 1; The directions are the same, so that the disassembly of the chute main body 1 can be completed without unscrewing all the fixing bolts during disassembly, which improves the convenience of disassembling the chute main body 1 .

[0030] refer to as image 3 , the cooling structure 2 includes a cooling pipe 201 and a connecting seat 202. The cooling pipe 201 is inserted into the chute main body 1, and a connecting seat 202 is installed at the he...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com