Copper plate polishing temperature on-line detection device

A detection device and copper plate technology, which is applied to measuring devices, thermometers, electrical devices, etc., can solve the problems of uneven surface temperature of large-sized copper plates, difficult to control the surface shape accuracy of large-sized copper plates, etc., achieving high timeliness, Fast response time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

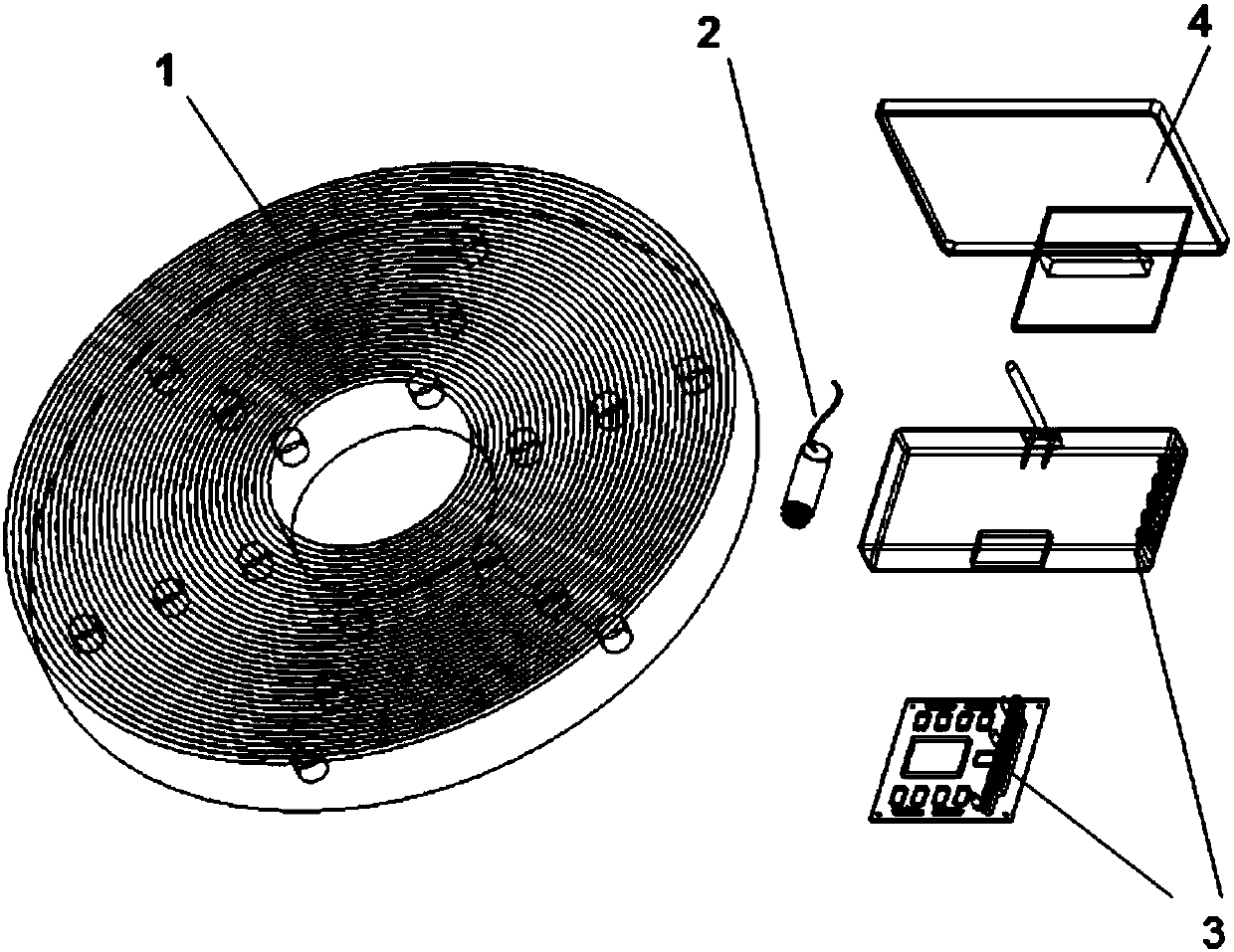

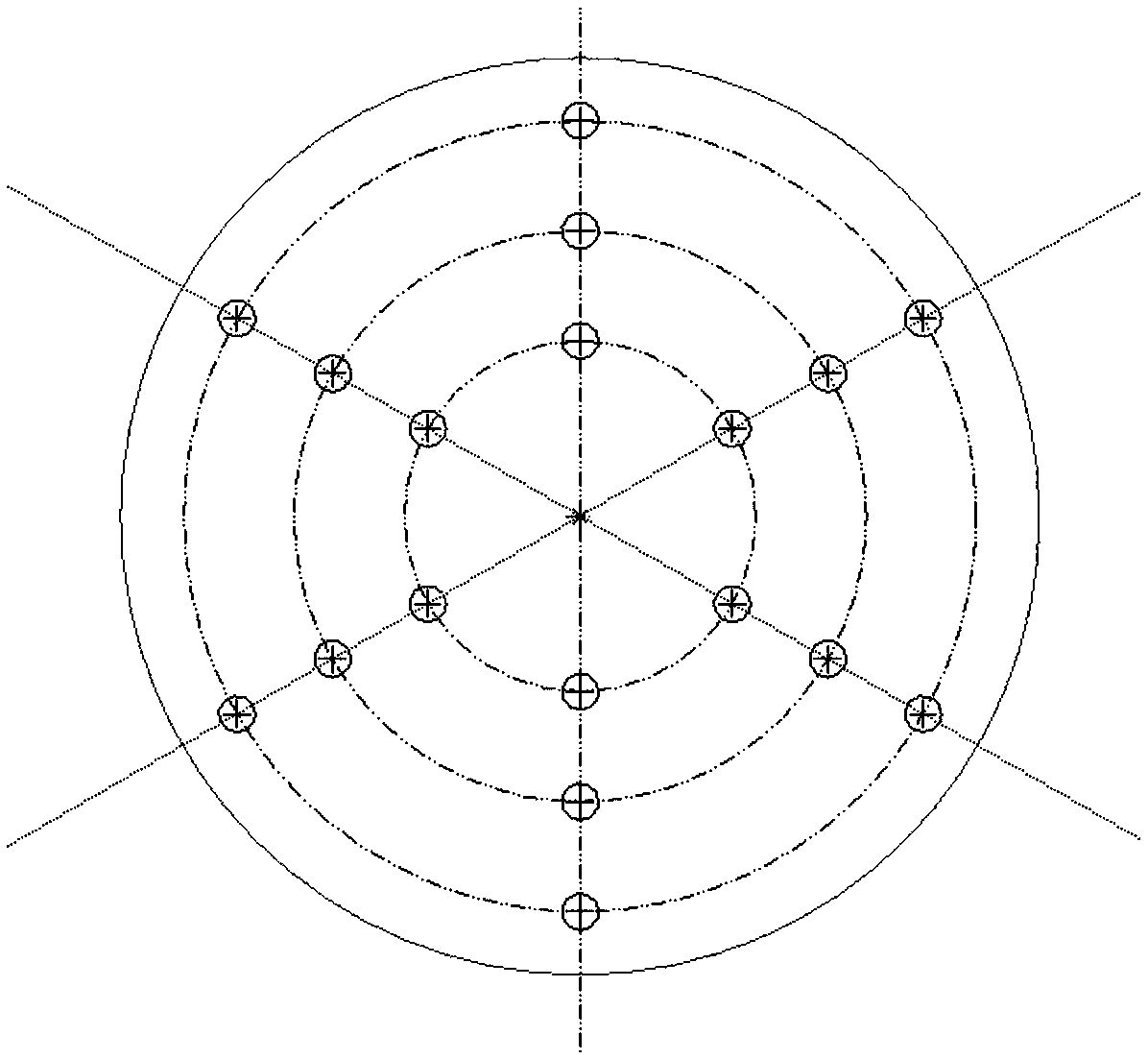

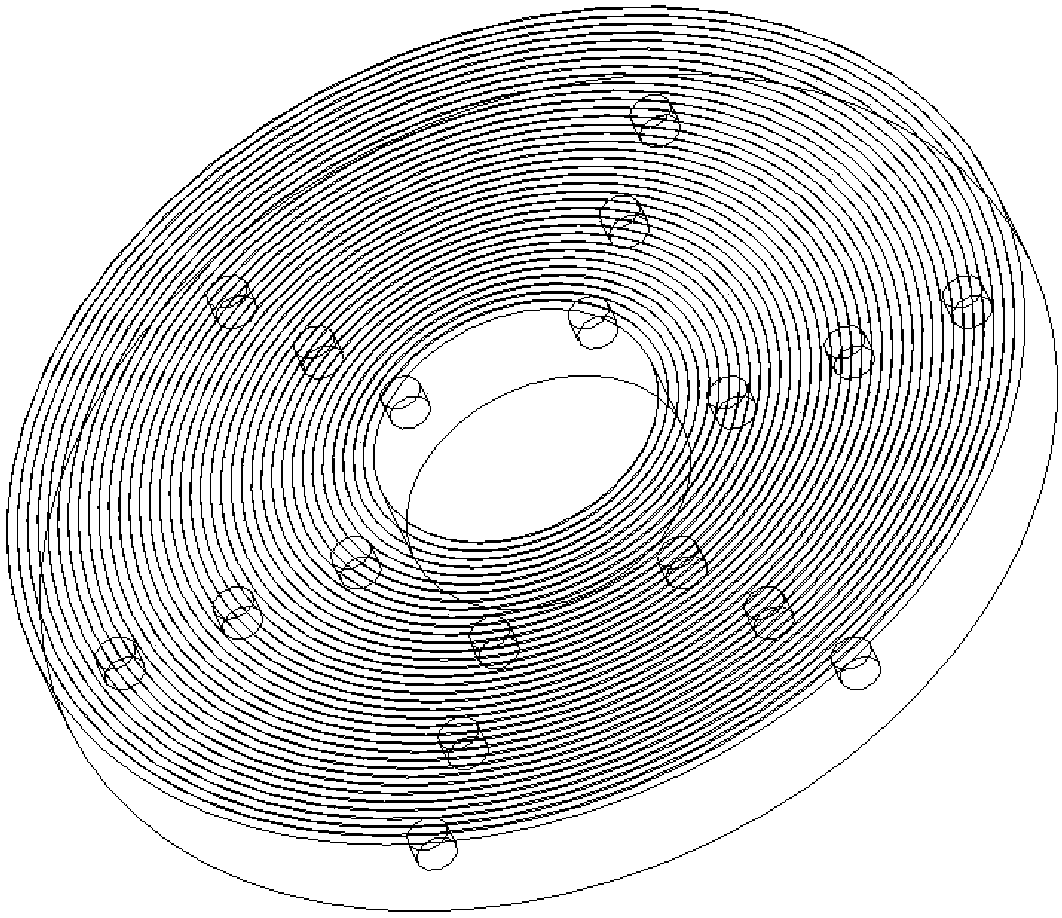

[0028] Copper plate and copper throw temperature online detection device, please refer to Figure 1 to Figure 7 , including a large-size copper plate 1, a temperature sensor 2, a wireless data acquisition system 3 and a digital display 4.

[0029] The temperature sensor 2 is distributed on the copper pan 1 according to a certain rule to measure the temperature of different positions on the copper pan 1; the wireless data acquisition system 3 includes an acquisition module, a wireless transmission module and a wireless signal receiving module, and the acquisition module signal Connect the temperature sensor 2 to collect the temperature data measured by the temperature sensor 2, the wireless transmission module signal connection acquisition module to transmit the temperature data in the form of a wireless signal, the wireless signal receiving module receives the temperature emitted by the wireless transmission module Data; the display screen 4 is connected to the wireless signal...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com