Patents

Literature

314results about "Cells cooling/heating" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

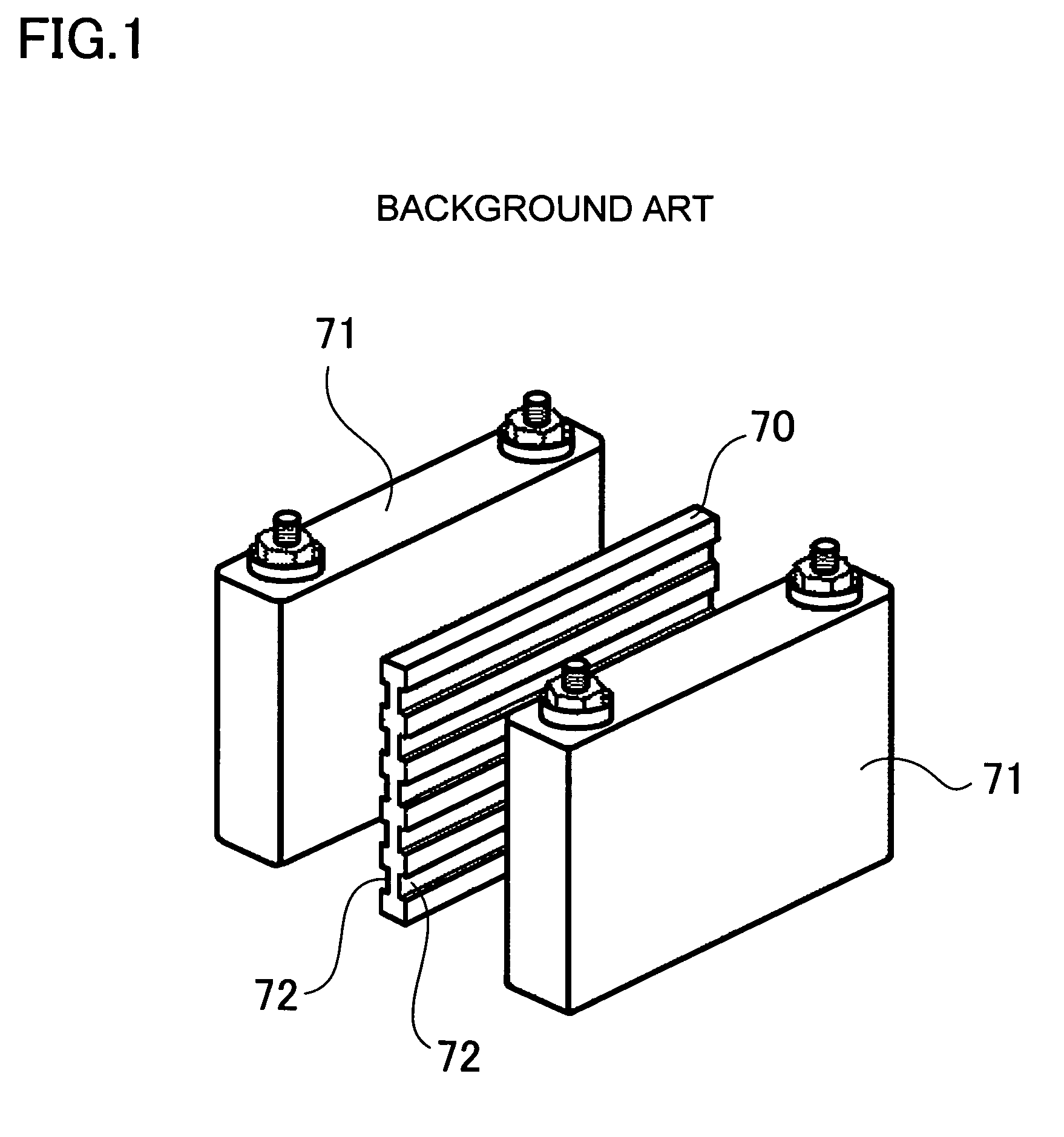

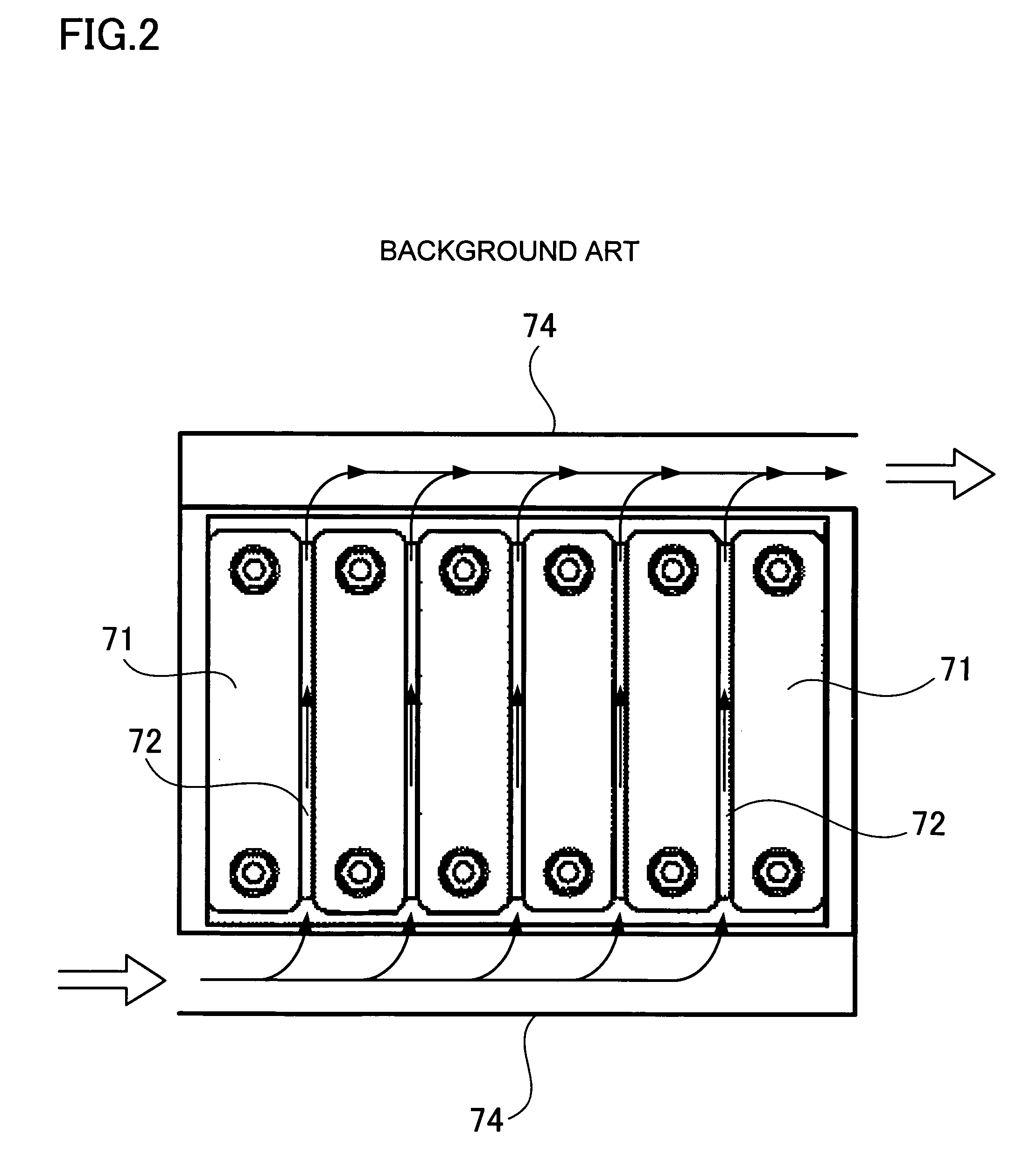

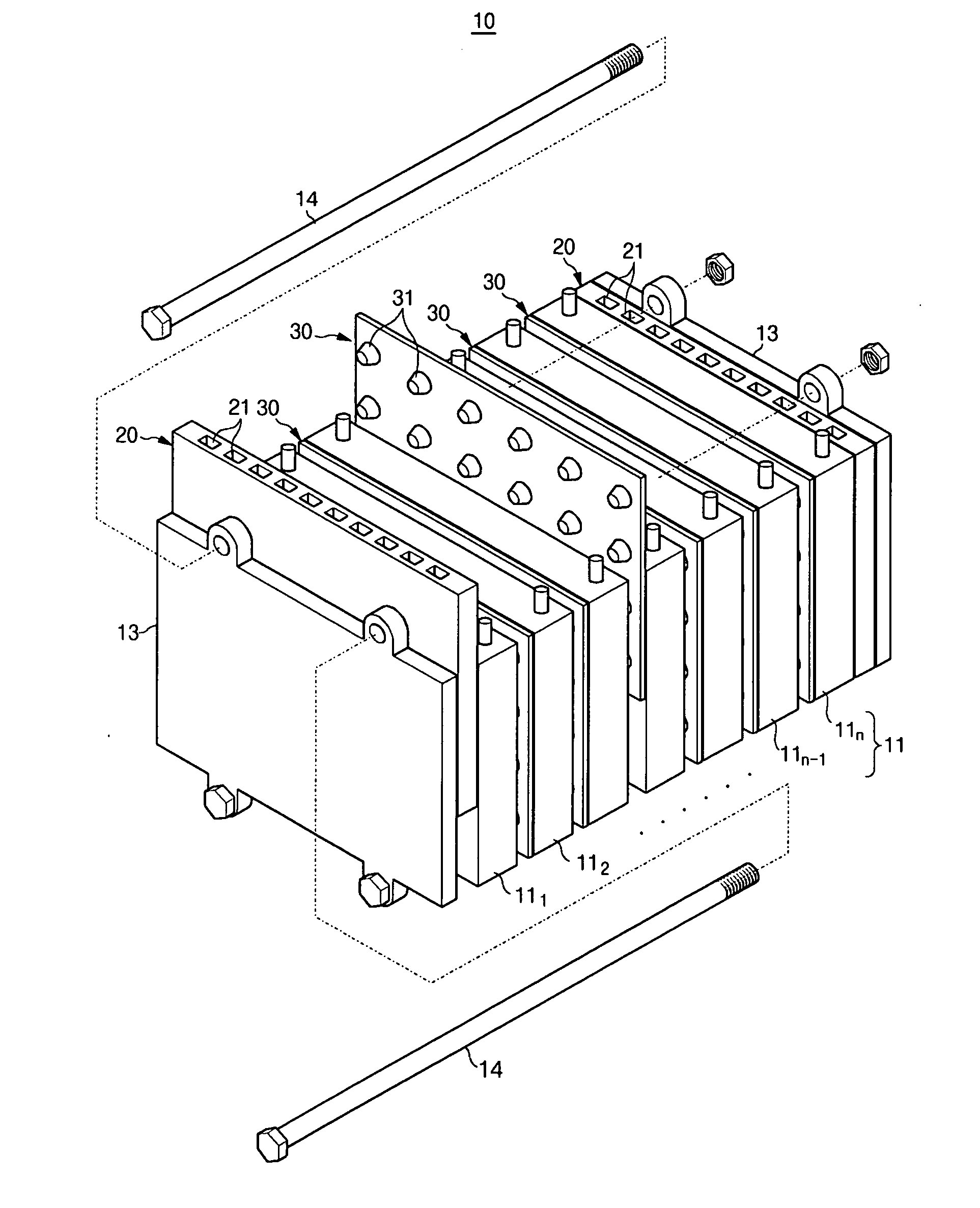

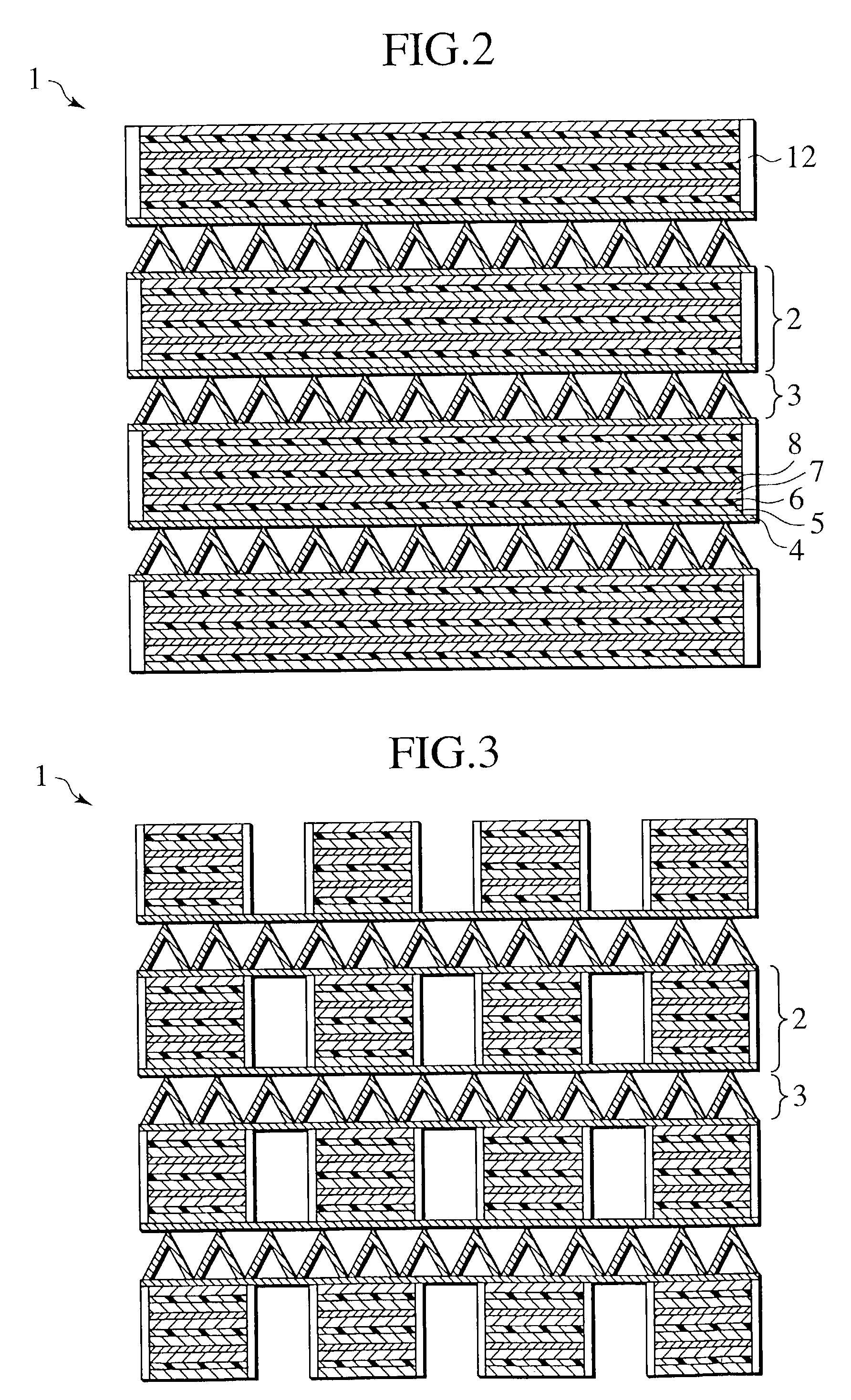

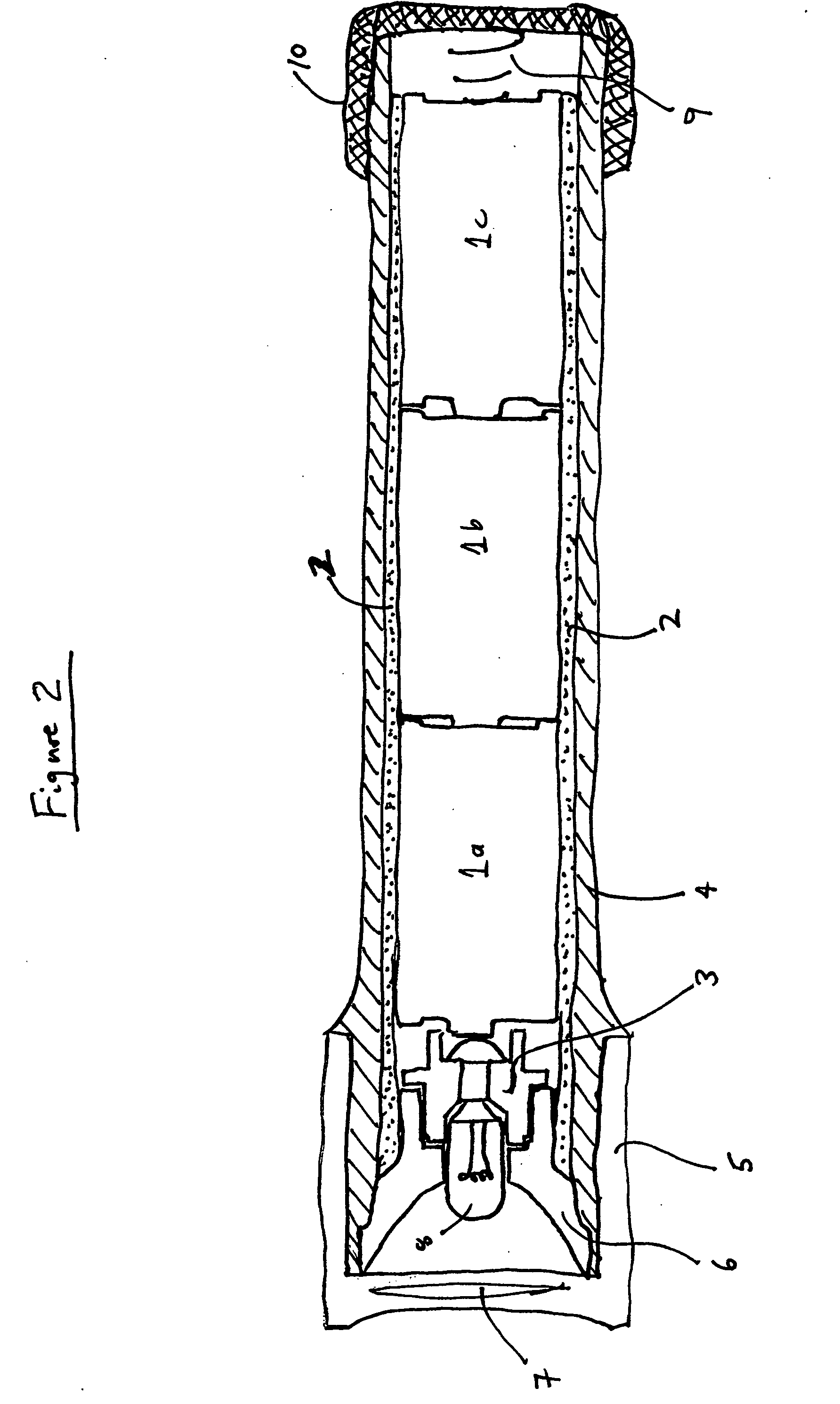

Battery pack and battery pack separator

ActiveUS20090111010A1Reduces cooling gas pressure lossDifference in pressureCell temperature controlCells cooling/heatingEngineeringBattery cell

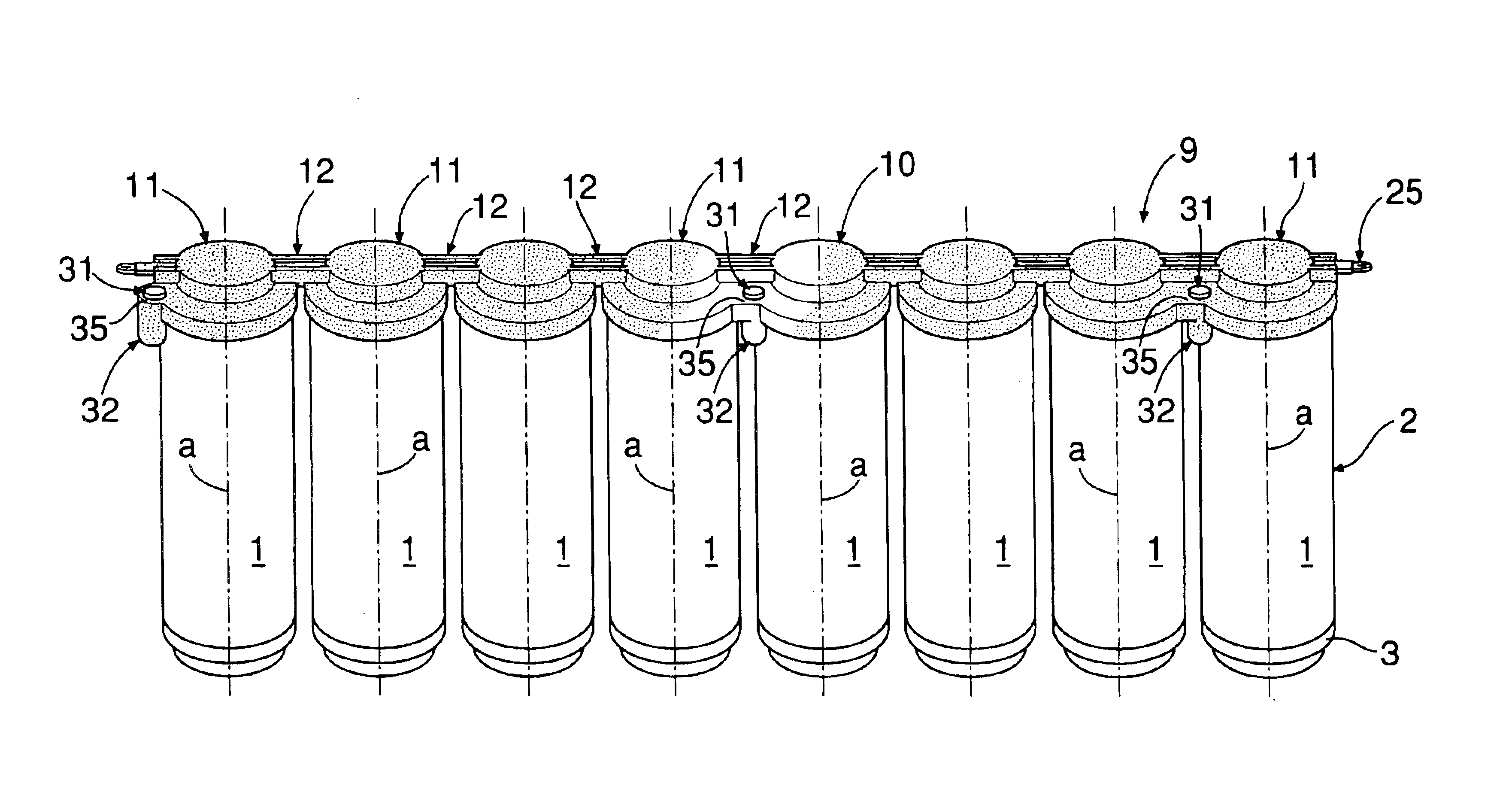

The battery pack includes plural battery cells 1, and insulating separators 10 disposed between adjacent battery cells 1, where the plurality of battery cells 1 are disposed in a stacked configuration with a prescribed gap between adjacent battery cells 1. A separator 10 has a plural gas channels that enable the flow of cooling gas. The gas channels have cooling gas entranceways and exit ways, which open at the sides of the battery block formed by the stacked battery cells 1. A separator 10 has cut sections formed to position the entranceways and exit ways of the gas channels inward from the sides of the battery block. This allows cooling gas near entranceways and exit ways to be smoothly introduced to, and exhausted from the gas channels, and reduces cooling gas pressure losses in those regions.

Owner:SANYO ELECTRIC CO LTD

Battery module

ActiveUS20060204840A1High strengthOvercome problemsCell seperators/membranes/diaphragms/spacersCell temperature controlEngineeringElectrical and Electronics engineering

Owner:SAMSUNG SDI CO LTD

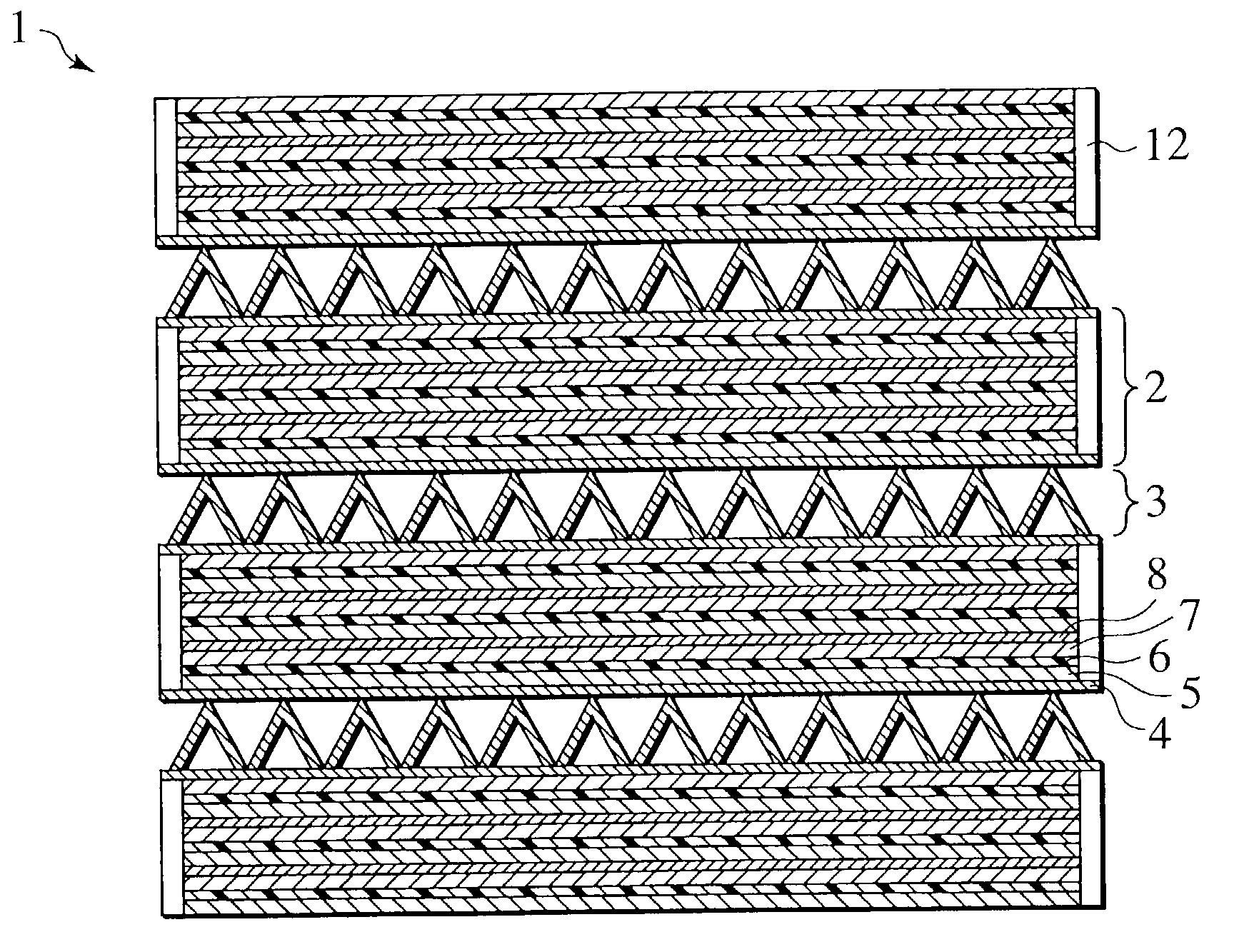

Battery system with excellent controllability for temperature

InactiveUS7264902B2Reduce heating capacityImprove thermal efficiencyPrimary cell to battery groupingFinal product manufactureEngineeringControllability

A battery system of the present invention includes one or more cell groups, each having a positive electrode, a negative electrode and a solid electrolyte layer, and one or more heat mediating structures adjacent to the cell groups. The cell groups and the heat mediating structures are alternately stacked. A solid electrolyte is applied to the electrolyte layer. The respective cell groups have a thin plate shape, and adjacent thereto, the heat mediating structures are provided.

Owner:NISSAN MOTOR CO LTD

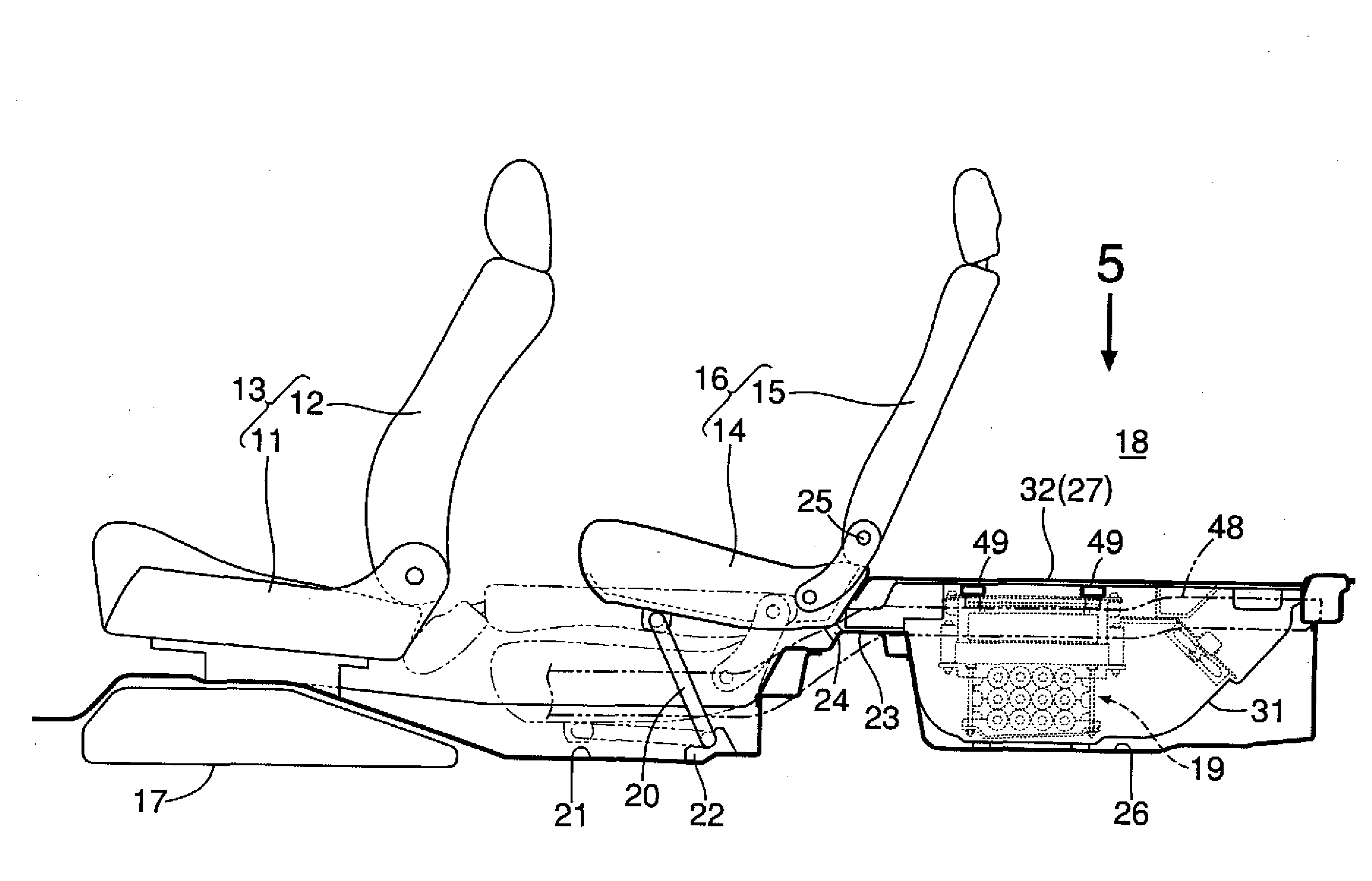

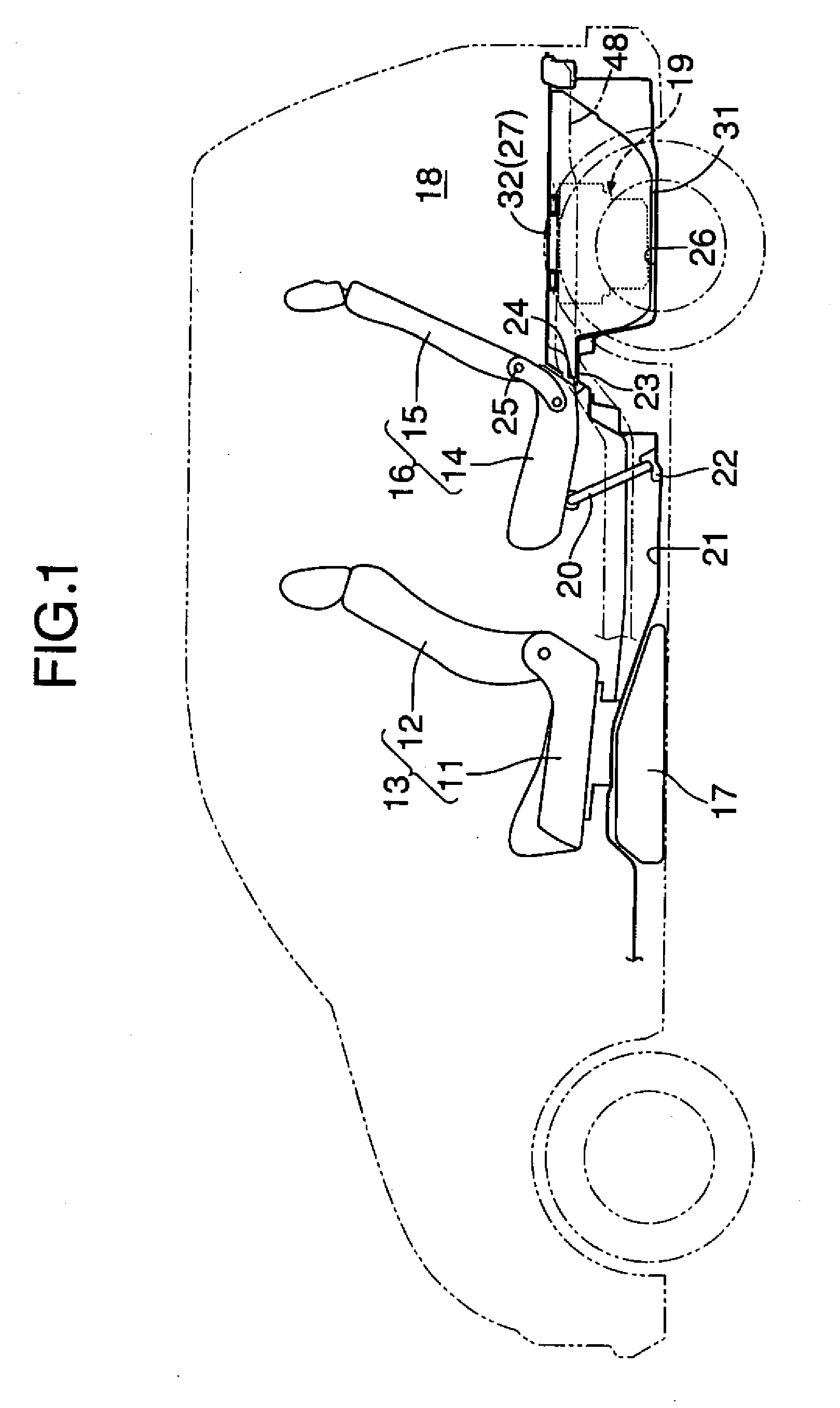

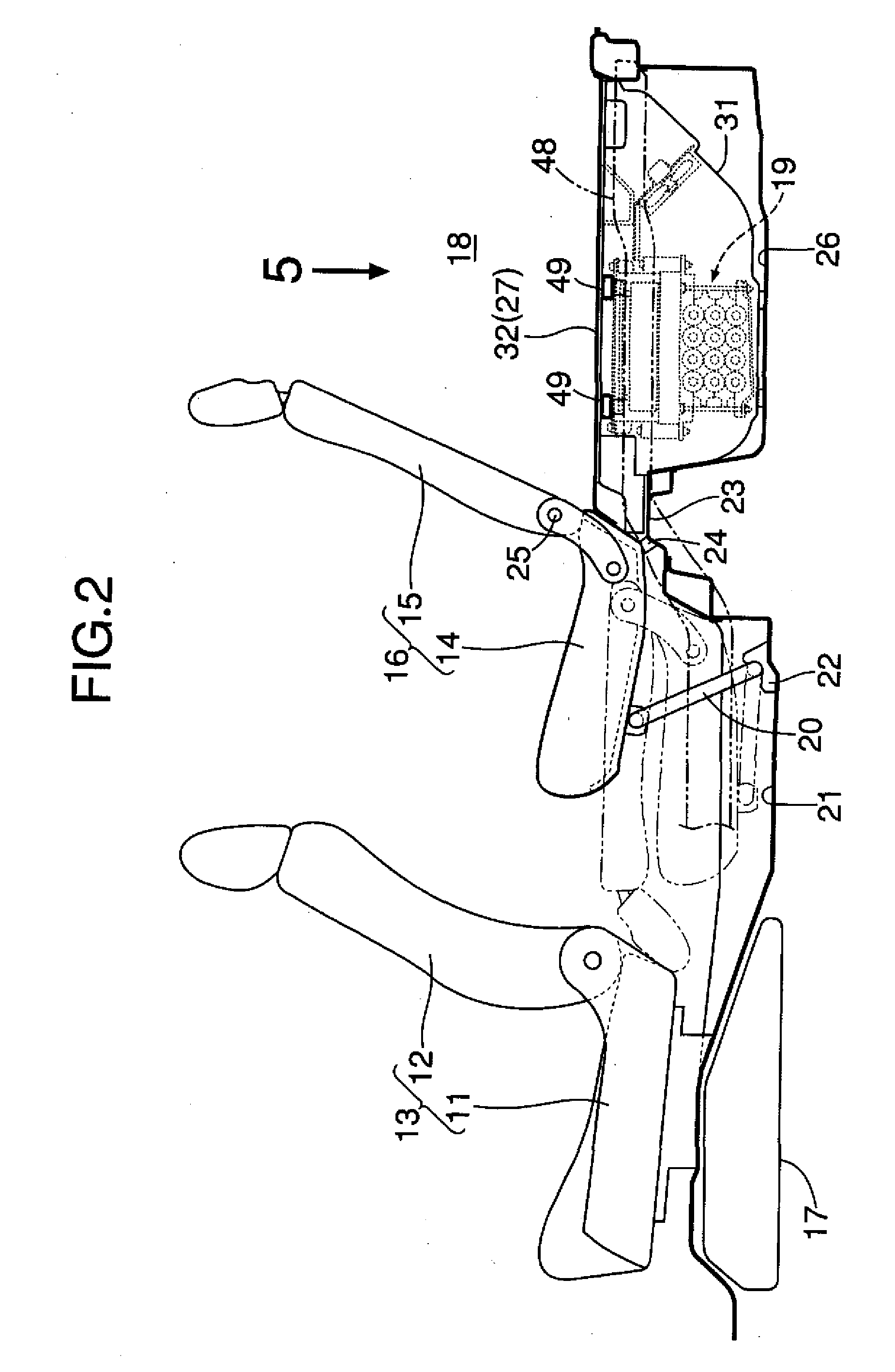

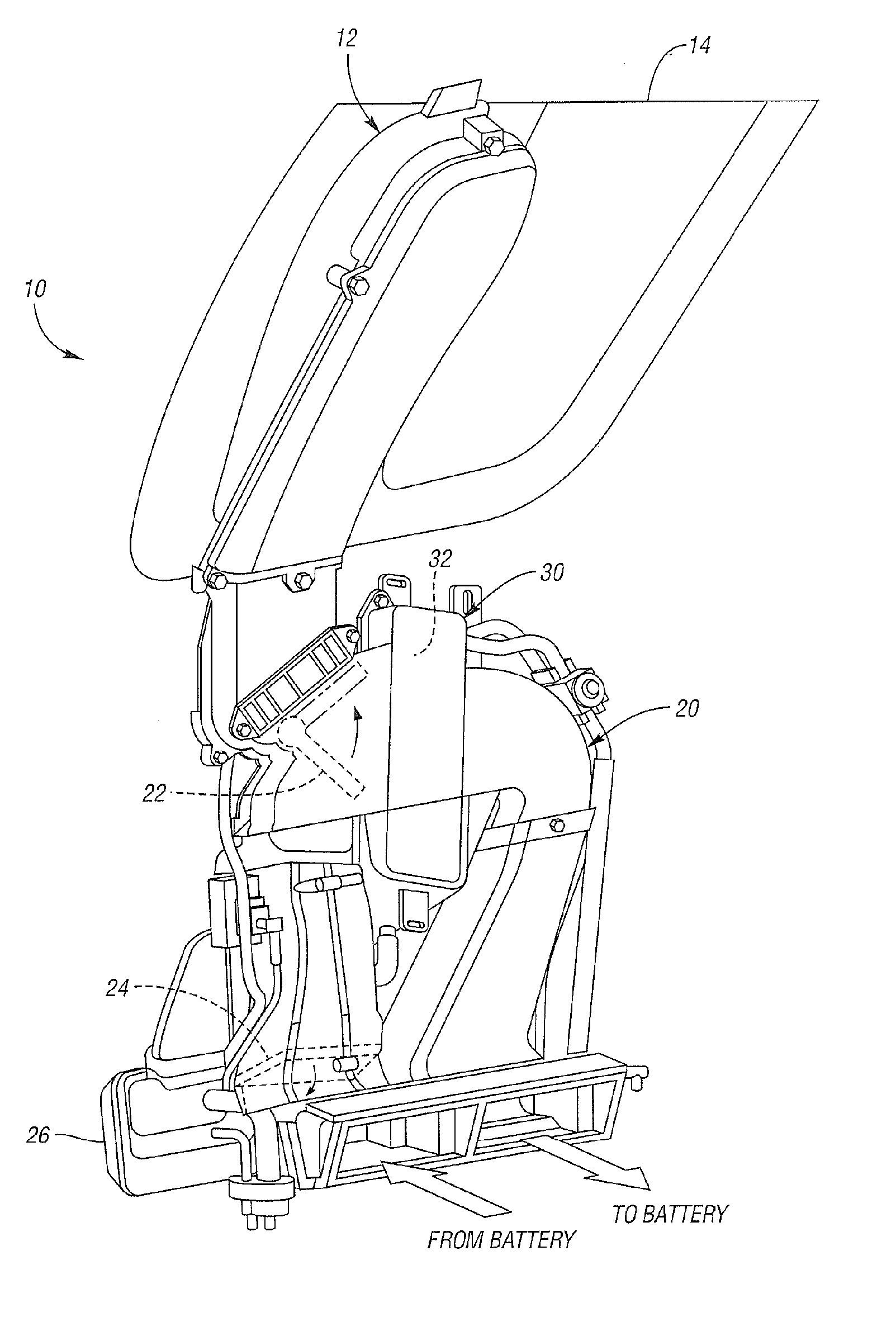

Electrical device cooling structure in vehicle

InactiveUS20080062622A1Improve cooling effectIncrease electrical sizeHybrid vehiclesModifications for power electronicsMotor driveIn vehicle

In a power supply unit disposed below a floor behind a seat, battery modules are disposed in a lower position, and a DC / DC converter and a motor driving inverter are disposed side by side in a vehicle width direction above the battery modules. Thus, cooling air flowing from the front side to the rear side of a vehicle body is divided into upper and lower portions to cool in parallel the DC / DC converter 41 and the motor driving inverter on the upper side and the battery modules on the lower side. Thus, it is possible to simplify a passage of the cooling air to reduce the size of the entire power supply unit, and improve mountability of the power supply unit on the vehicle body. Also, it is possible to apply cooling air at low temperature before heat exchange to all the battery module, the DC / DC converter, and the motor driving inverter, thereby enhancing cooling effect.

Owner:HONDA MOTOR CO LTD

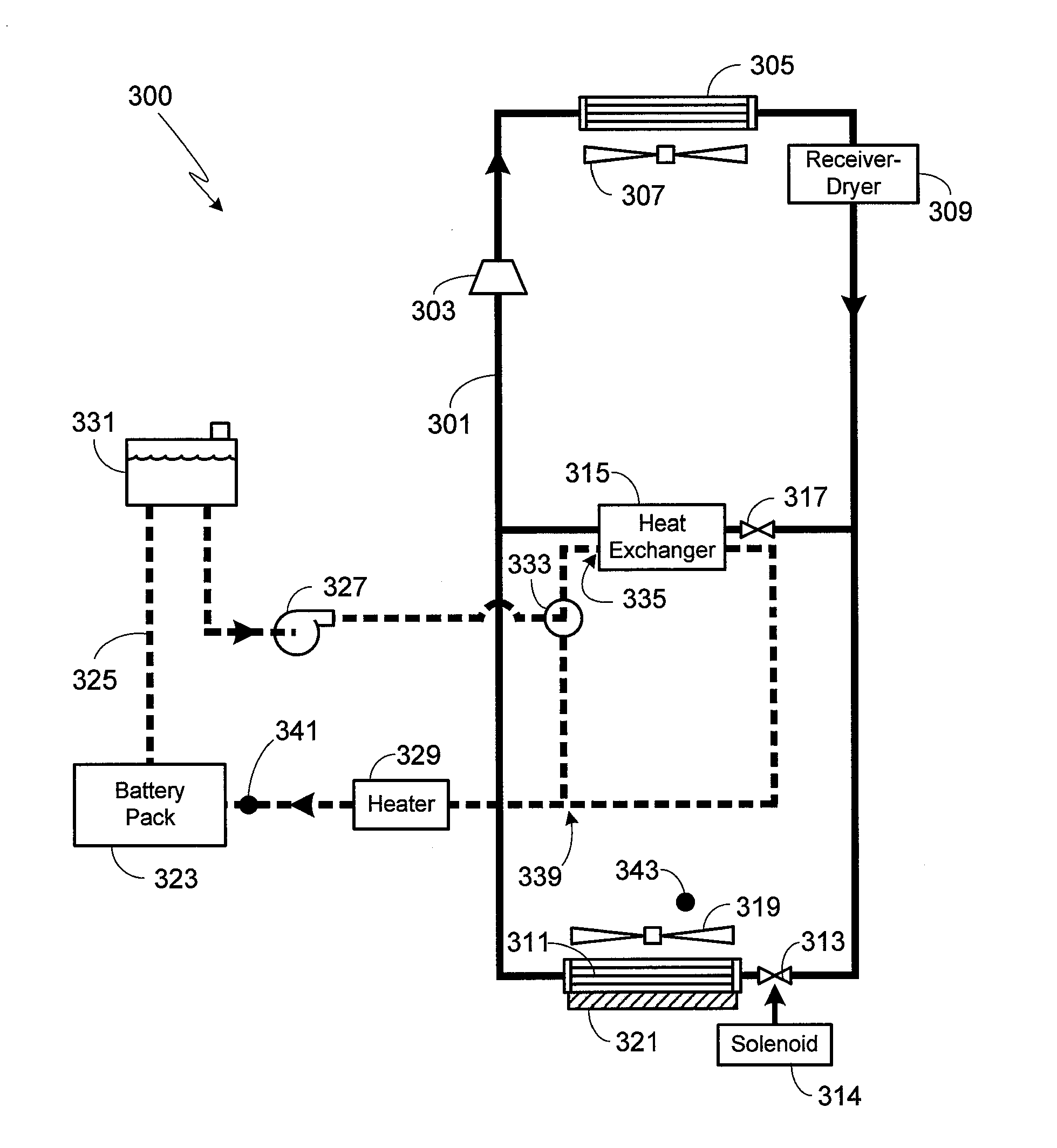

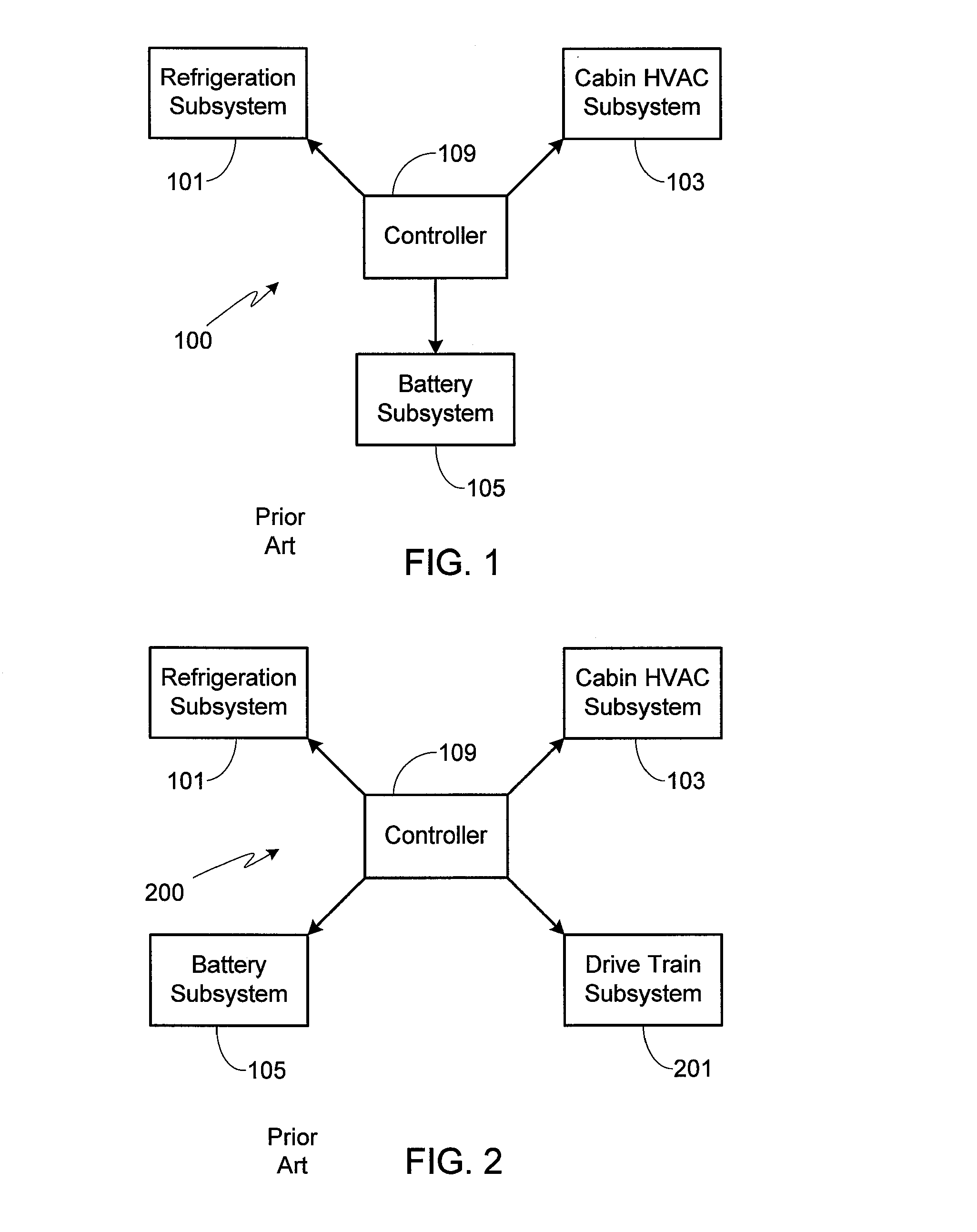

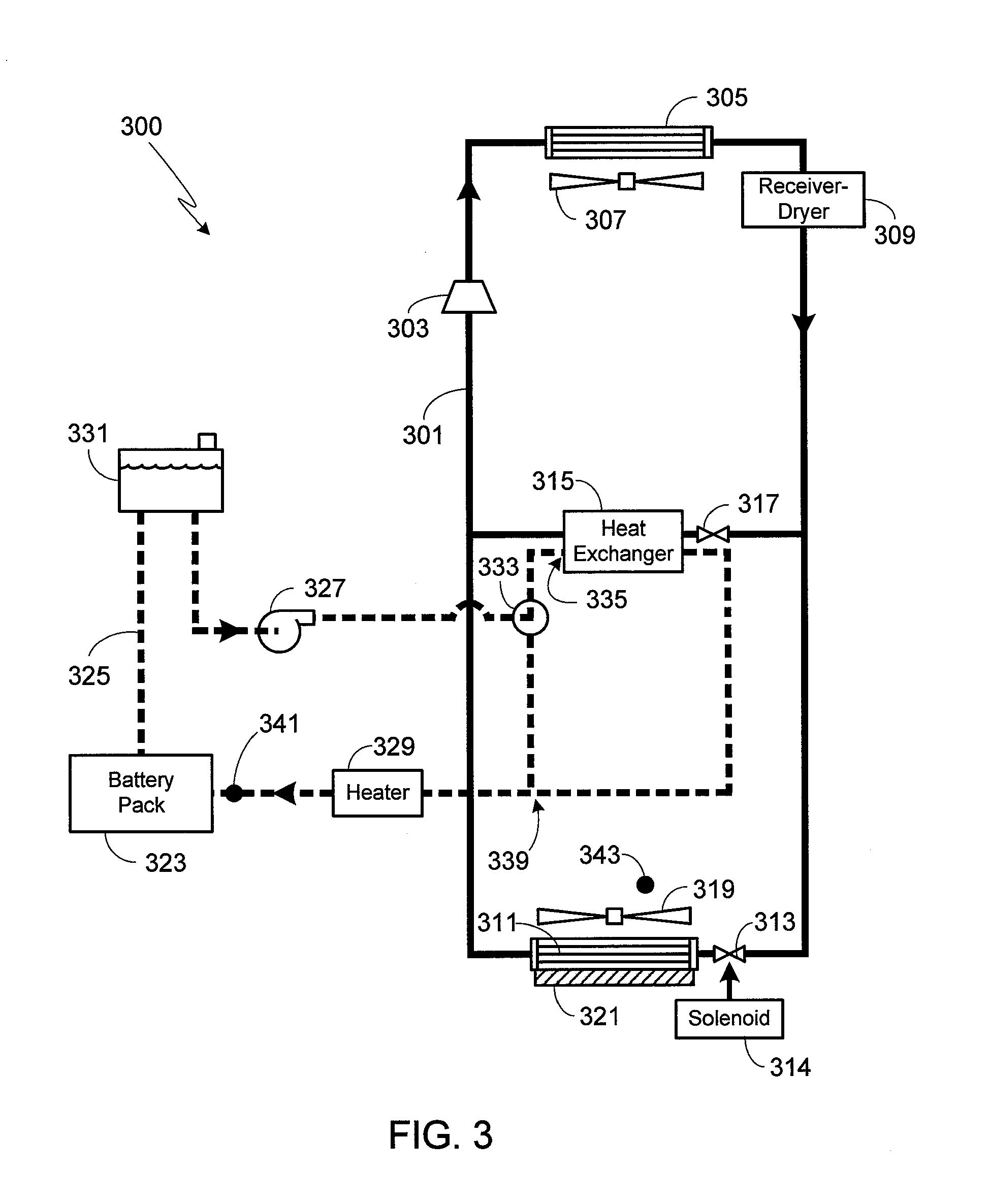

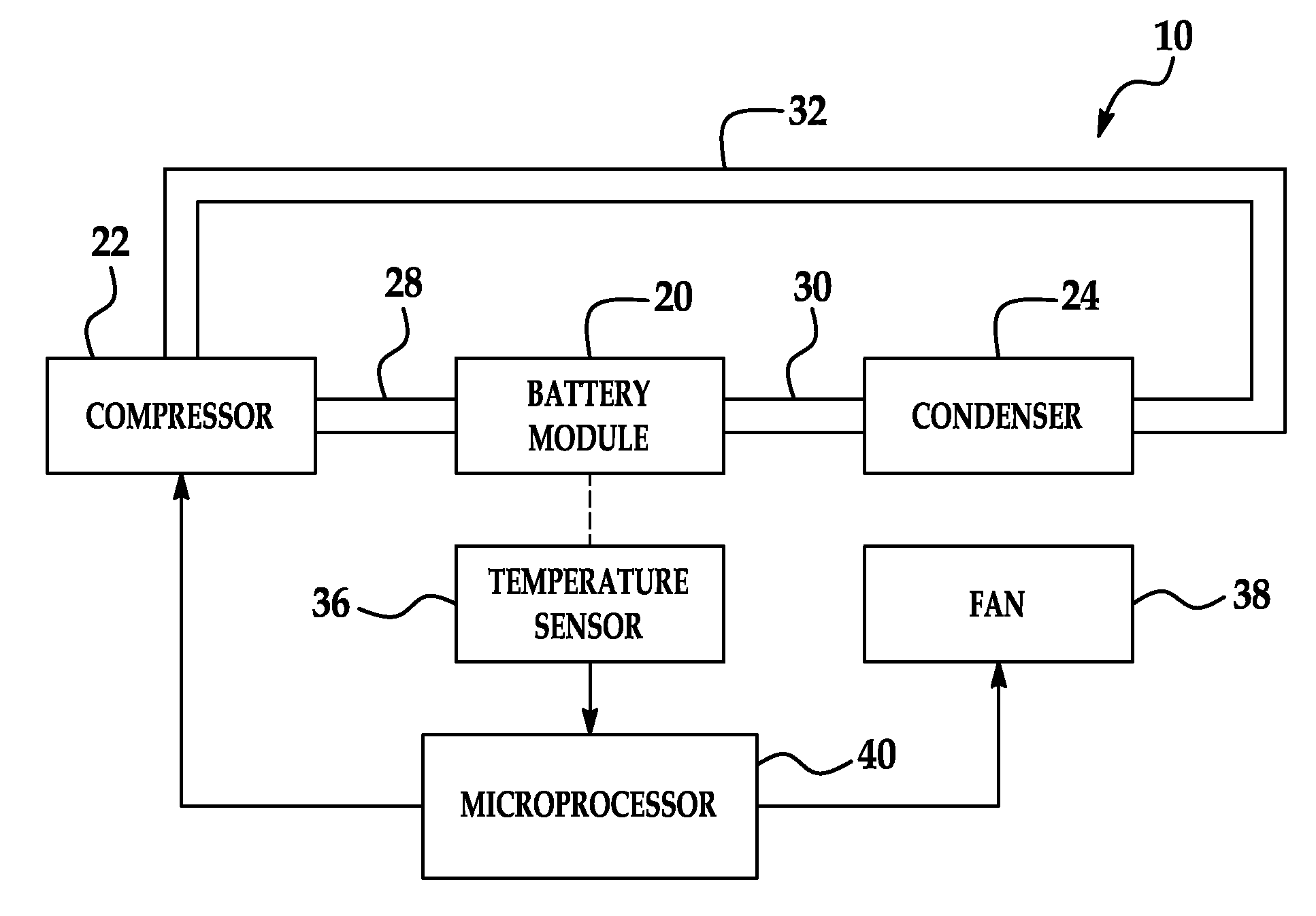

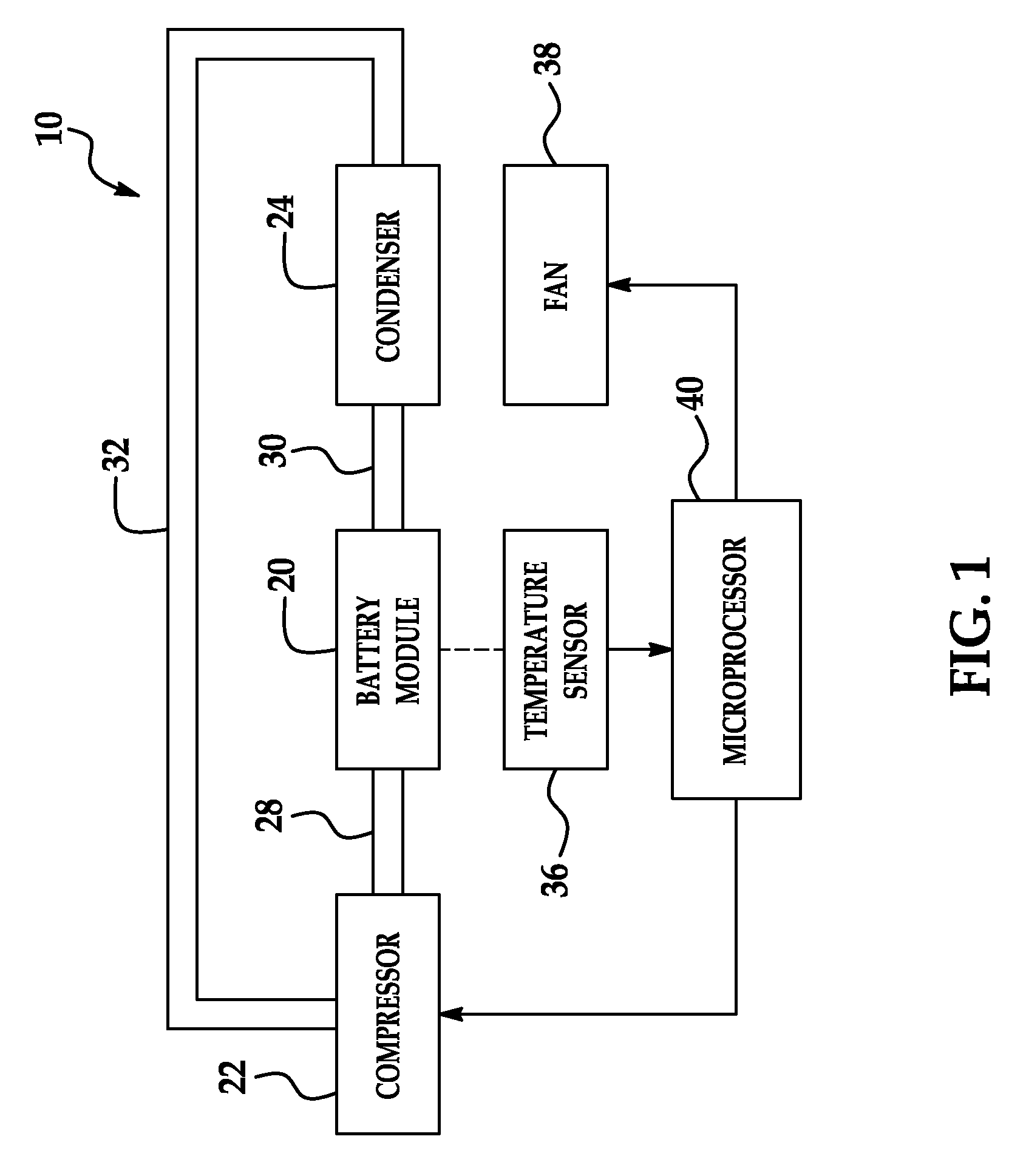

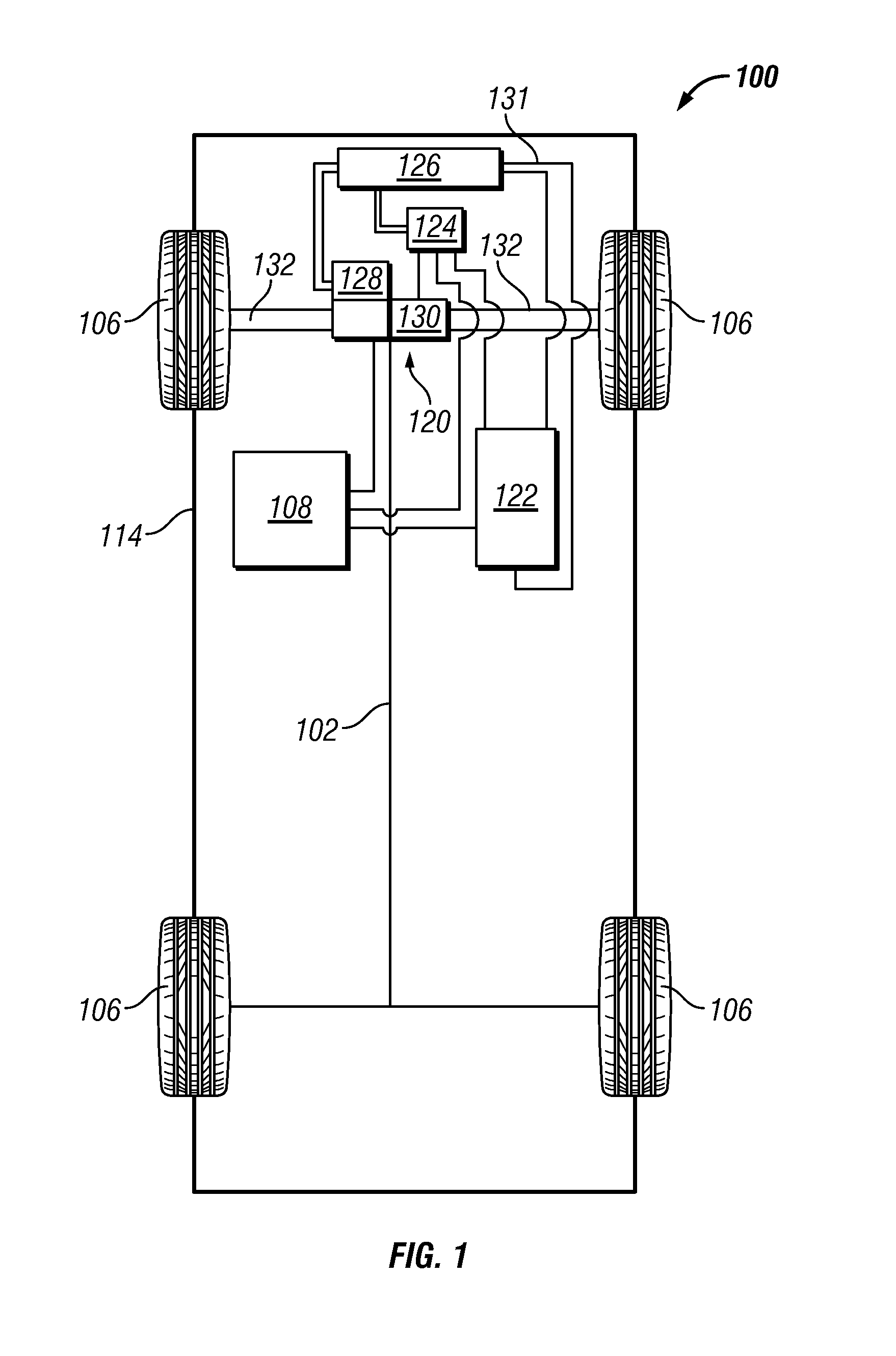

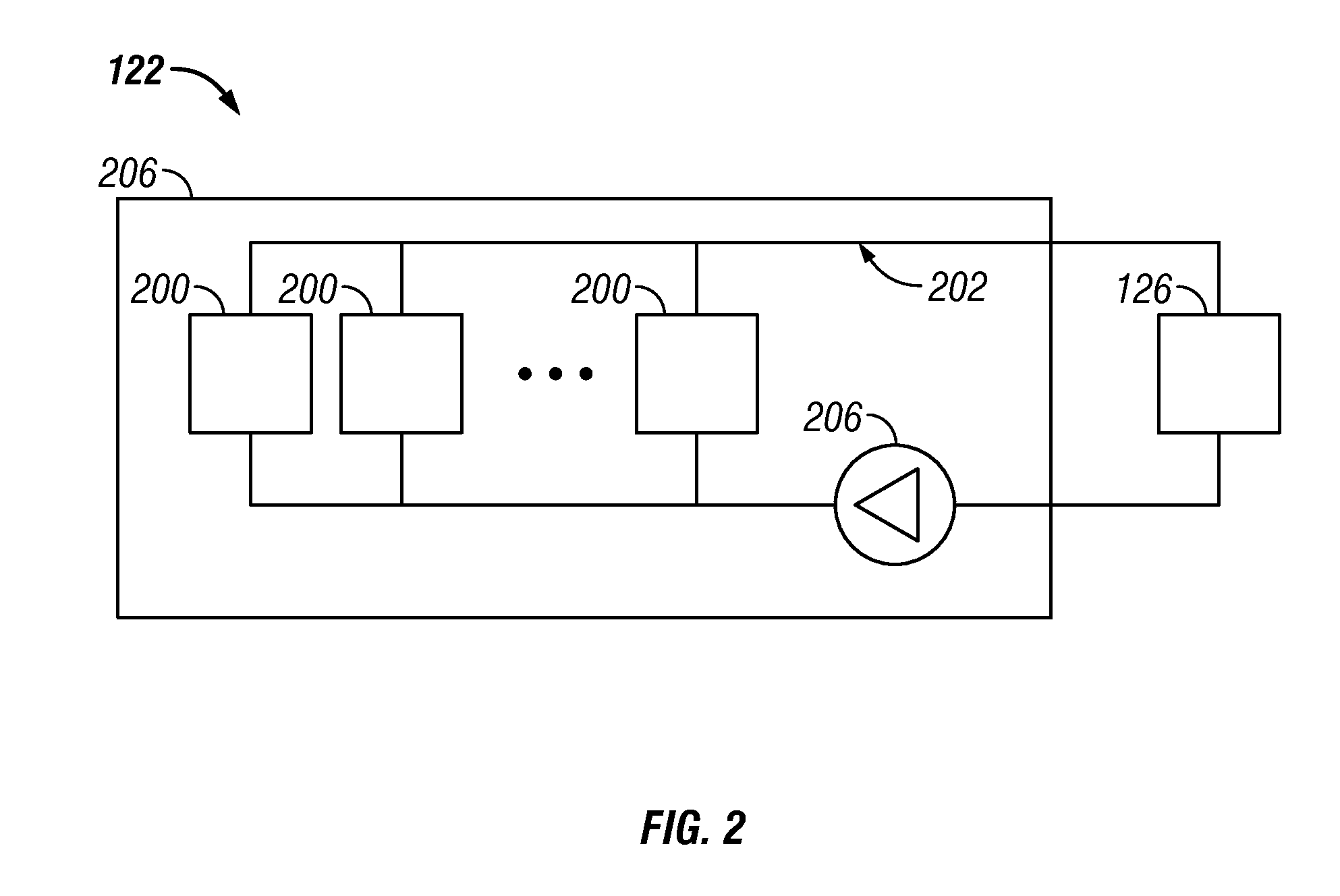

Battery Centric Thermal Management System Utilizing a Heat Exchanger Blending Valve

ActiveUS20130298583A1Compression machines with non-reversible cycleCells cooling/heatingThermal management systemEngineering

A method of regulating thermal dissipation from a vehicle battery pack is provided in which a by-pass valve is used to control the amount of battery pack coolant either passing through, or by-passing, a heat exchanger, where the coolant passing through the heat exchanger is cooled by a refrigeration system. The vehicle's HVAC system is controlled to insure that HVAC operation does not compromise maintaining the battery pack within an acceptable range of temperatures.

Owner:TESLA INC

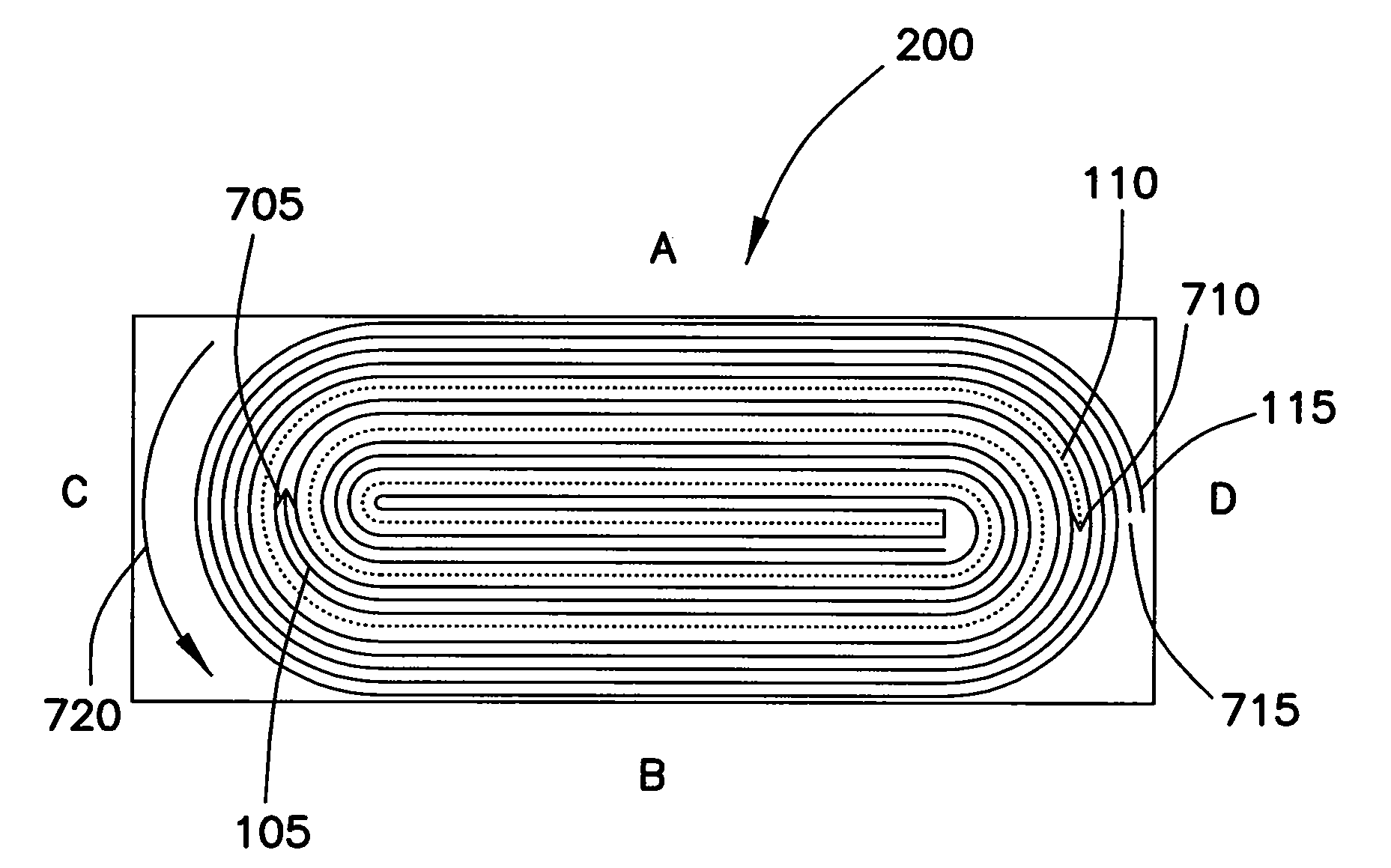

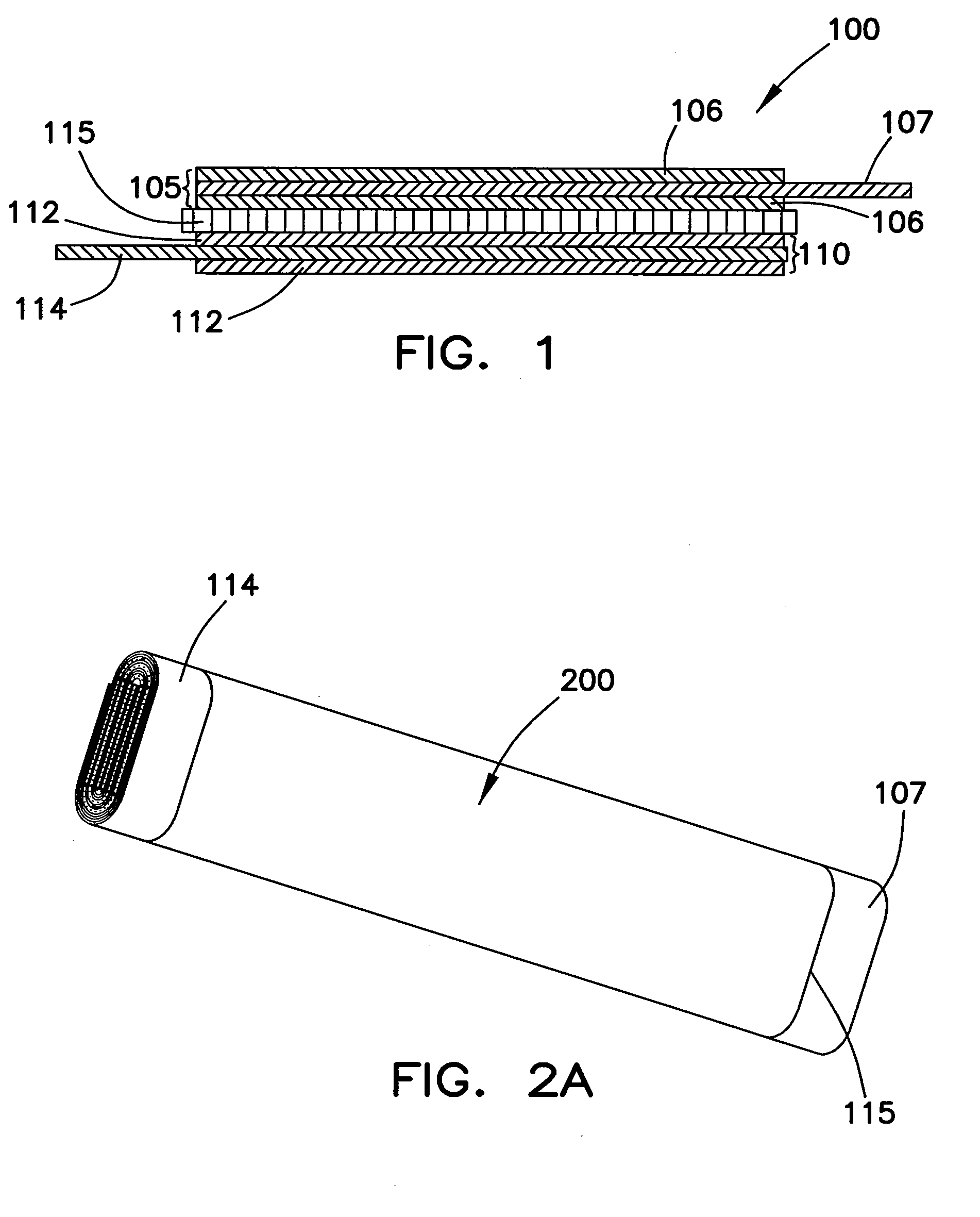

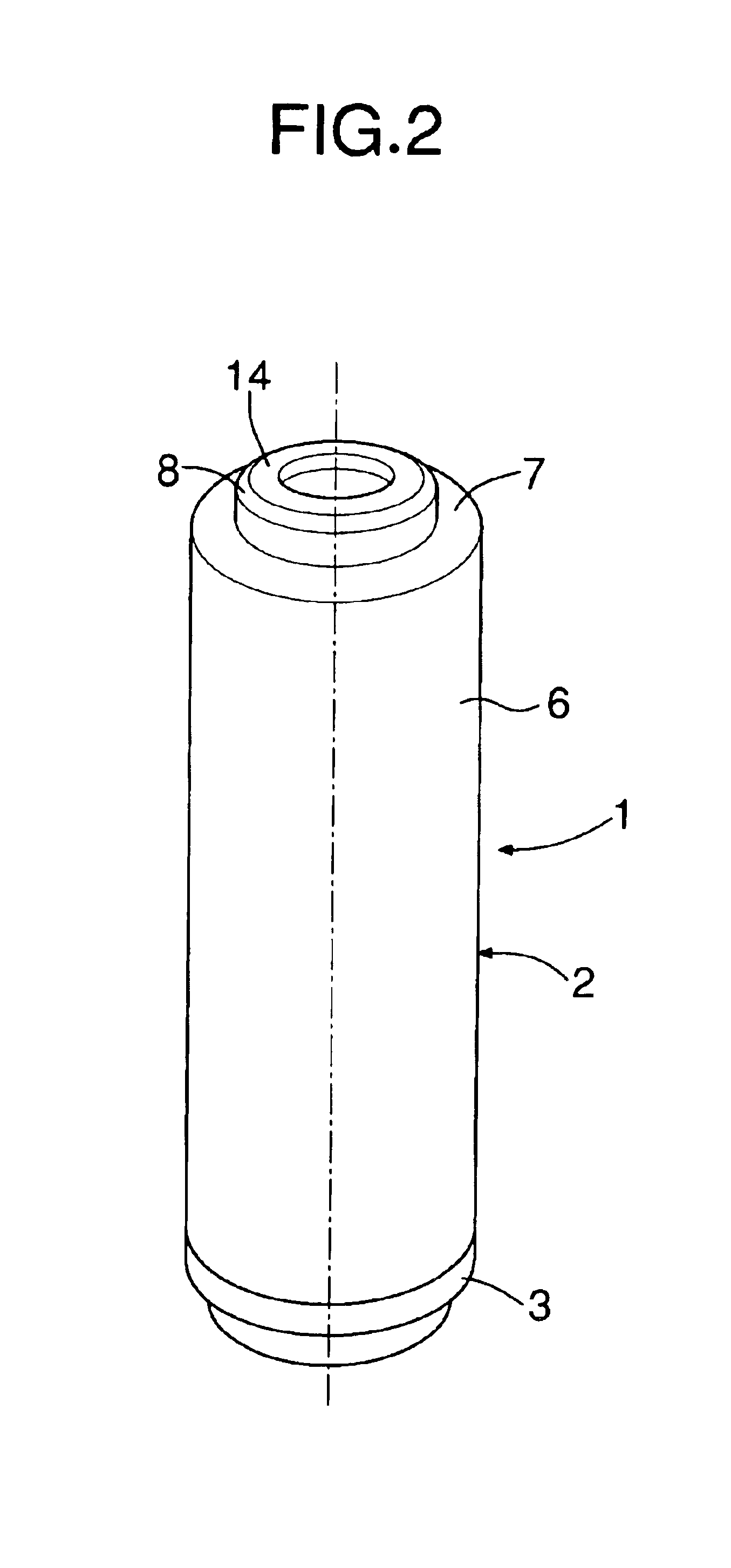

Electrochemical cell having a coiled core

There is disclosed a core for an electrochemical cell that comprises an anode sheet, a cathode sheet, and a separator sheet disposed between the anode sheet and cathode sheet. The anode sheet, cathode sheet, and separator sheet are wound to form a flattened coil structure. The flattened coil structure has opposed flattened sides and opposed arcuate sides. The anode and cathode sheets terminate at the same or different arcuate sides. Further, the separator sheet may terminate at one of the arcuate sides.

Owner:BYD CO LTD

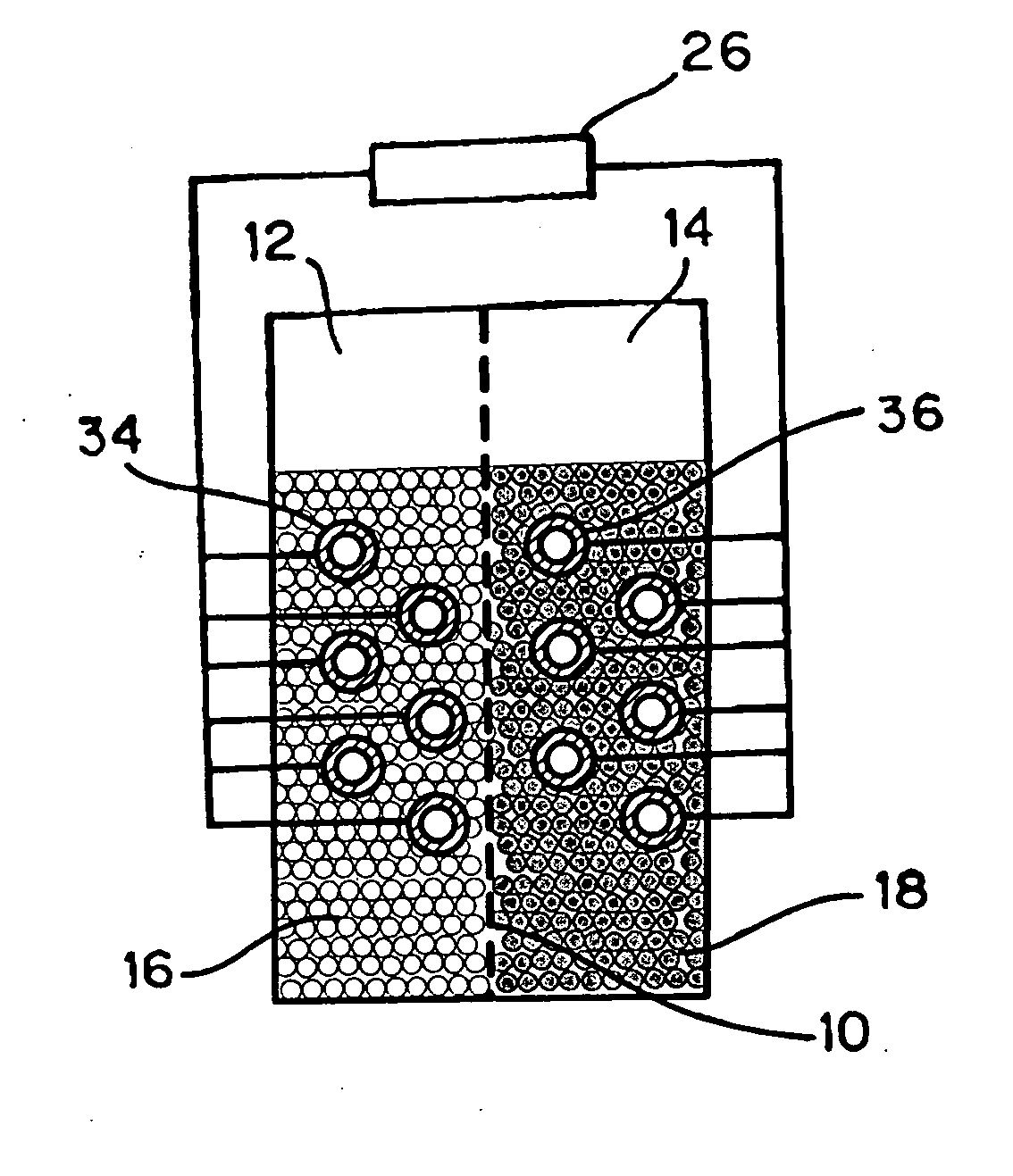

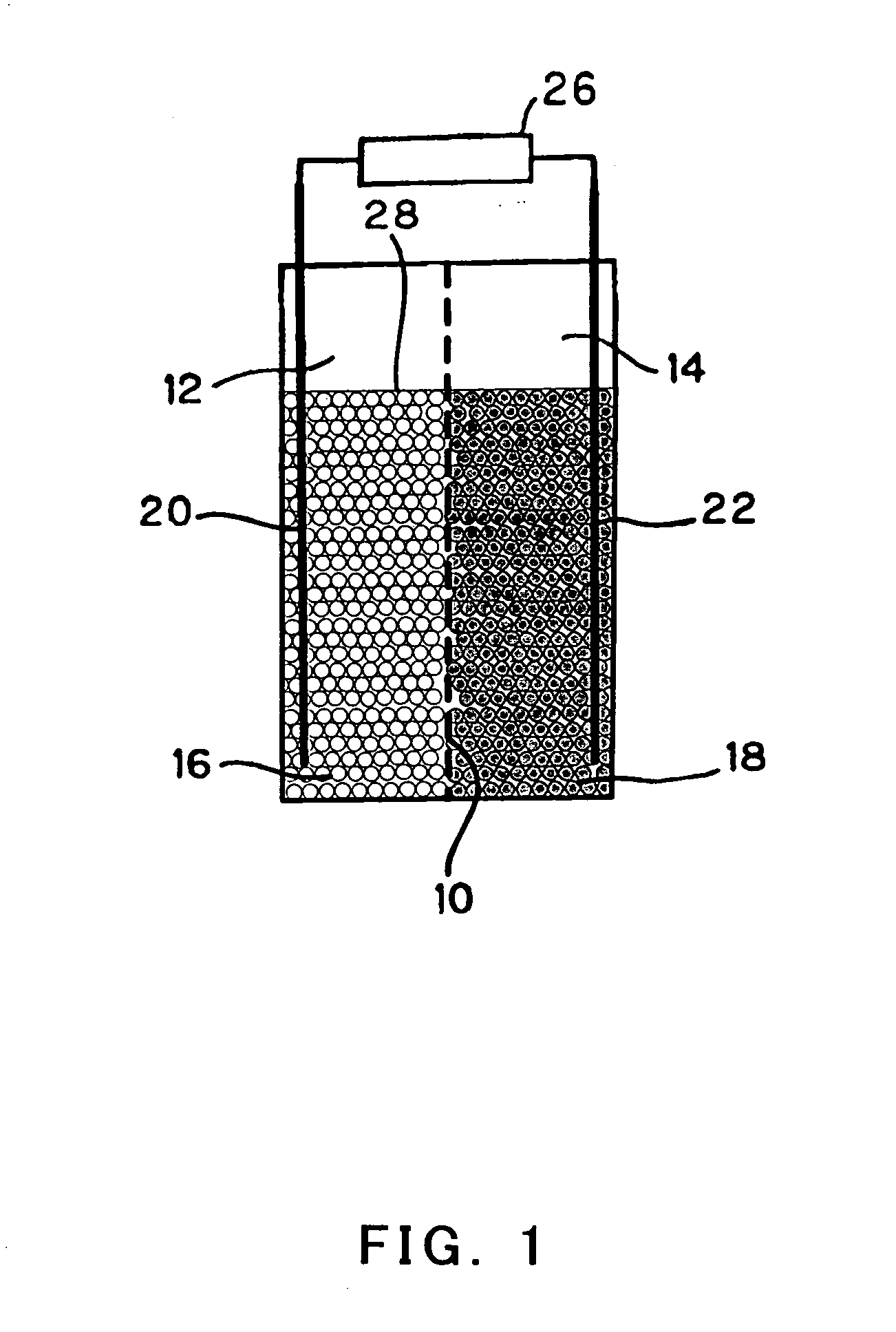

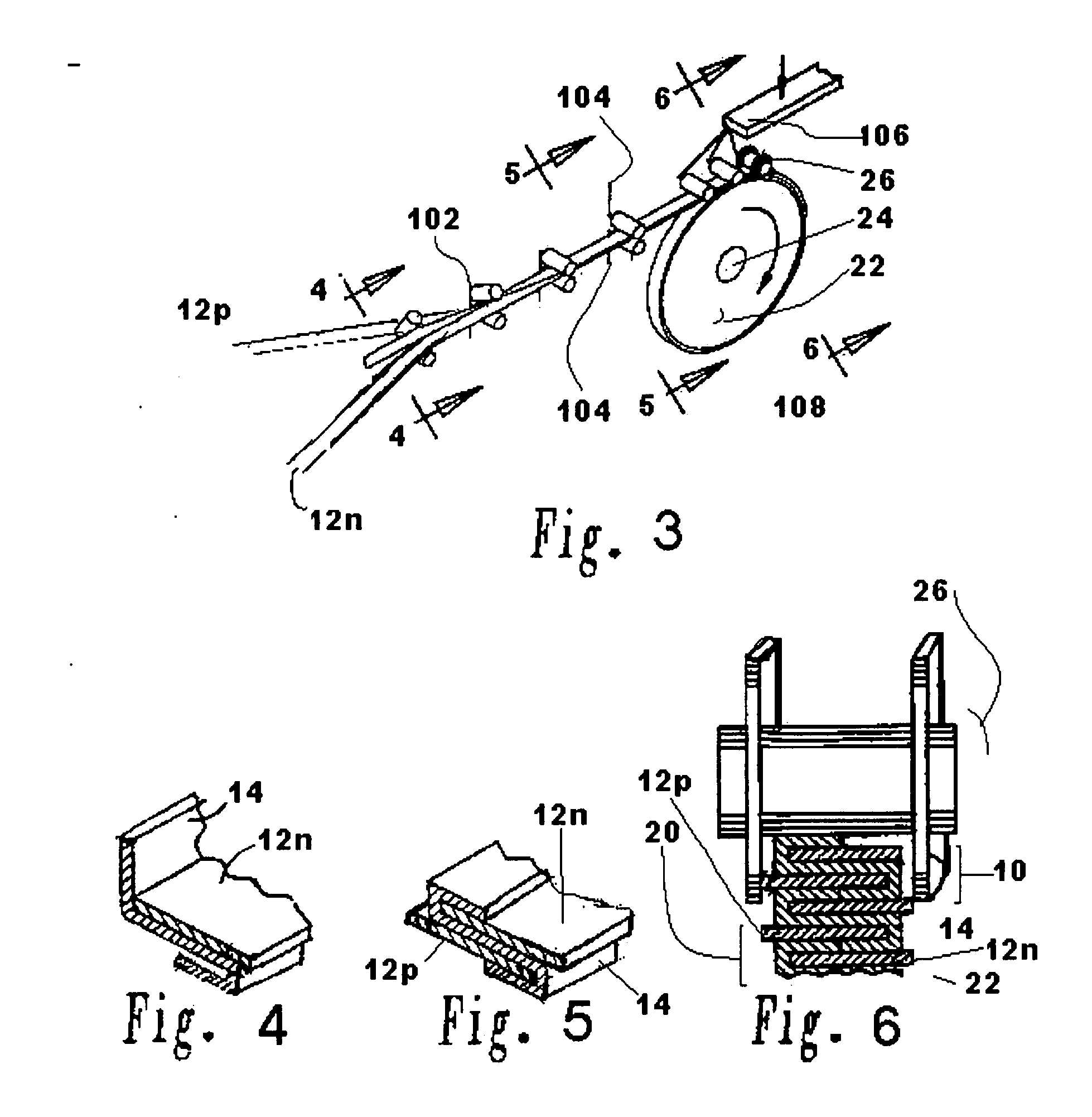

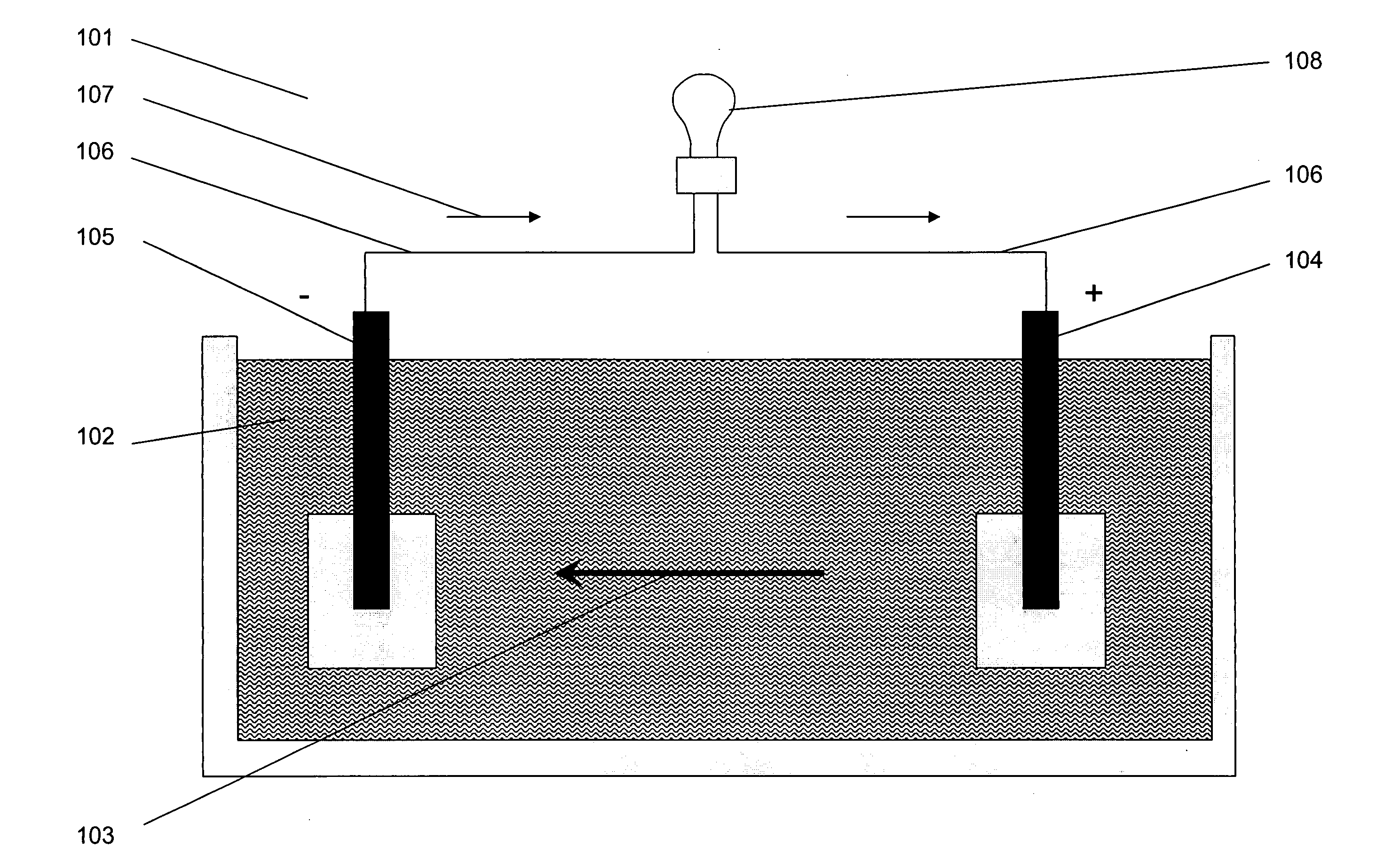

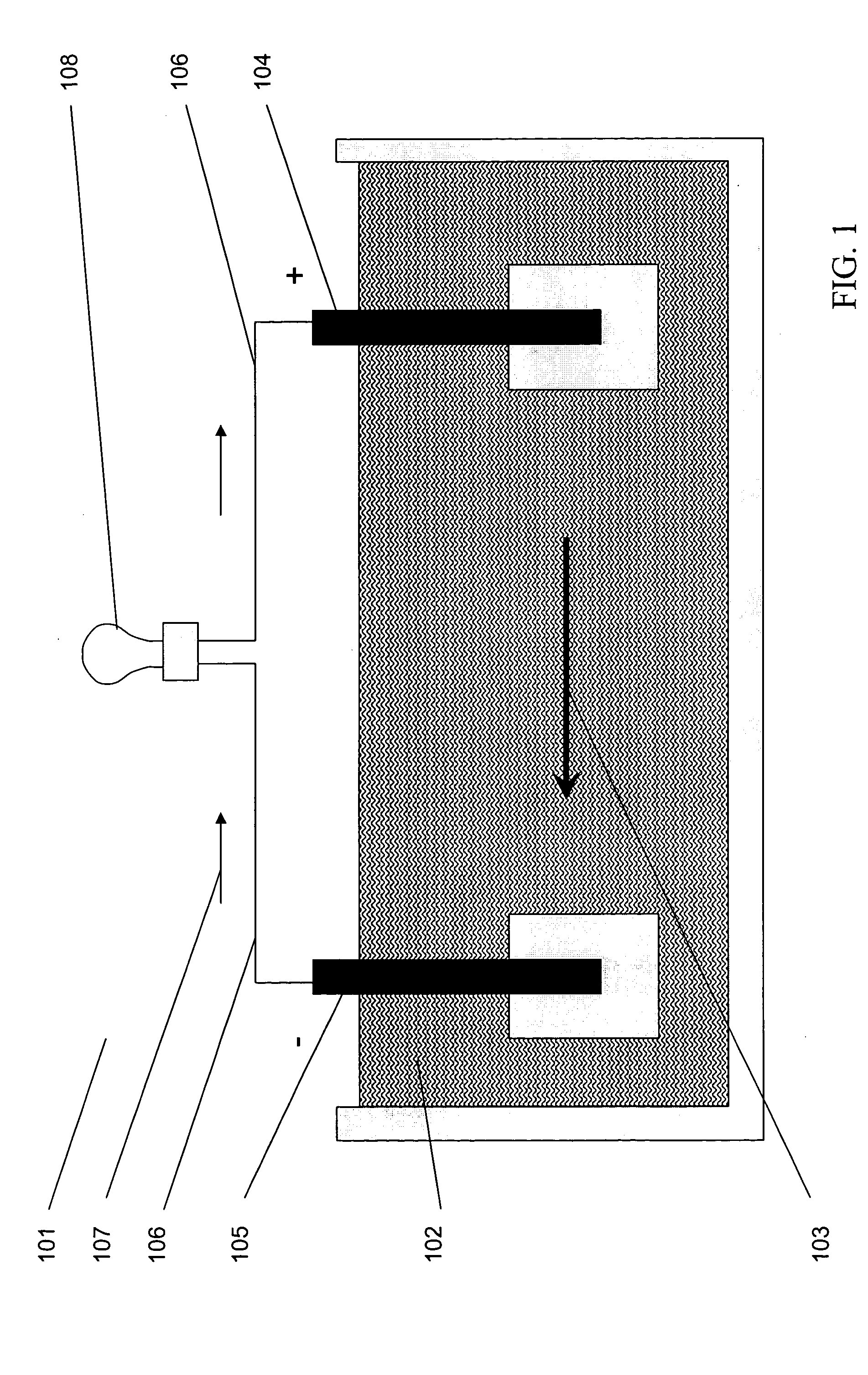

Battery

InactiveUS20050175890A1Production cost advantageIncrease capacityPrimary cell to battery groupingMoving electrode arrangementsEngineeringIon

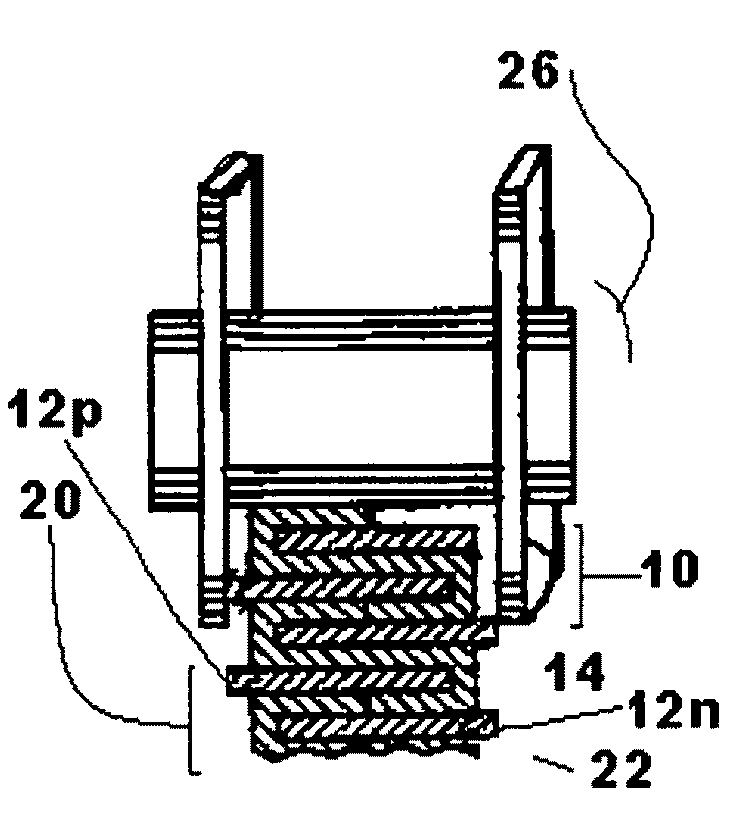

Anode active material particles and an electrolytic solution 16 are filled in an anode cell 12 as one of two vessels connected to each other with an ion-permeable separator 10 interposed therebetween, and cathode active material particles and an electrolytic solution 18 are filled in a cathode cell 14 as the other vessel. Electrically conductive current collectors 20 and 22 are provided in contact with the active material particles within the two vessels. The active material particles form fixed layers.

Owner:KAWASAKI HEAVY IND LTD

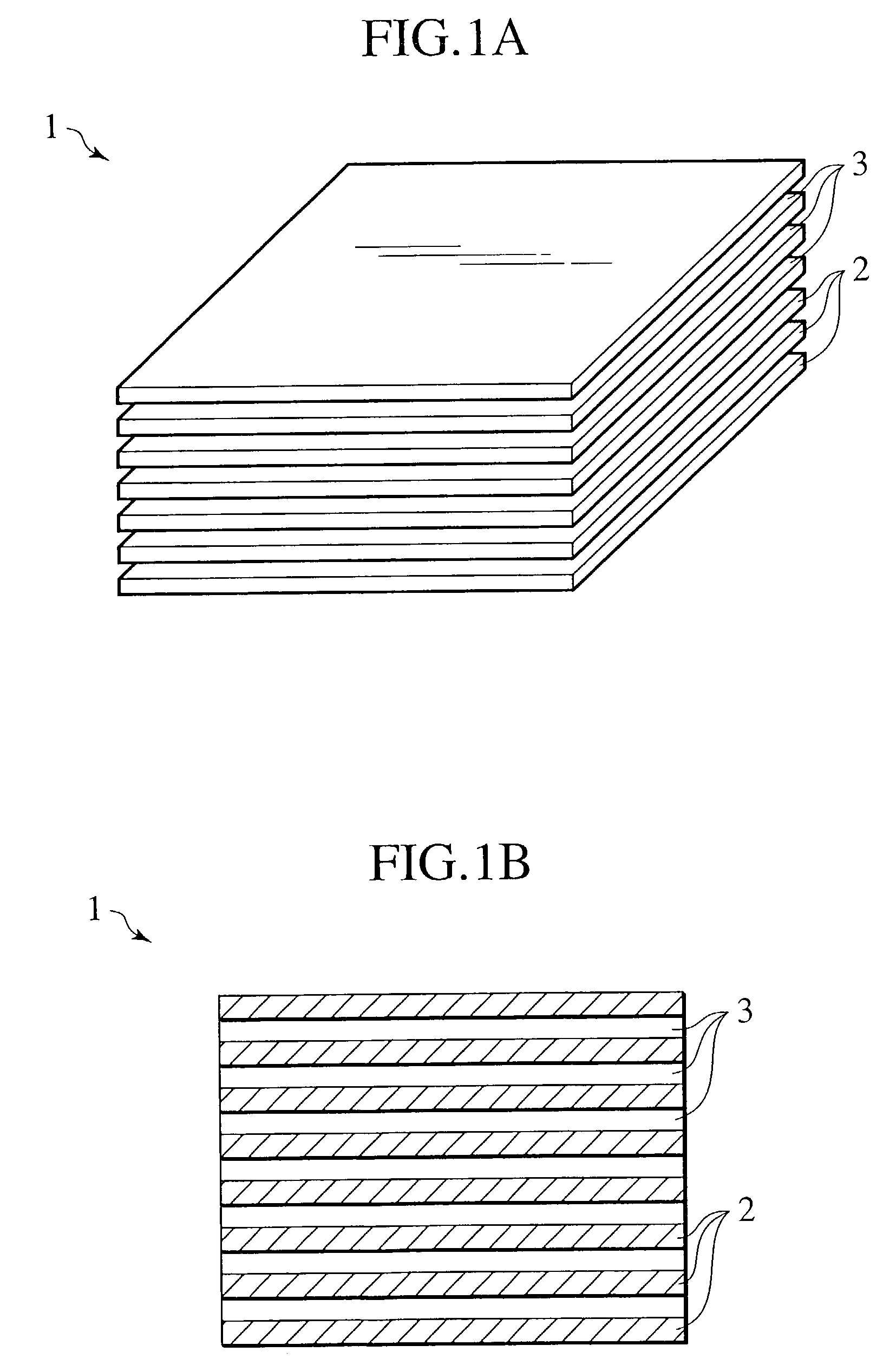

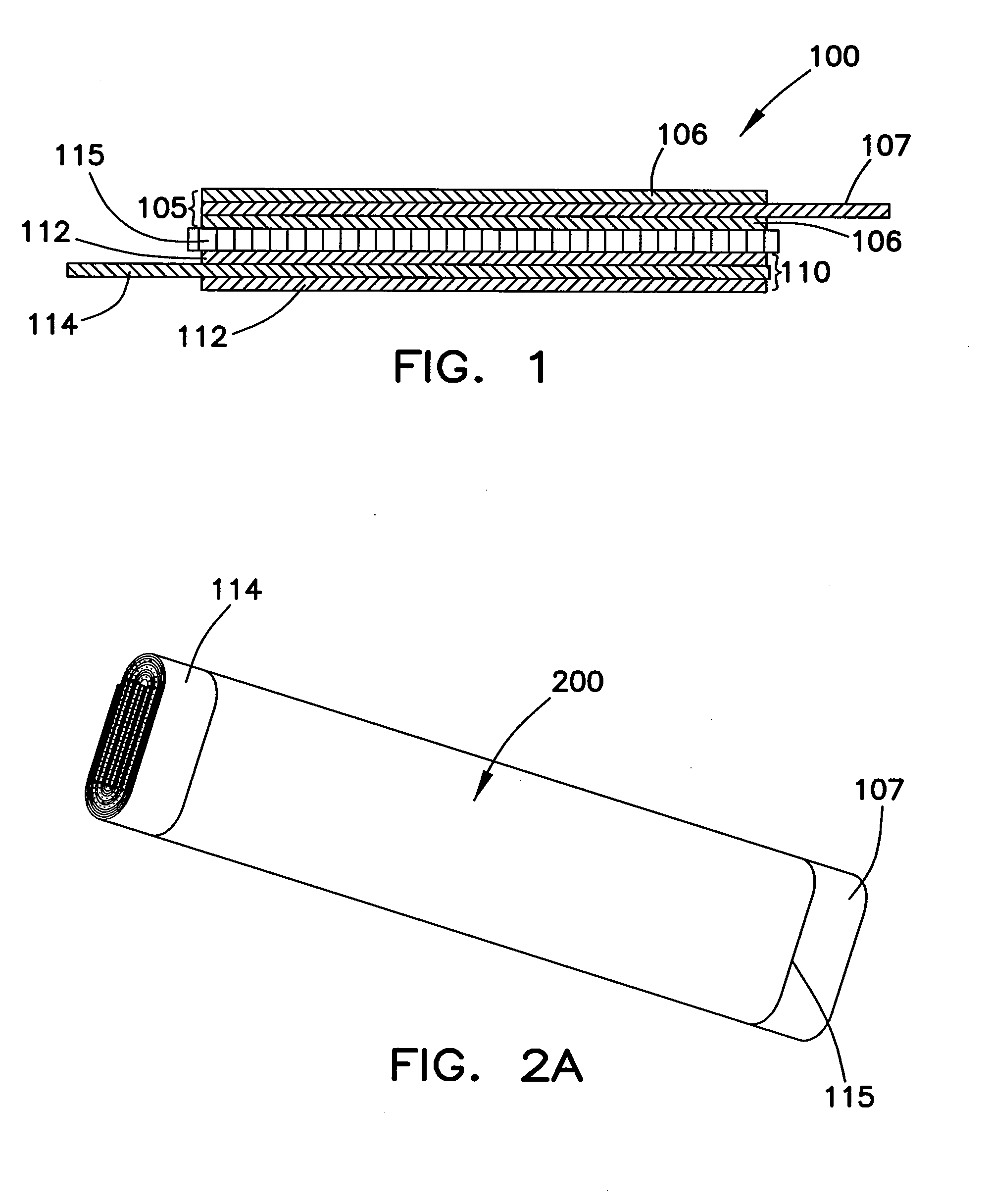

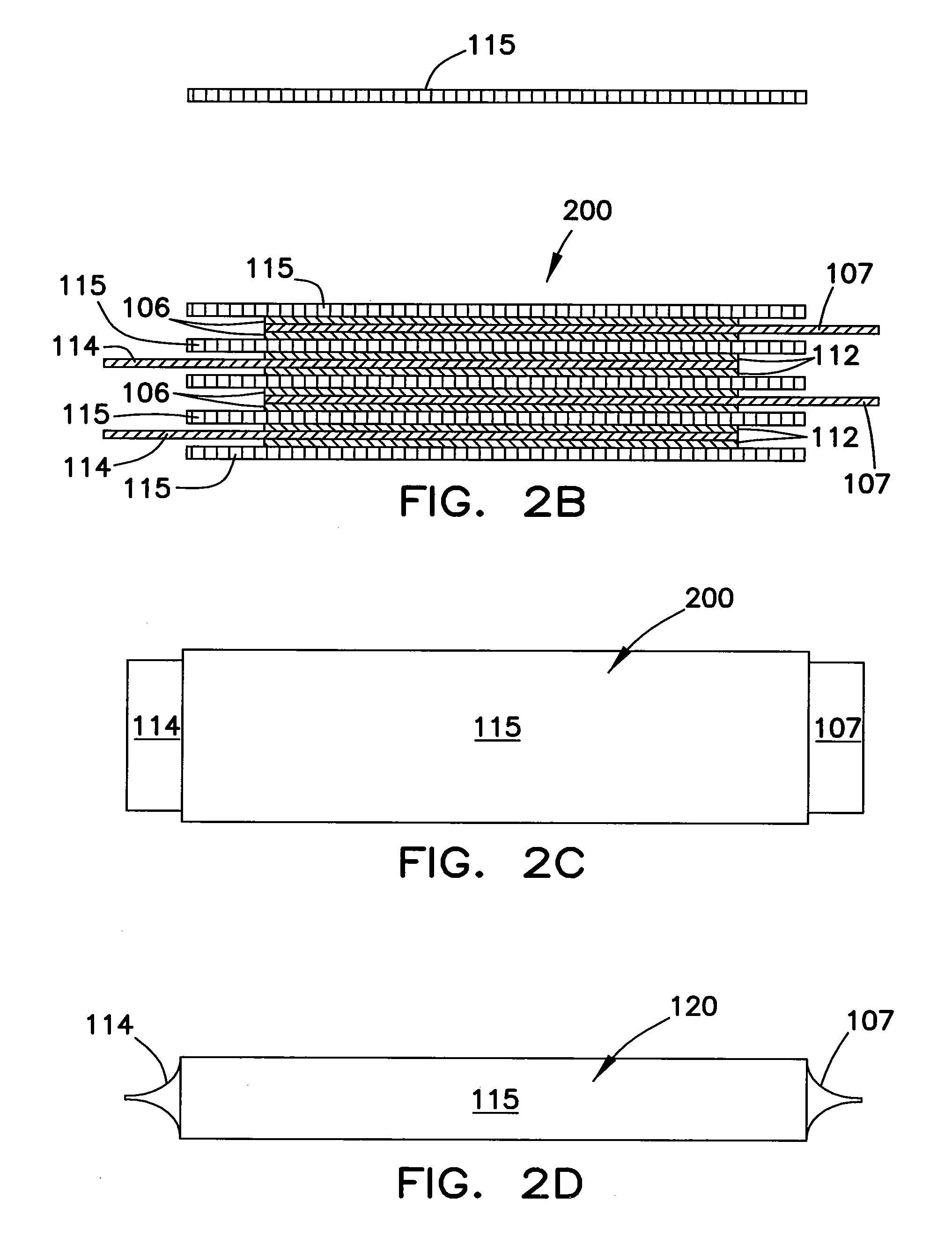

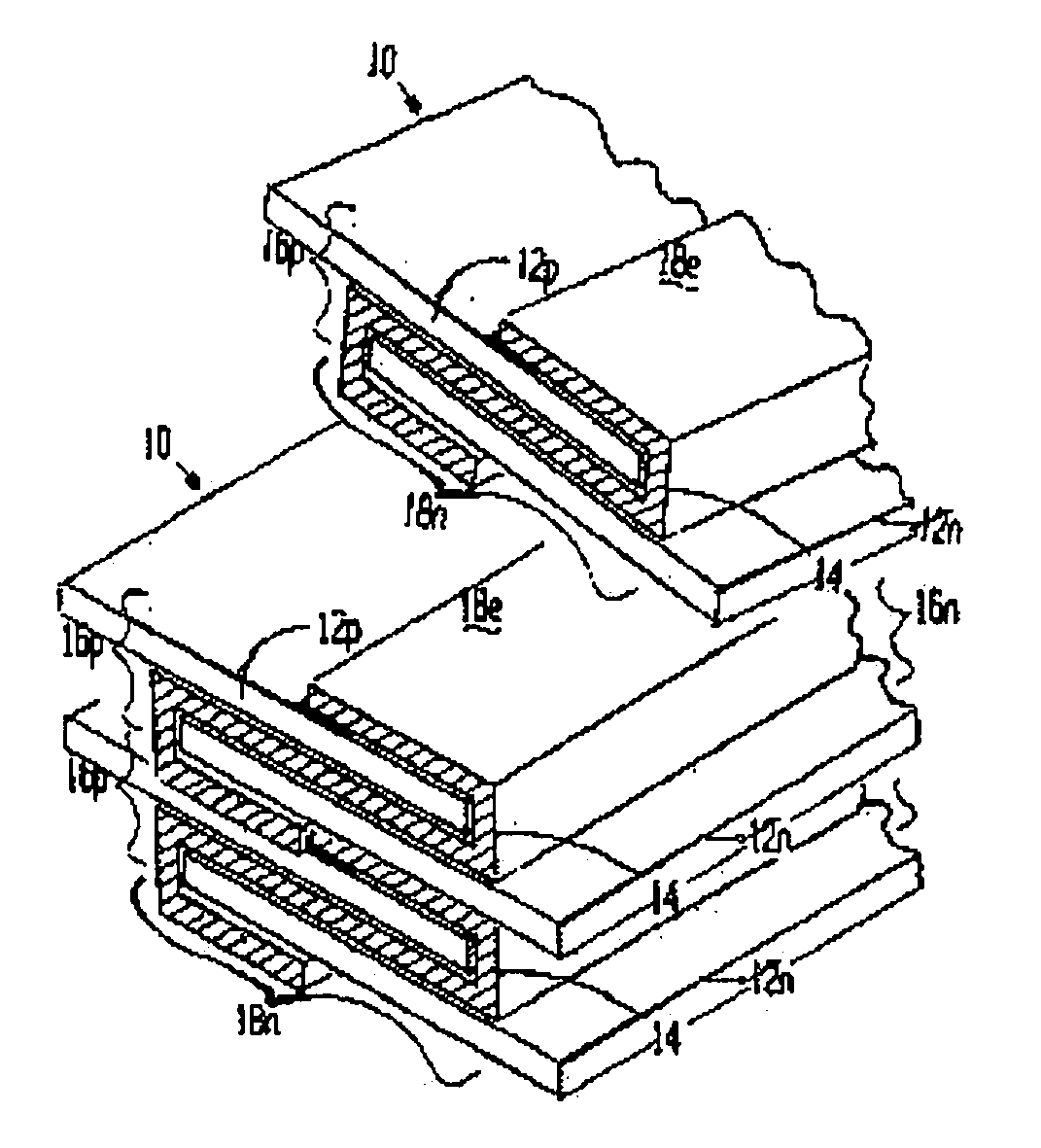

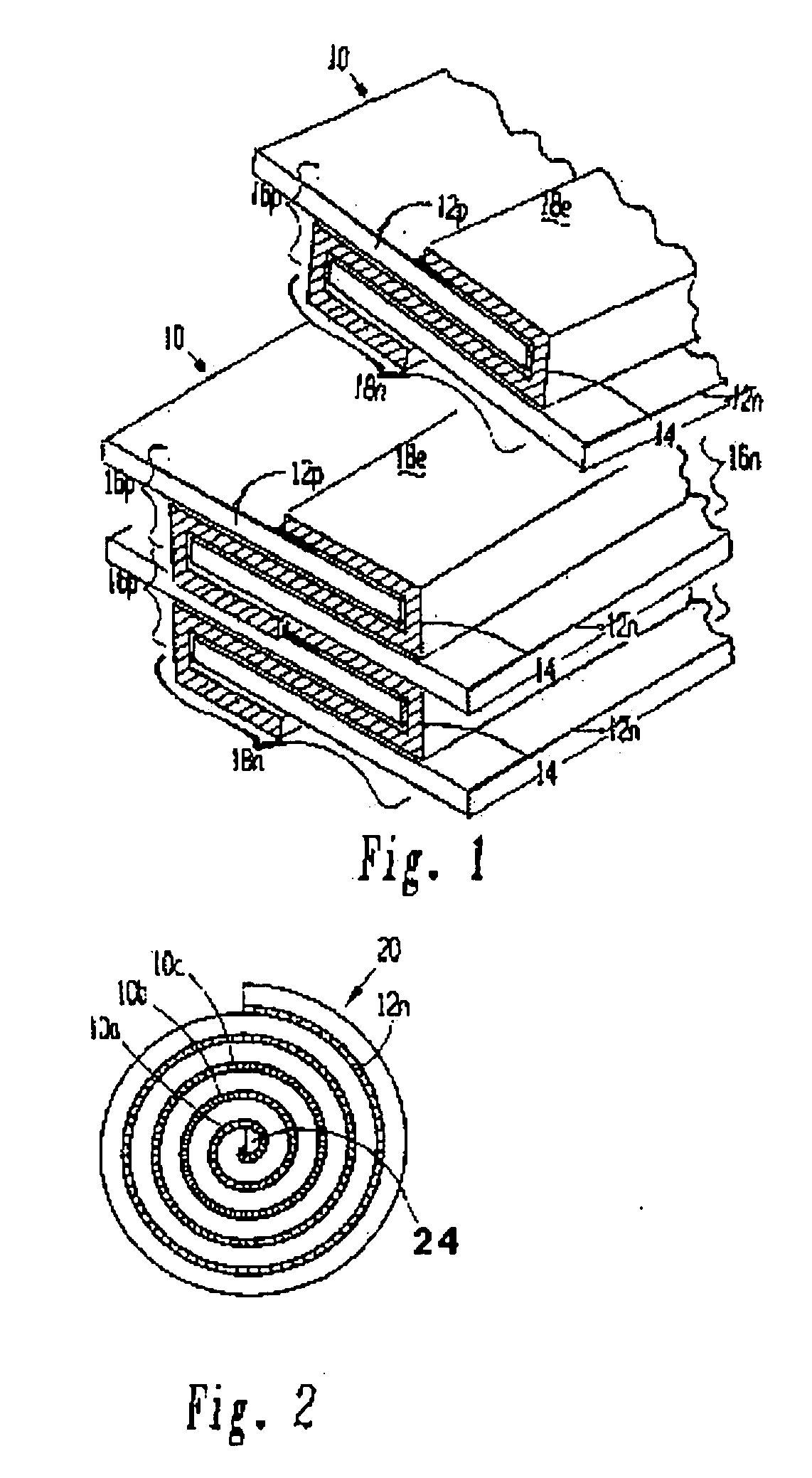

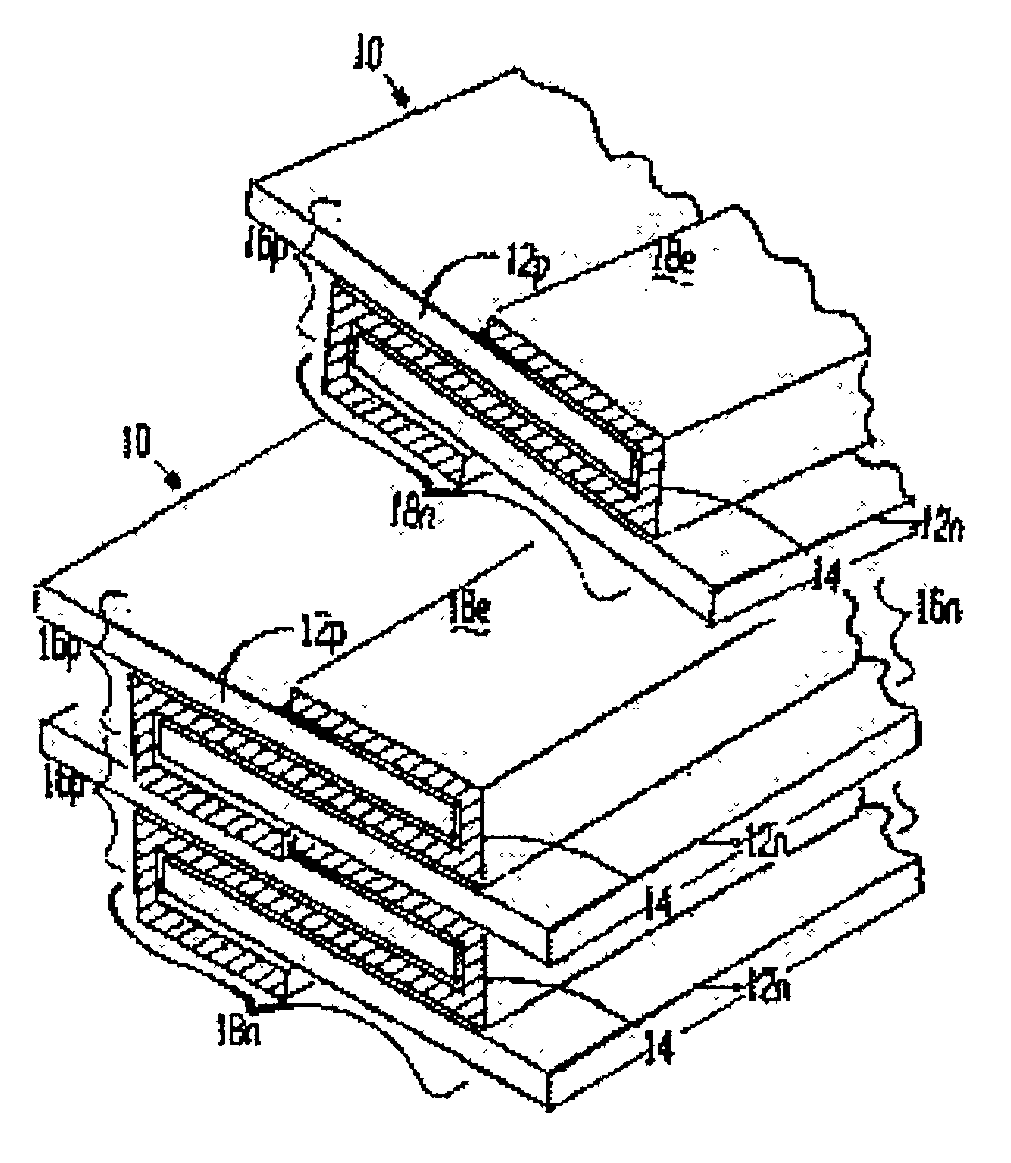

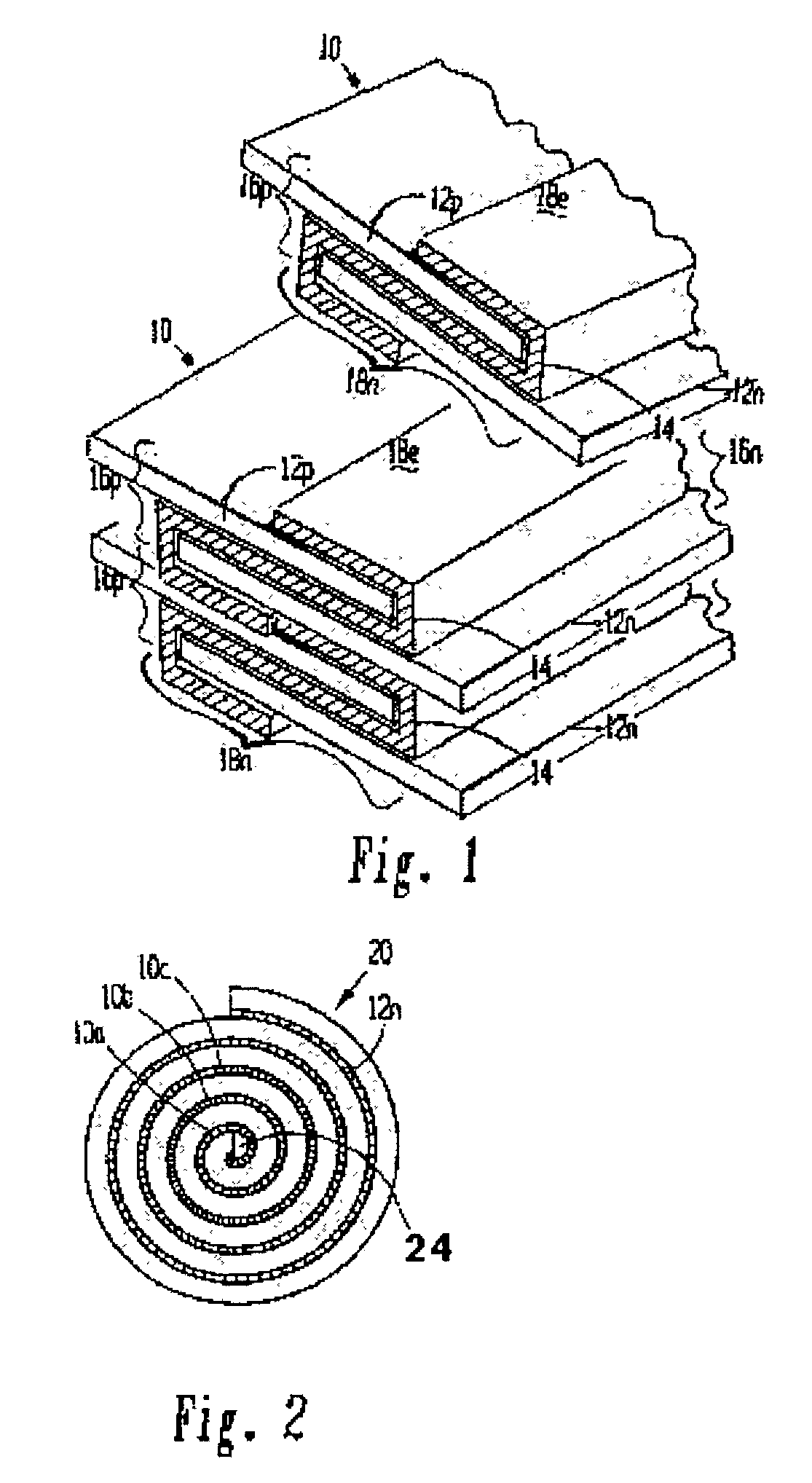

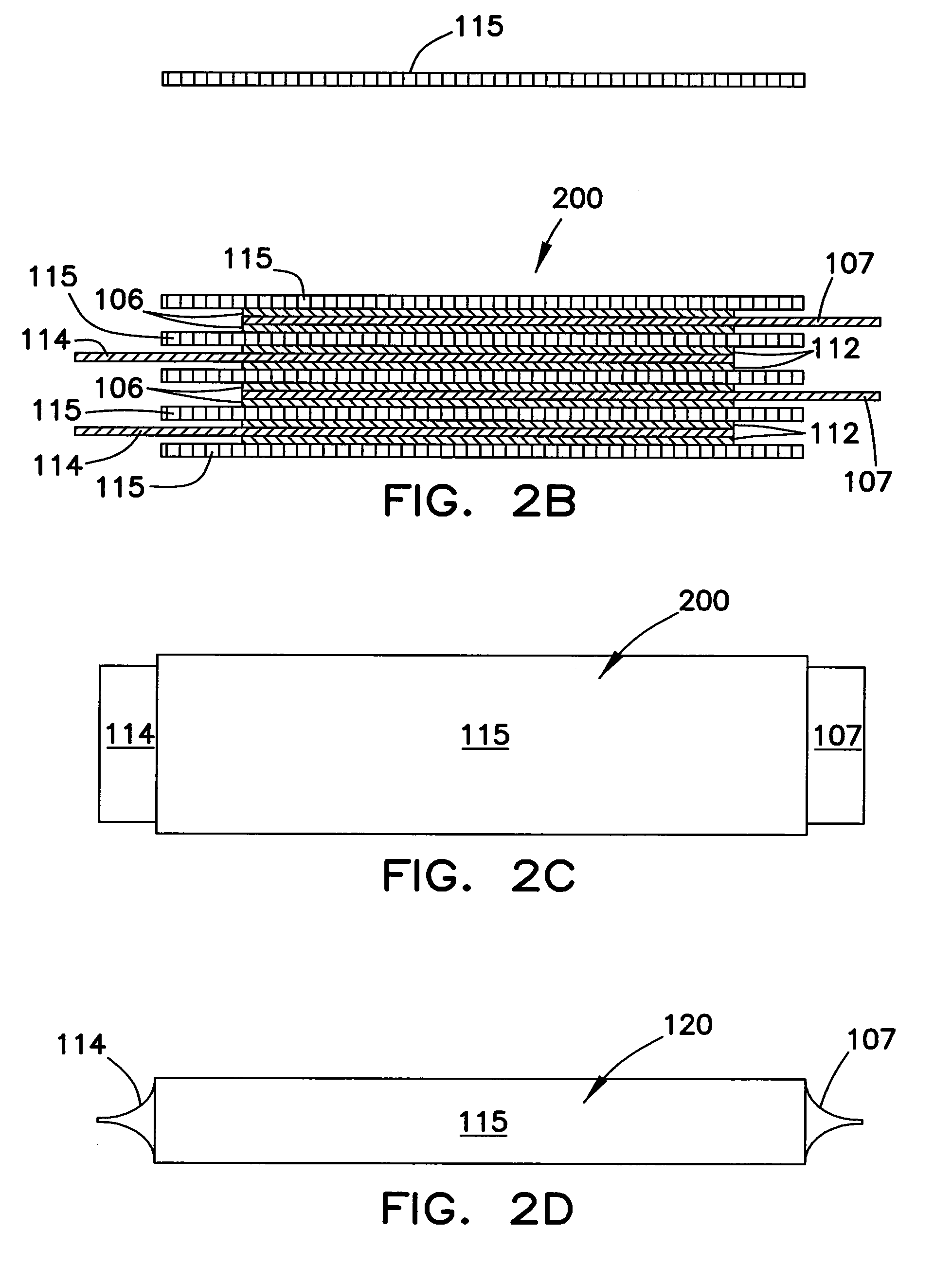

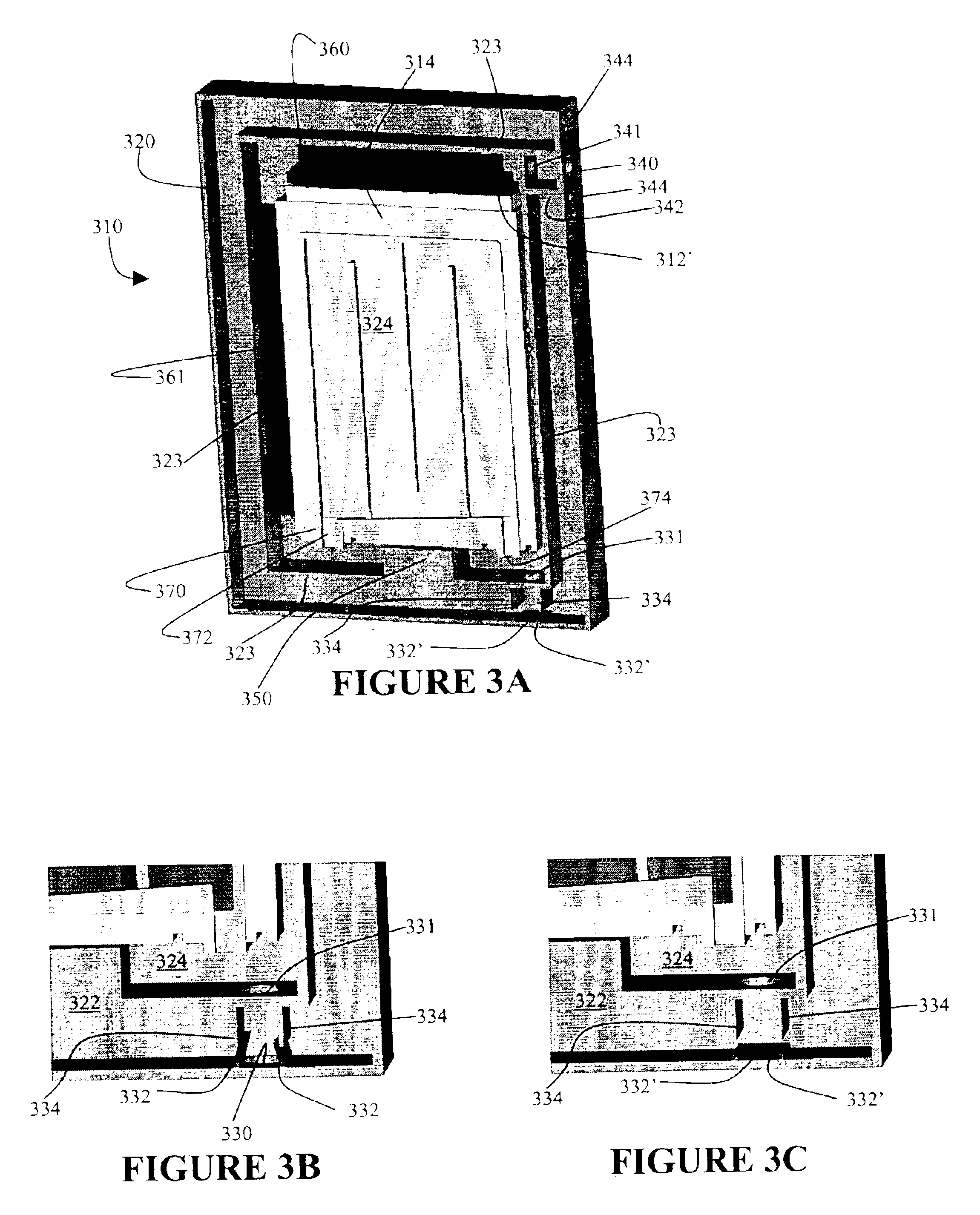

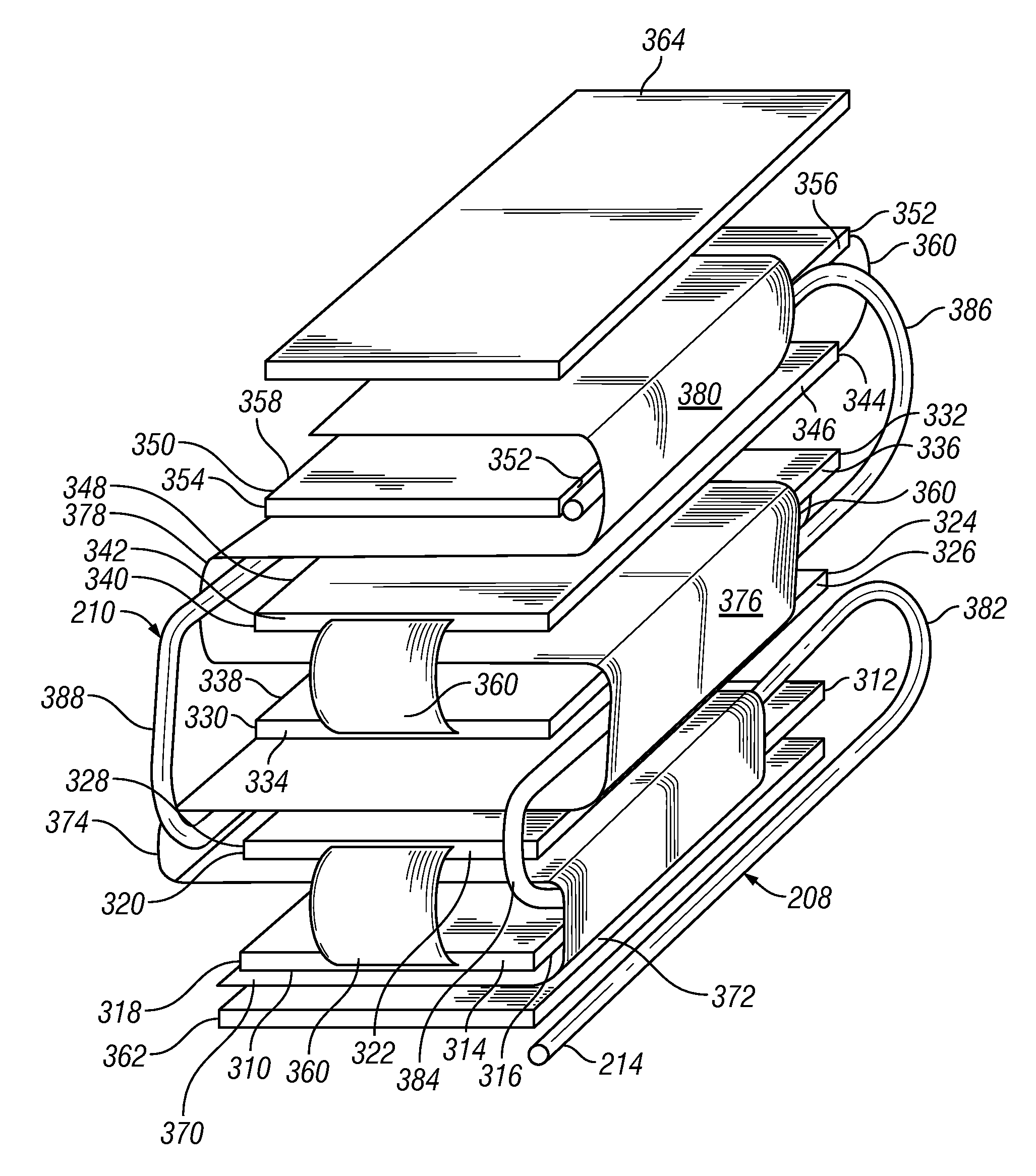

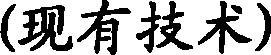

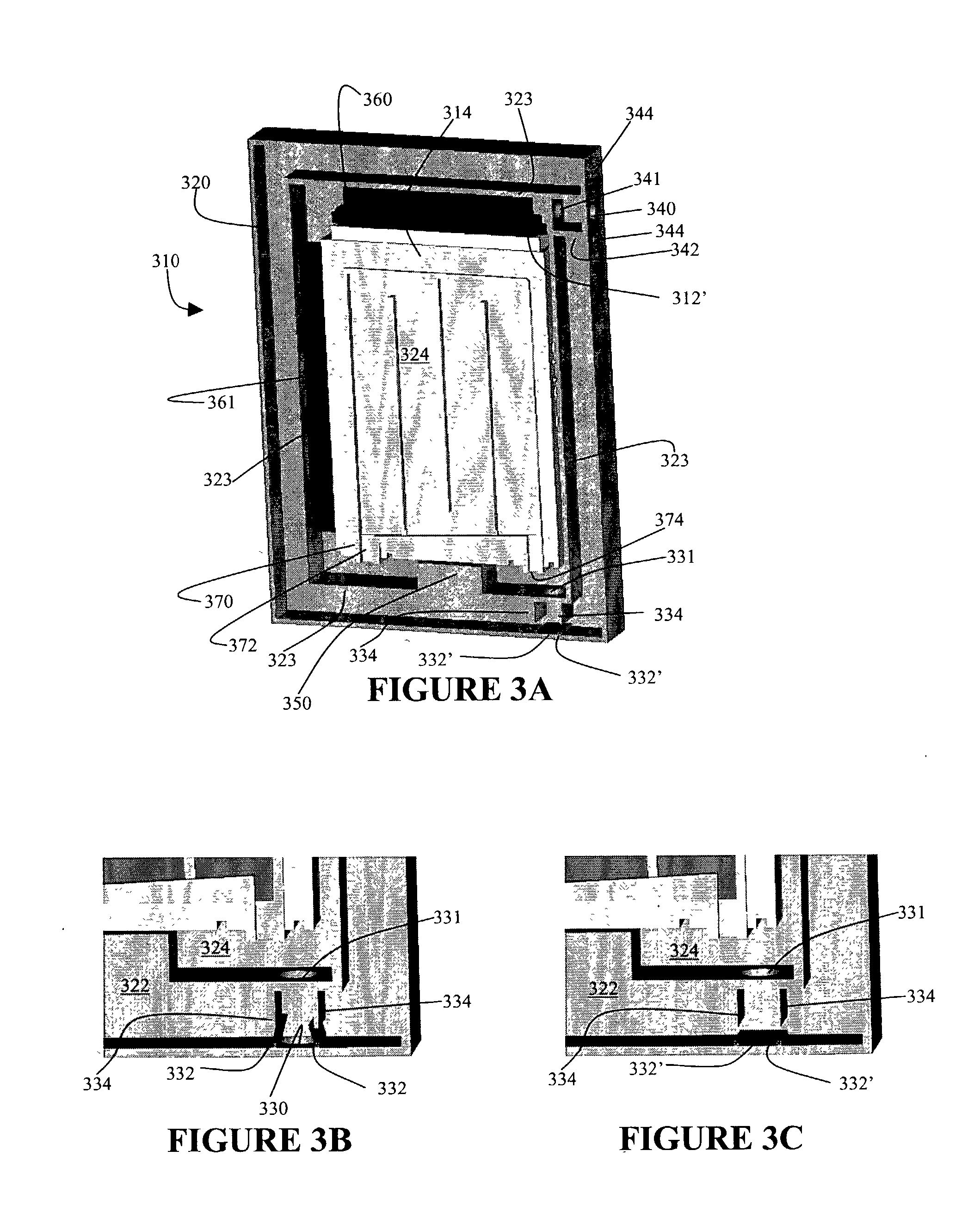

Cell structure for electrochemical devices and method of making same

InactiveUS20070160901A1Cell seperators/membranes/diaphragms/spacersLarge-sized flat cells/batteriesInternal pressureElectrochemistry

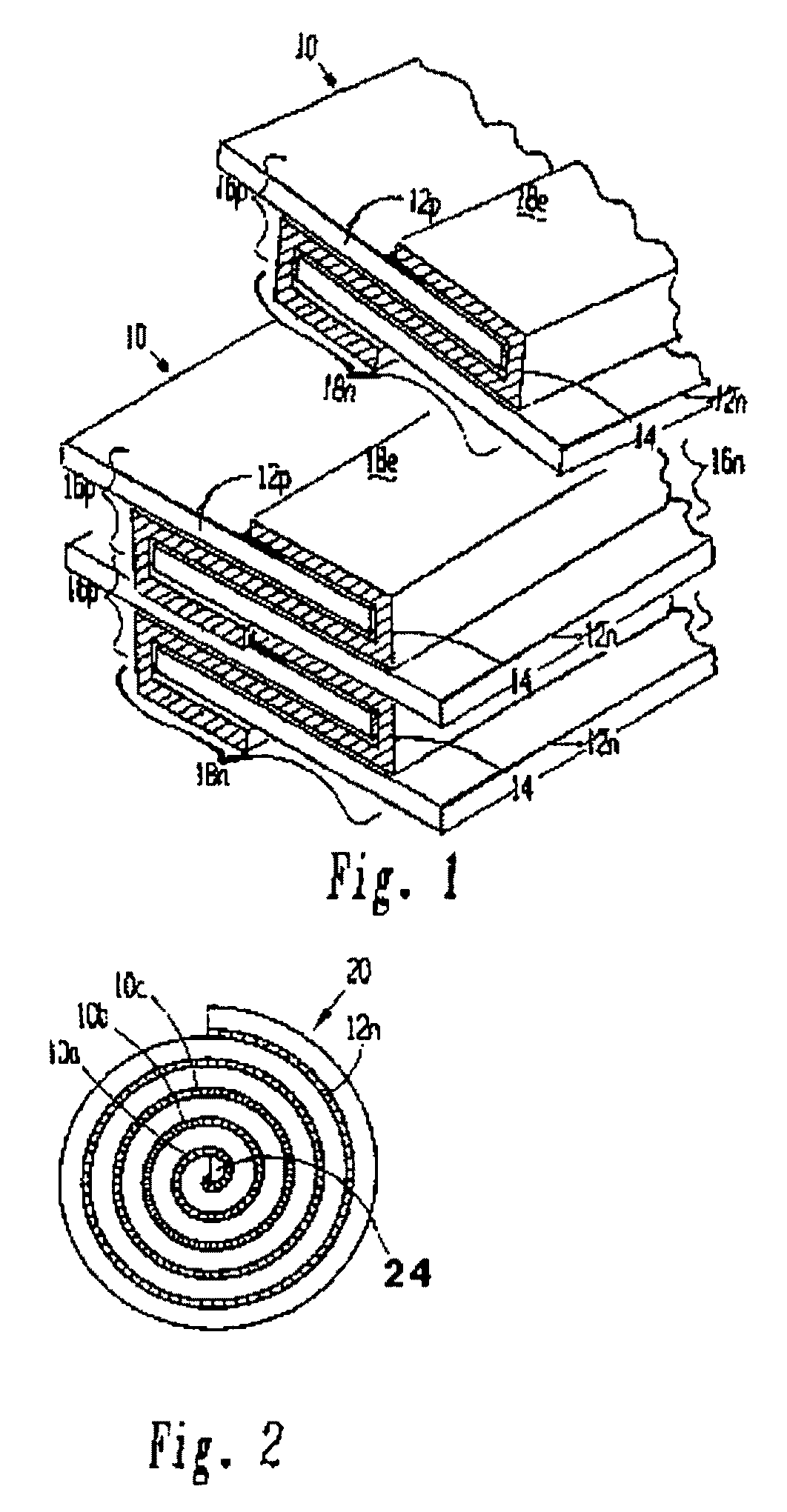

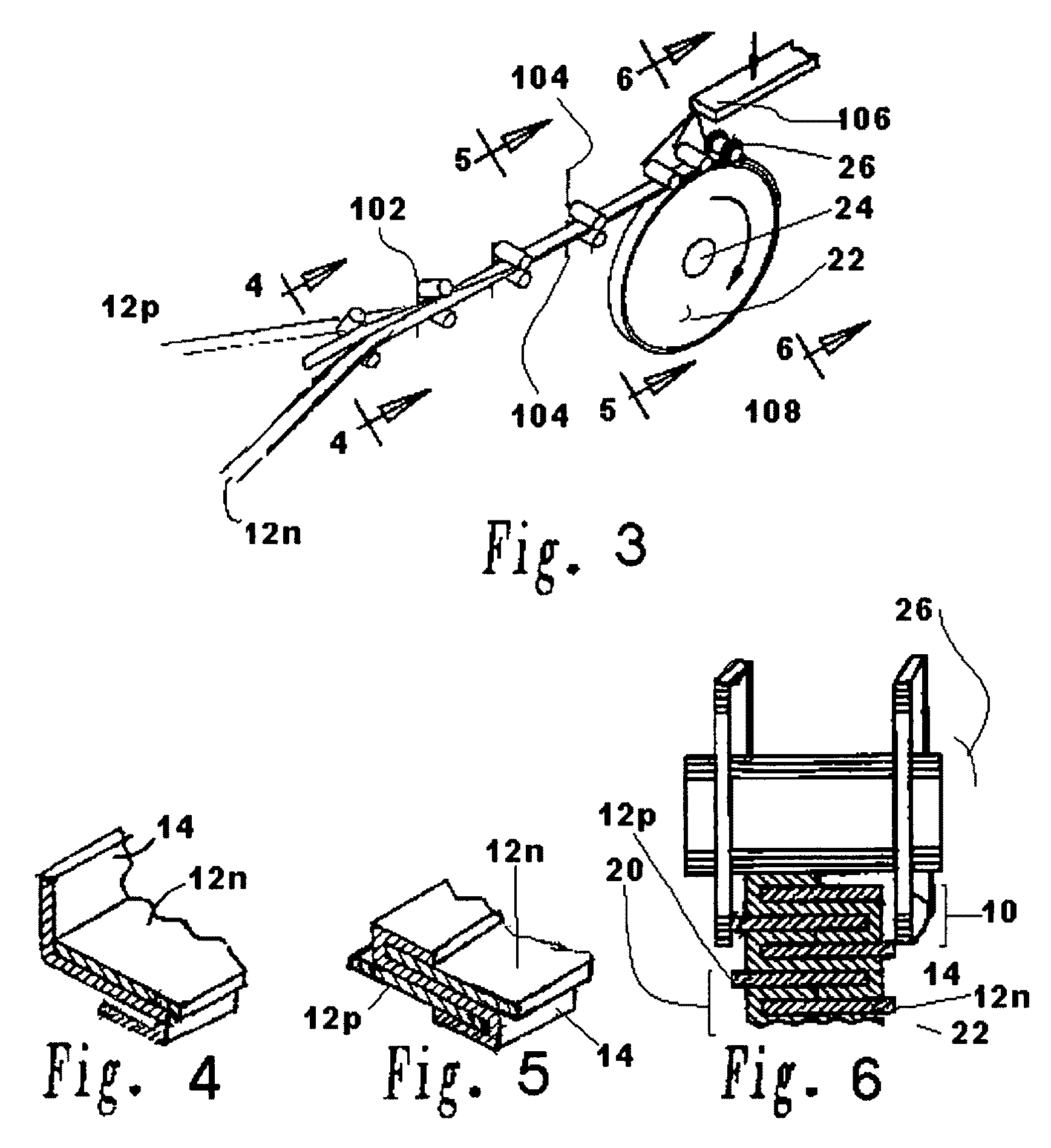

An electrochemical device comprising alternating layers of positive and negative electrodes separated from each other by separator layers. The electrode layers extend beyond the periphery of the separator layers providing superior contact between the electrodes and battery terminals, eliminating the need for welding the electrode to the terminal. Electrical resistance within the battery is decreased and thermal conductivity of the cell is increased allowing for superior heat removal from the battery and increased efficiency. Increased internal pressure within the battery can be alleviated without damaging or removing the battery from service while keeping the contents of the battery sealed off from the atmosphere by a pressure release system. Nonoperative cells within a battery assembly can also be removed from service by shorting the nonoperative cell thus decreasing battery life.

Owner:INVENTEX

Cell structure for electrochemical devices and method of making same

InactiveUS7195840B2Optimize power outputTransmit power can be effectivelyCell seperators/membranes/diaphragms/spacersLarge-sized flat cells/batteriesInternal pressureElectrochemical cell

An electrochemical device comprising alternating layers of positive and negative electrodes separated from each other by separator layers. The electrode layers extend beyond the periphery of the separator layers providing superior contact between the electrodes and battery terminals, eliminating the need for welding the electrode to the terminal. Electrical resistance within the battery is decreased and thermal conductivity of the cell is increased allowing for superior heat removal from the battery and increased efficiency. Increased internal pressure within the battery can be alleviated without damaging or removing the battery from service while keeping the contents of the battery sealed off from the atmosphere by a pressure release system. Nonoperative cells within a battery assembly can also be removed from service by shorting the nonoperative cell thus decreasing battery life.

Owner:INVENTEX

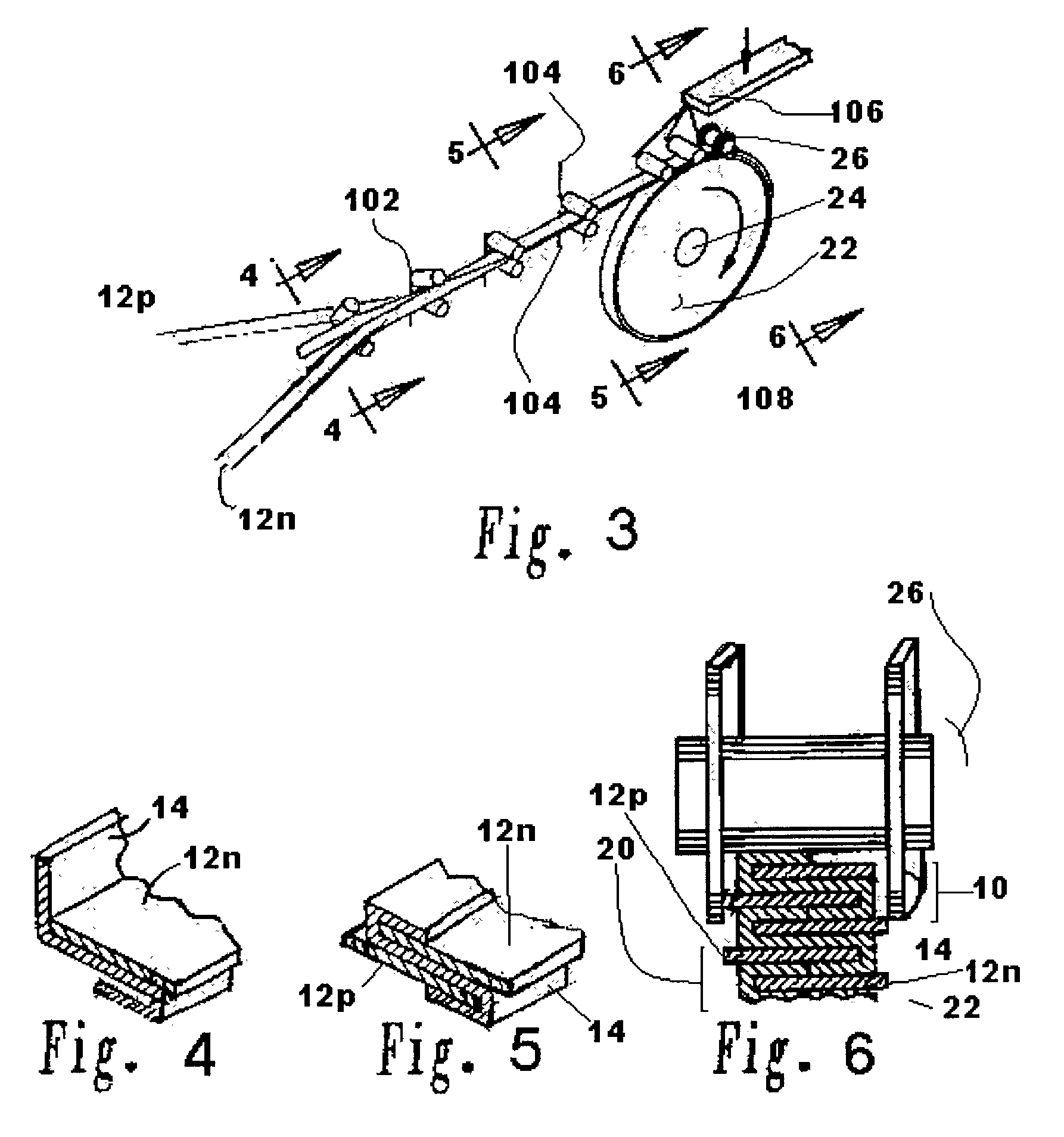

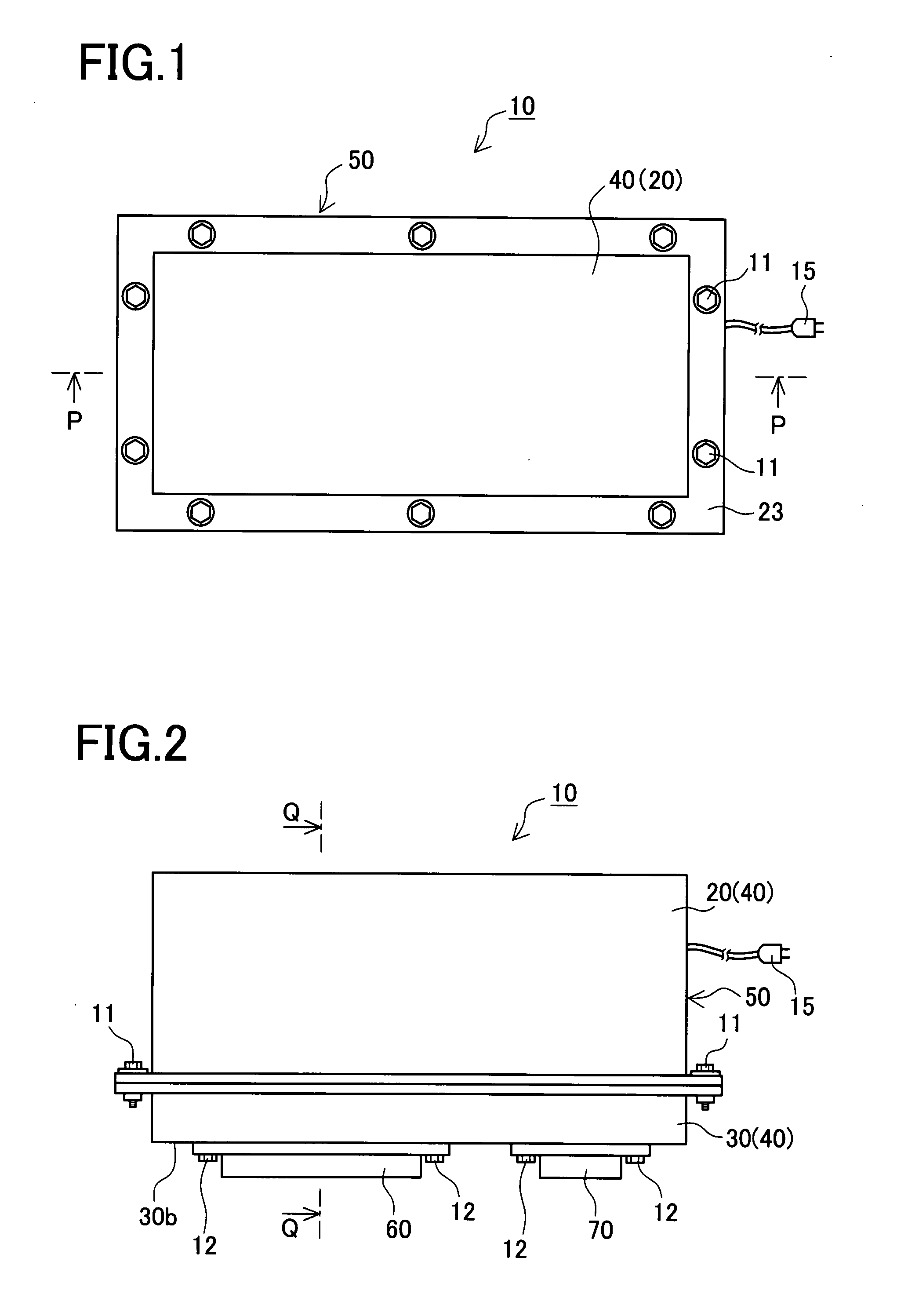

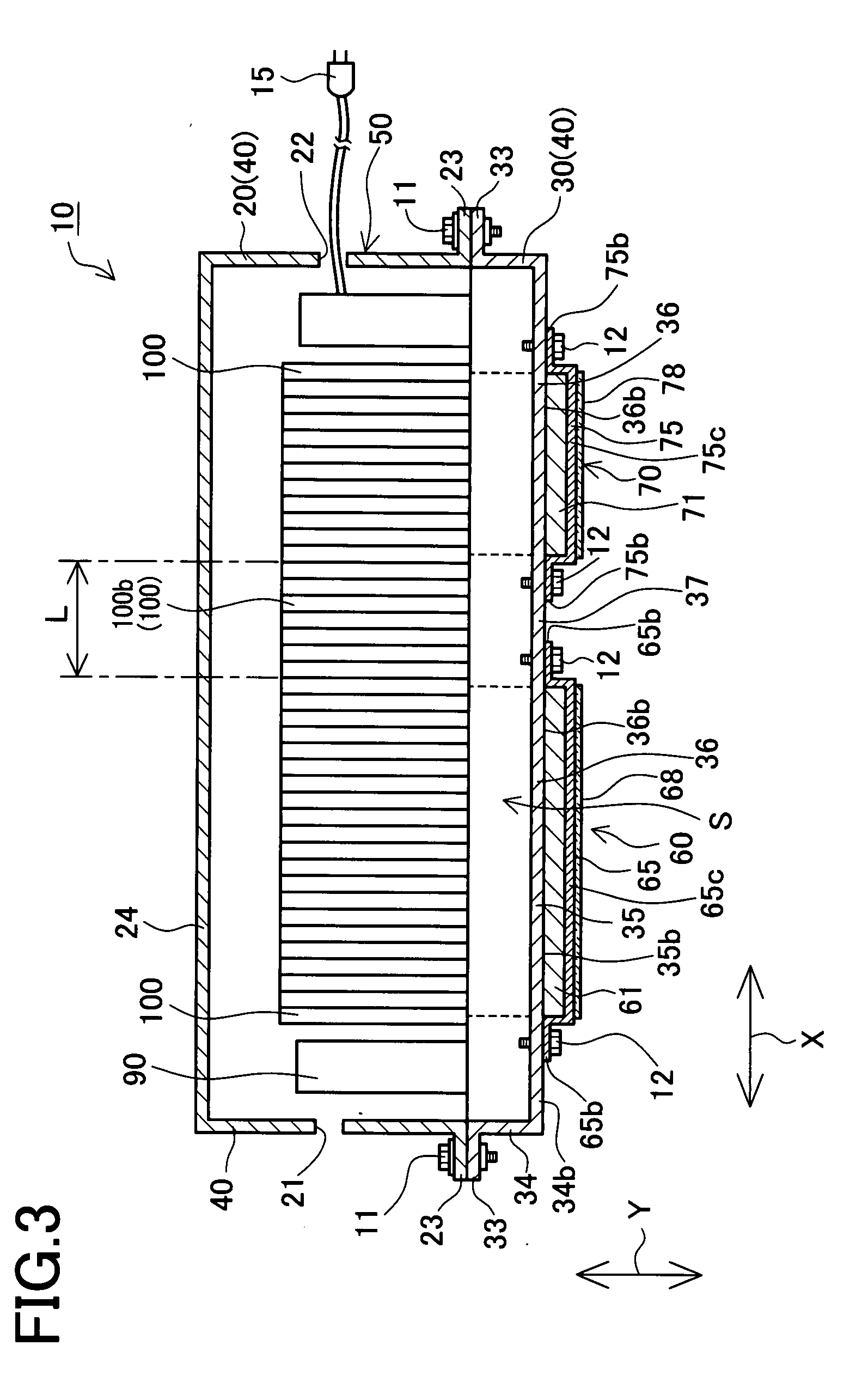

Battery pack structure with heater

ActiveUS20080096072A1Avoid uneven heatingMinimizing temperature variationFuel cells groupingCurrent conducting connectionsBattery packElectrical and Electronics engineering

A battery pack structure with heater including a plurality of secondary batteries, a housing case housing them, and a heater is arranged to prevent uneven heating among the secondary batteries, reducing temperature variations among the secondary batteries. Specifically, the battery pack structure with heater of the present invention includes: a battery pack including a plurality of secondary batteries and a housing case housing them; a first heater; and a second heater. The housing case includes a metal spaced part separated with a space S from each of the secondary batteries. The first heater and the second heater are placed on at least part of an outer surface of the spaced part of the housing case.

Owner:PANASONIC EV ENERGY CO LTD

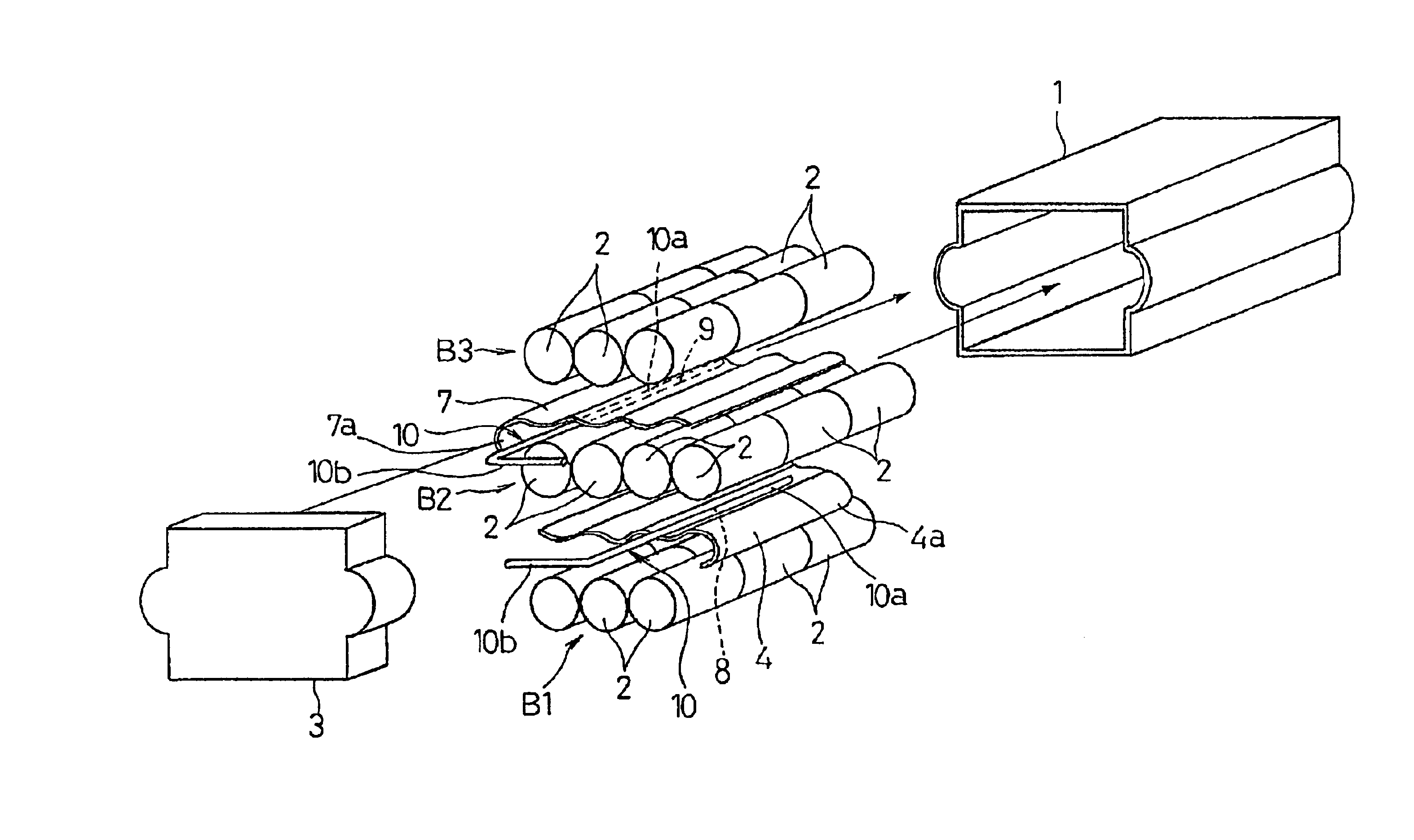

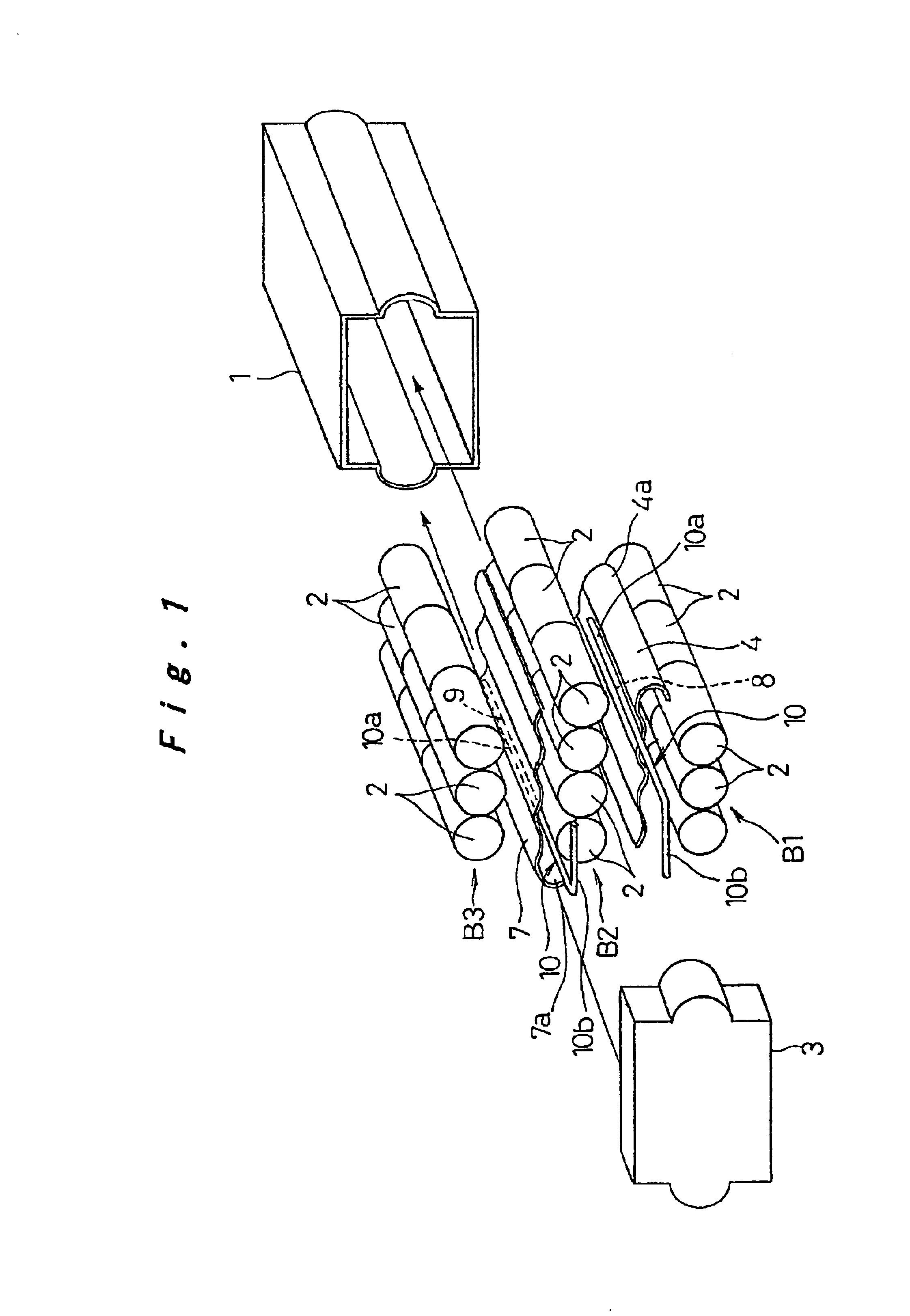

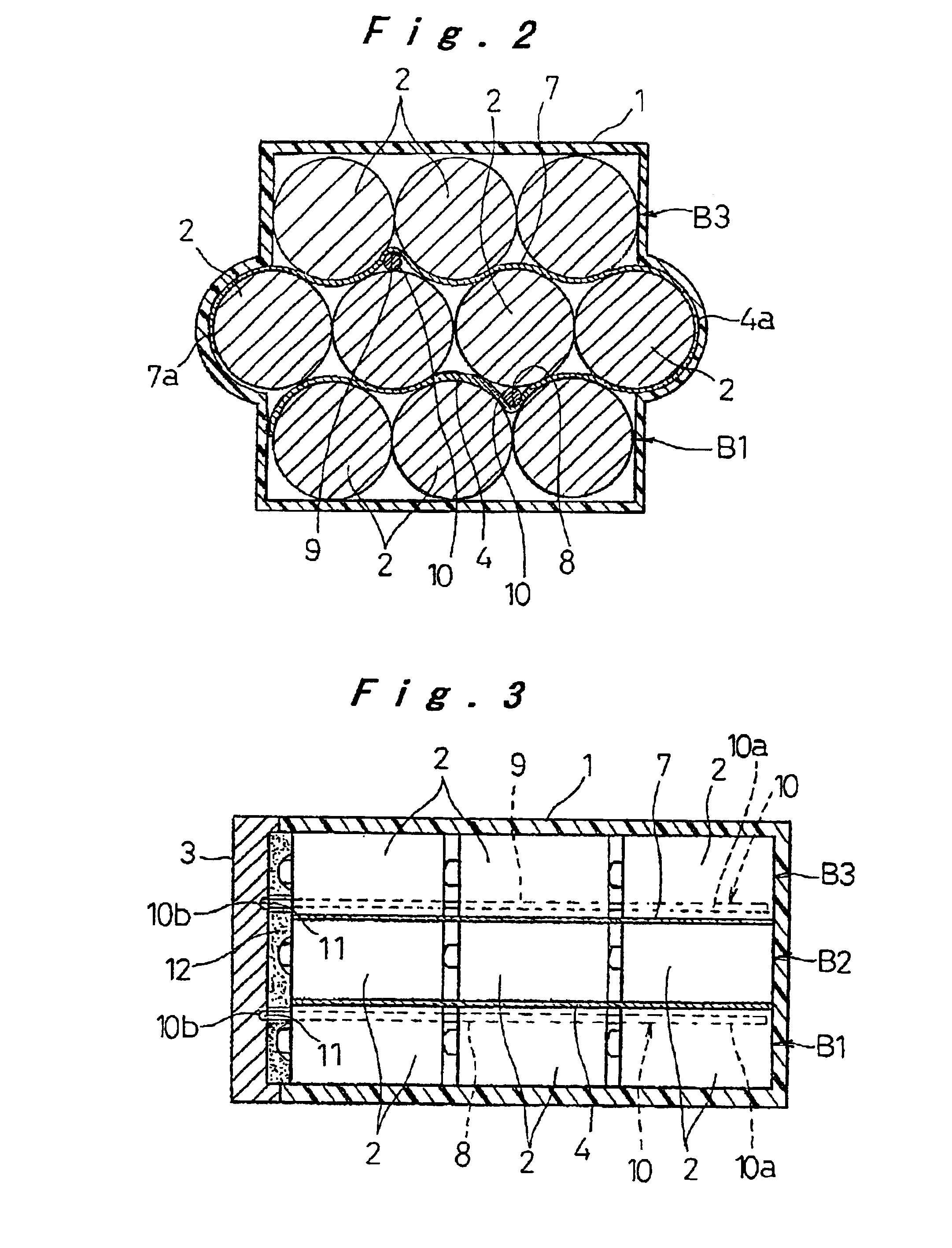

Heat dissipating battery pack

InactiveUS6933076B2Small differenceCollected substantially evenly and efficientlyPrimary cell to battery groupingCell temperature controlMetal sheetEngineering

A battery pack includes a plurality of cells (2) stacked on top of one another in tiers; a heat collecting plate (4, 7) made of a wave-like metal sheet and interposed between tiers of the cells so as to make contact with outer peripheral surfaces of upper and lower tiers of the cells alternately; a heat pipe (10) having its heating portion (10a) fitted into a fitting groove (8, 9) formed in the heat collecting plate; a pack case (1) for accommodating the cells, the heat collecting plate, and the heat pipe; and a heat dissipating member (3) attached to the pack case so as to close an opening of the pack case and having on its inner-surface side a concavely-formed receiving groove (11) into which a heat dissipating portion (10b) of the heat pipe is fitted.

Owner:PANASONIC CORP

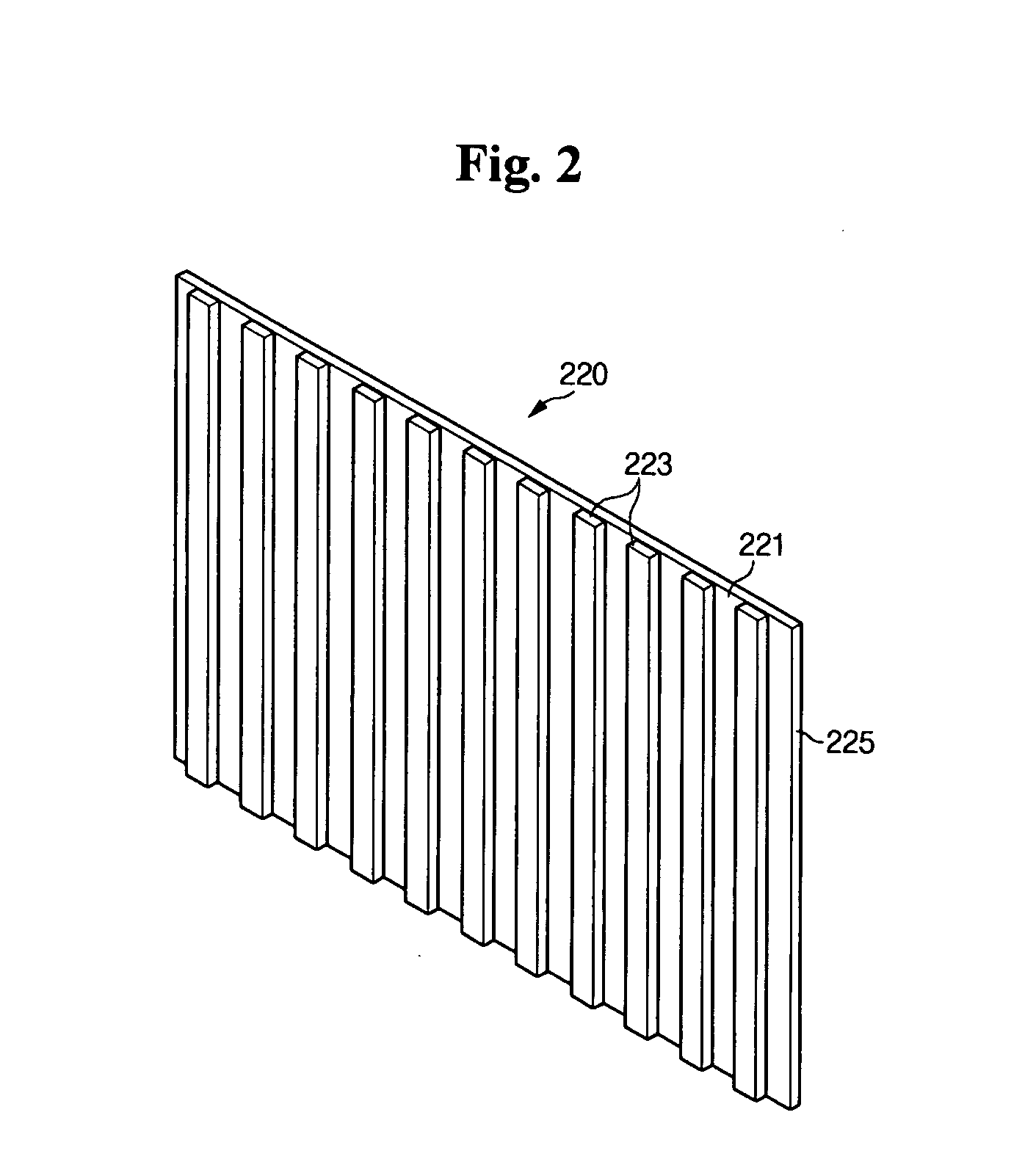

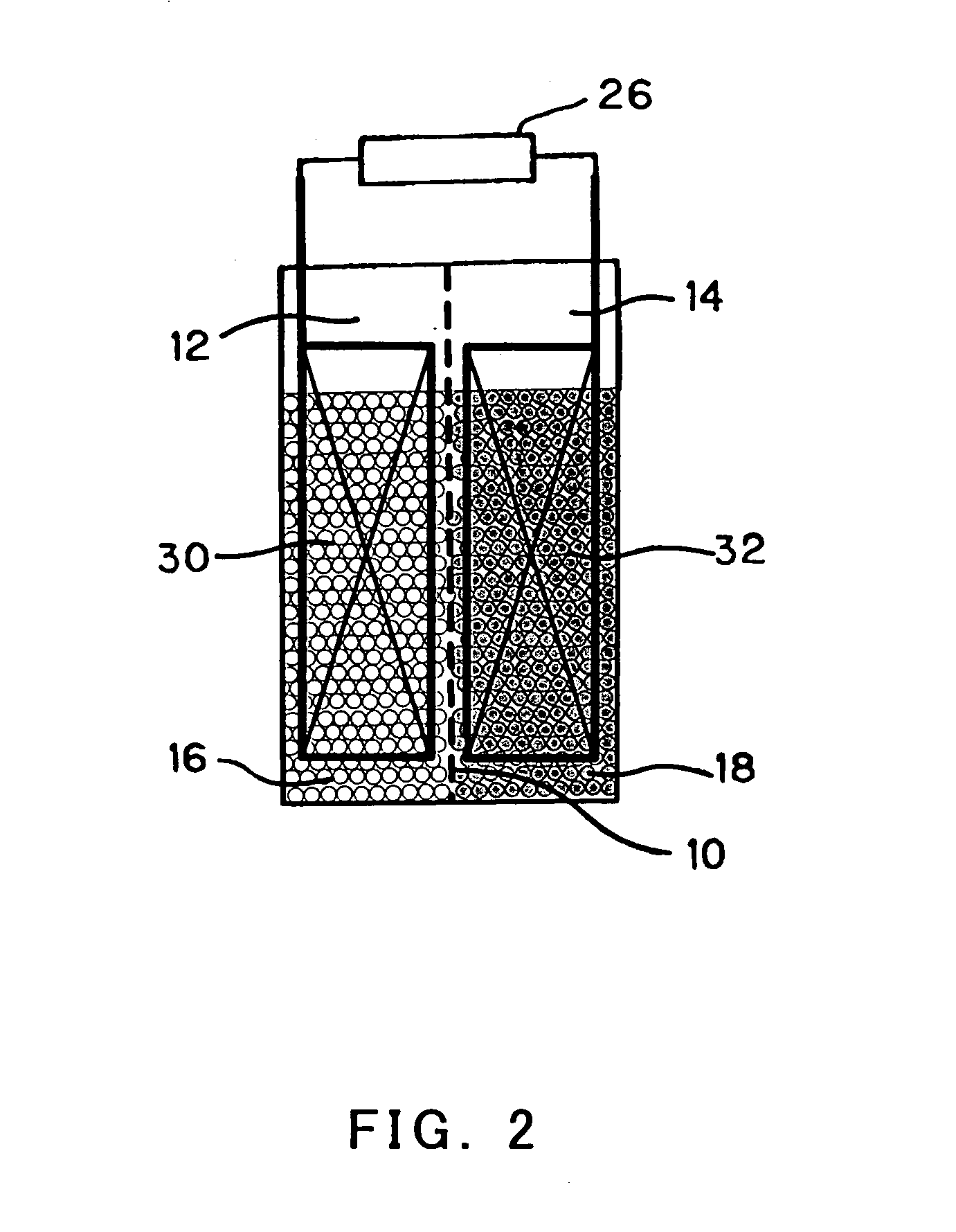

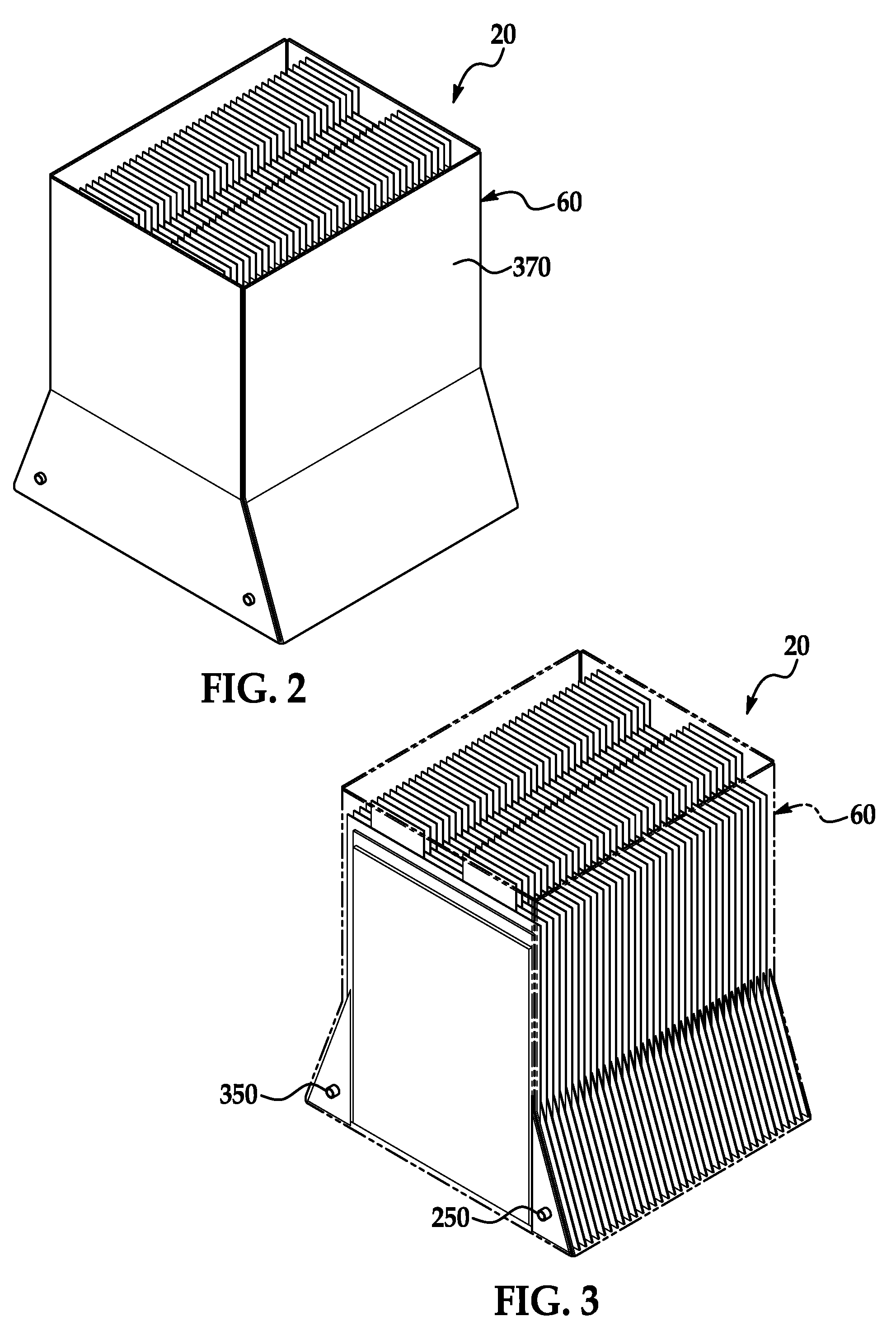

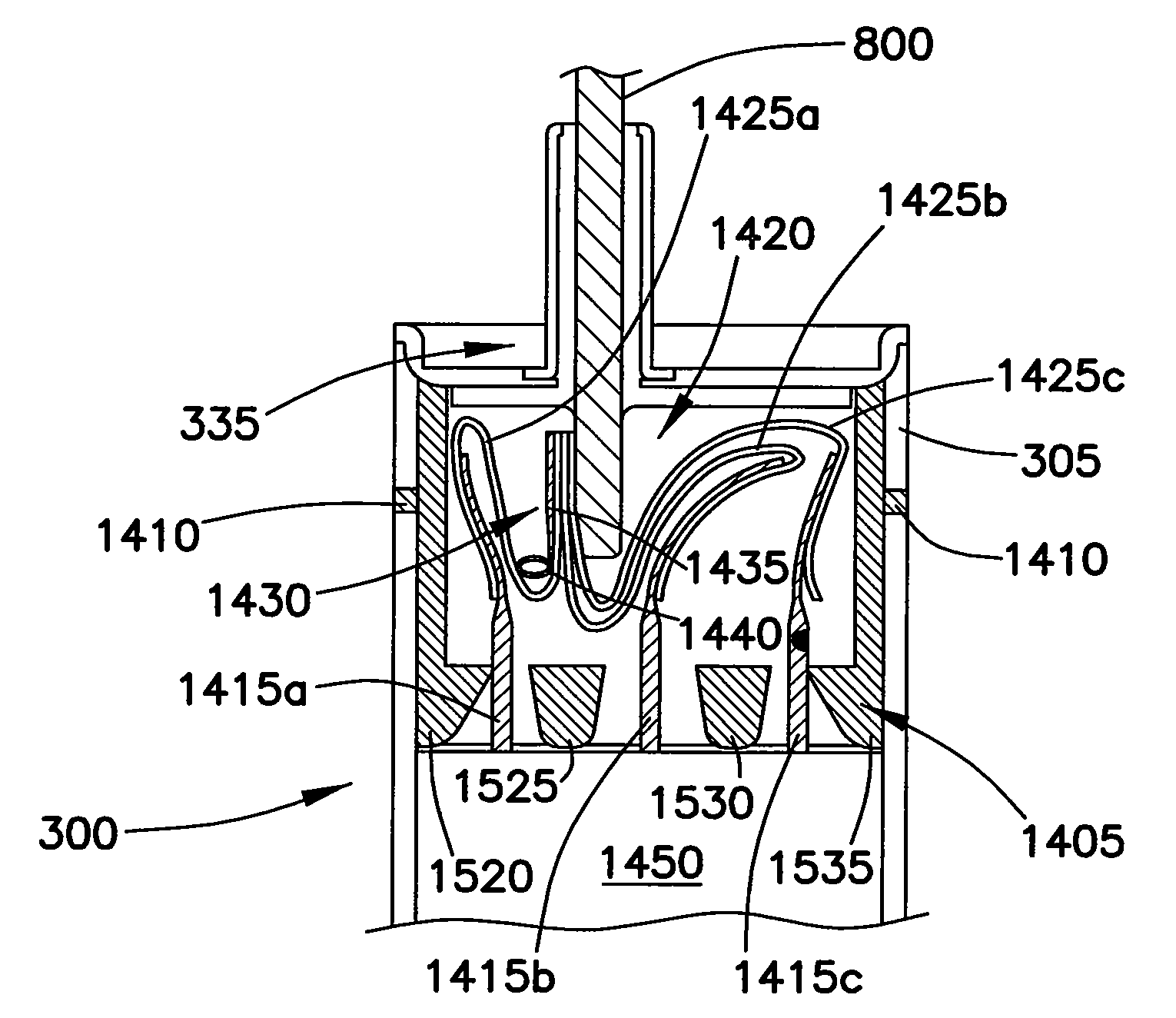

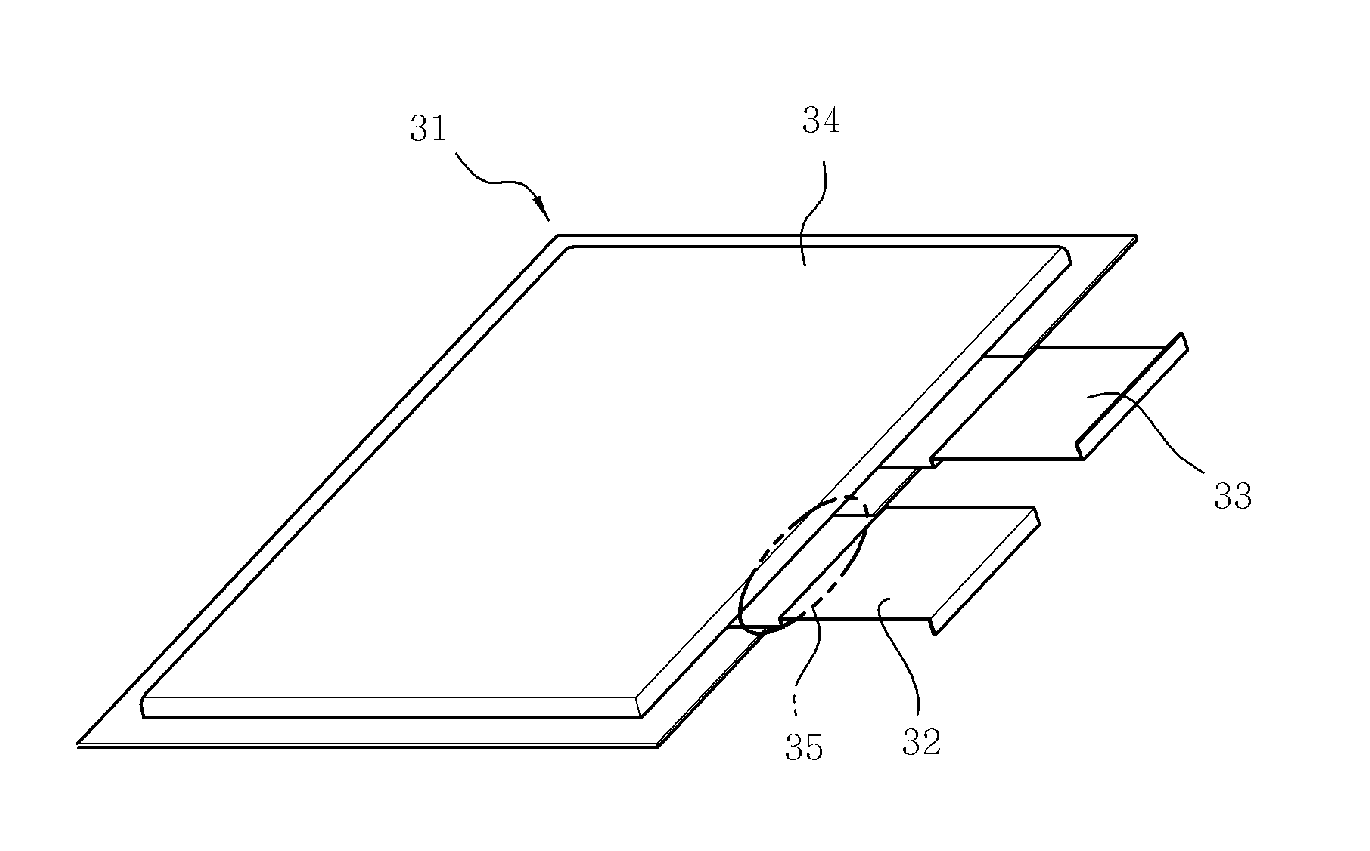

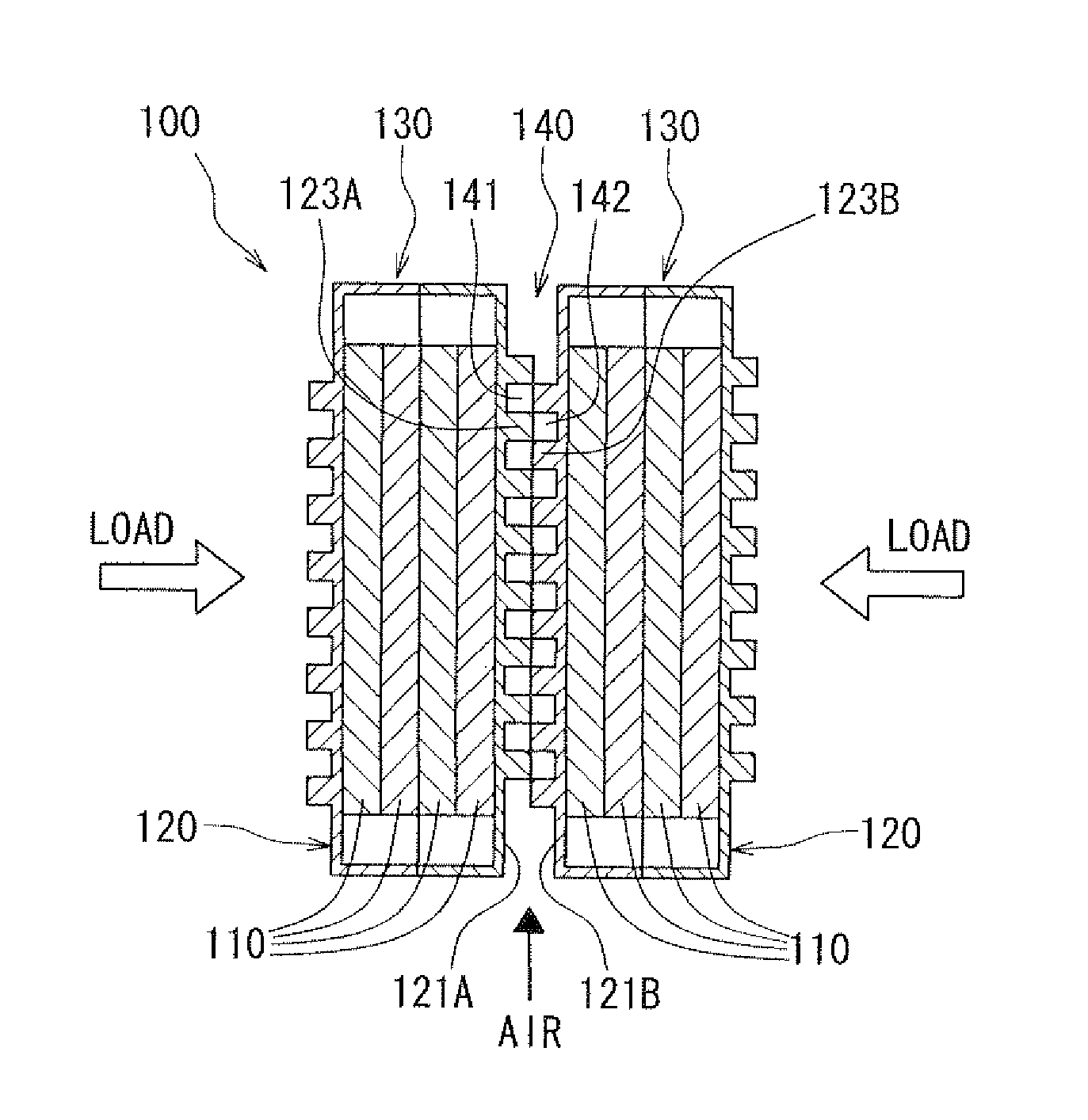

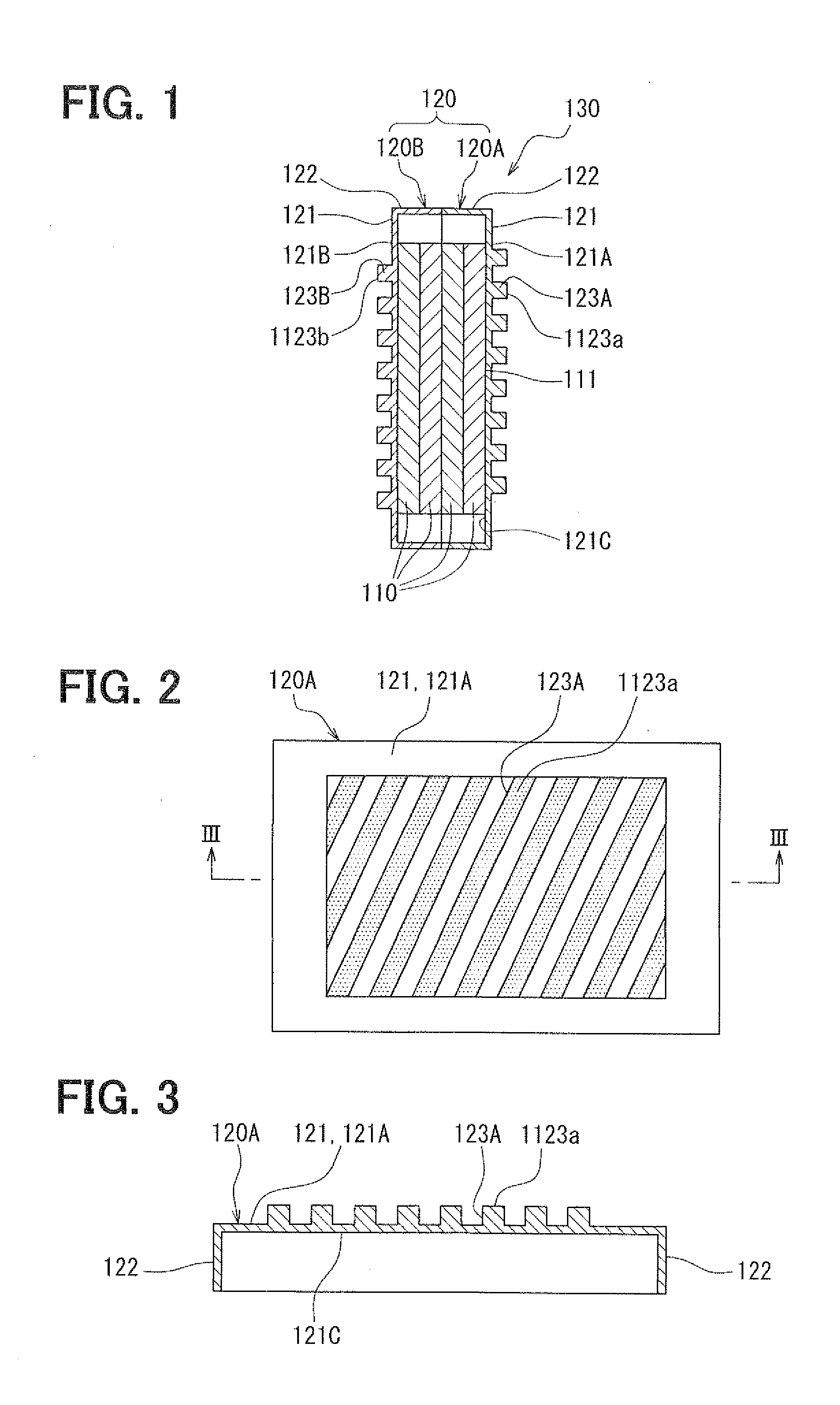

Battery module and method for cooling the battery module

A battery module and a method for cooling the battery module are provided. The battery module includes a housing having an electrically non-conductive oil disposed therein, and a battery cell disposed in the housing that contacts the electrically non-conductive oil. The battery module further includes first and second heat conductive fins disposed in the housing that contacts the electrically non-conductive oil. The first and second heat conductive fins extract heat energy from the electrically non-conductive oil. The battery module further includes first and second conduits extending through the first and second heat conductive fins, respectively. The first and second conduits receive first and second portions of a fluid, respectively, therethrough and conduct heat energy from the first and second heat conductive fins, respectively, into the fluid to cool the battery cell.

Owner:LG ENERGY SOLUTION LTD

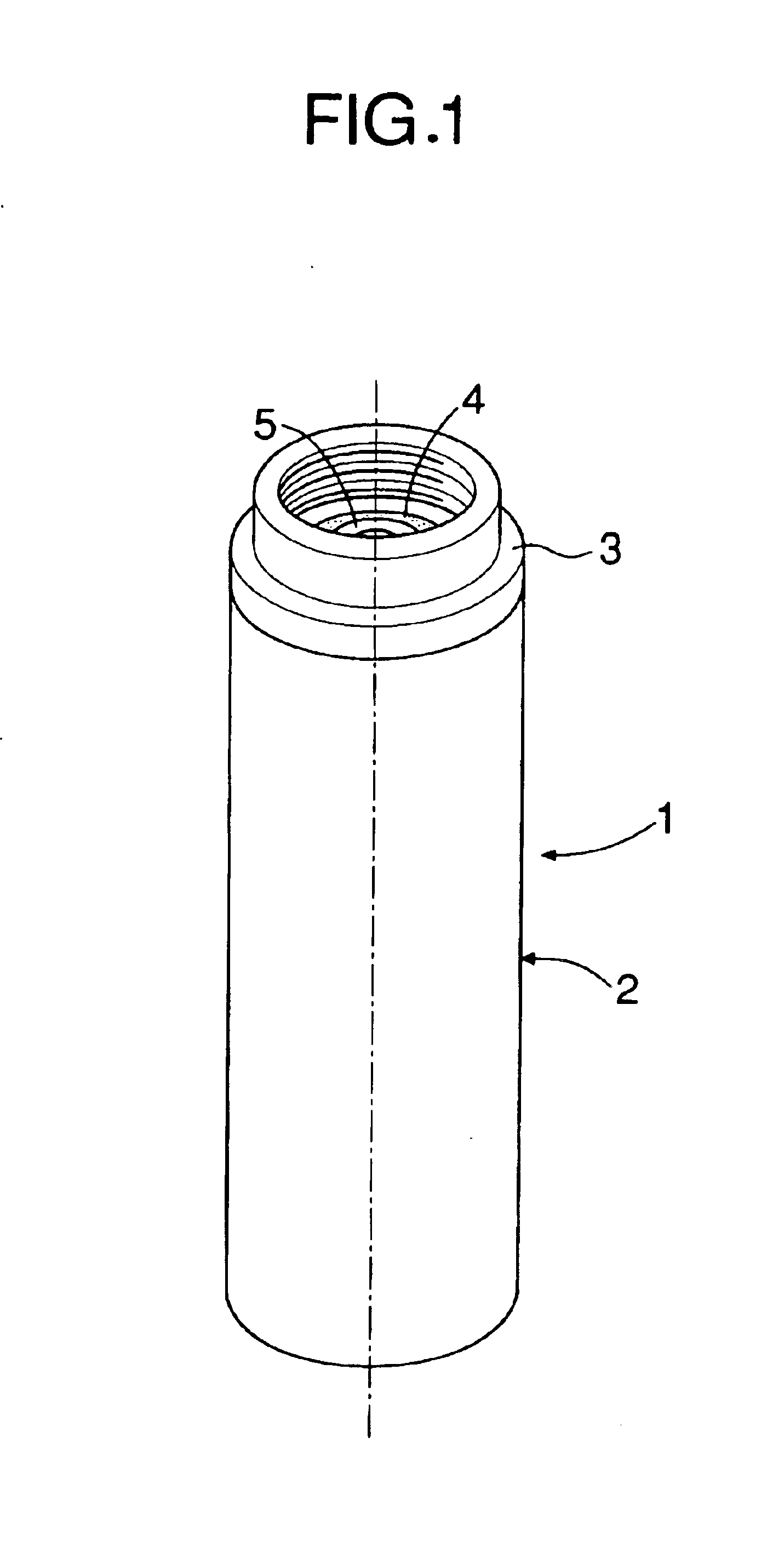

Protection cover for an end cap assembly of a battery cell

ActiveUS20090162747A1Primary cell to battery groupingFinal product manufactureEngineeringElectrochemistry

An electrochemical storage cell is disclosed. The cell includes a core having a cathode sheet, an anode sheet, and a separator sheet. The core is located snuggly within a shell having an open end. An end cap assembly is provided to close the open end. A terminal in electrical communication with one of the cathode sheet and the anode sheet extends through the end cap from an interior portion of the electrochemical storage cell to an external portion thereof. A protection cover that generally conforms to the outermost portions of the end cap assembly is provided and includes a first cover half having a first mating structure and a second cover half having a second mating structure for engagement with the first mating structure. The first and second cover halves are adapted for assembly with one another about the terminal.

Owner:BYD CO LTD

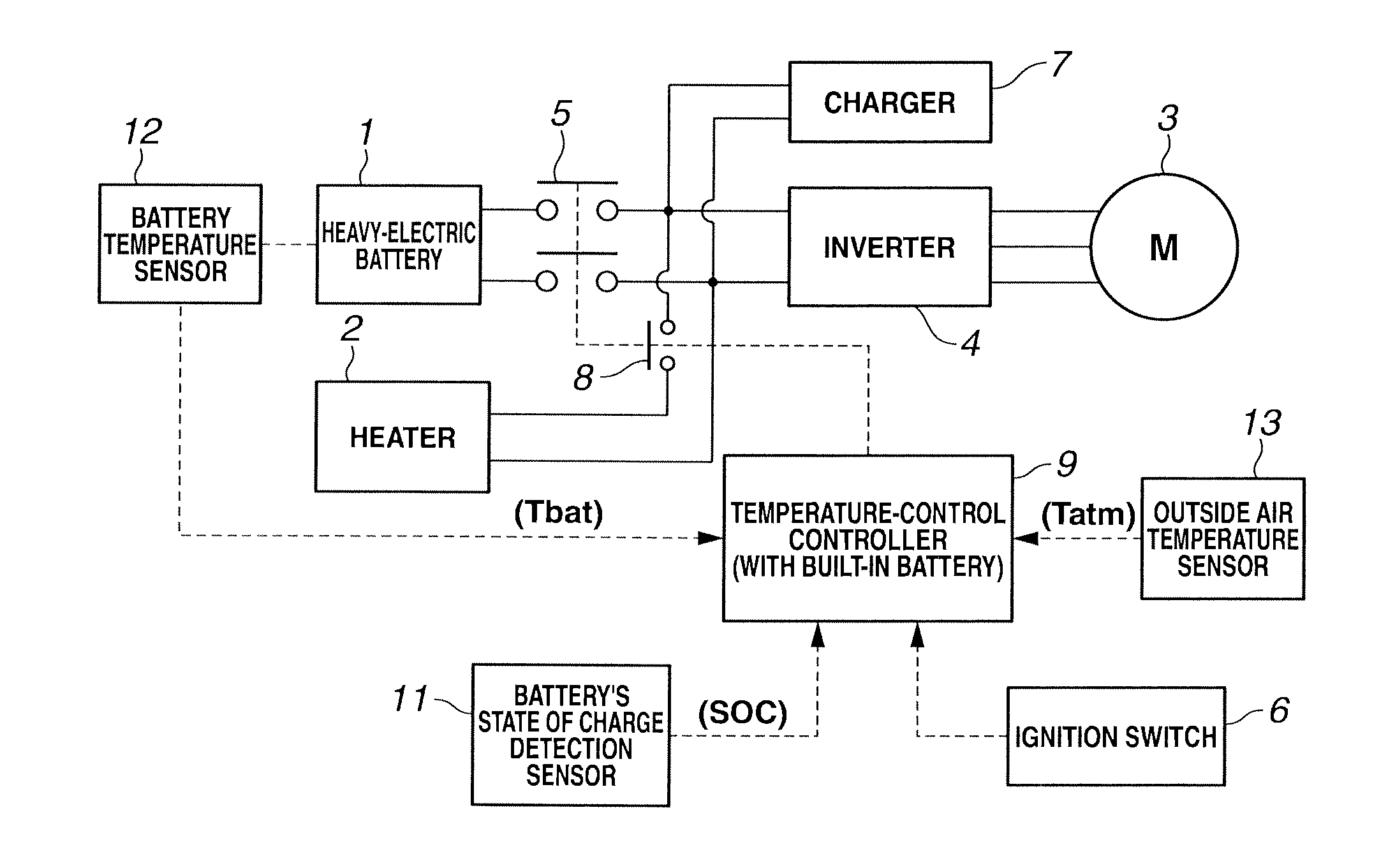

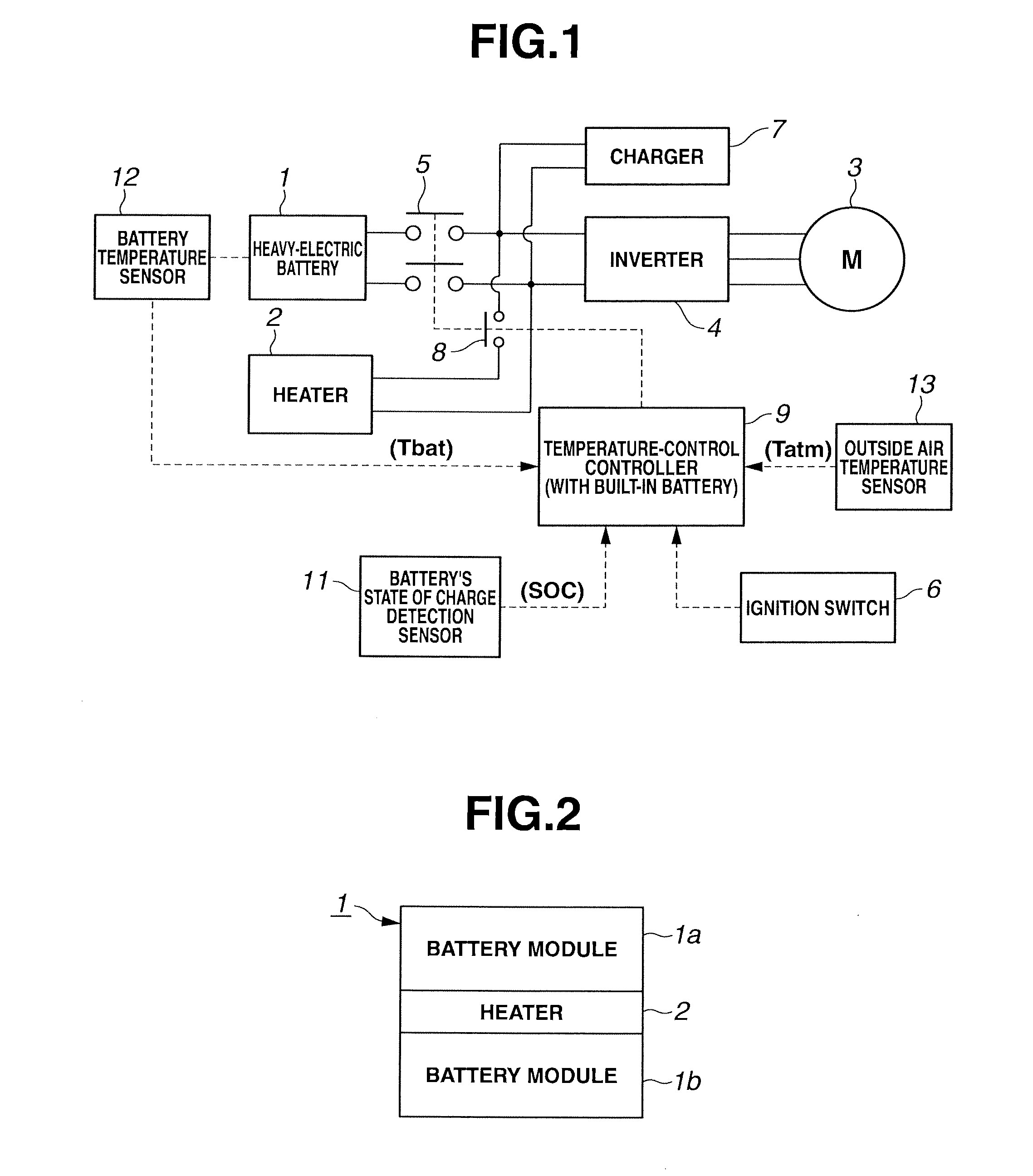

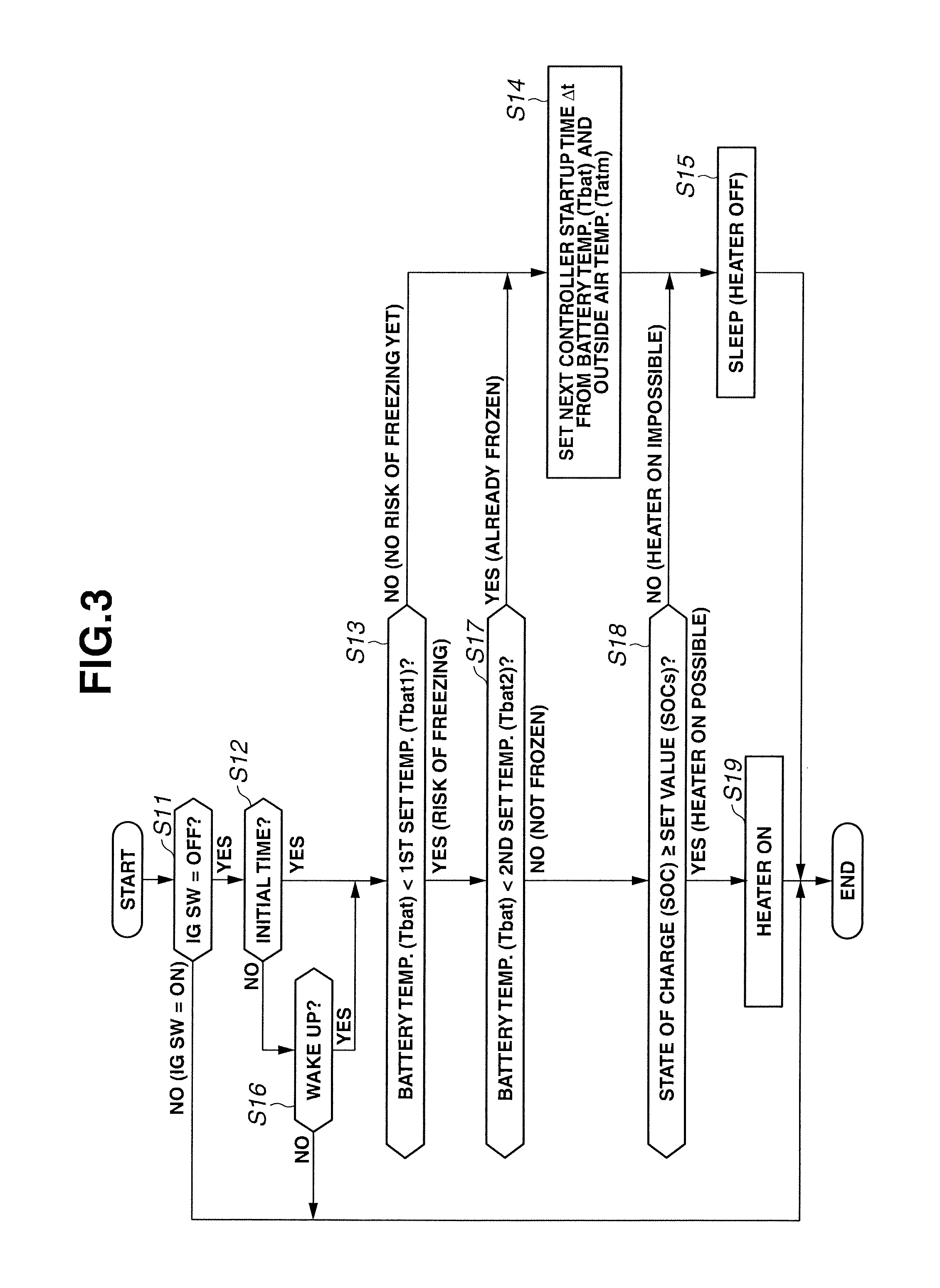

Battery temperature control device

ActiveUS20130288089A1Minimum consumptionHybrid vehiclesCell temperature controlTemperature controlEngineering

Provided is a battery temperature control device configured to automatically heat a battery with a battery-driven heater so that the battery does not freeze at a minimum electric power consumption when the battery is out of use. The battery temperature control device predicts, based on a combination of a battery temperature and an outside air temperature, a predictive time that the battery temperature is likely to be less than a first set temperature, while the battery temperature is higher than or equal to the first set temperature at which there is no risk of freezing, and sets the predictive time as the next controller startup time, and determines whether or not the battery temperature has fallen to below the first set temperature with a control program wakeup when the predictive time has expired, and battery-drives the heater when the battery temperature fall has occurred, to heat the battery.

Owner:NISSAN MOTOR CO LTD

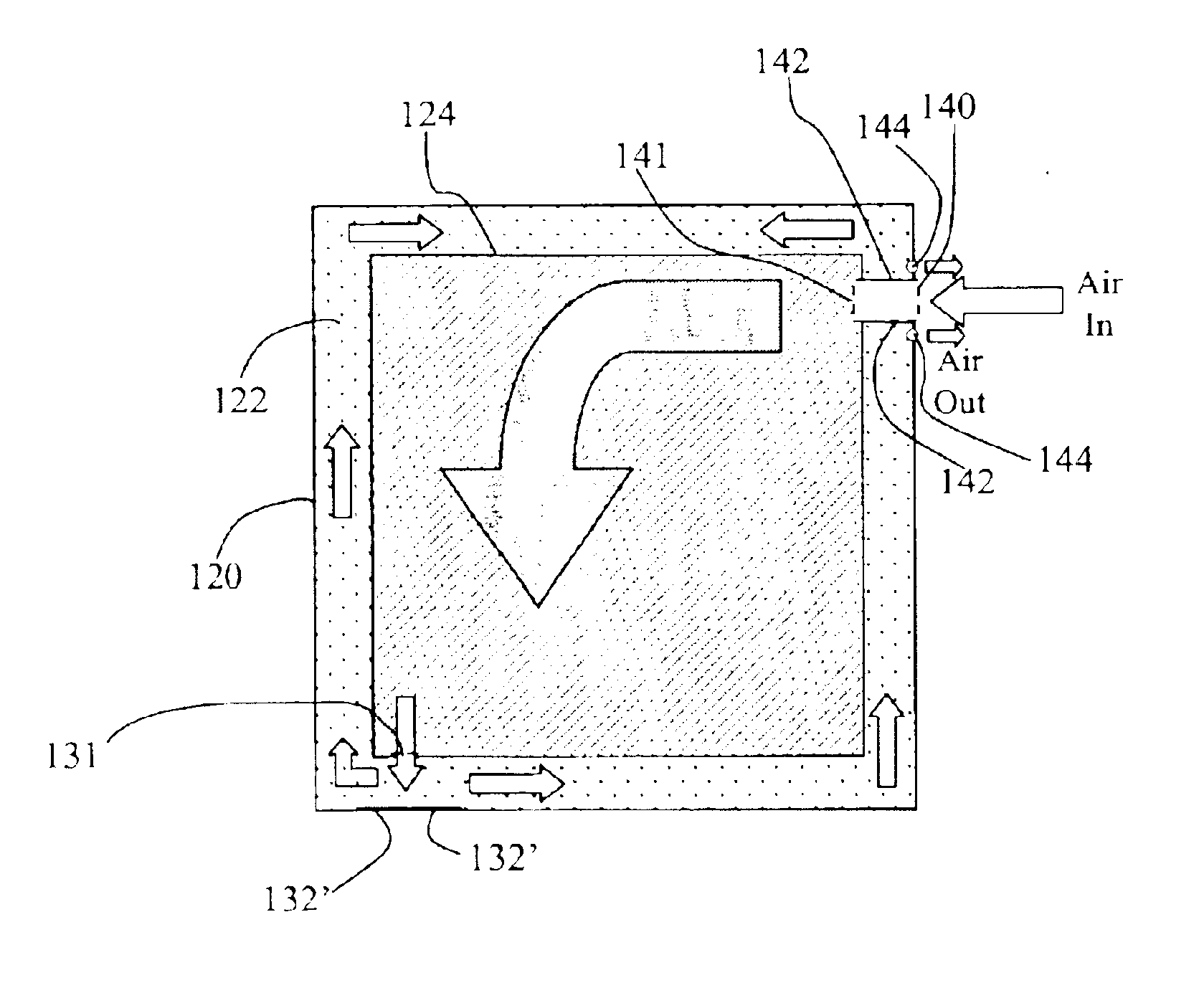

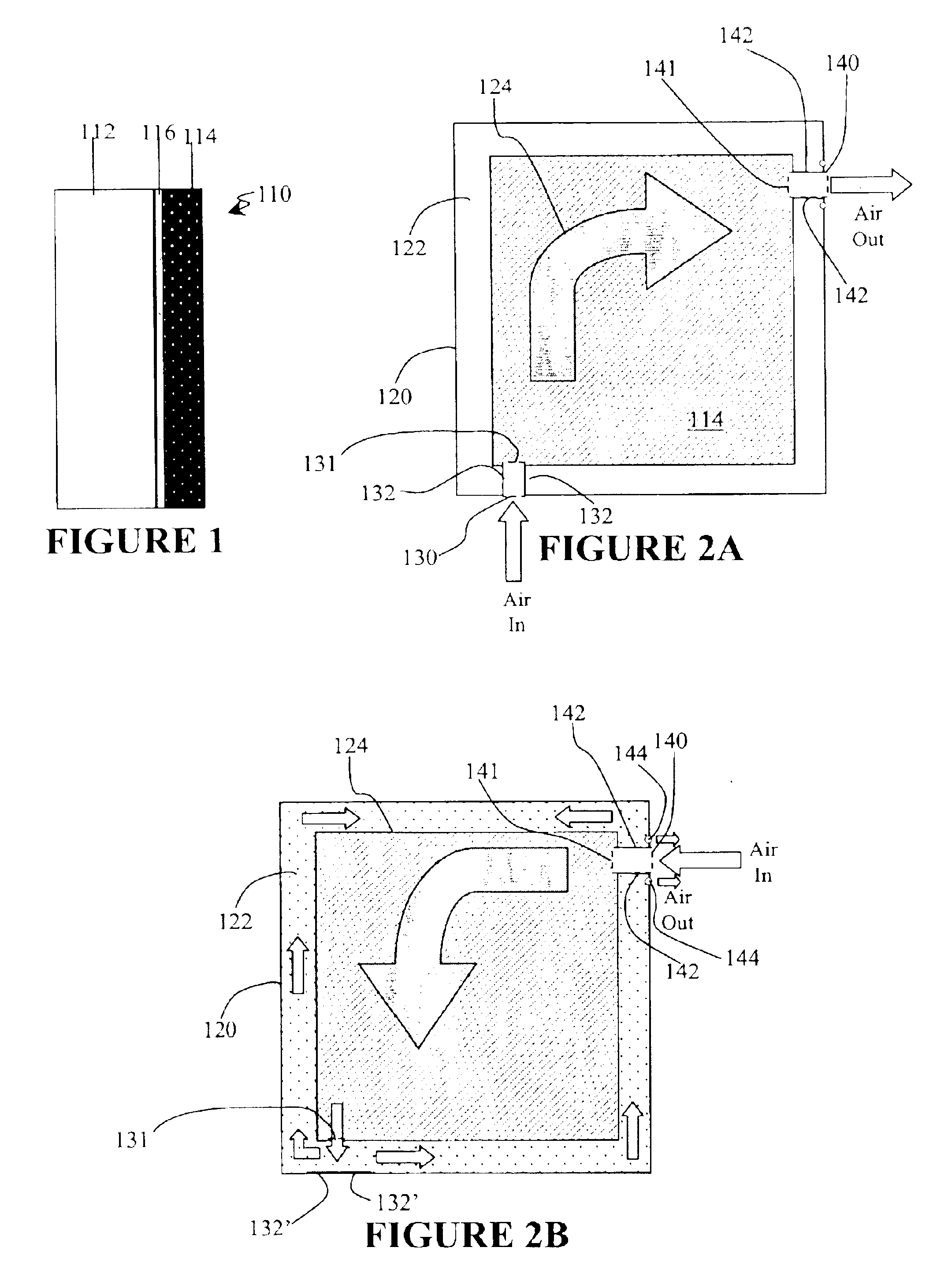

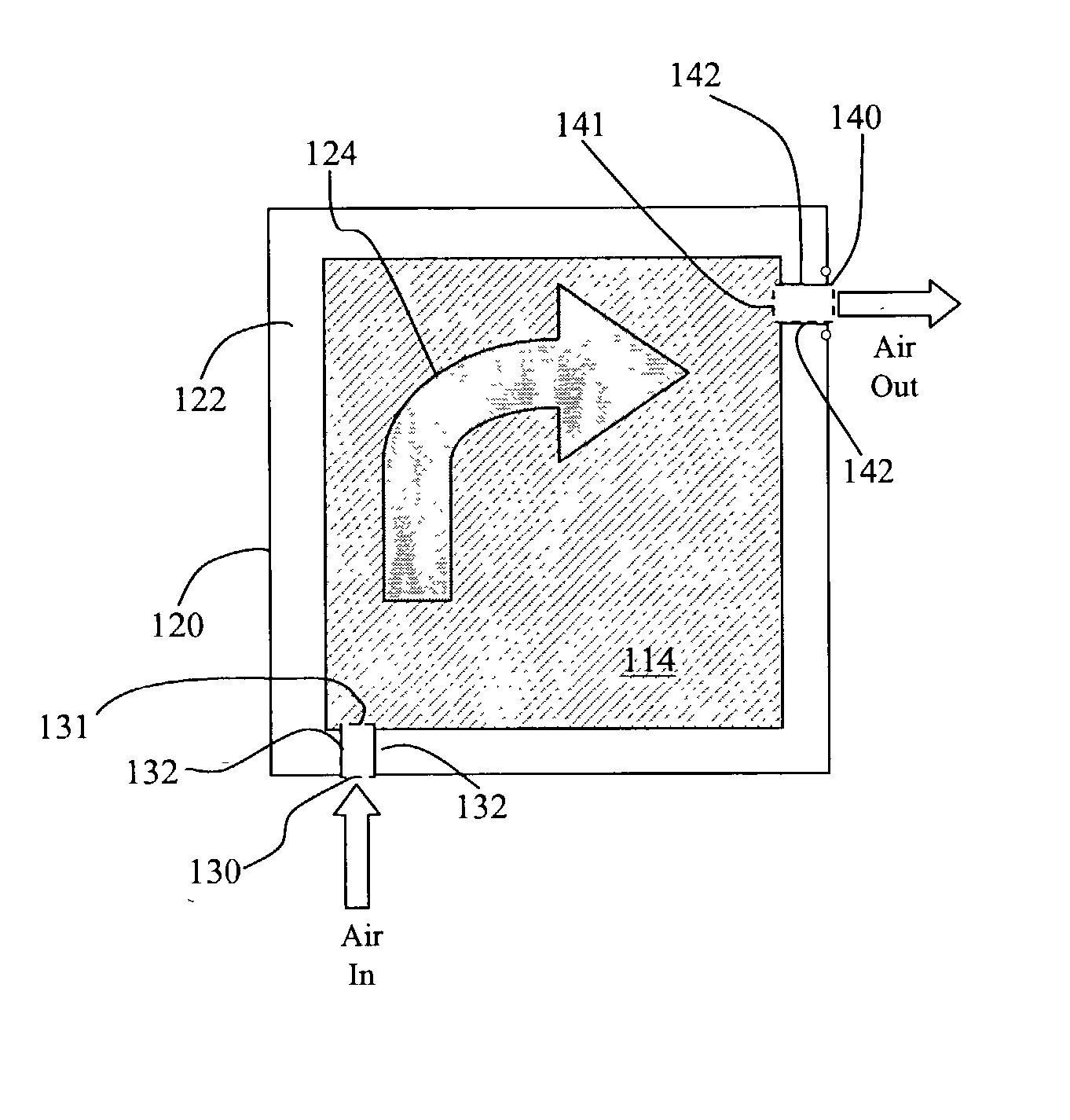

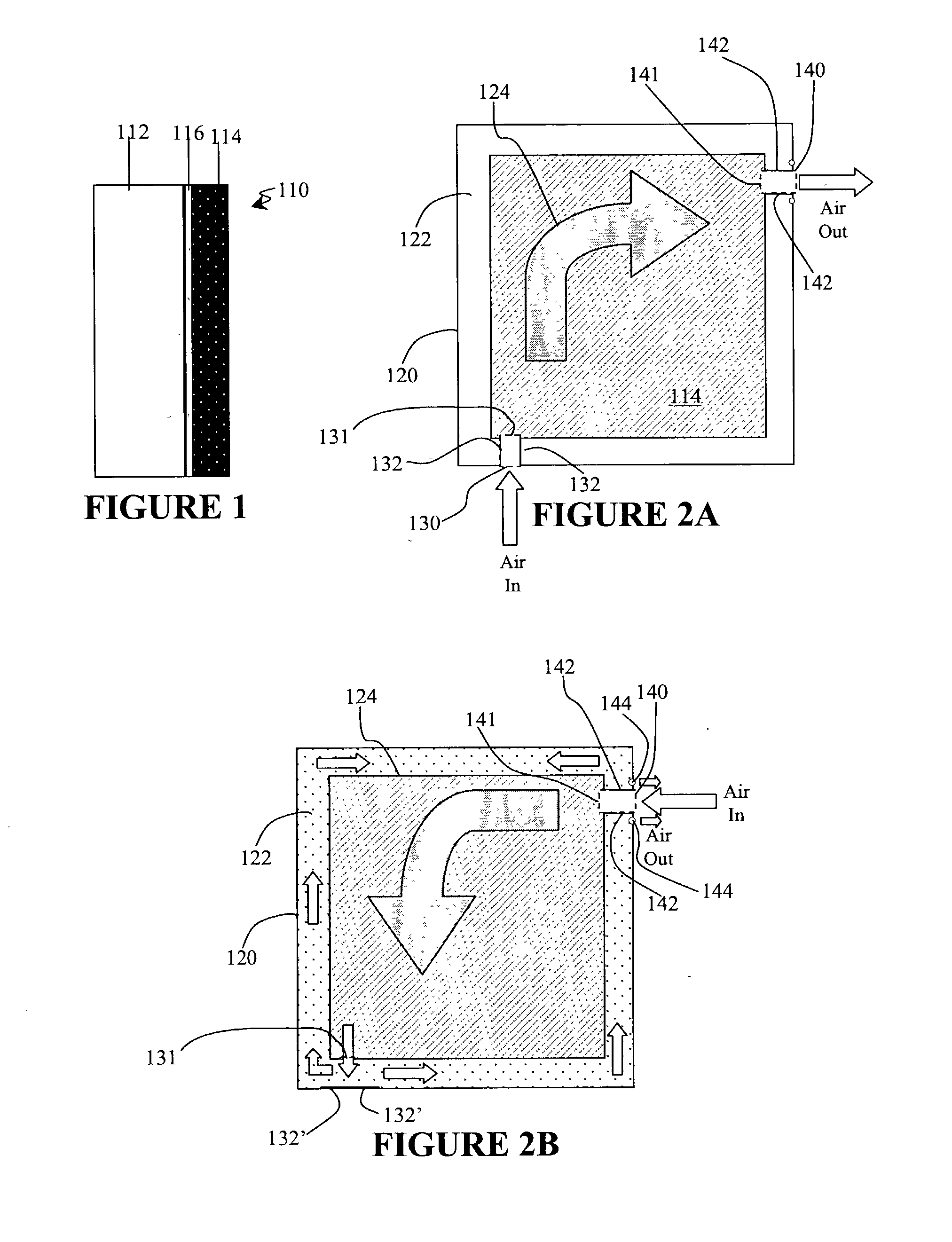

Metal air cell incorporating air flow system

A metal air cell system comprises a frame structure configured with variable airflow paths. The variable airflow paths provide alternatives between direct open loop airflow and semi-closed loop air flow, wherein air is at least partially circulated around the cell components. This is particularly useful for operation in different temperature environments. The open loop mode is useful for high temperature environments, and the semi-closed loop mode is useful for low temperature environments.

Owner:EVIONYX INC

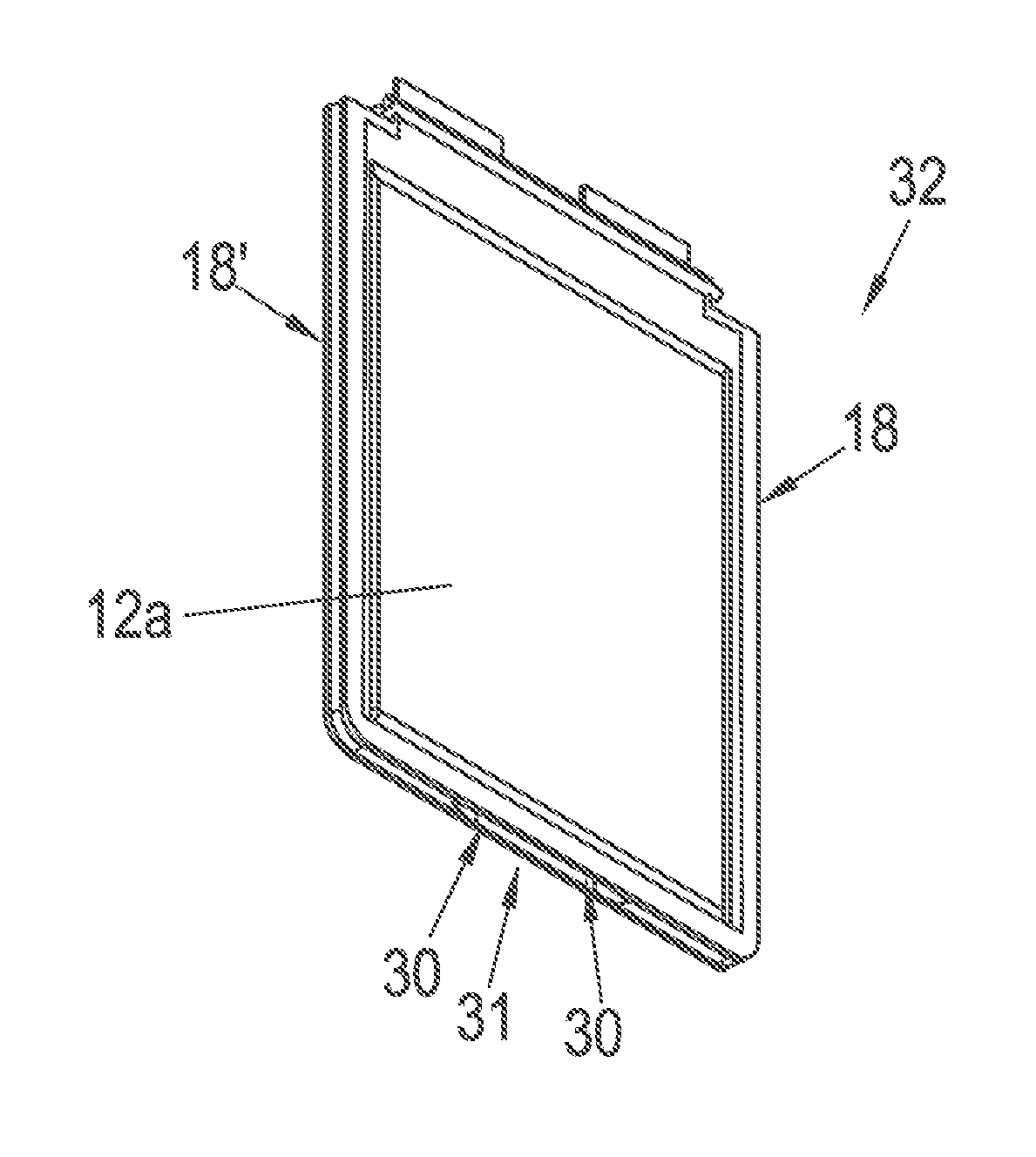

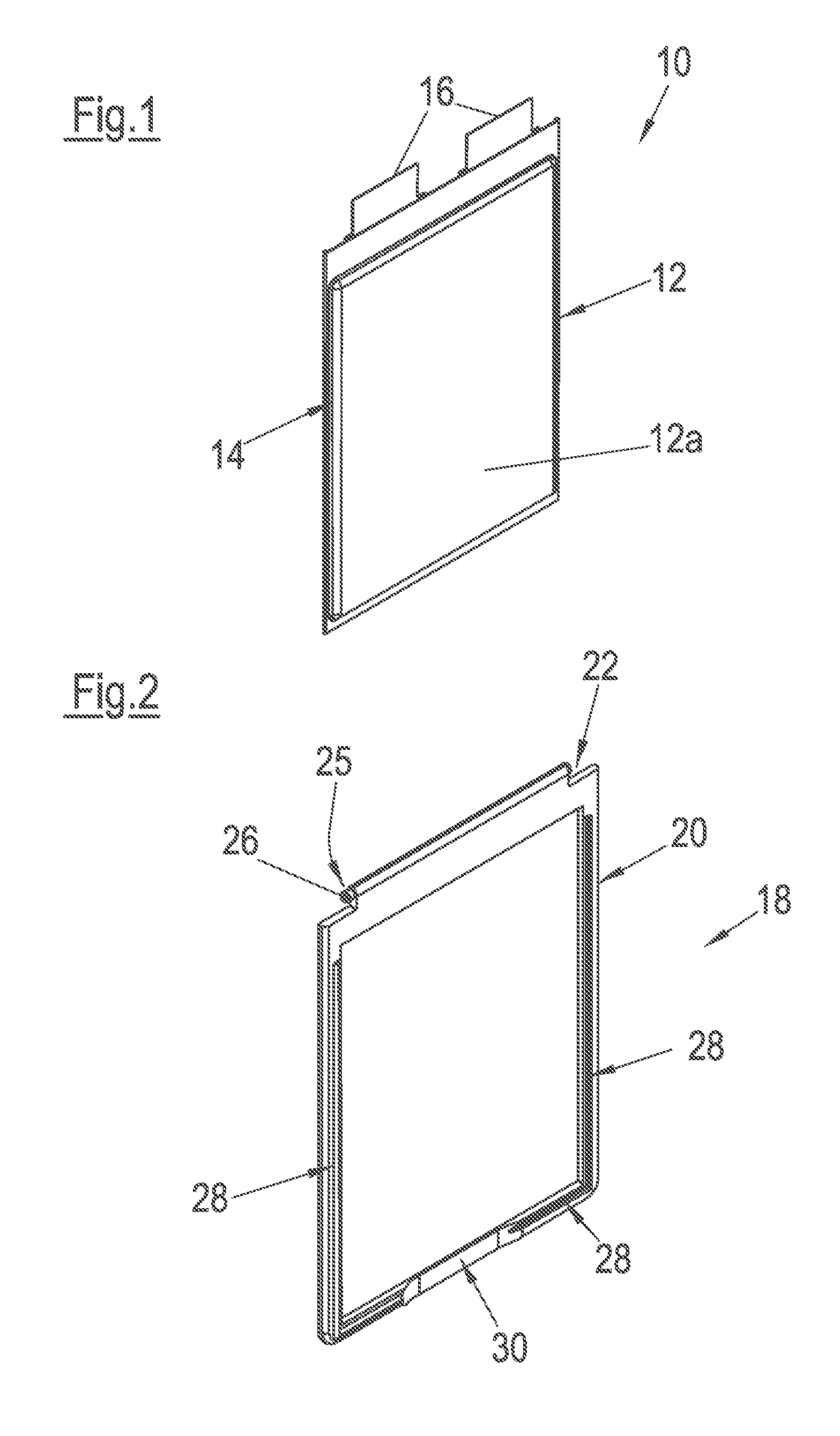

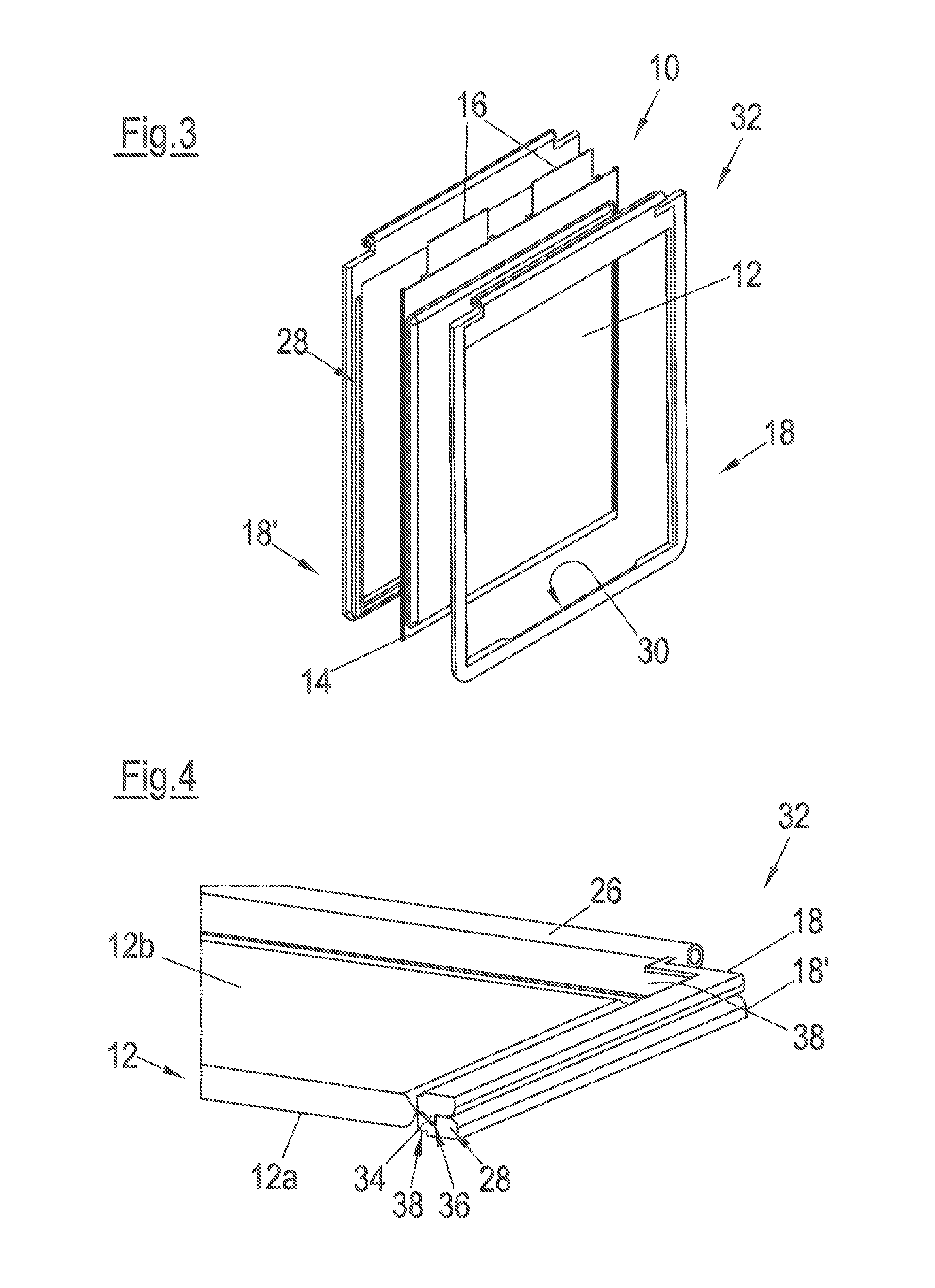

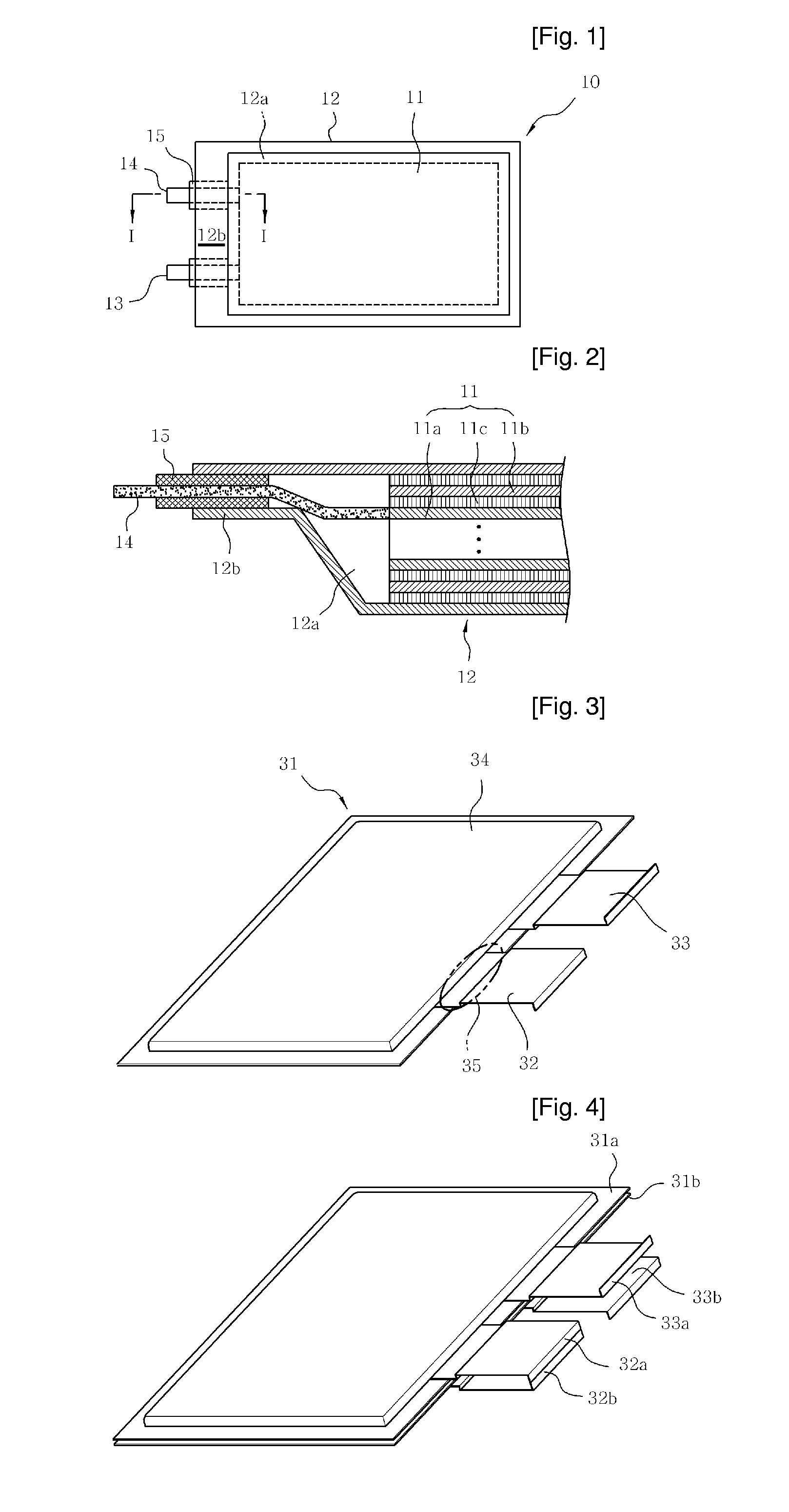

Battery cell arrangement

ActiveUS20120214033A1Easy to fixProducible cost-effectivelyPrimary cell to battery groupingLarge-sized flat cells/batteriesEngineeringCell bodies

A battery cell arrangement having a battery cell which is in the form of a film cell and includes a flat cell body with two end faces, a flexible cell rim surrounding the cell body, and two contact sections arranged on a rim side of the battery cell. The battery cell arrangement further has a frame arrangement which includes a first frame element and a second frame element which frames the cell body on all sides on the rim. At least one vent opening is provided on a side of the frame arrangement which faces away from the end faces of the cell body, in order to allow fluid, in particular gas, to emerge from the battery cell arrangement in the event of damage.

Owner:SAMSUNG SDI CO LTD

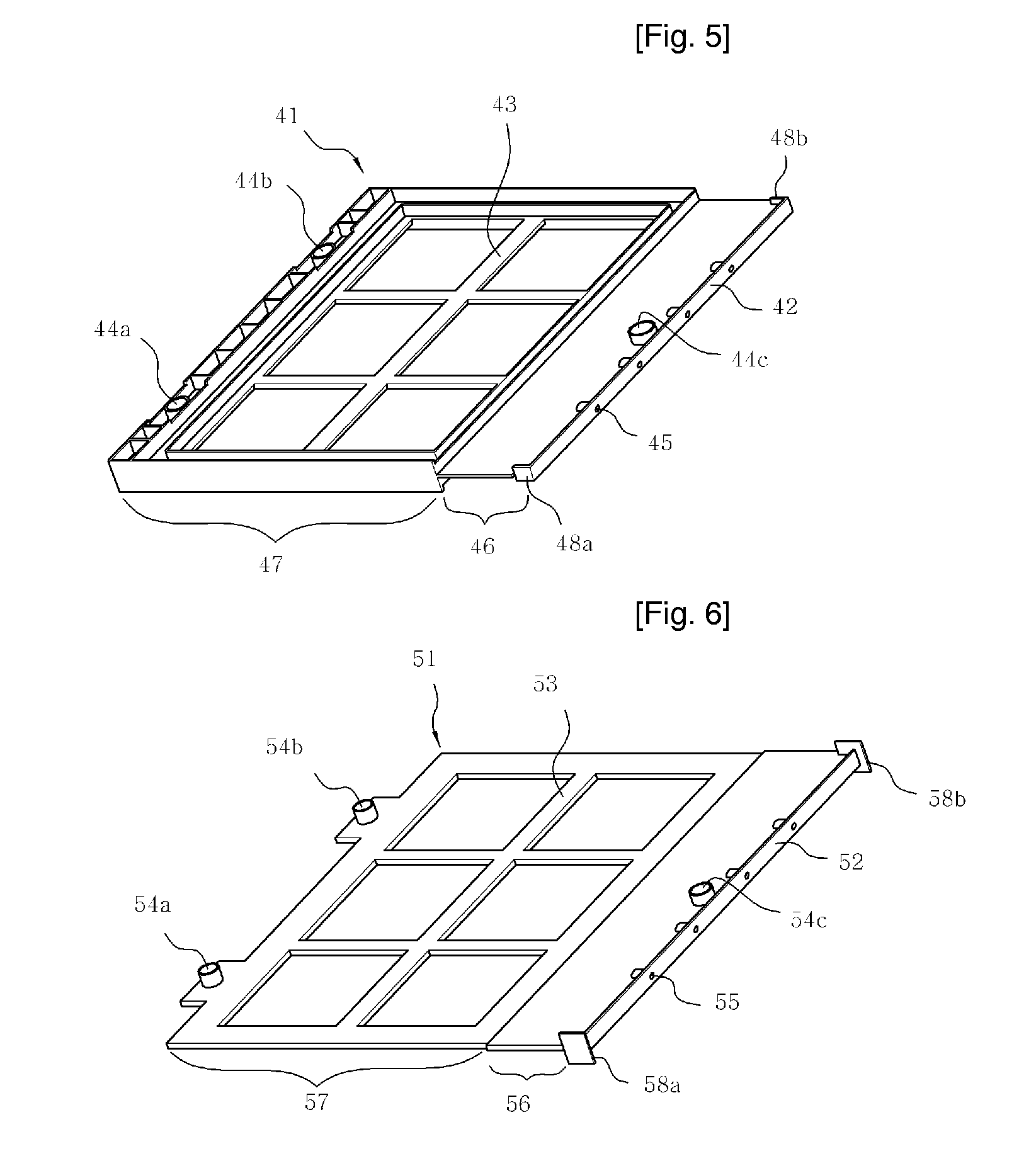

Case For High-Power Rechargeable Lithium Battery

Disclosed herein is a case which protects a plurality of flexible lithium polymer unit cells, has a compact structure to reduce volume, has a simple assembly process, and minimizes heat generated during a high-power charging or discharging operation. The battery case includes a pouch support frame to support a pouch of a unit cell having the pouch and electrode terminals. A heat radiating part having the shape of a shelf is provided on a surface of the pouch support frame, and defines a space for dispersing heat generated from the pouch. A terminal support having the shape of a wall is provided on an edge of the heat radiating part, thus supporting the electrode terminals of the unit cell.

Owner:SK ON CO LTD

Battery assemblies

ActiveUS20110151300A1Large-sized flat cells/batteriesCell temperature controlBattery cellElectrical and Electronics engineering

A battery module includes first, second, and third stacked battery cells, the second battery cell being arranged between the first battery cell and the third battery cell. The battery module further includes a first heat transfer layer arranged between the first battery cell and the second battery cell and a second heat transfer layer arranged between the second battery cell and the third battery cell. The battery module may further include a fluid conduit coupled to the first heat transfer layer and the second heat transfer layer.

Owner:GM GLOBAL TECH OPERATIONS LLC

Battery-powered devices

InactiveUS20070002559A1Easy to operateReduce the temperaturePoint-like light sourceLighting support devicesElectrical conductorElectrical battery

Battery-powered devices in which an energy consumption unit is associated with a heat conductor coupled to the battery-based power supply are described. A portion of the waste heat generated during operation of the energy consumption unit is transferred to the power supply, particularly to the one or more batteries that comprise the energy source of the power supply. The power supply may contain a housing composed of heat-insulating material. Heating of the batteries or battery housing warms the battery(ies), mitigating functional problems associated with battery operation at low temperatures.

Owner:UNDERWATER KINETICS

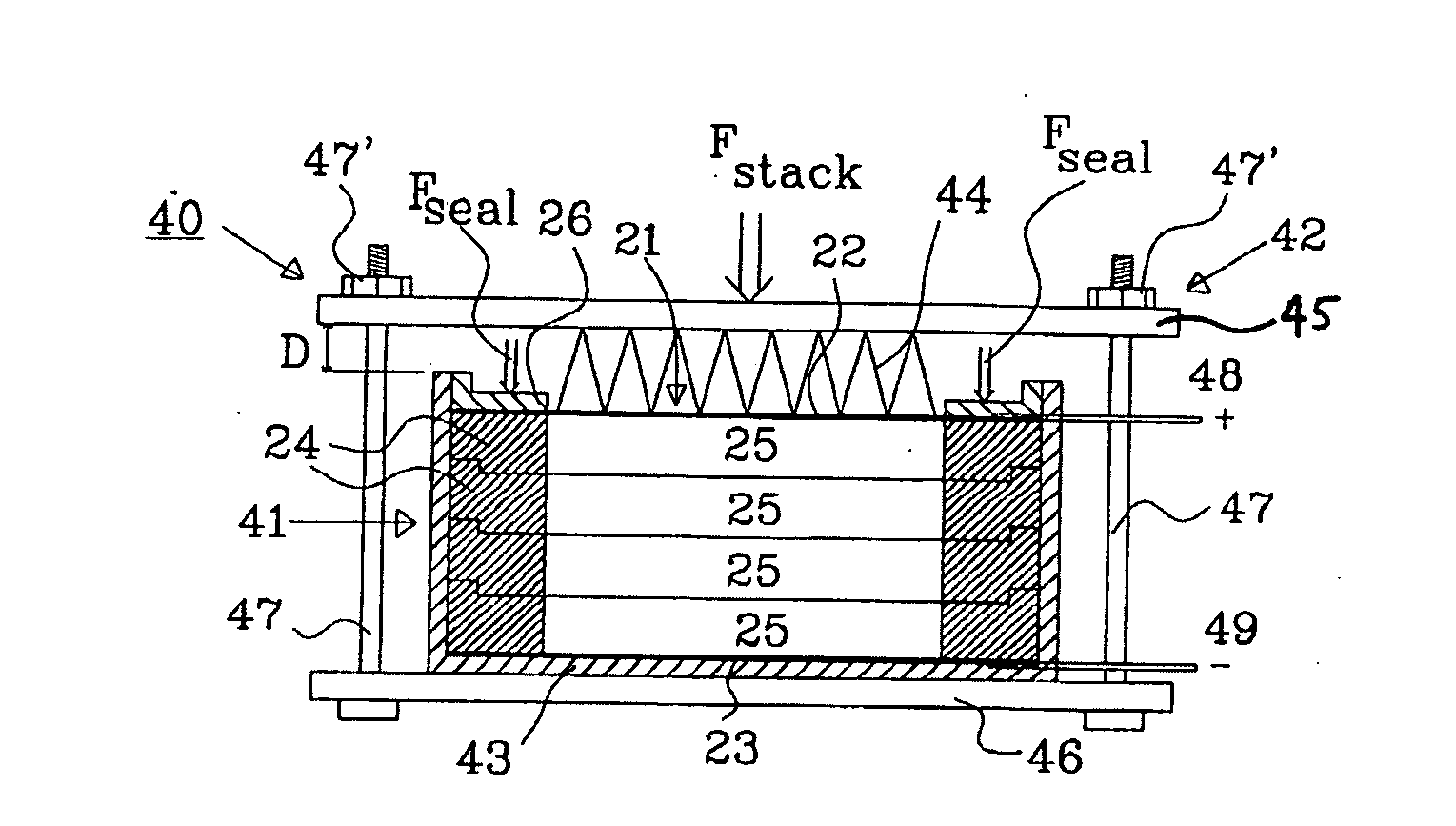

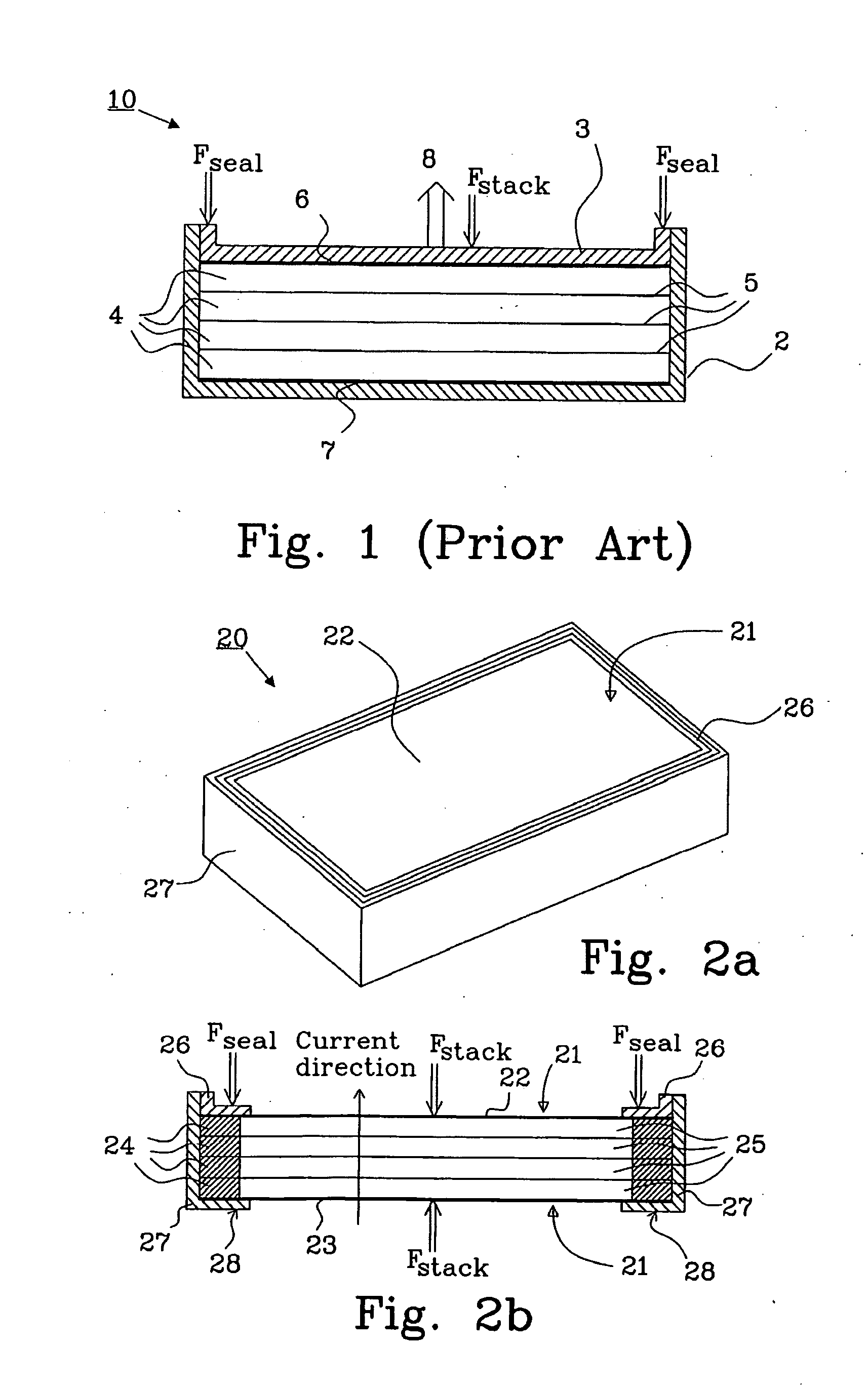

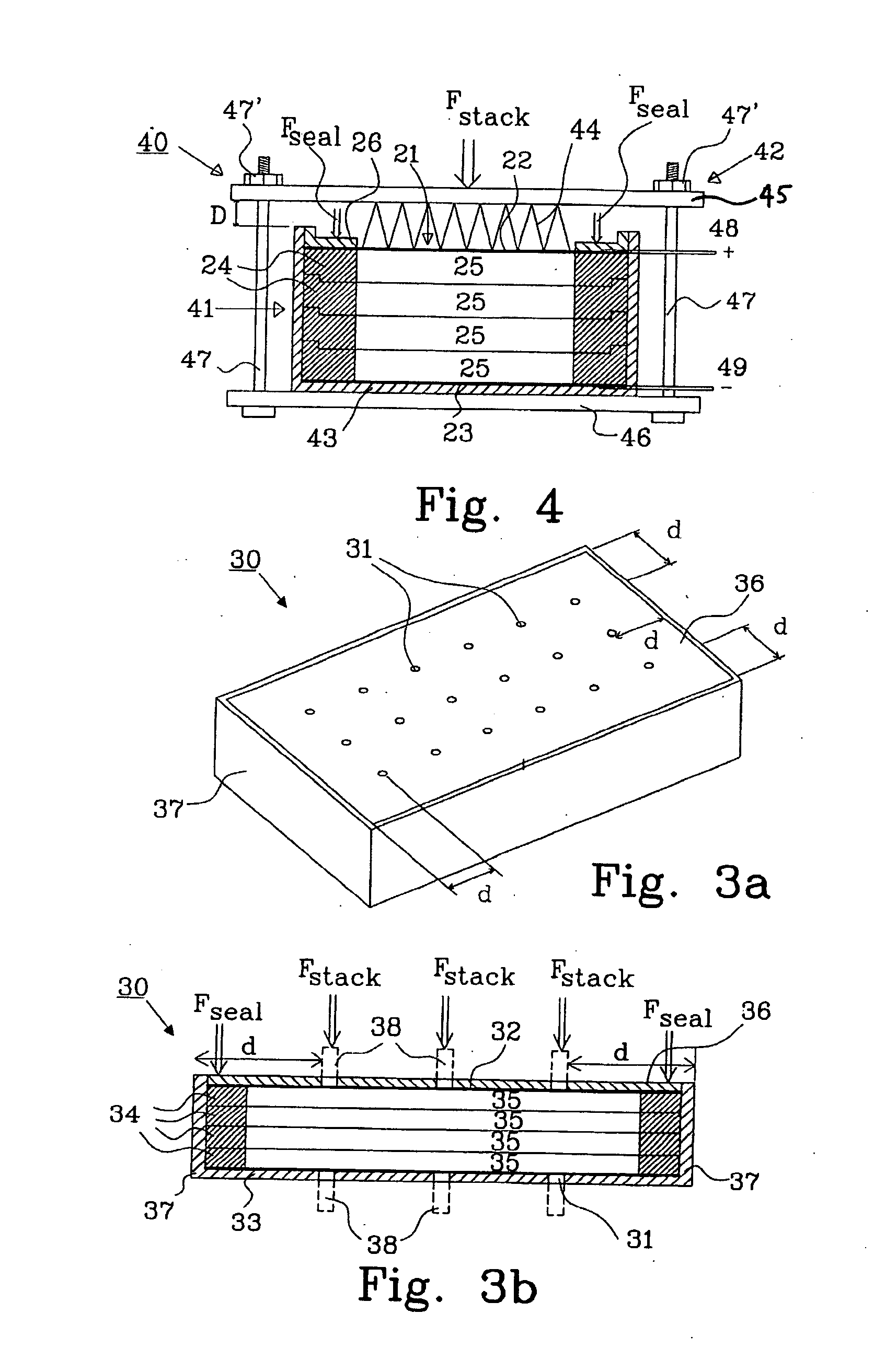

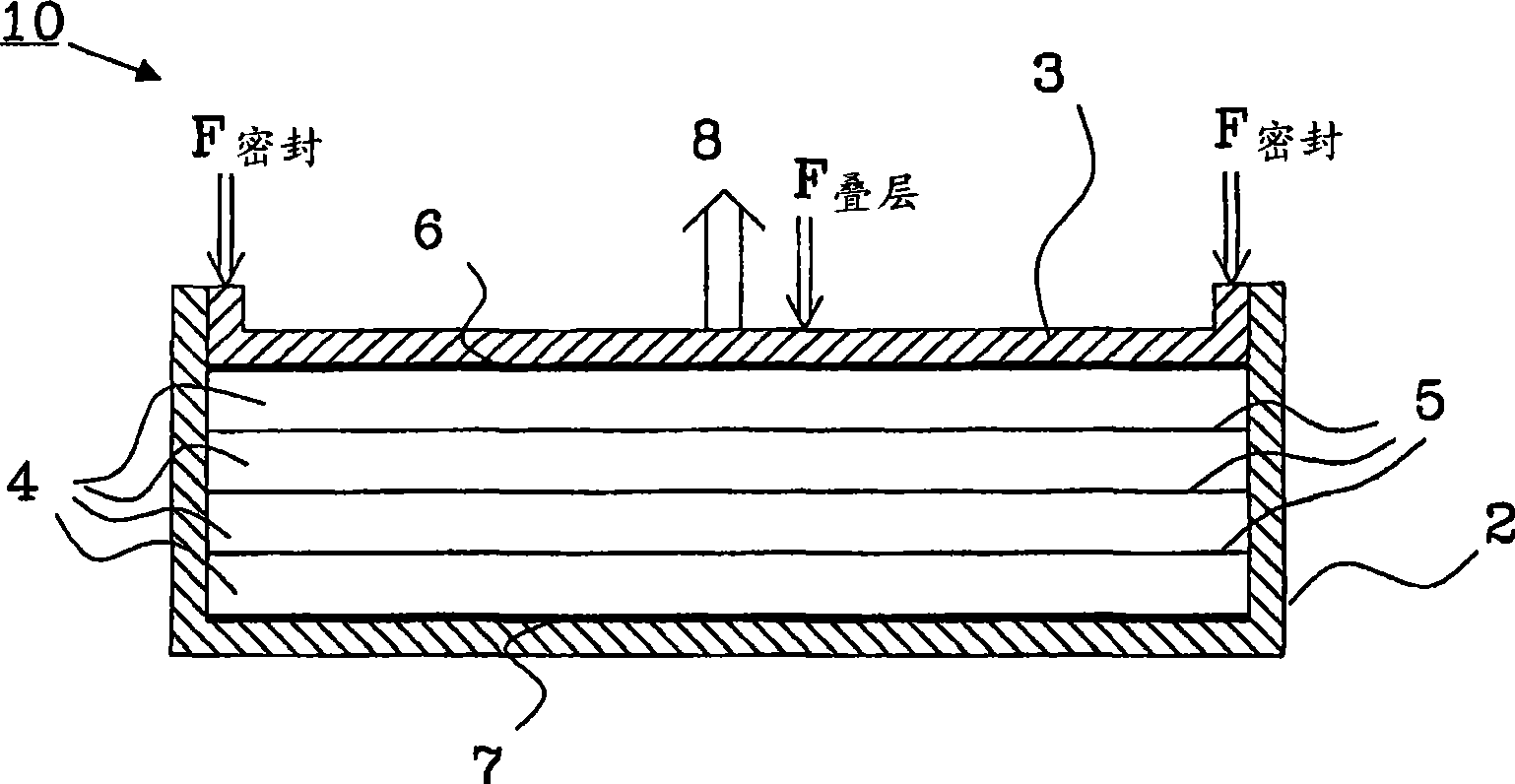

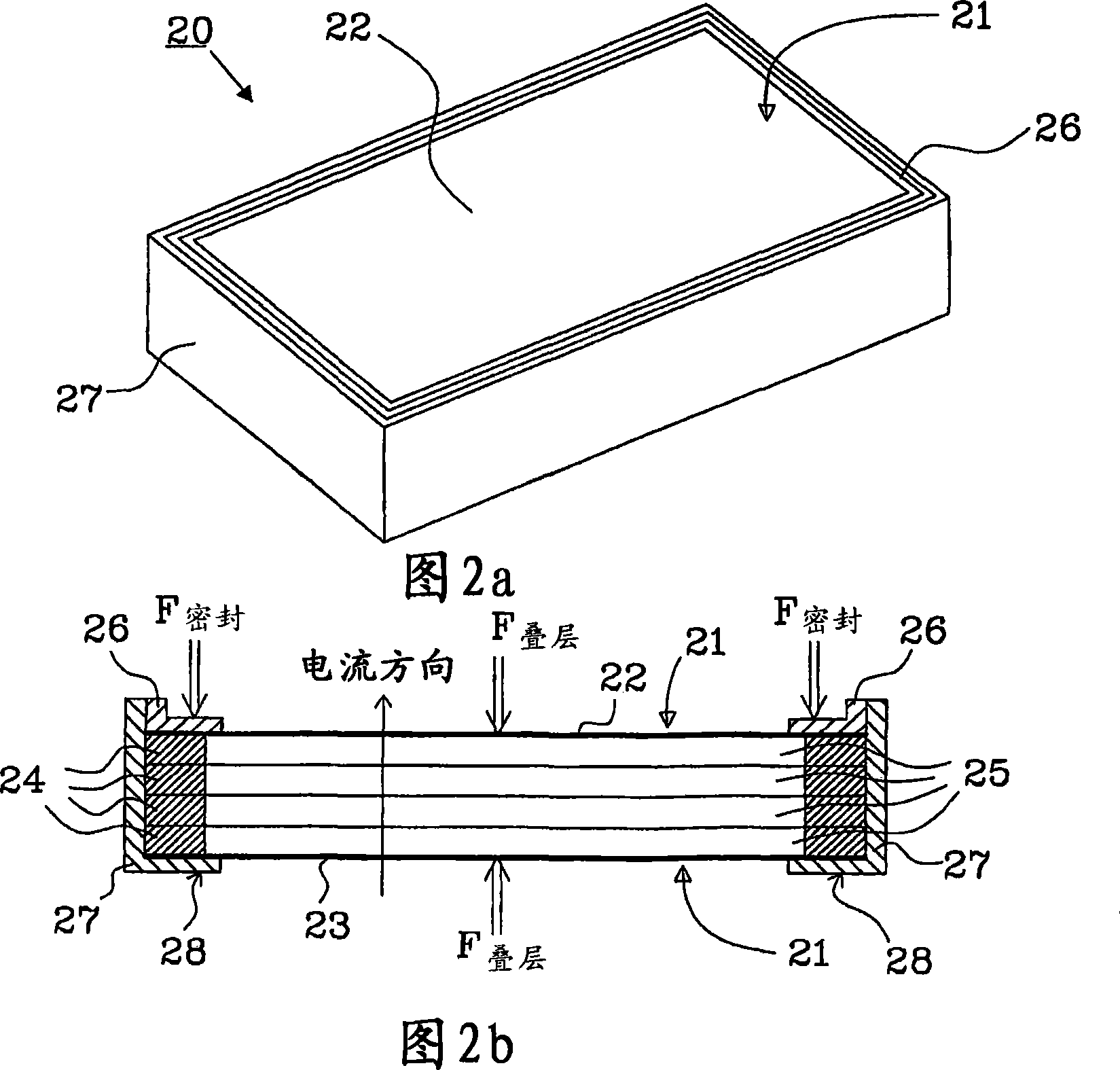

Battery stack arrangement

ActiveUS20100151306A1Increase pressureCell seperators/membranes/diaphragms/spacersLarge-sized flat cells/batteriesElectrolyte leakageBattery cell

The present invention relates to a battery stack arrangement (50) comprising at least one bipolar battery. Each bipolar battery comprises a plurality of battery cell arranged between endplates (22,23). Each battery cell is provided with a seal (24) arranged around the entire periphery of each cell, and a sealing pressure Fseal is applied over the seal to prevent electrolyte leakage between adjacent cells. The battery stack arrangement further comprises a mounting frame (57) including: at least two mounting units (58,59) and at least one tie unit (60, 60′, 60″) holding said mounting units together. The bipolar battery is arranged between the mounting units (58,59), and the battery stack arrangement further comprises at least one spacing element (61) arranged between the mounting units (58,59) and each spacing element (61) abuts against at least one endplate (22,23) and is held in place by said mounting frame (57) to create a stack pressure Fstack, independent of the sealing pressure Fseal. The stack pressure is controlled by the tie unit.

Owner:NILAR INT AB

Cell structure for electrochemical devices and method of making same

InactiveUS8021775B2Cell seperators/membranes/diaphragms/spacersLarge-sized flat cells/batteriesInternal pressureElectrical battery

Owner:INVENTEX

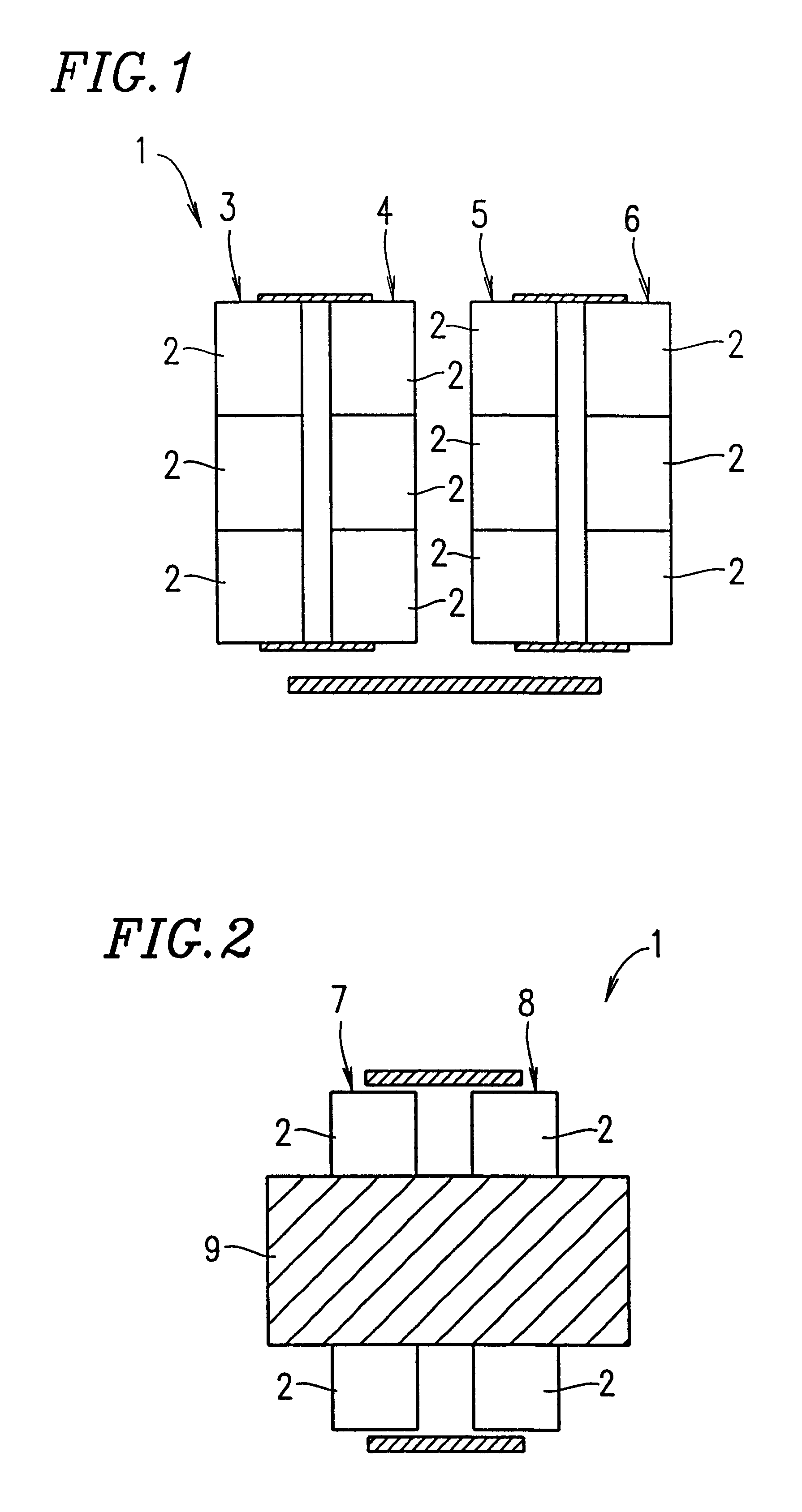

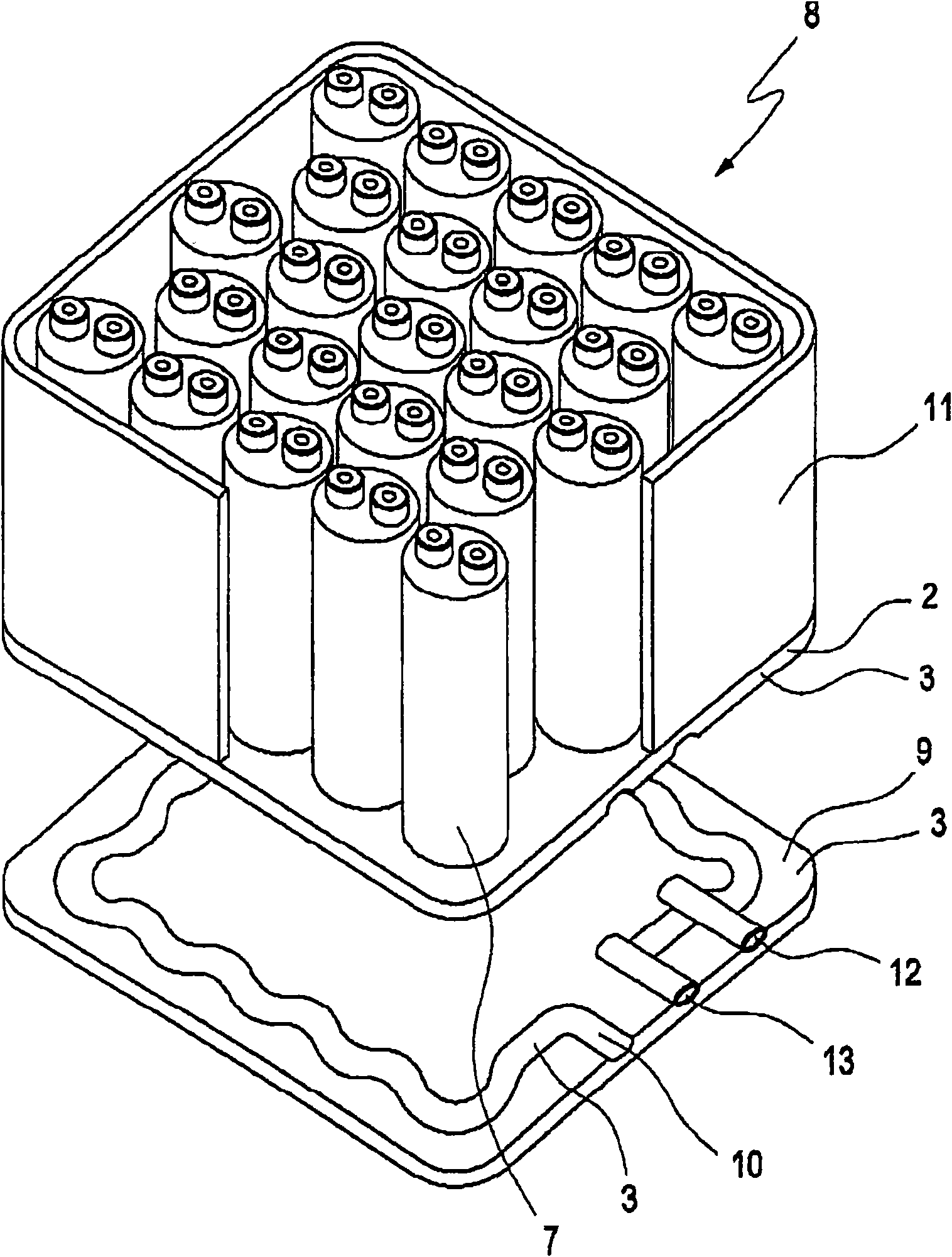

Accumulating element module

InactiveUS6922326B2Improve abilitiesIncreased footprintSeveral cell simultaneous arrangementsMultiple fixed capacitorsBand shapeEngineering

An accumulating element module includes a plurality of accumulating elements, each having a positive pole terminal and a negative pole terminal at one end. The accumulating elements are connected together at their other ends by an insulating connecting member made of a synthetic rubber. The insulating connecting member includes a plurality of caps and connectors. A deformation-resistant, band-shaped, temperature sensing member having a plurality of excessively raised temperature detectors is inserted through the caps.

Owner:HONDA MOTOR CO LTD

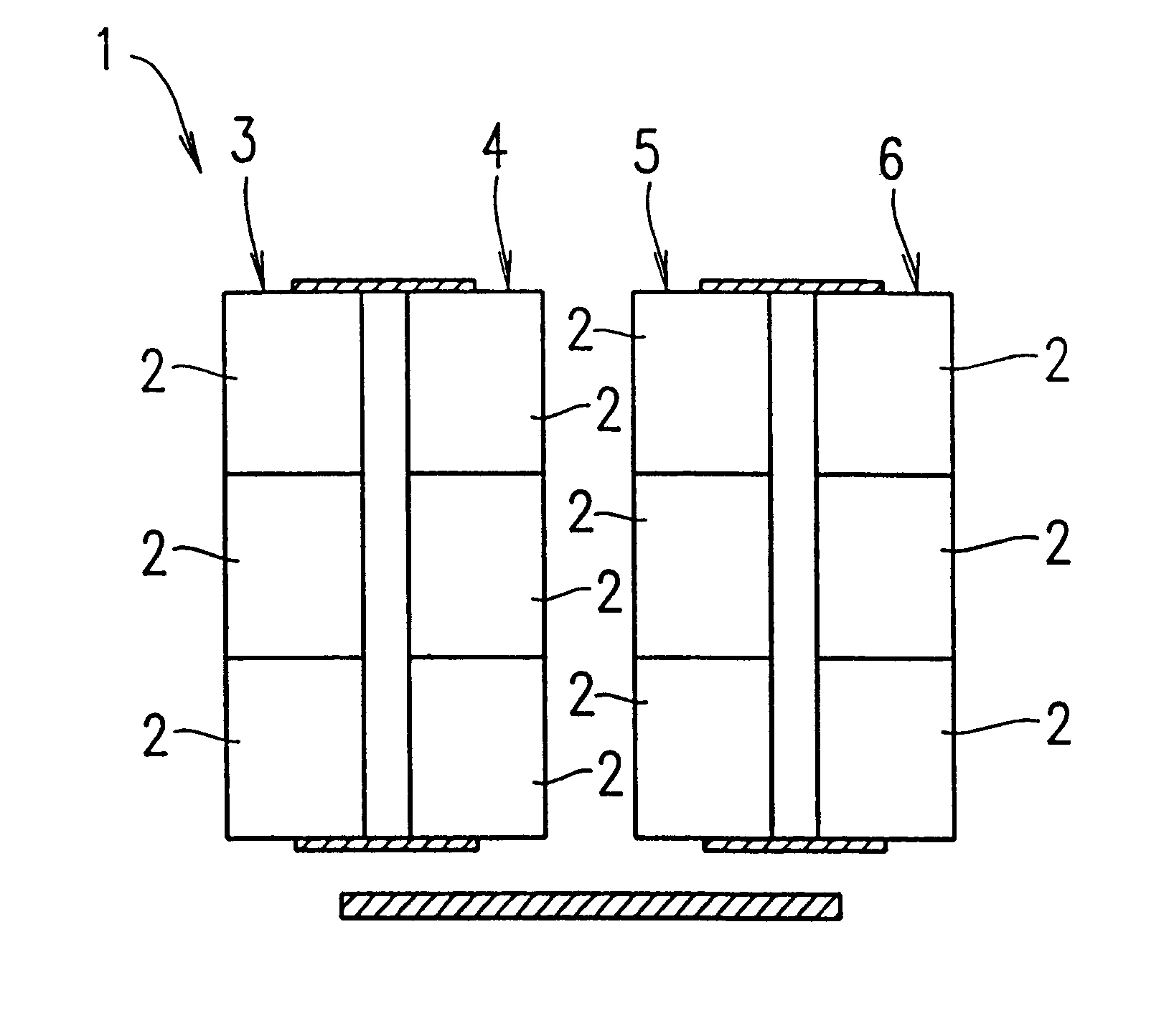

Battery pack

A battery pack comprises at least one pair of battery modules, each of the battery modules including a plurality of battery cells connected in series, in which the at least one pair of the battery modules are connected in parallel and are positioned in close vicinity to each other such that radiant heat can be transferred between the battery modules.

Owner:PANASONIC CORP +1

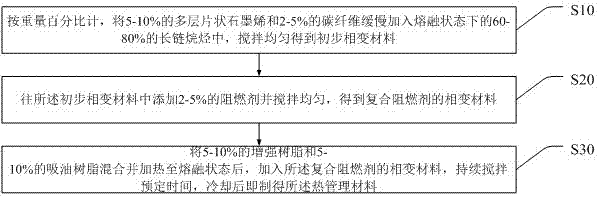

Thermal management material, preparation method thereof and application

InactiveCN106987233AImprove thermal conductivityGood temperature control functionCells cooling/heatingSecondary cellsMolten stateFiber

The invention discloses a thermal management material, a preparation method thereof and an application. The method includes the steps: in weight percentage, slowly adding 5-10% of multilayer flake graphene and 2-5% of carbon fibers into 60-80% of molten long-chain alkane, and uniformly stirring mixture to obtain initial phase-change materials; adding 2-5% of flame retardants into the initial phase-change materials to uniformly stir to obtain phase-change materials of compound flame retardants; mixing 5-10% of reinforced resins and 5-10% of oil-absorptive resins to heat to a molten state, adding the phase-change materials of the compound flame retardants, continually stirring for predetermined time, and cooling the mixture to obtain the thermal management material. The thermal management material prepared by the method has high flame resistance, insulation performance, high-thermal storage performance and heat-conducting performance, the thermal management material contacts with the surface of a new-energy power lithium battery, good heat-conducting effect can be achieved, heat storage effect can be also achieved, heat moment rising of a lithium battery pack is solved, thermal runaway risks are reduced, and safety of the battery pack is improved.

Owner:深圳航美新材料科技有限公司

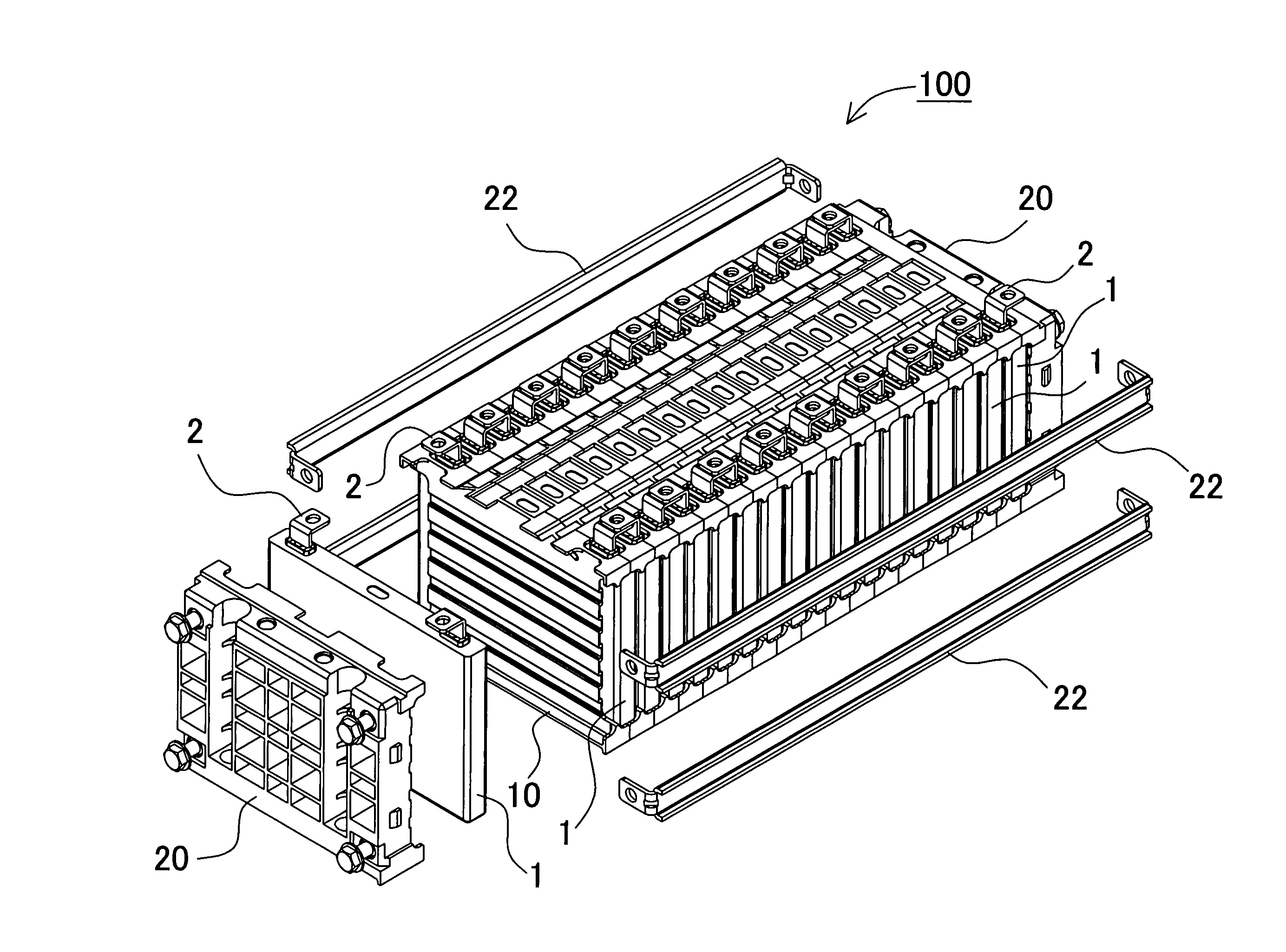

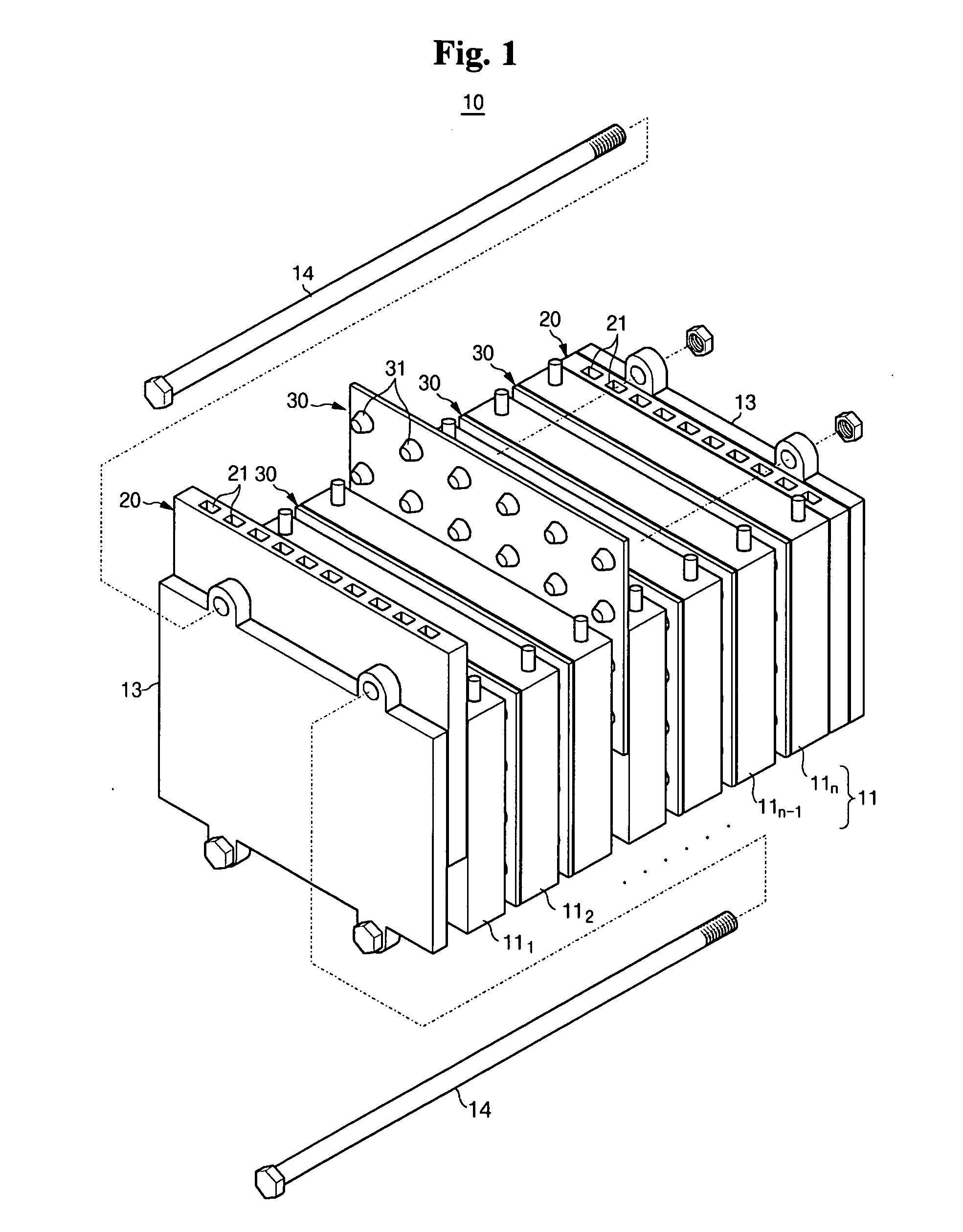

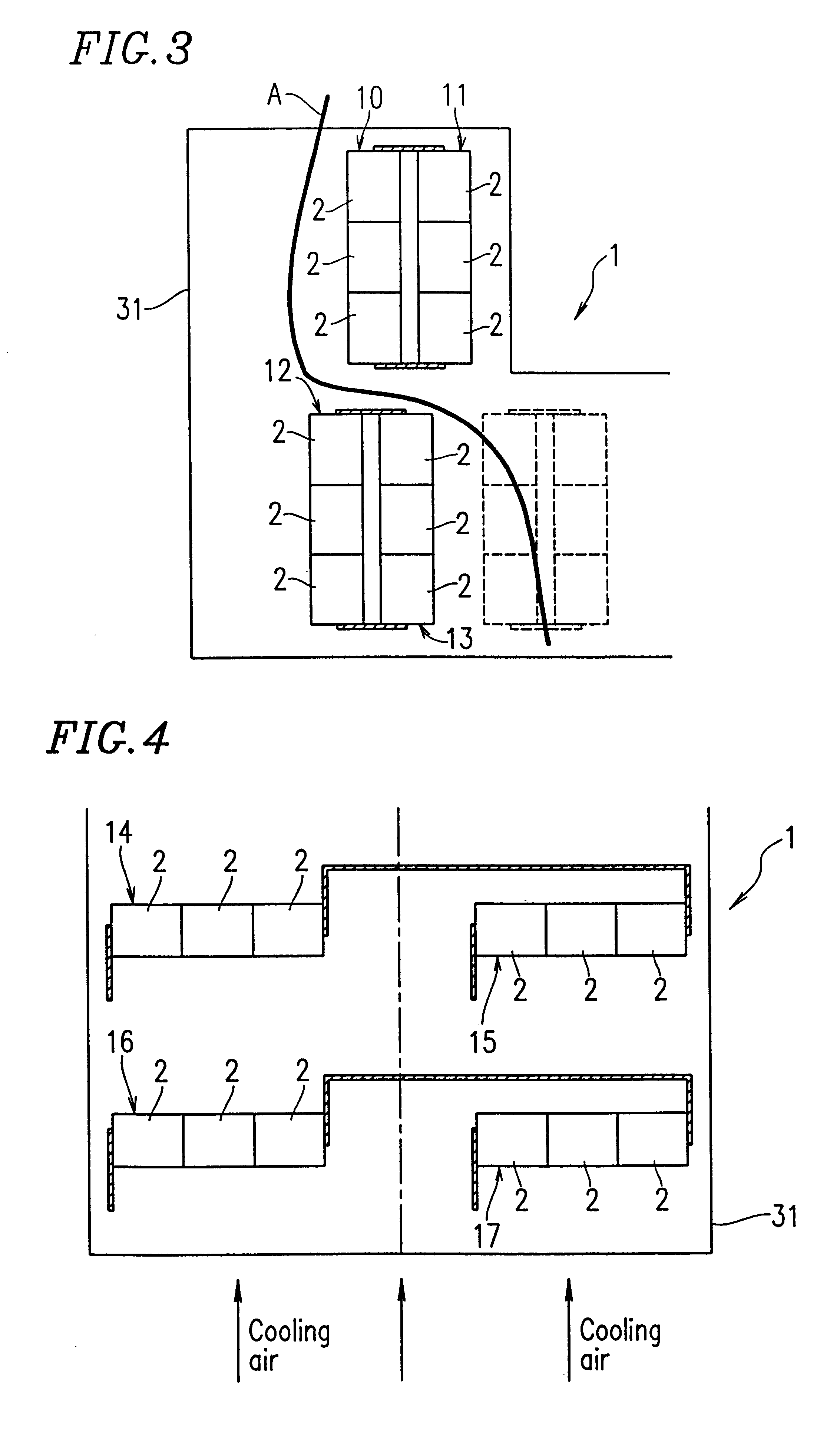

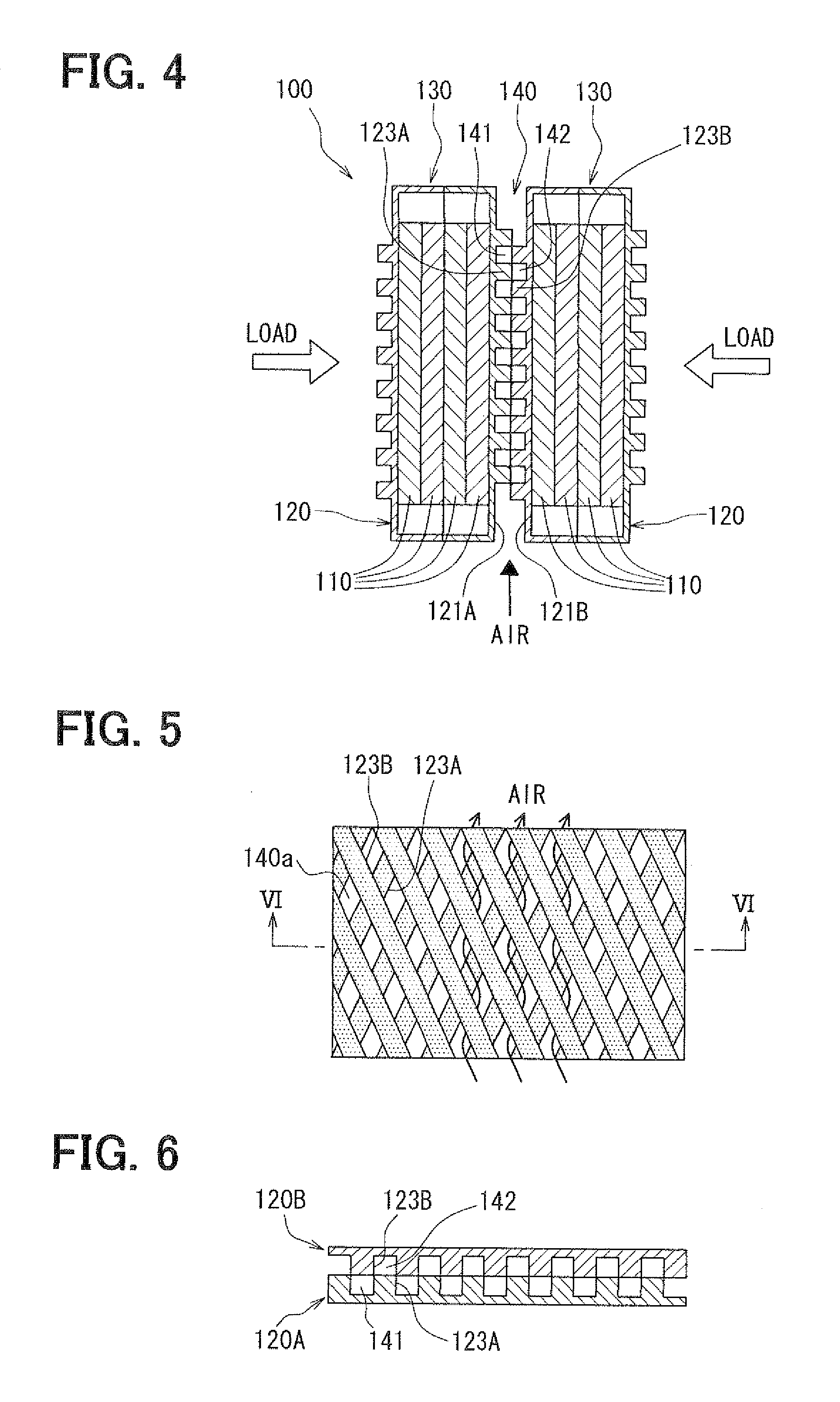

Battery pack with cooling passage

ActiveUS20120070711A1Effectively and evenly cooledIncrease in heat transfer coefficientCell temperature controlCells cooling/heatingCooling channelBattery cell

A battery pack includes battery modules each having a battery cell and a battery case housing the battery cell therein. The battery modules are stacked in a stacking direction so that a cooling passage for allowing a cooling medium to flow is defined between opposed surfaces of adjacent battery cases. One of the opposed surfaces has first ribs projecting toward the other of the opposed surfaces and extending parallel to each other along the one. The other of the opposed surfaces has second ribs projecting toward the one of the opposed surfaces and extending parallel to each other along the other. In the cooling passage, the first ribs and the second ribs intersect each other and end portions of the first ribs and end portions of the second ribs are in contact with each other in the stacking direction.

Owner:DENSO CORP

A battery stack arrangement

ActiveCN101390232ACell seperators/membranes/diaphragms/spacersLarge-sized flat cells/batteriesElectrolyte leakageBattery cell

The present invention relates to a battery stack arrangement (50) comprising at least one bipolar battery. Each bipolar battery comprises a plurality of battery cell arranged between endplates (22,23). Each battery cell is provided with a seal (24) arranged around the entire periphery of each cell, and a sealing pressure Fseal is applied over the seal to prevent electrolyte leakage between adjacent cells. The battery stack arrangement further comprises a mounting frame (57) including: at least two mounting units (58,59) and at least one tie unit (60, 60', 60'') holding said mounting units together. The bipolar battery is arranged between the mounting units (58,59), and the battery stack arrangement further comprises at least one spacing element (61) arranged between the mounting units (58,59) and each spacing element (61) abuts against at least one endplate (22,23) and is held in place by said mounting frame (57) to create a stack pressure Fstack, independent of the sealing pressure Fseal. The stack pressure is controlled by the tie unit.

Owner:NILAR INT AB

Metal air cell incorporating air flow system

A metal air cell system comprises a frame structure configured with variable airflow paths. The variable airflow paths provide alternatives between direct open loop airflow and semi-closed loop air flow, wherein air is at least partially circulated around the cell components. This is particularly useful for operation in different temperature environments. The open loop mode is useful for high temperature environments, and the semi-closed loop mode is useful for low temperature environments.

Owner:EVIONYX INC

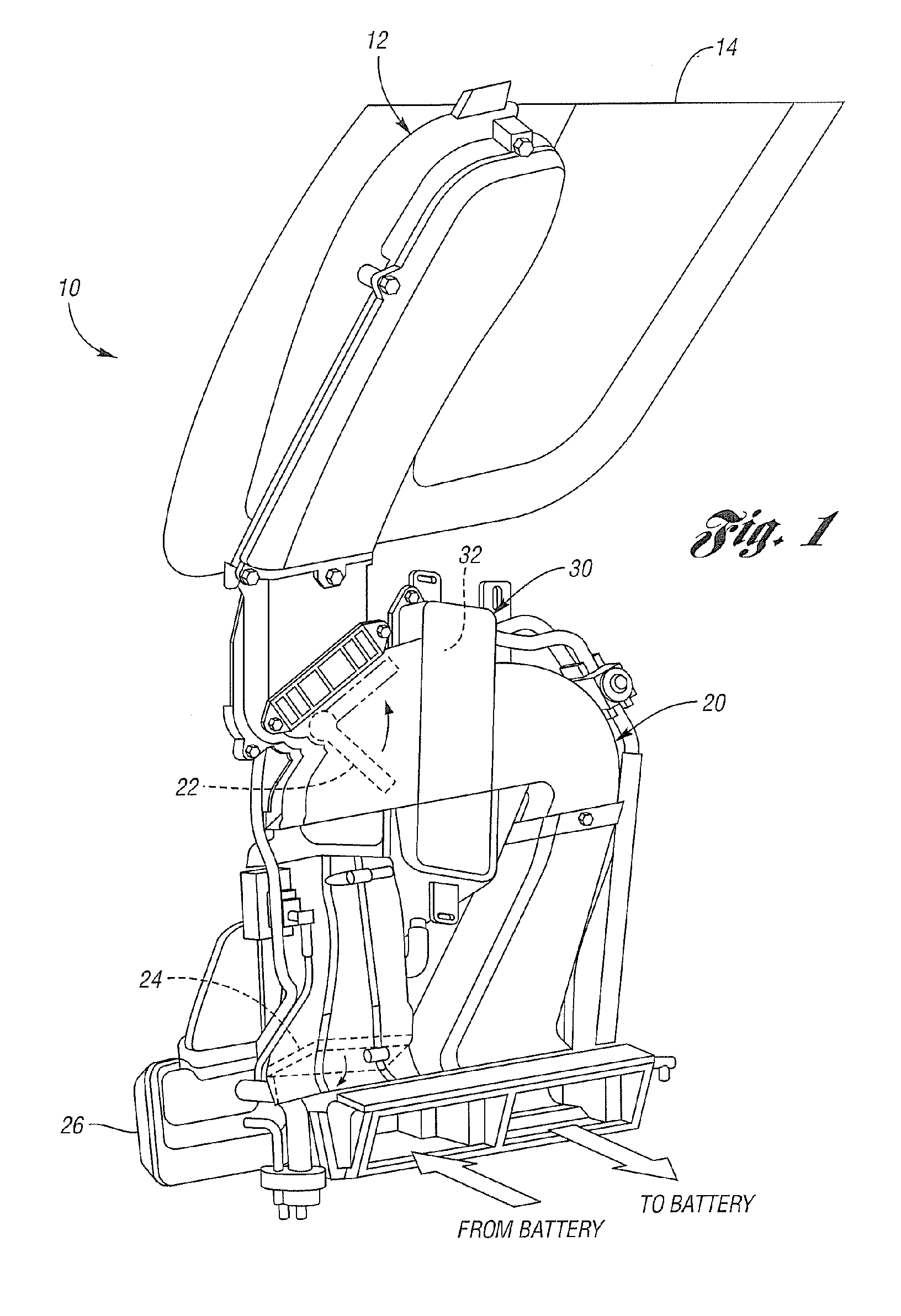

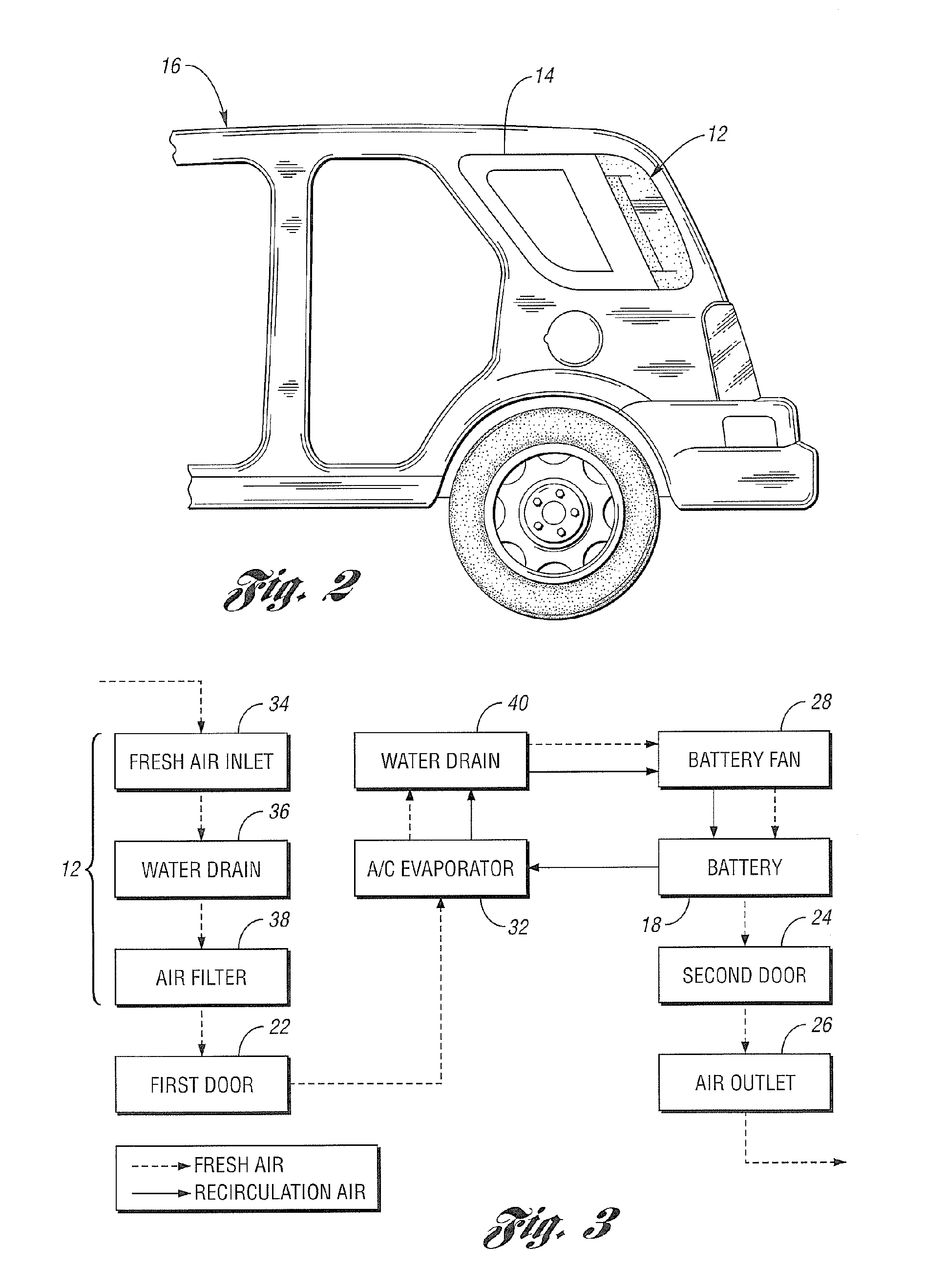

Environmental control system and method for a battery in a vehicle

ActiveUS20060033468A1Selectively allow and inhibitCool and ventilateBatteries circuit arrangementsFuel cell heat exchangeControl systemFresh air

An environmental control system for a battery in a vehicle includes an air intake for receiving ambient air from outside the vehicle. A duct system provides communication between the air intake and the battery. The duct system includes a movable door which can facilitate or inhibit movement of air between the air intake and the battery. An air outlet facilitates air flow from the duct system to the ambient environment outside the vehicle. A fan cooperates with the duct system for moving the air through a heat exchanger in the duct system and across the battery. A control system controls operation of the fan and the movable door, and is configured to determine whether the battery environment requires fresh air or recirculated air.

Owner:FORD GLOBAL TECH LLC

Reversibly-activated nanostructured battery

InactiveUS20050208370A1Material nanotechnologyDeferred-action cellsNanostructureBiomedical engineering

A battery having a nanostructured battery electrode is disclosed wherein it is possible to reverse the contact of the electrolyte with the battery electrode and, thus, to return a battery to a reserve state after it has been used to generate current. In order to achieve this reversibility, the nanostructures on the battery electrode comprise a plurality of closed cells and the pressure within the enclosed cells is varied. In a first embodiment, the pressure is varied by varying the temperature of a fluid within the cells by, for example, applying a voltage to electrodes disposed within said cells. In a second illustrative embodiment, once the battery has been fully discharged, the battery is recharged and then the electrolyte fluid is expelled from the cells in a way such that it is no longer in contact with the battery electrode.

Owner:ALCATEL-LUCENT USA INC

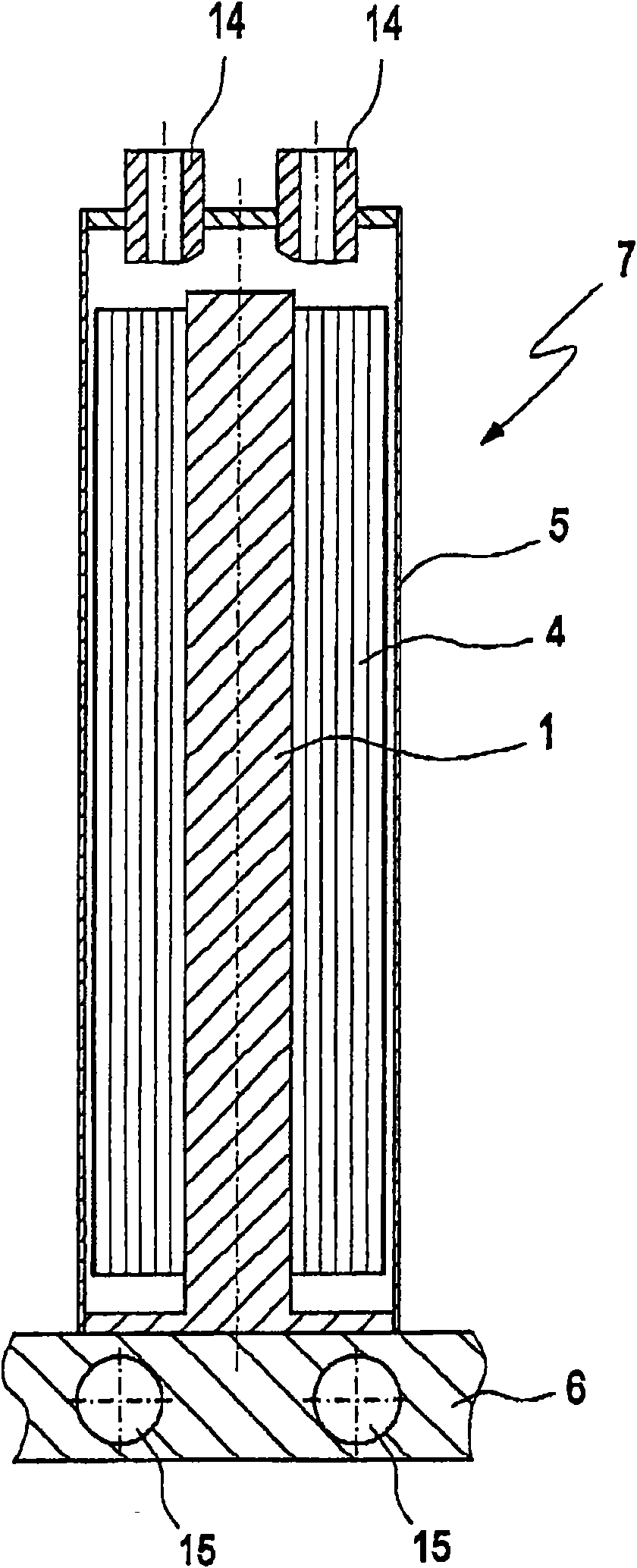

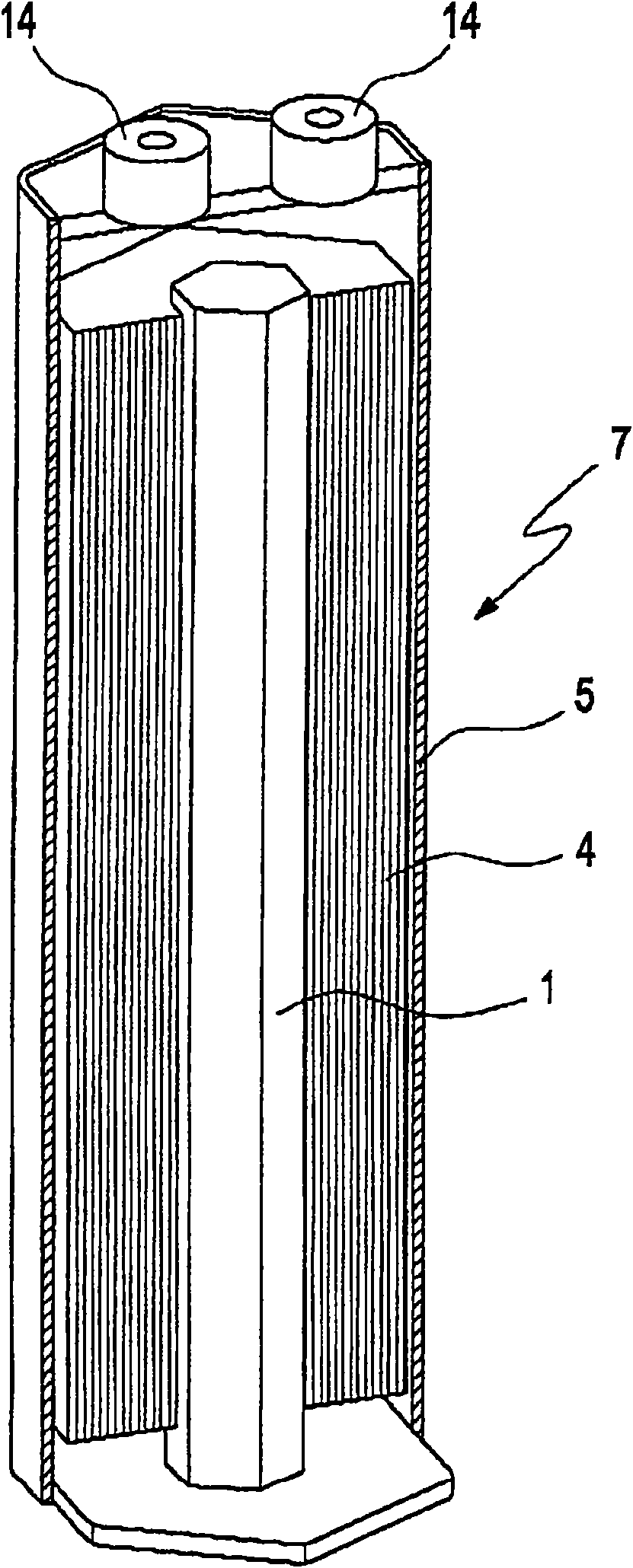

Electrochemical single cells for a battery and battery

InactiveCN101627501AAchieve temperature controlFinal product manufactureCells cooling/heatingTemperature controlHeat conducting

An electrochemical single cell for a battery and battery made from said single cells. The single cell comprises an electrode stack wound about a heat conducting bar and / or folded around a heat conducting bar. Temperature control of the single cells can be achieved by means of the heat conducting bar being at least partly made from a highly thermally conductive material on the surface thereof facing the electrode stack and having a solid construction. An economical and simple temperature management of a battery can be guaranteed, wherein the battery has a thermally conducting bar in thermal connection with a temperature control unit.

Owner:DAIMLER AG

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com