A battery stack arrangement

A battery stacking and battery technology, applied in the direction of flat batteries, secondary batteries, battery pack components, etc., can solve the problems of shell pressure, electrode thickness change, shell cracking, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

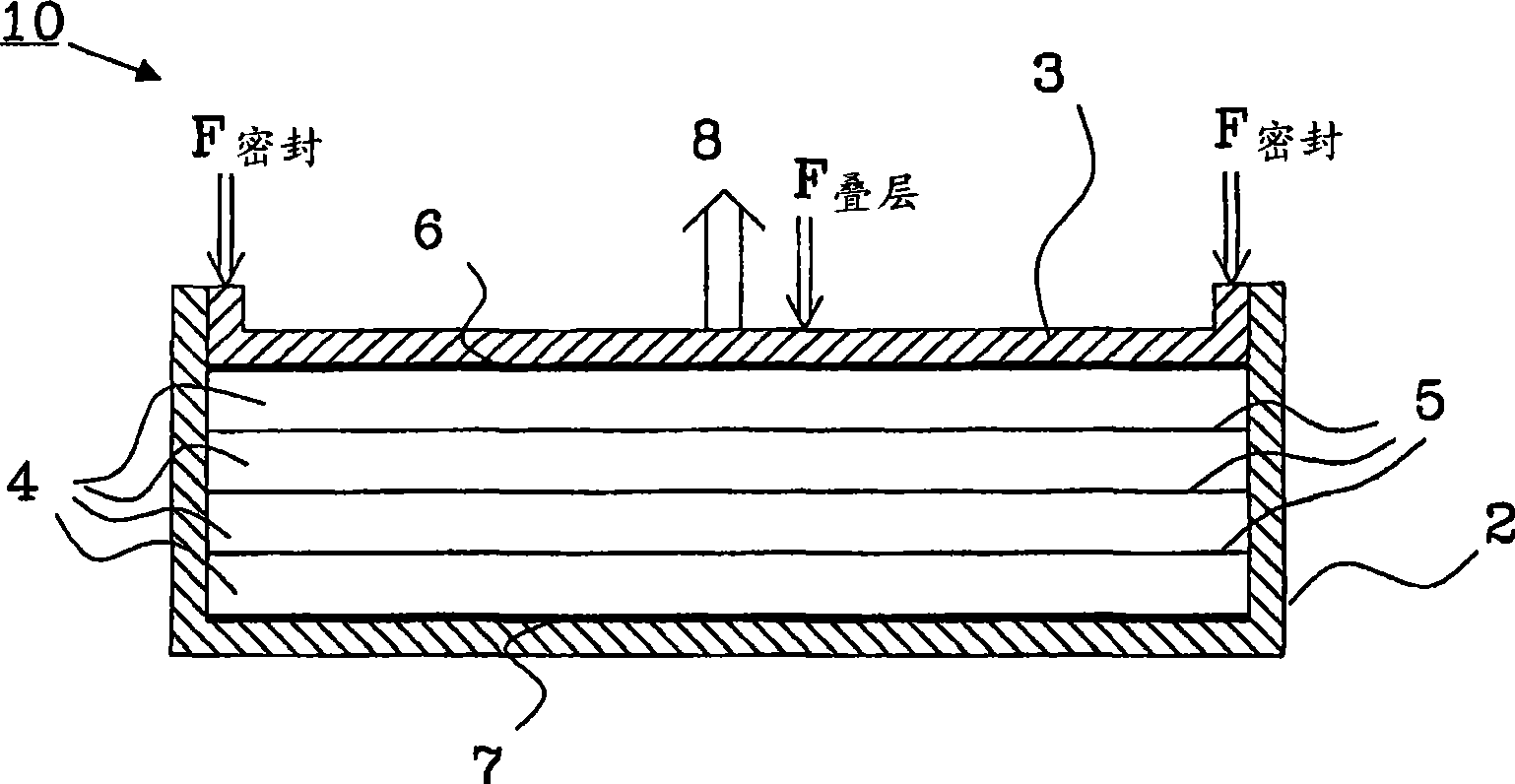

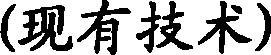

[0019] Each battery cell in a bipolar battery includes a negative electrode and a positive electrode with a spacer in between. Each electrode includes a non-metallic substrate, which makes the electrode inexpensive. Each battery cell is separated from each other by conductive double plates, and positive and negative end plates are arranged on each side of the battery stack, respectively. It is disclosed in the published international patent application WO 03 / 026042 assigned to the applicant that the battery is preferably provided with a common gas space to distribute the pressure in the battery during gas discharge, but the invention can be used with at least one separately arranged battery The unit is implemented in a bipolar battery.

[0020] At the start of the bi-electrode electrical cycle, the cell swells irreversibly. When housed in a rigid case, the expansion of the electrode can generate enormous forces because of the high modulus of elasticity of the electrode itsel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com