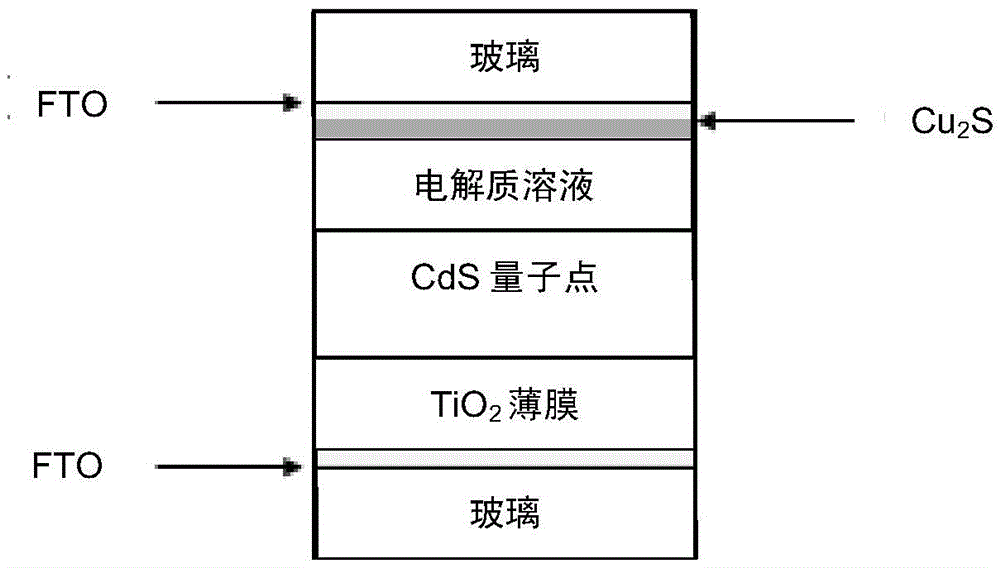

Solar cell Cu2S/FTO counter electrode and electrochemical deposition preparation method thereof

A solar cell and electrochemical technology, applied in the field of solar cells, can solve problems such as electrolyte leakage and poor electrode mechanical stability, and achieve the effects of low cost, simple preparation process, and reliable preparation scheme

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0013] Preparation of FTO / TiO 2 Film: First, ultrasonically wash FTO conductive glass with detergent, distilled water, acetone, isopropanol and ethanol; then weigh 0.66g of titanium dioxide P25 with an electronic balance and dissolve it in 3mL of absolute ethanol, stir at room temperature for 24h to obtain P25 slurry. Stick scotch tape on both sides of the upper surface of the clean FTO conductive glass (that is, one side of the FTO) to form a scraping area and use it to control TiO 2 Thickness of the film, drop excess P25 slurry on the scraping area, and scrape the P25 slurry with a glass rod to form a uniform coating. After being dried naturally, it was calcined in a muffle furnace at 450°C for 60 minutes to obtain FTO / TiO 2 film.

[0014] Preparation of FTO / TiO sensitized by CdS quantum dots 2 Thin film: Quantum dots prepared by continuous ion adsorption and reaction method (SILAR), that is, FTO / TiO 2 Film immersed in 0.125MCd(NO 3 ) 2 4H 2 O in ethanol solution for ...

Embodiment 2

[0019] Preparation of FTO / TiO by the same method 2 FTO / TiO sensitized by thin films and CdS quantum dots 2 film.

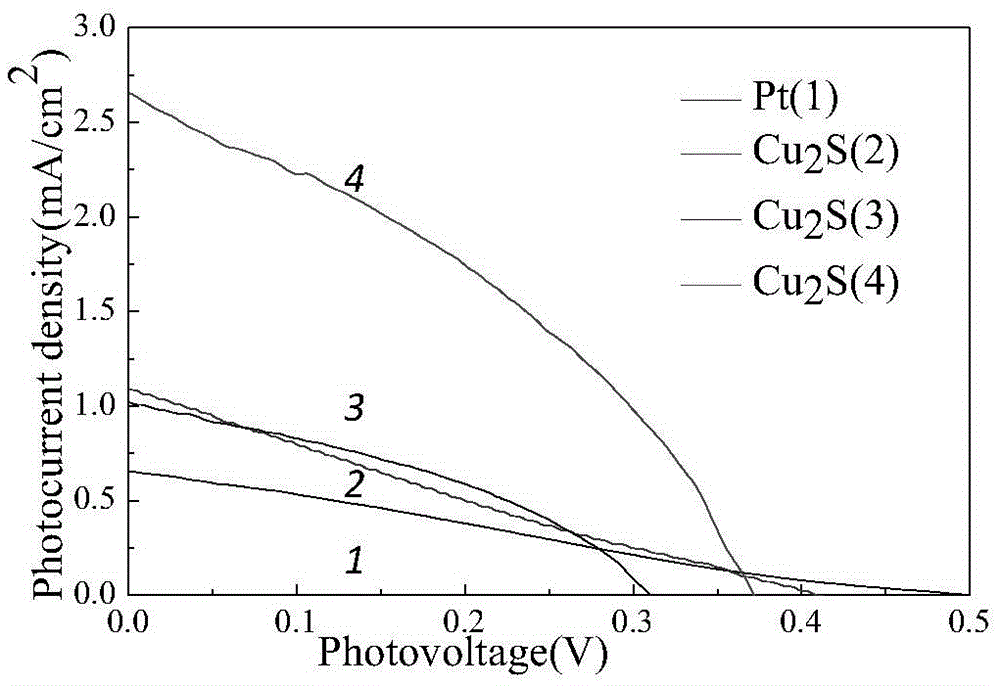

[0020] Preparation of Cu 2 S / FTO counter electrode: prepare electrolyte first, containing 0.0333mol / LCuCl 2 , 6.7×10 -3 mol / L thiourea, 0.333mol / L lactic acid, and NaOH to adjust the pH of the solution to a buffer system of 6.0. A three-electrode system electrochemical workstation (CHI660A, Shanghai Chenhua Instrument Co., Ltd.) using platinum wire as the counter electrode, calomel as the reference electrode, and FTO as the working electrode deposited Cu on the FTO by a potentiostatic method, and the potential was set to -0.8V , deposition for 60min. Then prepare polysulfide solution for vulcanization: 0.5MNa 2 S·9H 2 O, 0.5MS and 0.05M KCl in methanol. Put Cu-deposited FTO into the polysulfide solution for 5 seconds, take it out, rinse it with ethanol, and dry it to obtain Cu 2 S / FTO counter electrode.

[0021] Assembled solar cells: FTO / TiO sensitized ...

Embodiment 3

[0024] Preparation of FTO / TiO by the same method 2 FTO / TiO sensitized by thin films and CdS quantum dots 2 film.

[0025] Preparation of Cu 2 S / FTO counter electrode: prepare electrolyte first, 0.05mol / LCuCl 2 , 1.3×10 -2 mol / L thiourea and 0.5mol / L lactic acid were mixed, and NaOH was used to adjust the buffer system with a pH value of 7.0. A three-electrode system electrochemical workstation (CHI660A, Shanghai Chenhua Instrument Co., Ltd.) using platinum wire as the counter electrode, calomel as the reference electrode, and FTO as the working electrode deposited Cu on the FTO by the constant potential method, and the potential was set to -1.2 V, deposited for 60 min. Then prepare the polysulfide solution for vulcanization: the polysulfide solution is 1MNa 2 S·9H 2 O, 1MS and 0.1M KCl in methanol. Put Cu-deposited FTO into the polysulfide solution for 5 seconds, take it out, rinse it with ethanol, and dry it to obtain Cu 2 S / FTO counter electrode.

[0026] Assembled...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com