Patents

Literature

50results about How to "Control Surface Roughness" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

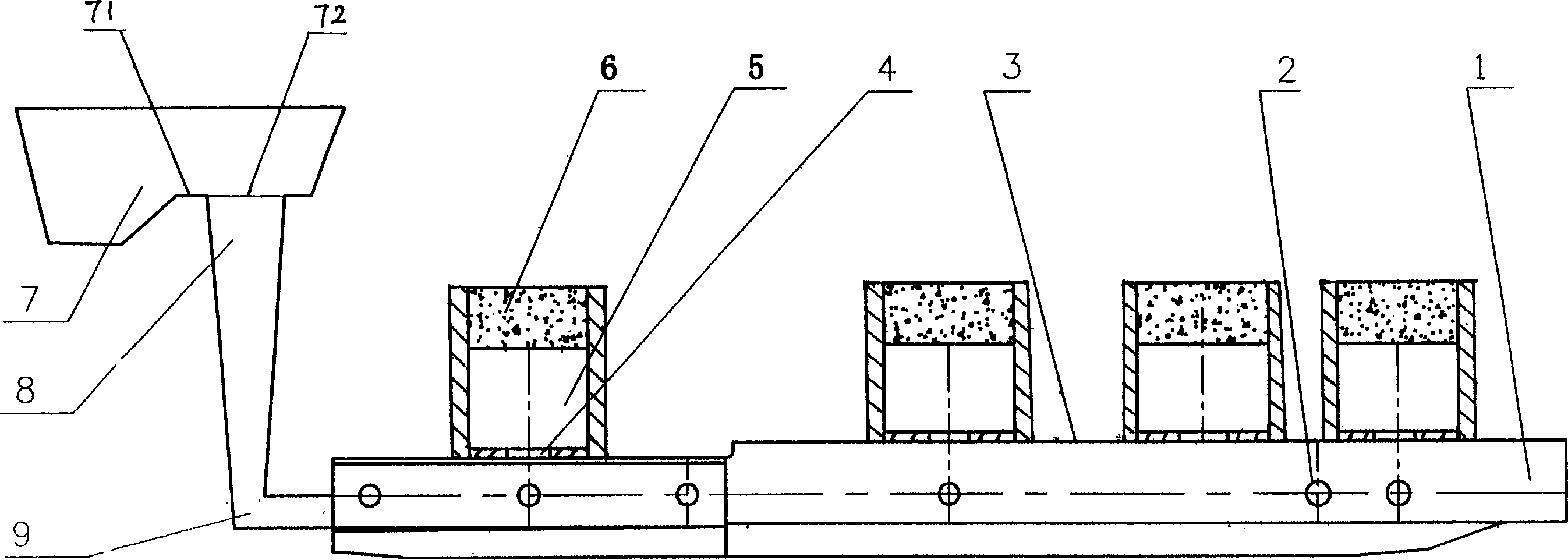

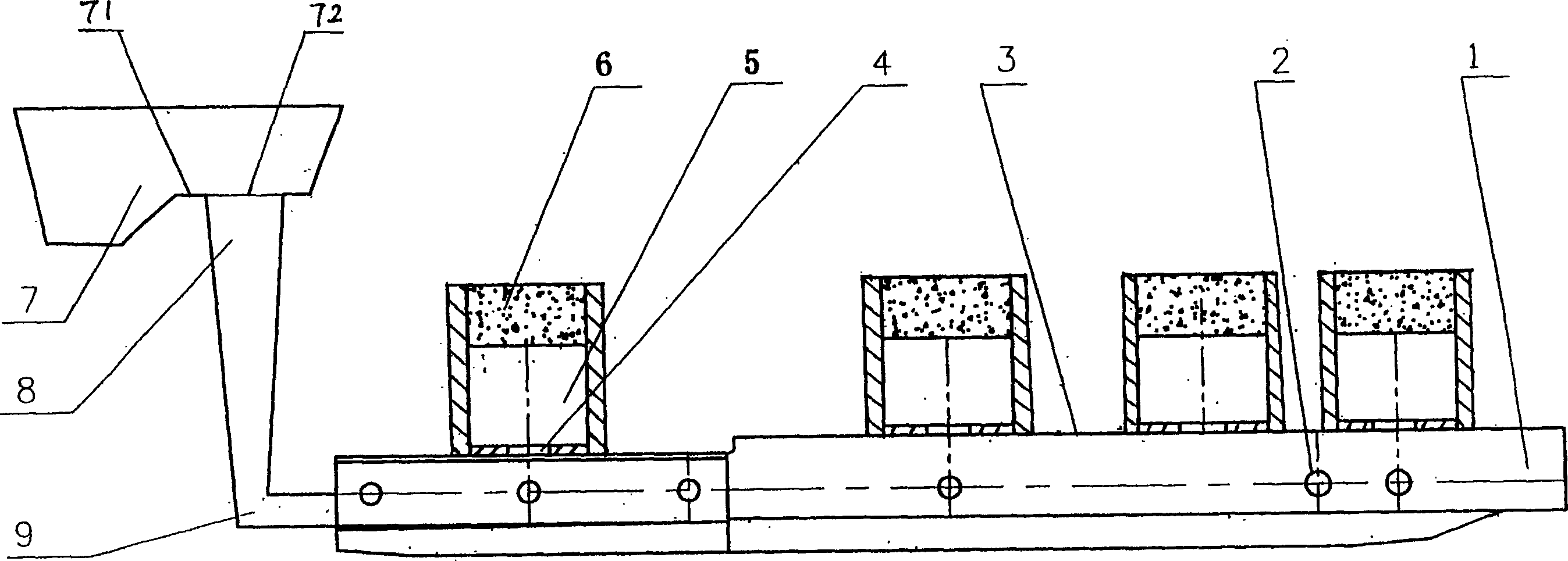

High manganese steel railway assembled frog centre rail casting process

A technology for casing the high-Mn steel frog of combined switch for railway features that the ferrochromium sand is used as surficial sand and core sand, the alkaline Mg sand powder paint is coated on the surfaces of moulding cavity and core, and an easily cutting plate is added under the insulating siser head. It includes such steps as applying the insulating and heat generating agent to the surface of riser head, horizontal pouring, cutting off the riser head, burying it is sand, and heat treating.

Owner:中科西王特钢有限公司

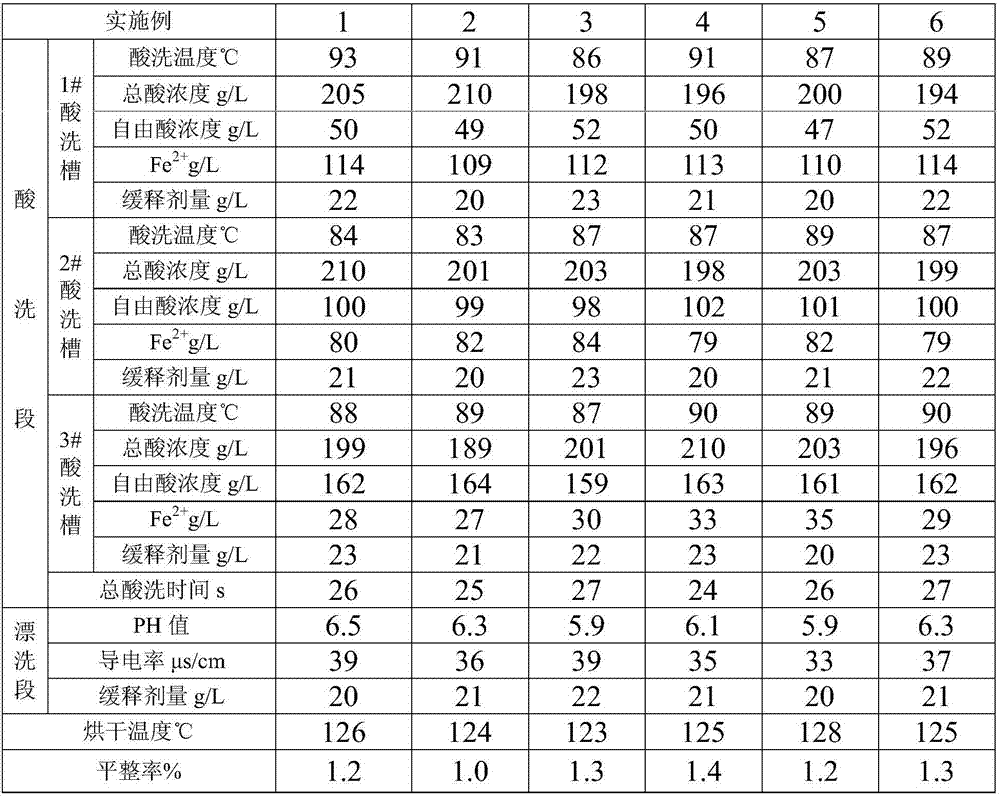

Hot-rolled pickling steel with high surface quality and tensile strength of 490 MPa and manufacturing method for hot-rolled pickling steel

The invention discloses a hot-rolled pickling steel with a high surface quality and a tensile strength of 490 MPa and a manufacturing method. The weight percentages of its chemical components are: C: 0.060-0.080%, Si: 0.100-0.200%, : 1.000~1.250%, P≤0.020%, S≤0.008, Nb: 0.015~0.025%, Als: 0.015~0.040%, Cu≤0.300%, Ni≤0.300%, Cr≤0.300%; the rest is Fe and unavoidable impurity; the method is through hot metal desulfurization, converter smelting, vacuum treatment, continuous casting, shaping, slab heating, hot continuous rolling, laminar cooling, coiling, finishing, pickling process, levelling, coiling, recoiling, Manufactured by oiling and packaging, the hot-rolled pickled steel of the invention has the characteristics of good ductility, cold stamping performance, welding performance and good cold bending performance.

Owner:武汉钢铁有限公司

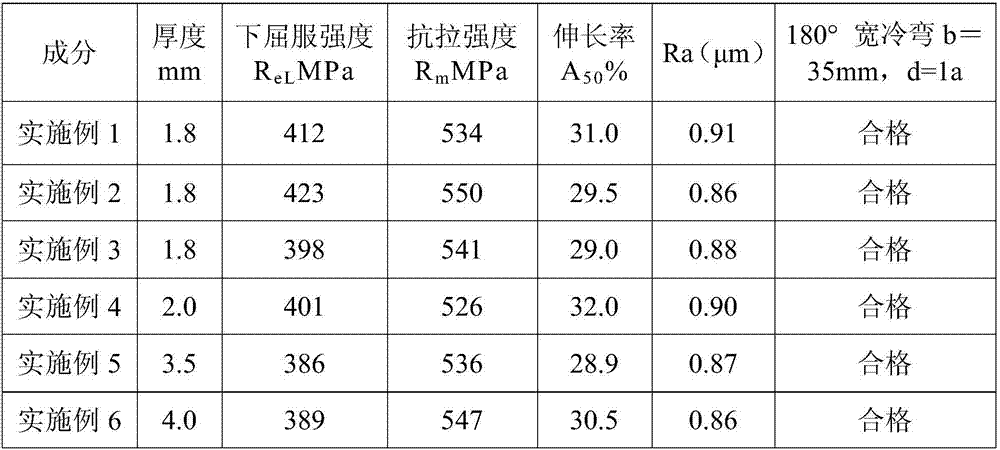

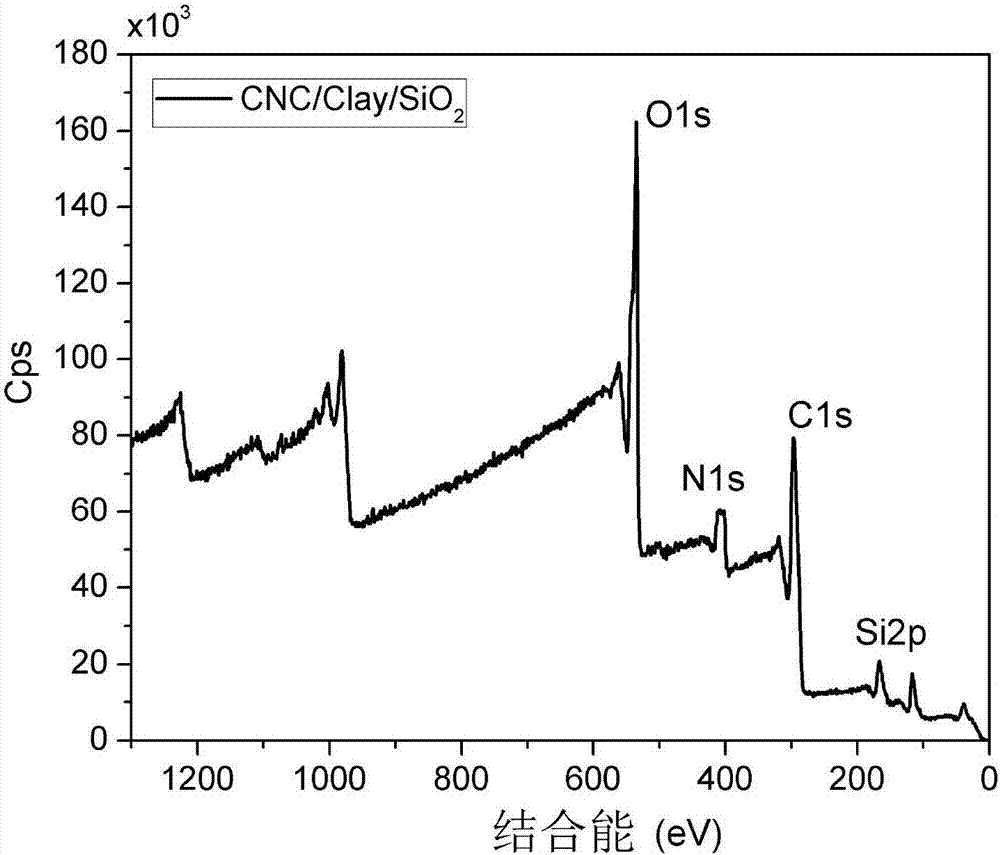

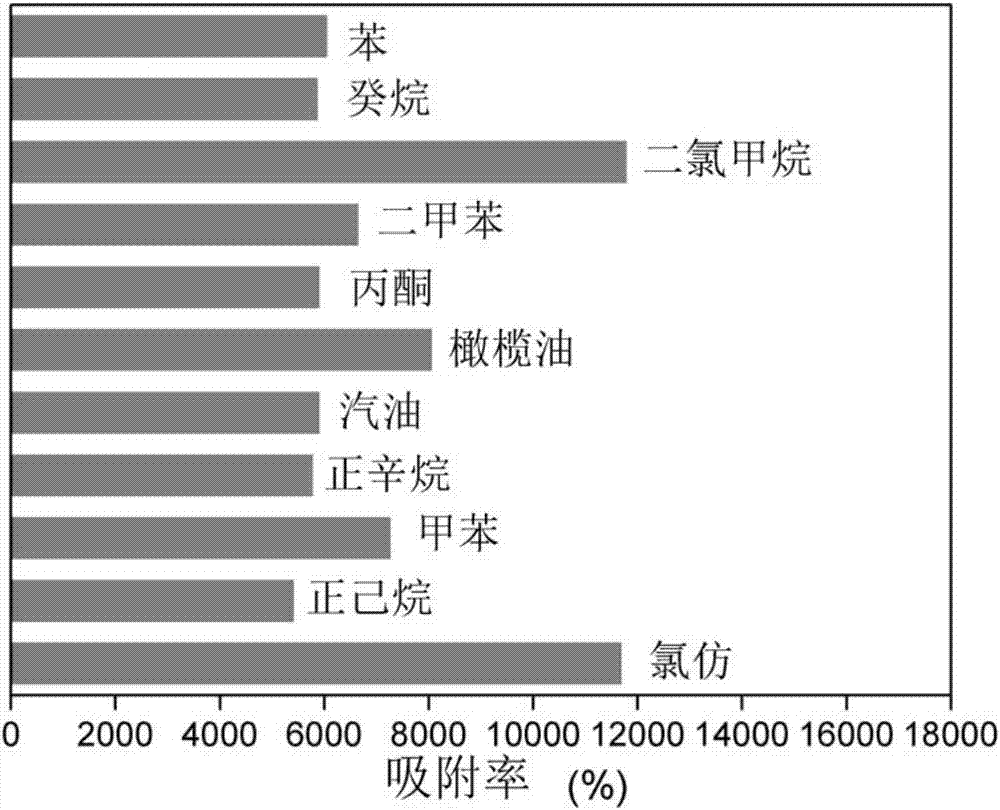

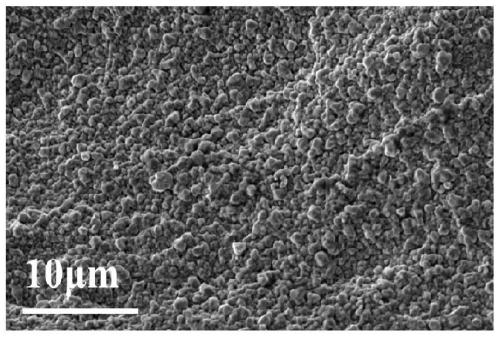

Multi-dimensional nano-particle modified super-hydrophobic oil-absorbing foam material and preparation method thereof

The invention discloses a multi-dimensional nano-particle modified super-hydrophobic oil-absorbing foam material and a preparation method thereof. According to the method, nano particles of different dimensions are grafted on the surface of a three-dimensional foam material by covalent bonds through a dual-functional group chemical modification method, and further, hydrophobic modification is performed by using a simple silane coupling agent, so that the super-hydrophobic oil-absorbing foam material is acquired. In the method, particle adhesion is improved effectively through chemical grafting, multi-layer modification by nano particles is realized by grafting repeatedly, so as to regulate the surface roughness of the material. The super-hydrophobic oil-absorbing foam material overcomes defects of single size of particles and poor adhesion on a matrix, is prepared through a simple process, is low-cost, and can be produced in a large scale.

Owner:SOUTH CHINA UNIV OF TECH

Selective laser melting manufacturing process for annular array blade guide

ActiveCN110202142AReduced dimensional accuracyControl stress deformationAdditive manufacturing apparatusIncreasing energy efficiencySelective laser meltingAfter treatment

The invention relates to a selective laser melting manufacturing process for an annular array blade guide. The process comprises the steps of 1, model segment processing, specifically, an annular array blade guide three-dimensional model is equally divided into multiple sections; 2, material selection and setting of process parameters; 3, determining of a placing mode and designing of a support structure; 4, correcting of the size precision; 5, selective laser melting forming; 6, after-treatment, specifically, parts together with a base plate are placed into a vacuum heat treatment furnace, warm is kept for one hour at the temperature of 800 DEG C to eliminate residual stress, and then the parts are cut and the support structure is removed; and 7, welding, specifically, all the segmented parts are fixed on a welding fixture and welding is carried out to obtain an integral annular array blade guide part in an argon-arc welding or laser welding mode. The part size precision, stress deformation and surface roughness are well controlled in the process, mechanical performance of the parts is superior to traditional castings, the manufacturing cycle is short, and the efficiency is high.

Owner:航发优材(镇江)增材制造有限公司

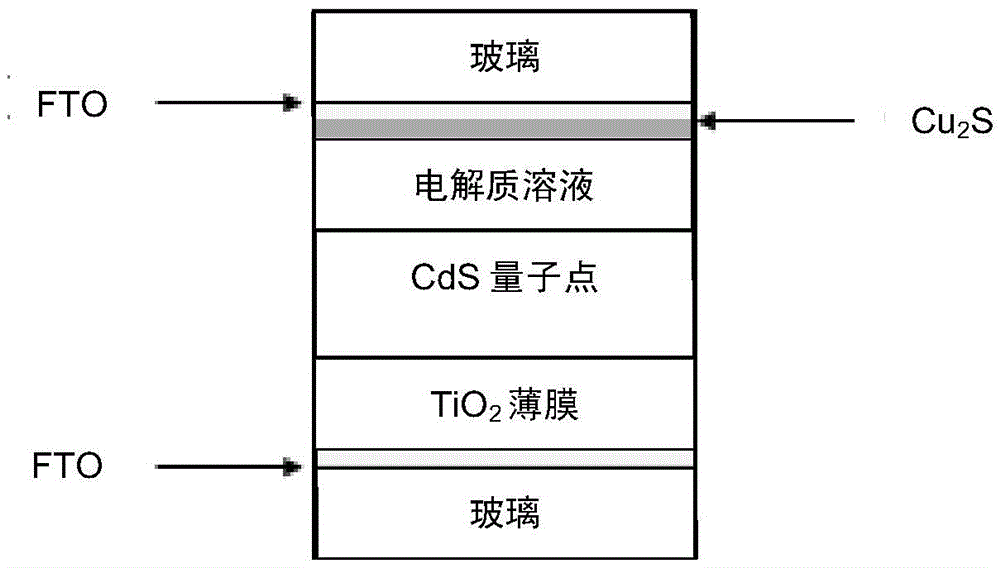

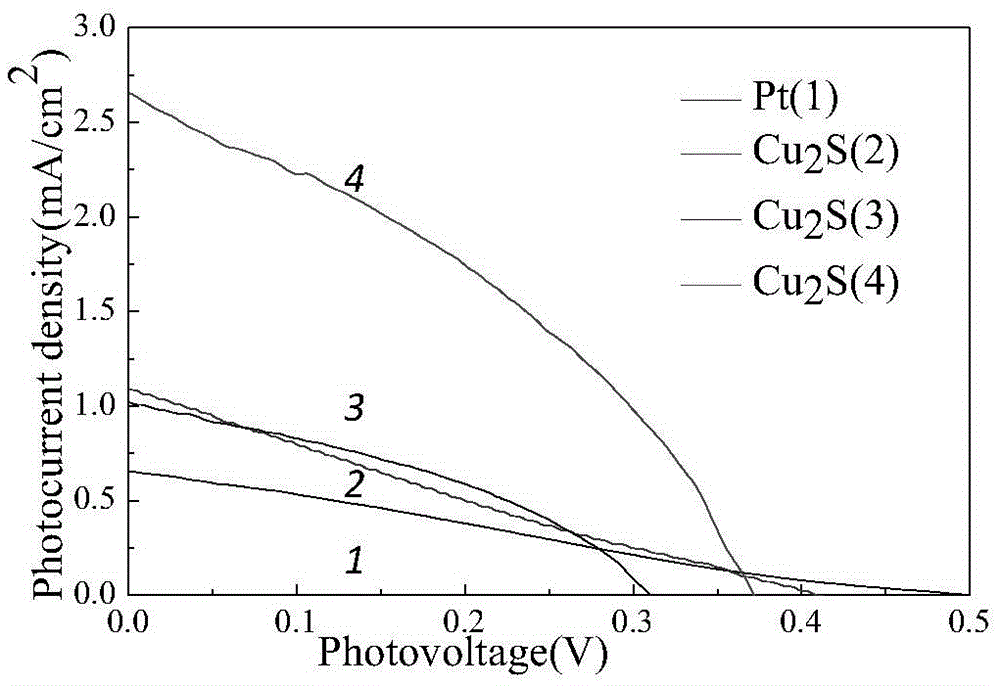

Solar cell Cu2S/FTO counter electrode and electrochemical deposition preparation method thereof

InactiveCN105655131ASimple preparation processLow costLight-sensitive devicesFinal product manufactureElectrolyte leakageThiourea

The invention provides a method for preparing a solar cell Cu2S / FTO counter electrode based on the electrochemical deposition process and belongs to the technical field of solar cells. According to the method, an electrolyte is prepared firstly and then a Cu2S / FTO counter electrode is obtained in a three-electrode system through electrochemically depositing the Cu material on an FTO according to the potentiostatic method and then sulfurizing the deposited Cu material in a polysulfide solution. The above electrolyte is composed of a buffer system comprising 0.03-0.05 mol / L of CuCl2, 6.6*10<-3>-1.3*10<-2> mol / L of thiourea and 0.3-0.5 mol / L of lactic acid, and the pH value of the buffer system is 5.0-7.0. The polysulfide solution is composed of a methanol solution comprising 0.5-1 M of Na2S*9H2O, 0.5-1 M of S and 0.05-0.1 M of KCl. The method is simple in preparation process and low in cost, which provides a reliable preparation scheme for the preparation of QDSCs counter electrodes. Meanwhile, the problems of the mechanical stability and the electrolyte leakage of Cu2S / FTO counter electrodes can be solved.

Owner:JILIN UNIV

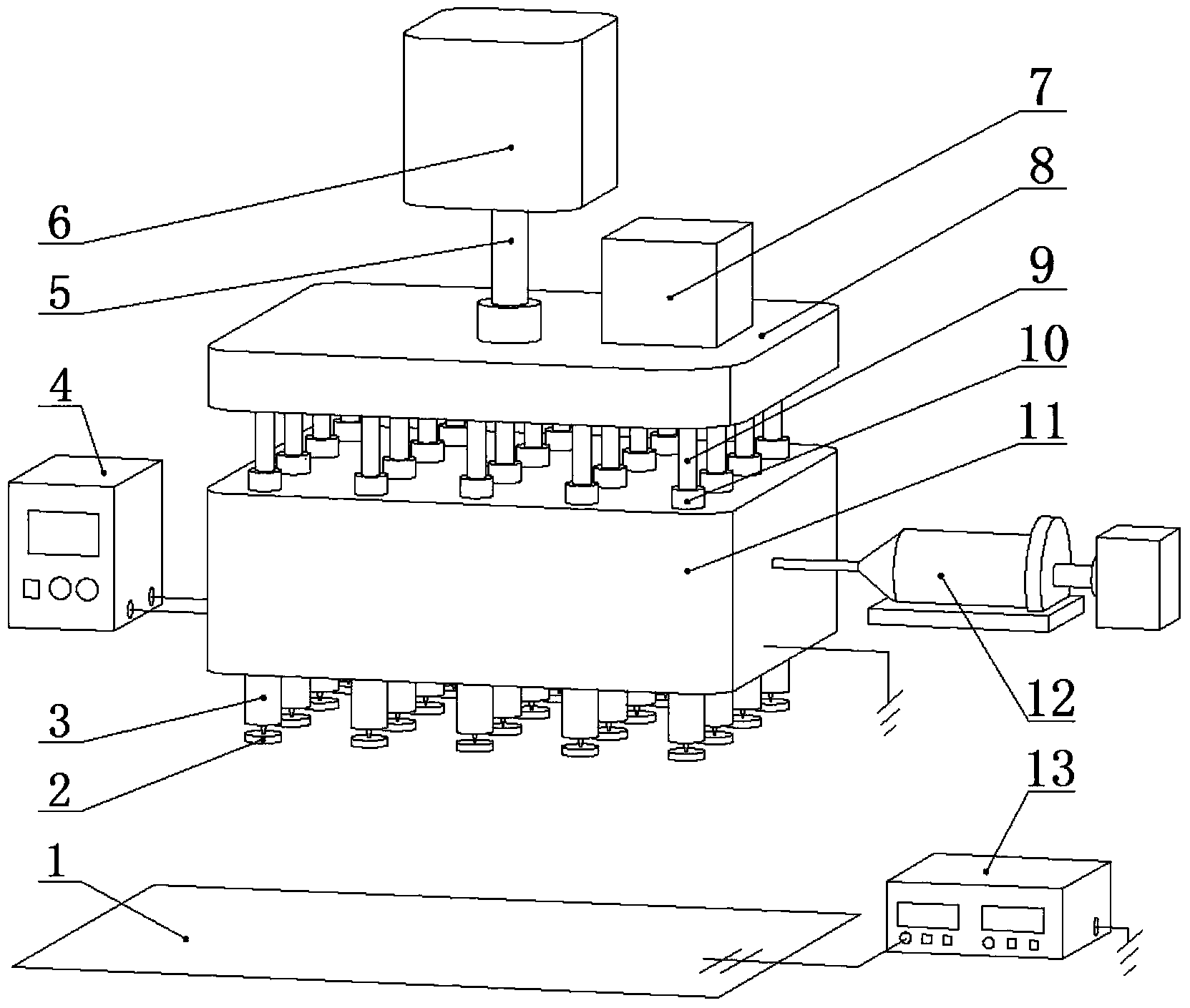

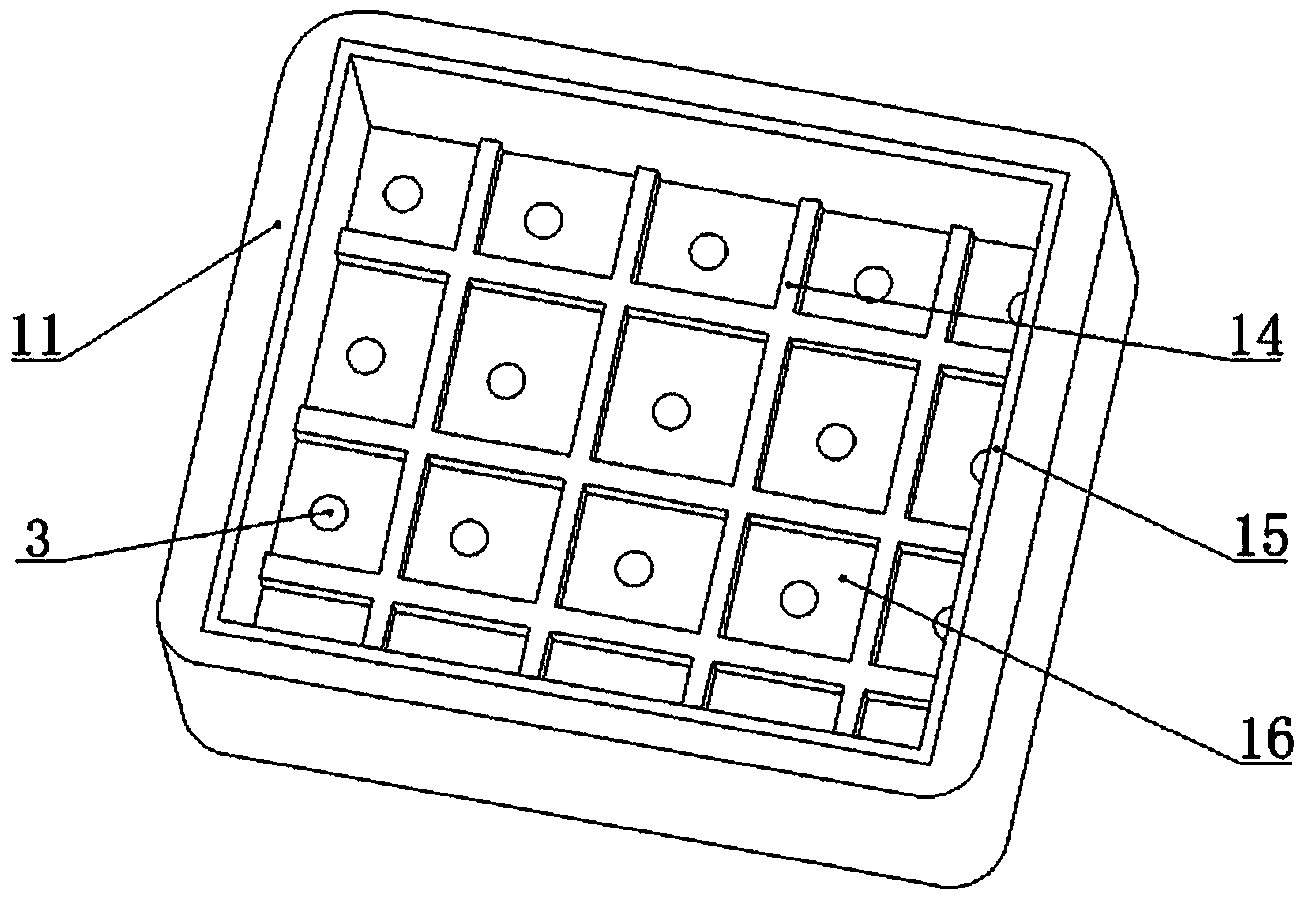

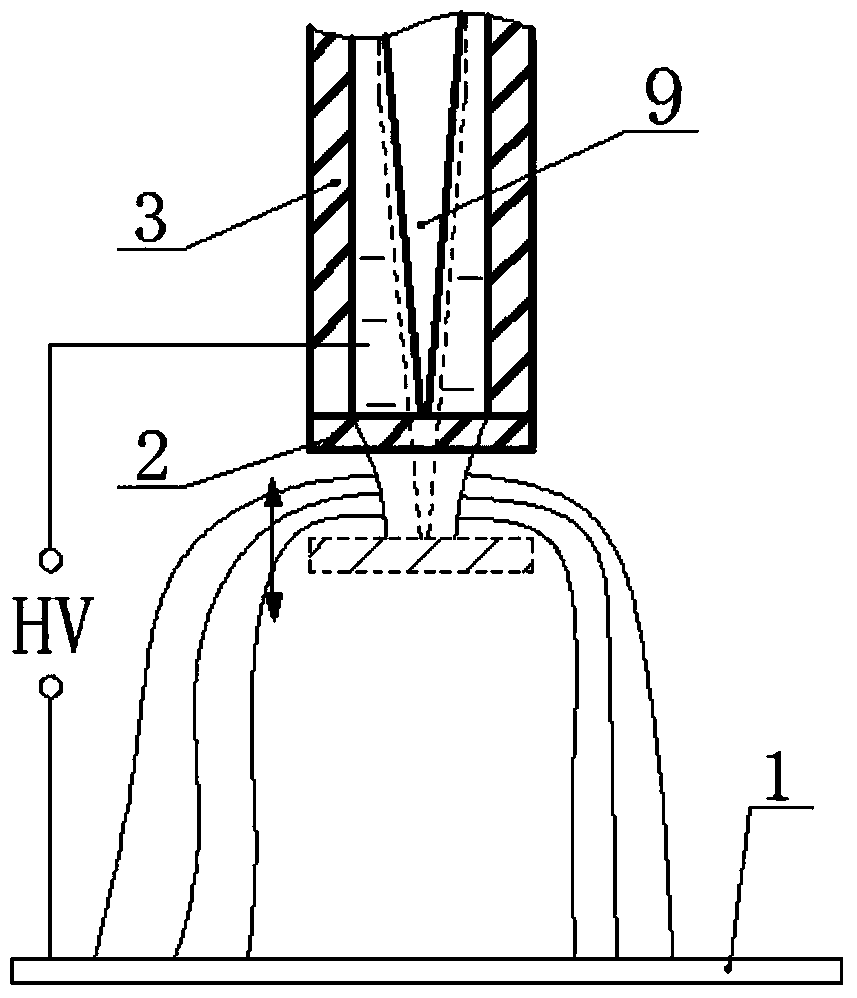

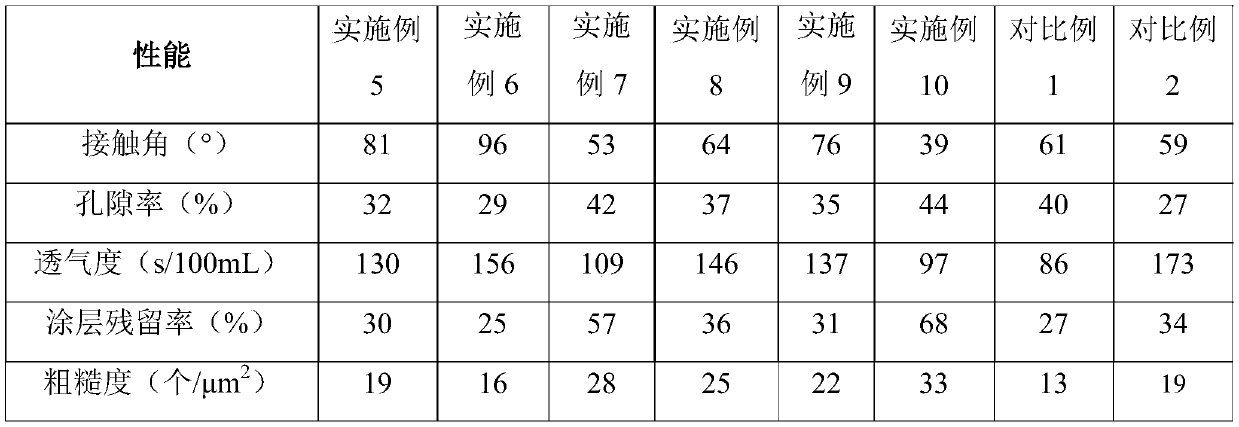

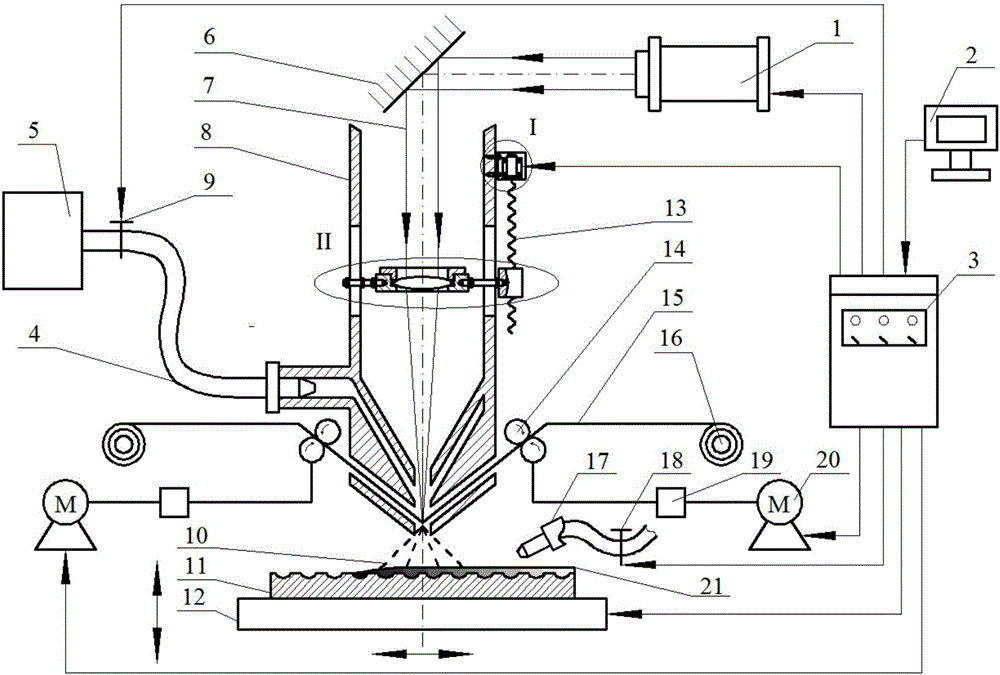

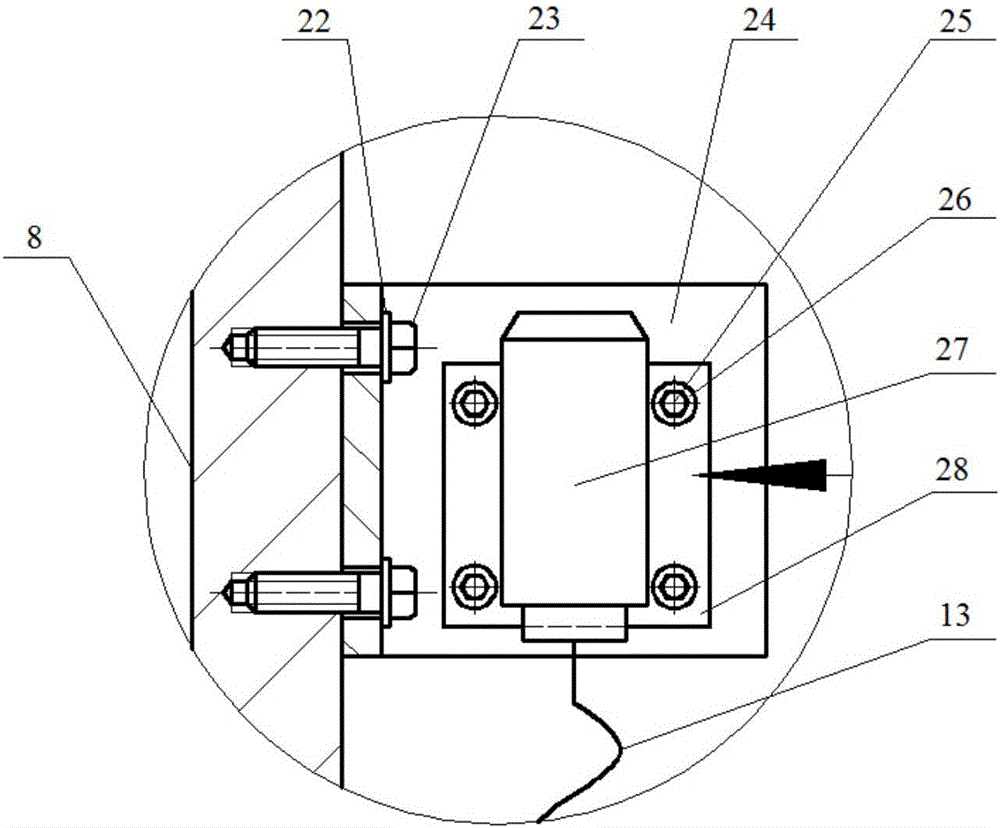

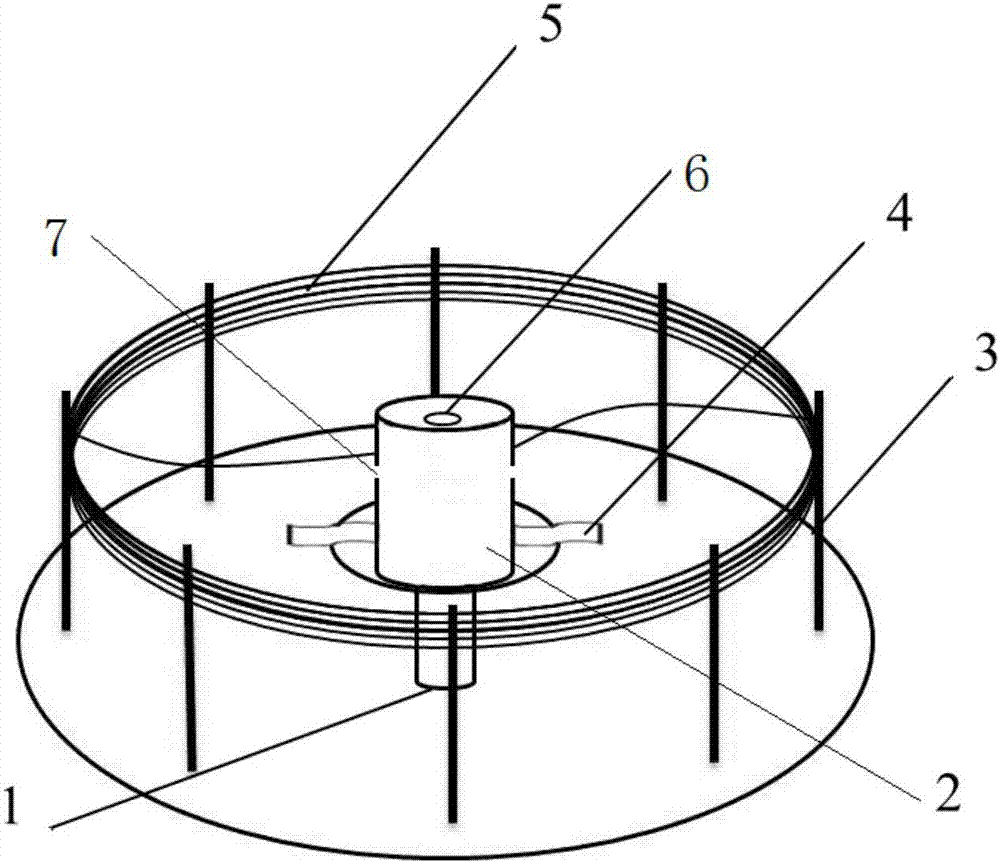

Opening-closing induction type batch electro-spinning device

ActiveCN103993371AImprove delivery efficiencyIncrease delivery speedFilament/thread formingElectricityTemperature control

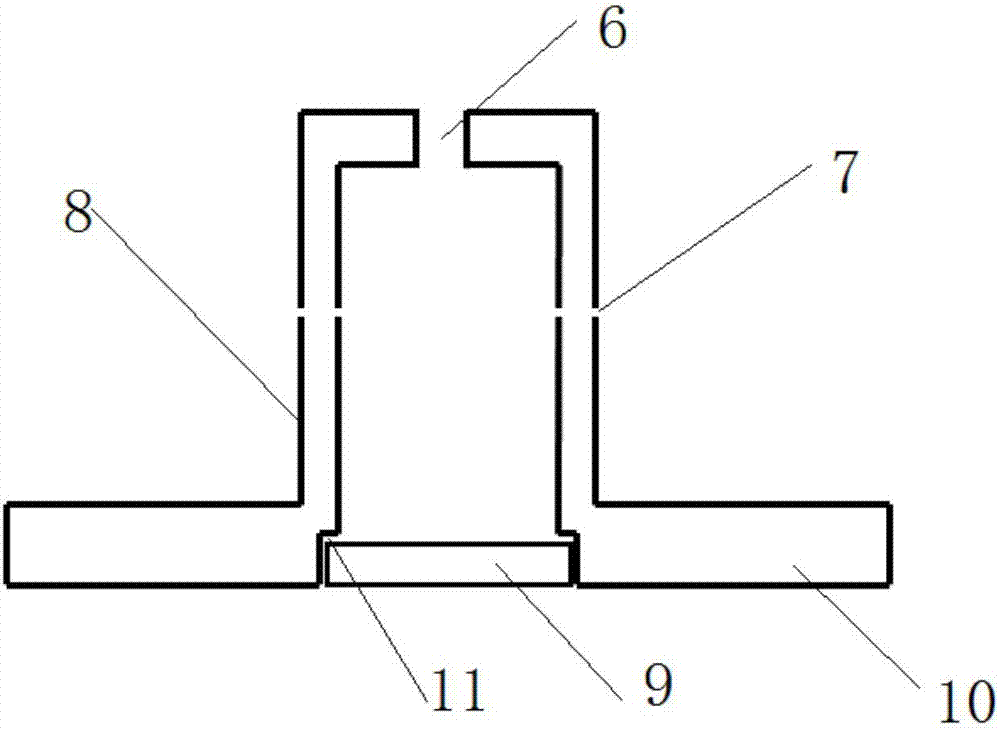

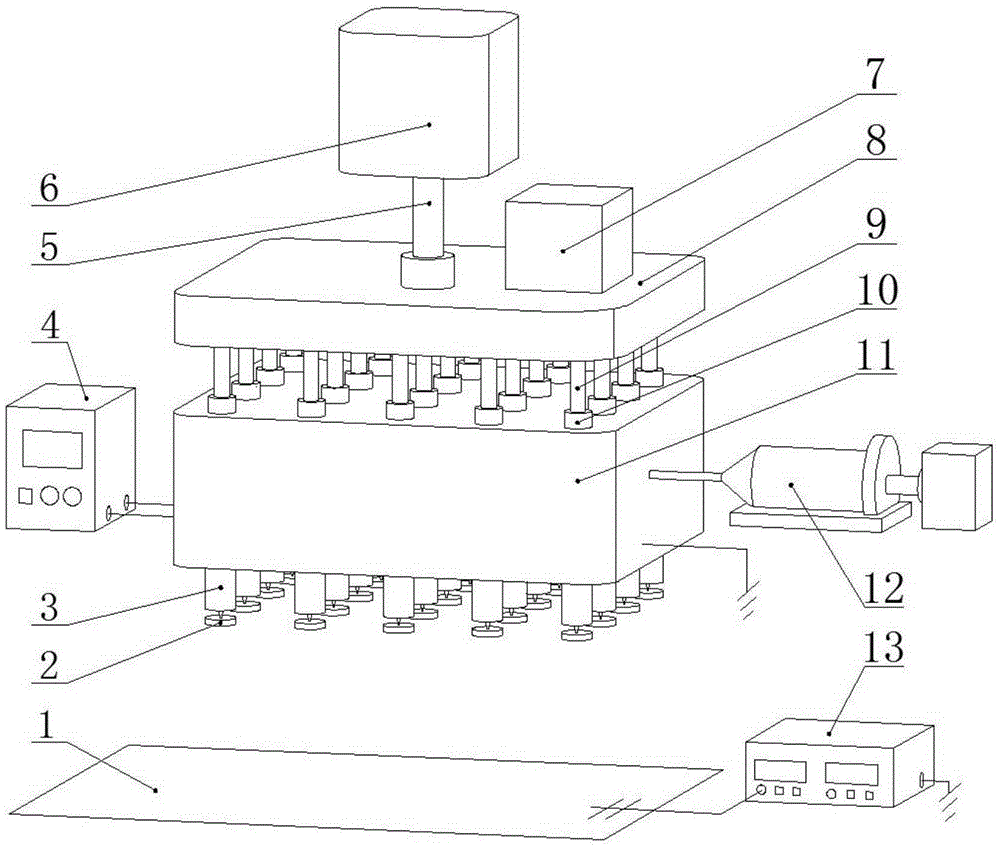

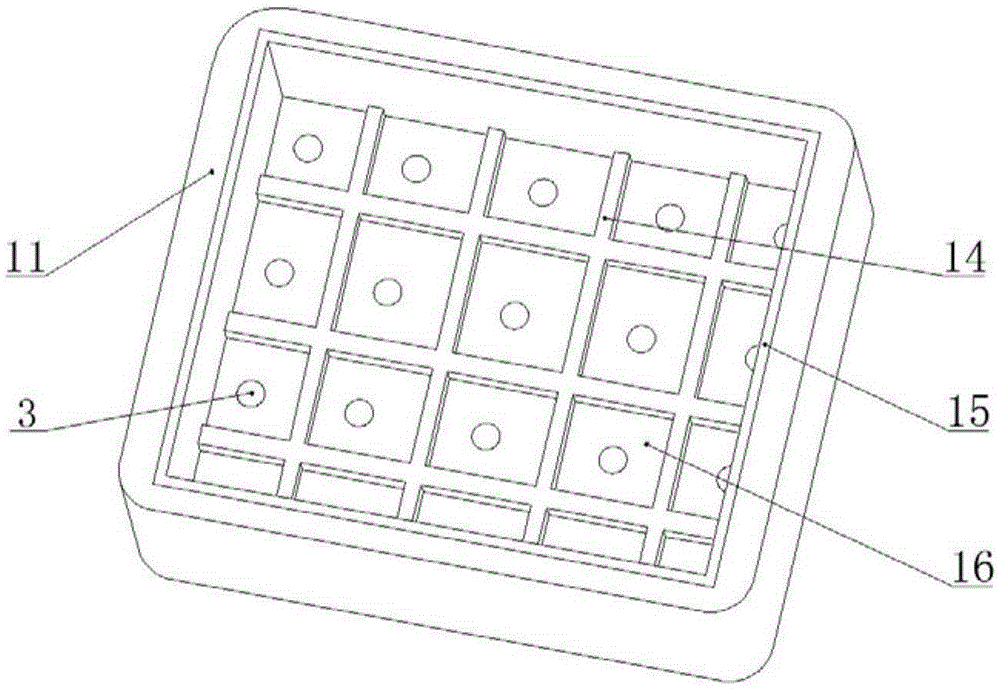

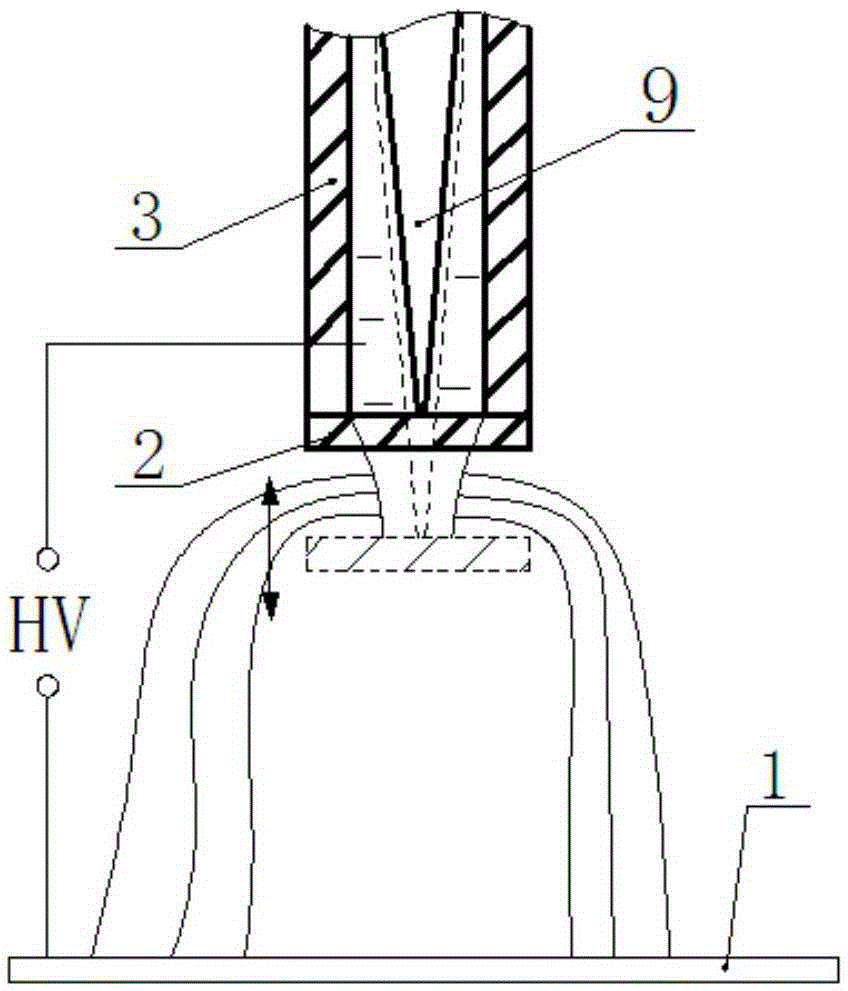

The invention discloses an opening-closing induction type batch electro-spinning device and relates to an electrostatic spinning device. A material storage box is communicated with a liquid supply device. A heating piece and a temperature sensor are arranged on an inner cavity wall of the material storage box. The heating piece and the temperature sensor are electrically connected with a temperature control box. A nozzle array is arranged at the bottom of the material storage box. Center shafts are arranged in nozzles. The center shafts penetrate through the material storage box vertically. The lower ends of the center shafts are connected with nozzle covers which are placed outside nozzle outlets. The upper ends of the center shafts extend out of the upper end face of the material storage box. A driving motor and a multi-shaft output box are arranged above the material storage box. The driving motor is arranged on the multi-shaft output box. An output shaft of the driving motor is connected with the input end of the multi-shaft output box. The output ends of the multi-shaft output box are connected with the upper ends of the center shafts. A vibration output end of a vibration generator is in rigid connection with the multi-shaft output box. Conducting metal strips are arranged on the bottom face in the material storage box at intervals horizontally and longitudinally. The conducting metal strips are connected to the ground or are electrically connected with a high-voltage power supply. A collecting device is placed below the material storage box. The collecting device is electrically connected with the high-voltage power supply or is connected to the ground.

Owner:XIAMEN UNIV

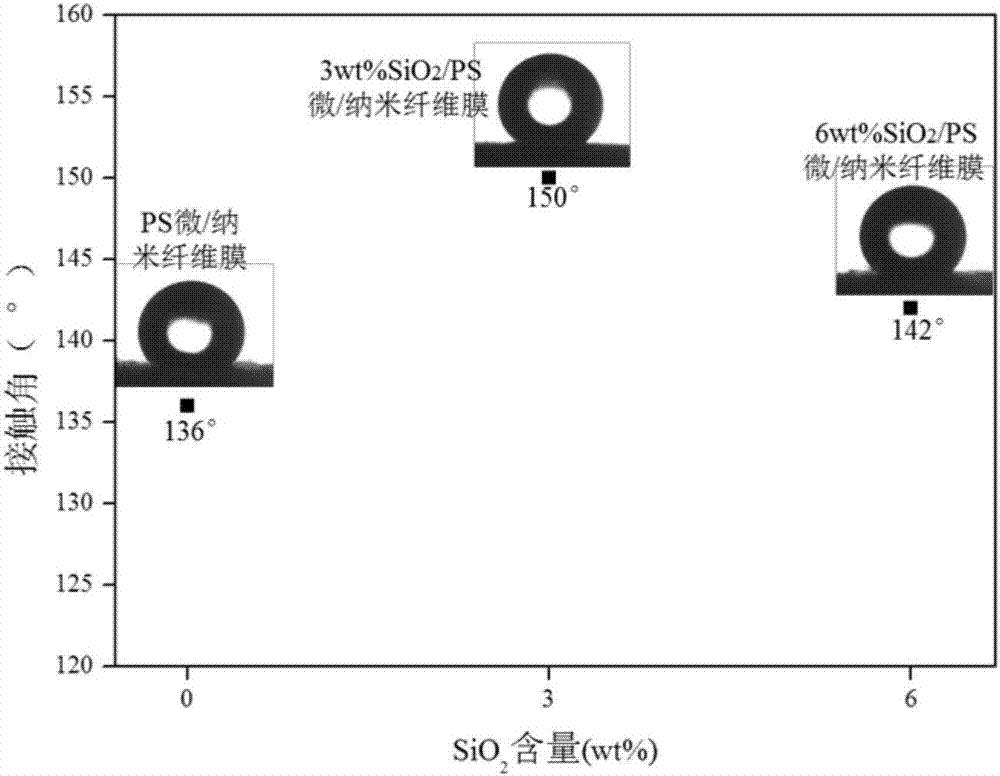

Centrifugal spinning preparation method of silicon dioxide and polystyrene micro-nano fiber membrane

ActiveCN105506761AEasy to prepareImproved wear and aging resistanceFilament/thread formingMonocomponent synthetic polymer artificial filamentMicro nanoChemistry

Provided is a centrifugal spinning preparation method of a silicon dioxide and polystyrene micro-nano fiber membrane. The method comprises the following steps that 1, hydrophobic silicon dioxide is prepared, wherein silicon dioxide sol is prepared through a sol-gel method, hydrophobic modification is conducted on the prepared silicon dioxide sol by taking methacryloxy propyl trimethoxyl silane (MPS) as a modifying agent, and hydrophobic silicon dioxide is obtained; 2, a centrifugal spinning solution is prepared, wherein hydrophobic silicon dioxide prepared in the first step and polystyrene (PS) are mixed and dissolved in N,N-dimethylformamide (DMF), and the uniformly dispersed centrifugal spinning solution is obtained after stirring is conducted, wherein the mass concentrations of PS and SiO2 are 18+ / -2 wt% and 3+ / -1 wt% respectively; 3, centrifugal spinning is conducted, wherein centrifugal spinning is conducted by adopting the centrifugal spinning solution prepared in the second step, and the silicon dioxide and polystyrene (SiO2 / PS) super-hydrophobic micro-nano fiber membrane is obtained.

Owner:博森纺织科技股份有限公司

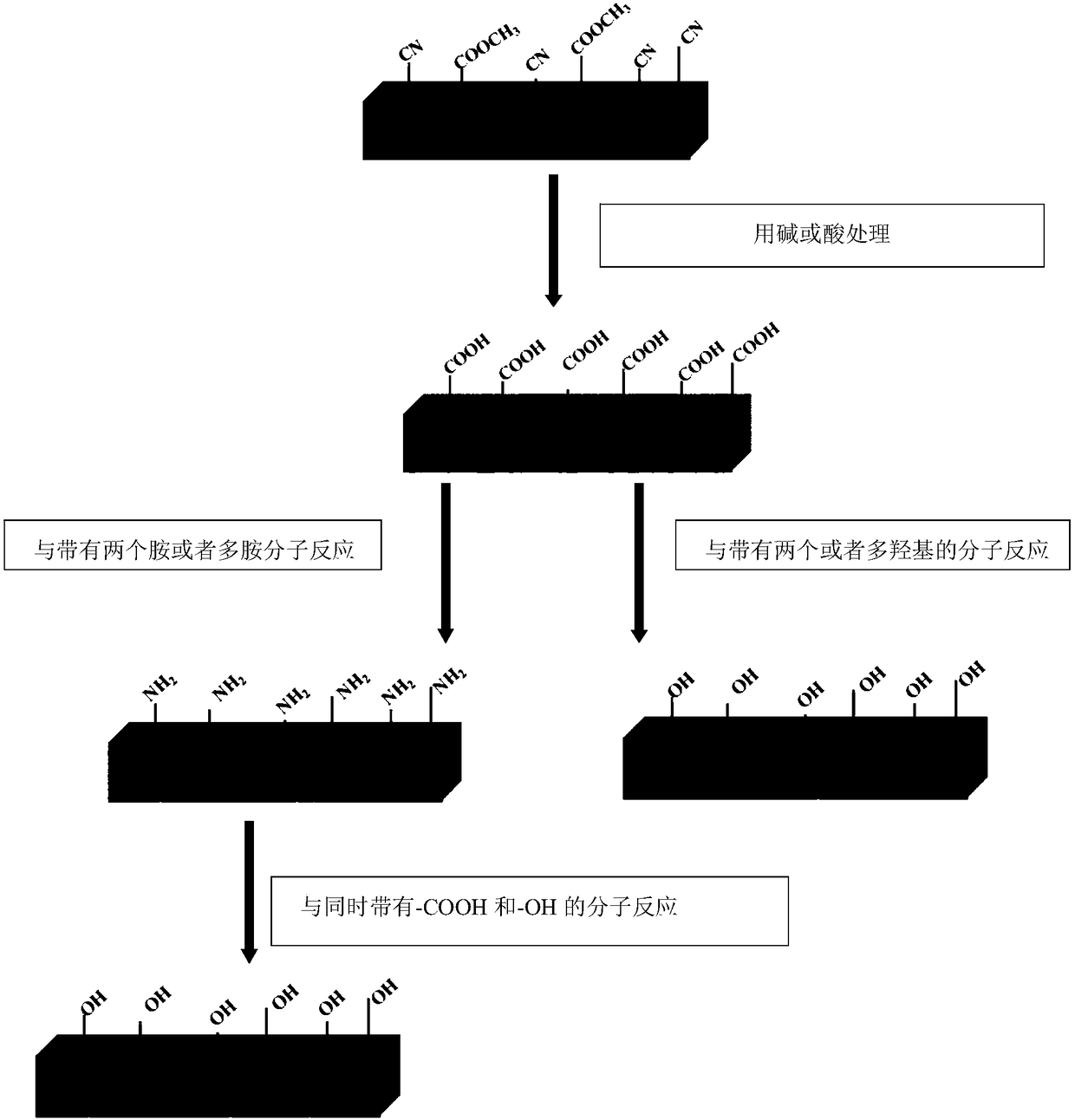

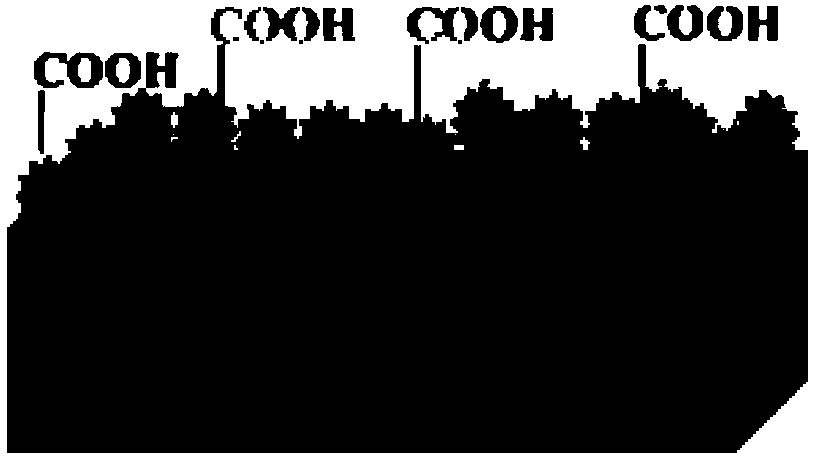

Preparation method of superhydrophilic and underwater-superoleophobic polyacrylonitrile-based oil-water separating membrane

ActiveCN108246112ALow costUniform pore size distributionMembranesSemi-permeable membranesPorosityNano structuring

The invention provides a preparation method of a superhydrophilic and underwater-superoleophobic polyacrylonitrile-based oil-water separating membrane. The preparation method comprises the following steps of: adopting acrylonitrile monomer as a main-body raw material, and adopting an aqueous-phase precipitated polymerization method to synthesize a polyacrylonitrile-based copolymer; selecting a crystalline diluting agent, combining with a thermally-induced phase separation method to construct a polyacrylonitrile-based microporous membrane with a micro / nano structure and high flux on the surface, and preparing the superhydrophilic and underwater-superoleophobic microporous membrane by simple modification and grafting, wherein the use of an organic solvent is avoided in synthesis and modification of the process. The oil-water separating membrane prepared by the preparation method has the advantages of high porosity, good pressure resistance, permanent hydrophilia and excellent underwateroleophobic property; in addition, the adhesion to oil drops is very low, the pollution resistance is good, long-time and stable operation can be achieved, and high-efficiency separation from an oil-water mixture to oil-in-water type oil-water emulsion can be realized only by means of gravity or lower pressure.

Owner:TIANJIN POLYTECHNIC UNIV

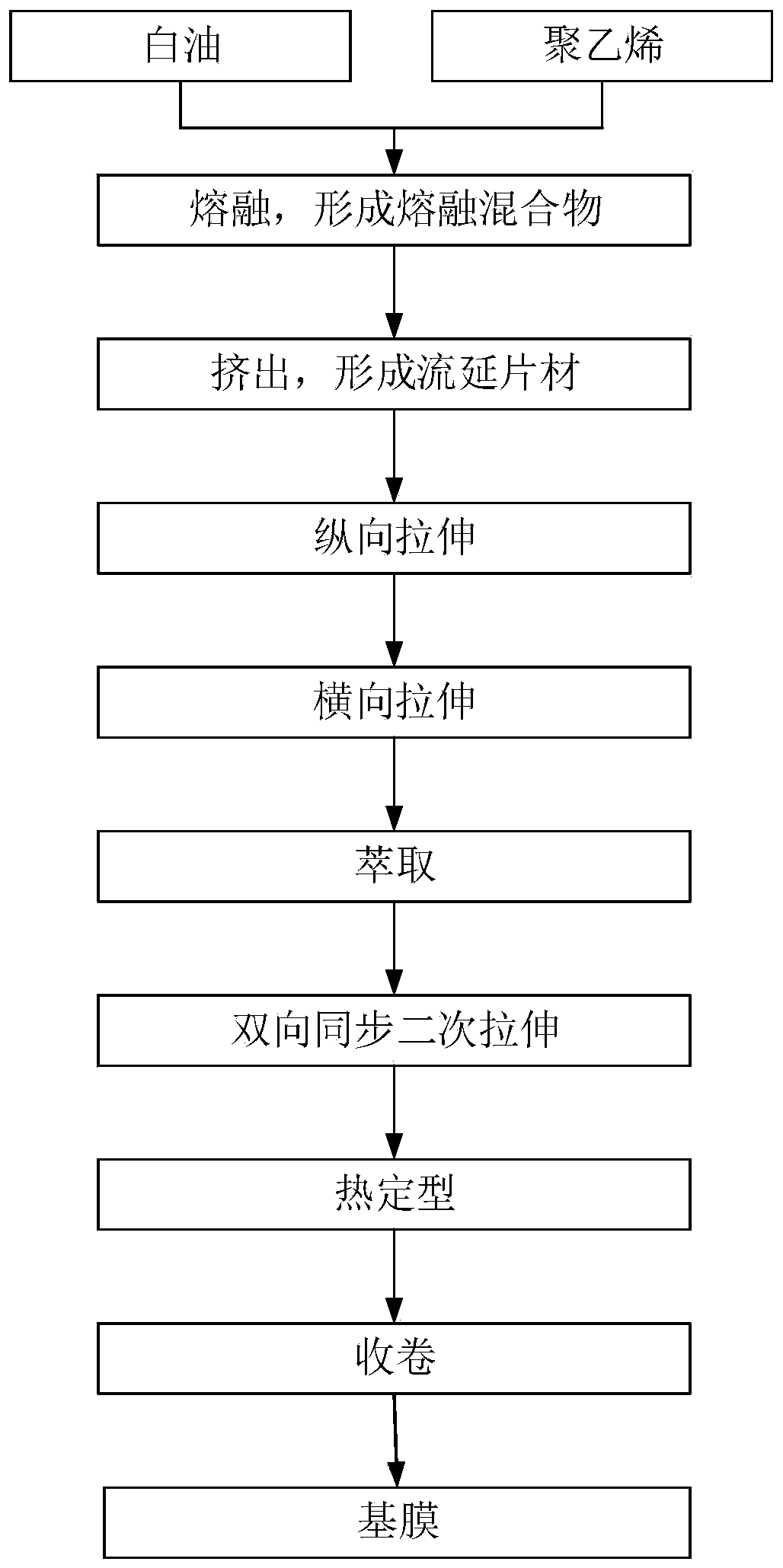

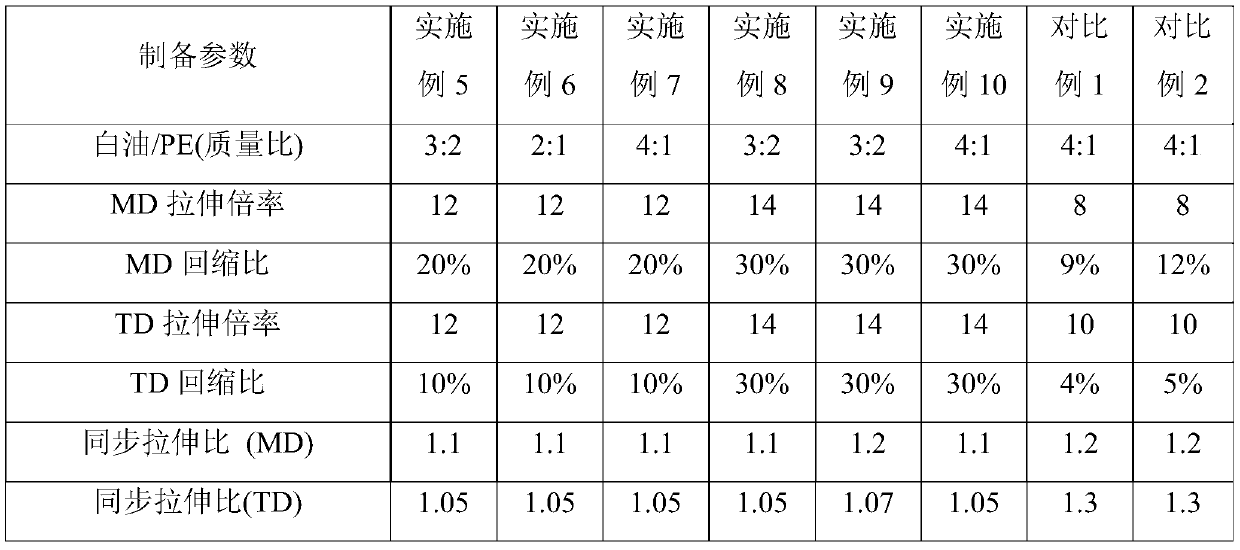

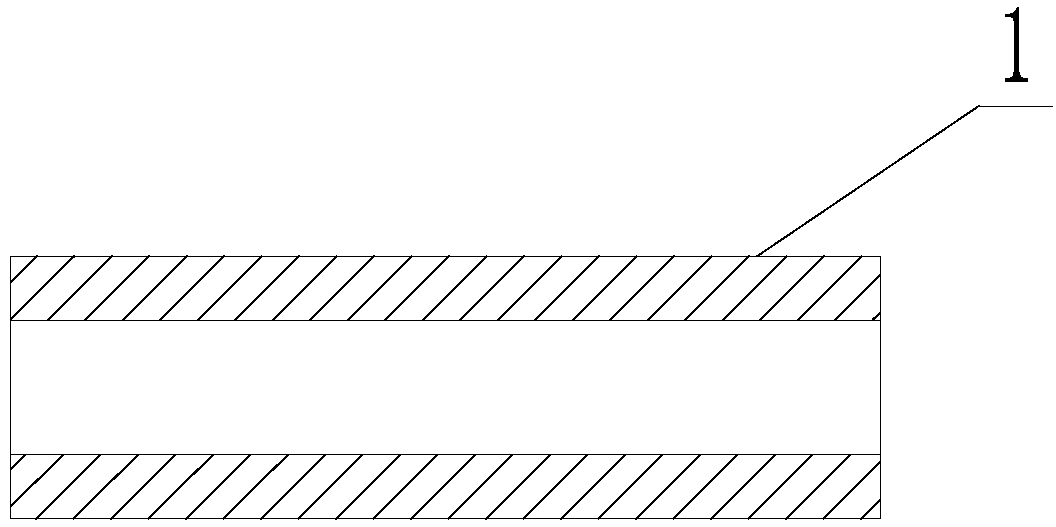

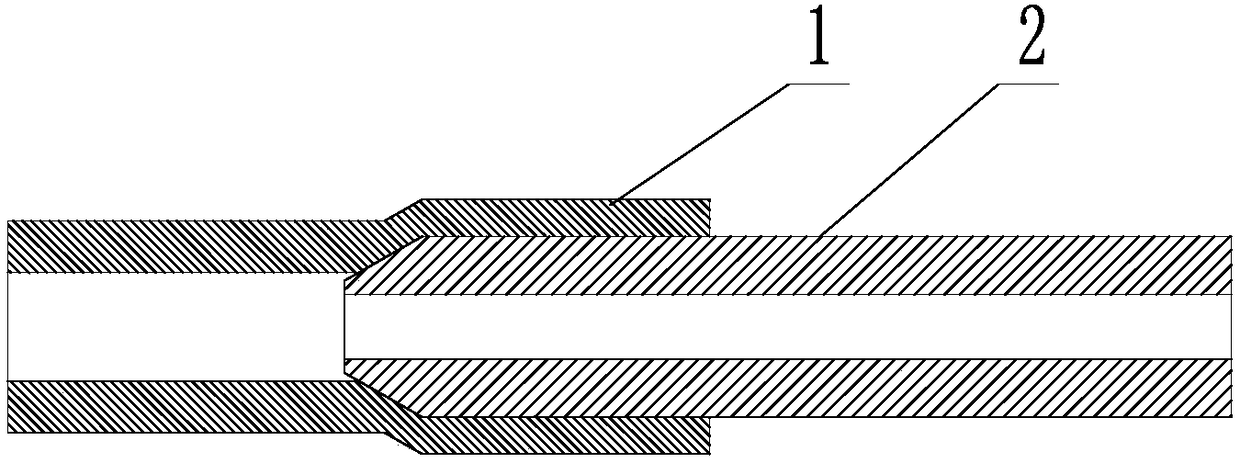

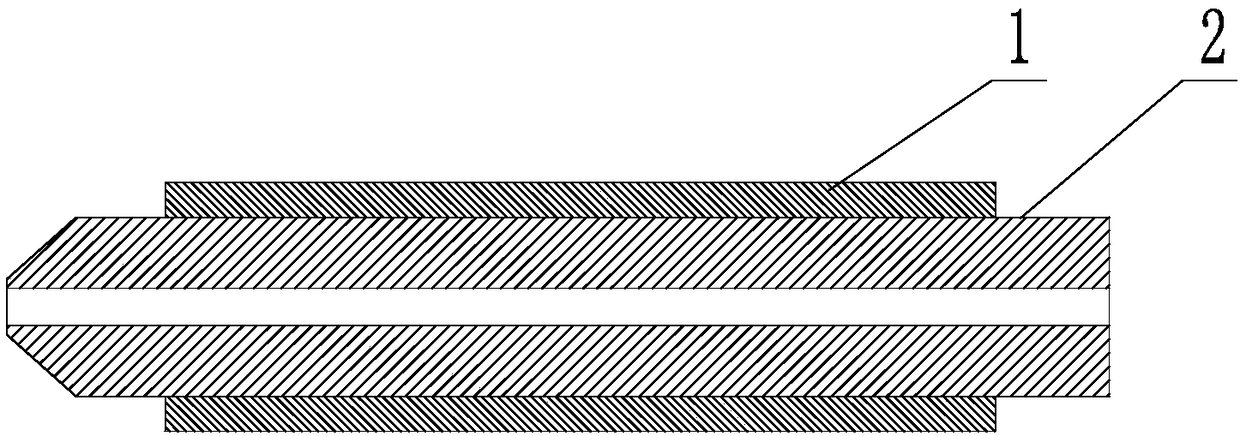

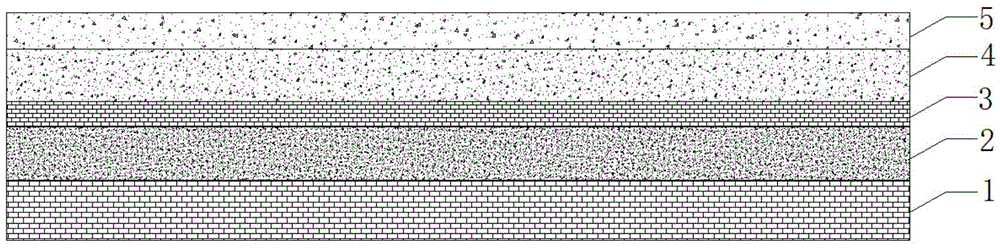

Base membrane suitable for coating, preparation method, lithium battery diaphragm and lithium ion battery

ActiveCN110993858AControl surface structureControl Surface RoughnessCell seperators/membranes/diaphragms/spacersSecondary cellsPhysical chemistryMembrane surface

The invention belongs to the technical field of lithium battery diaphragms, and particularly relates to a base membrane suitable for coating, a preparation method, a lithium battery diaphragm and a lithium ion battery. The preparation method of the base film comprises the following steps: mixing and melting raw materials to form a molten mixture; extruding the molten mixture to form a casting sheet; longitudinally stretching the casting sheet; transversely stretching the casting sheet; performing extraction; performing bidirectional synchronous secondary stretching; heat setting; and rolling to obtain the lithium battery base film. The surface structure and the surface roughness of the base film can be controlled, so that the base film has a special surface structure, the adhesive force ofthe coating on the surface of the base film is improved, the overall cohesiveness of the coating film is enhanced, and the coating coated on the surface of the base film is not easy to fall off.

Owner:JIANGSU HORIZON NEW ENERGY TECH CO LTD

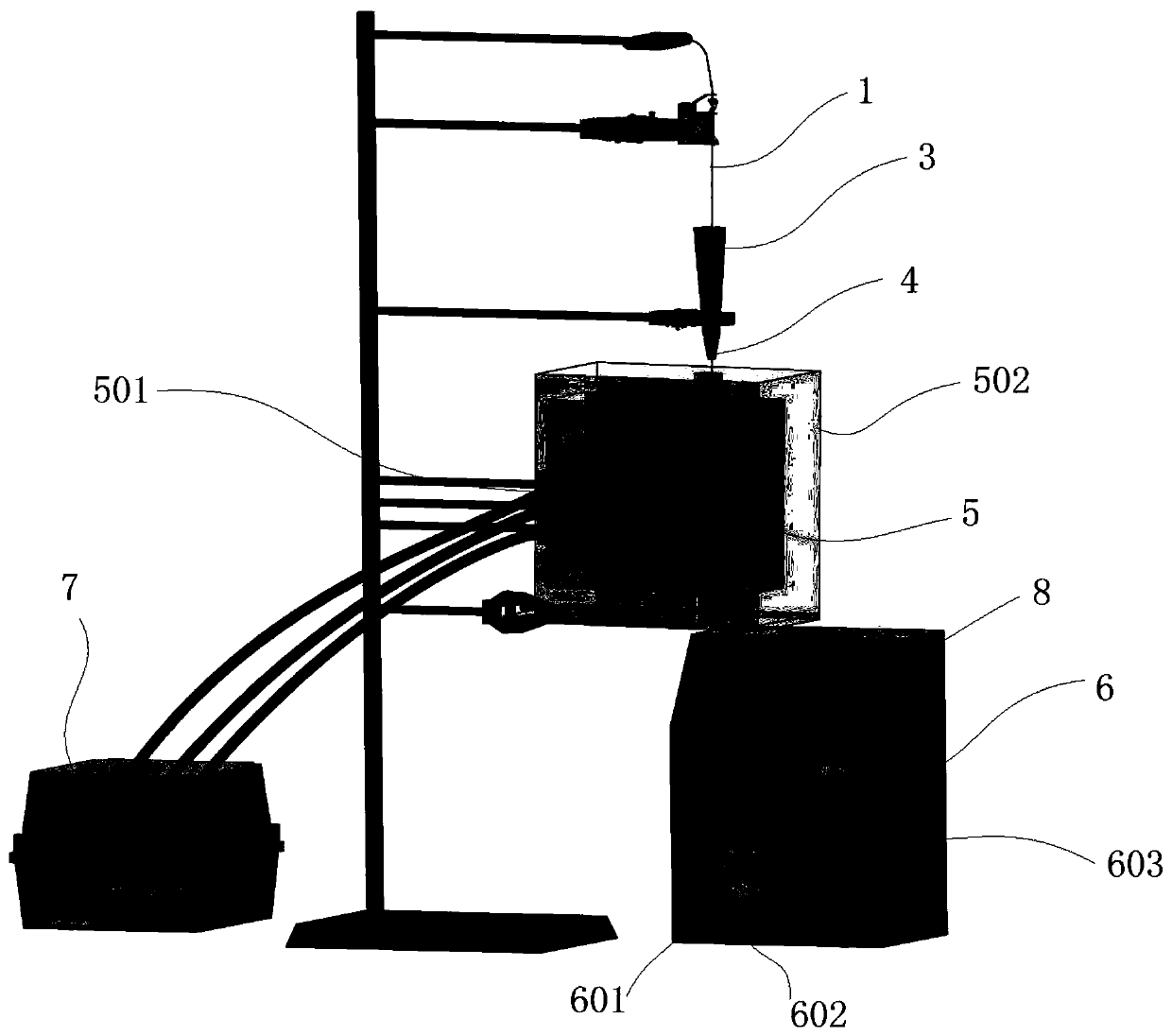

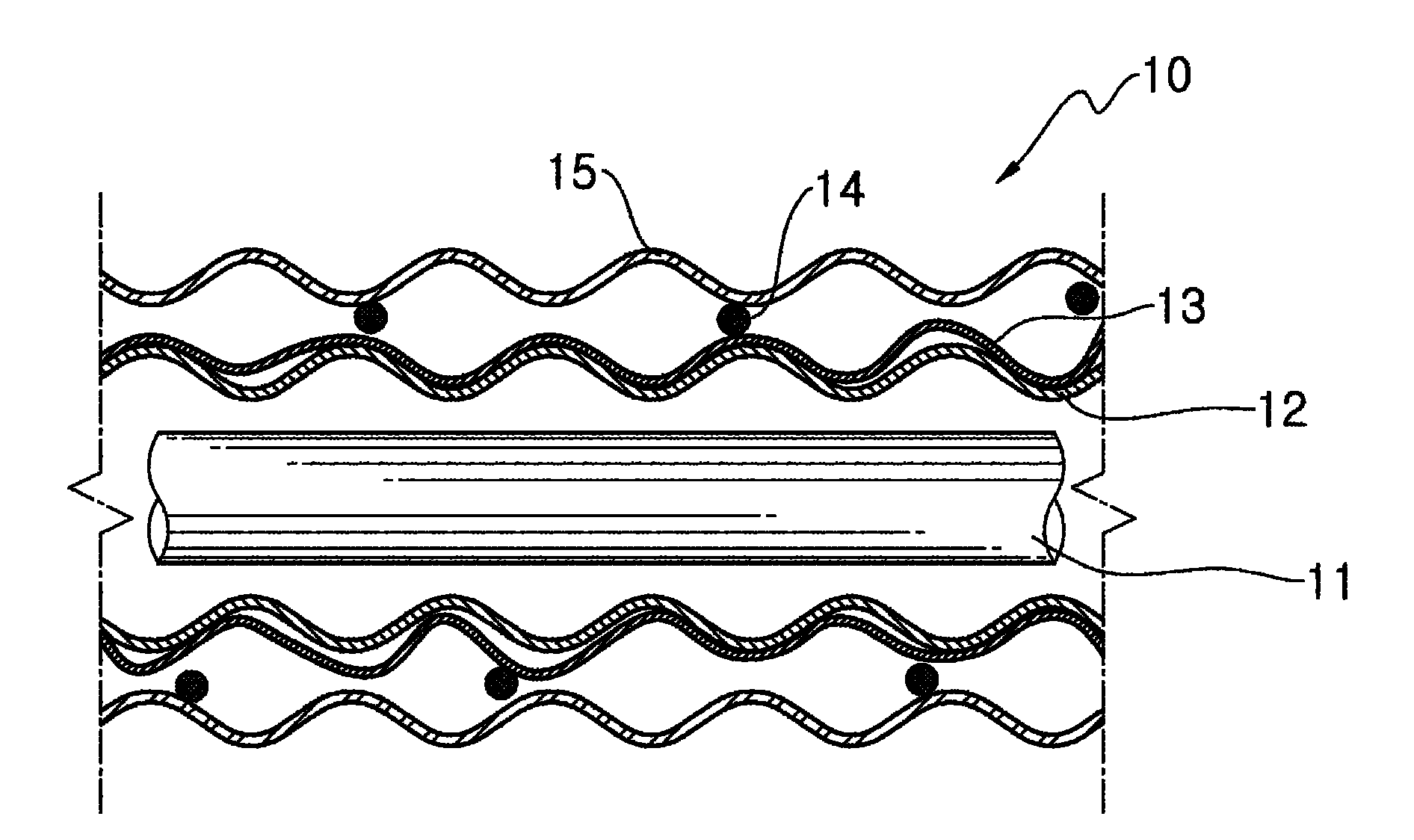

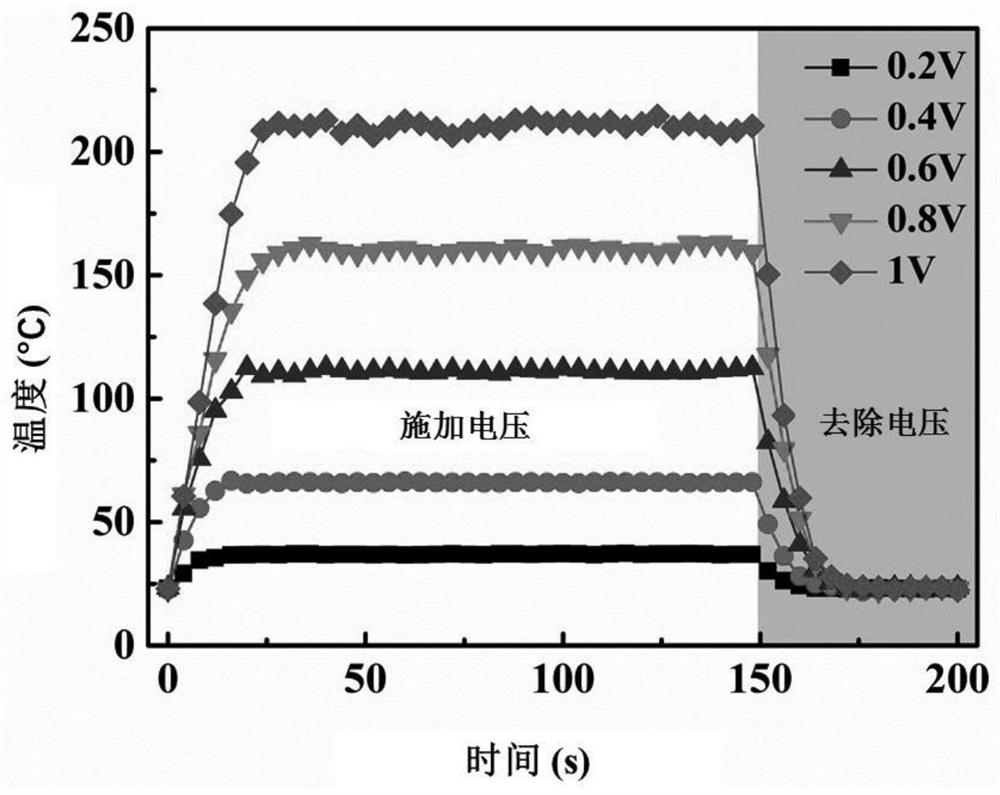

Composite yarn and preparation method and application thereof

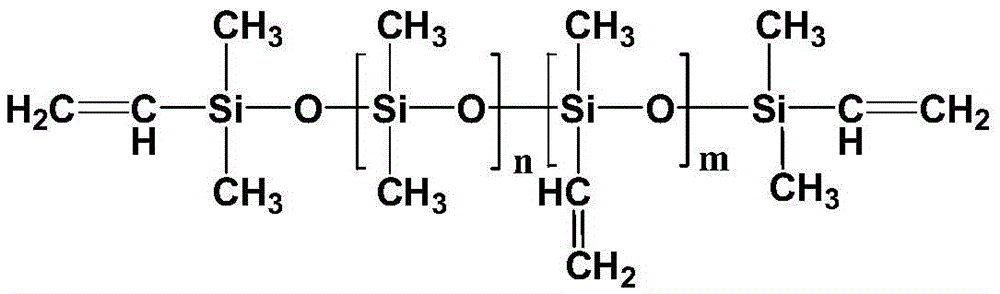

ActiveCN111334954ASuitable for scaleSuitable for industrial productionFibre typesLiquid/gas/vapor removalPolymer scienceCross linker

The invention discloses composite yarn and a preparation method and application thereof. The composite yarn comprises conductive yarn and a silicone rubber coating covering the surface of the conductive yarn; and the silicone rubber coating is used for triboelectrification, and the conductive yarn is used as an output electrode. The composite yarn can be applied to the preparation of a triboelectric nano-generator or a wearable fabric sensor. The preparation method of the composite yarn comprises the following steps that a cross-linking agent and a silicone rubber prepolymer are mixed uniformly, and then transferred into a vacuum pump for vacuumizing to obtain silicone rubber colloid; the silicone rubber colloid is loaded into a liquid storage pipe connected with a coating nozzle, and thesurface of the conductive yarn is coated in the process of pulling the conductive yarn fed into the liquid storage pipe out of the coating nozzle; and the coated yarn passing through the coating nozzle is solidified to form the composite yarn. The preparation method of the composite yarn can continuously obtain a large amount of composite yarn at a time.

Owner:SUZHOU UNIV

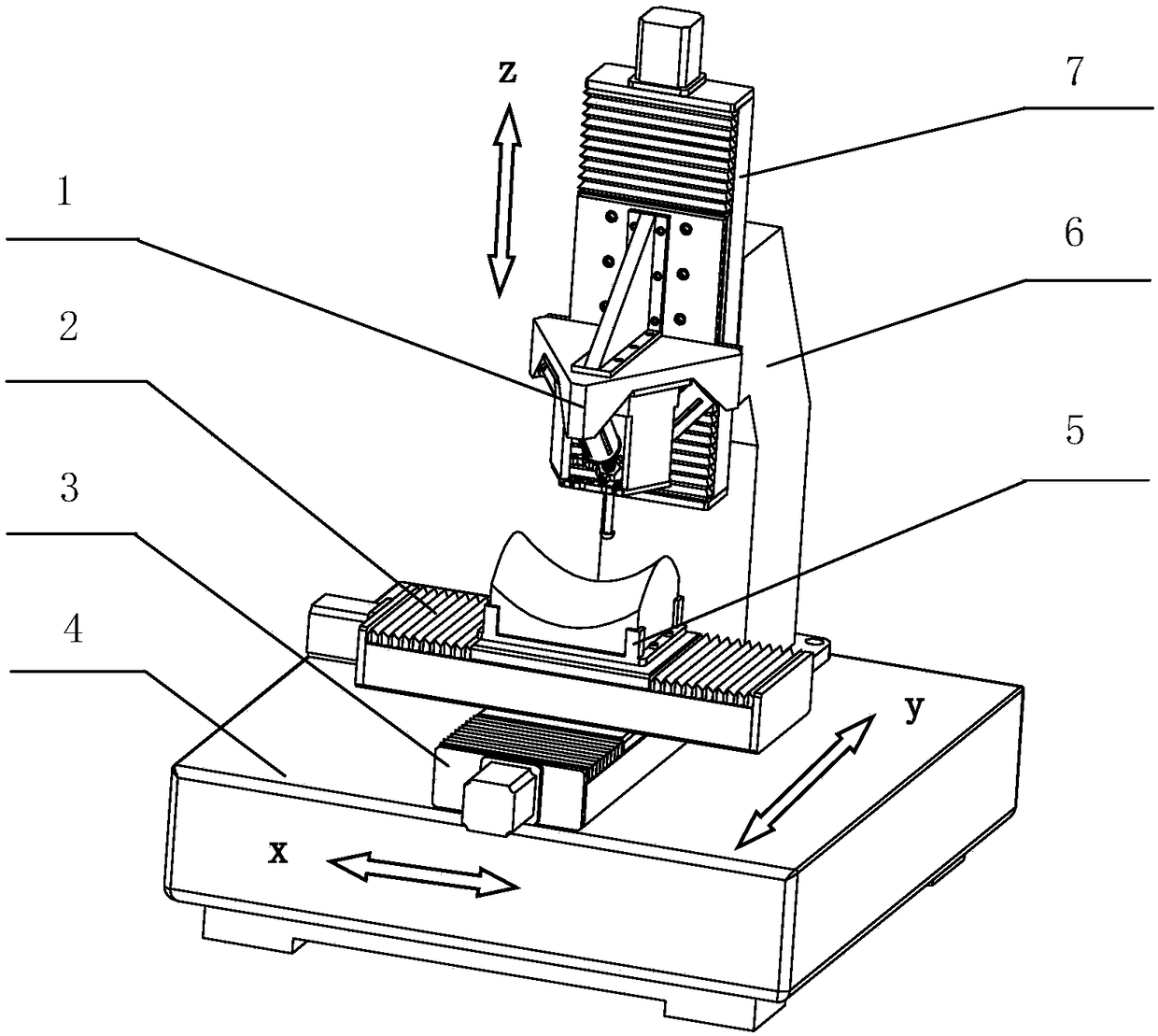

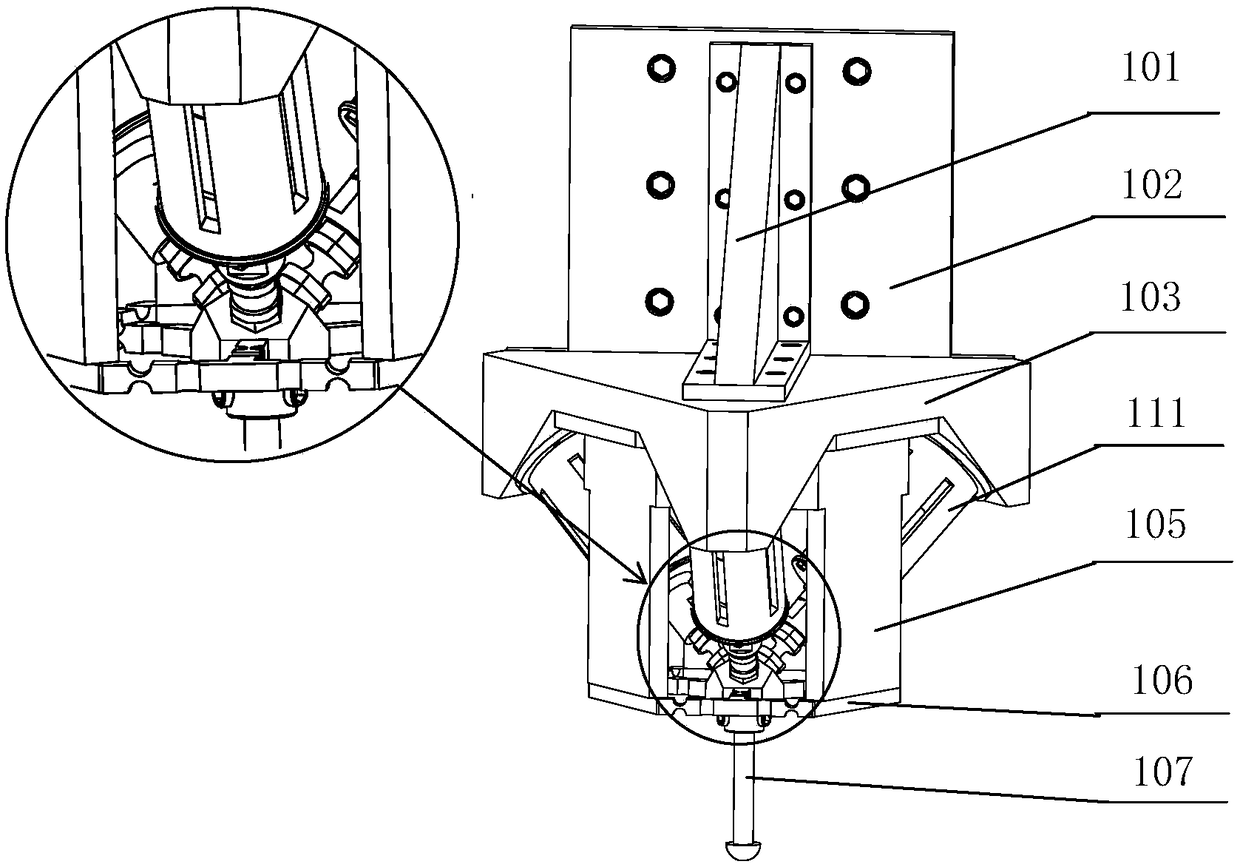

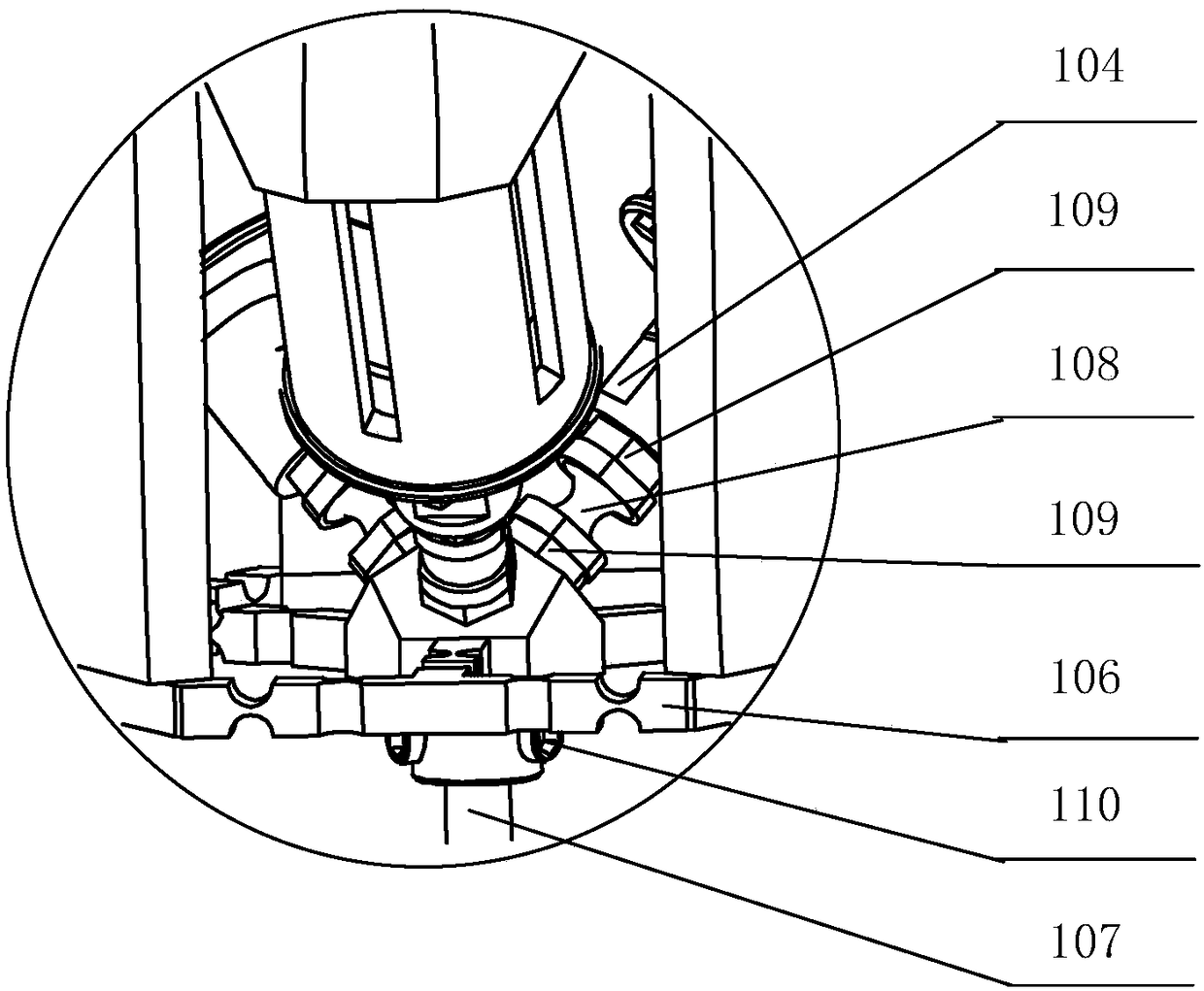

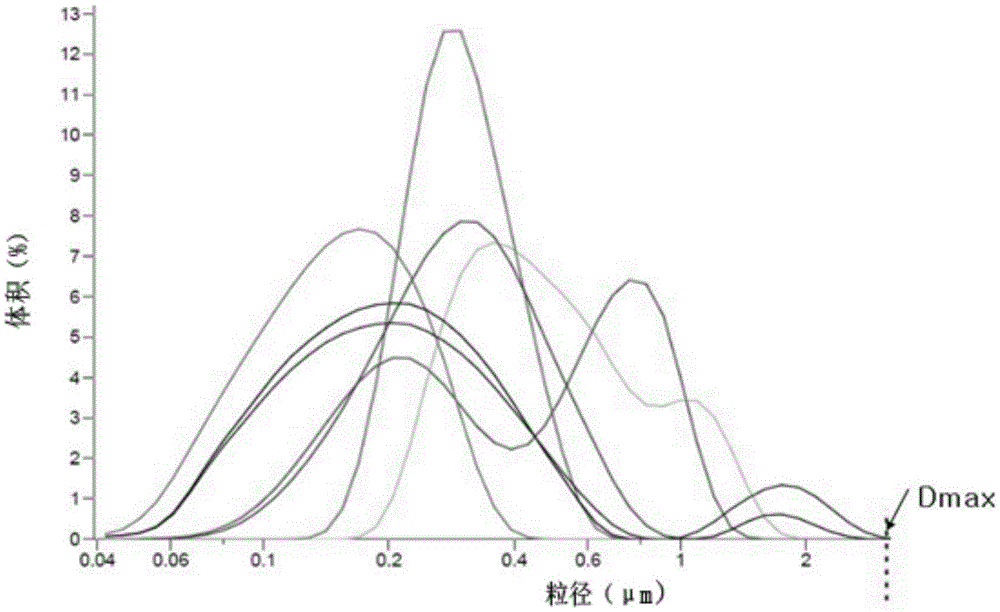

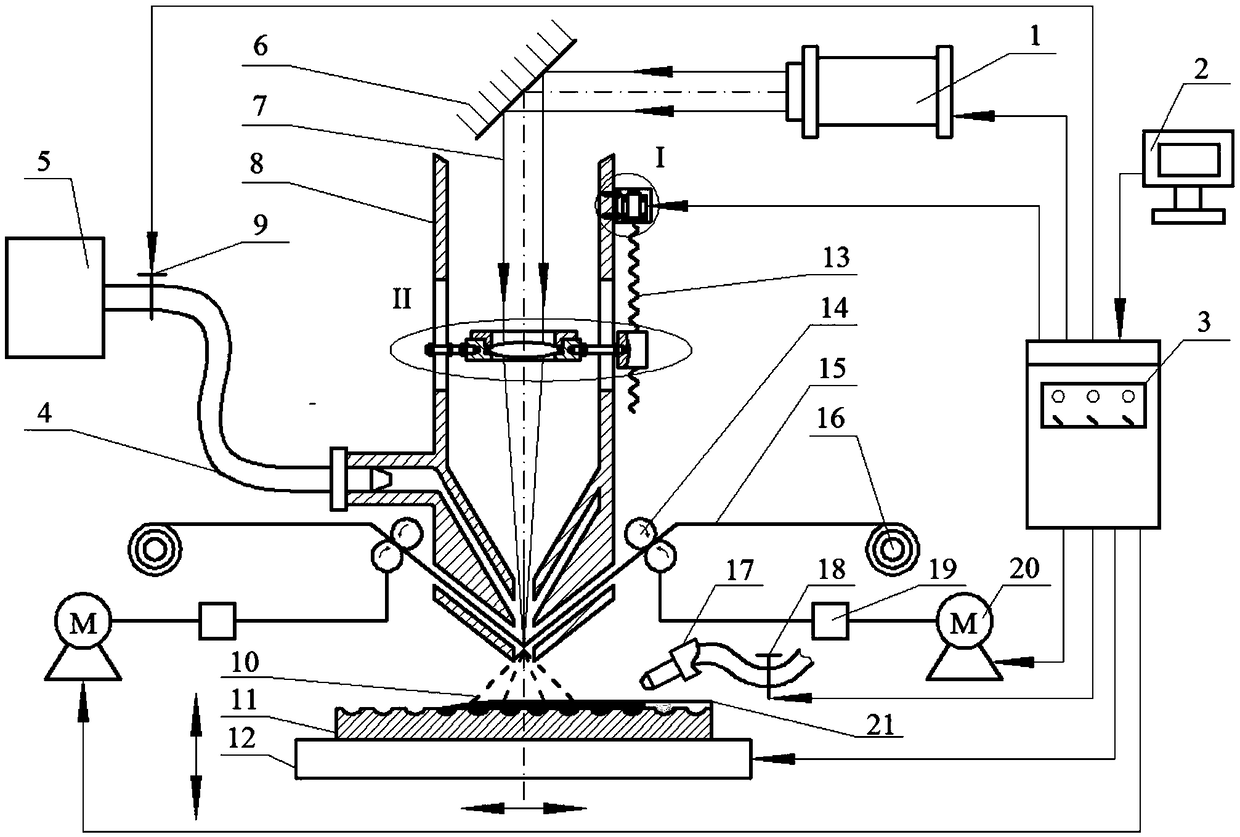

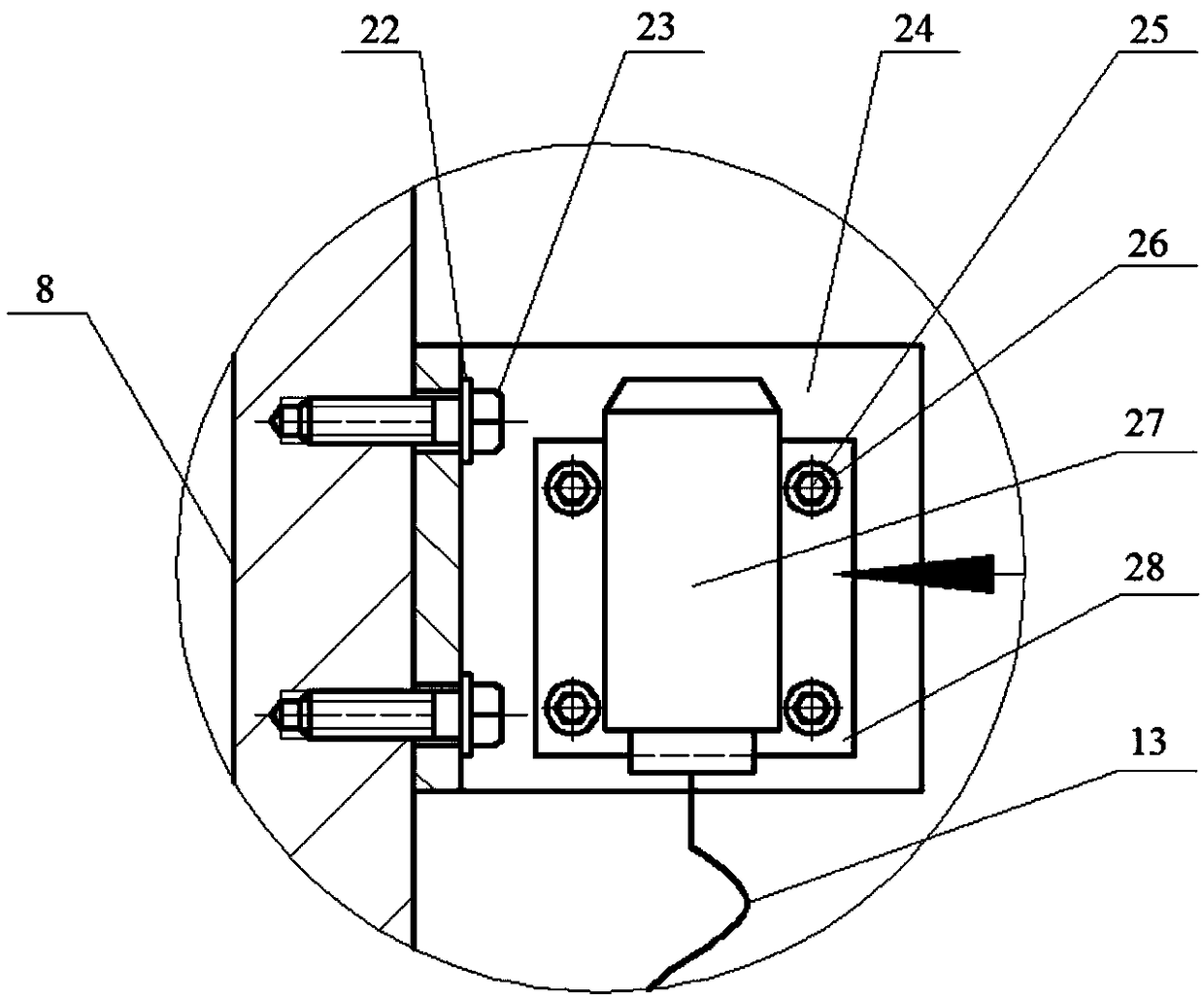

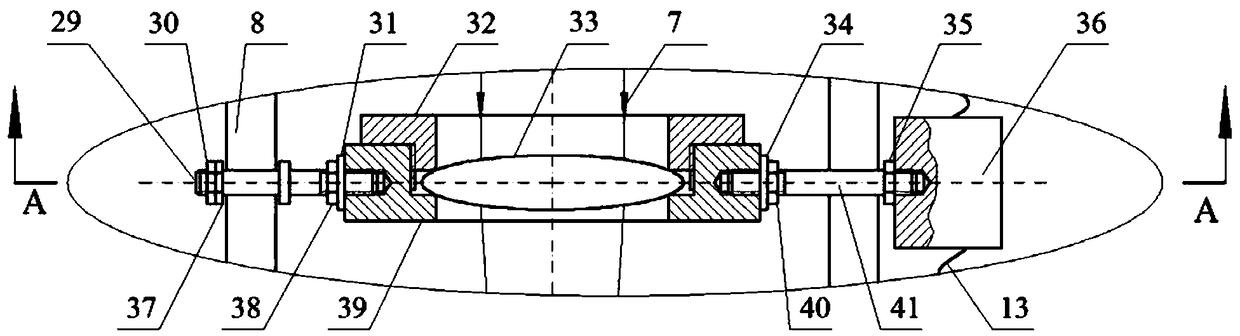

Ultrasonic machining tool with three groups of ultrasonic vibrators formed into conical structure and controlling method

ActiveCN108381306AAchieve intermittent contactAvoid it happening againGrinding drivesAutomatic grinding controlUltrasonic machiningEngineering

The invention discloses an ultrasonic machining tool with three groups of ultrasonic vibrators formed into a conical structure and a controlling method. A hinge base is mounted on the lower side of atriangular fixed plate; a flexible hinge is mounted at the lower end of the hinge base; three ultrasonic vibrator fixed sleeves are respectively fixed on three inclined mounting bases positioned on the lower side of the triangular fixed plate; three ultrasonic vibrators are respectively sleeved in the ultrasonic vibrator fixed sleeves; one corresponding end of each of three small hinges is respectively connected with the corresponding output end of the corresponding ultrasonic vibrator through double-end bolts while the other end of each of the three small hinges is connected with a corresponding mounting platform positioned in the middle of the upper side of the flexible hinge; and a cutter is mounted in a cutter mounting hole formed in the middle of the lower side of the flexible hinge.The three ultrasonic vibrators of a tool system of the ultrasonic machining tool disclosed by the invention are formed into the conical structure, and an inverse solution thinking way of a micro-motion track of a sphere point of a grinding and polishing head and a macro-control method using isotropic tangential length incremental method as a main content, the aims that the machining precision of an ultrasonic grinding and polishing machine tool is improved and the surface quality of machined parts is improved are fulfilled.

Owner:JILIN UNIV

Release film and manufacturing method therefor

ActiveCN105637042AControl Surface RoughnessImprove surface propertiesFilm/foil adhesivesCoatingsCeramic capacitorElectronic materials

The present invention relates to a release film. More specifically, the invention relates to an in-line coating release film used for a multi-layer ceramic capacitor (MLCC), protecting a polarizing plate, and electronic materials for an OCA and the like.

Owner:KOLON IND INC

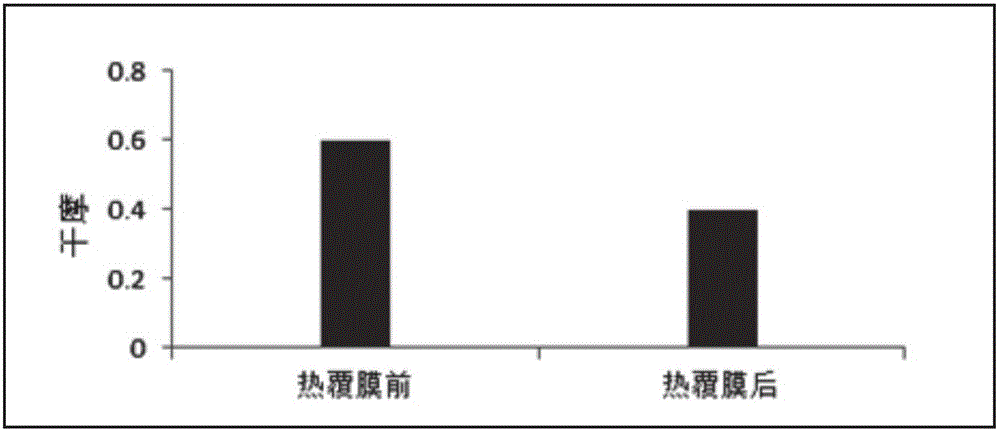

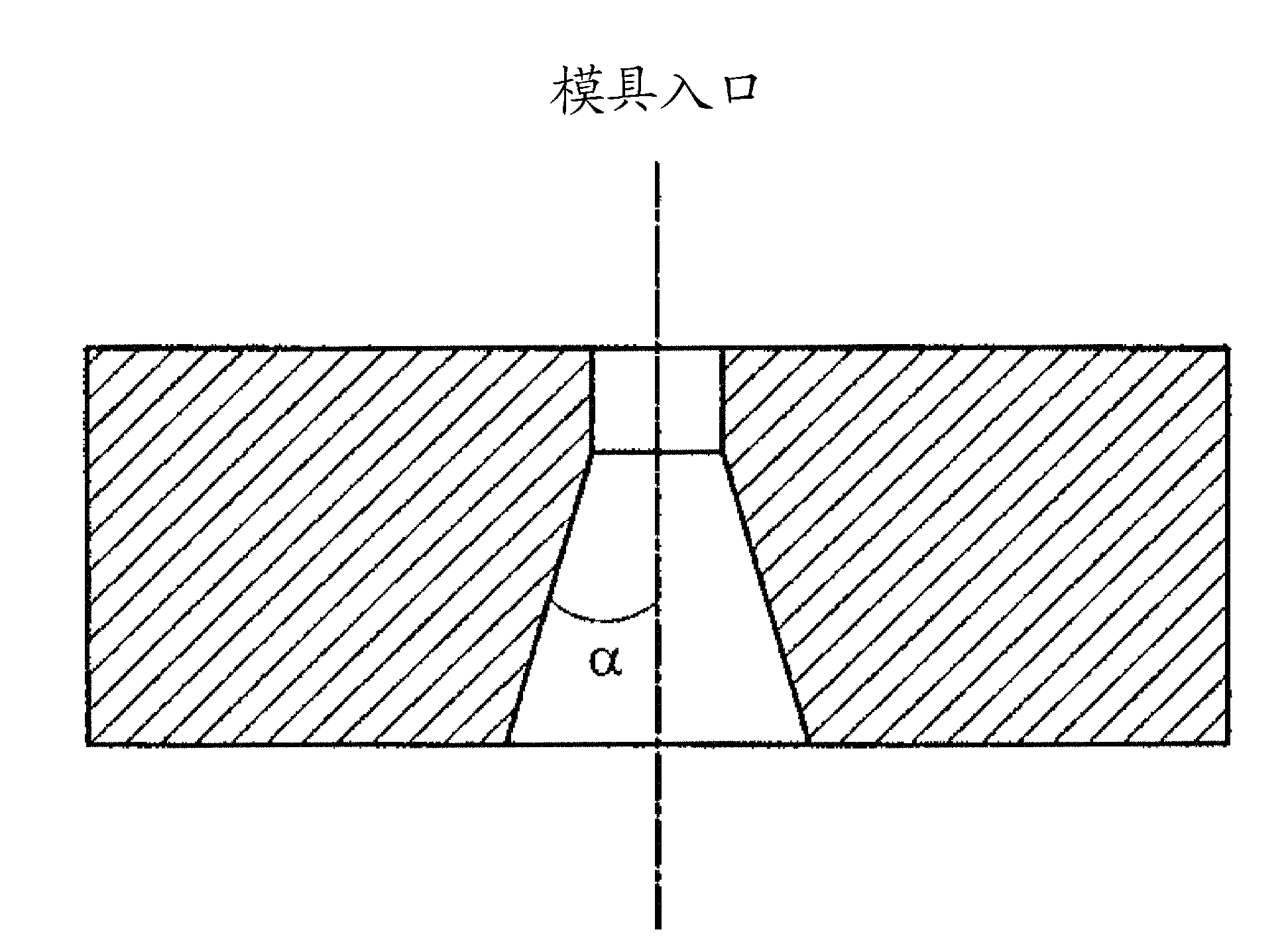

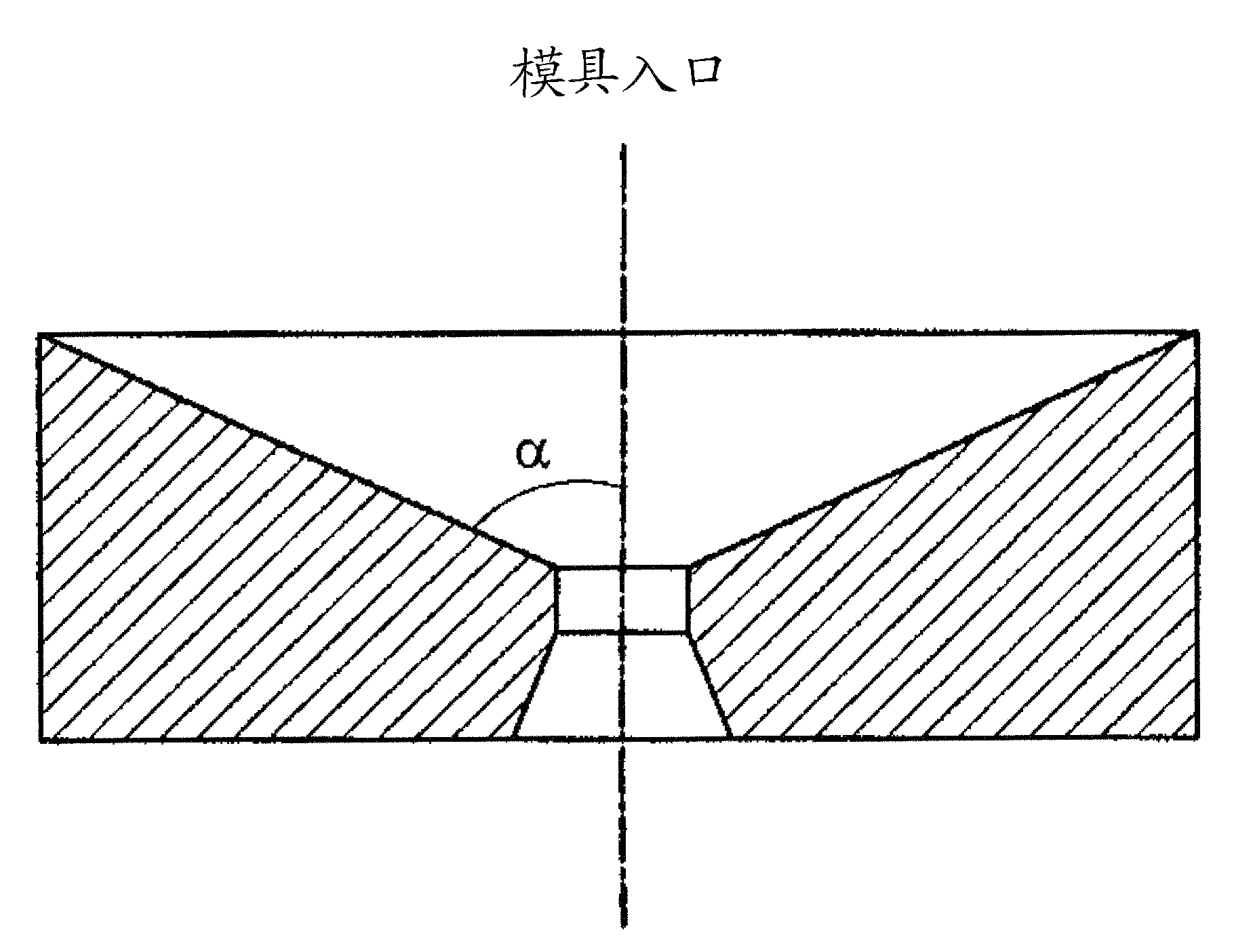

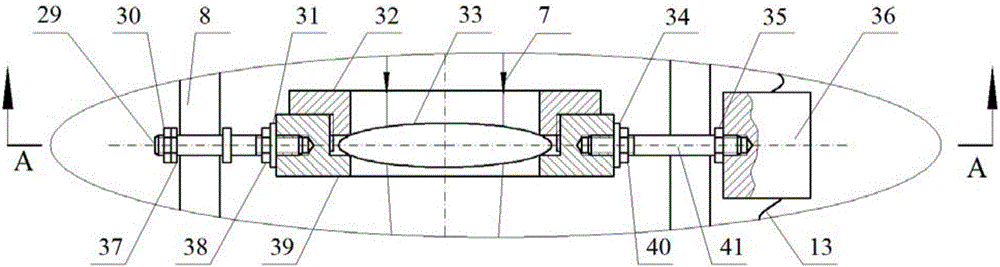

Mold manufacturing method for preventing stamping workpiece surface galling

ActiveCN106319182ASmall sizeReduced dimensional accuracySolid state diffusion coatingFurnace typesSize changeSurface roughness

The invention provides a mold manufacturing method for preventing stamping workpiece surface galling. The method comprises a thermal diffusion coating treatment process and a mold manufacturing process. The method is used for effectively controlling a mold precision in thermal diffusion coating treatment. The thermal diffusion coating treatment process comprises a, mold salt bath treatment and quenching, b, quenched mold low temperature tempering and c, high temperature tempering of the mold subjected to low temperature tempering according to size change. The whole thermal diffusion coating treatment process prepares a VC coating on the surface of cold work die steel. Roughness is reduced, a friction coefficient is reduced, heat radiation is good in mold stamping and adhesion is reduced so that a mold temperature increasing degree is small. The method well controls a mold size precision and surface roughness and realizes the appropriate stamping workpiece size.

Owner:SHANGHAI HUIZHONG AUTOMOTIVE MFG

Superconducting cable with aluminum cryostat

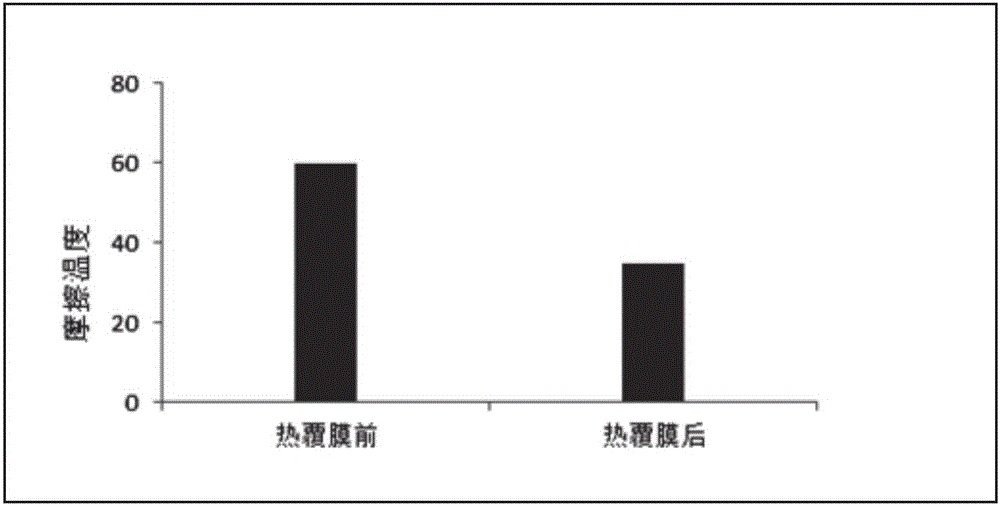

InactiveCN102163477AControl Surface RoughnessMinimizes radiant heat energySuperconductors/hyperconductorsSuperconductor devicesElectrical conductorSurface roughness

Provided is a superconducting cable with aluminum cryostat configured to improve superconductivity by increasing reflectivity of cryostats and enhancing cooling performance. The superconducting cable includes: a core provided with a conductor; and a cryostat surrounding a periphery of the core. A material of the cryostat is aluminum or an aluminum alloy and a surface roughness of the cryostat is 30 microns or less in terms of RMS value.

Owner:LG CABLE LTD (KR)

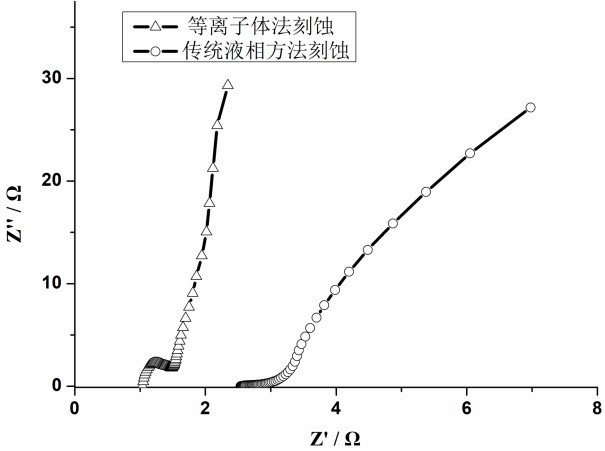

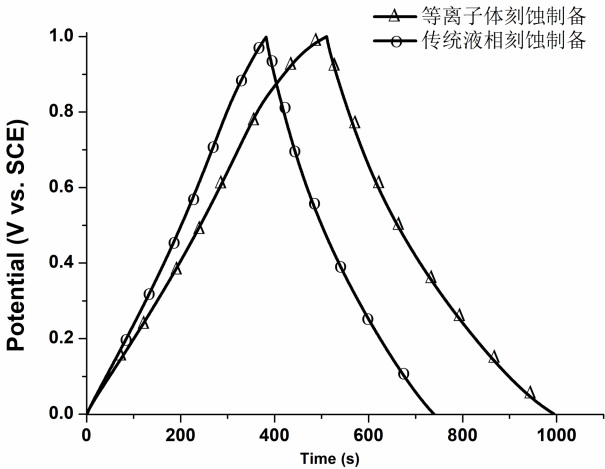

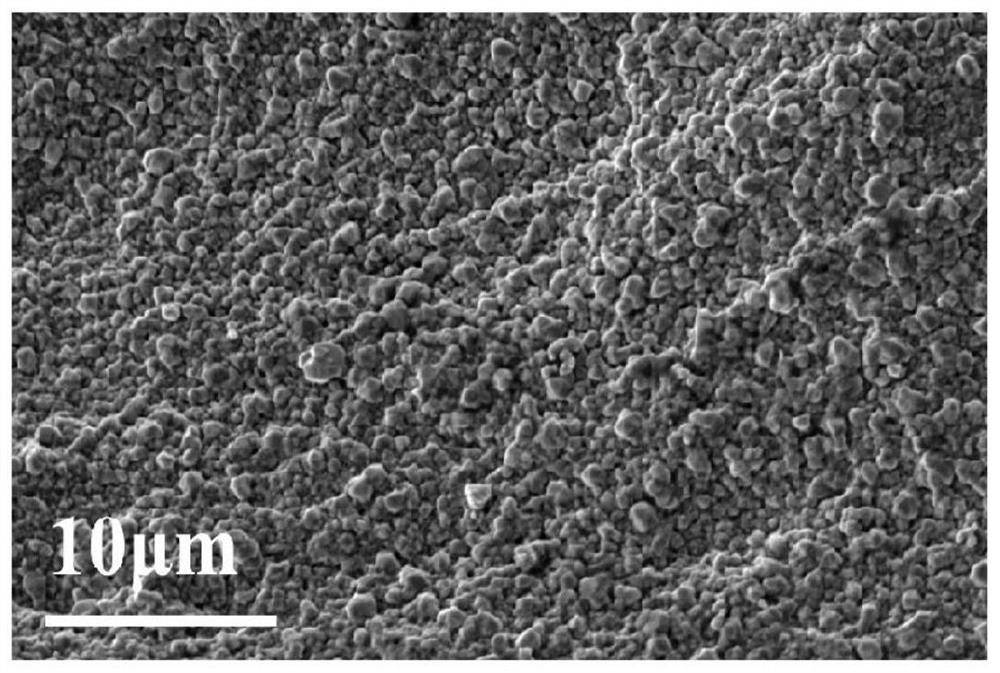

Method for preparing pure-phase MXene by using plasma etching technology

PendingCN111847456AAvoid it happening againGuaranteed purityTungsten/molybdenum carbideRadio frequencyFluorine containing

The invention discloses a method for preparing pure-phase MXene by using a plasma etching technology. According to the invention, Mo2Ca2C is used as a precursor, conventional plasma etching equipmentis used, CF4 / Ar gas is used for replacing a strongly-corrosive HF solution as an etching agent, and a plasma etching technology is conuducted to prepare the pure-phase MXene; the etching agent is excited into a fluorine-containing plasma air mass under the action of radio frequency, so on one hand, the F element with selective etching capability is reserved, and on the other end, interference of an O element source and an H element source is eliminated and the purity of the etching agent is kept to the greatest extent; furthermore, inert gas Ar contained in the etching agent forms the chargedplasma air mass with relatively large molecular weight under the action of radio frequency, and an electric field generated by bias voltage of an etching cavity is used for accelerating the moving speed of an Ar charged group and generating a bombardment effect so as to strip a multilayer MXene material generated by etching into a single-layer MXene material; and compared with a traditional liquid-phase ultrasonic stripping method, adsorption interference of impurity groups in a liquid phase is eliminated in the invention.

Owner:YANCHENG INST OF TECH

Method and device for preparing coating on basis of laser processing technology

ActiveCN106756721AWon't scratchControl Surface RoughnessMolten spray coatingTunable laserPower density

The invention discloses a method and device for preparing a coating on the basis of a laser processing technology and belongs to the technical field of part refabrication. The method includes the steps that firstly, the surface of a workpiece is coated with a thin black organic matter layer which serves as a laser energy absorption layer; pulse laser with the power density being GW / cm<2> grade is adopted for irradiating the surface of the workpiece, so that plastic pits are formed in the surface of the workpiece; the treated surface of the workpiece is cleaned and dried; and laser pulse beams with the power density being 10<4>-10<6> W / cm<2> are adopted for irradiating spraying wires and then melting the spraying wires into liquid state, liquid spraying wires are blown by high-pressure protective gas to impact on the surface of the workpiece at a high speed, and the coating is formed. According to the method and the device, an adjustable laser device is adopted, and the laser pulse beam diameter and output energy can be controlled; the coating prepared through the method has the characteristics of being high in interface bonding force and quality; and the method and the device have the technical characteristics of being short in spraying time, low in energy consumption, free of pollution and the like.

Owner:ANHUI UNIVERSITY OF TECHNOLOGY

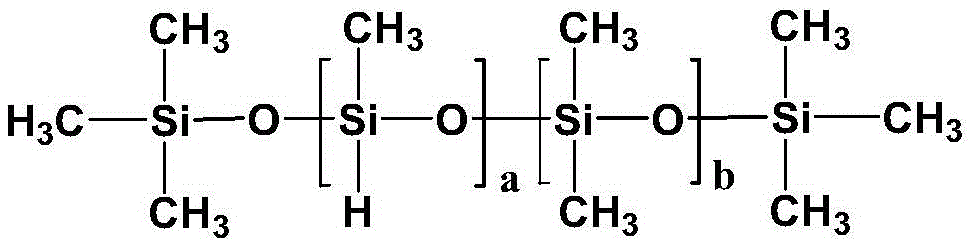

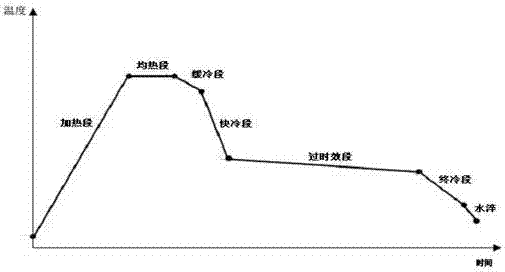

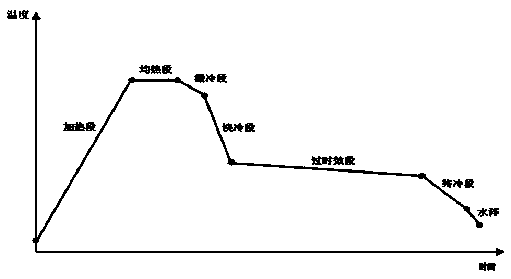

Continuous annealing method for hot stamping forming steel

ActiveCN106929662AImprove bindingNot easy to fall offFurnace typesHeat treatment process controlHot stampingSurface roughness

The invention discloses a continuous annealing method for hot stamping forming steel. The continuous annealing method comprises an annealing procedure and a leveling procedure, wherein in the annealing procedure, the temperature of an uniform temperature section is 780-800 DEG C, the starting temperature of fast cooling is 670-690 DEG C, the final temperature of fast cooling is 390-410 DEG C, the final temperature of aging is 360-380 DEG C, the end temperature of a final cooling section is 140-160 DEG C, and the temperature after water quenching is 43-50 DEG C. The continuous annealing method is adopted for production, and thus the production efficiency is higher. The method is matched with the dew point in a furnace to produce products, thereby improving the combination firmness of subsequent hot stamping forming scale and a matrix. The method adopts the reasonable leveling process, is matched with a leveling working roller with certain roughness, and controls the surface roughness of band steel, thereby improving the combination firmness of subsequent hot stamping forming scale and the matrix. The scale of the hot stamping forming product produced by the method is not easy to shed off, and the combination firmness of the scale and the matrix is good.

Owner:TANGSHAN IRON & STEEL GROUP +1

Thin-wall sleeve machining method

The invention discloses a thin-wall sleeve machining method. The thin-wall sleeve machining method comprises a molding machining step. The molding machining step comprises the steps that a cylindricalblank of which a through hole is a circular through hole is machined to have the finished product size, and in the molding machining step, a cylindrical core rod is adopted to constrain the blank firstly, specifically, the core rod is inserted into the through hole, and the through hole is in interference connection with the core rod; then the outer circle of the blank is machined, specifically,the core rod is fixed to equipment capable of driving the core rod to rotate around the axis of the core rod, and the outer circle of the blank is machined to have the finished product outer circle size in the process that the blank rotates along with the core rod; and the through hole diameter is machined into the finished product through hole diameter through the following step that the blank generates plastic deformation under the action of the core rod through interference connection till the through hole diameter is machined into the finished product through hole diameter. The machining method is simple in process and suitable for thin-wall sleeve batch production on the condition that the thin-wall sleeve machining quality is guaranteed.

Owner:SICHUAN HUADU NUCLEAR EQUIP MFR

Polishing method for indium antimonide single crystal wafer

PendingCN114800058AControl thicknessControl Surface RoughnessPolishing machinesAutomatic grinding controlWaferingPolishing

The invention relates to the technical field of indium antimonide wafer surface treatment, in particular to a polishing method for an indium antimonide single crystal wafer, which comprises the following steps of: S1, roughly polishing the indium antimonide single crystal wafer on a polishing machine by adopting polishing cloth PV2700 and setting polishing pressure, rotating speed and flow of a polishing solution A; s2, polishing cloth Suba400 is adopted, the polishing pressure, the rotating speed and the flow of the polishing solution B are set, and the indium antimonide single crystal wafer is subjected to intermediate polishing on a polishing machine; and S3, polishing cloth CP is adopted, the polishing pressure, the rotating speed and the flow of the polishing solution C are set, meanwhile, a stabilizer is added, and the indium antimonide single crystal wafer is subjected to intermediate polishing on a polishing machine. Compared with the prior art, the polishing efficiency can be effectively improved on the basis that the thickness and the surface roughness of the indium antimonide wafer are controlled.

Owner:厦门华芯晶圆半导体有限公司

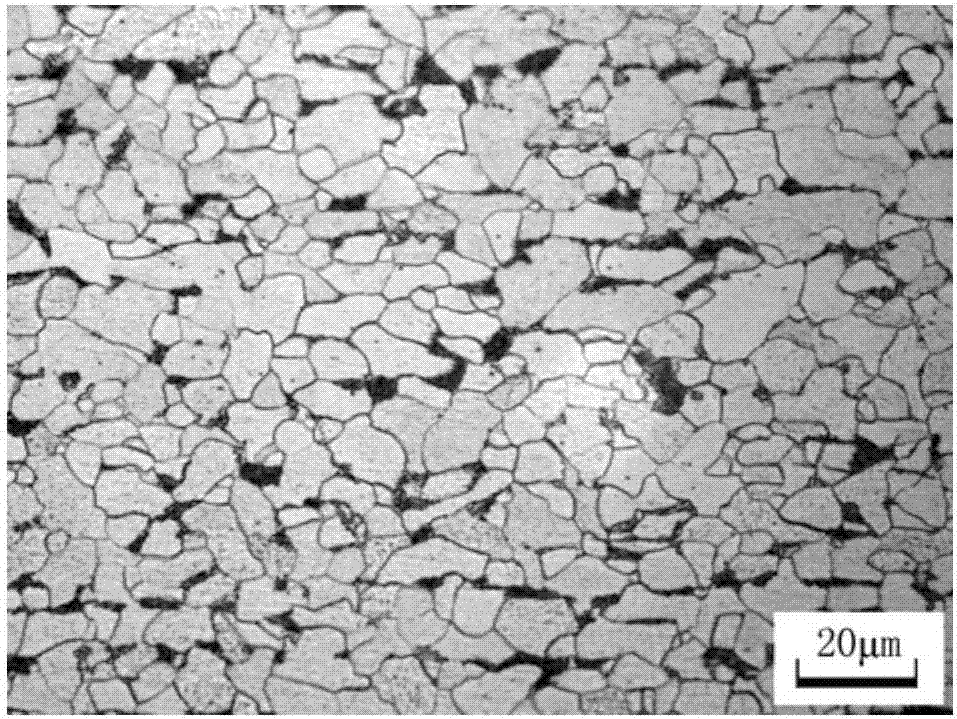

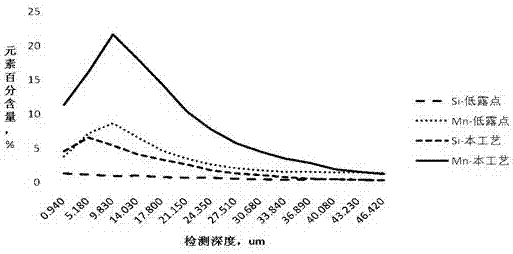

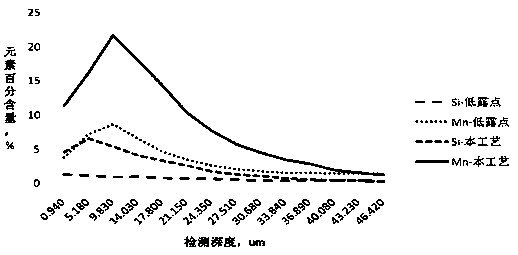

Method for reducing roughness of hot-rolled pickled surface of 10Cr17 stainless steel

InactiveCN111575452AQuality assuranceControl Surface RoughnessAbrasion apparatusFurnace typesSurface roughnessSS - Stainless steel

The invention discloses a method for reducing the roughness of a hot-rolled pickled surface of 10Cr17 stainless steel. The method comprises the following steps that 1, annealing of a steel coil is performed, wherein cover annealing treatment is performed on a hot-rolled 10Cr17 stainless steel black skin coil, the annealing temperature is 760-850 DEG C, and the heat preservation time is 18-22 hours; 2, the shot blasting process is performed, wherein through a shot blasting machine striking angle test, the striking angle of a shot blasting head is adjusted to enable a shot blasting striking surface to be uniformly distributed on the steel strip, and the rotating speed on a transmission side is adjusted to be 25-30Hz, the rotating speed on an operation side is adjusted to be 33-38Hz; and 3, sulfuric acid and mixed acid pickling is performed, wherein sulfuric acid and mixed acid pickling is performed on the shot-blasted steel strip, the concentration of sulfuric acid is 200 g / L-280 g / L, and the concentration of hydrofluoric acid in mixed acid liquor is 0.5 g / L-1.5 g / L. The method can effectively control the surface roughness Ra of the steel strip to be less than or equal to 3.5 micronsso as to solve the contradiction problem between the pickling quality and the surface roughness of the steel strip.

Owner:SHANDONG TAISHAN STEEL GROUP

Silver-plated conductive aramid paper and preparation method thereof

ActiveCN111364283ASimple preparation processLow costPaper/cardboardPhysical paper treatmentAramidPlasma processing

The invention discloses a silver-plated conductive aramid paper and a preparation method thereof. The preparation method comprises the following steps: step a, washing an aramid paper substrate with acleaning agent, removing the impurities on the surface, and drying; step b, performing a plasma treatment on the cleaned aramid paper substrate to obtain a surface-activated aramid paper substrate; and step c, putting the aramid paper substrate processed by the plasma treatment into a silver ammonia solution, activating for a certain period of time, slowly dropwise adding a reducing agent into the solution, reacting for a certain period of time, taking out the aramid paper substrate, fully cleaning the aramid paper substrate with deionized water, and drying to finally obtain the conductive aramid paper with a silver-plated surface. The mass ratio of the silver content in the prepared conductive aramid paper is 3%-12%, the conductive aramid paper has good conductivity and electromagnetic shielding performance, the preparation process is simple, and the operation is convenient.

Owner:QINGDAO UNIV

Composite forming method of component with large-angle thin-wall twisted narrow-depth cavity feature

ActiveCN110421077AEliminate featuresEliminate structureShaping toolsMachine partsModel reconstruction

The invention relates to a composite forming method of a component with a large-angle thin-wall twisted narrow-depth cavity feature. The composite forming method comprises the steps of model reconstruction, mold manufacturing as well as processing and forming; the model reconstruction comprises the steps that a three-dimensional model of the component is reconstructed in software, two side wing thin walls of the component three-dimensional model are unfolded outwards towards the two sides to form the three-dimensional model of a pre-machined part; mold manufacturing comprises the steps that acorrecting mold comprising a plurality of mold components is manufactured according to the outline design of the component; and processing and forming comprise the steps that production and processingof the pre-machined parts of a plate part is performed, then, the two side wing thin walls which are unfolded outwards of the pre-machined part are heated and folded inwards by using the correcting mold, and component processing is completed. Compared with the prior art, the component is reconstructed into the pre-processing part with no deep-cavity features, the side wing sheets on the two sidescan be recovered to form the large-angle twisted narrow-depth cavity during heating and folding, the defect that the narrow-depth cavity is damaged or lost due to the fact that the cutting processingis directly adopted can be overcome, and the product precision and the finished product rate are guaranteed to the maximum degree.

Owner:SHANGHAI JIAO TONG UNIV +1

Manufacturing method of vehicle speed changing box module

InactiveCN109351921AShorten the development cycleExtended service lifeAdditive manufacturing apparatusFoundry mouldsManufacturing technologyDevelopment period

The invention belongs to the technical field of car part manufacturing and particularly relates to a manufacturing method of a vehicle speed changing box module. The method comprises the following steps that 1, according to a three-dimensional model of the vehicle speed changing box part design mould, layering and slicing are carried out on the three-dimensional model, and the mould comprises a base portion, a buffering portion and a forming portion; 2, parameters of the three-dimensional model of the mould are input into 3D printing equipment, and the base portion of the mould is printed andobtained; 3, the buffering portion is printed on the base portion; 4, the forming portion is printed on the buffering portion; and 5, surface treatment is carried out on the forming portion. Accordingto the method, multiple first blind holes are formed in the upper surface of the base portion, first protrusions corresponding to first blind holes correspondingly are arranged on the lower surface of the buffering portion, the upper surface of the buffering portion is provided with multiple second protrusions with the axis not coinciding with that of the first protrusions, and second blind holescorresponding to the second protrusions are formed in the lower surface of the forming portion. The method well solves the problems that for existing vehicle speed changing box part moulds, the development period is long, the service life is shortened gradually, and the precision is reduced gradually.

Owner:HEFEI KANGZHIHENG MACHINERY TECH CO LTD

Nanosilver wire polymer compound antibacterial product and preparation method thereof

ActiveCN105648774AReduce dosageEasy to controlBiochemical fibre treatmentGrip property fibresPrepolymerAntibacterial effect

Disclosed is a nanosilver wire polymer compound antibacterial product comprising a nanosilver wire layer, a nanosilver particle layer, a first polymer layer, a second polymer layer and a third polymer layer which are sequentially stacked. The nanosilver wire polymer compound antibacterial has the advantages that the antibacterial product is obtained through one-step forming by polymerizing a macromolecular prepolymer on the nanosilver wire layer in situ, and nanosilver wires are closely combined with the polymer, so that the antibacterial product is lasting in antibacterial effect and free of shedding; by using a preparation method of the nanosilver wire polymer compound antibacterial product, consumption is reduced, large-area and industrialized production is easy to realize, and the preparation process is easier to adjust and control.

Owner:YANGTZE UNIVERSITY

A kind of silver-plated conductive aramid paper and preparation method thereof

ActiveCN111364283BSimple preparation processLow costPaper/cardboardPhysical paper treatmentCleansing AgentsAramid

The invention discloses a silver-plated conductive aramid paper and a preparation method thereof. The preparation method is as follows: a. cleaning the aramid paper substrate with a cleaning agent to remove surface impurities and drying; b. cleaning the cleaned aramid paper substrate Carry out plasma treatment to obtain a surface-activated aramid paper substrate; c. Put the plasma-treated aramid paper substrate into the silver ammonia solution, and after activation for a certain period of time, slowly drop the reducing agent into the above solution, and react for a certain period of time Afterwards, the aramid paper substrate is taken out, fully washed with deionized water and dried, and finally a silver-plated conductive aramid paper is obtained. The mass ratio of silver content in the prepared conductive aramid paper is 3%-12%, and has good electrical conductivity and electromagnetic shielding performance, and the preparation process is simple and the operation is convenient.

Owner:QINGDAO UNIV

High manganese steel railway assembled frog centre rail casting process

ActiveCN1238136CPrevent getting involvedEvenly filledRailway tracksSuperficial massMaterials science

A technology for casing the high-Mn steel frog of combined switch for railway features that the ferrochromium sand is used as surficial sand and core sand, the alkaline Mg sand powder paint is coated on the surfaces of moulding cavity and core, and an easily cutting plate is added under the insulating siser head. It includes such steps as applying the insulating and heat generating agent to the surface of riser head, horizontal pouring, cutting off the riser head, burying it is sand, and heat treating.

Owner:中科西王特钢有限公司

A kind of centrifugal spinning preparation method of silica/polystyrene micro/nano fiber membrane

ActiveCN105506761BEvenly dispersedEasy to prepareFilament/thread formingMonocomponent synthetic polymer artificial filamentMicro nanoFiber

Provided is a centrifugal spinning preparation method of a silicon dioxide and polystyrene micro-nano fiber membrane. The method comprises the following steps that 1, hydrophobic silicon dioxide is prepared, wherein silicon dioxide sol is prepared through a sol-gel method, hydrophobic modification is conducted on the prepared silicon dioxide sol by taking methacryloxy propyl trimethoxyl silane (MPS) as a modifying agent, and hydrophobic silicon dioxide is obtained; 2, a centrifugal spinning solution is prepared, wherein hydrophobic silicon dioxide prepared in the first step and polystyrene (PS) are mixed and dissolved in N,N-dimethylformamide (DMF), and the uniformly dispersed centrifugal spinning solution is obtained after stirring is conducted, wherein the mass concentrations of PS and SiO2 are 18+ / -2 wt% and 3+ / -1 wt% respectively; 3, centrifugal spinning is conducted, wherein centrifugal spinning is conducted by adopting the centrifugal spinning solution prepared in the second step, and the silicon dioxide and polystyrene (SiO2 / PS) super-hydrophobic micro-nano fiber membrane is obtained.

Owner:博森纺织科技股份有限公司

An opening and closing induction batch electrospinning device

ActiveCN103993371BImprove delivery efficiencyIncrease delivery speedFilament/thread formingTemperature controlElectricity

Owner:XIAMEN UNIV

A method and device for preparing coating based on laser processing technology

ActiveCN106756721BWon't scratchControl Surface RoughnessMolten spray coatingPulse beamManufacturing technology

The invention discloses a method and device for preparing a coating on the basis of a laser processing technology and belongs to the technical field of part refabrication. The method includes the steps that firstly, the surface of a workpiece is coated with a thin black organic matter layer which serves as a laser energy absorption layer; pulse laser with the power density being GW / cm<2> grade is adopted for irradiating the surface of the workpiece, so that plastic pits are formed in the surface of the workpiece; the treated surface of the workpiece is cleaned and dried; and laser pulse beams with the power density being 10<4>-10<6> W / cm<2> are adopted for irradiating spraying wires and then melting the spraying wires into liquid state, liquid spraying wires are blown by high-pressure protective gas to impact on the surface of the workpiece at a high speed, and the coating is formed. According to the method and the device, an adjustable laser device is adopted, and the laser pulse beam diameter and output energy can be controlled; the coating prepared through the method has the characteristics of being high in interface bonding force and quality; and the method and the device have the technical characteristics of being short in spraying time, low in energy consumption, free of pollution and the like.

Owner:ANHUI UNIVERSITY OF TECHNOLOGY

A continuous annealing method for hot stamping steel

ActiveCN106929662BImprove bindingNot easy to fall offFurnace typesHeat treatment process controlHot stampingSurface roughness

The invention discloses a continuous annealing method for hot stamping forming steel. The continuous annealing method comprises an annealing procedure and a leveling procedure, wherein in the annealing procedure, the temperature of an uniform temperature section is 780-800 DEG C, the starting temperature of fast cooling is 670-690 DEG C, the final temperature of fast cooling is 390-410 DEG C, the final temperature of aging is 360-380 DEG C, the end temperature of a final cooling section is 140-160 DEG C, and the temperature after water quenching is 43-50 DEG C. The continuous annealing method is adopted for production, and thus the production efficiency is higher. The method is matched with the dew point in a furnace to produce products, thereby improving the combination firmness of subsequent hot stamping forming scale and a matrix. The method adopts the reasonable leveling process, is matched with a leveling working roller with certain roughness, and controls the surface roughness of band steel, thereby improving the combination firmness of subsequent hot stamping forming scale and the matrix. The scale of the hot stamping forming product produced by the method is not easy to shed off, and the combination firmness of the scale and the matrix is good.

Owner:TANGSHAN IRON & STEEL GROUP +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com