Composite yarn and preparation method and application thereof

A technology of yarn and conductive yarn, which is applied in yarn, liquid/gas/steam yarn/filament treatment, textile material carrier treatment, etc. It can solve the complex process and the inability to realize large-scale production of triboelectric composite yarn, etc. problems, to achieve the effects of simplifying the preparation process, shortening the curing time, good air permeability and softness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

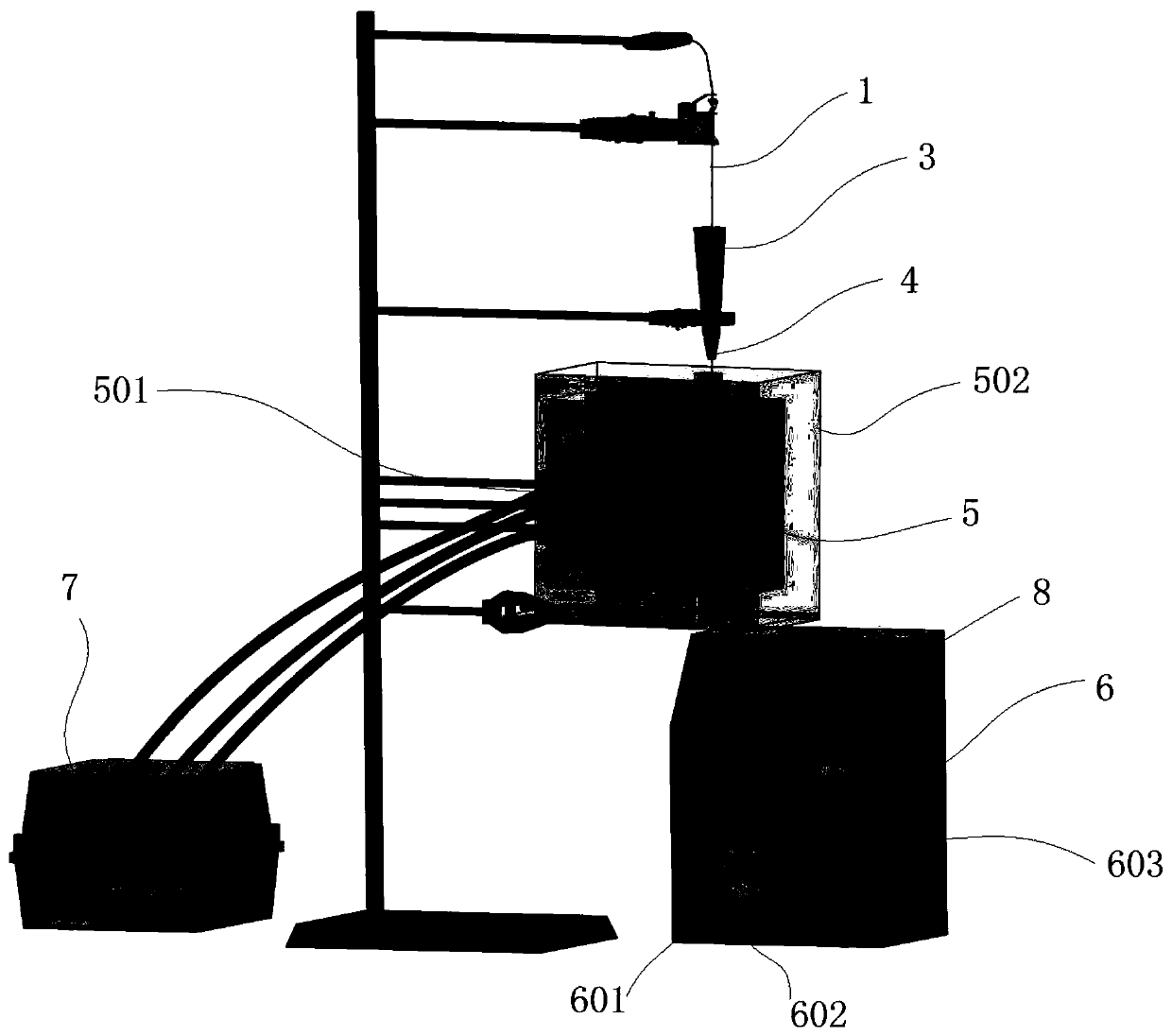

[0053] S1: Mix Eco flex silicone rubber 0050 and cross-linking agent at a mass ratio of 1:1, and stir at 25°C for 3 minutes, then transfer to a vacuum pump, vacuum for 5 minutes to eliminate air bubbles, and take out to obtain a silicone rubber gel .

[0054] S2: The conductive yarn is prepared by twisting silver fiber filaments and polyester filaments.

[0055] S3: passing the lower end of the conductive yarn in step S2 sequentially through the liquid storage tube, the coating nozzle, the heat preservation channel, the first roller and the second roller, and finally fixing it on the yarn collecting roller. Among them, the coating nozzle is circular with a caliber of 0.8 mm. By controlling the caliber of the coating nozzle, the thickness of the silicone rubber coating on the conductive yarn is controlled, and the coating process is made more uniform. The temperature of the heat preservation channel is 100°C.

[0056] S4: Inject the silicone rubber colloid in step S1 into the...

Embodiment 2

[0058] S1: Mix Eco flex silicone rubber 0050 and cross-linking agent at a mass ratio of 2:1, and stir at 25°C for 3 minutes, then transfer to a vacuum pump, vacuumize for 5 minutes to eliminate air bubbles, and take out to obtain a silicone rubber gel .

[0059] S2: The conductive yarn is prepared by covering the elastic yarn with the silver fiber yarn, and the elastic yarn is polyurethane elastic yarn.

[0060] S3: passing the lower end of the conductive yarn in step S2 sequentially through the liquid storage tube, the coating nozzle, the heat preservation channel, the first roller and the second roller, and finally fixing it on the yarn collecting roller. Wherein, the coating nozzle is circular with a caliber of 1 mm. By controlling the caliber of the coating nozzle, the thickness of the silicone rubber coating on the conductive yarn is controlled, and the coating process is made more uniform. The temperature of the heat preservation channel is 100°C.

[0061] S4: Inject t...

Embodiment 3

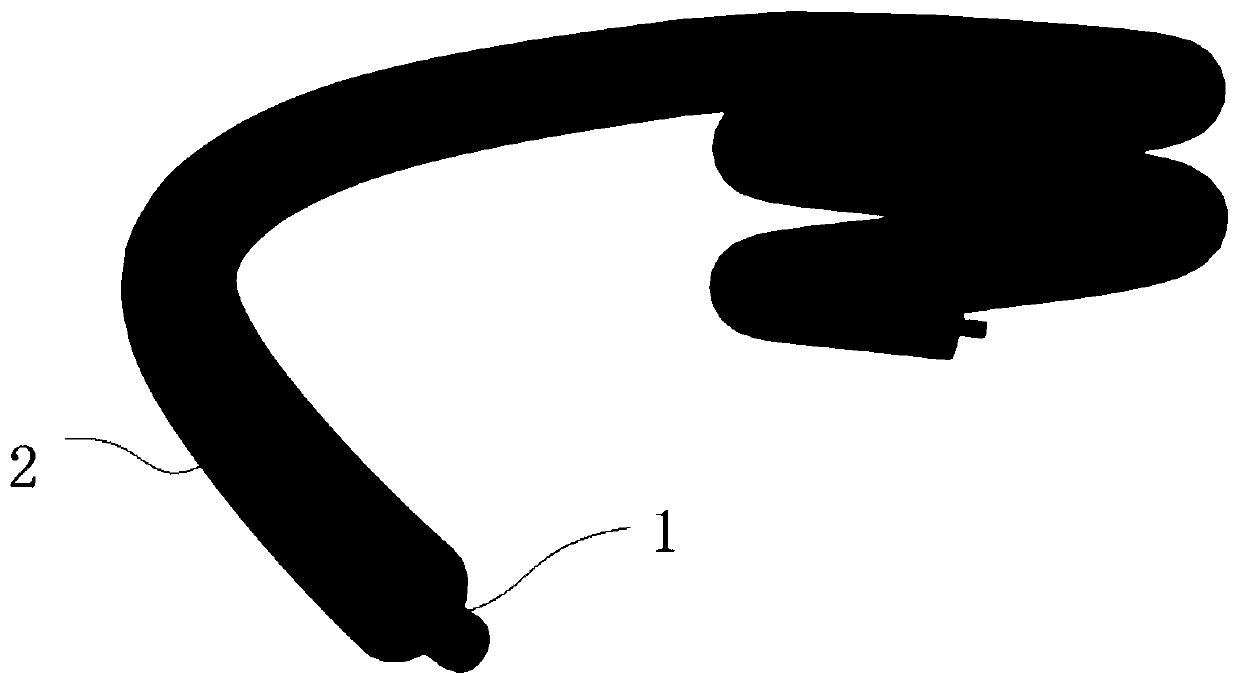

[0067] In this example, a triboelectric fabric is prepared, which is prepared by using the conductive yarn prepared in Example 2. Reference attached Figure 5 , the conductive yarn is woven with one or more of plain weave, twill weave, satin weave, warp knitting and weft knitting to obtain a triboelectric fabric with a size of 5cm×5cm. This triboelectric fabric accumulates charges on the surface of the triboelectric fabric during the contact and separation process with human skin and clothing fabrics, so it can also be used as a wearable fabric sensor for a flexible triboelectric nanogenerator. The fabric is placed on the joints of the human body, such as knee joints, elbow joints, etc., and can monitor the range of motion and frequency of motion of the joints in real time.

[0068] Reference attached Figure 4 , the triboelectrification fabric and the conductive film with good electropositive property are contacted and separated. The conductive film 13 is a PET film with a ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Caliber | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com