Novel Ni3Al based self-lubricating material with hollow spherical powder as lubricating phase and preparation method

A technology of hollow spherical powder and lubricating materials, applied in the field of new Ni3Al-based self-lubricating materials and its preparation, can solve the problems of poor fracture toughness, limited application, low room temperature plasticity of intermetallic compounds, etc., and achieve good compactness and stable sintering reaction , The effect of stabilizing and excellent tribological properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0029] In the following examples, the hollow spherical powders are all made of MoS 2Prepared from powder and aqueous solution of sodium silicate containing auxiliary reagents. The present invention provides a specific preparation method, but does not limit the preparation method. Hollow spherical powders prepared by other methods that meet the requirements of the present invention are also suitable for the present invention.

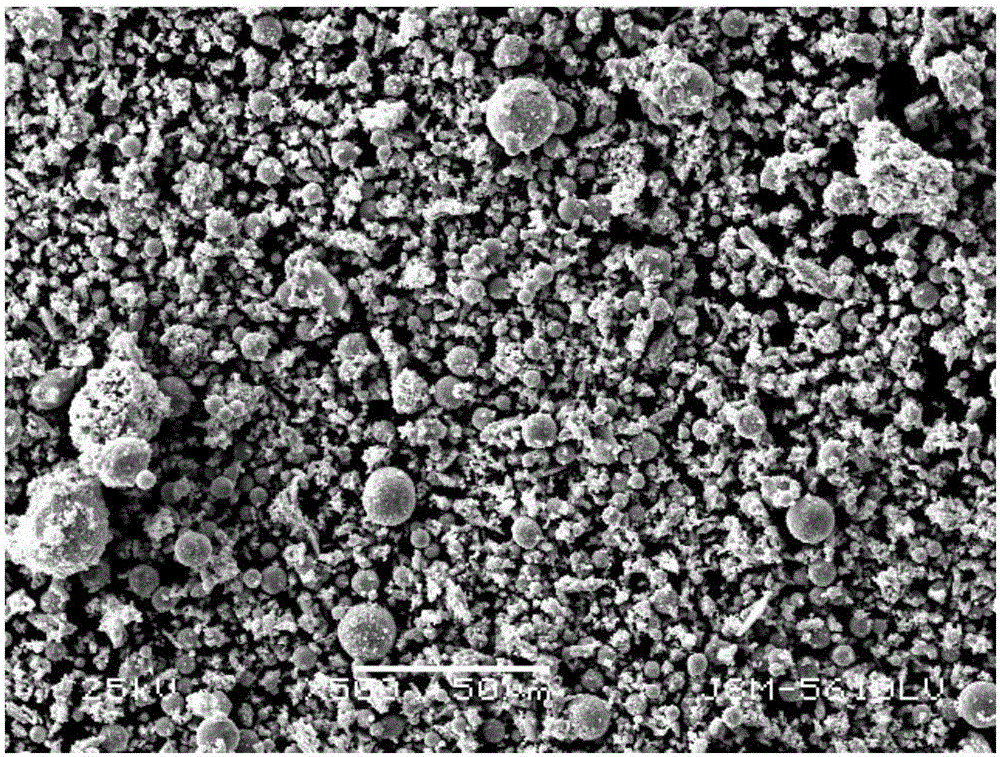

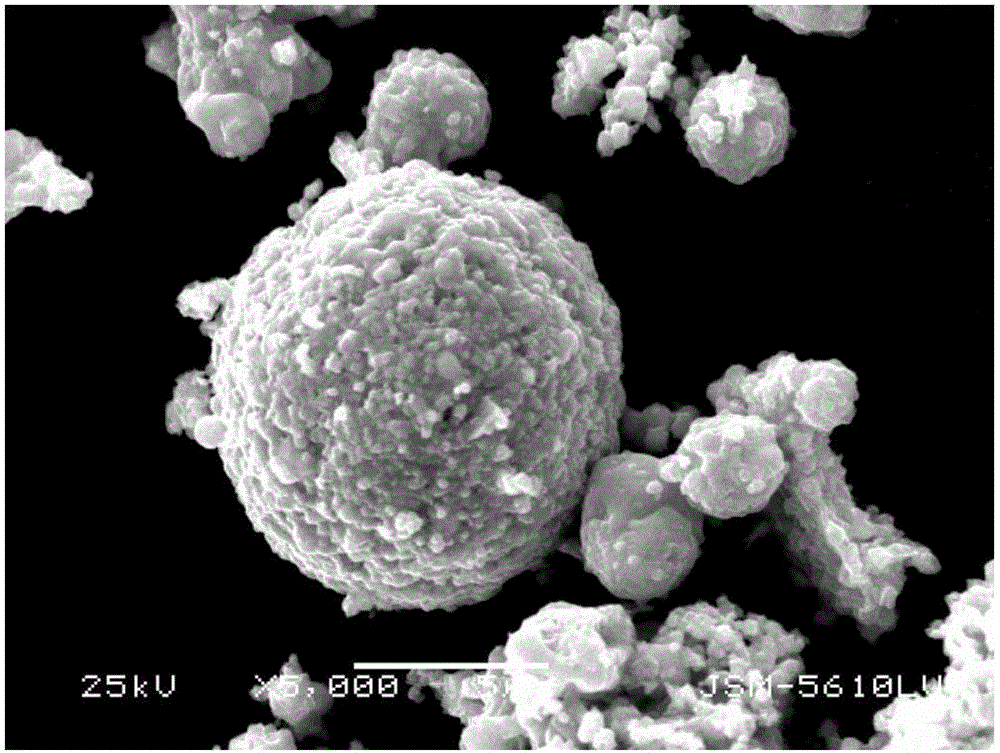

[0030] The preparation method of the hollow spherical powder provided by the present invention is: selecting MoS 2 The powder is added to the sodium silicate aqueous solution containing auxiliary reagents to form a mixed solution, and the resulting mixed solution is dried to obtain powder particles; the powder particles are melted at high temperature, and the obtained droplet-shaped reactant is sprayed into water for condensation, and the upper layer on the water surface is collected The floating particles are the required hollow spherical powder after ...

Embodiment 1

[0033] A new type of Ni with hollow spherical powder as lubricating phase 3 Al-based self-lubricating material, which is prepared from Ni powder, Al powder and hollow spherical powder, wherein the molar ratio of Ni:Al is 3:1, and the mass of hollow spherical powder is 1.0wt of the total mass of Ni powder and Al powder. %, the hollow spherical powder is composed of lubricating phase MoS 2 composed of glass.

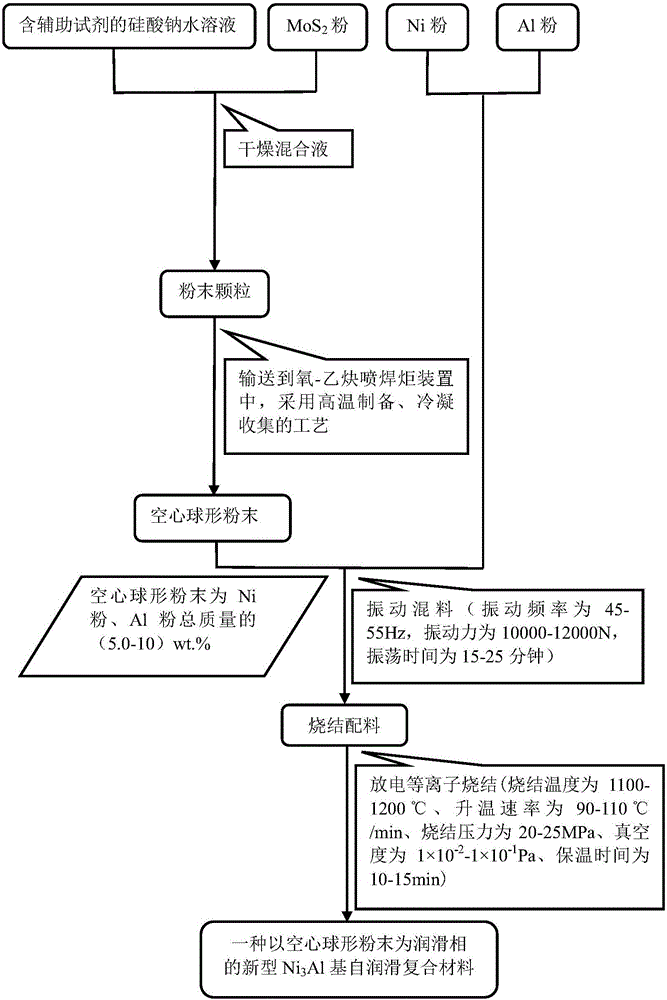

[0034] Such as figure 1 As shown, the above new type of Ni with hollow spherical powder as lubricating phase 3 The preparation method of Al base self-lubricating material, it comprises the steps:

[0035] 1) Select 13.0 grams of Ni powder, 7.0 grams of Al powder and 0.2 grams of the hollow spherical powder prepared above according to the molar ratio of Ni:Al=3:1; mix the Ni powder, Al powder and hollow spherical powder to obtain the ingredients;

[0036] 2) Put the above ingredients into a vibrating mixer for dry mixing. The outer tank of the vibrating mixing material ...

Embodiment 2

[0040] A new type of Ni with hollow spherical powder as lubricating phase 3 Al-based self-lubricating material, which is prepared from Ni powder, Al powder and hollow spherical powder, wherein the molar ratio of Ni:Al=3:1, and the mass of hollow spherical powder is 1.5wt of the total mass of Ni powder and Al powder. %, the hollow spherical powder is composed of lubricating phase MoS 2 composed of glass.

[0041] The above-mentioned novel Ni with hollow spherical powder as lubricating phase 3 The preparation method of Al base self-lubricating material, it comprises the steps:

[0042] 1) Select 13.0 grams of Ni powder, 7.0 grams of Al powder and 0.3 grams of the hollow spherical powder prepared above according to the molar ratio of Ni:Al=3:1; mix the Ni powder, Al powder and hollow spherical powder to obtain the ingredients;

[0043] 2) Put the above ingredients into a vibrating mixer for dry mixing. The outer tank of the vibrating mixing material is a steel tank with a buil...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com