Method for preparing magnesia-stabilized zirconia crucible through casting molding

A technology for stabilizing zirconia and grouting, which is used in the field of superalloy or special precious metal smelting and refractory materials, which can solve the problems of sintering and cracking of zirconia crucibles, and achieve low cost, high strength and refractoriness, good thermal stability and performance. The effect of erosion resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

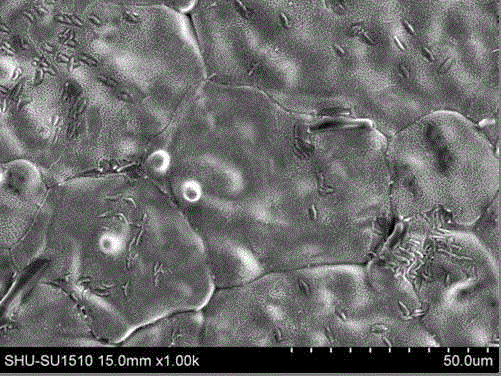

Image

Examples

Embodiment 1

[0016] Commercial magnesia stabilized zirconia powder (MgO3.5%, ZrO 2 96.5%), deionized water, binder and dispersant citric acid are mixed in the ball mill tank according to the ratio of 100:22:14:3 (mass ratio), and zirconia balls are added to the ball mill tank, and the slurry and zirconia The ratio of the balls is 1:1, and then placed in the drum to mix the slurry for 10 hours, configured to form a slurry with good fluidity, passed through a 120-mesh sieve, removed large particles in the slurry, and vacuum degassed the slurry for 5 minutes . Pour the slurry into the gypsum mold. The grouting time is 5 minutes and the slurry is continuously replenished. At this time, the wall thickness of the crucible is 3mm, and the remaining slurry is poured out. The gypsum mold is placed obliquely in the air, demoulded after 1 hour, poured out the green body, placed in a dry and shaded place for 2-3 days, and finally repaired the green body. Place the formed dry biscuit sample in a high...

Embodiment 2

[0019] Commercial magnesia stabilized zirconia powder (MgO3.5%, ZrO 2 96.5%), deionized water, binder and dispersant triethanolamine are mixed in the ball mill tank according to the ratio of 100:20:13:1 (mass ratio), and zirconia balls are added to the ball mill tank, and the slurry and zirconia The ratio of the balls is 1:1, and then placed in the drum to mix the slurry for 10 hours, configured into a slurry with good fluidity, passed through a 120-mesh sieve, removed large particles in the slurry, and vacuum degassed the slurry for 5 minutes . Pour the slurry into the gypsum mold. The grouting time is 7 minutes and the slurry is continuously replenished. At this time, the wall thickness of the crucible is 3mm, and the remaining slurry is poured out. The gypsum mold is placed obliquely in the air, demoulded after 1 hour, poured out the green body, placed in a dry and shaded place for 2-3 days, and finally repaired the green body. Place the formed dry bisque sample in a high...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com