Patents

Literature

86results about How to "Weave evenly" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Preparation method of hollow fabric with radial elastic shrinkage

ActiveCN102776649AHigh tensile strengthHigh temperature resistantWoven fabricsEngineeringWear resistance

The invention discloses a preparation method of a hollow fabric with radial elastic shrinkage and relates to the preparation method of the hollow fabric. The object of the invention is to solve the problem that elastic hollow fabric available in the market does not meet the requirement of thin diameter and longitudinal elasticity and very large radial elasticity when being used in a specific task, has poor strength of bearing accidental drawing and poor wearability, as well as poor dimensional stability, and especially poor radial elasticity. The method comprises the preparation work of warp yarns, which includes selecting fine denier 75-200D aramid fiber fibers, 100-300D PBO (p-phenylene-2,6- benzobisoxazazole fiber) fibers or aramid fibers and PBO combined filament yarns as warp yarns; preparation work of weft yarns; directly winding of the weft yarns to form a pirn with a size same as that of a shuttle of a shuttle loom; and a determining and weaving process of metric portie. The hollow fabric prepared by the preparation method provided by the invention has excellent radial elastic recovery, and also the characteristics of superstrong resistance to longitudinal stretching force and wear resistance and corrosion resistance. The method is used for preparing elastic hollow fabrics.

Owner:HARBIN INST OF TECH

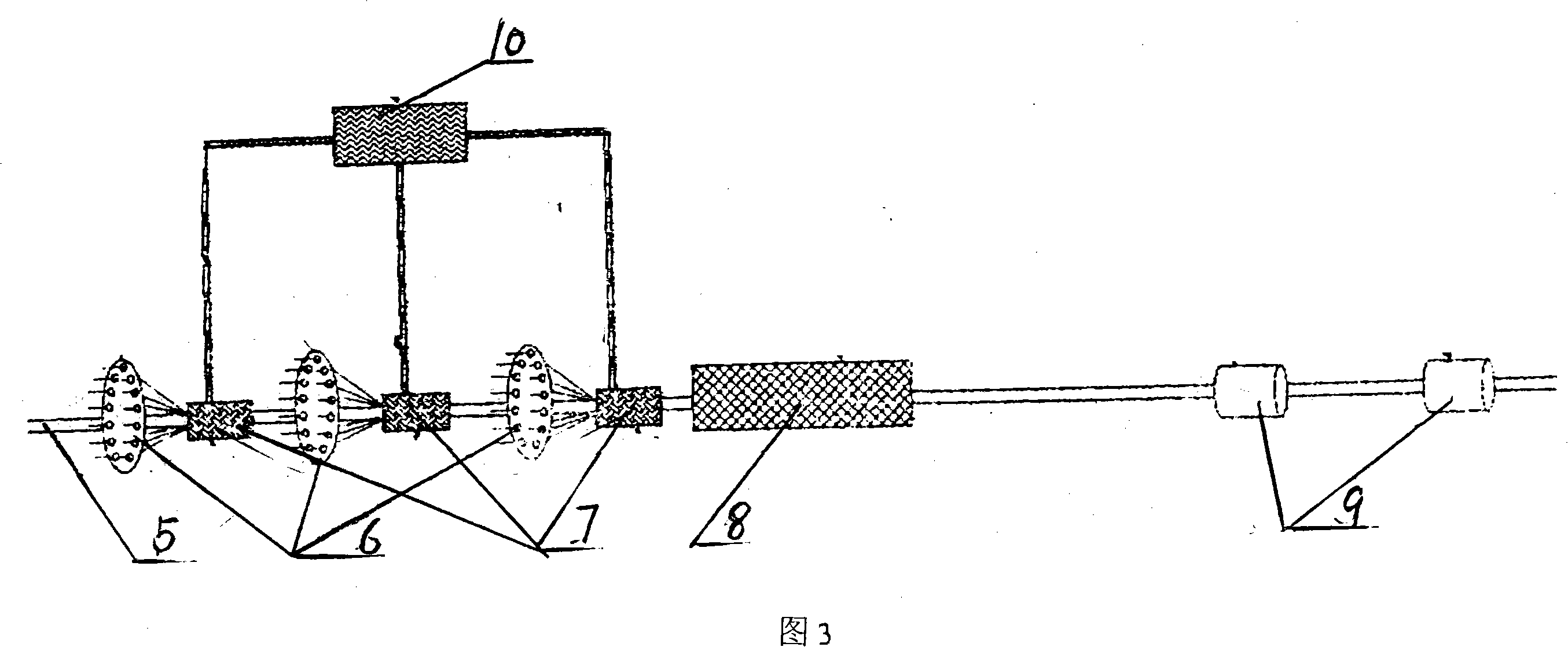

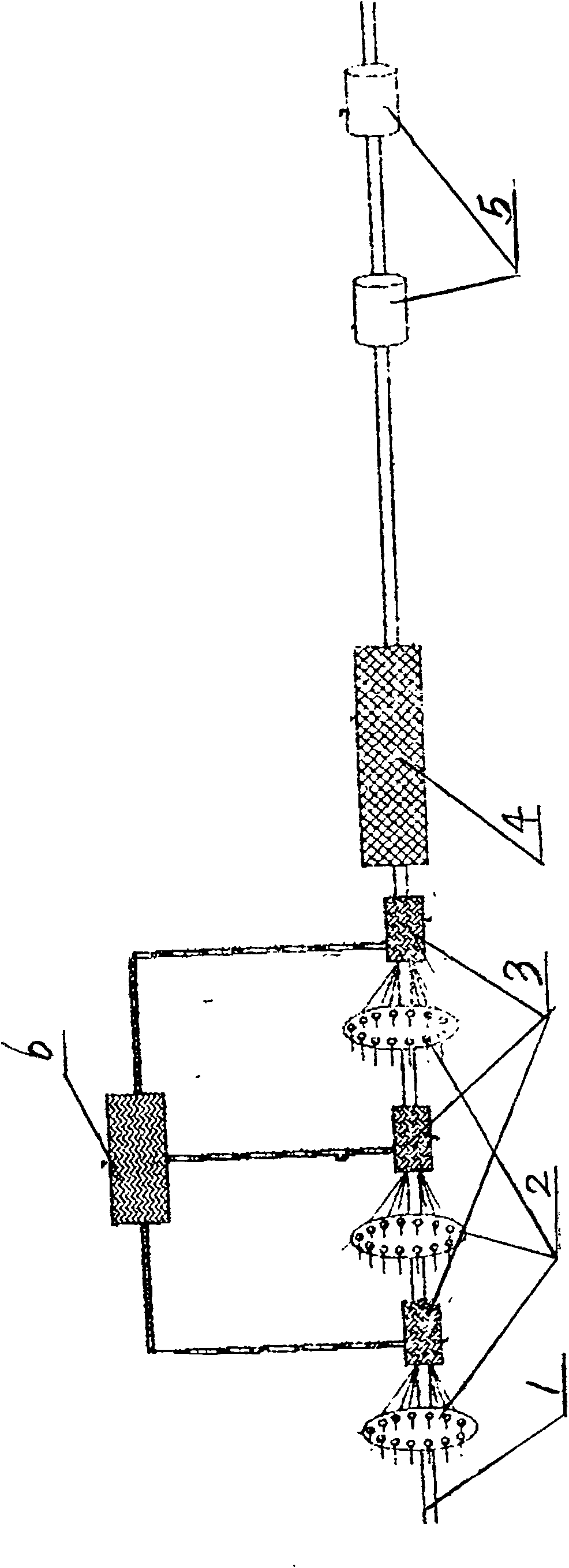

Preparation method for on-line pulling and extruding glass steel tube with multilayer annular weaving structure

InactiveCN101085551AWeave evenlyHigh precision of inner and outer diameterTubular articlesFiberMaterials science

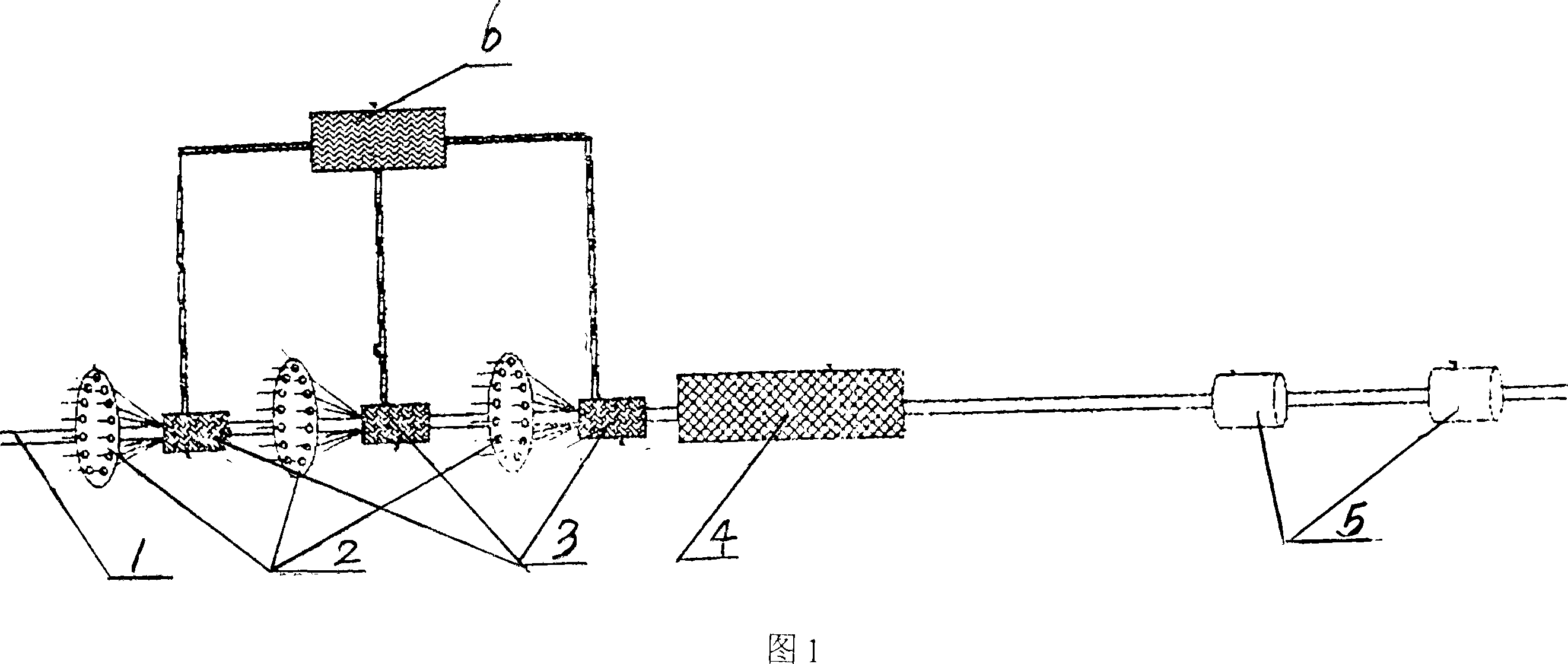

The invention relates to the making of multi layer knitting structure on the wire pulling glass steel tube using several computers controlling the two dimensional horizontal knitter, using core mold, stretch mold, extractor synthesizing the glass steel tube, setting resin dipping slot at the back of each knitter, even direct core mold at both ends of the core mold that follows with the movement of the ring knitting layer in the direction from the first two dimensional horizontal knitter to the last knitter through the dipping slot to the stretch mold. The glass tube in and out radius has high precision, thickness of each knitting layer adjustable, even in each dipping and consistent in strength.

Owner:郝跟进

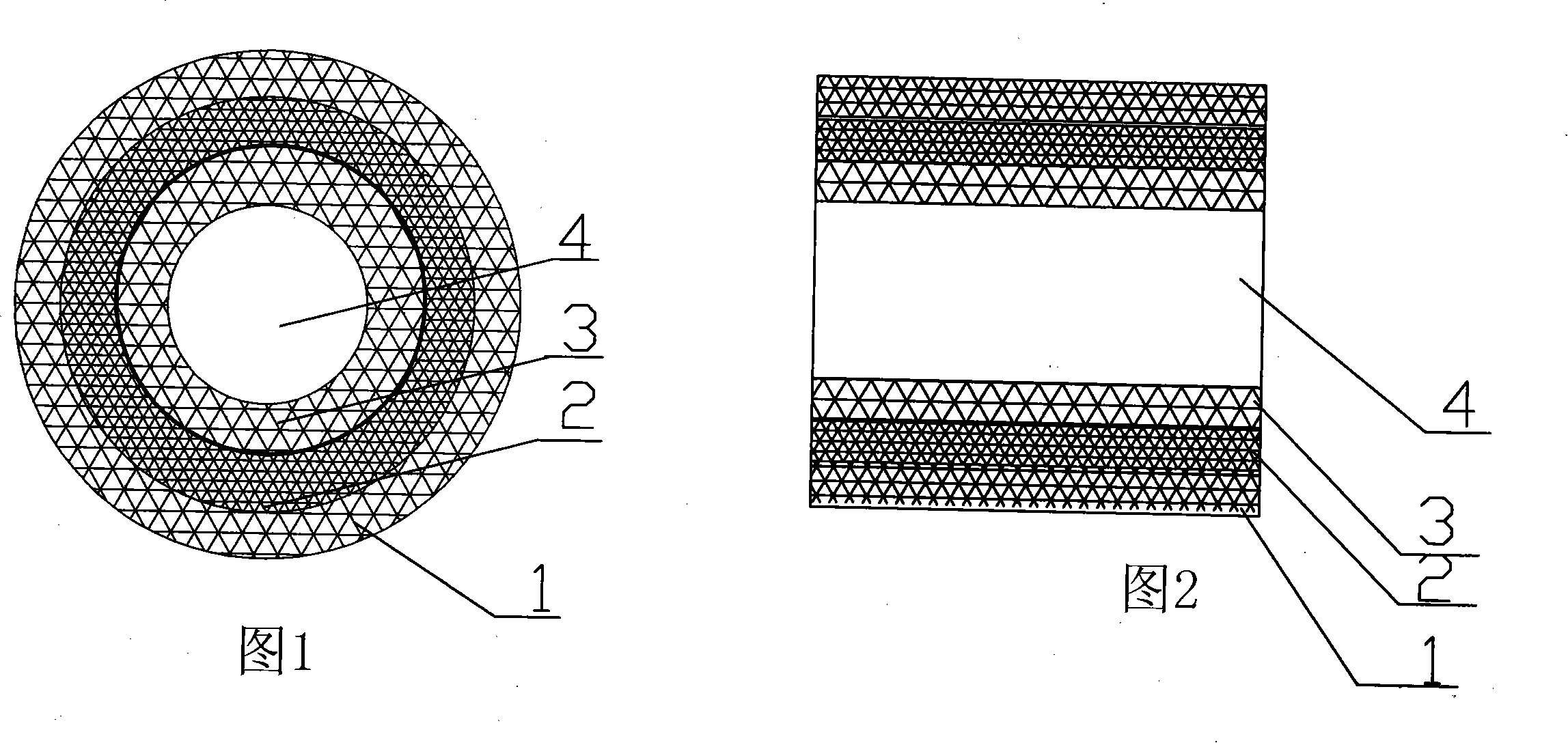

Fiberglass insulating tube with multi-layer ring shaped braiding structure

InactiveCN101119042AWeave evenlyHigh precision of inner and outer diameterWindings insulation materialWindings insulation shape/form/constructionUltimate tensile strengthManufacturing efficiency

The present invention discloses a glass steel insulating tube with the multi-layer round structure, which is compounded with the multi-layer glass steel insulating tube, each glass steel insulating tube of the compounded glass steel insulating tube is the glass steel insulating weaving tube which is weaved at the moving type core tube by the horizontal knitting machine, each layer of the lass steel insulating weaving tube is dipped by the bond before the compound; the compounded glass steel insulating tube is compound under the same straight core mould, and finally shape and solidified by a pulling mould; the glass steel insulating tube is formed by the 2 to 5 layers of the glass steel insulating weaving tube. Compared with prior compound tube, the intensity and the accuracy of the glass steel insulating tube are improved greatly, the thickness of the tube wall only differ from 1 to 2 threads, in particular to the application of the micro electromotor double insulating tubes make the manufacture efficiency of the micro electromotor improve, and the cost is reduced, and the production craftwork is simple.

Owner:郝跟进

Full-drawn yarn of super fine polyester and manufacturing process thereof

InactiveCN101724923AImprove spinnabilityImprove stylingArtificial filament heat treatmentMelt spinning methodsYarnAdditional values

The invention relates to a full-drawn yarn of super fine polyester manufactured by using polyester continuously. The full-drawn yarn of super fine polyester with a specification of 75D / 192F is manufactured by a one-step process route of circular blowing, cooling and spinning, and the yarn has good performance. The manufacturing process of the full-drawn yarn of super fine polyester comprises the following steps of: esterifying phthalic acid and glycol by using the refined raw material, preparing the melted polyester by the prepolycondensation and the final polycondensation, and directly spinning the melted polyester. The manufacturing process route comprises melted polyester, conveying the melted polyester, a spinning box, a metering pump, a member, circular blowing cooling, bundling and oiling, a paved path, a first hot roller, an interlacer, a second hot roller and winding. The invention has advantages of reasonable manufacturing processing, good fibre spinnabilitty, smooth weaving, light, flexible quality of the fabric and good style of the fabric, thereby meeting weaving request of fabric and lining of high-grade clothes and improving the grade and the additional value of products.

Owner:JIANGSU SHENGHONG CHEM FIBRE CO LTD

Two-side front jacquard satin towel and weaving process thereof

The invention discloses a two-side front jacquard satin towel and a weaving process thereof. The two-side front jacquard satin towel is formed by weaving warp yarns and weft yarns, the warp yarns are divided into four layers, the ground warps of the upper two warp yarn layers and the weft yarns are woven to form a front side pattern texture, the looped warps of the lower two warp yarn layers and the weft yarns are woven to form a reverse side pattern texture, the front pattern texture and the reverse side pattern texture are connected into a whole body through a plurality of uniformly-distributed tying textures formed by the looped warps and the weft yarns, the weft density of the weft yarns is 80-90 / cm, and the tying texture is wefted by 5-15. The double sides of the towel have different patterns or the same pattern, so that the towel can reach a new level in visual appearance, the new pattern development field is opened up, and compared with the traditional double-color weft satin jacquard towel, the two-side front jacquard satin towel has high level and has high market competitive power.

Owner:SUNVIM GROUP

Production technology of kraft vermicelli case board paper

InactiveCN105696395AHigh strengthIncrease the lengthPulp beating methodsPaper recyclingEnvironmental resistanceSurface layer

The invention discloses a production technology of kraft vermicelli case board paper. The production technology comprises the steps that recycled waste paper materials are screened, the recycled waste paper with low ash content is selected for pulping with softwood pulp, preliminary pulping is conducted through the processes of repulping, purifying, screening and the like, the fiber strength is emphatically improving in the grading and beating processes, longer fibers are screened to serve as surface layer pulp, the fiber beating degree is improved on the condition that the fiber strength is not damaged, and the fiber bonding strength is improved through the fiber arrangement mode on a net portion so as to improve the surface strength, toughness and folding strength of finished paper; by means of the measures of surface sizing, after-drying moisture precise control and finished paper coating, the product has the better explosion-proof line quality advantage and is more environmentally friendly, and the market share of the product is bound to be increased.

Owner:JIANGSU LEE & MAN PAPER MFG

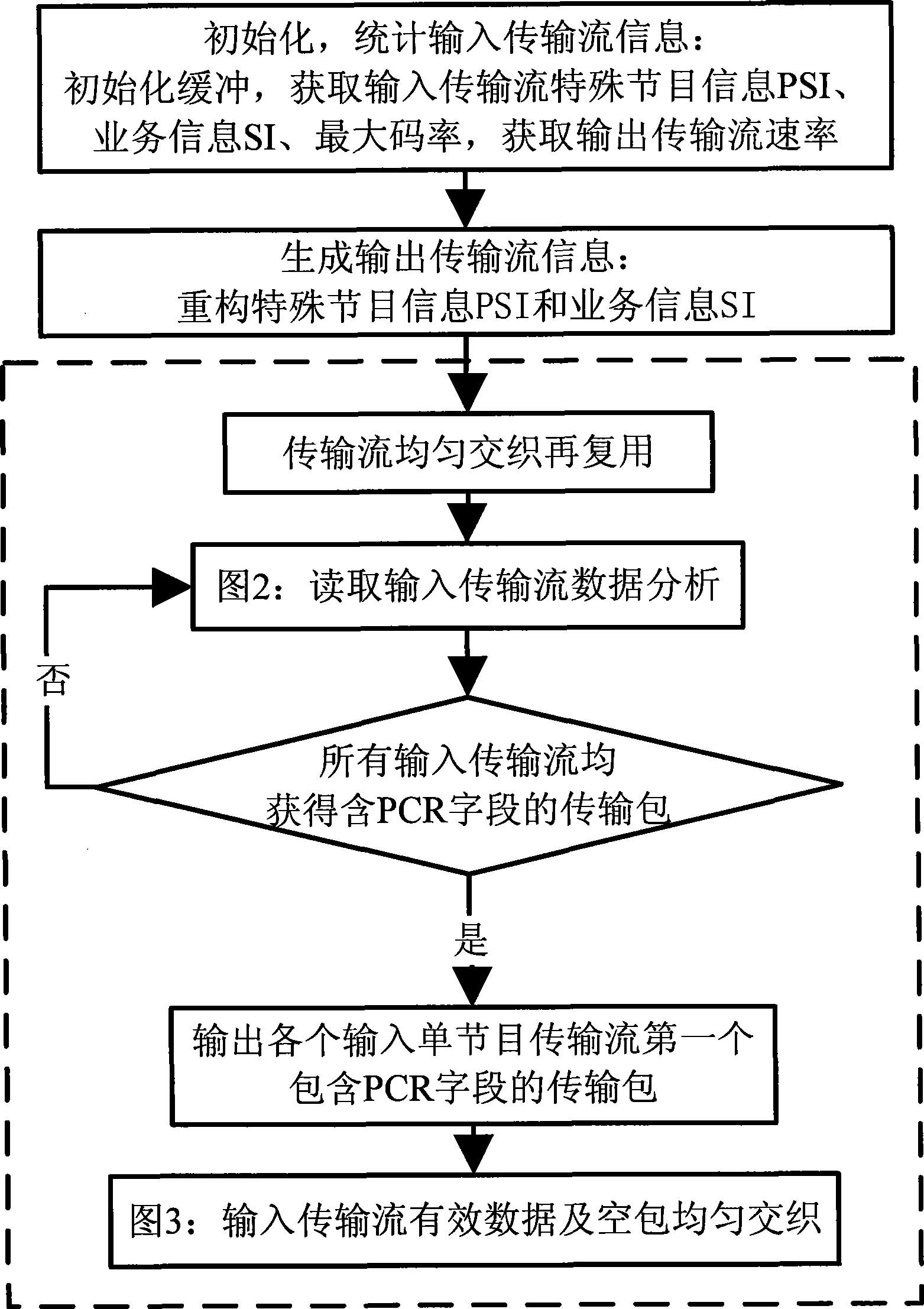

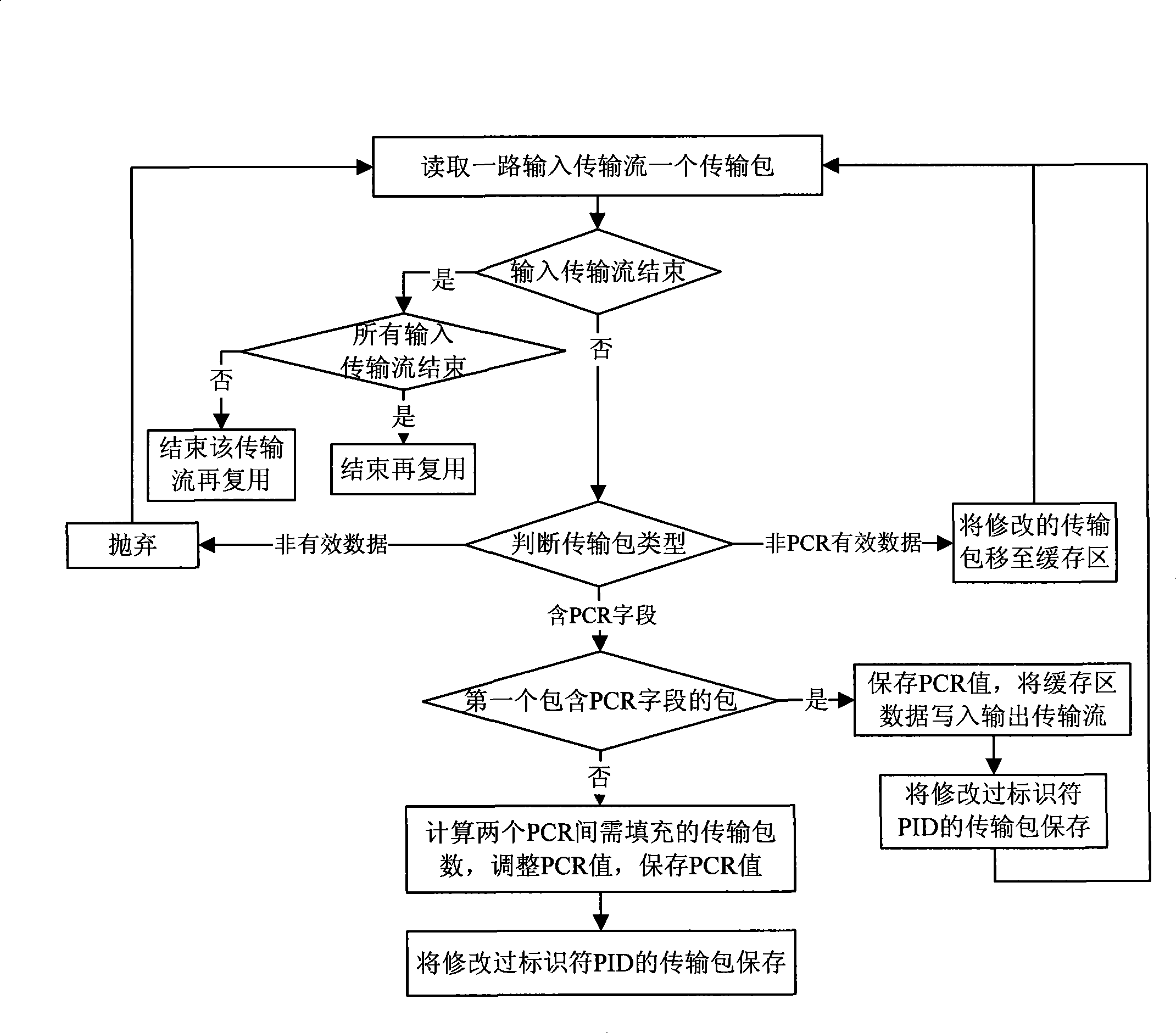

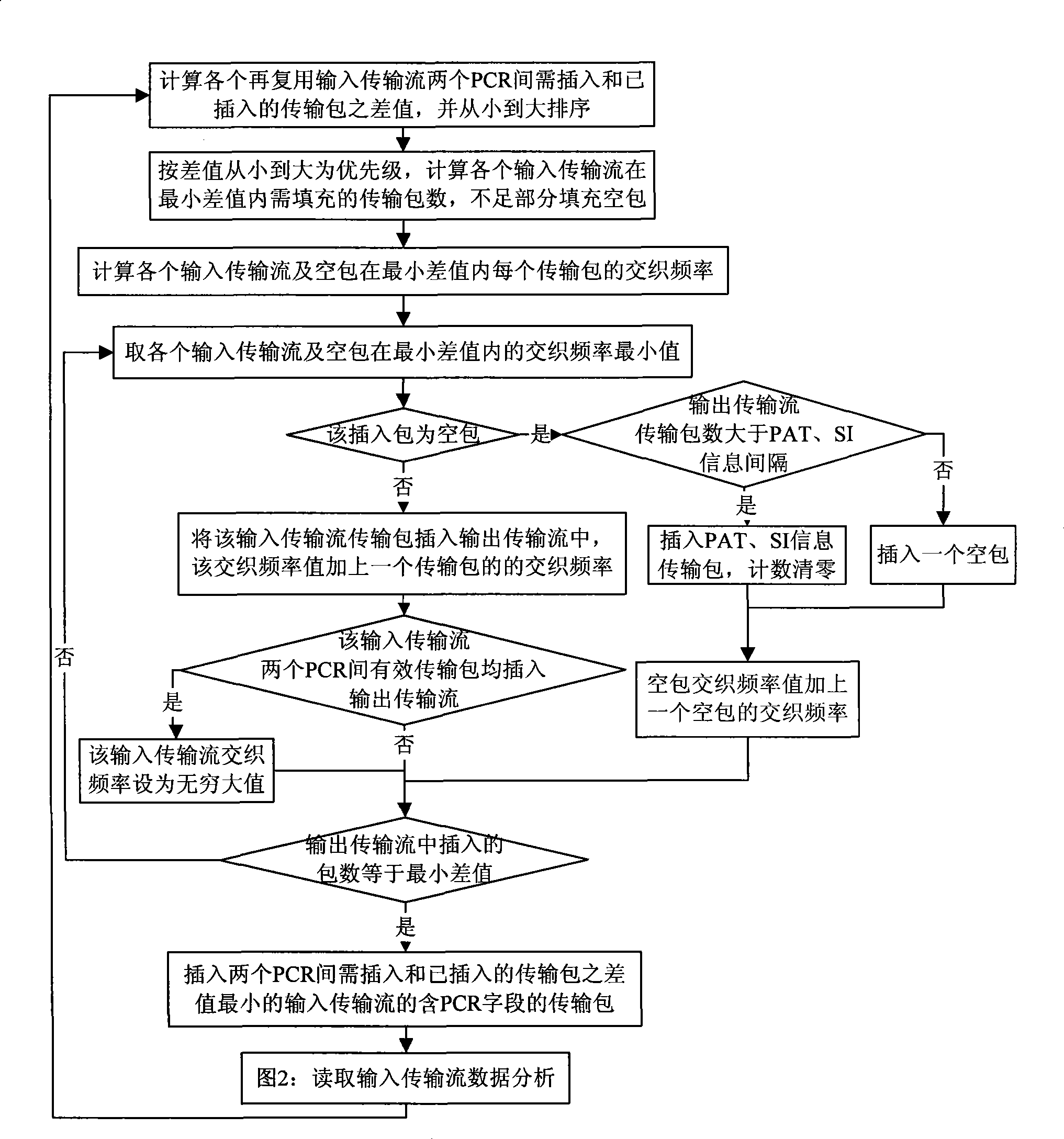

Transmission stream remultiplexing method

InactiveCN101426142ASimple and flexible technical solutionsImprove channel utilizationPulse modulation television signal transmissionSelective content distributionService informationMPEG transport stream

The present invention relates to a transport stream re-multiplexing method, which re-multiplexes multi-input single-program transport stream into a multi-program transport stream for outputting. The method includes: first of all, reconfiguring the program specific information PSI and service information SI of the output transport stream according to counted program specific information PSI and service information SI of the input transport stream; secondly, dynamically uniformly and interlacedly outputting the valid data and empty packets of each transport stream according to the rate of the output transport stream; and substituting the empty packets in a certain interval into the program specific information PSI and service information SI. The invention only differentially tunes the original PCR rather than rewriting the PCR value.

Owner:SHANGHAI UNIV

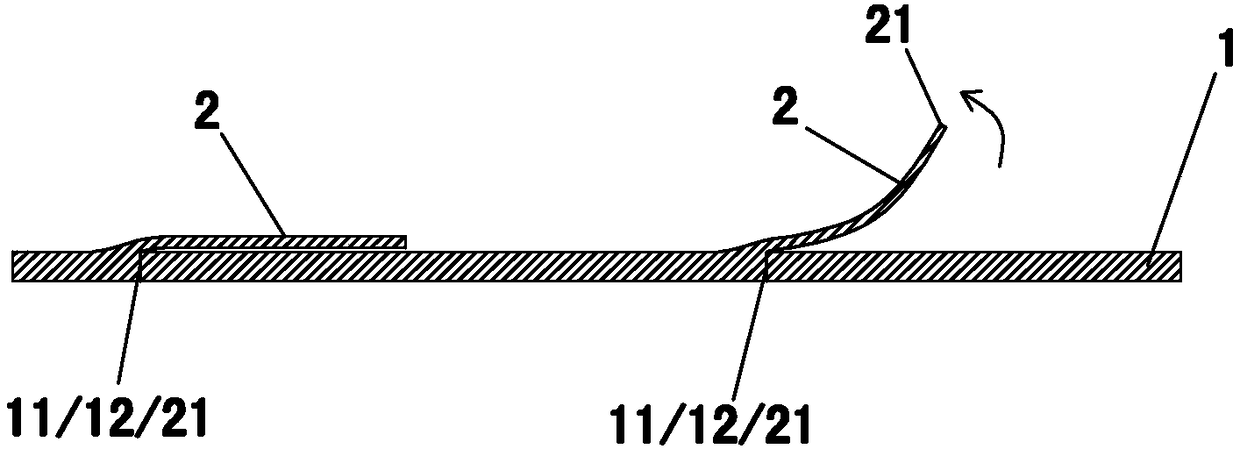

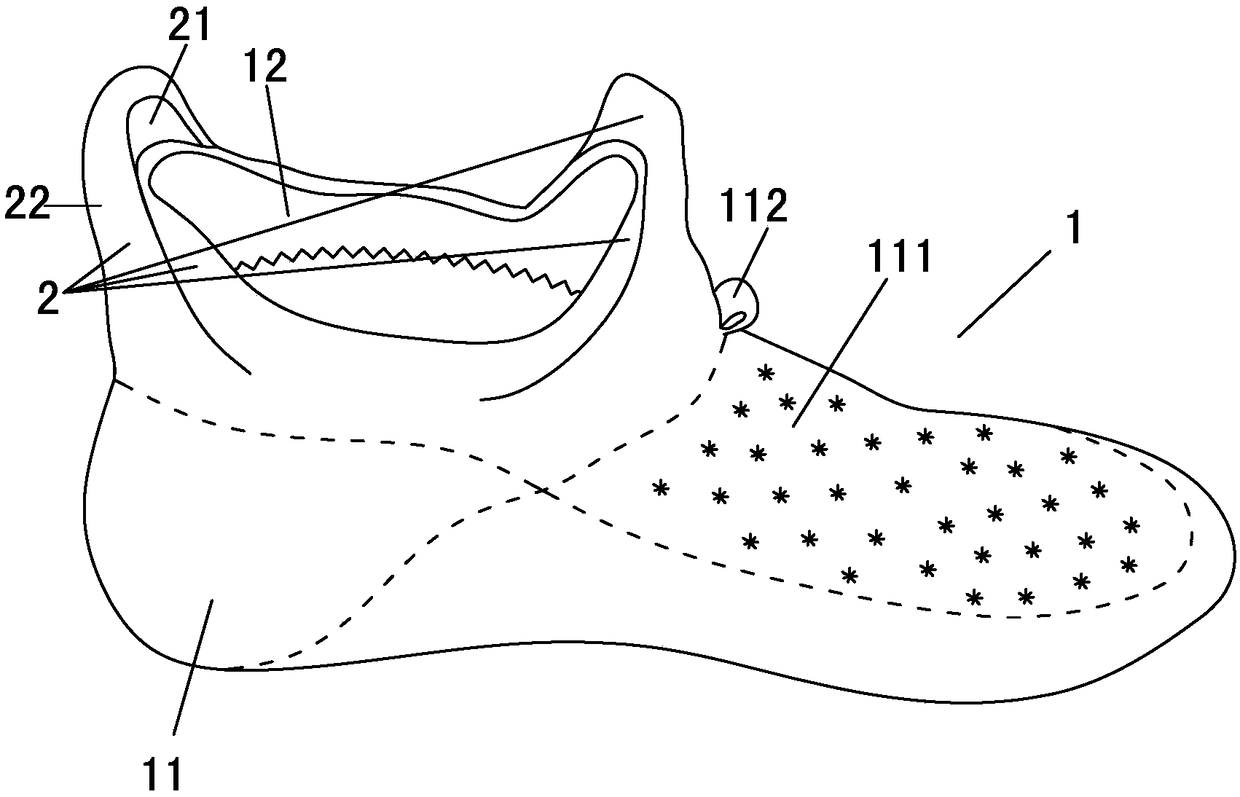

Flyknit vamp with breathing scale structure and flyknit method thereof

PendingCN108588993AConducive to fly weaving forming timeImprove breathabilityWeft knittingUpperYarnScale structure

The invention discloses a flyknit vamp with a breathing scale structure and a flyknit method thereof, wherein the flyknit vamp comprises a vamp base body and a scale main body, wherein the scale mainbody comprises a connecting edge, a free edge and an extending end; a part of the vamp base body corresponding to the scale main body is provided with a through hole; one edge of the through hole is aconnecting edge, the other edge of the through hole is an initial edge, and the flyknit comprises the following steps of, 1) using a flyknit machine with a multi-plate needle bed; 2) importing the pattern of the flyknit vamp into the flyknit machine, and threading the yarn on a yarn nozzle; 3) starting the flyknit machine to realize reciprocating weaving until finished; in this step, narrowing and knitting the part of the through hole when knitting to the line of the initial edge; for the next row, a rear needle bed knitting needle corresponding to the part of the through hole passes throughthe through hole and is matched with the corresponding front needle bed knitting needle for knitting the free edge of the needle knitting scale main body, and other parts are suspended; the scale mainbody is formed by the reciprocating knitting of one or more rows, and the other parts of the row or the other part of the connecting edge are continuously knitted; the knitting of the next row continues.

Owner:福建荣荣新材料股份有限公司

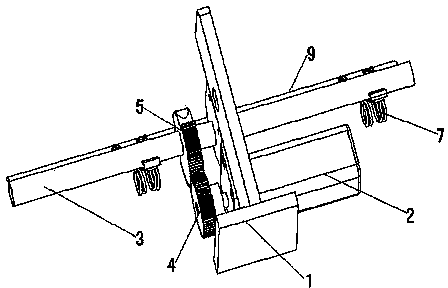

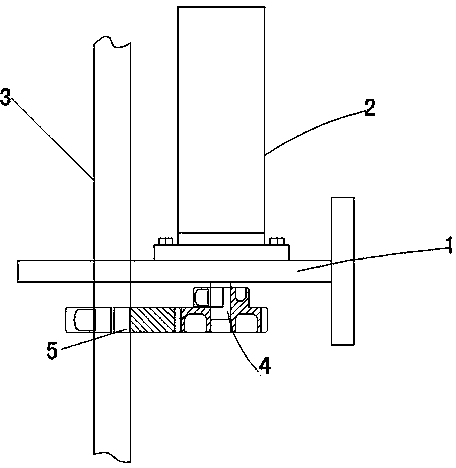

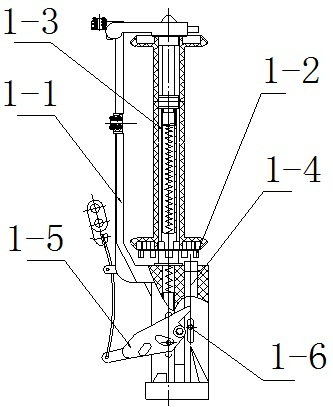

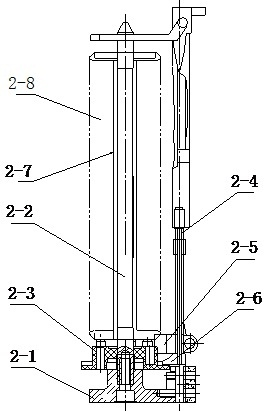

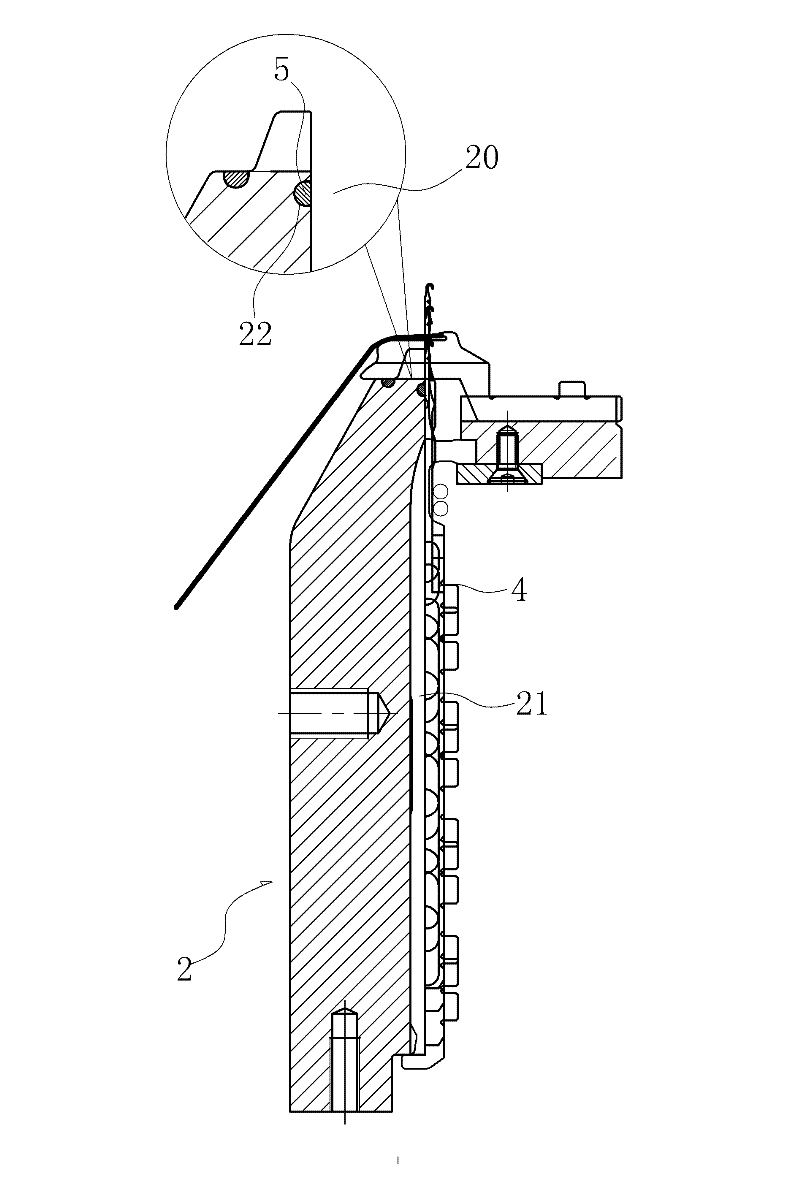

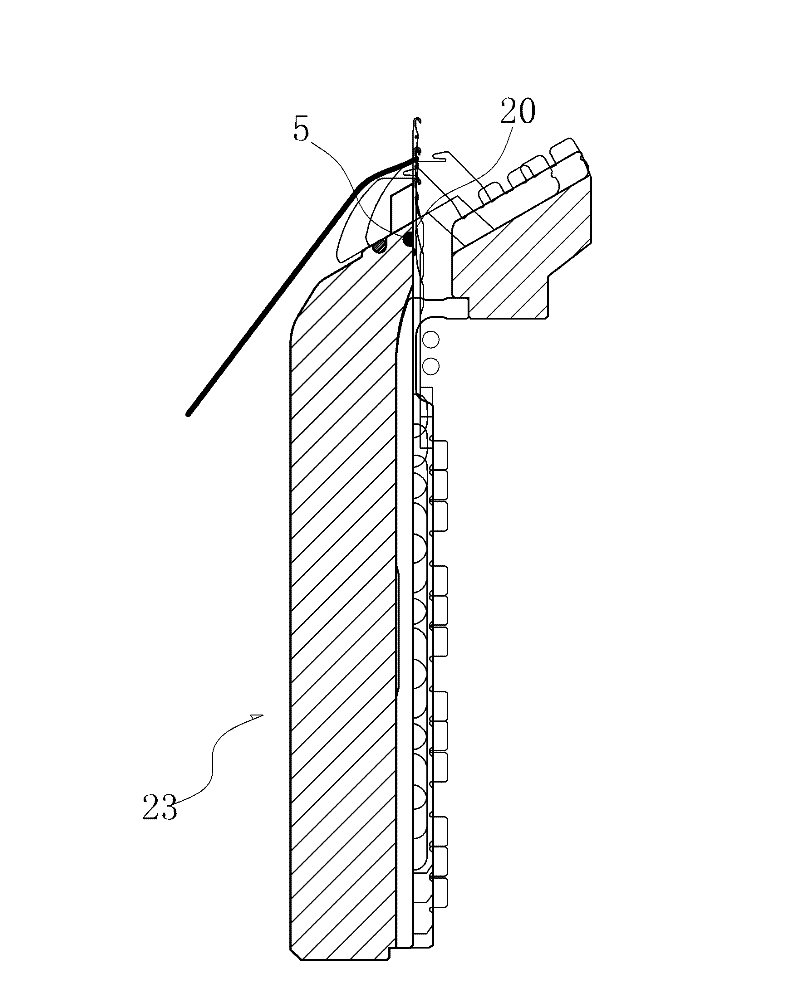

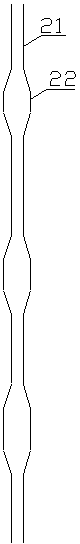

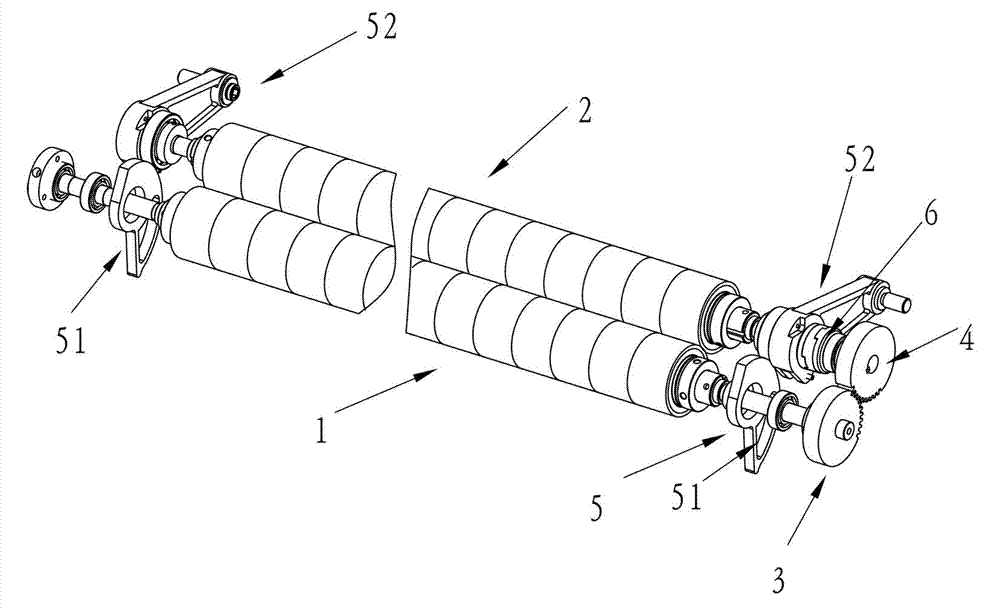

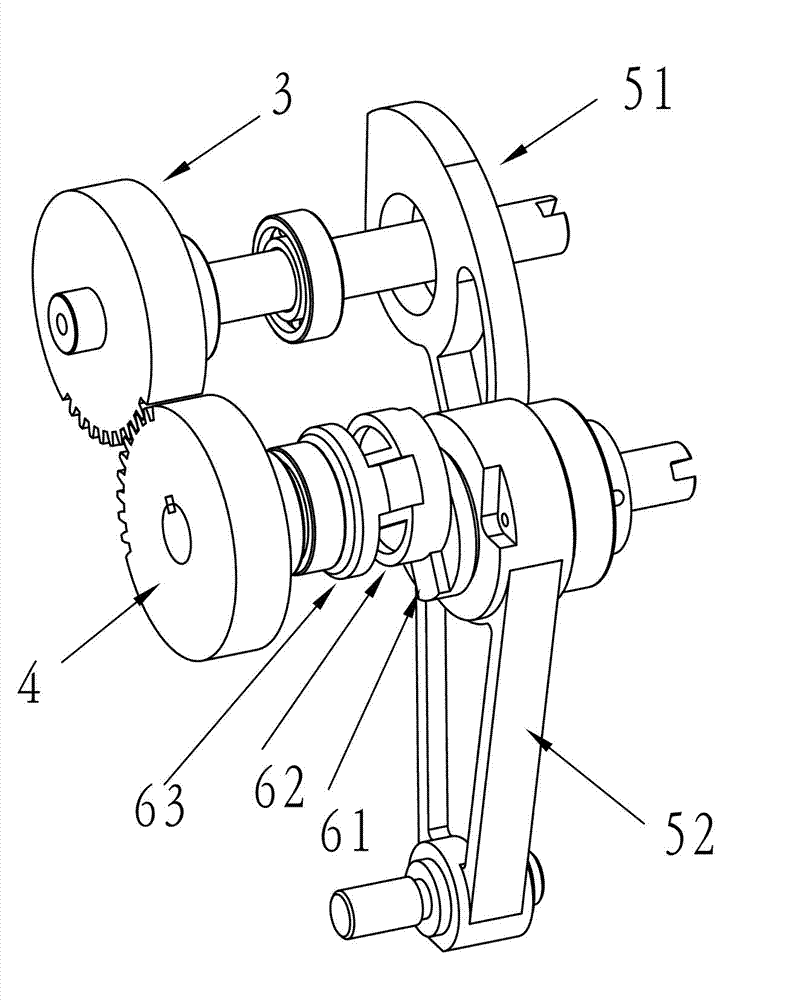

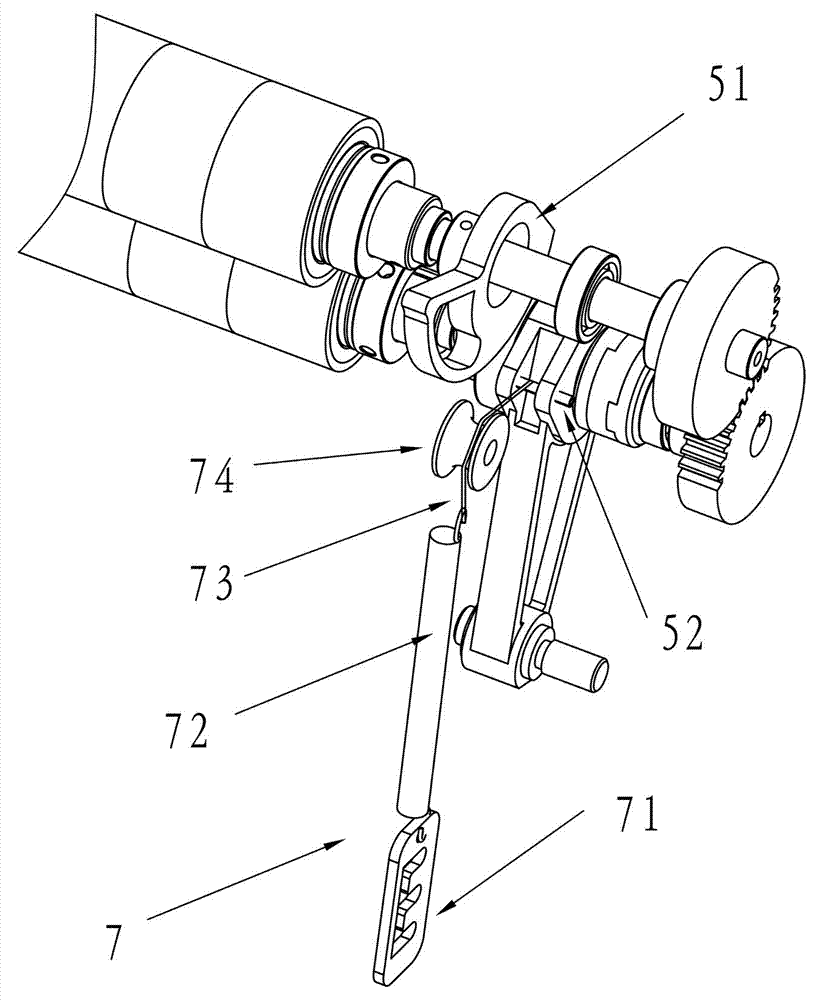

Yarn tension control mechanism of warp knitting machine

The invention discloses a yarn tension control mechanism of a warp knitting machine, which comprises a tension seat, a tension rod, a yarn-through rod, a driving gear, a driven gear and a servo motor, wherein the tension rod and the yarn-through rod are mounted on the tension seat; the driven gear is mounted on the tension rod; tension springs of certain number are equidistantly mounted in the same direction on the tension rod; yarn guide caps are clamped by the tail-end openings of the tension springs; a flange of the servo motor is fixed on the tension seat through a bolt; the driving gear is arranged on an output shaft of the servo motor; the driving gear is meshed with the driven gear; when the servo motor rotates back and forth under the control of the set program, the driving gear rotates along with the servo motor and the driven gear is driven to rotate; the rotation of the driven gear drives the tension rod and the yarn guide caps of the tension springs to rotate; and the control program controls the motor to rotate back and forth according to the rotation speed of a main shaft of the wrap knitting machine to cooperate with the looping motion of the warp knitting machine so as to control the tightness of the yarn tension. The uniformity of the yarn tension is guaranteed, thus the knitting of the warp knitting machine is smooth, the quality of the grey cloth is good, and the production efficiency is high.

Owner:FUJIAN XIN GANG TEXTILE MACHINERY

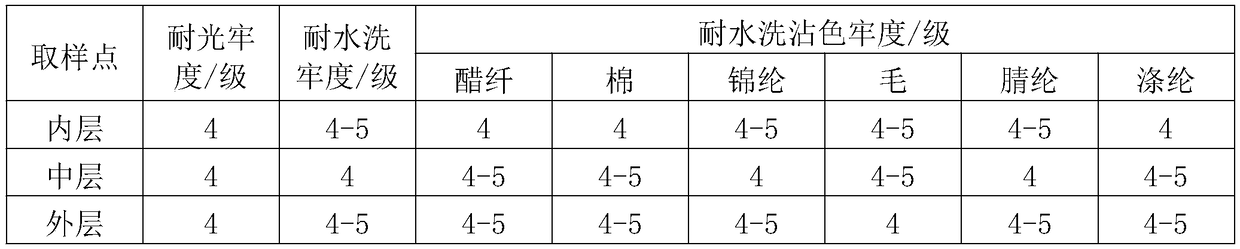

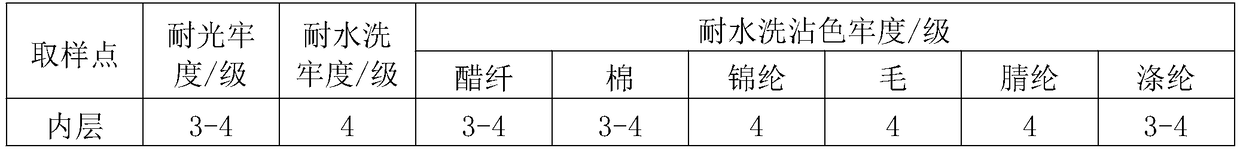

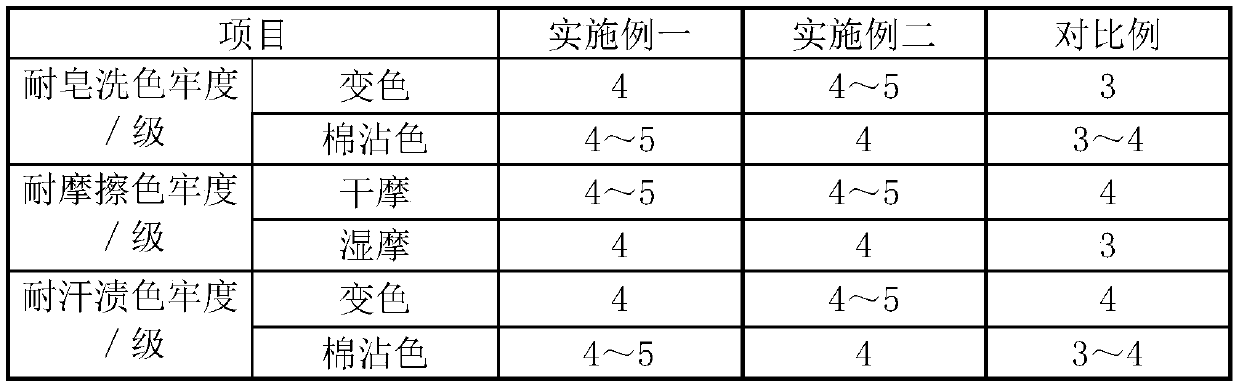

Production process of thin side-stretch fabric

InactiveCN109505049AImprove comfortHigh color fastnessSingeingHeating/cooling textile fabricsPolyesterFiber

The invention discloses a production process of a thin side-stretch fabric. The production process comprises the following steps of S1 warping, S2 beam dyeing pretreatment, S3 beam dyeing, S4 soapingand color fixing, S5 foam slashing, S6 weft yarn unwinding, S7 weft yarn pretreatment, S8 weft yarn dyeing, S9 weft yarn soaping, S10 weaving and S11 after treatment. According to the production process of the thin side-stretch fabric, warp yarn is dacron spandex core-spun yarn, beam dyeing and sizing are adopted, weft yarn is subjected to cone yarn dyeing, stain fabric weave is adopted, and therefore polyester fibers are arranged on one face of the fabric, and blended tencel and Coolmax fibers are presented on the other face of the fabric. The polyester fibers have the advantages of being resistant to wear, high in brute force and the like, the face, in contact with the skin, of the tencel and Coolmax fibers has the functions of being good in hygroscopicity, resistant to static and bacteria and the like, and the comfort of the fabric is improved. Beam dyeing and sizing are adopted, fluff and nep on warp yarn can be reduced, and weaving is conducted smoothly.

Owner:浙江鸣春纺织股份有限公司

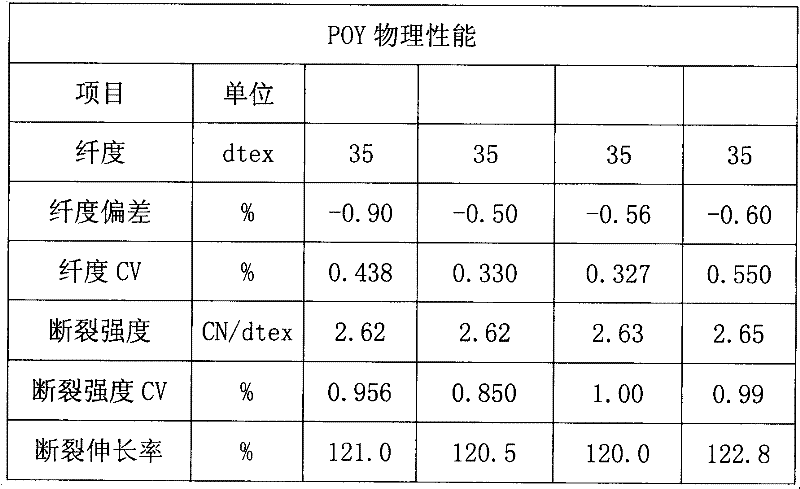

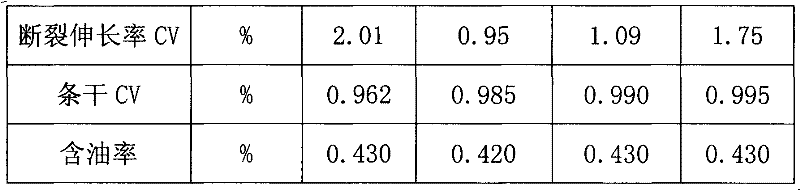

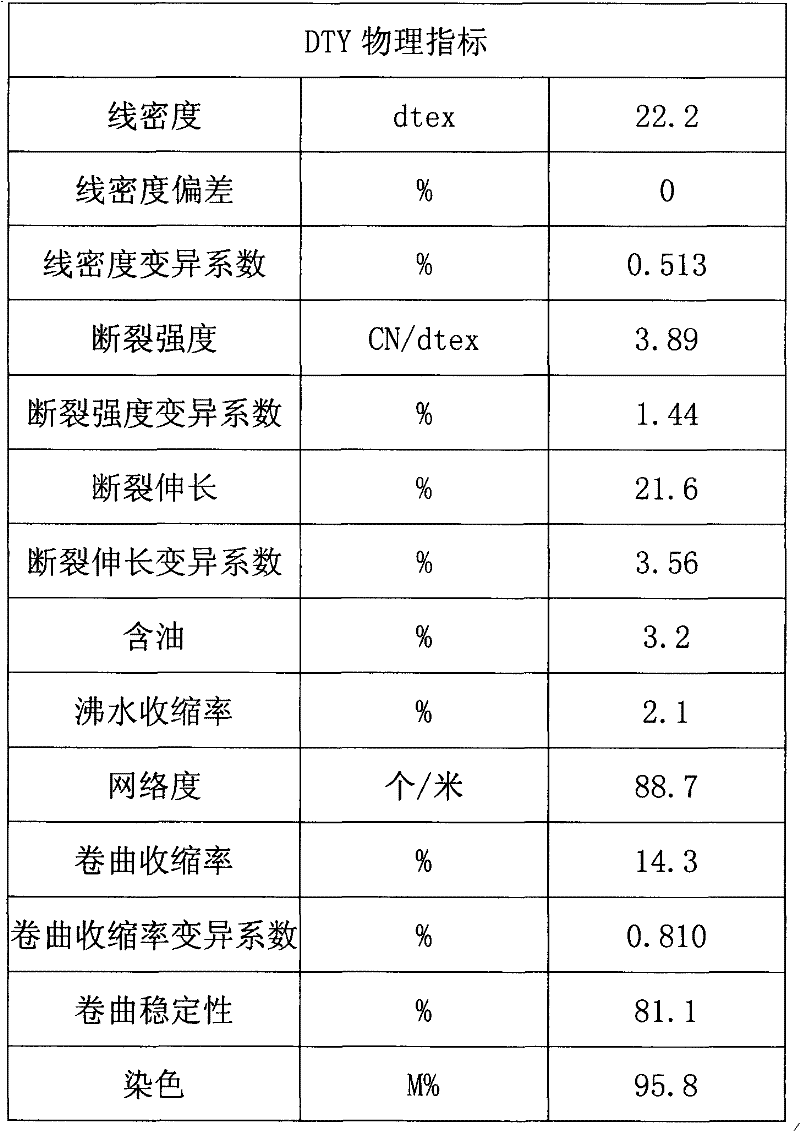

Ultrafine polyester draw textured yarns and method for processing same

InactiveCN102505226AImprove spinnabilityImprove stylingFilament/thread formingMonocomponent polyesters artificial filamentFiberYarn

The invention relates to ultrafine polyester draw textured yarns and a method for processing the same. The melt direct spinning technique is used for production of the yarns, pure terephthalic acid and ethylene glycol are subjected to esterification, and polyester melt is prepared by means of pre-polycondensation and final-polycondensation and used for direct spinning, and viscosity of the prepared polyester melt is 0.650. The ultrafine polyester draw textured yarns and the method for processing are characterized in that the specification 20D / 144F is adopted, circular blow and a POY (partially oriented yarn)-DTY (draw textured yarn) two-step process line are adopted for production. The method is reasonable, the fibers are fine in spinnability and excellent in physical indexes, broken ends of filaments are few, conversion success rate is high, dyeing uniformity can reach more than 99%, and full bobbin rate can reach more than 98%. The ultrafine polyester draw textured yarns are smooth in weaving, fabrics made of the ultrafine polyester draw textured yarns are light and soft and have good style, weaving requirements of high-grade apparel fabrics are met, and the grade and added values of products are improved.

Owner:JIANGSU SHENGHONG CHEM FIBRE CO LTD

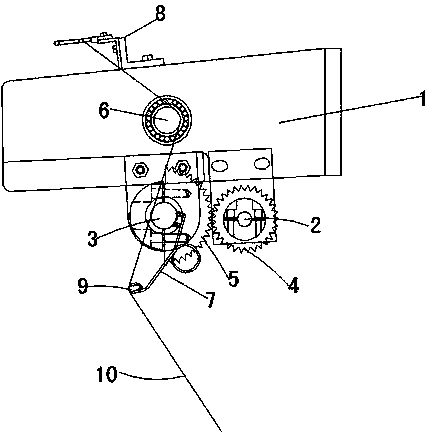

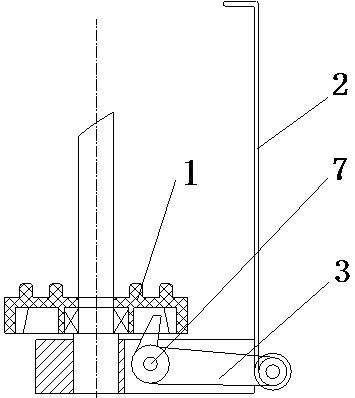

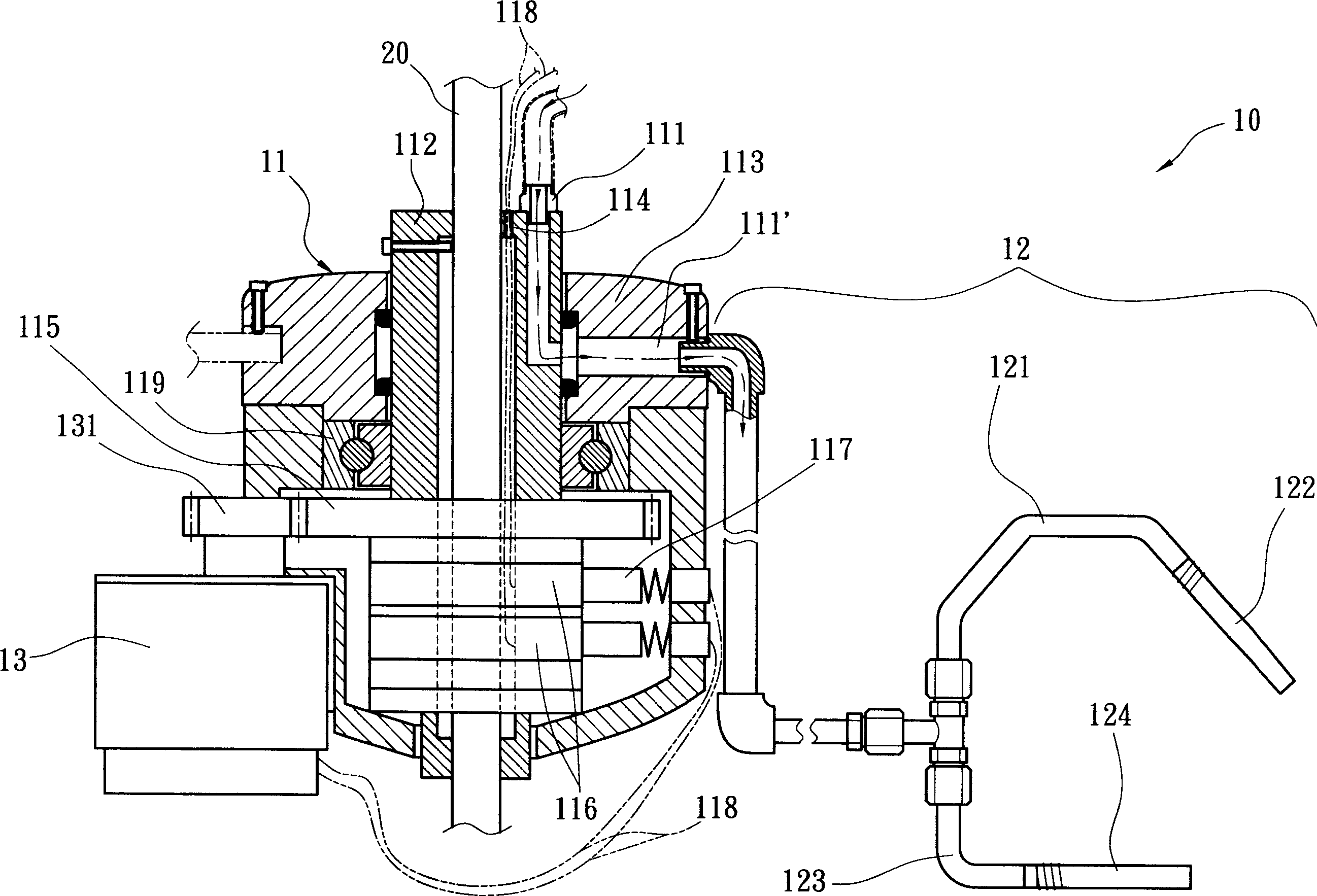

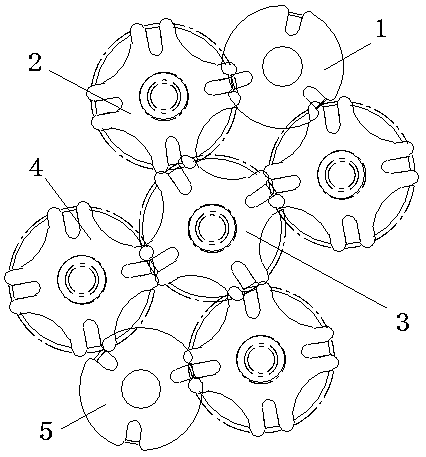

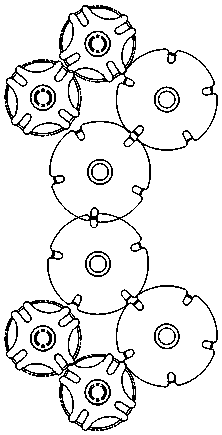

Pay-off braking device for spindle of high-speed braiding machine

InactiveCN102644159ALight and sensitive pay-offLine brakes are light and sensitiveBraidCircular discYarn

The invention relates to a pay-off braking device for a spindle of a high-speed braiding machine and belongs to a spindle braking structure of a braiding machine. The pay-off braking device comprises a spool base, a braking claw and a connecting rod, wherein one end of the braking claw is pressed on a side wall of an inner circular groove under the spool base; the other end of the braking claw is connected with the connecting rod; the spool base has a shape of a disc; a hole is formed in the middle of the disc; cylinders are uniformly distributed on the circumference of the same circle center as the hole; the inner circular groove is arranged under the disc; raised platforms are arrayed on an inner wall of the inner circular groove; the braking claw is L-shaped; the front end of the braking claw is pawl-shaped and moves in the inner circular groove under the spool base; a small hole is formed at a bent part of the braking claw and is sleeved on a pivot shaft; and the rear end of the braking claw is in sliding connection with the connecting rod. The pay-off braking device has the advantages that: a pay-off line is controlled by the pay-off braking device in a point contact way; the spindle pay-off is easy and flexible; the abrasion is small; the braking is accurate and gapless; a transmission part is simple in structure, low in cost, high in flexibility and long in service life; a rough yarn and a spun yarn are compatible; the yarn is free from being broken; and the braiding is uniform.

Owner:韩百峰

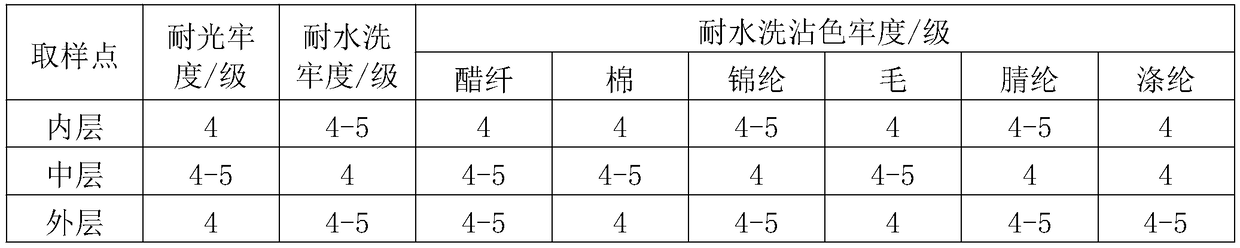

Production technology of beam-dyed double-layer two-way stretch fabric

The invention discloses a production technology of beam-dyed double-layer two-way stretch fabric. The production technology comprises the following steps: preparation of a surface beam, dyeing pretreatment of the surface beam, dyeing of the surface beam, soaping of the surface beam, foam slashing of the surface beam, preparation of a lining beam, pretreatment of the lining beam, dyeing of the lining beam, soaping of the lining beam, foam slashing of the lining beam, weaving and after finishing. According to the production technology of the beam-dyed double-layer two-way stretch fabric, the surface is formed by interweaving nylon fiber core spun yarn, and the lining is formed by interweaving corn spun yarn taking tencel and Coolmax as a coating layer. According to the double double-layer two-way stretch fabric, the surface has wear resistance of nylon fiber, the lining has moisture absorption and removal effect of the tencel and the Coolmax fiber, and the creativity and durability of the fabric are improved. Besides, yarn hairiness and neps on warp can be reduced by beam dyeing sizing, so that weaving is performed smoothly. The process of the production technology can be shortened and production efficiency can be improved.

Owner:浙江鸣春纺织股份有限公司

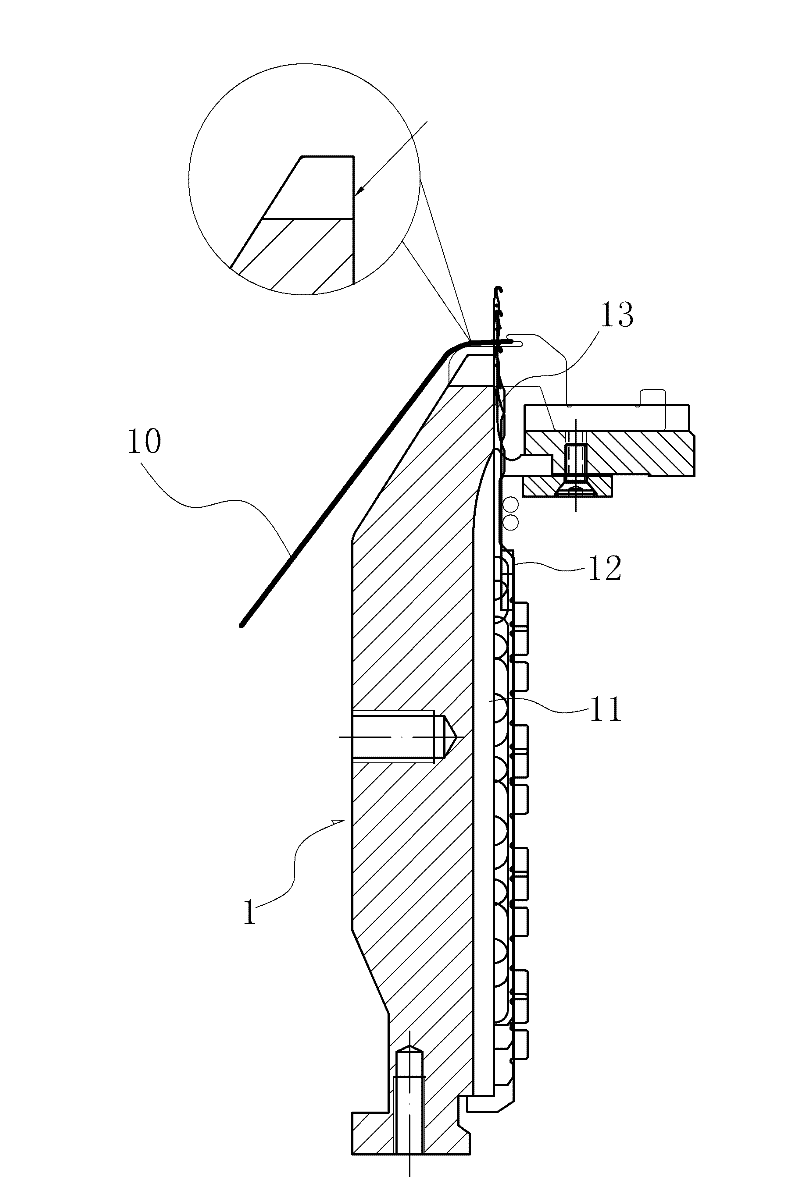

Wear-resistant structure of circular needle cylinder

InactiveCN102505317AExtended service lifeAvoid wear and tearWeft knittingWear resistantBiomedical engineering

The invention relates to the technical field of knitting machines, in particular to a wear-resistant structure of a circular needle cylinder. The wear-resistant structure comprises a needle cylinder, wherein a needle groove for containing a knitting needle is formed on the surface of the needle cylinder; a ring-shaped groove is formed in the position near the mouth of the needle cylinder; a wear-resistant wire is installed in the groove; and the knitting needle in the needle groove rubs with the wire in the reciprocation process. The wear-resistant structure has the following beneficial effects: the groove is formed in the position near the mouth and the ring-shaped wear-resistant wire is arranged in the groove, thus ensuring the unity of the hardness of the mouth of the needle cylinder and the hardness of the knitting needle; generally, the hardness of the wire is higher than that of the knitting needle, thus avoiding wear for a long time; when the knitting needle is used for knitting, wear of the mouth caused by stressed knitting can be completely eradicated; and besides, after the wear-resistant structure is adopted, smoother knitting of the knitting needle can be ensured, so that the quality of the knitted cloth cover is ensured and the service life of the needle cylinder is further prolonged.

Owner:洪荣豪

Pure cotton slub elastic stocking yarn and manufacturing process thereof

The invention discloses a manufacturing process for a pure cotton slub elastic stocking yarn and the pure cotton slub elastic stocking yarn manufactured by the process, and belongs to the field of spinning. The manufacturing process for the pure cotton slub elastic stocking yarn comprises the following steps of preparing raw materials; blowing; carding; drawing; roving; spinning; spooling; and performing high pressure setting. The pure cotton slub elastic stocking yarn comprises a yarn core; the yarn core is coated with a coating layer formed by blending carded cotton silvers and long stapled cotton silvers; and the coating layer comprises nubs and snicks at intervals. The pure cotton slub elastic stocking yarn manufactured by the process takes spandex silk as the yarn core, so a finished garment material is soft in handfeel, comfortable in wearing, and good in dyeing effect without color shading, and is suitable for current trends.

Owner:ANHUI YUHUA TEXTILE

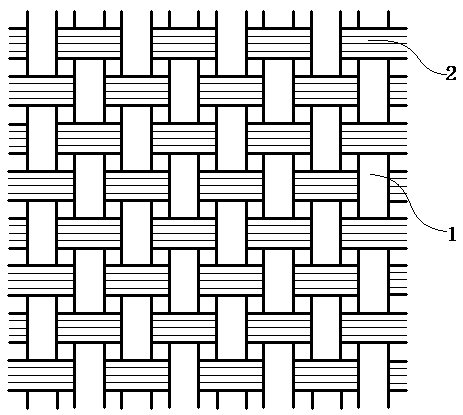

Textile fabric blended with graphene fibers

The invention discloses a textile fabric blended with graphene fibers. The textile fabric comprises warps and wefts. The warps and the wefts are transversely and longitudinally interwoven to form thetextile fabric. The warps are made of pure cotton yarns, the wefts are made of yarns, cotton fibers and the graphene fibers are blended to form the yarns, and a weight ratio of the cotton fibers to the graphene fibers in the wefts is 5-8:1; paraffin layers are smeared on the outer surfaces of the graphene fibers before the wefts are spun, and the average lengths of the graphene fibers for spinningthe wefts are 30-50 mm. The textile fabric has the advantages that the surfaces of the graphene fibers are preliminarily waxed, and accordingly the spinning properties of the graphene fibers can be improved to a certain extent; the graphene fibers and the cotton fibers are blended, and the yarns with certain quantities of graphene fibers can be formed under the assisting effects of large quantities of cotton fibers easy to spin when cotton threads account for most of the weight ratio; each pure cotton single yarn with relatively high structural strength and each cotton single yarn with low structural strength and blended with the corresponding graphene fibers are twisted with each other, and accordingly the integral strength of the textile fabric can be improved by the aid of twisting ofevery two corresponding single yarns.

Owner:FOSHAN LANRUI OUTE INFORMATION SERVICES CO LTD

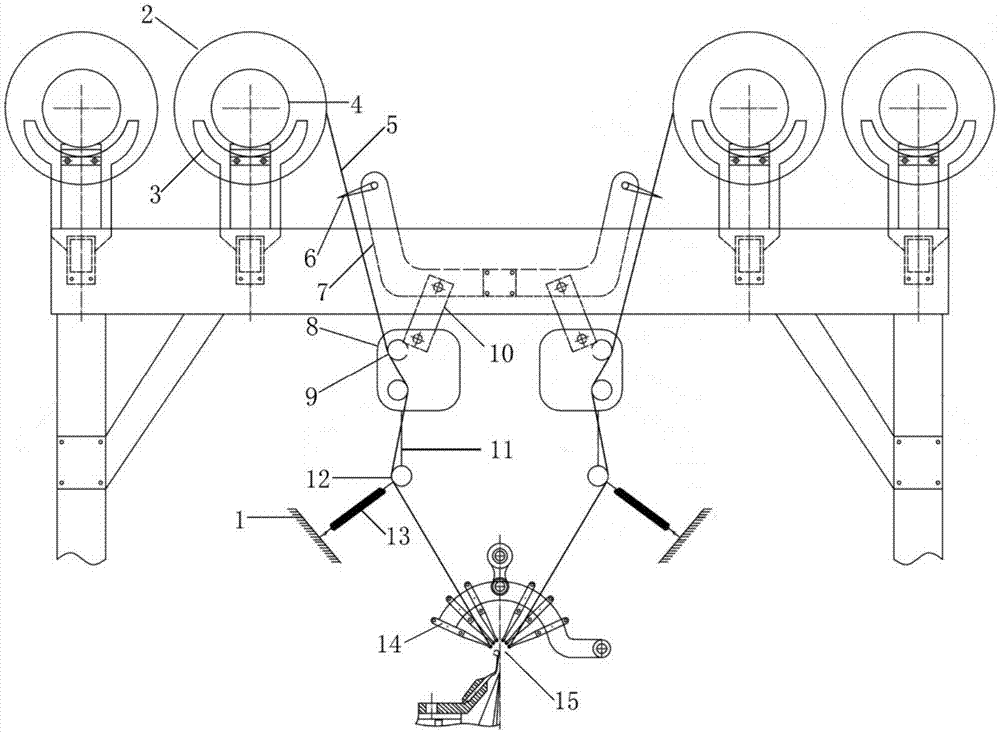

Symmetric warp let-off method and device of single needle bed warp knitting machine

ActiveCN107059237AConsistent tensionOvercoming Weaving EffectsWarp knittingYarn tensionWarp knitting

The invention relates to a symmetric warp let-off method and device of a single needle bed warp knitting machine. Yarns are conveyed to a weaving portion from a front side and a back side of a machine body of the single needle bed warp knitting machine respectively; and let-off paths of yarns at two sides of the machine body are mutually symmetrical, i.e., a symmetrical axis of the let-off paths is perpendicular to a central cross beam. The warp let-off device includes an even number of warp let-off systems which are horizontally symmetrical and positioned on the two sides of the machine body of the warp knitting machine; each warp let-off system includes a yarn unfolding mechanism, a yarn tension adjustment mechanism, and a looping mechanism; yarns are unfolded by the yarn unfolding mechanism, the tension of the yarns is adjusted by the yarn tension adjustment mechanism, and the yarns are conveyed to the looping mechanism. The influence of yarn tension difference on knitting can be avoided, the knittability of the yarns can be improved; a plurality of rows of yarn division needles and yarn guide needles can disperse extreme fine metal wires, tangled metal wires can be reduced, broken ends can be reduced, and the quality and the production efficiency of fabrics can be improved.

Owner:DONGHUA UNIV

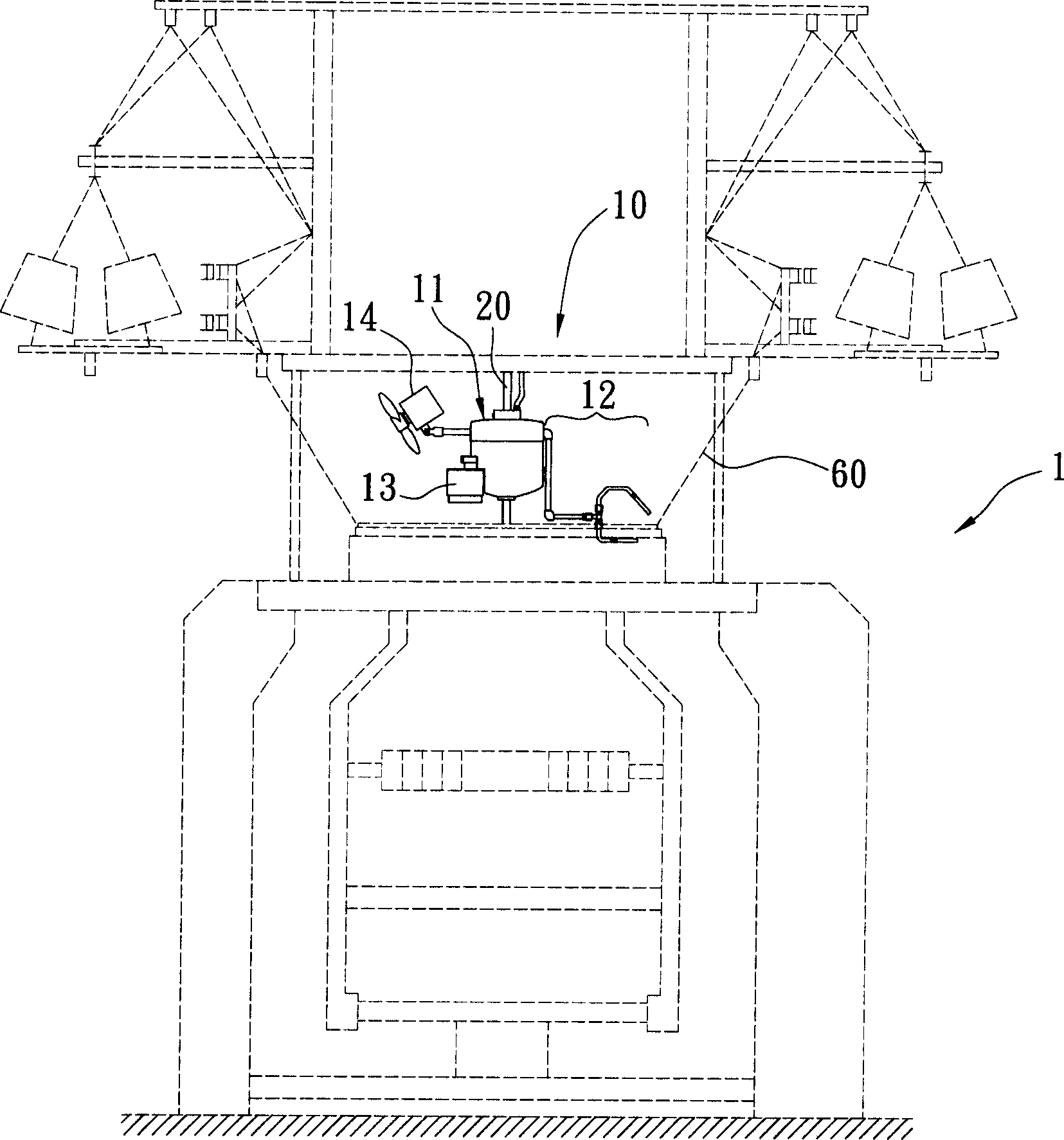

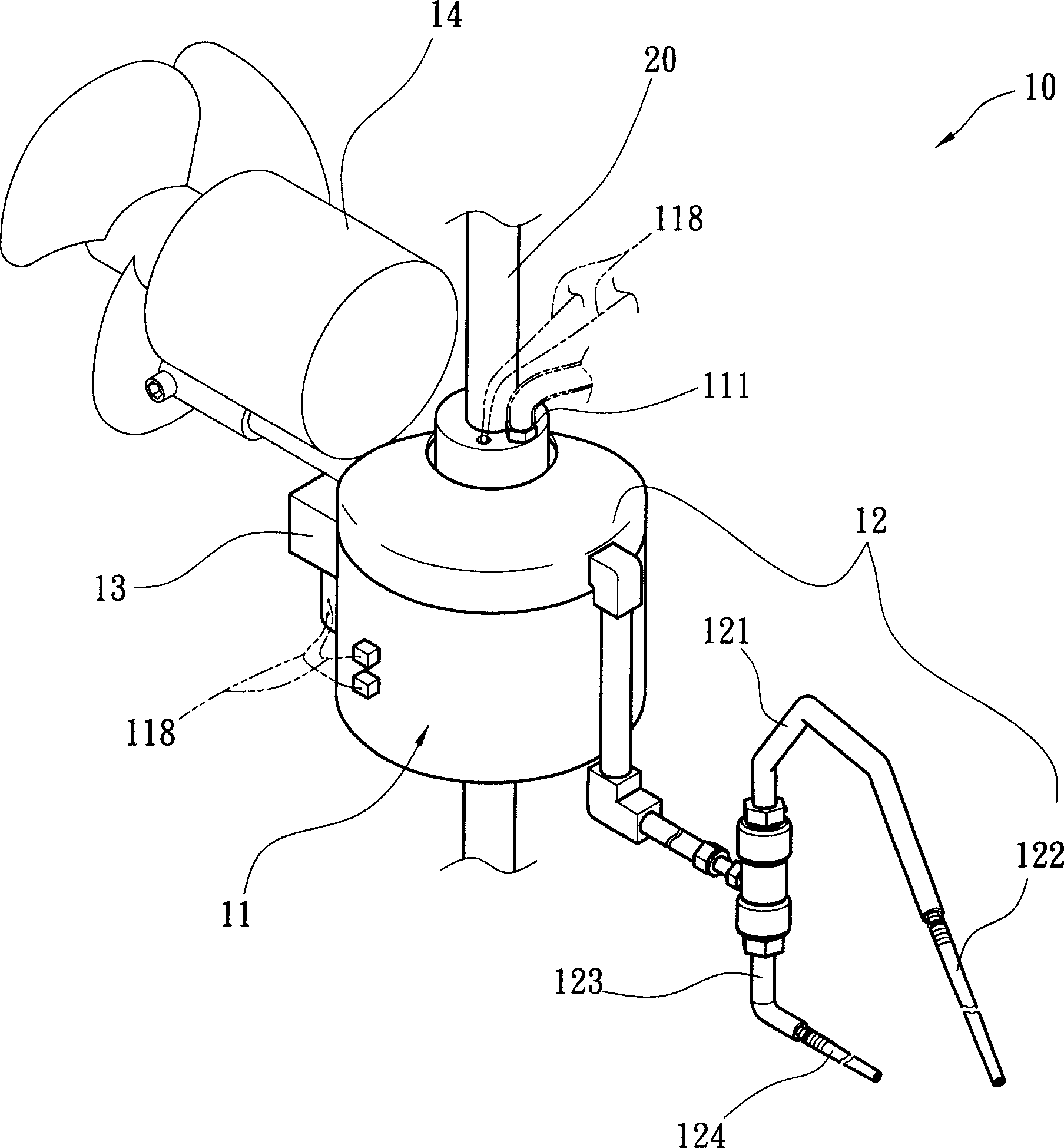

Flock blowing and heat radiation system for one-side circular knitting machine

The invention relates to the blowing and heat emission system of single-surface circular knitting machine, which comprises: one fixing rod, one rotation supplier, and one blower, wherein the rotation supplier has one fixing axle, one rotation gas supplier, and one driving motor, while the fixing axle has one gas inlet above, the rotation gas supplier has one channel through to the gas inlet, and through to the blower, to drive the fixing axle via the driving motor, to blow the cotton wool from the yarn eye of yarn plate, the yarn eye of yarn open and the weave needle; in addition, the invention can reduce the heat generated by the friction between the rotation of needle cylinder and the weave needle.

Owner:PAI LUNG MACHINERY MILL CO LTD

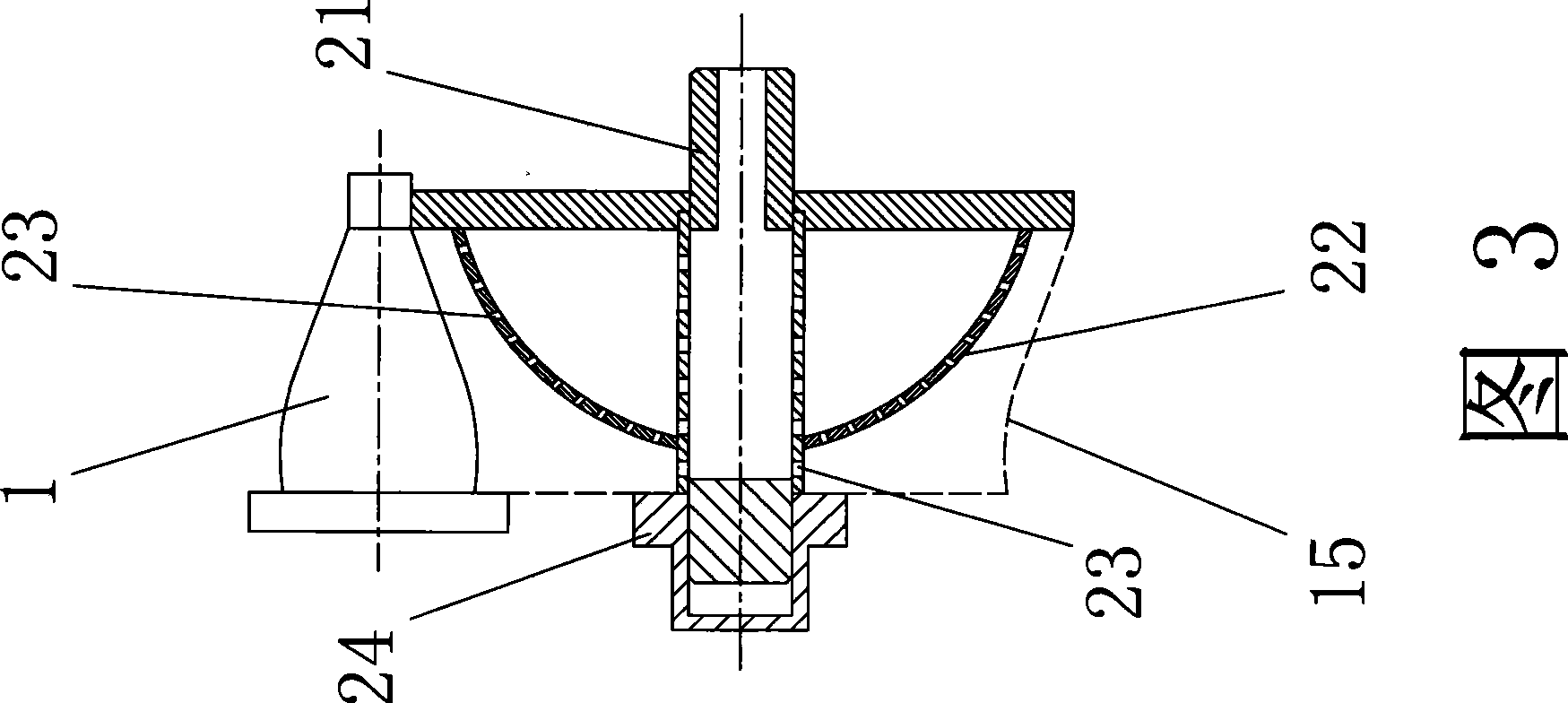

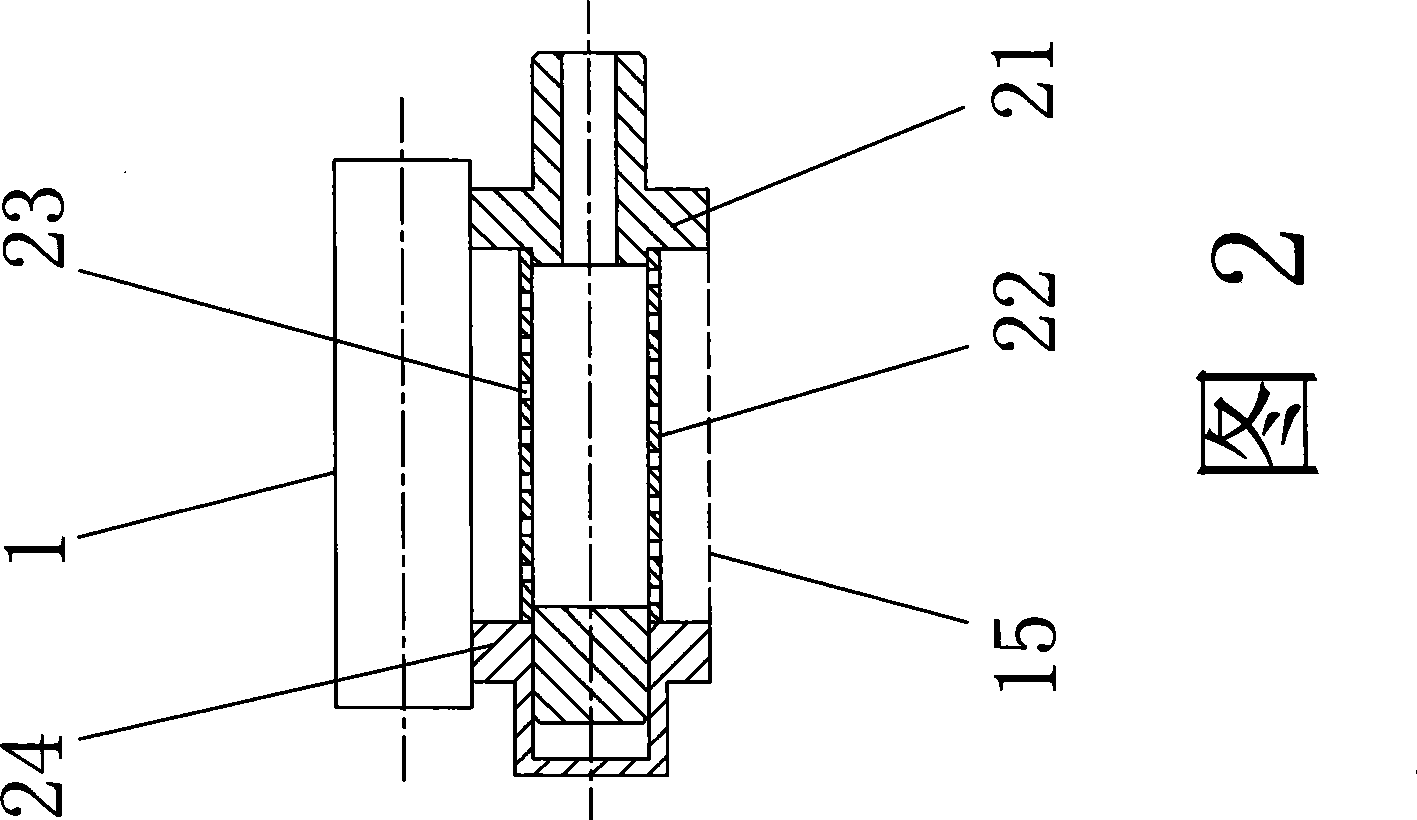

Flame-proof fibre product molding method and special equipment thereof

The invention discloses a method for molding a refractory fiber product and special equipment thereof. With the method, filtering molding can be realized by rotating a mould and pouring a refractory fiber suspension material, even interlacement and absorption of the fiber can be ensured through manually selecting and regulating the pouring position timely; a bore surface of a molded product is molded depending on an absorption surface of the mould; the periphery of the molded product is molded through rolling of the periphery of a compression roller, thereby ensuring the specification of the appearance of the molded product; and rapping of the molded product can be conveniently realized through rotating the mould positively and negatively under the pressure of the compression roller, thereby avoiding the problem of rapping difficulty by the prior method. The technical proposal has the advantages of simple mould, convenient operation, high production efficiency, easy rapping, even interlacement of product fiber, good rupture strength and the like.

Owner:姚志刚

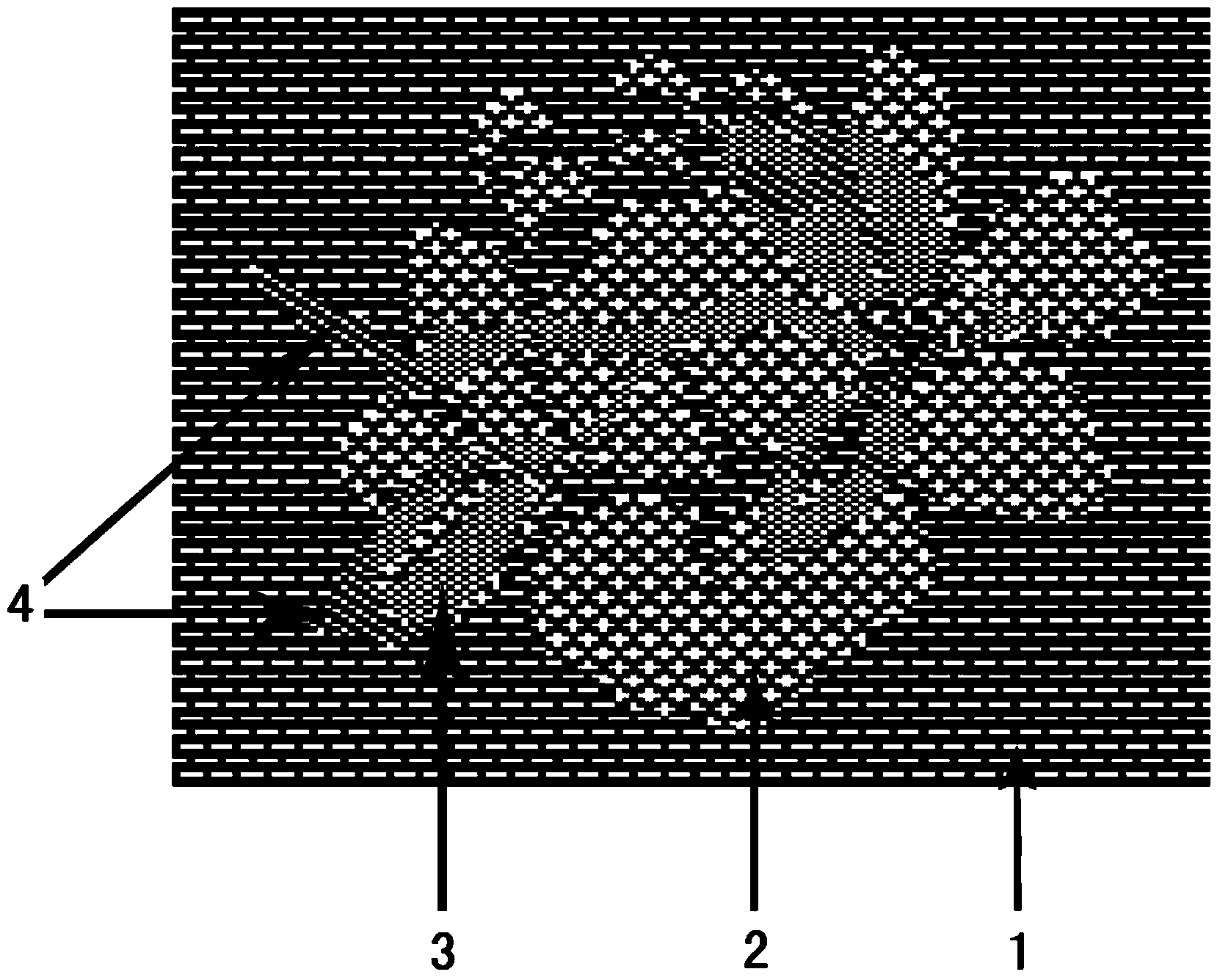

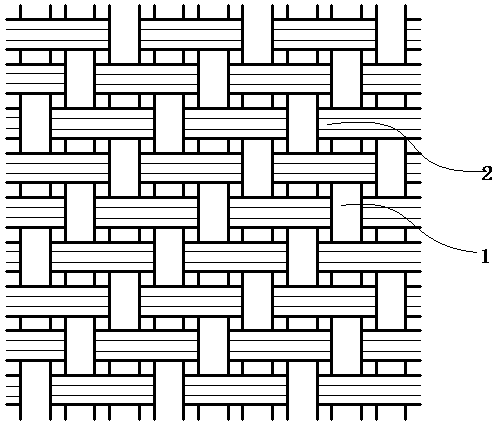

Nuclear radiation shielding alloy lead fiber woven fabric

InactiveCN102650088AHas the function of shielding nuclear radiationWeave evenlyShieldingWoven fabricsYarnNuclear radiation

A nuclear radiation shielding alloy lead fiber woven fabric relates to the field of nuclear radiation protection biological shielding technology and is particularly applicable to the technical field of core materiasl for the production of nuclear radiation biological protection flexible shielding products. According to the nuclear radiation shielding alloy lead fiber woven fabric, nuclear radiation shielding alloy lead fiber yarns with the diameter of 0.01 mm-1 mm are arranged in the weft direction, and nuclear radiation shielding alloy lead fiber yarns with the diameter of 0.001 mm-1 mm and glass fiber yarns with the diameter of 0.05-0.5 mm are arranged in the warp direction. The nuclear radiation shielding alloy lead fiber woven fabric not only has a certain function of shielding nuclear radiation, but also ensures the weaving process to proceed smoothly by adopting the glass fiber yarns, meanwhile, the tensile strength of products is improved, and the follow-up production of light, thin and material-saving nuclear radiation shielding products is facilitated.

Owner:扬州锦沃科技有限公司

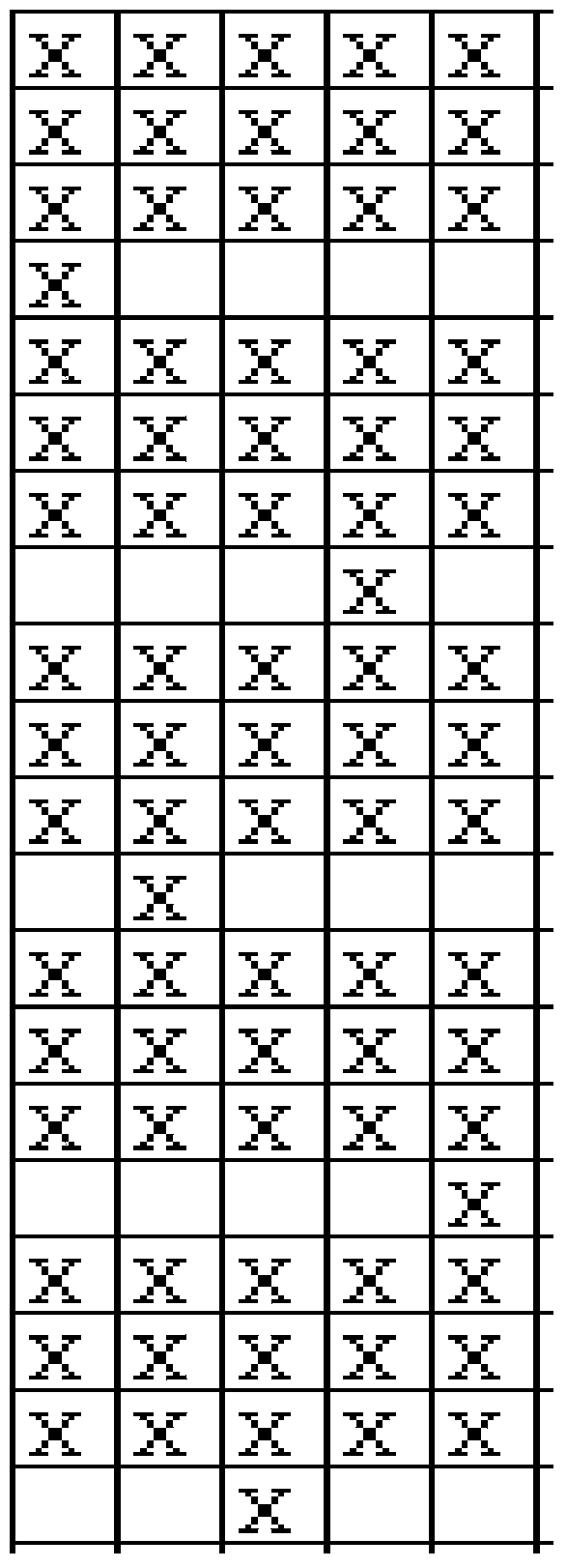

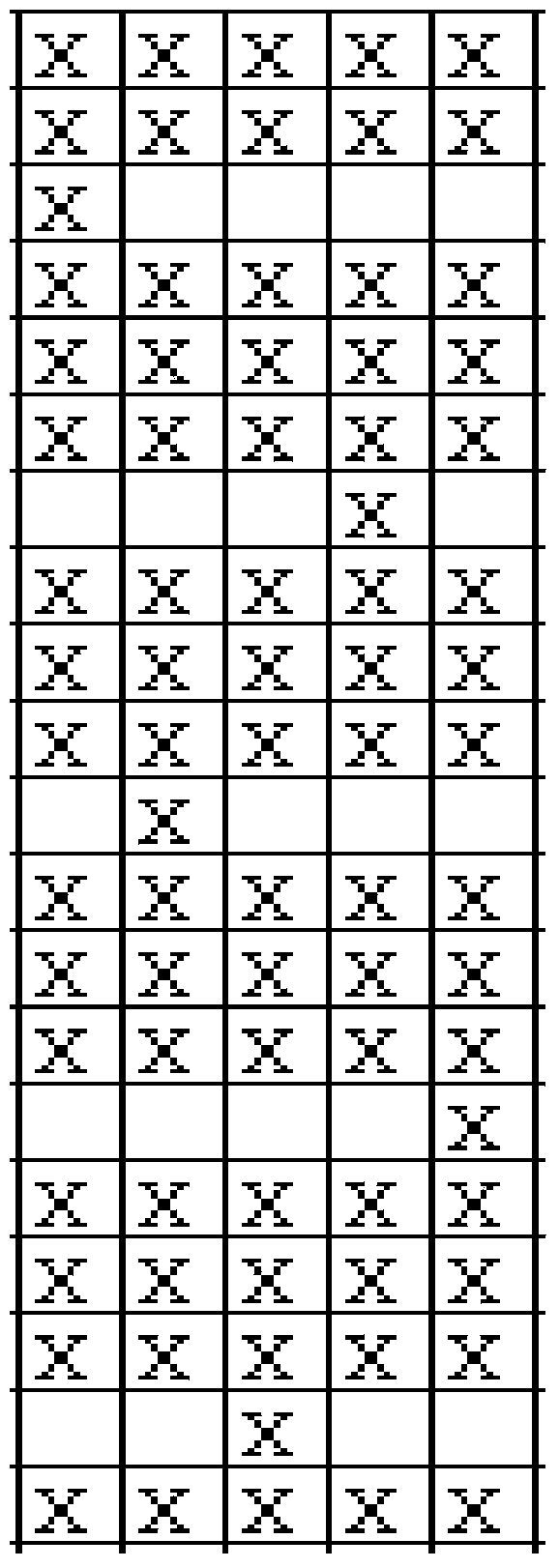

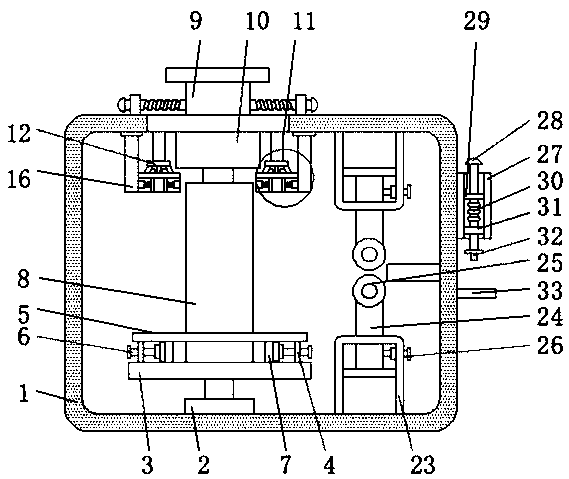

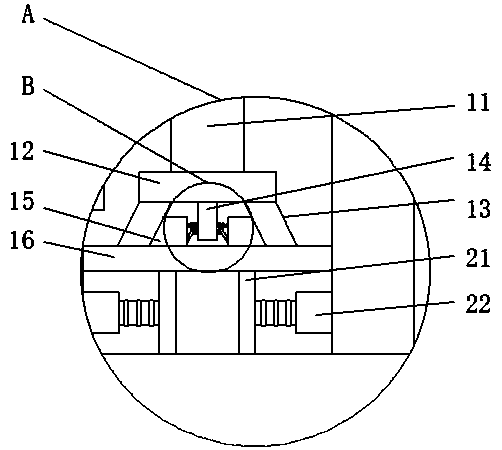

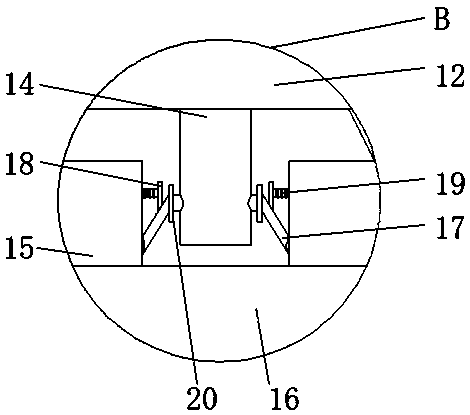

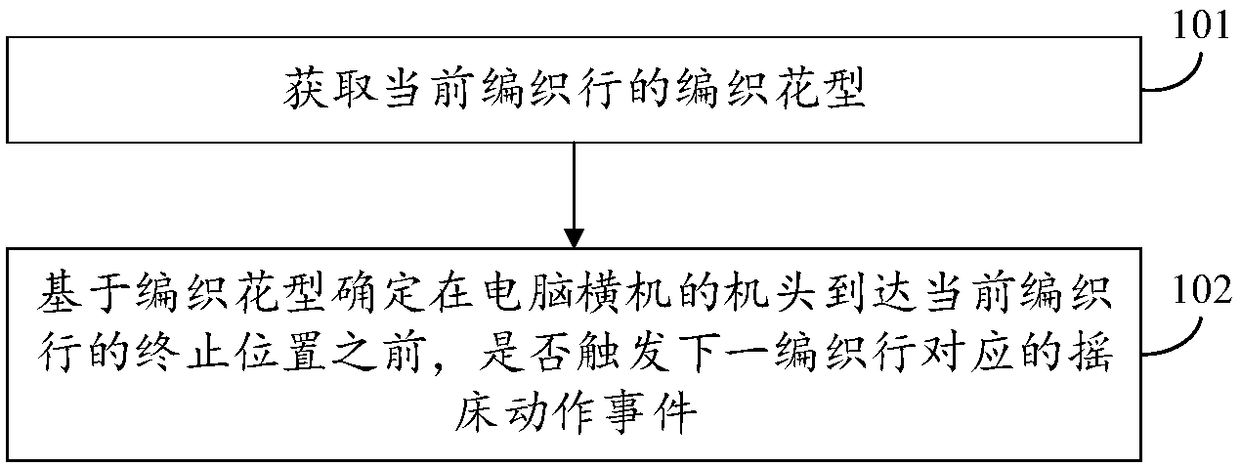

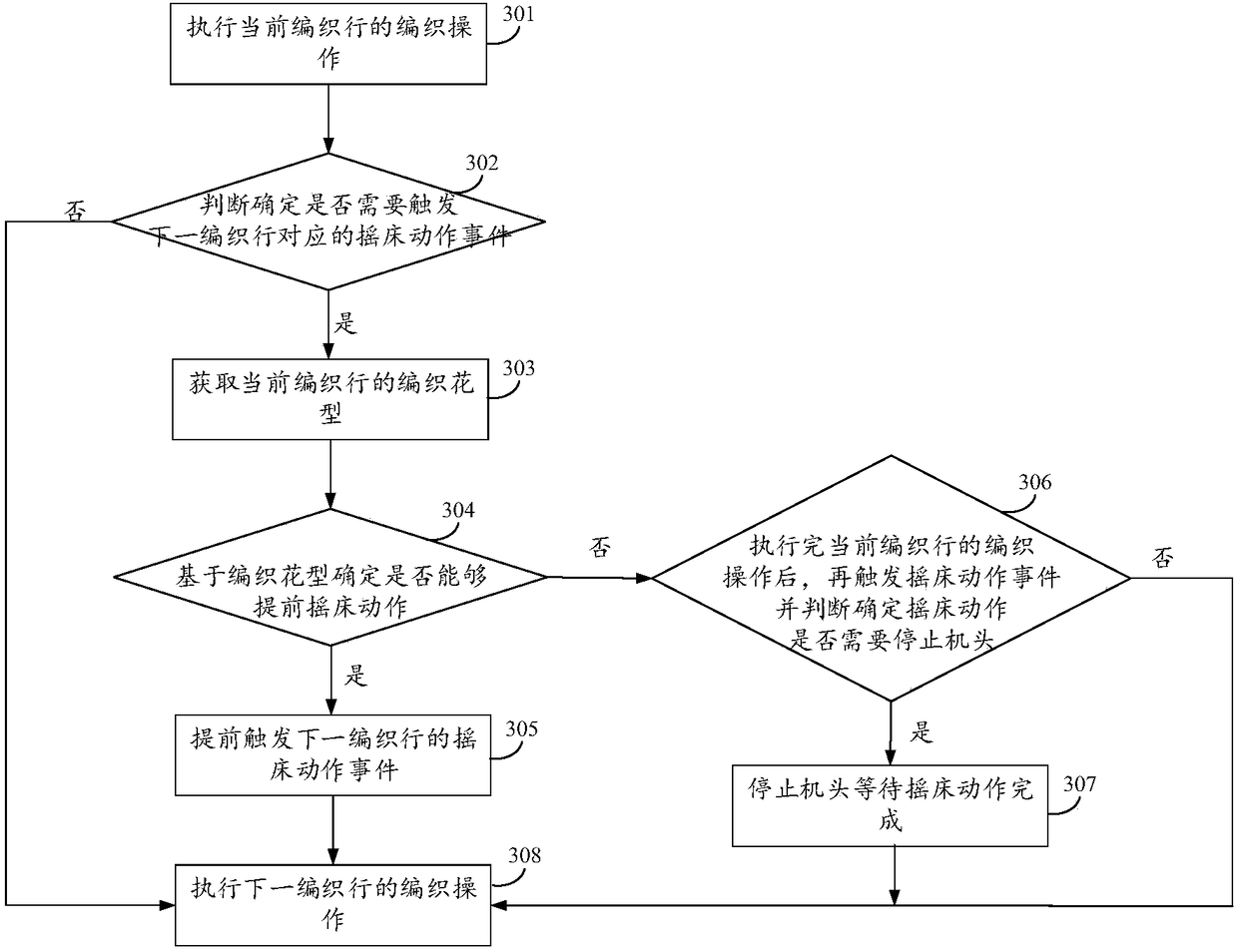

Computerized flat knitting machine, knitting method thereof and device with storage function

The invention discloses a computerized flat knitting machine, a knitting method thereof and a device with a storage function. The knitting method comprises the steps of obtaining a knitting pattern style of a current knitting line; based on the knitting pattern style, before a machine head of the computerized flat knitting machine reaches the ending position of the current knitting line, determining whether to trigger a table motion event corresponding to the next knitting line or not. By means of the knitting method, by adding judgment conditions on whether a table motion can be advanced or not according to the knitting pattern style, the unnecessary waiting time for stopping the machine head during running of the computerized flat knitting machine is shortened, so that knitting is more coherent, and the production efficiency is improved.

Owner:FUJIAN RAYNEN TECH

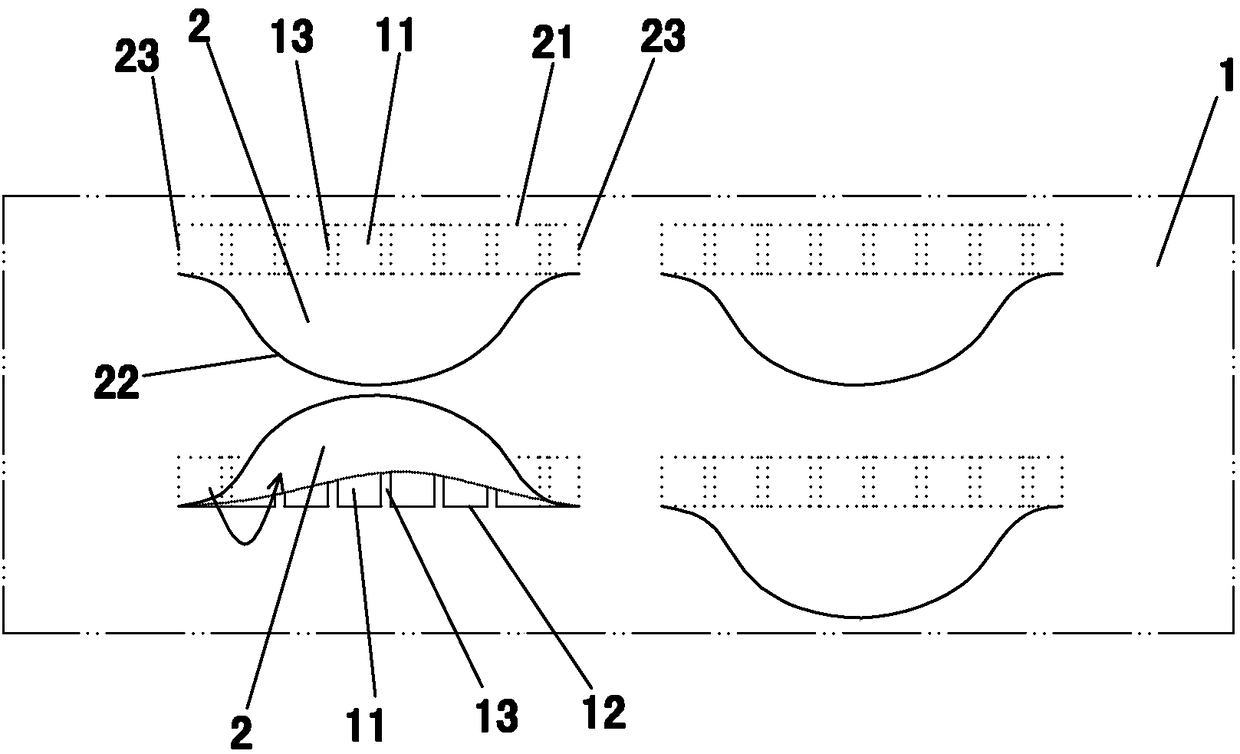

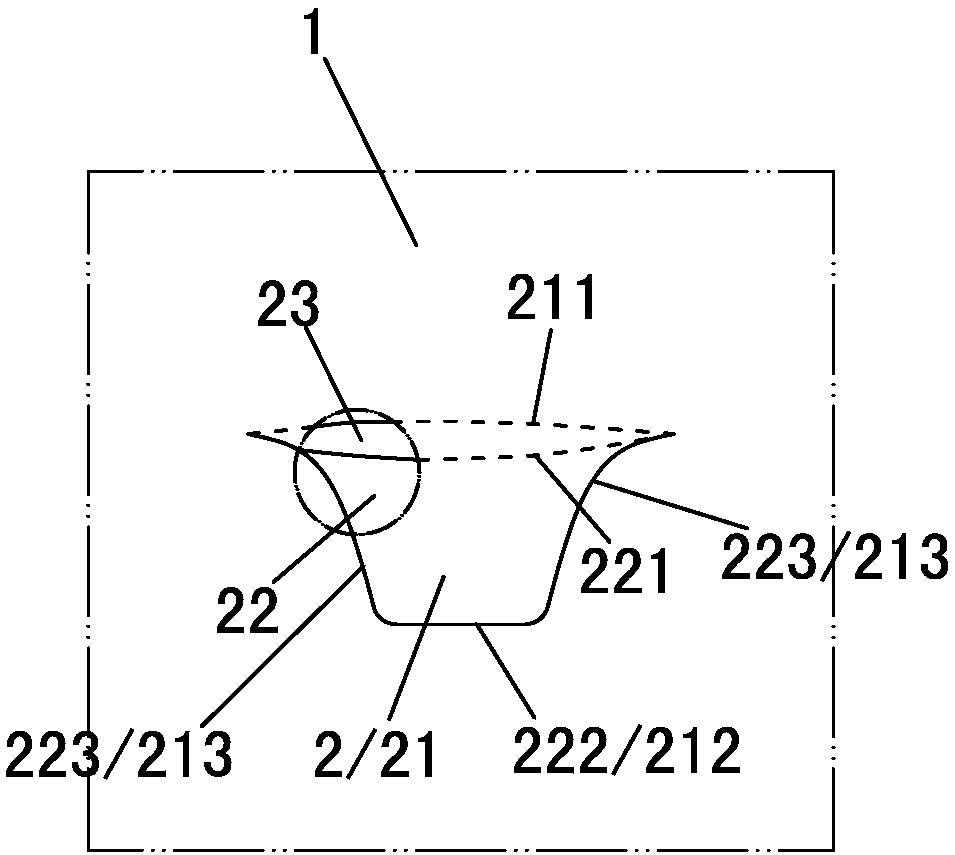

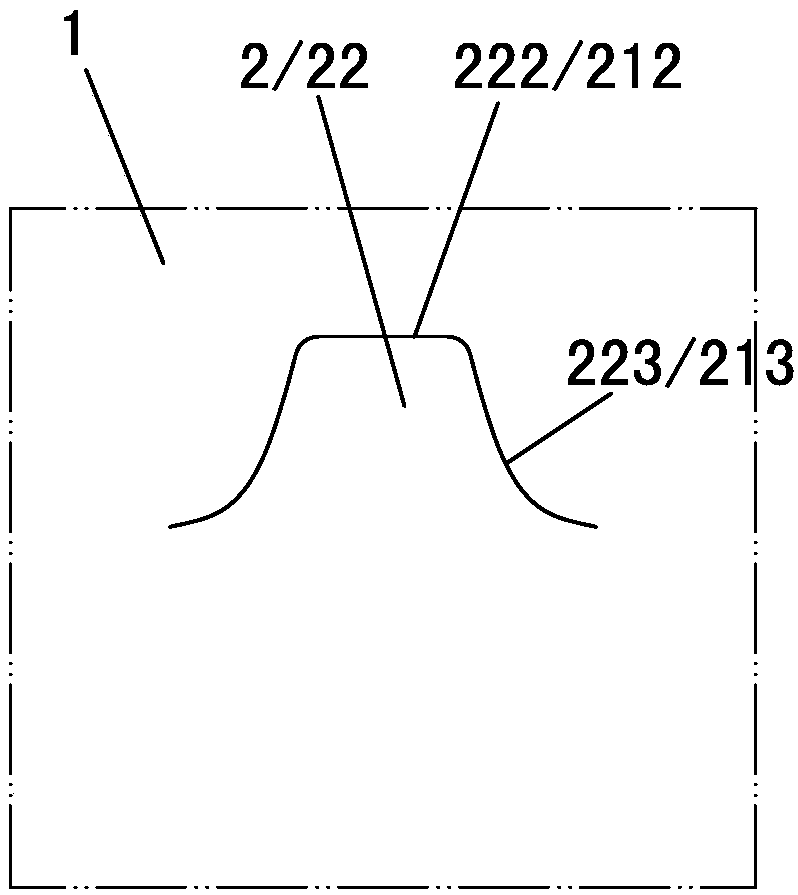

Fabric with ear piece structure formed by knitting and knitting method thereof

PendingCN108588998AGood molding effectThe molding effect is good-lookingWeft knittingUpperYarnEngineering

The invention discloses a fabric with an ear piece structure formed by knitting and a knitting method thereof. The fabric comprises a fabric body. The ear piece structure is integrally knitted on thefabric body. The ear piece structure comprises a first layer and a second layer. Each of the first layer and the second layer comprises a connecting side, an outer edge and a suture side. The outer edges are in knitted connection, the suture sides are correspondingly in suture connection,, and an ear piece opening is formed between the connecting sides. The knitting method includes the following steps that 1), a hosiery machine with a work drum capable of rotating forwards and reversely is adopted; 2), patterns are input in the hosiery machine, and yarn penetrates through a yarn nozzle; 3), the hosiery machine is started, and knitting is carried out till the fabric is obtained. In the step 3), starting from the situation that the fabric body is knitted to the connecting side of the first layer of the ear piece structure, the work drum rotates forwards and reversely, the fabric body continues to be knitted to the connecting side of the second layer, other parts stop being knitted when the ear piece structure is knitted, and other parts continue to be knitted after the ear piece structure is knitted. According to the fabric structure, the problem that a knitted fabric is single in structure can be relieved, and the appearance of the fabric structure is richer and more stereoscopic.

Owner:福建荣荣新材料股份有限公司

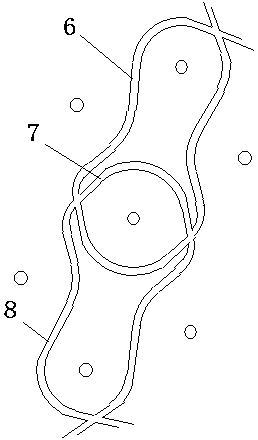

Entwined drive-cross system for national costume decoration belt knitting machine

The invention relates to an entwined drive-cross system for a national costume decoration belt knitting machine, and belongs to the national costume decoration belt knitting machine. The number of front-transition gear driving plates and rear-transition gear driving plates of the entwined drive-cross system is separate two; front-rotation gear driving plates and rear-rotation gear driving plates are separately meshed with the two front-transition gear drivings and the two rear-transition gear driving plates to form a front transmission system and a rear transmission system, an entwined weavingsystem is formed between the front transmission system and the rear transmission system through common gear driving plates meshed with each other, and adjacent drive-cross slots are aligned synchronously during operation; the rear part of a front guide rail overlaps the front part of a rear guide rail to form a common guide rail; the intersection of the front guide rail and the rear guide rail islocated on one side of the rear guide rail; and the diameter of the front guide rail at the common guide rail is larger than that of the rear guide rail. The entwined drive-cross system for the national costume decoration belt knitting machine has the advantages that the guide rail of the knitting machine has no spindle interference phenomenon, the shape of the machine is reduced, and the space is saved; the reduction of the number of teeth of a drive-cross gear increases the rotation speed of the machine, and the production volume increases with the improvement of the rotation speed of the machine; and a spindle is woven evenly smoothly, and the weaving quality is improved.

Owner:XUZHOU HENGHUI BRAIDING MACHINE

Roller device of flat knitting machine

The invention discloses a roller device of a flat knitting machine. The roller device comprises a cam device, a coupler device and a tension spring device, wherein the cam device comprises a cam and a bearing; the coupler device is mounted between the bearing and a driven gear; and the tension spring device is provided with a steel wire rope which is fixed on the bearing of the cam device. The roller device of the flat knitting machine has the advantages that a roller can be timely reset accurately after being opened thoroughly, and the position of a gear connected with the roller cannot be changed even if the position of the roller is changed, and the purpose of smoothly weaving is achieved.

Owner:NINGBO CIXING

Inorganic fireproof roller shutter fabric and production method thereof

ActiveCN102242438BImprove the current situation of low refractory temperatureSimple structureFibre treatmentWoven fabricsYarnFiber

The invention relates to an inorganic fireproof rolling curtain fabric, which is made of aluminum silicate yarn and stainless steel wire through parallel twisting, warping, sizing, threading and weaving. The inorganic fireproof rolling fabric of the present invention can be spun smoothly without adding organic fibers, which effectively improves the current situation of low fire resistance temperature of the fireproof rolling fabric caused by the addition of organic fibers in the prior art. And without the auxiliary effect of fire-resistant coating, the fire-resistant time can reach 180min, and the fire-resistant temperature exceeds 1100°C. The structure is simple, and it can be woven smoothly by using common looms. The inorganic fireproof roller blind fabric of the present invention can be used as an inorganic super fireproof roller blind base cloth, can play good fireproof and heat insulation functions without the auxiliary function of a water curtain, and is convenient to use. Inorganic fireproof rolling fabric adopts the production method of aluminum silicate yarn and stainless steel wire twisting together, which improves the dimensional stability of the fabric and will not cause deformation of the fabric surface due to multiple windings.

Owner:应急管理部四川消防研究所

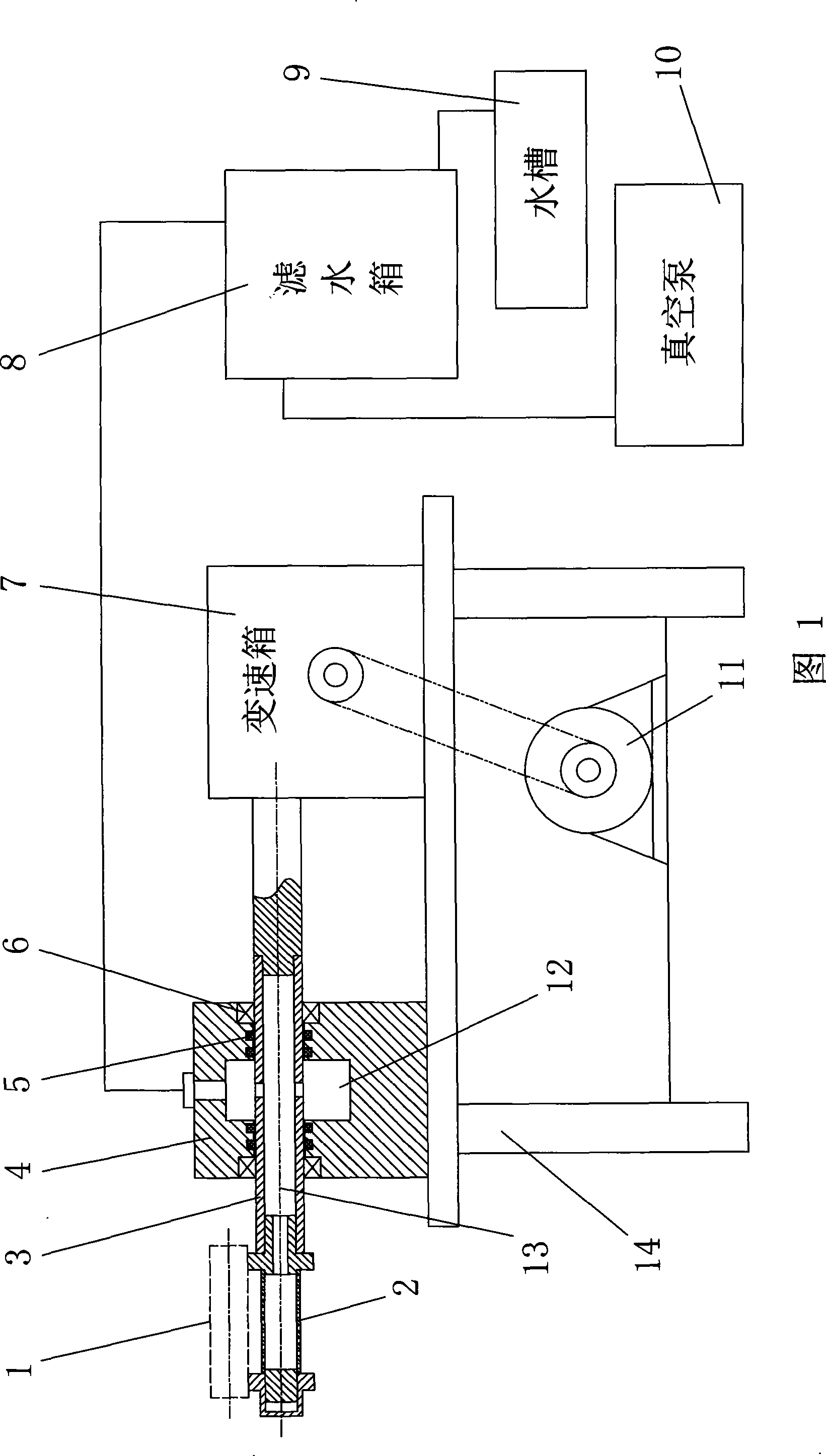

Vacuum reverse sucking technology for shaping refractory fibre products

InactiveCN1124192CWeave evenlyReduce labor intensityCeramic shaping apparatusAbnormal shapedThermal conductivity

A vacuum reverse-sucking technology for manufacturing refractory fibrous product features that the mould for manufacturing the said refractory fibrous product is turned over by 180 deg.C to make its sucking mouth deconward, the vacuum sucking region has multiple cavities and multiple segments, and the sucking net is composed of overlapped multiple layers. Its advantages include precise control of volume density, uniform fibre interleaving, high antiflex cracking strength and low thermal conductivity.

Owner:LUYANG ENERGY SAVING MATERIALS CO LTD

Simple and convenient production method of knitted paper strings

The invention discloses a simple and convenient production method of knitted paper strings. The simple and convenient method comprises the following steps: (A) dividing paper: cutting base paper with definite gram weight so as to obtain paper strip reels with specified width through a paper dividing machine or a paper cutting machine; (B) immersing the paper for humidifying: blending 2-8% environment-friendly silicone oil with water so as to obtain a water-oil solution, completely immersing the paper strip reels divided and cut in the step (A) into the water-oil solution, after the paper strip reels are soaked for a definite time, taking out the soaked paper strip reels, airing the paper strip reels till the paper strip reels have appropriate humidity, and then enabling the paper strip reels to be loaded on a bearded needle machine for knitting strings; (C) weaving strings: levelly placing the paper strip reels which are aired to have the appropriate humidity to a material placing platform of the bearded needle machine, enabling the paper strip reels to directly penetrate through a string guiding hole to a needle barrel of the bearded needle machine for weaving the strings, exerting twist on paper through the rotation of the bearded needle machine around a circle of the bearded needle machine when the bearded needle machine is used for knitting the strings, and further knitting the paper into needle-penetrating paper strings. According to the making method of the needle-penetrating paper strings disclosed by the invention, the middle complex working procedure of spinning paper yarns can be eliminated; besides, after the working procedure is eliminated, when the strings are hooked, the operation is smooth, the needles are not liable to block, and the hand feel of woven strings is soft and comfortable; in addition, the use of varied industrial addition agents is also eliminated.

Owner:余智华

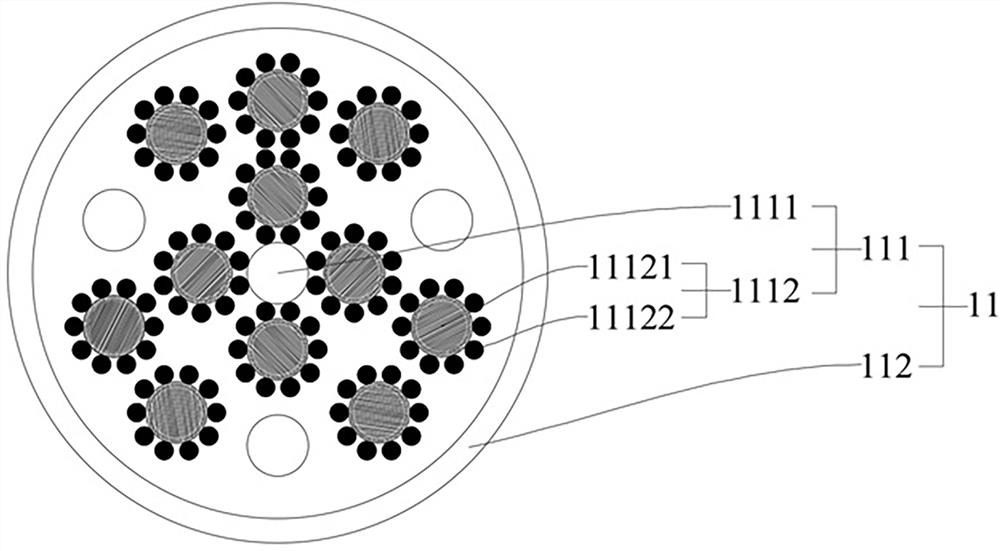

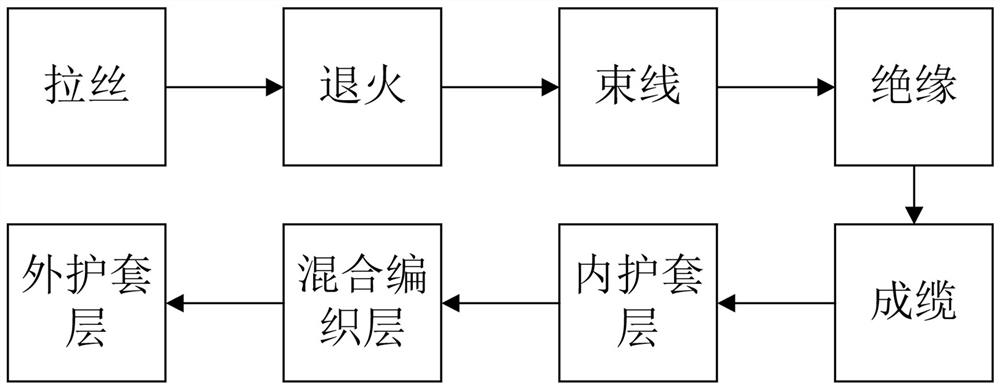

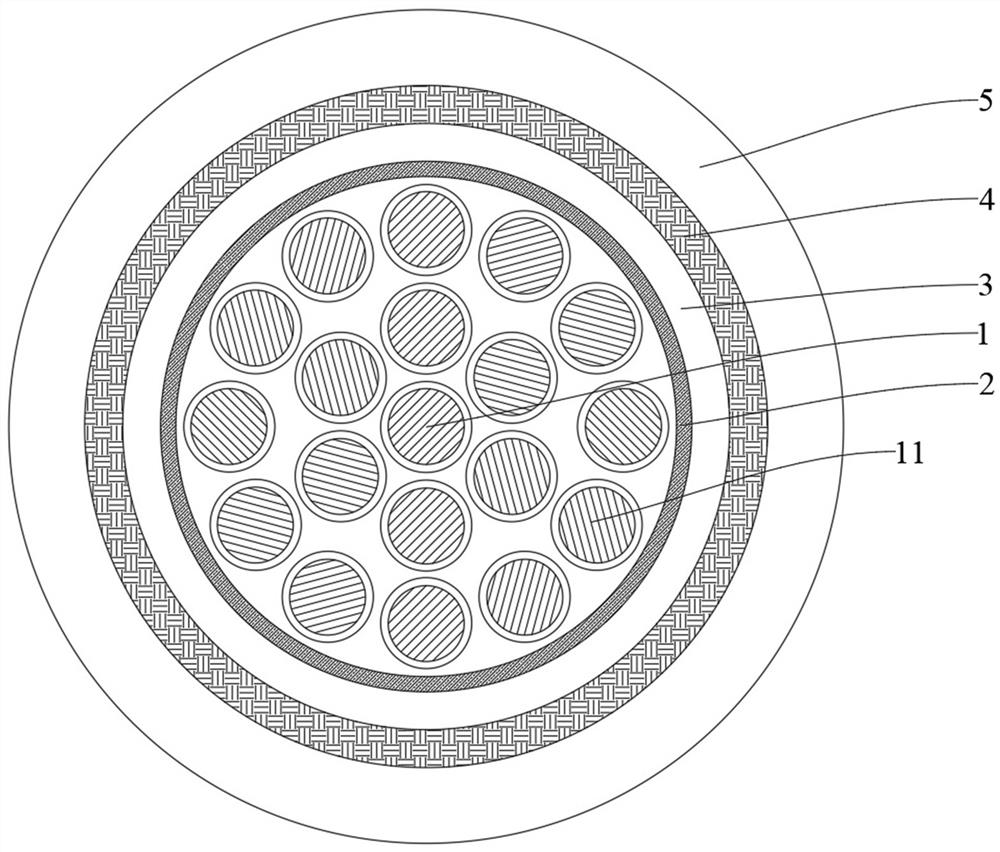

Long-life-cycle anti-torsion cable for offshore wind power

ActiveCN112908539AHigh tensile strengthIncreased torsional strengthPlastic/resin/waxes insulatorsLiquid organic insulatorsFiberElectrical conductor

The invention relates to the field of power cables, in particular to a long-life-cycle anti-torsion cable for offshore wind power, which comprises a cable core formed by a plurality of insulating wire cores and a wrapping tape layer wrapping the surface of the cable core, the outer surface of the wrapping tape layer is coated with an inner sheath layer; the outer surface of the inner sheath layer is coated with a mixed braid layer; and the outer surface of the mixed braid layer is coated with an outer sheath layer. Each insulating wire core comprises a conductor and an insulating layer wrapping the conductor. The conductor is formed by mixing and winding a plurality of copper wires and a plurality of fiber copper composite wires; each fiber copper composite wire comprises an organic fiber in the center and one or more layers of copper foils spirally wound on the outer surface of the organic fiber; the fiber copper composite wires can achieve the purposes of high-strength tensile strength, torsion resistance and light weight; and the cable is applied to a control system of an offshore high-power generator set or a control system of a land wind turbine generator set.

Owner:TBEA DEYANG CABLE CO LTD

Preparation method for on-line pulling and extruding glass steel tube with multilayer annular weaving structure

InactiveCN100581794CWeave evenlyHigh precision of inner and outer diameterTubular articlesFiberSteel tube

The invention relates to the making of multi layer knitting structure on the wire pulling glass steel tube using several computers controlling the two dimensional horizontal knitter, using core mold, stretch mold, extractor synthesizing the glass steel tube, setting resin dipping slot at the back of each knitter, even direct core mold at both ends of the core mold that follows with the movement of the ring knitting layer in the direction from the first two dimensional horizontal knitter to the last knitter through the dipping slot to the stretch mold. The glass tube in and out radius has high precision, thickness of each knitting layer adjustable, even in each dipping and consistent in strength.

Owner:郝跟进

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com