Fabric with ear piece structure formed by knitting and knitting method thereof

A technology of lugs and fabrics, applied in the direction of weft knitting, knitting, textiles and papermaking, which can solve the problems of monotony and unsightly appearance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] In order to further explain the technical solution of the present invention, the present invention will be described in detail below through specific examples.

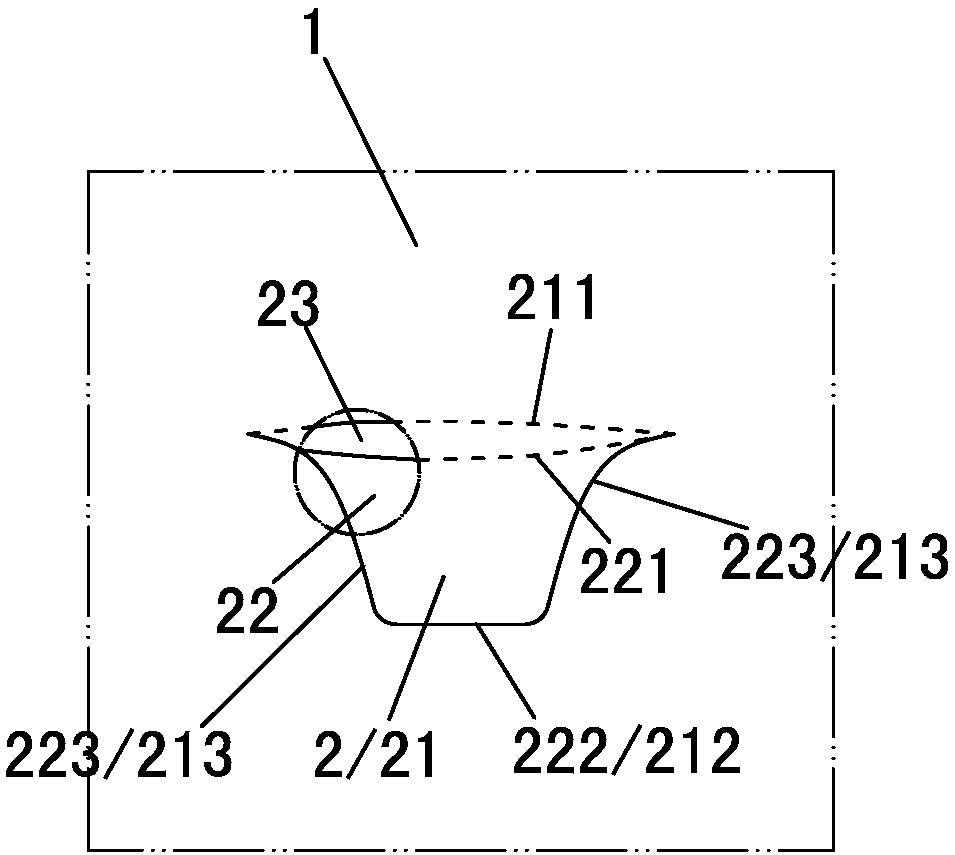

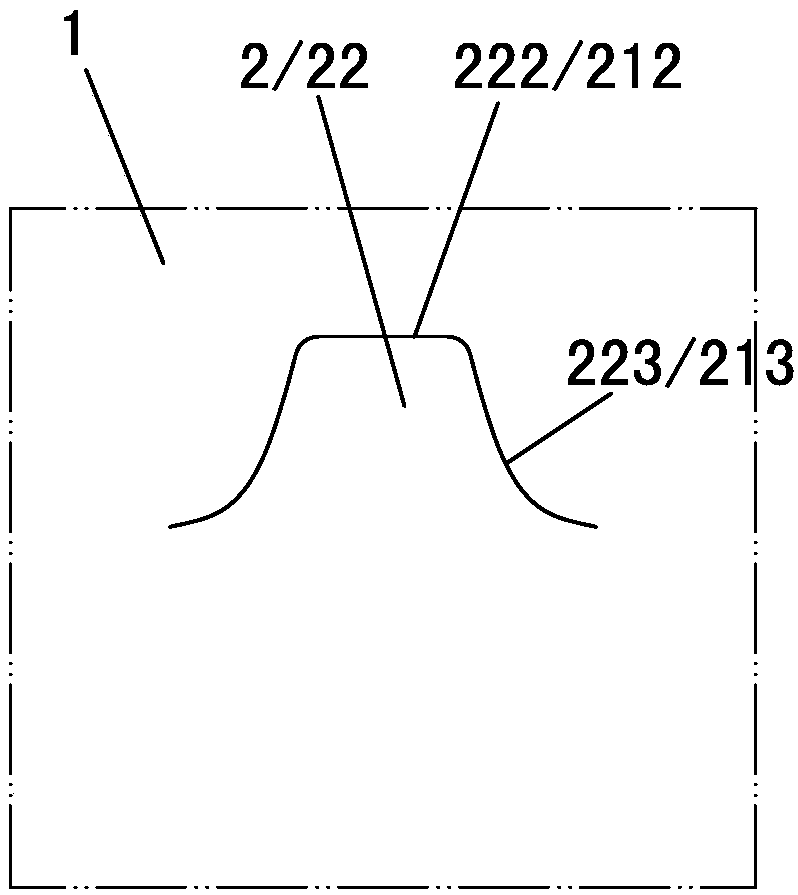

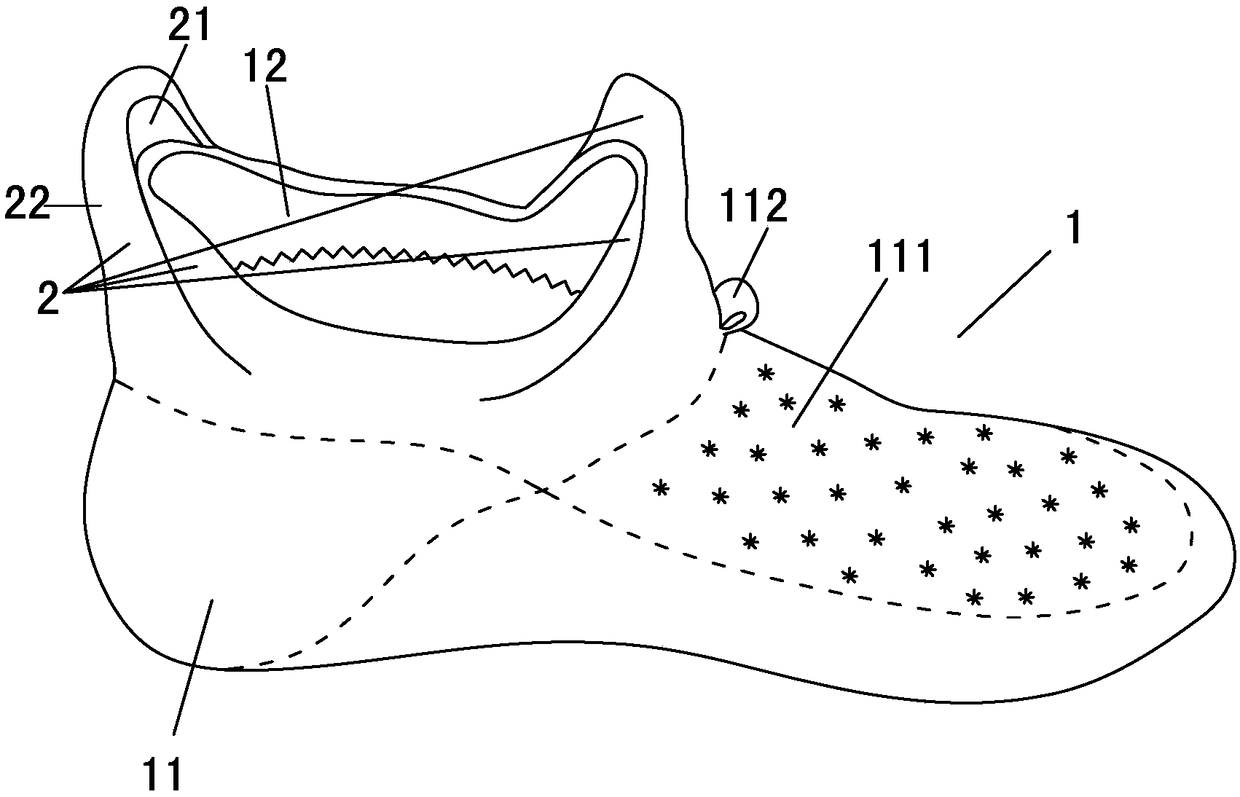

[0034] A fabric that is woven to form an ear piece structure disclosed by the invention, such as figure 1 and figure 2 As shown, the fabric body 1 is included, and the fabric body 1 is also integrally woven with an ear piece structure 2 extending and protruding toward the side of the fabric body 1. It can be seen from the figure that the ear piece structure 2 is a solid piece. The main body can be flipped at will, and the ear piece structure 2 is a double-layer structure as shown in the figure, including a first layer 21 and a second layer 22, and the first layer 21 and the second layer 21 respectively include The connecting edge 211 / 221 of the weaving connection of the fabric body 1, the outer edge 212 / 222 of the protruding end of the ear piece structure 2, and the sewing edges 213 / 223 on both sides between ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com