Pure cotton slub elastic stocking yarn and manufacturing process thereof

A technology of making craft and knitting yarn, which is applied in the direction of yarn, textiles and papermaking, etc. It can solve the problems of lack of elasticity of slub yarn, and achieve good dyeing effect, comfortable wearing and soft hand feeling.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] Below in conjunction with specific embodiment the present invention is described in further detail:

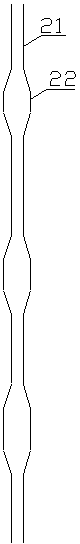

[0024] Examples such as figure 1 , figure 2 As shown, a pure cotton slub elastic knitting yarn includes a core yarn 1, and the core yarn 1 is covered with a coating layer 2 mixed with carded cotton sliver and long-staple cotton sliver. Layer 2 consists of thick places 22 and thin places 21 spaced apart from each other. The core yarn 1 is 20D spandex yarn, the draft ratio is 3.5 times, the weight ratio of the carded sliver in the cladding layer 2 is 90%, and the weight ratio of the long-staple sliver is 10%. Detail 21 (base yarn) of pure cotton slub stretch knitting yarn is C47 S , the thick joints 22 (i.e. bamboo joints) have lengths of 2.5cm, 3.0cm, 3.8cm, 4.5cm, 4.8cm and are irregularly arranged, and the pitches are 8cm-20cm irregular intervals. The outer diameter of the thick joints 22 is 2.2 times the outer diameter of detail 21.

[0025] The manufacturing pr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Fineness | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com