Roller device of flat knitting machine

A flat knitting machine and cam device technology, which is applied in knitting, weft knitting, textiles and papermaking, etc. It can solve problems such as collision between the bottom plate and rollers, incomplete opening of the rollers, and influence on the normal operation of the machine, so as to achieve the effect of smooth weaving.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

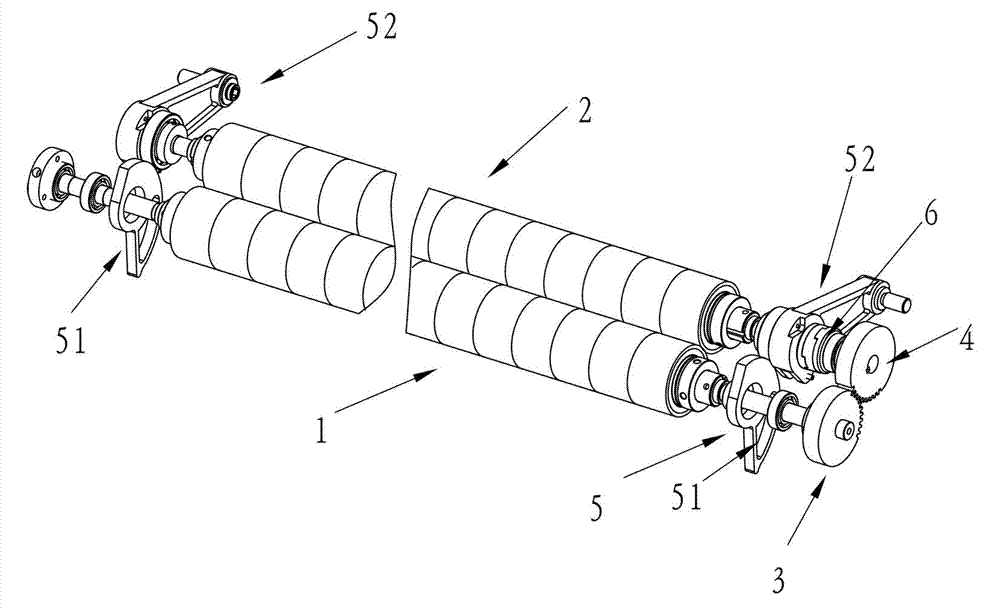

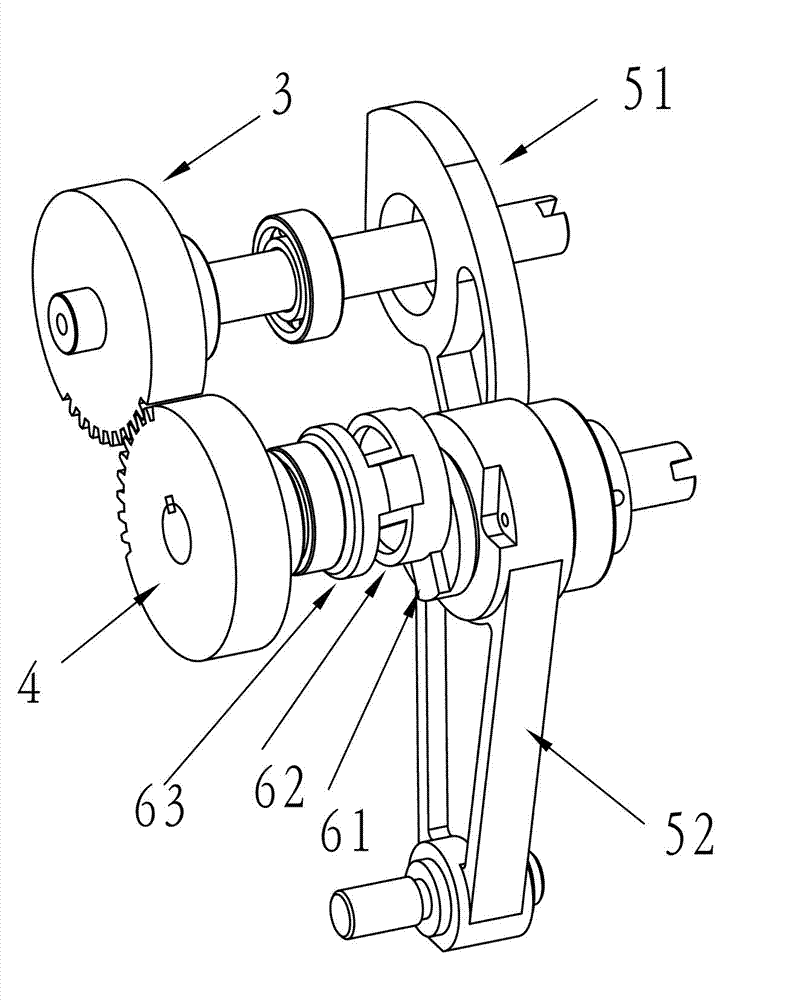

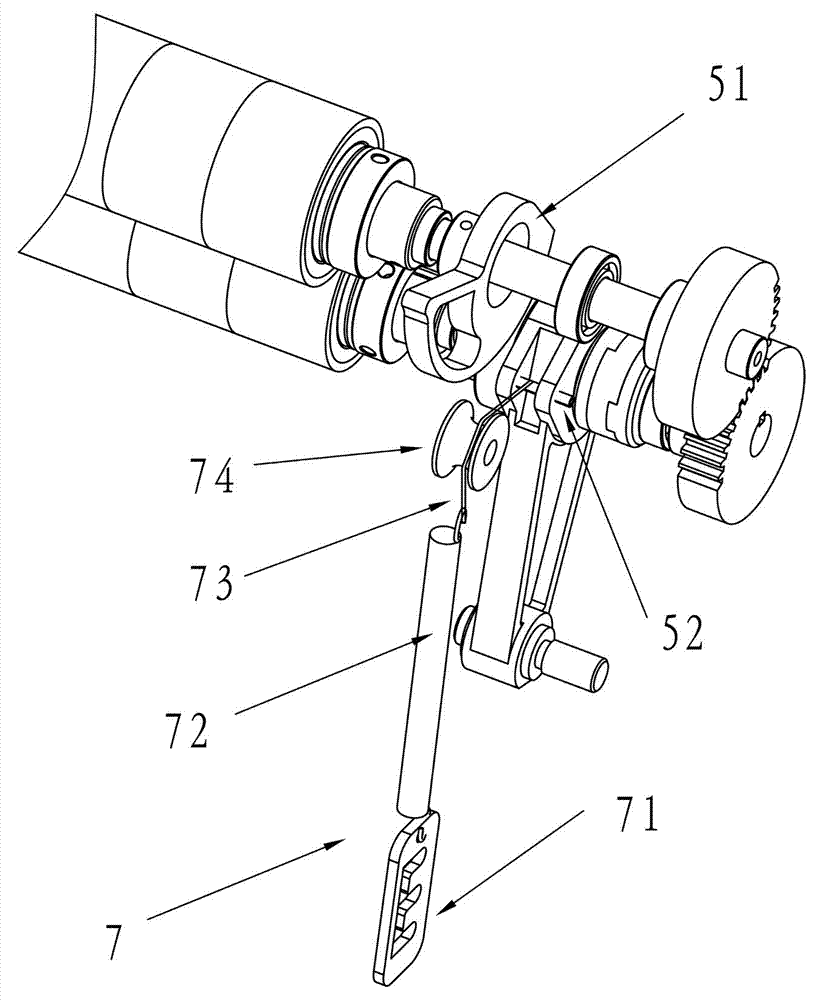

[0018] see figure 1 and Figure 4 . The driving gear 3 and the driven gear 4 of this specific embodiment mesh and rotate to drive the driving wheel 1 and the driven wheel 2 to rotate. The cam device 5 includes a fan-shaped cam 51 and a bearing 52 with a one-way self-locking function, and the cam 51 is installed on the driving wheel. On the shaft of 1, the rolling bearing 52 is installed on the shaft of the driven wheel 2, both of which are located at one end of the roller, and the outer circumference of the bearing 52 has an arc-shaped protrusion. below the joint. The cam 51 is self-locking in one direction and can only rotate counterclockwise relative to the driving wheel 1, and will be stuck when rotating clockwise. Therefore, when the driving wheel 1 rotates clockwise, the cam 51 rotates counterclockwise relative to each other, and the driving wheel 1 and the cam 51 can move with each other, so that the cam 51 can be locked by the arc-shaped protrusion on the bearing, so...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com