Casting die

A mold and movable template technology, applied in the field of manual casting molds, can solve the problems of easy deflection of copper terminals, inability to place copper terminals in place at one time, and reduce production qualification rate of pole terminals, so as to improve production qualification rate and production efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

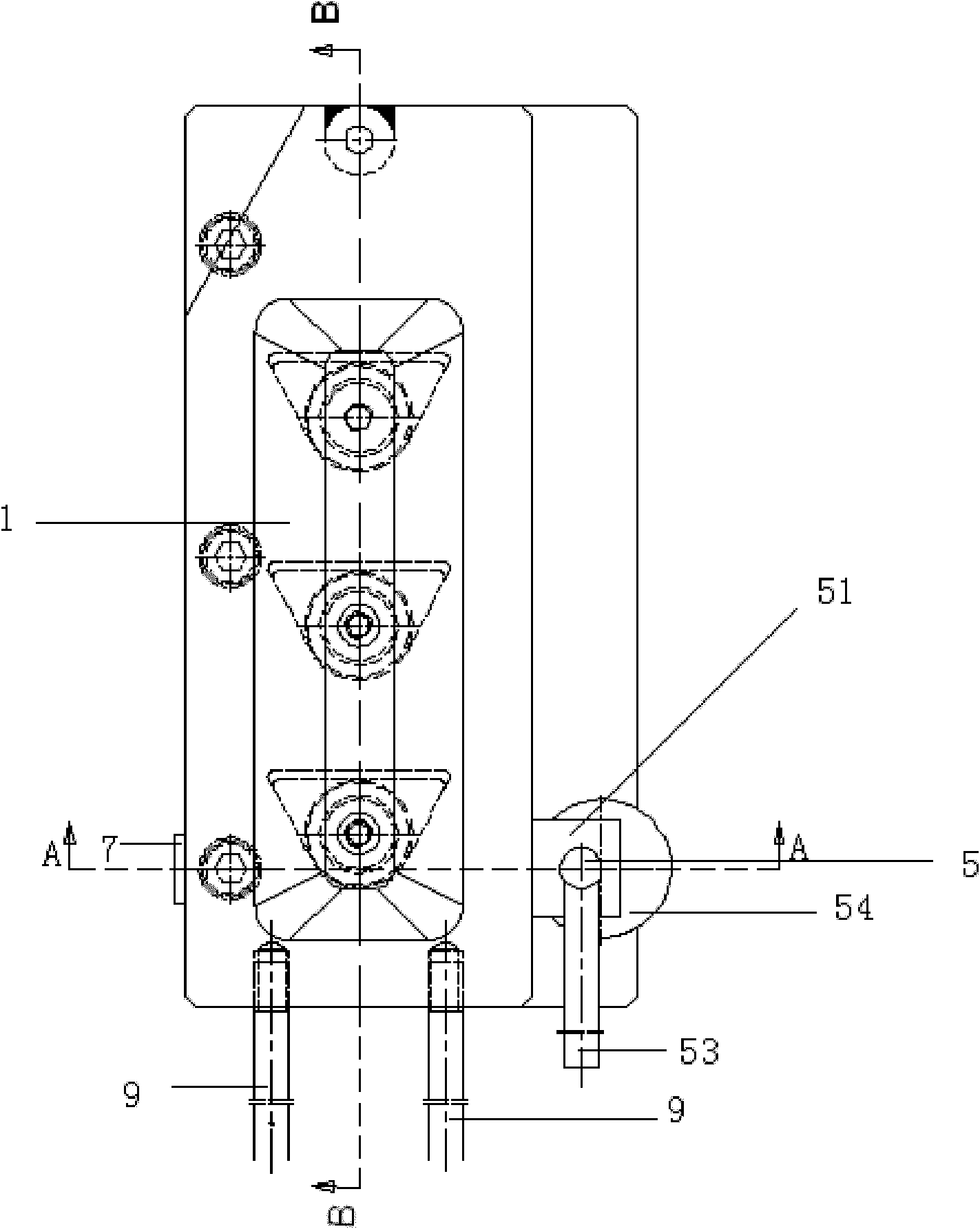

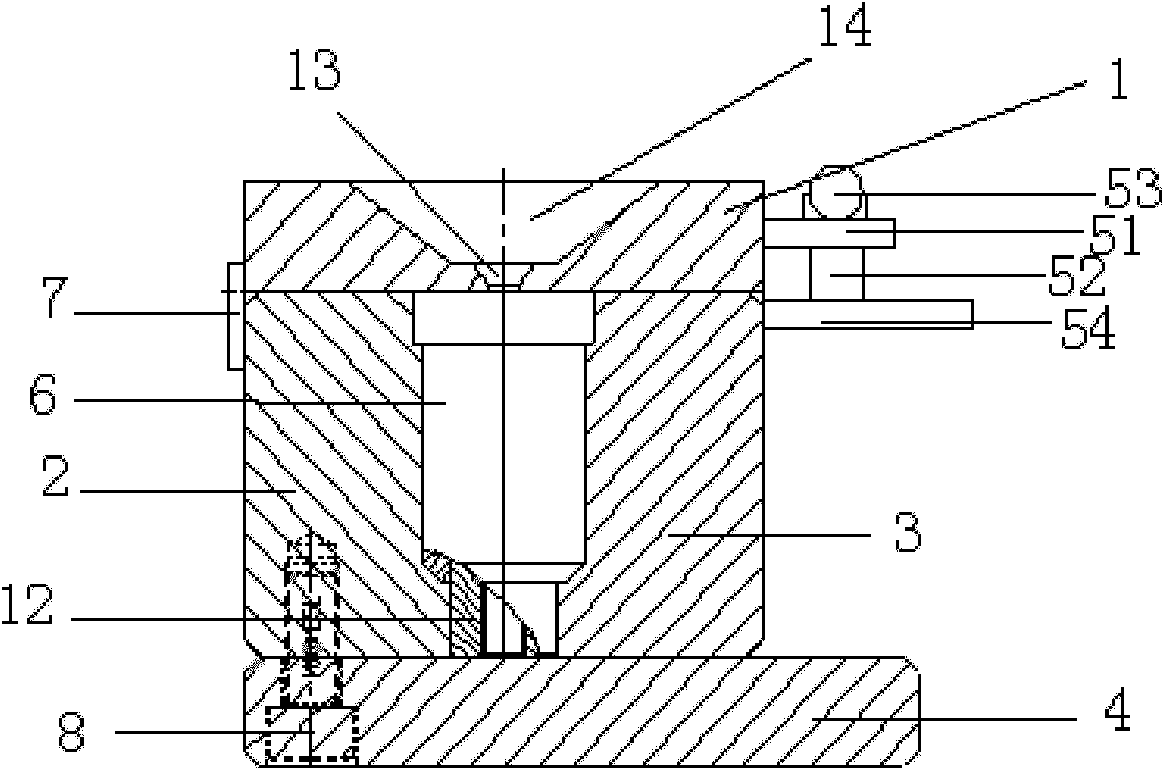

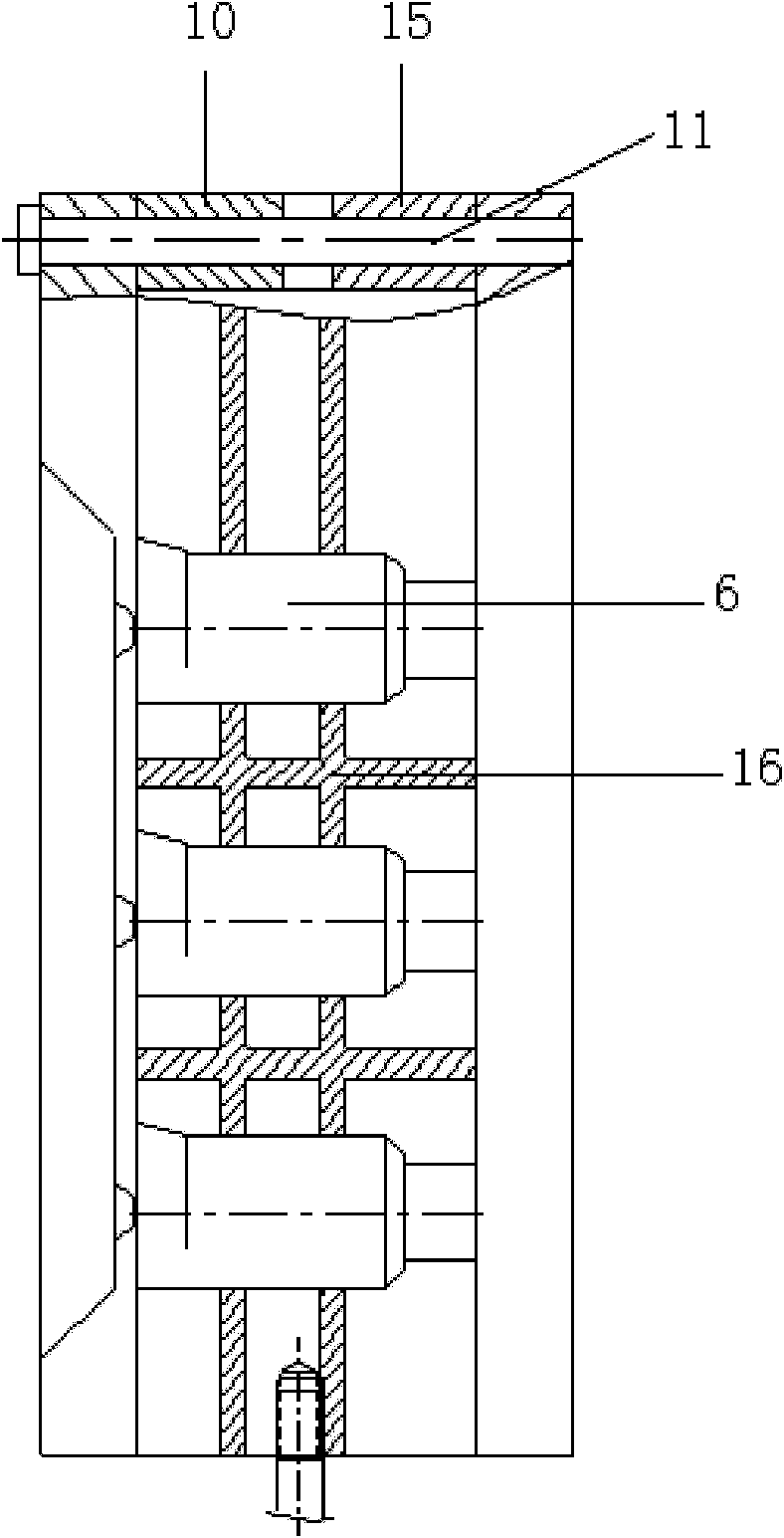

[0018] The pole terminal casting mold provided by the present invention includes a movable template, a fixed template fixed on the bottom plate, and a movable sprue plate located on the two templates when the movable template and the fixed template are molded together, and the movable template and the fixed template are symmetrical. When the mold is closed, the lower end of the product cavity formed by the cooperation of the movable module and the fixed module communicates with the bottom plate, that is, the lower end of the product cavity is in direct contact with the bottom plate, so that the lower end of the product directly leans against the bottom plate. On the bottom plate, even if the copper terminal of the pole terminal is directly against the bottom plate, when closing the mold, the copper terminal can be placed at the lower end of the cavity on the fixed template first, and one end of the copper terminal is against the bottom plate, and then Close the movable template...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com