Air spring for railway passenger vehicle and production method of air spring

A rail transit and air spring technology, applied in the direction of spring, spring/shock absorber, shock absorber-spring combination, etc., can solve the problems of high air tightness risk, friction damage at joints, and high manufacturing cost of throttle valve, Achieve the effect of improving production qualification rate, reducing friction and wear, and reducing production and manufacturing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

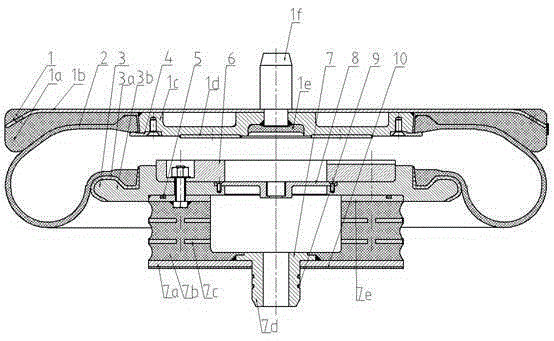

[0033] Such as figure 1 As shown, an air spring for a rail transit passenger car includes an upper cover plate composition 1, an air bag 2, a rubber seat 3, an auxiliary spring composition 7, a throttling flange 8 located in the middle of the rubber seat and connected with the rubber seat; The rubber seat is installed on the auxiliary spring composition, and the air bag is installed between the rubber seat and the upper cover plate composition. The upper cover plate 1b, the upper cover positioning pin 1f, and the upper cover support plate 1c are connected together by welding, and the upper cover wear plate 1d is connected under the upper cover support plate. The upper cover wear plate is located between the upper cover support plate and the air bag. The upper cover plate is a structure with a flat center and a downward slope around (near the edge), and several through holes with a diameter of less than 20mm are evenly distributed on the inclined surface of the plate; then the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com