Wafer processing device

A technology for processing devices and wafers, which is applied in the direction of electrolytic components, cells, and electrolytic processes. It can solve the problems of large space required for wafer processing devices, inability to meet large-scale production, and endangering workers' health, so as to eliminate harm to workers. Physical health, improving work efficiency and production pass rate, improving production efficiency and production pass rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0052] The present invention is described in detail below in conjunction with accompanying drawing:

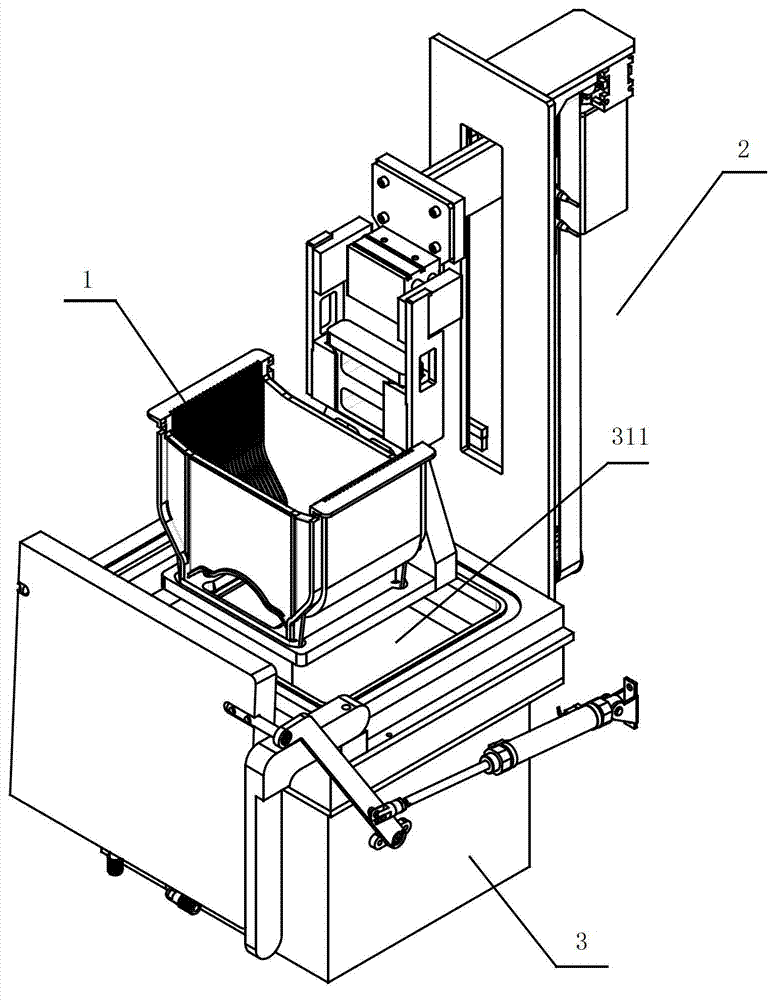

[0053] Such as figure 1 As shown, the wafer processing device includes a grab lifting device 2 and a processing tank 3; the processing tank 3 is provided with a sealable cavity 311, which is used to hold a processing liquid to process the wafer; grab The lifting device 2 is arranged on one side of the processing tank 3 and is used for transporting the wafer into the chamber 311 .

[0054] Such as figure 1 As shown, the wafer processing device also includes a wafer storage tank 1 for storing wafers to realize batch processing of wafers.

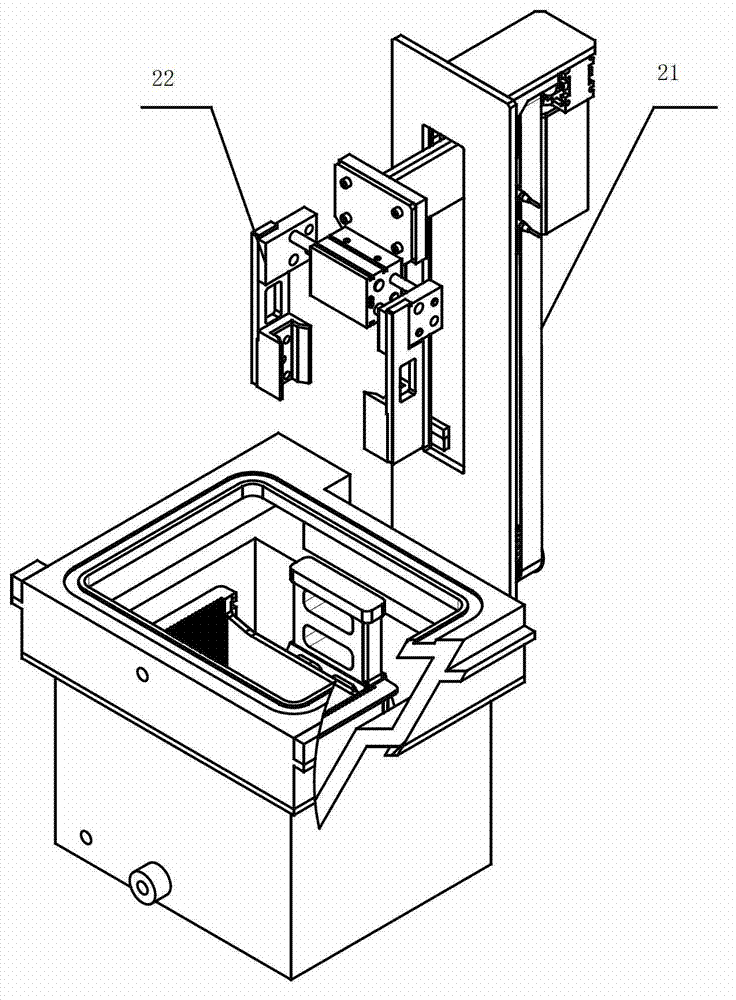

[0055] Such as figure 2As shown, it is the grasping and lifting device 2 of the wafer processing device, including the lifting device 21 and the grasping device 22; Lifting movement.

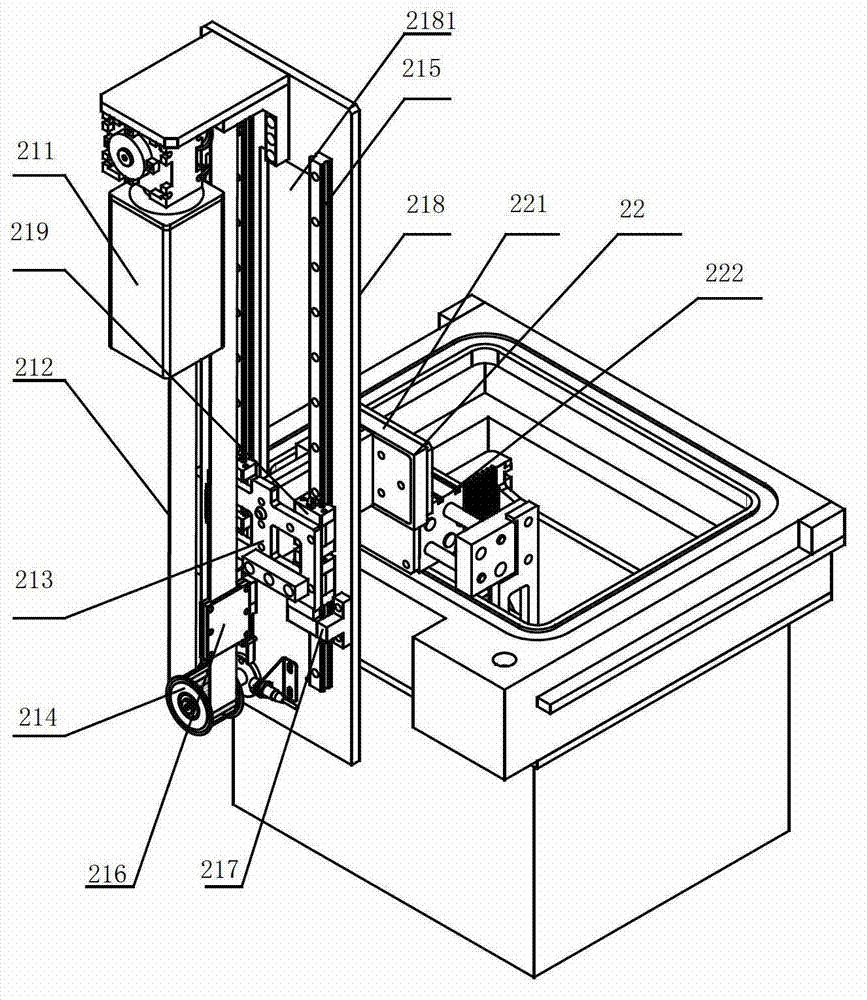

[0056] Such as image 3 As shown, the lifting device 21 of the wafer processing device includes a fixed base plate 218, a transmission device 212 and a l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com