Guide rail machining technology for automobile skylight

A technology for rail processing and automotive sunroofs, which is applied to manufacturing tools, vehicle parts, and other manufacturing equipment/tools, etc., can solve the problems of high cost and long production cycle, and achieve low production cost, short cycle, and reduced production cycle. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

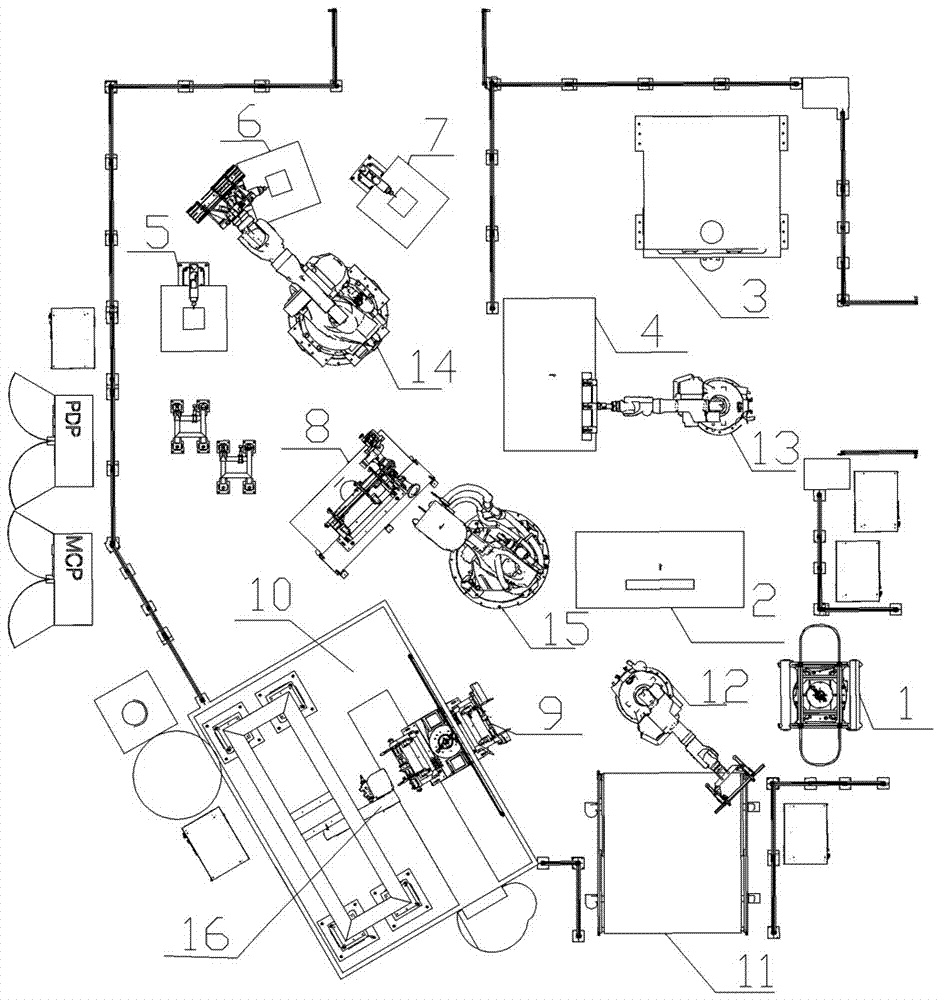

[0037] Such as figure 1 As shown, a kind of automobile sunroof guide rail processing technology,

[0038] In step a, the operator takes the workpiece as Figure 4 The raw materials shown are placed on the rotary feeder 1, and the rotary feeder 1 rotates, waiting to be grabbed;

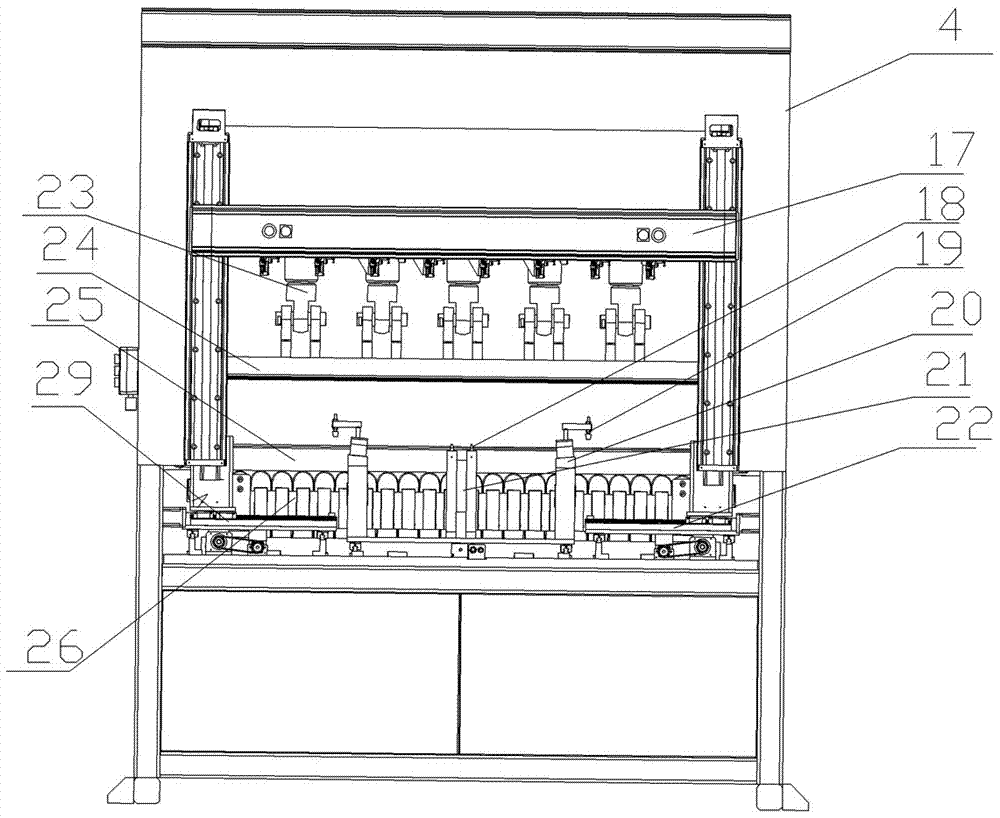

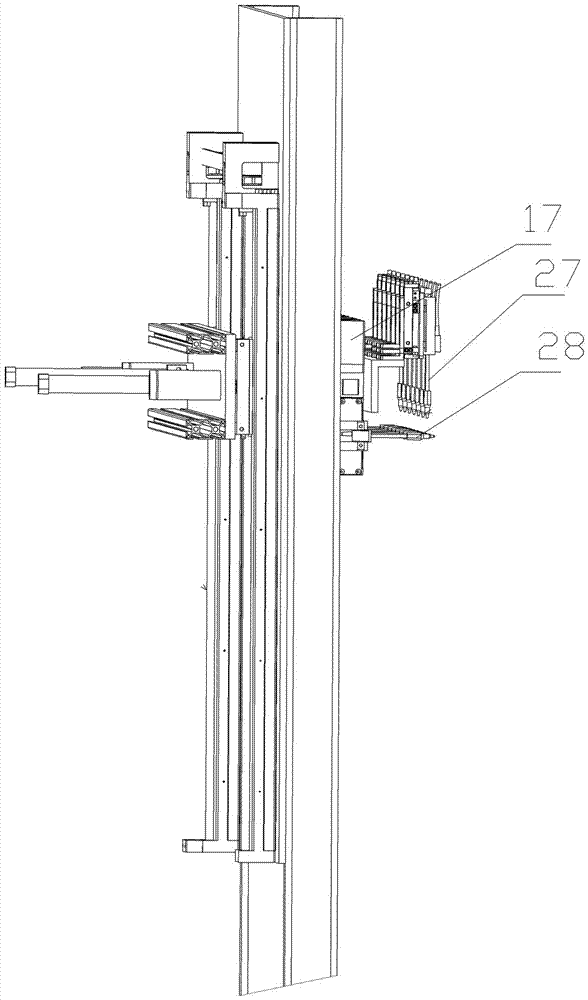

[0039] Step b, the first robot 12 grabs the workpiece on the rotary feeder 1 and places it on the double-head sawing machine 2. The double-head sawing machine recognizes the workpiece and performs double-head sawing on both ends of the workpiece according to the set size. formed as Figure 5 The workpiece shown in the figure, after sawing, automatically detects whether the length of the workpiece meets the set size and waits to be grabbed. Here, existing technologies such as infrared rays can be used to detect the length of the workpiece;

[0040] Step c, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com