Patents

Literature

204results about How to "Shorten the takt time" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

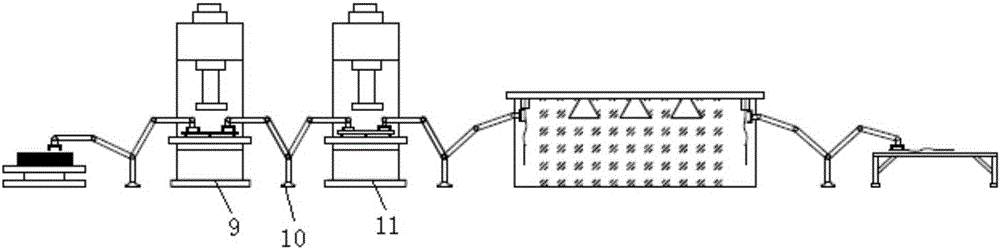

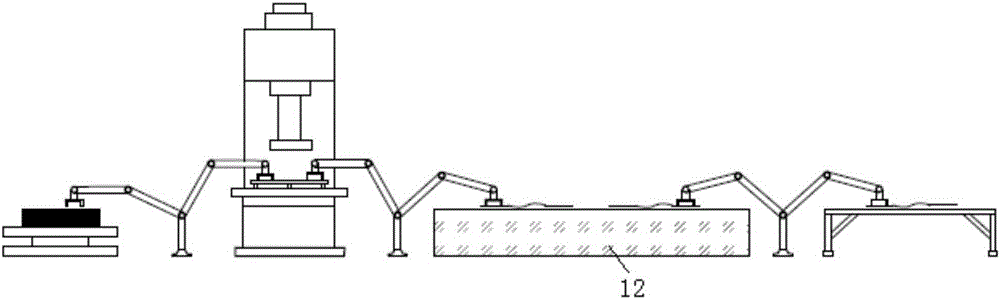

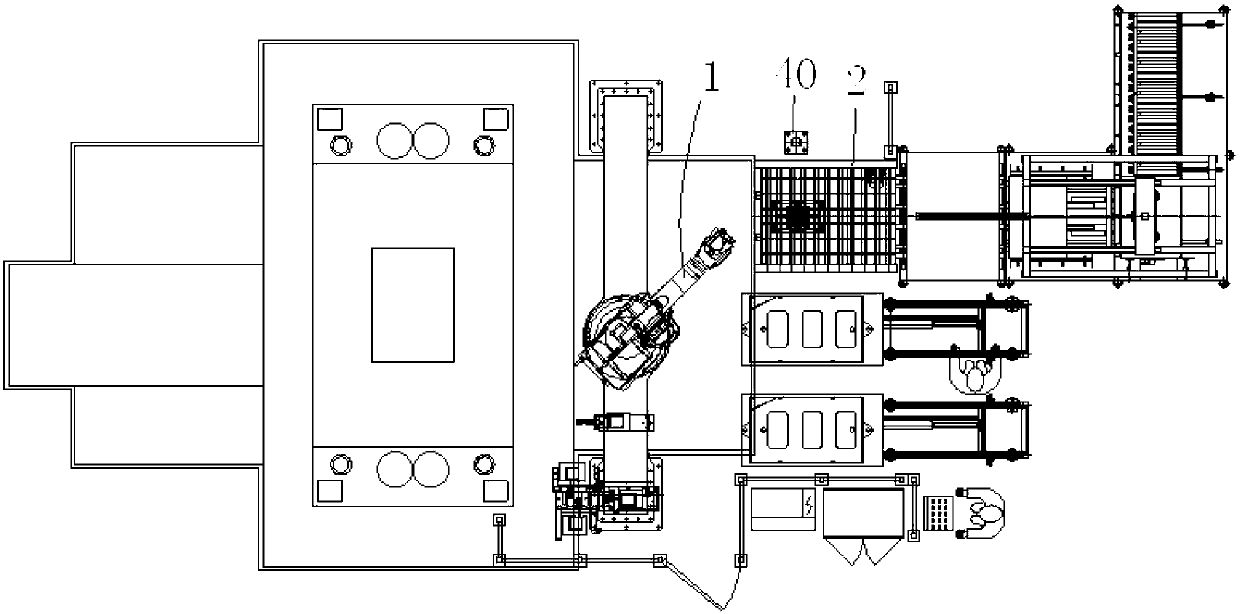

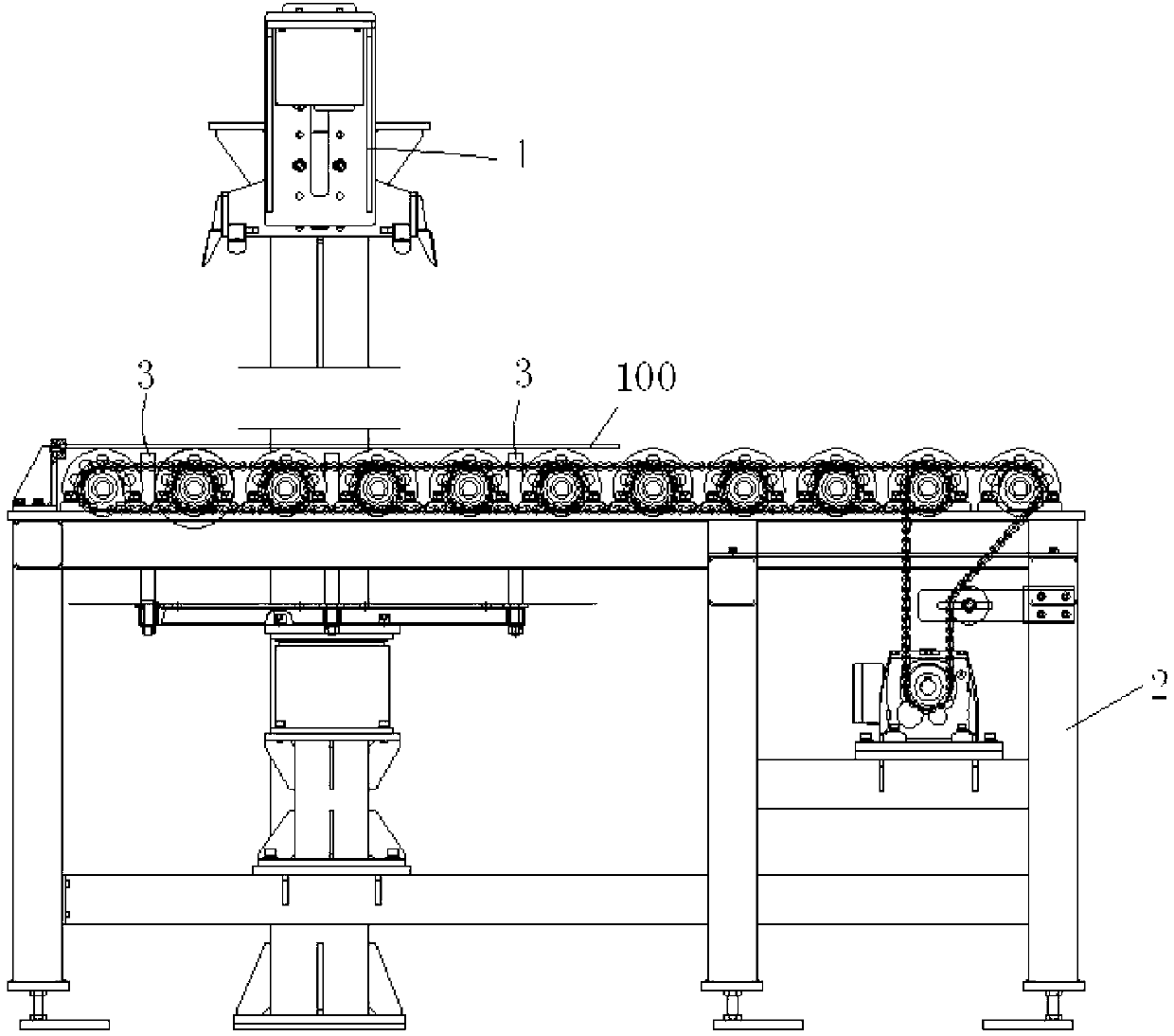

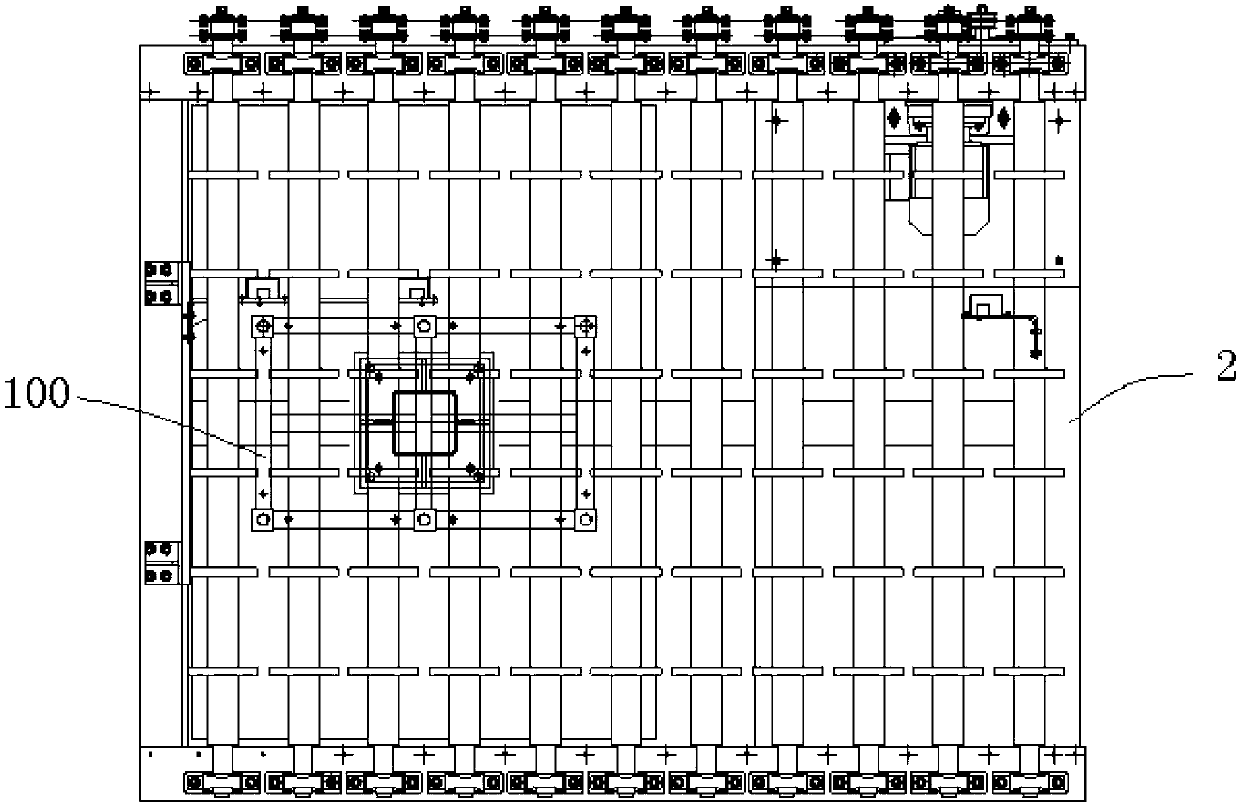

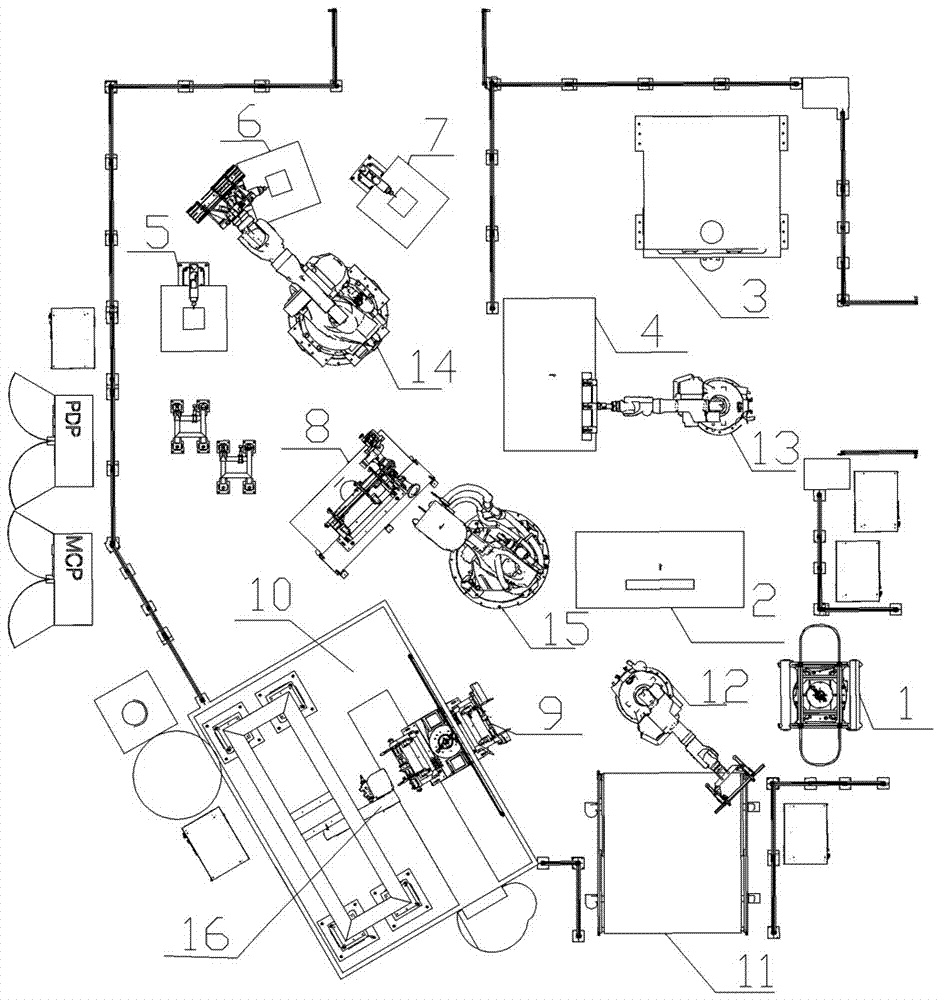

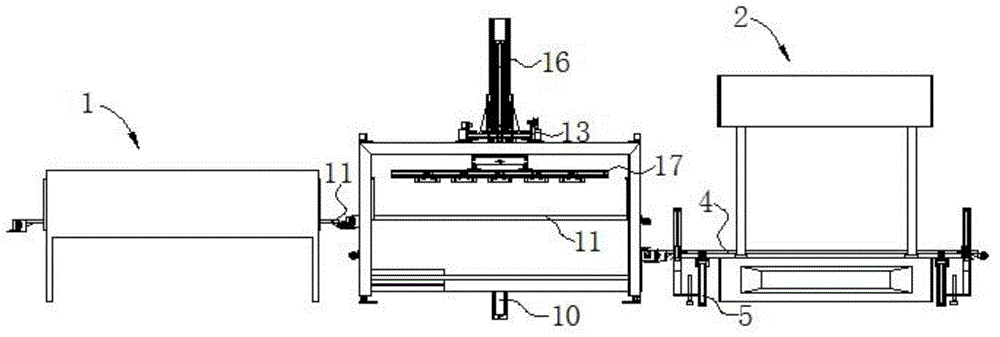

Multi-station continuous hot stamping production line and method

ActiveCN105215160AGuaranteed surface qualityReduce lossesShaping toolsMetal-working feeding devicesHot stampingProduction line

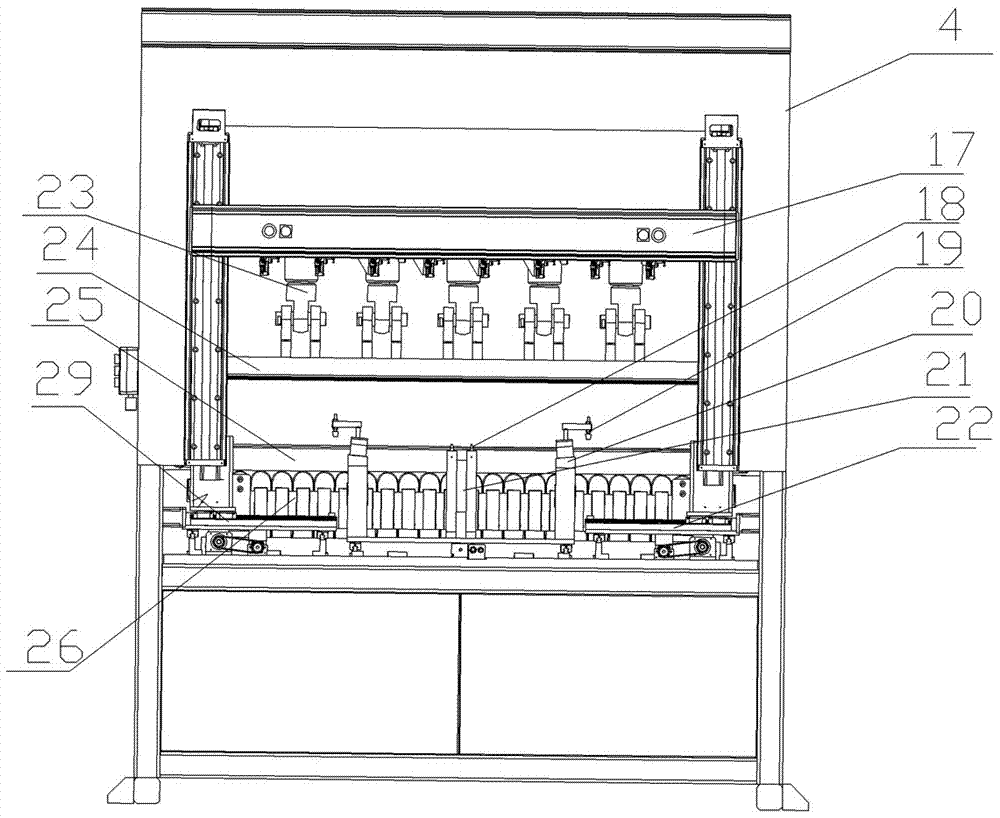

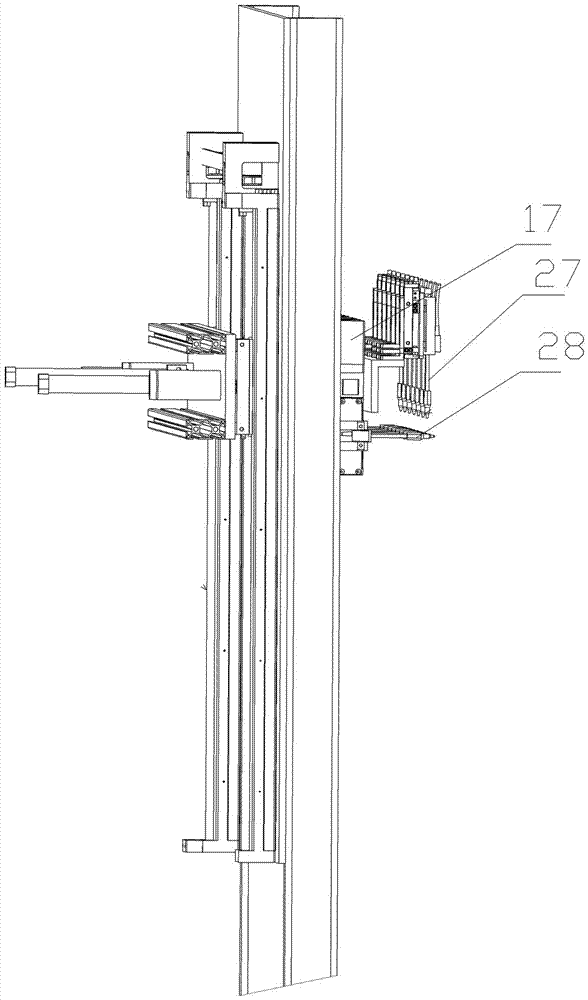

The invention discloses a multi-station continuous hot stamping production line and method. The production line comprises a material loading table, a feeding robot, a press unit, a material conveying robot, a quenching device, a material unloading robot and a conveyor belt which are arranged in sequence. The press unit comprises a heating device, a mould device and at least one press used for installation of the mould device; the heating device is used for wholly or locally heating a prefabricated blank to obtain a hot blank, and the mould device is used for conducting stamping forming, pressure maintaining setting and trimming and punching on the hot blank to obtain a hot stamped part. The rapid heating, stamping forming, pressure maintaining setting, trimming and punching and quenching can be continuously completed, so that the heating efficiency is improved, and the transportation process before punching of the hot blank is also avoided. For steel plates, stamped parts are blanked at a high temperature, increasing of cutting difficulty caused by generation of a martensitic structure at normal temperature is avoided, the blanking force is reduced, and the optimal blanked edge can be obtained.

Owner:WUHAN UNIV OF TECH

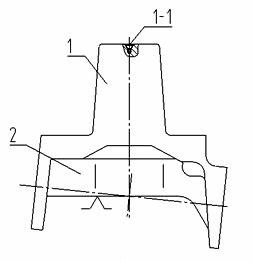

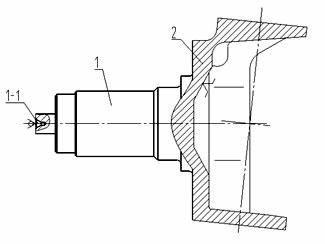

Machining method of automotive non-driven vehicle-bridge steering knuckle

InactiveCN102091922ASolve the burden of drilling processShorten the takt timeEngineeringScrew thread

The invention discloses a machining method of an automotive non-driven vehicle-bridge steering knuckle. The method comprises the following steps: (1) forming an axle-end central hole; (2) coarsely turning; (3) forming a frame-end central hole; (4) drilling the axle-end central hole for the second time; (5) coarsely processing a main pin hole; (6) polishing a central hole; (7) performing half-finish turning on an axle; (8) performing finish turning; (9) polishing the outer circle of the axle; (11) finishing the main pin hole and the end face thereof; (12) drilling a threaded hole and a bottom hole on the end face of the main pin hole; (13) tapping screw threads; (14) milling an arc R; (15) milling a fastening groove; and (16) cleaning the parts and conveying the parts to an inspection section. By improving the procedures in the machining process, the method can reduce the loads of drilling processes, reduce the machining cost, shorten the production period, and improve the product quality.

Owner:重庆大江信达车辆股份有限公司

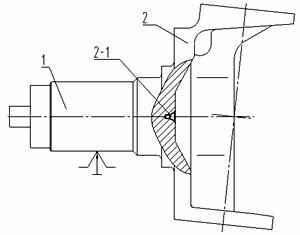

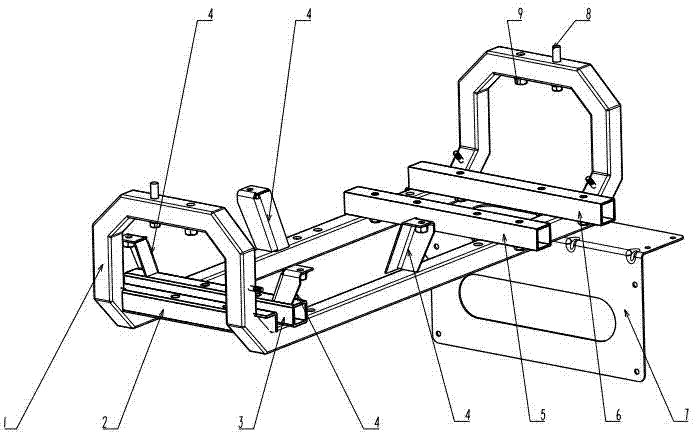

Power assembly support beam mechanism for pure electric automobile

InactiveCN102765317AReasonable arrangementImprove assembly manufacturabilityElectric propulsion mountingChinese charactersEngineering

The invention relates to a power assembly support beam mechanism for a pure electric automobile. A main beam frame of the mechanism consists of two parallel horizontal beams. A left support rod and a right support rod of an air conditioning compressor are respectively and parallelly arranged at the bending position at one end of the main beam frame, and a left support rod and a right support rod of a storage battery are respectively and parallelly arranged at the bending position at the other end of the main beam frame. Two sides of the right support rod of the air conditioning compressor are respectively and correspondingly provided with two first short support rods which are in shapes like inverted Chinese characters 'ba' mutually and correspondingly. Two second short support rods which are in shapes like inverted Chinese characters 'ba' mutually and correspondingly are respectively arranged on two main beams in the middle of the main beam frame. The two first short support rods and the two second short support rods form a driving motor controller support. A charger support is fixedly connected to the bottom of the main beam frame adjacent to the right support rod of the storage battery. A special part of a pure electric automobile power assembly can be directly or indirectly fixed and hard connected to the power assembly support beam mechanism to form an integrated power assembly, and vehicle front cabin arrangement space is utilized to the most extent under the conditions that passenger cabin space is not changed and comfort of passengers is not influenced.

Owner:ANHUI JIANGHUAI AUTOMOBILE GRP CORP LTD

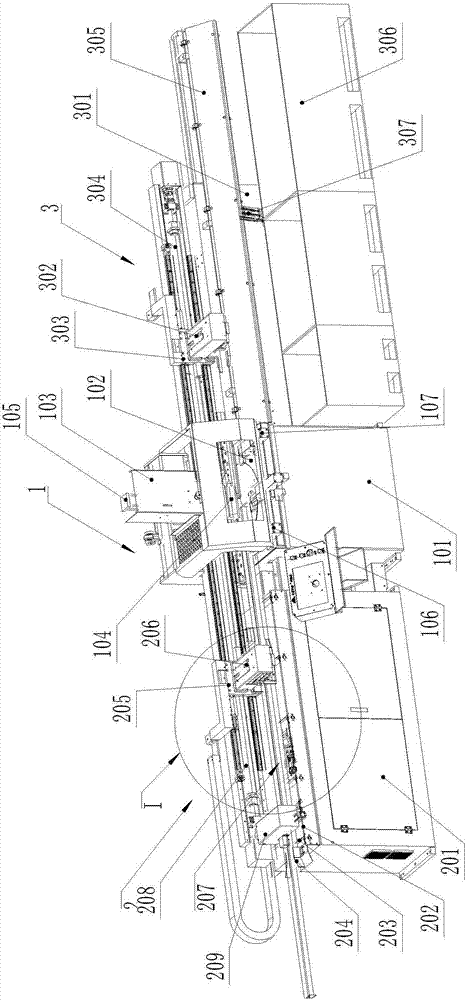

Workpiece positioning method in robot transportation system by means of intelligent camera

ActiveCN103273496AImprove intelligenceImprove the level of flexibilityManipulatorFeature extractionControl engineering

The invention discloses a workpiece positioning method in a robot transportation system by means of an intelligent camera. The important and complex work of characteristic extraction of a workpiece is separated from the measuring process, and is integrated in the intelligent camera. By means of man-machine interaction software arranged on the intelligent camera, an intelligent camera characteristic extraction algorithm is chosen and parameters are set. Secondary conversion of a transportation robot is needless, and what is needed is to directly quote a conversion coordinate value of the intelligent camera. The production cycle is shortened, efficiency is improved, labor intensity of workers is reduced, cost is greatly reduced, and the intelligentization level and the flexibility level of the robot transportation system are improved. Known from the above, by means of the workpiece positioning method in the robot transportation system by means of the intelligent camera, the intelligent camera and the robot are combined for automatic positioning and transportation, the automation degree is high, efficiency is high, precision is high, and the method meets requirements of large-scale high-precision stamping production.

Owner:CHANGSHA CTR ROBOTICS

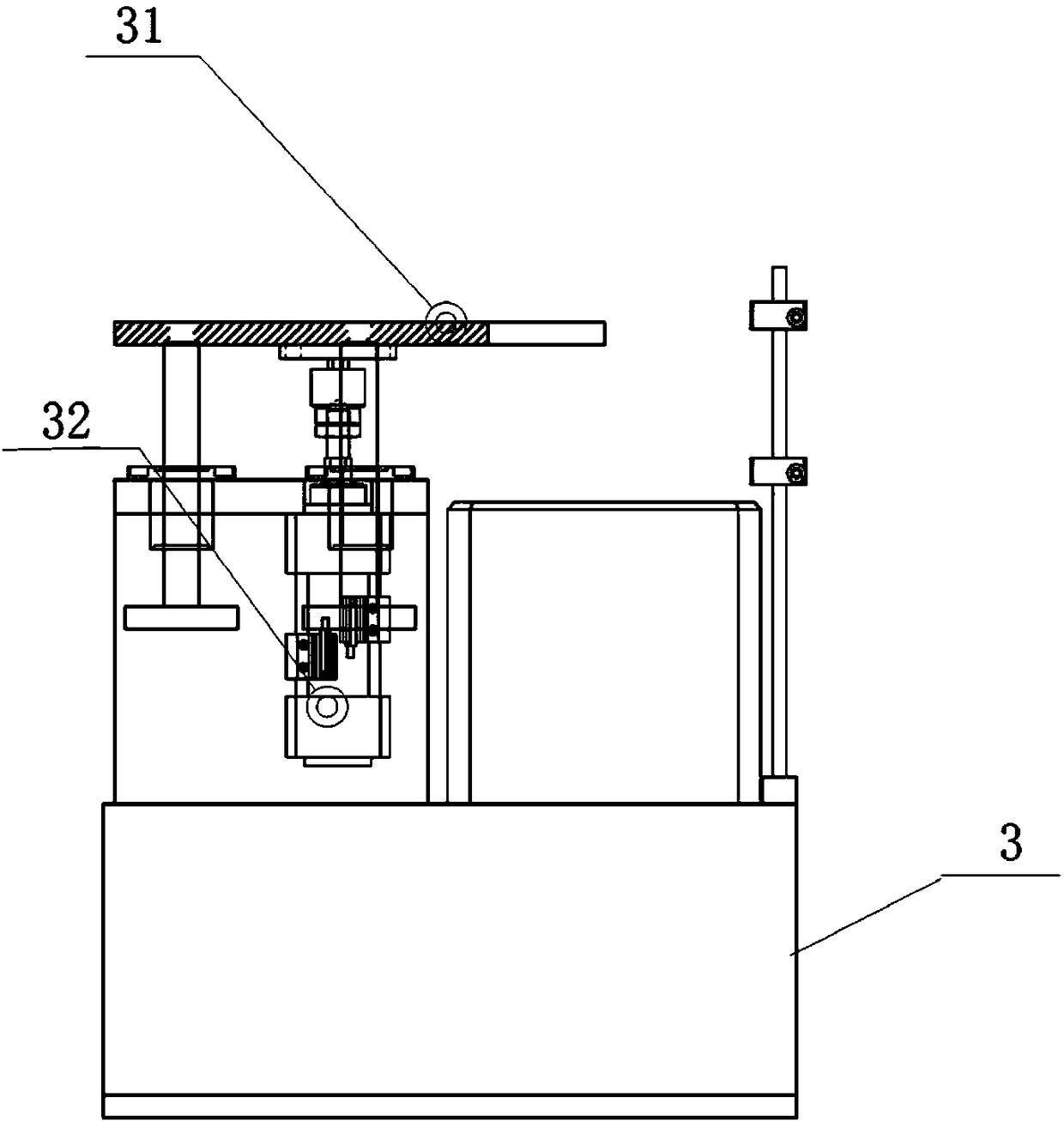

Square tube multi-angle saw cutting machine

ActiveCN106862652AEasy to adjust the angleImprove sawing efficiencyMetal sawing devicesEngineeringMechanical engineering

The invention discloses a square tube multi-angle saw cutting machine. The square tube multi-angle saw cutting machine comprises a rotary saw cutting machine head, a feeding conveyance device and a discharging device. The rotary saw cutting machine head comprises a machine box. A saw cutting platform is arranged at the upper end of the machine box. A rotating box body driven by a rotating servo motor is installed inside the machine box in a rotating mode. A lifting pedestal driven by a lifting power device is installed inside the rotating box body. A saw blade is installed on the lifting pedestal in a rotating mode. A through hole is formed in the rotating box body. The saw cutting platform is provided with an upstream positioning clamp and a downstream positioning clamp. The upstream positioning clamp and the downstream positioning clamp transversely clamp a square tube and position the same side face of the square tube. The saw cutting platform is vertically provided with an upper pressing plate used for tightly pressing the square tube from the upper side in a sliding mode, the upper pressing plate is driven by an upper pressing power device, and the bottom of the upper pressing plate is detachably provided with an upper cushion block. The square tube multi-angle saw cutting machine is reasonable in structure, the saw cutting angle can be adjusted by rotating the angle of the saw blade, and thus the square tube can be sawed from different angles.

Owner:苏州斯马拓智能化装备有限公司

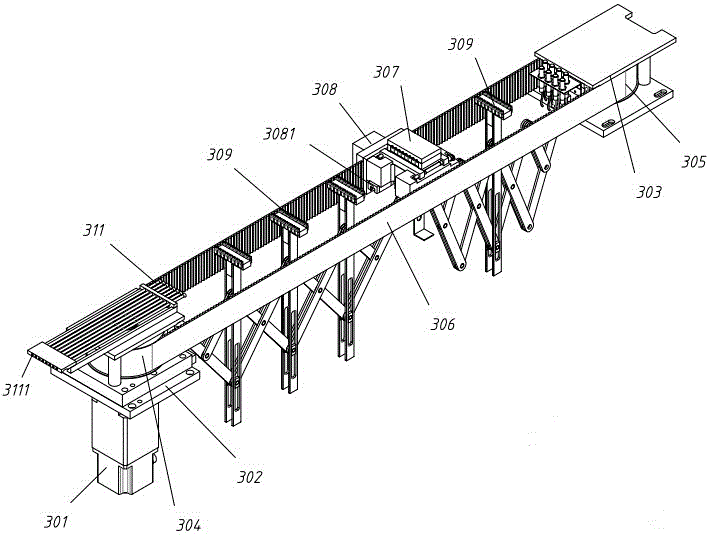

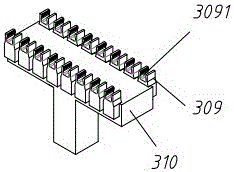

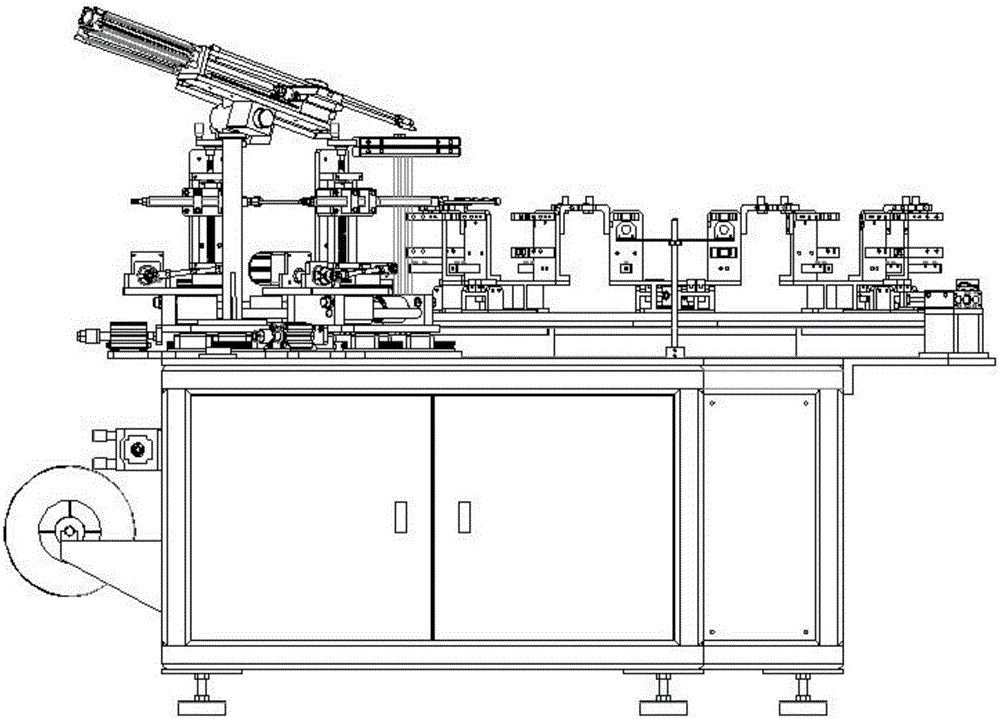

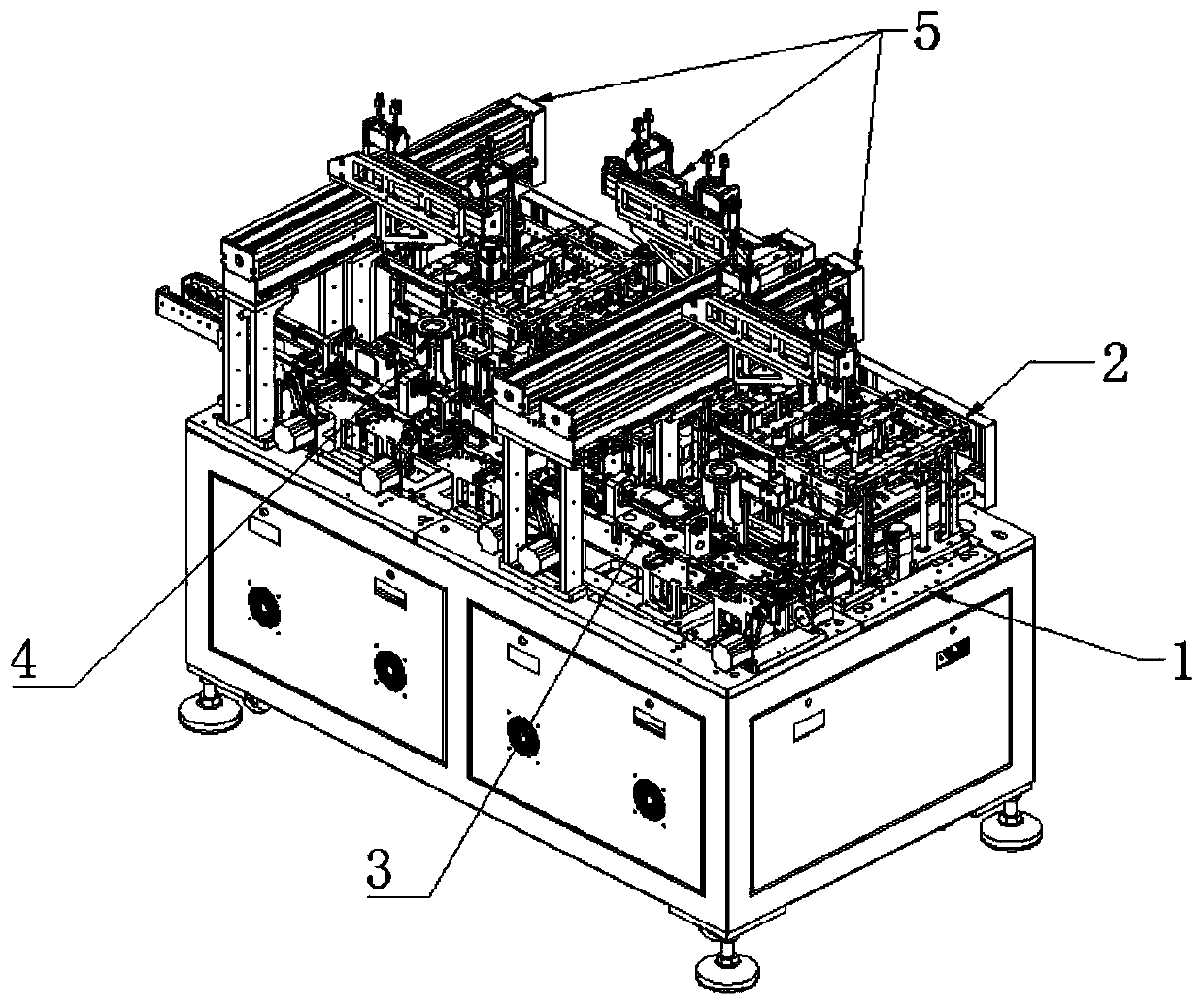

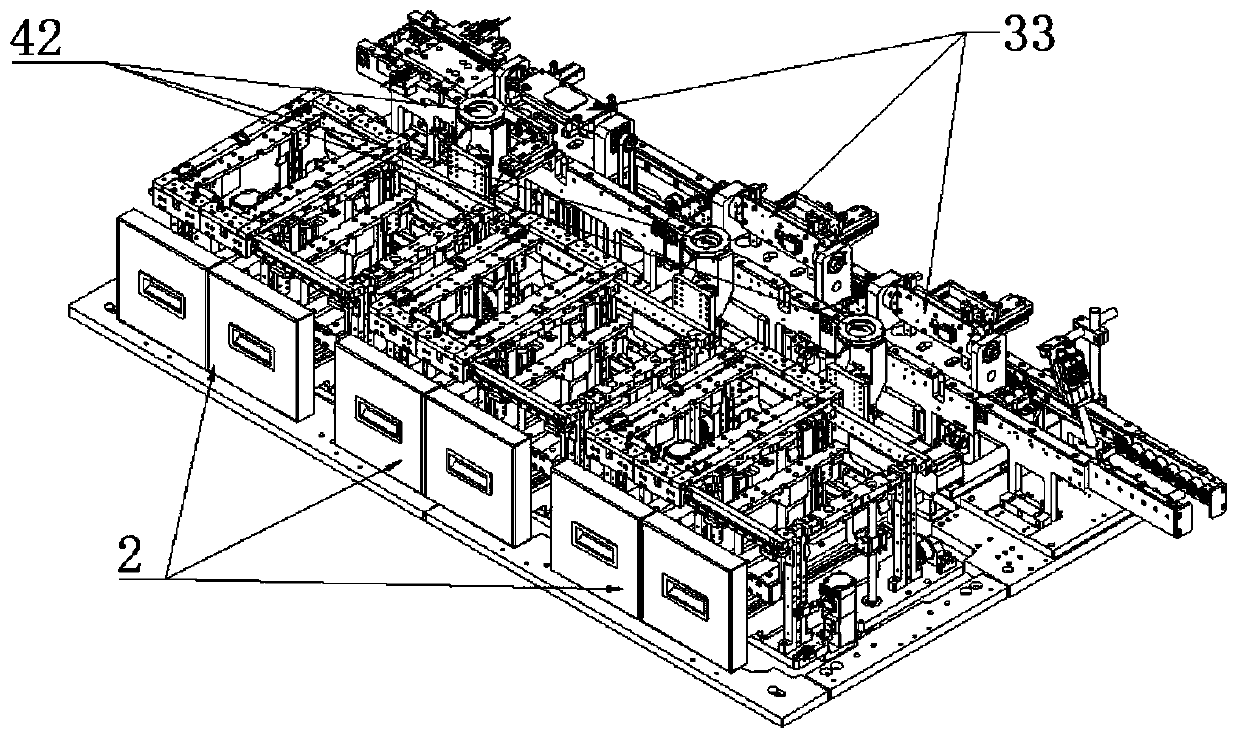

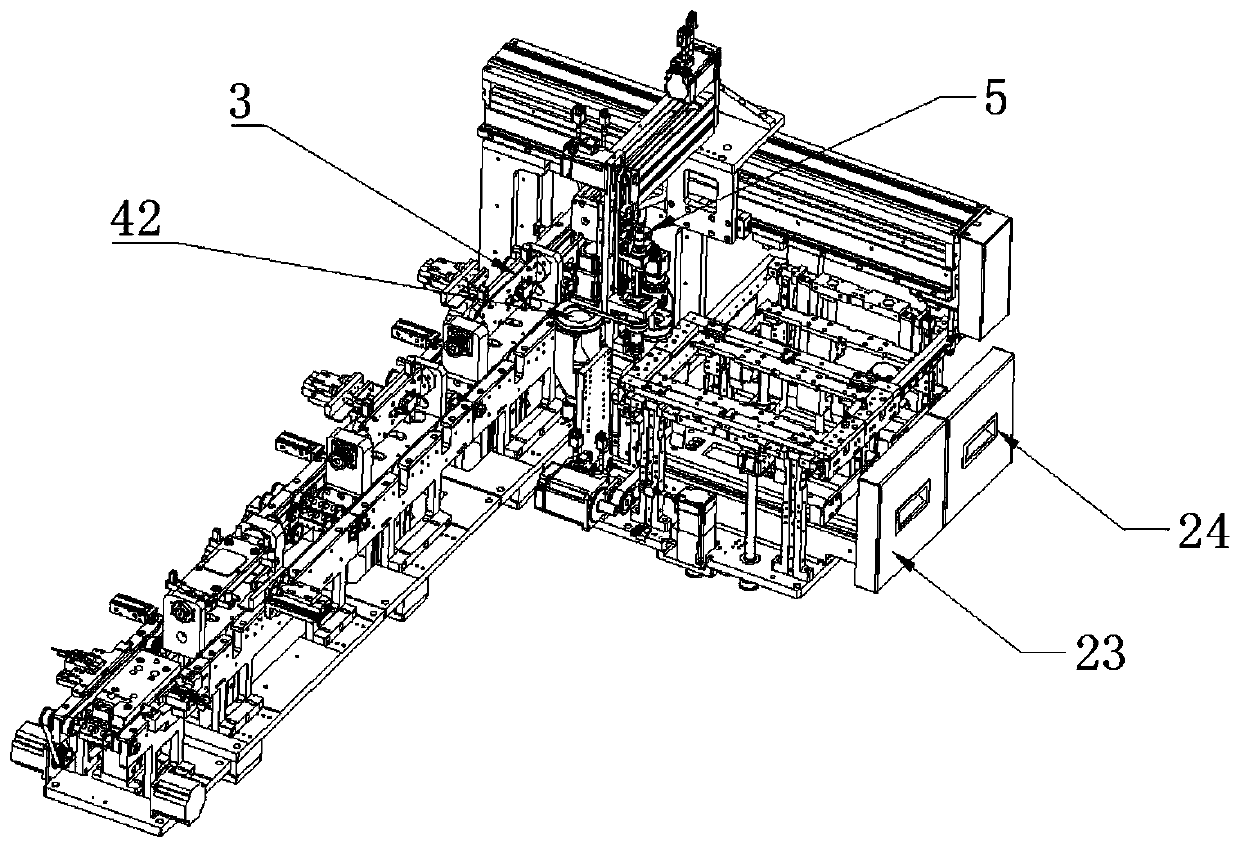

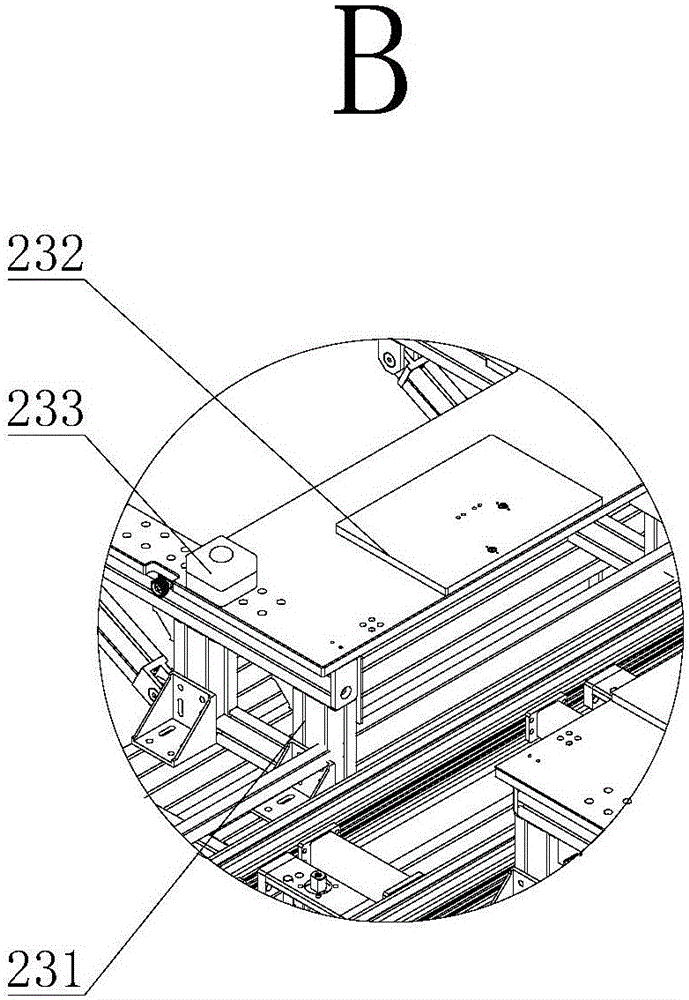

Automatic online dispenser

ActiveCN105234044AShorten the takt timeHigh degree of automationLiquid surface applicatorsCoatingsEngineeringAssembly line

The invention discloses an automatic online dispenser which comprises a base plate. A feeding assembly line and a discharging assembly line are arranged on the two sides of the base plate respectively. A moving conveying line is installed on the base plate. A dispensing system is arranged above the moving conveying line and is connected with the base plate. The automatic online dispenser hast the beneficial effects that automatic online dispensing can be achieved, products can be automatically connected to a main assembly line in a butting manner through the moving conveying line while dispensing is conducted, output and input of products are completed, and the production tact is shortened greatly.

Owner:SICHUAN CHANGHONG ELECTRIC CO LTD

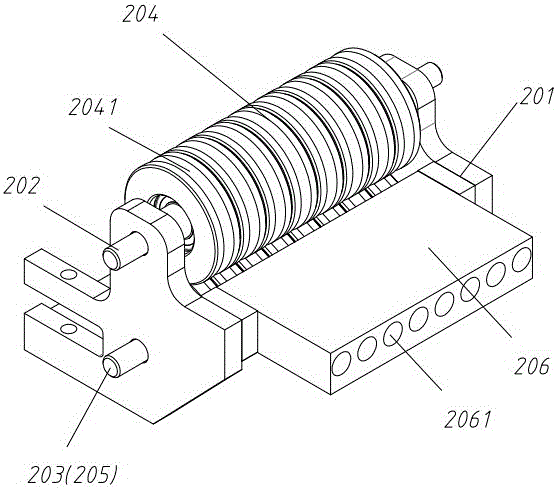

Pipe bender

InactiveCN106311835AAvoid wear and tearFast feedingMetal-working feeding devicesMetal working apparatusEngineeringMechanical engineering

The invention discloses a pipe bender which comprises a rack, a rounding part, a feeding part, a die bending mechanism, cutting parts and a core shaft part; the rounding part, the feeding part, , the cutting parts and the die bending mechanism are sequentially installed on the rack; the feeding part is composed of a clamping part and a transmission part for transmitting the clamping part; the clamping part clamps and loosens a copper pipe and moves through the transmission part and enables the copper pipe to move to a position capable of being bended after clamping the copper pipe; the die bending mechanism rotates 180 degrees to bend the pipe and process the pipe into a U-shaped pipe after tightly clamping the pipe; the core shaft part is composed of a core shaft, a core shaft sleeve, a moving seat and a moving seat driver; the core shaft penetrates through the core shaft sleeve; the front end of the core shaft and the core shaft sleeve are fixed together; the core shaft sleeve penetrates through a front core shaft sleeve clamp and can move therein; the front core shaft sleeve clamp is fixed to a bending frame of the die bending mechanism; the back part of the core shaft sleeve is closely fit by a back core shaft sleeve clamp; and the back core shaft sleeve clamp is fixed to the moving seat.

Owner:JDM JINGDA MASCH (NINGBO) CO LTD

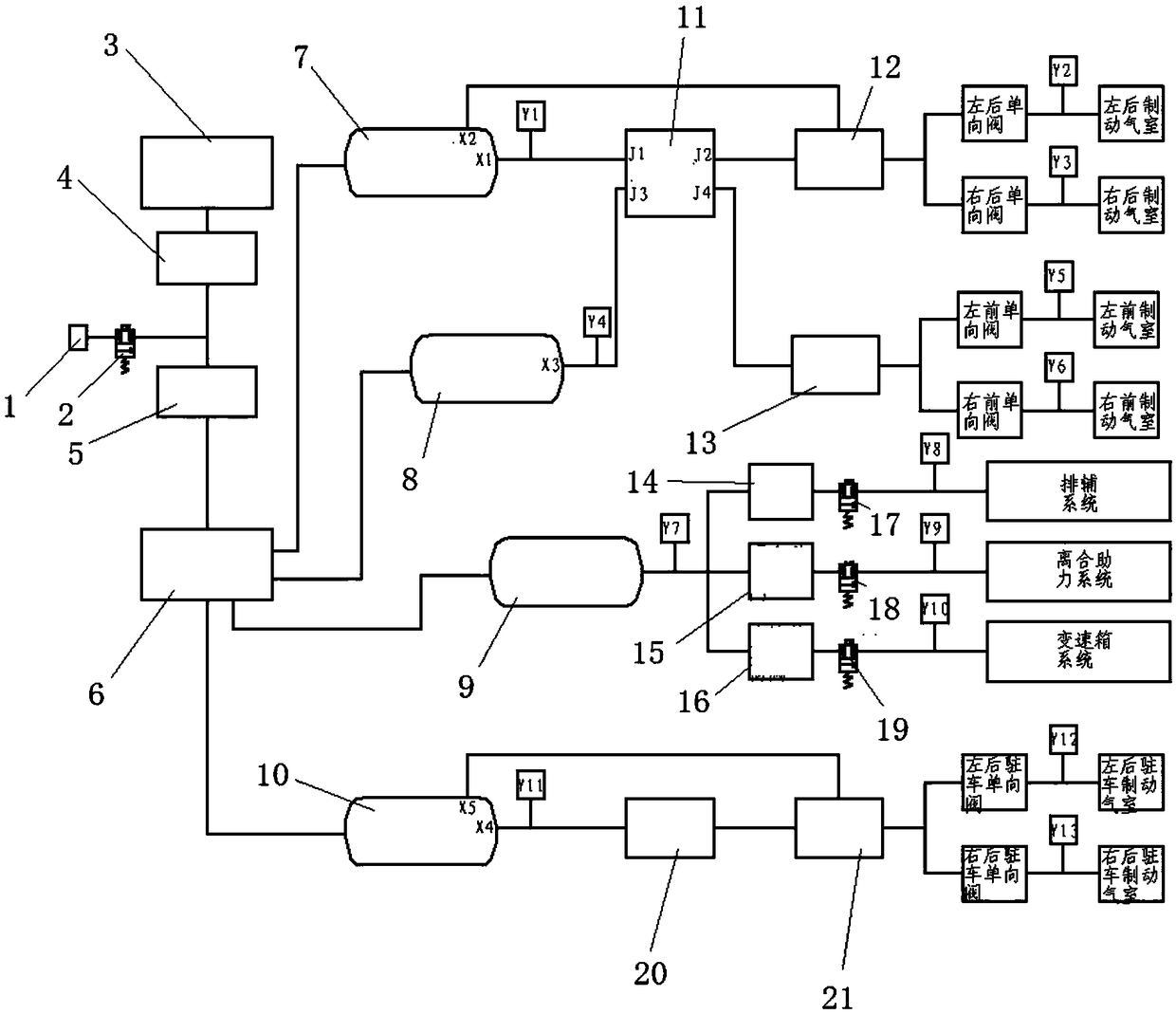

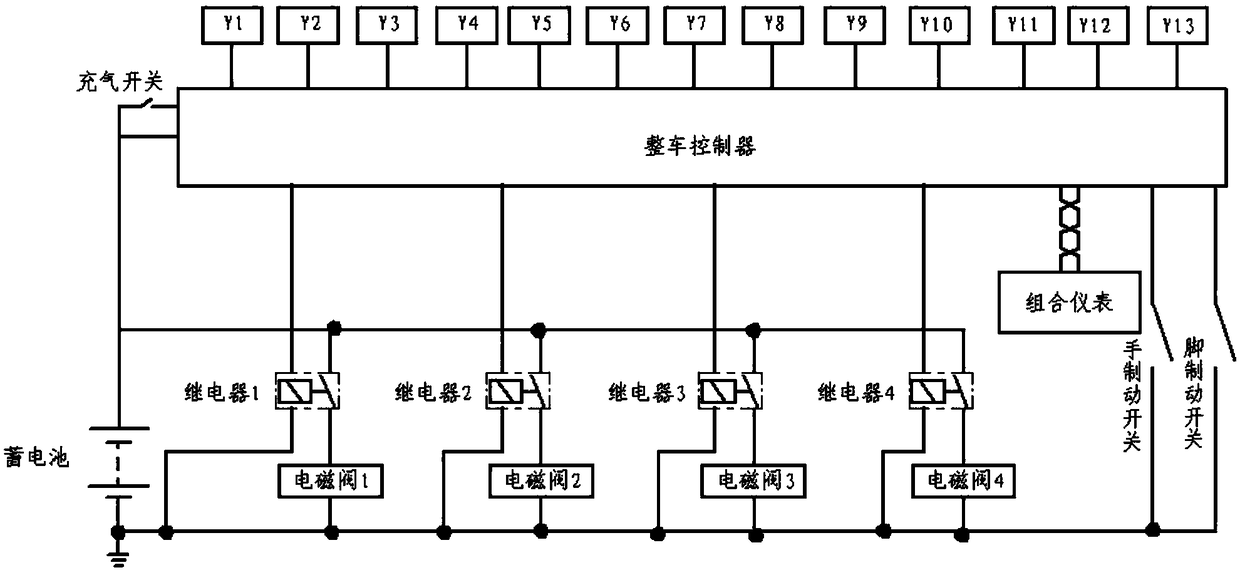

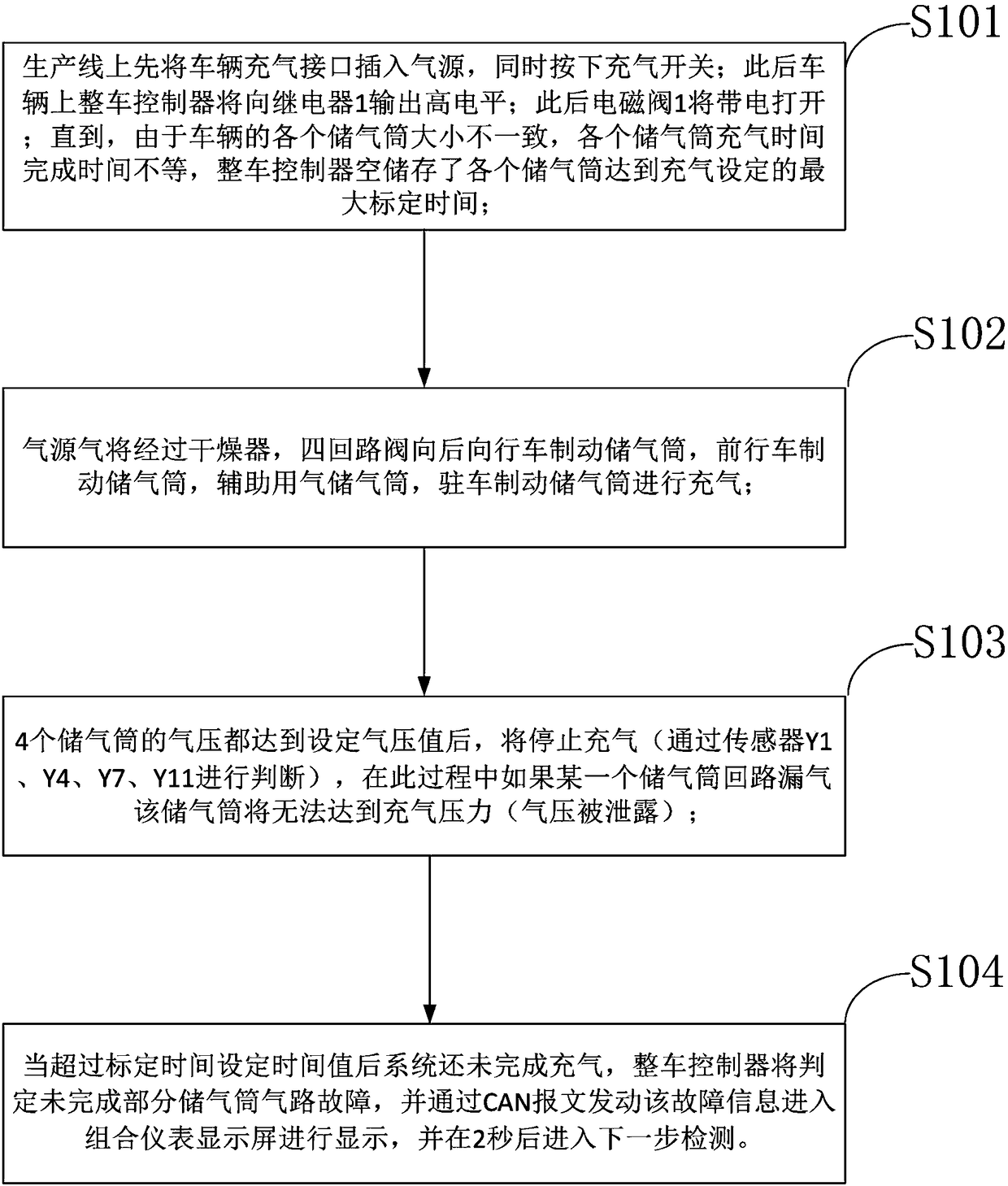

Online inflation and detection system and method for pneumatic brake vehicle

InactiveCN108128299AReduce working inflation timeReduce security risksBraking action transmissionBrake safety systemsAir compressorAtmospheric pressure

The invention belongs to the technical field of automobile brake and detection, and discloses an online inflation and detection system and method for a pneumatic brake vehicle. An air compressor is connected with a one-way valve tube, a one-way valve is connected with a dryer tube, and a dryer is connected to a four-circuit valve tube; an inflation port is connected to a pipeline between the one-way valve and the dryer through a first electromagnetic valve; the four-circuit valve is in parallel connection with a rear vehicle brake air storage valve, a front vehicle brake air storage valve, anauxiliary air storage cylinder and a parking brake air storage cylinder through the pipeline. According to the system, the four-circuit valve is in parallel connection with the rear vehicle brake airstorage valve, the front vehicle brake air storage valve, the auxiliary air storage cylinder and the parking brake air storage cylinder through the pipeline, the time of inflation of the vehicle through the engine is reduced, and production cycles are shortened; simultaneously the brake system can be debugged online, brake abnormalities are found in advance, and safety hazards caused by brake system defects are reduced.

Owner:CHONGQING IND POLYTECHNIC COLLEGE

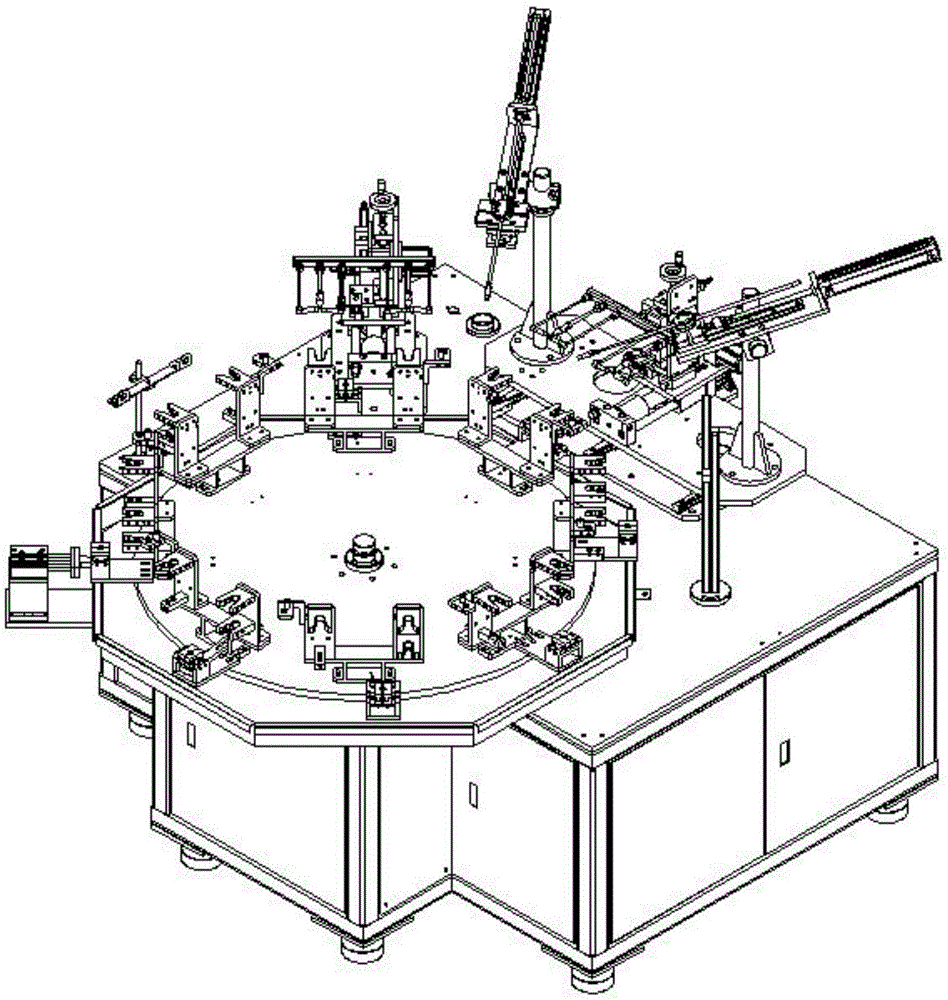

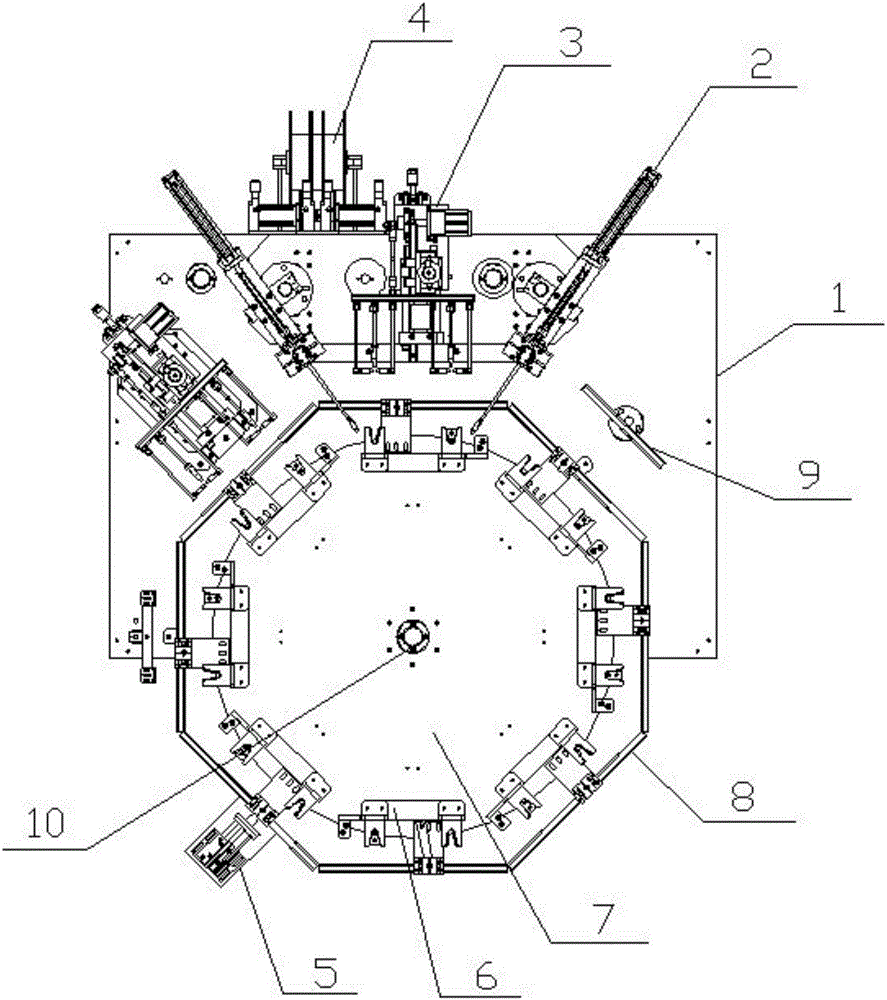

Rotary plate type multi-station automatic flame brazing machine for household air conditioner silencer assembly

InactiveCN106735683ASimple structureReasonable designMetal working apparatusSolder feeding devicesWire speedEngineering

The invention discloses a rotary plate type multi-station automatic flame brazing machine for a household air conditioner silencer assembly. The rotary plate type multi-station automatic flame brazing machine comprises a machine frame and an index rotary plate arranged at the top of the machine frame. Two welding devices and two wire feeding devices are arranged on one side of the index rotary plate. A plurality of wielding tools are arranged at the top of the index rotary plate. The whole machine adopts the rotary plate type multi-station design, servo wire feeding is adopted by the wire feeding devices, the wire speed and wire amount can be regulated and controlled, through a self-made reinforcement wire pressing device, wire feeding is stable, and slipping and wire stuck are avoided; through the self-designed welding tools, as for the same station, the left side is used for a former procedure, and the right side is used for a later procedure, so that finished products can be produced through one machine, the yield reaches 99.5% or above during usage, and the production takt is shorter than 8 second / set; the former and later procedure product can be met through the machine, finished products are obtained directly, and carrying and equipment input are reduced; two sets of products are perfectly compatible, gapless model change is achieved, machine debugging is avoided, and the equipment utilization rate is high; and the rotary plate type multi-station automatic flame brazing machine is suitable for being operated with robots and special machines online, and full-automatic manless production is achieved.

Owner:佛山市奥拓玛智能设备有限公司

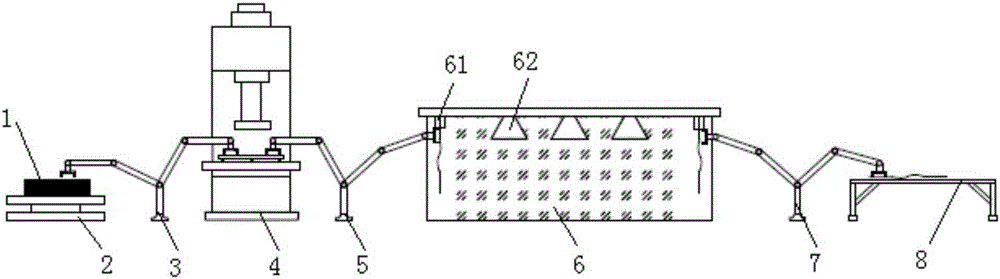

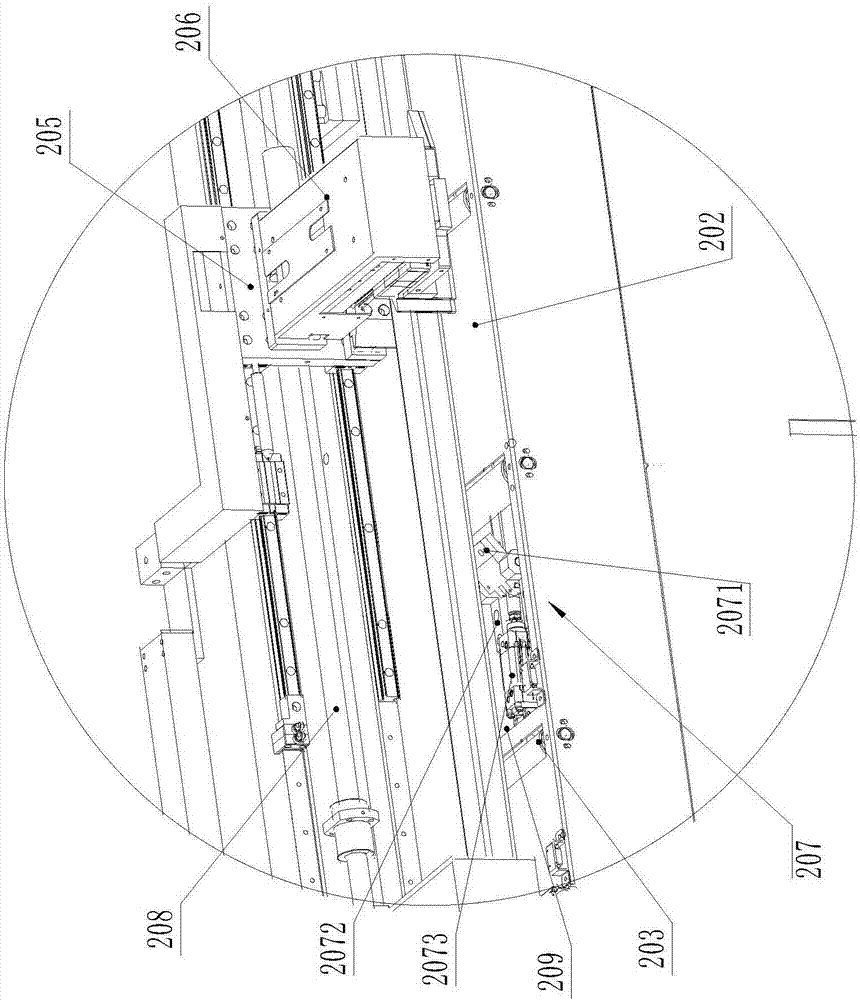

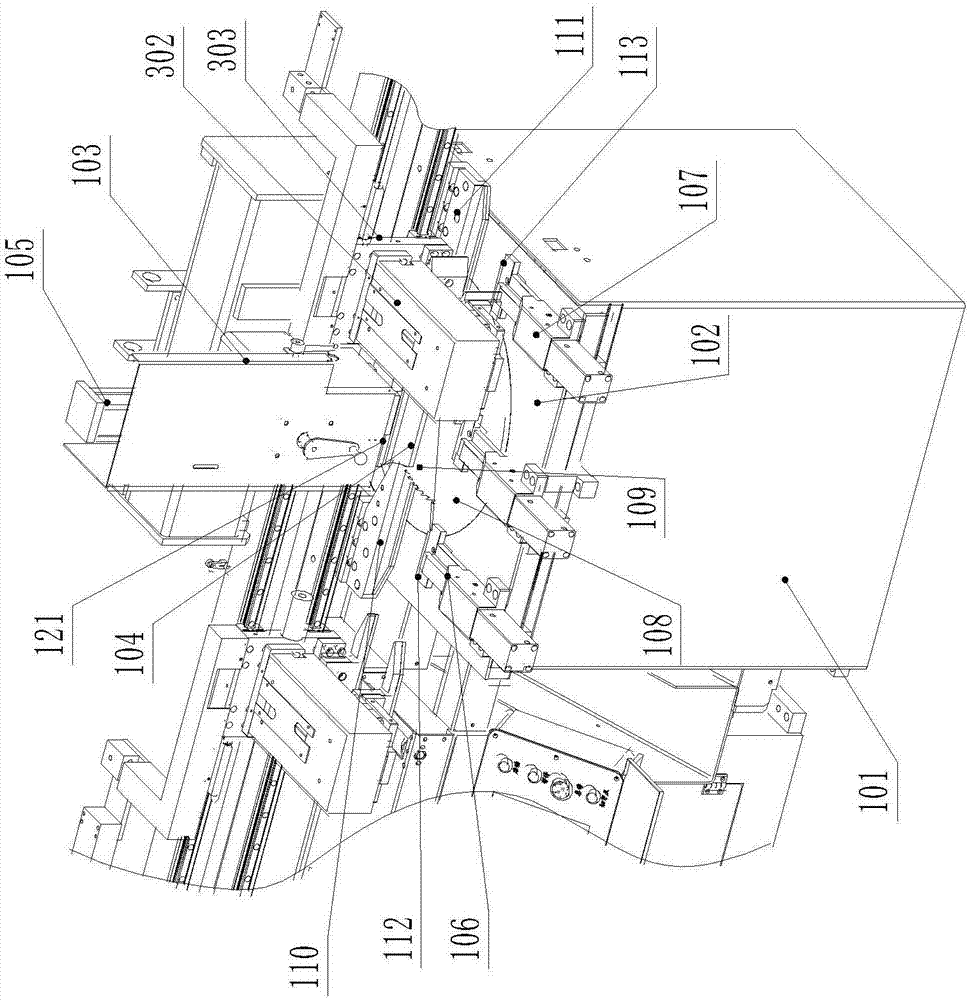

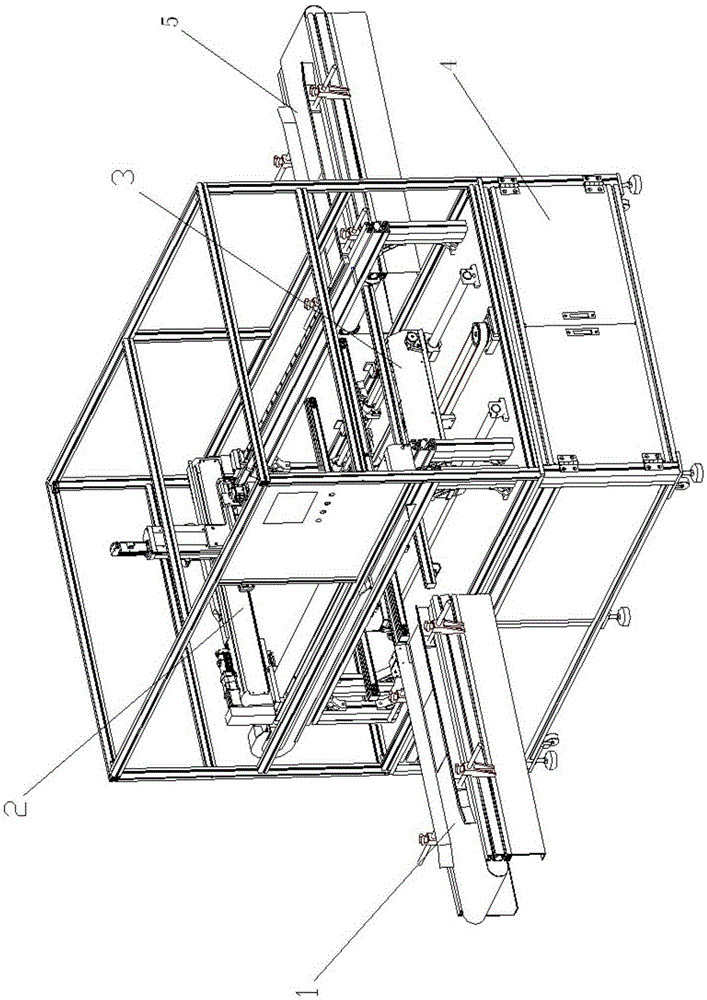

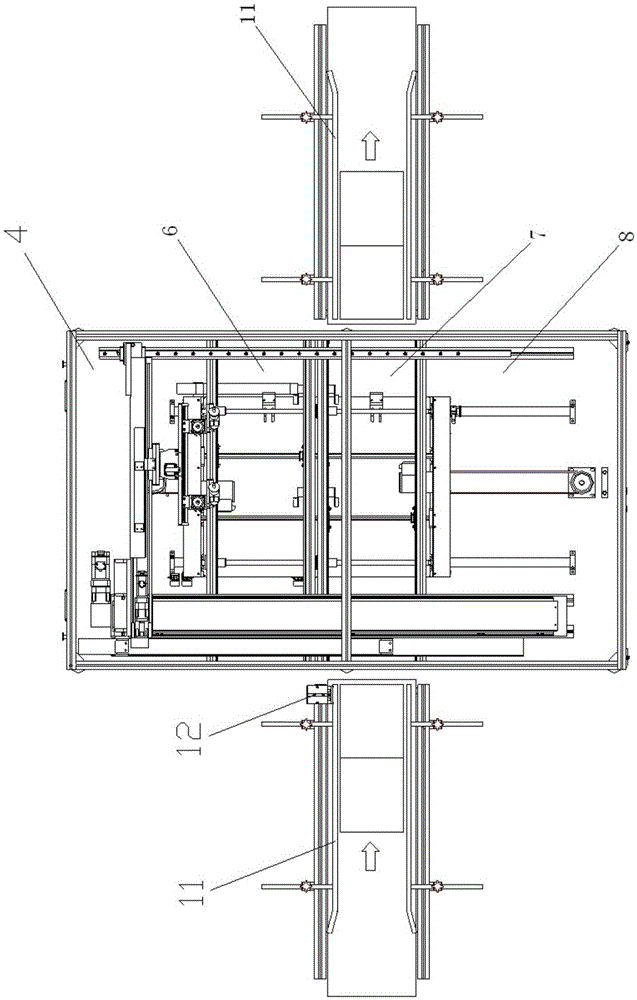

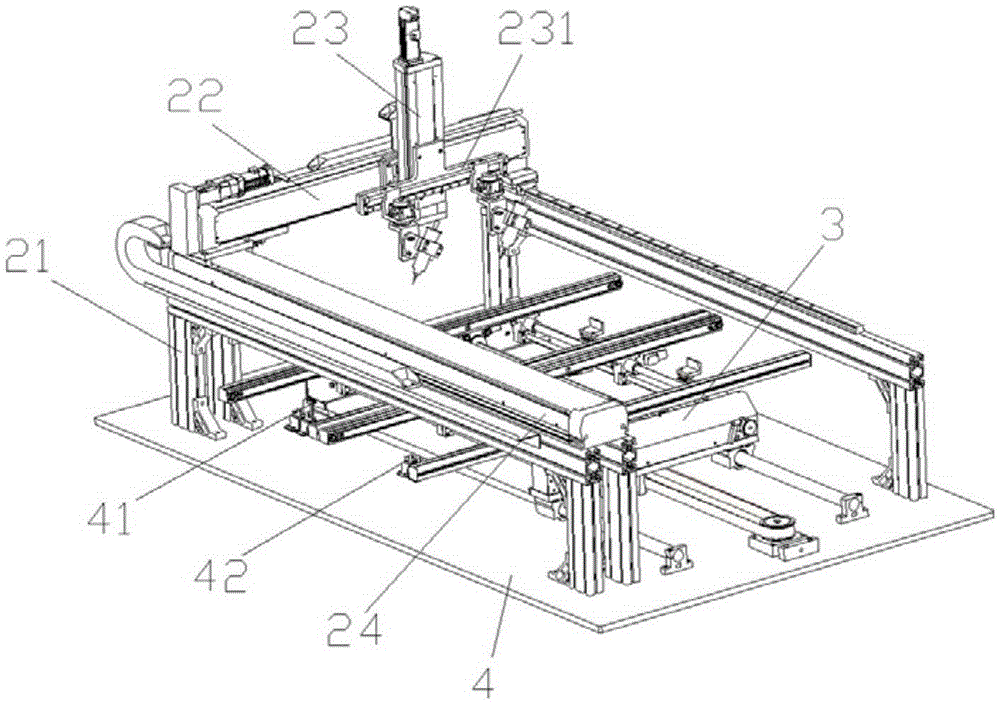

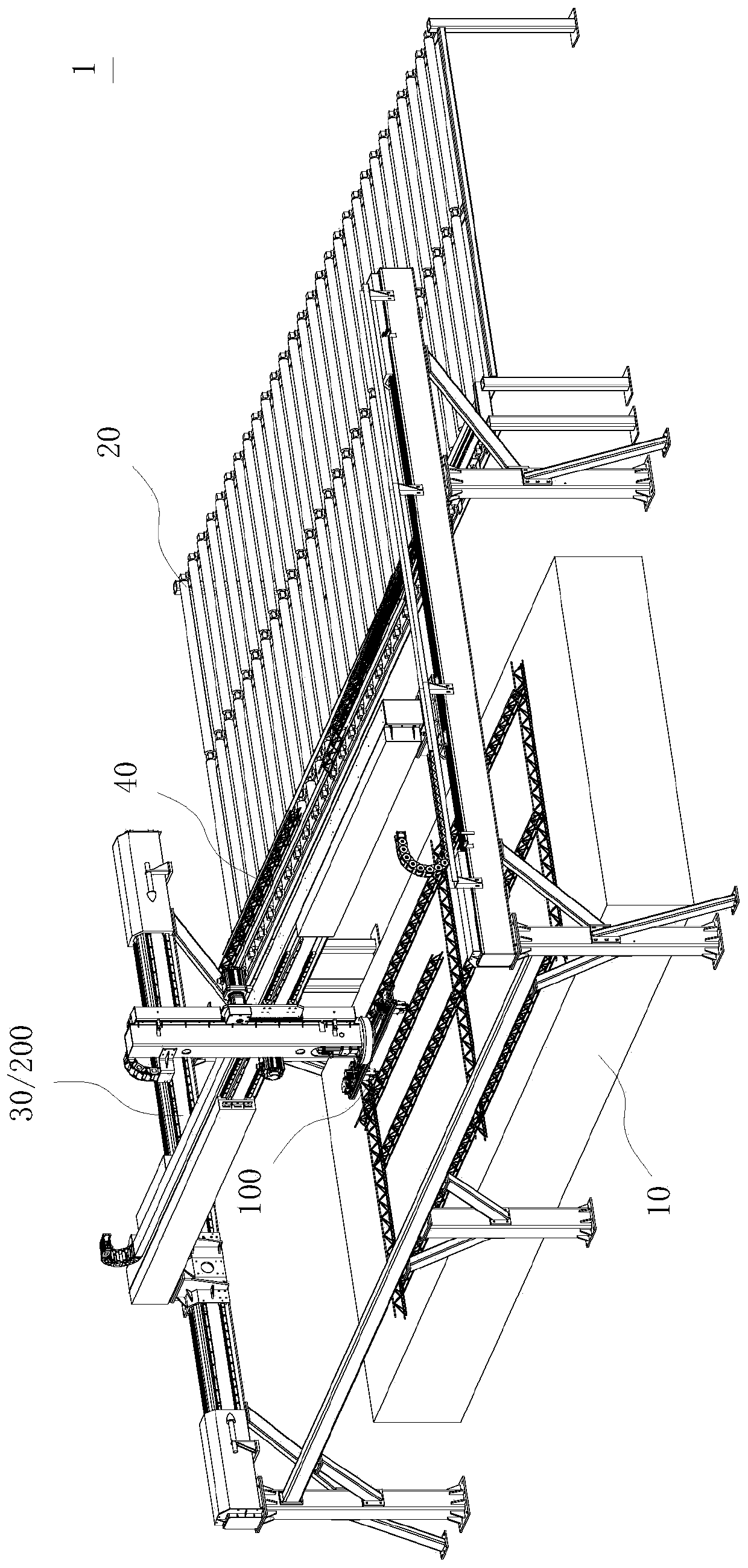

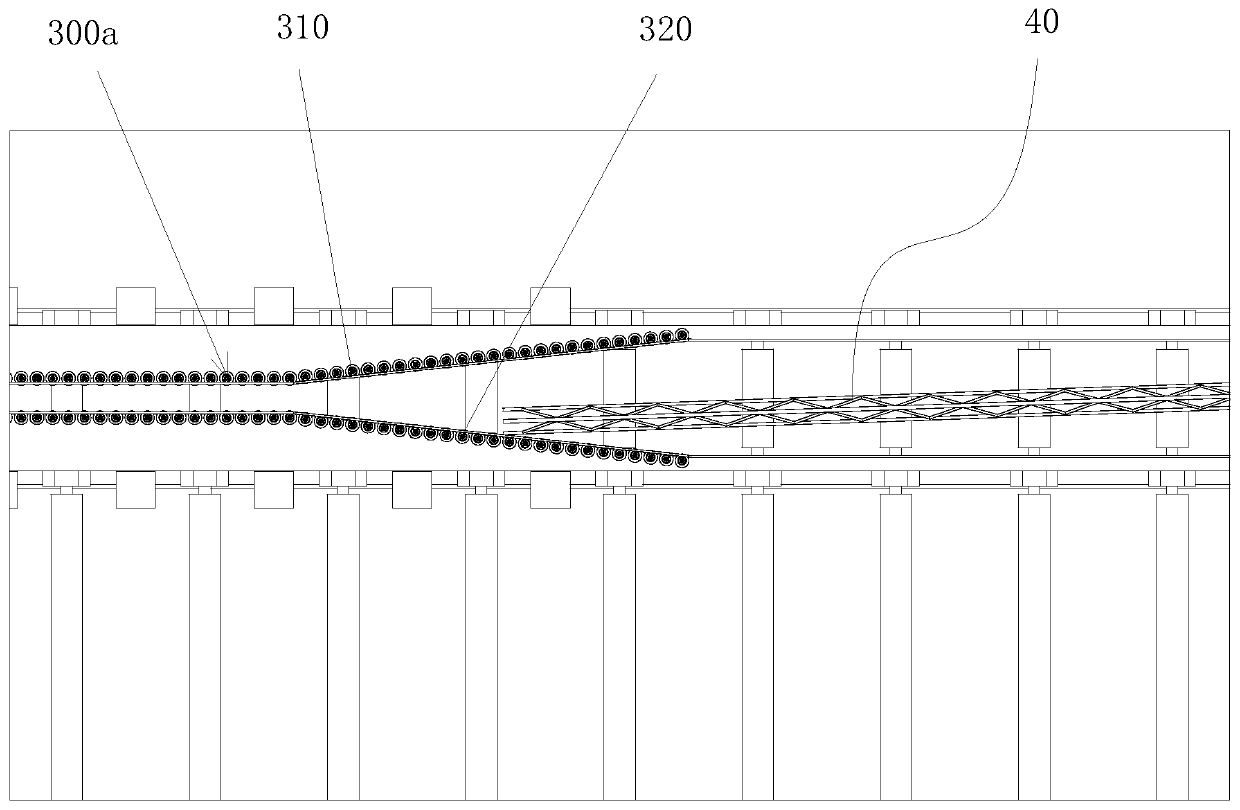

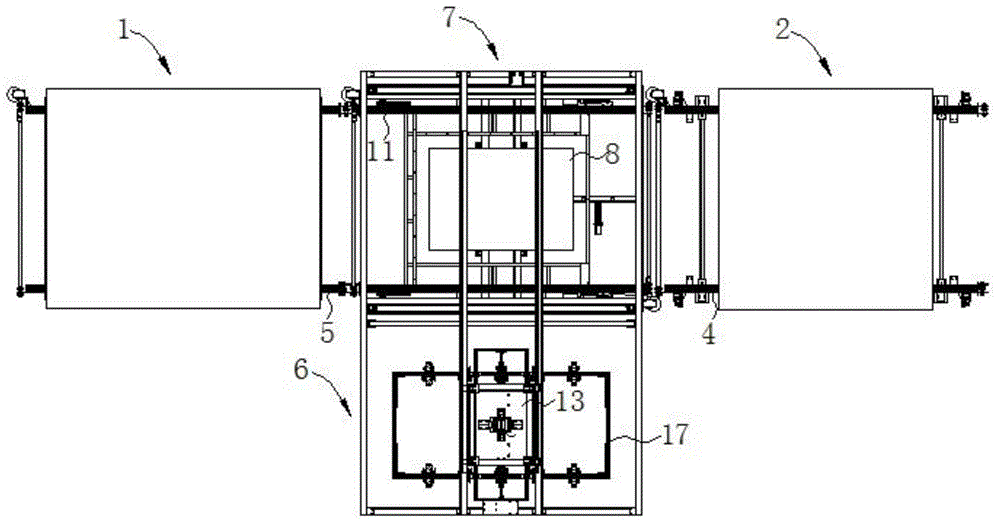

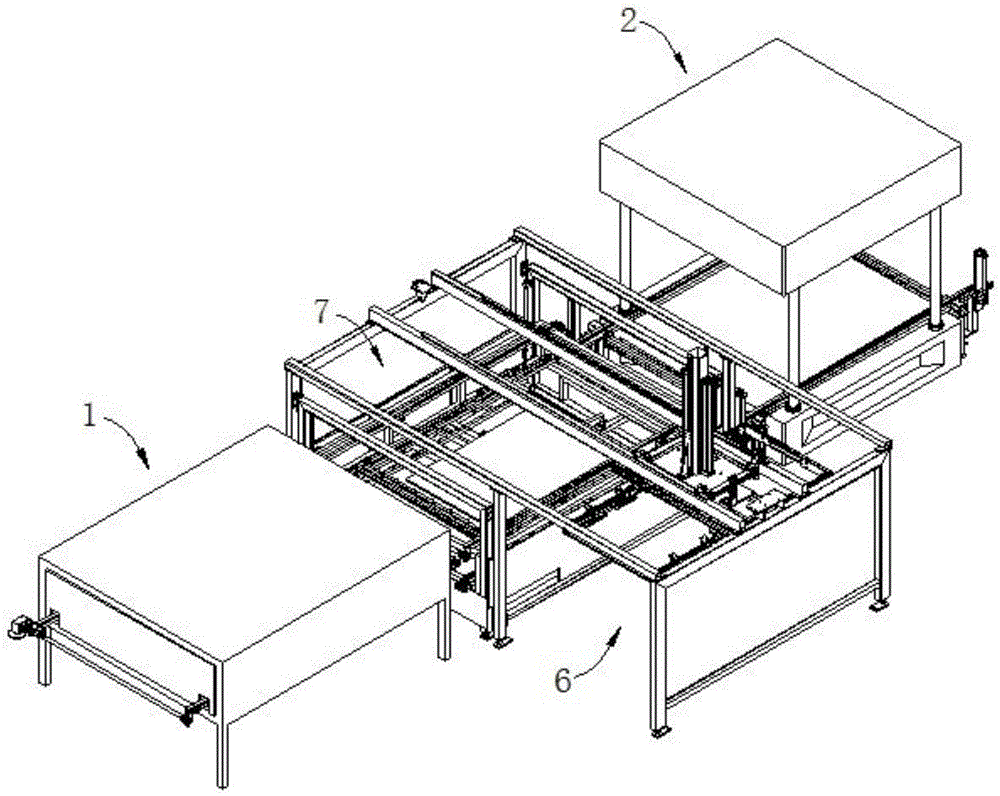

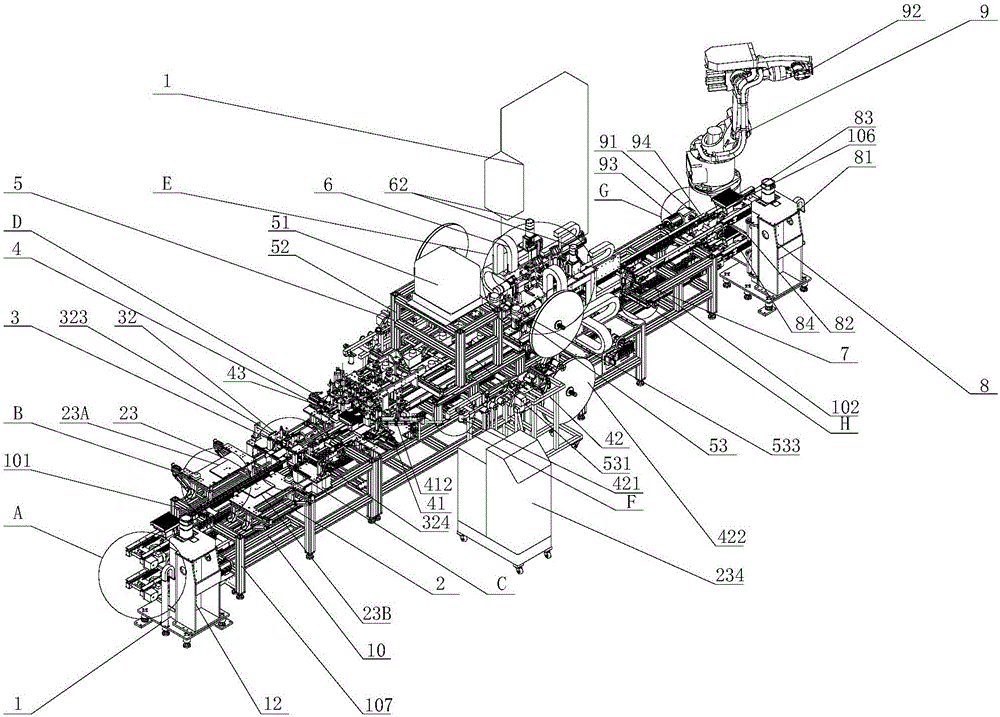

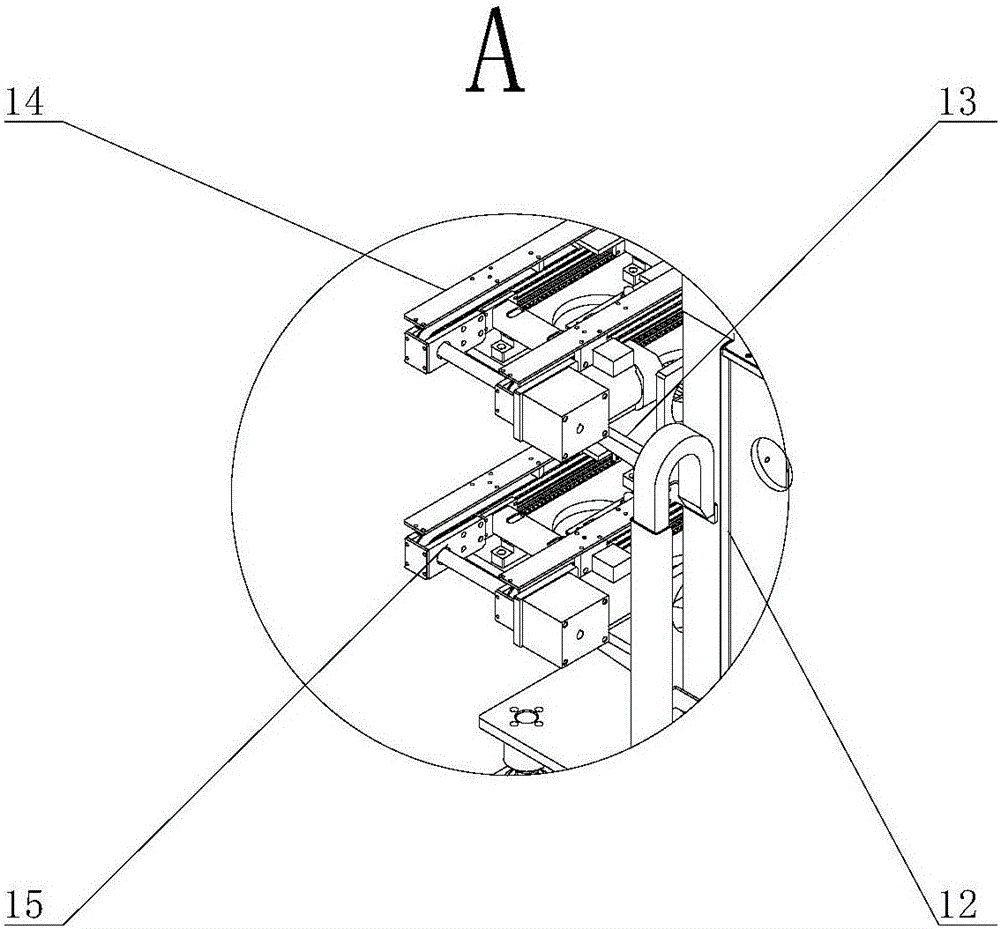

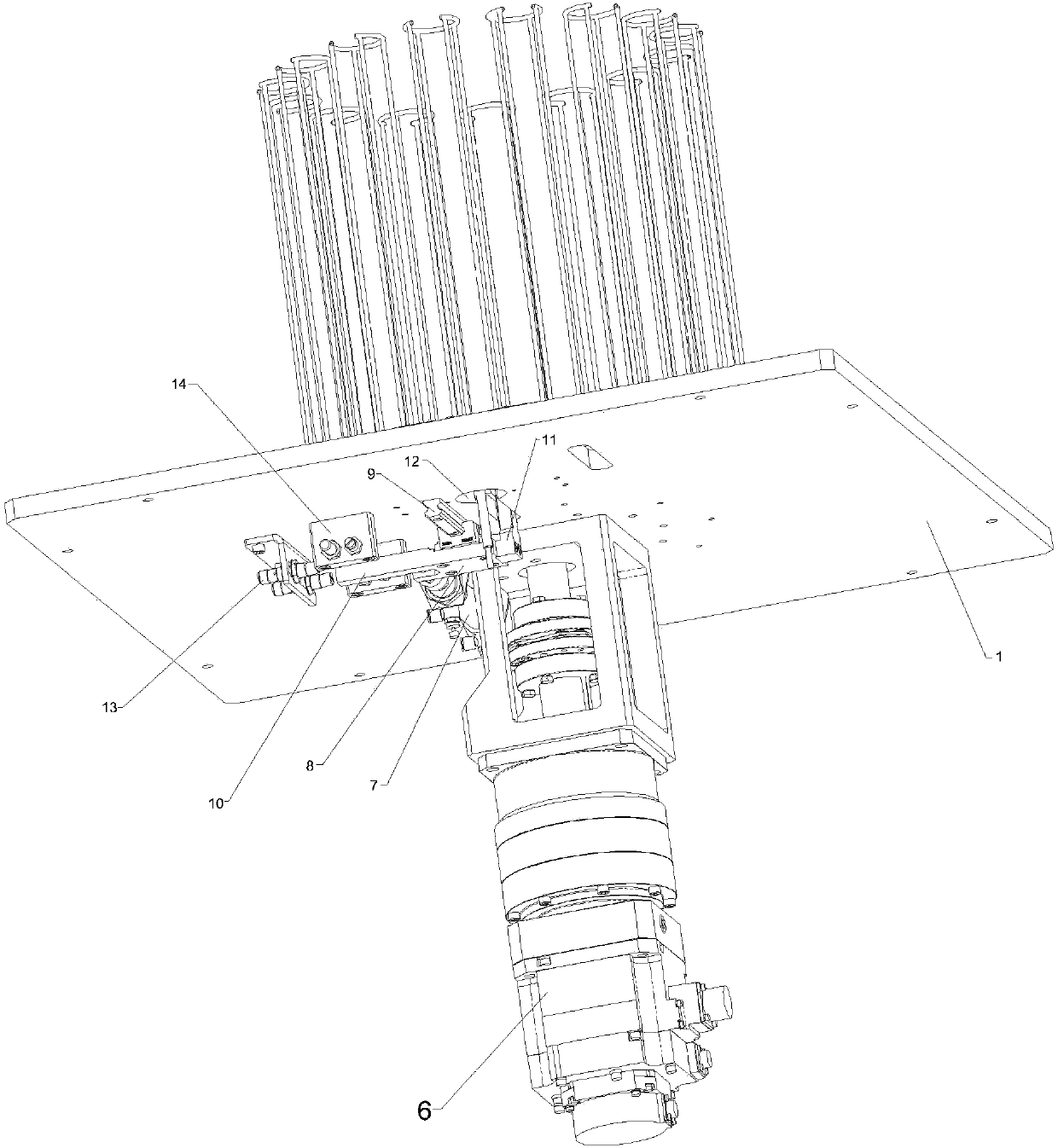

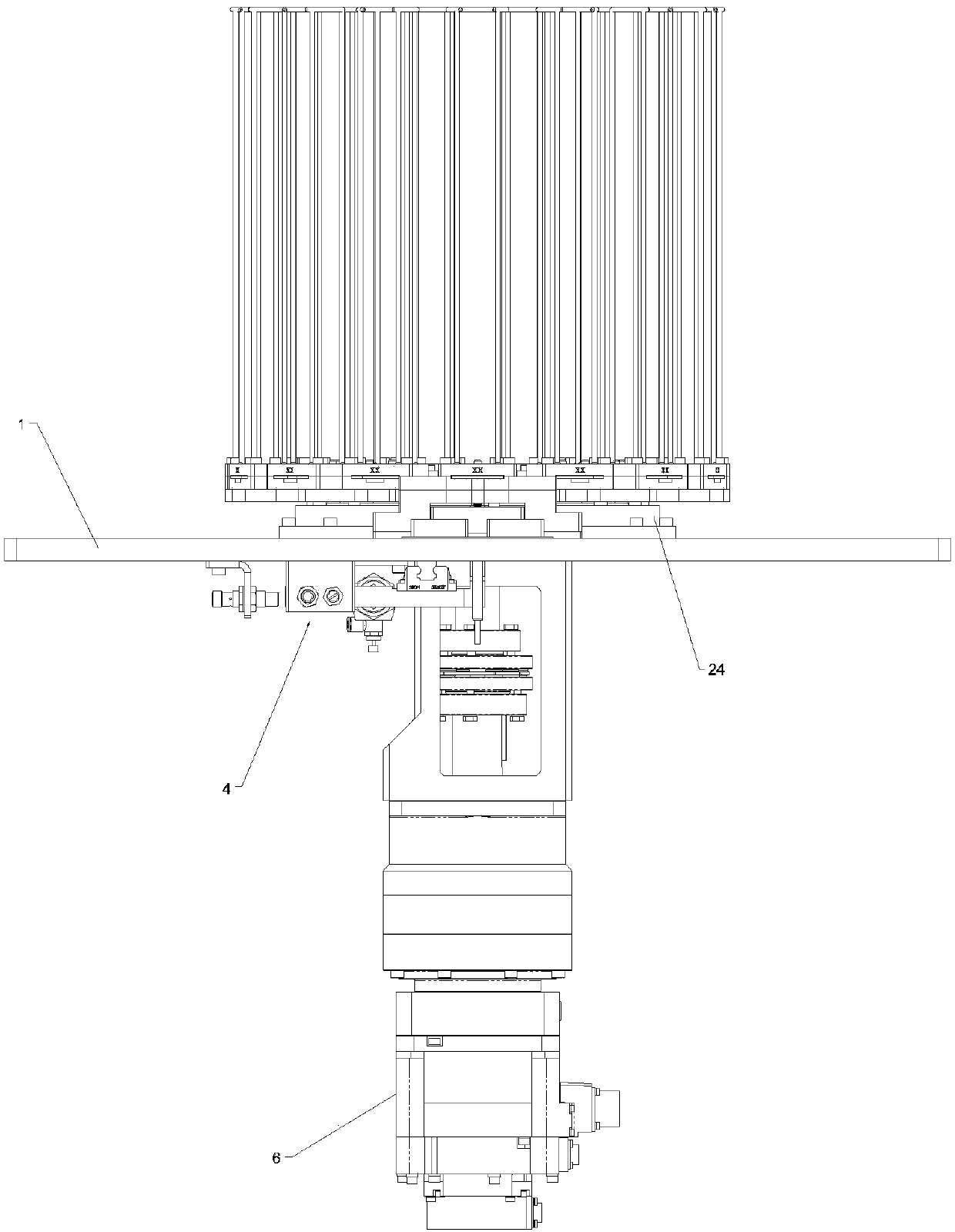

Special machine for automatically placing trusses and method for automatically placing trusses

PendingCN111571570ARealize intelligent pickingRealize batch layoutProgramme-controlled manipulatorRobot handStructural engineering

The invention discloses a special machine for automatically placing trusses and a method for automatically placing the trusses. The special machine for automatically placing the truss comprises a formtable, a truss conveying device, and a truss placing device, wherein the truss conveying device is arranged on the side edge of the form table, and the trusses are conveyed to the side edge of the form table by the truss conveying device; and the truss placing device comprises a space moving frame and a mechanical arm connected to the space moving frame, and the mechanical arm is used for takingthe trusses from the truss conveying device and placing the trusses at a preset position on the form table. According to the special machine and the method for automatically placing the trusses, intelligent picking and batched arrangement of the pre-component trusses can be achieved, the production takt can be greatly shortened, the labor intensity can be reduced, the form arrangement precision can be improved, and the production efficiency and the operation safety can be improved.

Owner:BEIJING RES INST OF AUTOMATION FOR MACHINERY IND

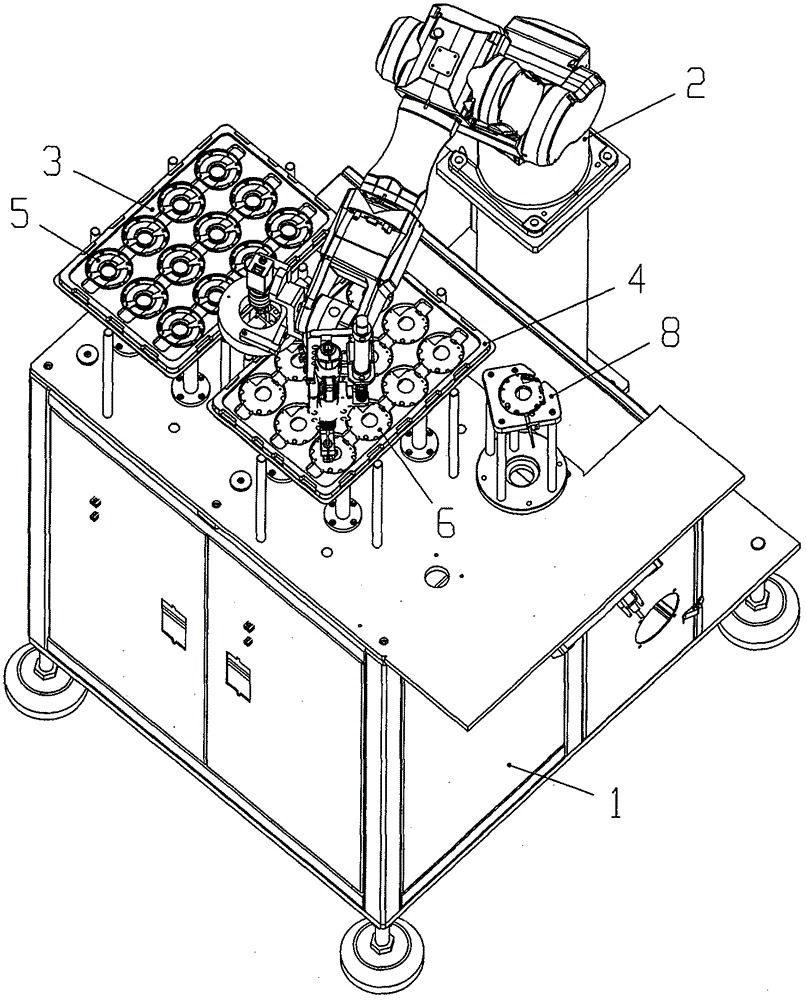

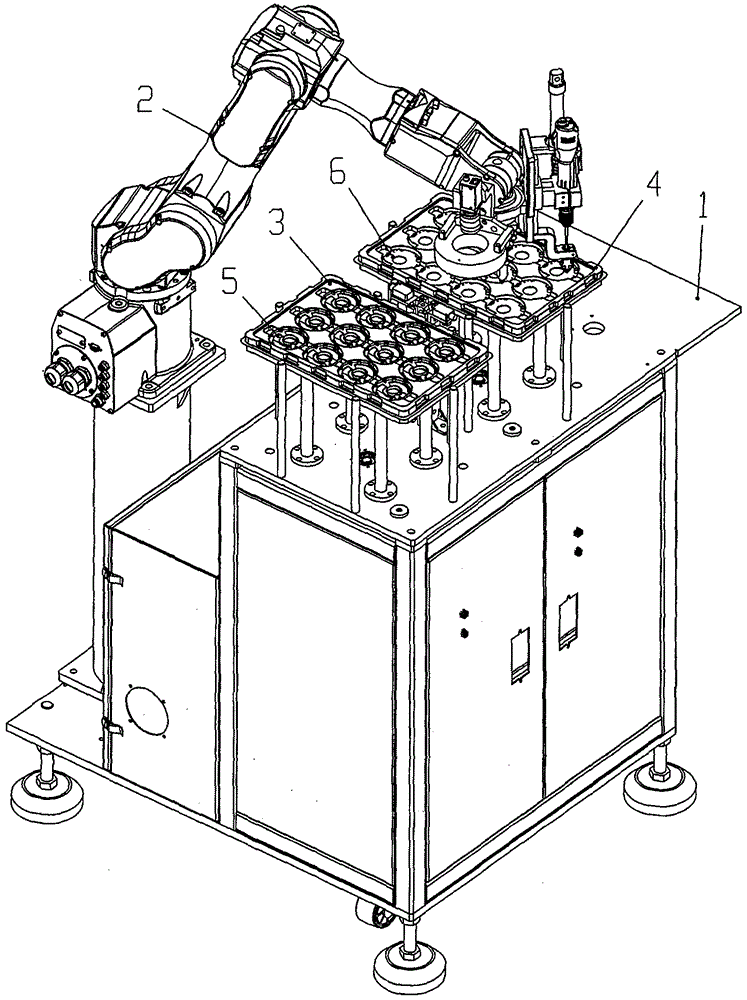

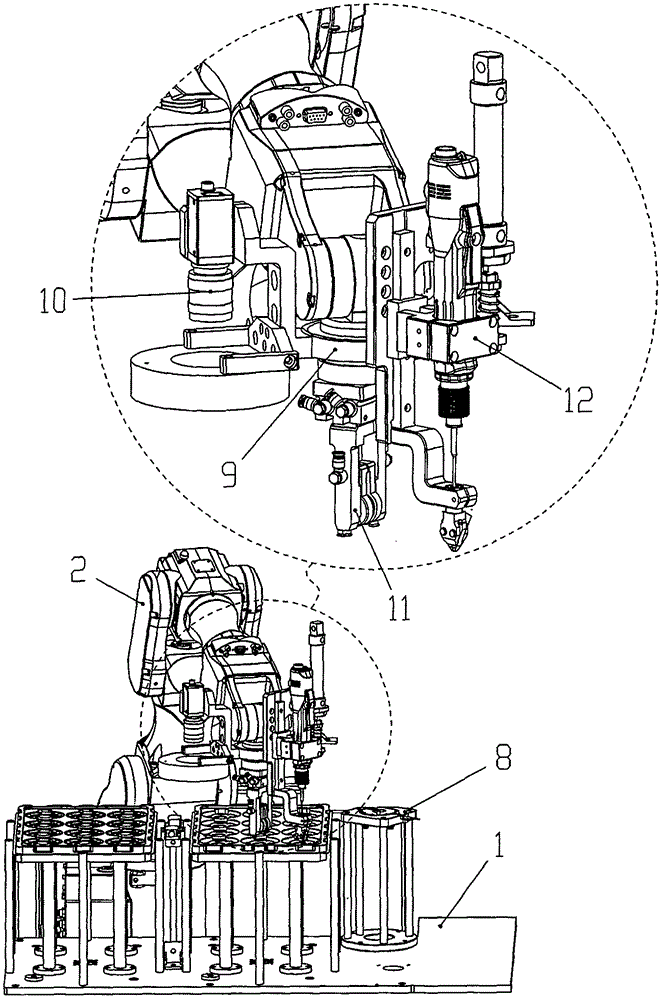

Robot-assisted visual assembly system for PCB (Printed Circuit Board)

InactiveCN105792629AAchieve connectionReduce mechanical movementElectrical componentsMachine visionEngineering

The invention relates to an automated assembly device, in particular to an automated assembly device for a PCB (Printed Circuit Board). A robot-assisted visual assembly system for the PCB comprises a worktable, a robot, a bracket tray, a PCB tray, a visual system, a clamping mechanism and a lock screw mechanism, wherein the robot, the bracket tray and the PCB tray are fixedly connected to the worktable; a bracket is arranged on the bracket tray; the PCB is arranged on the PCB tray; and the visual system, the clamping mechanism and the lock screw mechanism are fixedly connected to the wrist of the robot. The robot-assisted visual assembly system for the PCB is used for mounting the PCB to the bracket; the robot integrates a machine vision function, a clamping function and a lock screw function simultaneously; and the three functions take effects synchronously in a working process, so that higher working efficiency can be achieved, the product quality is improved, and full-automatic operation is realized.

Owner:WENZHOU POLYTECHNIC

Automatic ink-jet blowing system for hot die forging press

InactiveCN103111574AQuality improvementExtended service lifeForging/hammering/pressing machinesMechanical engineering

The invention discloses an automatic ink-jet blowing system for a hot die forging press. The automatic ink-jet blowing system comprises an ink-jet system and a blowing system, which are arranged on an upper die seat of the hot die forging press, wherein the ink-jet system is used for jetting ink to cavities of dies on upper and lower die seats of the hot die forging press; and the blowing system is used for blowing air to the cavity of the die on the lower die seat of the hot die forging press. The automatic ink-jet blowing system is simple in structure, reduces the labor intensity of workers, can shorten production takt and improve the production efficiency; and particularly, the system is good in blowing cleaning effect, uniform and disperse in spraying, high in spraying speed and stable and reliable in operation.

Owner:CHONGQING UNIV +2

Guide rail machining technology for automobile skylight

ActiveCN107309360AFast tempoReduce manufacturing costOther manufacturing equipments/toolsVehicle componentsEngineeringSkylight

The invention relates to a guide rail machining technology for an automobile skylight. Parts are grasped and conveyed to different stations through a robot and different operations are carried out. A whole guide rail production technology flow and equipment are improved, so that the production pace is reduced, the yield of production is improved and a process of producing and detecting synchronously is realized. The guide rail machining technology can be switched through one key according to different project guide rails, different radians and pre-adjusted parameters.

Owner:NINGBO HENGHE PRECISION INDUSTRY CO LTD

Friction stir welding stirring head with integrated welding and milling

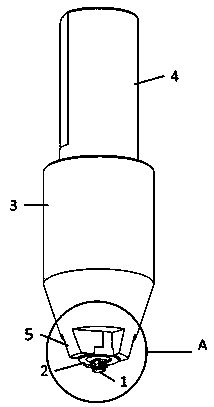

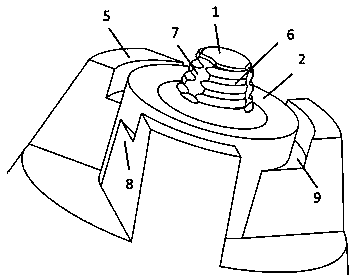

ActiveCN110653617AEasy loading and unloadingReduce manufacturing costOther manufacturing equipments/toolsNon-electric welding apparatusEngineeringWeld seam

The invention discloses a friction stir welding stirring head with integrated welding and milling. The friction stir welding stirring head comprises a clamping end, a supporting body, a shaft shoulder, a stirring needle and milling teeth, wherein the stirring needle is integrally connected with the front end of the shaft shoulder, the rear end of the shaft shoulder is connected with the small endof a conical end of the supporting body, the large end of the conical end of the supporting body is connected with a cylindrical end, the cylindrical end of the supporting body is connected with the clamping end, the shaft shoulder is arranged in the middle of the front end of the conical end, and a plurality of milling teeth are uniformly arranged around the shaft shoulder. According to the milling tooth uniformly distributed outside the shaft shoulder of the stirring head, as the shaft shoulder and the stirring needle rotate at a high speed, when a weld joint generates a flash in the rotating downward pressing process, large-area flash cutting is rapidly carried out on the edge of the welding seam, and the flash is discharged along the gap of the milling tooth, so that the process of mechanically removing the flash after the welding of a traditional stirring head is omitted.

Owner:AEROSPACE ENG EQUIP SUZHOU CO LTD

Full-automatic key assembly machine

PendingCN111195818ARealize automatic feeding processRealize automatic assembly functionAssembly machinesKey pressingAssembly line

The invention discloses a full-automatic key assembly machine comprising a machine frame, multiple automatic feeding mechanisms, a conveying mechanism, multiple vision positioning mechanisms and multiple transferring and assembling mechanisms. The automatic feeding mechanisms, the conveying mechanism, the vision positioning mechanisms and the transferring and assembling mechanisms are installed onthe machine frame. Multiple assembly stations are arranged in the length direction of the conveying mechanism at intervals. Each assembly station corresponds to one automatic feeding mechanism, one vision positioning mechanism and one transferring and assembling mechanism. The conveying mechanism is used for conveying mobile phone shell bodies. The automatic feeding mechanisms are located on onesides of the assembly stations. The transferring and assembling mechanisms are used for transferring materials to the corresponding assembly stations to be subjected to assembly work from the automatic feeding mechanisms. The vision positioning mechanisms are used for correcting material grabbing positions of the corresponding transferring and assembling mechanisms. According to the full-automatickey assembly machine, by adopting the continuous material supply technology, the assembly line automatic turnover alignment technology and the vision positioning assembly technology, the automatic feeding function and the automatic assembly function of mobile phone keys are achieved, the production efficiency is improved, and the assembly yield is increased.

Owner:深圳市昇茂科技有限公司

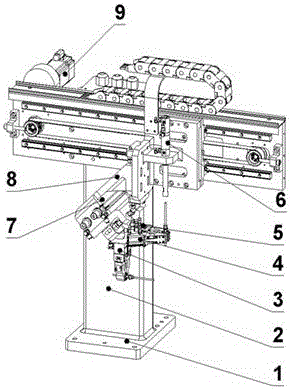

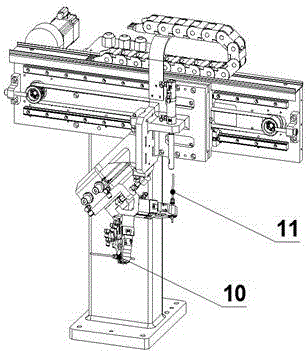

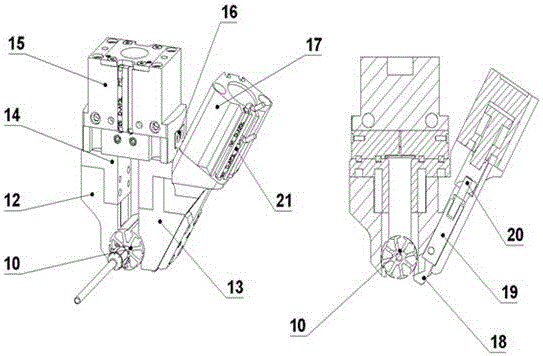

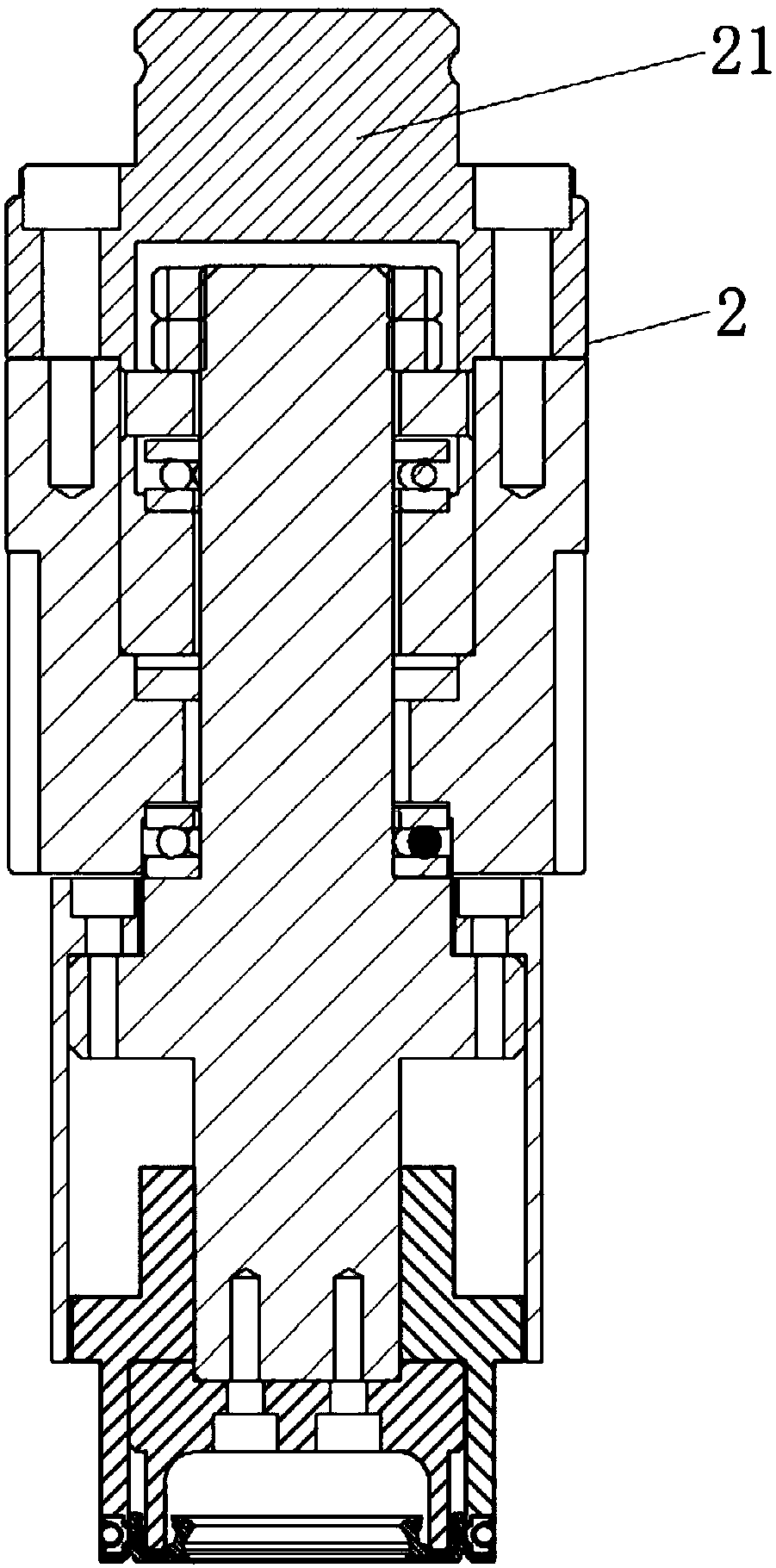

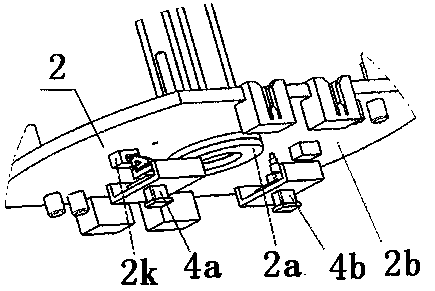

Multifunctional automatic taking and placing manipulator

PendingCN106113000AQuick changeoverMeet the requirements of quick changeoverProgramme-controlled manipulatorGripping headsWinding machineModular design

The invention discloses a multifunctional automatic taking and placing manipulator and particularly relates to a winding machine in the motor industry and an automatic taking and placing manipulator relevant to equipment in the motor manufacture industry. The manipulator comprises a fixed base (1), a supporting main body (2), a finished product material clamping jaw (3), an initial material locating structure (4), a semi-finished product material clamping jaw (5), an axial material locating structure (6), a clamping jaw rotating structure (7), a clamping jaw rotating structure fixing angle block (8) and a clamping jaw horizontal movement servo module (9). According to the multifunctional automatic taking and placing manipulator, the modular design is adopted, and each functional module can be rapidly remodeled, so that the rapid remodeling requirements of customers are met, meanwhile, the maintenance cost of equipment and the stock of spare parts are reduced, and the multifunctional automatic taking and placing manipulator helps the customers increase the production efficiency and ensure the product quality.

Owner:SHENZHEN KAISHENG TECH

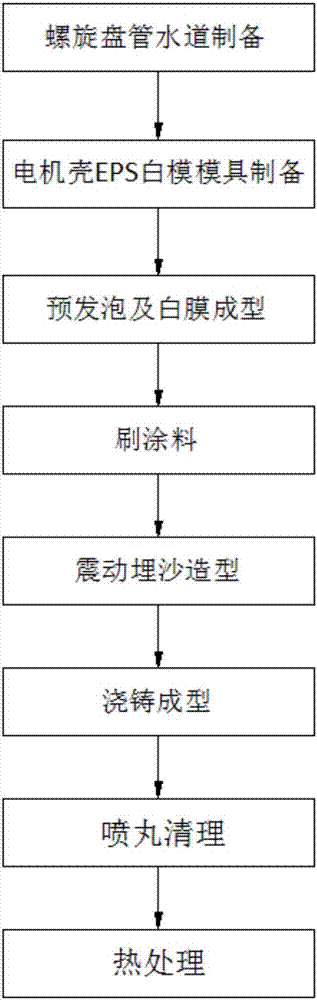

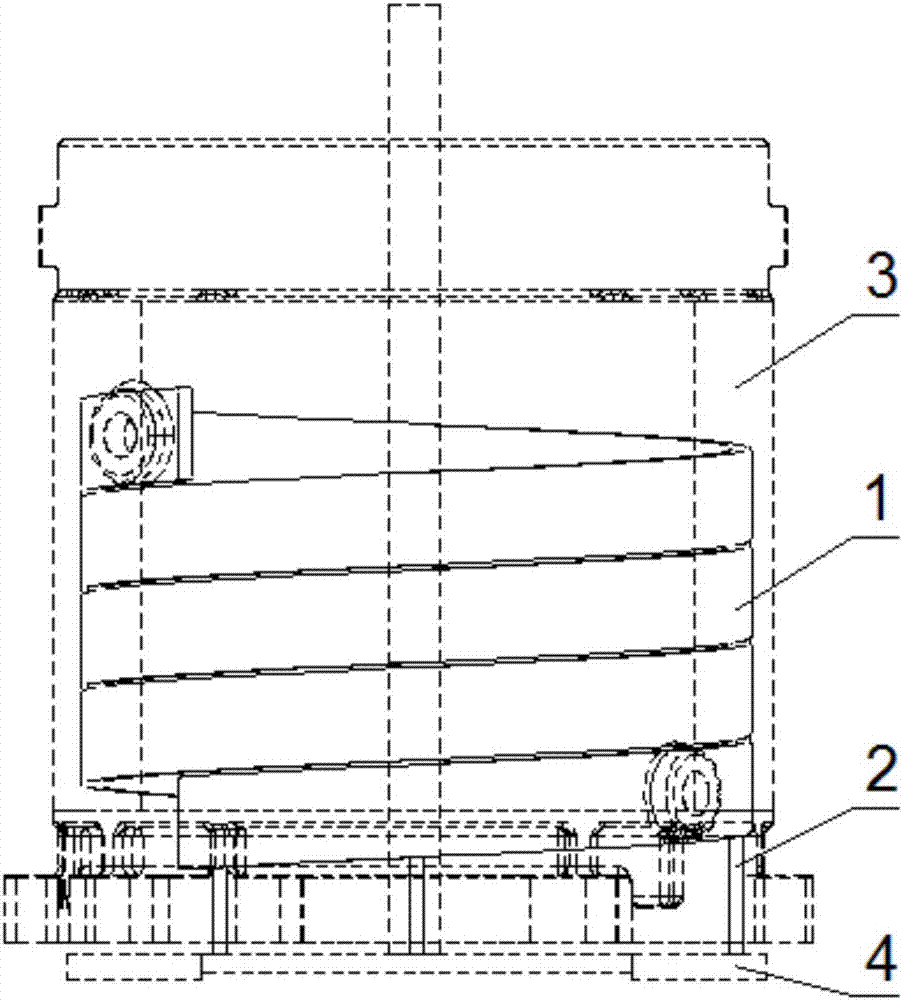

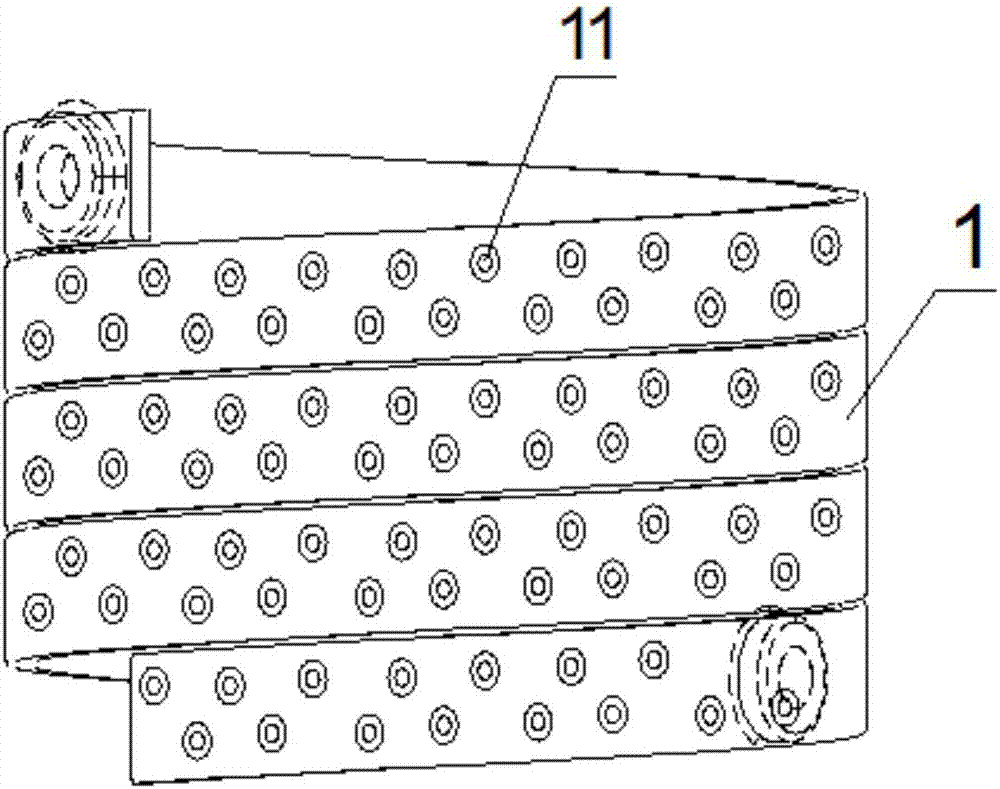

Expendable pattern casting technique for aluminum alloy internally provided with spiral coiled tube water passage

InactiveCN107282886ATightly boundReduce internal stressFoundry mouldsFoundry coresCooling effectCopper

The invention discloses an expendable pattern casting technique for an aluminum alloy internally provided with a spiral coiled tube water passage. According to the technique, the spiral coiled tube water passage made of stainless steel or copper is prefabricated firstly, and the upper end and the lower end of the spiral coiled tube water passage are provided with a water inlet and a water outlet which are capable of being exposed out of the column face of a motor shell correspondingly. A foaming mold is utilized for positioning and forming, an integrated motor shell EPS white mold internally comprising the prefabricated spiral coiled tube water passage can be machined through one-time forming, and then through the expendable pattern casting technique, the aluminum alloy motor shell internally provided with the spiral coiled tube water passage in an embedded mode is casted. An auxiliary structure capable of being tightly combined with the casted aluminum alloy shell is arranged on the spiral coiled tube water passage, internal stress generated by cold-hot change is reduced, and the shell is prevented from cracking. The spiral coiled tube water passage is further connected with a casting technique supporting framework, the aluminum alloy motor shell internally provided with the spiral coiled tube water passage can be stably and reliably casted on a large scale through an expendable pattern, the prefabricated spiral coiled tube water passage does not need to be filled with sand before casting, the water passage is smooth and not prone to being plugged, and it is ensured that the cooling effect is good.

Owner:FUJIAN JU NENG MACHINERY MFG CO LTD

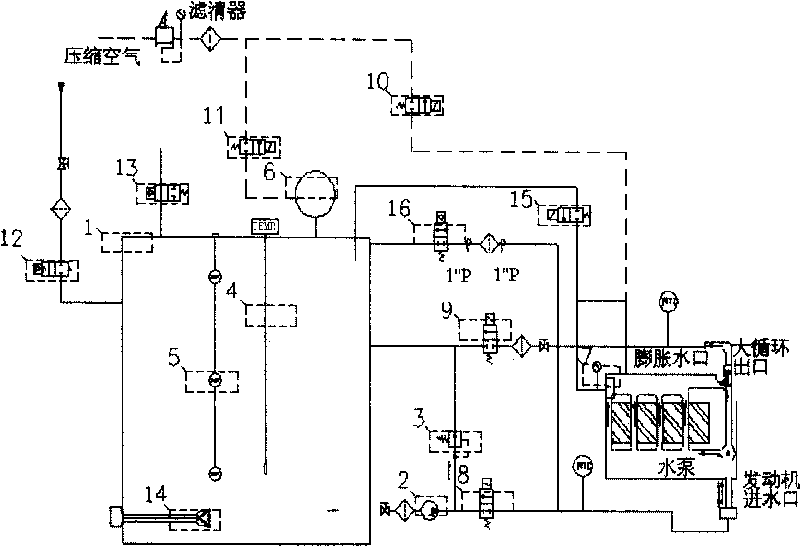

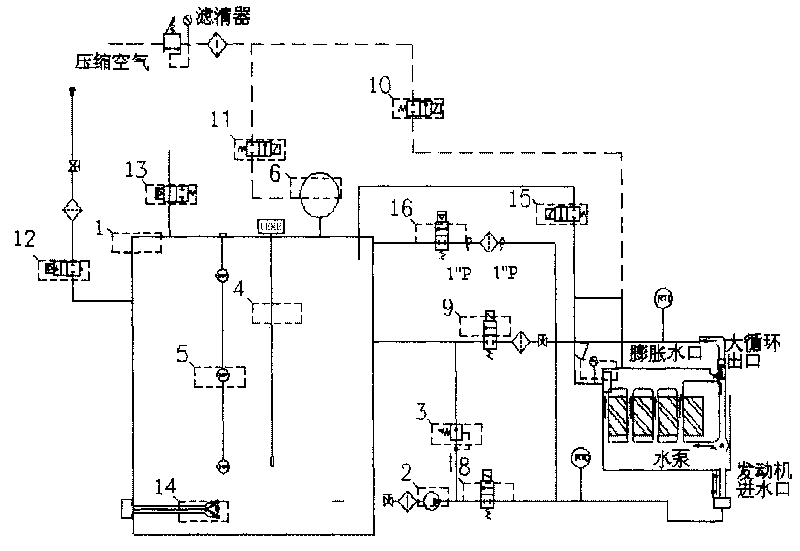

Coolant system of heat testing machine of automobile engine and coolant supplying method

InactiveCN101706369AShorten warm-up timeShorten the takt timeEngine testingLeakage testCooling fluid

The invention discloses a coolant system of a heat testing machine of an automobile engine and a treatment method. The invention heats the coolant to be about 80 DEG C, thus saving the warming-up time when in heat test and reducing production rhythm; the filling is carried out automatically and the coolant is recovered, thus reducing the production rhythm; compressed air is used to carry out leakage test on the whole pipeline before the engine runs so as to solve the problem that the coolant pipeline is aged to produce leaked coolant; if the leakage is generated, the following test steps are not carried out. The water pump is used for automatically filling the coolant before the engine runs, and after the engine test is finished, the coolant in the pipeline is recovered by a mode of combining compressed air blowing and a vacuum generator so as to solve the problem of residual coolant after the heat test. Compared with the original cooling system of the heat testing machine, the system and the method shorten the production rhythm and avoid the leakage of the coolant system when the engine is in the heat test.

Owner:CHERY AUTOMOBILE CO LTD

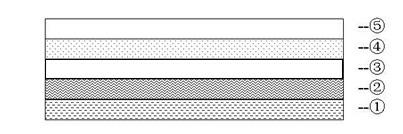

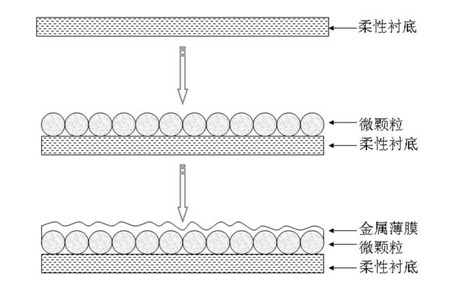

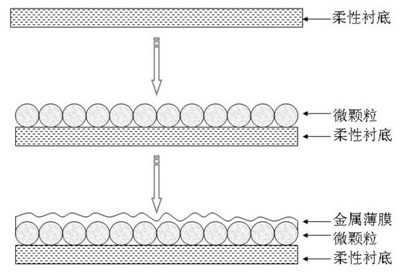

Metal back electrode of flexible film solar cell and preparation method thereof

InactiveCN102403411AAdjustable velvet valueImprove reflectivityFinal product manufacturePhotovoltaic energy generationElectrical batteryThin membrane

The invention relates to a metal back electrode of flexible film solar cell and a preparation method thereof, which belong to the technical field of solar cell. The technical solution is that a metal back electrode with texture structure on the surface is directly prepared on a flexible substrate, and the method comprises the following technological steps of: (1) forming a concave-convex texture structure on the flexible substrate; and (2) depositing a metal film on a substrate with the concave-convex surface structure as the metal back electrode of the flexible cell. The method for preparing the flexible film solar cell by using the texture metal back electrode has the following advantages that: 1) the surface structure of the back electrode can be adjusted by changing microparticle size and interval, which is convenient, flexible and favorable for realizing optimization of technological parameters; 2) the metal back electrode has high reflection rate, and can improve utilization rate of sunlight and improve efficiency of the solar cell; and 3) the sunlight has high optical distance in the cell, so thickness of absorption layer of film battery can be reduced, production time can be shortened, production cost can be reduced and production efficiency is improved.

Owner:BAODING TIANWEI GRP CO LTD

Automatic puncture feeding device

ActiveCN102910452AShorten the takt timeIncrease productivityCharge manipulationConveyor partsMechanical engineeringEngineering

The invention discloses an automatic puncture feeding device which comprises a baking oven and a hydraulic machine. A baking rail is arranged in the baking oven; a press lifting rail is arranged in the hydraulic machine; the automatic puncture feeding device also comprises an automatic grasping device and a double-layer frame lifting device; the double-layer frame lifting device comprises a base and a double-layer frame; an upper layer rail and a lower layer rail are arranged in the double-layer frame; a movable open-close type puncture frame is laid on the lower layer rail; and the upper layer tail and the lower layer rail of the double-layer frame are positioned between the baking rail and the press lifting rail. The automatic puncture feeding device realizes the automated production of loading, puncture, baking and pressing processes, after the automatic puncture feeding device is adopted, the movable open-close type puncture frame can realize that the hydraulic machine can automatically withdraw the puncture frame from a die in advance before die assembly, and by adopting the operating mode of double-frame circulating lifting rails, the production time is greatly shortened, and the production efficiency is effectively improved.

Owner:CHONGQING HONGNAN MACHINERY

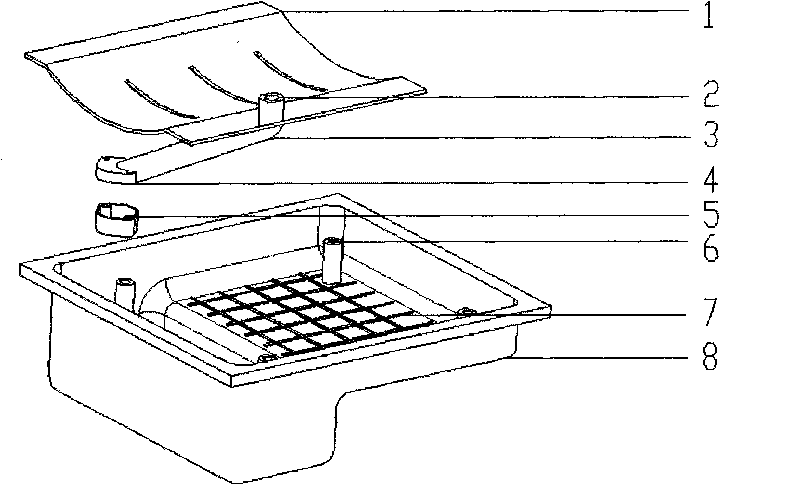

Automatic edge pasting device for air conditioner filter screen

ActiveCN105805115AShorten the takt timeRealize automated productionMaterial gluingWork in processMechanical engineering

The invention discloses an automatic edge pasting device for an air conditioner filter screen. The automatic edge pasting device for the air conditioner filter screen comprises a conveying mechanism, a front lifting mechanism, a press-fitting shaping mechanism, a glue coating and material supplying mechanism, an edge pasting and cooling mechanism, a shearing mechanism and a rear lifting mechanism, wherein the conveying mechanism is used for supporting and conveying a tray tool; the front lifting mechanism makes the air conditioner filter screen move in the vertical direction; the press-fitting shaping mechanism is used for pressing and outputting the air conditioner filter screen; the glue coating and material supplying mechanism is used for supplying materials to a frame and performing glue coating and press-fitting on the frame and the air conditioner filter screen; the edge pasting and cooling mechanism is used for cooling the air conditioner filter screen and the frame; the shearing mechanism is used for shearing the frame to form a semi-finished or finished air conditioner filter screen; and the rear lifting mechanism is used for receiving the tray tool. The automatic edge pasting device for the air conditioner filter screen has the beneficial effects that automatic production of the edge pasting work of the air conditioner filter screen is achieved, labor cost input is reduced, the production efficiency is improved, and the production and maintenance cost is reduced; meanwhile, the upper side and the lower side conveying manner of the tray tool is achieved, and the floor area is reduced; and the production takt of the air conditioner filter screen is shortened, and the production efficiency is further improved.

Owner:SHANGHAI TUOZHAN ELECTRICAL & MECHANICAL EQUIP

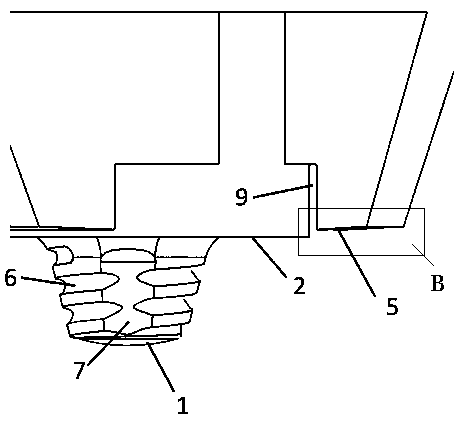

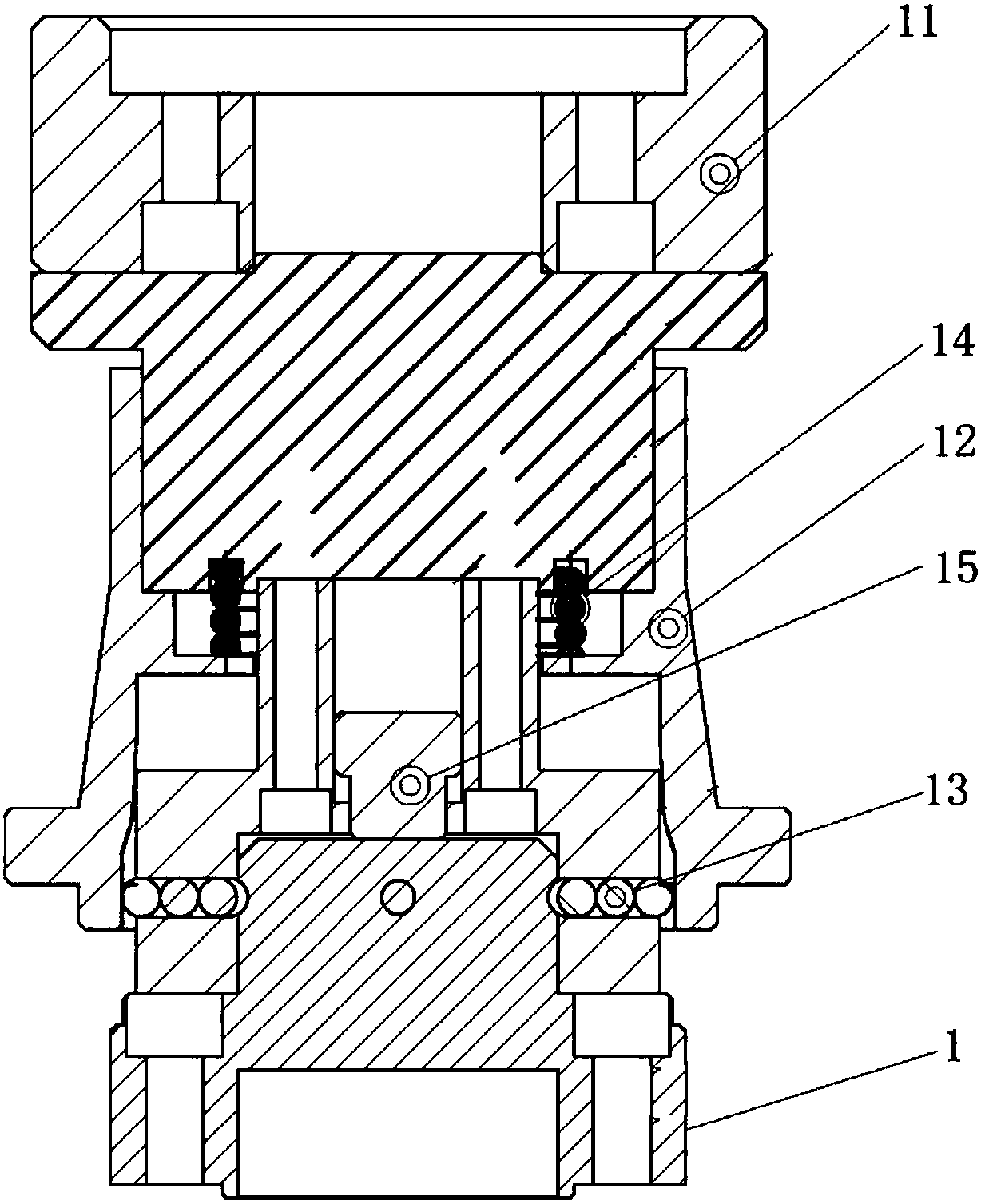

Pressure head automatic quick-change device

PendingCN108099255AReduce riskShorten the takt timeMetal working apparatusPressesEngineeringLocking mechanism

The invention discloses a pressure head automatic quick-change device. The pressure head automatic quick-change device comprises a pressure head locking mechanism, a pressure head and a quick-change auxiliary intervention mechanism, wherein the pressure head locking mechanism is provided with a grabbing main body and a floating locking sleeve. A pressure head quick-change main shaft is arranged atthe pressure head, matched with the pressure head locking mechanism, the pressure head quick-change main shaft and the pressure head form a whole, the quick-change auxiliary intervention mechanism isprovided with a quick-change intervention plate, and a quick-change intervention plate is powered by an air cylinder and is connected with a floating locking sleeve of the pressure head locking mechanism. According to the structural design, not only can the error caused by machining and assembling be compensated, but also the device can be compatible with multiple types of press-fitting, and hasthe advantages of being convenient to install and debug, reducing the risk, improving the production time and the like. According to the pressure head automatic quick-change device, the pressure headscorresponding to the corresponding parts can be conveniently replaced when the pressure heads of multiple types of press-in parts are assembled in the same machine type and in the same station, so that the production rhythm can be further compressed, and the device can be compatible with multiple types of press-fitting, and has the advantages of being simple in structure, convenient to install and debug, and flexible in equipment installation and debugging.

Owner:天永锂电自动化设备(太仓)有限公司

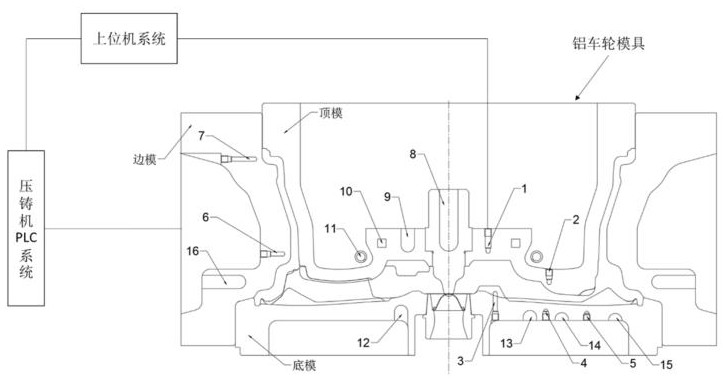

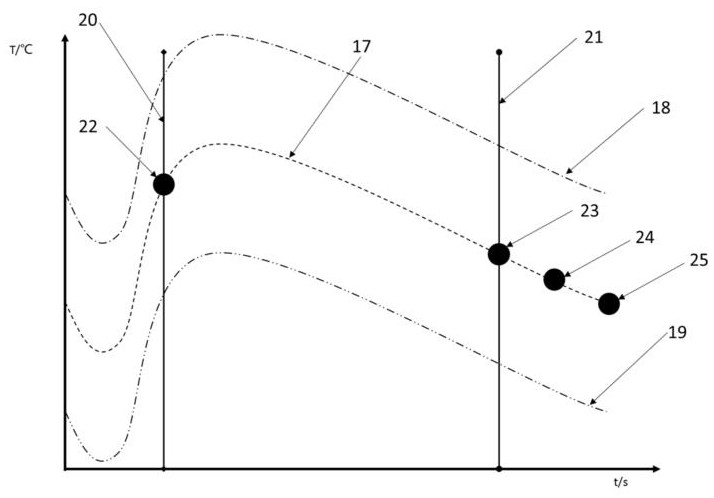

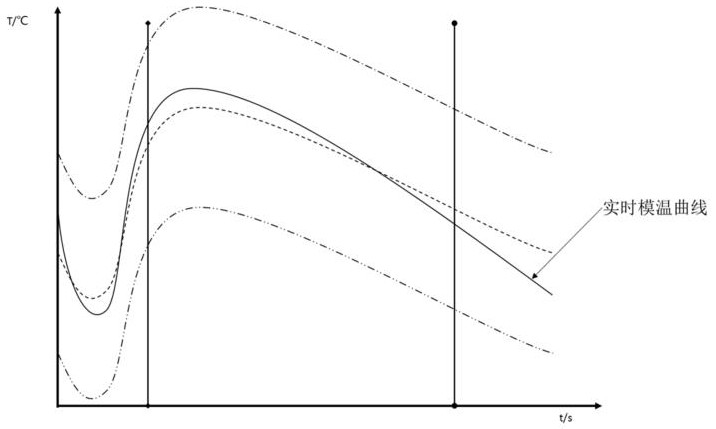

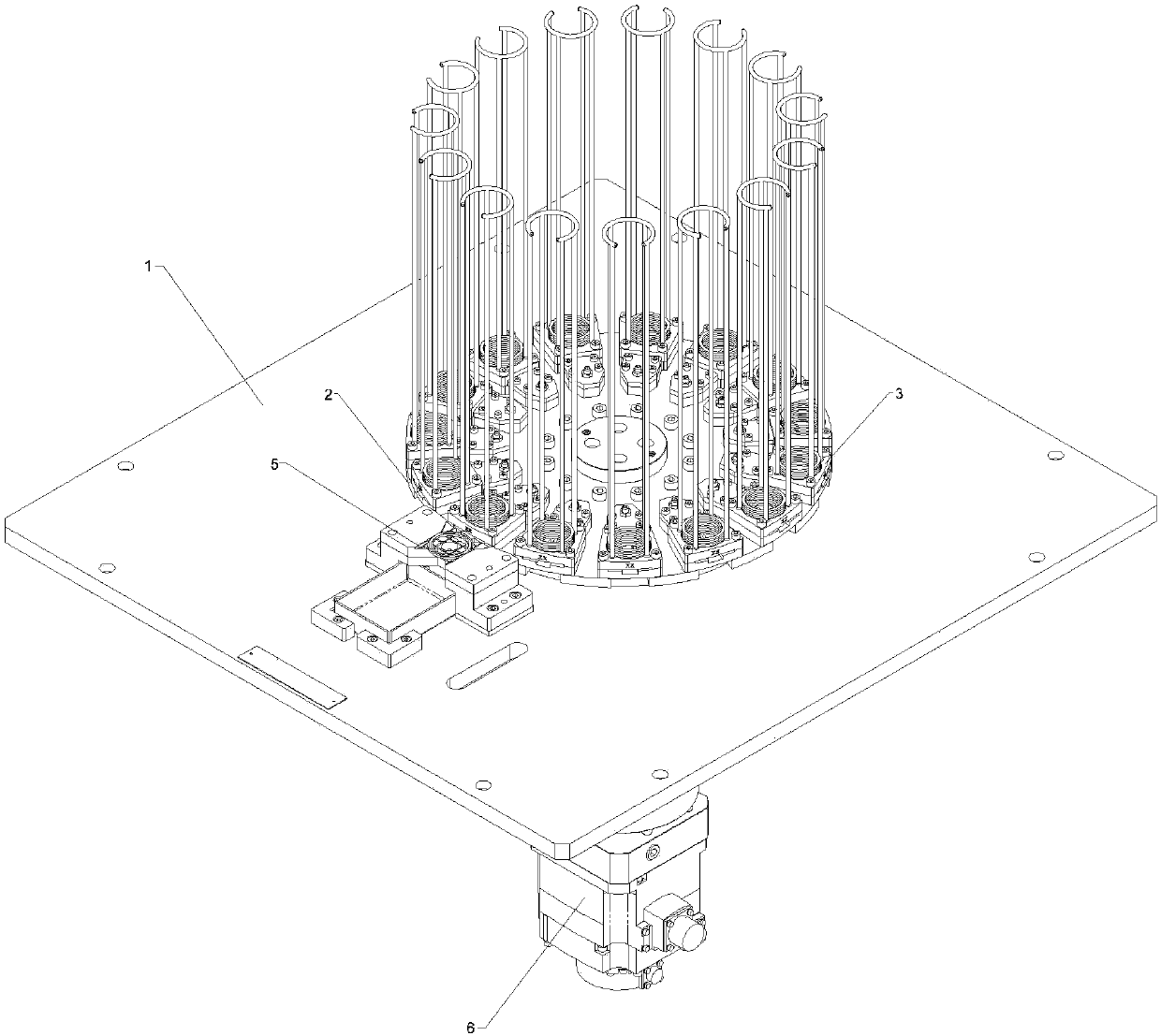

Intelligent control method for cooling process and pressurizing process of aluminum wheel mold

An intelligent control method for a cooling process and a pressurizing process of an aluminum wheel mold is characterized in that an upper computer system, a die-casting machine PLC system, the aluminum wheel mold and a standard temperature curve for temperature control of the aluminum wheel mold are included, the aluminum wheel mold serves as an installation carrier of a thermocouple, and the upper computer system is responsible for real-time mold temperature analysis, decision making and instruction sending; the die-casting machine PLC system is responsible for completing corresponding adjustment according to the instruction sent by the upper computer system. By means of the method, the pressurization process can be automatically adjusted according to the actually-measured temperature change of the aluminum wheel mold, and stable mold filling and timely pressurization and pressure relief are implemented; and meanwhile, the cooling process of the die can be automatically adjusted according to the actually measured temperature change of the aluminum wheel die, so that the temperature of the die fluctuates in a stable interval, and the production process is stable.

Owner:CITIC DICASTAL

Material storage mechanism achieving automatic gasket selecting and feeding

ActiveCN107840136ASimple structureThe structure takes up little spaceConveyor partsReciprocating motionMaterial storage

The invention provides a material storage mechanism achieving automatic gasket selecting and feeding. A rotatable rotating disk driven by a motor is arranged on the upper side of an operation platform. Multiple gasket storage mechanisms are distributed at the upper end of the rotating disk in the circumferential direction at equal intervals. A storage station is arranged at the upper end of the operation platform and located on the outer side of the rotating disk, and the storage station is used for receiving selected gaskets. All the gasket storage mechanism rotating along with the rotating disk are on the work stations when being opposite to the storage station. The lower end of the operation platform is provided with a driving push rod assembly which is driven by an air cylinder to conduct linear reciprocating motion. The driving push rod assembly conducting linear reciprocating motion pushes the gaskets stored in the gasket storage mechanism located on the work station to the storage station, and automatic gasket selecting and feeding are achieved. The material storage mechanism achieving automatic gasket selecting and feeding has the advantages of being compact in structure, reducing cost and increasing benefits.

Owner:ANHUI JEE AUTOMATION EQUIP CO LTD

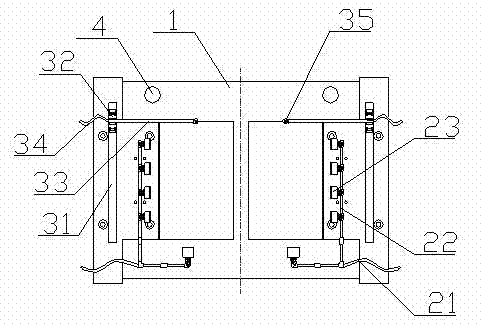

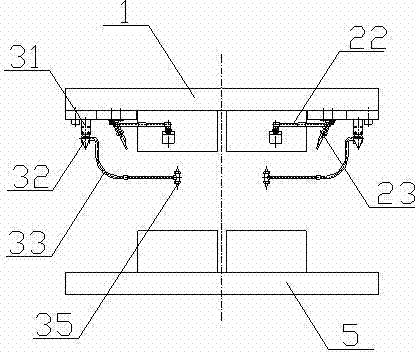

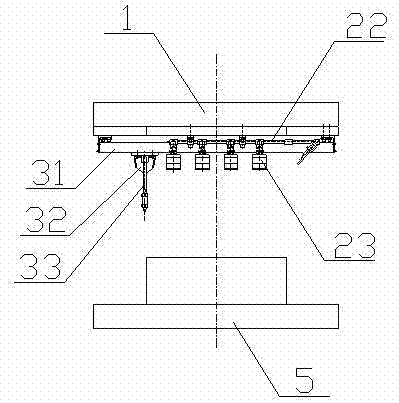

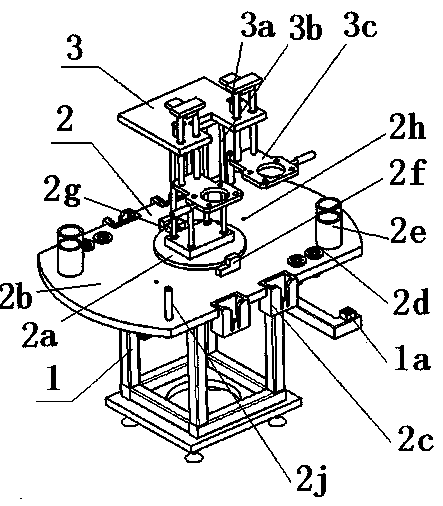

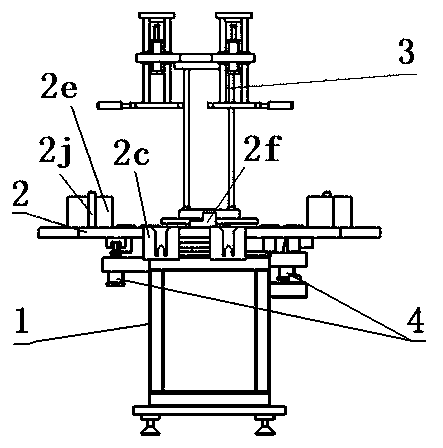

Double-station assembly table for rotary automobile front slide column

ActiveCN104260039AEasy to assembleEasy to operateAssembly machinesMetal-working hand toolsPlate pressureEngineering

The invention discloses a double-station assembly table for a rotary automobile front slide column. The double-station assembly table comprises a base, a working platform, a vibration reducer support fork mounting table, a limiting mechanism, a rotating bearing and a press, wherein the working platform comprises a fixed platform and a rotating platform; a mounting hole for fixing the platform is formed in the center of the rotating platform; the fixed platform is mounted in a fixed platform mounting hole in the center of the rotating platform, and is tightly mounted on the base; a shaft of the rotating bearing is mounted on the base; the rotating platform is tightly connected with an outer ring of the rotating bearing, and rotates for 180 degrees surrounding the shaft of the rotating bearing; a first station and a second station are separated at the two sides of the rotating assembly table; the press is positioned in front of the side of the rotating platform opposite to a spring connecting plate pressure table of the vibration reducer support fork mounting table; a pressure head of the press is positioned above the rotating platform in the second station; the limiting mechanism is mounted below the working platform, and rotates the rotating platform for 180 degrees; and in assembly operation of single station, the limiting mechanism locks the rotating platform. The double-station assembly table largely reduces the production takt, and improves the assembly efficiency.

Owner:采埃孚富奥底盘技术(长春)有限公司

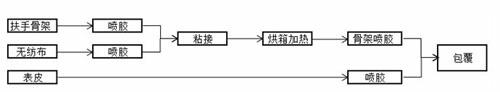

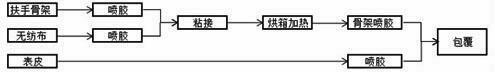

Coating process for vehicle armrest

The invention discloses a coating process for a vehicle armrest. The process comprises the following steps of: a, spraying glue onto the surfaces of a vehicle armrest framework and a non-woven fabric; b, bonding the non-woven fabric to the surface of the vehicle armrest framework, and trimming the edge of the non-woven fabric by using an art knife; c, placing the vehicle armrest framework on which the non-woven fabric is bonded into an oven to be baked and heated, and spraying glue onto the surface of the vehicle armrest framework after the vehicle armrest framework is taken out; d, spraying glue onto the inner side of the surface skin; and e, through a coating process, coating the surface skin onto the vehicle armrest framework on which the non-woven fabric is bonded. In such a way, a non-woven fabric coating process substitutes a polyurethane foaming process, so that while the touch sense of softness is increased, the development period and the cost investment of equipment and dies are reduced, and the requirement on the overall design standard of a vehicle type is met.

Owner:常熟安通林汽车饰件有限公司

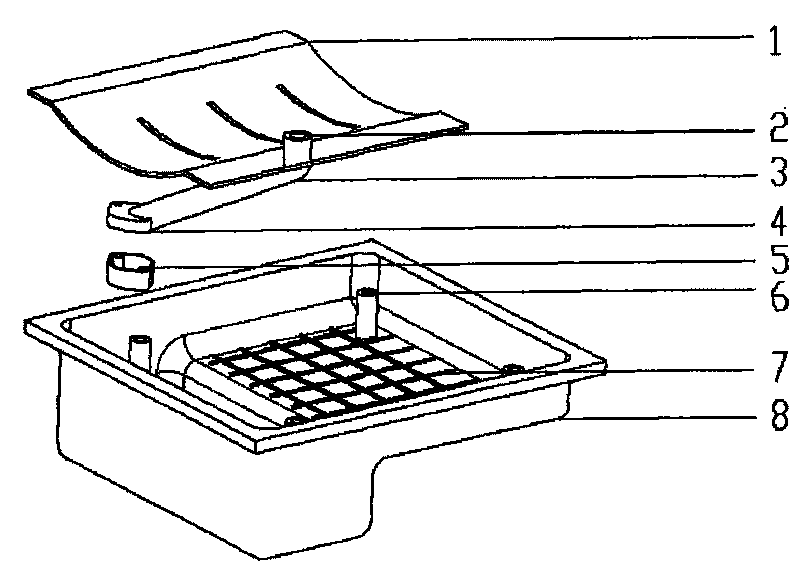

Vehicle oil pan assembly

InactiveCN101737118AShorten the takt timeEasy to cleanMachines/enginesPressure lubricationLower upperLight quality

The invention discloses an oil pan assembly which comprises an oil pan, a diaphragm and an engine oil collector, wherein the engine oil collector consists of an oil suction pipe, the upper half part of an oil suction disc and the lower upper half part of the oil suction disc, which is provided with a filter screen, and the oil pan, the diaphragm and the engine oil collector are all plastic parts; and the oil suction pipe and the upper half part of the oil suction disc of the engine oil collector form an unable-dismantled part with the diaphragm through a mode of hot plate welding, and the lower upper half part of the oil suction disc, which is provided with the filter screen, and the upper half part of the oil suction disc are installed together through bolts so as to form the complete engine oil collector. In the invention, the oil pan, the diaphragm and the engine oil collector are integrated into a whole, and an engine can be directly assembled when being assembled, thereby shortening the production beat; in addition, the oil bottom shell, the diaphragm and the engine oil collector are all the plastic parts, thereby having light quality and greatly reducing the quality of the engine; and the part with the filter screen on the engine oil collector can be dismantled, thereby enabling the engine oil collector to be convenient to dismantle and clean.

Owner:CHERY AUTOMOBILE CO LTD

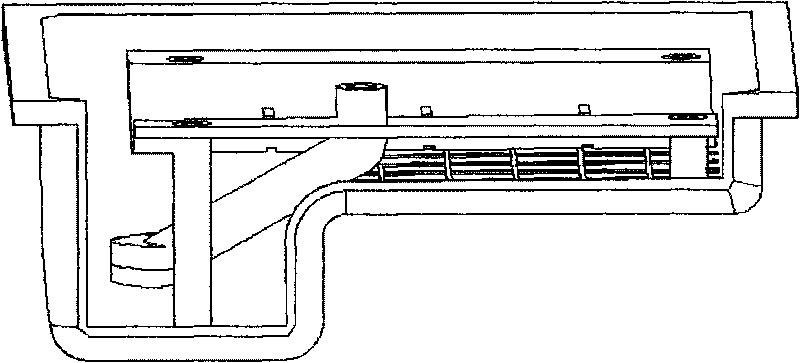

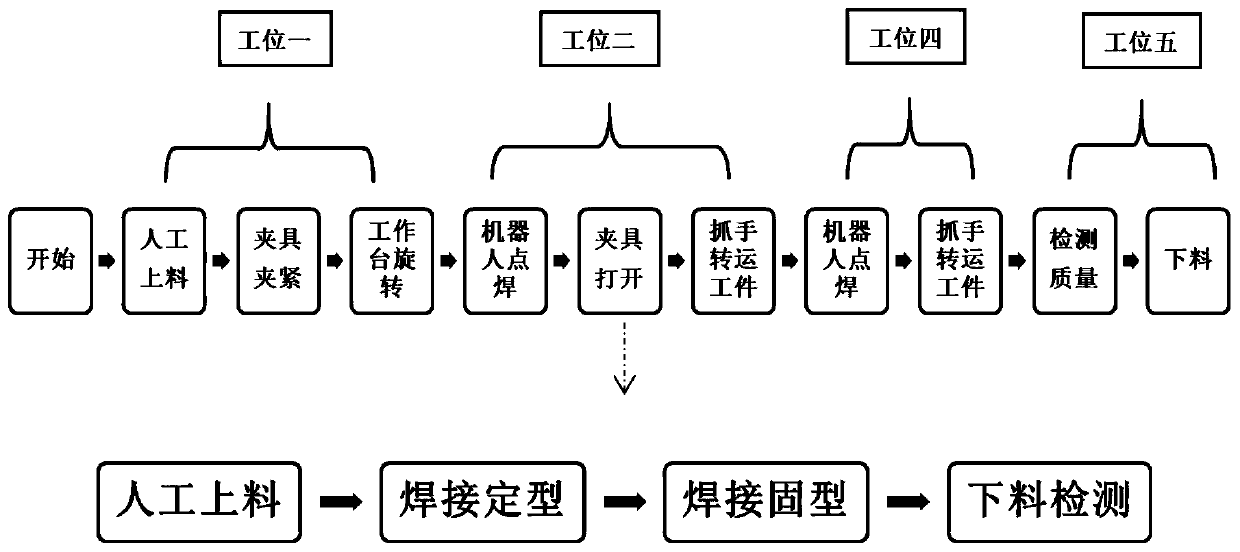

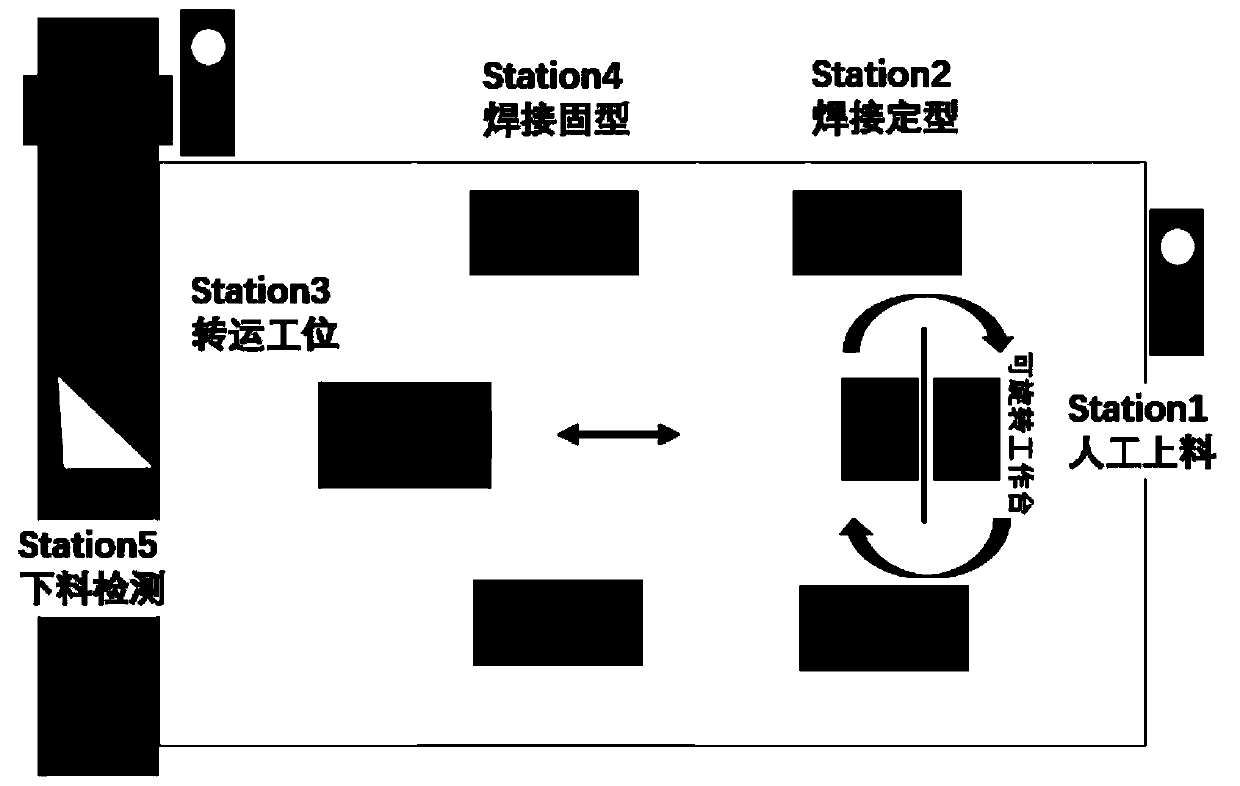

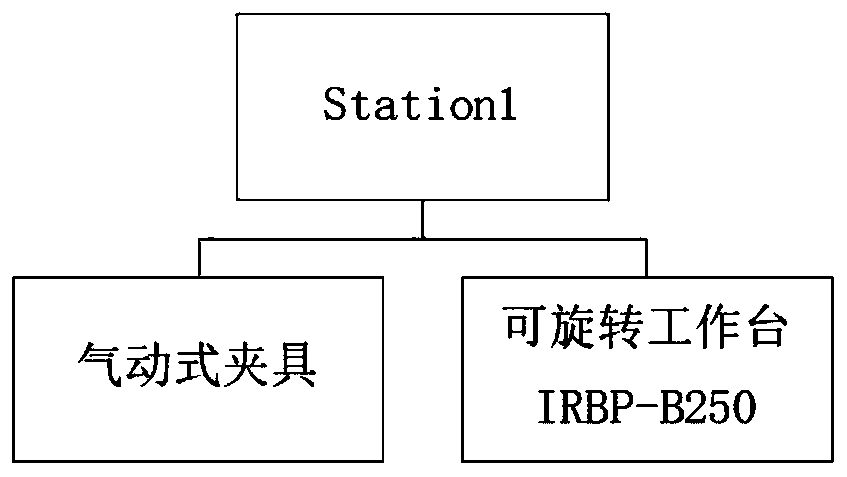

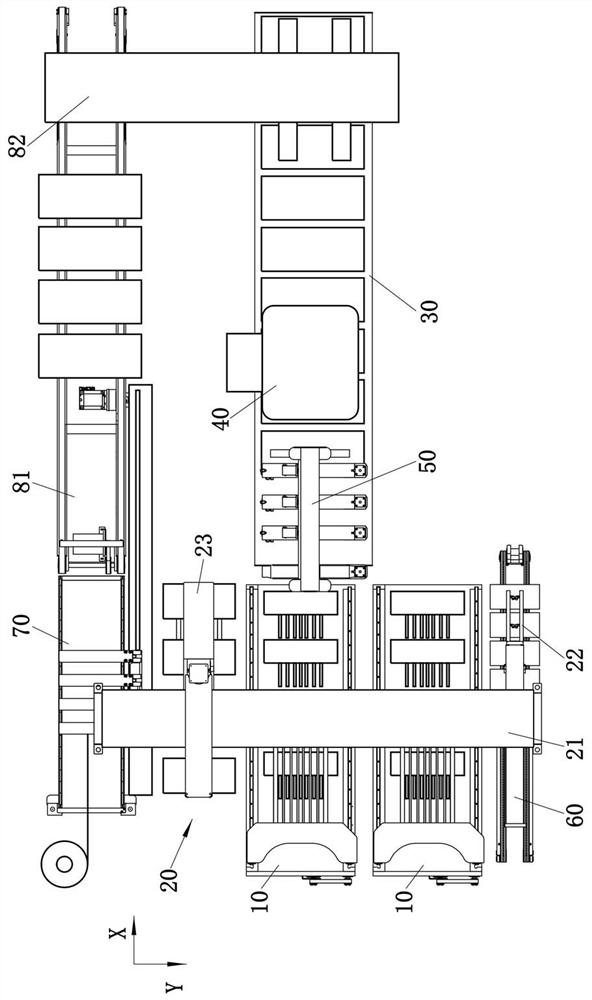

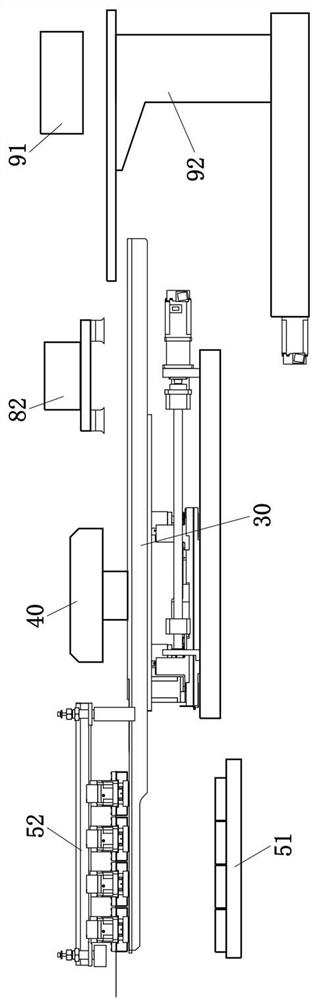

Welding production line of automobile body side wall outer plate assembly

ActiveCN111590226AIntelligentIncrease productivityWelding/cutting auxillary devicesAuxillary welding devicesProduction lineSpare part

The invention discloses a welding production line of an automobile body side wall outer plate assembly, and relates to the technical field of automobile production. The welding production line aims torealize comprehensive automation, multi-station paralleling and high-efficiency production of welding of the automobile body side wall outer plate assembly. The welding production line is technicallycharacterized in that the welding production line comprises a rotatable workbench, a pneumatic clamp mounted on the rotatable workbench, two shaping welding robots, two shape fixing welding robots and a grabbing robot; a set of spare parts on a working unit of the pneumatic clamp are welded and shaped through the two shaping welding robots, and a grabbing robot of a transfer station grabs the shaped and welded parts and moves to the corresponding position between the two shape fixing welding robots along sliding rails, and shape fixing welding on the parts is carried out through the two shapefixing welding robots; and the grabbing robot transfers the parts subjected to shape fixing welding to a discharging detection station. The welding production line is used for automatically welding the automobile body side wall outer plate assembly.

Owner:XIAMEN UNIV

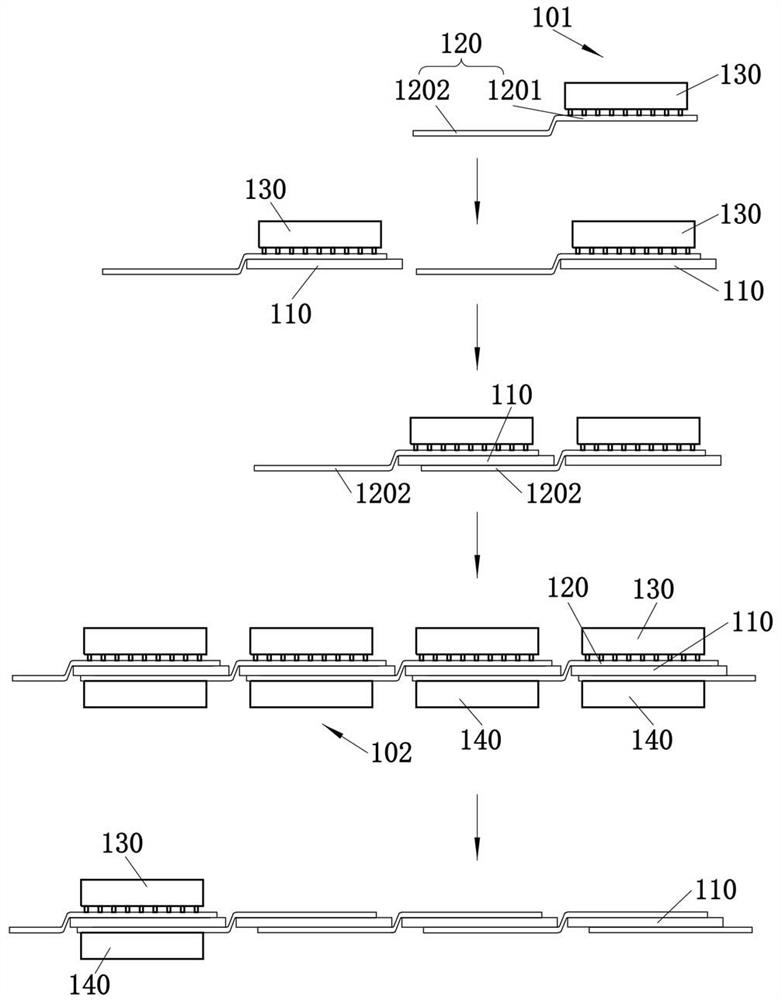

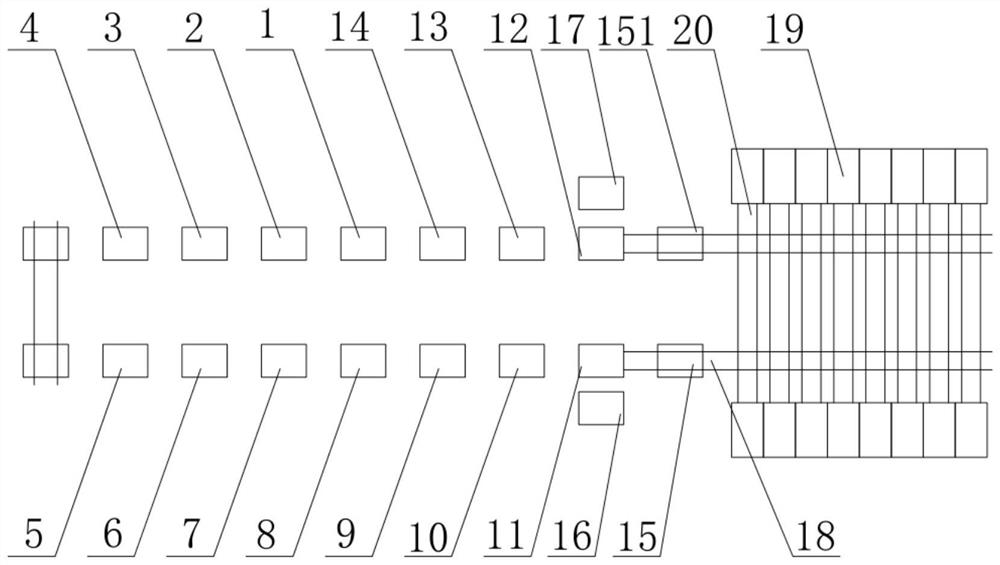

Battery string preparation method and battery string welding equipment

ActiveCN114833504AIncrease productivityShorten the takt timeFinal product manufactureWelding/cutting auxillary devicesElectrical batteryEngineering

The invention belongs to the technical field of solar cells, and discloses a cell string preparation method and cell string welding equipment. The battery string preparation method comprises the steps that S1, a welding strip and an upper pressing tool are stacked on a battery piece to form a laying unit, the upper pressing tool and the front face welding section of the welding strip are sequentially stacked on the battery piece, and the back face welding section extends out of the surface of the battery piece; s2, the laying units are stacked, so that the back face of the next battery piece is arranged on the back face welding section of the previous laying unit; s3, laying a lower mold, enabling the lower mold to enable the back welding section in the previous laying unit to abut against the back of the battery piece in the next laying unit, and enabling the laying units and the corresponding lower mold to form a welding unit; s4, the laying unit and the lower mold are transferred to a heating station together; s5, the heated welding unit is transferred to a cooling station to be cooled, so that the welding strip is fixed to the two adjacent battery pieces; and when the welding unit at the front end is cooled, the steps from S1 to S4 are carried out at the rear end at the same time, so that the battery string production efficiency is improved.

Owner:江苏小牛自动化设备有限公司

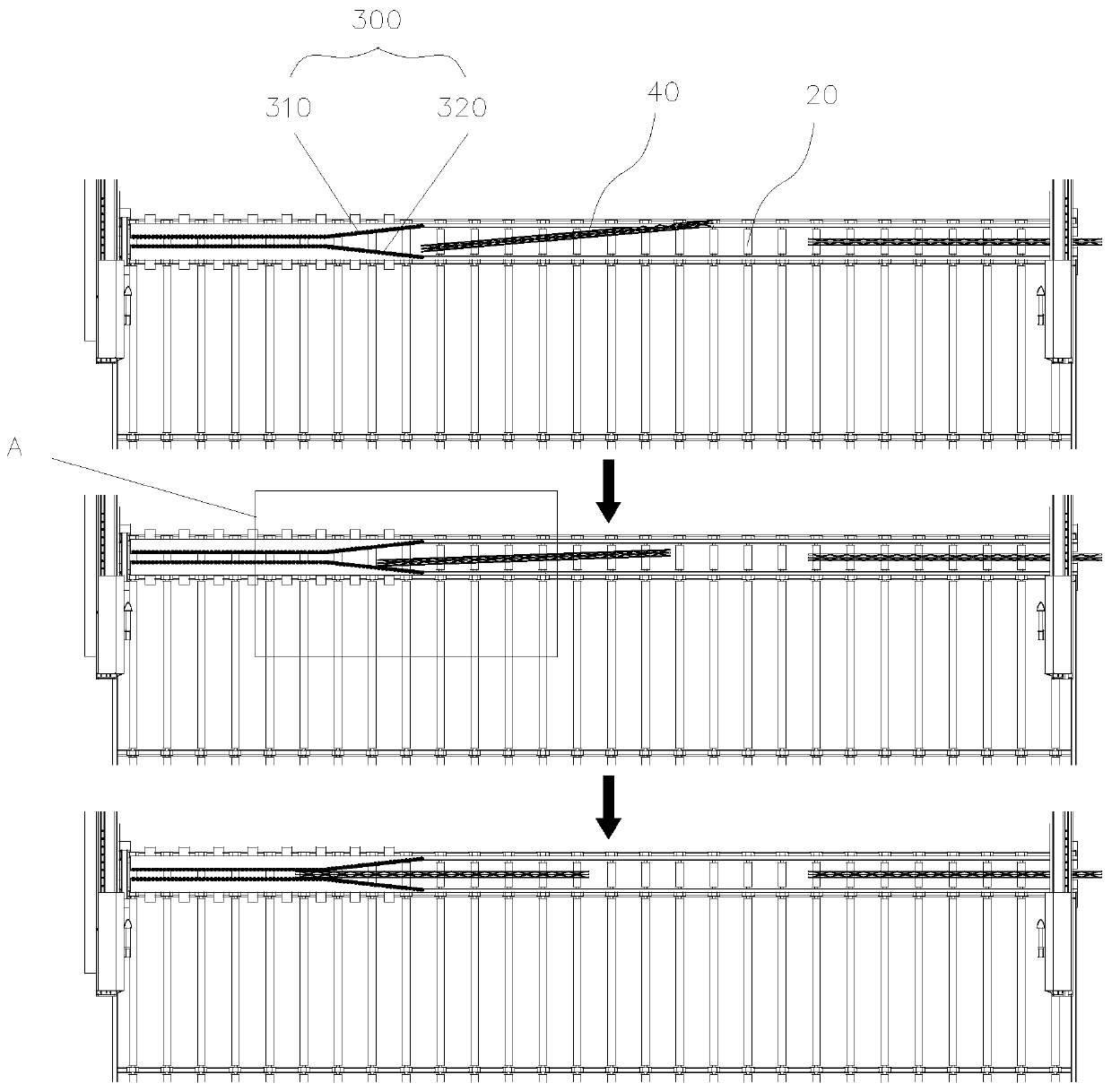

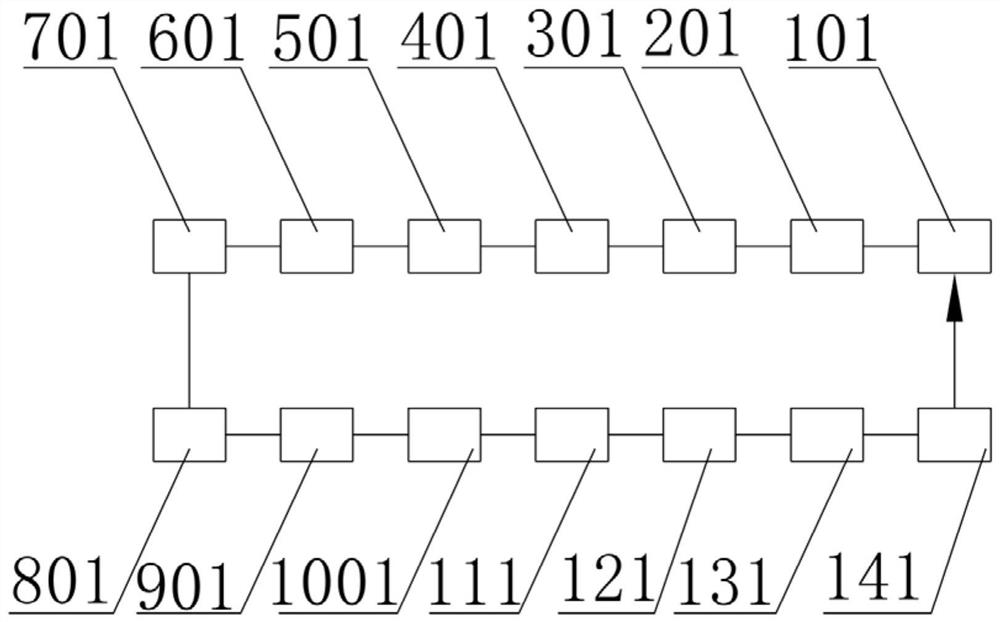

Production process and production line of steel bar truss laminated slab

PendingCN112792974AReduce duplicationReduce production capacityCeramic shaping plantsAuxillary shaping apparatusProduction lineEngineering

The invention discloses a production process and production line of a steel bar truss laminated slab, and relates to the technical field of building construction. The production process is characterized by comprising the following steps in sequence: cleaning a mold and a trolley; assembling the mold; spraying a release agent into a side mold frame; mounting and fixing an embedded part; entering a reinforcement cage; performing hidden inspection; pouring concrete; performing surface treatment; adopting a plate lifting machine to lift a trolley; transferring the whole stack of the trolley to a curing kiln; transferring the whole stack of the trolley to a plate descending machine; adopting the plate descending machine to descend the trolley; demoulding a laminated slab; and performing hoisting and demoulding. The production line comprises the curing kiln, the plate descending machine, a first transfer rail car, a second transfer rail car, the trolley, running rails, the plate lifting machine and stations 1-14. By means of the arrangement, the transfer rail cars cooperate with the plate lifting machine and the plate descending machine, the trolley is fed into the curing kiln in a whole stack mode, the trolley in the curing kiln is taken out in a whole stack mode, therefore, the production takt time can be shortened, and the productivity is increased.

Owner:吴昌鹏

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com