Full-automatic key assembly machine

A button group and fully automatic technology, which is applied in the direction of assembly machines, metal processing equipment, manufacturing tools, etc., can solve the problems that the conveyor line cannot adjust the assembly position, the button incoming materials cannot be automatically grasped, and the conveyor line cannot adjust the line width. Achieve the effects of saving production beats, facilitating feeding actions, and improving operating efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0060] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

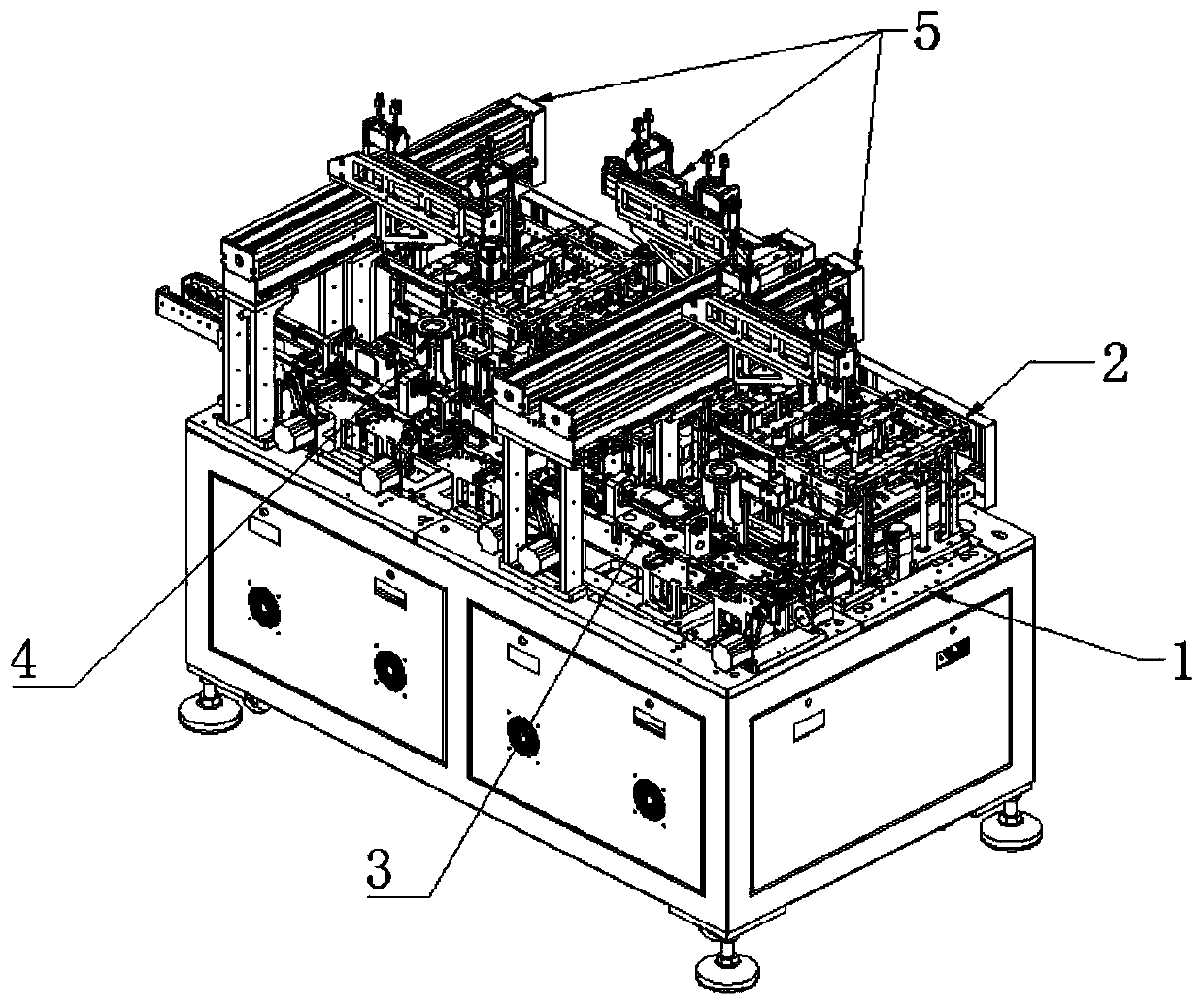

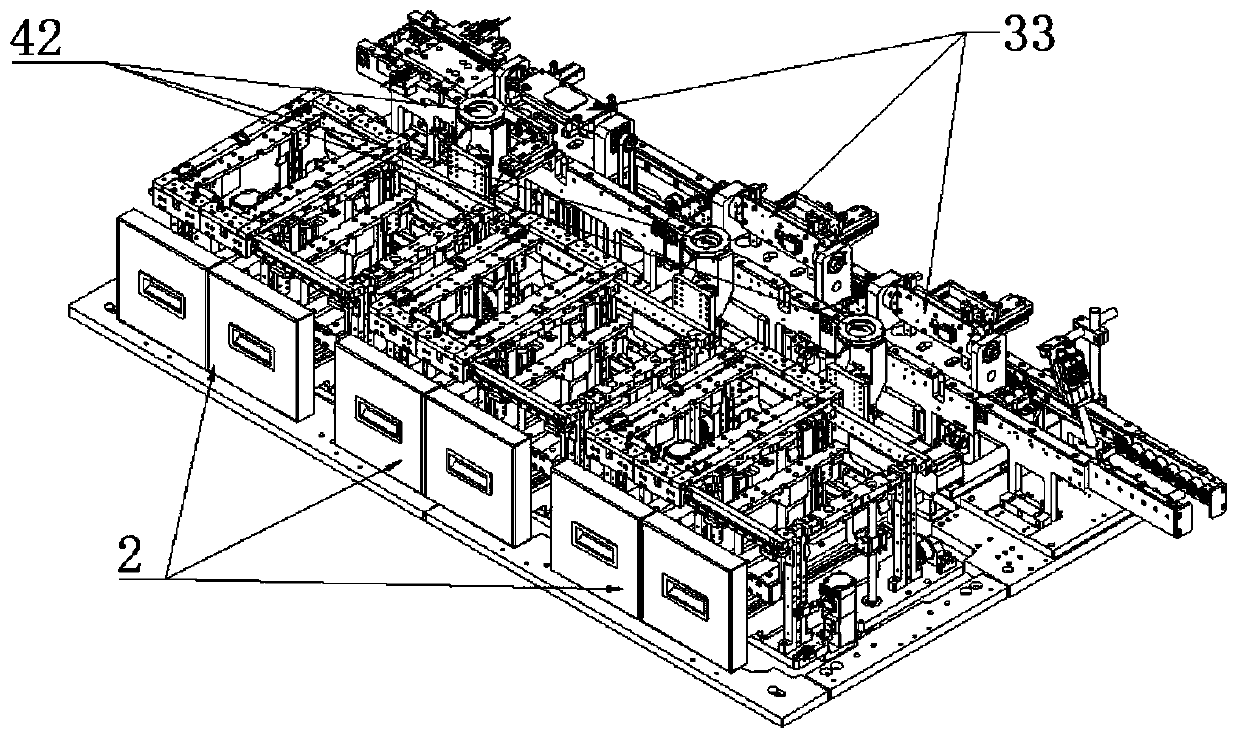

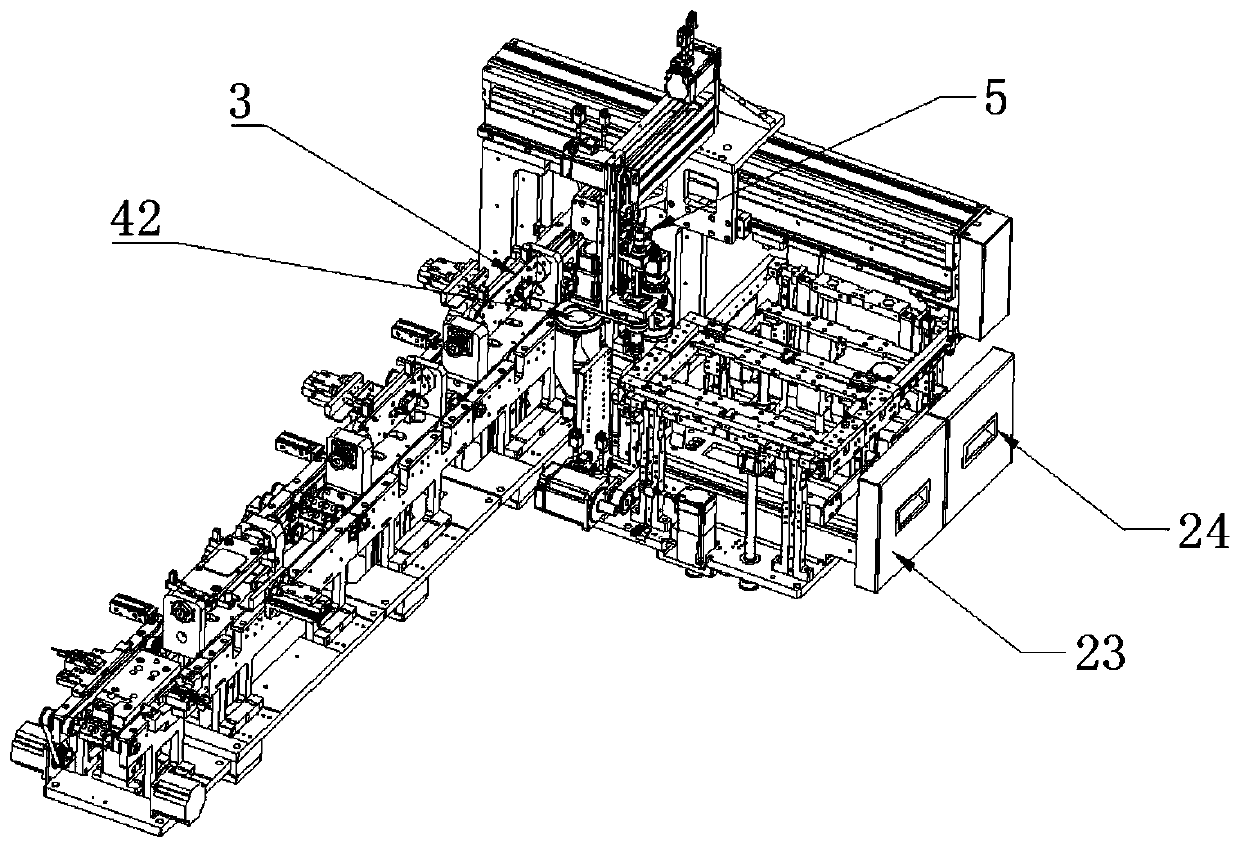

[0061] refer to Figure 1 to Figure 10 As shown, a fully automatic button assembly machine includes a frame 1, and several automatic feeding mechanisms 2, conveying mechanisms 3, several visual positioning mechanisms 4, and several transfer and assembly mechanisms 5 installed on the frame 1; The length direction of the conveying mechanism 3 is provided with several assembly stations at intervals, and each assembly station corresponds to an automatic feeding mechanism 2, a visual positioning mechanism 4, and a transfer assembly mechanism 5; the conveying mechanism 3 is used for conveying Assemble the main body and adjust the assembly position of the assembly body at the assembly station; the automatic feeding mechanism 2 is located on one side of the assembly station, and is used to transfer the assembly parts to the bottom of the transfer ass...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com