Patents

Literature

152results about How to "Realize automatic feeding function" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

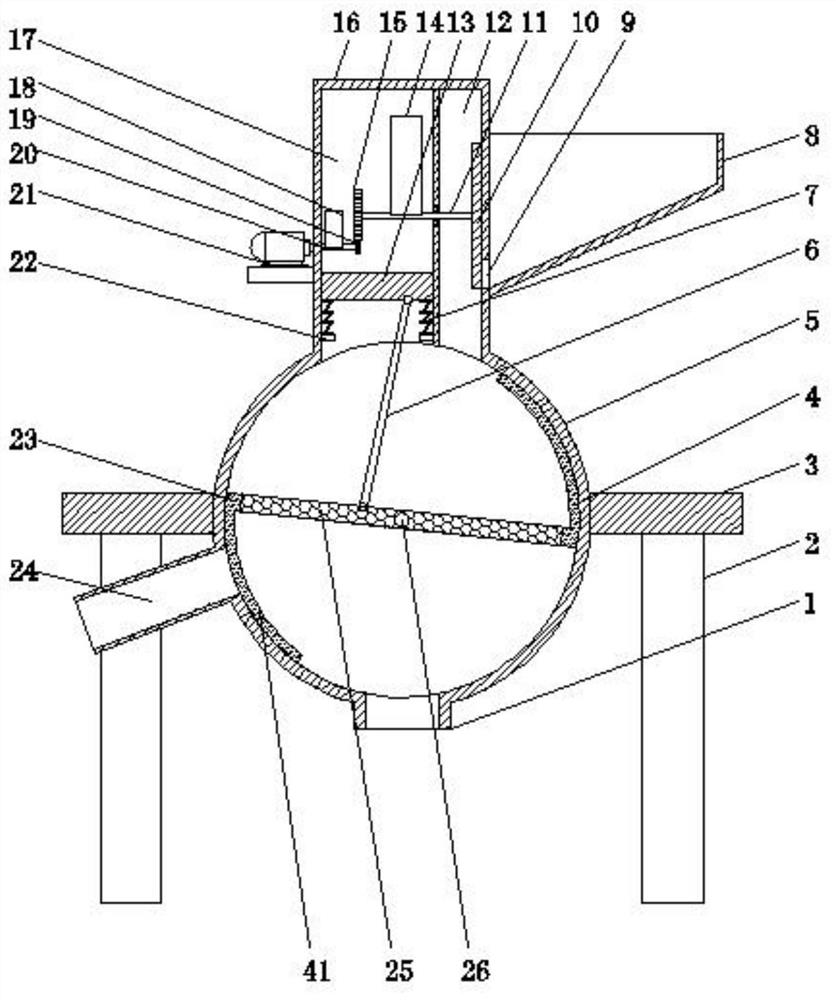

Steel tube inner wall polishing machine

InactiveCN108326721AImprove work efficiencyImprove working precisionGrinding carriagesPolishing machinesEngineeringSteel tube

The invention relates to a steel tube inner wall polishing machine. The steel tube inner wall polishing machine comprises fixing mechanisms and polishing mechanisms and further comprises a feeding area and a transverse movement rail. The polishing mechanisms comprise the first polishing mechanism and the second polishing mechanism, and the first polishing mechanism and the second polishing mechanism are arranged on the two sides of the feeding area correspondingly. The fixing mechanisms comprise the first fixing mechanism and the second fixing mechanism, and the first fixing mechanism and thesecond fixing mechanism are arranged on the transverse movement rail in a slippage manner correspondingly. The transverse movement rail is provided with a first drive device. By the adoption of the scheme, the two fixing mechanisms and the two polishing mechanisms are arranged, when a tube on one of the fixing mechanisms is subjected to polishing, the other fixing mechanism can detach a polished tube and install a tube to be polished, the tube needing to be polished can be subjected to polishing directly after polishing is finished, therefore the preparation time between two times of polishingis eliminated, and the steel tube inner wall polishing machine has high work efficiency.

Owner:WENZHOU POLYTECHNIC

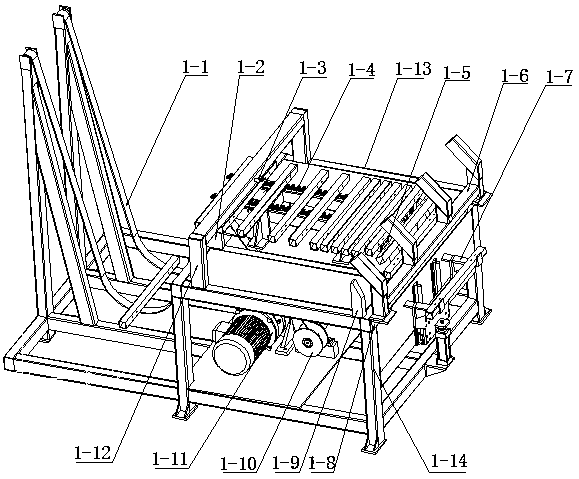

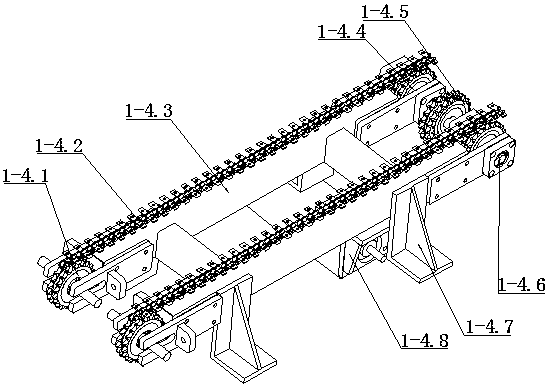

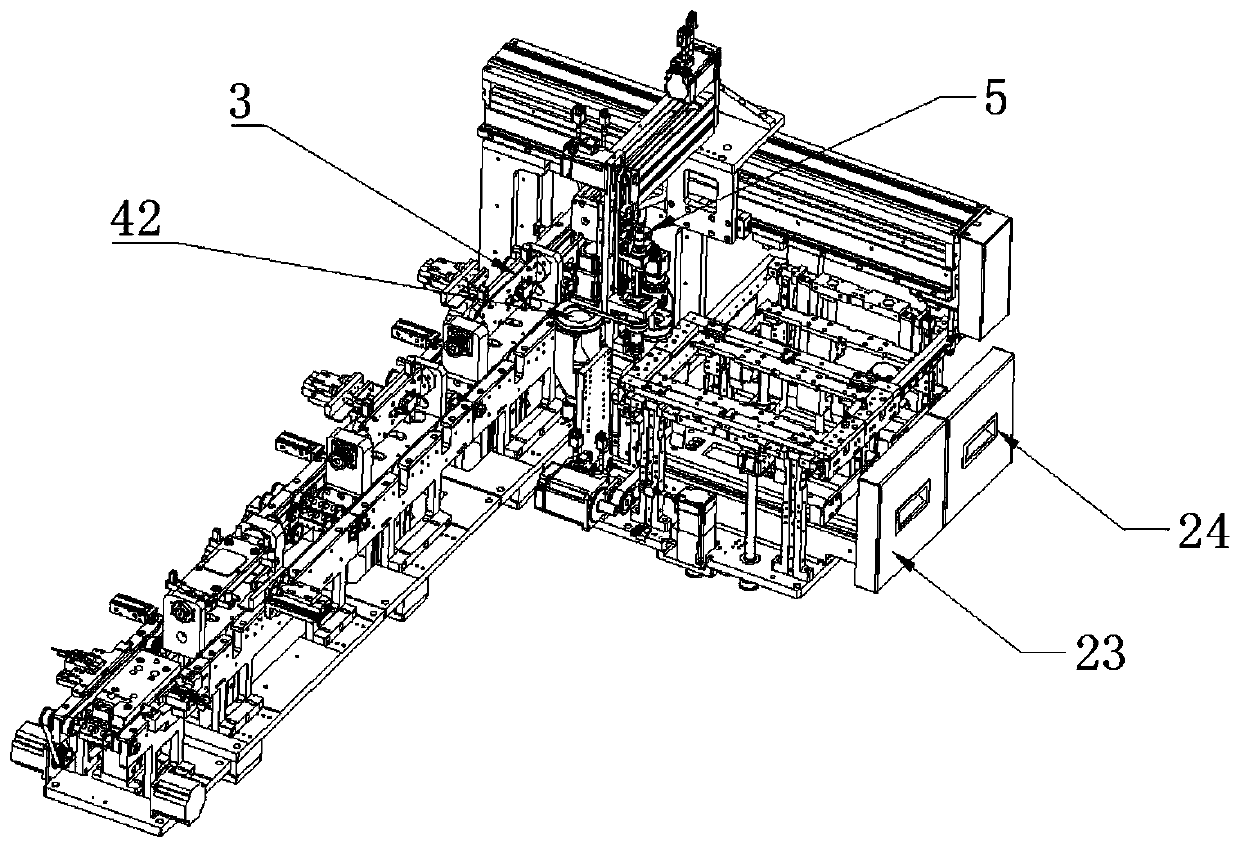

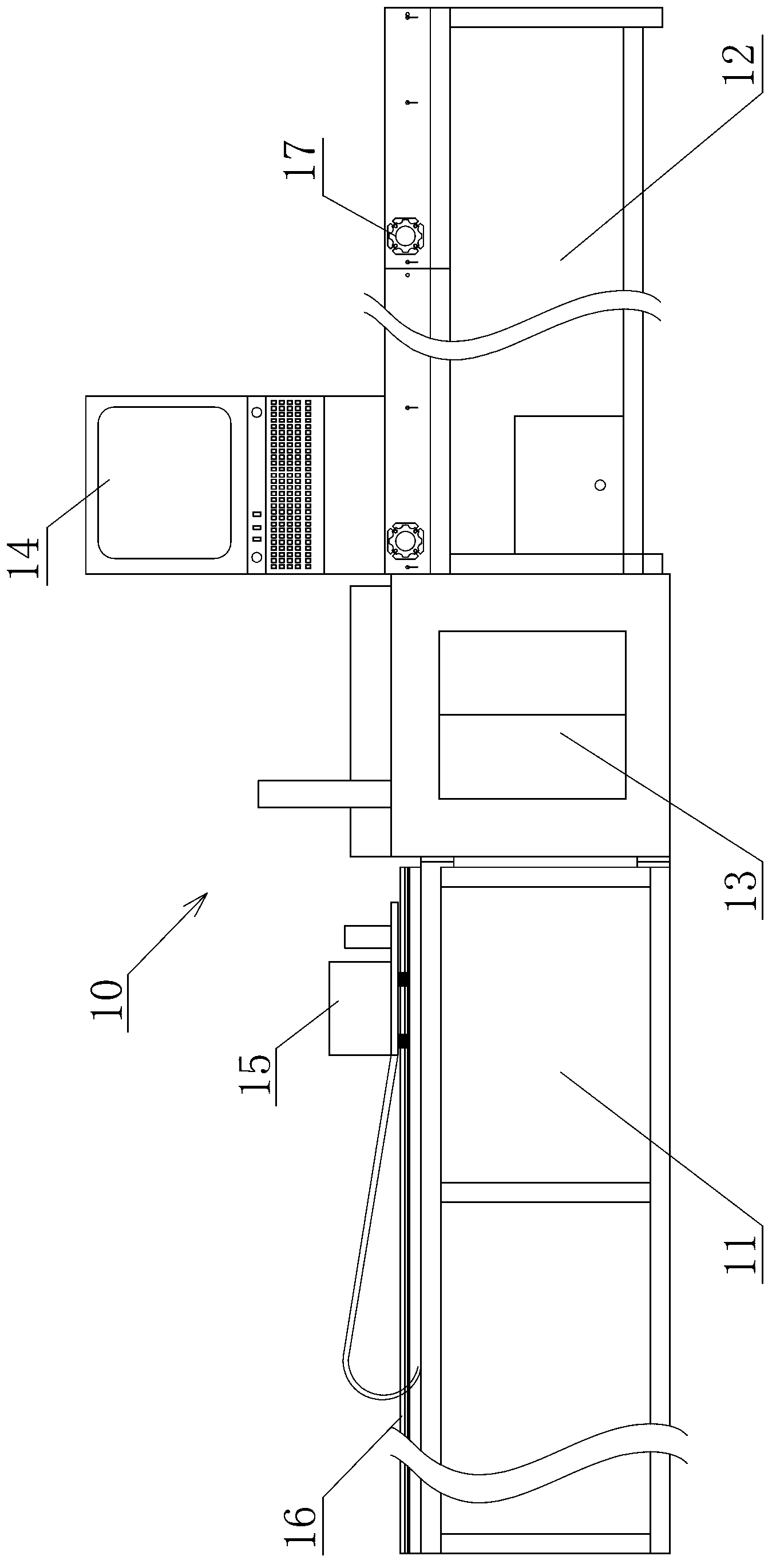

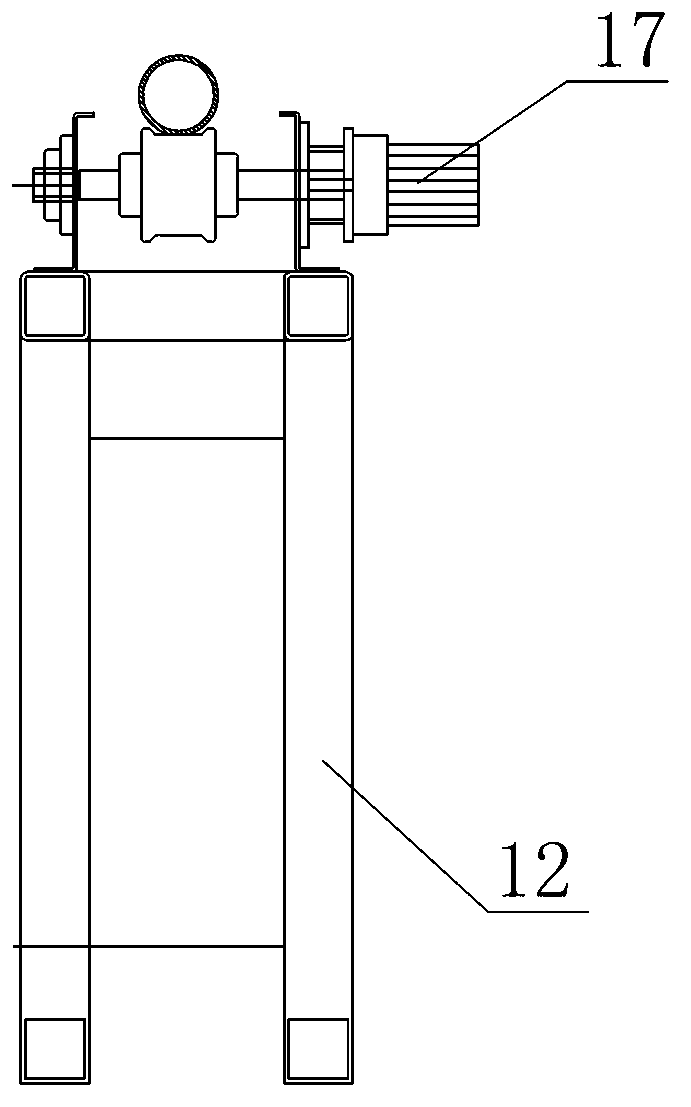

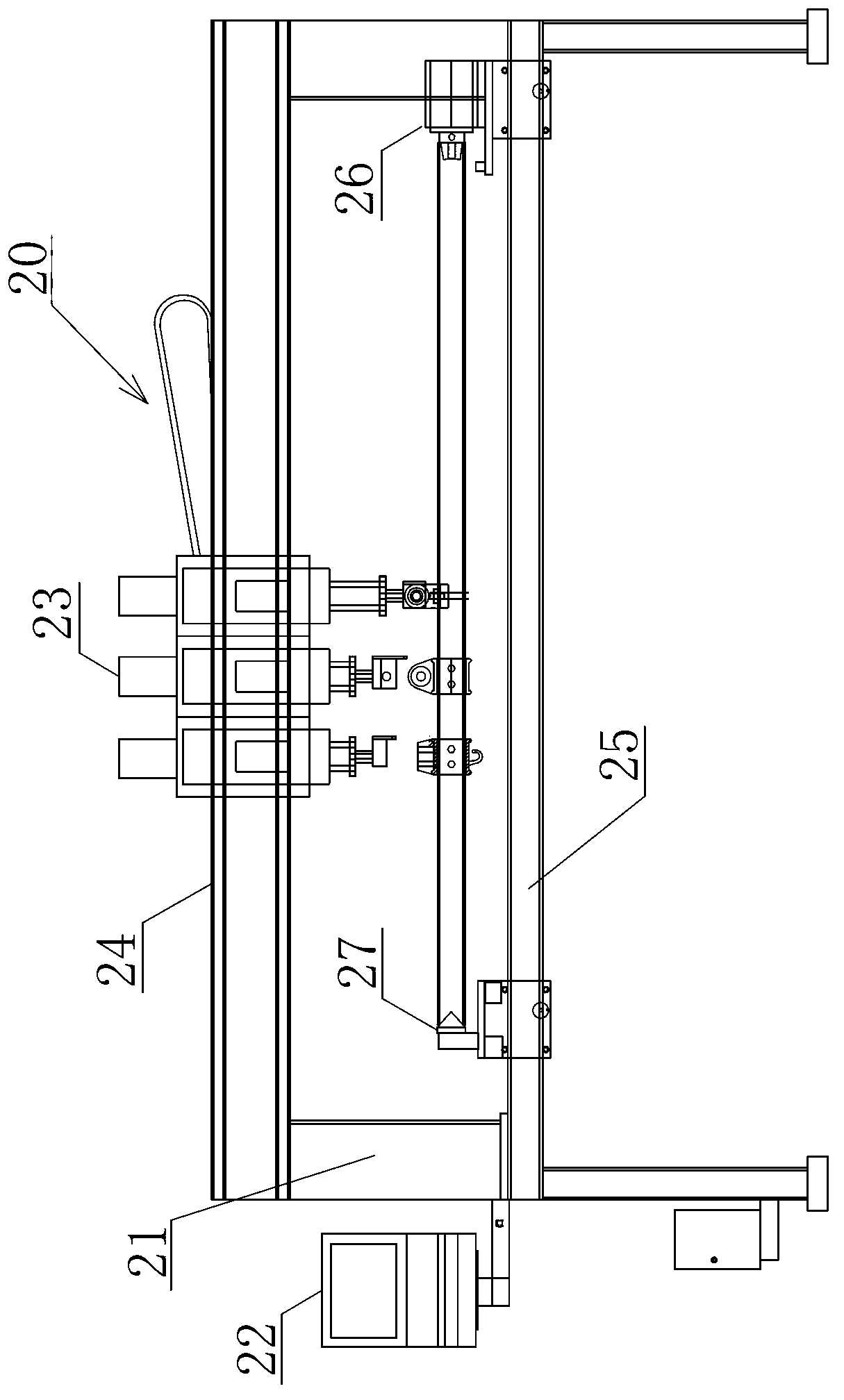

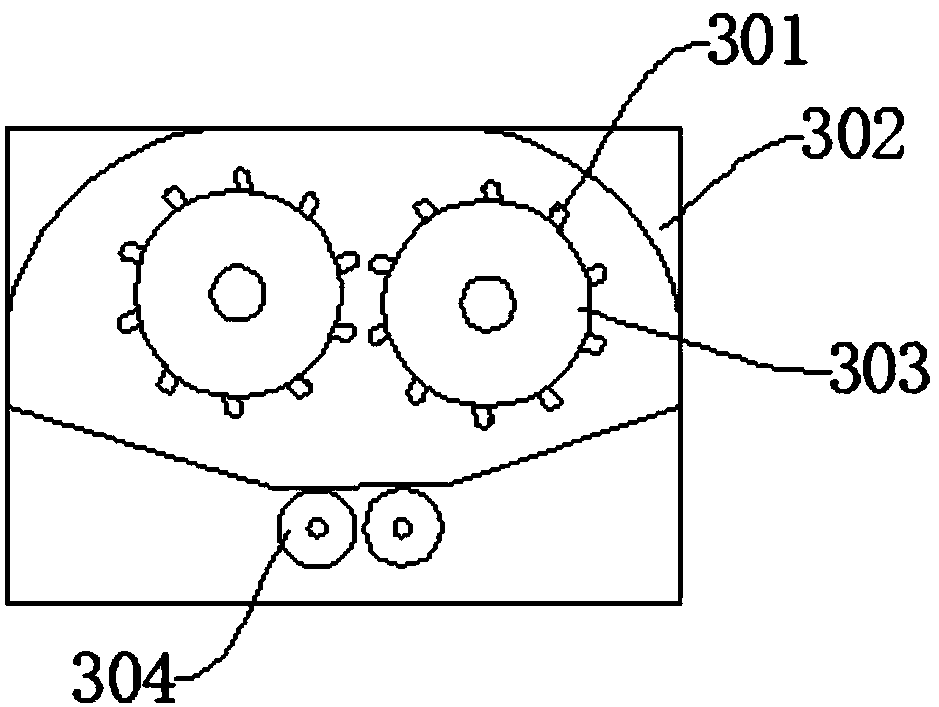

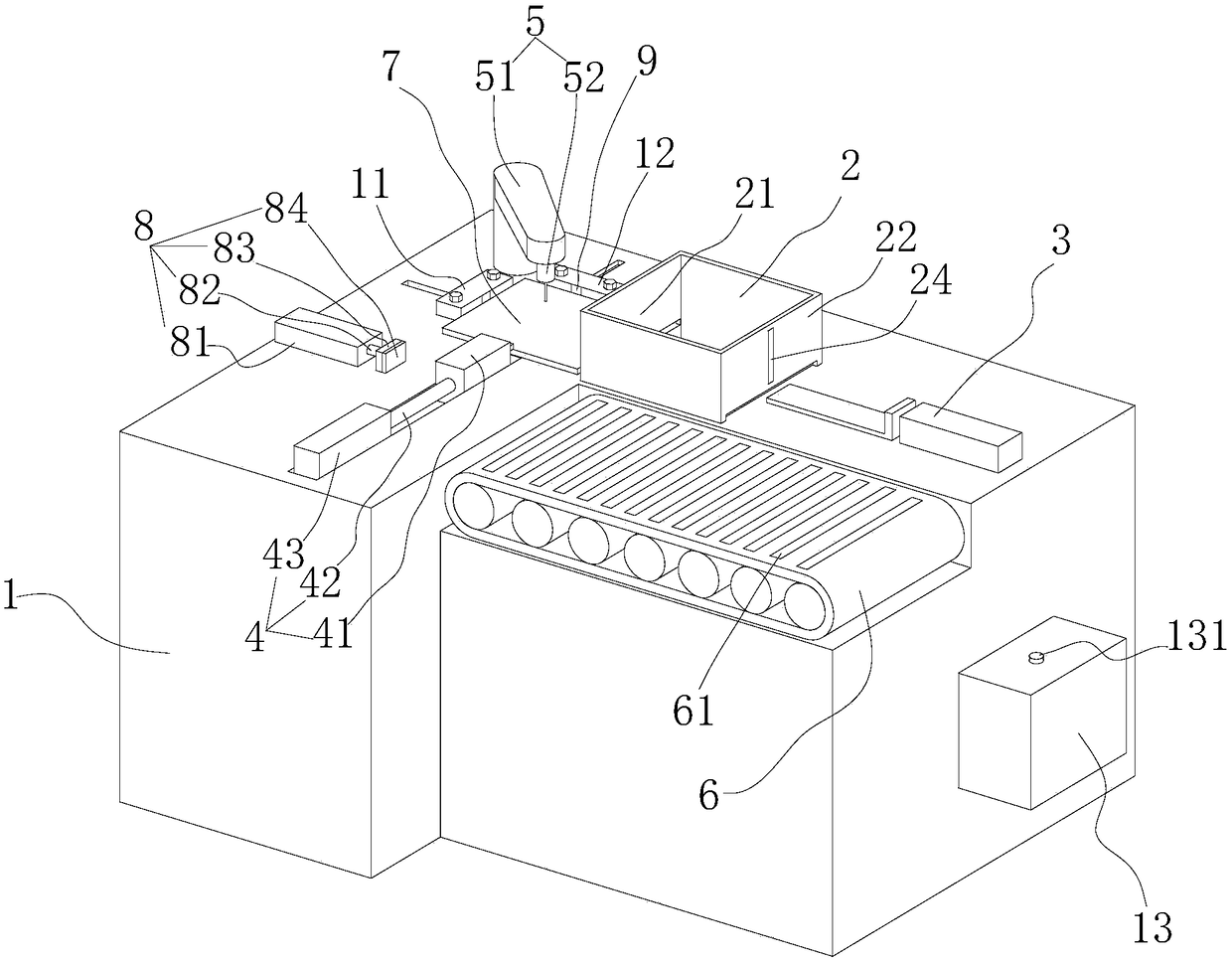

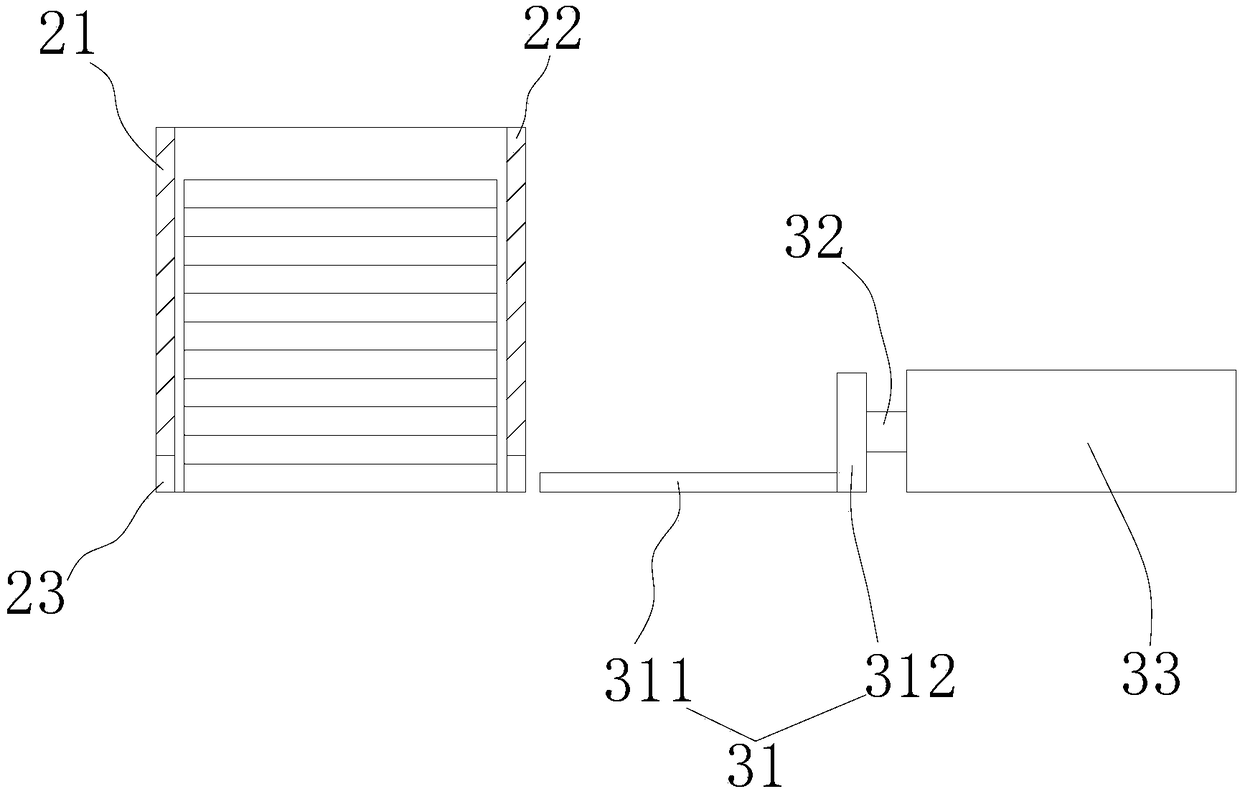

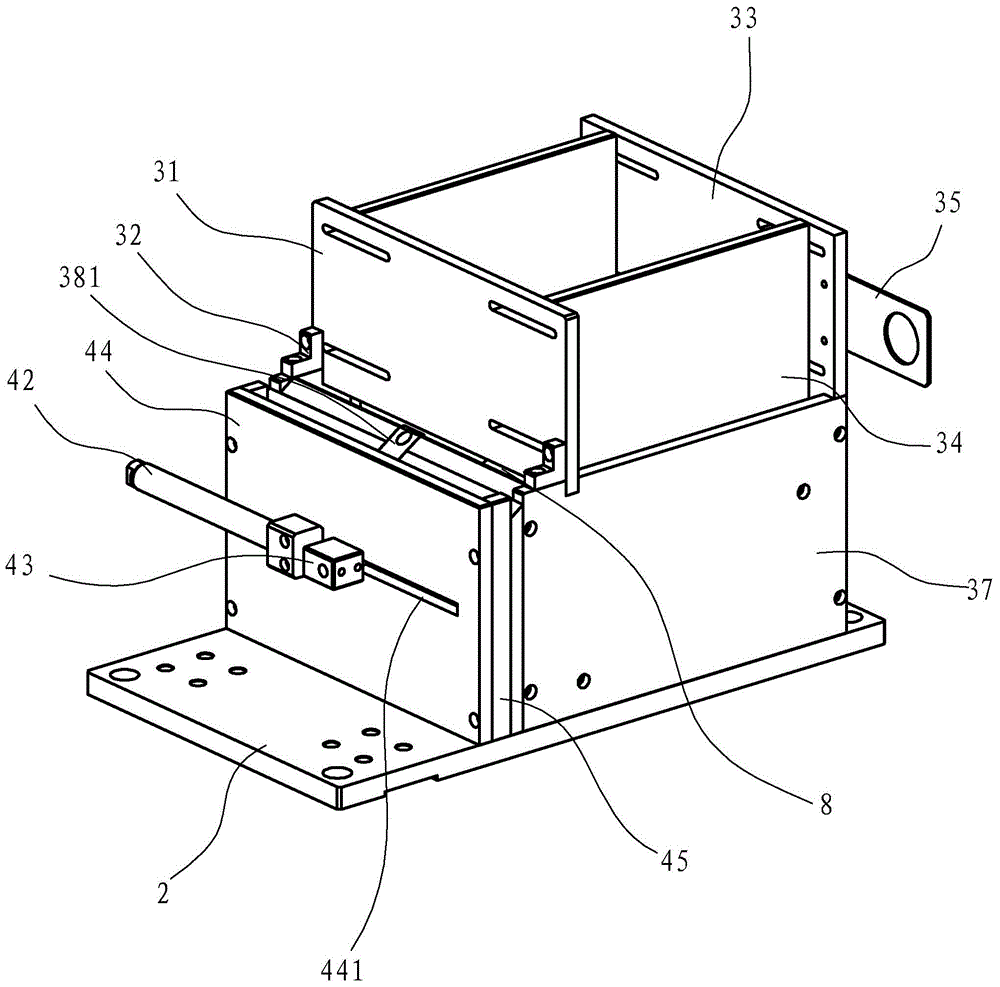

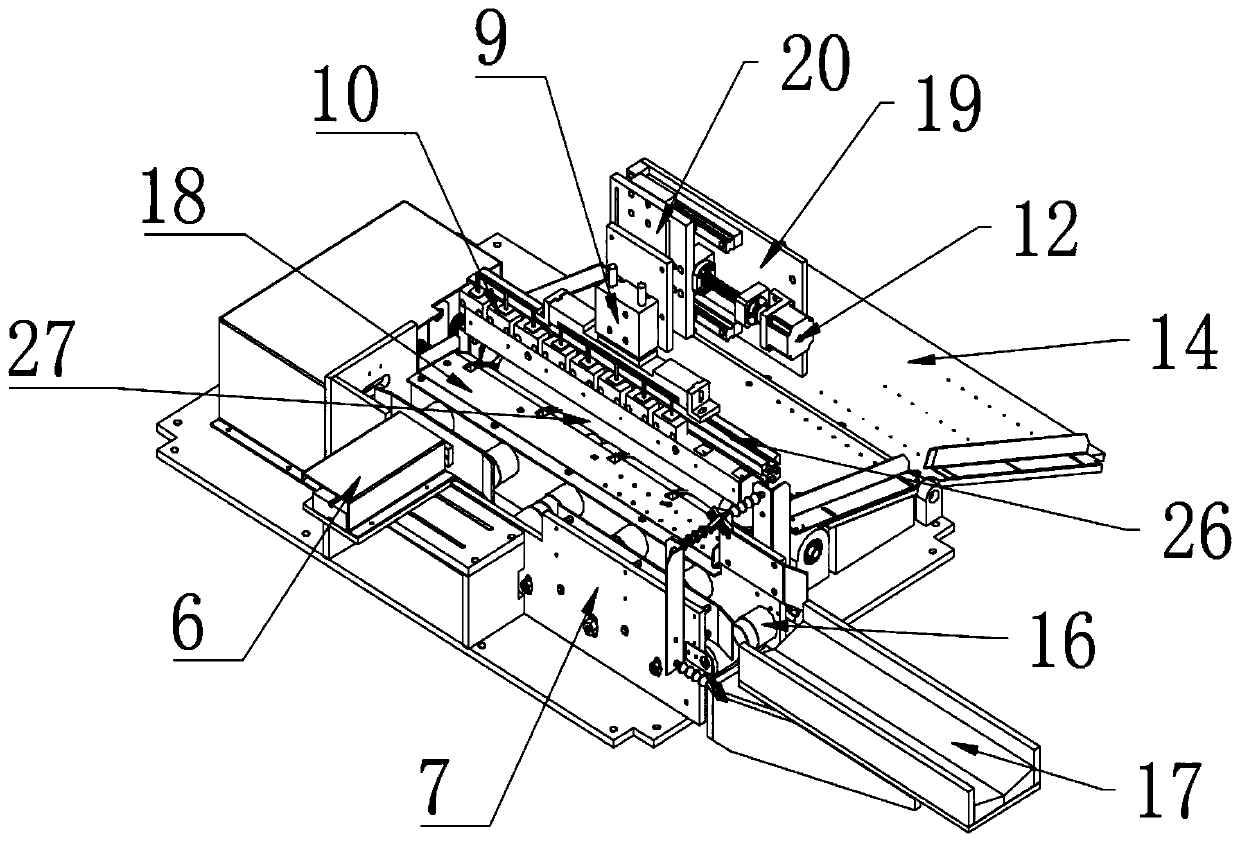

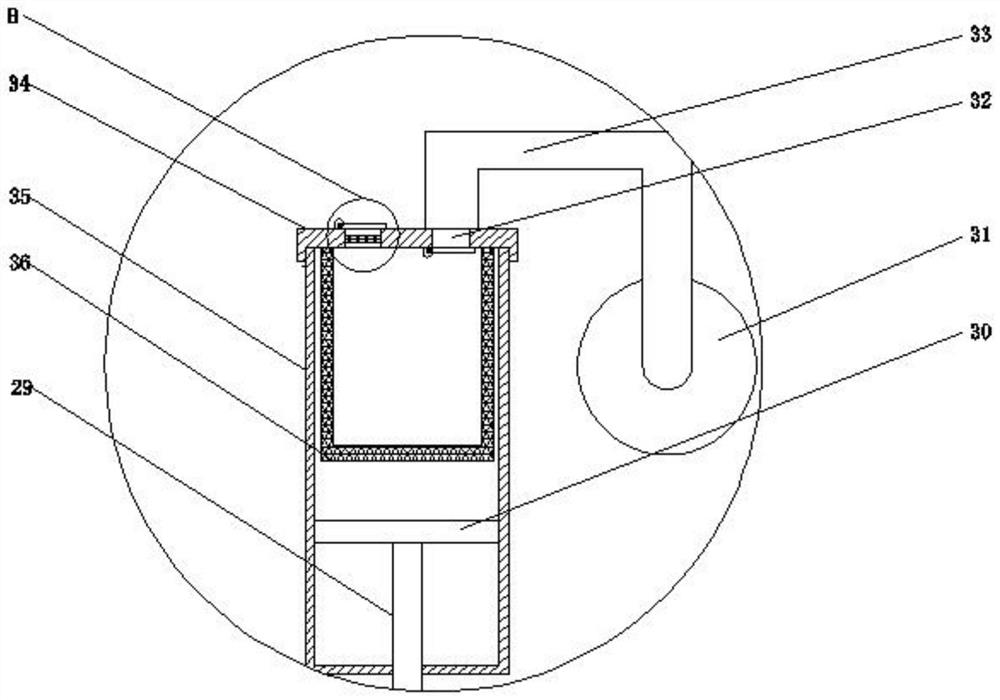

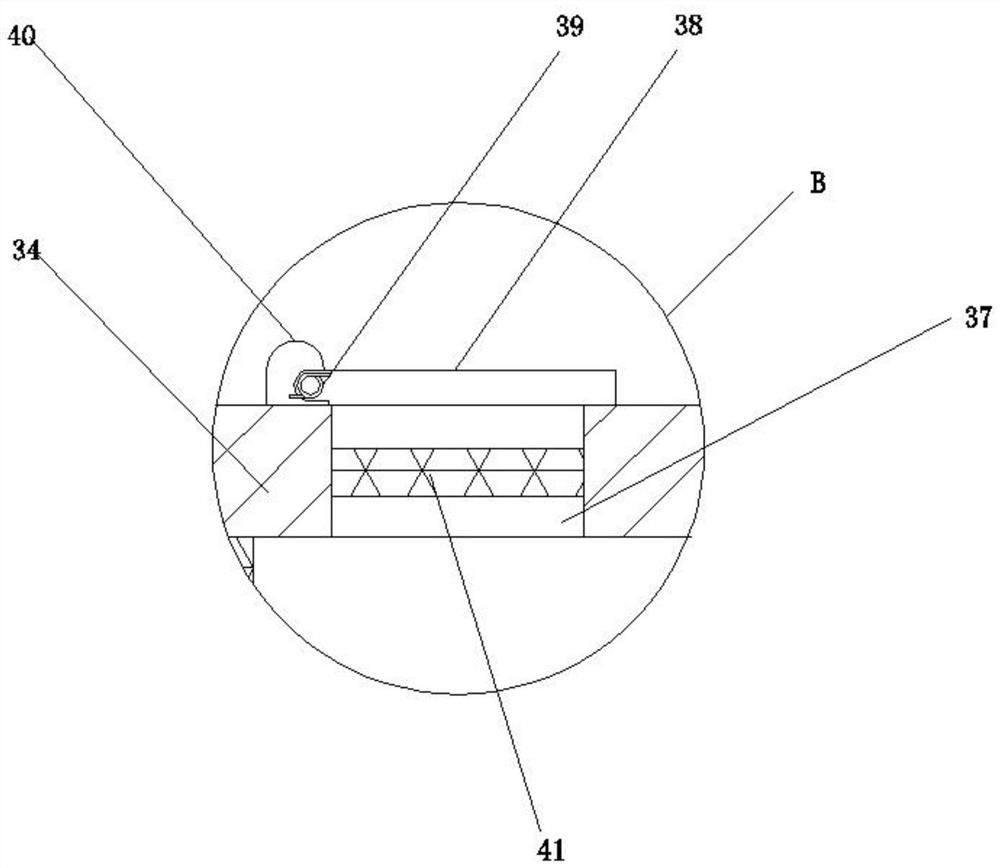

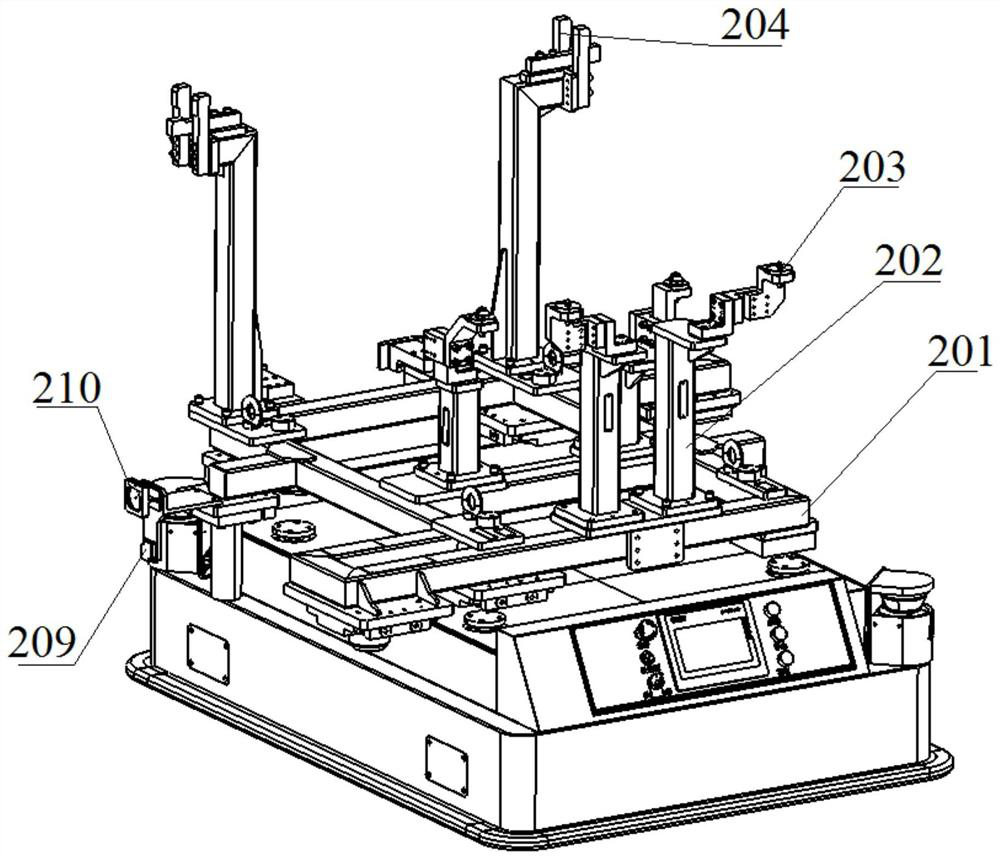

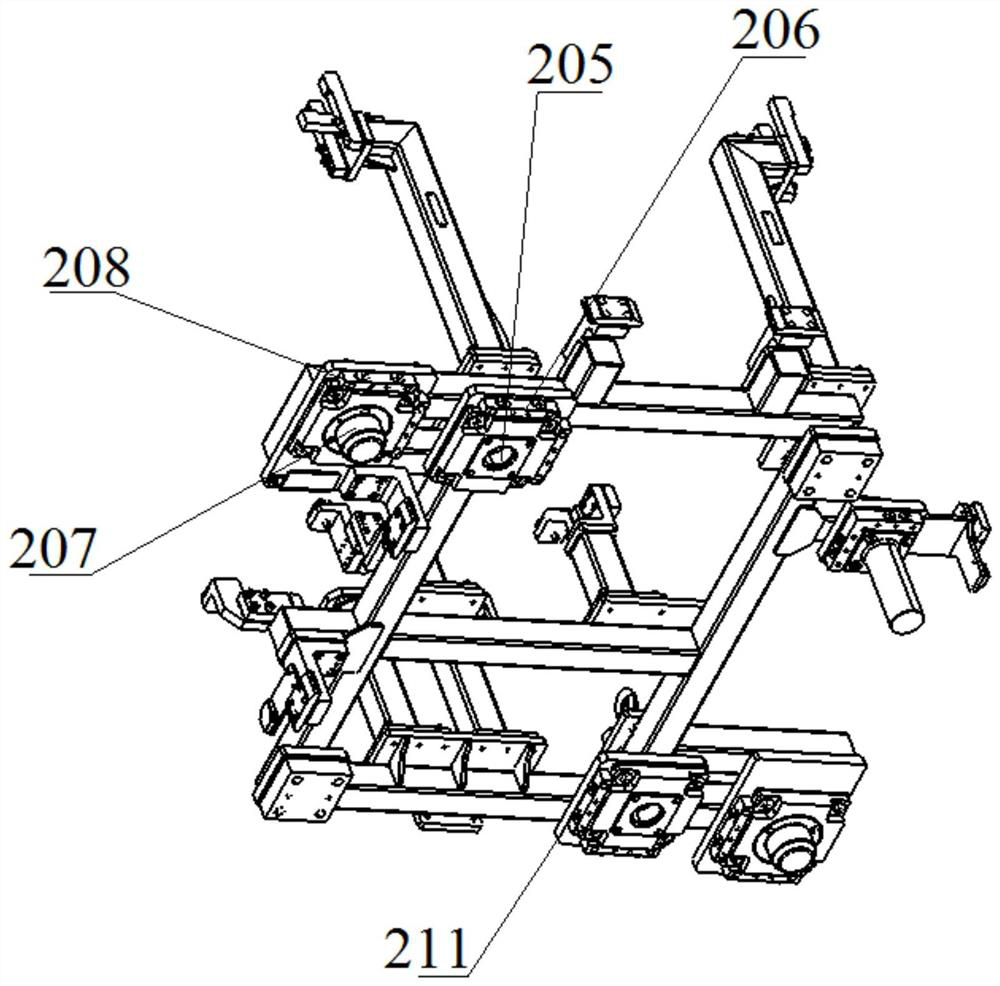

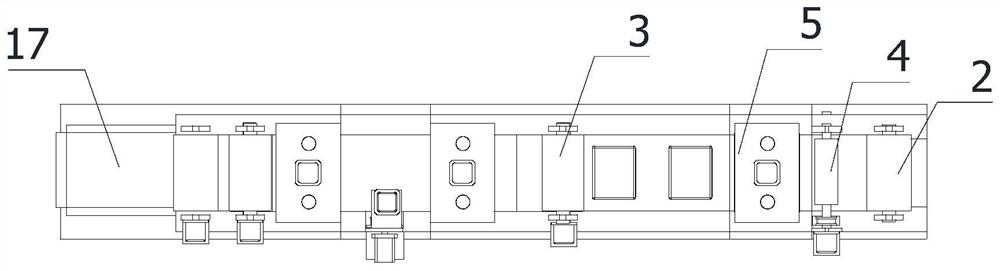

Automatic square tube feeding and servo locating mechanism

ActiveCN109250467AHigh positioning accuracyAutomateConveyorsConveyor partsMaterial transferEngineering

The invention discloses an automatic square tube feeding and servo locating mechanism, and belongs to the technical field of machining automation. The automatic square tube feeding and servo locatingmechanism comprises an automatic square tube feeding mechanism, a servo locating mechanism and a material transferring mechanism. When a hoisting mechanism works, a lifting rope starts to rise, workpieces are driven to ascend, and the workpiece fall onto a chain conveying mechanism through the gravity action. When the workpieces advance one by one along the chain conveying mechanism, after the workpiece advance to a certain position, the workpiece fall along with a guide plate, and are vertically placed under the action of a rear blocking frame. The vertically placed workpieces are pushed by apush air cylinder, and the workpieces are smoothly transferred to a lifting receiving mechanism. After the lifting receiving mechanism receives the workpieces, the workpieces are placed on the material transferring mechanism. The workpieces are transferred to the servo locating mechanism through the material conveying mechanism. The automatic square tube feeding and servo locating mechanism achieves an automatic square tube feeding function and can achieve a servo feeding function on the workpieces, and the locating precision of the workpieces is improved. Automation of square tube machiningis achieved, and labor force is freed up.

Owner:江苏众利达自动化设备有限公司

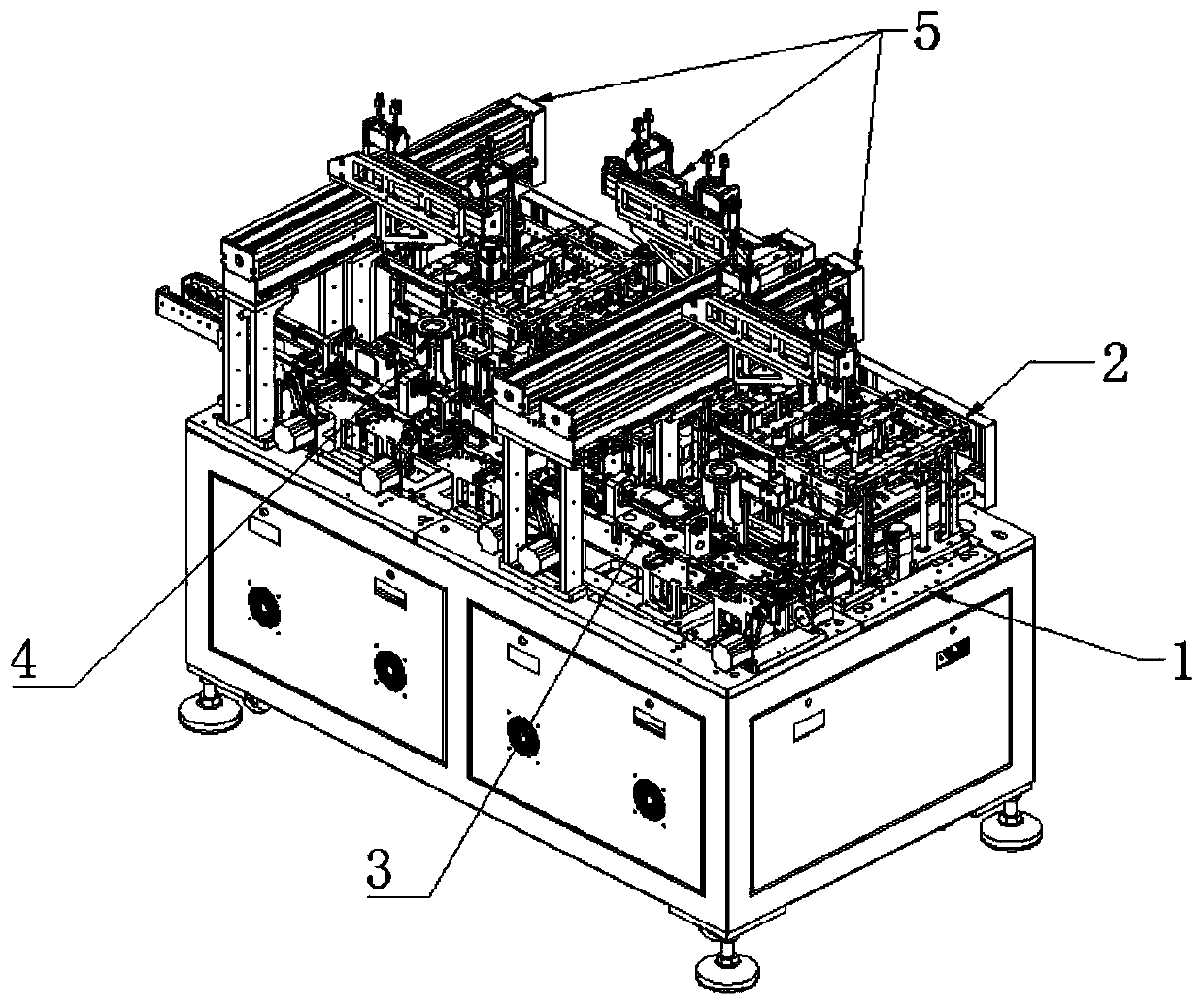

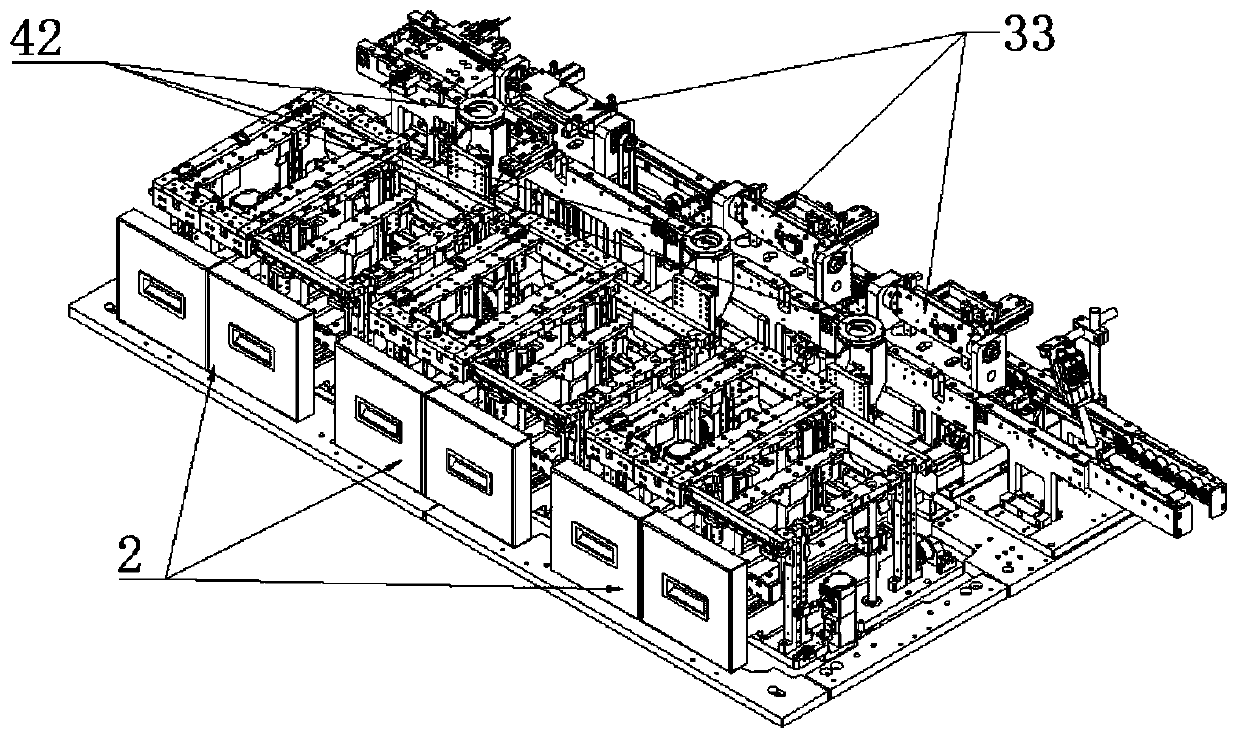

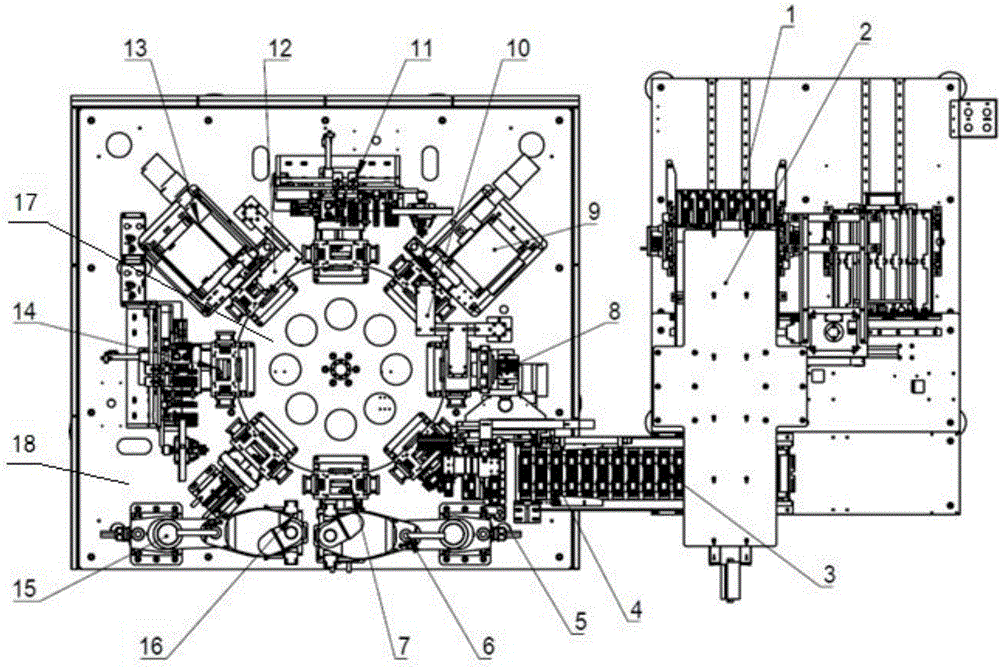

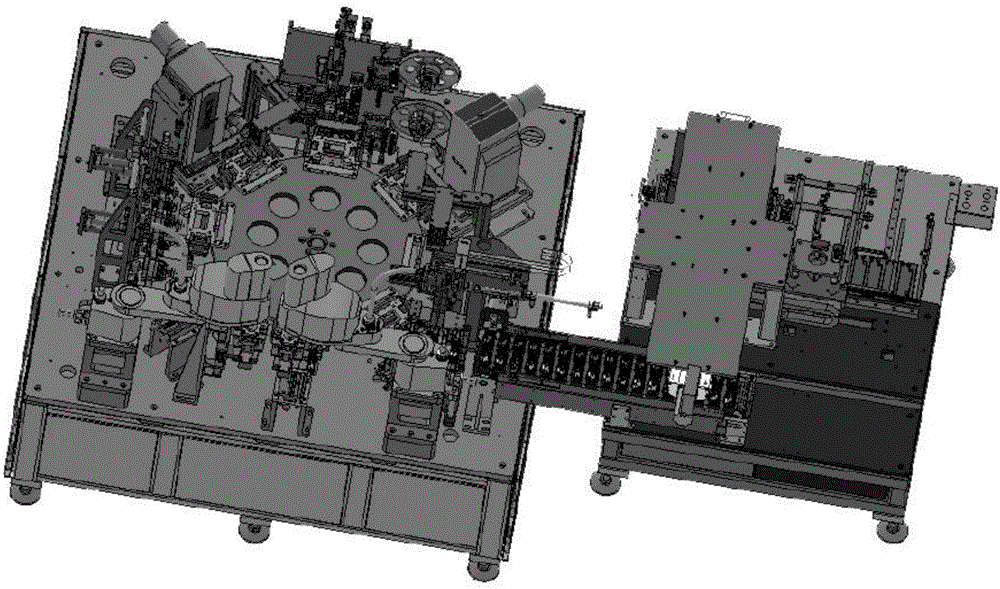

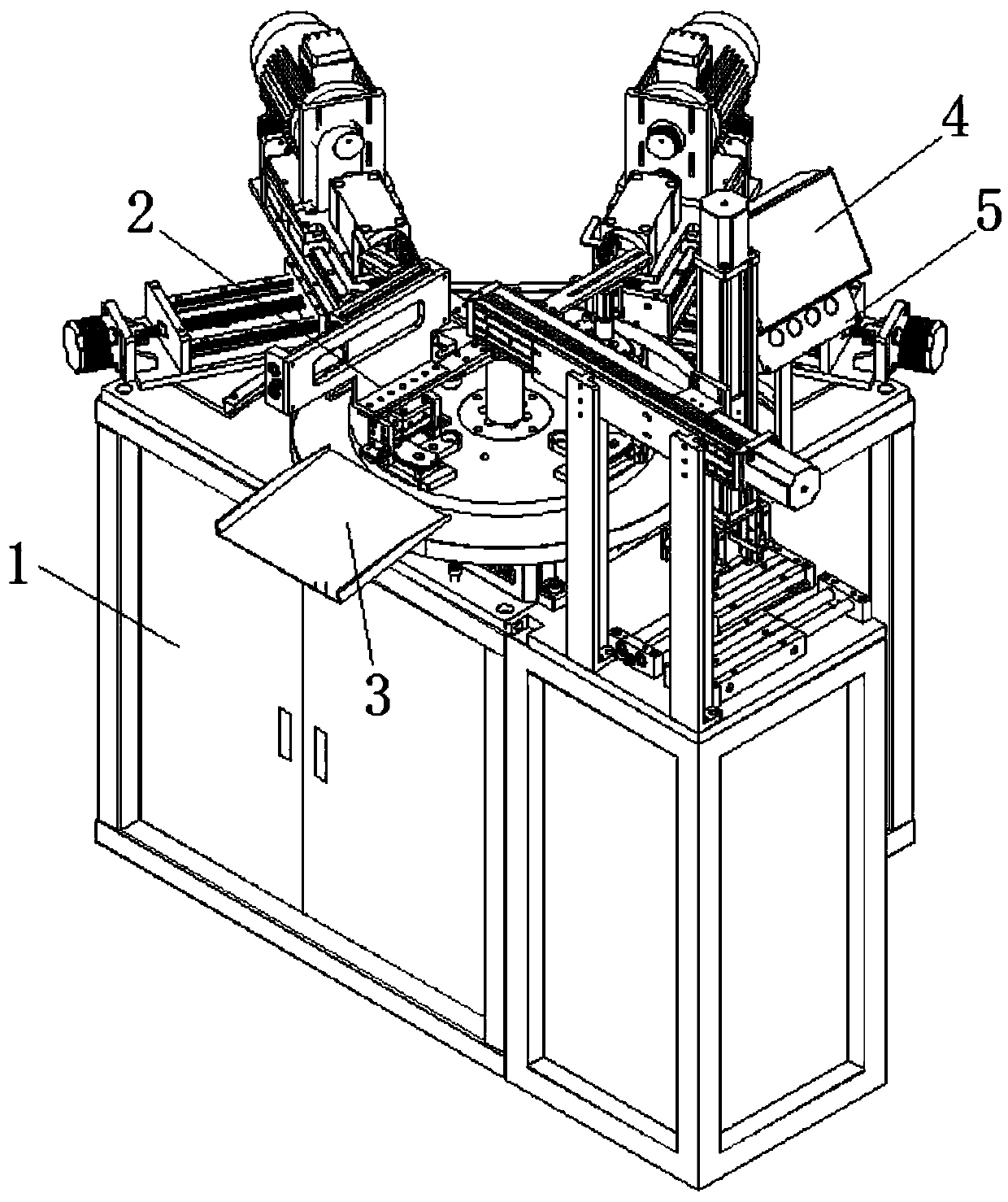

Full-automatic key assembly machine

PendingCN111195818ARealize automatic feeding processRealize automatic assembly functionAssembly machinesKey pressingAssembly line

The invention discloses a full-automatic key assembly machine comprising a machine frame, multiple automatic feeding mechanisms, a conveying mechanism, multiple vision positioning mechanisms and multiple transferring and assembling mechanisms. The automatic feeding mechanisms, the conveying mechanism, the vision positioning mechanisms and the transferring and assembling mechanisms are installed onthe machine frame. Multiple assembly stations are arranged in the length direction of the conveying mechanism at intervals. Each assembly station corresponds to one automatic feeding mechanism, one vision positioning mechanism and one transferring and assembling mechanism. The conveying mechanism is used for conveying mobile phone shell bodies. The automatic feeding mechanisms are located on onesides of the assembly stations. The transferring and assembling mechanisms are used for transferring materials to the corresponding assembly stations to be subjected to assembly work from the automatic feeding mechanisms. The vision positioning mechanisms are used for correcting material grabbing positions of the corresponding transferring and assembling mechanisms. According to the full-automatickey assembly machine, by adopting the continuous material supply technology, the assembly line automatic turnover alignment technology and the vision positioning assembly technology, the automatic feeding function and the automatic assembly function of mobile phone keys are achieved, the production efficiency is improved, and the assembly yield is increased.

Owner:深圳市昇茂科技有限公司

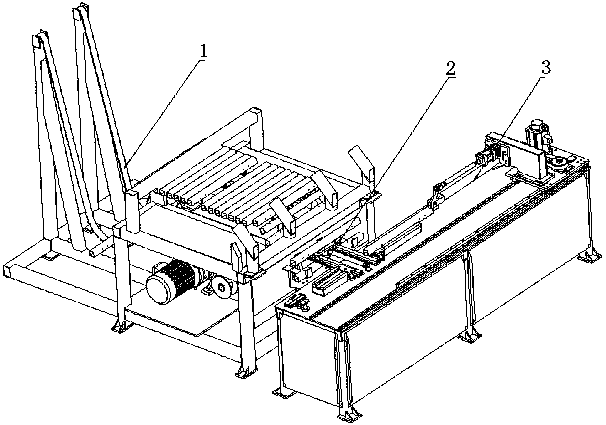

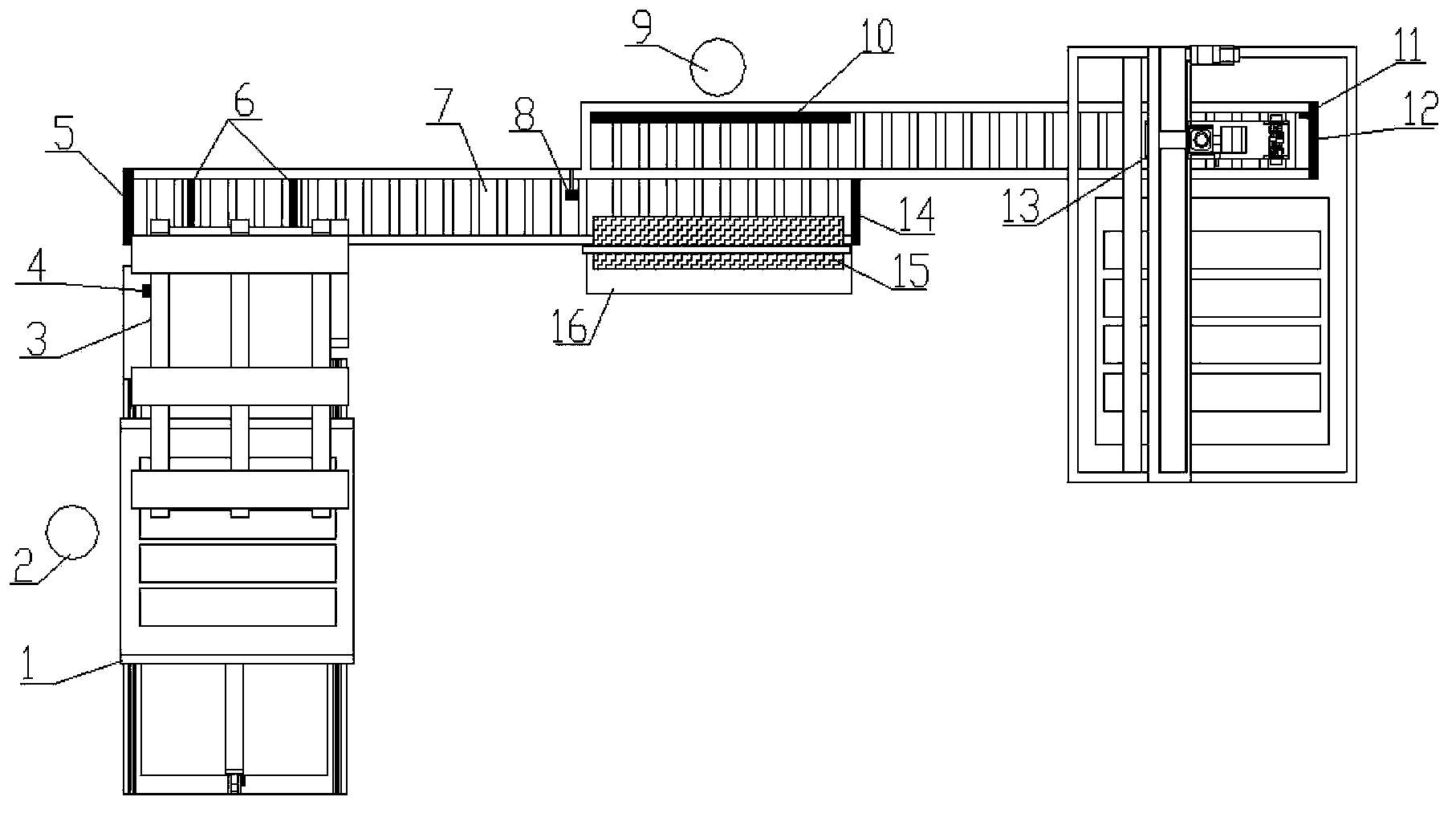

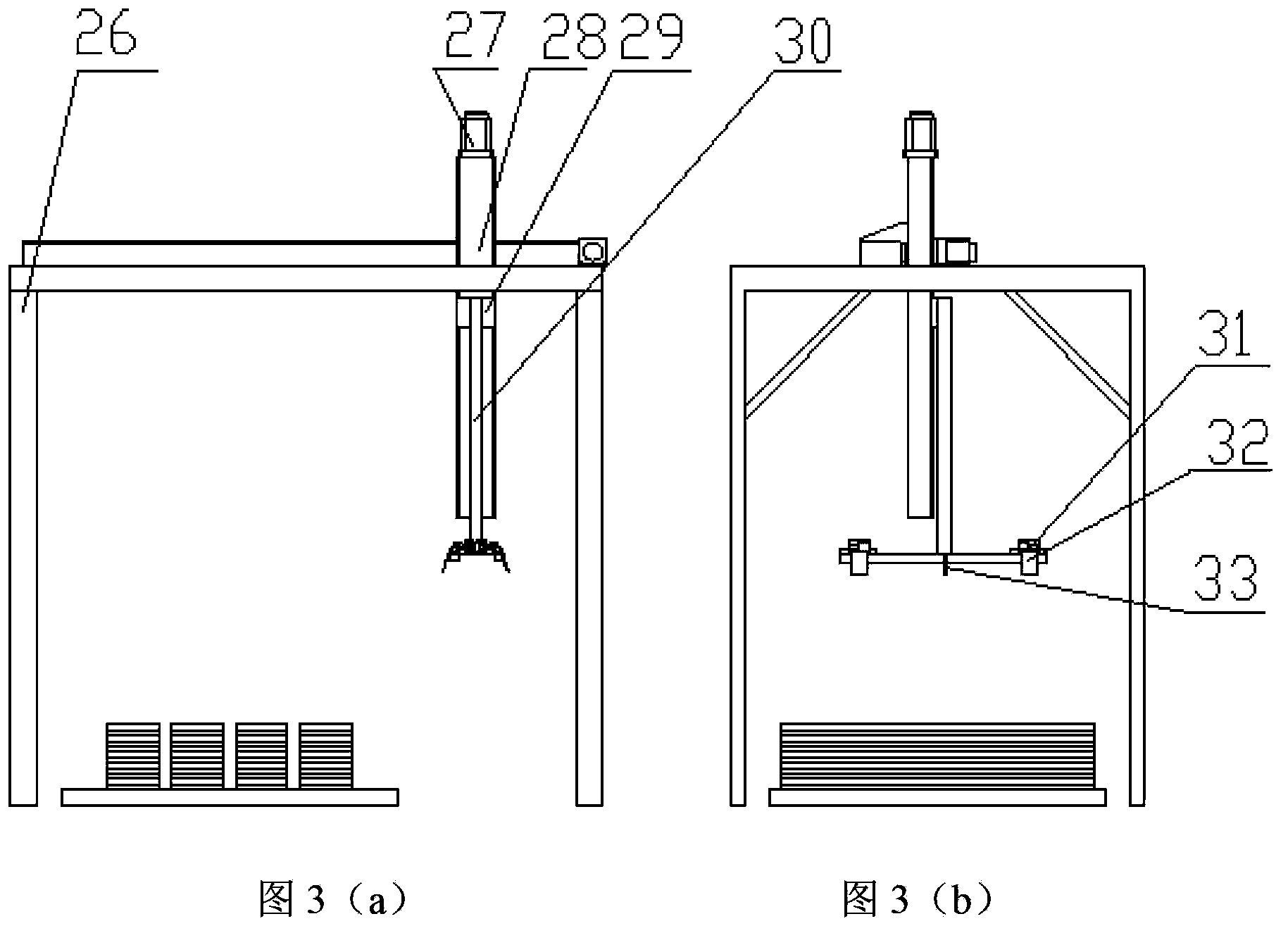

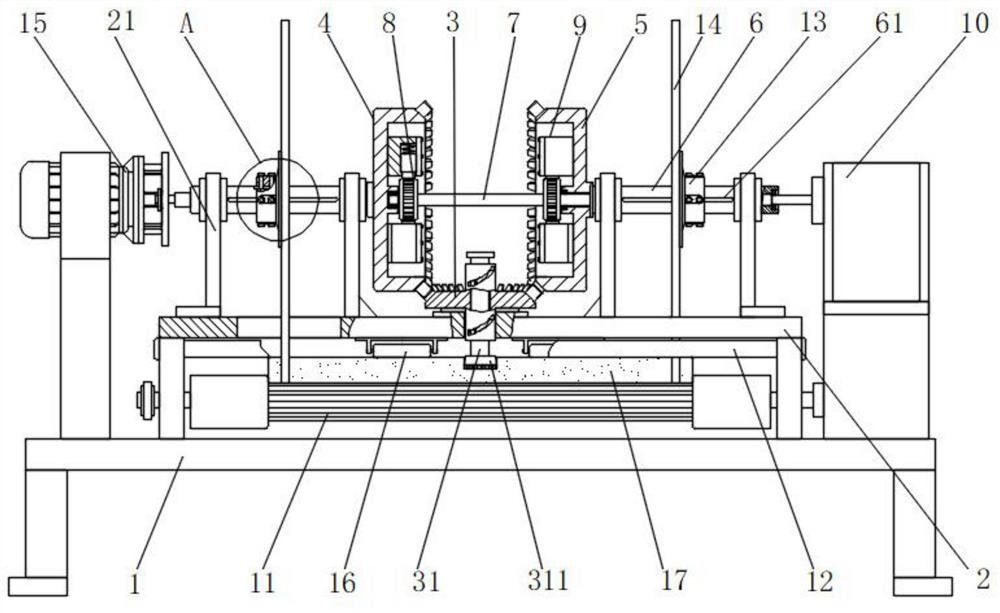

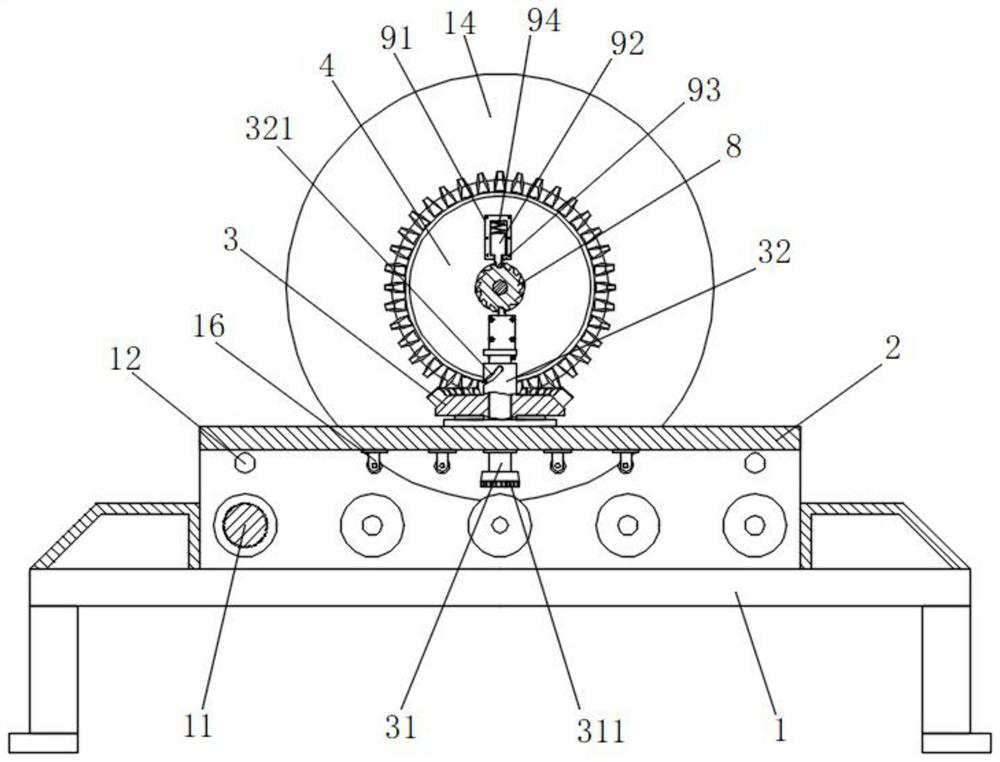

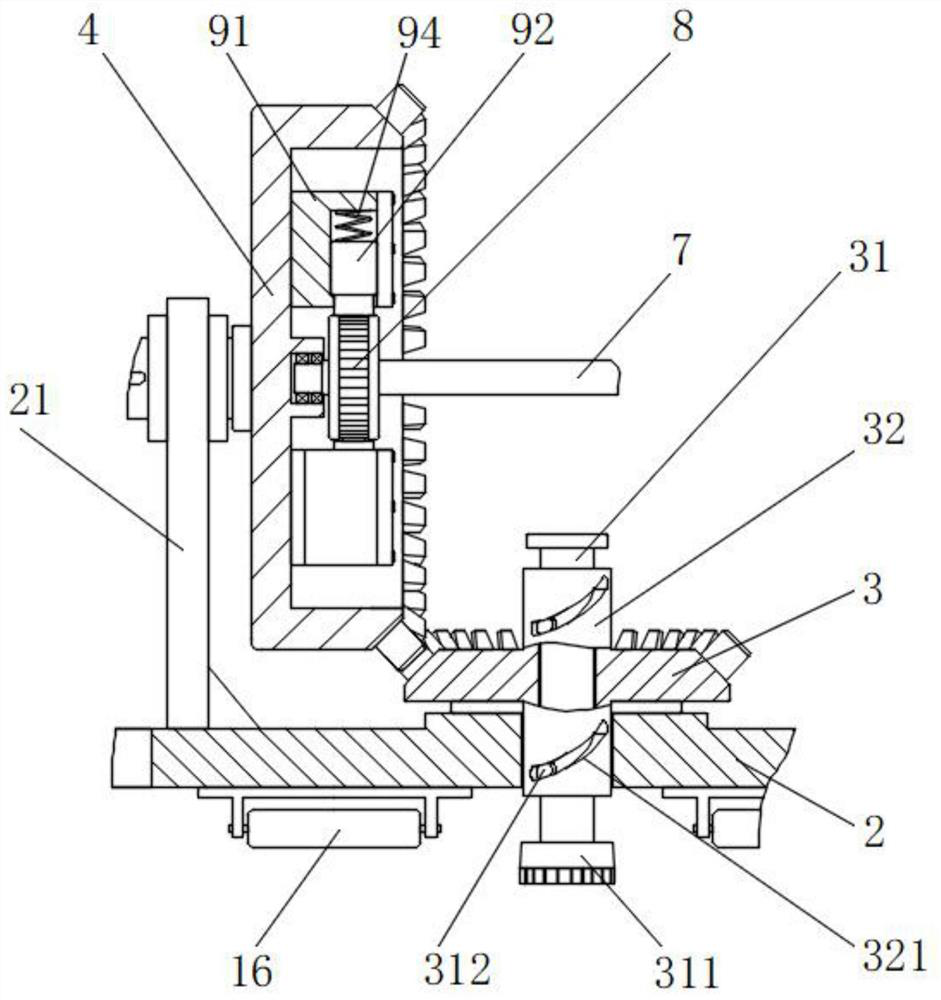

Catenary cantilever numerical control preassembly platform

ActiveCN103171456AGuarantee the construction qualityImprove quality and efficiencyTrolley linesNumerical controlEngineering

The invention discloses a catenary cantilever numerical control preassembly platform. The catenary cantilever numerical control pre-equipped platform comprises mutually independent pipe-cutting platforms and a part assembly platform. Each of the pipe-cutting platforms comprises a material discharge end main body, a cutting machine and a material feeding end main body, wherein a first linear guideway is fixed on the material discharge end main body, a first positioning device is mounted on the first linear guideway, and a pipe driving device is mounted on the material feeding end main body. The part assembly platform comprises a main body, wherein an upper linear guideway and a lower linear guideway are fixed on the main body, a second positioning device is mounted on the upper linear guideway, and a rotating device and a fixing device are mounted on the lower linear guideway. The catenary cantilever numerical control preassembly platform has the advantages of improving cantilever preassembly mechanization degree, the processing quality of a cantilever, and the production efficiency of the cantilever.

Owner:CHINA CREC RAILWAY ELECTRIFICATION BUREAU GRP +2

Automatic cover plate welding and rubberizing machine

ActiveCN106571488ARealize automatic feeding functionIncrease productivityAssembling battery machinesFinal product manufactureManipulatorEngineering

The invention discloses an automatic cover plate welding and rubberizing machine, which comprises a machine frame and a workbench arranged on the machine frame. The machine further comprises a rotating disc, a rotating disc driving device, eight positioning fixtures uniformly arranged at intervals at the outer edge of the rotating disc along the circumferential direction thereof, an electrical core loading robot, a cover plate loading manipulator, a cover plate shaping assembly, an anode welding assembly, an anode rubberizing assembly, a cathode welding assembly, a cathode rubberizing assembly, and a blanking robot. Each positioning fixture comprises an electrical core positioning mechanism used for positioning the position of an electrical core, and a cover plate positioning mechanism used for positioning the position of a cover plate. The electrical core loading robot, the cover plate loading manipulator, the cover plate shaping assembly, the anode welding assembly, the anode rubberizing assembly, the cathode welding assembly, the cathode rubberizing assembly, and the blanking robot are arranged on the workbench and are sequentially arranged at intervals at the periphery of the rotating disc along the circumferential direction thereof. According to the technical scheme of the invention, by means of the cover plate welding and rubberizing machine, the full automatic operation of the welding and the rubberizing of battery cover plates and electrical core tabs can be realized. Meanwhile, the problem in the prior art that an electrical core tab can only be welded and rubberized after being manually wrapped into a cover plate flexible connection sheet and then shaped in the prior art can be solved. The labor cost is saved and the production efficiency is improved.

Owner:GEESUN AUTOMATION TECH

Robot and maintenance method of railway track for robot

PendingCN108797239AReduce labor intensityImprove securityRailway track constructionRailway transportFastenerMaintenance Problem

The invention discloses a robot. The robot is mounted on a railway track and used for the maintenance of nuts and fasteners. The robot is characterized by comprising a base, traveling wheels, a material charging device, a combination device, a material feeding device, a gripping mechanical arm, manipulators and a detection device, wherein all the components except the traveling wheels are arrangedon the base; the combination device is connected to the material charging device; the gripping mechanical arm is connected between the combination device and the material feeding device; and the detection device and the manipulators are arranged on the same side of the material feeding device. Meanwhile, the robot is used for the maintenance of the railway track. Compared with the prior art, therobot can achieve the automatic material charging function by virtue of the material charging device and the combination device, thereby achieving a modernized robot integrating material charging withmaintenance. In addition, by virtue of the reasonable function of the gripping mechanical arm, the manipulators and the detection device, the robot solves the maintenance problem caused by the different inclination of manually-pre-embedded bolts so as to successfully complete the maintenance of the railway track. The robot is time-saving, labor-saving, precise and quick.

Owner:SHANDONG JIAOTONG UNIV

Construction waste recovery device and method

InactiveCN108672017AReduce labor intensityGuaranteed cleanlinessUsing liquid separation agentGrain treatmentsScrapWater pipe

The invention discloses a construction waste recovery device and method. The construction waste recovery device comprises a vehicle body, a processing box, a transport frame and a bracket, the four corners of the lower end of the vehicle body are provided with wheels, and the processing box is disposed on one side of the upper end of the vehicle body. A control board is disposed on the middle portion of one side wall of the processing box, and a discharge hopper is disposed on the middle portion of the lower end of the other side wall of the processing box. A feeding hopper is disposed on themiddle portion of the upper end of the processing box, and first drive blocks are arranged on both sides of the upper end of the side wall, away from the discharge hopper, of the processing box. Second drive blocks are disposed directly below the first drive blocks. The construction waste recovery device and method have the beneficial effects that the automatic feeding function can be realized byarranging a third motor, a conveyor belt and a material lifting roller, and the manual labor intensity can be reduced; dust removal operation can be performed while feeding by arranging a first motor,a water pump, a water pipe and atomizing nozzles, and the cleanliness of the environment can be ensured; and by arranging rotors, impact hammers and grinding rollers, waste can be double treated andthe treatment effect is good.

Owner:广西柳州市三集科技有限公司

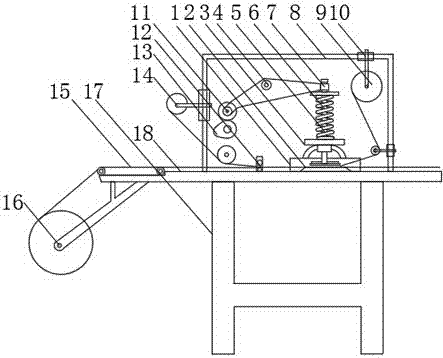

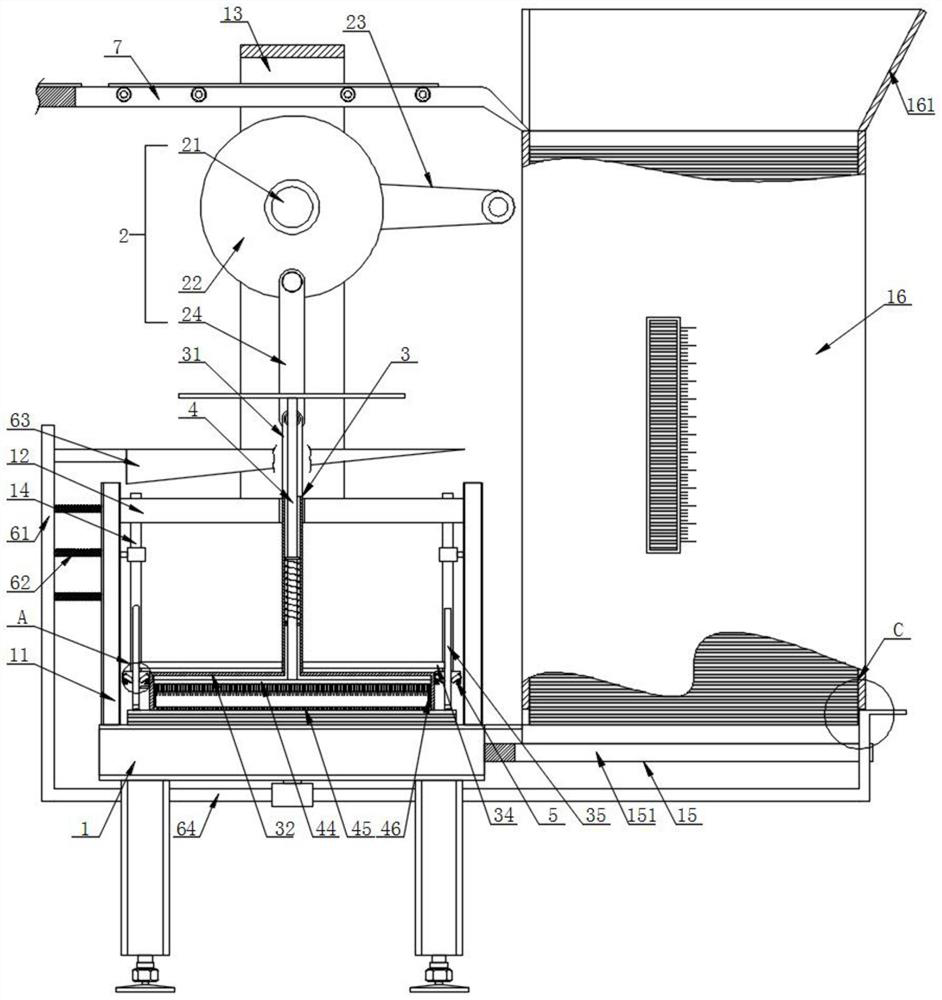

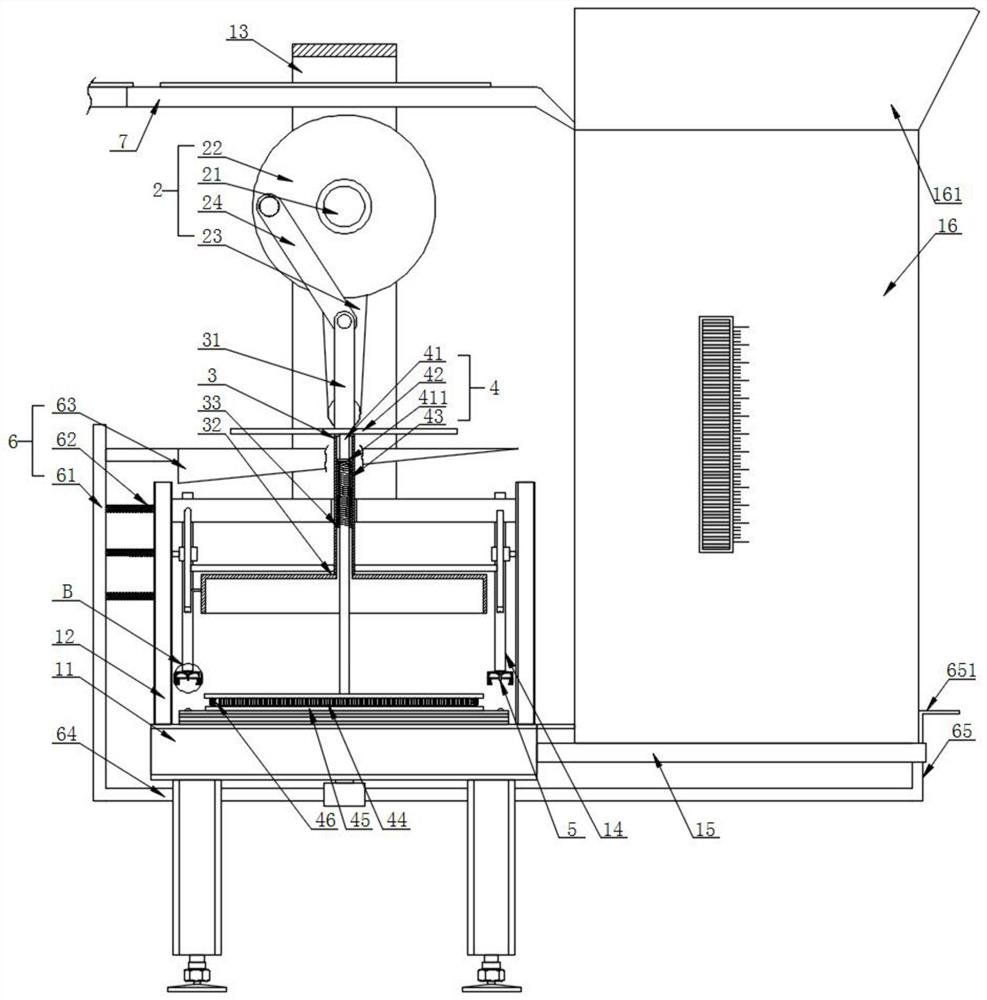

Single pendulous vertical type flat-pressing flat-die-cutting machine

InactiveCN107471313ASimple structureDie-cut structure is simpleMetal working apparatusWebs handlingBar pressingCam

The invention discloses a single pendulous vertical type flat-pressing flat-die-cutting machine, which comprises a working table and a rack. The working table and the rack are integrally connected; a shell is fixed at one side, relative to the side on which the rack is arranged, on the working table; a membrane roller is arranged at any side, perpendicular to the working table, of the shell; a conveyor belt is arranged at a position, at the same side of the membrane roller, on the working table; a feed shaft is arranged on the working table at the lower end of the conveyor belt; a cam structure is arranged in the shell; a high-strength spring is arranged on a pressing rod; the rotating cam enables a die-cutting cutter and a die-cutting table on the pressing rod to press fit through a crank; and after press fit, the spring on the pressing rod springs the pressing rod, and the die-cutting cutter and the die-cutting table are separated so as to realize a sequential die-cutting process. The device is simple in structure and convenient to maintain; and the automatic-feeding conveyor belt and a material collecting shaft for collecting waste materials are arranged, so that the automation degree is high, the labor cost can be saved, and the production efficiency is improved.

Owner:成都佳欣诚信科技有限公司

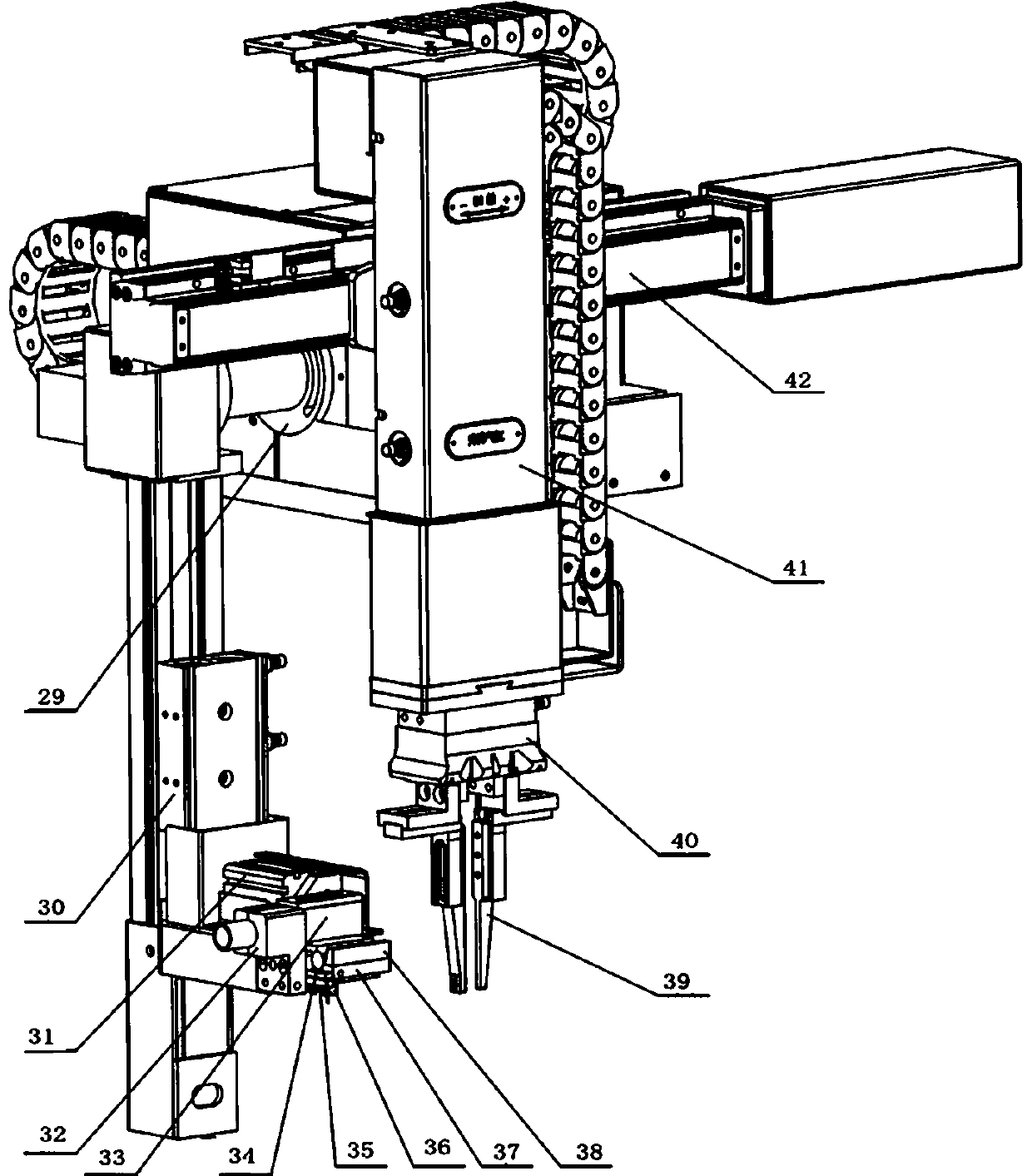

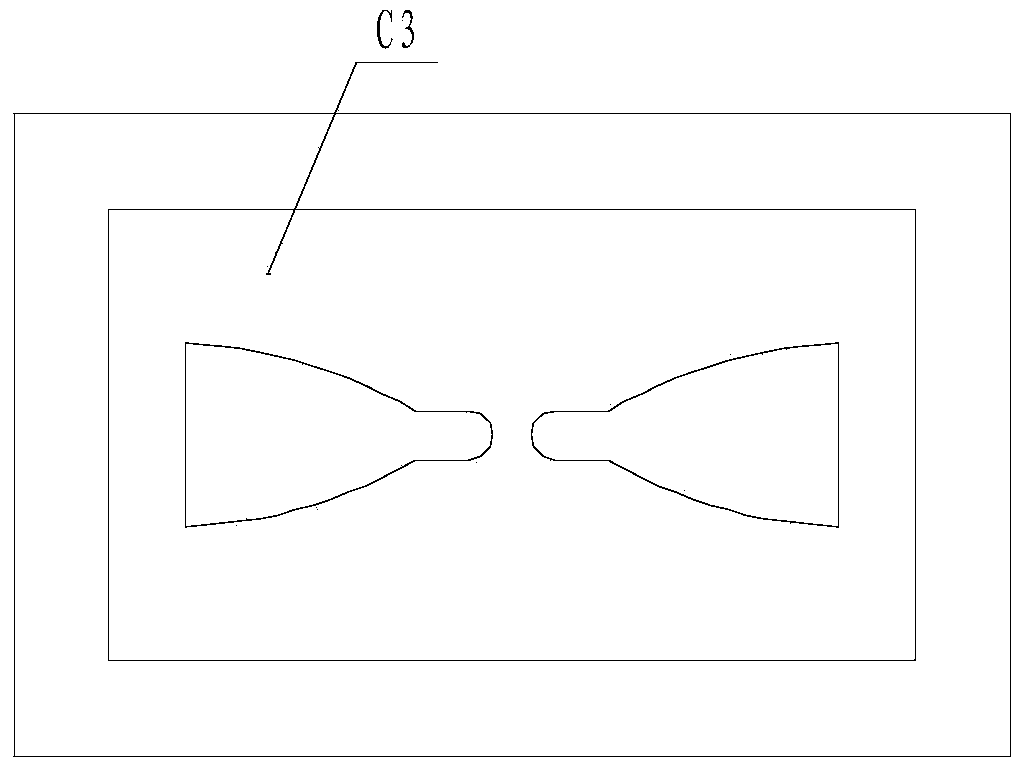

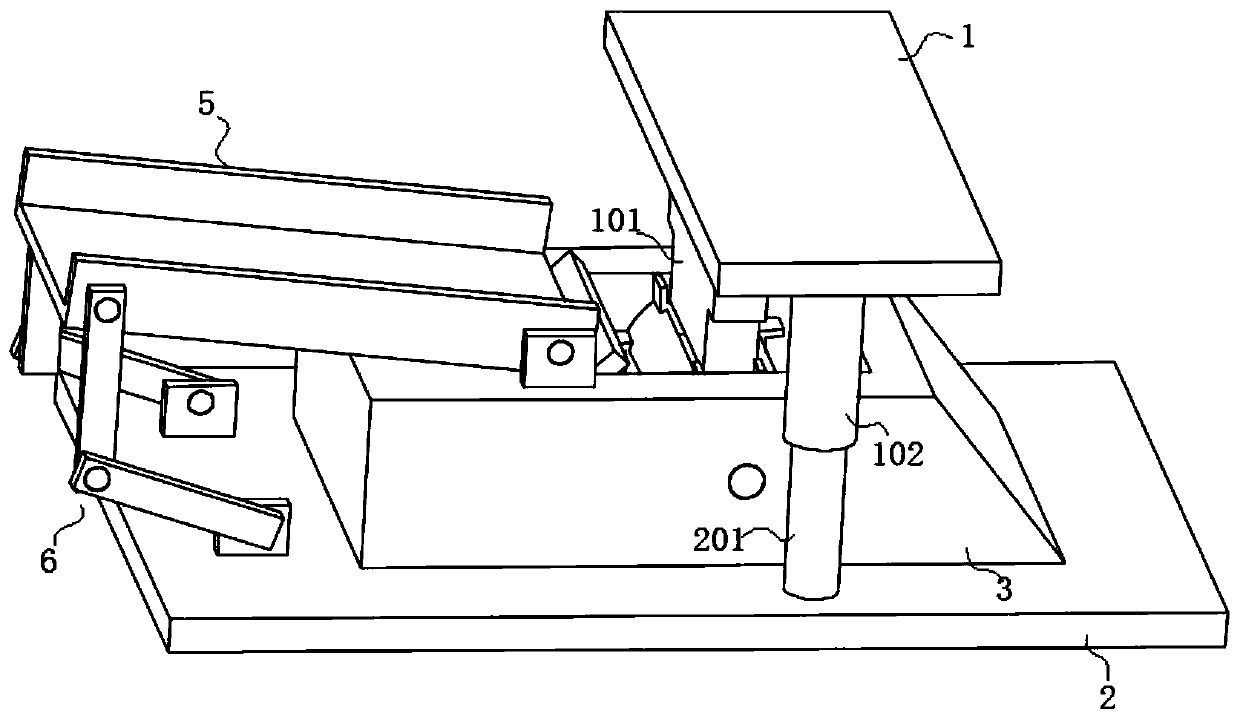

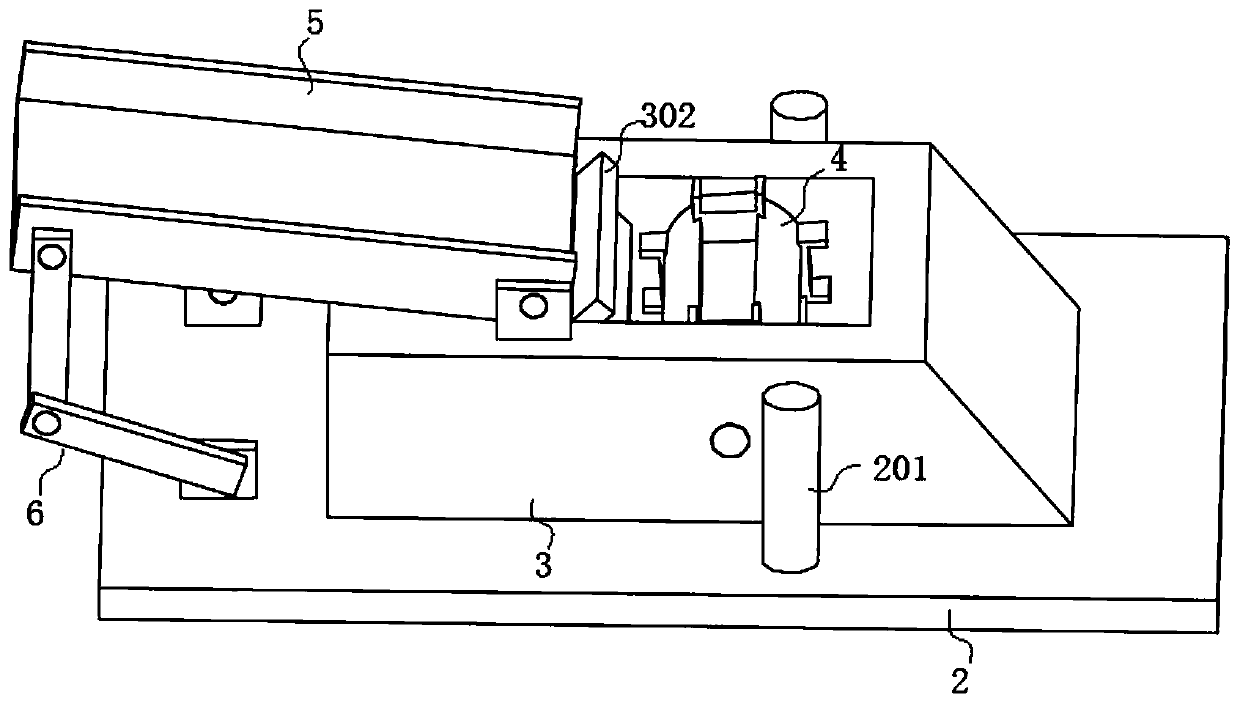

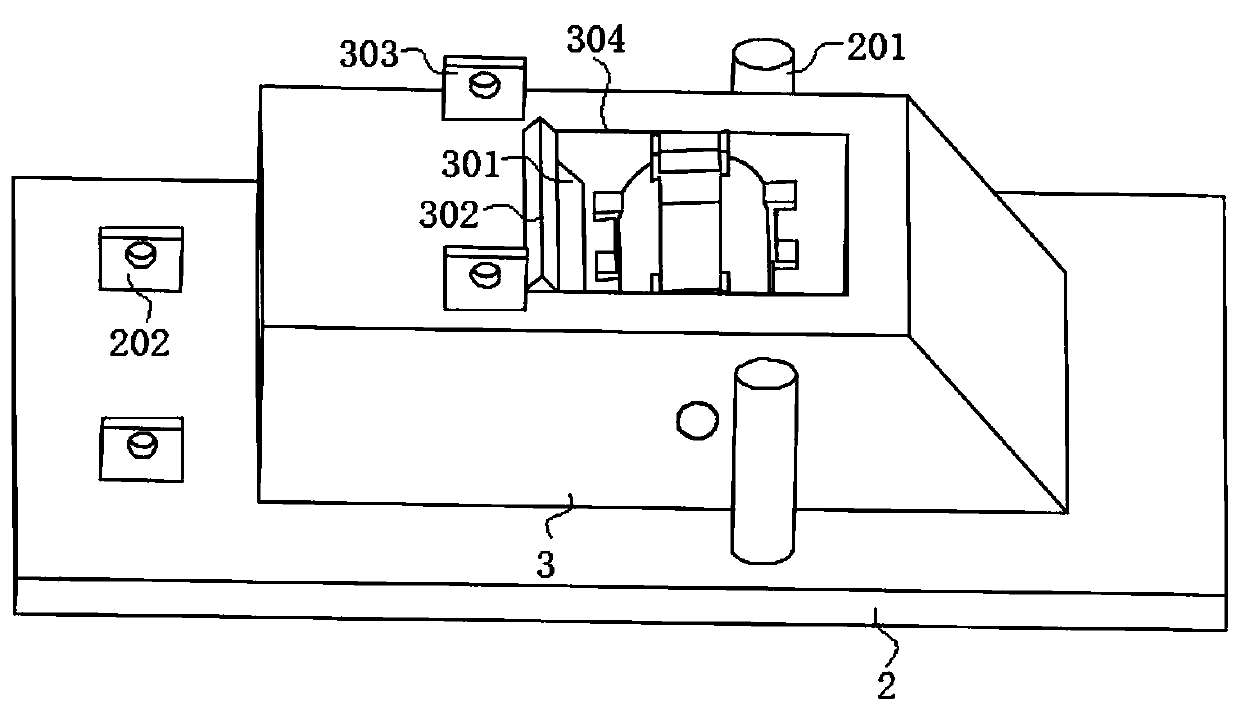

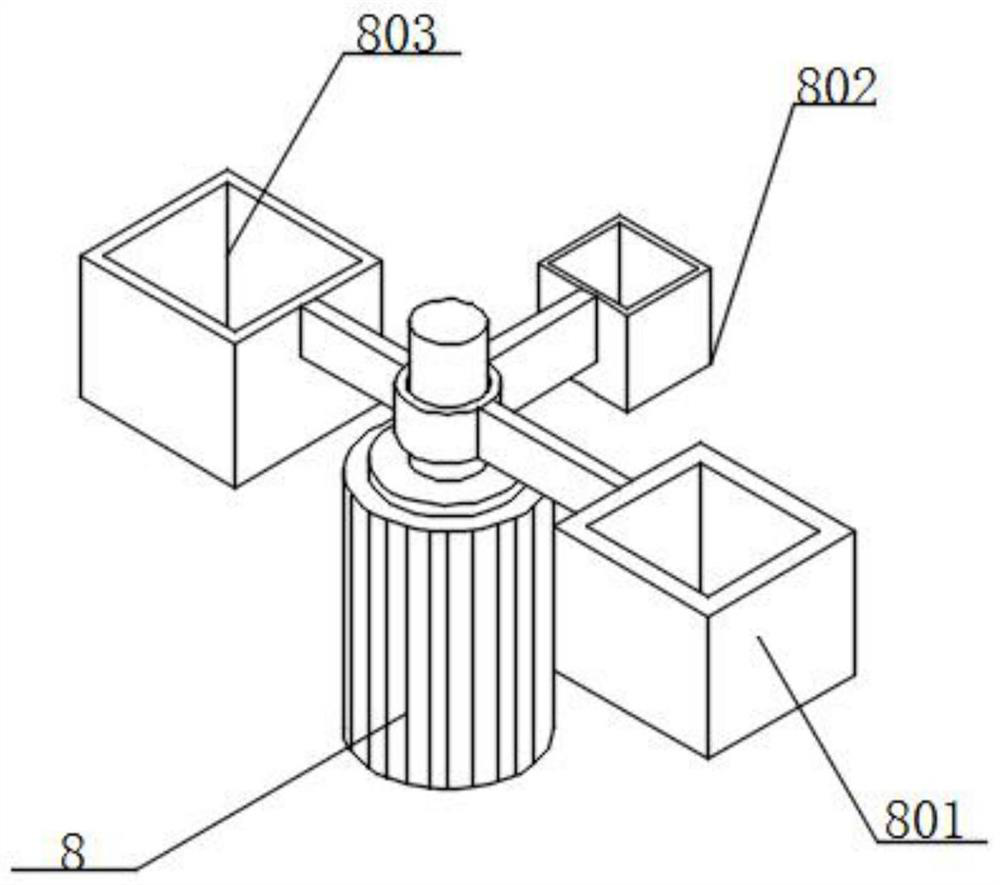

Automatic assembling structure for supercharger C-type ring

ActiveCN106891144ARealize automatic feeding functionRealize the function of guiding and receiving materialsInternal combustion piston enginesMetal working apparatusEngineeringAssembly structure

The invention discloses an automatic assembling structure for a supercharger C-type ring. The automatic feeding function for the C-type ring is achieved through a C-type ring automatic feeding mechanism, the guide receiving function for the C-type ring is achieved through an automatic receiving guide mechanism, and the C-type ring horizontally placed in a guide sleeve is pressed into a middle shell through an automatic press-mounting mechanism. The function of detecting whether the C-type ring pressed into the middle shell meets assembling requirements or not is achieved through an automatic detecting mechanism. The automatic assembling structure for the supercharger C-type ring can guarantee that the C-type ring is automatically and accurately installed in place, the stability of detecting results and the assembling process is high, and the whole assembling and detecting process can be completed within 5-10 seconds. Thus, a testing method is high in efficiency and speed, and suitable for industrial production sites.

Owner:BORGWARNER AUTOMOTIVE COMPONENTS (JIANGSU) CO LTD

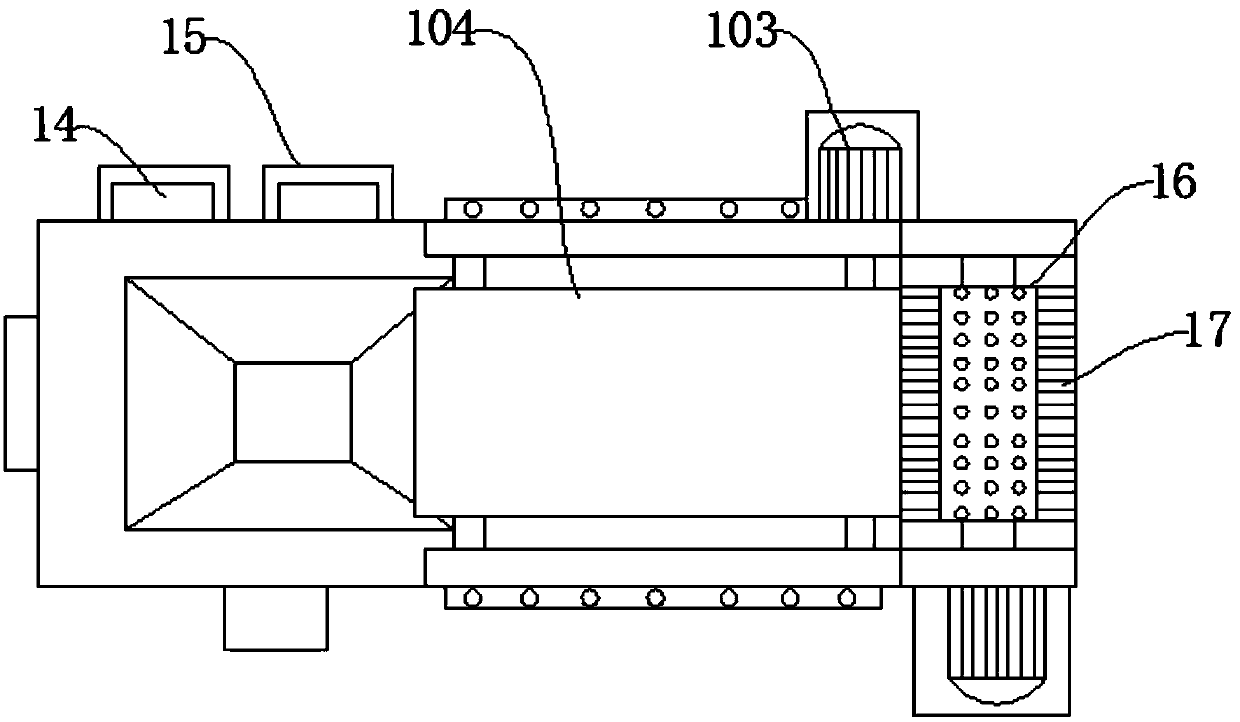

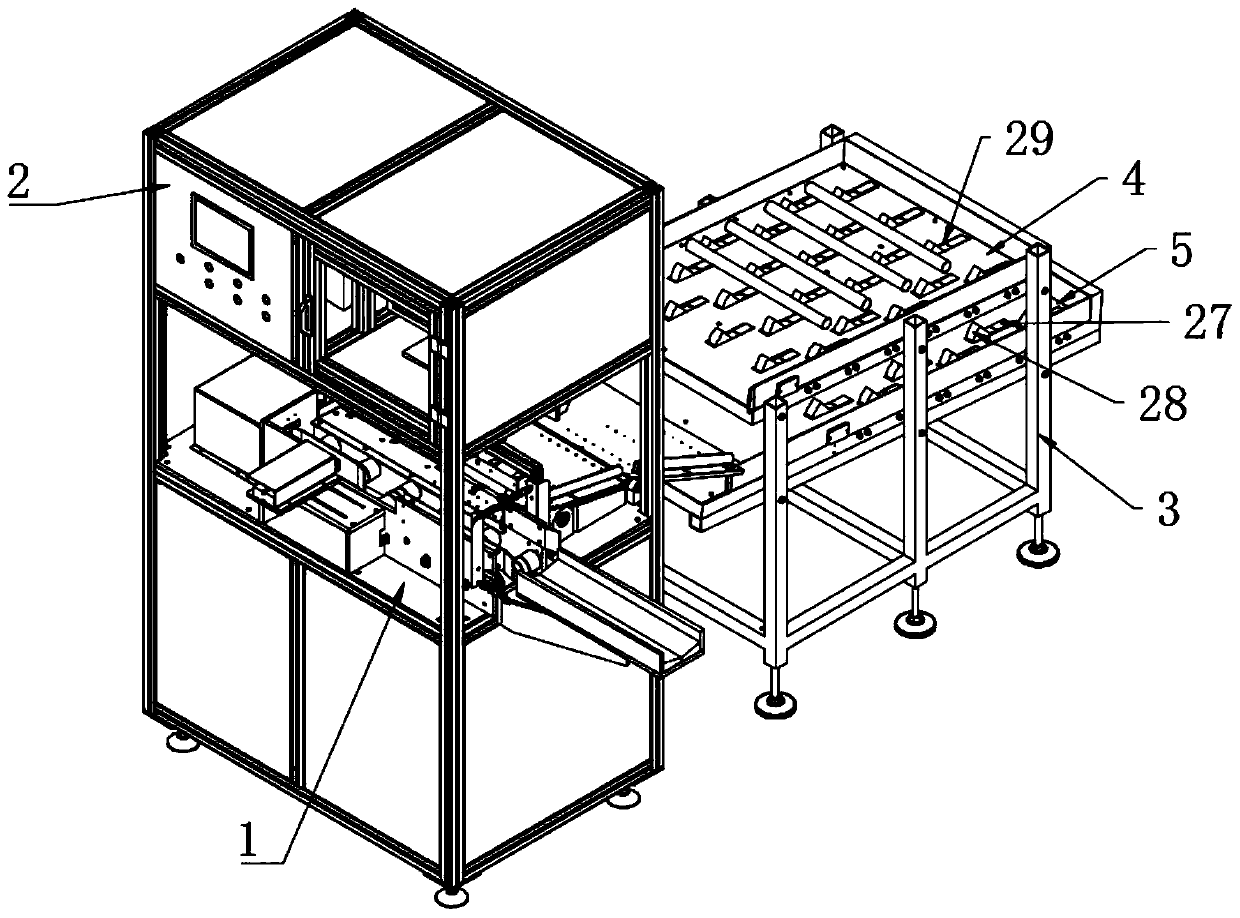

Manufacturing equipment of HDI circuit board capable of realizing accurate fixing

ActiveCN108834313ARealize automatic feeding functionPrecise positioningPrinted circuit manufactureMetal working apparatusContinuous/uninterruptedMaterial storage

The invention discloses manufacturing equipment of an HDI circuit board capable of realizing accurate fixing, wherein the manufacturing equipment belongs to the field of circuit board manufacturing equipment. The manufacturing equipment comprises a worktable, a material storage box for storing to-be-processed HDI circuit boards, a material inlet device, a material withdrawing device, a drilling device and a conveyor. The material inlet device, the material withdrawing device, the drilling device and the conveyor are mounted on the tabletop of the worktable. According to the manufacturing equipment of the HDI circuit board capable of realizing accurate fixing, through arranging the material inlet device and the material storage box, an automatic material feeding function of the manufacturing equipment is realized. Through arranging the material withdrawing device, a material pushing cylinder and the conveyor, an automatic material withdrawing function of the manufacturing equipment is realized. Therefore, the manufacturing equipment of the HDI circuit board capable of realizing accurate fixing realizes continuous material feeding and material withdrawing and has advantages of high automation degree and high speed. The manufacturing equipment realizes accurate mechanical drilling on the HDI circuit board.

Owner:江西志博信科技股份有限公司

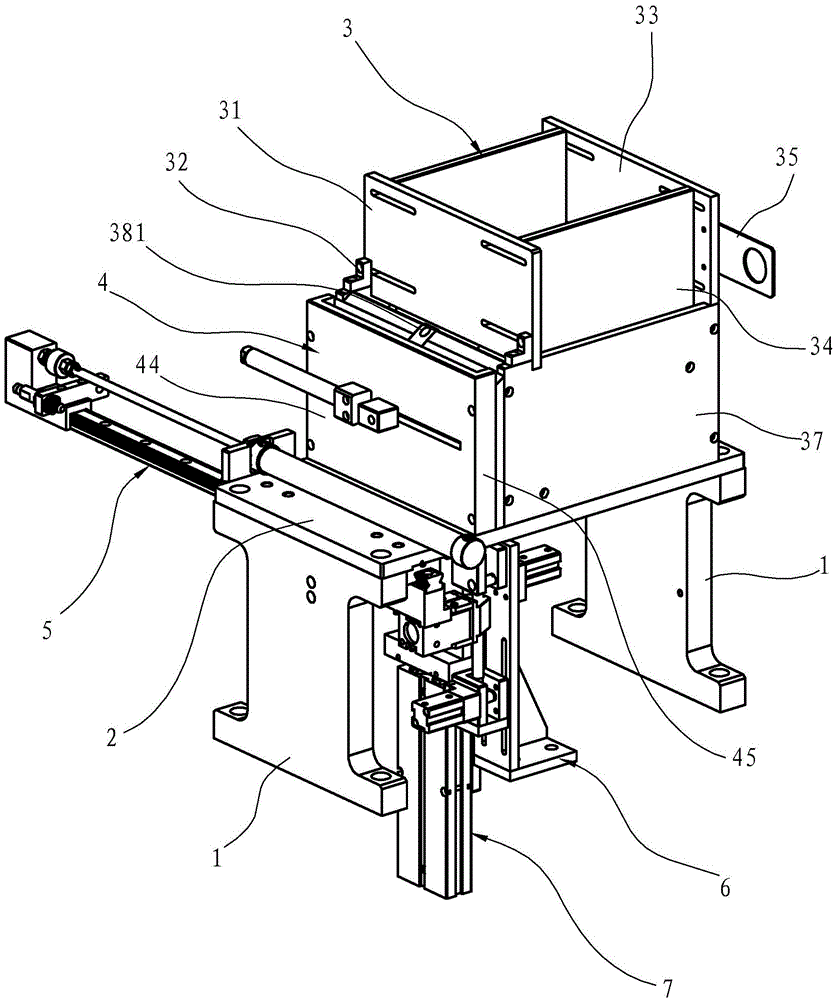

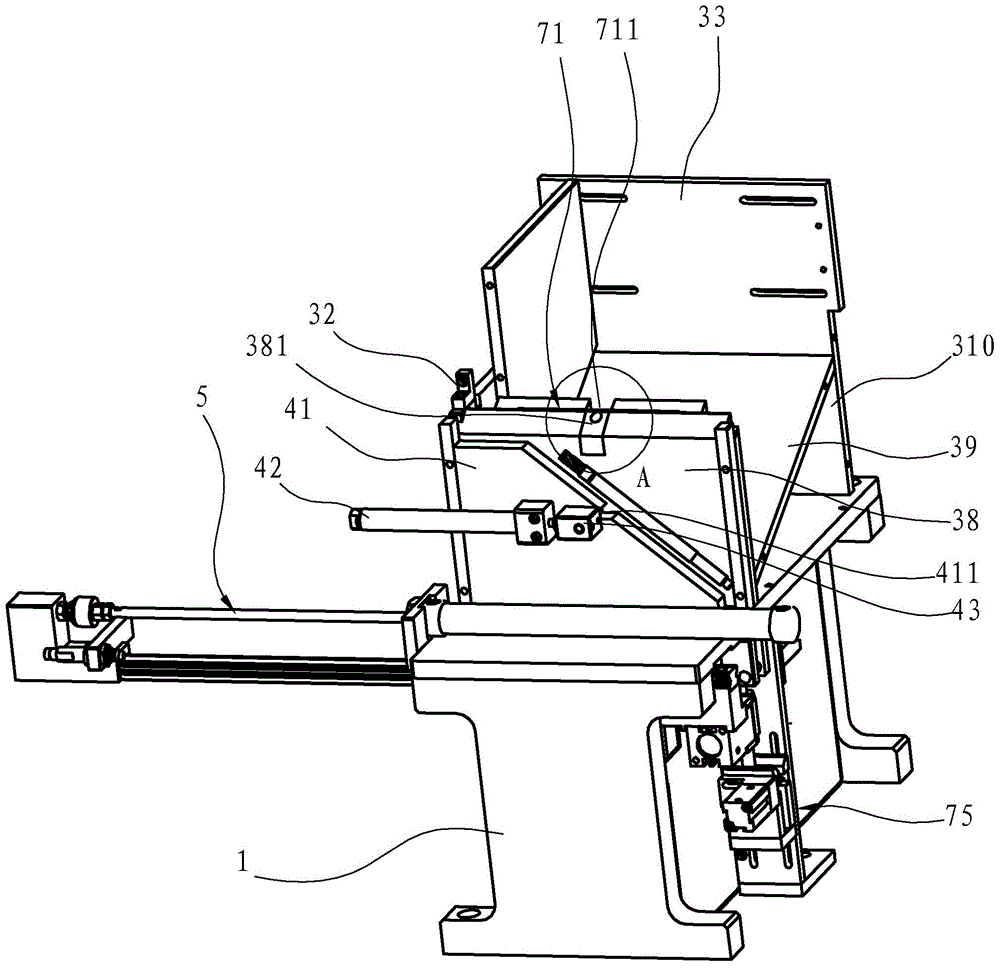

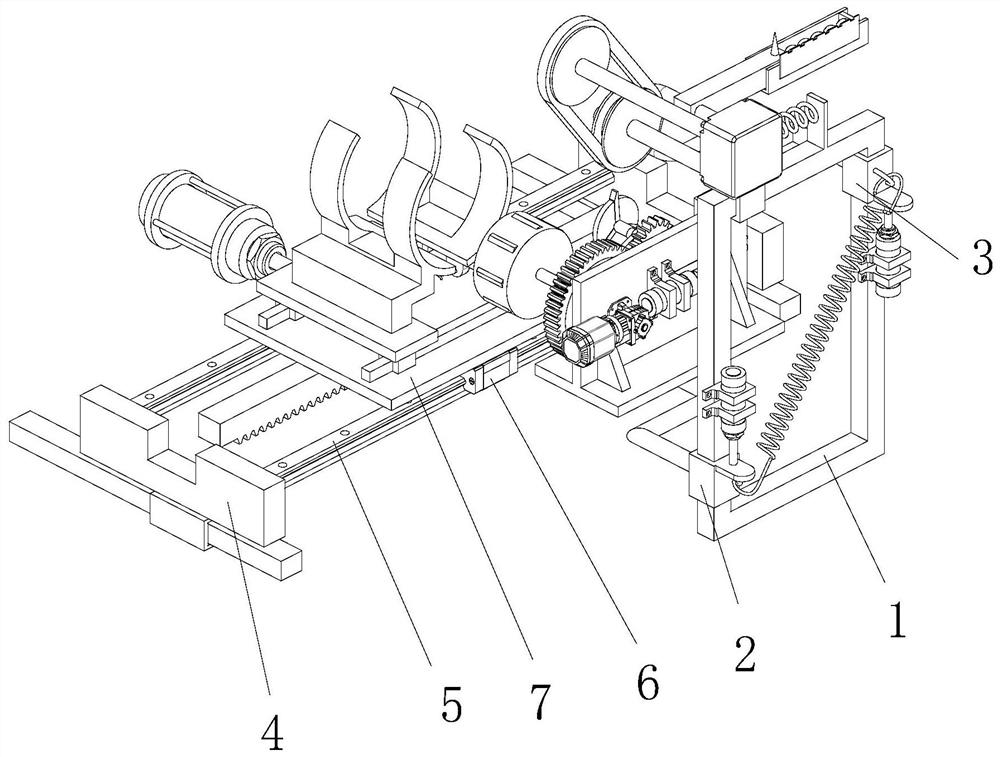

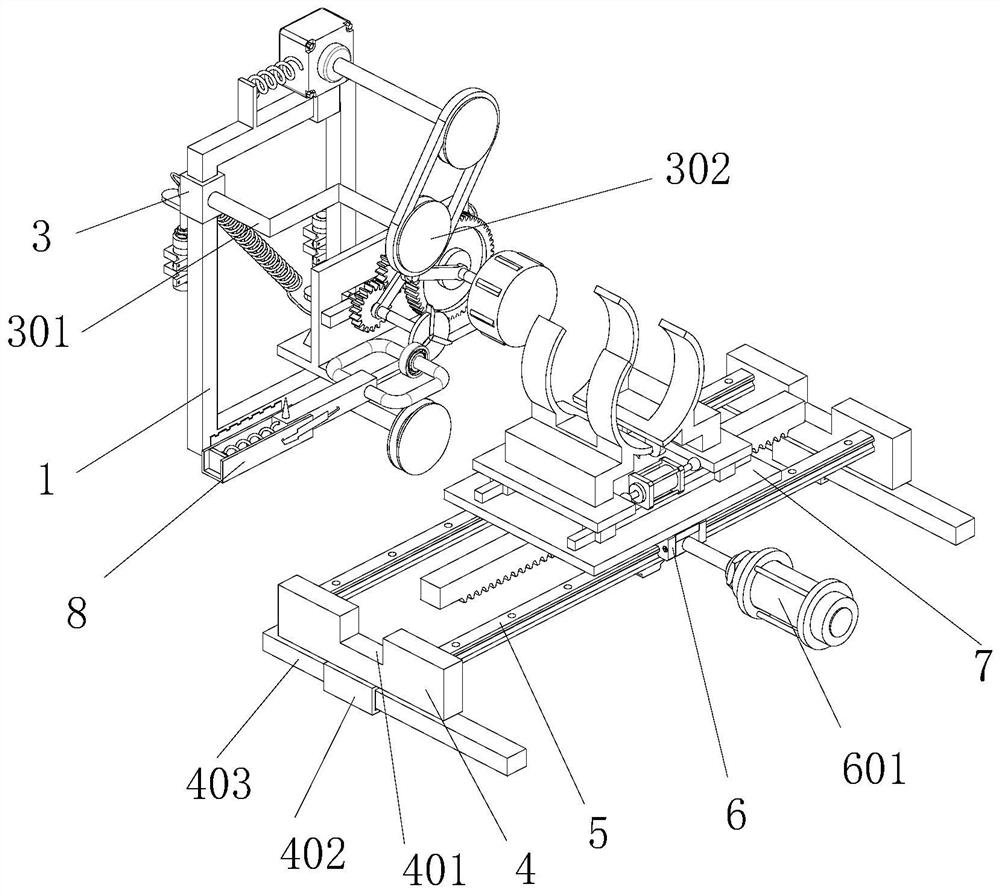

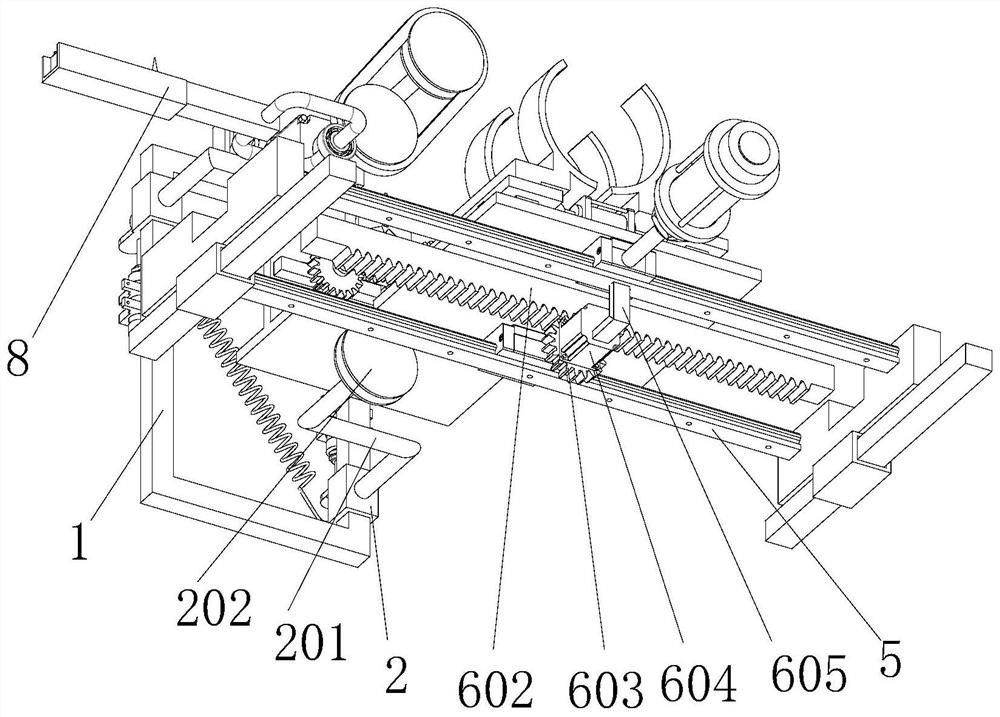

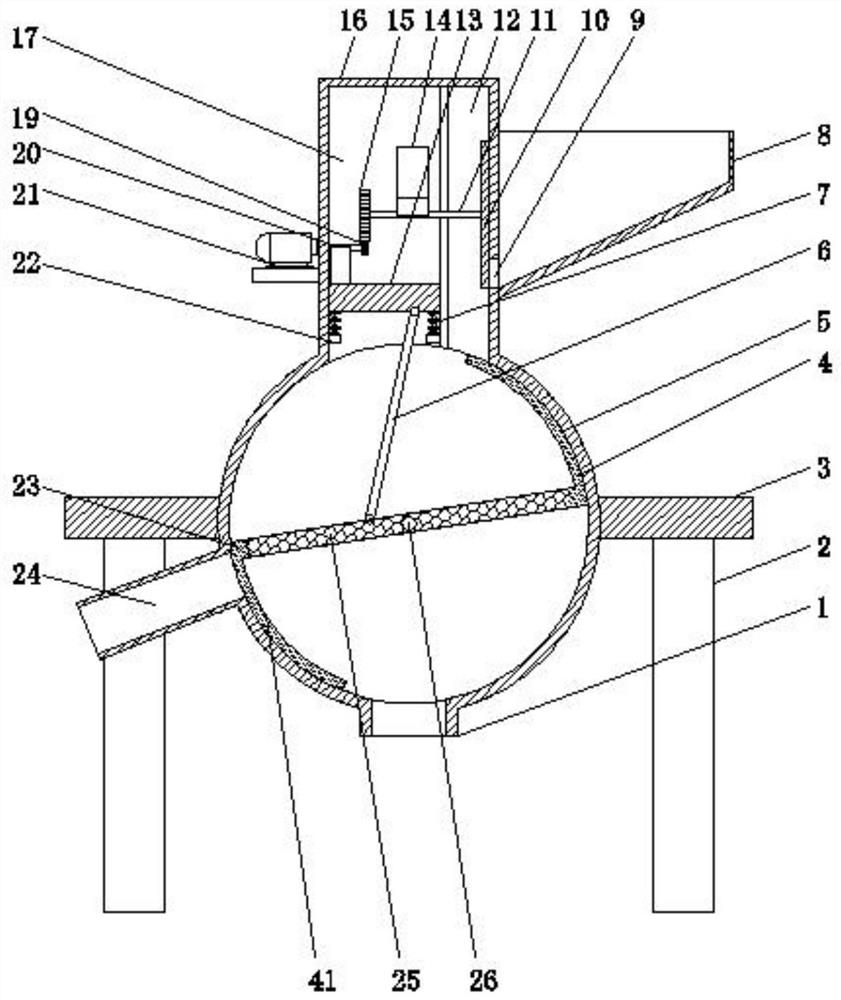

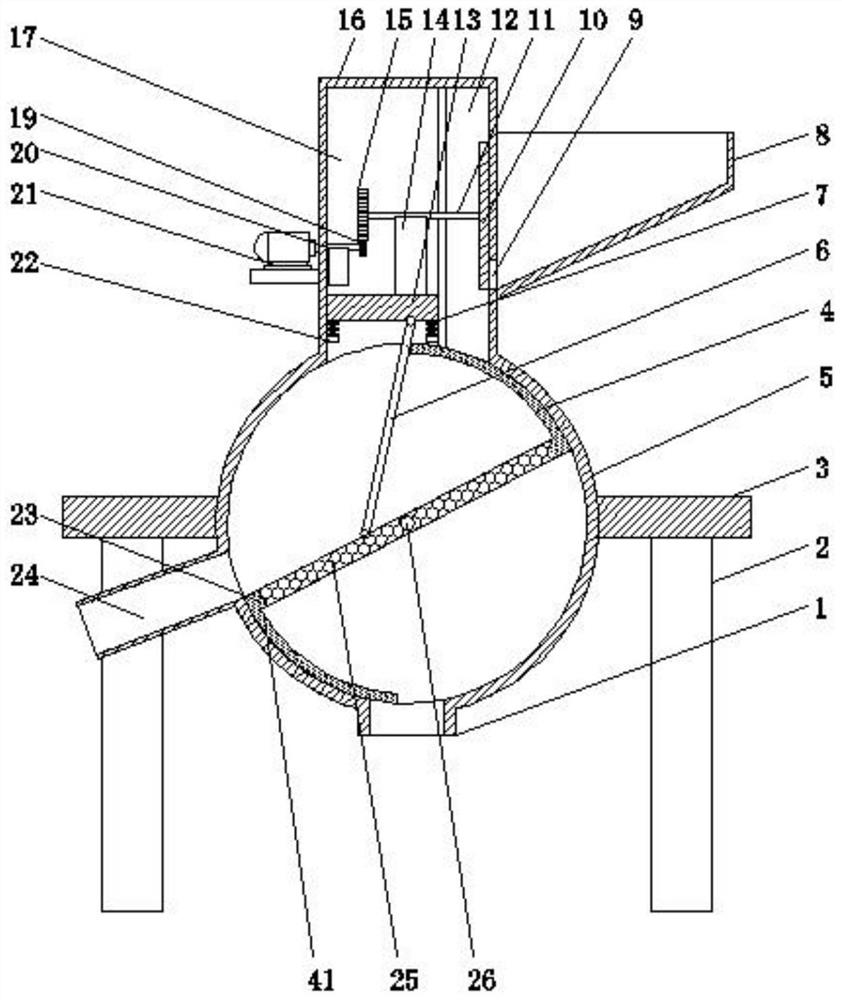

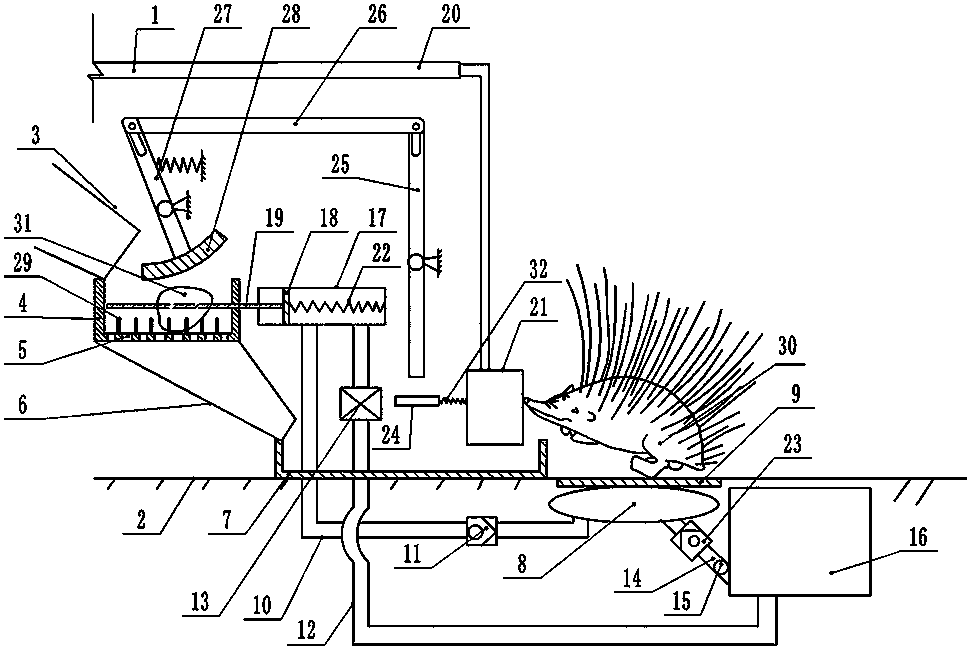

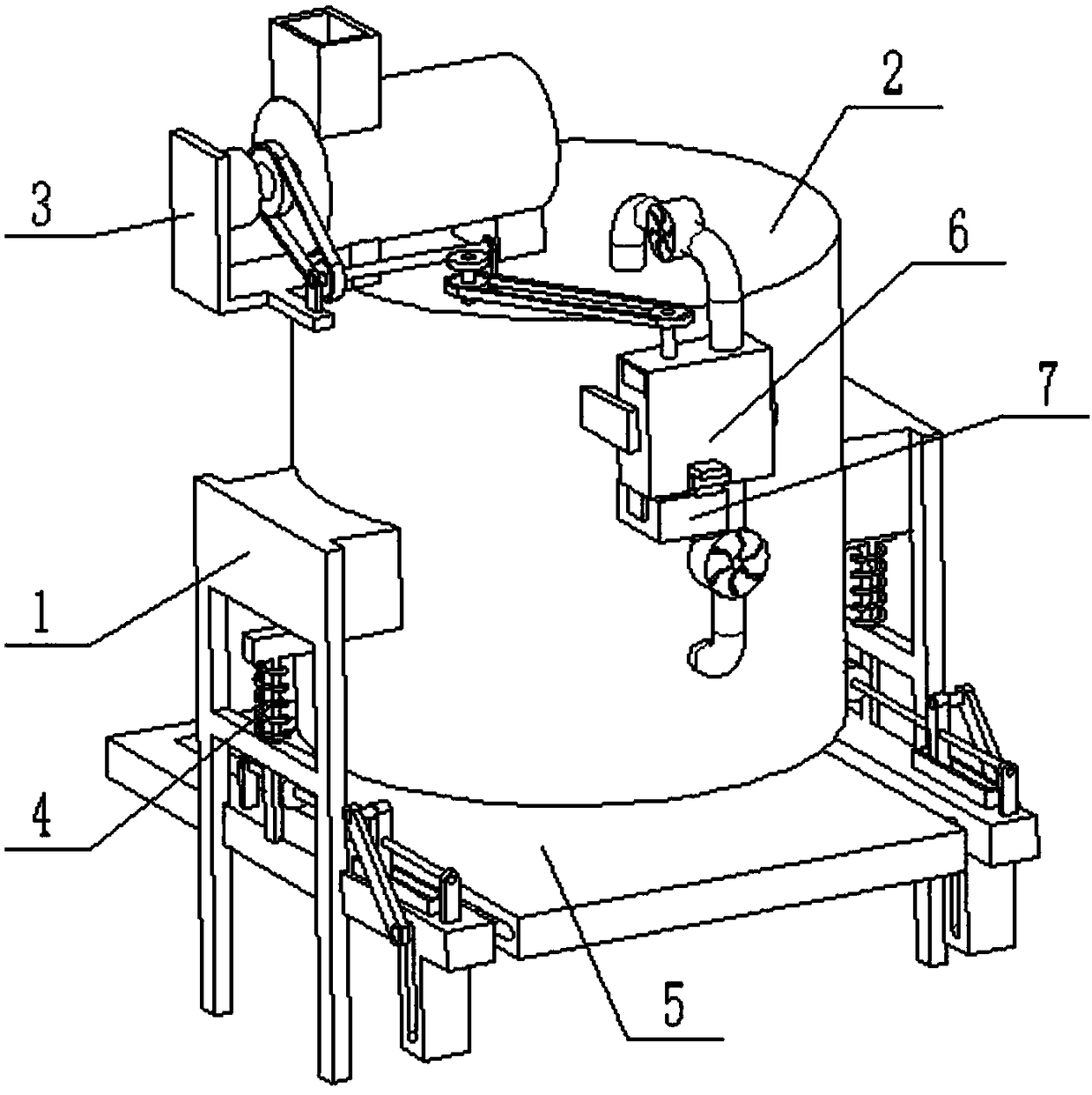

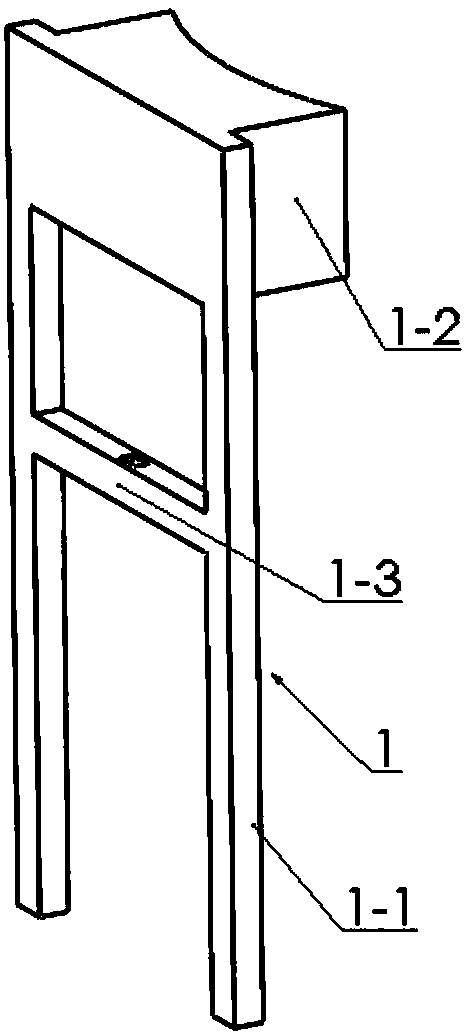

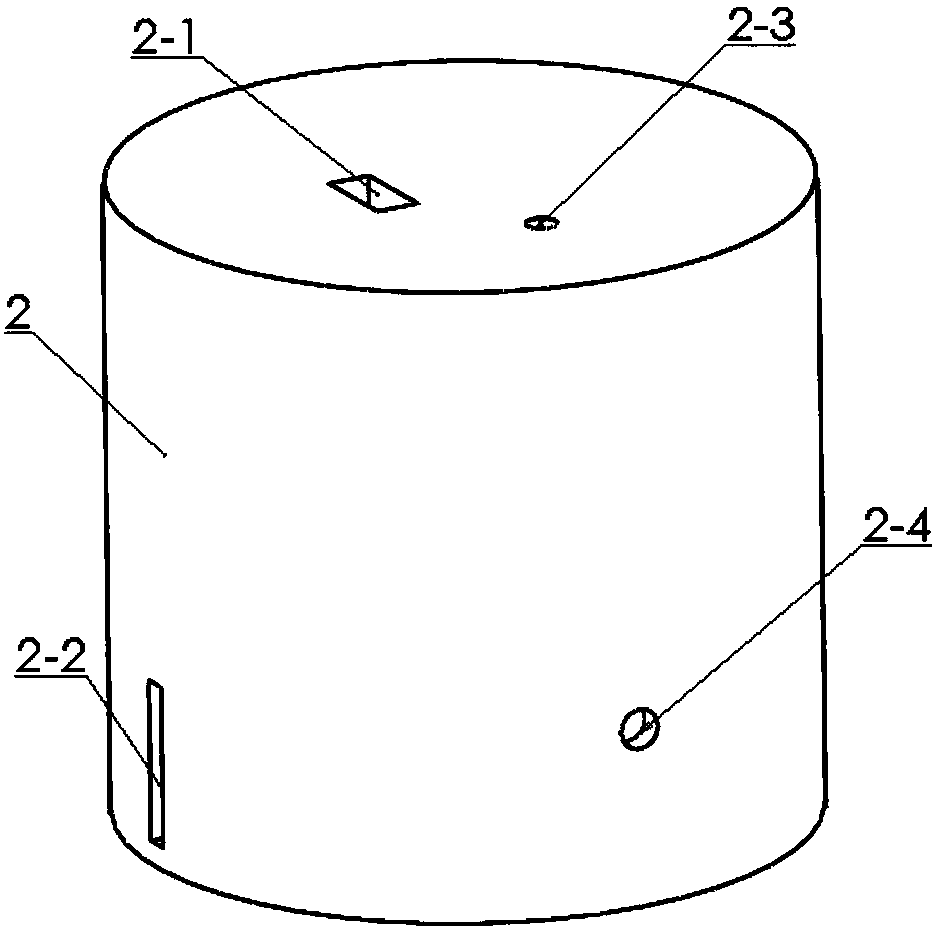

An automatic feeding mechanism used for quenching of shaft type workpieces

ActiveCN104831031ARealize automatic feeding functionIncrease the level of automationFurnace typesHeat treatment furnacesEngineeringMechanical engineering

An automatic feeding mechanism used for quenching of shaft type workpieces is disclosed. The automatic feeding mechanism is characterized in that the automatic feeding mechanism comprises a material layout box allowing shaft type workpieces to be disposed transversely, a material arrangement box adjacent to the material layout box, and a conveying assembly for conveying the shaft type workpieces to a quenching station; the top of the material arrangement box is open; a material jacking plate passing through the bottom plate of the material layout box and jacking the shaft type workpieces in the material layout box up into the material arrangement box is disposed longitudinally in the material layout box; a material receiving inclined plate one side of which is inclined is disposed in the material arrangement box so that the shaft type workpieces jacked up into the material arrangement box are in an inclined state; an erecting pushing element for converting the shaft type workpieces in the inclined state into longitudinally erect shaft type workpieces is disposed at the material arrangement box; the bottom of the material arrangement box is provided with an opening through which the longitudinally erect shaft type workpieces can pass; the conveying assembly comprises a conveying pushing element, a clamping jaw pushed by the conveying pushing element and used for clamping the longitudinally erect shaft type workpieces; and trace bending deflection caused by traditional transverse quenching is avoided, thus improving quenching quality and increasing the quenching efficiency of the shaft type workpieces.

Owner:NINGBO HAWK ELECTRICAL APPLIANCE CO LTD

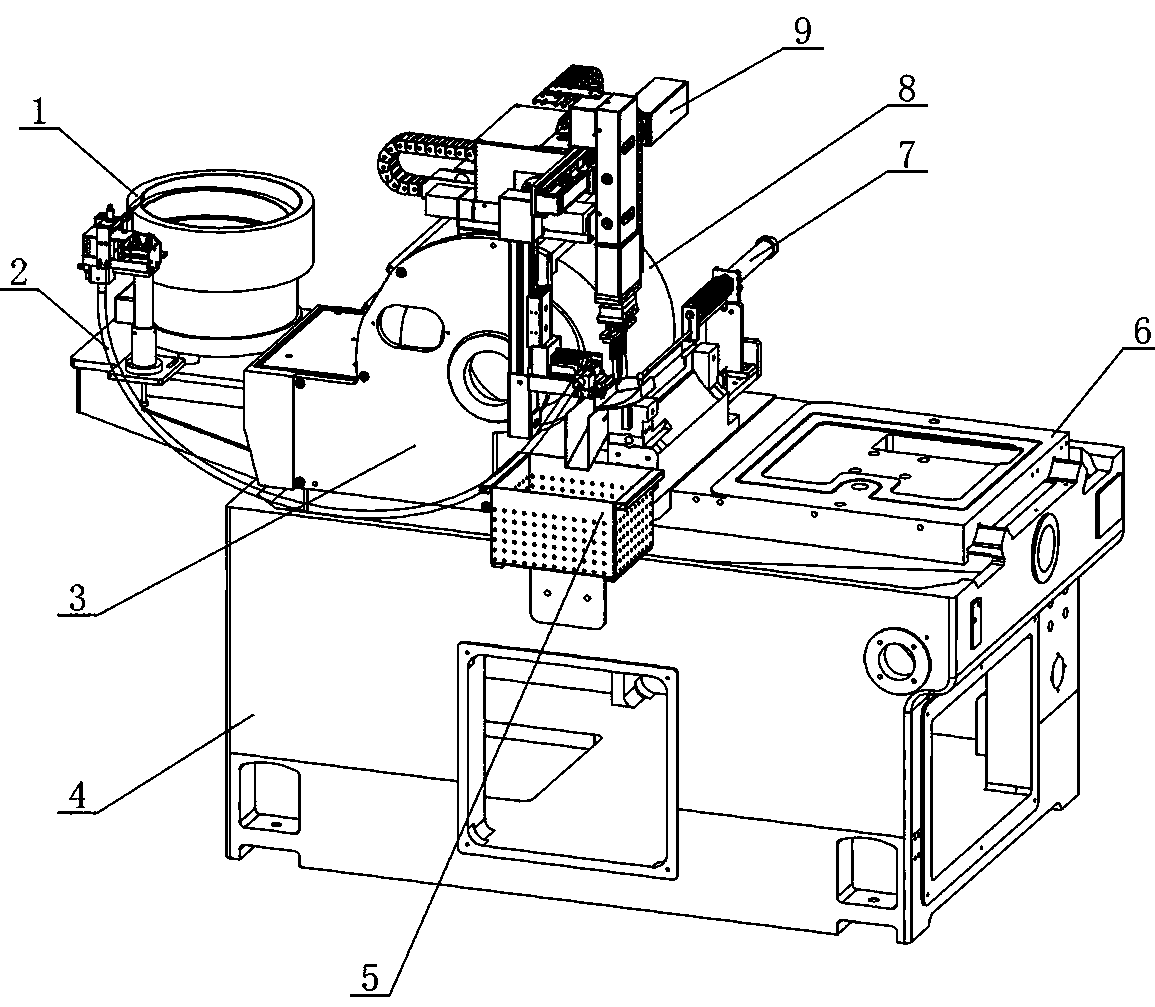

Friction plate steel backing full-automatic drilling machine

InactiveCN109551002AReasonable structural designShorten the processing cycleLarge fixed membersMetal working apparatusHuman–machine interfaceEngineering

The invention discloses a friction plate steel backing full-automatic drilling machine. The friction plate steel backing full-automatic drilling machine comprises a machine frame, an automatic discharging device, a trough, a human-computer interface controller, a system supporting frame, a first tray assembly, a second tray assembly, an automatic feeding device, a multi-station rotation disc device, product pressing blocks, drilling power devices, an angle adjusting device and a sliding table Z shaft. The friction plate steel backing full-automatic drilling machine is a horizontal multi-station drilling machine, a multi-station rotation disc system is adopted so that feeding, drilling machining and discharging can be conducted at the same time, the structural design is more reasonable, small-size friction plate steel backings and small-included-angle friction plate steel backings can be machined, in addition, a friction plate steel backing of which the two holes are parallel is machined, the two holes are machined at the same time, mutual noninterference is achieved, the machining cycle is shortened, and the production efficiency is greatly improved from 25s / pcs to smaller than orequal to 10s / pcs; and through the scheme, the product automatic feeding function is achieved, the labor intensity of workers is greatly relieved, and the equipment automation degree is improved.

Owner:杭州众享机械技术有限公司

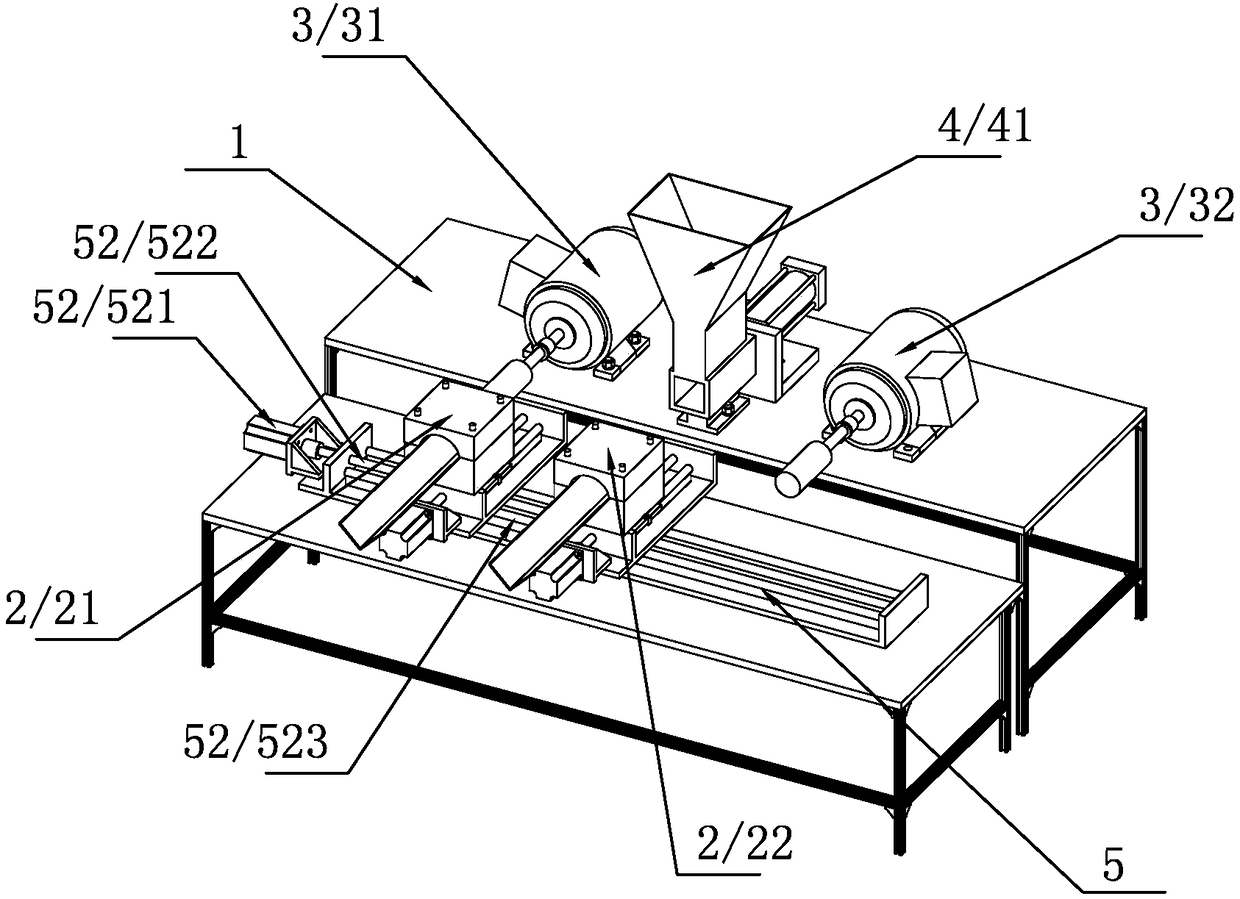

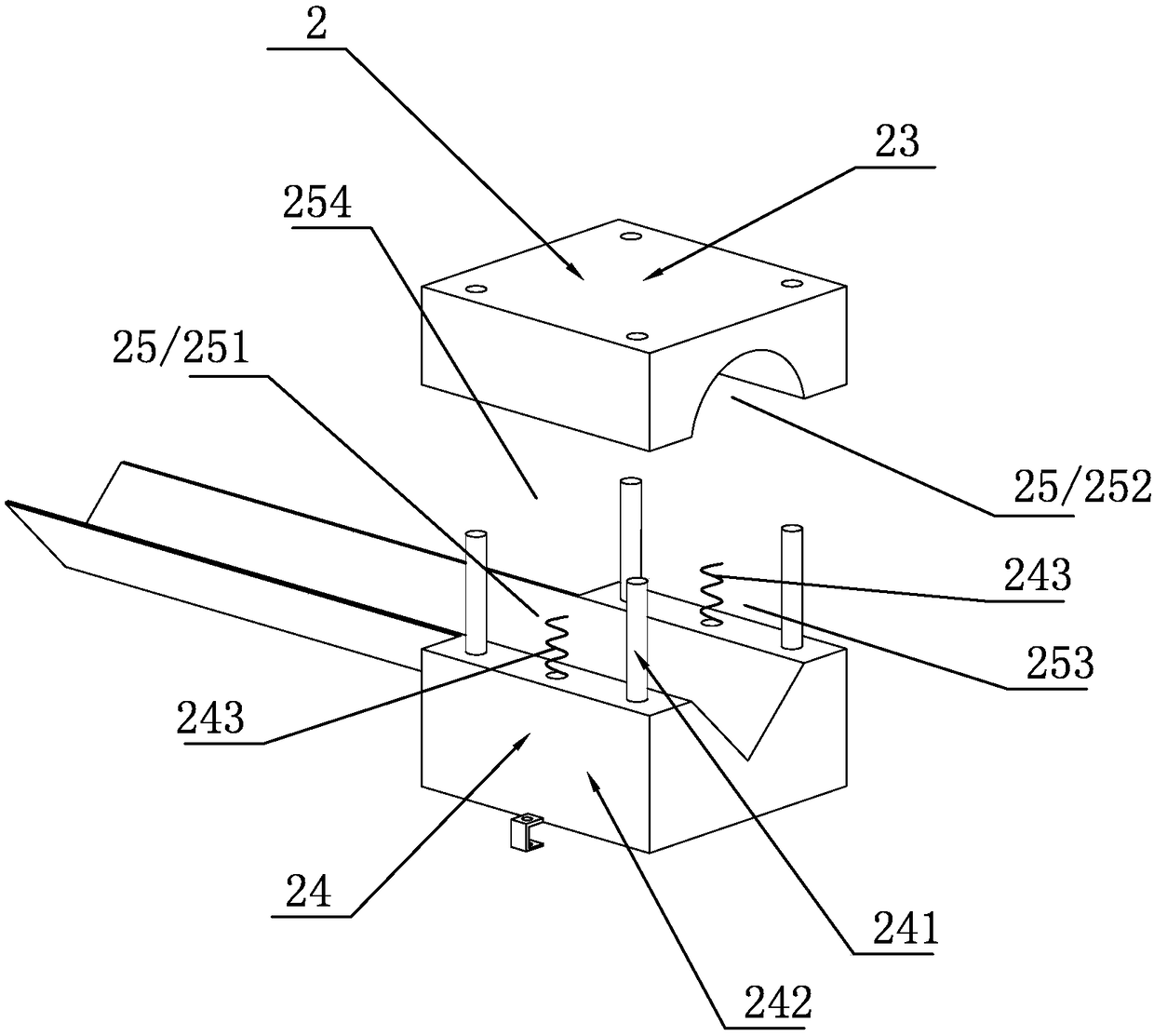

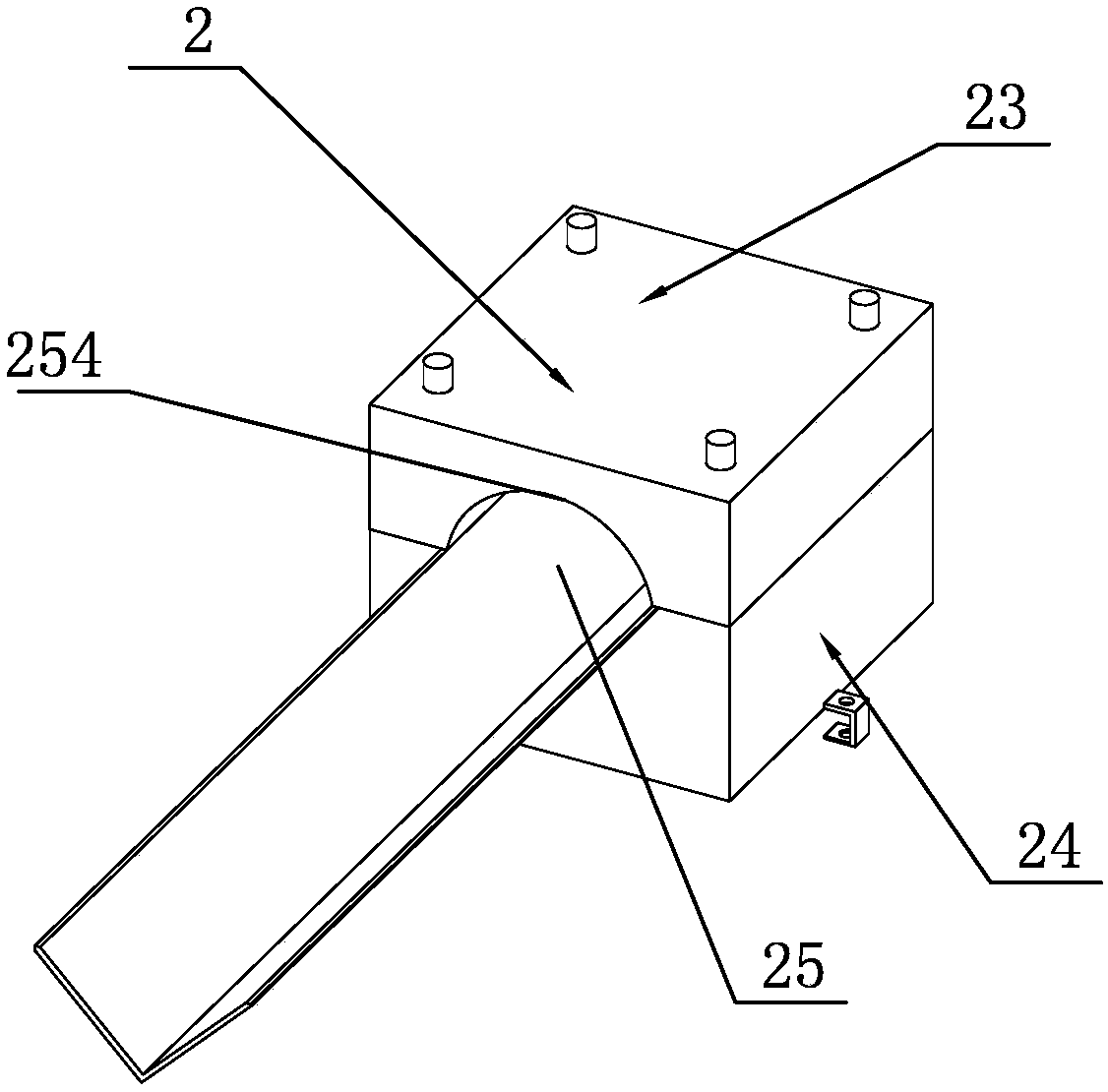

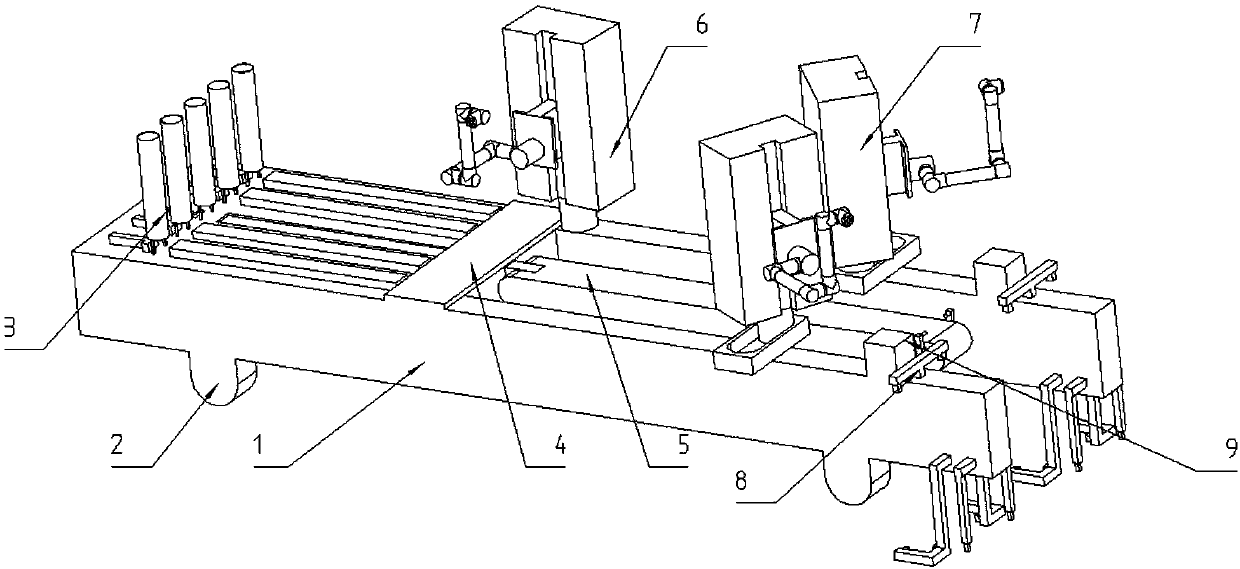

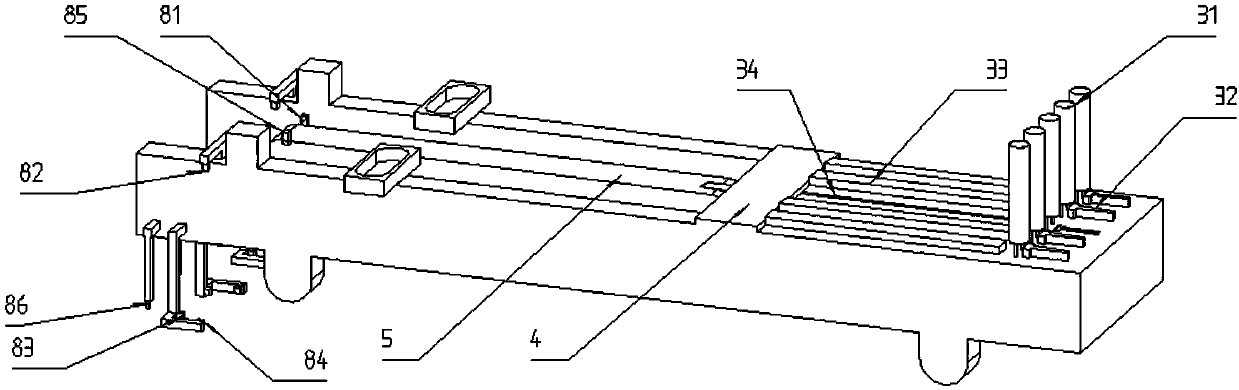

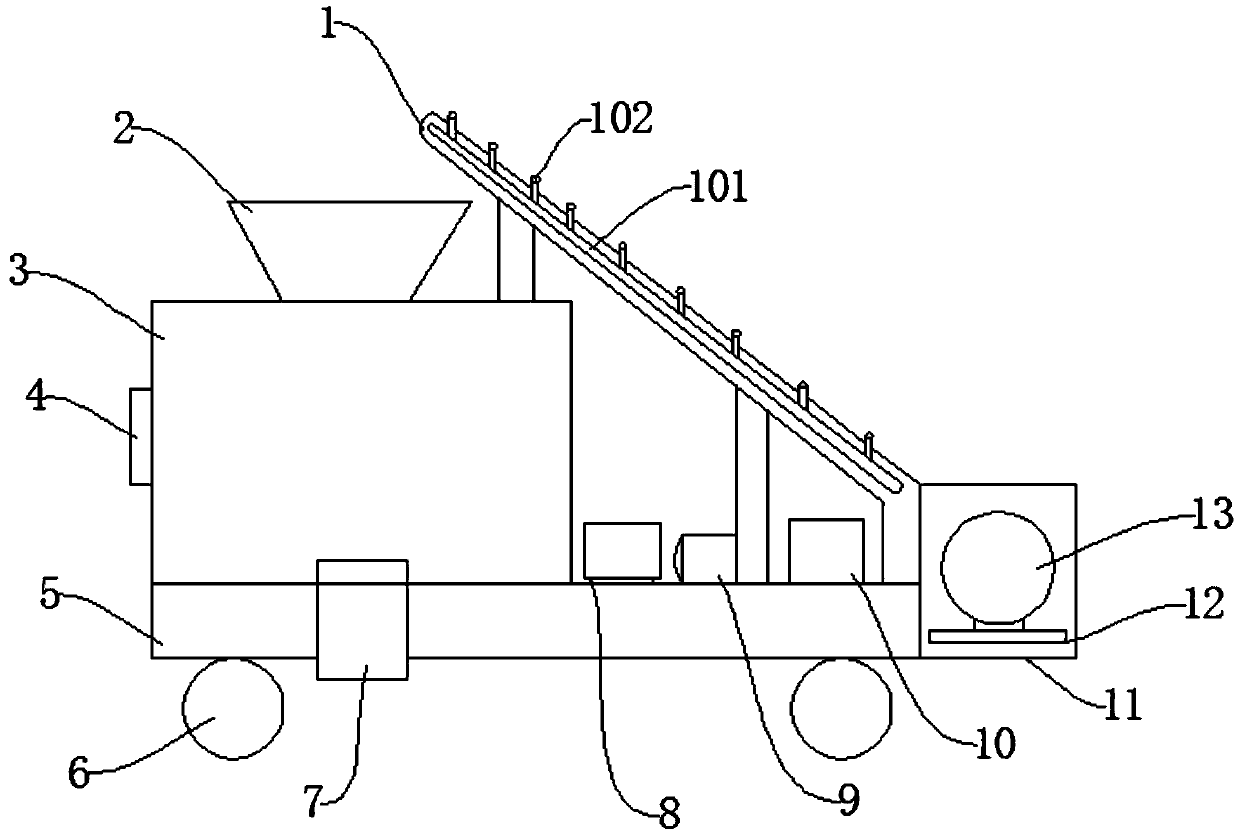

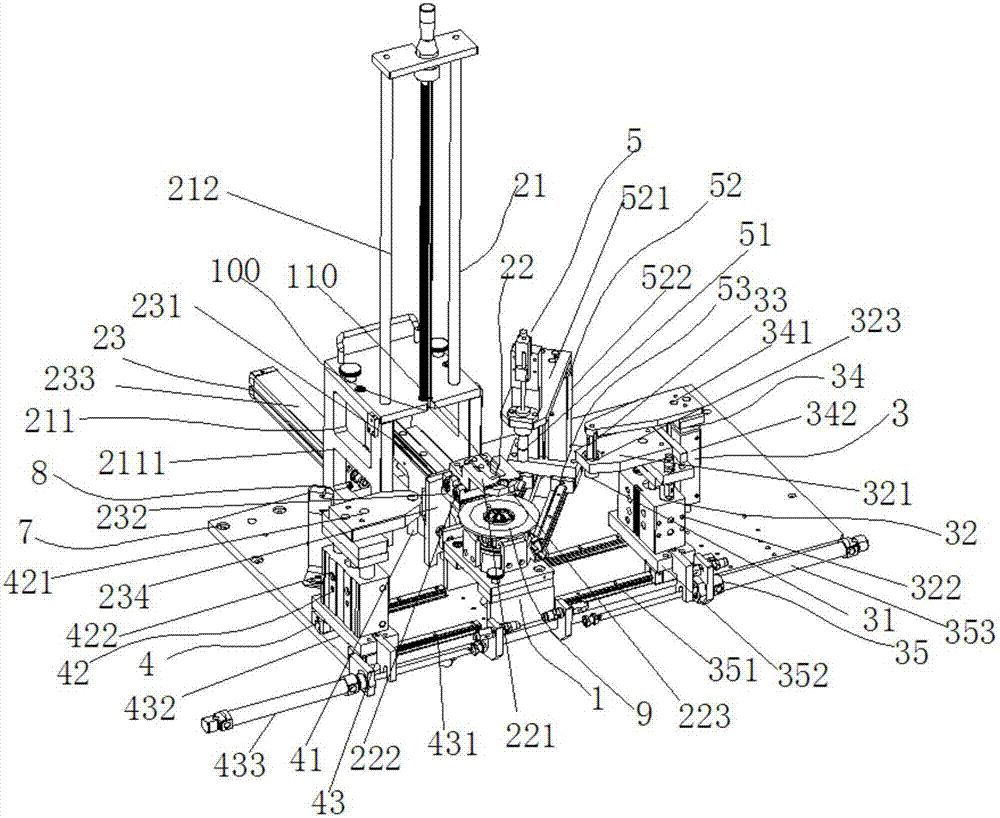

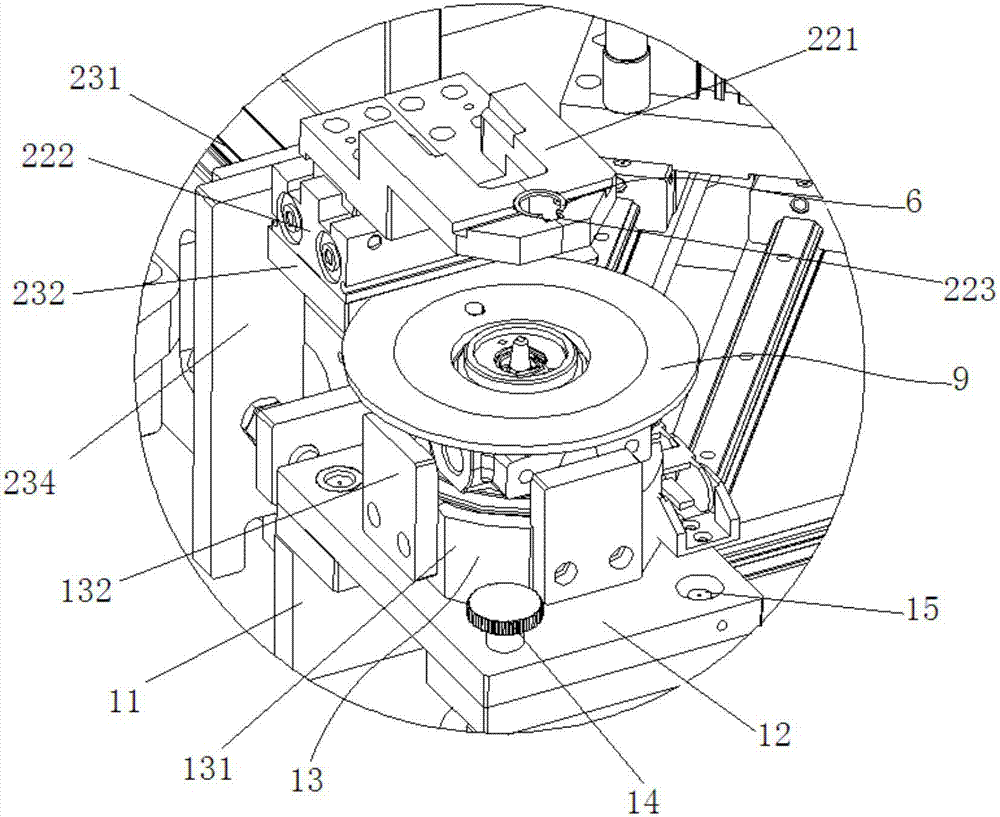

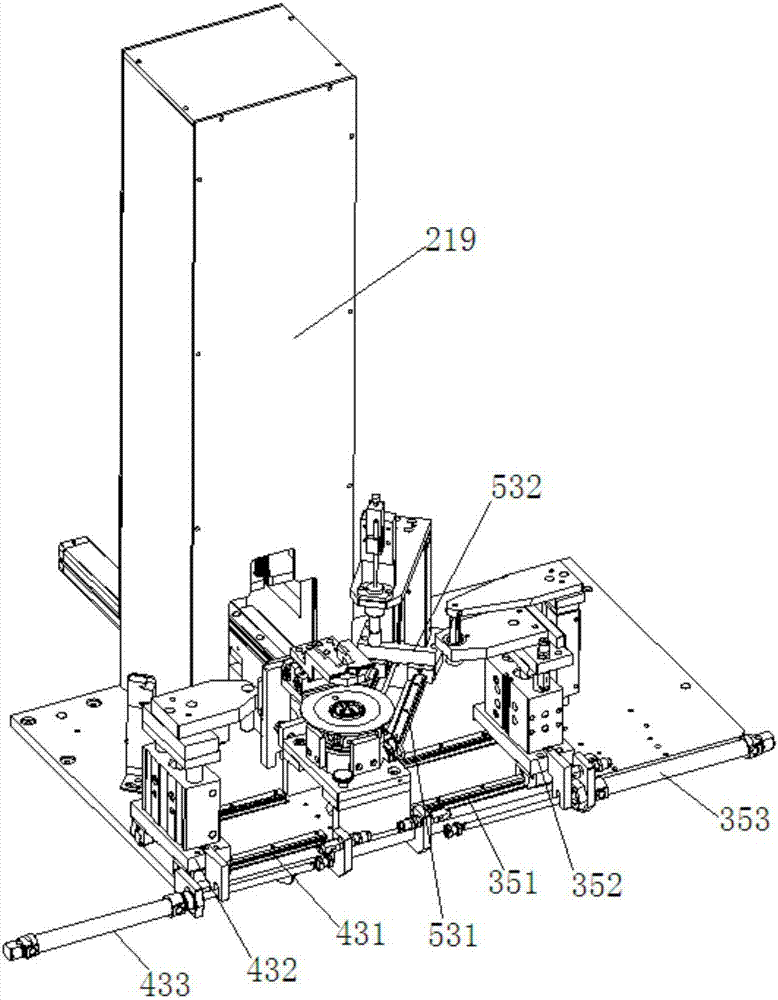

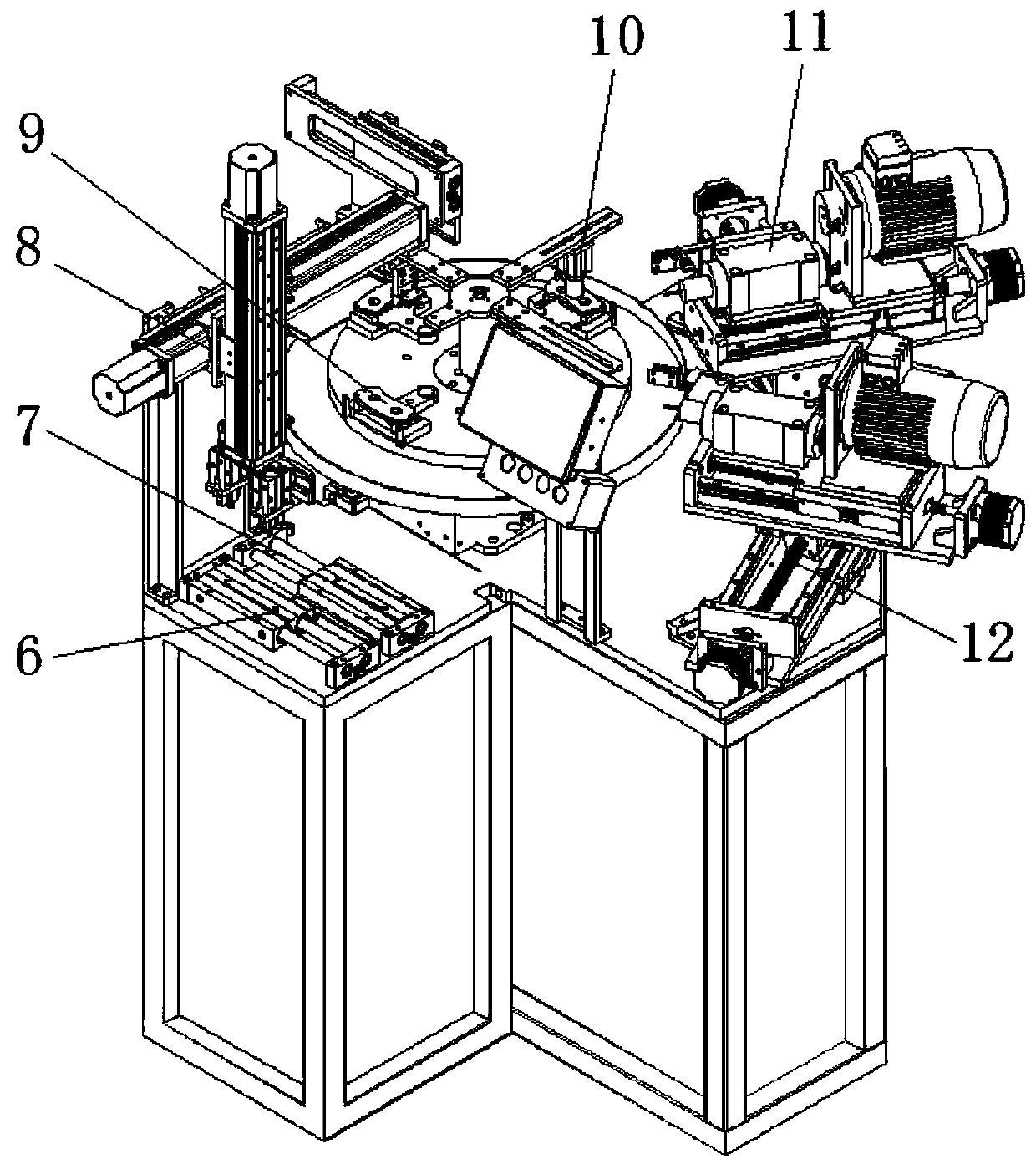

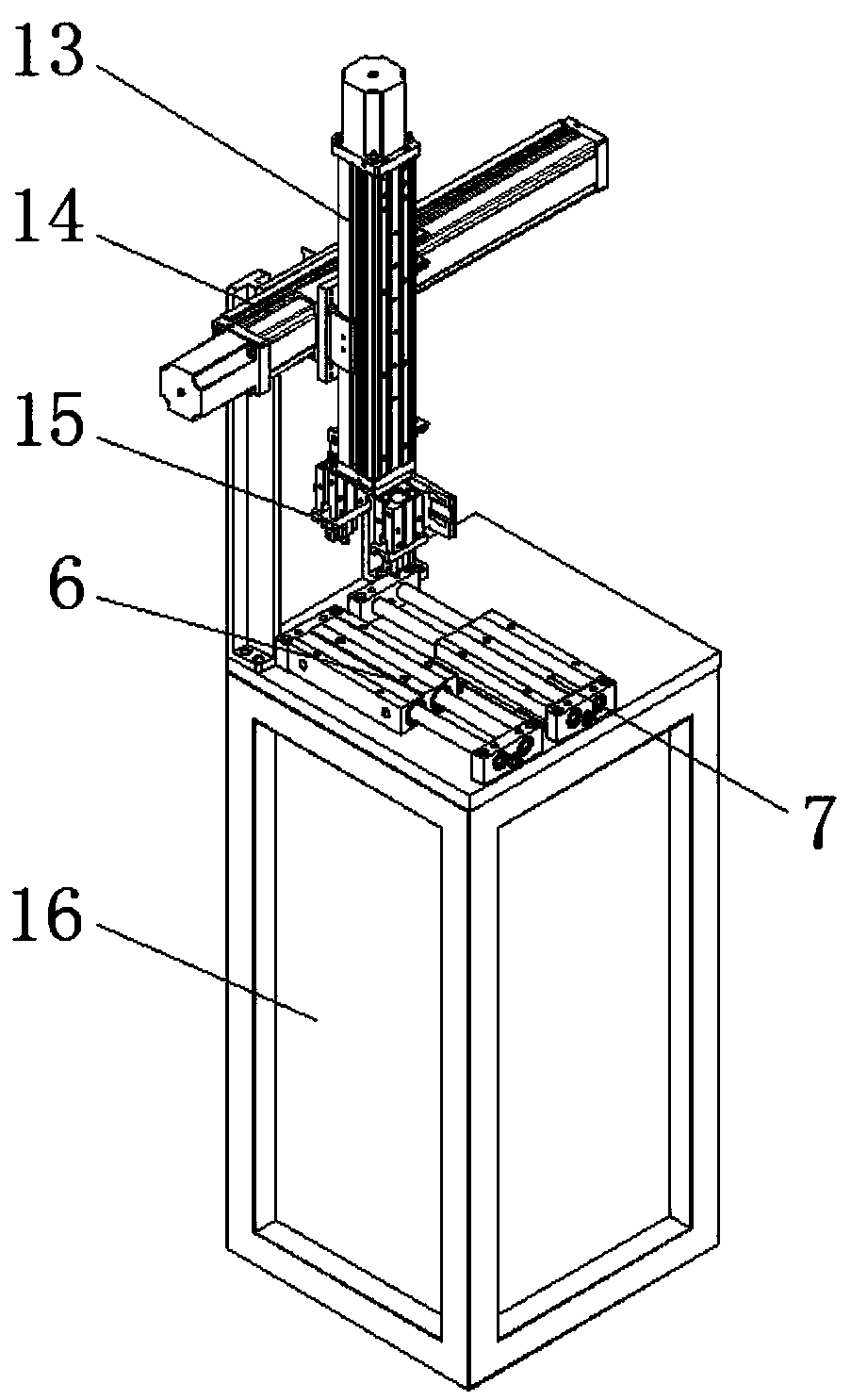

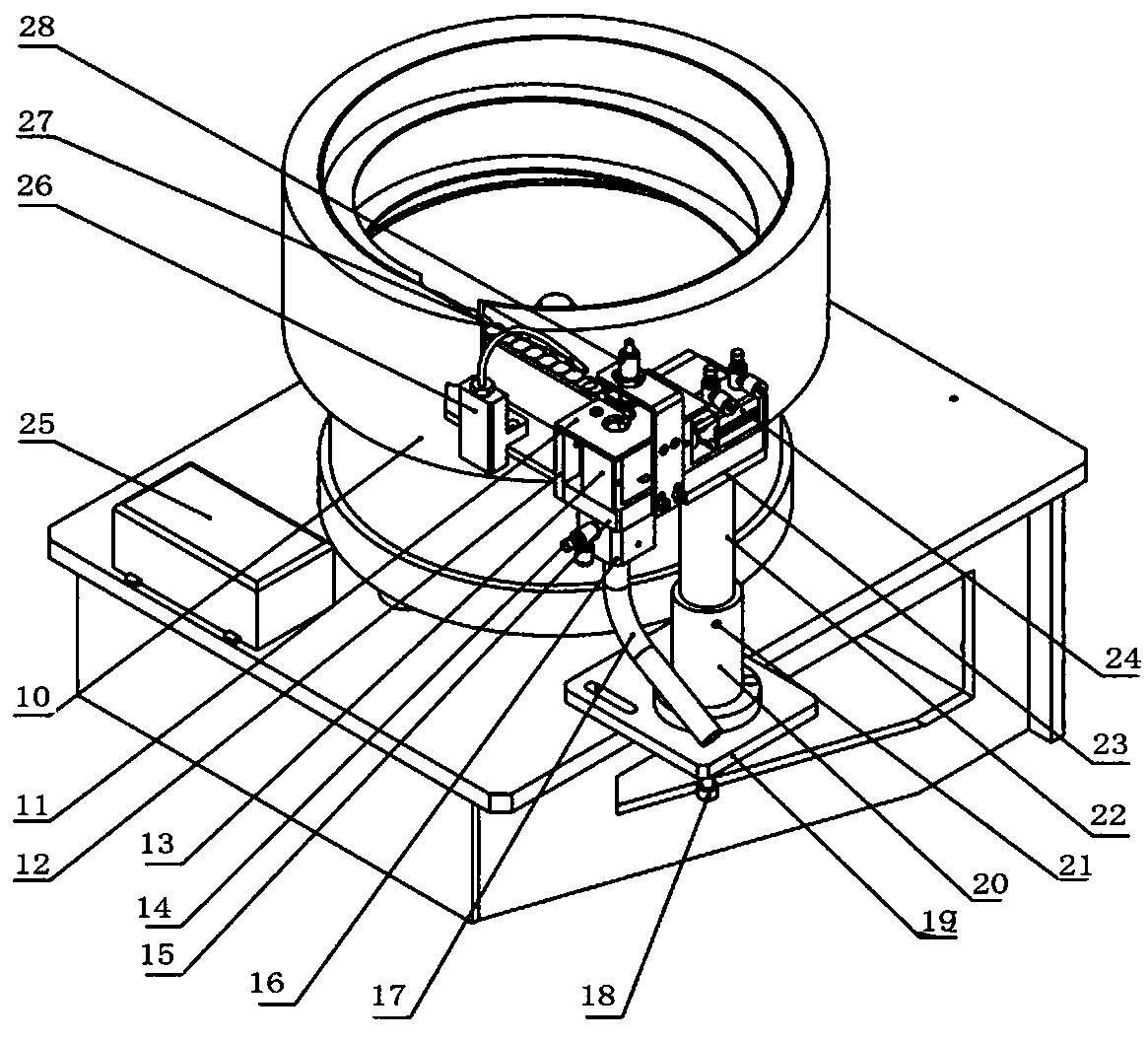

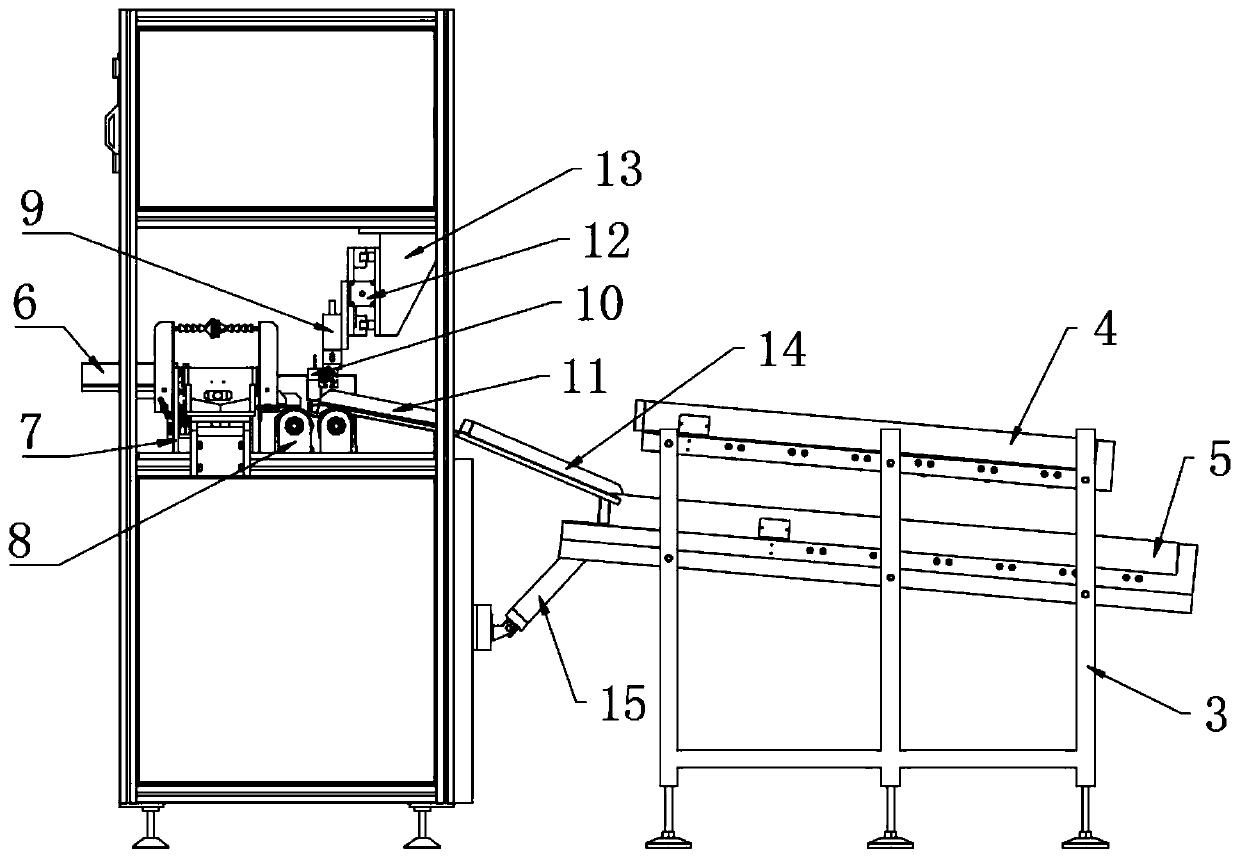

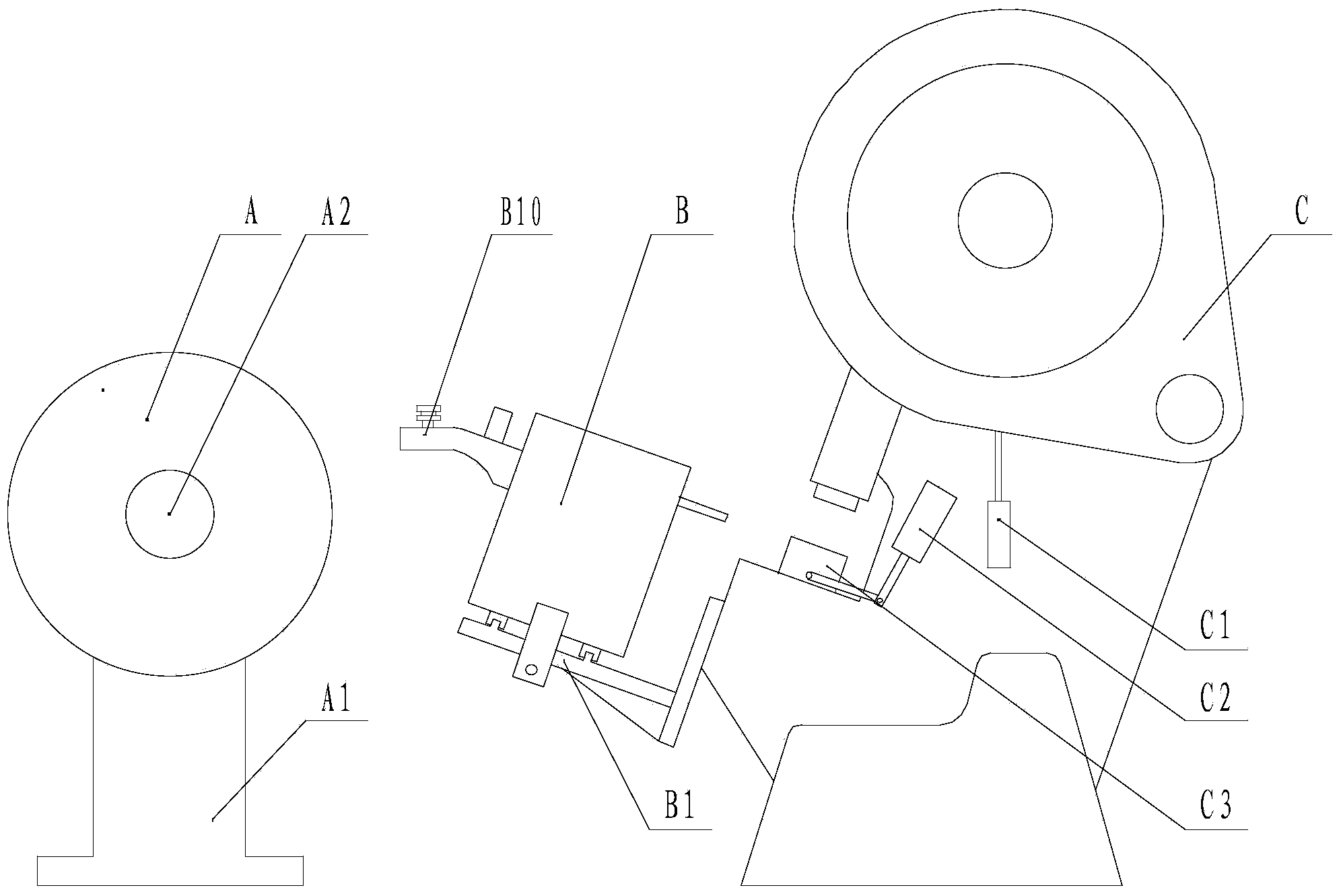

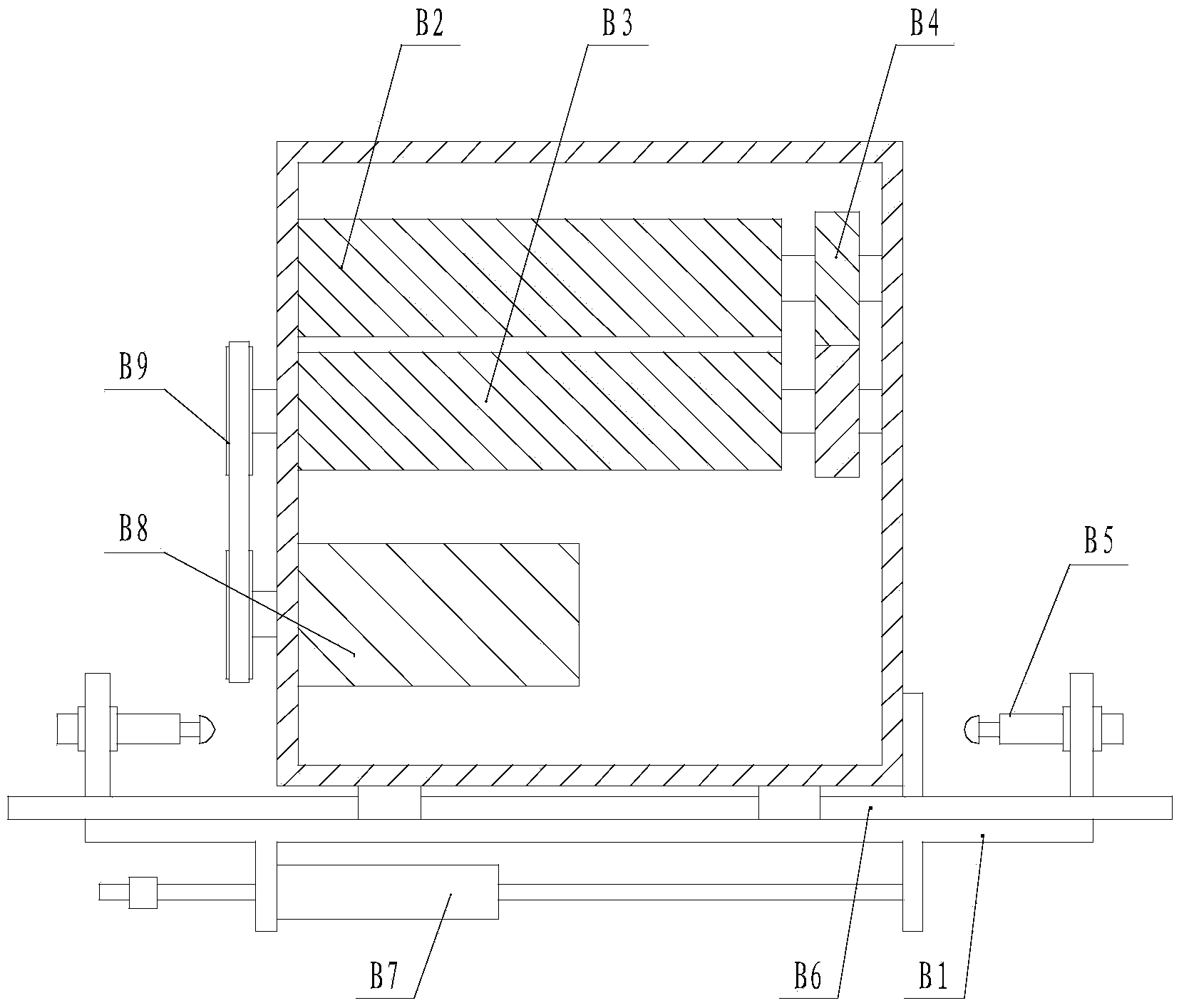

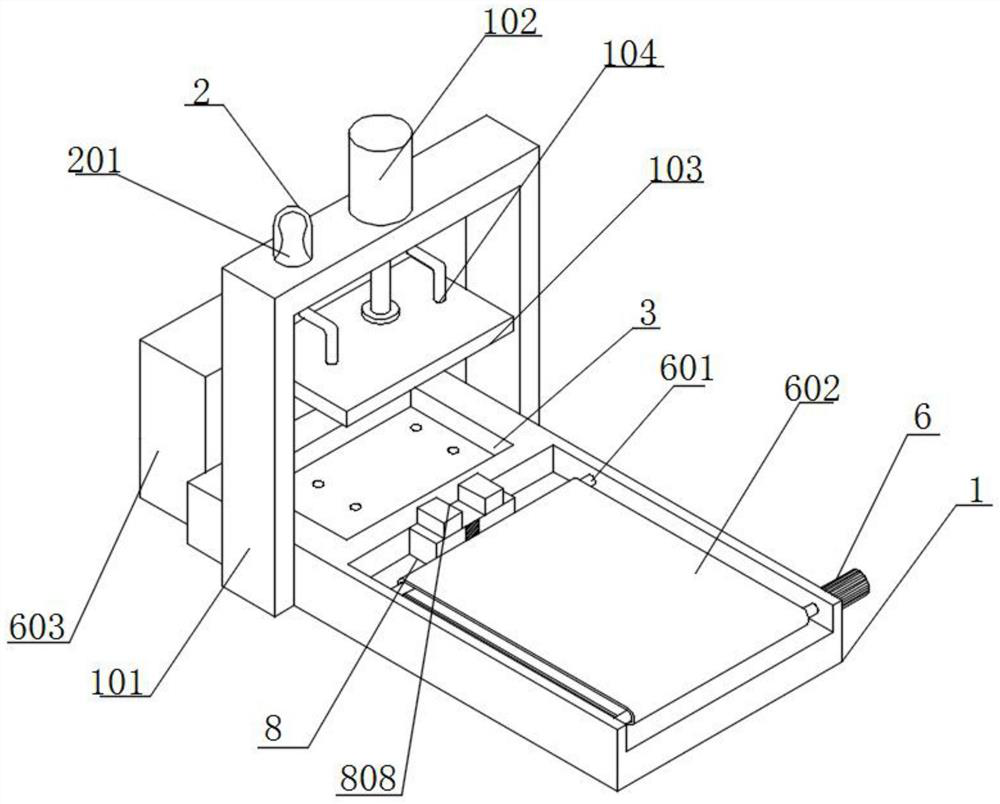

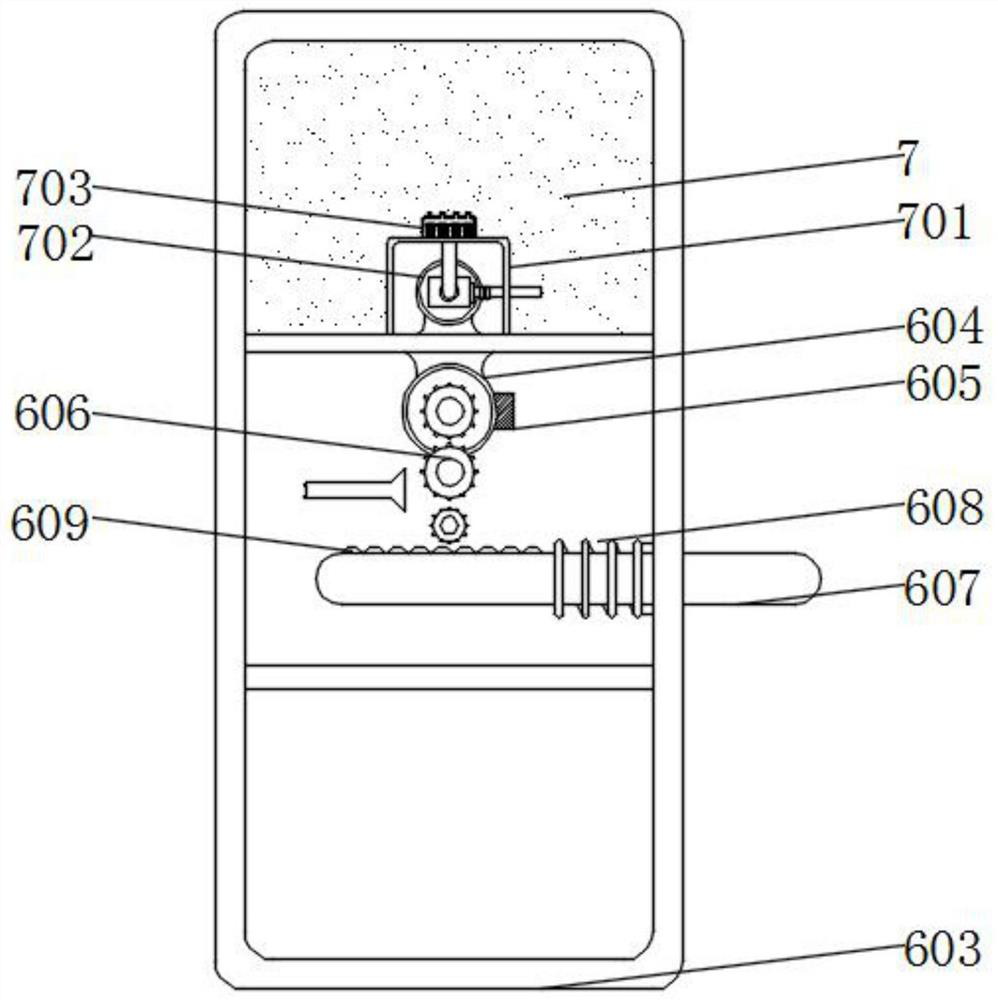

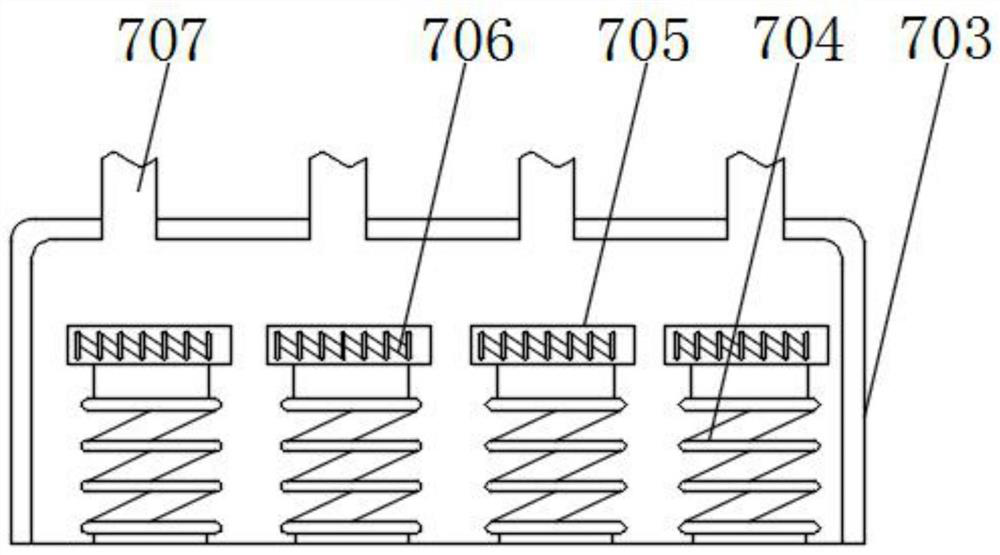

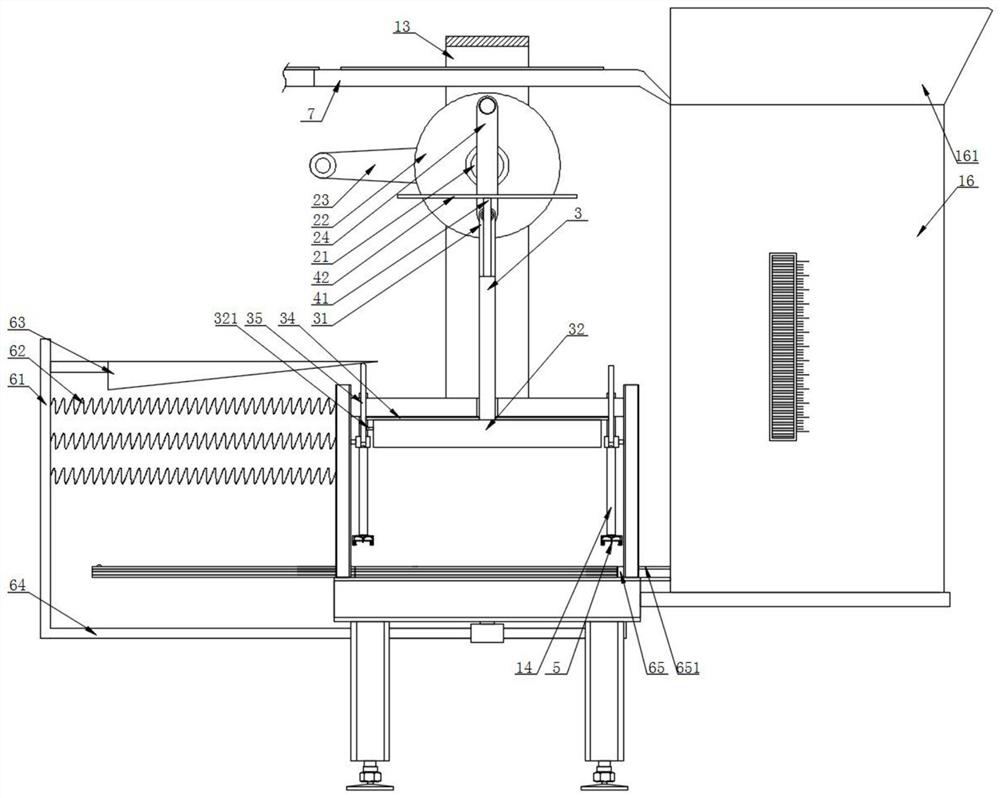

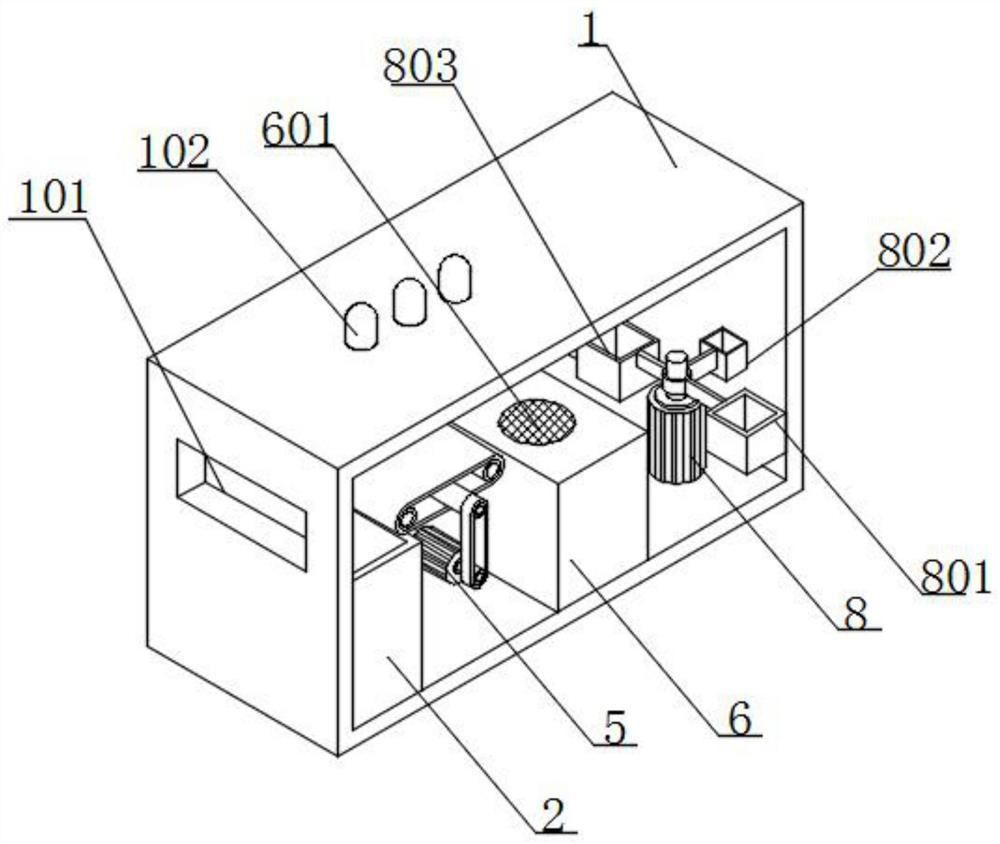

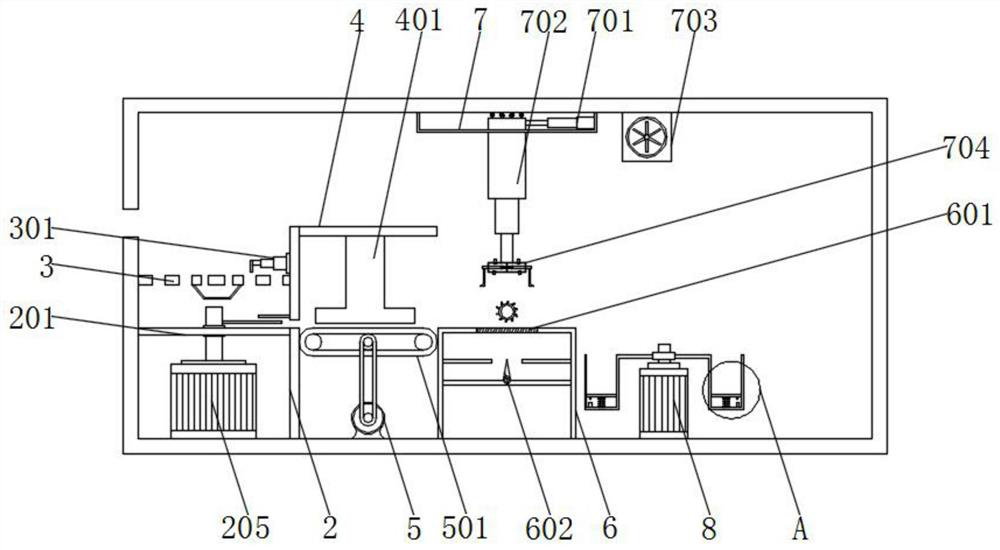

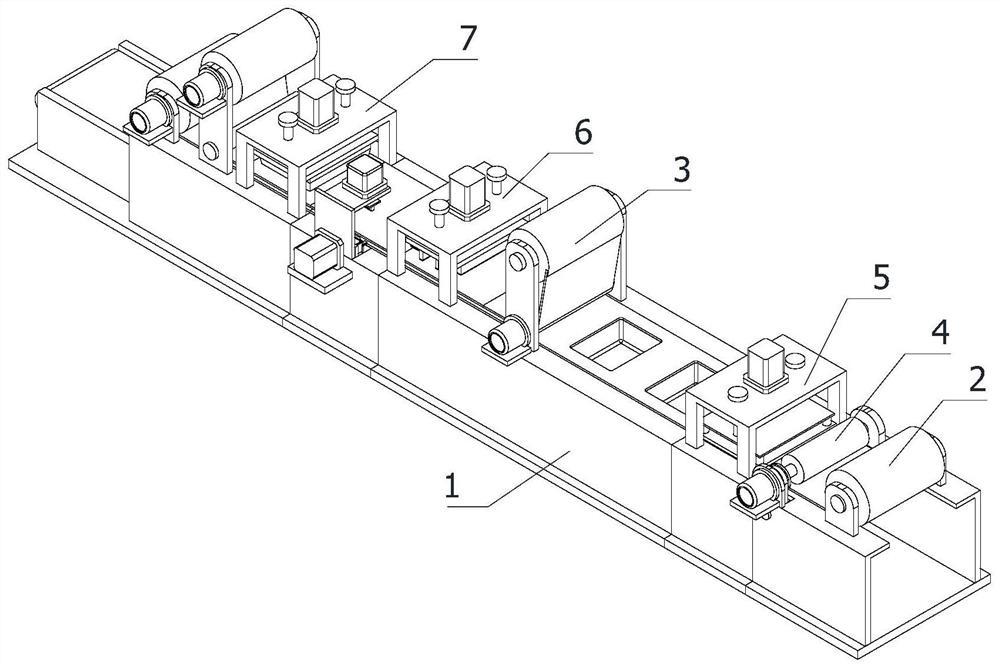

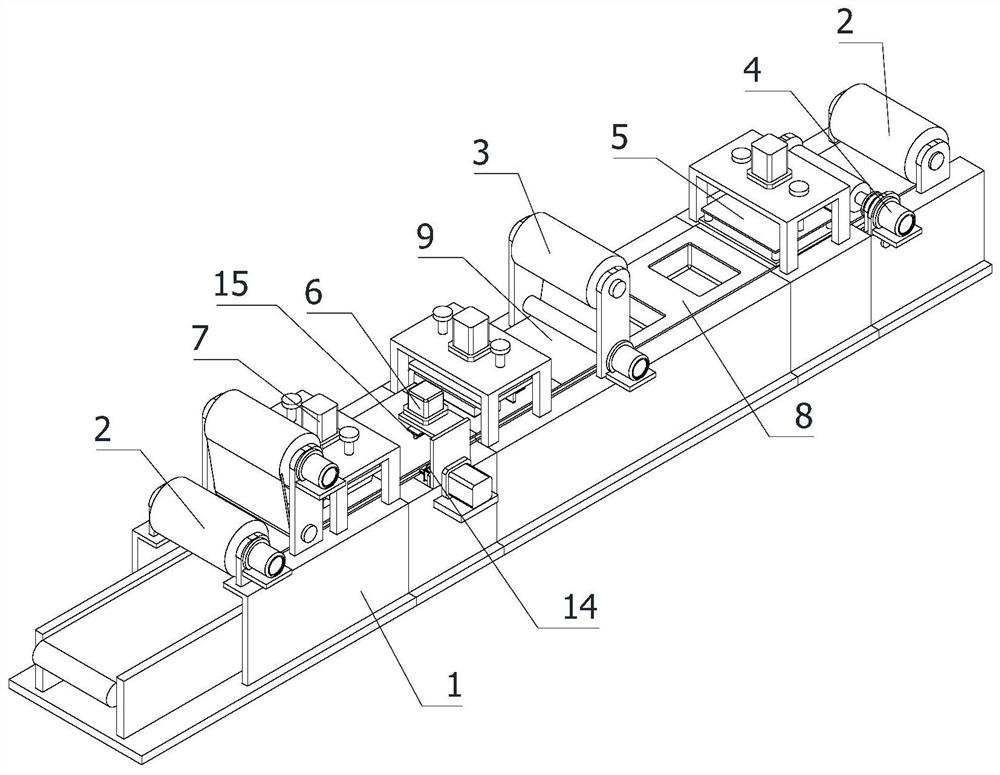

Automatic feeding and blanking system for centerless grinding machine screws

PendingCN107900895ACompact and reasonable structure designGood rigidityGrinding feedersPhysicsCenterless grinding

The invention discloses an automatic feeding and blanking system for centerless grinding machine screws, and belongs to the technical field of non-standard automatic feeding. The automatic feeding andblanking system comprises a vibrating feeding part (1), a material guiding pipe (2), a grinding wheel box cover (3), a machine tool body (4), a material receiving box (5), an upper sliding plate (6),a rear positioning and ramming device (7), a grinding wheel (8) and a manipulator feeding part (9). The automatic feeding and blanking system is characterized in that the vibrating feeding part (1) mainly achieves automatic vibrating feeding; the manipulator feeding part (9) mainly achieves material transferring and precise positioning and sending workpieces into a grinding area for grinding machining; and the rear positioning and ramming device (7) ensures the fact that the workpieces occupy the correct grinding positions and has the function of material pushing, and after grinding machiningis completed, a material ramming rod (52) jacks out the workpieces to make the workpieces slide down into the material receiving box (5). The automatic feeding and blanking system for the centerlessgrinding machine screws is compact and reasonable in structural design, good in rigidity, excellent in workmanship and attractive in appearance, and the automatic feeding and blanking system can worksfor a long term continuously and stably.

Owner:贵州兴富祥立健机械有限公司

Eddy current testing equipment of piston rod

PendingCN110038816ARealize automatic feeding functionImplement automatic detectionSortingEddy-current testingElectrical and Electronics engineering

The invention relates to eddy current testing equipment of a piston rod. The eddy current testing equipment comprises a workbench, wherein a storage rack is arranged on one side of the workbench, a feed mechanism, a detection mechanism and a distribution mechanism are arranged on the workbench in sequence in the direction close to the storage rack, a workpiece rotating assembly and a discharge turnover mechanism are arranged on the workbench below the detection mechanism, the workpiece rotating assembly comprises two rotary driving rollers, the discharge turnover mechanism is located between the two rotary driving rollers, and the feed mechanism is connected with the workpiece rotating assembly by virtue of a first guide plate. The eddy current testing equipment has the functions of automatically feeding, automatically detecting and automatically sorting qualified workpieces and unqualified workpieces so as to enter the corresponding storage plate to be stored and has the advantages ofhigh degree of automation and no need of manual detection, and a plurality of probes are arranged so as to detect the workpieces at the same time by sections, so that the detection efficiency is improved.

Owner:NANJING BOKENA AUTOMATION SYST

System for realizing PVC flooring inspecting and conveying, and stacker blanking

ActiveCN103407751ALabor savingRealize intelligenceControl devices for conveyorsStacking articlesElevator systemCollision detection

The invention discloses a system for realizing PVC flooring inspecting and conveying, and stacker blanking. The system comprises a shear model elevator system, a conveying belt system, a rolling bed system and a stacker system, wherein the shear model elevator system is provided with an anti-collision detection system and a positioning system; a first light-sensitive system and a counter system are arranged on one side of the conveying belt system; the rolling bed system is provided with pneumatic lifting plates and a second light-sensitive system; the anti-collision detecting system is used for preventing PVC floorings on a supporting plate from colliding with a conveying belt in the lifting process of an elevator; the positioning system is used for controlling the maximum lifting height of the elevator; the counter system is used for counting the PVC floorings; the pneumatic lifting plates are used for supporting a certain amount of PVC floorings; the light-sensitive systems are used for controlling the transportation and the blanking of the PVC floorings. According to the system, the intelligentized transportation of equipment is realized, the PVC floorings are tidy and ordered in the whole process; with the design of a stacker, an automatic blanking function is realized, and the inspecting efficiency is improved.

Owner:JIANGSU UNIV OF SCI & TECH

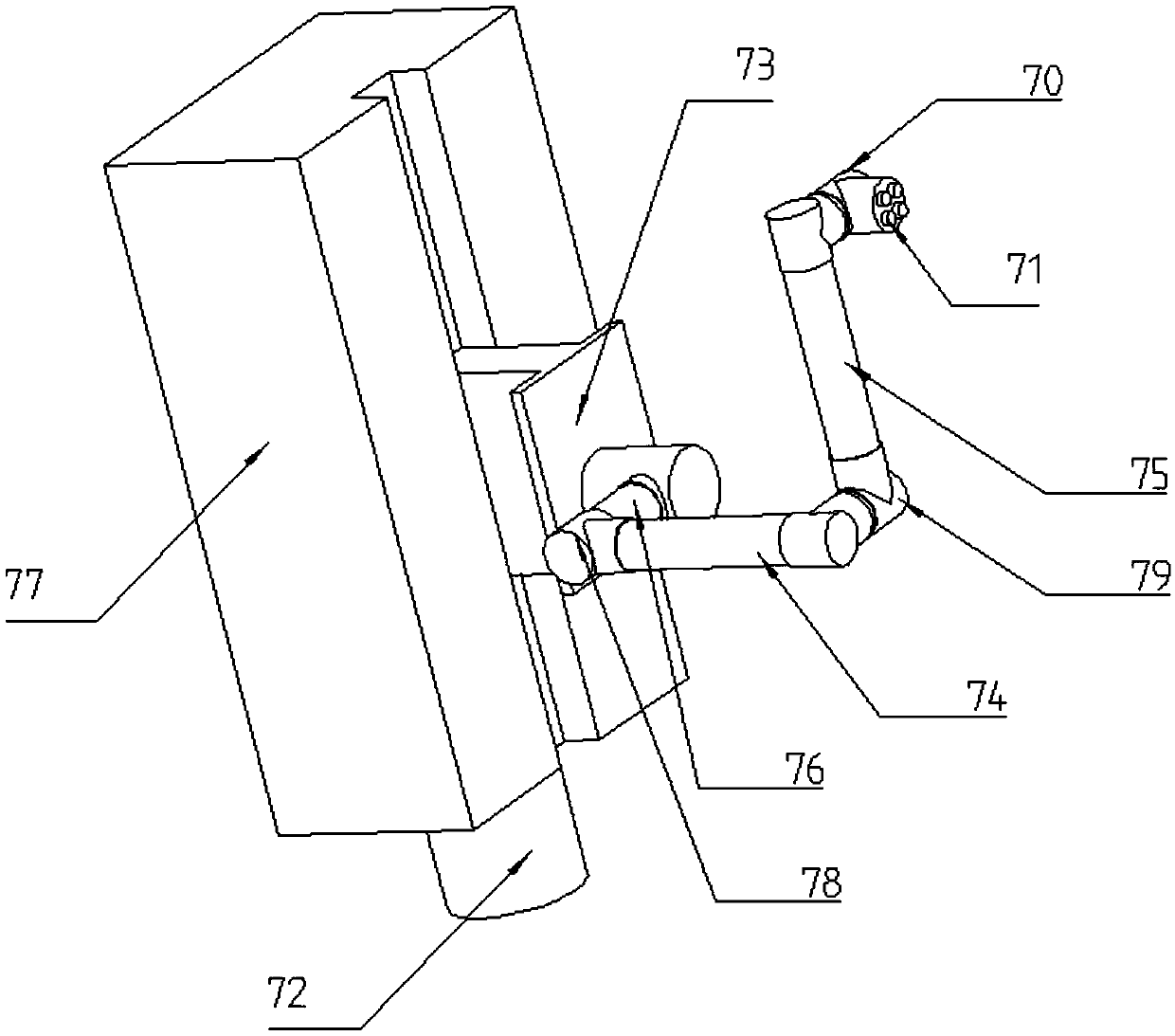

Steel pipe machining mechanism

InactiveCN112846790ARealize automatic feeding functionRealize the grinding functionOther manufacturing equipments/toolsPositioning apparatusPipe fittingMachining

The invention discloses a steel pipe machining mechanism, and belongs to the field of pipe fitting machining. The steel pipe machining mechanism comprises a square frame, the square frame is fixedly installed, a bottom square sleeve and a top square sleeve are installed on the square frame and are both in sliding connection with the square frame, and a zigzag arm is arranged on one side of the bottom square sleeve. A balance weight roller is arranged at the end of the zigzag arm, and the balance weight roller is rotationally connected with the zigzag arm. An extension arm is installed on one side of the top square sleeve, and a pressing roller is installed at the end of the extension arm. The steel pipe machining mechanism integrates grooving and polishing functions.

Owner:苏州市佳信美智能装备有限公司

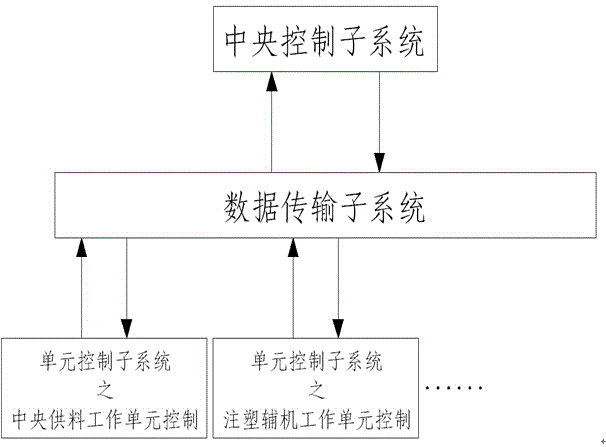

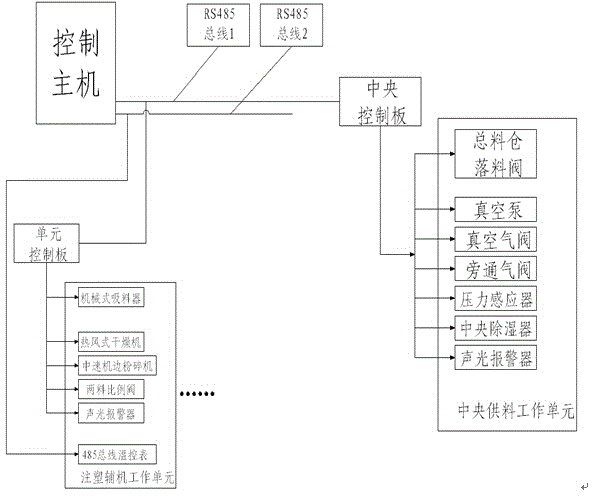

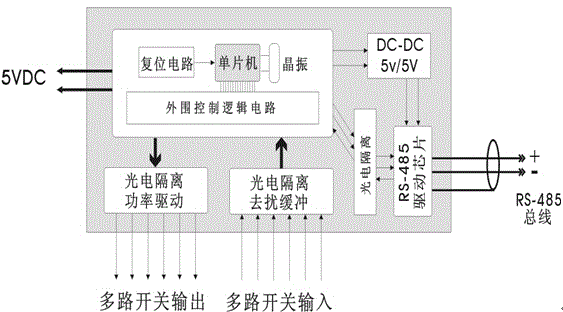

Digitized centralized feed control system

InactiveCN104460639AGood effectAchieve coordinated actionTransmissionTotal factory controlControl systemData transmission

The invention discloses a digitized centralized feed control system. The digitized centralized feed control system comprises a central control subsystem, a unit control subsystem and a data transmission subsystem. The central control subsystem comprises a central control host. The unit control subsystem comprises a plurality of unit control boards, the unit control boards complete the on-off control and working state inquiry work of machine devices, are connected to an RS-485 bus and is in communication with the central control host. An eight-bit microprocessor controls, manages and communicate the unit control boards, and each unit control board is provided with a unique identification code or address. The data transmission subsystem is achieved through an RS-485 serial bus, and the master-slave mode access control method is adopted in access of the bus.

Owner:明利机电(深圳)有限公司

Screening device

ActiveCN112138993AImprove screening efficiencyRealize automatic feeding functionSievingScreeningPipeMechanical engineering

The invention discloses a screening device which comprises a main body unit and a screening unit. The main body unit comprises a cylindrical shell, fixing plates, supporting legs, a first dischargingpipe, a second discharging pipe, a rectangular shell, fixing blocks and a hopper; the fixing plates are perpendicularly arranged on the two sides of the cylindrical shell; the supporting legs are evenly arranged at the bottoms of the fixing plates; the first discharging pipe is arranged at the bottom of the cylindrical shell; the second discharging pipe is obliquely arranged on the outer side of the cylindrical shell between the fixing plate located on the left side and the first discharging pipe; the rectangular shell is perpendicularly arranged at the top of the cylindrical shell; an adjusting cavity and a feeding cavity are formed in the rectangular shell from left to right; the adjusting cavity communicates with the feeding cavity and the interior of the cylindrical shell; and the fixing blocks are arranged on the two sides of the bottom end in the adjusting cavity correspondingly. The screening device is simple in structure, low in manufacturing cost, capable of continuously screening a small amount of materials through the simple structure, high in screening efficiency, good in screening effect and worthy of popularization.

Owner:湖南旺龙食品有限公司

Hardware tool discharging device and feeding equipment special for hardware tool discharging device

InactiveCN103658288AReduce labor intensityReduce consumptionMetal-working feeding devicesPositioning devicesMotor drivePunch press

The invention discloses a hardware tool discharging device and feeding equipment special for the hardware tool discharging device, and belongs to the field of hardware tool machines. The hardware tool discharging device mainly comprises a punching machine, and a special feeding device capable of moving left and right is arranged on the punching machine. The special feeding device comprises a first rack, and a feeding device capable of moving left and right is arranged on the first rack and comprises a motor, a first feeding roller and a second feeding roller, wherein the motor drives the first feeding roller to rotate, and the first feeding roller drives the second feeding roller to rotate. A guide rail is arranged between the feeding device and the first rack, and a third air cylinder is arranged at the bottom of the first rack. The two sides of the feeding device are respectively provided with a hydraulic buffer, and the hydraulic buffers are fixedly connected to the first rack. According to the hardware tool discharging device and the feeding equipment special for the hardware tool discharging device, repeated turnover feeding of steel belts is avoided, materials are saved, batch forming of hardware products is easily achieved, labor intensity of workers is relieved, dependence on operation techniques of the workers is small, and energy consumption is reduced. The hardware tool discharging device is mainly used for batch production of hardware tools.

Owner:莒南县舜耕五金工具有限公司

Light self-insulation assembly plate forming device

PendingCN114535121ARealize the lubrication functionRealize automatic feeding functionFinal product manufactureSortingElectric machineGear wheel

The light self-heat-preservation assembly plate forming device comprises a main body, a warning indicator, a groove, a first motor and a detector, a discharging device is installed on the back face of the main body, a lubricating box is installed on the top wall of the interior of the discharging device, a fixing frame is installed on the outer wall of the main body, and the warning indicator is installed on the top of the fixing frame; a groove is formed in the top of the main body, a second motor is installed on the bottom wall in the main body, a first motor is installed on the outer wall of the main body, and a detector is installed on the inner wall of the main body. The lubricating function can be achieved by installing the control valve, when the device is lubricated, a first water pump is started, the first water pump conveys lubricating oil in the lubricating box into the control valve, an electromagnet is powered off, a first spring contracts to drive a sealing block to leave a pipe opening of a lubricating pipe, and therefore the lubricating oil is sprayed out of the lubricating pipe; and then the water enters the spraying pipe to lubricate the gear meshing part of the device, so that the lubricating function is realized.

Owner:南通鑫范新型建材有限公司

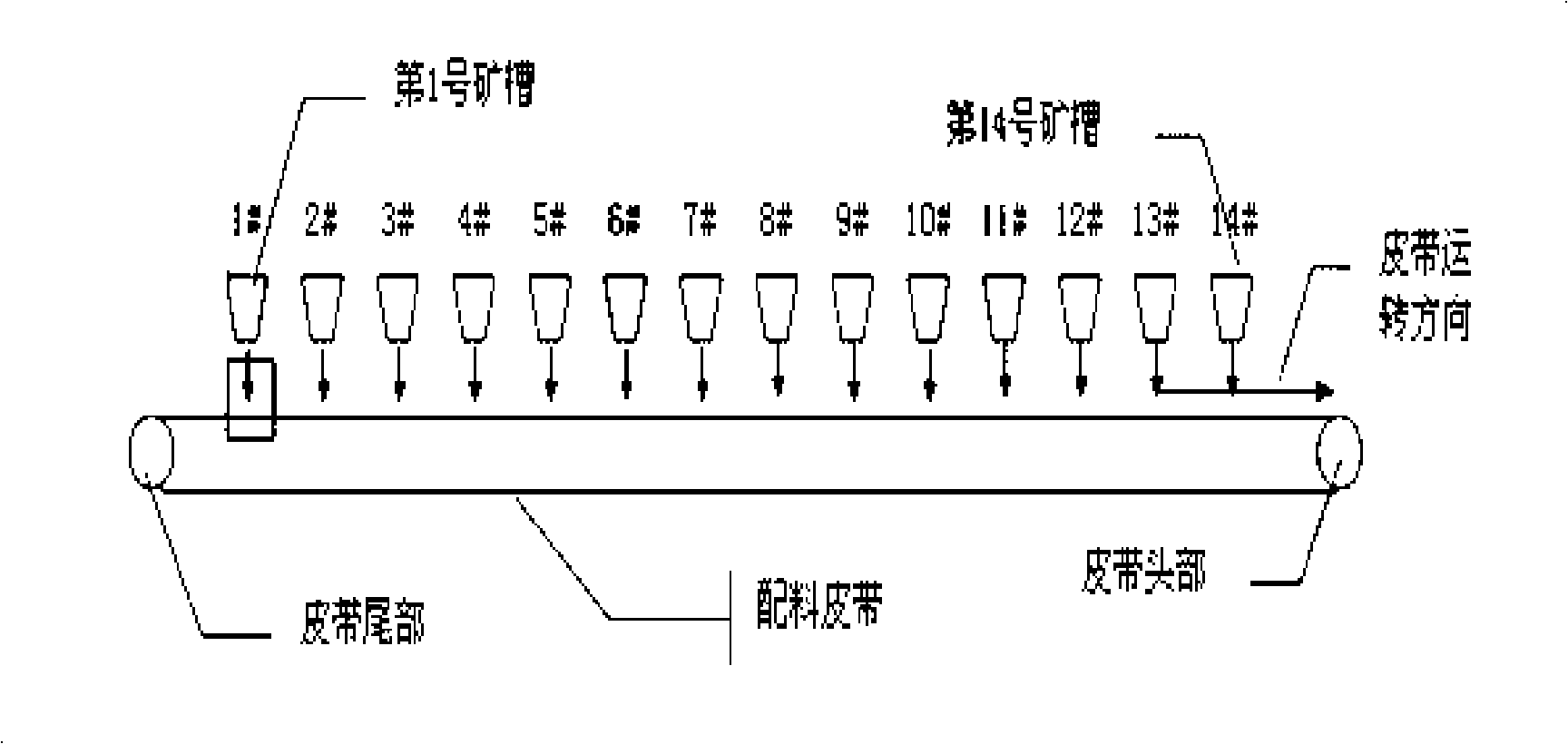

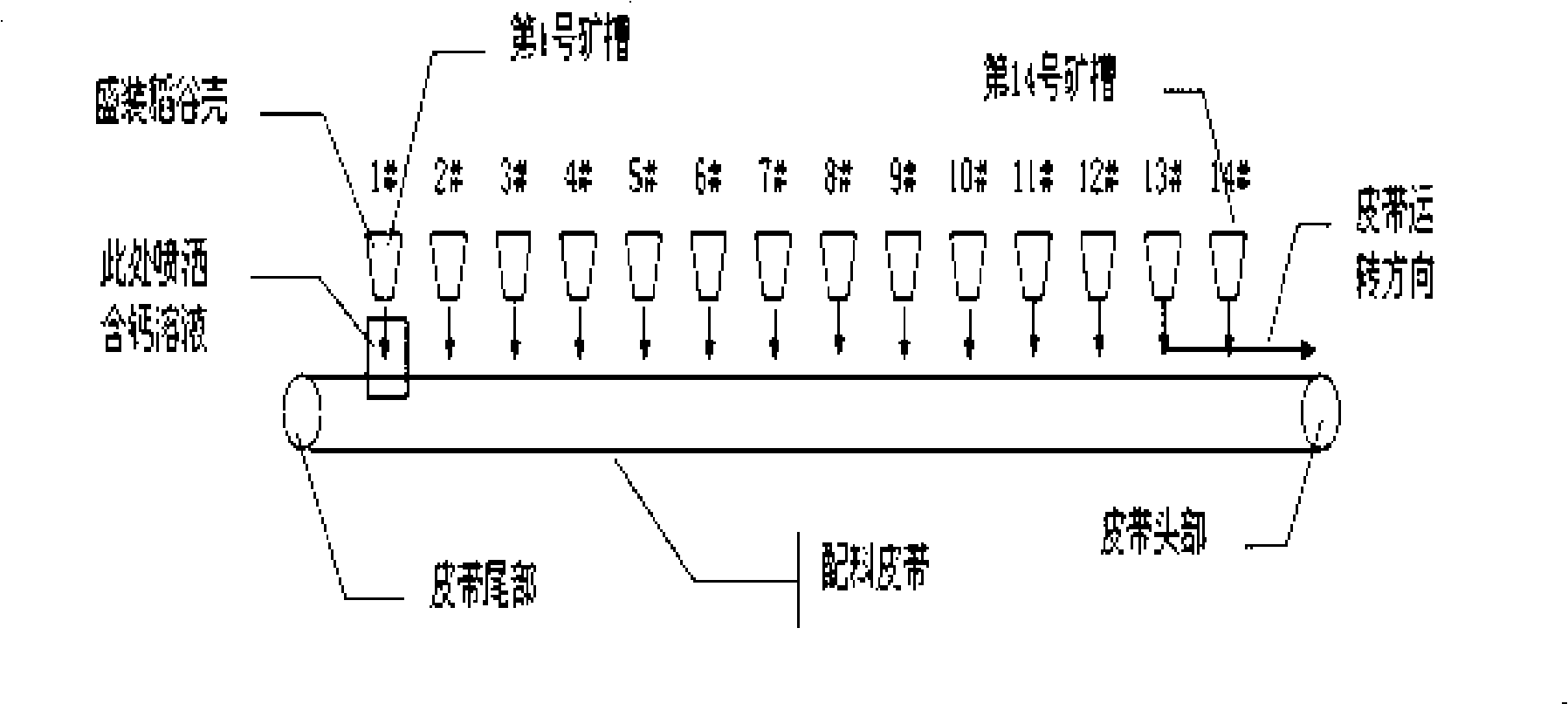

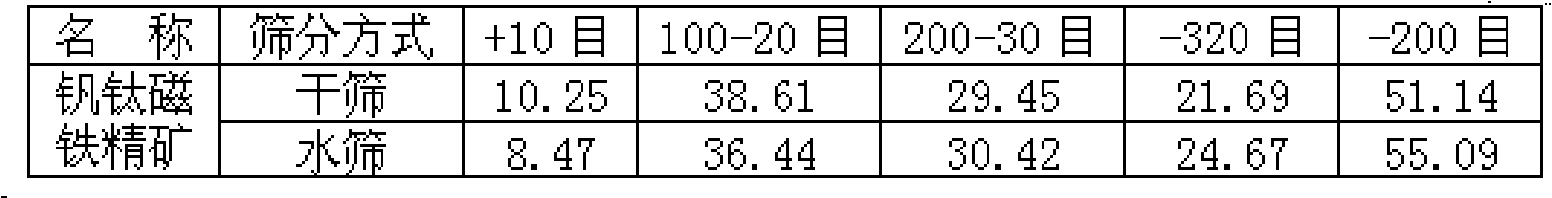

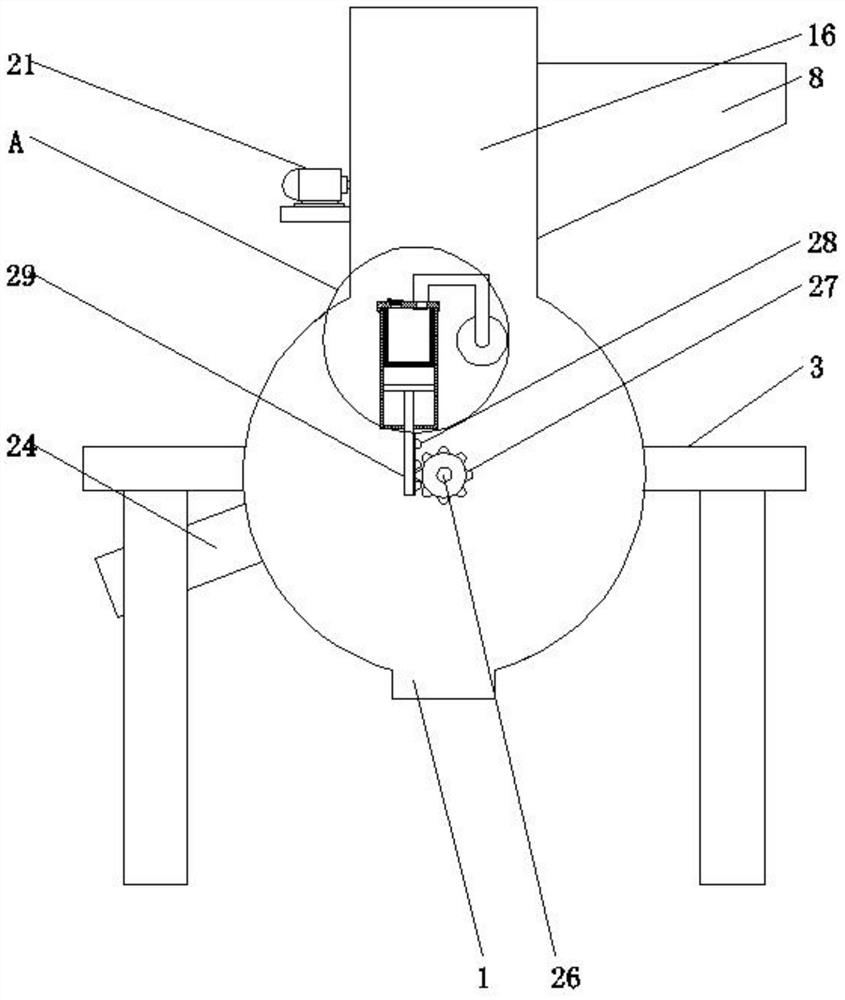

Pelletization method for vanadium titanium magnet ore concentrate mix with additive rough rice shell

The invention relates to a V-Ti-bearing magnetite concentrate mixing material adding rice hull granulating method, which belongs to the metallurgical field. The invention solves the technical problem that a granulating method of V-Ti-bearing magnetite concentrate mixing material with stable granulating effect is provided. The V-Ti-bearing magnetite concentrate mixing material adding rice hull granulating method of the invention comprises the steps that the rice hull which weight percentage is 0.4 percent to 0.6 percent of that of the mixing material is added into the V-Ti-bearing magnetite concentrate mixing material and is mixed evenly, then granulating is performed; wherein, the rice hull is sprayed with calcium content solution before being mixed. The V-Ti-bearing magnetite concentrate mixing material adding rice hull granulating method of the invention, can not only improve the granulating effect, but also prevent the rice hull from being burned by hot return fines, thus to ensure the sintered ore production stable, and improve the product quality; in addition, the automatic material feeding function of the rice hull is realized, which is convenient for accurate control of the material feeding quantity and the labor intensity of manual feeding is decreased, therefore, the V-Ti-bearing magnetite concentrate mixing material adding rice hull granulating method has an extensive application prospect.

Owner:PANGANG GROUP VANADIUM TITANIUM & RESOURCES

Environment-friendly grain screening machine

ActiveCN112138995AImprove screening efficiencyRealize automatic feeding functionSievingDispersed particle filtrationStructural engineeringPolluted environment

The invention discloses an environment-friendly grain screening machine comprising a main body unit and a screening unit. The main body unit comprises a cylindrical shell, fixed plates, supporting legs, a first discharging pipe, a second discharging pipe, a rectangular shell, fixed blocks and a hopper. The fixed plates are perpendicularly arranged on the two sides of the cylindrical shell correspondingly, and the supporting legs are evenly arranged at the bottoms of the fixed plates. The first discharging pipe is arranged at the bottom of the cylindrical shell, the second discharging pipe is obliquely arranged on the outer side of the portion, between the fixed plate located on the left side and the first discharging pipe, of the cylindrical shell. The rectangular shell is perpendicularlyarranged on the top of the cylindrical shell. A regulation cavity and a feeding cavity are formed in the rectangular shell from left to right. The regulation cavity communicates with the inner portionof the feeding cavity and the inner portion of the cylindrical shell. The fixed blocks are arranged on the two sides of the bottom end in the regulation cavity correspondingly. The environment-friendly grain screening machine is simple in structure and low in manufacturing cost, dust can be treated during screening, and the dust is prevented from polluting the environment.

Owner:贵州星鼎农业发展有限公司

PXIe backboard production tool

InactiveCN113382559ARealize automatic feeding functionInsulating substrate metal adhesion improvementPrinted circuit secondary treatmentWorkbenchIndustrial engineering

The invention discloses a PXIe backboard production tool, and relates to the field of circuit board production. The PXIe backboard production tool comprises a workbench, supporting columns are fixedly installed at the four ends of the top of the workbench, a top plate is fixedly installed among the tops of the four supporting columns, a mounting frame is fixedly installed at the top of the back side of the top plate, a driving mechanism is arranged on one side of the mounting frame, a sleeve is movably installed on the top of the top plate in a penetrating mode, a connecting plate is integrally formed on one side of the top end of the sleeve, a drilling mechanism is arranged in the sleeve, and a pressing frame is fixedly connected to the bottom of the sleeve. Through the sleeve, the pressing frame and the drilling mechanism, not only is a backboard pressed and formed, but also the backboard is drilled, and the function of pressing and riveting the plate is achieved; and through a pin feeding mechanism and a plate feeding mechanism, the automatic feeding function of pins and plates is achieved in the upward moving process of the pressing frame and a pressing rivet rod.

Owner:深圳市厚物科技有限公司

Hoop stamping die capable of achieving automatic discharging

InactiveCN111531006ARealize automatic dischargeRealize automatic feeding functionMetal-working feeding devicesPositioning devicesStampingManufacturing engineering

The invention discloses a hoop stamping die capable of achieving automatic discharging, and relates to the technical field of hoop machining devices. The hoop stamping die comprises an upper die and alower die. A stamping head is fixedly connected to the upper die. A boss is arranged on the lower die. A rectangular groove is formed in the boss. A work barrel is connected in the rectangular groovein a rotating manner. Multiple machining grooves matched with the stamping head are formed in the circumferential face of the work barrel. The end, located on the rectangular groove, on the boss is connected with a feeding plate in a rotating manner. A discharge port is arranged on the portion, located below the work barrel, in the rectangular groove. According to the hoop stamping die, the rectangular groove is formed in the boss, the work barrel is connected in the rectangular groove in the rotating manner, meanwhile, the feed plate is connected to a work table in a rotating manner, and therefore automatic feeding and discharging of hoops are achieved, and the machining efficiency of the hoops is improved.

Owner:HEFEI ZHENGTE MACHINERY CO LTD

Slotting and trimming machine for building environmental-protection plates

ActiveCN111805334AImprove practicalityImprove convenienceEdge grinding machinesGrinding carriagesMilling cutterStructural engineering

The invention discloses a slotting and trimming machine for building environmental-protection plates. The slotting and trimming machine comprises a base, wherein a rack is fixedly installed at the topof the base, a first gear disc is rotatably connected to the middle of the top end of the rack, a second gear disc and a third gear disc are correspondingly arranged on the two sides of the first gear disc, the second gear disc and the third gear disc are correspondingly engaged with the first gear disc, connecting shafts are correspondingly and fixedly connected to the outer sides of the secondgear disc and the third gear disc, brackets are correspondingly and fixedly installed on the two sides of the top of the rack, and the two connecting shafts are correspondingly and rotatably connectedwith the brackets on the two sides of the rack. According to the slotting and trimming machine, the second gear disc and the third gear disc are correspondingly connected with the first gear disc inan engaged mode, the driving of the first gear disc and a face milling cutter is achieved, the function of slotting is achieved, two grinding cutting pieces are driven to conduct the trimming and cutting functions on the two sides of a plate, thus the practicability and convenience of the plate processing are greatly improved, the energy utilization rate is improved, and the processing efficiencyis improved.

Owner:HEBEI TIANXIN CONSTR GRP CO LTD

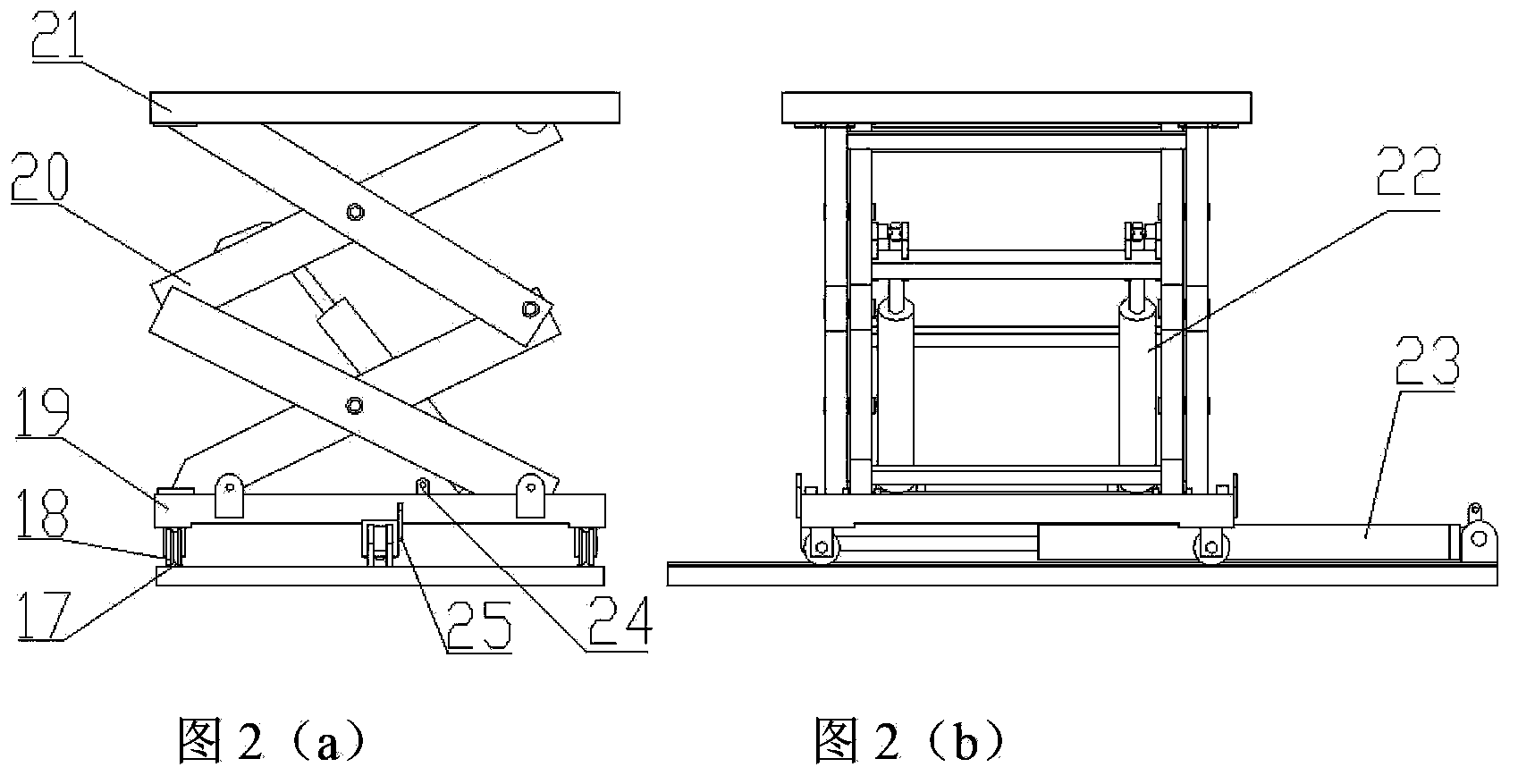

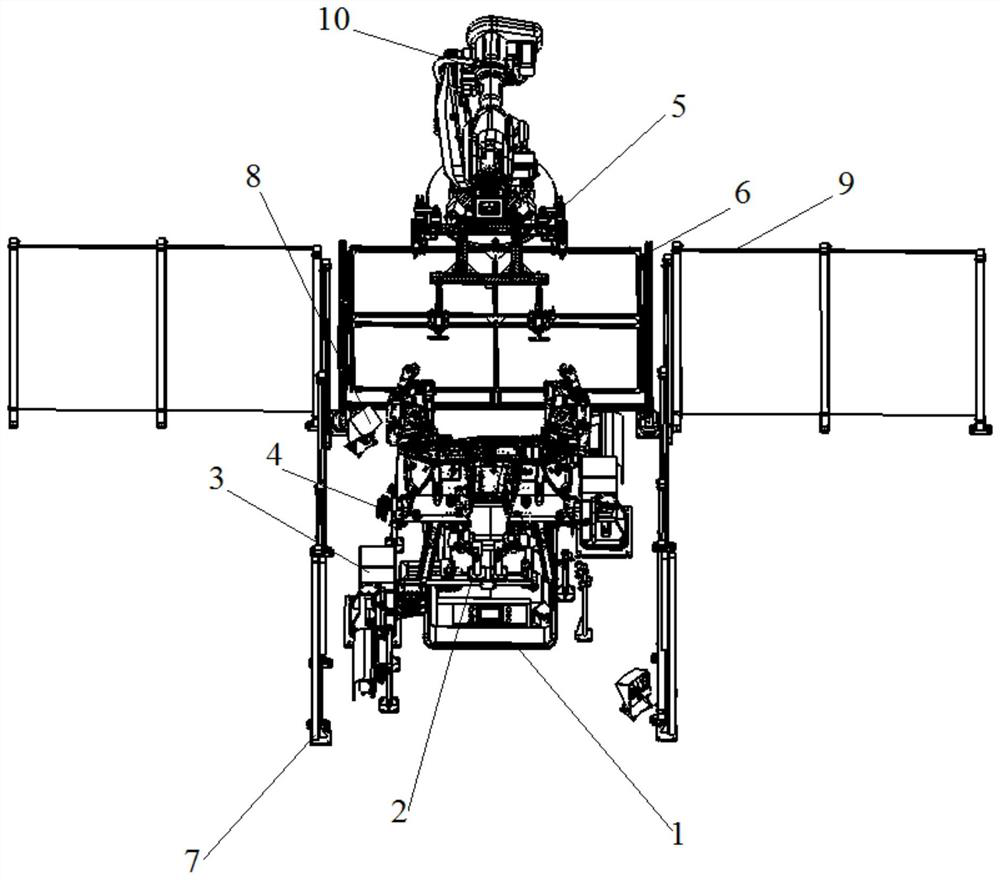

Flexible lifting feeding system based on AGV and feeding control method

PendingCN113441879AReduce labor intensityPrecise feedingWelding/cutting auxillary devicesControl devices for conveyorsVisual systemRoboty

The invention provides a flexible lifting feeding system based on an AGV and a feeding control method. The system comprises an AGV logistics vehicle, an appliance, a fine positioning lifting mechanism, an RFID system, a visual system, a lifting sliding door and a robot. The appliance and the AGV logistics vehicle are installed in a positioning mode, the appliance is loaded with the body-in-white part products, the fine positioning lifting mechanism is arranged at a feeding port and matched with the appliance to achieve positioning and lifting with the appliance, the RFID system is used for reading information of the appliance and further identifying vehicle type information corresponding to the body-in-white part products, the visual system is used for identifying specific characteristics of the body-in-white part products, the lifting sliding door is arranged between the appliance and the robot, and the robot switches a gripping apparatus according to vehicle type information and adjusts the gripping form of the gripping apparatus according to the specific characteristics of the body-in-white part products. The welding automation requirement can be met, flexible integration of multiple vehicle types can also be met, and meanwhile high grade is achieved.

Owner:CHINA FIRST AUTOMOBILE +1

Magnetic ring internal crack detection device

InactiveCN113617692AAvoid dischargeRealize automatic feeding functionMechanical diameter measurementsCleaning using toolsElectric machineryStructural engineering

The invention discloses a magnetic ring internal crack detection device. The magnetic ring internal crack detection device comprises a main body, a feeding box, a placement table and a fixed sliding groove, wherein the feeding box is installed on the inner bottom wall of the main body, a screening disc is installed on the inner wall of the feeding box, a fixed plate is installed on the outer wall of the feeding box, a second motor is installed on the inner bottom wall of the main body, the placement table is installed on the bottom wall inside the main body, and the fixed sliding groove is formed in the top of the main body. According to the magnetic ring internal crack detection device, by installing a feeding disc and a first motor, automatic feeding can be achieved, magnetic rings move and are discharged from a discharging hole, the distance between a limiting plate and the feeding disc is the thickness of the magnetic rings, the limiting plate can prevent the multiple magnetic rings from being discharged at the same time, the magnetic rings enter a conveying belt after being discharged, the second motor drives a belt to rotate, the belt drives the conveying belt to rotate, the conveying belt drives the magnetic rings to enter the top of the placement table, and the magnetic rings move to the top of a piezoelectric ceramic, so that the automatic feeding function is achieved.

Owner:南通和力磁材有限公司

Automatic feeding device for porcupines

The invention relates to the technical field of livestock feeding devices, in particular to an automatic feeding device for porcupines. The automatic feeding device comprises an enclosing wall, a floor, an eating portion, a horizontal cutting system and a vertical cutting system, the eating portion comprises a feeding hopper, a material cutting tank, a pig feed tank, a discharging port and a flowing material tank, the material cutting tank is communicated with the pig feed tank through the flowing material tank, the material cutting tank is positioned above the pig feed tank, the horizontal cutting system comprises a water bag, a water tank, a cover, a piston cylinder, a piston, a horizontal cutting knife, a first water pipe and a third water pipe, a one-way water outlet valve is arrangedon the first water pipe, a water pump and a one-way water inlet valve are arranged on the third water pipe, the vertical cutting system comprises an L-shaped arm rod, a second water pipe, a switch valve and a vertical cutting blade group, a stopper is arranged on the lower portion of the L-shaped arm rod, a cross rod is arranged on the stopper, a first lever is arranged between the stopper and theswitch valve, a second level is arranged on the first level, a third level is arrange don the second level, and a downward pressing piece is arranged at the lower end of the third level. By the aid of the technical scheme, food can be supplied as required when the porcupines are fed.

Owner:滨州农一电子商务有限公司

Full-automatic oxygen extraction packaging equipment for quick-frozen meat

InactiveCN112758412ARealize automatic feeding functionImprove work efficiencyWrapping material feeding apparatusWrappingBiotechnologyVacuum pumping

The invention relates to the technical field of quick-frozen meat packaging, in particular to full-automatic oxygen extraction packaging equipment for quick-frozen meat. The equipment comprises a rack, a lower-layer packaging film winding and unwinding assembly, an upper-layer packaging film winding and unwinding assembly, a tensioning assembly, a box forming assembly, a vacuum sealing assembly and a shearing and discharging assembly; the box body forming assembly comprises a lifting mechanism, an air exhaust box, a first vacuum air exhaust pipe and a pressing and abutting mechanism, the vacuum sealing assembly comprises an edge sealing mechanism and an air exhaust sealing mechanism, the edge sealing mechanism comprises a rectangular edge sealing heating plate capable of combining a lower packaging film and an upper packaging film, and a rectangular notch is formed in one side of the rectangular edge sealing heating plate; and the air exhaust sealing mechanism comprises a rectangular air exhaust head and a sealing heating plate, and the shearing and discharging assembly comprises a rectangular cutting knife capable of cutting packaging films and a discharging conveying belt. According to the full-automatic oxygen extraction packaging equipment for the quick-frozen meat, full-automatic oxygen extraction packaging of the quick-frozen meat is achieved in the mode that the quick-frozen meat is wrapped with the upper packaging film and the lower packaging film; and the sealing effect is good and the working efficiency is high.

Owner:PUTIAN CHENGXIANG DISTRICT CHENGWEI FOOD CO LTD

Energy-saving and environment-friendly automatic lime kiln furnace

ActiveCN108503244ARealize automatic feeding functionRealize automatic ash unloading functionFurnace temperatureCombustion

The invention relates to the technical field of energy-saving and environment-friendly lime kiln furnaces and particularly relates to an energy-saving and environment-friendly automatic lime kiln furnace. The lime kiln furnace is provided with two brackets, wherein a kiln furnace is connected between the two brackets, a feeding assembly is arranged on the kiln furnace, an ash filtering plate assembly is connected to the kiln furnace in a sliding manner, and two ends of the ash filtering plate assembly are connected with two ends of an ash receiving seat; and an exhaust gas circulating controlprocessing component is arranged on the lime kiln and is connected with the feeding assembly. According to the lime kiln furnace, the waste heat of high-temperature smoke exhausted from the kiln furnace is adequately introduced into an air inlet of the kiln furnace, and air entering the kiln is heated through heat exchange, so that the oxygenation and combustion assisting are realized, and the furnace temperature can be rapidly increased; and the lime kiln furnace has the functions of automatically feeding and discharging ash.

Owner:山西九元石灰制造股份有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com