Energy-saving and environment-friendly automatic lime kiln furnace

An energy-saving and environmentally friendly furnace technology, which is applied in the field of energy-saving and environmentally friendly automatic lime furnace, can solve the problems of waste and waste heat of high-temperature flue gas not being used, and achieve the effects of increasing furnace temperature, increasing oxygen and combustion, and achieving obvious energy-saving effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

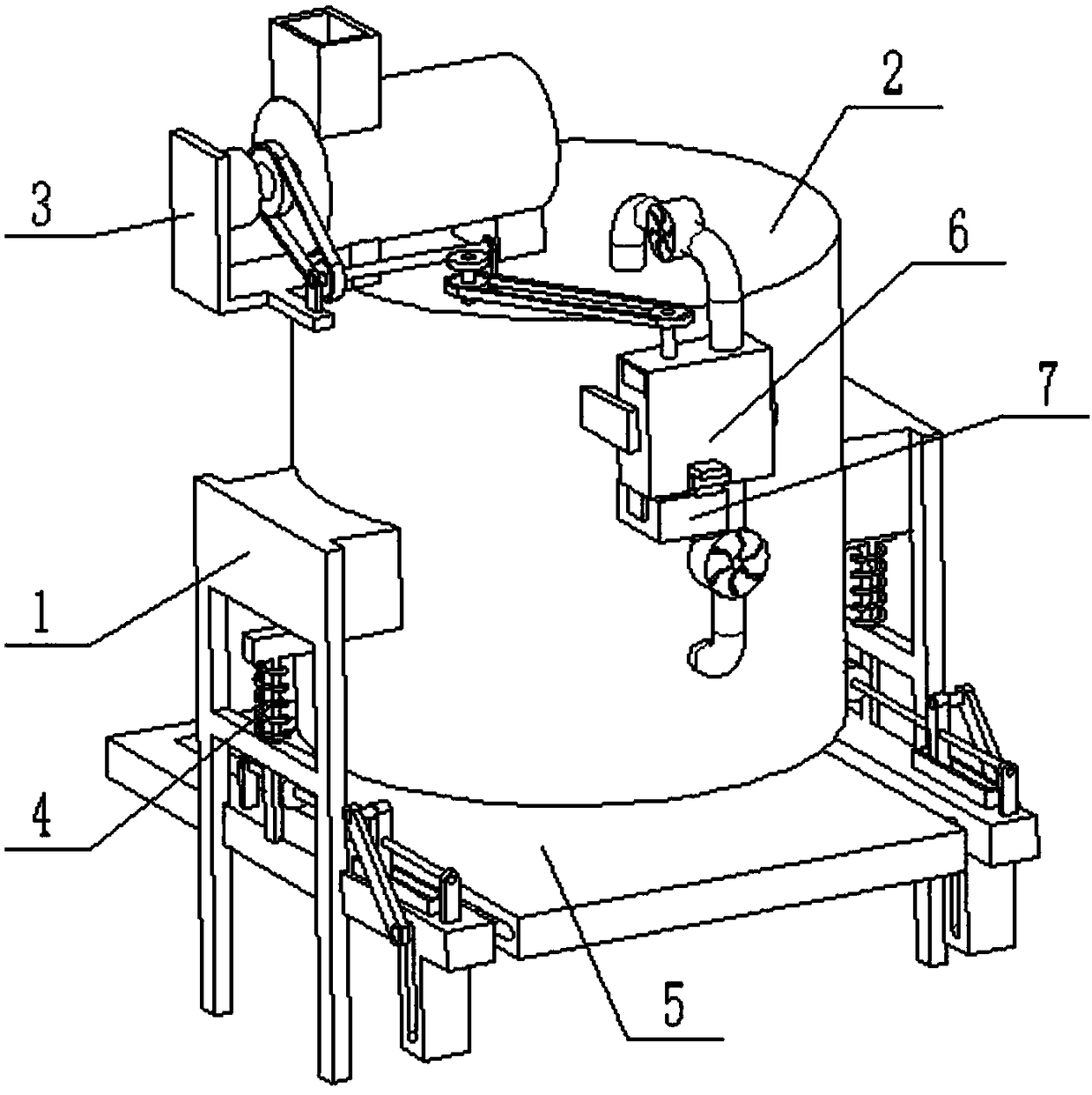

[0028] Combine below Figure 1-11 Describe this embodiment, an energy-saving and environment-friendly automatic lime kiln furnace, including a bracket 1, a kiln furnace 2, a feed assembly 3, an ash filter plate assembly 4, an ash receiving seat 5, a flue gas circulation control processing part 6, and a lime box assembly 7 , two supports 1 are provided, the pit furnace 2 is connected between the two supports 1, the feed assembly 3 is arranged on the pit furnace 2, the ash filter plate assembly 4 is slidably connected in the pit furnace 2, and the ash filter plate The two ends of the component 4 are respectively connected with two supports 1, the ash receiving seat 5 is connected between the two supports 1, the ash receiving seat 5 is located directly below the kiln furnace 2, the two ends of the ash filter plate assembly 4 are connected with the ash receiving seat The two ends of 5 are connected, and the flue gas circulation control treatment part 6 is arranged on the kiln furn...

specific Embodiment approach 2

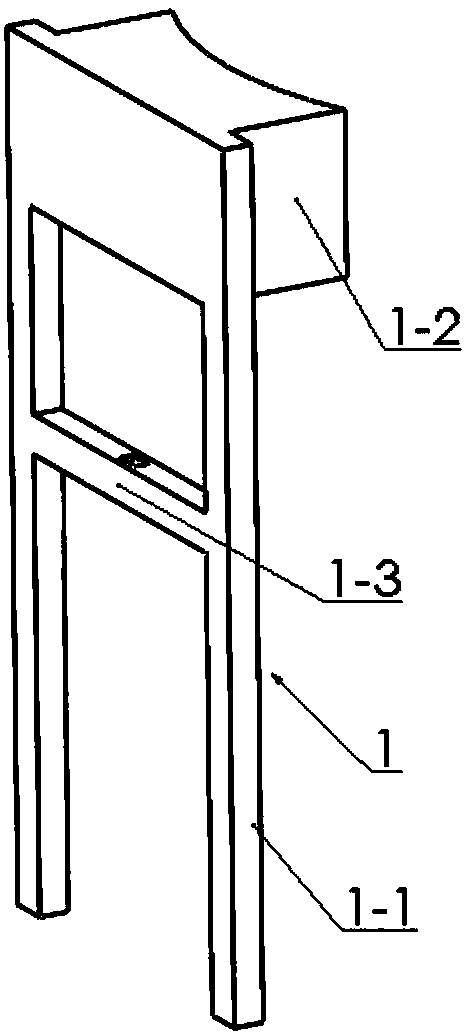

[0029] Combine below Figure 1-11 To illustrate this embodiment, the support 1 includes a support rod 1-1, a connecting seat 1-2 and a horizontal rod 1-3, the connecting seat 1-2 is fixedly connected to the upper ends of the two supporting rods 1-1, and the horizontal rod 1 -3 is fixedly connected to the middle ends of the two support rods 1-1.

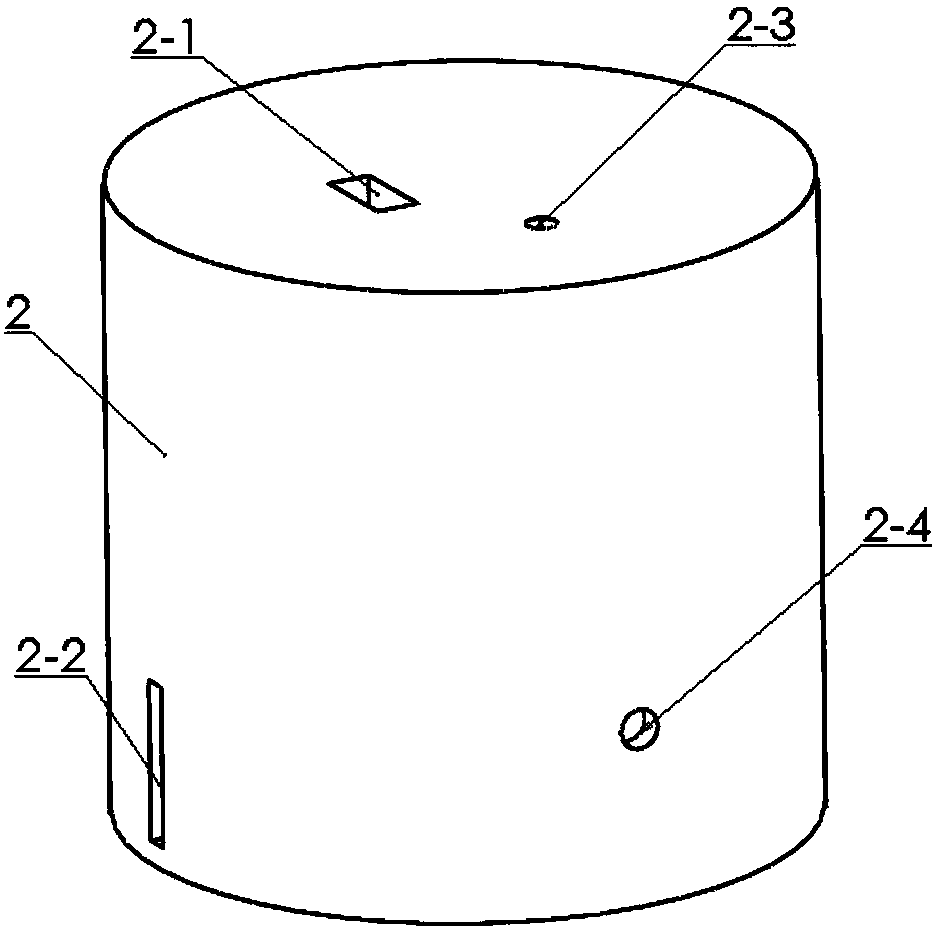

[0030] The pit furnace 2 is provided with a feed inlet 2-1, a vertical chute 2-2, a smoke outlet 2-3 and an air inlet 2-4, the lower end of the pit furnace 2 is hollowed out, and the pit furnace 2 is fixedly connected to two Between the two connecting seats 1-2, the upper end of the kiln furnace 2 is provided with a feed port 2-1 and a smoke outlet 2-3, and the lower end of the kiln furnace 2 is provided with an air inlet 2-4, and the lower end of the kiln furnace 2 is arranged symmetrically. There are two vertical chute 2-2.

[0031] The feed assembly 3 includes a feed cylinder 3-1, a feed pipe 3-2, a discharge pipe 3-3, a base 3-4...

specific Embodiment approach 3

[0033] Combine below Figure 1-11 To illustrate this embodiment, the ash receiving seat 5 includes a door-shaped seat 5-1, a connecting groove 5-2, an ash unloading plate 5-3, a groove-shaped groove 5-4, a round rod chute 5-5, a circular Rod 5-6, screw rod seat 5-7, screw rod 5-8, gear 5-9, slide seat 5-10, reciprocating slide block 5-11 and hinged rod 5-12, the left and right sides of door font seat 5-1 Two connection grooves 5-2 are arranged on each end, the support rod 1-1 is fixedly connected in the connection groove 5-2, and the ash unloading plate 5-3 is connected to the inside of the door-shaped seat 5-1 through the rotation of the hinge shaft. The left and right ends of the front end of the gray board 5-3 are all provided with grooved grooves 5-4, and the left and right ends of the front end of the door-shaped seat 5-1 are all provided with round rod chute 5-5, two round rods 5 The inner ends of -6 are respectively slidably connected in the two grooved grooves 5-4, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com