Digitized centralized feed control system

A technology of control system and central control, applied in general control system, control/regulation system, transmission system, etc., can solve the problems of low degree of intelligence and digitization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0051] The present invention is described by taking a specific digitalized centralized material supply control system as an embodiment.

[0052] As shown in the figure, the present invention includes two major parts: control system and peripheral equipment.

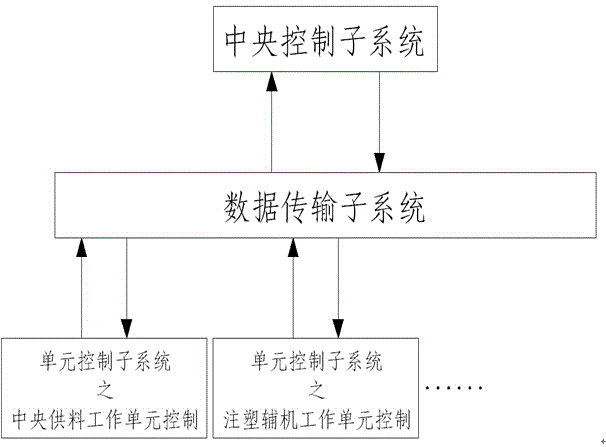

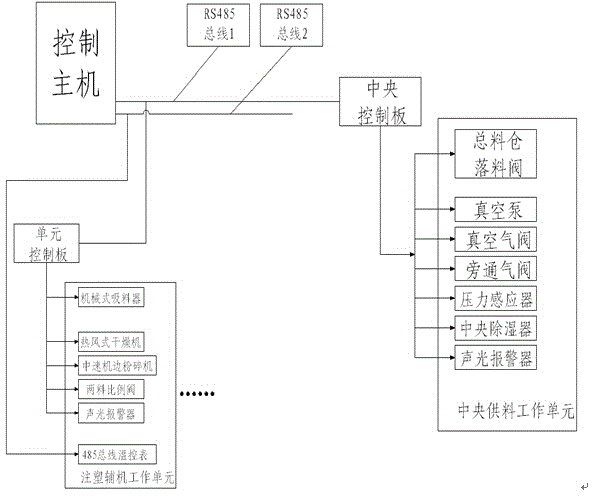

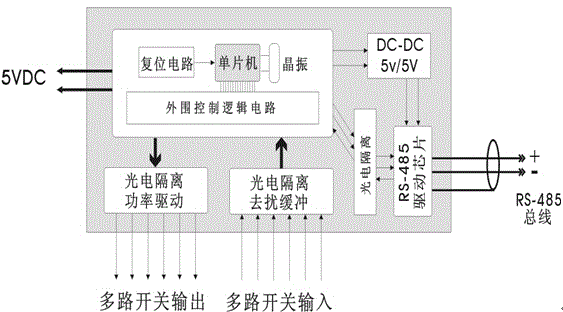

[0053] 1) Control system: It is composed of PC, central control board, unit control board and data communication system. It is the logic and control center of the whole system. It is divided into three parts: central control subsystem, unit control subsystem and data transmission subsystem , The upper computer and the lower computer adopt a master-slave structure.

[0054] The central control subsystem adopts a general industrial control host, and realizes the global control logic of the system through the central control software;

[0055] The unit control subsystem: realize the monitoring of a group of unit equipment and the key local control logic; wherein, a group of unit equipment is a logical work unit composed of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com