Catenary cantilever numerical control preassembly platform

A catenary and platform technology, applied in overhead lines and other directions, can solve the problems of low degree of automation, low pre-assignment accuracy, low qualified rate of finished products, etc., and achieve the effect of ensuring construction quality, reasonable structure, and ensuring accuracy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

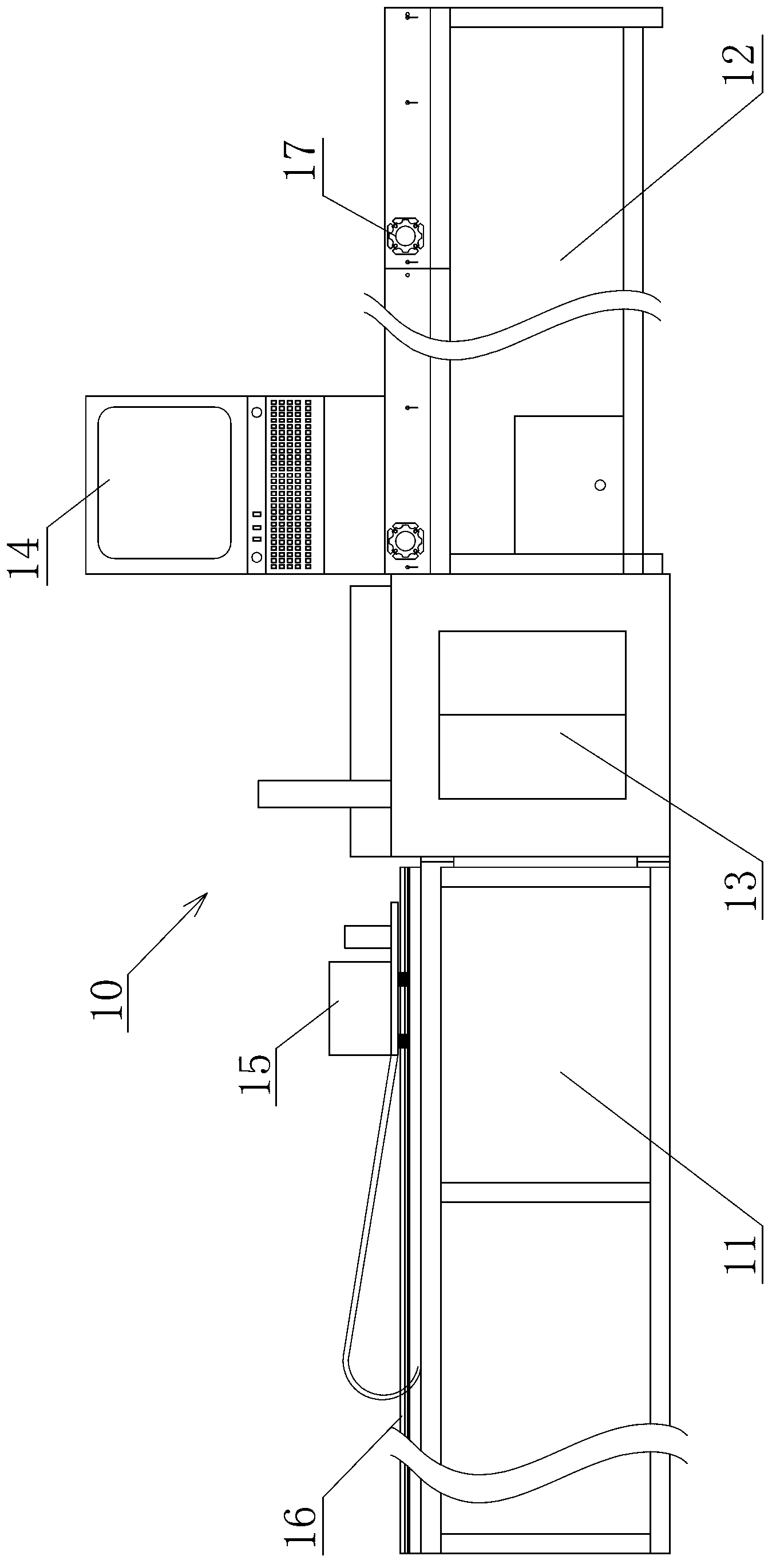

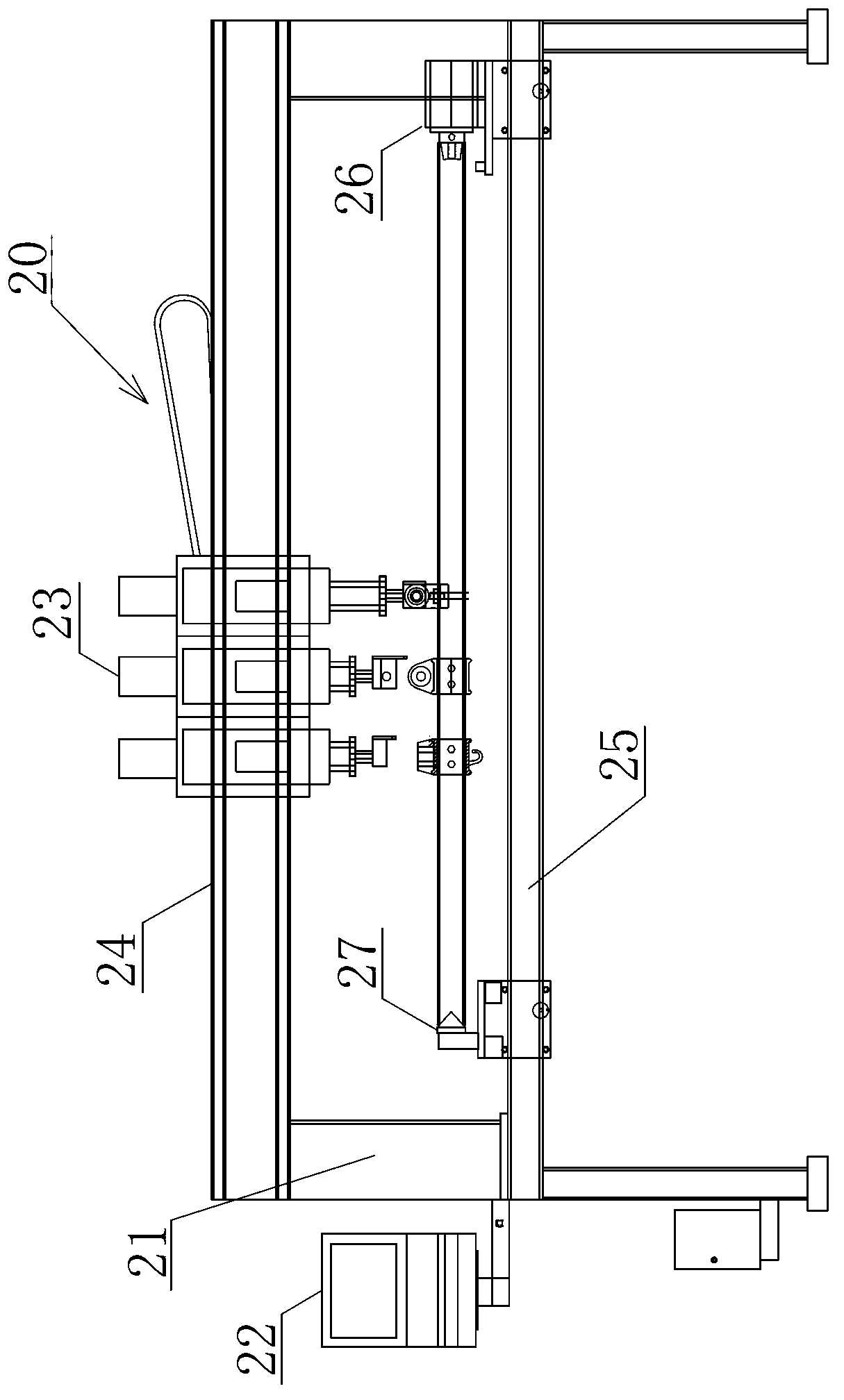

[0028] Examples, see Figure 1 to Figure 4 Shown: the catenary arm arm CNC pre-configuration platform, including a pipe cutting platform 10 for cutting pipes and a parts assembly platform 20 for assembling, which are independent of each other.

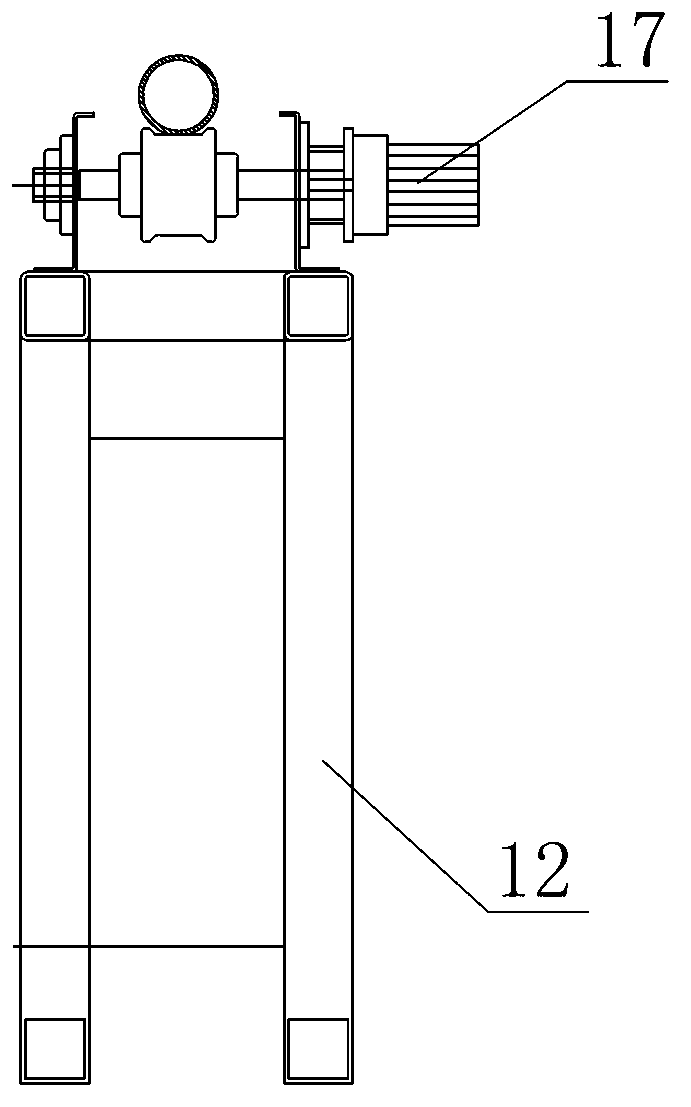

[0029] see details figure 1 , figure 2 : According to the processing direction of the workpiece, the pipe cutting platform 10 includes a discharge end main body 11, a cutting machine 13, and a feed end main body 12 in sequence. Wherein, the first linear guide rail 16 is fixed on the main body 11 of the discharge end, the first positioning device 15 is installed on the first linear guide rail 16, and the pipe driving device for realizing the automatic feeding of the pipe is installed on the main body 12 of the feeding end. device 17.

[0030] Furthermore, combining Figure 5 As shown, the first positioning device 15 includes a linear bearing guide rail slider 151 inserted on the first linear guide rail 16, a first motor bracket 152...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com