Patents

Literature

31results about How to "Ensure requirements" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

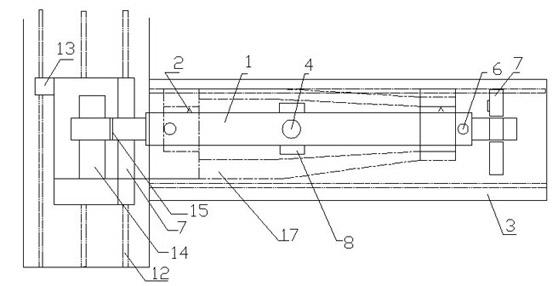

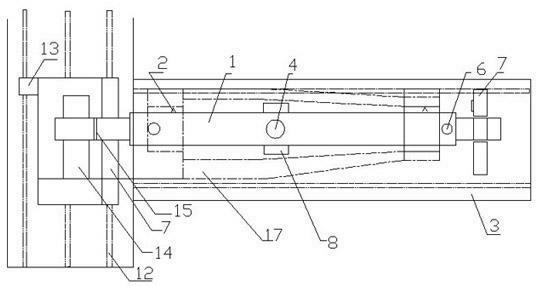

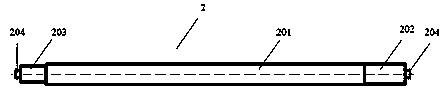

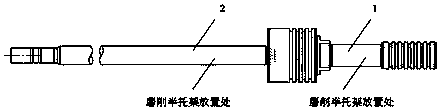

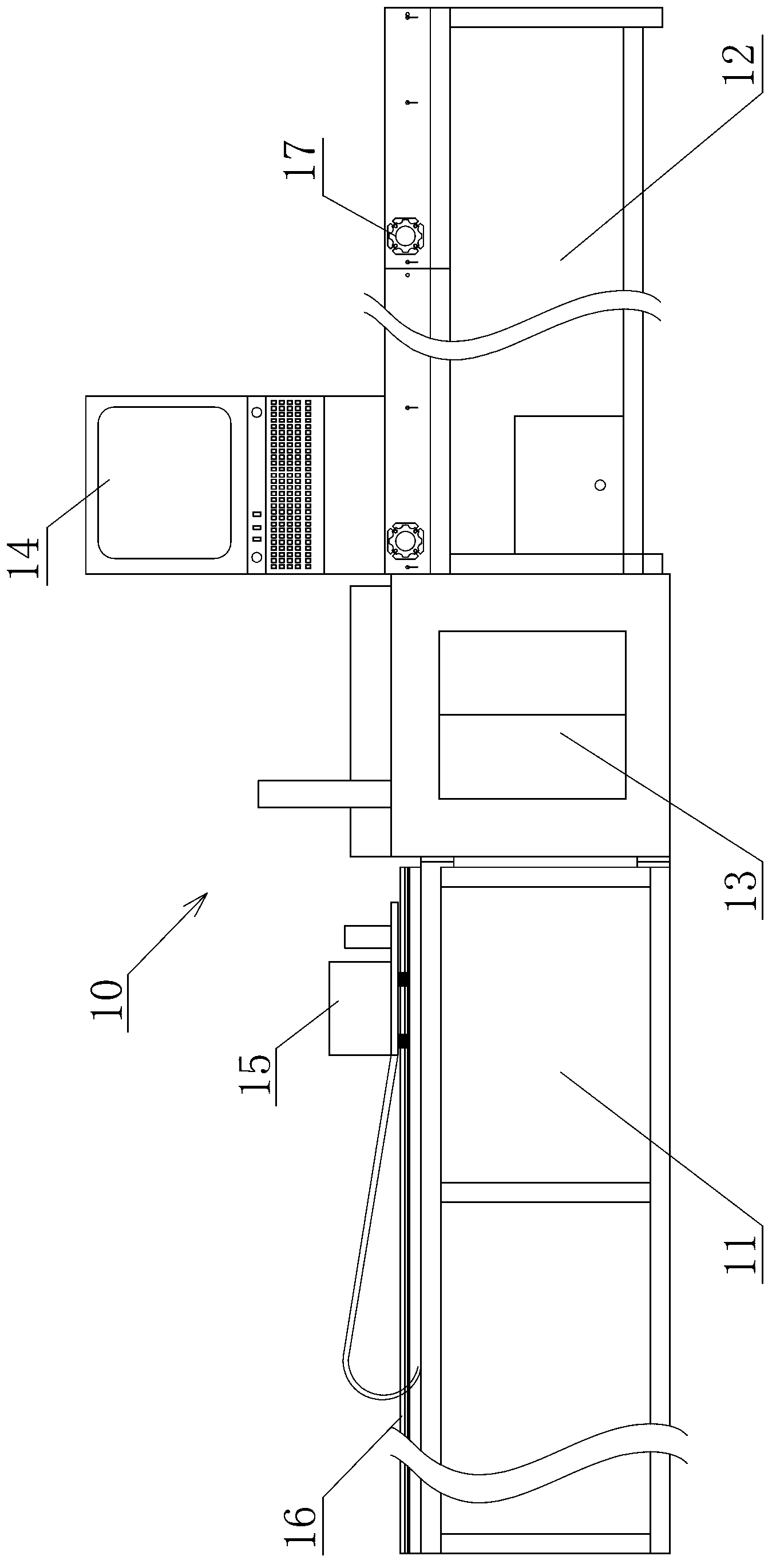

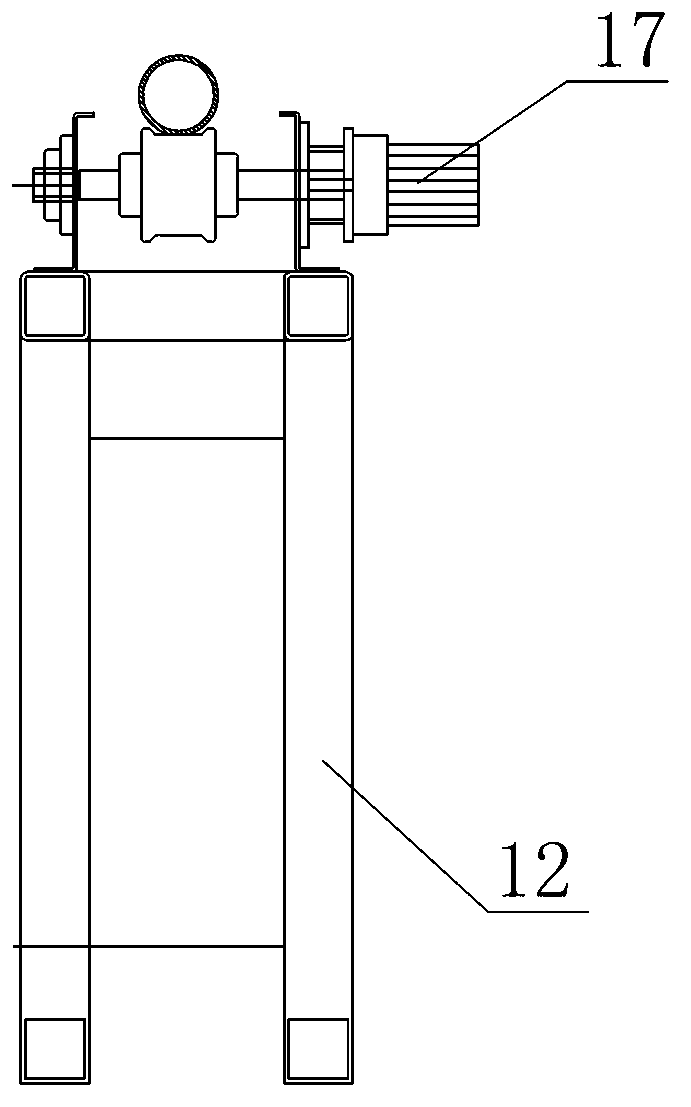

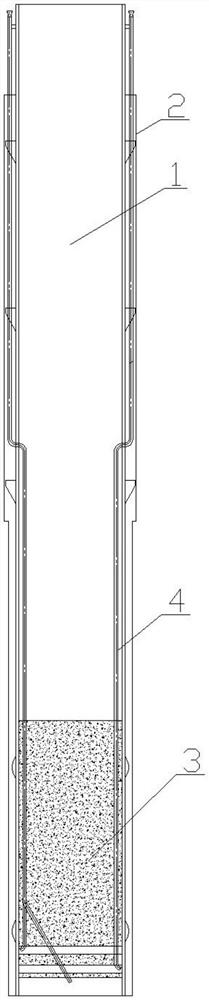

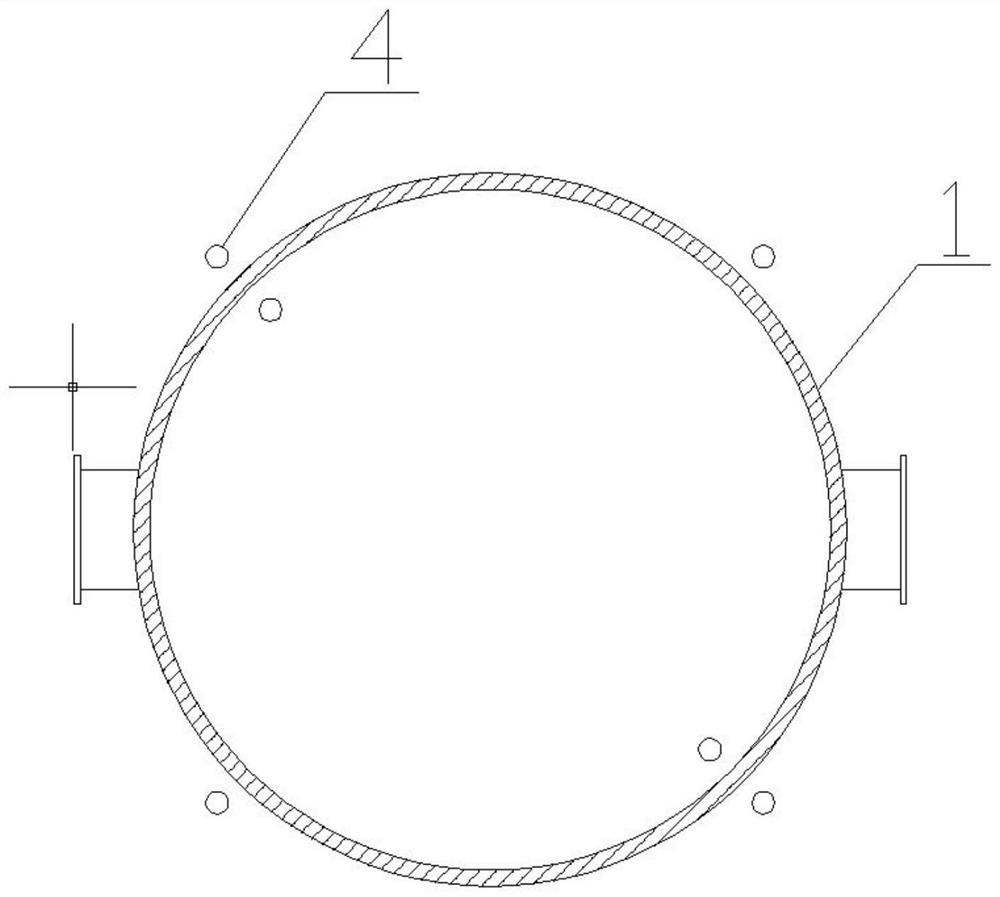

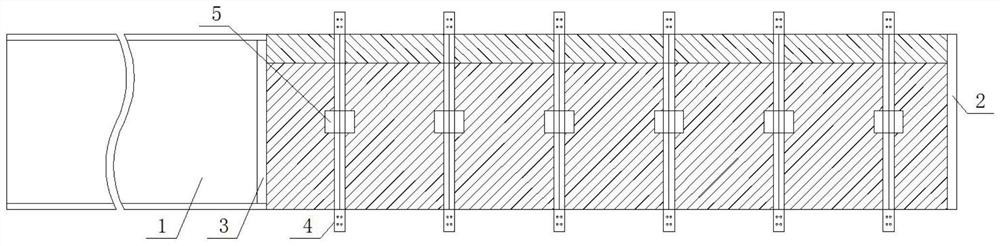

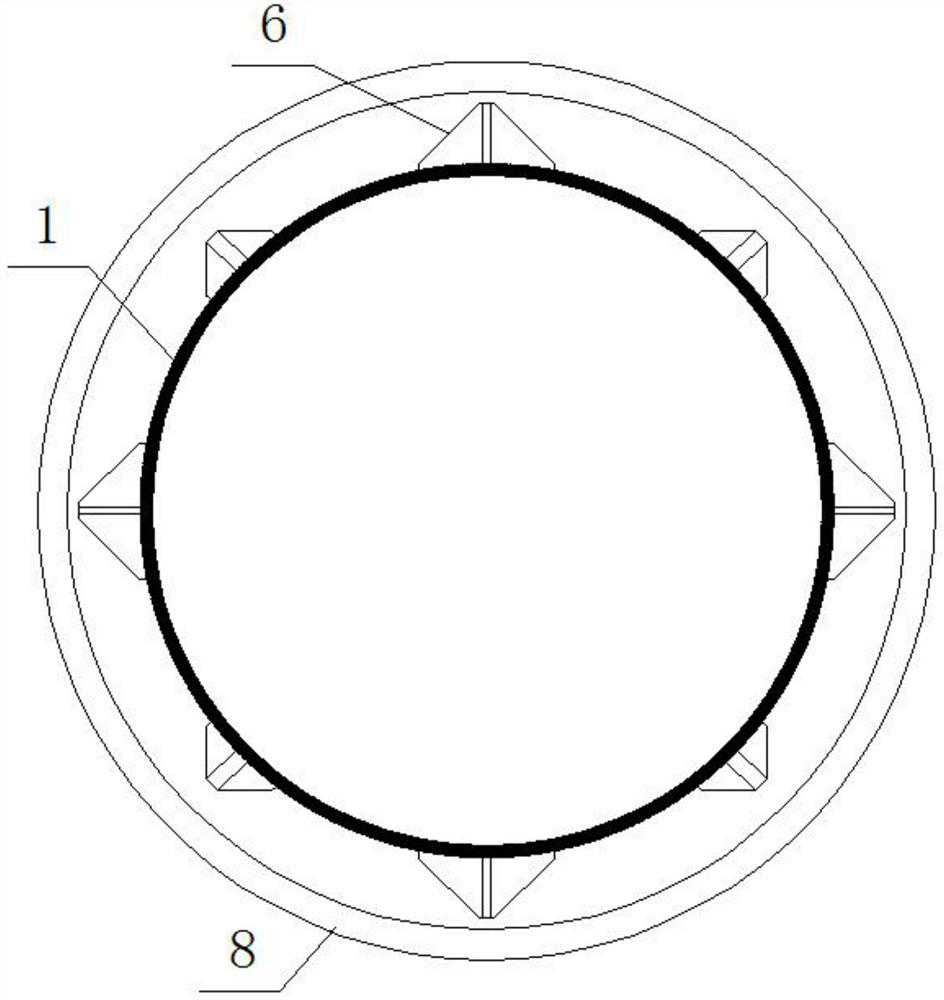

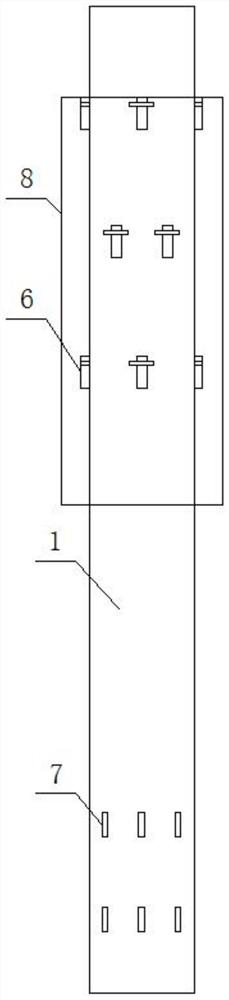

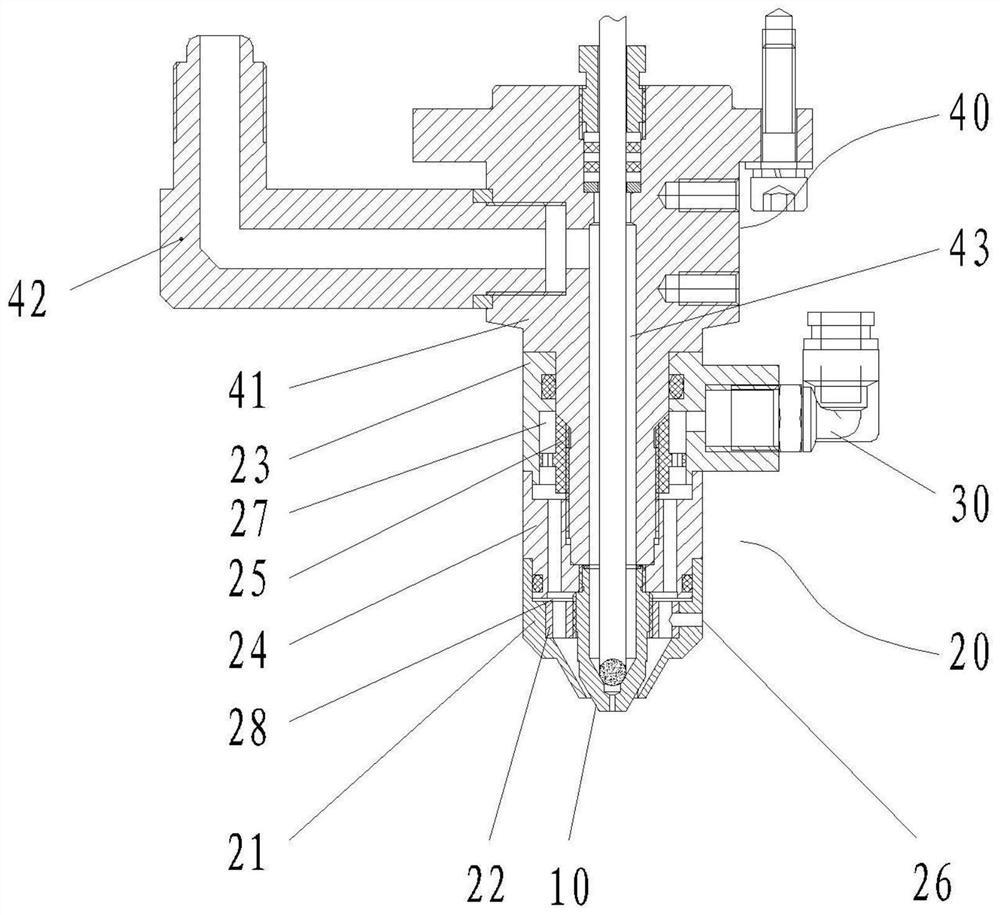

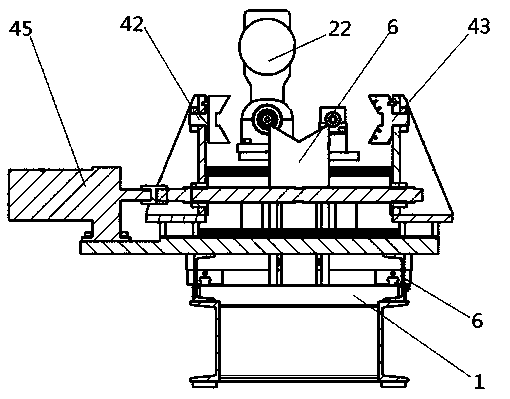

Porous boring machine for combined boring bar

InactiveCN102615309APrecise adjustment of deformationSolve the problem of difficult to control deflection deformationBoring barsTool holdersEngineeringMechanical engineering

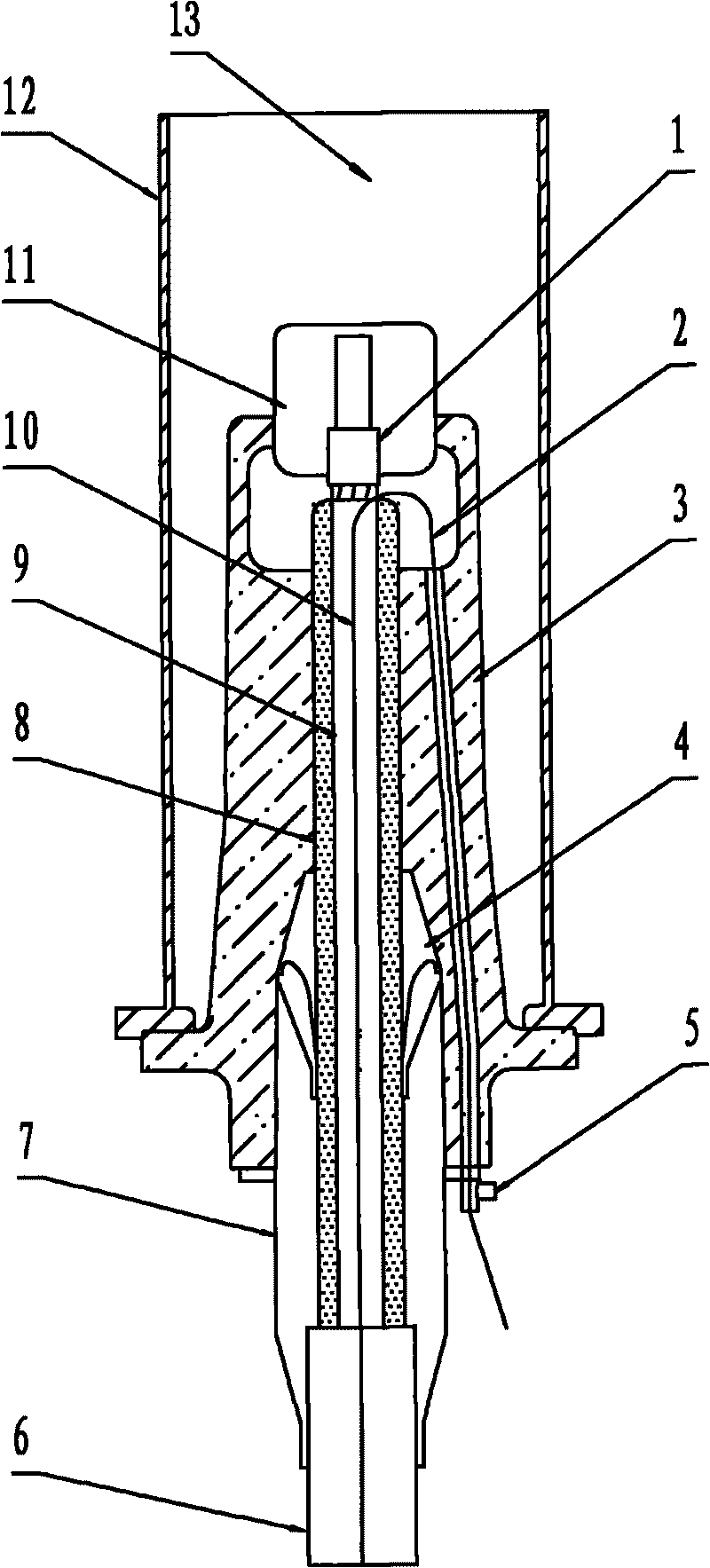

The invention discloses a porous boring machine for a combined boring bar. The porous boring machine comprises a drive device, a boring bar, boring cutters, a boring platform, a deflection fine adjusting mechanism and a boring cutter adjusting mechanism, wherein the boring bar is driven by the drive device; the boring cutters are arranged on the boring bar; the deflection fine adjusting mechanism is used for adjusting the deflection of the boring bar; the boring cutter adjusting mechanism is used for adjusting the telescopic length of the boring cutters; the two boring cutters are arranged in the boring cutter mounting holes in the boring bar respectively; the boring bar is provided with deflection test holes; both ends of the boring bar are connected to movable support seats respectively; the deflection fine adjusting mechanism is positioned between the two movable support seats and is connected with the boring bar; the boring cutter adjusting mechanism is arranged in the boring cutter mounting holes and is connected with the boring cutters; and the movable support seats and the deflection fine adjusting mechanism are arranged on the boring platform. According to the porous boring machine, the combined boring bar is adopted, the problem that the deflection and the deformation of the super-long boring bar are difficult to control is solved, the deformation amount of the boring bar can be accurately adjusted, and the concentricity and other machining accuracy of machined workpieces are ensured.

Owner:SICHUAN BAISHICHANG HEAVY MACHINERY

Processing method for piston rod assembly

The invention provides a processing method for a piston rod assembly. When an annular groove of a piston is processed, a 4 mm groove cutter is used for performing rough turning firstly, then a 2mm small-sized groove cutter is used for slowly turning a groove bottom excircle through cutting for two times to eliminate chatter marks, the groove is narrowed properly under the premise that the hardness is guaranteed, so that the transverse deformation of the groove subjected to carburization and quenching is still within the common difference required; 0.4-0.5 mm allowance of the total is taken out and is subjected to completely turning firstly, then an upper grinder is assembled, so as to control the concentricity, and guarantee the overall precision; chamfers and bottom diameter dimension of the excircle required when threads are subjected to thread rolling are subjected to completely turning on a numerically controlled lathe firstly, then threads are rolled, so as to guarantee the linear type of threads while ensuring concentricity; a piston and a piston rod are assembled by a spanner, so as to guarantee that the centers of the piston and the piston rod are positioned on the same operating horizontal plane; the torque is adjusted to guarantee the torque force, and the piston and the piston rod are tightly screwed; after the piston rod assembly is completely assembled, the bending deformation during grinding is remarkably reduced when the upper grinder is subjected to overall grinding, so that the straightness and concentricity during the grinding of the integral piston rod assembly are well guaranteed.

Owner:上海沪东造船油嘴油泵有限公司

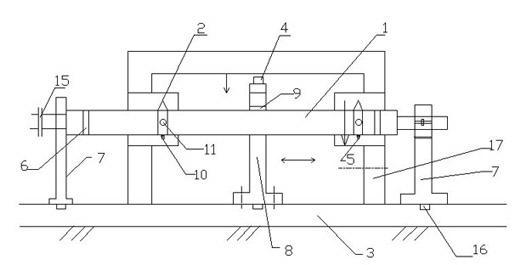

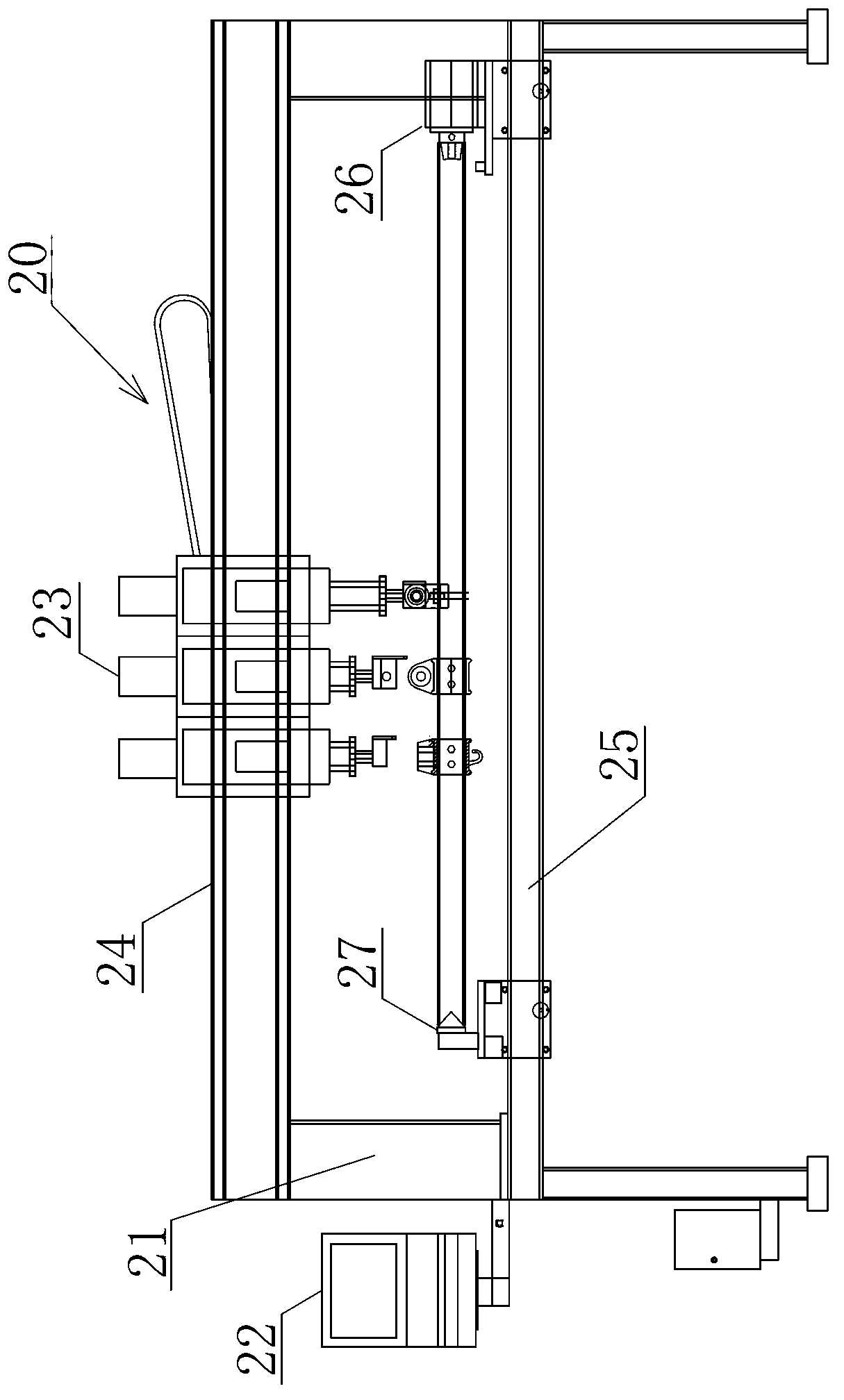

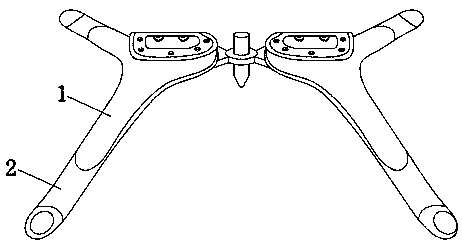

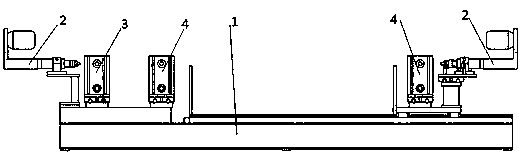

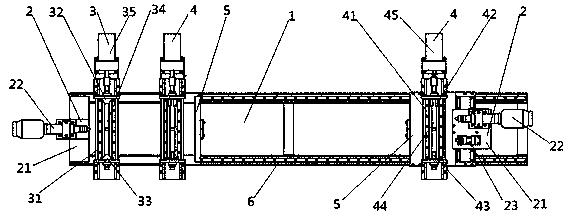

Catenary cantilever numerical control preassembly platform

ActiveCN103171456AGuarantee the construction qualityImprove quality and efficiencyTrolley linesNumerical controlEngineering

The invention discloses a catenary cantilever numerical control preassembly platform. The catenary cantilever numerical control pre-equipped platform comprises mutually independent pipe-cutting platforms and a part assembly platform. Each of the pipe-cutting platforms comprises a material discharge end main body, a cutting machine and a material feeding end main body, wherein a first linear guideway is fixed on the material discharge end main body, a first positioning device is mounted on the first linear guideway, and a pipe driving device is mounted on the material feeding end main body. The part assembly platform comprises a main body, wherein an upper linear guideway and a lower linear guideway are fixed on the main body, a second positioning device is mounted on the upper linear guideway, and a rotating device and a fixing device are mounted on the lower linear guideway. The catenary cantilever numerical control preassembly platform has the advantages of improving cantilever preassembly mechanization degree, the processing quality of a cantilever, and the production efficiency of the cantilever.

Owner:CHINA CREC RAILWAY ELECTRIFICATION BUREAU GRP +2

Cathode material used for high-energy tantalum mixed capacitor and preparation method thereof

ActiveCN101533715AEnlarging the specific volume surface area of the cathodeEnsure super capacityCapacitor electrolytes/absorbentsCapacitor electrodesHigh energyUltra fine

The invention relates to a cathode material used for a high-energy tantalum mixed capacitor and a preparation method thereof; the cathode material comprises a cathode base material made of tantalum foil; the surface of the cathode material made of tantalum foil is coated with composite material of amorphous metal oxide and ultra-fine activated carbon powder; and an electrochemical capacitor is formed between the composite cathode material coated on the surface and injected electrolyte. The amorphous metal oxide coated on the tantalum foil is composite material; the composite material comprises the following substances: pyrrolidone substance is used as a solvent, homopolymer of vinyl fluoride is used as a bonding agent and various metal oxides and ultra-fine carbon powder form the composite material. The composite material comprises the following substances by weight percentage: 56 percent to 73 percent of pyrrolidone, 5 percent to 10 percent of polymer of vinyl fluoride, 2 percent to 5 percent of ultra-fine activated carbon powder and 20 percent to 29 percent of various metal oxides.

Owner:ZHUZHOU RIWANG ELECTRONICS TECH

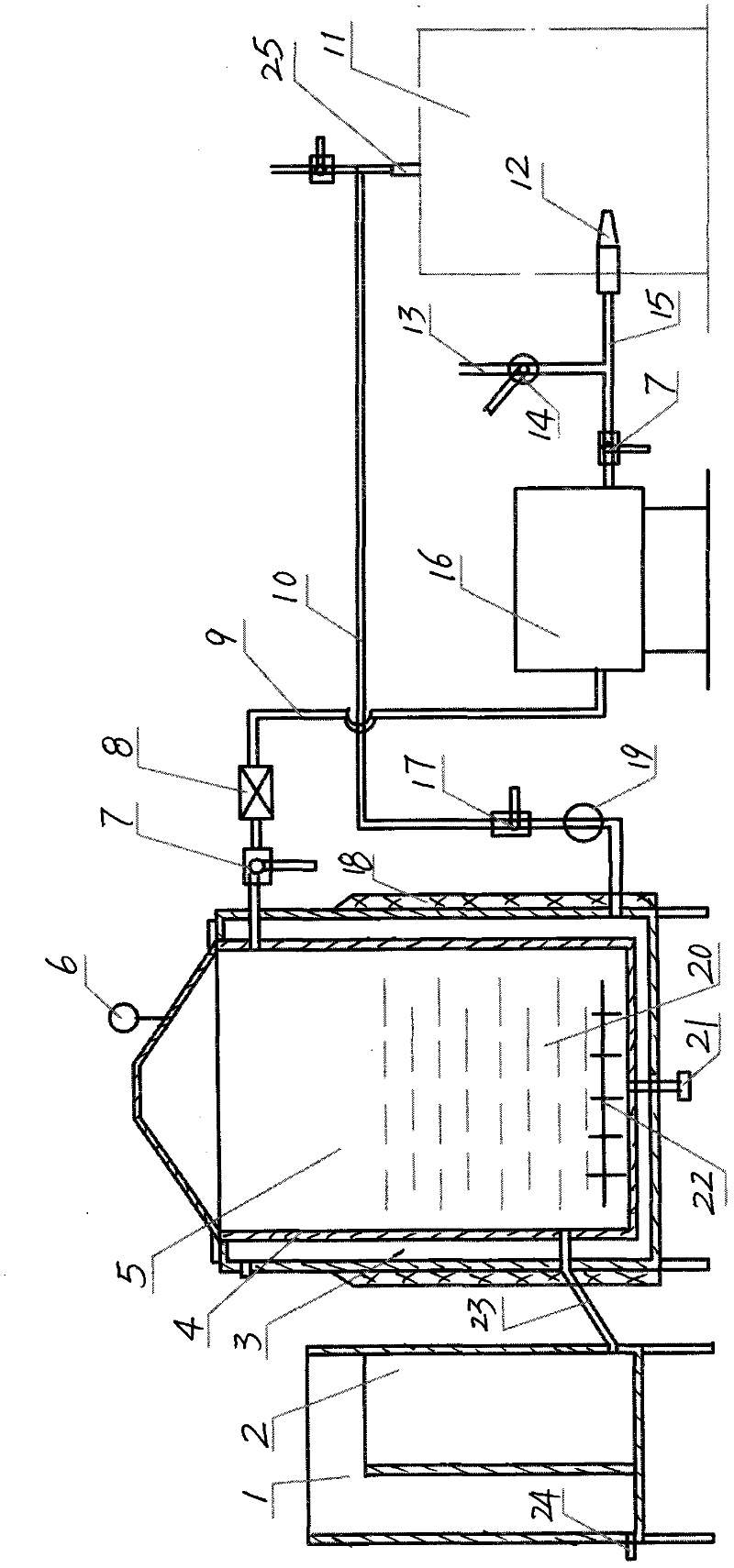

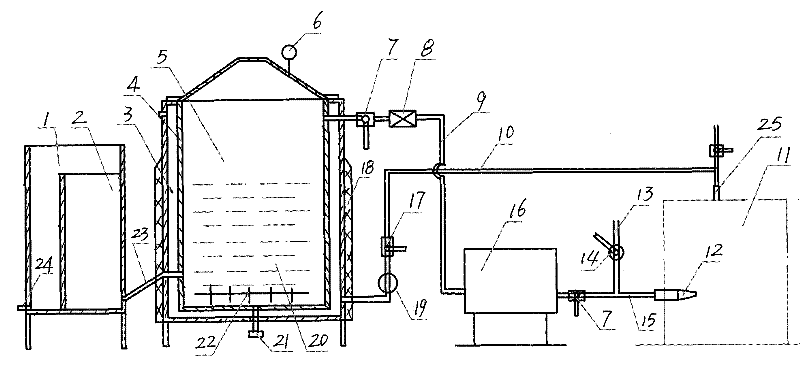

Method and device for applying methane to industrial hating furnace

InactiveCN102162000AEnsure usabilityEnsure requirementsBioreactor/fermenter combinationsBiological substance pretreatmentsAir compressionProcess engineering

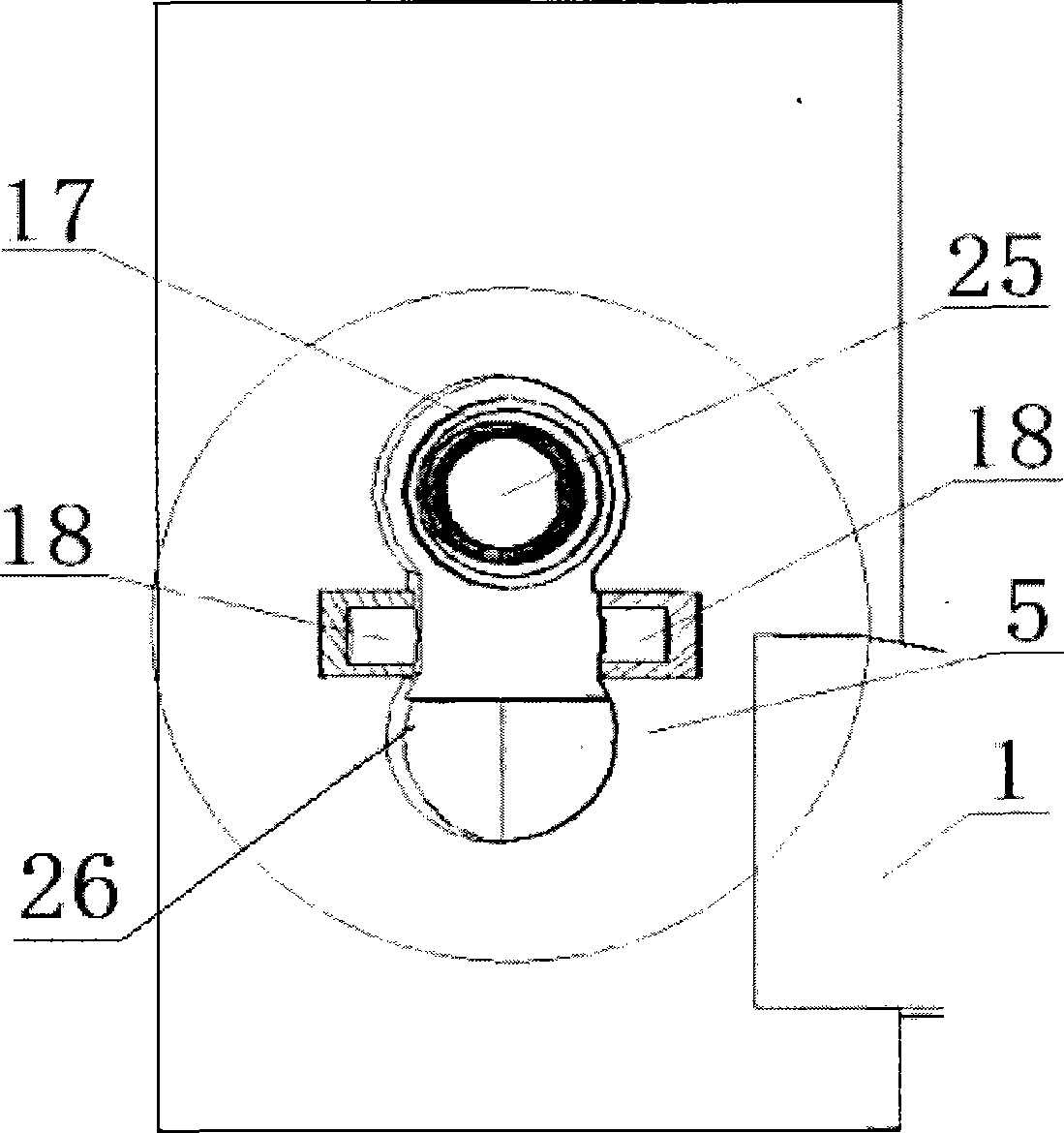

The invention discloses a method and device for applying methane to an industrial hating furnace. The device comprises a methane tank (4) and a heating chamber (3), wherein the methane tank is communicated with a bucket (2); the methane tank is connected with a methane storeroom (16) through a delivery pipe (9); the methane storeroom is connected with a flame gun (12) positioned in the industrial heating furnace through an output pipe (15); the output pipe is connected with an air compression pipe (13); and the heating chamber is connected with a hot air discharging pipe (25) in the industrial heating furnace through a hot air pipe (10). By utilizing the device, a fermentation material is filled in the methane tank firstly, the methane tank is heated to 50-80 DEG C so that the fermentation material is fermented and decomposed at high temperature to generate methane, then the methane is stored and delivered to the industrial heating furnace so as to be ignited, and then compressed air is introduced to the methane so that the methane sufficiently combusts in the industrial heating furnace after being mixed with the compressed air. By utilizing the method and device provided by the invention, the quality of the combusted product can be ensured, the gas cost can be greatly reduced, energy sources are saved, waste materials are sufficiently utilized, and the environmental pollution is reduced.

Owner:刘达苏

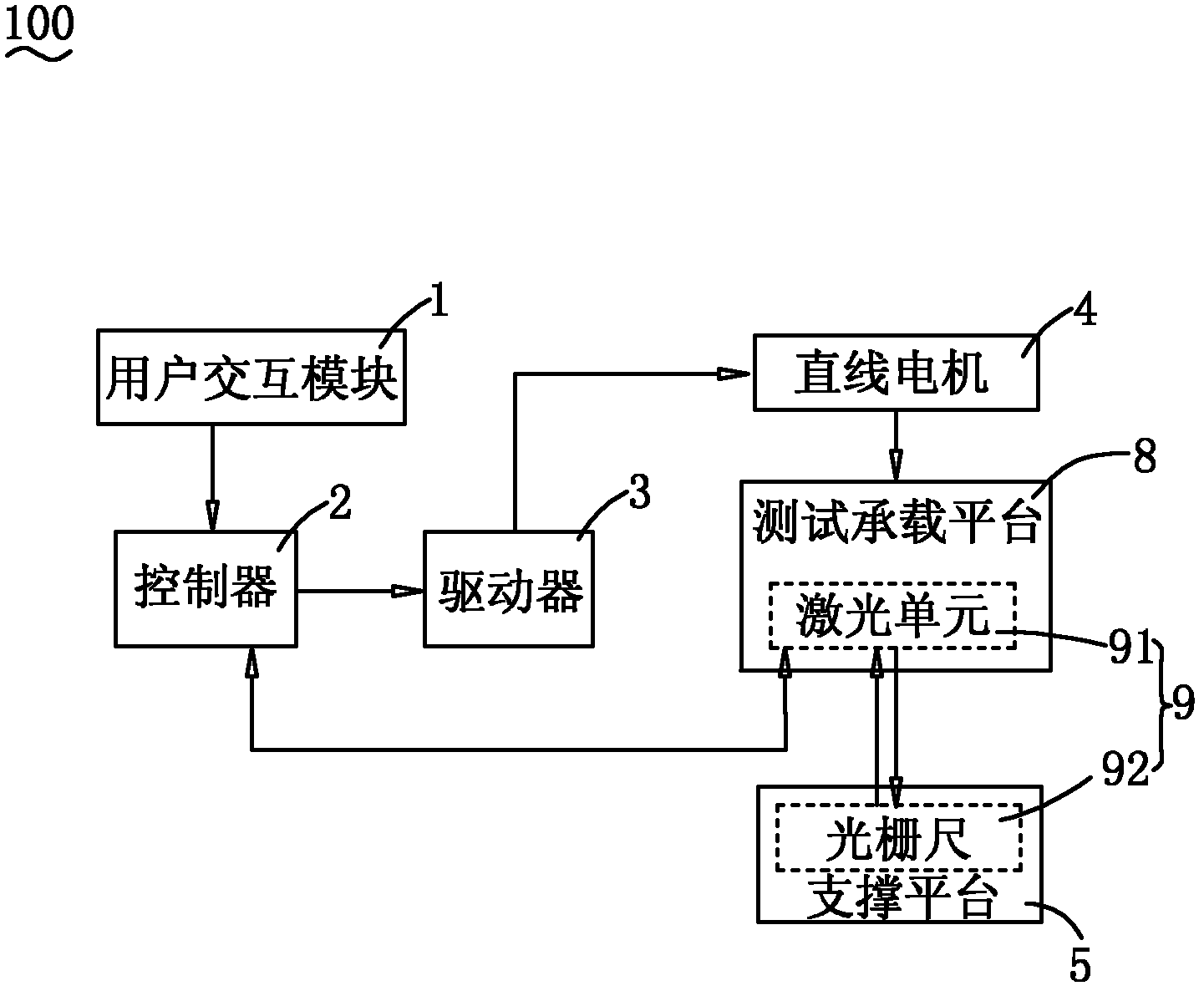

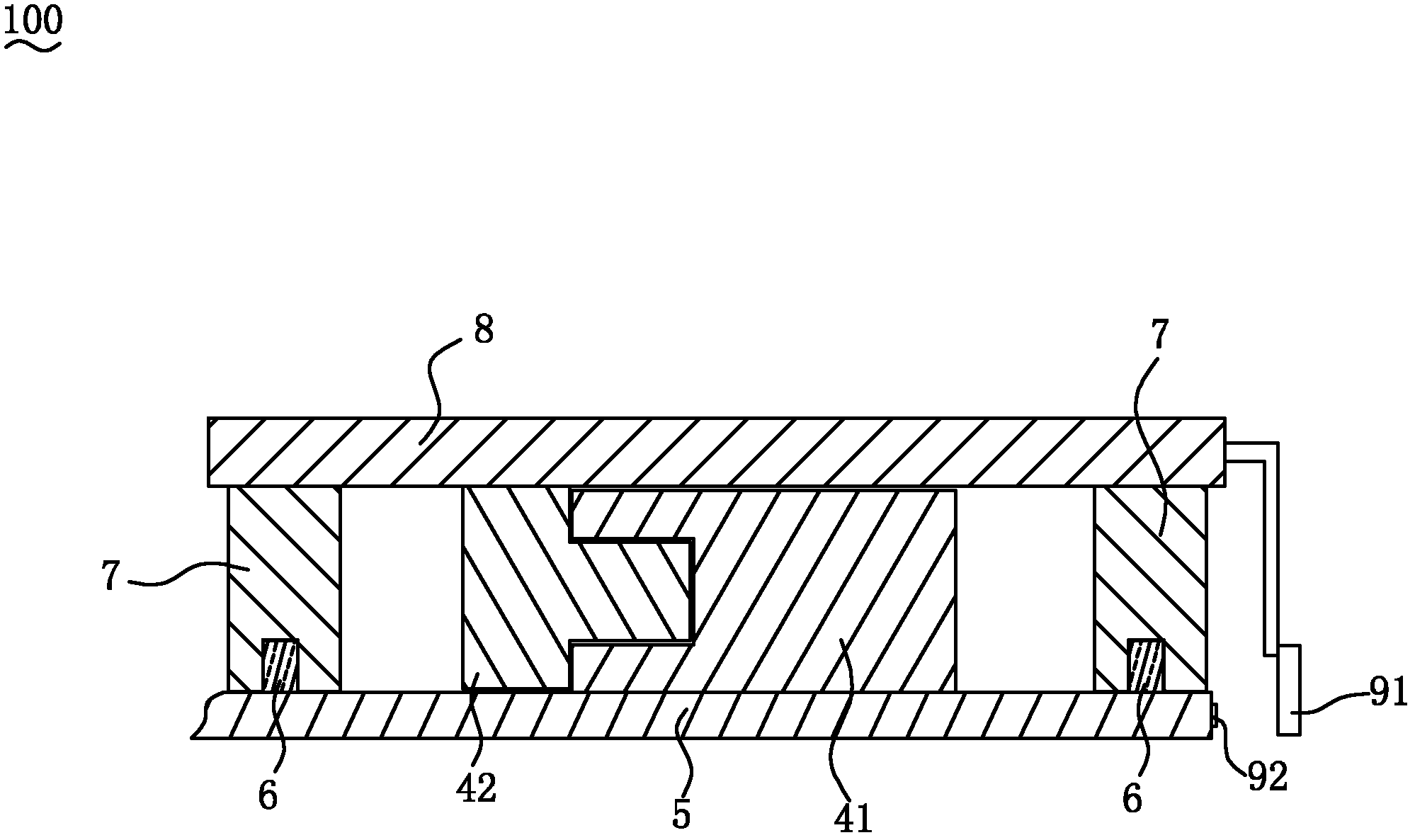

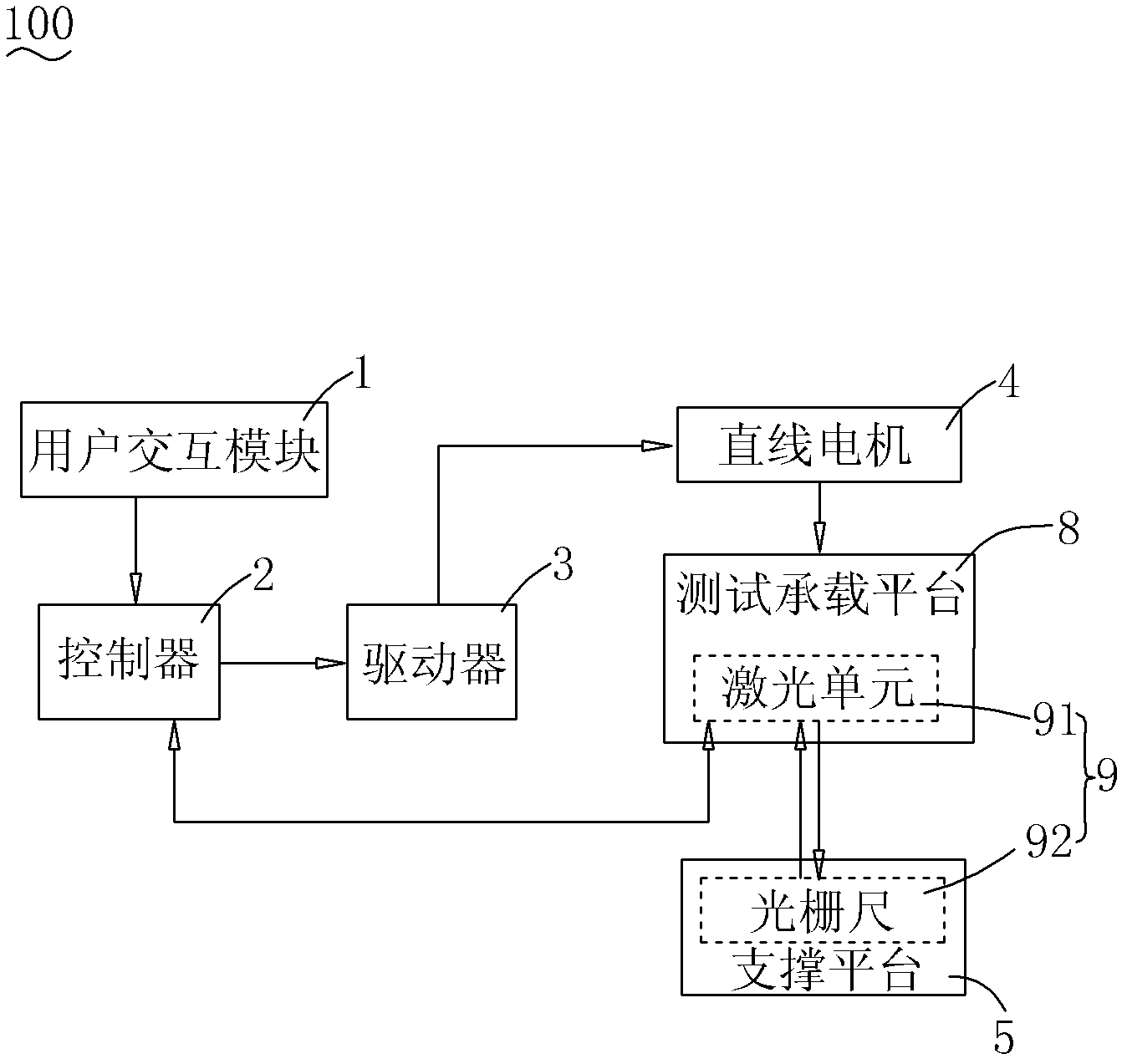

Vibration verification device based on linear motor and vibration detecting method thereof

InactiveCN102538954AEnsure accuracy andEnsure requirementsSubsonic/sonic/ultrasonic wave measurementElectric machineSimulation

The invention discloses a vibration verification device based on a linear motor and a vibration verification method thereof, which are used for verifying measurement accuracy of a low-frequency vibration monitoring instrument or a sensor. The vibration verification device based on the linear motor comprises a user interaction module, a controller, a driver, the linear motor, a support platform, two long stroke fixed rails, two moving guide rails, a test load bearing platform and a grating scale coder. The vibration verification device based on the linear motor can perform vibration verification on a tested vibration monitoring instrument or the sensor by means of joint matching of the linear motor, a laser head and a grating scale. Besides, the vibration verification device based on the linear motor not only can perform verification in a low vibration frequency range, but also can meet the test requirements of vibration tests for high accuracy and long stroke.

Owner:CHENGDU FORWARD TECH

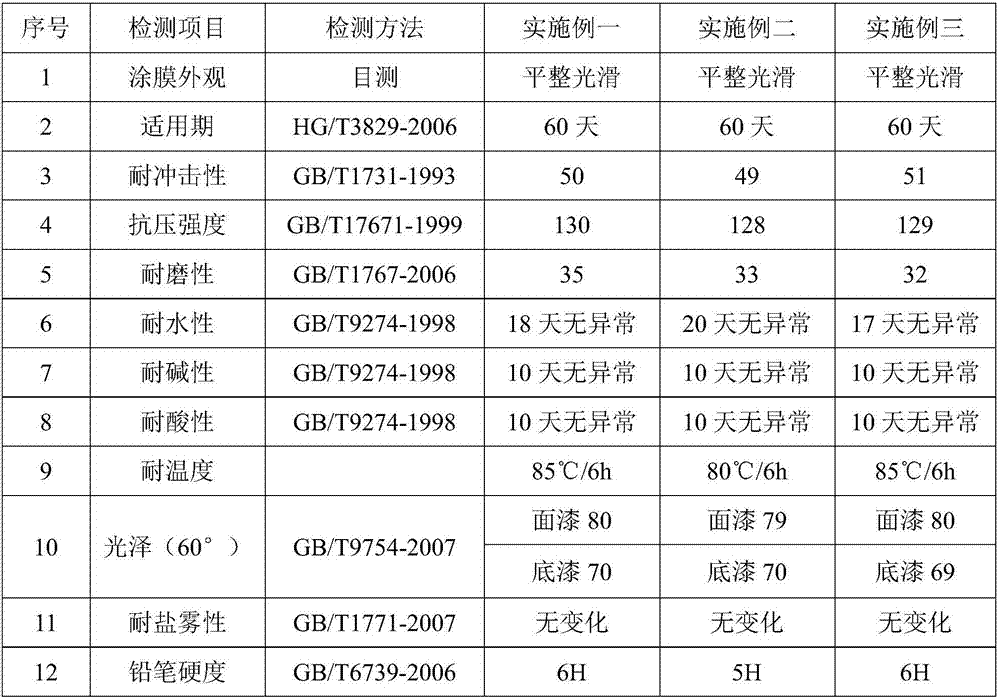

Waterborne bicomponent epoxy iron red shop primer and preparation method thereof

InactiveCN107974166APoisonousFlame retardant and explosion-proofEpoxy resin coatingsPriming paintsEpoxyNano al2o3

The invention discloses waterborne bicomponent epoxy iron red shop primer and a preparation method thereof, and relates to a coating composition. The waterborne bicomponent epoxy iron red shop primerprovided by the invention comprises a component A and a component B, wherein the component A is prepared from waterborne epoxy resin, an iron red pigment, nano alumina, a dispersant, a filling material, a waterborne antifoaming agent, a waterborne preservative, negative ion distilled water and a waterborne amine curing agent; the component B is prepared from a waterborne epoxy resin emulsion, a waterborne antifoaming agent, a waterborne wetting and flatting agent, a waterborne preservative, a water-soluble active thinner and water. The component A and the component B adopted by the waterbornebicomponent epoxy iron red shop primer provided by the invention are both waterborne products, and are easily mixed; a sufficient curing purpose can be achieved. The waterborne bicomponent epoxy ironred shop primer has higher impact resistance, cannot generate foaming and stripping phenomena, meanwhile, has advantages of nontoxicity, flame retarding effect, explosion-proof effect, long application period, high hardness of film and high toughness, has uniform color and cluster, and can be used for meeting requirements of safety and environmental protection.

Owner:YIXING JUREN PAINT

Water resistance aramid fiber yarn and method for producing the same

InactiveCN1737232ASimple structureThe manufacturing process remains unchangedFibre treatmentFibre mechanical structuresYarnPotassium peroxodisulfate

This invention relates to a water-proof aramid fiber yarn, which comprises ionic hydration, caustic soda, acroleic acid, aramid fiber yarn, acrylamide, potassium peroxodisulfate, and alcohol in a certain ratio; the manufacturing method comprises the following steps: a) mixing caustic soda and hydration to prepare caustic soda water solution; b) adding acroleic acid; c) adding acrylamide; d) adding potassium peroxodisulfate and mixing; e) adding alcohol and mixing to generate polyaromatics organic solvent; f) adding aramid fiber yarn to soak, drying and generating to molecular crystal. Said invention can be used in non-metal ADSS optical cable, indoor flexible-cable, which can prevent water.

Owner:罗雄

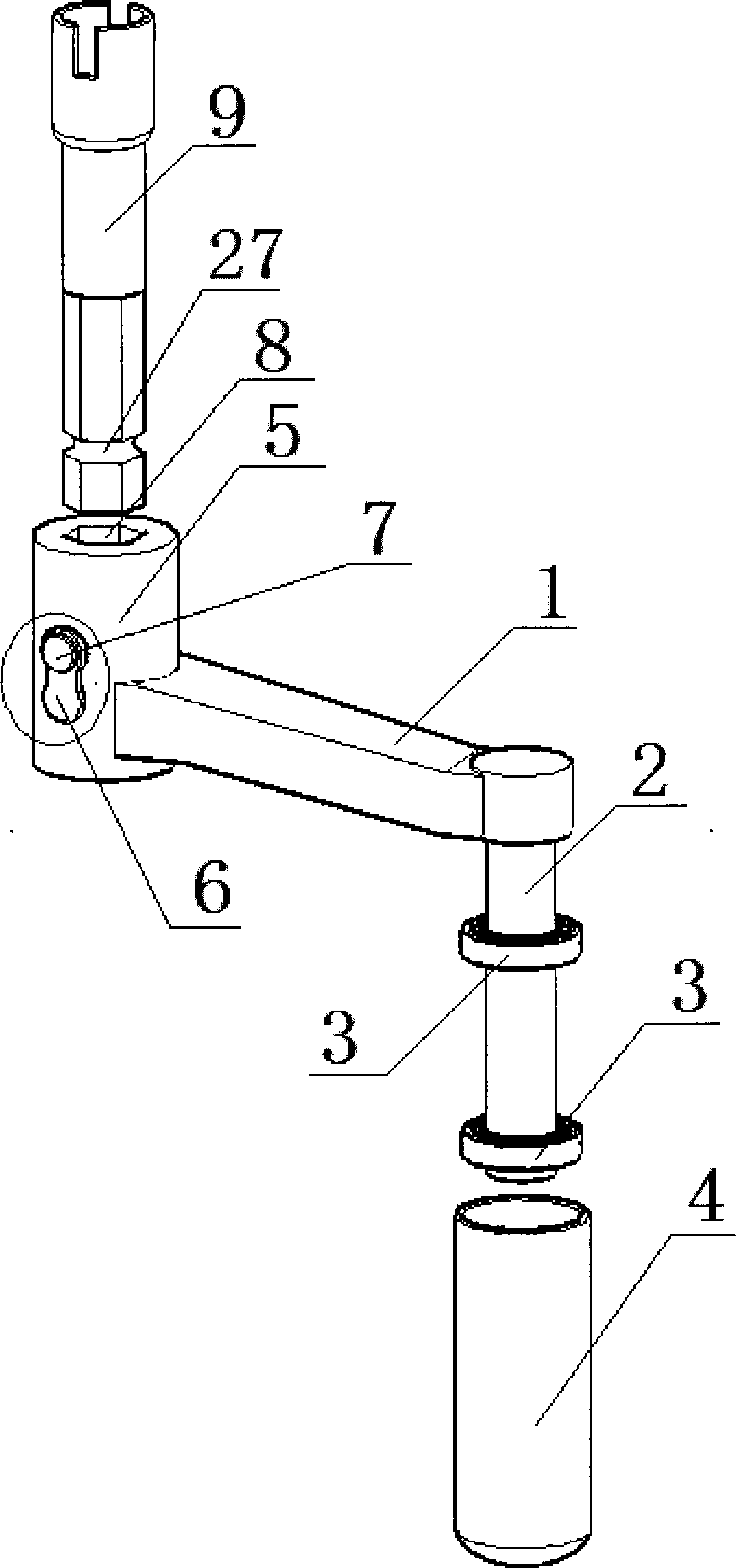

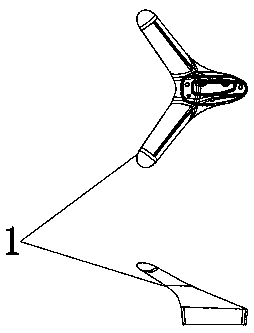

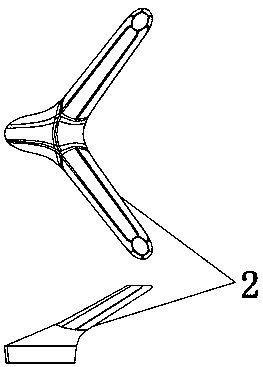

Special combined jiggle bar for transformer substation

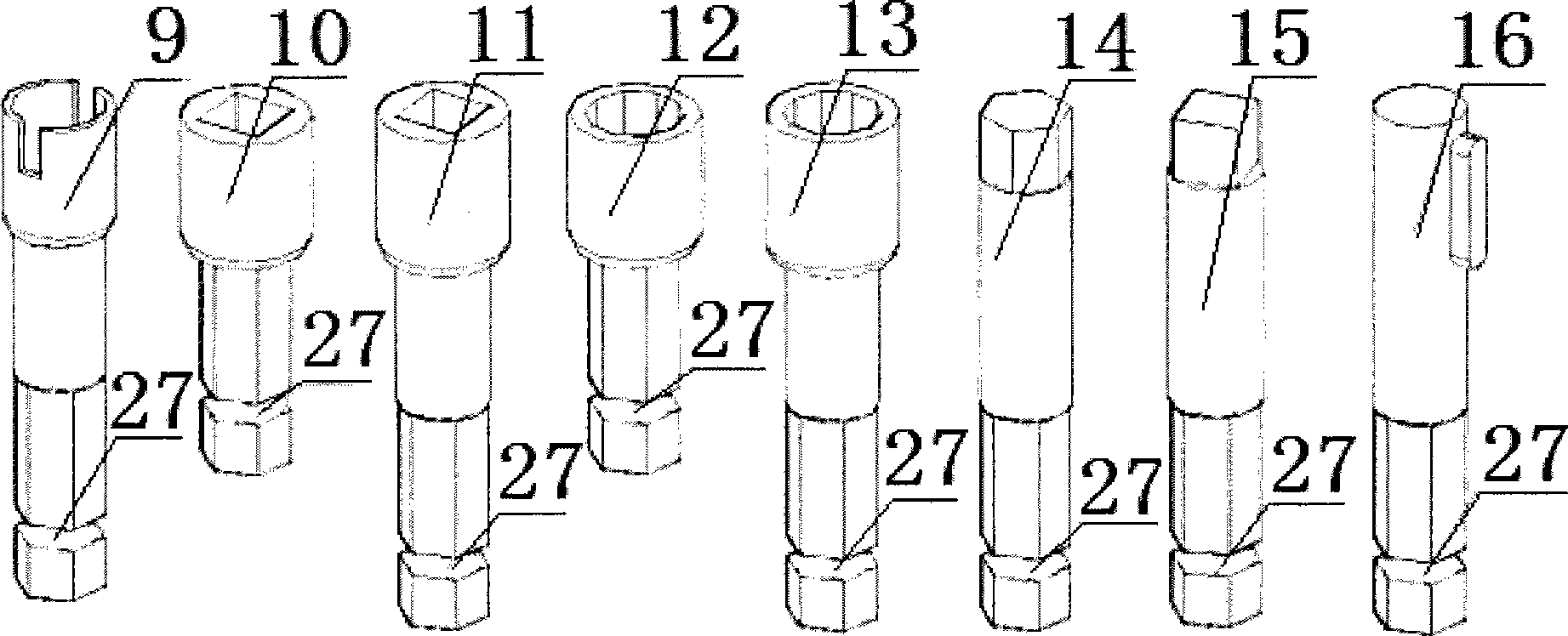

InactiveCN103457194AFunctionalSimple structureSwitchgear with withdrawable carriageContact operating partsTransformerEngineering

The invention provides a special combined jiggle bar for a transformer substation. The special combined jiggle bar comprises a bar arm, a bar shaft, a bearing, a bar movable sleeve, a rocker sleeve, a locating device, a button, a rocker fixing hole, an I-type rocker, an II-type rocker, an III-type rocker, an IV-type rocker, a V-type rocker, a VI-type rocker, a VII-type rocker, a VIII-type rocker, locating grooves, a reset spring, a fixing hole, a fixing pin mounting hole, a fixing pin, a fixing spring, a fixing sleeve, a locating protrusion, a spring seat, and a locating device mounting hole. The bar arm, the bar shaft and the rocker sleeve are integrated, the bearing is mounted on the bar shaft, the bar movable sleeve is mounted on the bearing, the locating device is mounted in the locating device mounting hole, all rockers are provided with the locating grooves, and all rockers can be mounted in the rocker fixing hole and fixedly connected with the locating protrusion. Compared with the prior art, the special combined jiggle bar for the transformer substation has the advantage of being strong in function, simple in structure, flexible in operation, safe, reliable, simple in use, convenient to carry and the like.

Owner:陈志源

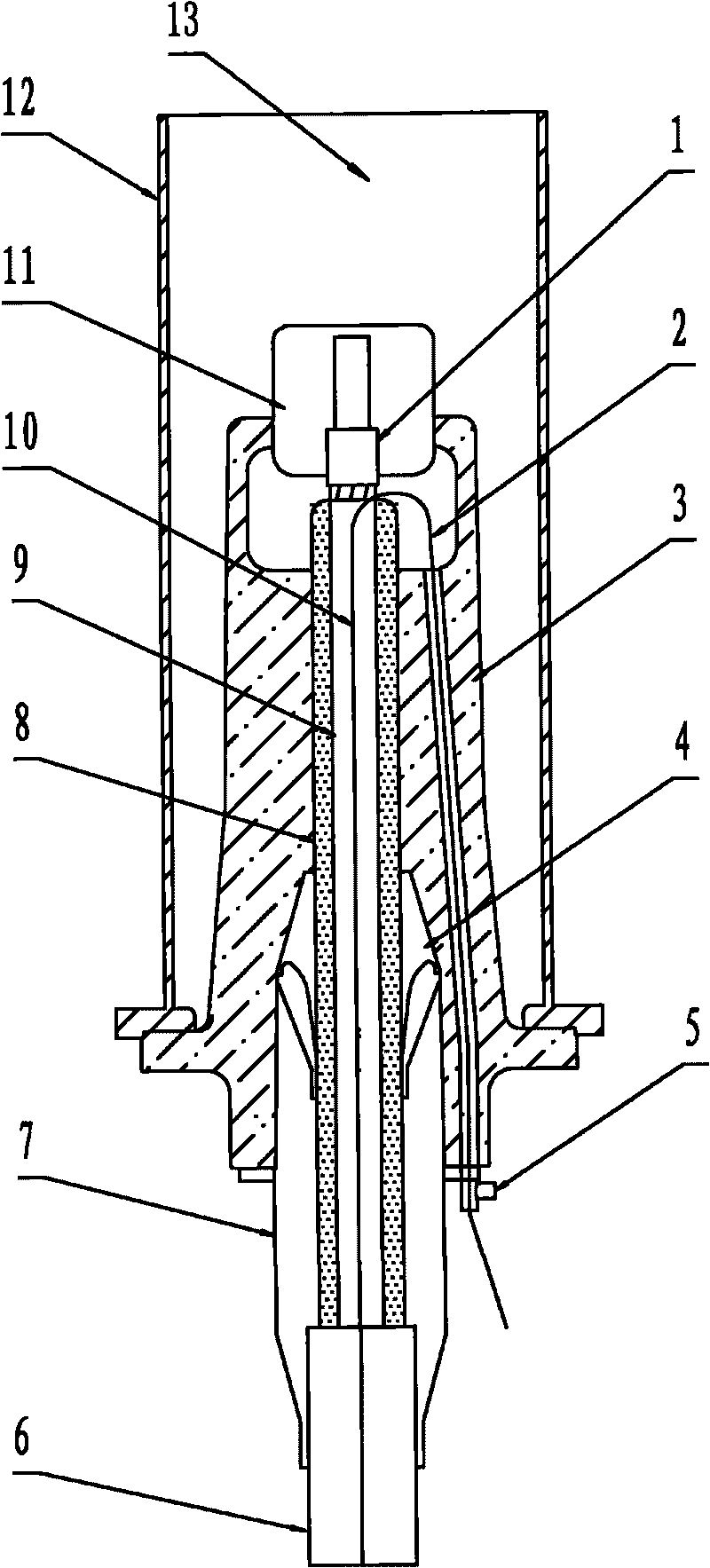

Application of composite power cable GIS terminal with optical fiber arranged in center of conductor

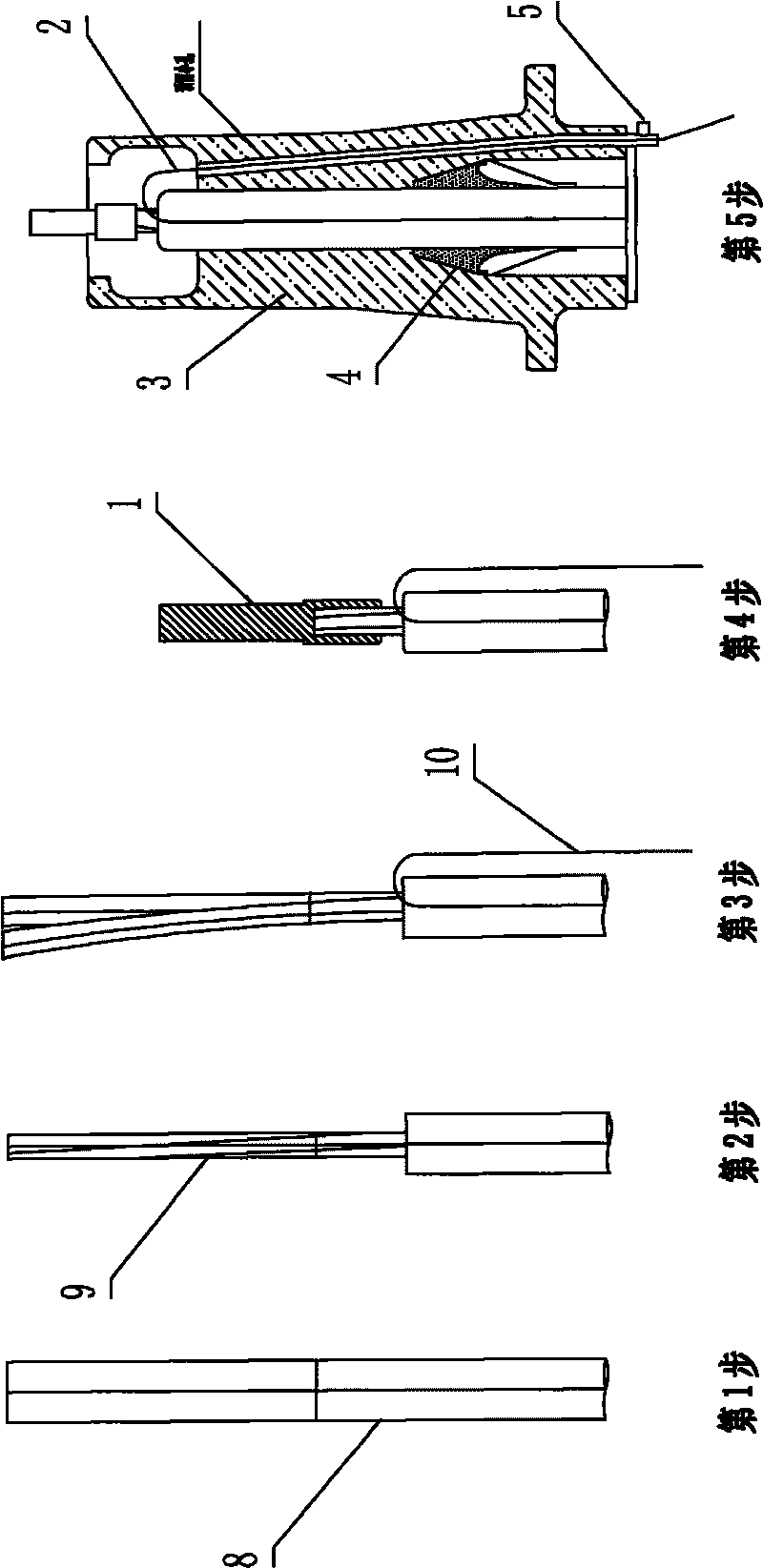

InactiveCN101719652AEasy to operateSolving Machining ComplexityCoupling light guidesCable fittings in presence of gas/oilElectrical conductorSteel jacket

The invention relates to an application of a composite power cable GIS terminal with an optical fiber arranged in the center of a conductor. The application comprises the following operation steps of: setting the reserved length of a cable, exposing the core of the cable, splitting a round cable split conductor and leading out the optical fiber with a stainless steel jacket from a gap between two fan-shaped conductor units; after cutting off a part of the round cable split conductor, crimping the optical fiber with a cable conductor lead-out bar; sleeving a corresponding terminal component and penetrating the led-out bare optical fiber into a small reserved hole of an insulating sleeve; leading the optical fiber out of a terminal from a lower reserved sealing armour clamp hole and then sealing the reserved hole; and finally, carrying out other mounting works of the terminal. The invention solves the problems that the traditional temperature measuring optical fiber cannot monitor the operation temperature of the terminal, binding posts of the traditional cable terminals are complicated to process and troublesome to operate, and the like; in addition, the invention has simple and convenient process and easy operation, meets the automatic monitoring requirements on on-line real-time temperature detection, aging monitoring, real-time fault monitoring and early warning of the safe operation of a power cable line, obviously improves the reliability and the efficiency of construction works and reduces the construction cost.

Owner:SHENYANG FURUKAWA CABLE

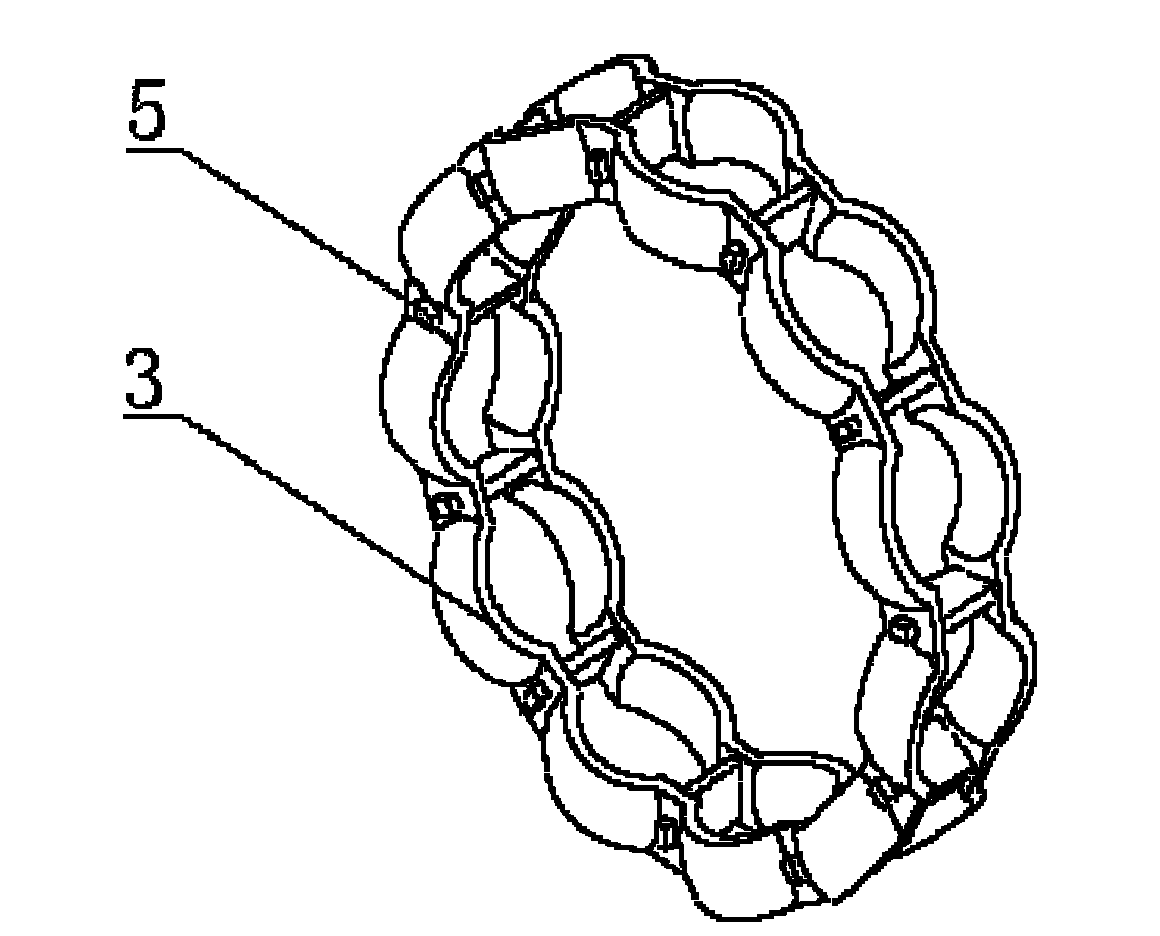

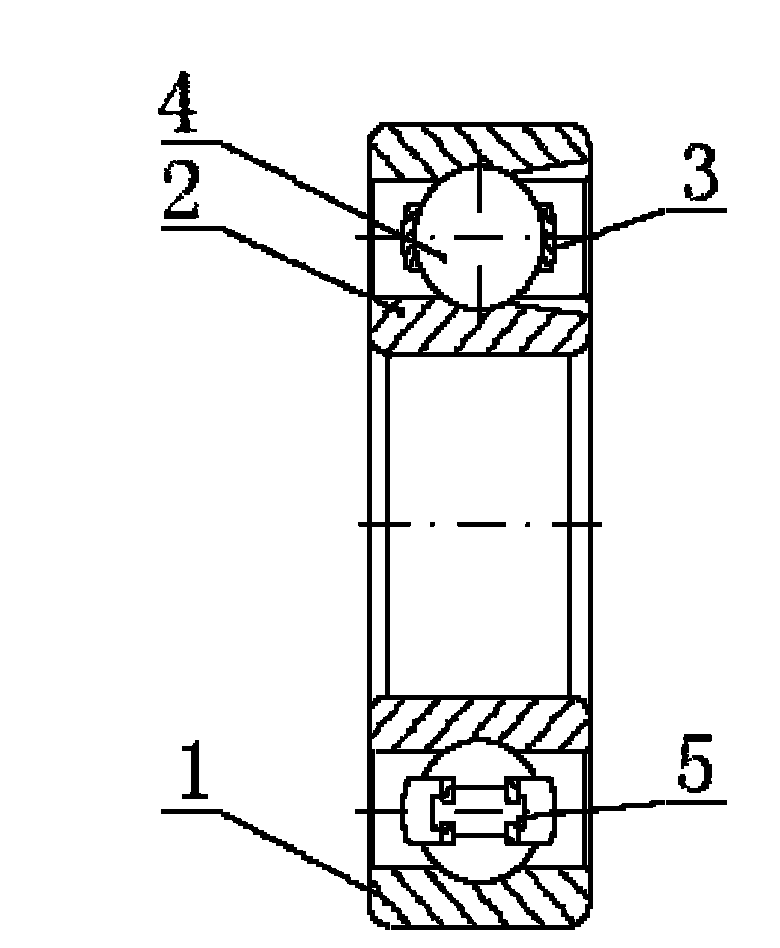

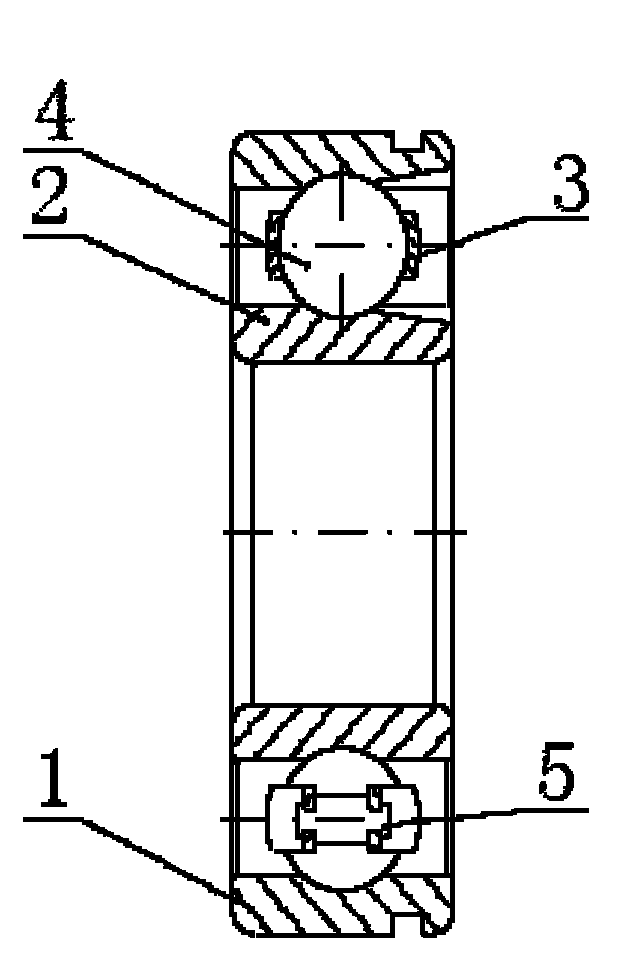

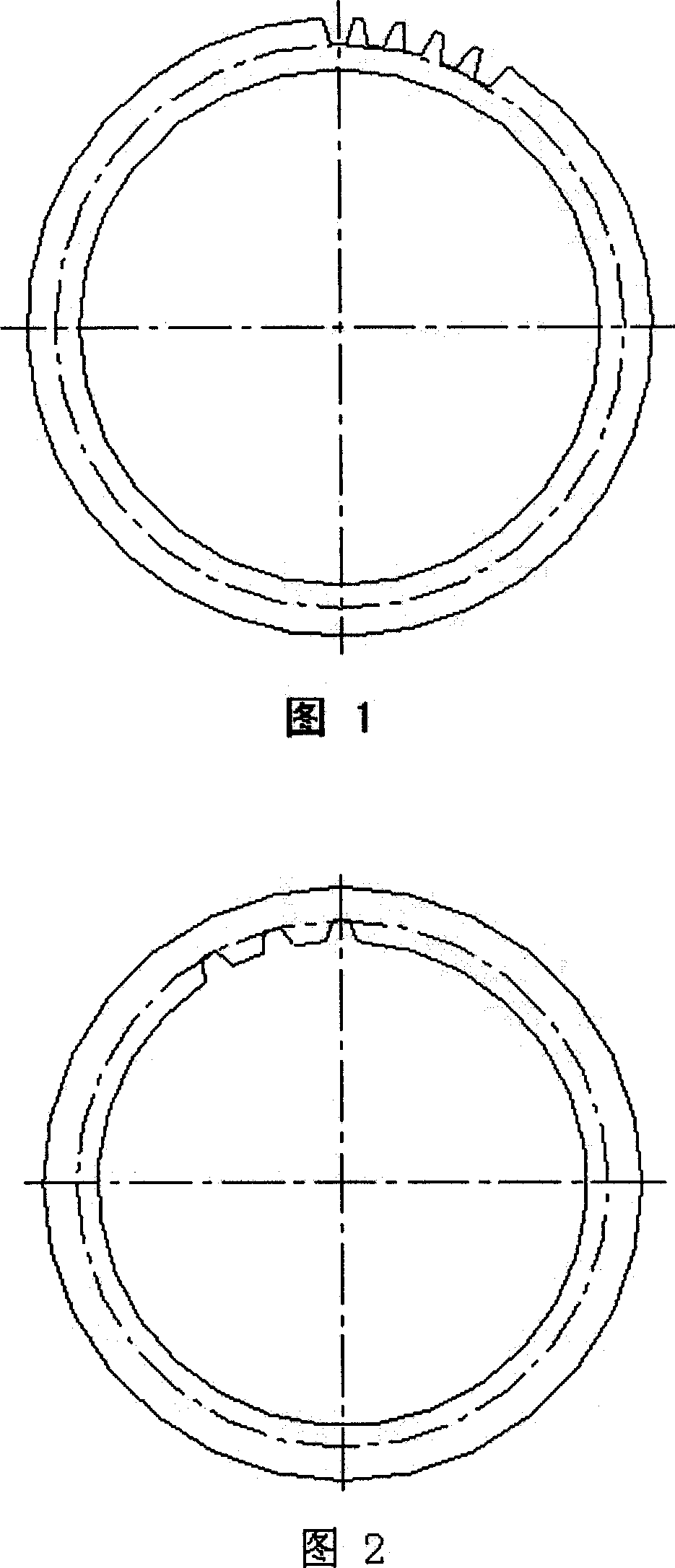

Enhanced heavy-duty deep groove ball bearing

InactiveCN102080686AIncrease the number ofIncrease the rated loadBall bearingsBearing componentsInterior spaceBall bearing

The invention provides an enhanced heavy-duty deep groove ball bearing. The bearing comprises an outer ring, an inner ring, rolling bodies and retainers, wherein the rolling bodies are arranged in a spherical pocket hole formed by two retainers; the inner ring and the outer ring are respectively arranged on the inner and outer sides of an annular body formed by the rolling bodies and the retainers; and a roller way of the inner ring and a roller way of the outer ring are respectively contacted with the rolling bodies. Platy rivets are adopted, and the two ribbon retainers are not directly contacted during riveting, so that inner space is increased; the enhanced heavy-duty deep groove ball bearing is provided with two to three more rolling bodies than the conventional deep groove ball bearing, and the diameter of the rolling bodies is one to two times larger than that of the rolling bodies of the conventional deep groove ball bearing, so that the bearing capacity of the bearing is 20 to 30 percent higher than that of the deep groove ball bearing of the same overall dimension, and the rated load of the bearing is equivalent to that of a cylindrical roller bearing of the same overall dimension; meanwhile, the limit rotating speed of the bearing is improved, and the rotating speed of the series bearing is 20 to 30 percent higher than that of the cylindrical roller bearing.

Owner:HARBIN BEARING GROUP CORP

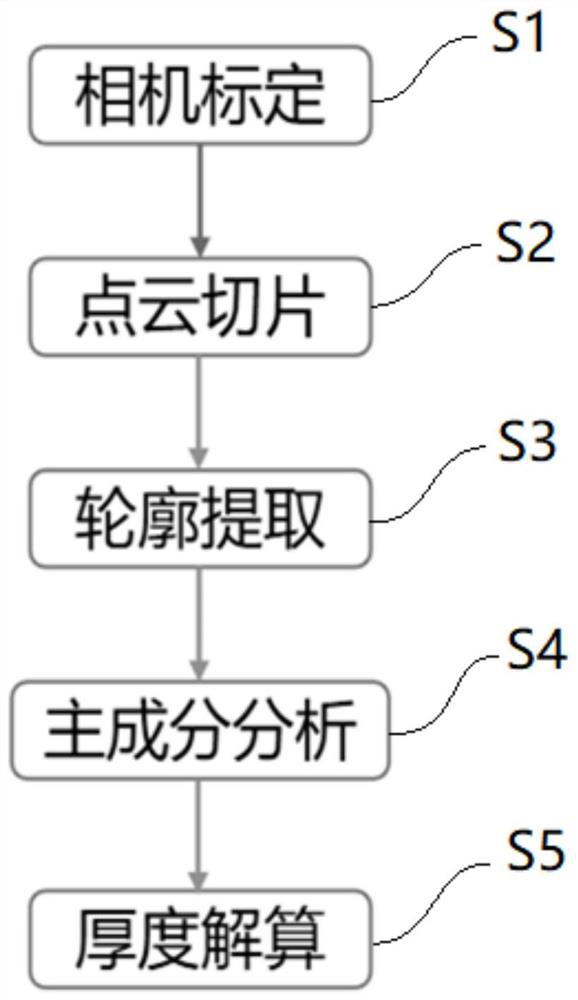

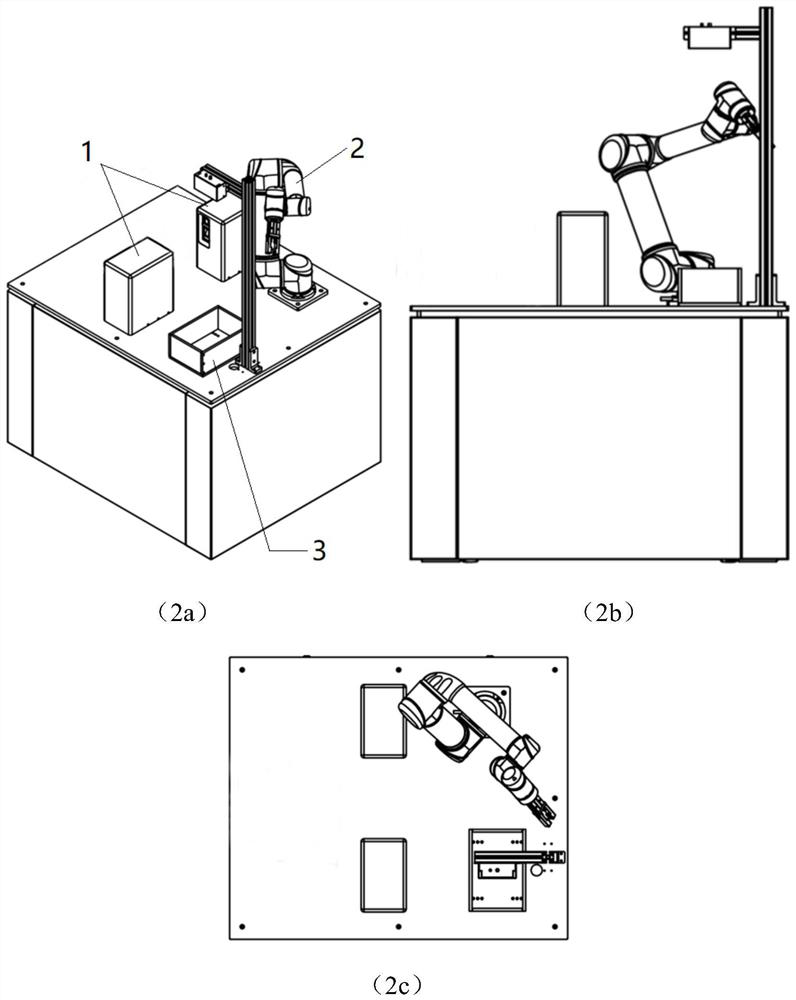

Aviation blade surface measurement method based on structured light cameras and measurement equipment

ActiveCN112964172AQuick measurementAccurate measurementImage enhancementImage analysisAviationPoint cloud

The invention relates to an aviation blade surface measuring method based on structured light cameras and measurement equipment. The method comprises the following steps of: collecting point cloud data of two surfaces of an aviation blade through two oppositely arranged structured light cameras, and forming a three-dimensional blade point cloud; slicing the blade point cloud in the axial direction, so as to obtain section point cloud, and the axial direction being the normal vector direction of a blade section; carrying out dimension reduction on the section point cloud to a two-dimensional space; performing contour extraction on the section point cloud in the two-dimensional space to form a blade section polygon; and obtaining the maximum inscribed circle radius of the polygon of the blade section through an iterative search method, thereby obtaining the thickness of the blade. Compared with the prior art, the method improves measurement efficiency of the aviation blade while ensuring the measurement precision.

Owner:聚时科技(上海)有限公司

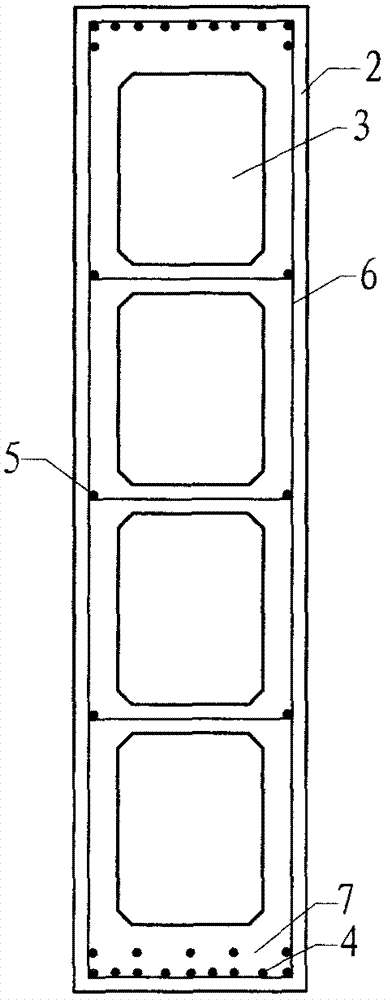

Precast reinforced concrete hollow lateral-force resisting pile and pile embedding method

InactiveCN102828504AIncrease stiffnessStrong bending and shear resistanceBulkheads/pilesReinforced concretePre stress

The invention discloses a precast reinforced concrete hollow lateral-force resisting pile comprising a pile body with a rectangular cross section; the pile body comprises a reinforcement cage; the pile body is provided with a hollow area along a vertical axis direction of the pile body, wherein the hollow area runs through the whole pile body; the reinforcement cage comprises a plurality of pre-stressed main reinforcements, a web reinforcement and a reinforcement stirrup; both ends of the long side of the rectangular section of the pile body are thickened areas in which the pre-stressed main reinforcements are arranged. The precast reinforced concrete hollow lateral-force resisting pile has the following beneficial effects: the bending resistance effective height of the long side of the rectangular section is increased by the reasonable arrangement of the hollow area; meanwhile, the concrete thickened areas are arranged at both ends of the long side of the rectangular section, the high-strength pre-stress reinforcements are arranged, and the overall bending shear resistance of the pile body is greatly enhanced, so that an enclosure pile wall has great bending shear resistance, and the demands of deep-pit enclosure works are met; and the pile embedding method of the precast reinforced concrete hollow lateral-force resisting pile has the following advantages of convenience in construction, simplicity, fastness, and the like, and meanwhile, the construction efficiency is increased.

Owner:HANGZHOU NANLIAN BASE FOUND ENG +1

Clutch friction plate steel back-steel friction plate working method

InactiveCN1935449AEasy to suckEnsure flatnessOther manufacturing equipments/toolsMetal working apparatusEngineeringMachining

The present invention discloses a machining method of clutch friction disk steel back and steel friction disk. Said machining method includes the following steps: 1, firstly, rough machining internal circumferential surface and external circumferential surface, remaining allowance; 2, heat treatment; 3, kemoving scale; 4, rough grinding two planes and demagnetizing; 5, thermal leveling and eliminating stress; 6, grinding two planes; 7, fine turning internal circumferential surface and external circumferential surface; and 8, machining inner teeth and outer teeth.

Owner:贵州凯星液力传动机械有限公司

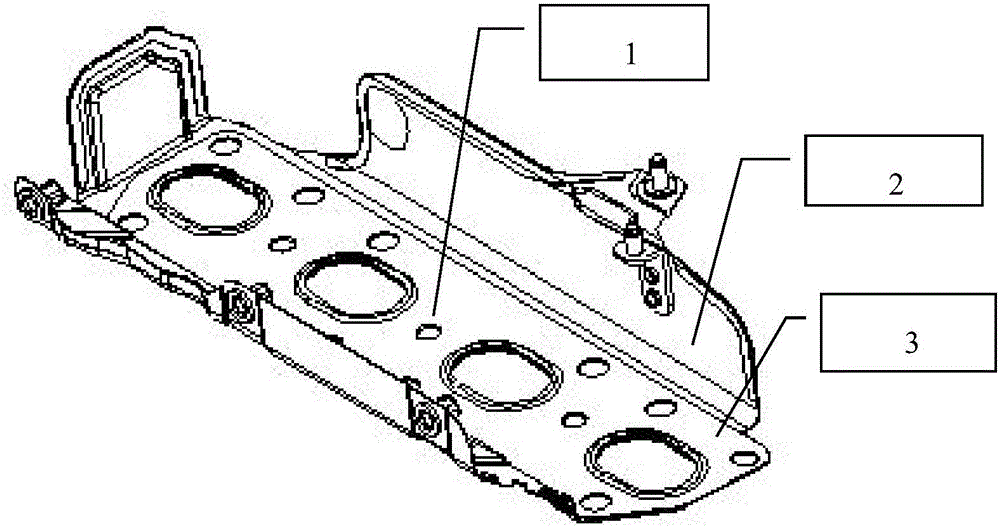

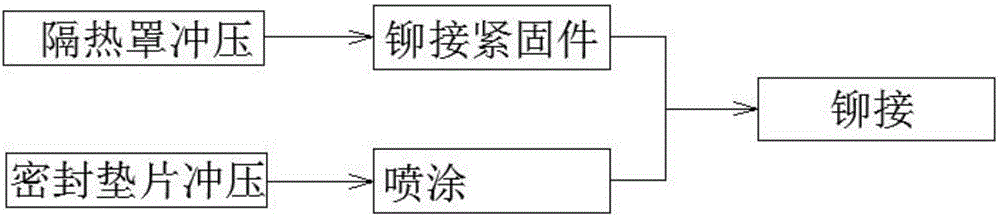

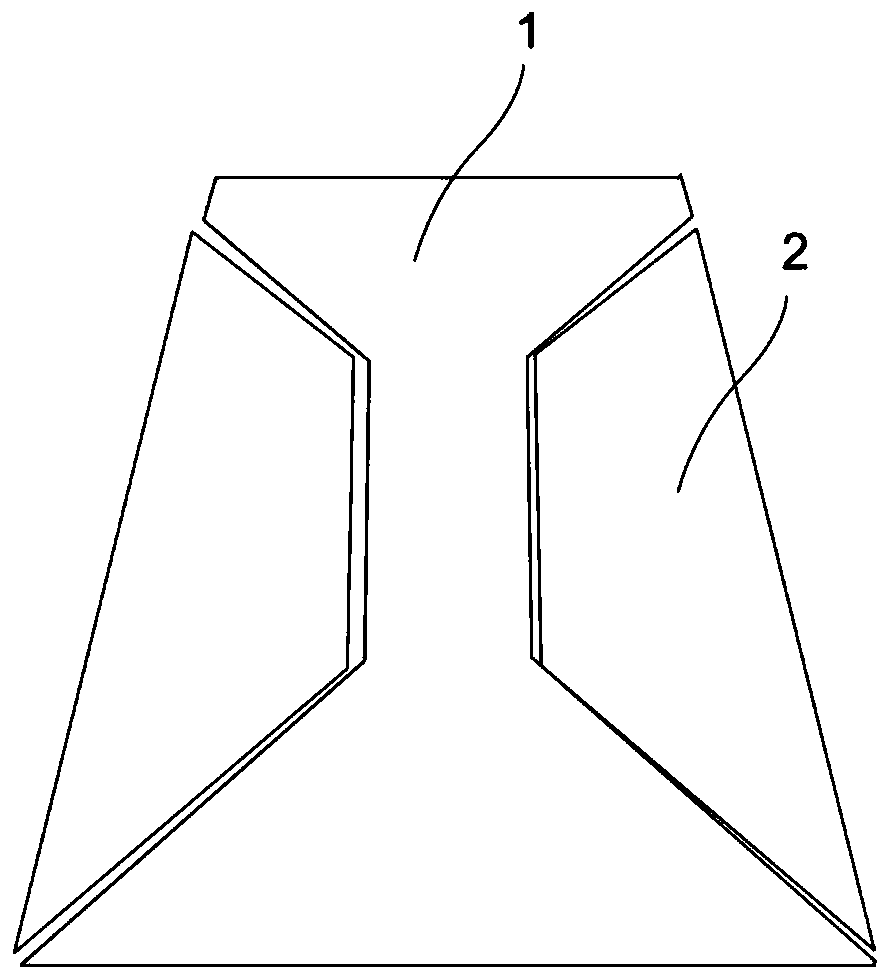

Exhaust manifold gasket heat shield assembly and supercharger gasket heat shield assembly

InactiveCN106321211AReduce volumeEnsure compactnessExhaust apparatusSealing arrangements for enginesEngineeringHeat shield

The invention discloses an exhaust manifold gasket heat shield assembly and a supercharger gasket heat shield assembly. The exhaust manifold gasket heat shield assembly and the supercharger gasket heat shield assembly comprises riveting holes, heat shields and sealing gaskets. The sealing gaskets are arranged at the tops of the heat shields, the heat shields and the sealing gaskets are provided with the riveting holes, the heat shields are of an integrated structure formed by stamping, and the heat shields are fixedly connected with the sealing gaskets in a riveting mode. According to the exhaust manifold gasket heat shield assembly and the supercharger gasket heat shield assembly, by integration of the heat shields and the sealing gaskets, two product functions are achieved on one assembly; the integrated supercharger gasket heat shield assembly / exhaust manifold gasket heat shield assembly improves integration, assembly space can be saved, the assembly process is simplified, part sizes are reduced, the requirements of compactness and efficiency of an engine are guaranteed, and the integral installation and maintenance cost are reduced through modularized installation.

Owner:DONGFENG SHIYAN GASKETS

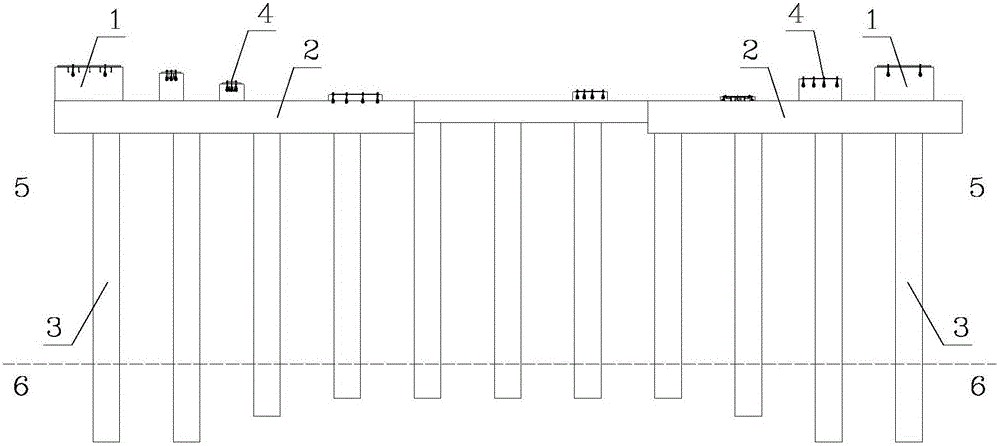

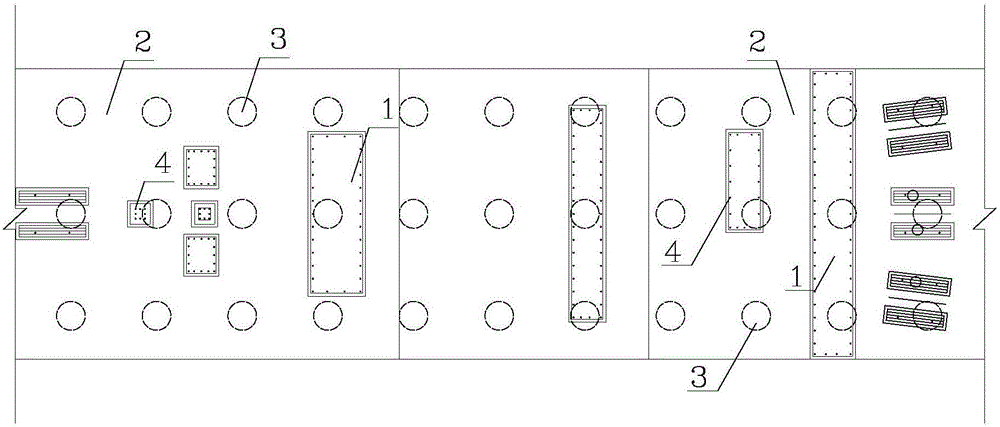

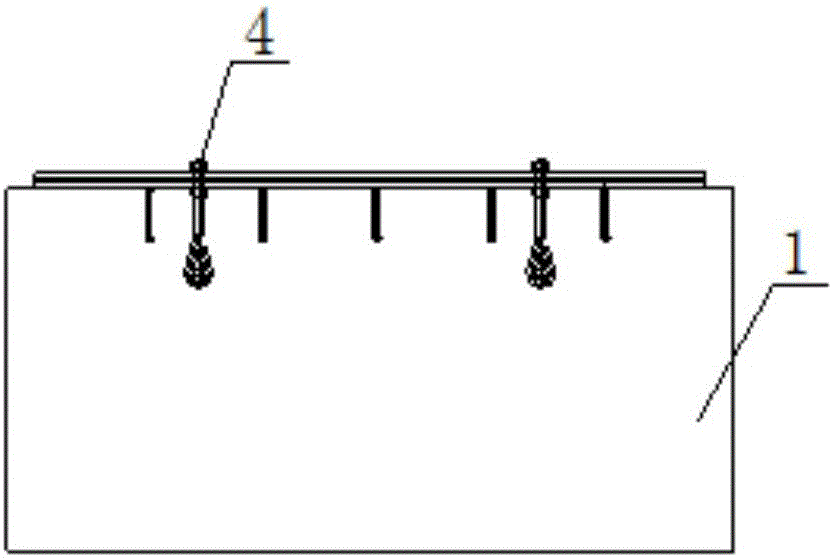

Rib column distributed turnout foundation structure of middle-low speed magnetic levitation low-arranged line

ActiveCN105951537AMeet strength requirementsMeet stability requirementsRailway tracksFoundation engineeringLow speedReinforced concrete

The invention discloses a rib column distributed turnout foundation structure for a middle-low speed magnetic levitation low-arranged line. The rib column distributed turnout foundation structure for the middle-low speed magnetic levitation low-arranged line comprises turnout zone foundation treatment reinforced concrete rafts, reinforced concrete turnout beam bar-type rib column foundations, reinforced concrete cast-in place piles, steel plates and embedded bolts. The turnout zone foundation treatment reinforced concrete rafts are arranged horizontally, and the multiple reinforced concrete cast-in place piles are arranged at the bottom end faces of the turnout zone foundation treatment reinforced concrete rafts; the reinforced concrete cast-in place piles penetrate a soft stratum to extend into a bearing stratum, to decrease the deformation of turnout beams in the rotation process. The rib column distributed turnout foundation structure for the middle-low speed magnetic levitation low-arranged line ensures that the turnout beams are not deformed greatly in the rotation process due to inadequate foundation stiffness, and meets the requirements for foundation strength and stability by the turnout beams.

Owner:CHINA RAILWAY SIYUAN SURVEY & DESIGN GRP

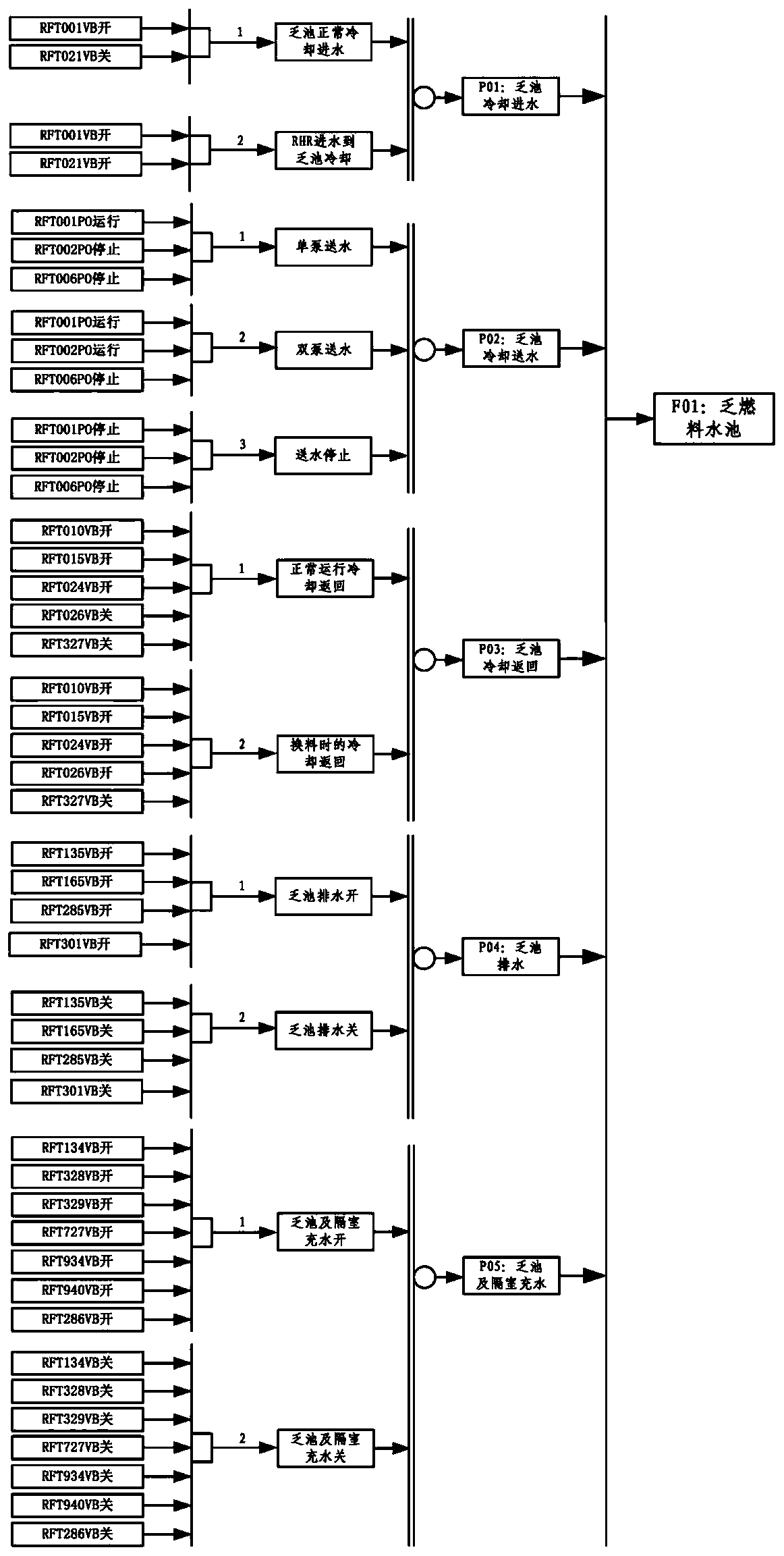

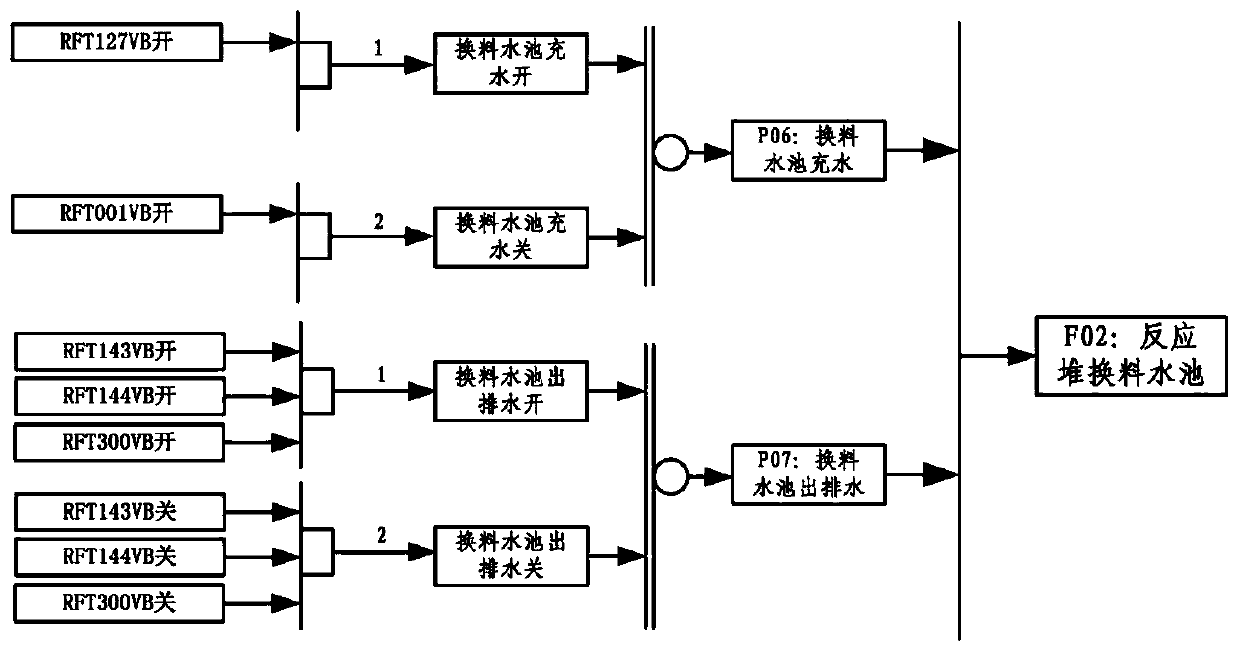

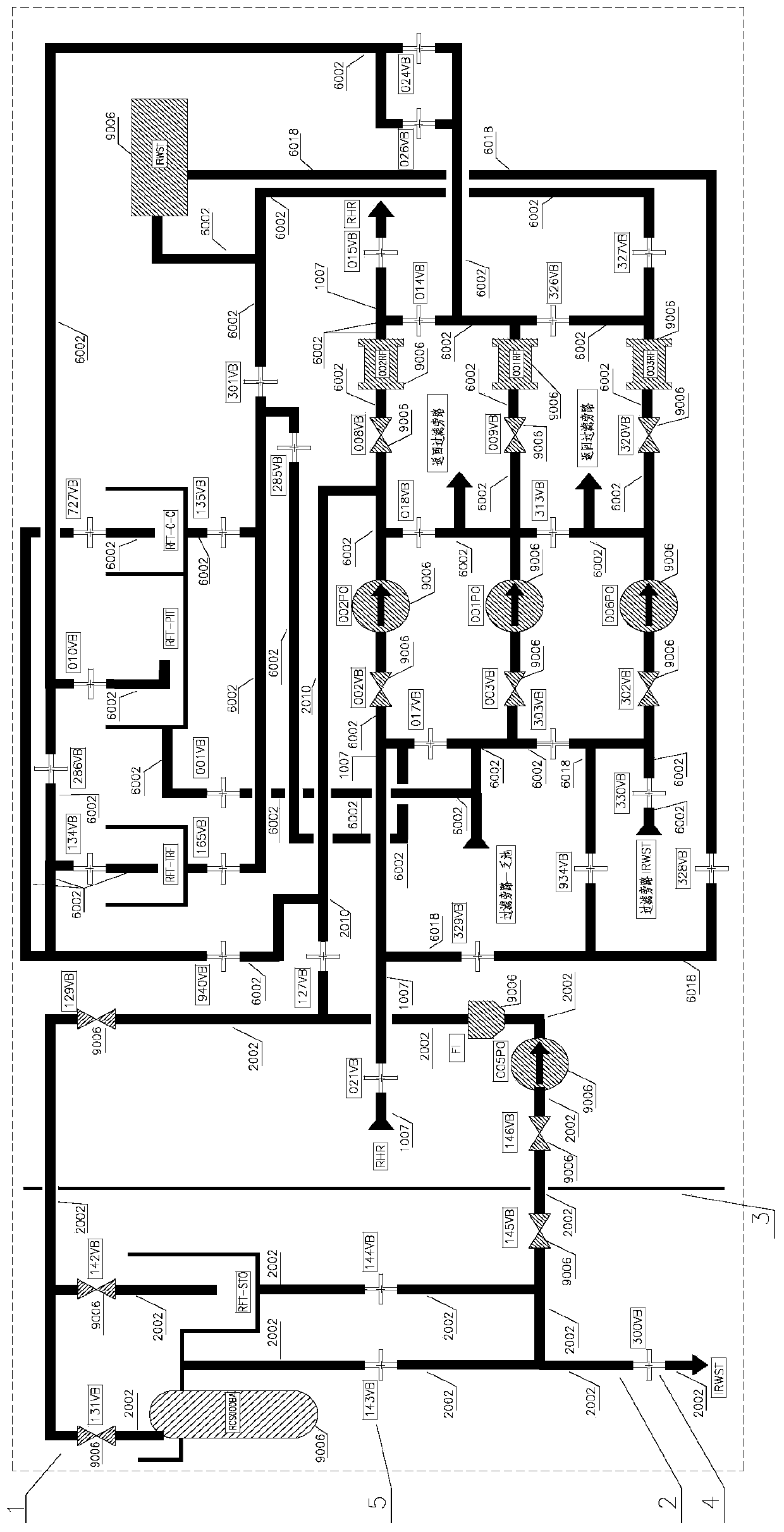

Design method of control simulation disc, and control simulation disc

ActiveCN111028960AOvercome the single color of the indicatorOvercoming disadvantages that are not conducive to monitoringNuclear energy generationNuclear monitoringColor ScaleSoftware engineering

The invention discloses a design method of a control simulation disc. The method comprises the following steps: carrying out function division on a plurality of fluid pipelines on the disc surface ofa control simulation disc, so that a plurality of function modules with different functions are formed on the disc surface; and marking the fluid pipelines through color codes, wherein the fluid pipelines belonging to the different function modules adopt different color codes. The invention further discloses a control simulation disc, which is obtained by adopting the design method of the controlsimulation disc. According to the invention, the control simulation disc designed through the design method of the control simulation disc is clear in function and good in identification degree, and can make an operator visually master the states of different fluid pipelines under different working conditions.

Owner:CHINA NUCLEAR POWER ENG CO LTD

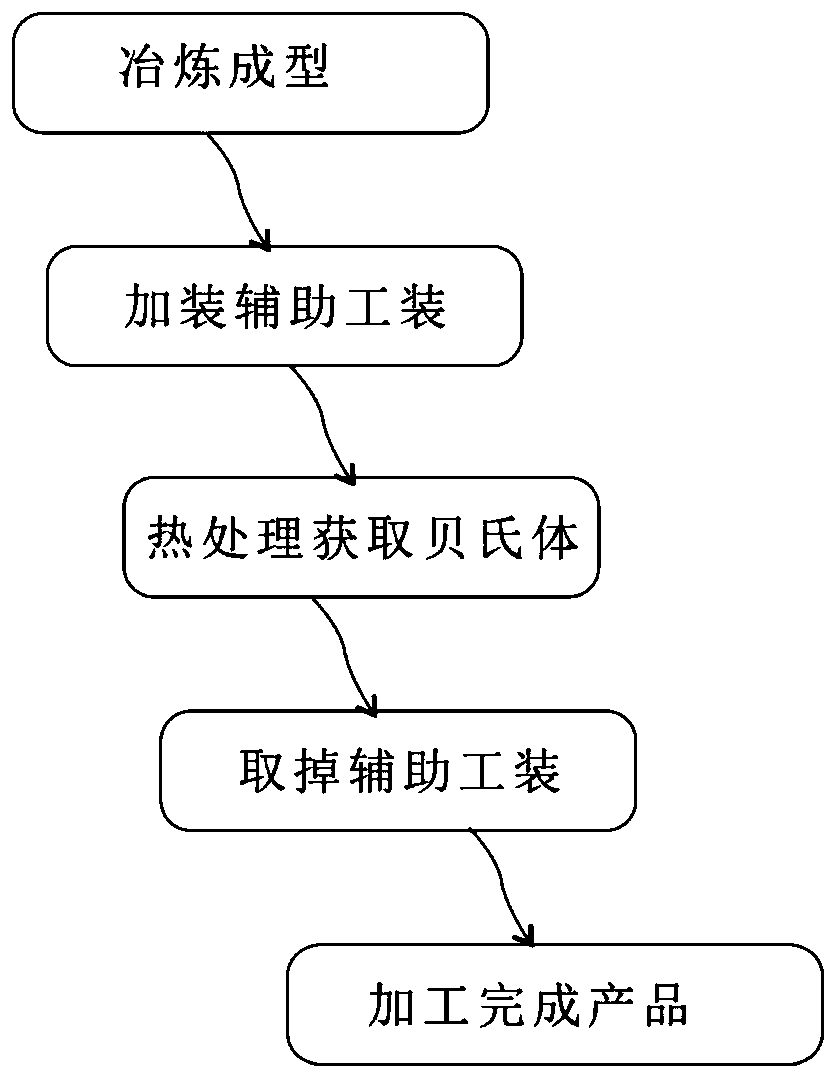

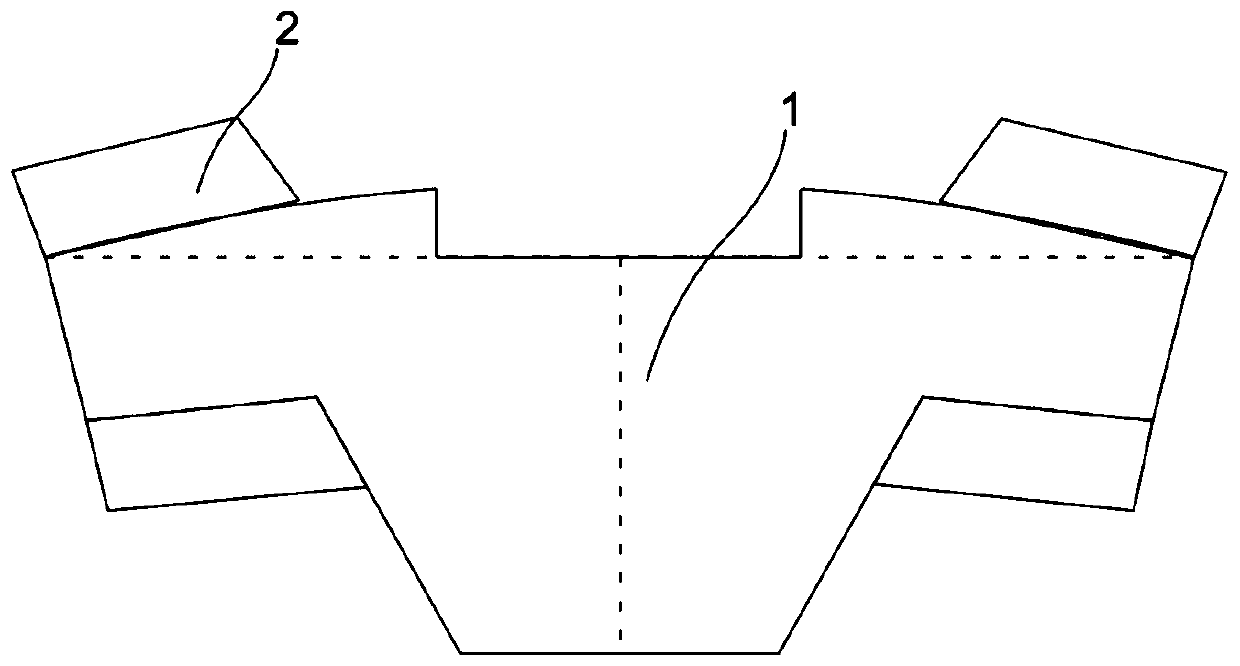

Method for acquiring bainite complex phase tissue with workpieces with different cross section thicknesses

The invention provides a method for acquiring bainite complex phase tissue with workpieces with different cross sections thicknesses. In the heat treatment method of products with different cross sections in the bainite complex phase tissue, performance requirements for different regions of the cross-sections on different workpieces in the bainite complex phase tissue are different or the performance requirements of different thicknesses for different parts of the same workpiece are the same, an additional protective layer is adopted, when the workpieces are subjected to quenching treatment and tempering treatment, and the same performance or different performance requirements of the workpiece quality can be ensured.

Owner:紫荆浆体管道工程股份公司

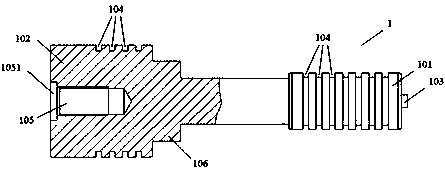

Abrasion-resistant counter sinking cutter

InactiveCN102873379AEnsure straightnessEnsure heightTransportation and packagingTrepanning drillsEngineeringMechanical engineering

The invention discloses an abrasion-resistant counter sinking cutter, which comprises a cylindrical cutter handle and a cutter bar; a rectangular main blade fixing groove is formed in the middle of the lower end face of the cutter bar; a first L-shaped gap is formed on the lower end face of the cutter bar and positioned on each of two sides of the main blade fixing groove; a main blade is arranged in the main blade fixing groove; a main cutting edge gradually approaches to the axis of the cutter bar from the outer side of the main blade to the center of the main blade so as to form an inclined shape; a second L-shaped gap extending axially along the cutter bar and communicated with the main blade fixing groove is formed on each of two sides of the lower end face of the cutter bar and is close to the main cutting edge, so that a chip removal groove of the main cutting edge is formed; a secondary blade is arranged on a lateral surface of each first L-shaped gap; an end cutting edge is formed at the end of each secondary blade; a lateral cutting edge is formed on the outer lateral surface of each secondary blade; and the end cutting edges are 0.1 to 0.2 millimeter shorter than the main cutting edge in the axial direction. According to the cutter, the service lives of the cutting edges are long; the size precision of the cutter is high; the cutter bar has high strength; and the cutter is high in cutting efficiency and easy and convenient to manufacture, install and maintain.

Owner:MAIN PLAN NINGBO BATHROOM COLLECTIONS

Seaborne implantable rock-socketed steel pipe pile bottom sealing construction method

A bottom sealing construction method for an offshore implantable rock-socketed steel pipe pile is characterized in that a steel casing, an assembled implantable core pile with pile bottom precast concrete and a high-performance grouting material are matched, after the steel pipe pile is manufactured, concrete is poured in a factory, the core pile is manufactured, and a plurality of distances are reserved from the bottom of the concrete to the section of the bottom of the steel pipe pile. An uneven surface in a rock-socketed formed hole can be conveniently implanted, and filling is carried out through follow-up pressure grouting high-performance grouting materials. According to the method, pile bottom concrete implanted into a core pile is prefabricated in a steel pipe pile factory, then a high-performance grouting material is used for filling and blocking a gap between the core pile and bed rock, the offshore concrete pouring construction process is omitted, the construction efficiency is greatly improved, and the construction window period is shortened. Meanwhile, the construction cost is saved, and the method has important significance on efficiency improvement and cost saving of offshore wind power socketed pile foundation construction.

Owner:CCCC THIRD HARBOR ENG

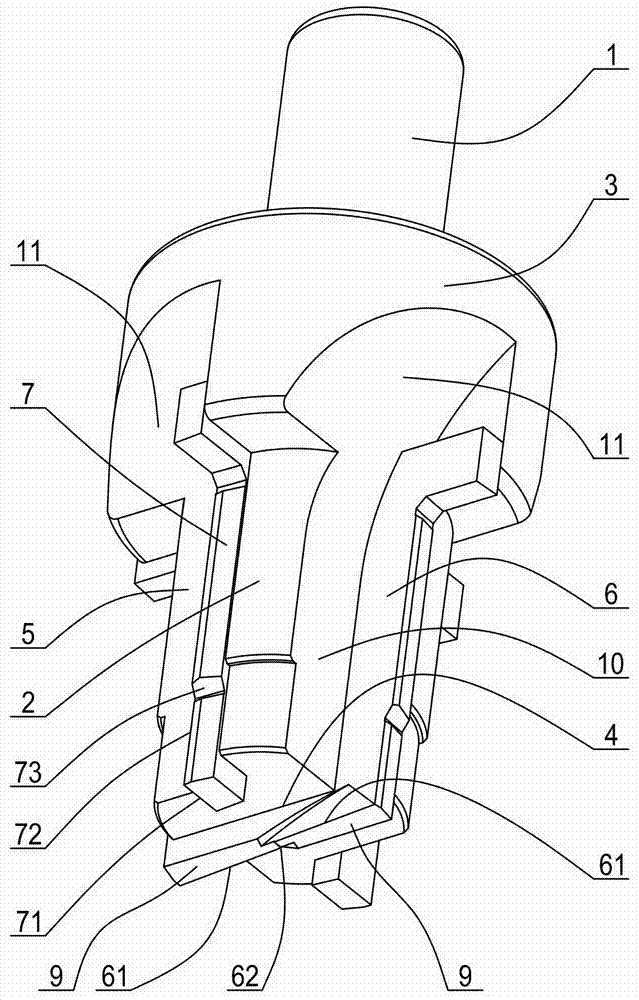

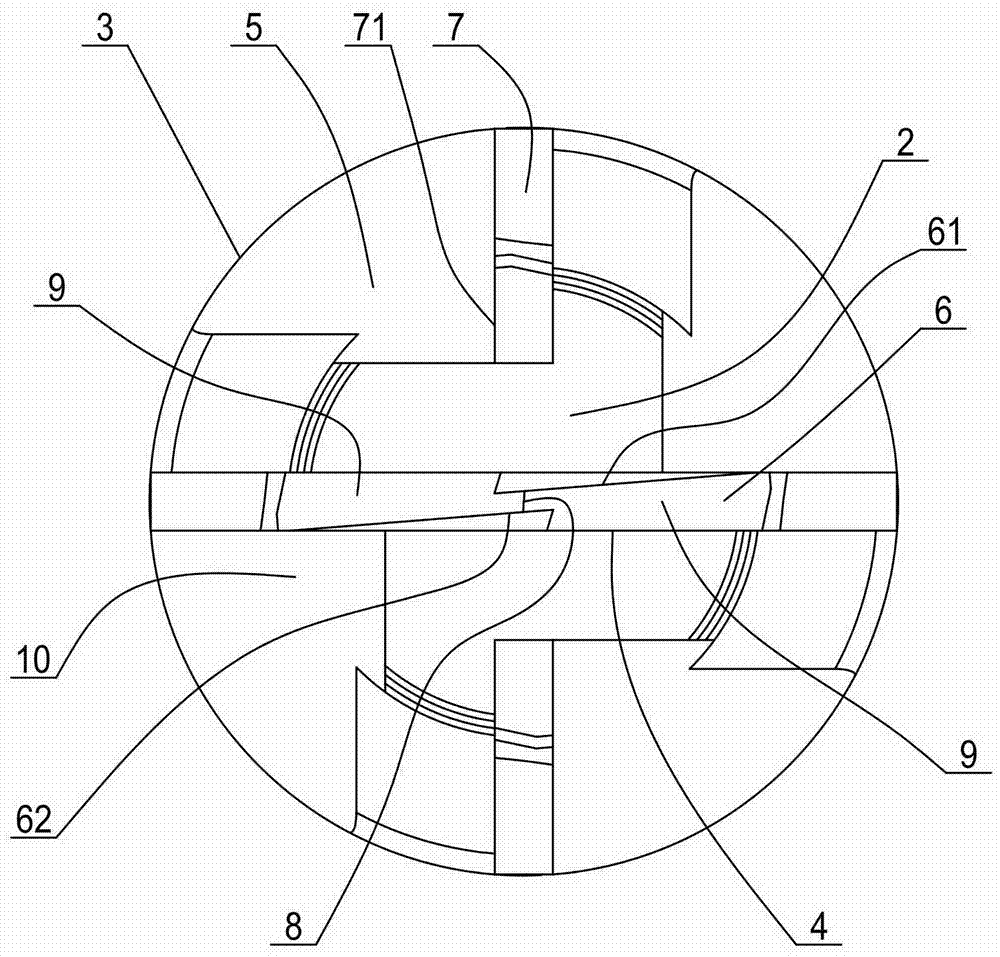

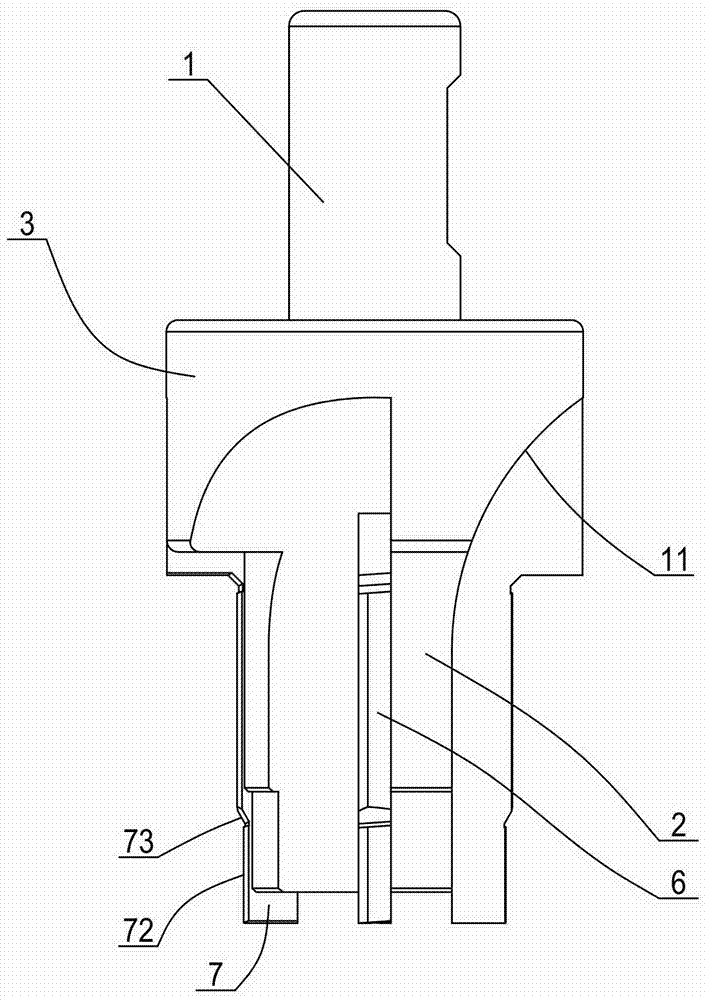

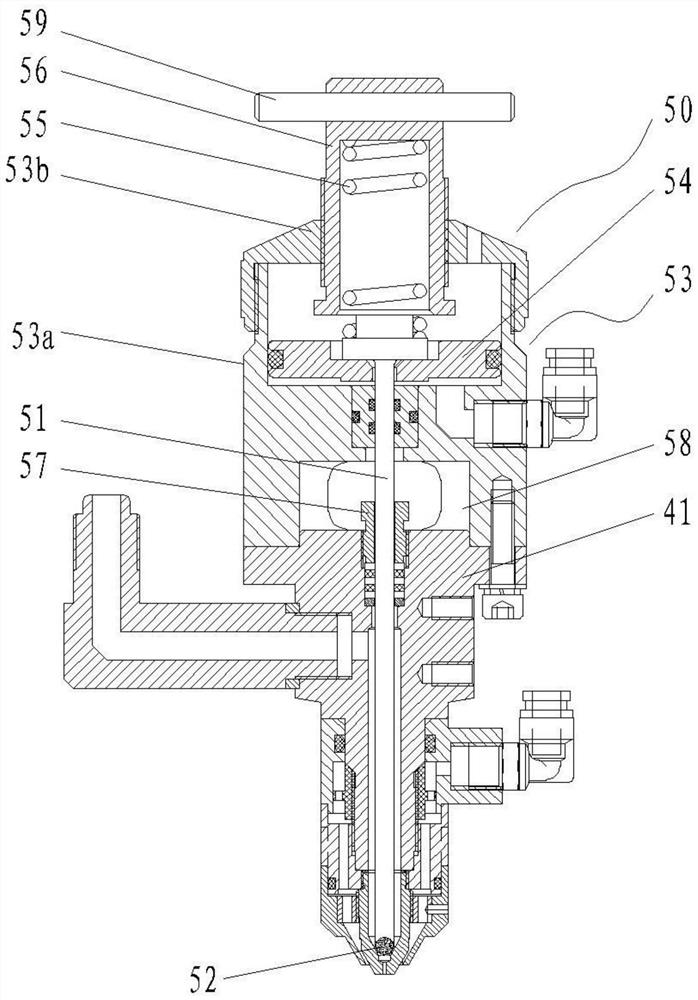

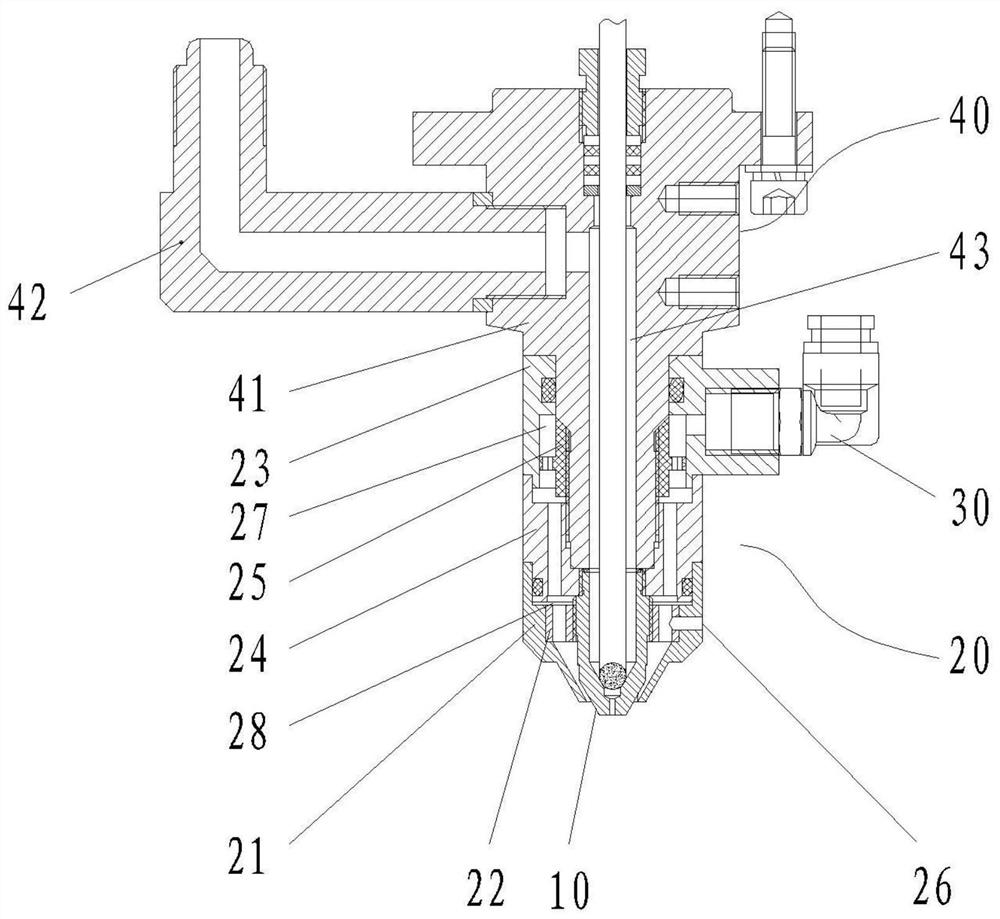

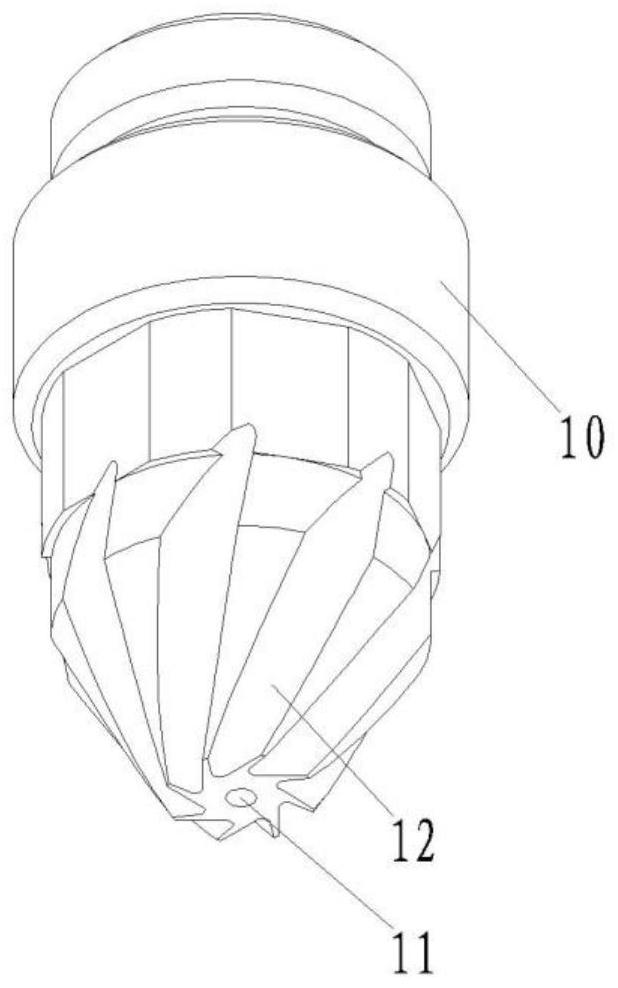

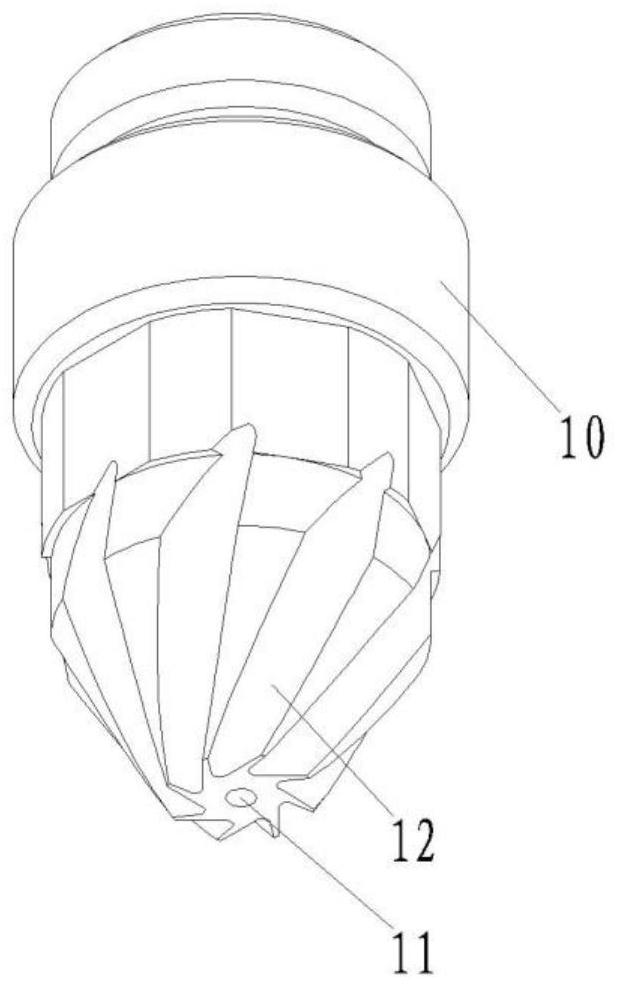

Spiral glue-shaped gluing valve

PendingCN113522647AGood for reasonable fillingReduce difficultyLiquid surface applicatorsCoatingsEngineeringGas supply

The invention discloses a spiral glue-shaped gluing valve. The spiral glue-shaped gluing valve comprises a core shaft body, an outer sleeve component, an air supply head and a valve element assembly, wherein the outer sleeve component arranged outside the core shaft body in a sleeving mode, and the air supply head is arranged on the outer sleeve component; an annular flow channel is formed between the core shaft body and the outer sleeve component; an extrusion opening for extruding glue is formed in the lower end of the core shaft body. a plurality of drainage grooves are symmetrically formed in the center of the outer circle face of the core shaft body and extend downwards to the lower end face of the core shaft body; the lower ends of the drainage grooves are distributed around the extrusion opening in the circumferential direction so as to guide high-pressure airflow to flow to form spiral airflow; and the valve element component is used for opening or closing the extrusion opening. According to the spiral glue-shaped gluing valve, the spiral air flow is formed through guiding of the multiple spiral drainage grooves, so that the extruded glue is driven to form a spiral shape; reasonable space distribution of the glue is achieved through the spiral gluing technology; the glue is extruded after two to-be-bonded parts make contact; the glue is filled into a glue-free gap between spiral lines; the whole bonding space is filled with the glue; and therefore, the bonding effect is improved, and the bonding strength is improved.

Owner:CHONGQING CHANGJIANG COATING EQUIP

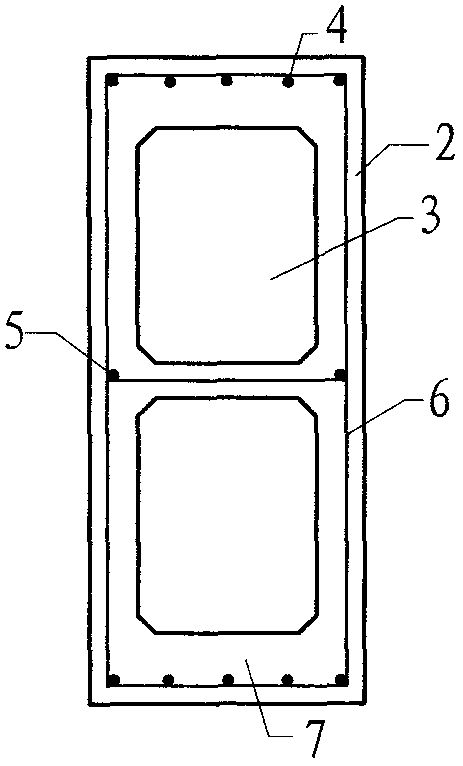

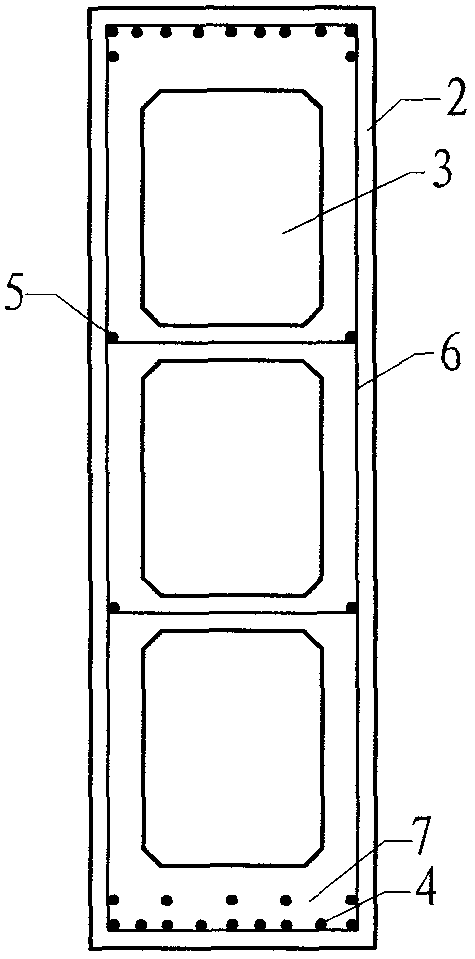

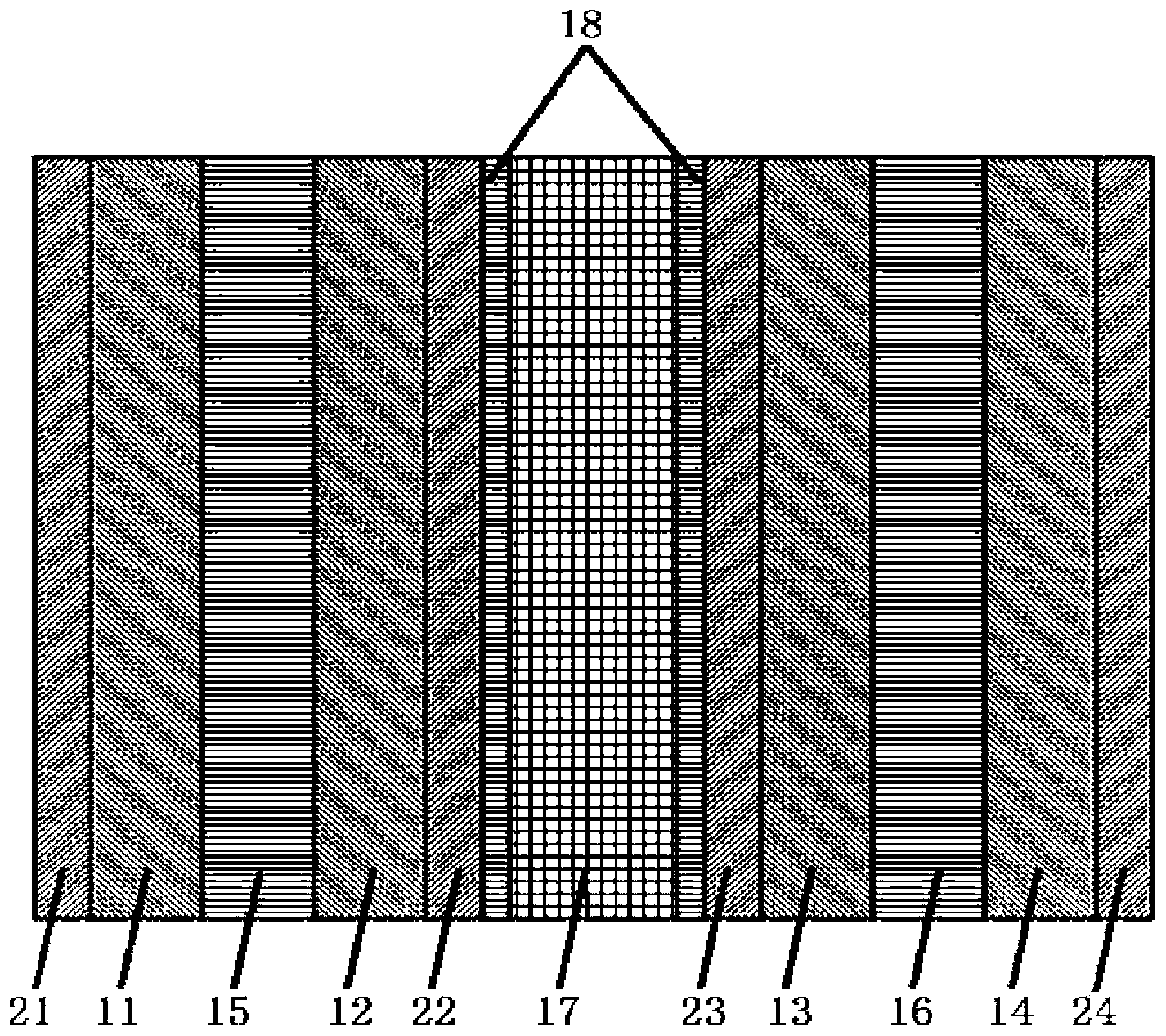

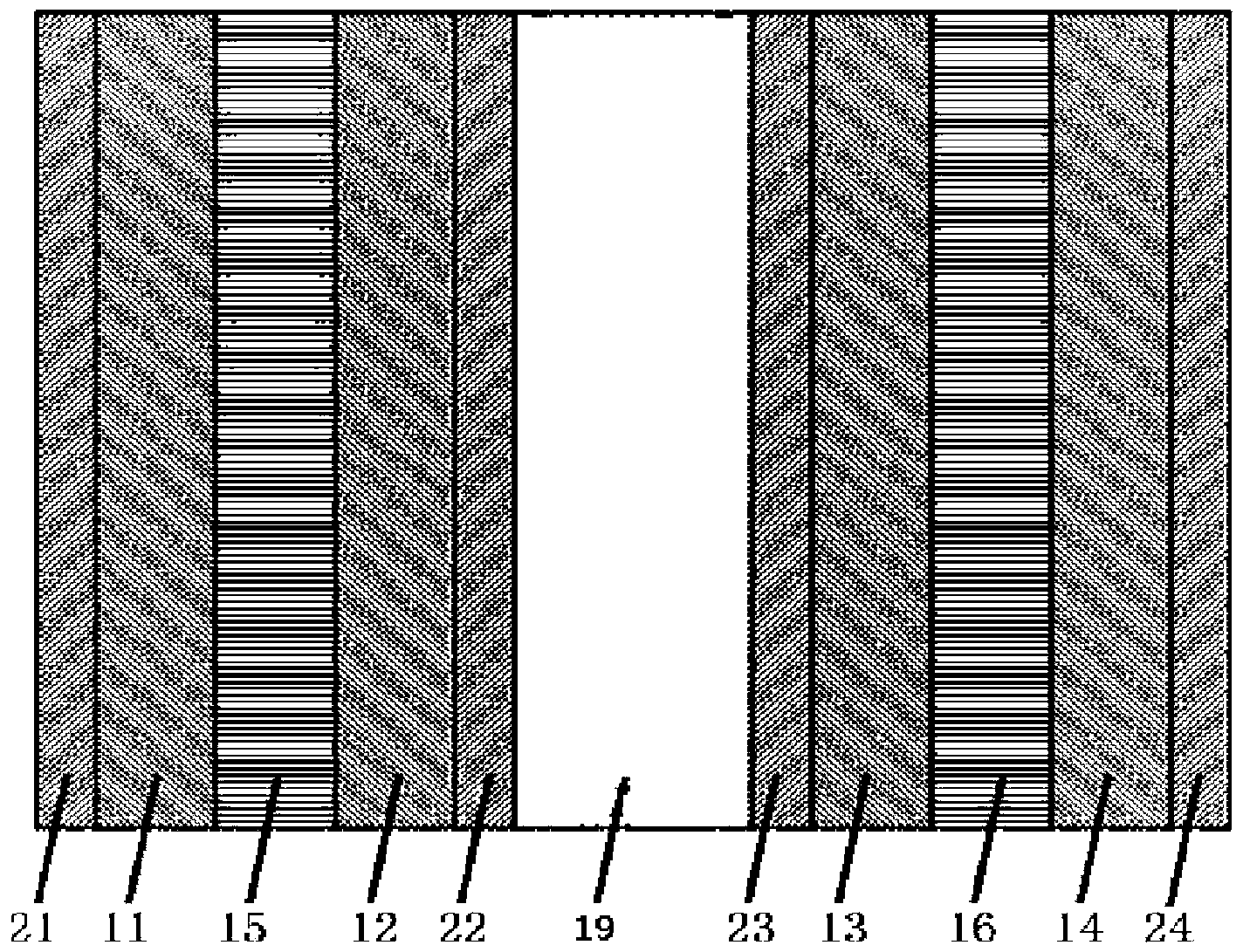

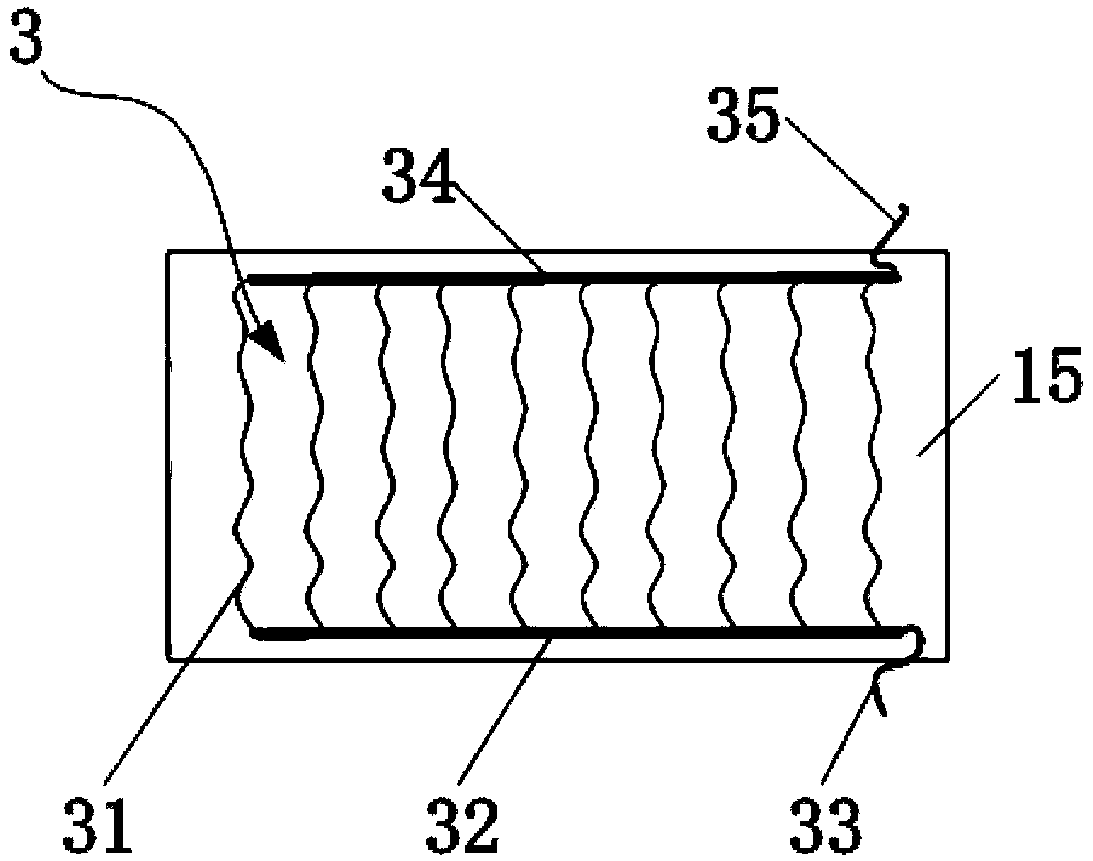

Composite hollow glass for building and preparation method thereof

ActiveCN103967394AGood mechanical propertiesGood thermal propertiesUnits with parallel planesOptical propertyControllability

The invention discloses composite hollow glass for a building and a preparation method of the composite hollow glass. The composite hollow glass comprises a first glass layer, a second glass layer, a third glass layer and a fourth glass layer, wherein the first glass layer, the second glass layer, the third glass layer and the fourth glass layer are sequentially combined. The first glass layer and the second glass layer are bonded through a first glue sheet layer, and the outer side face of the first glass layer and the outer side face of the second glass layer are coated with a first antireflection film and a second antireflection film respectively. The third glass layer and the fourth glass layer are bonded through a second glue sheet layer, and the outer side face of the third glass layer and the outer side face of the fourth glass layer are coated with a third antireflection film and a fourth antireflection film respectively. The edge of the outer side face of the second glass layer and the edge of the outer side face of the third glass layer are bonded in a sealing mode through a spacing bar. The composite hollow glass further comprises a first electric heating assembly which is arranged in the first glue sheet layer, and the electric heating assembly is connected with a power supply for heating the hollow glass. The composite hollow glass has the good mechanical property, the good thermal property and the good optical property, and the requirements of high and medium grade high-rise buildings for permeability and temperature controllability can be guaranteed.

Owner:CHINA BUILDING MATERIALS ACAD +1

Construction method of offshore implantable socketed pile

ActiveCN113684822ASave on leaseSave energyWind energy generationBulkheads/pilesArchitectural engineeringPipe

The construction method of the offshore implantable socketed pile comprises the steps of prefabrication of a core pile, pouring of the core pile, primary grouting of the core pile, secondary grouting of the core pile, grouting of a steel casing and the core pile, pouring of concrete grout between the core pile and a steel pipe pile and in the core pile, and completion of construction of the offshore implantable socketed pile after concrete is solidified. According to the method, one pouring link of underwater core pile pouring is changed into pouring before construction, the waiting time of underwater construction pouring is saved, the installation period of offshore socketed piles is greatly shortened, and the construction window period of each pile can be saved by 2-3 days; the link of pouring before construction is prefabricated pouring in a factory, so that the strength and compactness requirements of pile bottom concrete are ensured to a certain extent, the construction window period is shortened, and the rental and use cost of an offshore construction concrete mixing ship can be saved; through the upper limiting mechanism and the lower limiting mechanism which are arranged on the peripheral surface of the core pile, the core pile can be kept concentric with the steel casing in the sinking process.

Owner:CCCC THIRD HARBOR ENG

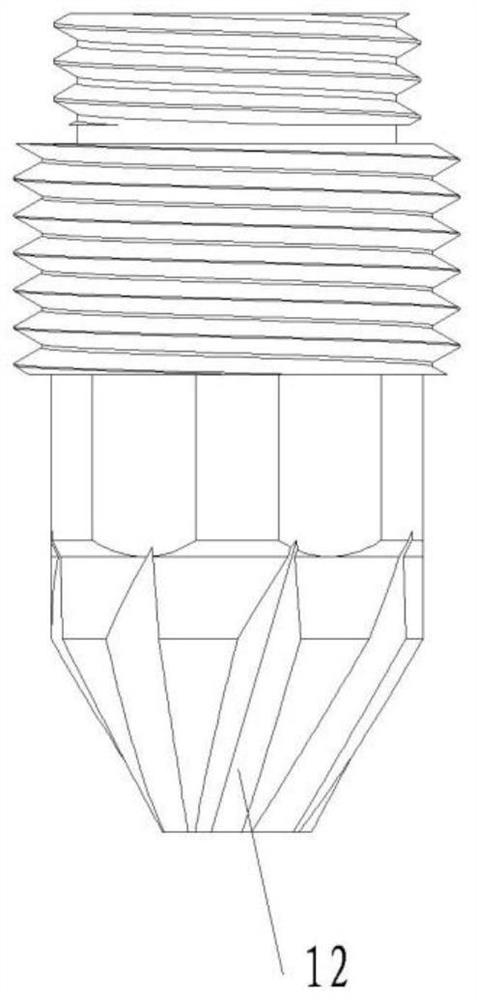

Spiral glue-shaped gluing nozzle

PendingCN113522648AReduce difficultyImprove applicabilityLiquid surface applicatorsCoatingsEngineeringStructural engineering

The invention discloses a spiral glue-shaped gluing nozzle. The spiral glue-shaped gluing nozzle comprises a core shaft body, an outer sleeve component and an air supply head, wherein the outer sleeve component is arranged outside the core shaft body in a sleeving mode, and the air supply head is arranged on the outer sleeve component; an annular flow channel is formed between the core shaft body and the outer sleeve component; an extrusion opening for extruding glue is formed in the lower end of the core shaft body; a plurality of drainage grooves are symmetrically formed in the center of the outer circle face of the core shaft body; the drainage grooves deviate towards the same circumferential direction of the core shaft body from top to bottom; and the lower ends of the drainage grooves are distributed around the extrusion opening in the circumferential direction so as to guide high-pressure airflow to flow to form spiral airflow. According to the spiral glue-shaped gluing nozzle, the spiral air flow is formed through guiding of the multiple spiral drainage grooves, so that the extruded glue is driven to form a spiral shape; reasonable space distribution of the glue is achieved through the spiral gluing technology; the glue is extruded after two to-be-bonded parts make contact, and the glue is filled into a glue-free gap between spiral line; the whole bonding space is filled with the glue; and therefore, the bonding effect is improved, and the bonding strength is improved.

Owner:CHONGQING CHANGJIANG COATING EQUIP

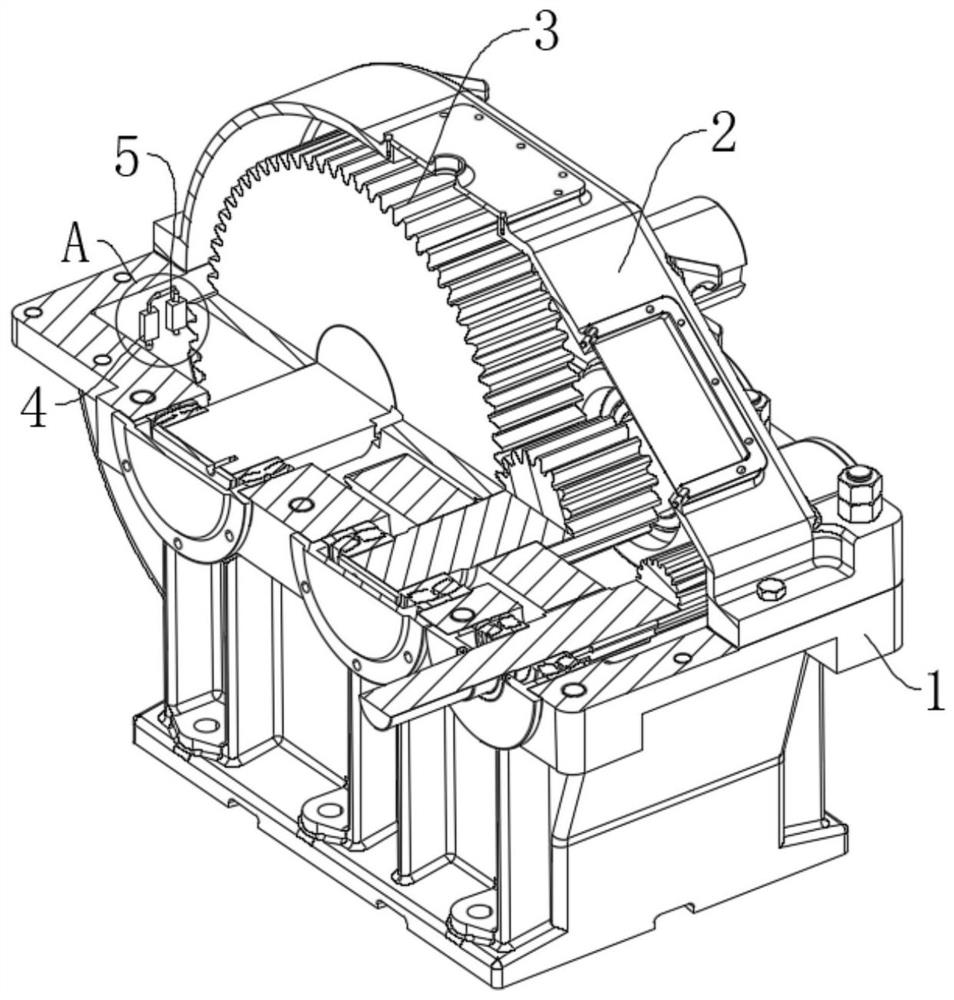

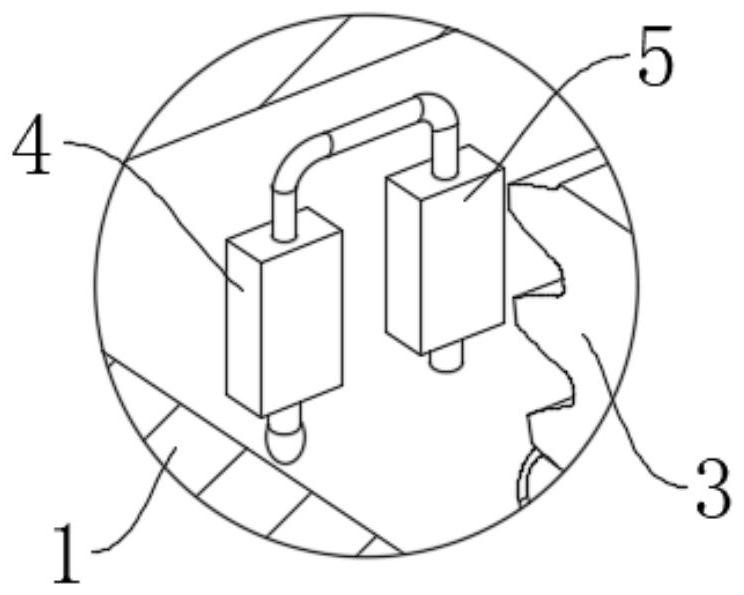

Bridge crane reduction gearbox with intelligent monitoring function

PendingCN112833172AEnsure safetyEnsure reliabilityGear lubrication/coolingLoad-engaging elementsControl engineeringReliability engineering

The invention discloses a bridge crane reduction gearbox with an intelligent monitoring function, and belongs to the technical field of port equipment. The bridge crane reduction gearbox comprises a box body, a box cover and a reducing mechanism. The reducing mechanism is movably arranged in the box body, and the box cover is buckled at the upper end of the box body; and the bridge crane reduction gearbox further comprises a monitoring assembly, the monitoring assembly is composed of an oil liquid collecting device, a detection and analysis device and a video unit, the oil liquid collecting device and the detection and analysis device are both arranged in the box body, and the oil liquid collecting device and the detection and analysis device are both in signal connection with the video unit. The output end of the video unit is in signal connection with a control terminal; and the oil collecting device and the detection and analysis device ensure the quality and the total amount requirement of oil in the box body, the situation that a reducing mechanism breaks down due to lack of assistance of the oil is avoided, the operation stability of the bridge crane reduction gearbox is improved, the maintenance frequency is reduced, meanwhile, the video unit feeds back the oil condition, obtained by the monitoring assembly, in the box body to the control terminal in a data form, so that a user can conveniently check and form a historical record, and the integrity of an evidence chain is ensured.

Owner:NINGBO GANGJI TERMINAL OPERATORS

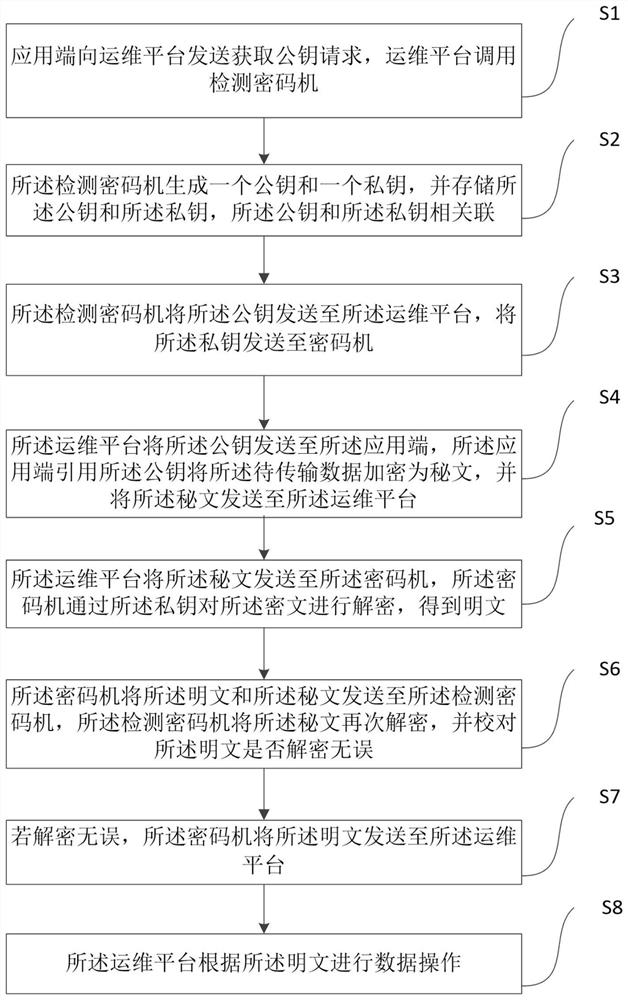

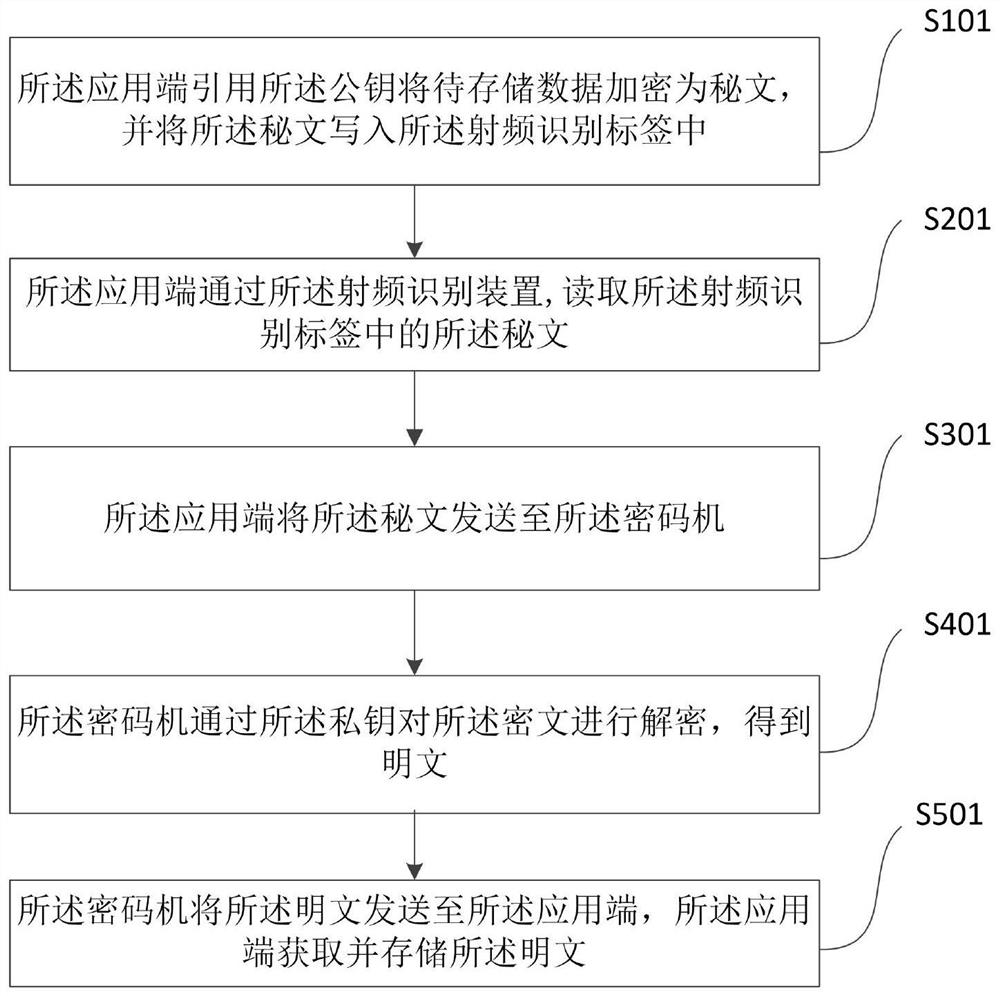

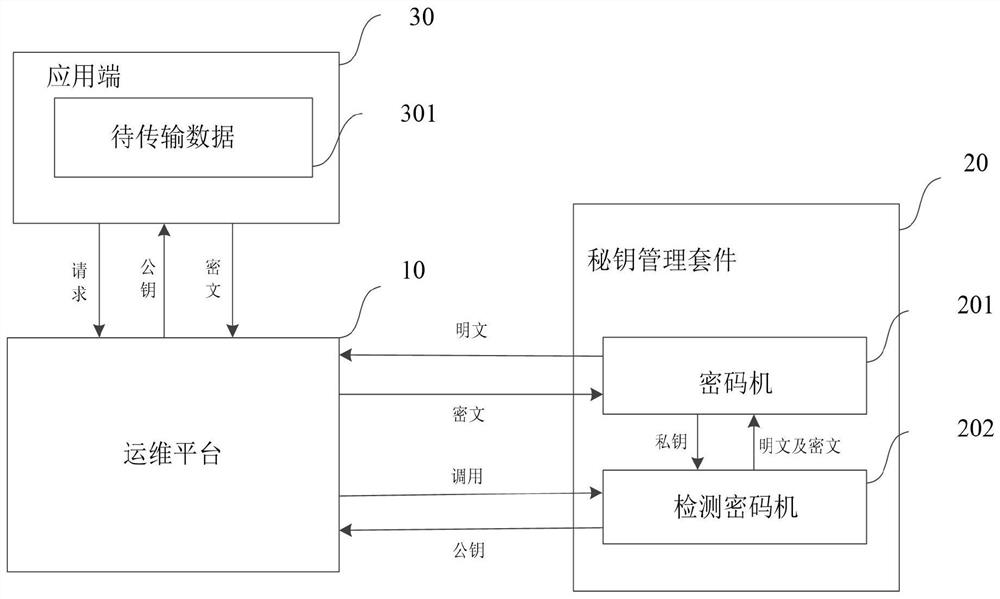

Metering operation and maintenance system data security transmission method and system

ActiveCN112217640AGuaranteed reliabilityEnsure safetyKey distribution for secure communicationInformation technology support systemPlaintextCiphertext

The invention discloses a metering operation and maintenance system data security transmission method and system, wherein the method comprises the steps that: an application end transmits a request toan operation and maintenance platform, the operation and maintenance platform calls a detection cipher machine, the detection cipher machine generates a public key and a private key and transmits thepublic key and the private key to the operation and maintenance platform and the cipher machine, and then the operation and maintenance platform transmits the public key to the application end; and the application end encrypts to-be-transmitted data into a ciphertext and sends the ciphertext to the operation and maintenance platform, the operation and maintenance platform sends the ciphertext tothe cipher machine, the cipher machine decrypts the ciphertext to obtain a plaintext, finally, the cipher machine sends the plaintext and the ciphertext to the detection cipher machine, the detectioncipher machine decrypts the ciphertext again and verifies the plaintext, and if decryption is correct, the cipher machine sends the plaintext to the operation and maintenance platform, and the operation and maintenance platform operates. According to the method and the system, the problem of low security of data transmission caused by the fact that a MD5 algorithm cannot prevent collision during data transmission and original transmission data is tampered but not found out is solved, and the security and reliability of data transmission are ensured.

Owner:云南电网有限责任公司迪庆供电局

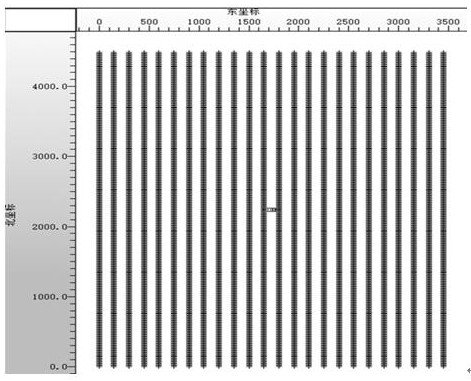

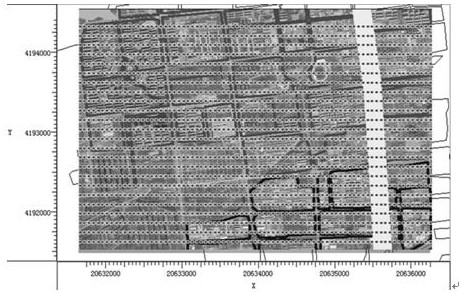

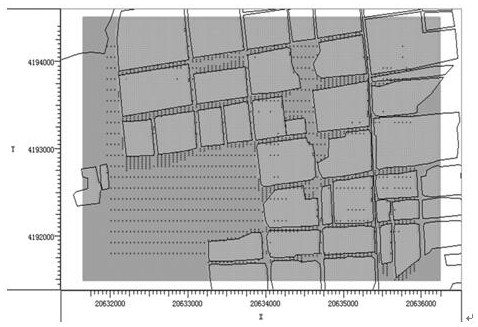

Observation system intelligent variable observation method combining earth surface and underground double factors

PendingCN113643430AImprove qualityEnsure accurate imagingSeismic signal processing3D-image renderingOriginal dataEarth surface

The invention relates to the technical field of oil and gas field exploration and development, in particular to an intelligent observation system variable observation method combining earth surface and underground double factors. The method comprises the following steps: establishing a shallow, middle and deep three-dimensional high-precision speed and geologic model, and designing a regular observation system; establishing a real earth surface three-dimensional structure model, and automatically identifying and delineating obstacles; automatically selecting shot points and detection points which need to be changed in view, and moving the selected shot points and detection points by utilizing an automatic view changing algorithm; calculating an observation system attribute graph, and quantitatively evaluating the observation system after automatic observation changing; and adjusting a variable observation position according to a quantitative evaluation result, encrypting the shot points or the detection points, and outputting a final observation system SPS file. According to the method, the variable observation influence of the observation system is considered from two factors of the earth surface and the underground, the requirements of accurate imaging and reservoir prediction of the underground target layer are ensured while the influence of earth surface obstacles and near-earth surface special geologic bodies is effectively avoided, and the observation system after intelligent variable observation can ensure that high-quality original data can be acquired.

Owner:CHINA PETROLEUM & CHEM CORP +1

Injection molding method for super-thick transparent bi-color cladding piece

The invention relates to the technical field of injection molding, in particular to an injection molding method for a super-thick transparent bi-color cladding piece. The injection molding method forthe super-thick transparent bi-color cladding piece comprises the following steps of (1) injection molding a colored inner layer; (2) injection molding a transparent outer layer; and (3) injection molding a bi-color transparent workpiece: placing the injection-molded colored inner layer into an injection mold prefabricated through the transparent outer layer, cladding for injection molding the second layer of transparent outer layer, and obtaining the bi-color transparent workpiece with two-color fusion. According to the injection molding method for the super-thick transparent bi-color cladding piece provided by the invention, through the reasonable layering of wall thicknesses of two layers of the colored inner layer and the transparent outer layer, the optimal design of a colored inner layer product injection molding tail end, the reasonable gate location and shape, the reasonable program processing control, and the bi-color injection molding process control, the super-thick transparent bi-color cladding piece with the transparent outer layer and the multi-color changeable inner layer is obtained, and the super-thick transparent product has no bubbles, sink marks or rill marks, and has a high-strength performance.

Owner:QINGDAO JUSTUSE MOLDS TECH

T-shaped piston rod processing positioning device

PendingCN110369940APrevent tamperingEnsure moderateWelding/cutting auxillary devicesAuxillary welding devicesBiochemical engineeringProcessing cost

The invention discloses a T-shaped piston rod processing positioning device, and belongs to the field of T-shaped piston rod processing. The technical problem to be solved is to provide the processingpositioning device which can clamp and position a support lug and a rod body to ensure perpendicularity and the centering degree, can weld the support lug andthe rod body which are subjected to finish machining, and reduces the processing difficulty and processing cost. According to the technical scheme adopted to solve the technical problem, the T-shaped piston rod processing positioning devicecomprises a base, and the base is a rectangular base; rod body end positioning mechanisms are symmetrically arranged on the left side and the right side of the upper part of the base; and a support lug positioning mechanism and a rod body positioning mechanism are arranged successively from left to right. The T-shaped piston rod processing positioning device can be widely applied to the field of T-shaped piston rod processing.

Owner:CHANGZHI QINGHUA MACHINERY FACTORY +1

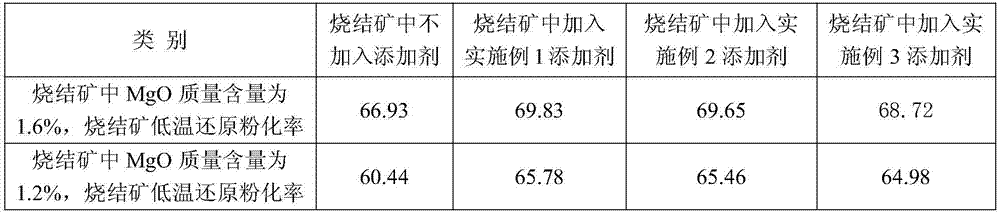

Additive for increasing low temperature reduction pulverization ratio of sintering ore and preparation method of additive

InactiveCN107955880AImprove low-temperature reduction pulverization performanceReduce the pulverization rate of low temperature reductionAlkalinityMetallurgy

The invention relates to an additive for increasing the low temperature reduction pulverization ratio of sintering ore and a preparation method of the additive. The additive for increasing the low temperature reduction pulverization ratio of the sintering ore and the preparation method of the additive mainly solve the technical problem of the poor low temperature reduction pulverization index of the sintering ore with the low content of MgO in the prior art. The additive for increasing the low temperature reduction pulverization ratio of the sintering ore comprises the components of, by weight, 30-32% of CaO, 2-4% of SiO2, 15-25% of MgO, and the balance burning loss and unavoidable impurities, wherein the sum of, by weight, MnO2, V2O5, and TiO2 is 0.7-1.0%, the weight of the additive withthe particle size being less than 1.0 mm accounts for 95% or above of the total weight of the additive, the weight of the additive with the particle size being less than 0.5 mm accounts for 75% or above of the total weight of the additive, and the weight of the additive with the particle size being less than 0.1 mm accounts for 20% or above of the total weight of the additive. The additive can notonly adjust the content and alkalinity of MgO in the sintering core, but also can improve low temperature reduction pulverization performance of the sintering ore.

Owner:SHANGHAI MEISHAN IRON & STEEL CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com