Patents

Literature

31results about How to "Ensure compactness" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Exercise machine

ActiveUS20190046830A1Improve direction accuracyQuick changeMuscle exercising devicesRotational axisClassical mechanics

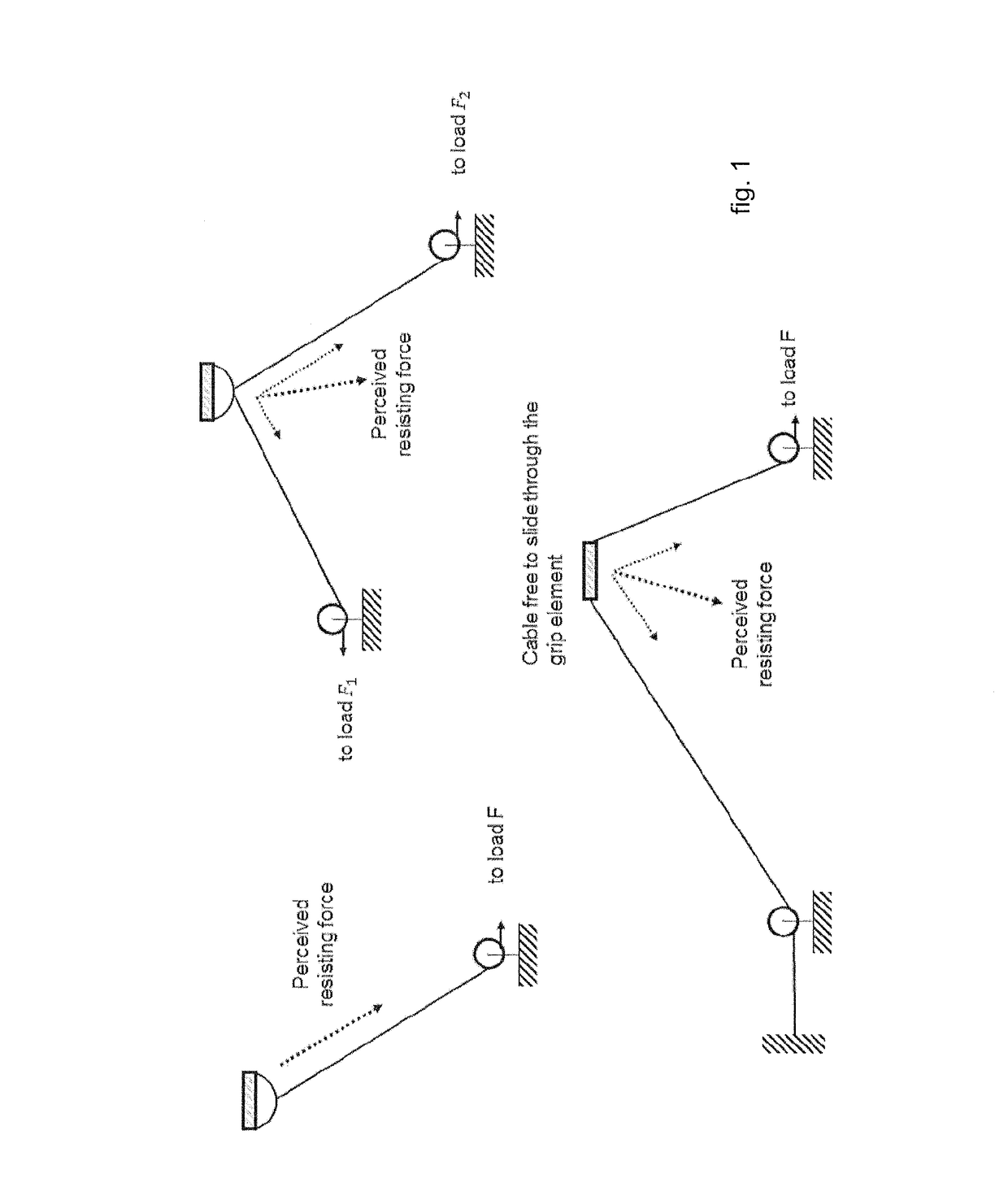

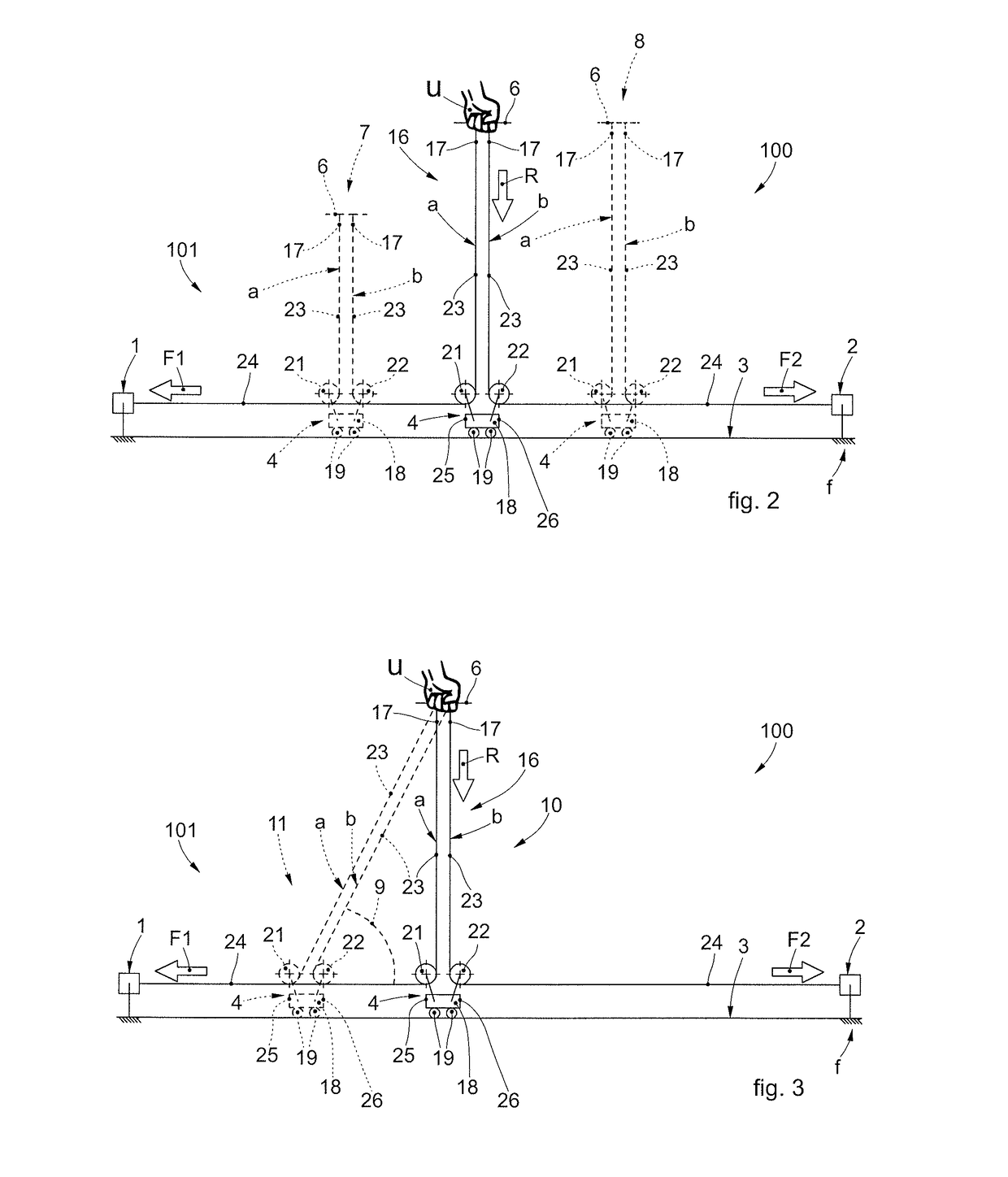

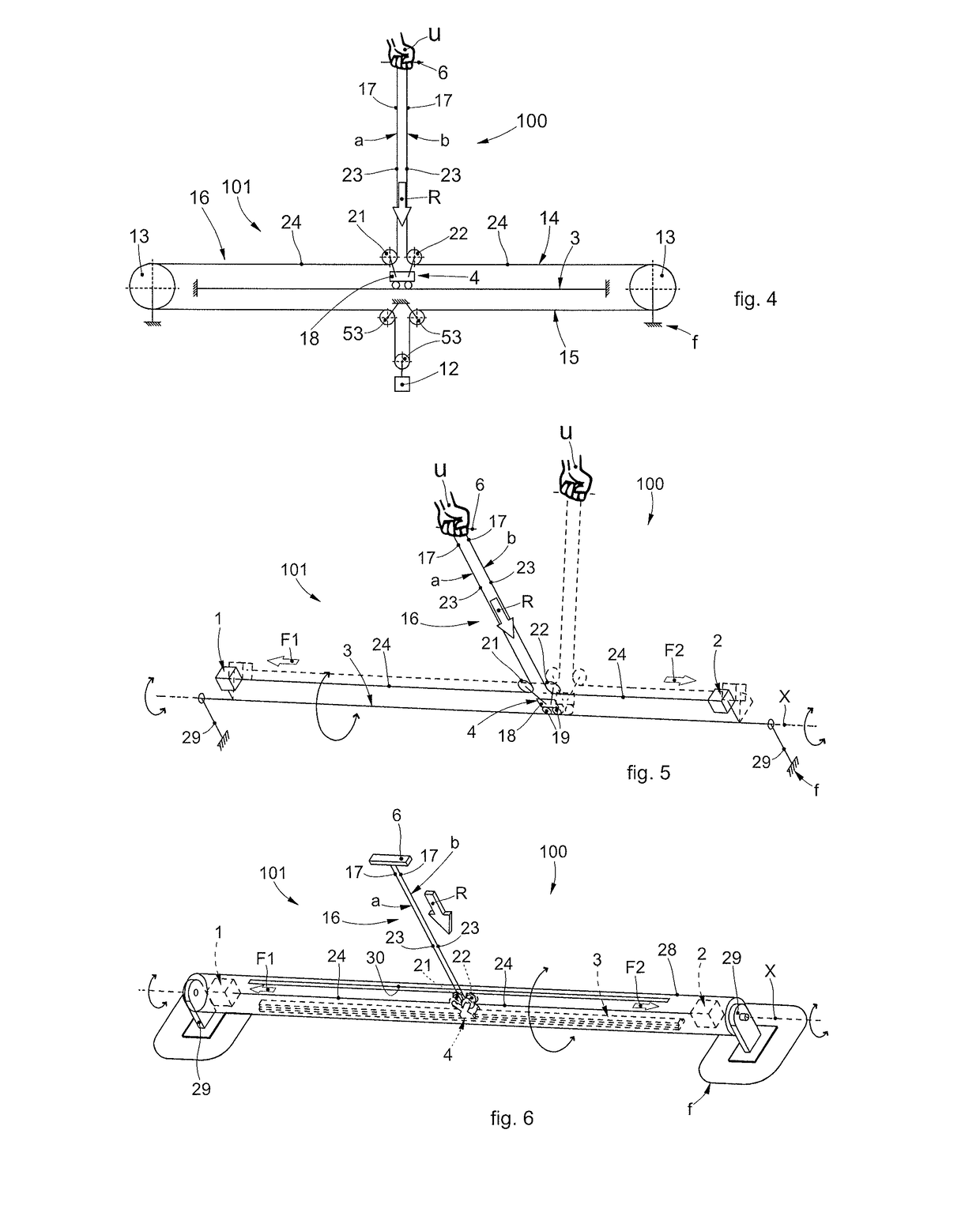

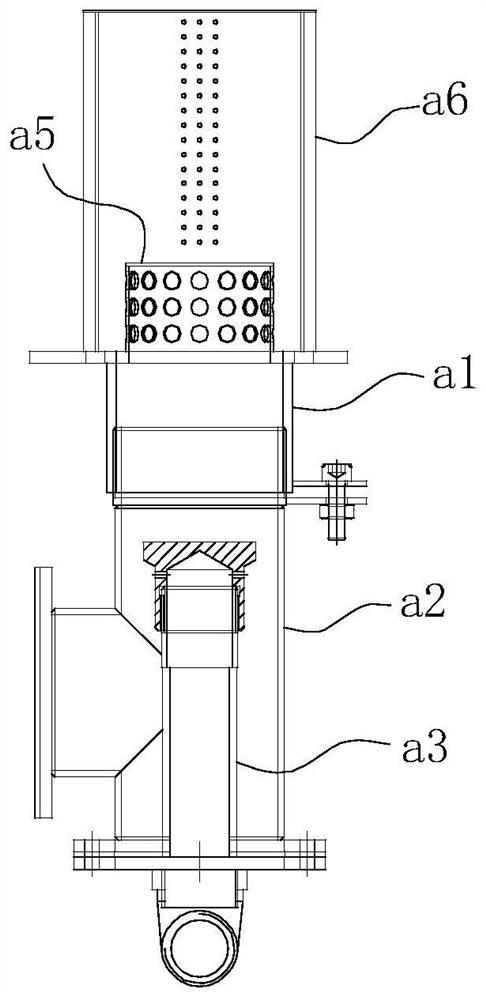

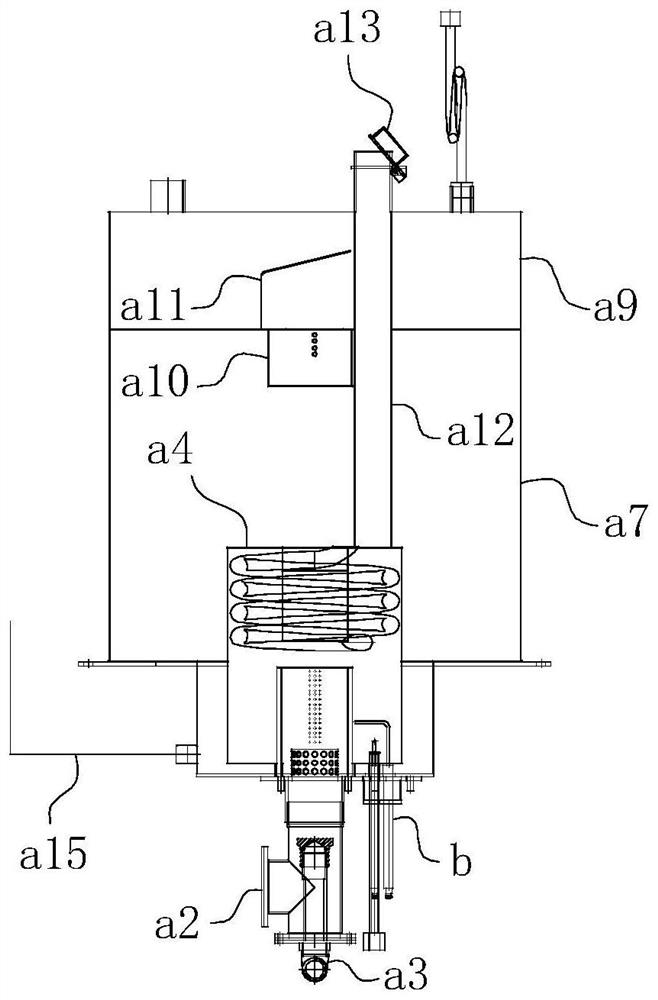

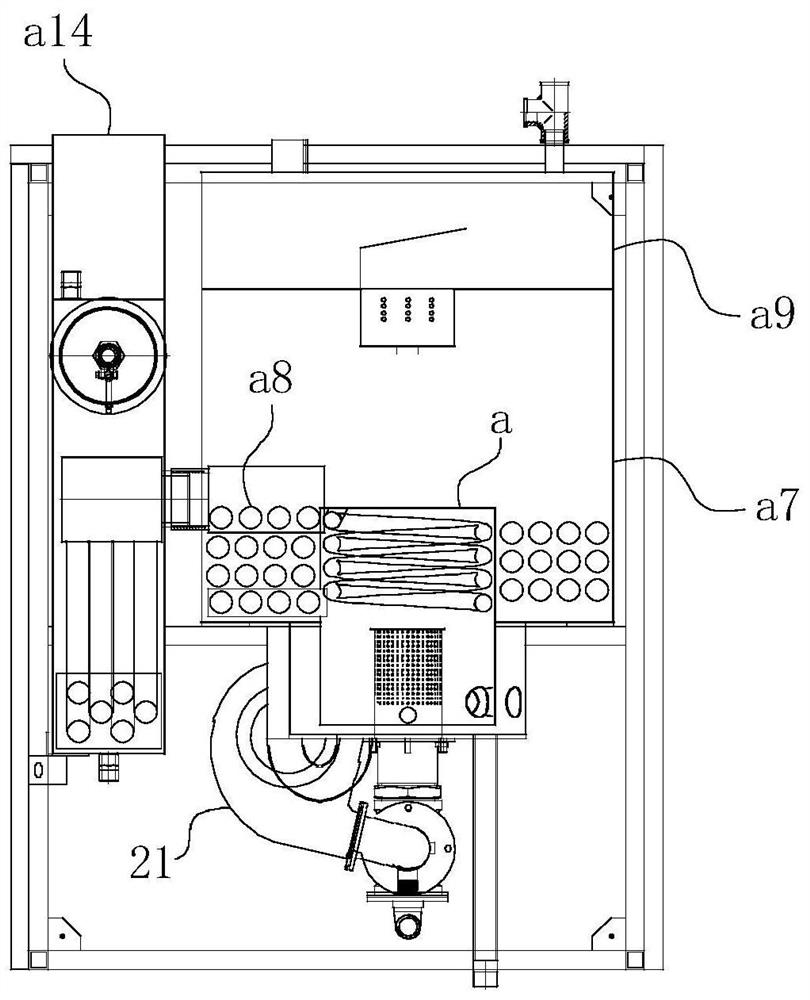

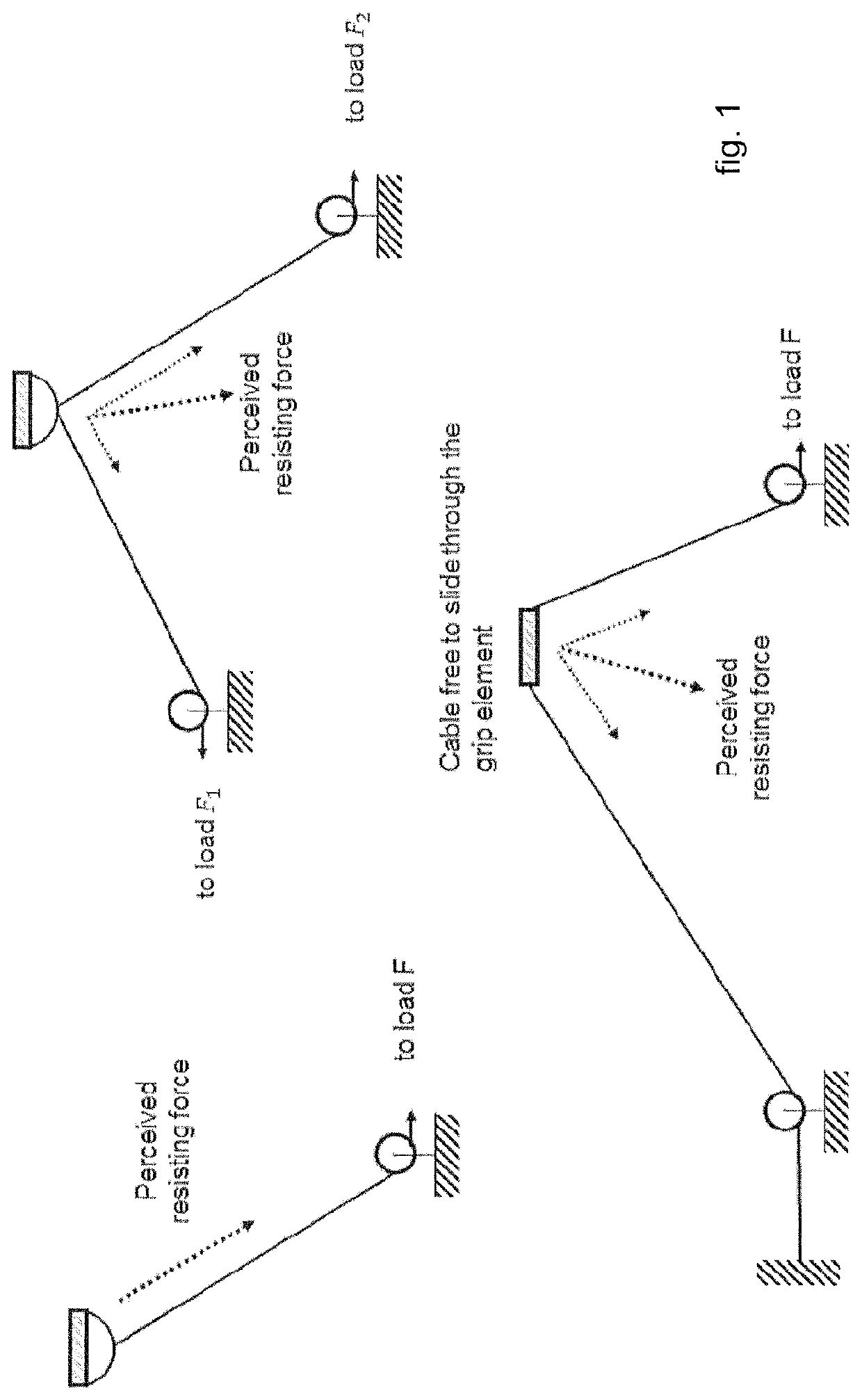

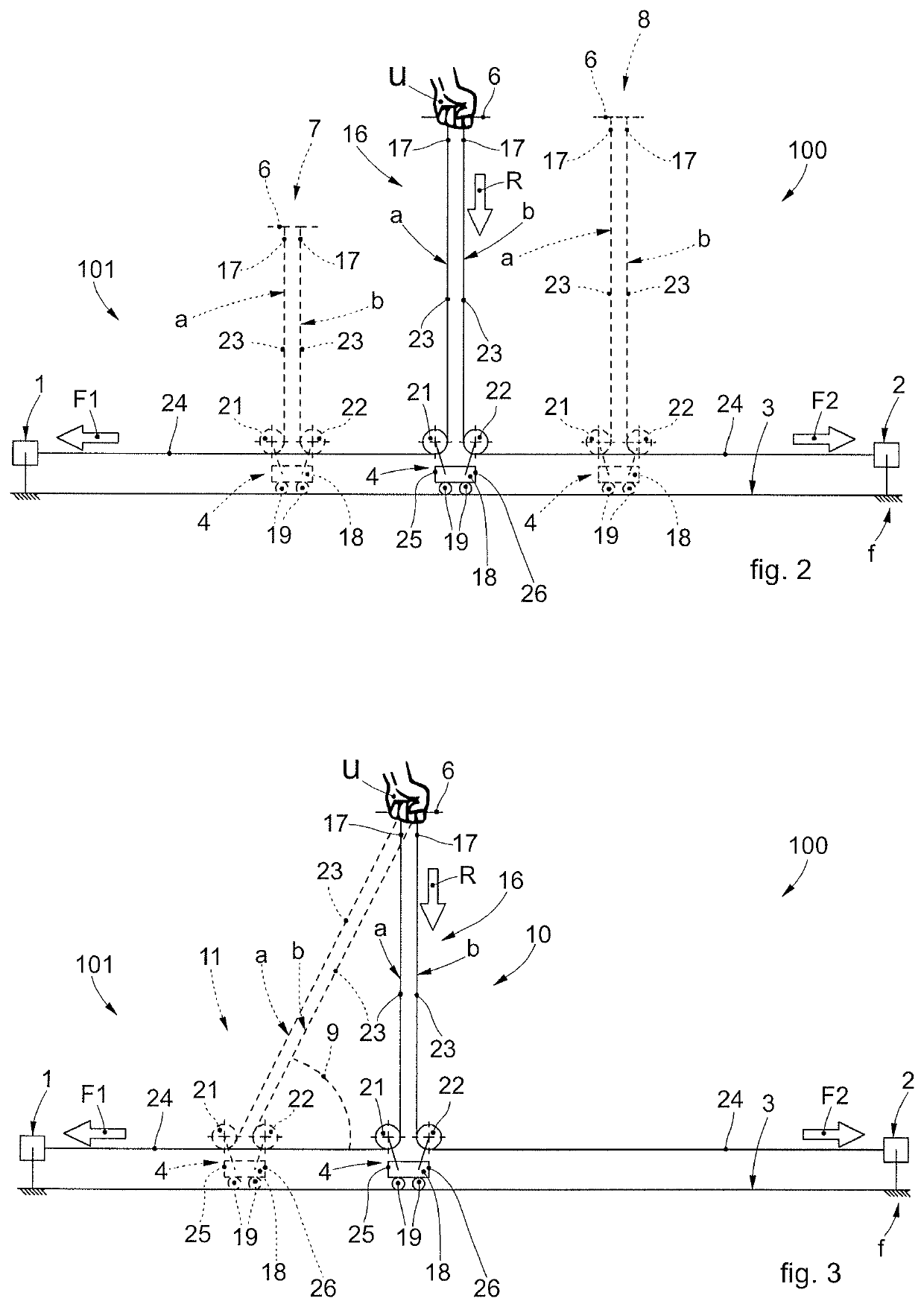

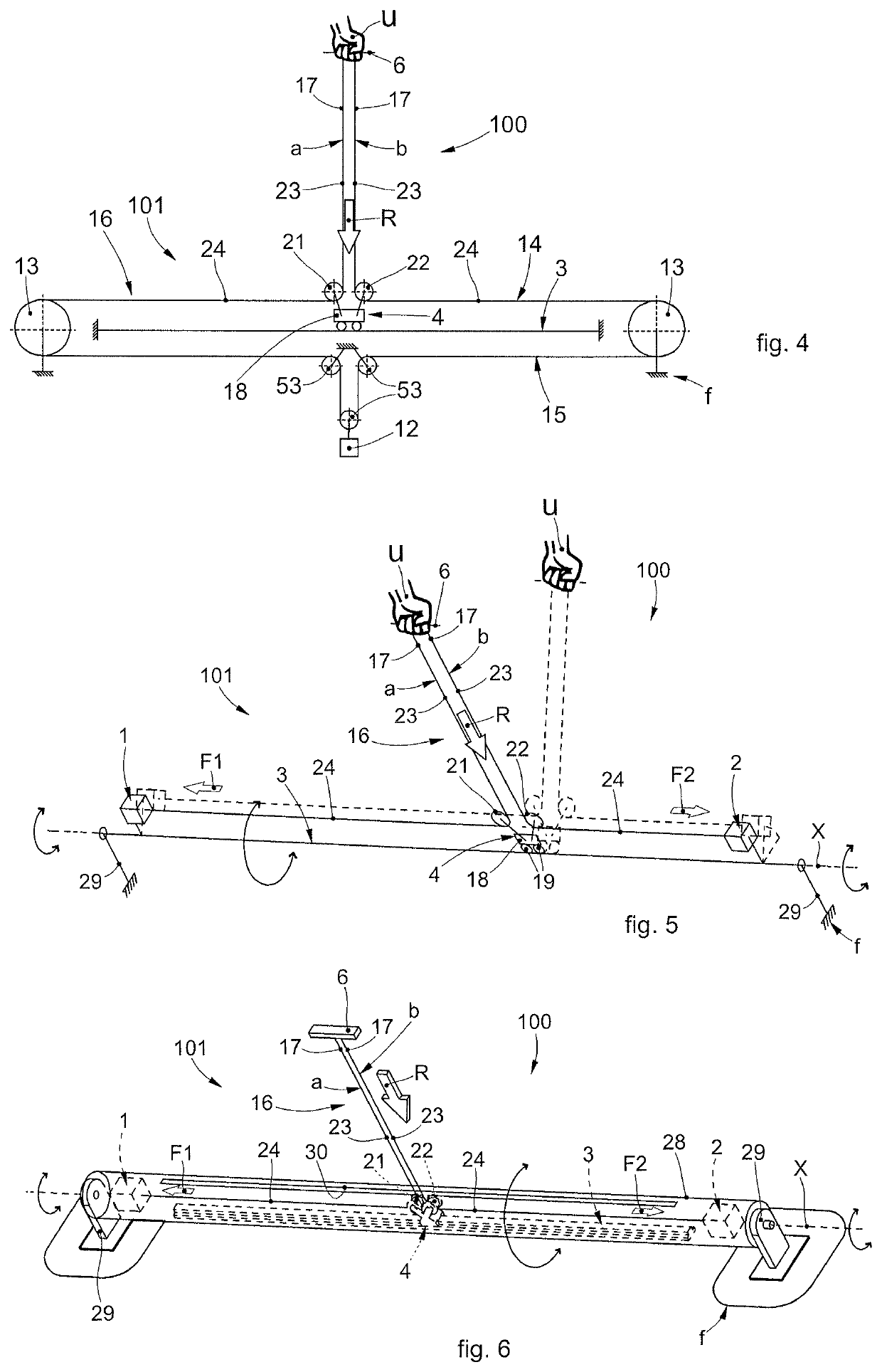

Machine for gymnastic exercises comprising a sliding rail (3), a carriage (4) installed in a sliding manner on the sliding rail (3), a first pulley (21) and a second pulley (22) installed on the carriage (4) and rotatable in an idle manner around respective axes of rotation, a gripping element (6), cable traction means (16) comprising a first cable branch (a) and a second cable branch (b) provided with respective and separate connection ends (17) attached to the gripping element (6). The first cable branch (a) and the second cable branch (b) wind at least partly around the first pulley (21) and respectively the second pulley (22) to define first return segments (23) comprised between the gripping element (6) and respectively the first pulley (21) and second pulley (22), and second return segments (24) that extend one on a first side (25) and the other on a second side (26), opposite the first side (25), of the carriage (4) and substantially parallel to the sliding rail (3).

Owner:AKUIS SRL

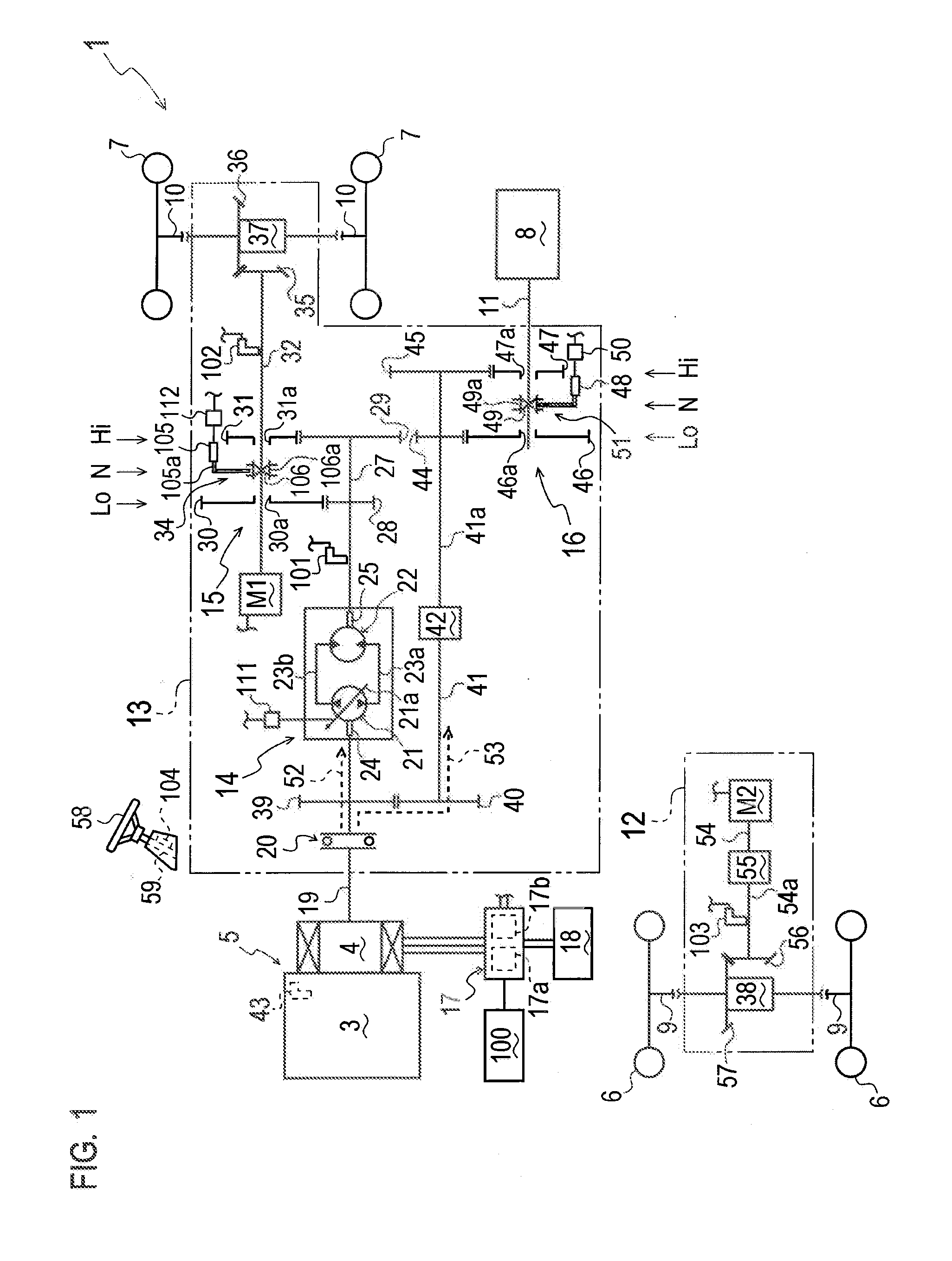

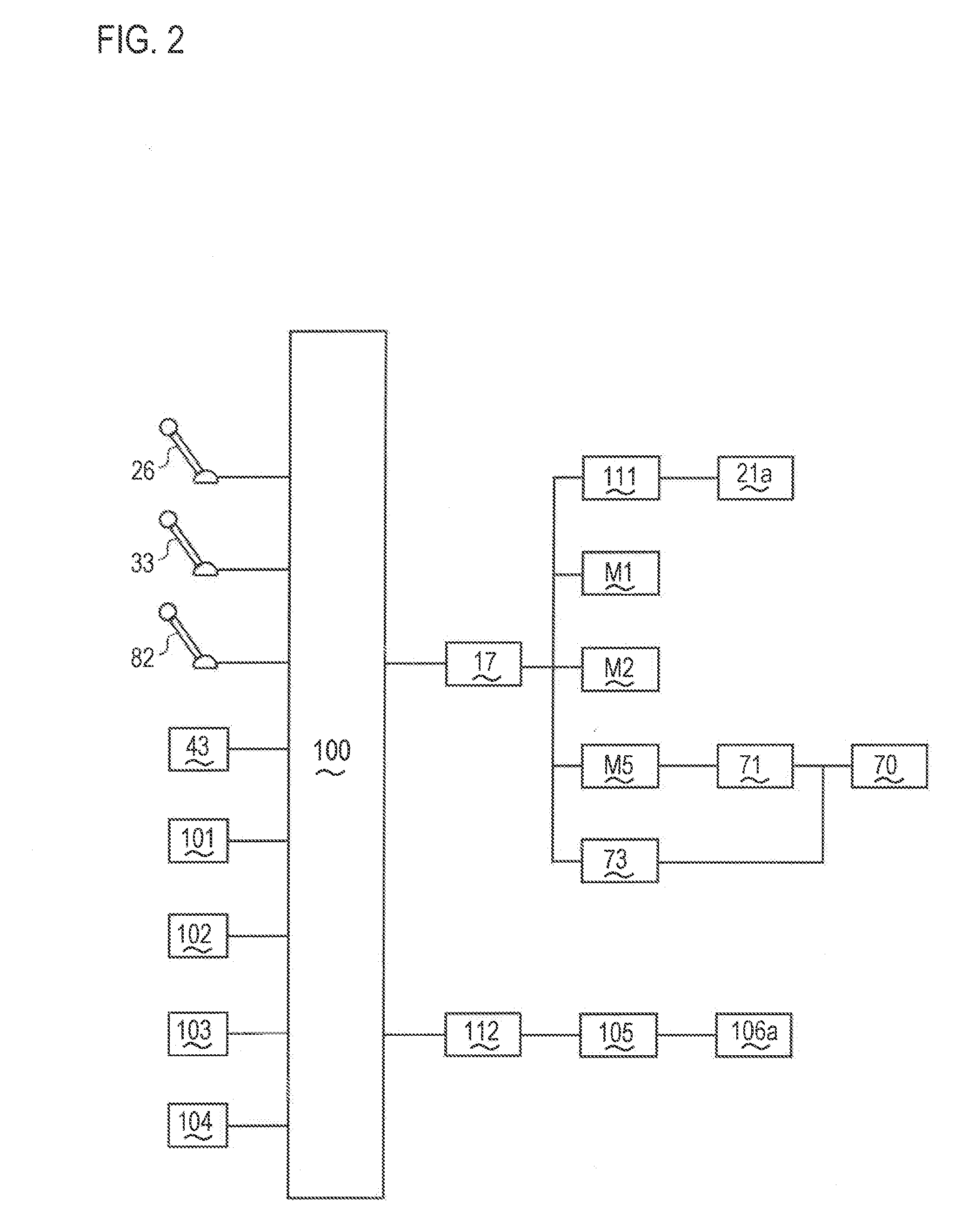

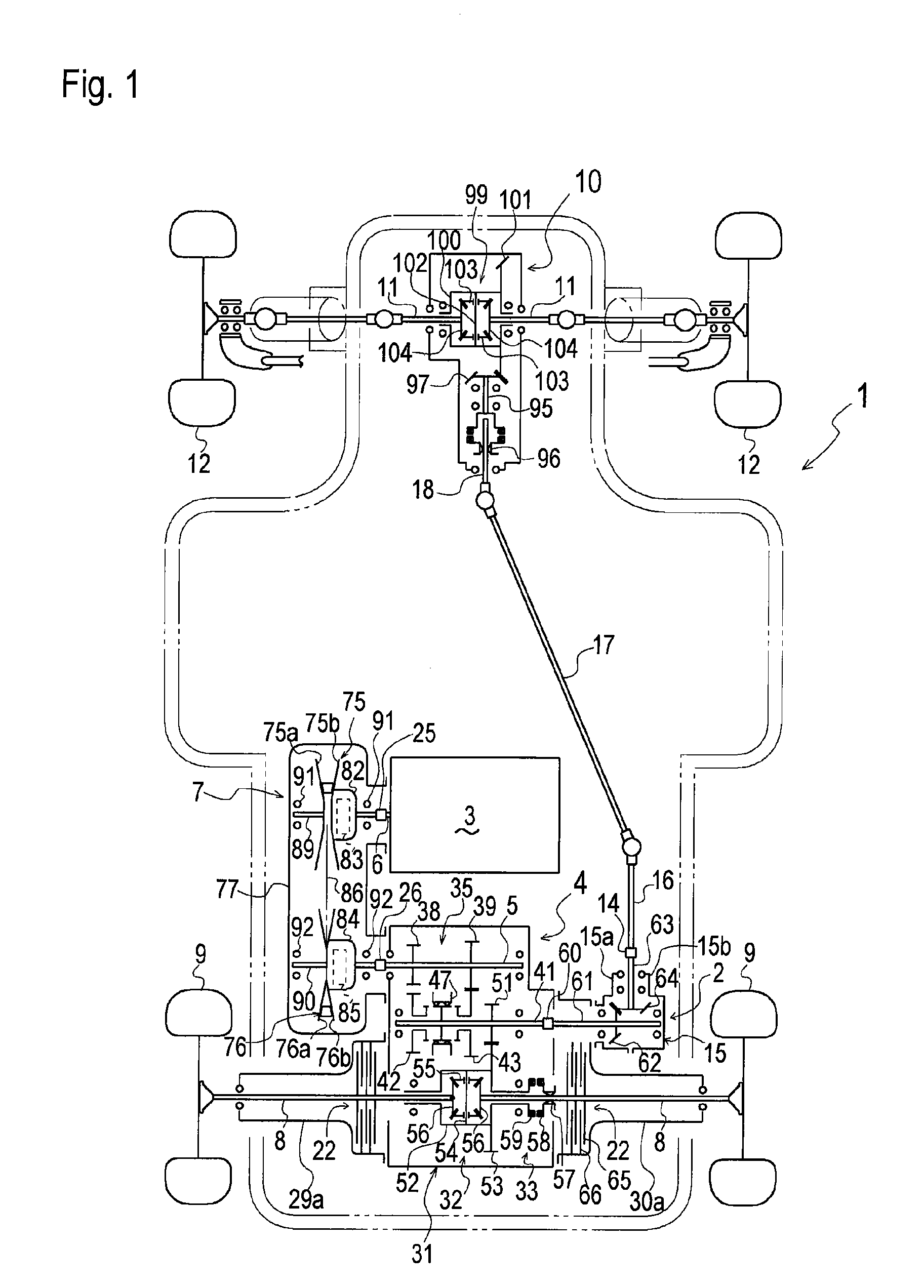

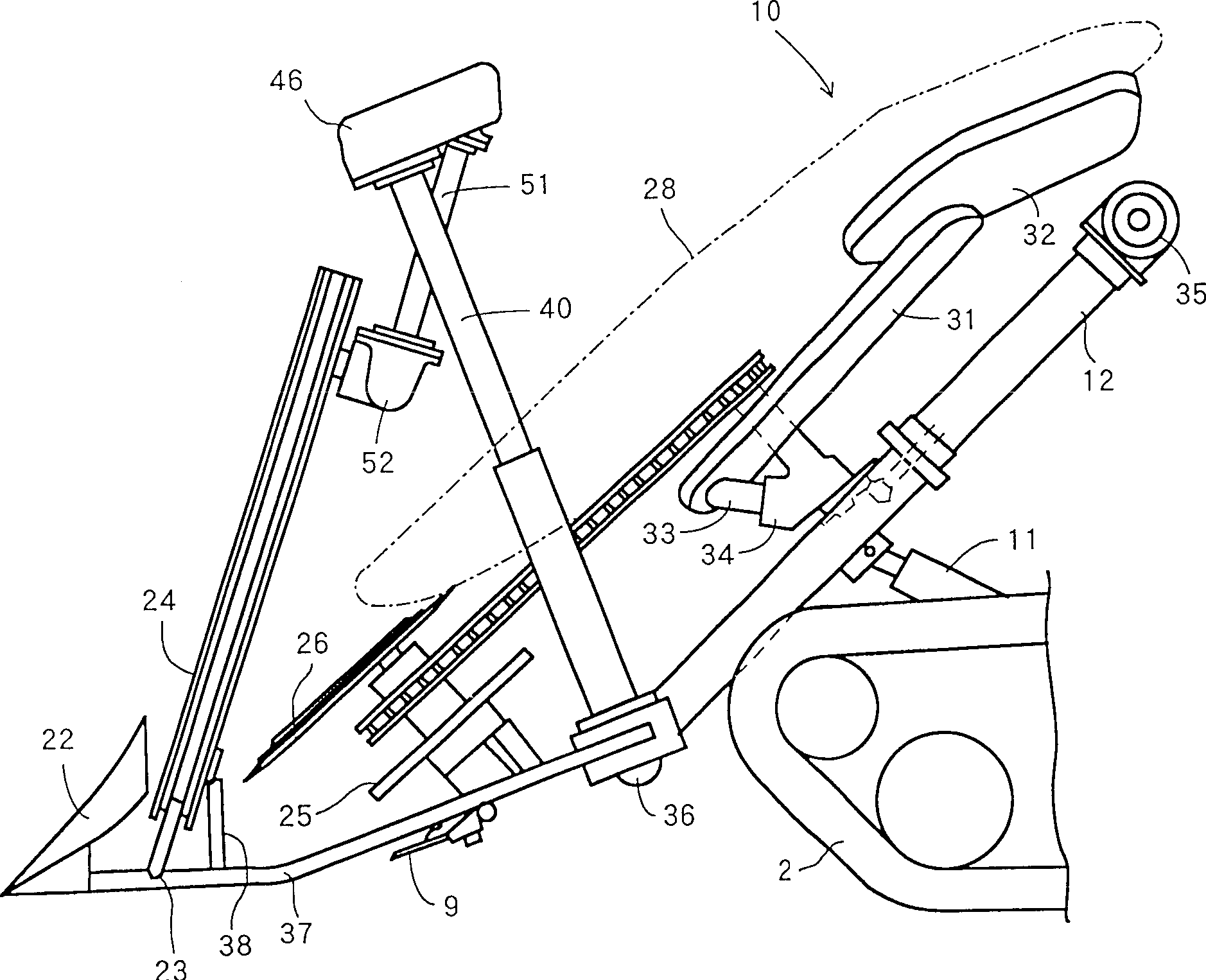

Hybrid Working Vehicle

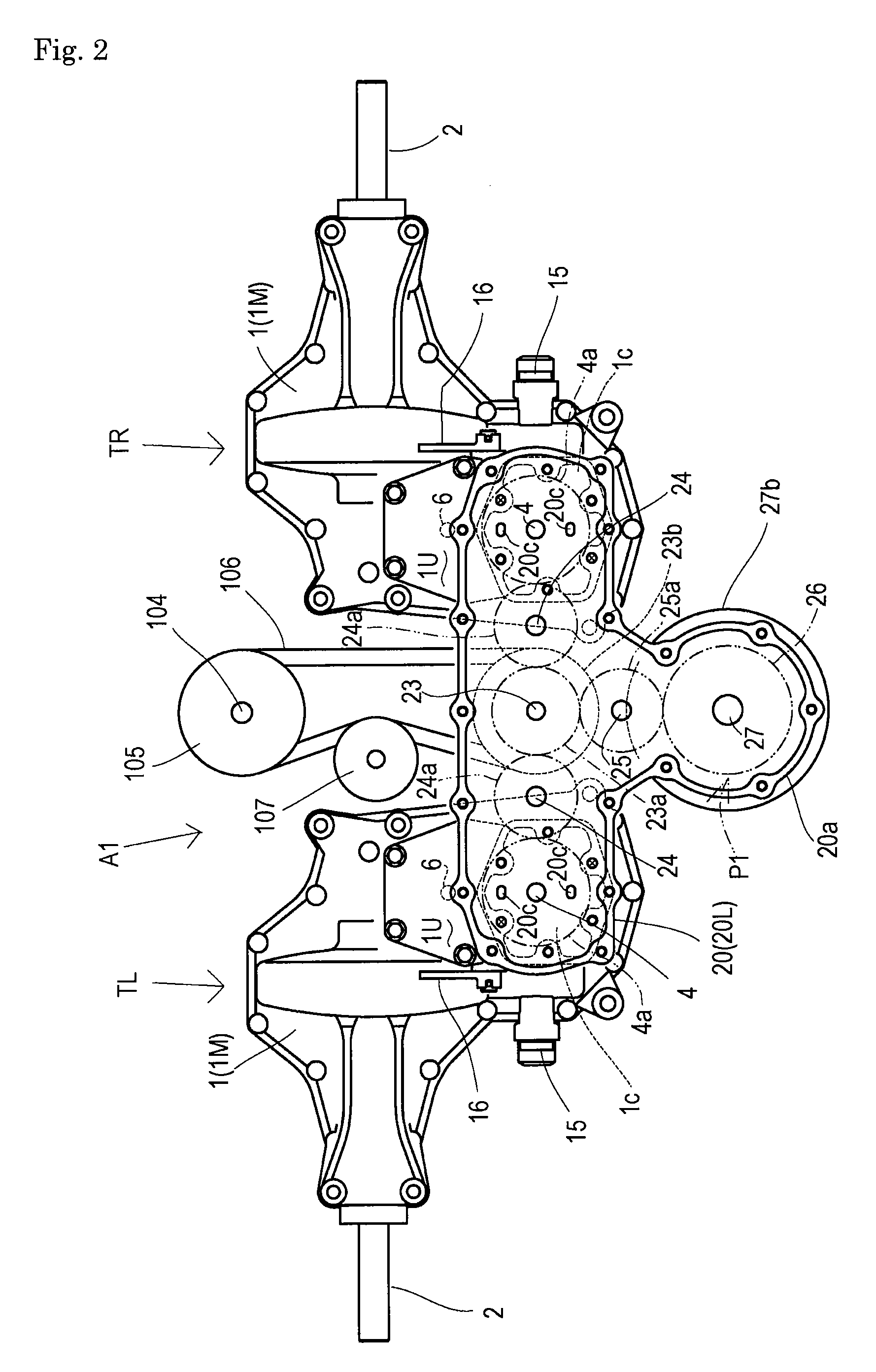

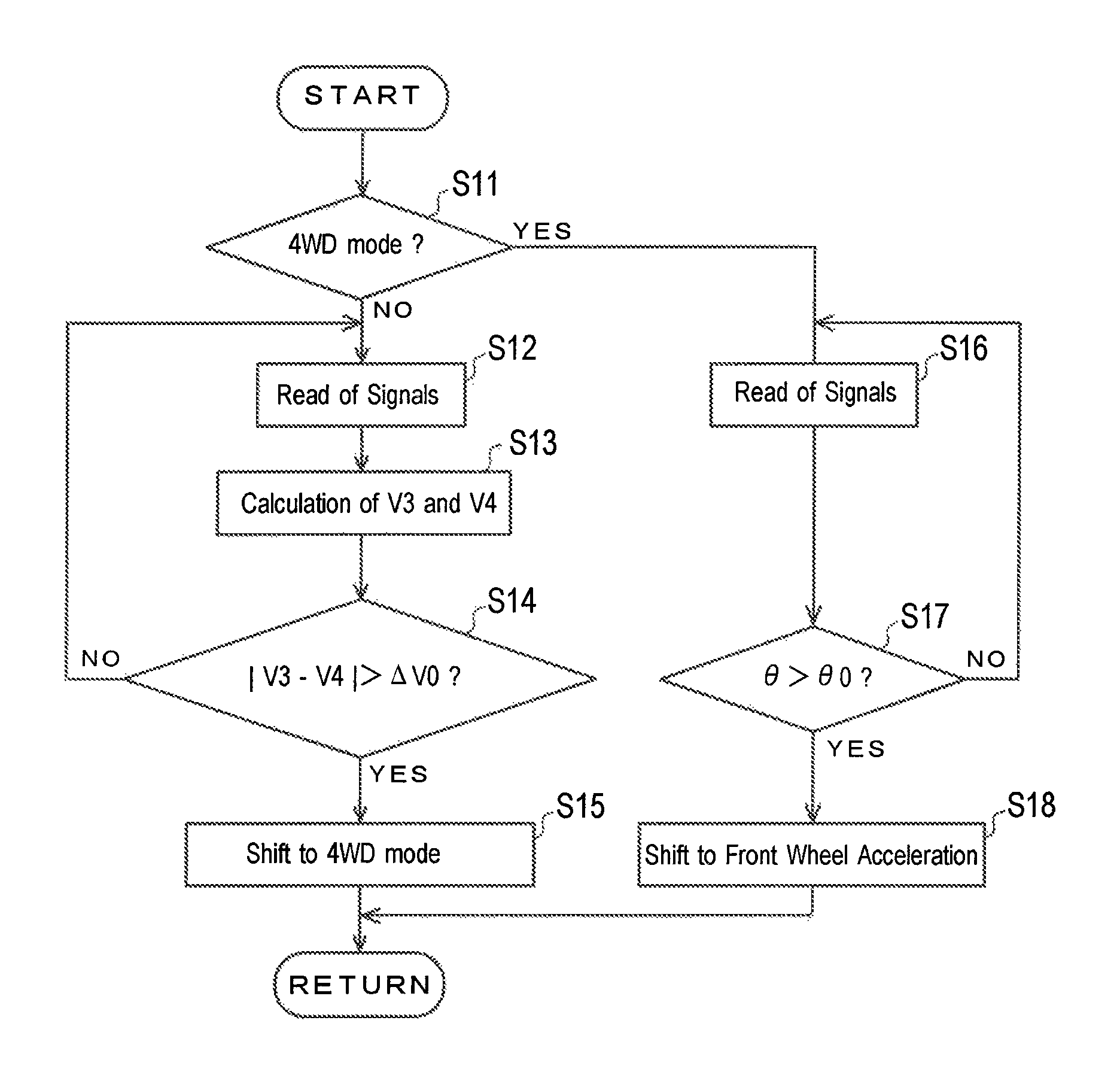

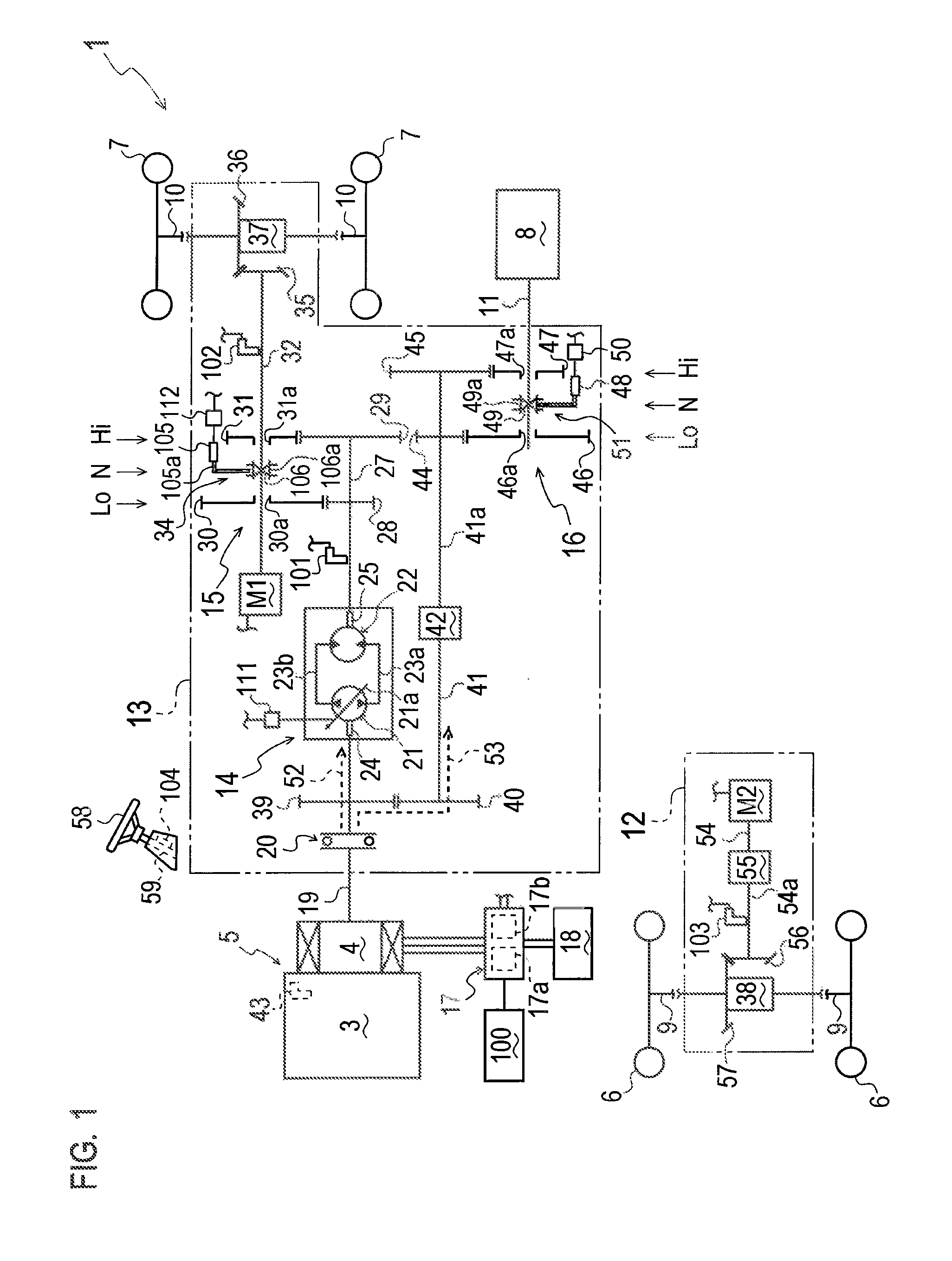

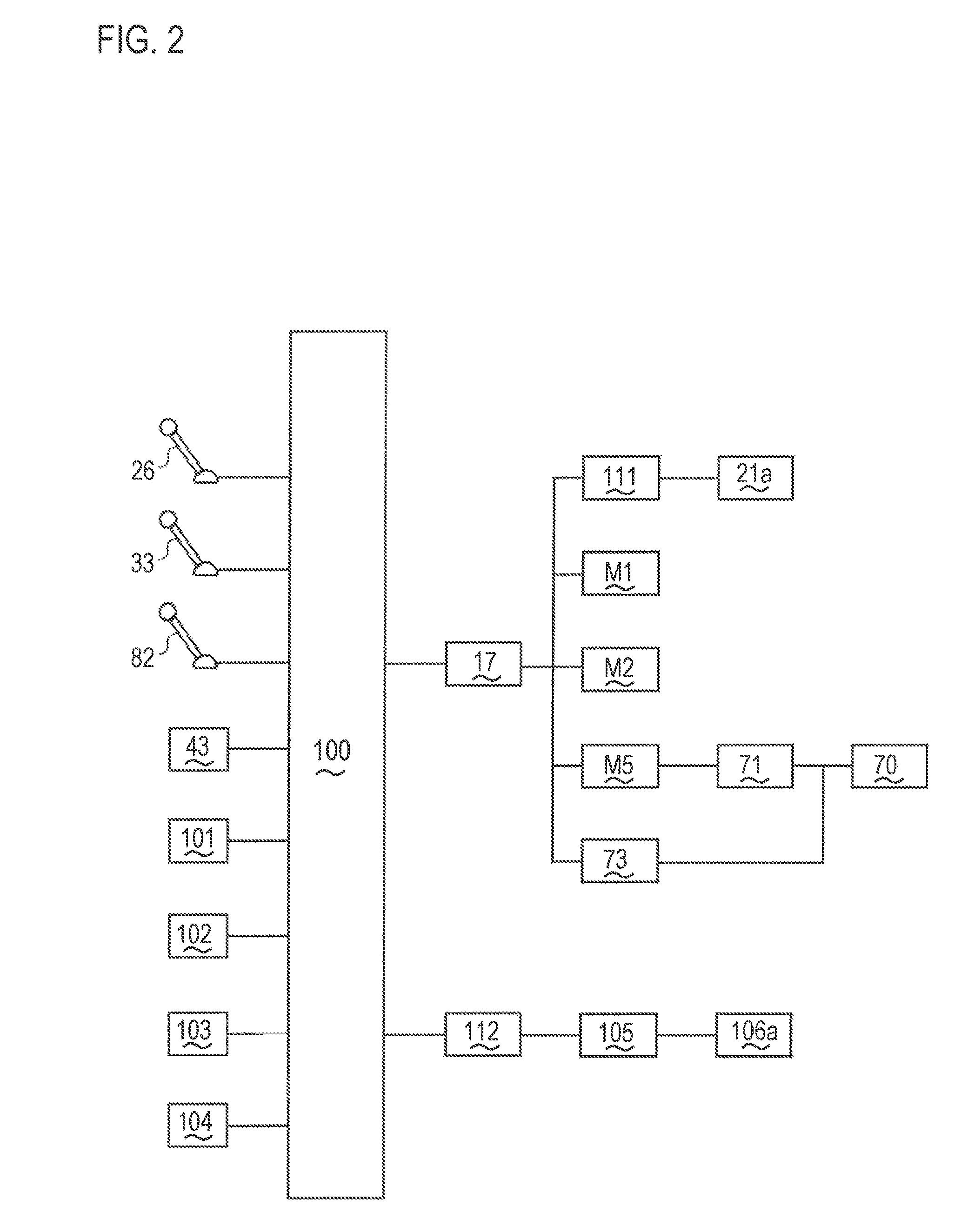

ActiveUS20130066496A1Improved turning performanceEnsure compactnessDigital data processing detailsPlural diverse prime-mover propulsion mountingDrive wheelTransmitted power

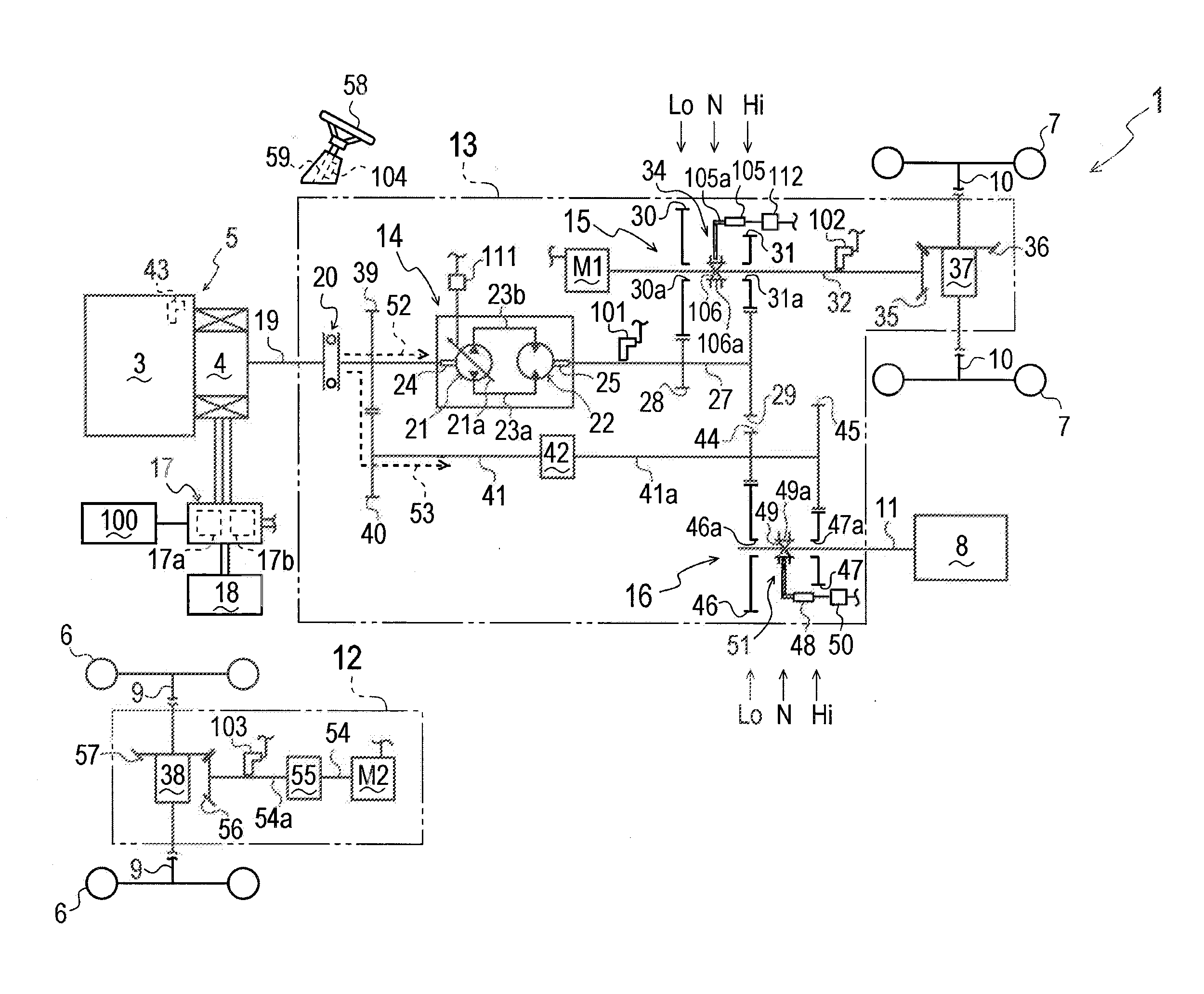

A hybrid working vehicle comprises an engine, a drive wheel, a power take-off (PTO) shaft, and a power transmission system for transmitting power from the engine to the drive wheel and the PTO shaft. The power transmission system is bifurcated at a bifurcating point into a traveling drive train for driving the drive wheel and a PTO drive train for driving the PTO shaft. A continuously variable transmission is provided on the traveling drive train, and a motor generator is provided on the power transmission system between the engine and the bifurcating point. The motor generator functions as a generator by power of the engine and functions as an electric motor for driving the power transmission system. The hybrid working vehicle includes a controller for controlling an output rotary speed of the motor generator functioning as the electric motor.

Owner:KANZAKI KOKYUKOKI MFG

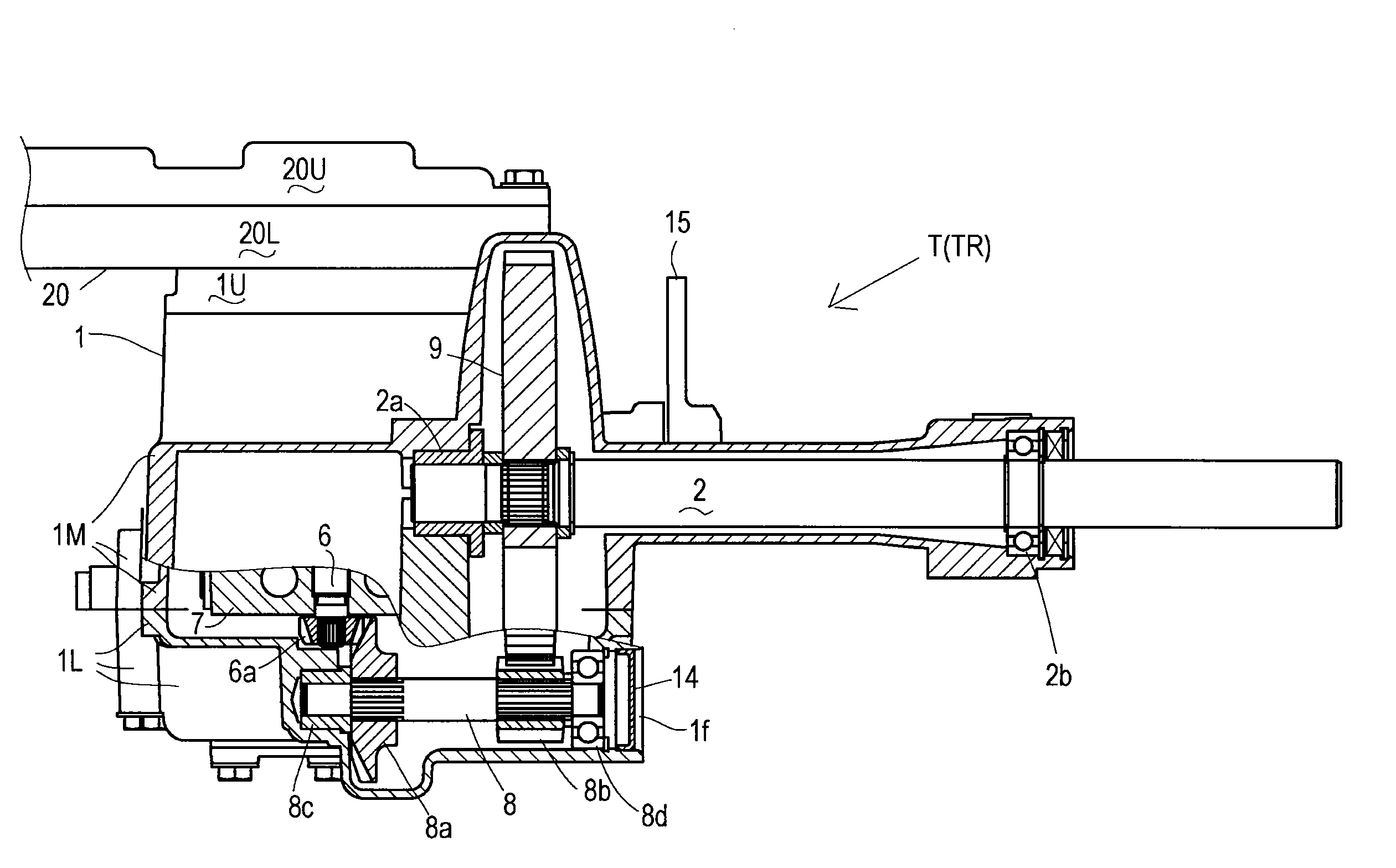

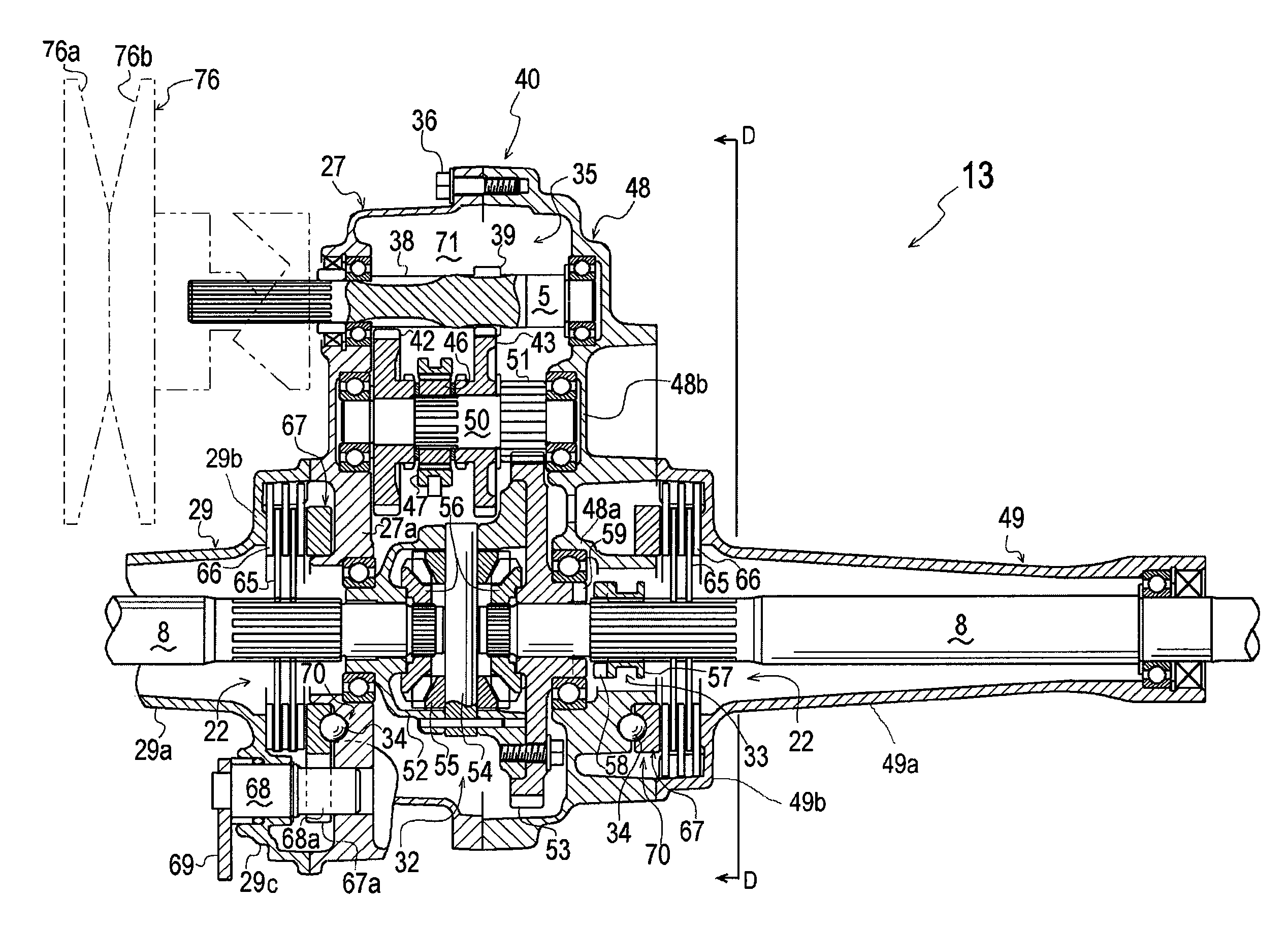

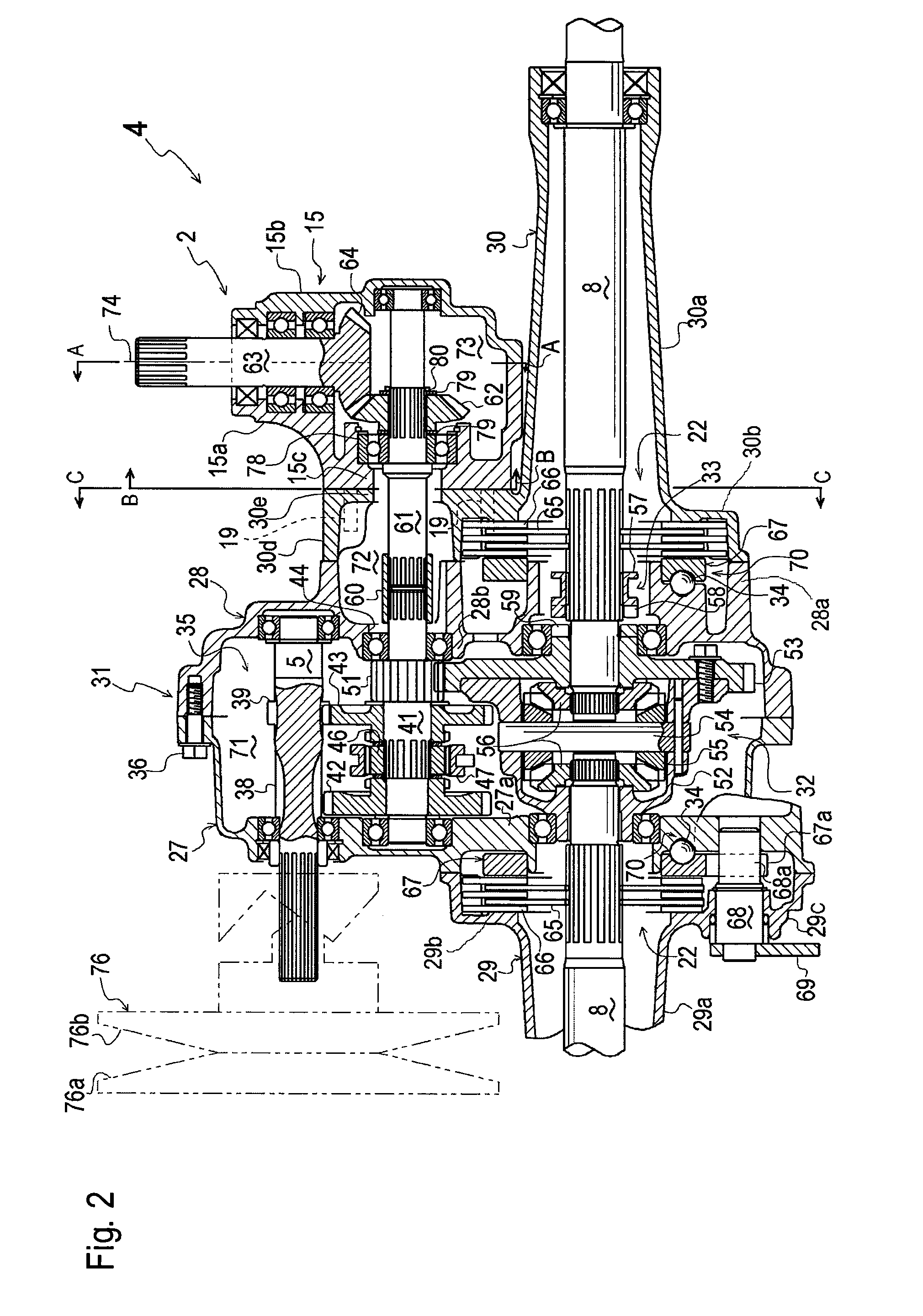

Power Transmission Apparatus for Working Vehicle

A power transmission apparatus for a working vehicle has substantially symmetrically disposed first and second transaxles, each of which supports a single axle, and a working apparatus driving power take-off device including an input member. A gear casing is spanned between the first and second transaxles. A primary drive shaft is disposed in the gear casing so as to be drivingly connected to a prime mover. A traveling drive train is disposed in the gear casing so as to drivingly connect the primary drive shaft to the input shafts of the respective transaxles. A working apparatus drive train is disposed in the gear casing so as to drivingly connect the primary drive shaft to the input member of the working apparatus driving power take-off device.

Owner:IRIKURA KOJI +2

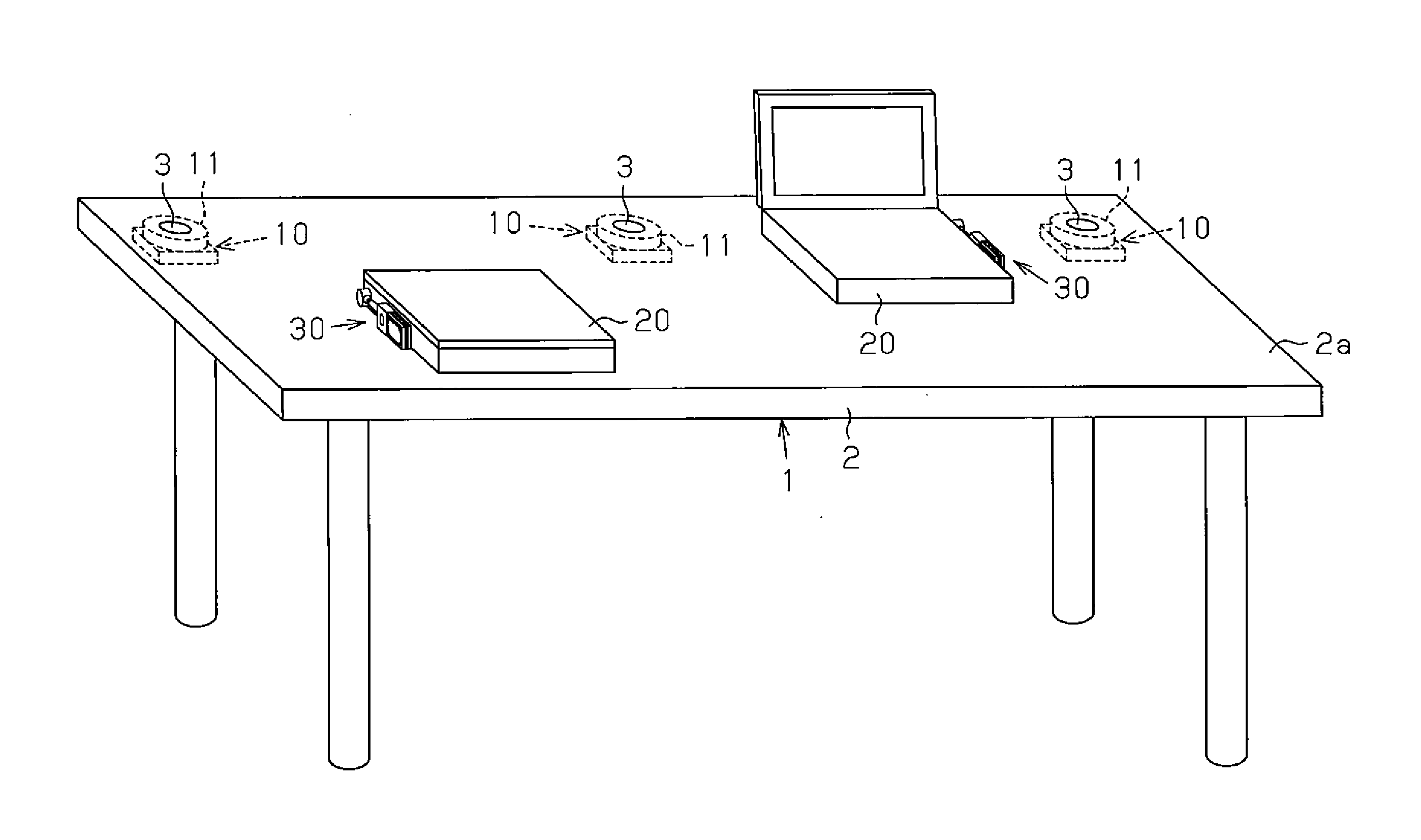

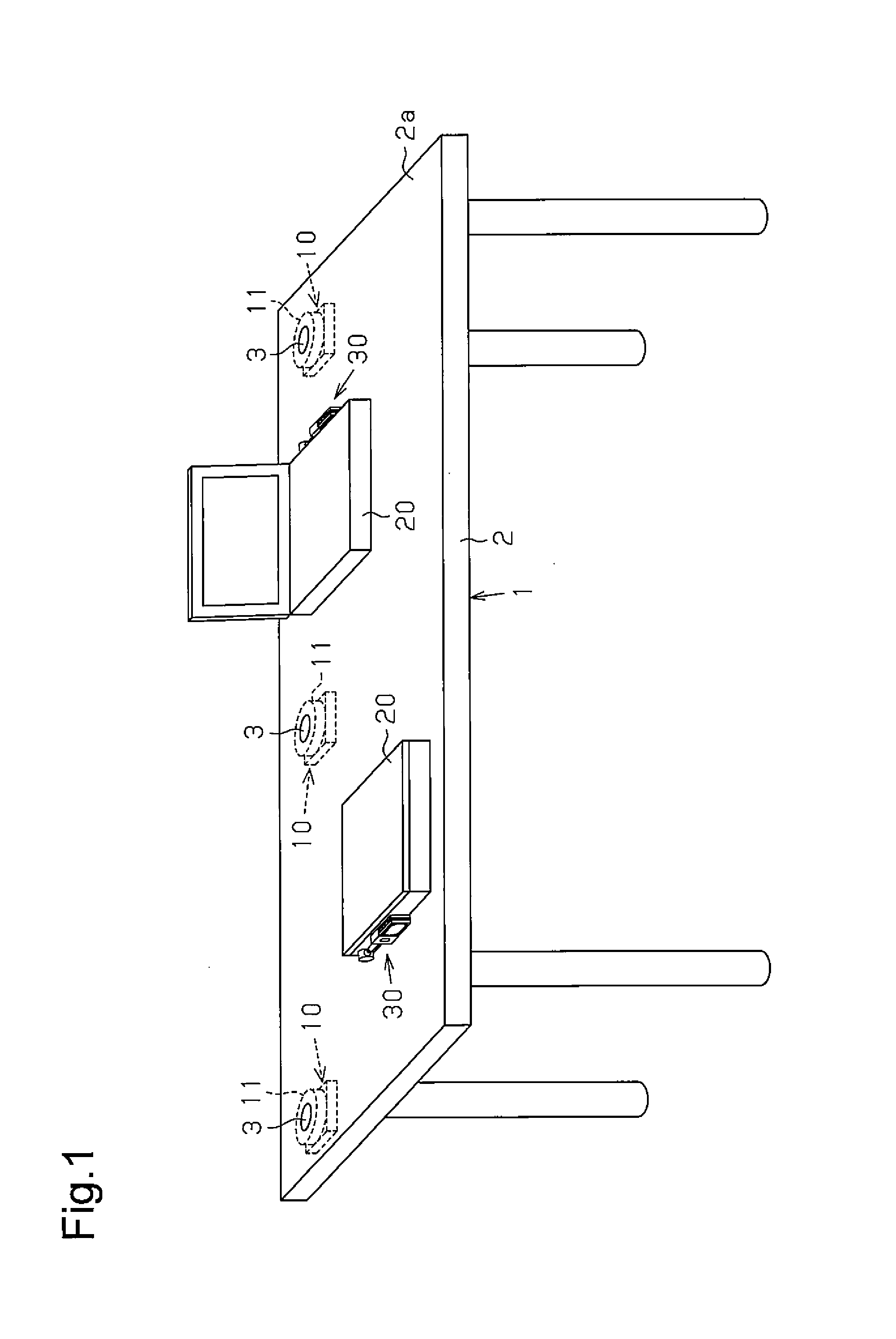

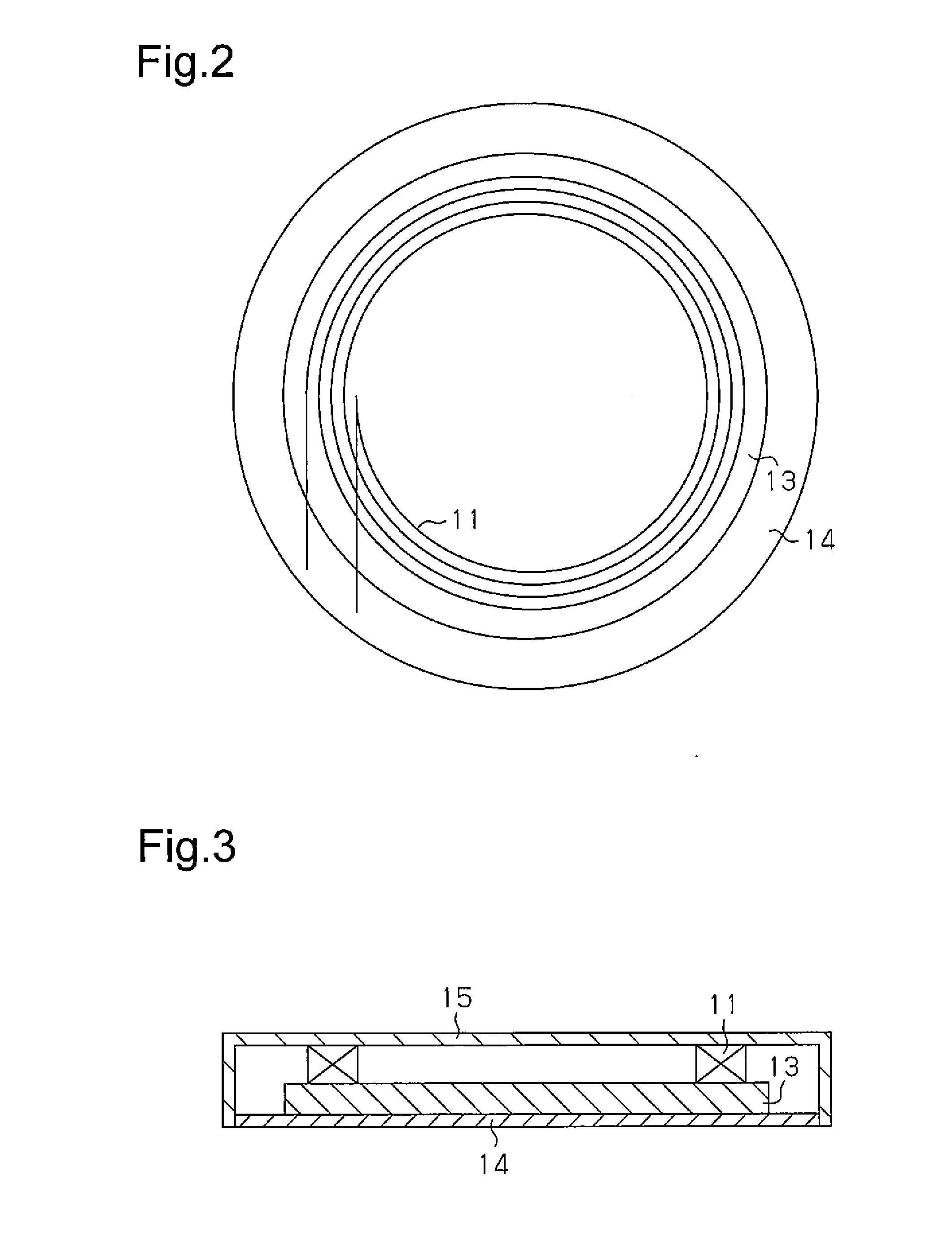

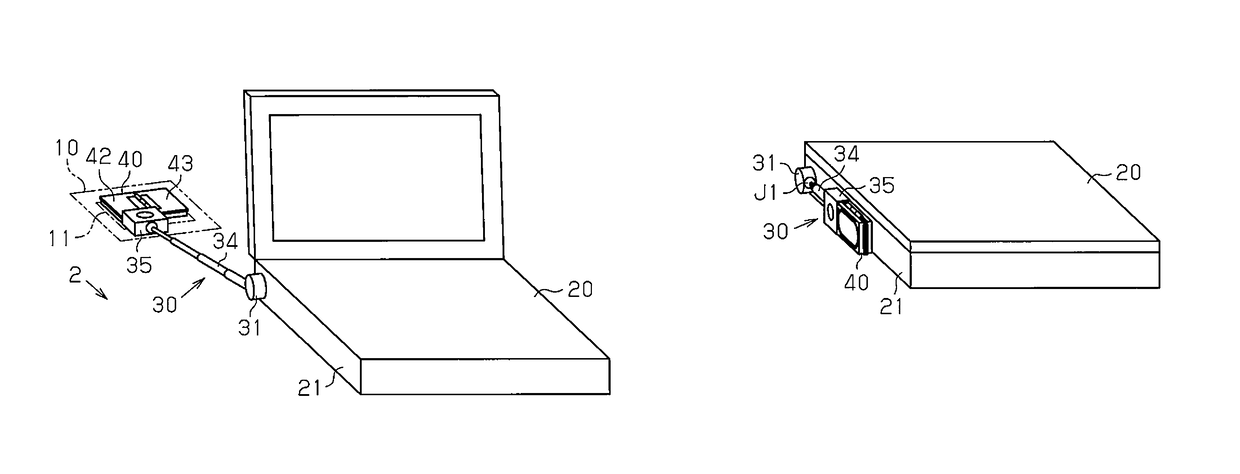

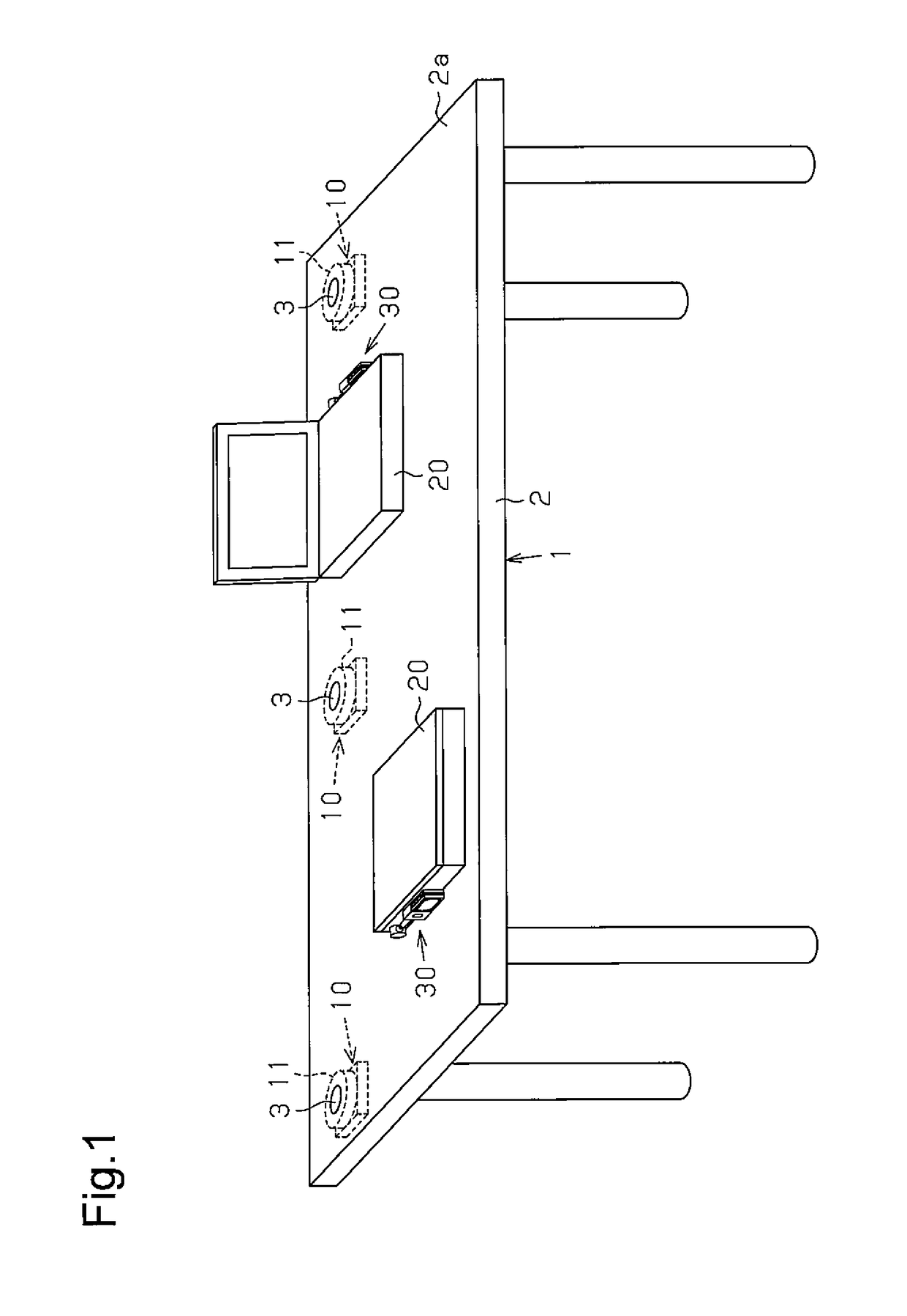

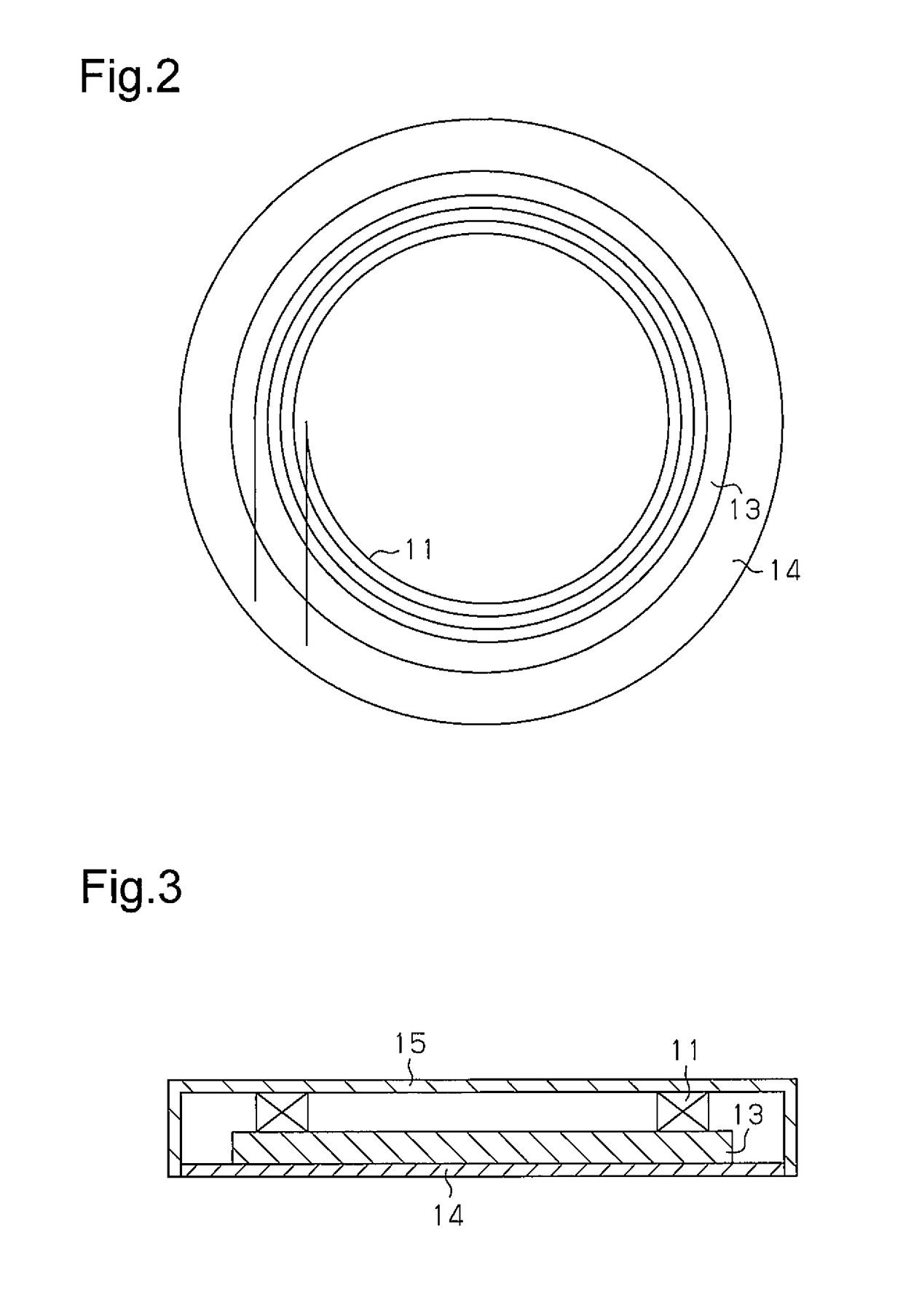

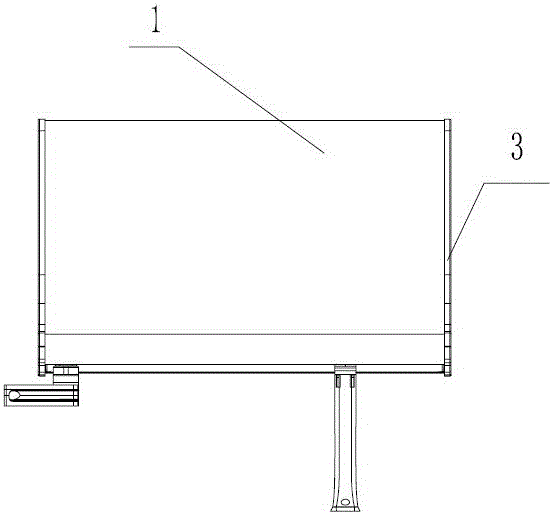

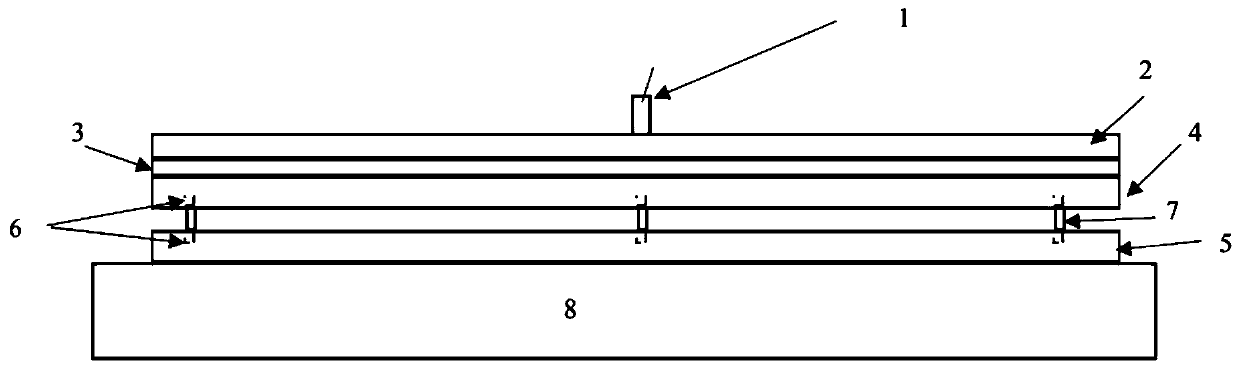

Contactless power-supply system, contactless adapter, and power-supply device

ActiveUS20150244175A1Increase freedomIncrease productionNear-field transmissionBatteries circuit arrangementsEngineeringPower circuits

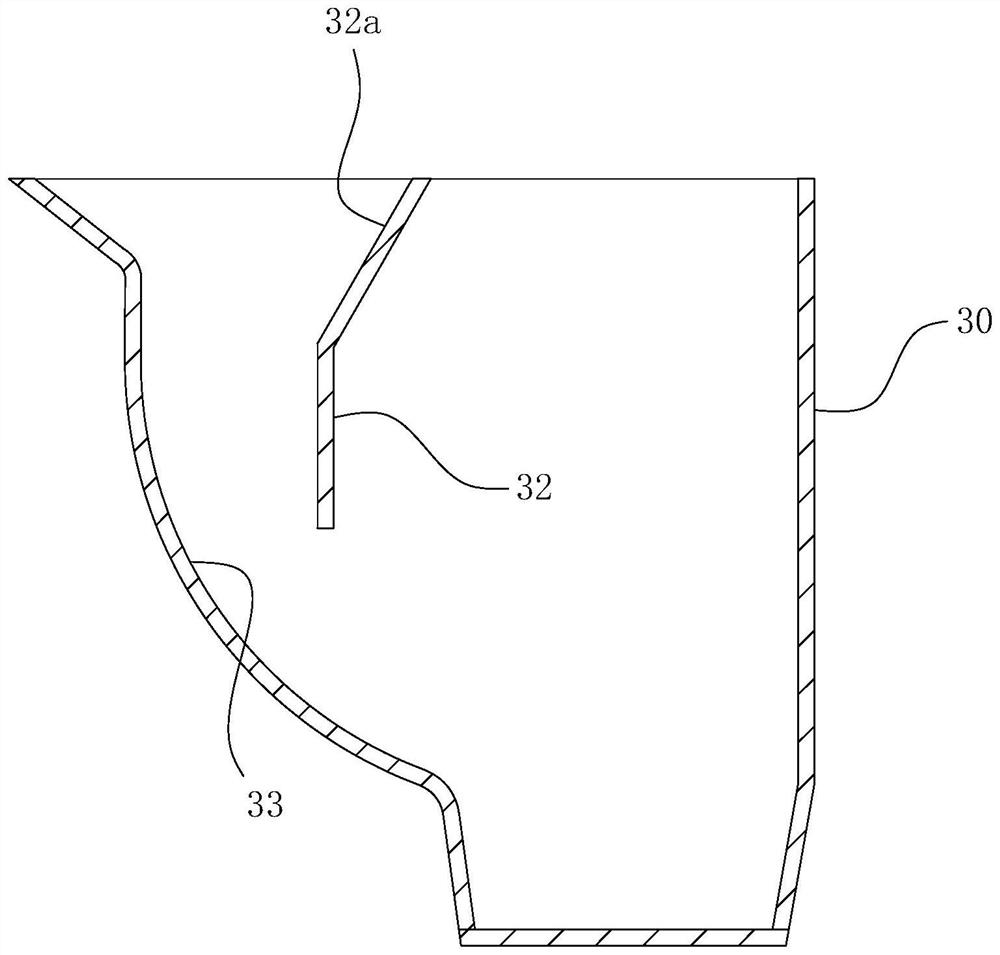

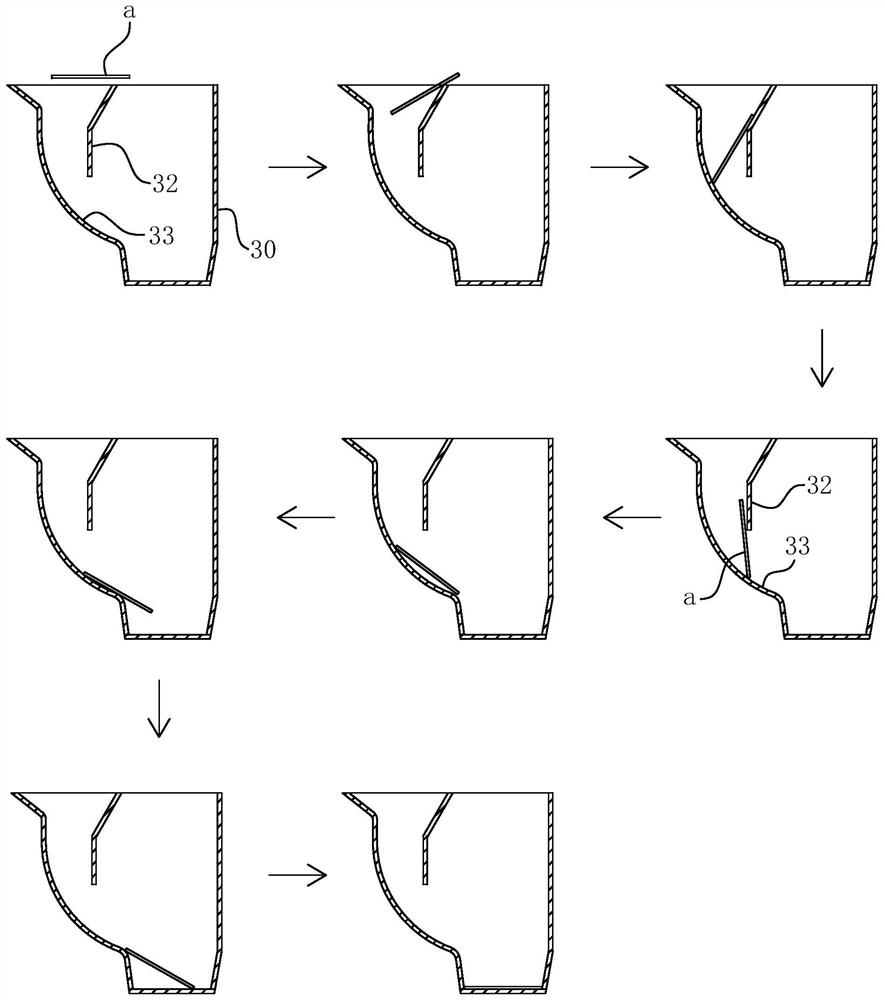

A contactless adapter (30) installed in a notebook computer (20) has a plug part (31), a telescopic arm (34), a power circuit part (35), and a power-receiving part (40). The power-receiving part (40) is provided with a secondary coil (41) and has a rotatably linked fixed base plate (42) and a rotating base plate (43). Power can be supplied without contact to the notebook computer (20) from a power-supply device (10) via the contactless adapter (30) by expanding the fixed base plate (42) and the rotating base plate (43) to cause the secondary coil (41) to face the primary coil (11) of the power-supply device (10) provided inside the tabletop (2) of a desk (1).

Owner:PANASONIC INTELLECTUAL PROPERTY MANAGEMENT CO LTD

Hybrid working vehicle

ActiveUS8996214B2Ensure compactnessEnsuring economyMonorailsDigital data processing detailsDrive wheelDrivetrain

Owner:KANZAKI KOKYUKOKI MFG

Transaxle

InactiveUS20080308340A1Improve external appearanceEnsure compactnessGearing detailsVehiclesTransaxleEngineering

In a transaxle, a transaxle housing includes a first divisional housing member and a second divisional housing member joined to each other. A transmission is disposed in the first divisional housing member. An axle is disposed in the mutually joined first and second divisional housing members and drivingly connected to the transmission in the first divisional housing member. A brake device is provided on the axle. The second divisional housing member is formed integrally with a brake chamber portion joined to the first divisional housing member so as to incorporate the brake device in the brake chamber portion. The transaxle is provided with a power take-off device for taking off power from the transmission, including a power take-off casing. A connection shaft is interposed between the transmission and the power take-off device. The second divisional housing member is formed integrally with a mount portion expanded from the brake chamber portion radially with respect to the axle. The power take-off casing is mounted onto the mount portion. The connection shaft is passed through the mount portion between the first divisional housing member and the power take-off casing.

Owner:KANZAKI KOKYUKOKI MFG

Contactless power-supply system, contactless adapter, and power-supply device

ActiveUS9948143B2Increase freedomIncrease productionNear-field transmissionBatteries circuit arrangementsElectric forcePower circuits

A contactless adapter (30) installed in a notebook computer (20) has a plug part (31), a telescopic arm (34), a power circuit part (35), and a power-receiving part (40). The power-receiving part (40) is provided with a secondary coil (41) and has a rotatably linked fixed base plate (42) and a rotating base plate (43). Power can be supplied without contact to the notebook computer (20) from a power-supply device (10) via the contactless adapter (30) by expanding the fixed base plate (42) and the rotating base plate (43) to cause the secondary coil (41) to face the primary coil (11) of the power-supply device (10) provided inside the tabletop (2) of a desk (1).

Owner:PANASONIC INTELLECTUAL PROPERTY MANAGEMENT CO LTD

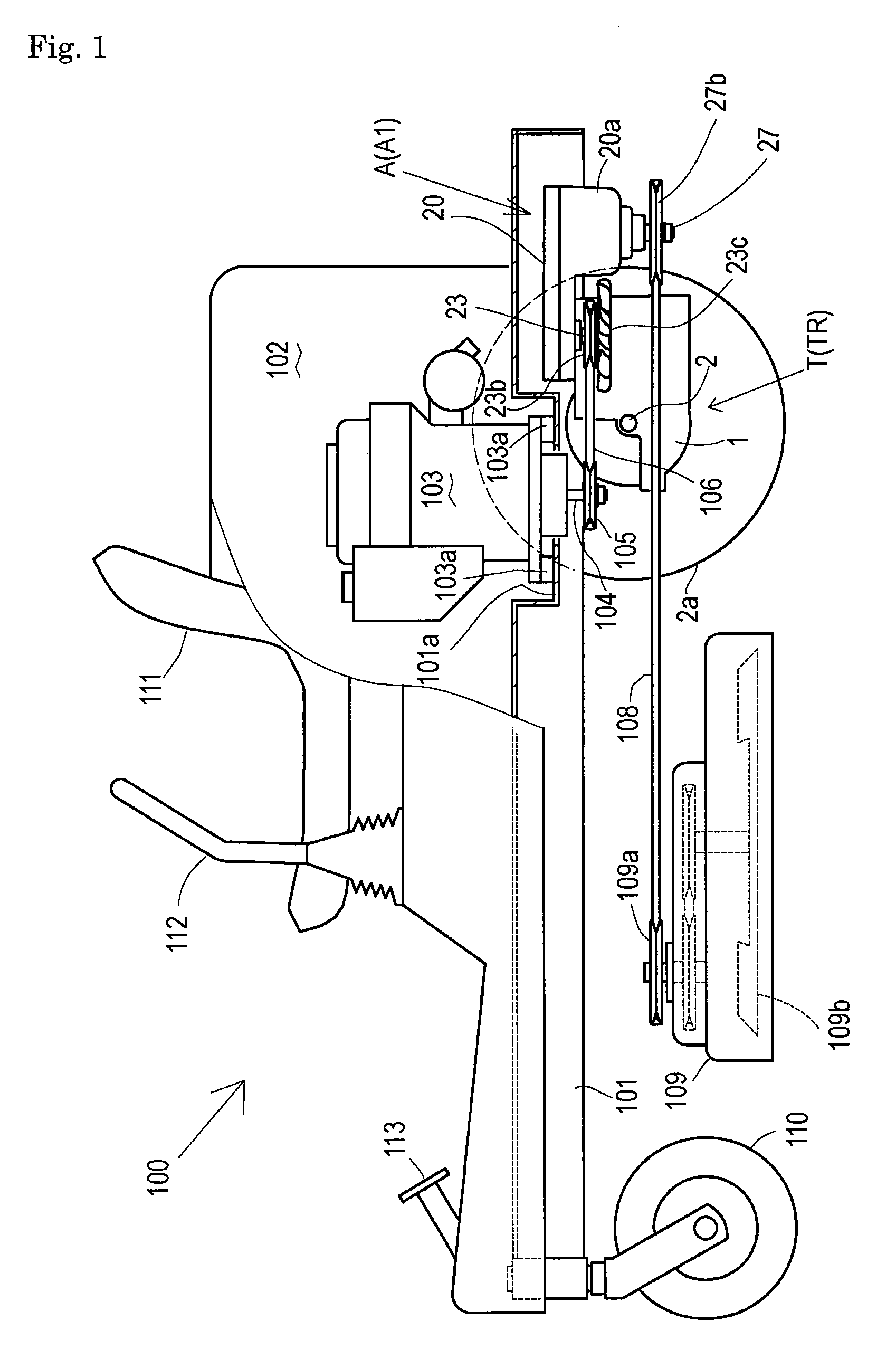

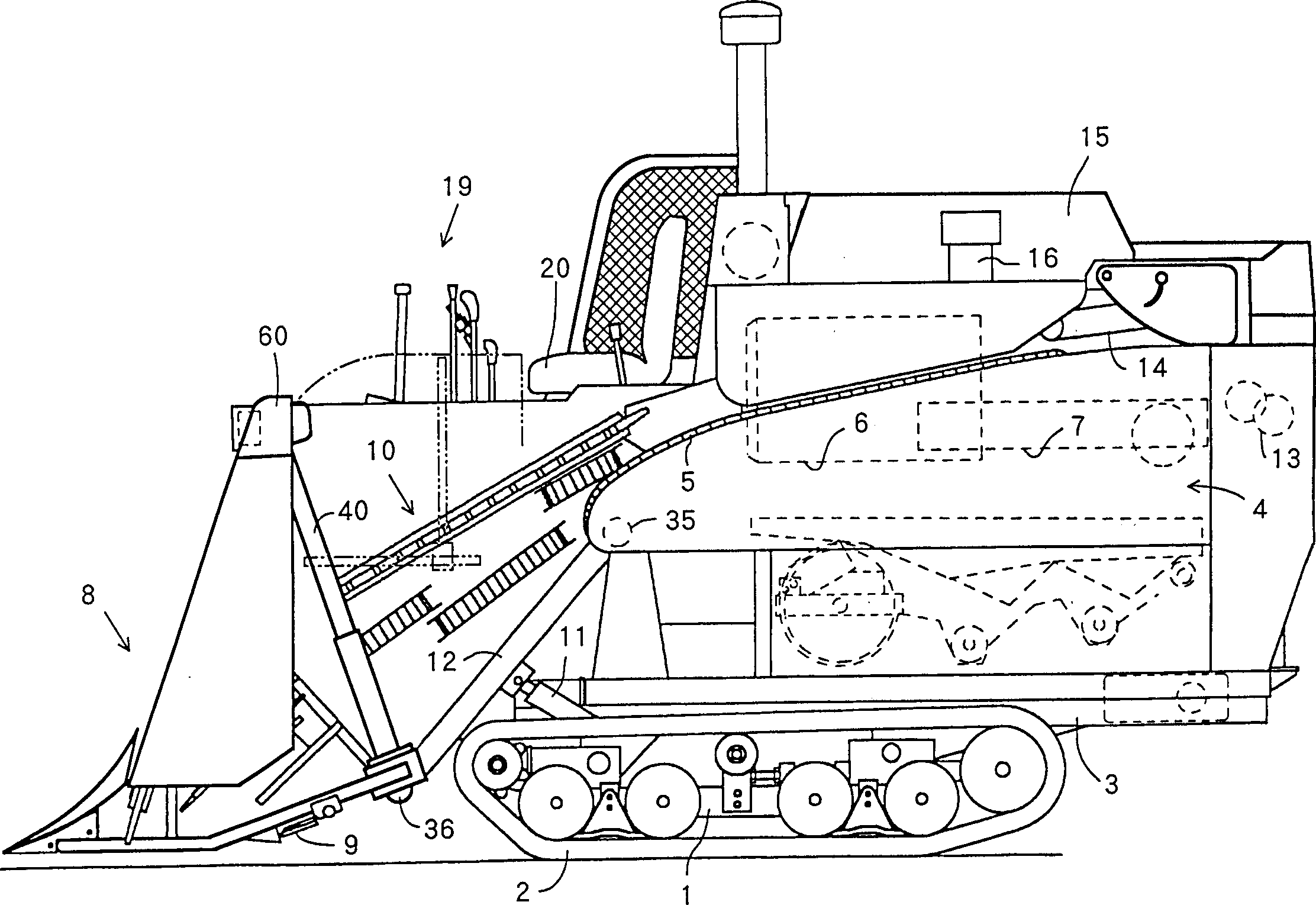

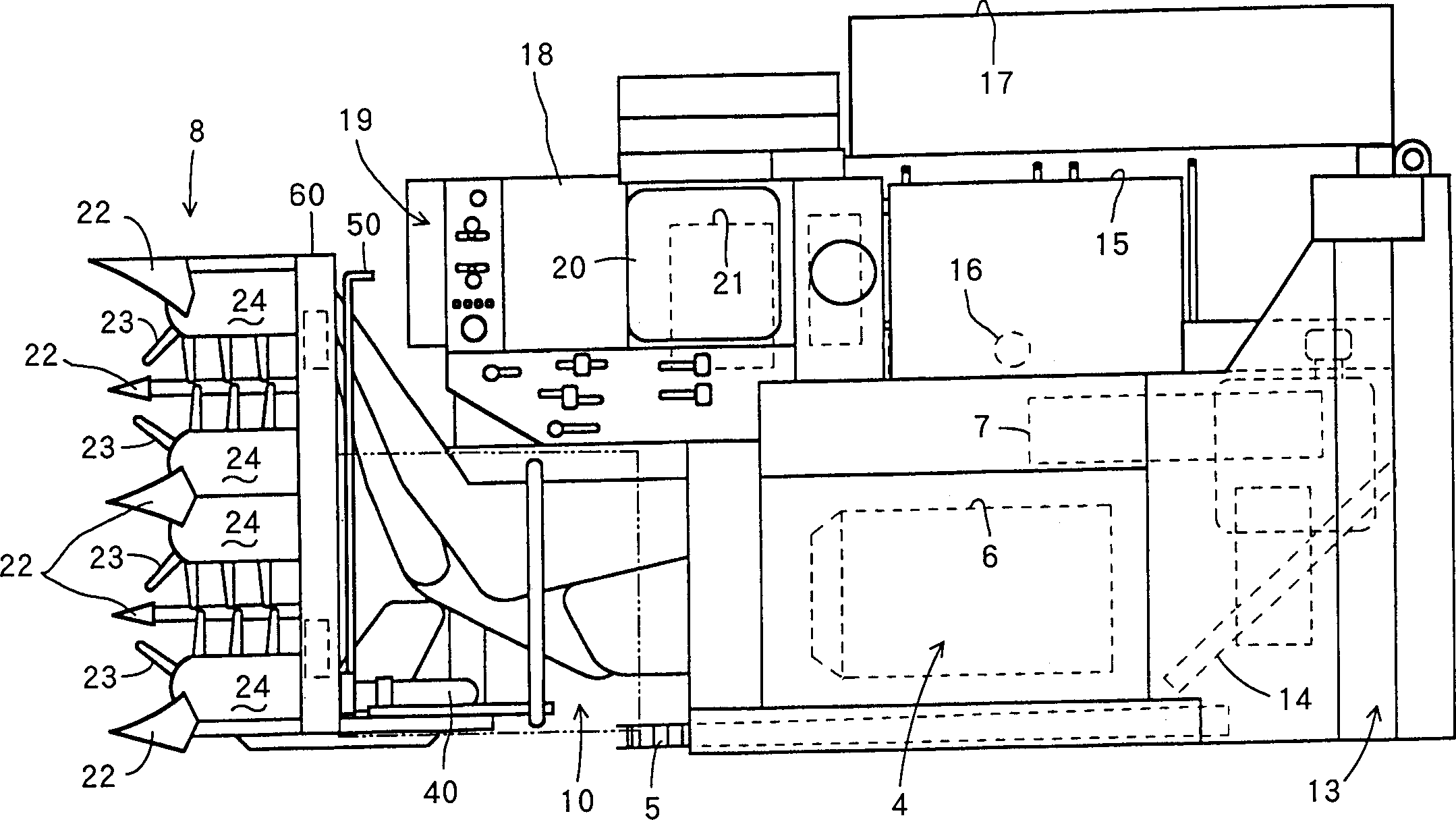

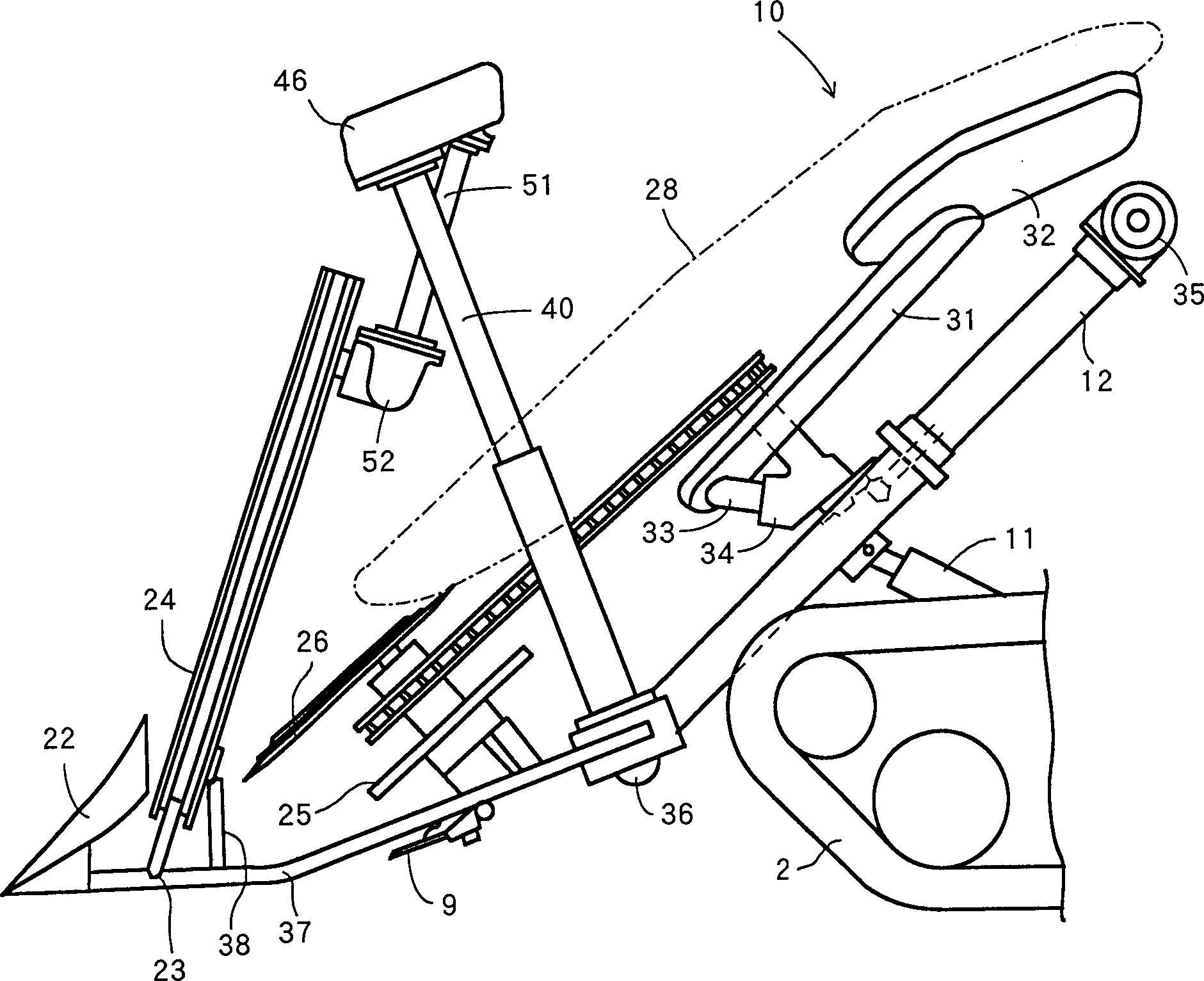

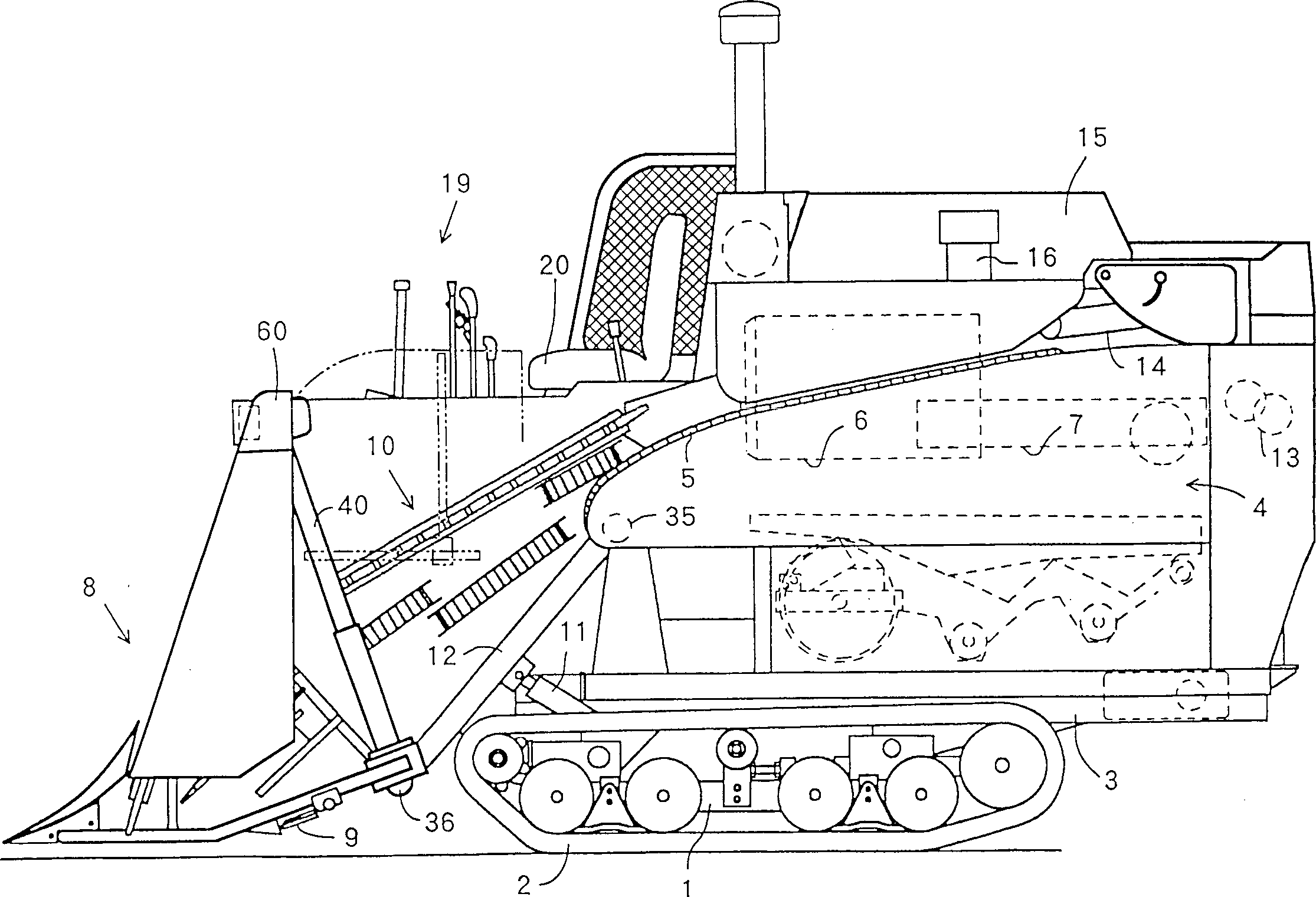

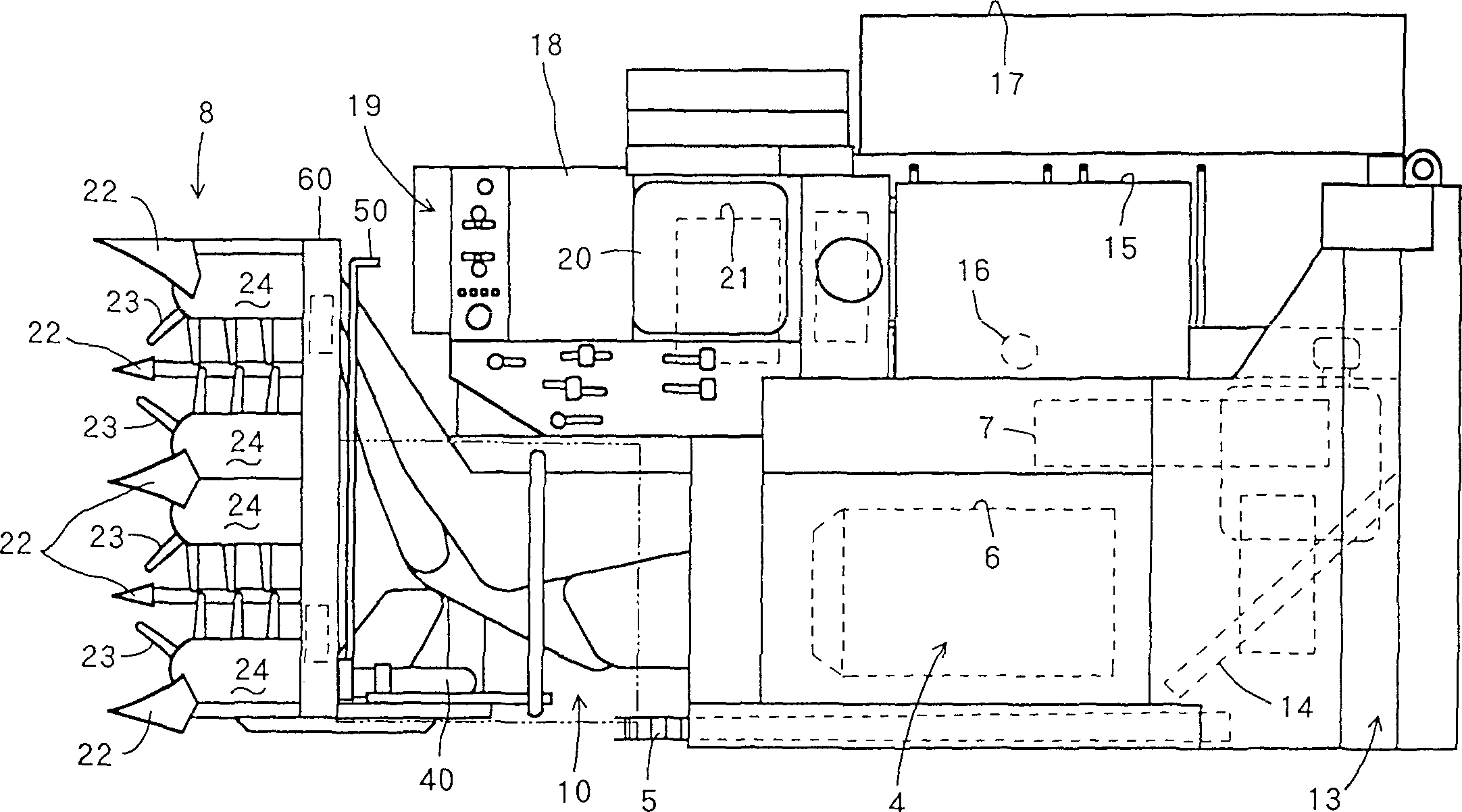

Combine

A combine harvester is provided. Several pull-up cases 24 are vertically installed in the front side of a reaping unit 8, a drive case 42 for pulling up is installed in the back side of a gate 60 above each pull-up case 24 and a motive power is transmitted from the aforesaid drive case 42 to each of the aforesaid pull-up cases 24 installed with pull-up tines 23. It is characterized in that: a sprocket 44 for driving the pull-up tine is installed below a vertical shaft 54 extended from the aforesaid drive case 42, an input shaft 39 for pulling-up is connected to the drive case 42 for pulling-up through a speed change case 46 for pulling-up and the aforesaid input shaft 39 is brought to obliquely cross to the vertical shaft 54 on the side view. In this way, the backward tilting angle of a pull-up case and the forward tilting angle of an input shaft can be easily ensured, and the compaction of a structure for pulling up long cereal stems and a bearing power for pulling up by the aforesaid input shaft can be ensured.

Owner:YANMAR POWER TECHNOLOGY CO LTD

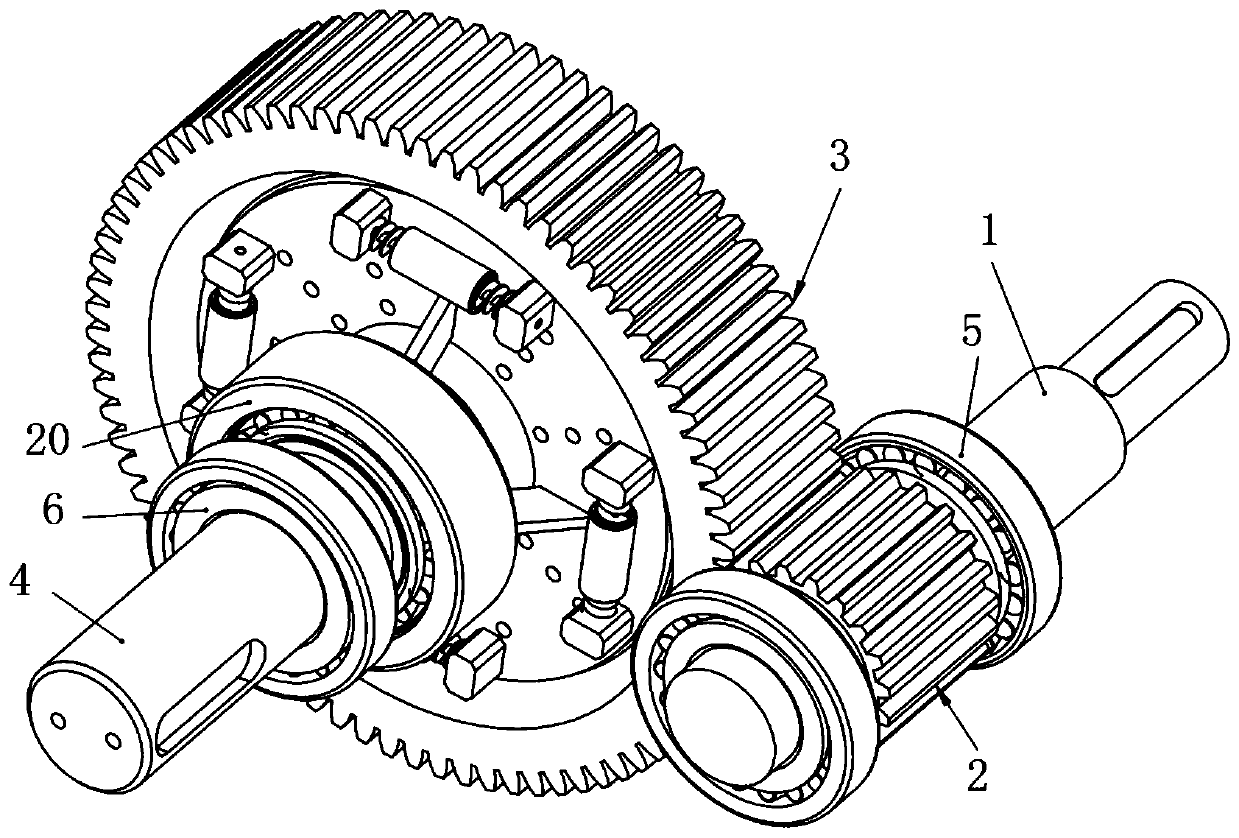

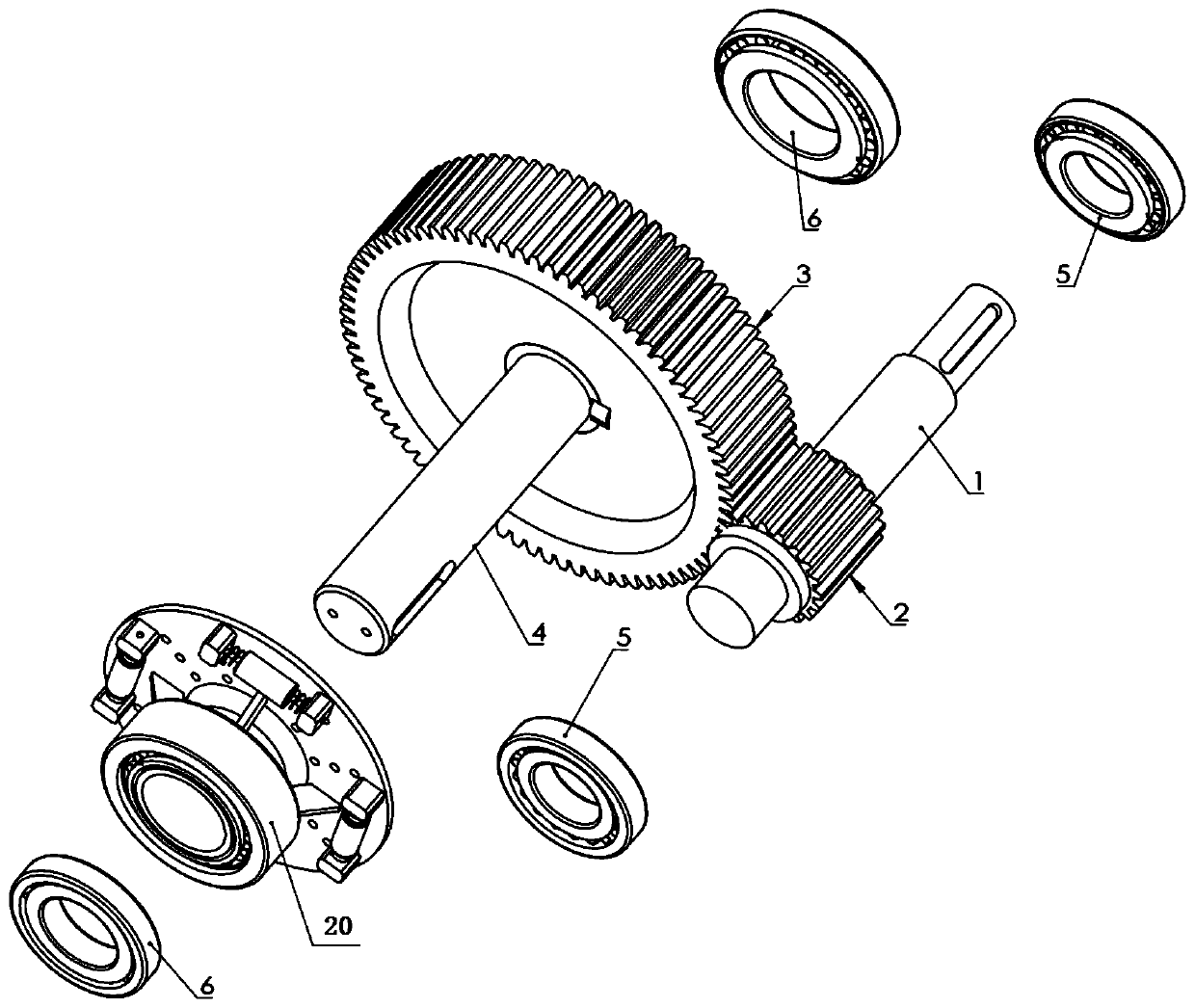

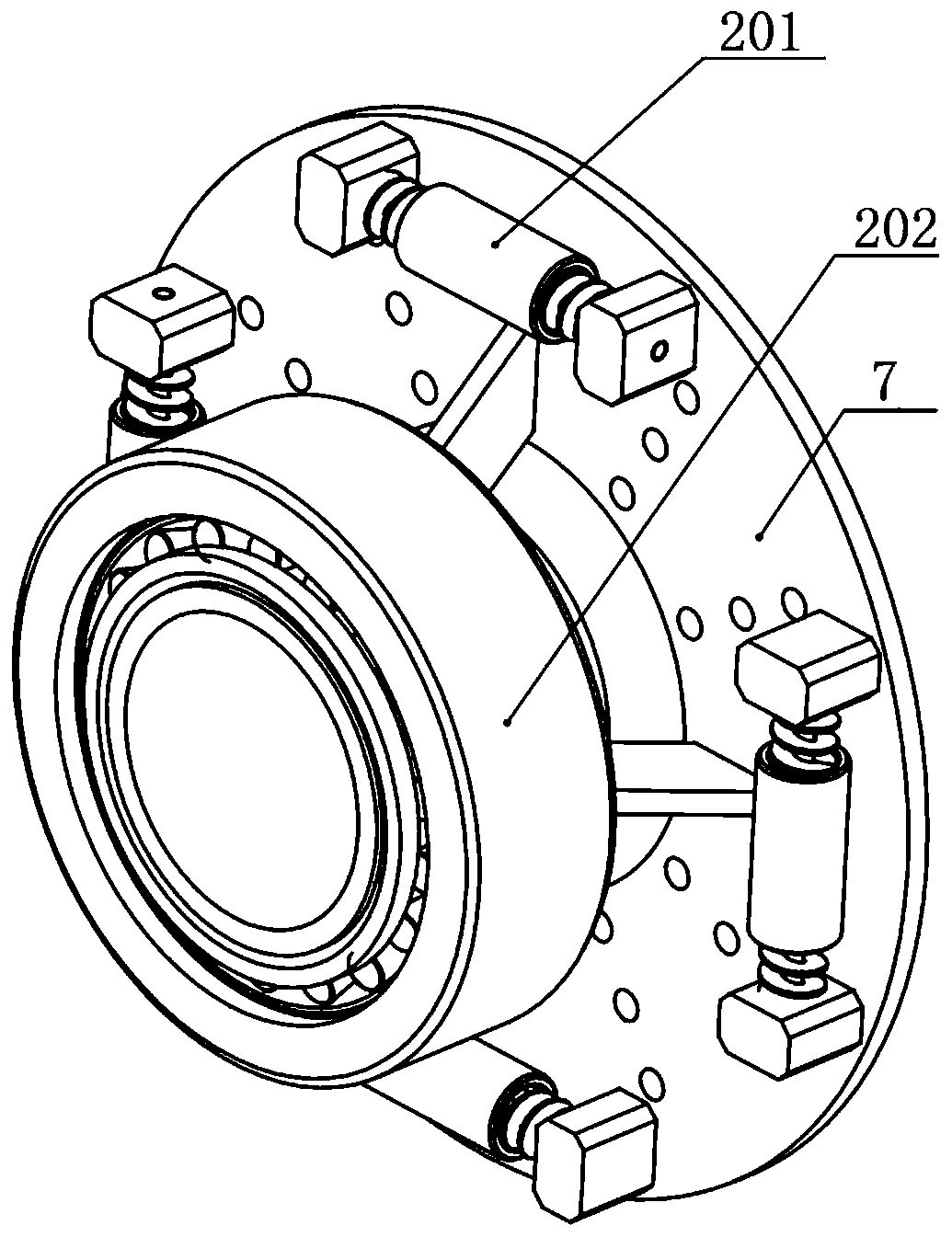

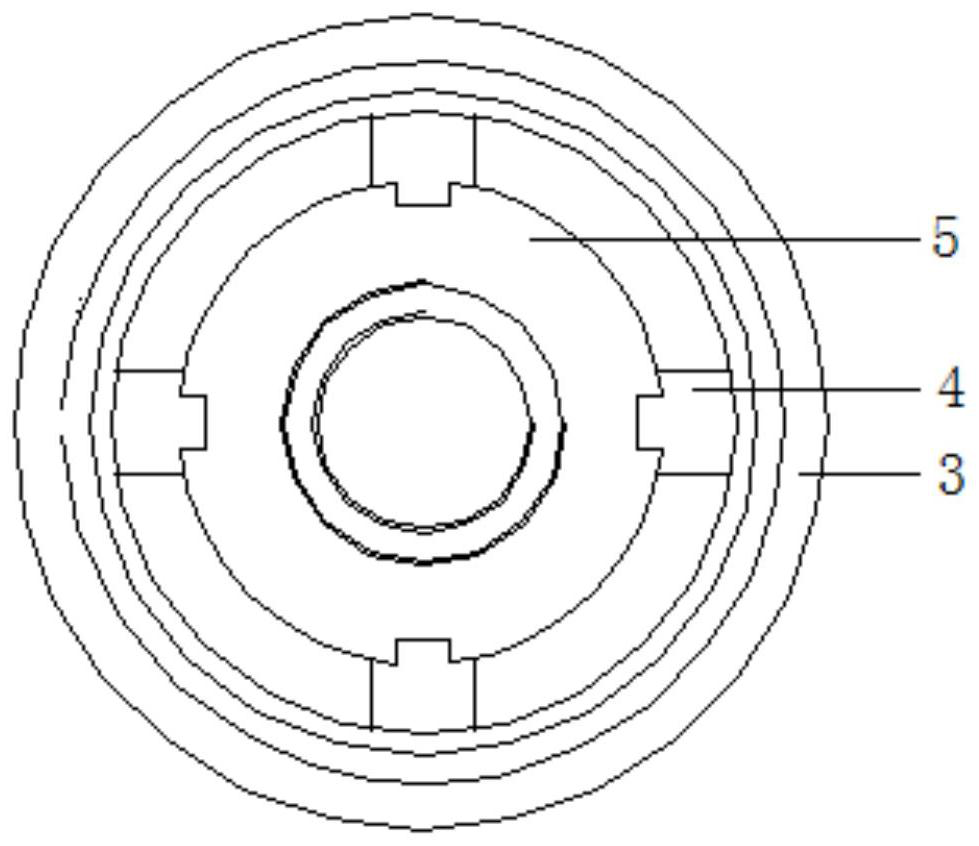

High-damping dual-frequency power damping gear transmission device

ActiveCN111288148AEnsure compactnessEnsure feasibilityInertia force compensationPortable liftingEngineeringClassical mechanics

The invention discloses a high-damping dual-frequency power damping gear transmission device. The high-damping dual-frequency power damping gear transmission device comprises an engagement frequency damping mechanism and a shaft driving rotating frequency damping mechanism. The engagement frequency damping mechanism comprises first compression springs, a guide rod and a mass block. The guide rod is sleeved with the mass block. The two ends of the guide rod are fixed to a pair of support frames. The first compression springs are arranged between the mass block and the support frames. The shaftdriving rotating frequency vibration damping mechanism comprises the mass block, a bearing and second compression springs. The outer side of the bearing is sleeved with the mass block. An inner ring of the bearing is mounted on a bearing mounting sleeve of a base. Upper compression spring seats and lower compression spring seats are arranged on the inner side of the mass block. Middle compressionspring seats are arranged between the upper compression spring seats and the lower compression spring seats. The second compression springs are arranged between the middle compression spring seats andthe upper compression spring seats and between the middle compression spring seats and the lower compression spring seats. By the adoption of the high-damping dual-frequency power damping gear transmission device, under the rated operating condition of a system, the problems of medium-high-frequency vibration and noise caused by the gear engagement vibration and shaft rotation vibration in the gear transmission system can be remarkably reduced.

Owner:CHANGZHOU INST OF TECH

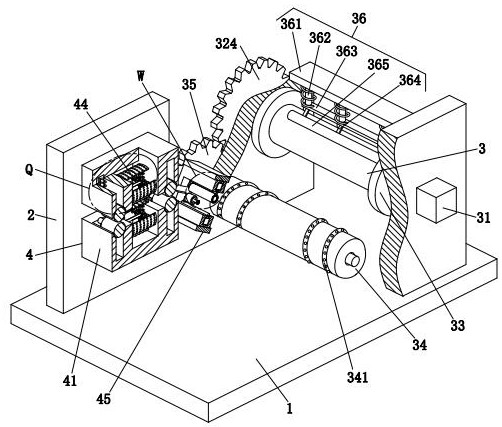

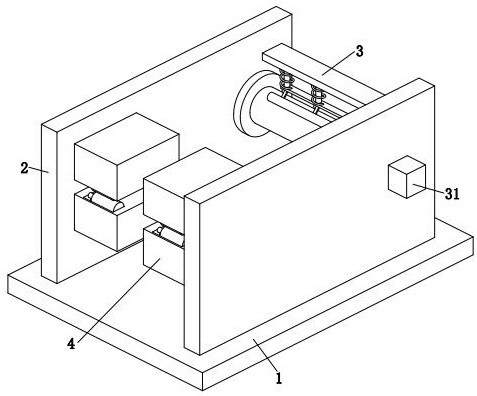

Garment fabric production, conveying and winding machine

ActiveCN113387220AEnsure compactnessGuaranteed cleanlinessMechanical cleaningPressure cleaningWinding machineWorkbench

The invention relates to the technical field of garment fabric winding, in particular to a garment fabric production, conveying and winding machine. The machine comprises a workbench, supporting plates, a winding unit and a flattening unit, the supporting plates are fixedly installed at the upper end of the workbench in a front-back symmetry mode, the winding unit is arranged on the right sides of the opposite ends of the supporting plates, and the flattening unit is mounted on the left side of the opposite ends of the supporting plates. The problems existing during garment fabric winding can be solved that traditional winding equipment cannot effectively conduct flattening treatment on garment fabric during garment fabric winding, so that the flatness of the garment fabric cannot be ensured, and dust and thread residues on the surface of the garment fabric cannot be removed through the traditional winding equipment, so that the cleanliness of the garment fabric is influenced. The two sides of the garment fabric can be stricken through the flattening unit, so that the flatness of the garment fabric is ensured; and dust and thread residues left on the surface of the garment fabric can be sucked out, and therefore the cleanliness of the garment fabric can be guaranteed.

Owner:江苏柏盛家纺有限公司

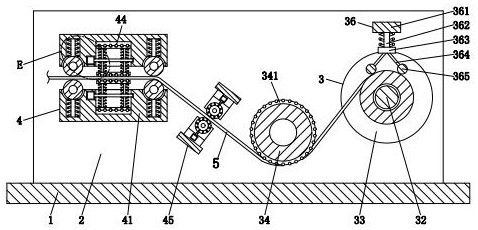

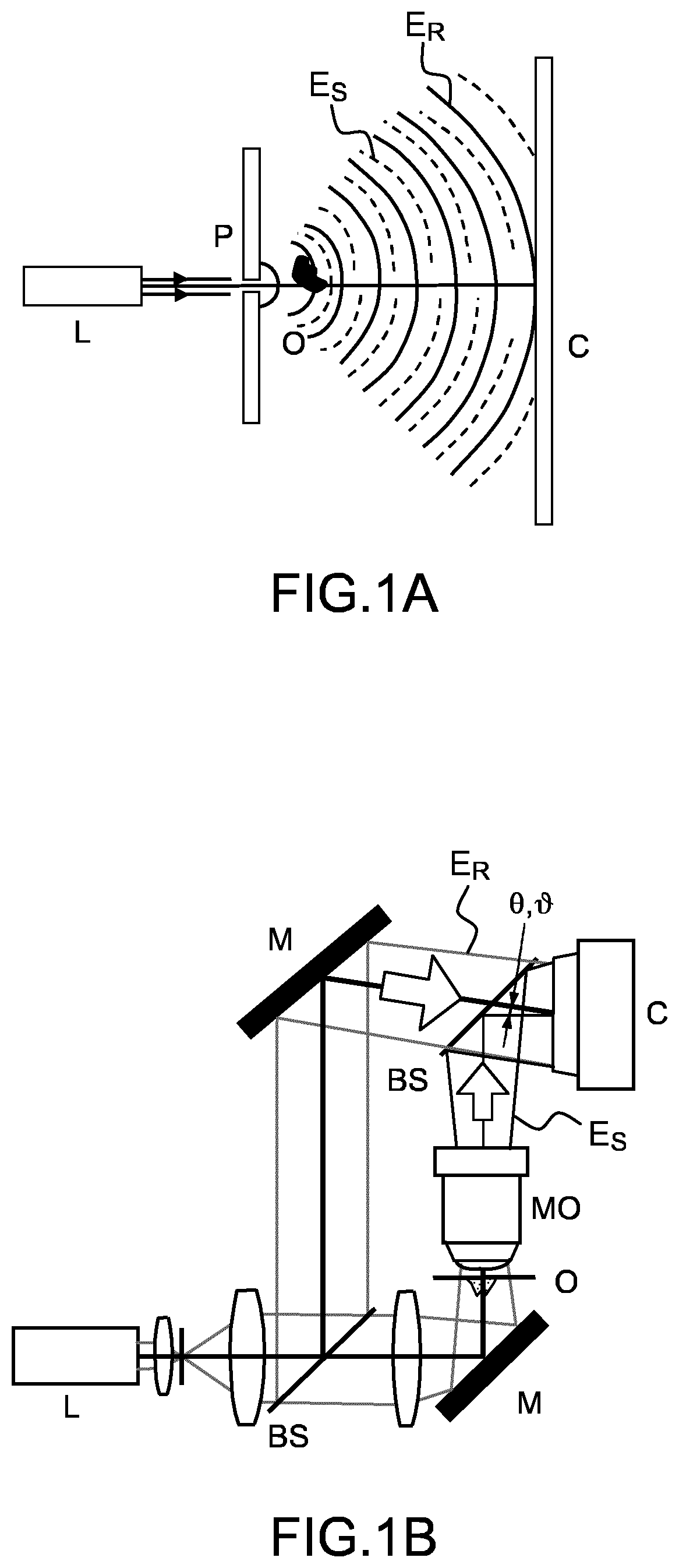

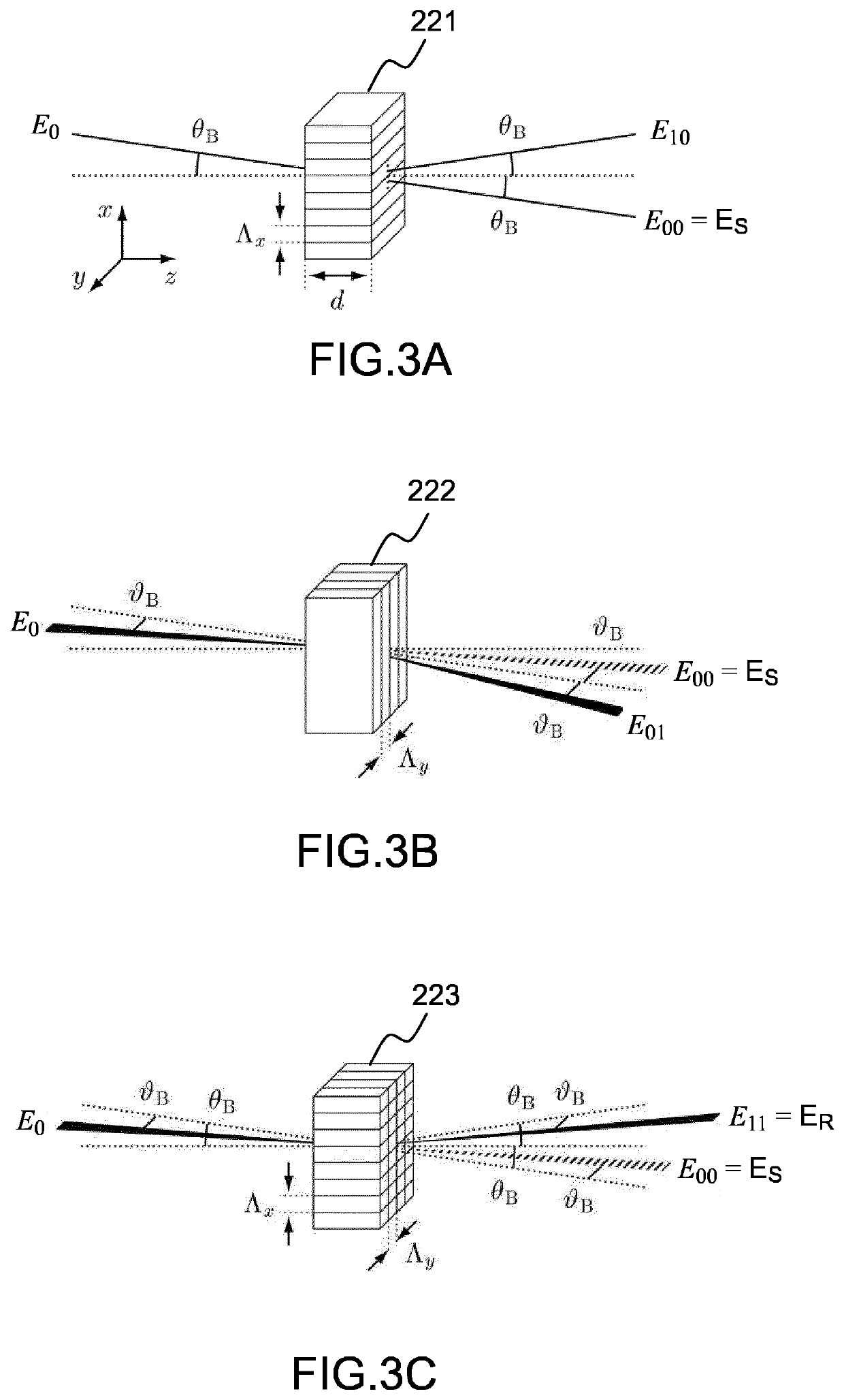

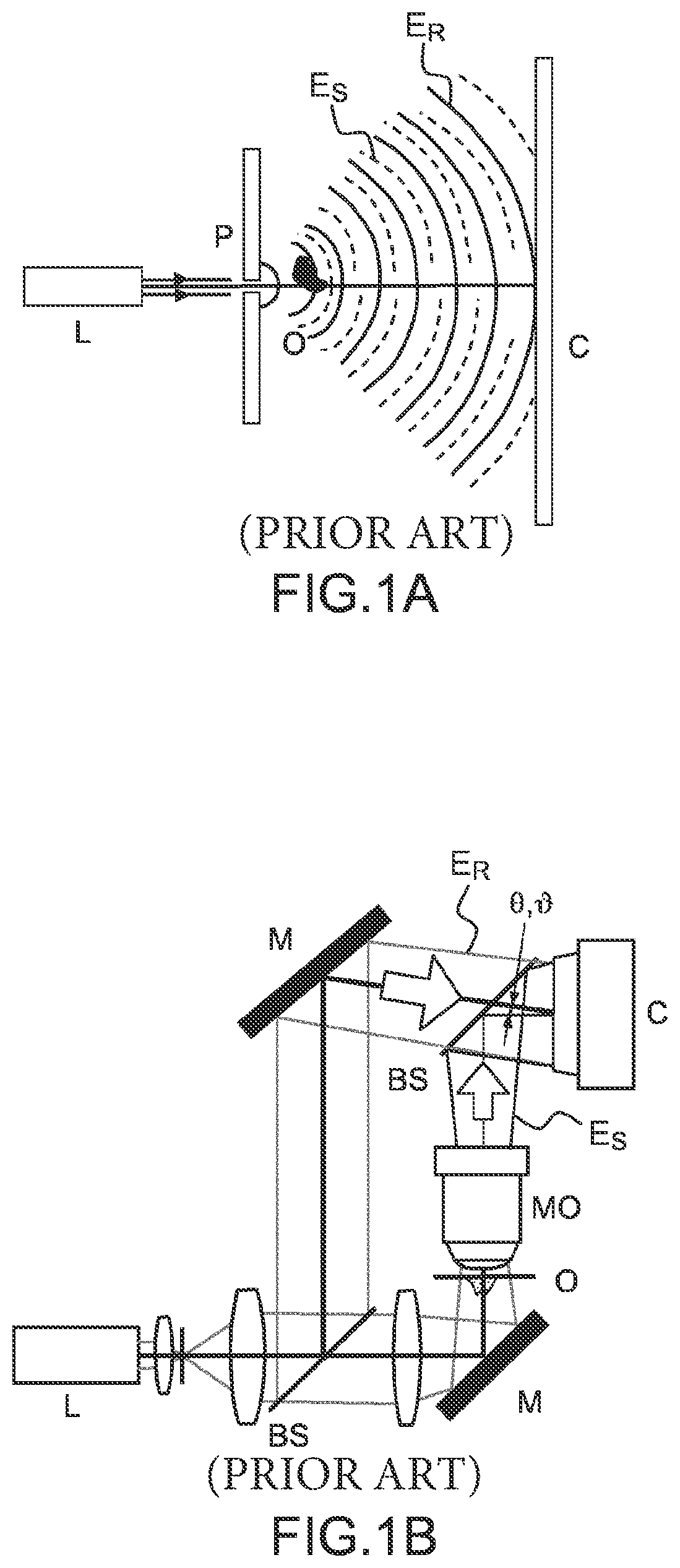

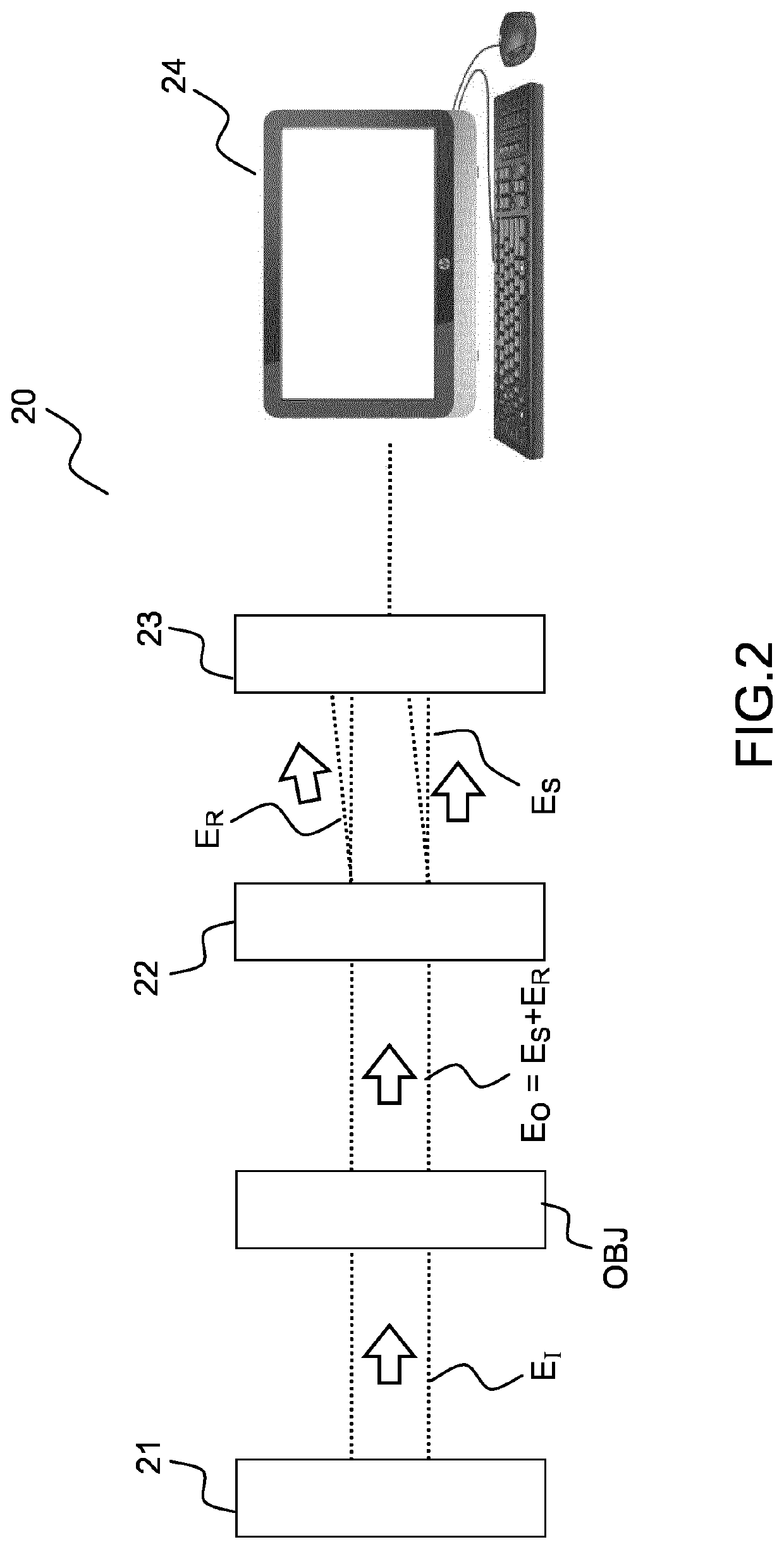

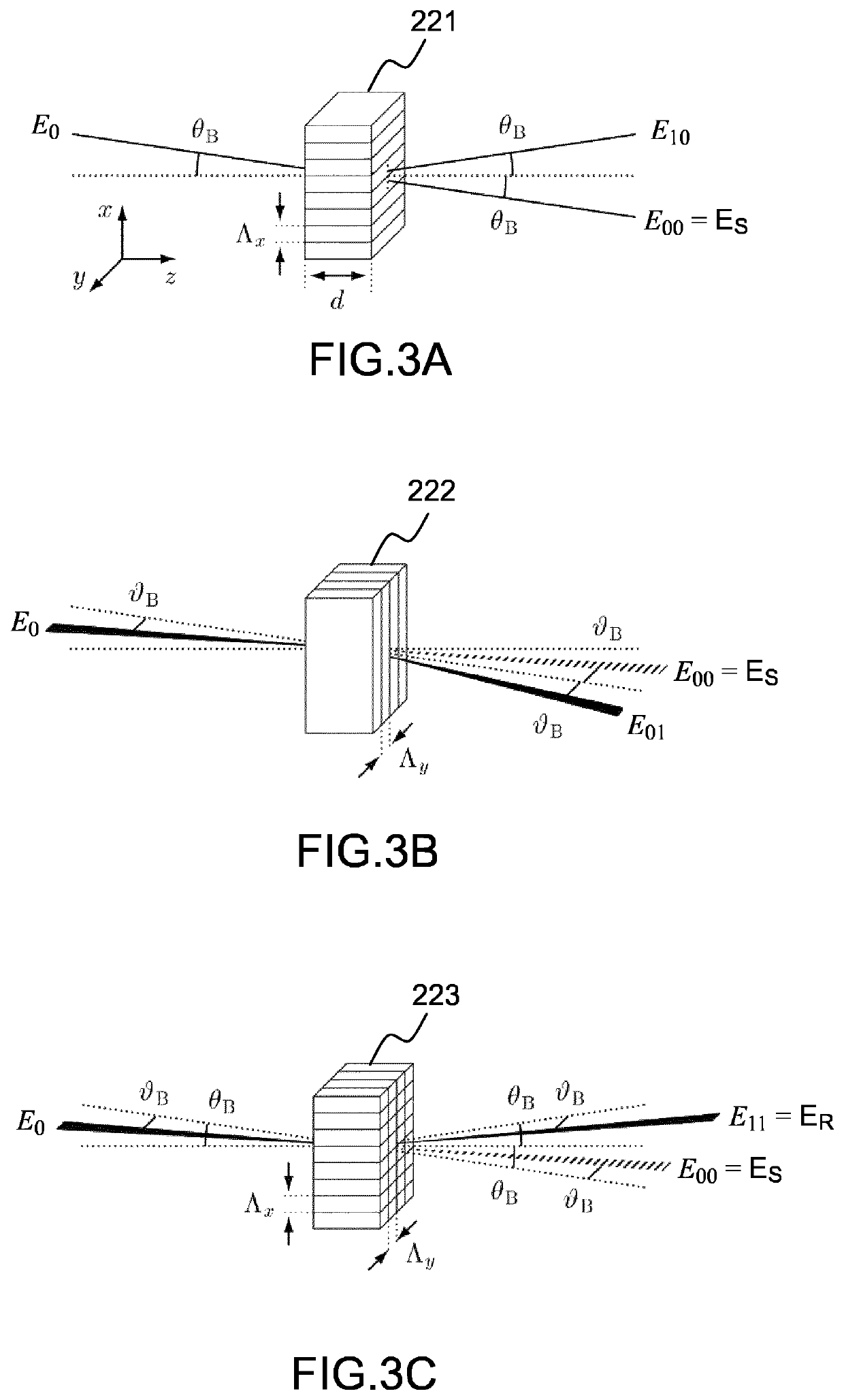

Devices and methods for optical imaging by means of off-axis digital holography

ActiveUS20200233378A1Ensure compactnessEnsured of device qualityHolographic light sources/light beam propertiesHolographic optical componentsSignal waveGrating

According to one aspect, the invention concerns an optical imaging device (20) for an object (OBJ) by off-axis holography comprising a light source (21) adapted for emitting an illumination wave (EI) on the object, in transmission or reflection, and an assembly formed by one or more thick Bragg gratings (22) for receiving a wave (EO) coming from the object thus illuminated and for deflecting a first component (ER) of the wave coming from the object, called the reference wave, and to allow a second component (ES) of the wave coming from the object, called the signal wave, to pass without deflection in such a way that the deflected reference wave presents predetermined deflection angles with respect to the non-deflected signal wave defined in two perpendicular planes. The imaging device according to the first aspect further comprises a two-dimensional detection device (23) for acquiring an interferogram resulting from the interference between said deflected reference wave and said signal wave and a computing unit for determining, from said interferogram, an amplitude and phase distribution of the signal wave in the plane of the object (hologram).

Owner:CENT NAT DE LA RECHERCHE SCI +1

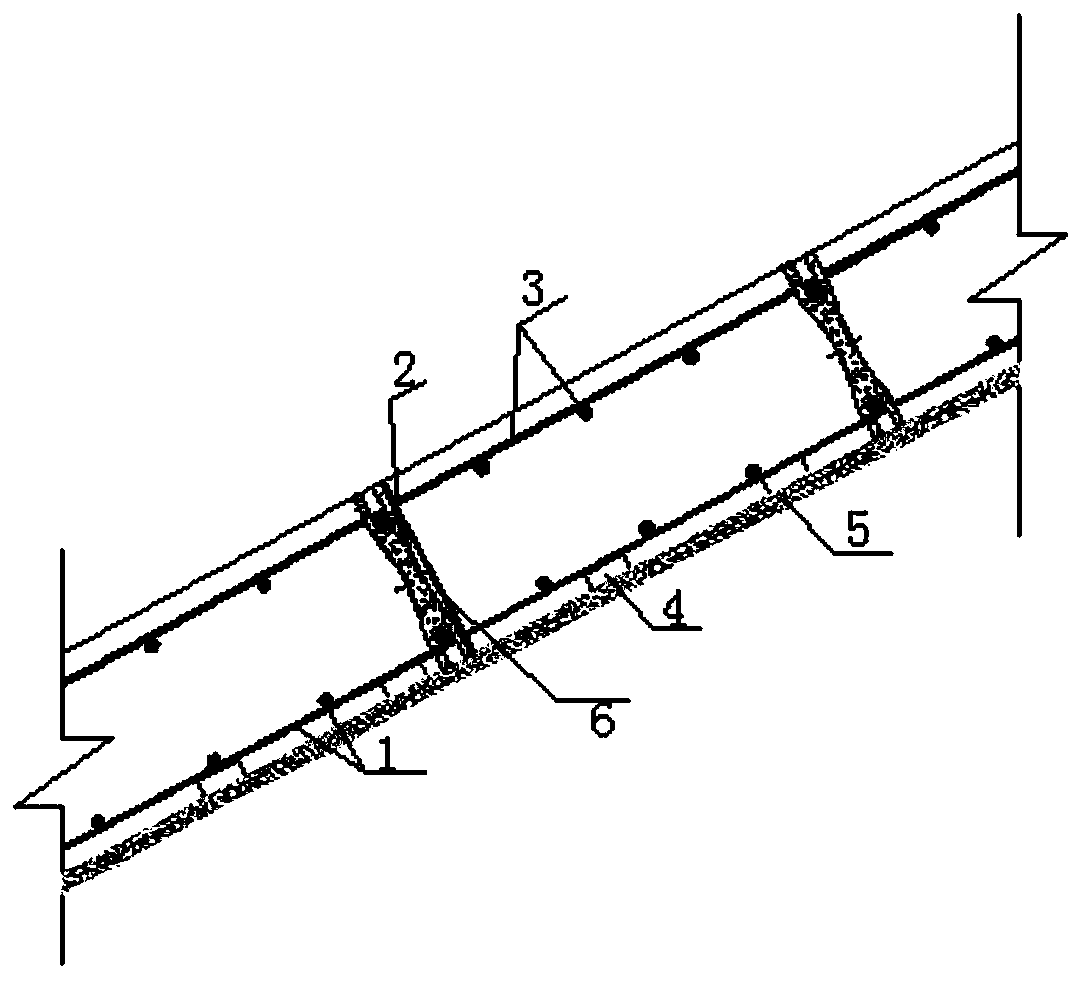

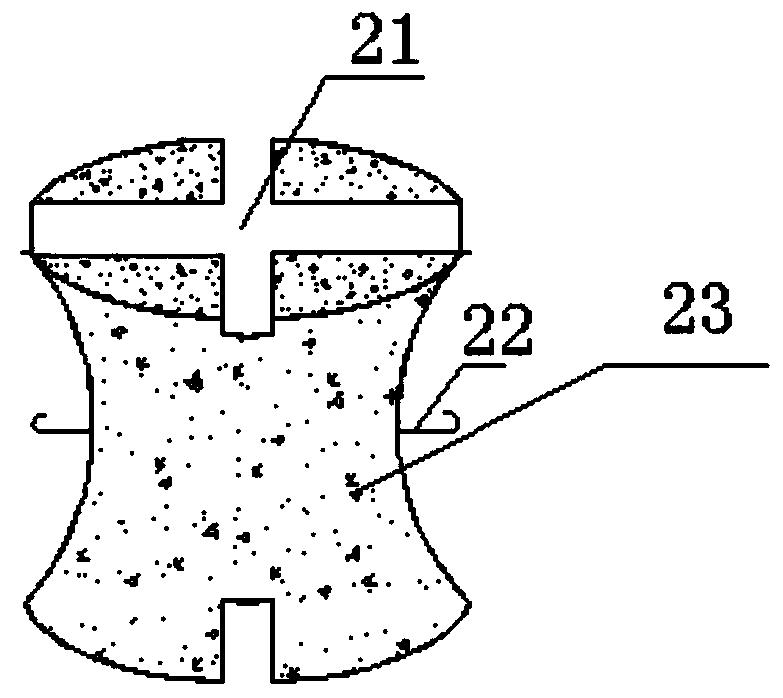

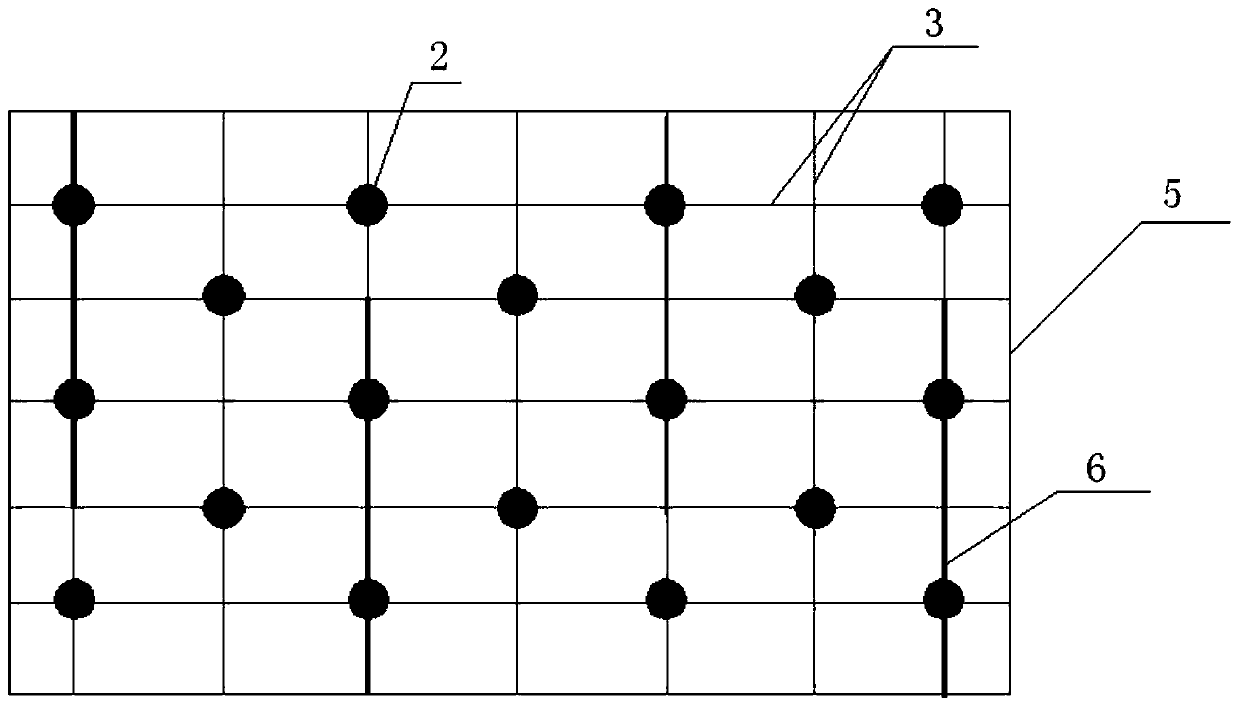

Sloping roof concrete structure and construction method thereof

The invention discloses a sloping roof concrete structure and a construction method thereof, and relates to the technical field of sloping roof construction. The sloping roof concrete structure comprises a bottom layer steel bar, a bottom layer template is arranged below the bottom layer steel bar, cushion blocks are arranged between the bottom layer steel bar and the bottom layer template, a surface layer steel bar is arranged above the bottom layer steel bar, prefabricated blocks are fixedly connected to the bottom layer template, the prefabricated blocks comprise prefabricated bodies, cross-shaped grooves are formed in the tops and the bottoms of the prefabricated bodies, extension hooks are arranged in the middles of the prefabricated bodies, and the bottom layer steel bar is arrangedin the grooves in the bottoms of the prefabricated blocks. According to the sloping roof concrete structure and the construction method thereof, the prefabricated blocks are adopted to control the thickness of a concrete structure layer and the thickness of an upper steel bar protection layer and a lower steel bar protection layer so as to ensure the flatness and compactness of the structure layerand reduce the possibility of hidden dangers of roof water seepage, the construction quality of the concrete structure layer is effectively ensured, repair is reduced, and the use value of the sloping roof is improved.

Owner:CHINA MCC17 GRP

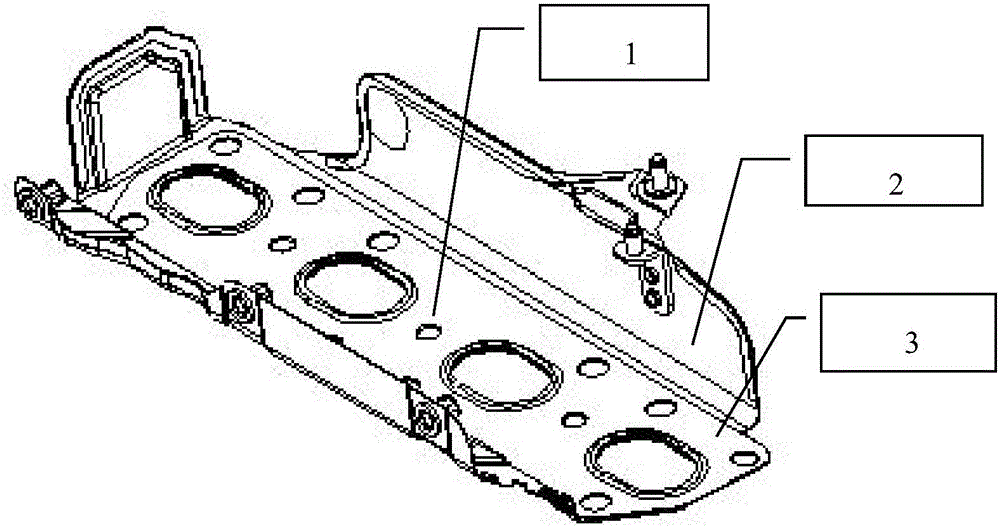

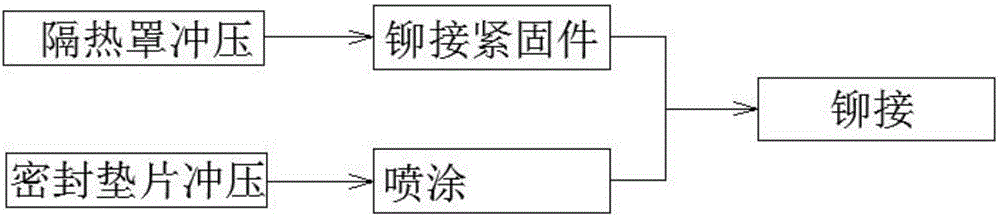

Exhaust manifold gasket heat shield assembly and supercharger gasket heat shield assembly

InactiveCN106321211AReduce volumeEnsure compactnessExhaust apparatusSealing arrangements for enginesEngineeringHeat shield

The invention discloses an exhaust manifold gasket heat shield assembly and a supercharger gasket heat shield assembly. The exhaust manifold gasket heat shield assembly and the supercharger gasket heat shield assembly comprises riveting holes, heat shields and sealing gaskets. The sealing gaskets are arranged at the tops of the heat shields, the heat shields and the sealing gaskets are provided with the riveting holes, the heat shields are of an integrated structure formed by stamping, and the heat shields are fixedly connected with the sealing gaskets in a riveting mode. According to the exhaust manifold gasket heat shield assembly and the supercharger gasket heat shield assembly, by integration of the heat shields and the sealing gaskets, two product functions are achieved on one assembly; the integrated supercharger gasket heat shield assembly / exhaust manifold gasket heat shield assembly improves integration, assembly space can be saved, the assembly process is simplified, part sizes are reduced, the requirements of compactness and efficiency of an engine are guaranteed, and the integral installation and maintenance cost are reduced through modularized installation.

Owner:DONGFENG SHIYAN GASKETS

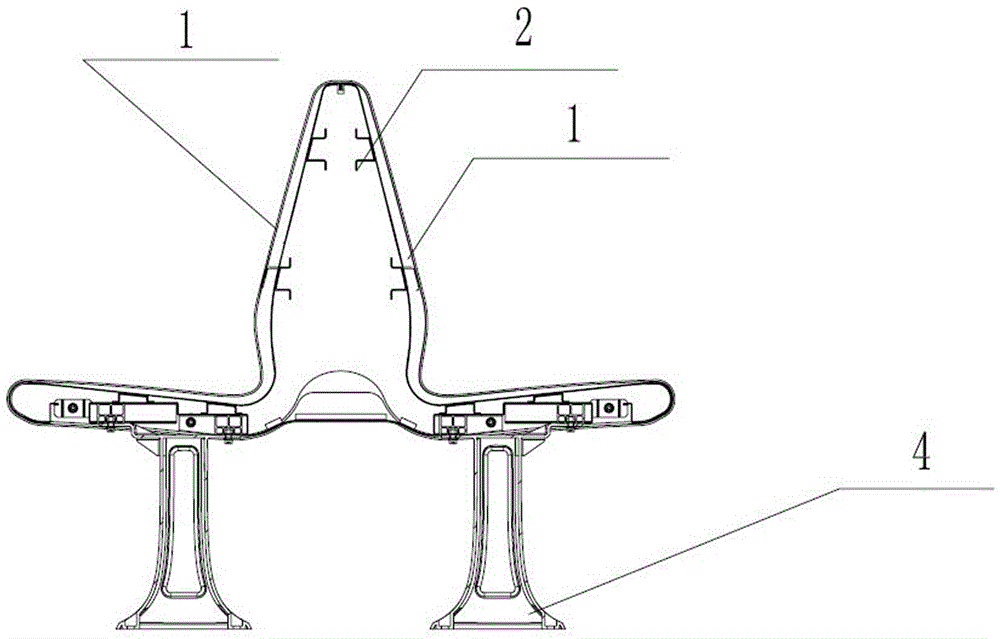

Forming method of independent integral stainless steel seat

The invention discloses a forming method of an independent integral stainless steel seat. The forming method comprises the steps that A, stainless steel plates with the thickness being 1.5 mm are adopted by seat face cover plates, forming die integral one-time forming stretching is adopted, injection molding is carried out so as to promote the surface structure of the steel plates to fully flow in the state that the plate thickness is not decreased, and therefore metal stress is generated, and the rigidity of the seat face cover plates is increased; B, a sectional material extruded and formed through an aluminum alloy is adopted in a reinforcement frame, stainless steel is embedded in the two ends of the reinforcement frame, a transverse connecting beam on the back of the reinforcement frame is formed by stretching a 2mm aluminum alloy plate, so that the rigidity of the reinforcement frame is increased, the reinforcement frame and the transverse connecting beam are welded, the reinforcement frame is matched with switches on the backs of the face cover plates, and the reinforcement frame and the face cover plates are welded; C, after a seat end plate is subjected to surface coating treatment, SMC material one-time compression moulding forming is adopted, and the seat end plate and a stainless steel insert are embedded when formed in the die; and D, glue is applied to the corresponding positions of the seat face cover plates and the seat end plate, the seat face cover plates and the seat end plate are compressed on a compressing mechanism frame, and meanwhile the stainless steel insert of the reinforcement frame and supports on the face cover plates are welded and formed. According to the forming method, the reinforcement frame and the face cover plates are matched accurately and closely, and the space needed for seat manufacturing production is saved.

Owner:ZHEJIANG JINZI MACHINERY&ELECTRICAL

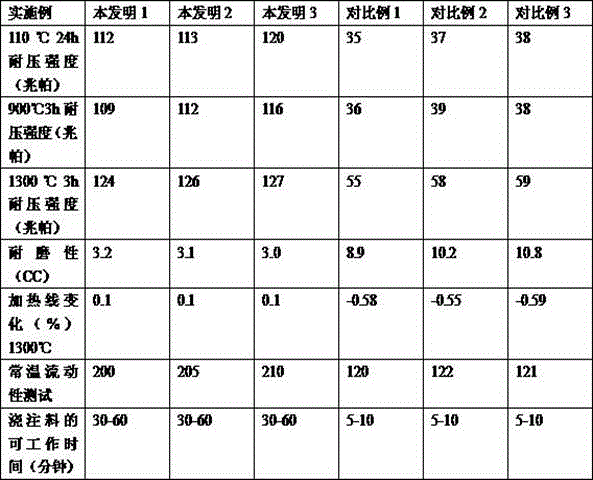

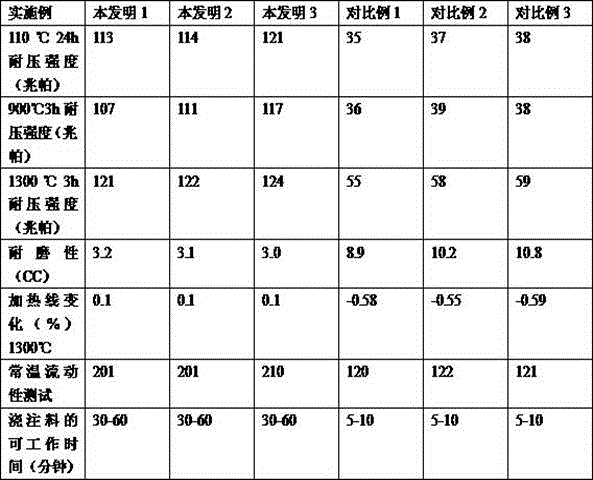

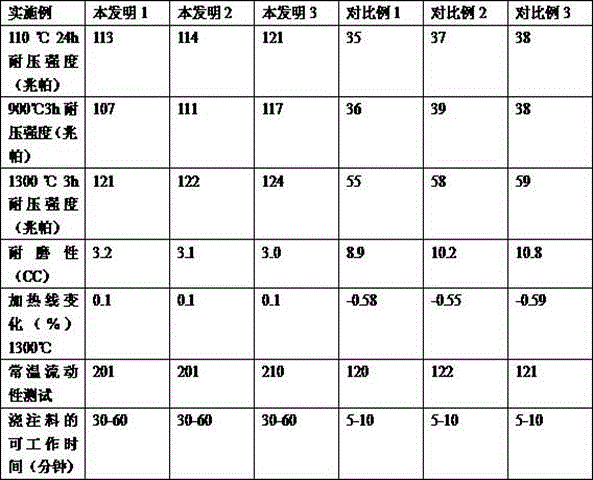

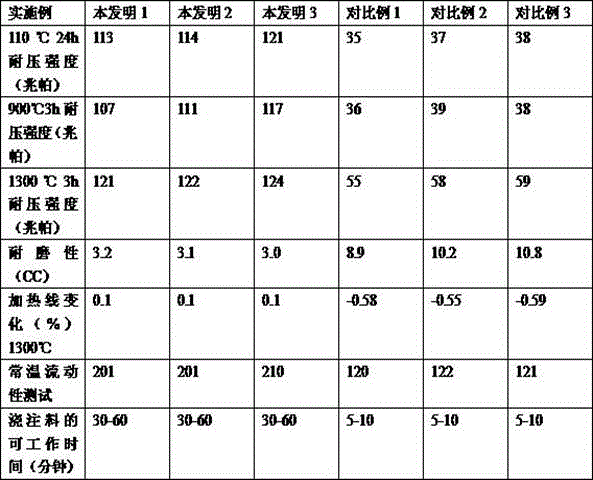

Zirconia alumina refractory castable

The invention provides a zirconia alumina refractory castable which is relatively high in CO erosion resistance in a strong reduction atmosphere, relatively high in wear resistance and high in construction performance; meanwhile, the castable is relatively high in strength and excellent in comprehensive performance in the whole temperature stage from low temperature to medium temperature and to high temperature; the original defect that the existing castable is only high in high temperature performance is avoided.

Owner:张婷

High-property fireproof casting material

InactiveCN106278307AImprove the immunityImprove corrosion resistanceReducing atmosphereHigh intensity

The invention provides a high-property fireproof casting material. The high-property fireproof casting material can have strong CO erosion resistance in strong reducing atmosphere, and also has good abrasion-proof properties and favorable workability; and besides, the condition that the casting material has high intensity and excellent comprehensive properties in the entire temperature stage from low temperature to moderate temperature and to high temperature is also guaranteed, and the defect that a conventional fireproof casting material is only good in high temperature property is overcome.

Owner:万燕杰

Surface treatment method for nuclear reactor waste container

ActiveCN110643920AMeet structural strength requirementsExtended service lifeMolten spray coatingPortable shielded containersNuclear reactorComposite pellet

The invention discloses a surface treatment method for a nuclear reactor waste container. The method includes the following steps of S1, mixing Al alloy and B<4>C powder in the mass ratio of 5-7% to 30-95% for 60-240 min by using a high-speed mixer to obtain mixed powder; S2, carrying out ultrasonic screening on the surface of the mixed powder obtained in the S1 by using ultrasonic waves to obtainB<4>C / Al composite particles; S3, directly spraying the B<4>C / Al composite powder in the S2 onto the surface of the nuclear reactor waste container through a spray gun by adopting a hypersonic flamespraying method to obtain a layer of B<4>C / Al composite coating, and then repeatedly spraying the B<4>C / Al composite powder back and forth on the surface of the nuclear reactor waste container throughthe spray gun to stack the B<4>C / Al composite coatings layer by layer, wherein the thickness of each layer of the B<4>C / Al composite coating is 10-20 micrometers. The structural strength requirementof the container is met, the aim of radioactive shielding is achieved, the bonding force of the B<4>C / Al composite coatings to the nuclear reactor waste container and the density of the B<4>C / Al composite coatings are improved, the porosity of the B<4>C / Al composite coatings is reduced, and it is ensured that B<4>C is uniformly dispersed.

Owner:上海离原环境科技有限公司

Spinel castable

The invention aims at providing a spinel castable. The spinel castable is good in construction performance and high in strength, impurities such as ferric oxide contained in a material can be purified, and finally, the castable which can have the high CO corrosion resistance, the good abrasion resistance and the good construction performance at the high reduction atmosphere, and meanwhile can have the good performance at the middle and low temperature and the high temperature is obtained.

Owner:万燕杰

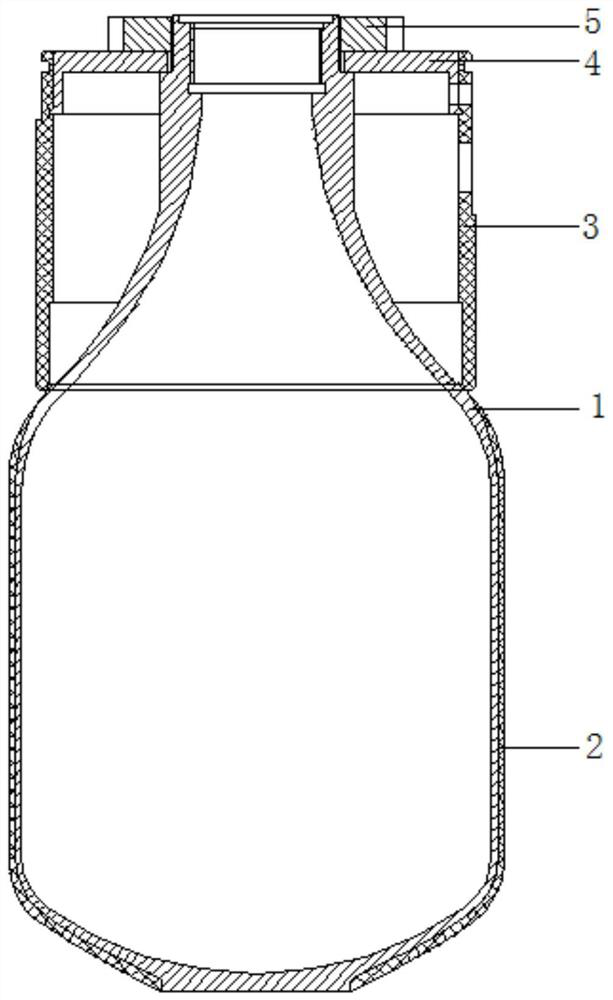

Fire extinguishing bottle with position-adjustable external connector

The invention discloses a fire extinguishing bottle with the position of an external connector adjustable, and belongs to the technical field of fire fighting equipment. The fire extinguishing bottle comprises a bottle liner, a carbon fiber layer, a connecting sleeve and a locking nut; the connecting sleeve is composed of a body and a top cover. A carbon fiber layer is wound on the outer surface of the glass liner, an external thread section is processed at the bottleneck of the glass liner, and a horizontal step surface is arranged at the tail end of the external thread section; the top cover is connected to the internal thread section at one end of the body through the external thread section, the other end of the body penetrates through a bottle opening of the bottle liner and then is sleeved on the neck portion of the bottle liner, a central through hole of the top cover penetrates through the bottle opening of the bottle liner, the locking nut is matched with threads on the bottle opening of the bottle liner and tightly presses the top cover, and the body is fixed on the bottle liner through the top cover. The connecting sleeve can be reliably fixed on the bottle body, and the position of the external interface on the connecting sleeve can be adjusted as required, so that the consistency of part assembly is ensured.

Owner:北京北机机电工业有限责任公司

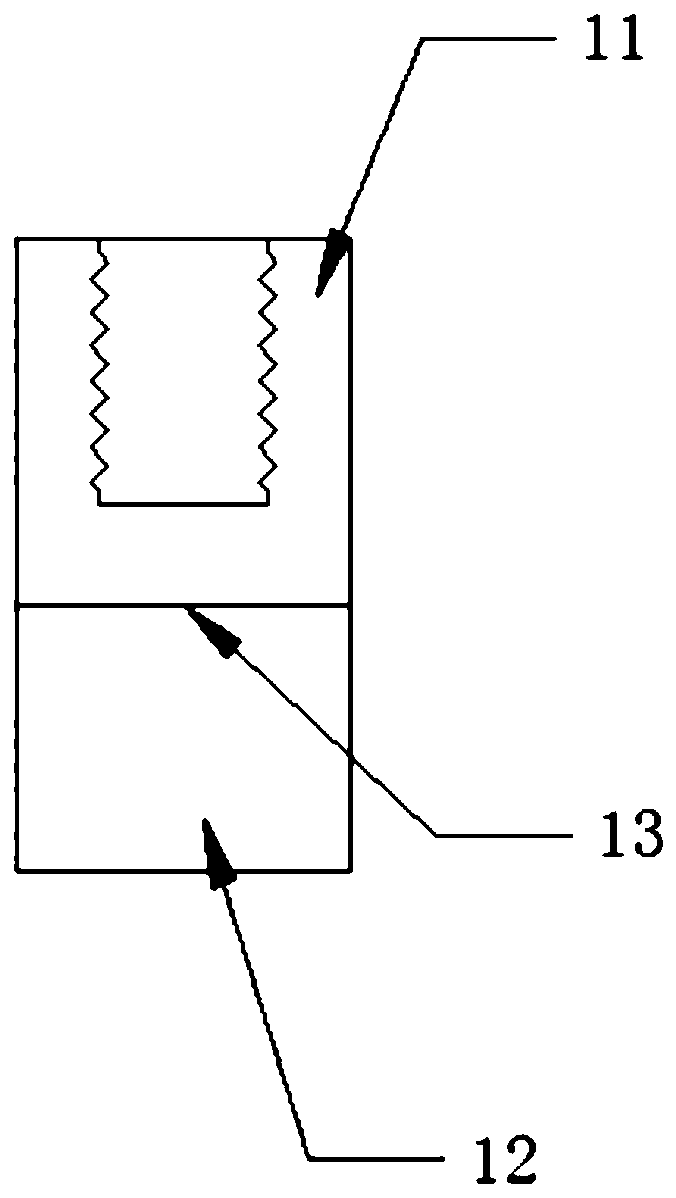

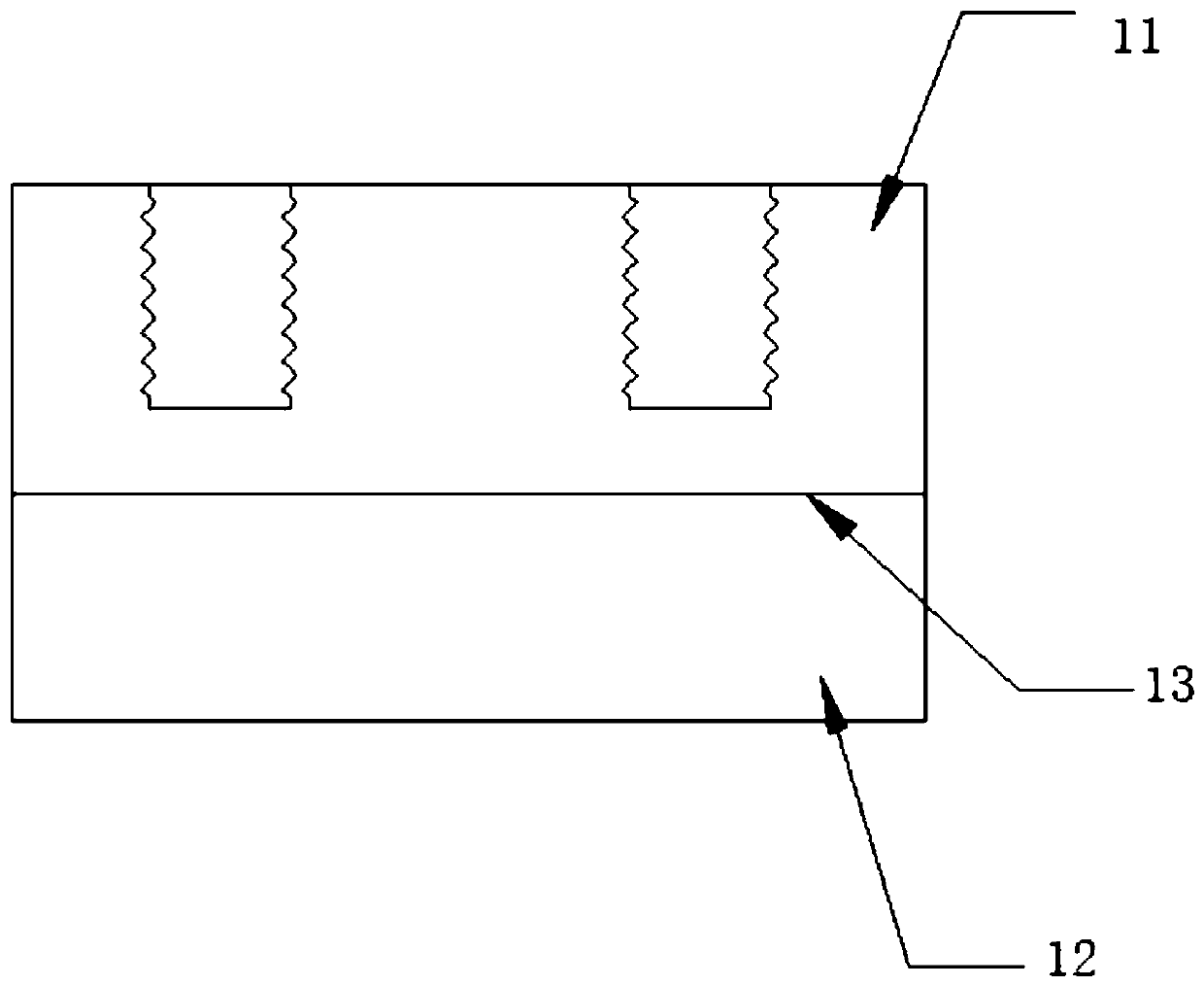

Bimetal composite grounding nut

InactiveCN111009807ASave resourcesReduce interface resistanceContact member manufacturingManufacturing technologyExplosive Agents

The invention discloses a bimetal composite grounding nut and relates to a manufacturing technology of a transportation grounding nut. The method comprises the following steps that two metal plates are selected; positioning holes are punched in four corners and a center of opposite surfaces of the two metal plates for positioning; rust removal, oil removal and blow-drying are performed; then metalstand columns are inserted into the positioning holes; the two metal plates are isolated by a certain distance; and explosive cladding is performed through explosives, and then the bimetal compositegrounding nut is manufactured. Operation is easy, leftover materials are less, and the nut is capable of meeting requirements for weldability, electrical conductivity, corrosion resistance, high bonding strength and the like at the same time, is high in reliability and safety, is long in service life and is capable of being applied to multiple fields of ships, power distribution equipment, transport vehicles, airplanes and the like.

Owner:HUNAN FORHOME COMPOSITE MATERIALS CO LTD

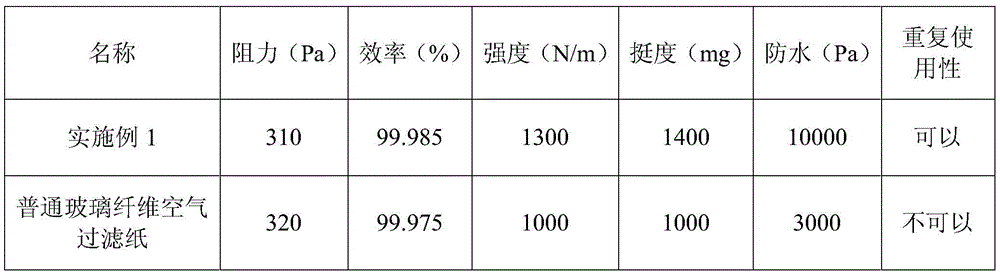

A kind of rewashable glass fiber air filter paper and preparation method thereof

ActiveCN104213470BHigh strengthDense surfaceSynthetic cellulose/non-cellulose material pulp/paperFiltration separationFiberCross-link

The invention discloses glass fiber air filter paper which can be repeatedly cleaned. The glass fiber air filter paper comprises glass fibers and bonding glue stock, wherein the glass fibers are prepared by mixing 25-45 parts by mass of alkali-free glass fiber cotton with the diameter of 3.5-6.0 microns and 55-75 parts by mass of alkali-free glass fibers with the diameter of 0.4-0.8 micron; the bonding glue stock comprises acrylic resin, macromolecular fluorocarbon, a surfactant and a cross-linking agent; the dry weight of the bonding glue stock accounts for 1-3 percent of the total weight of the glass fiber air filter paper. A method for preparing the glass fiber air filter paper provided by the invention comprises the following steps: dispersing and pulping; conveying pulp to a former for forming, applying glue to the surface of wet paper, and performing suction and dehydration; performing primary drying on the wet paper by an infrared drying device; and finally, drying the wet paper at the temperature of 100-200 DEG C, thereby obtaining the glass fiber air filter paper. According to the invention, the water resistance of the air filter paper can be obviously improved under the condition that other performance of the air filter paper is not influenced, and the air filter paper can be repeatedly used after being cleaned.

Owner:CHONGQING ZAISHENG TECH CORP

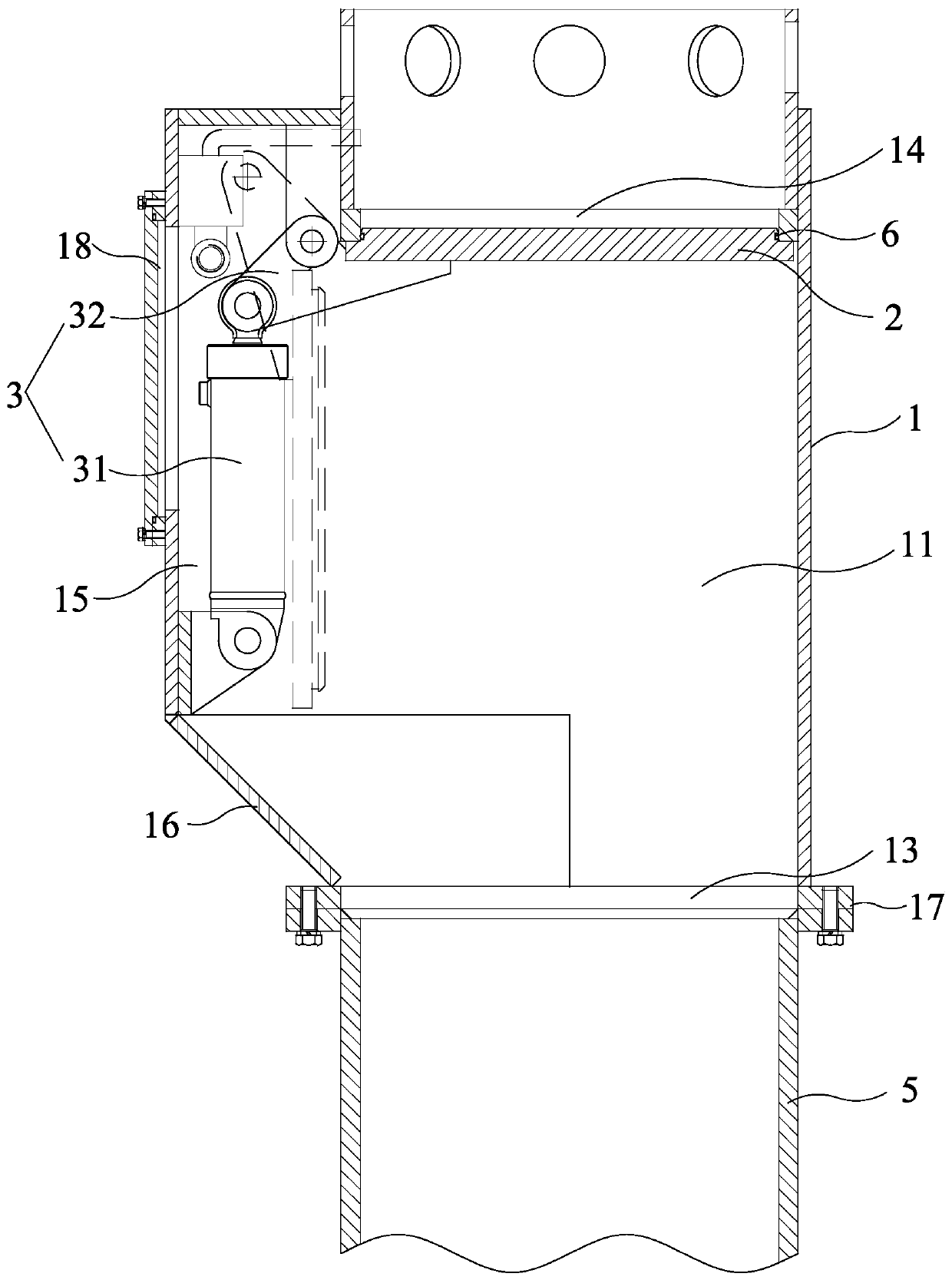

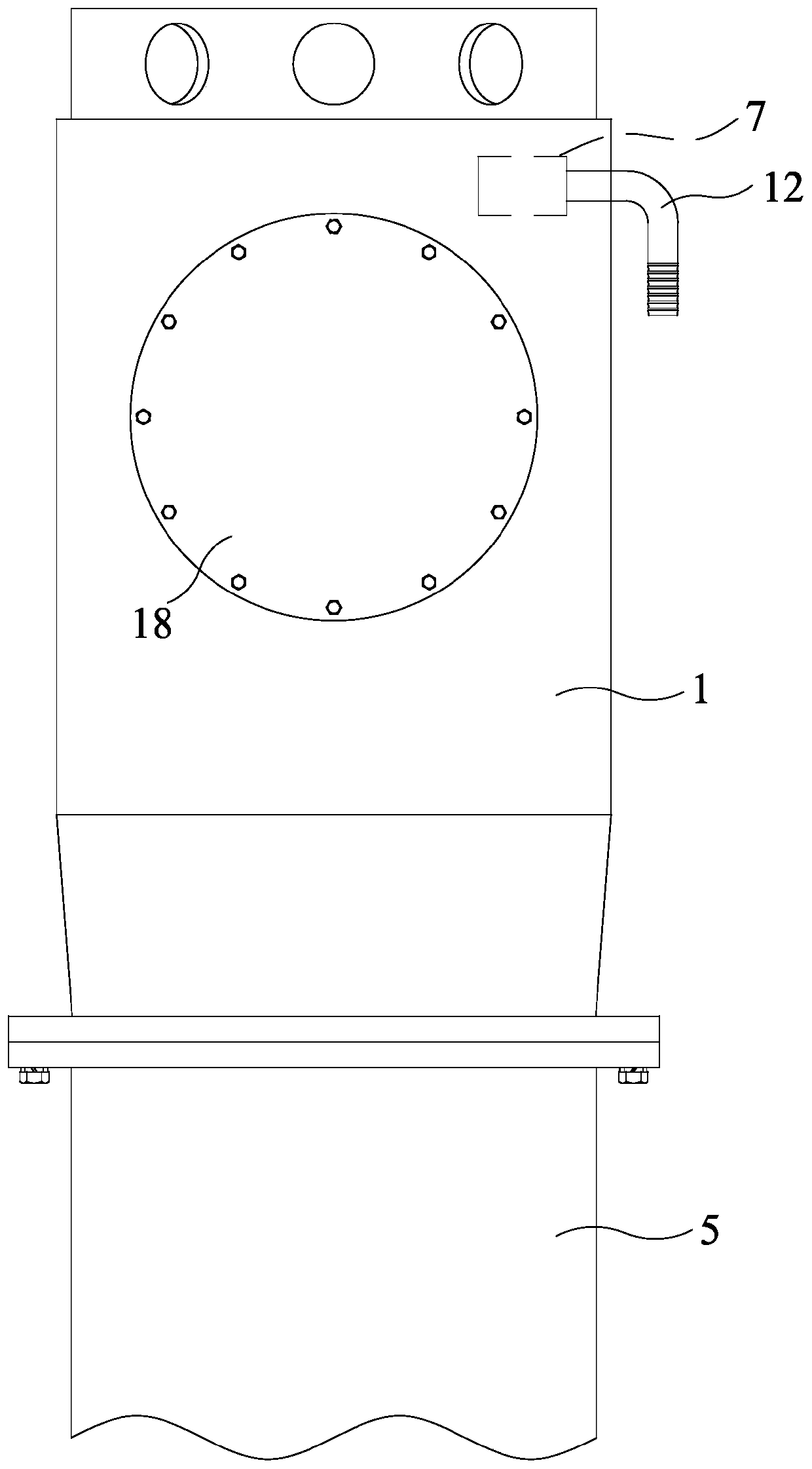

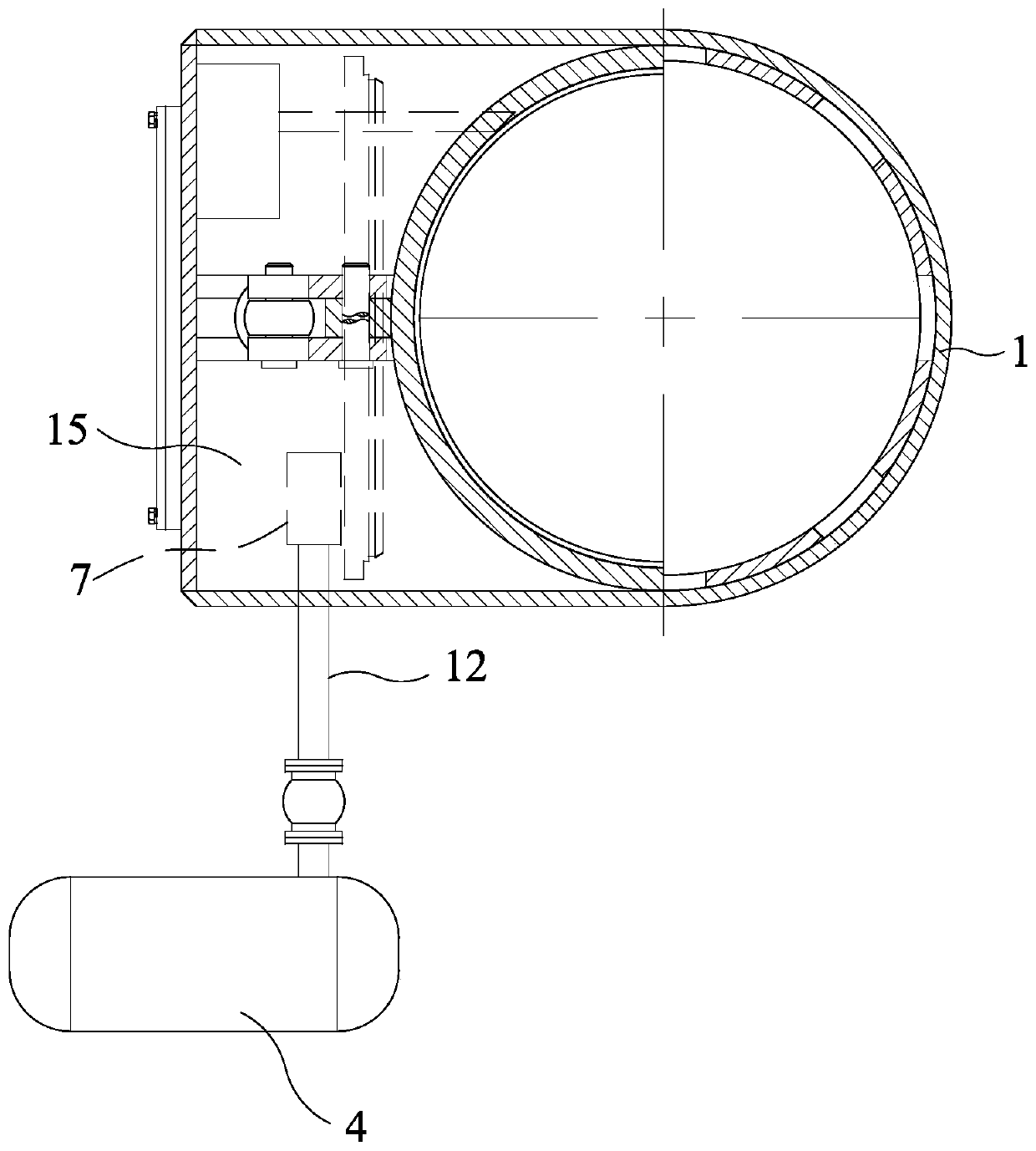

Gas extrusion sealing device of tube-sinking cast-in-place pile machine

The invention discloses a gas extrusion sealing device of a tube-sinking cast-in-place pile machine. The gas extrusion sealing device of the tube-sinking cast-in-place pile machine comprises a valve body, a cover plate, a control mechanism and a gas supercharging mechanism, wherein a valve cavity is arranged in the valve body, an air inlet channel is formed in the valve cavity, the air inlet channel communicates with the gas supercharging mechanism through a pipeline, an interface is formed below the valve cavity, the interface is used for sealing connection of construction steel pipes, a feeding port is formed above the valve cavity, the cover plate is arranged in the valve cavity and rotationally arranged at the feeding port, and the control mechanism drives the cover plate to rotationally open or seal the feeding port in the valve cavity. According to the gas extrusion sealing device of the tube-sinking cast-in-place pile machine, the structure is simple, when a bottom pile is rammed and expanded, the gas supercharging mechanism inputs high-pressure gas from the air inlet channel to enable the valve cavity to be filled with the high-pressure gas, the high-pressure gas can continuously push the cover plate upwards, so that the feeding port is more tightly closed by the cover plate, the air tightness of the whole device is improved, the pile forming quality is high, and the construction convenience and the construction efficiency are greatly improved.

Owner:陈清贵

Wear-resistant anti-erosion castable

InactiveCN106278306AImprove the immunityImprove corrosion resistanceWear resistantUltimate tensile strength

The invention provides wear-resistant anti-erosion castable. The castable has great ability of resisting CO corrosion in a strong reduction atmosphere and is good in wear resistance and excellent in construction performance. High strength and excellent overall performance of the castable are ensured in the entire temperature stage from the low temperature to the medium temperature and to the high temperature. The defect that the original castable only has good high-temperature performance is overcome.

Owner:万燕杰

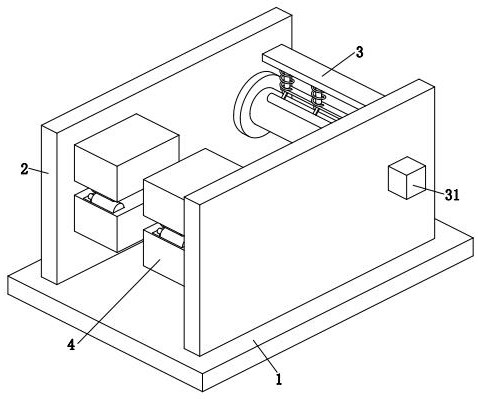

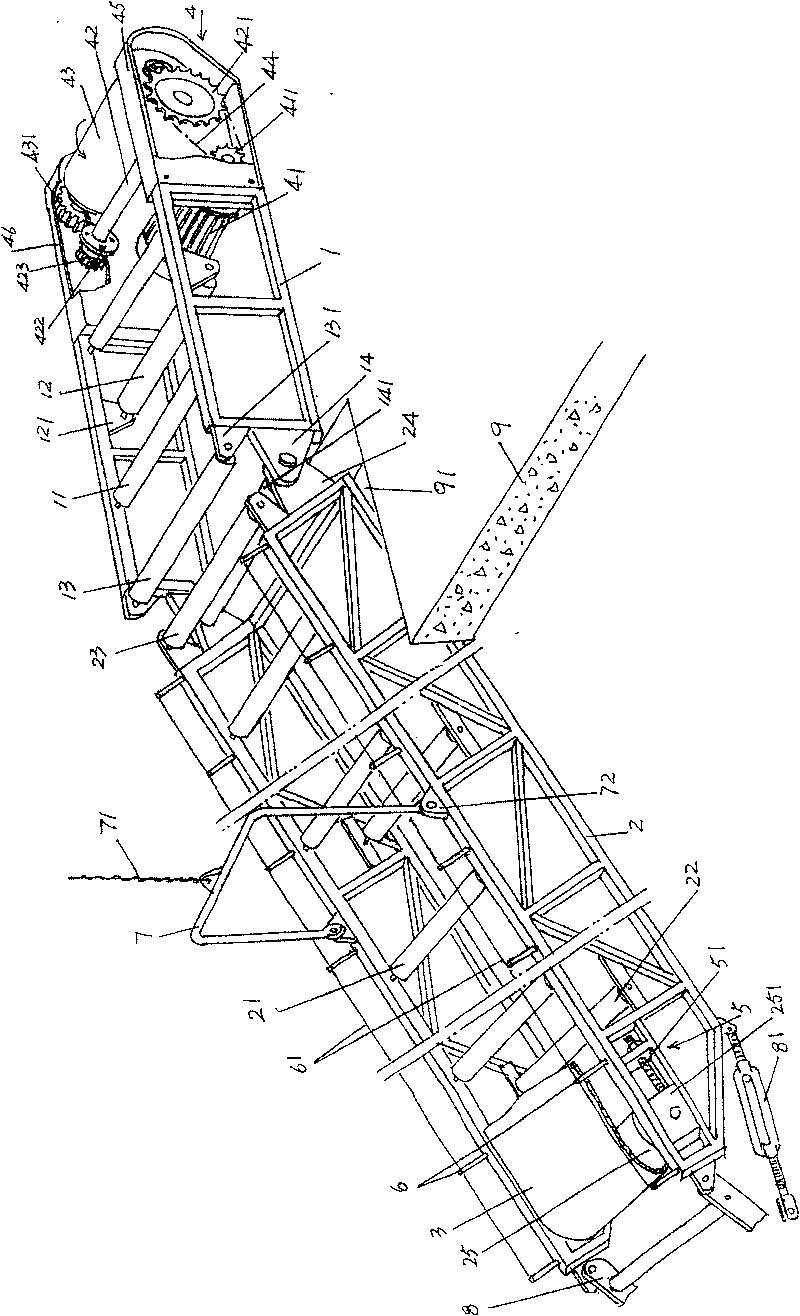

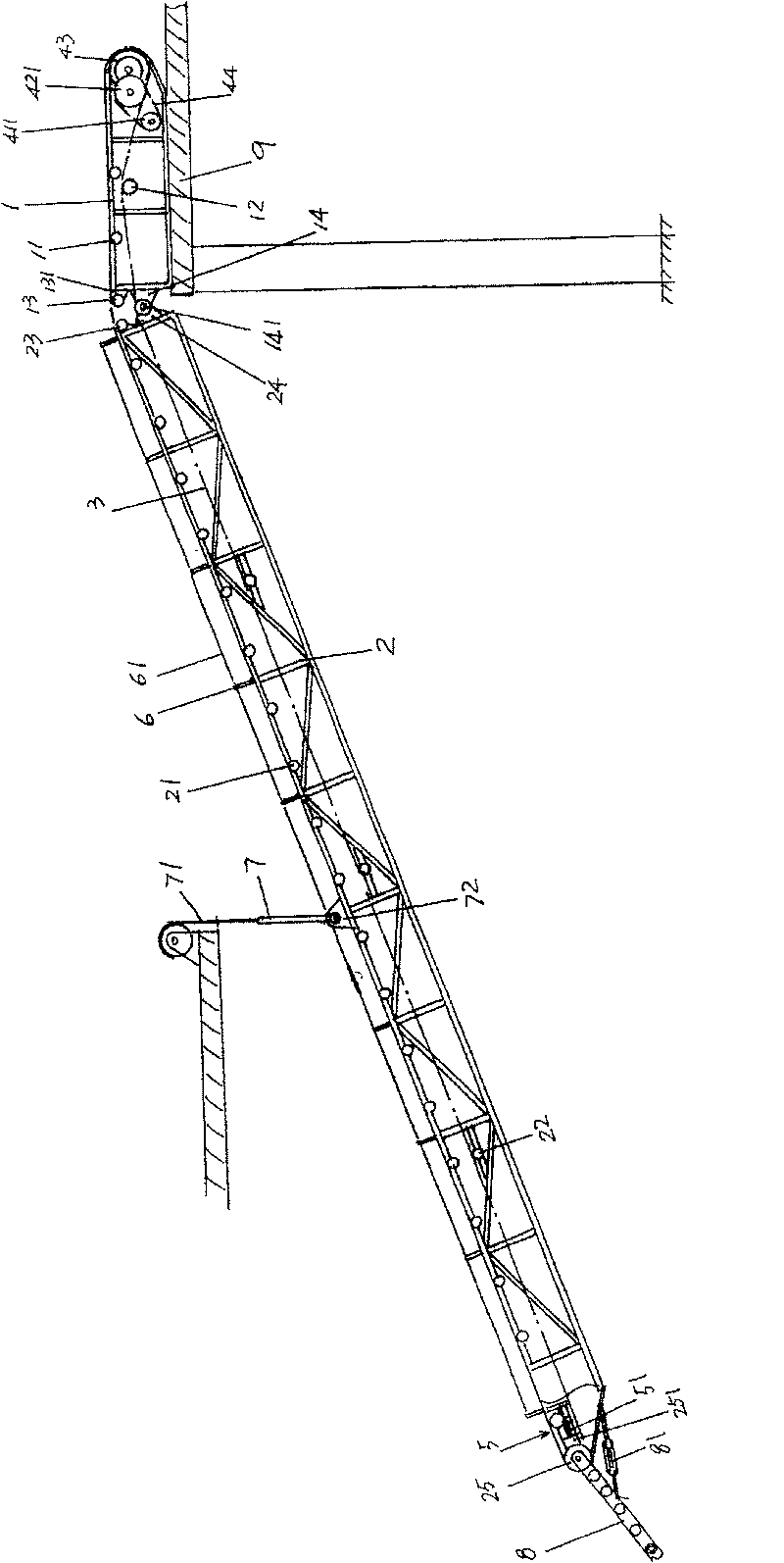

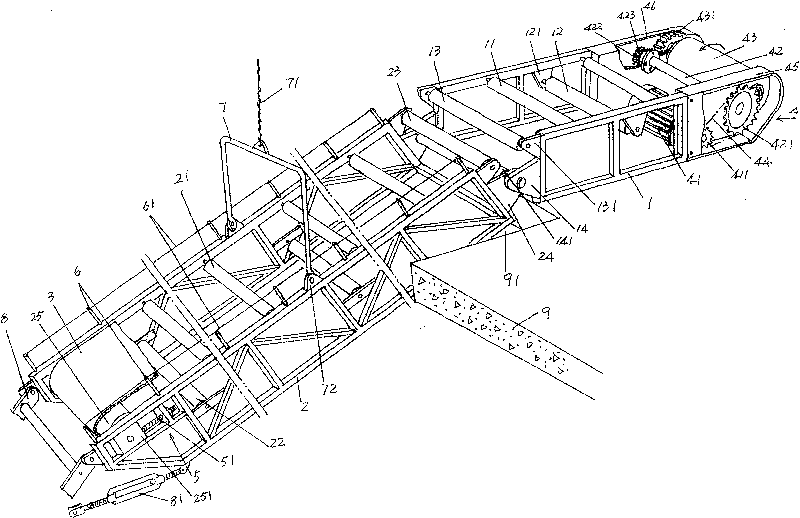

Lift conveyor

InactiveCN101016115BFree from attackEnsure compactnessConveyorsSupporting framesEngineeringUpper floor

A lifting transmitter comprises a stable support fixed on upper floor, a movable support whose one end is connected with the stable support and another end extends to lower floor, a force gear on thestable support, and a transmission band connected with the force gear for moving around the movable and stable supports to form a transmission plane. The connection between the movable and stable supports is hinge connection, while the movable support is extended arranged with a movable support landing device. The invention can use the landing device to lift up the free movable support, to save space and shade all gears in the force gear. And the invention arranges bars on the movable support to protect the elements.

Owner:常熟市诚达港务机械设备厂

Devices and methods for optical imaging by means of off-axis digital holography

ActiveUS11099522B2Ensure compactnessEnsure qualityHolographic light sources/light beam propertiesHolographic optical componentsSignal waveGrating

According to one aspect, the invention concerns an optical imaging device (20) for an object (OBJ) by off-axis holography comprising a light source (21) adapted for emitting an illumination wave (EI) on the object, in transmission or reflection, and an assembly formed by one or more thick Bragg gratings (22) for receiving a wave (EO) coming from the object thus illuminated and for deflecting a first component (ER) of the wave coming from the object, called the reference wave, and to allow a second component (ES) of the wave coming from the object, called the signal wave, to pass without deflection in such a way that the deflected reference wave presents predetermined deflection angles with respect to the non-deflected signal wave defined in two perpendicular planes. The imaging device according to the first aspect further comprises a two-dimensional detection device (23) for acquiring an interferogram resulting from the interference between said deflected reference wave and said signal wave and a computing unit for determining, from said interferogram, an amplitude and phase distribution of the signal wave in the plane of the object (hologram).

Owner:CENT NAT DE LA RECHERCHE SCI +1

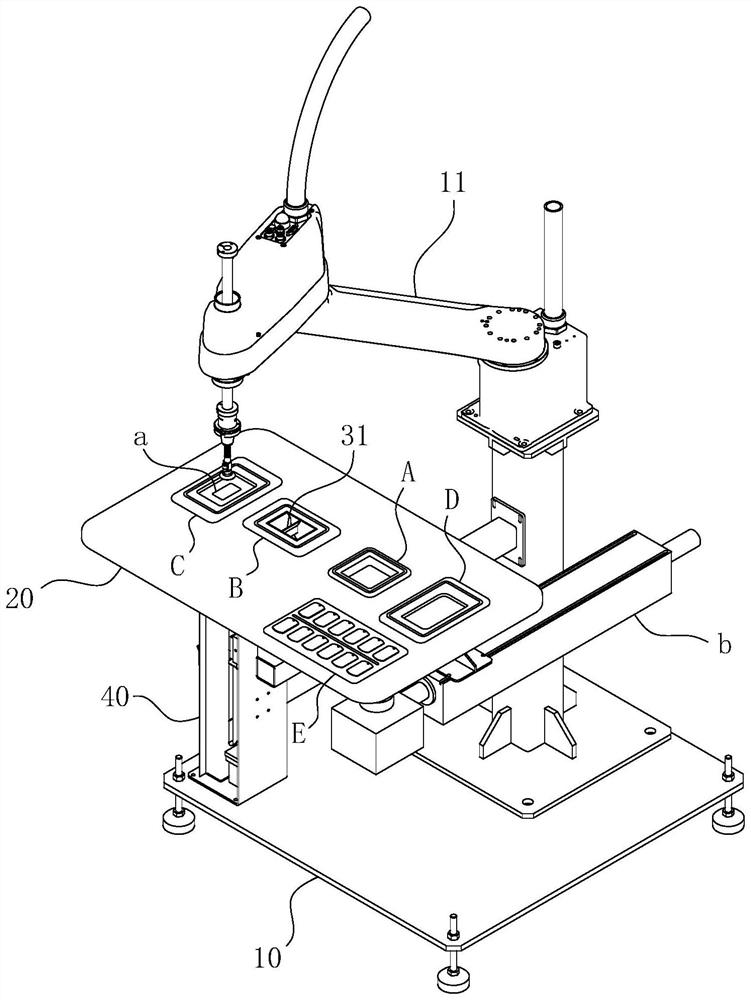

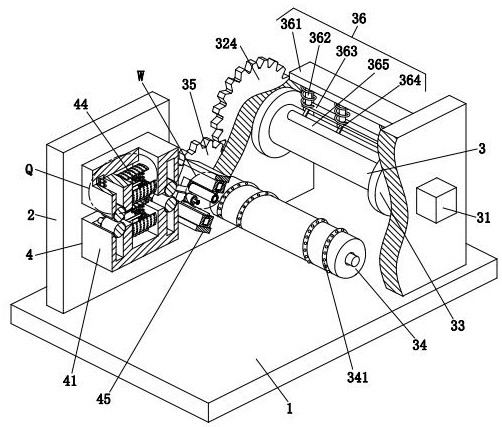

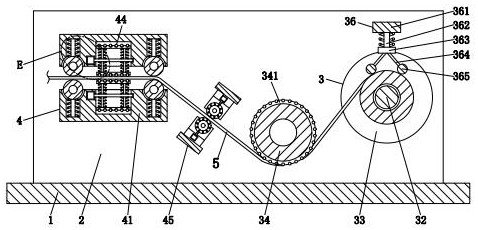

An engraving robot with self-turning function

ActiveCN114012270BRealize the purpose of online autonomous flipGuaranteed reliabilityManipulatorLaser beam welding apparatusEngravingEngineering

The invention belongs to the technical field of intelligent engraving, and in particular relates to an engraving robot with a self-turning function. The invention includes a base and a worktable arranged on the base, and the worktable is divided into an engraving area for engraving and a turning area for turning over the engraving sheet; a turning opening is set at the turning area, and extends downward from the turning opening There is a bin-shaped turning chamber with an opening facing upwards; a vertical turning plate is arranged in the middle of the turning opening, and the area between the front wall of the turning cavity and the vertical turning plate forms a space for engraving pieces to enter. The material and the feeding area for one-way turning, and the area between the vertical turning plate and the rear wall of the turning chamber constitutes the feeding area for taking out the engraved piece after turning over. The invention can realize the intelligent and automatic material turning requirement based on the engraving robot, thereby effectively improving its engraving efficiency.

Owner:HEFEI PANSHI AUTOMATION TECH

Combine

A combine harvester is provided. Several pull-up cases 24 are vertically installed in the front side of a reaping unit 8, a drive case 42 for pulling up is installed in the back side of a gate 60 above each pull-up case 24 and a motive power is transmitted from the aforesaid drive case 42 to each of the aforesaid pull-up cases 24 installed with pull-up tines 23. It is characterized in that: a sprocket 44 for driving the pull-up tine is installed below a vertical shaft 54 extended from the aforesaid drive case 42, an input shaft 39 for pulling-up is connected to the drive case 42 for pulling-up through a speed change case 46 for pulling-up and the aforesaid input shaft 39 is brought to obliquely cross to the vertical shaft 54 on the side view. In this way, the backward tilting angle of a pull-up case and the forward tilting angle of an input shaft can be easily ensured, and the compaction of a structure for pulling up long cereal stems and a bearing power for pulling up by the aforesaid input shaft can be ensured.

Owner:YANMAR POWER TECHNOLOGY CO LTD

Conveying and winding machine for garment fabric production

ActiveCN113387220BEnsure compactnessGuaranteed cleanlinessMechanical cleaningPressure cleaningWinding machineIndustrial engineering

The invention relates to the technical field of clothing fabric winding, in particular to a clothing fabric production, conveying and winding machine, comprising a workbench, a support plate, a winding unit and a leveling unit. A winding unit is arranged on the right side of the opposite end of the plate, and a flattening unit is arranged on the left side of the opposite end of the support plate; the invention can solve the problems existing in the winding of clothing fabrics: the traditional winding equipment cannot effectively wind the clothing fabrics. The clothing fabric is flattened, so that the flatness of the clothing fabric cannot be ensured, and the traditional winding equipment cannot remove the dust and thread ends on the surface of the clothing fabric, thus affecting the cleanliness of the clothing fabric; The two sides of the cloth are scraped to ensure the flatness of the clothing fabric; the present invention can suck out the residual dust and thread ends on the surface of the clothing fabric, thereby ensuring the cleanliness of the clothing fabric.

Owner:江苏柏盛家纺有限公司

Combustor and steam generation system using same

PendingCN113685816ARealize convenient cleaning functionReduce distanceFuel supply regulationFurnace-tube steam boilersLow noiseThermodynamics

The invention belongs to the technical field of steam generators, and particularly relates to a combustor and a steam generation system using the same. The combustor comprises a combustion chamber, a premixing pipe and an air inlet pipe, wherein a furnace cavity of the combustion chamber, a pipe cavity of the premixing pipe and a straight pipe section pipe cavity of the air inlet pipe jointly match to form a straight-through type vertical channel, a hearth chamber used for forming a hearth is wrapped around the combustion chamber, a communicating pipe is arranged on the chamber wall position of the hearth chamber so that the hearth chamber can communicate with the external environment. The combustor and the steam generation system using the same have the advantages of compact structure, small size, low noise, energy conservation and high burning efficiency, the steam generation system comprises the combustor, the ignition efficiency and the service life of a steam generator are effectively improved while the operation threshold is lowered.

Owner:夏光超

Exercise machine

ActiveUS10617904B2Improve direction accuracyQuick changeMuscle exercising devicesRotational axisClassical mechanics

Machine for gymnastic exercises comprising a sliding rail (3), a carriage (4) installed in a sliding manner on the sliding rail (3), a first pulley (21) and a second pulley (22) installed on the carriage (4) and rotatable in an idle manner around respective axes of rotation, a gripping element (6), cable traction means (16) comprising a first cable branch (a) and a second cable branch (b) provided with respective and separate connection ends (17) attached to the gripping element (6). The first cable branch (a) and the second cable branch (b) wind at least partly around the first pulley (21) and respectively the second pulley (22) to define first return segments (23) comprised between the gripping element (6) and respectively the first pulley (21) and second pulley (22), and second return segments (24) that extend one on a first side (25) and the other on a second side (26), opposite the first side (25), of the carriage (4) and substantially parallel to the sliding rail (3).

Owner:AKUIS SRL

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com