Patents

Literature

31results about How to "Improve direction accuracy" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

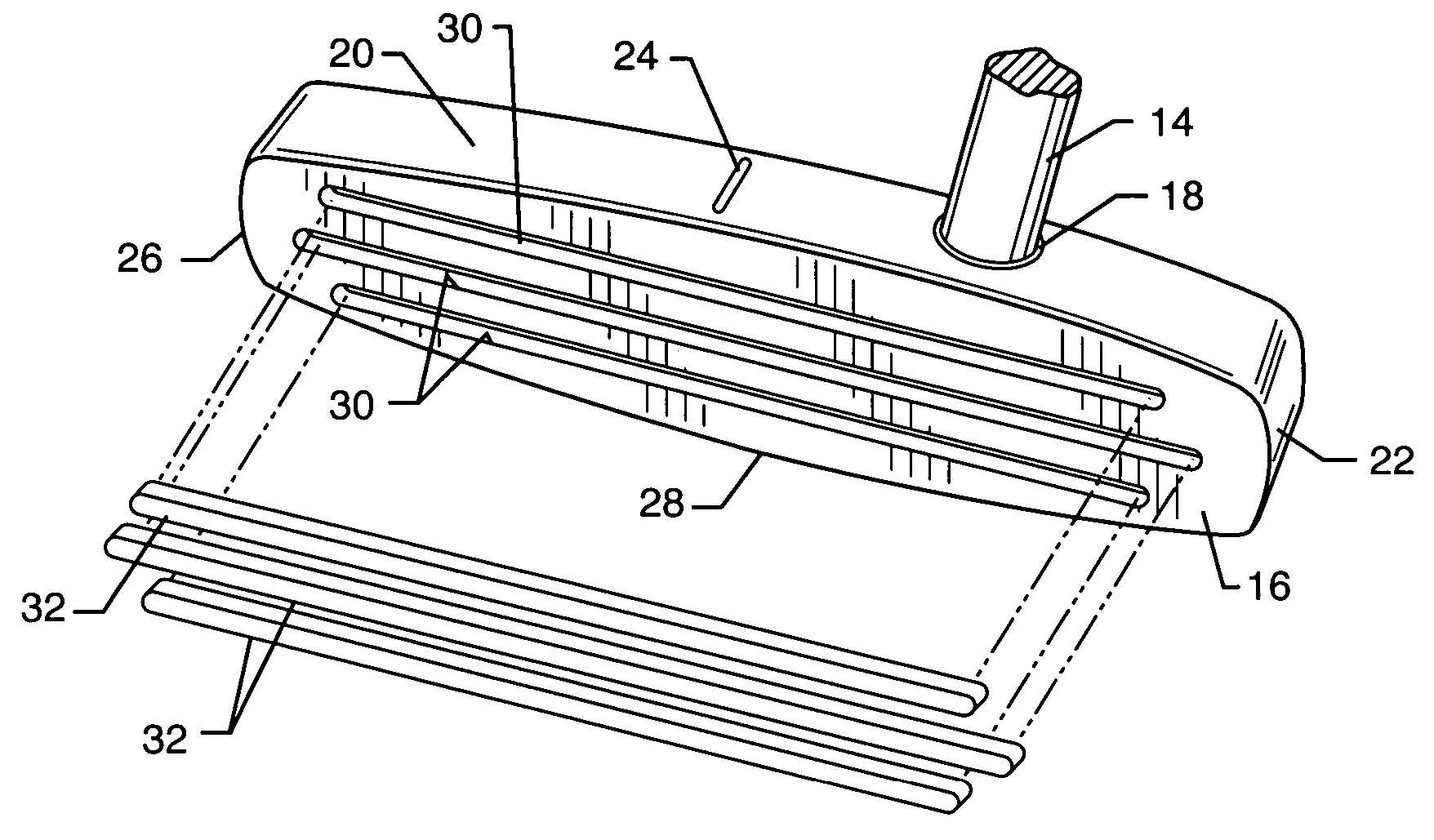

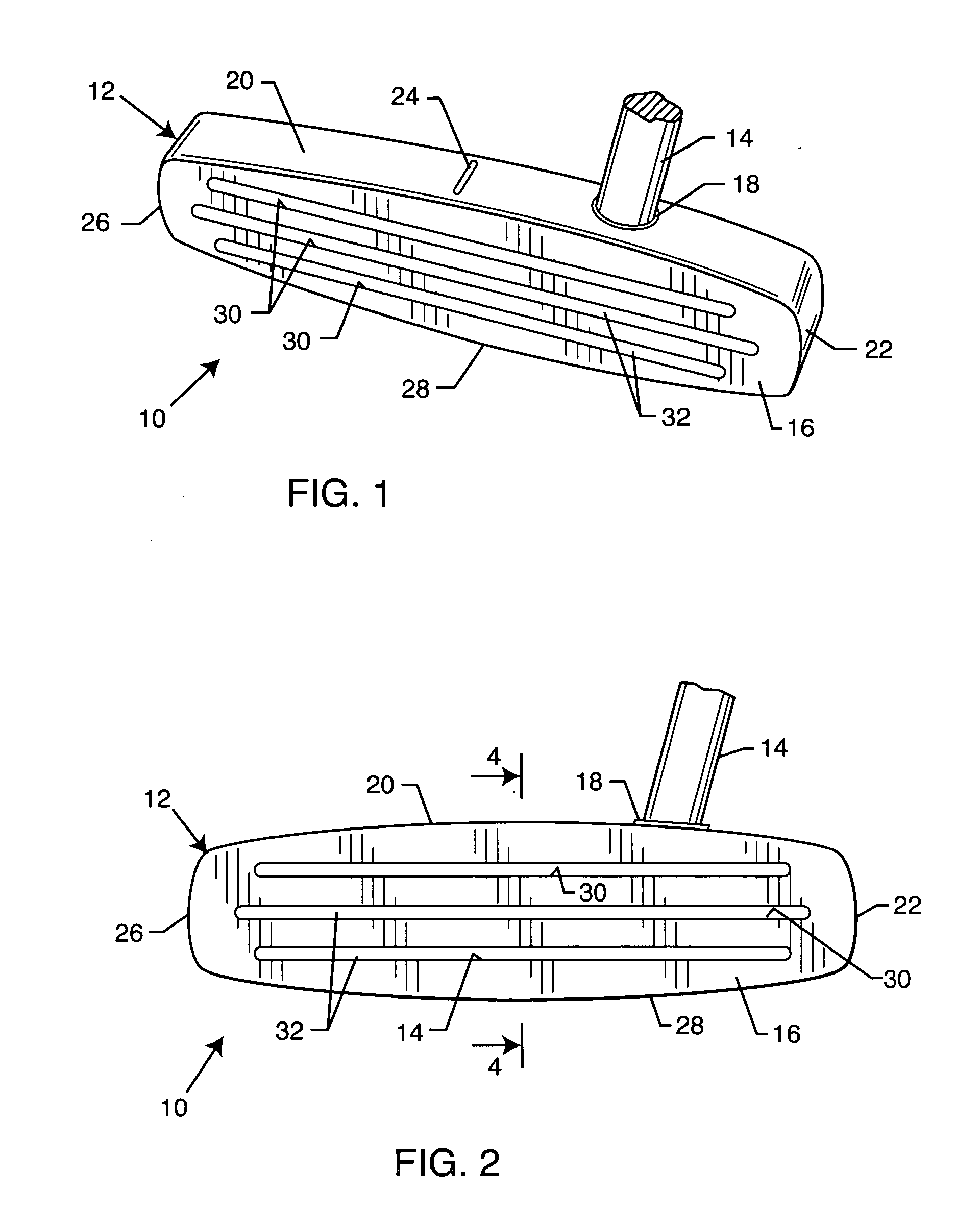

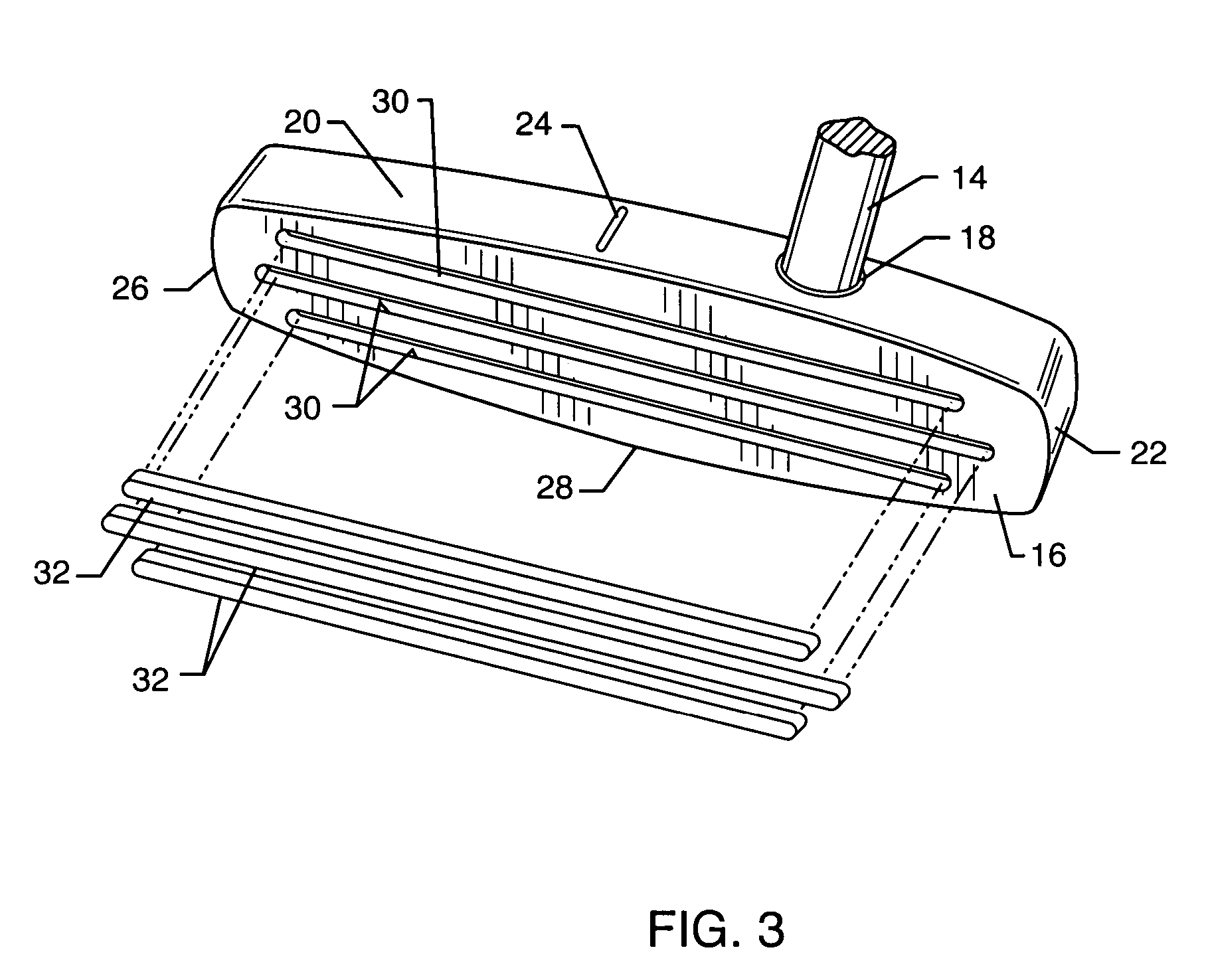

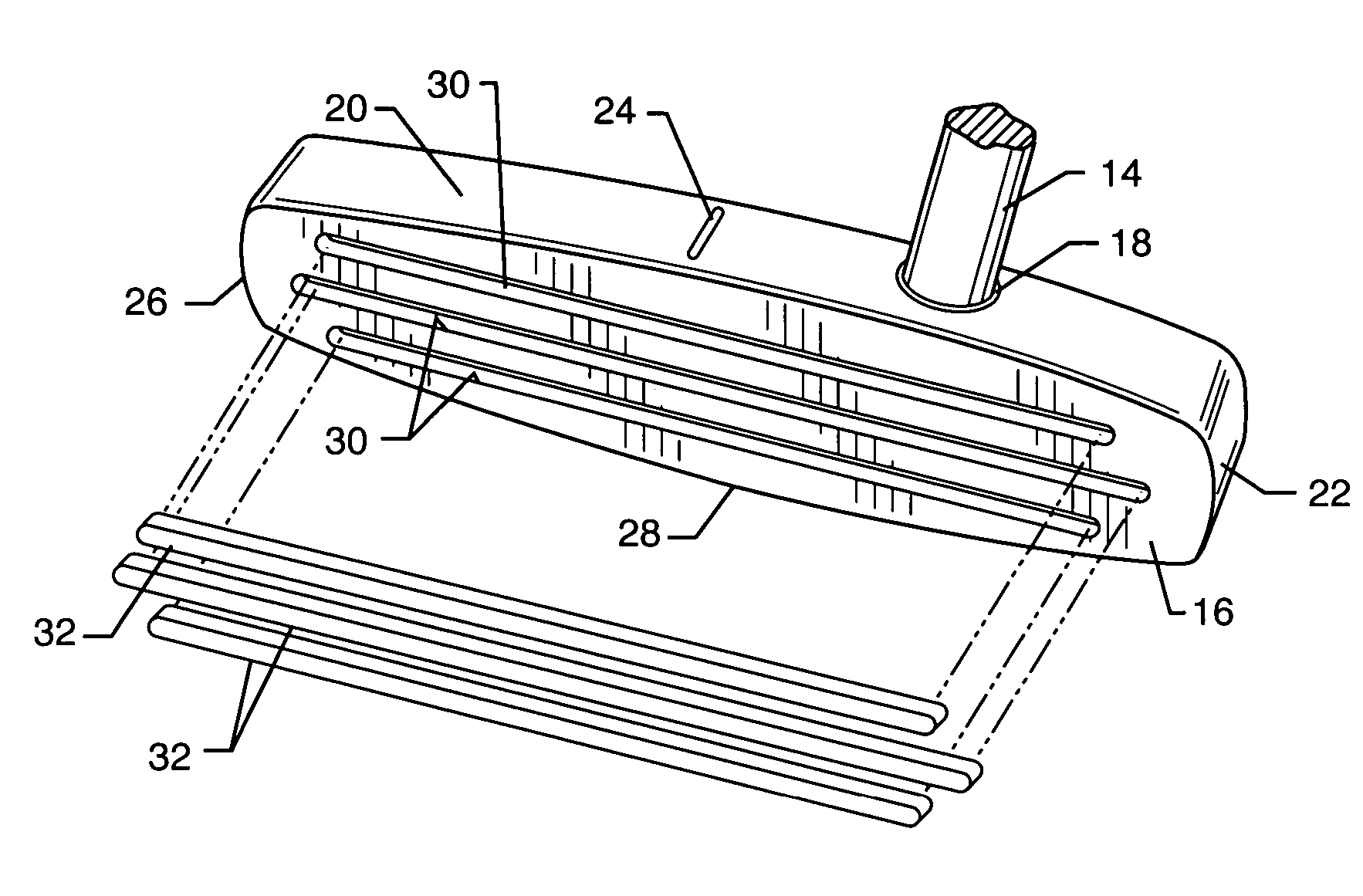

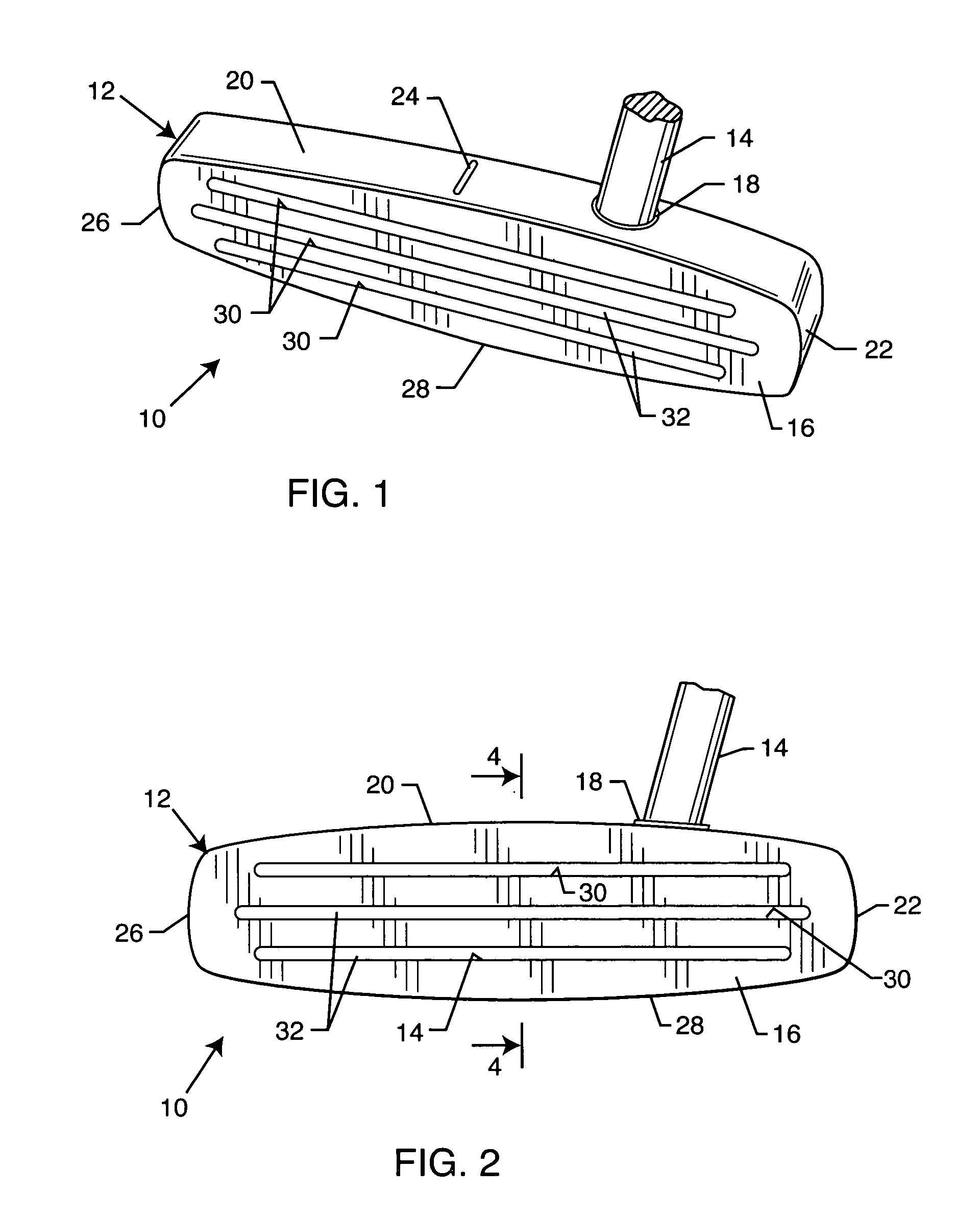

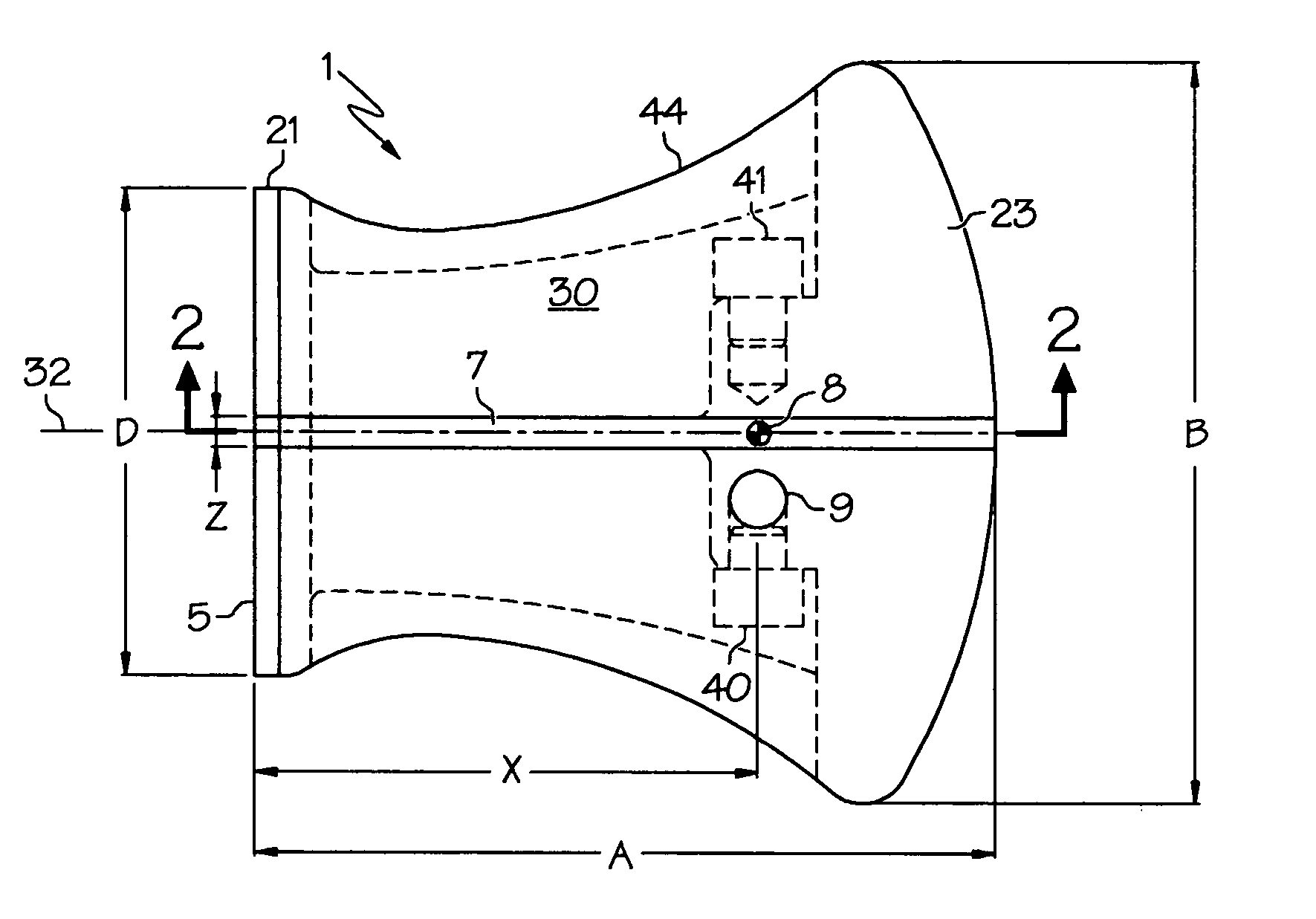

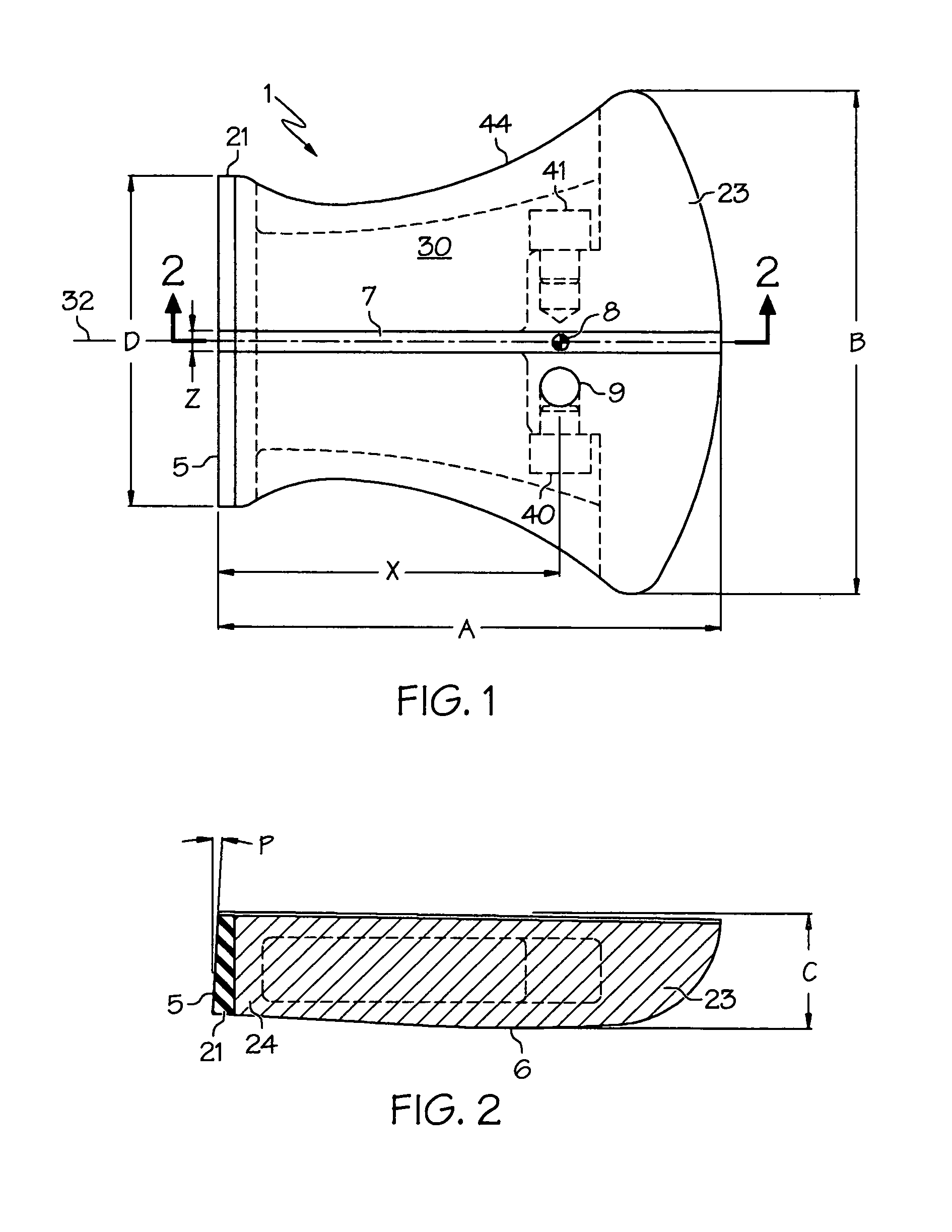

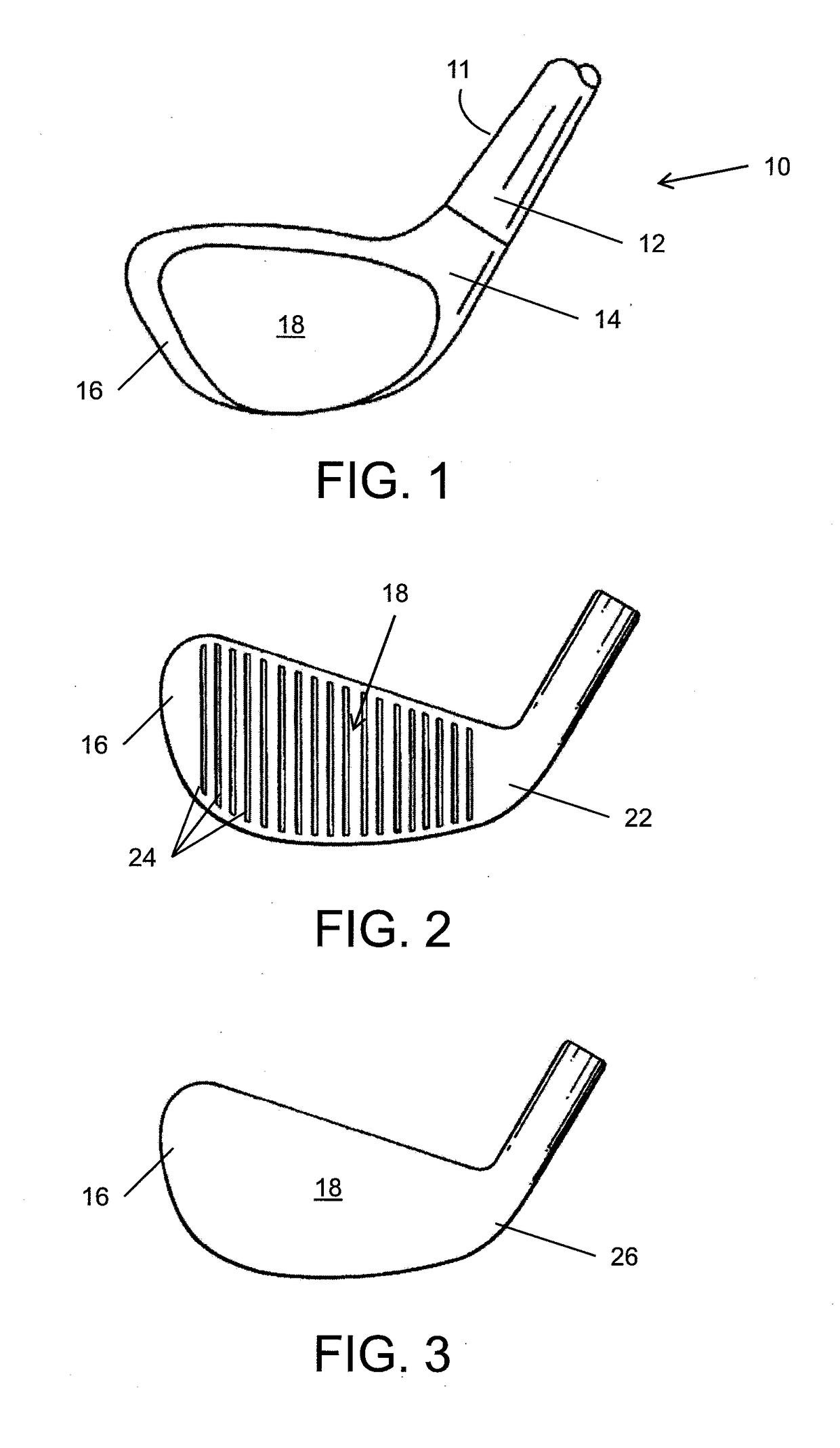

Faceplate groove pattern for a golf club putter head

InactiveUS20050209020A1Minimize initial ball skiddingPromote early smooth ball rollGolf clubsGravity centerGolf Ball

A golf club putter head includes a faceplate groove pattern configured to provide the putter head with an elevated center of gravity. In one preferred form, a club head body defines a faceplate having at least one and preferably multiple elongated grooves formed therein to extend generally in a heel-to-toe direction, with at least one groove positioned above a vertical mid-point of the club head body. The groove depths progressively increase in a top-to-bottom direction so that the putter head center of gravity is elevated to a position spaced above the vertical mid-point of the club head body. When striking a golf ball, the elevated center of gravity functions to minimize initial ball skidding and to promote early smooth ball roll toward a target such as a cup on a golf green.

Owner:BGI ACQUISITION

Faceplate groove pattern for a golf club putter head

InactiveUS7261644B2Promote early smooth post-impact rolling of a golf ballMinimizing initial post-impact ball skiddingGolf clubsGravity centerGolf Ball

A golf club putter head includes a faceplate groove pattern configured to provide the putter head with an elevated center of gravity. In one preferred form, a club head body defines a faceplate having at least one and preferably multiple elongated grooves formed therein to extend generally in a heel-to-toe direction, with at least one groove positioned above a vertical mid-point of the club head body. The groove depths progressively increase in a top-to-bottom direction so that the putter head center of gravity is elevated to a position spaced above the vertical mid-point of the club head body. When striking a golf ball, the elevated center of gravity functions to minimize initial ball skidding and to promote early smooth ball roll toward a target such as a cup on a golf green.

Owner:BGI ACQUISITION

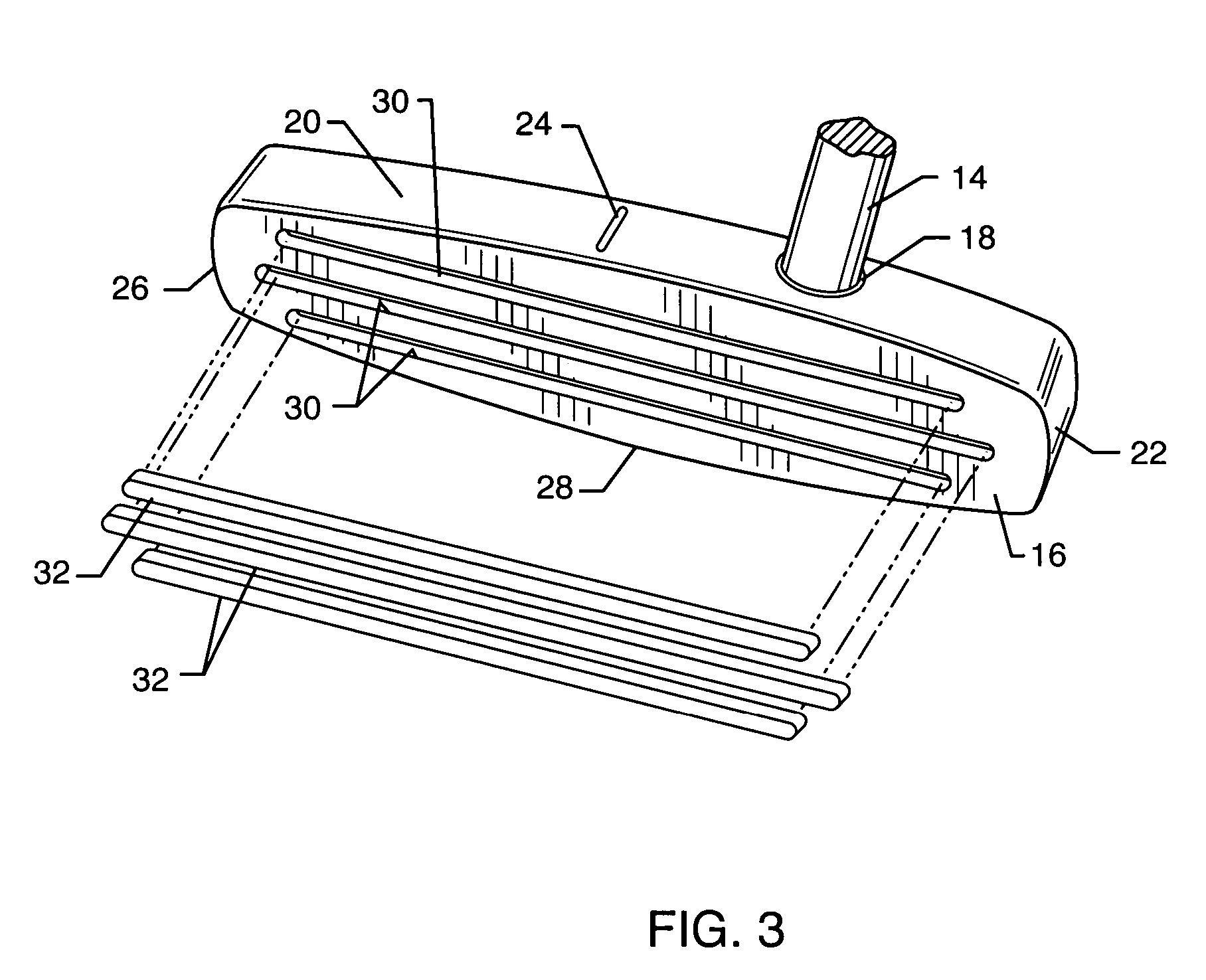

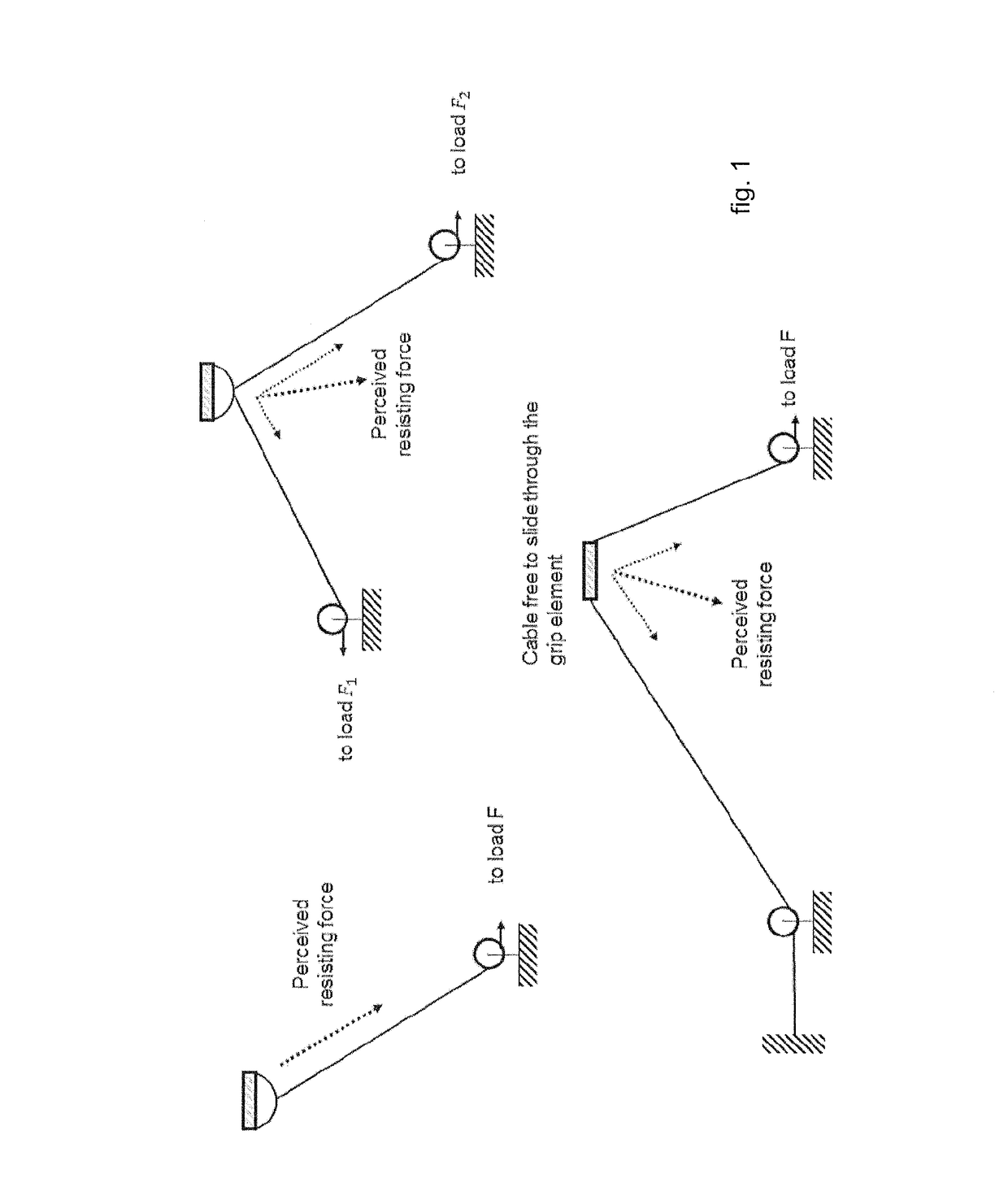

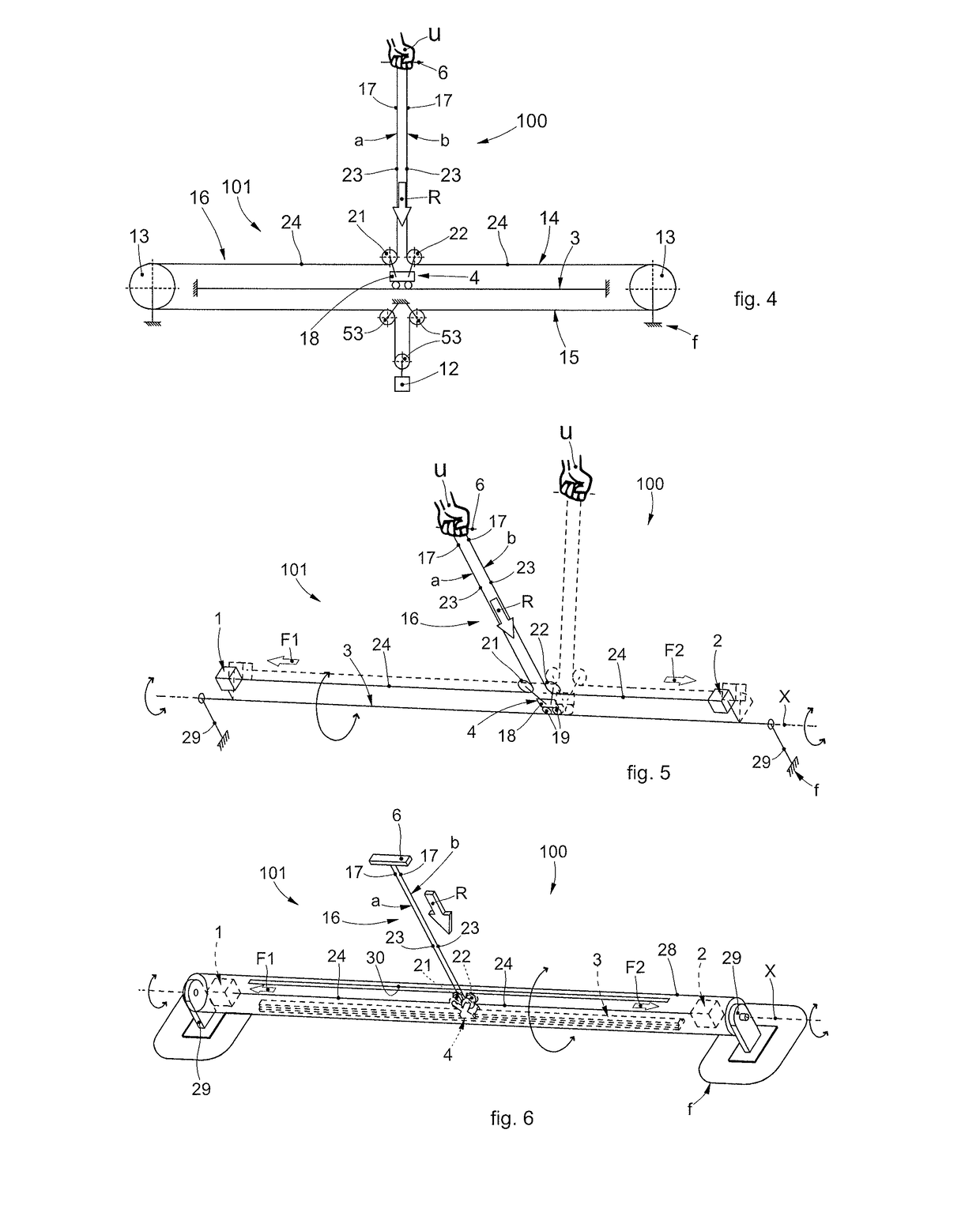

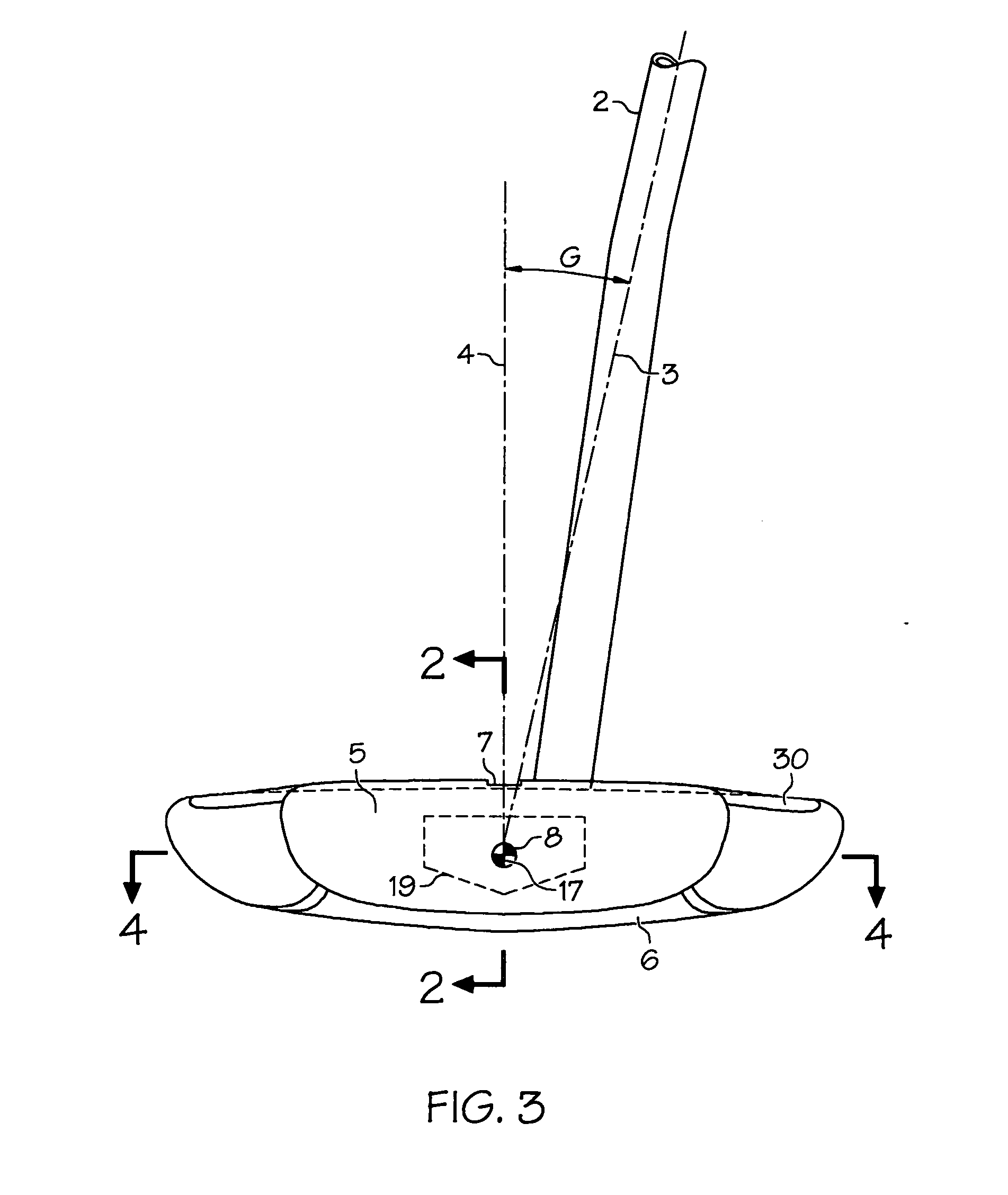

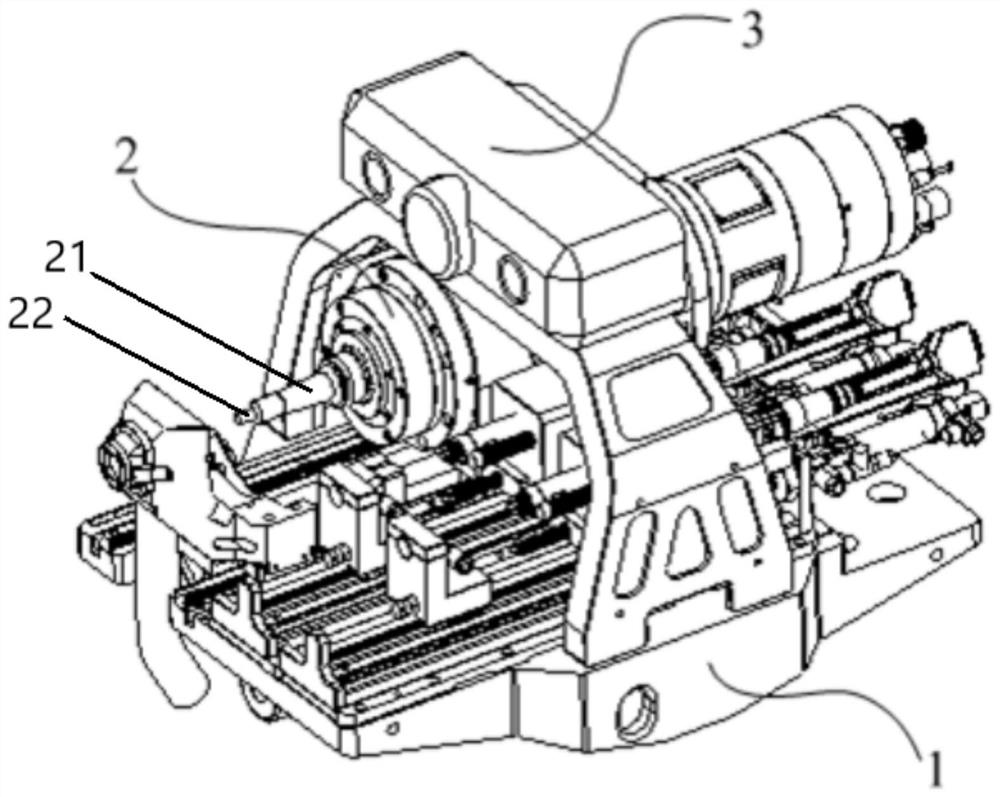

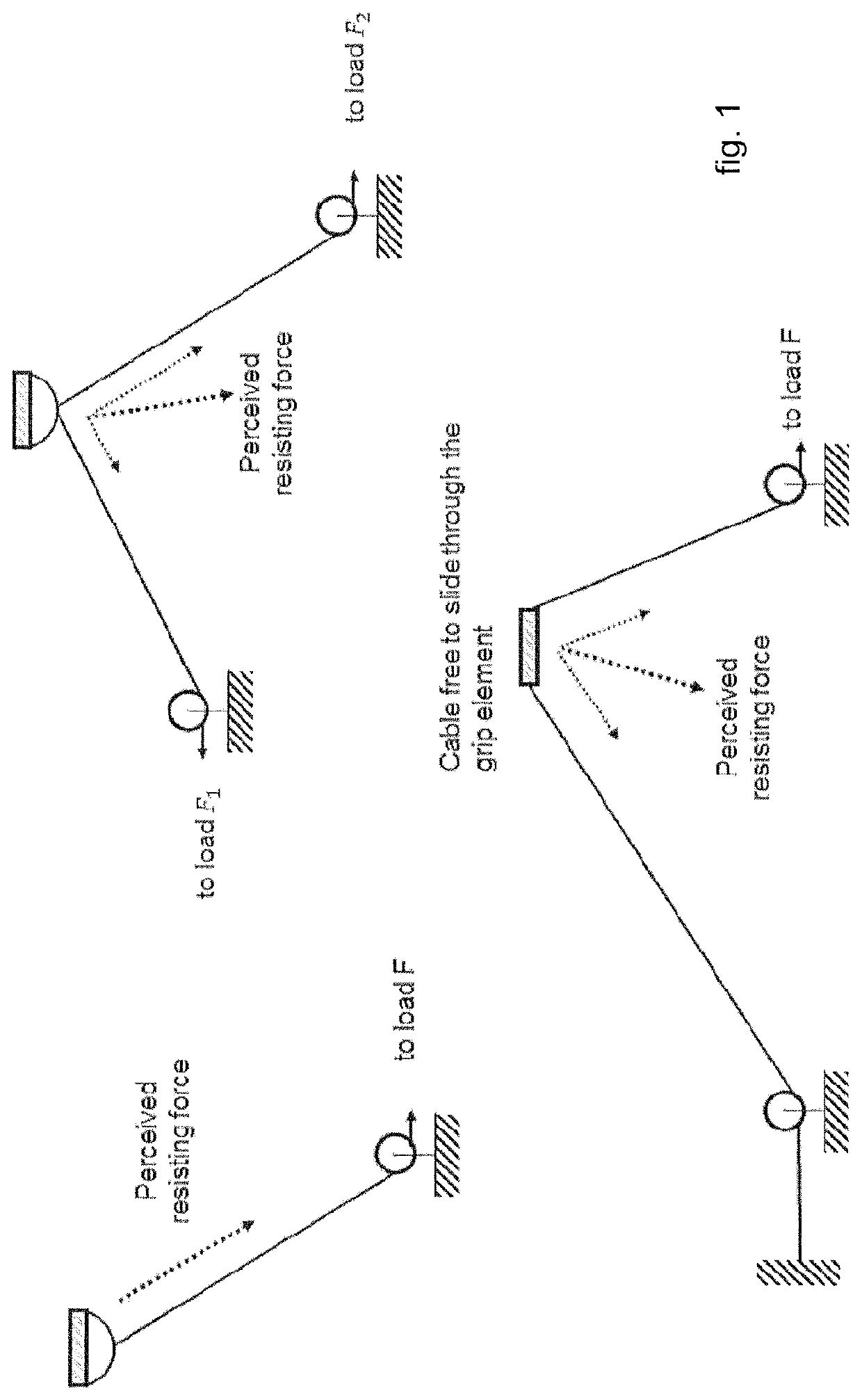

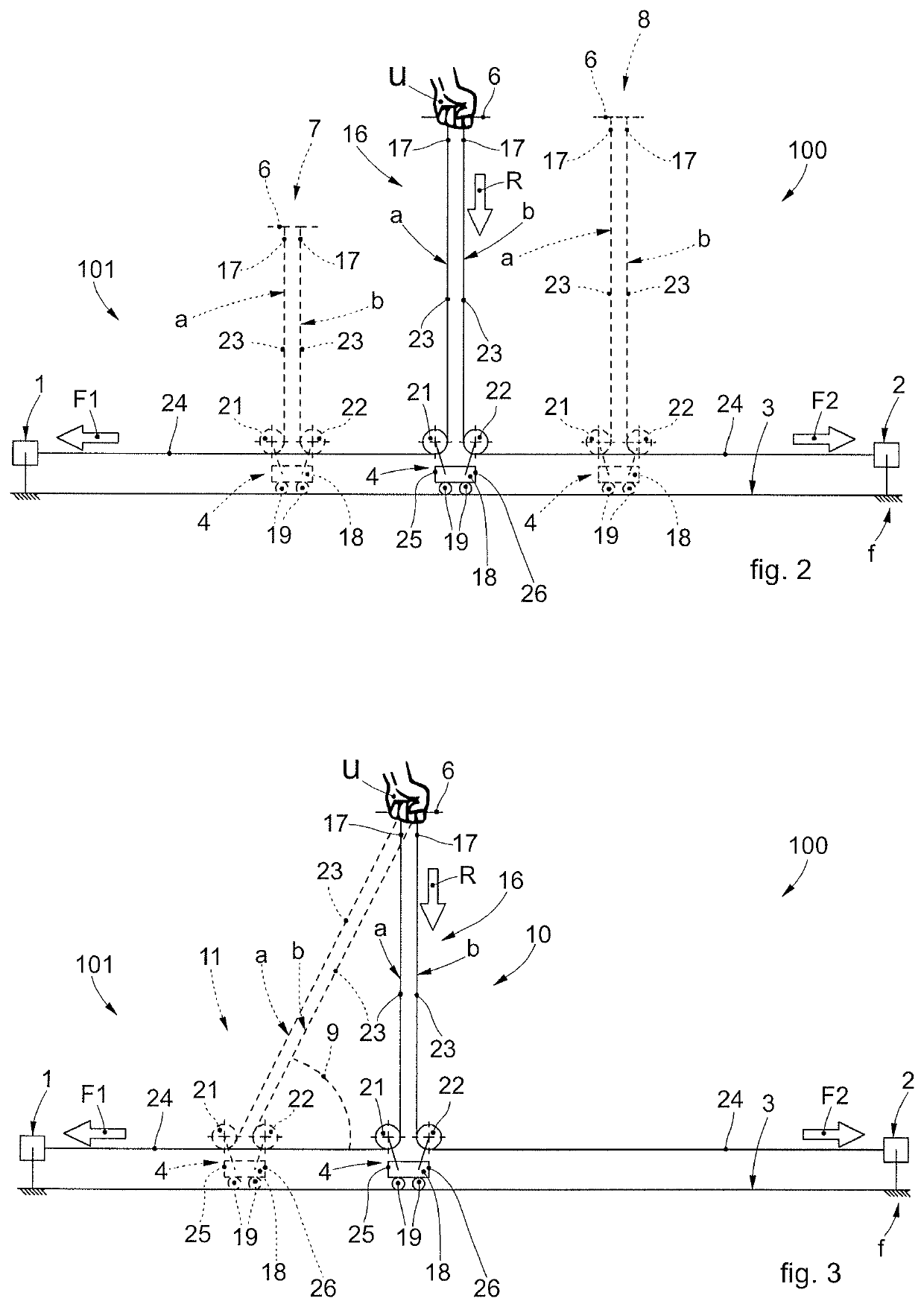

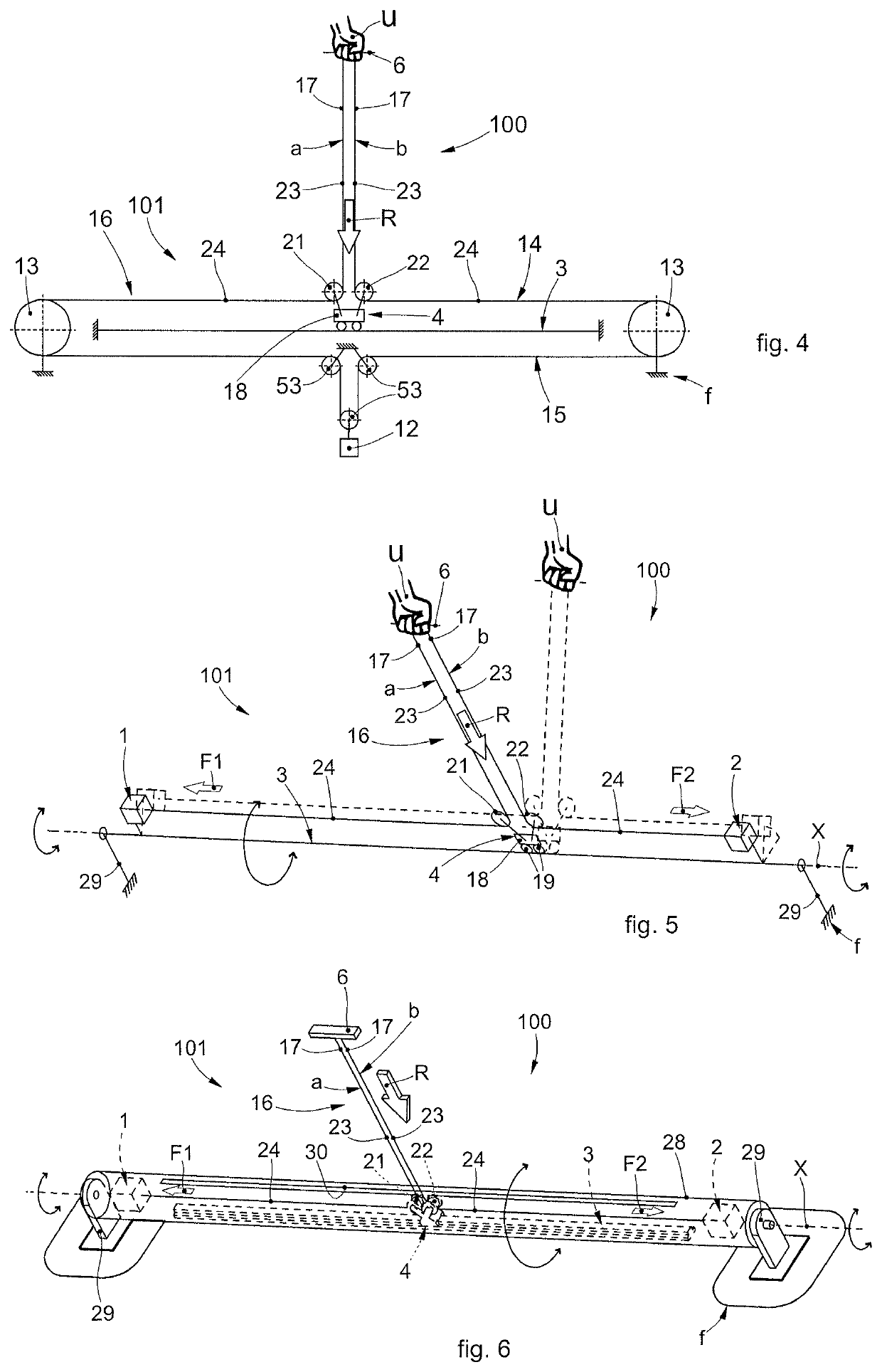

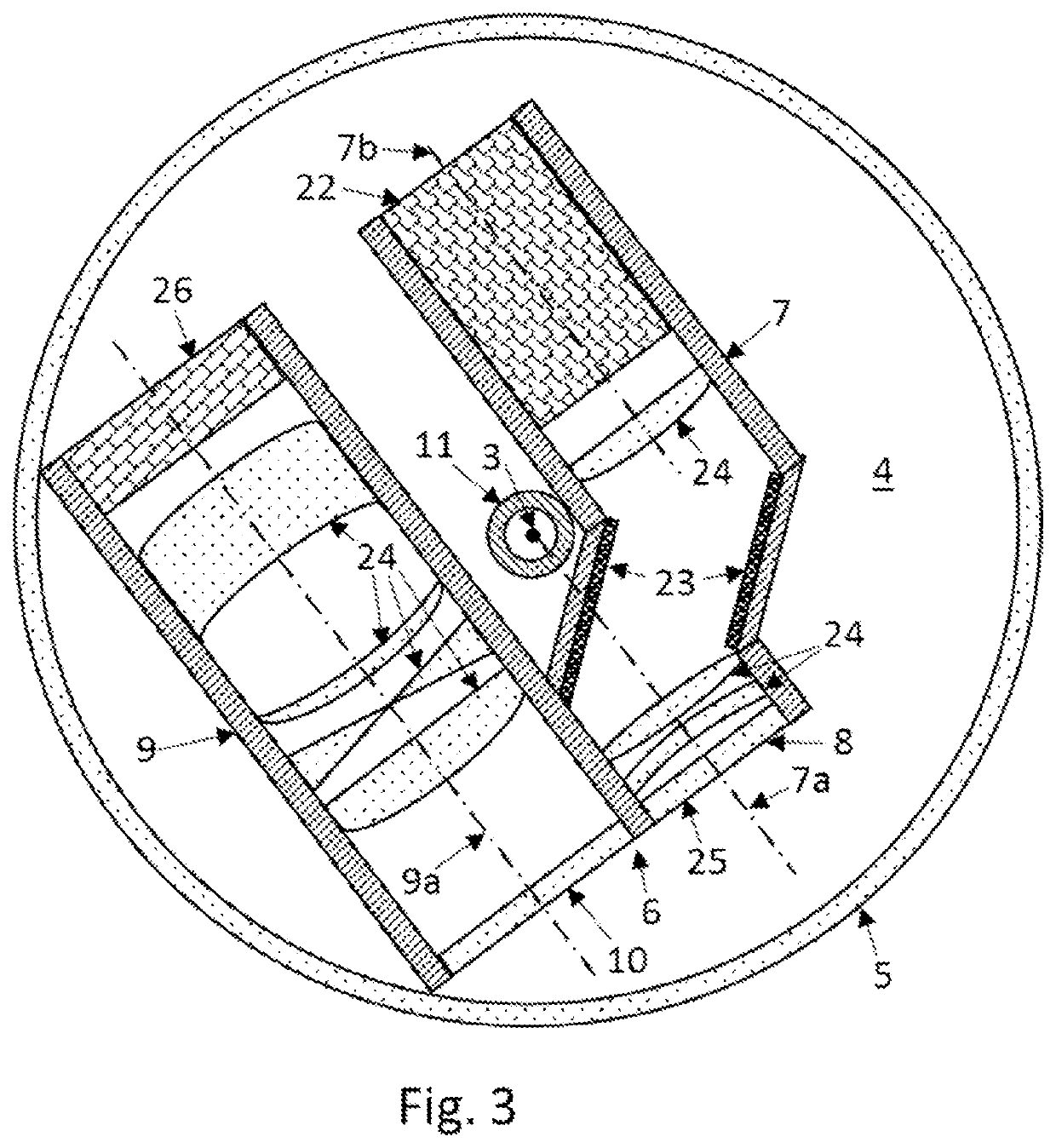

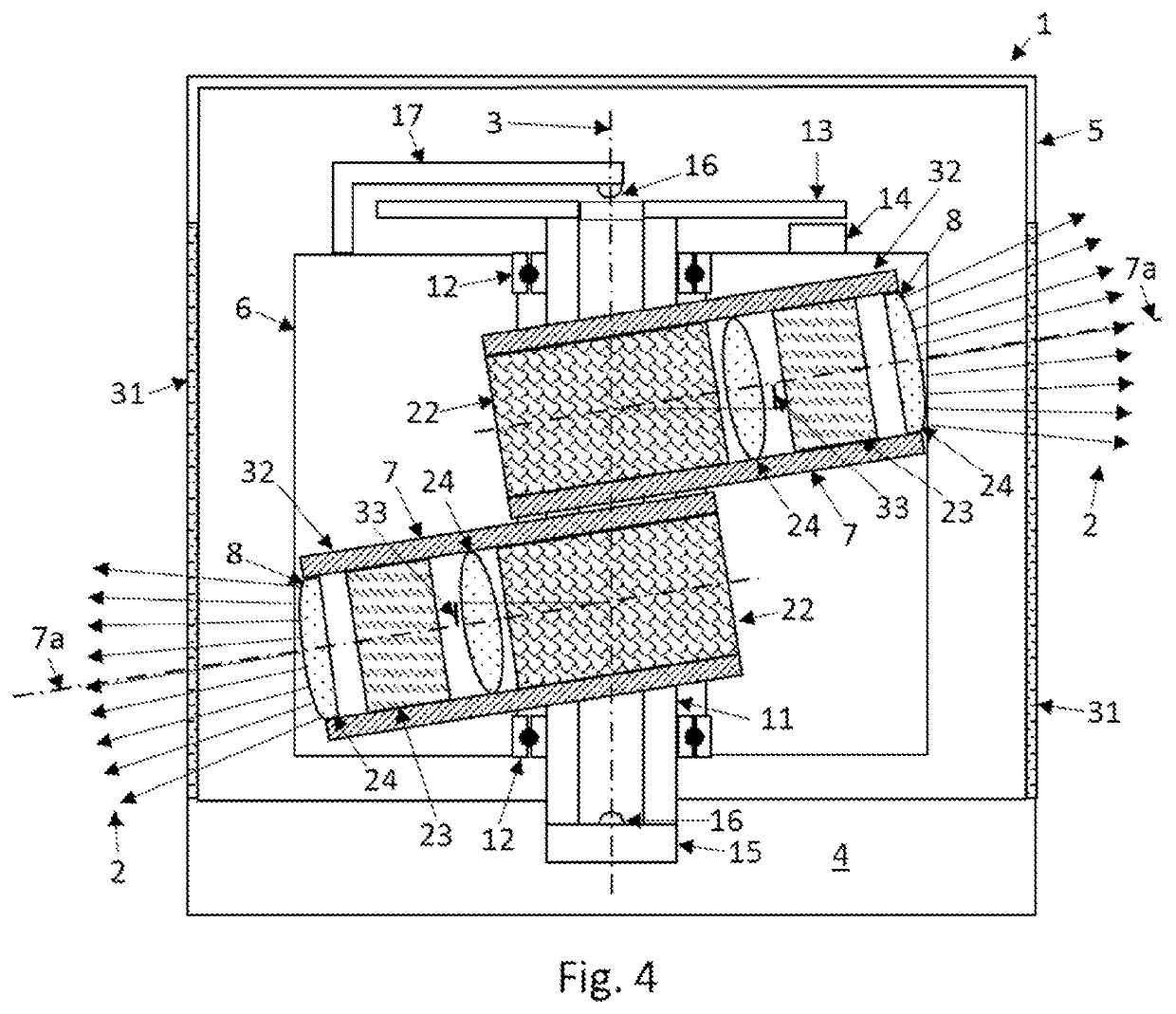

Exercise machine

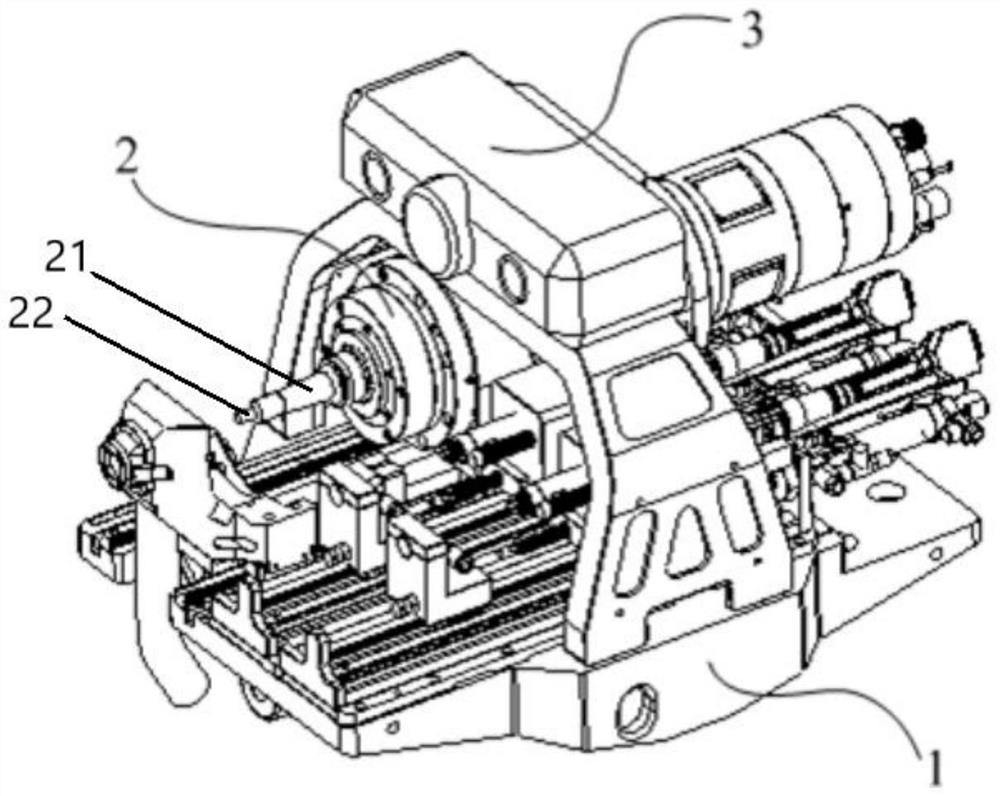

ActiveUS20190046830A1Improve direction accuracyQuick changeMuscle exercising devicesRotational axisClassical mechanics

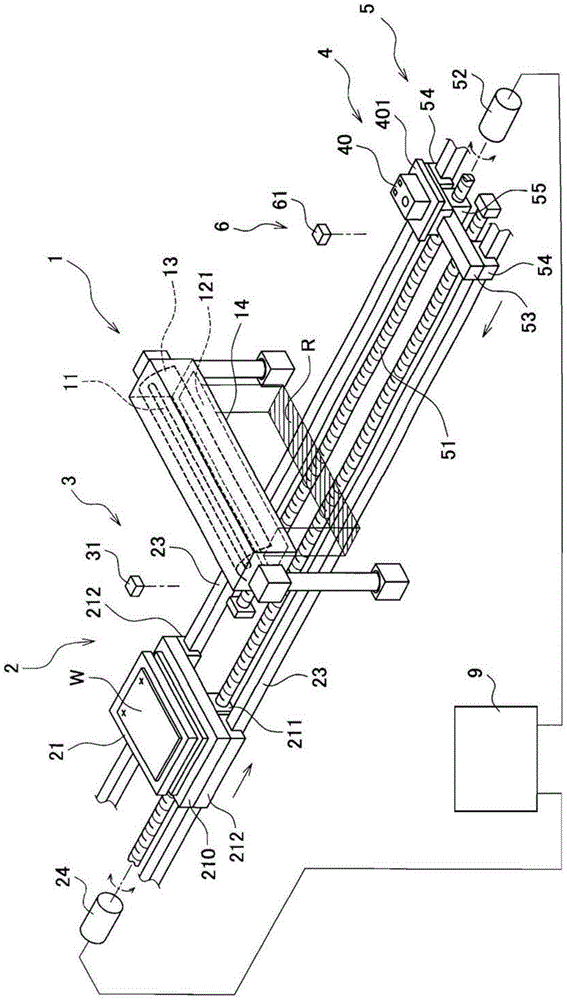

Machine for gymnastic exercises comprising a sliding rail (3), a carriage (4) installed in a sliding manner on the sliding rail (3), a first pulley (21) and a second pulley (22) installed on the carriage (4) and rotatable in an idle manner around respective axes of rotation, a gripping element (6), cable traction means (16) comprising a first cable branch (a) and a second cable branch (b) provided with respective and separate connection ends (17) attached to the gripping element (6). The first cable branch (a) and the second cable branch (b) wind at least partly around the first pulley (21) and respectively the second pulley (22) to define first return segments (23) comprised between the gripping element (6) and respectively the first pulley (21) and second pulley (22), and second return segments (24) that extend one on a first side (25) and the other on a second side (26), opposite the first side (25), of the carriage (4) and substantially parallel to the sliding rail (3).

Owner:AKUIS SRL

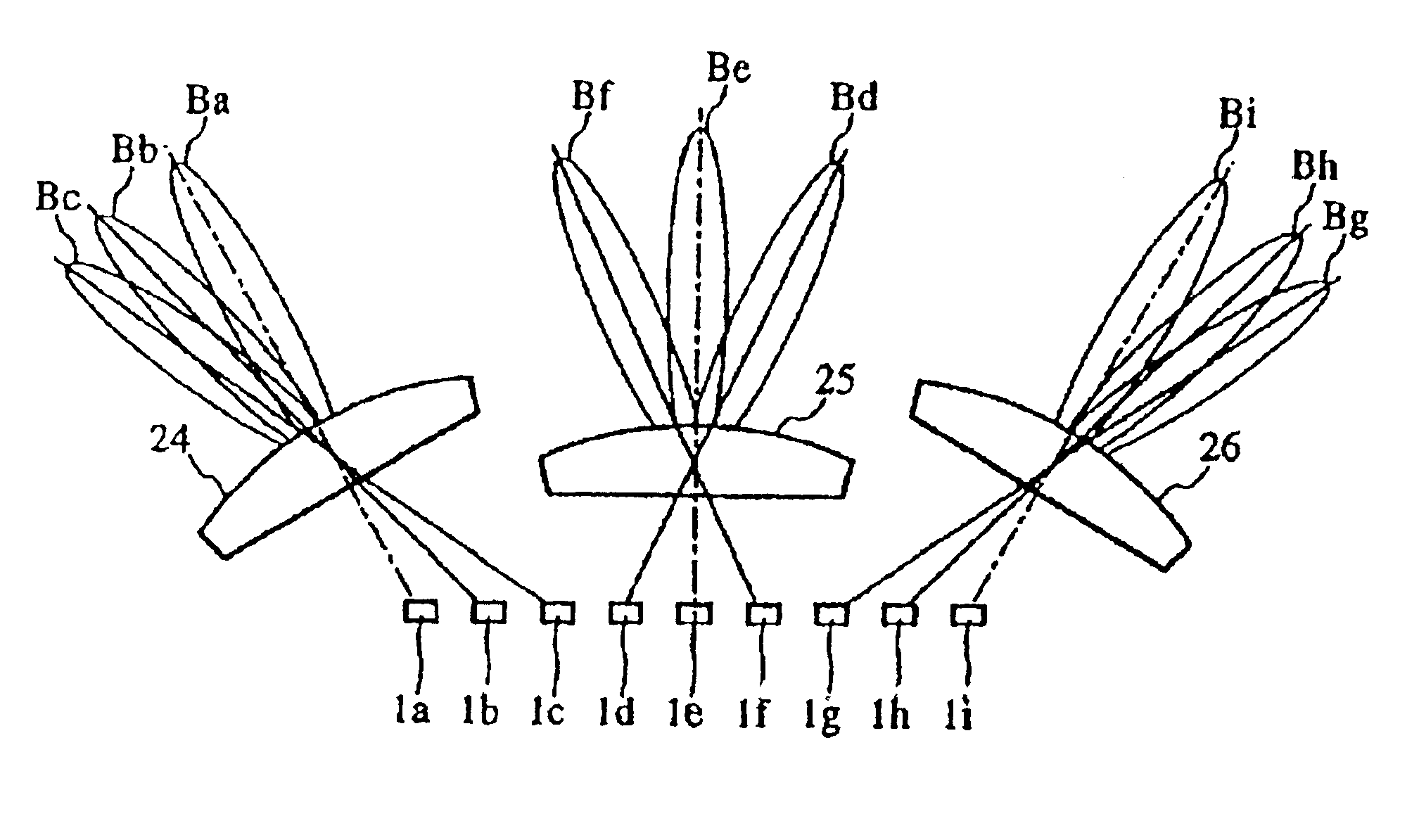

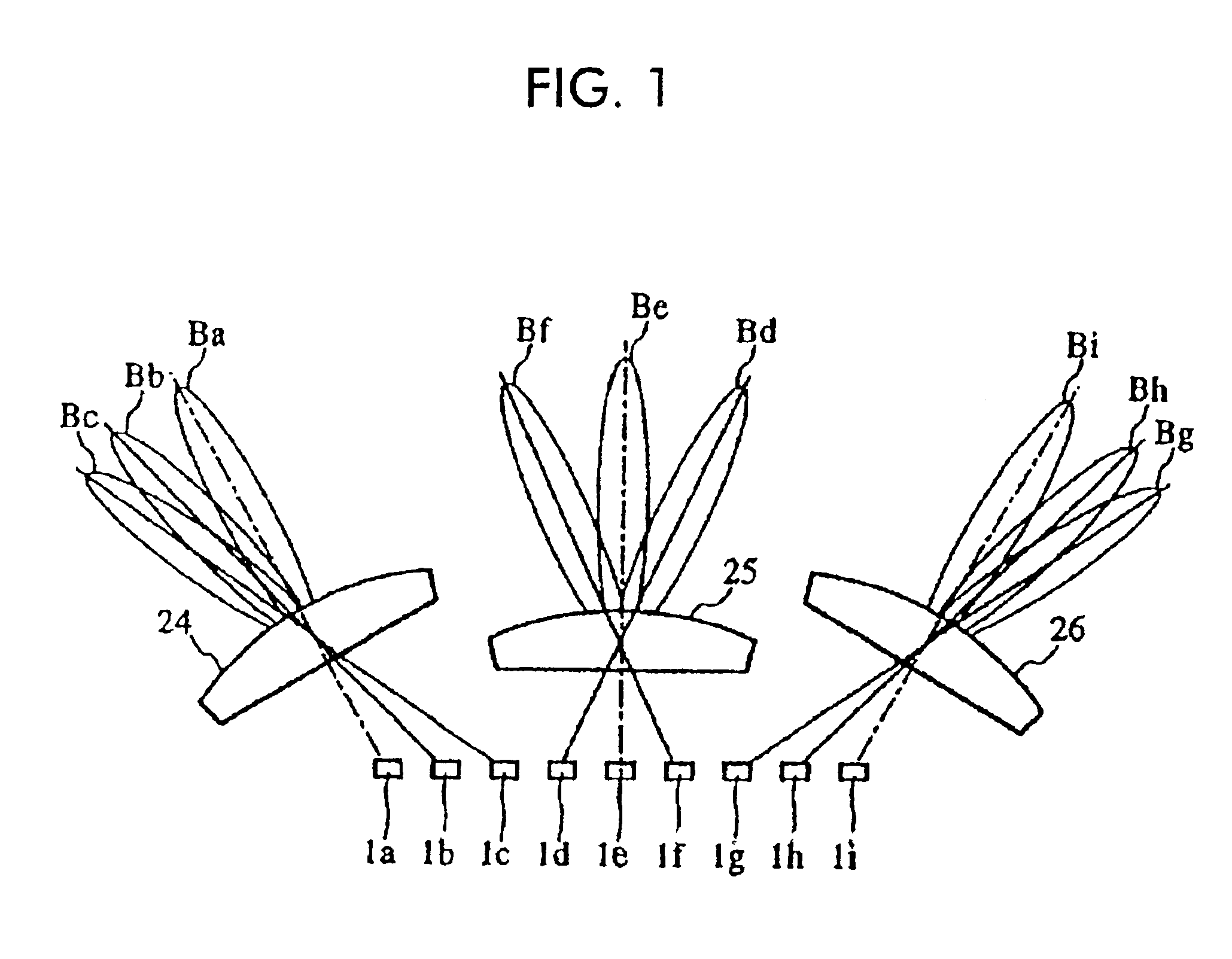

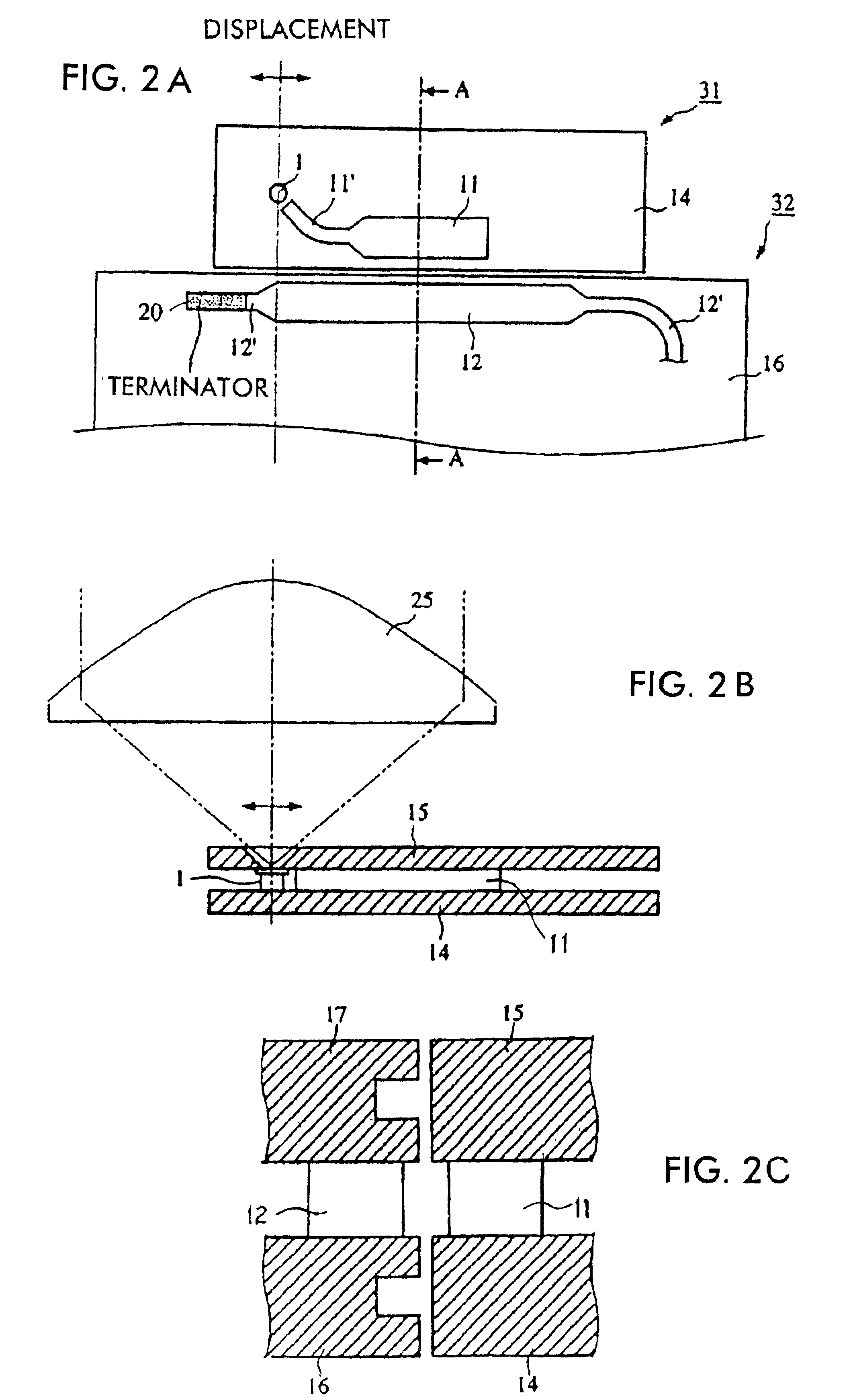

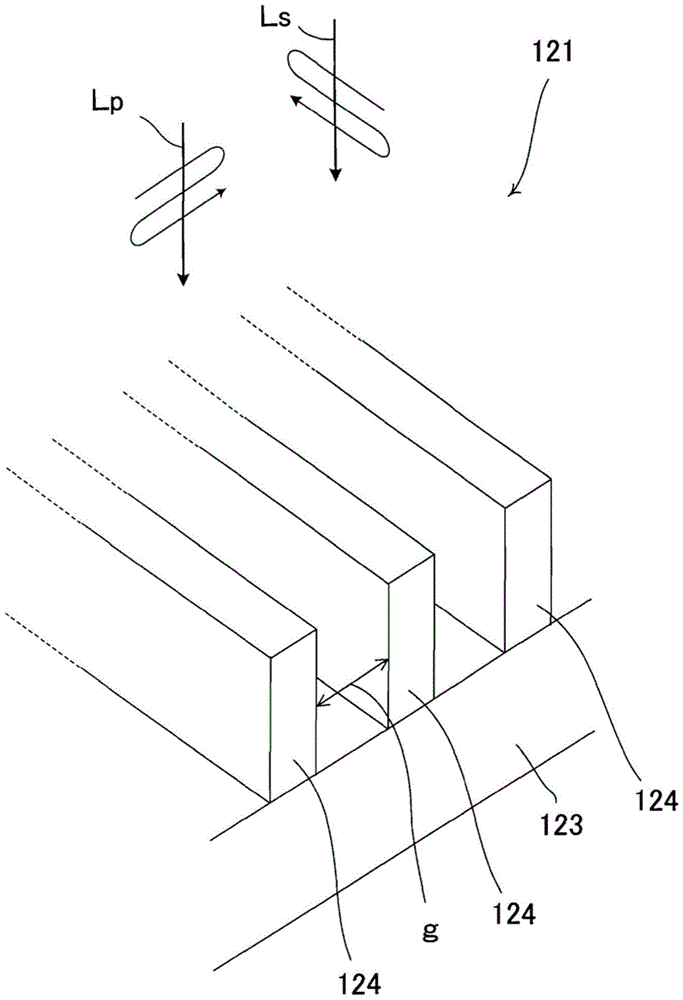

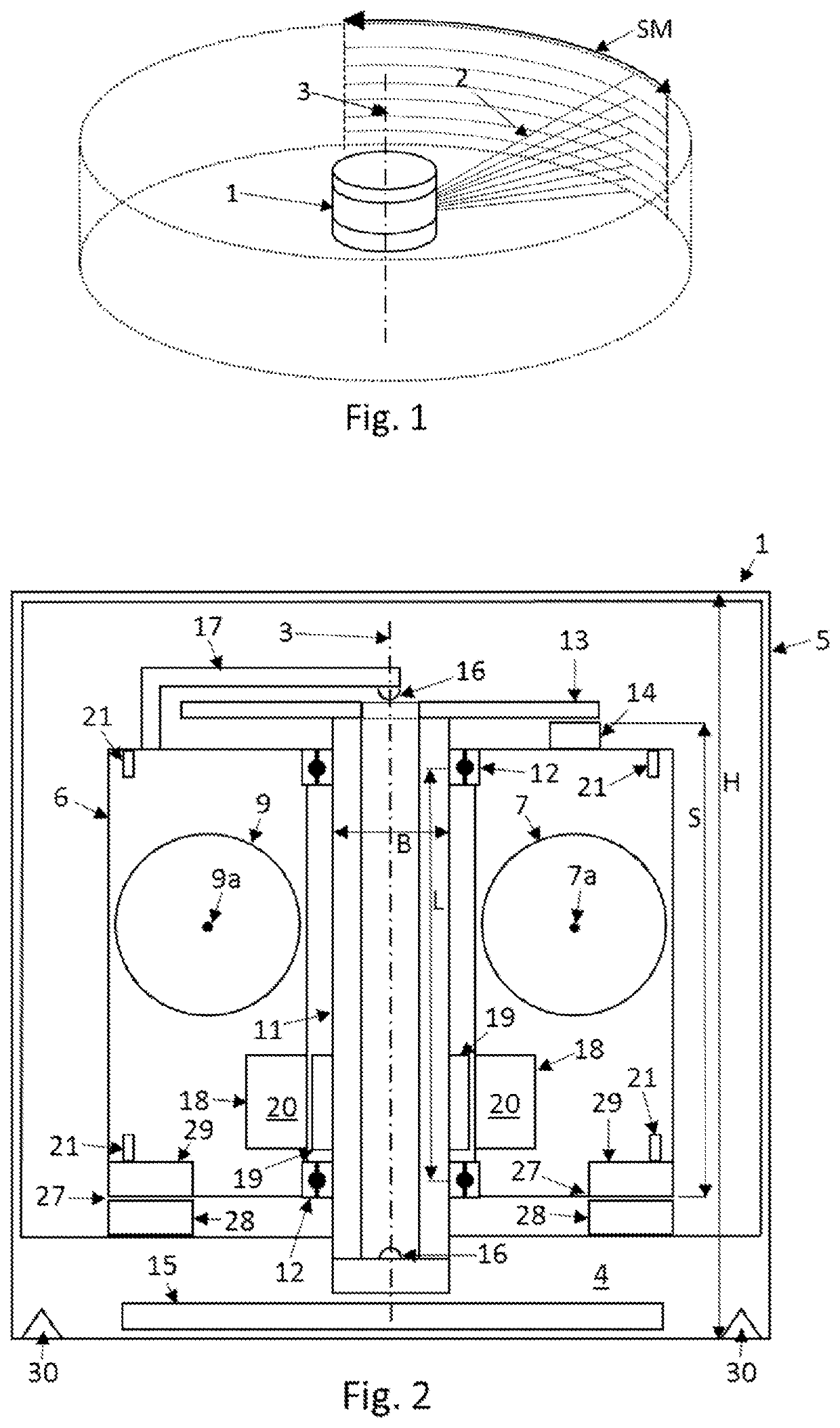

Antenna device, communication apparatus and radar module

InactiveUS6822612B2Easy to detectEasy to assembleAntenna adaptation in movable bodiesIndividually energised antenna arraysRadarLight beam

An antenna device capable of increasing the speed of scanning as well as extending the scanning angular range of a beam to obtain a high gain. A radar module and a communication apparatus having enhanced detection capabilities obtainable by using the antenna device. In the antenna device, electromagnetic waves radiated from a primary radiator are transmitted to a plurality of openings, e.g., dielectric lenses and / or reflectors or optical transmitters. The dielectric openings are arranged on a fixed portion and the primary radiator is arranged on a moving portion. The moving portion is displaced relatively with respect to the fixed portion. This arrangement enables the selection of an opening used for receiving each of the electromagnetic waves from the primary radiator to change the direction of the beam.

Owner:MURATA MFG CO LTD

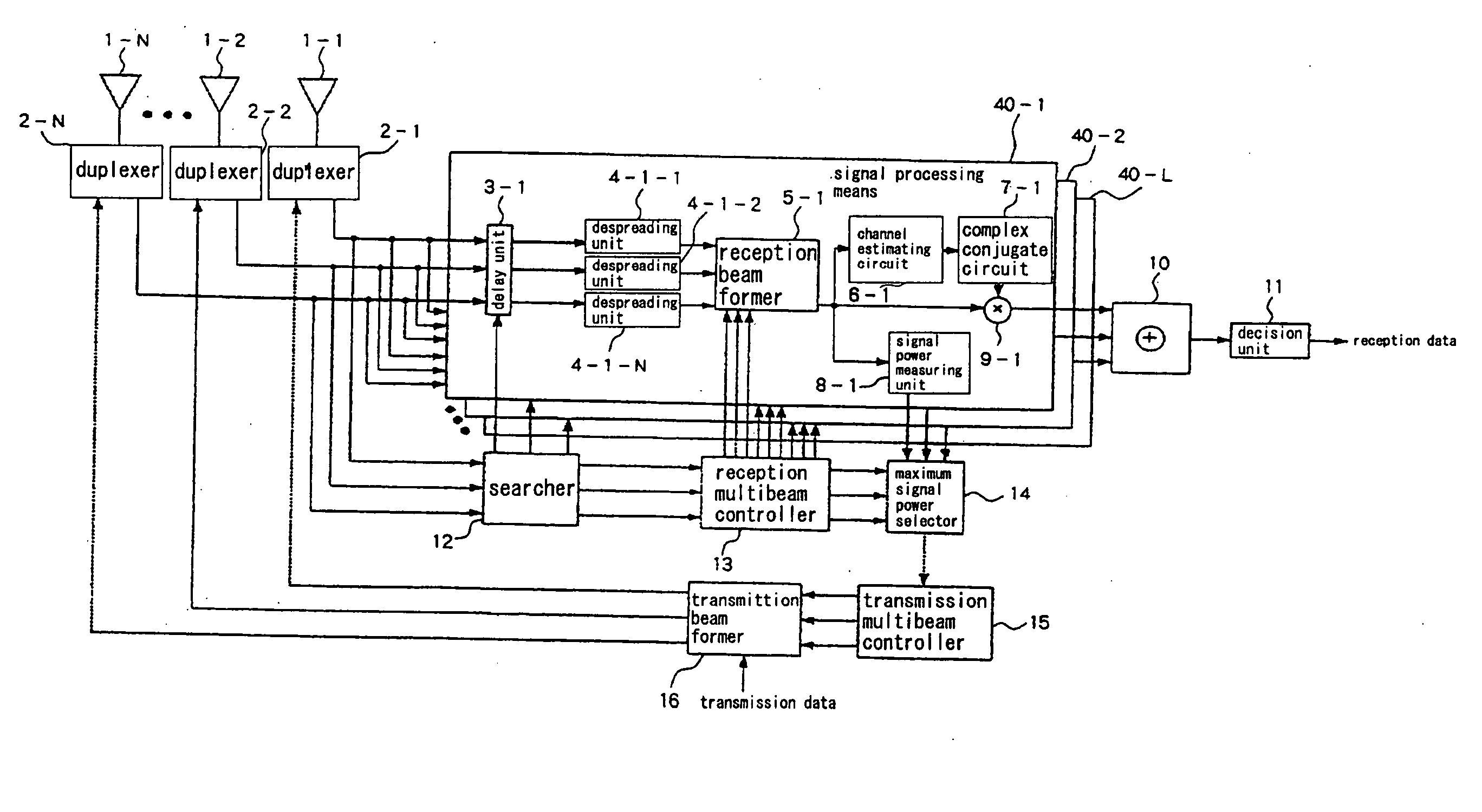

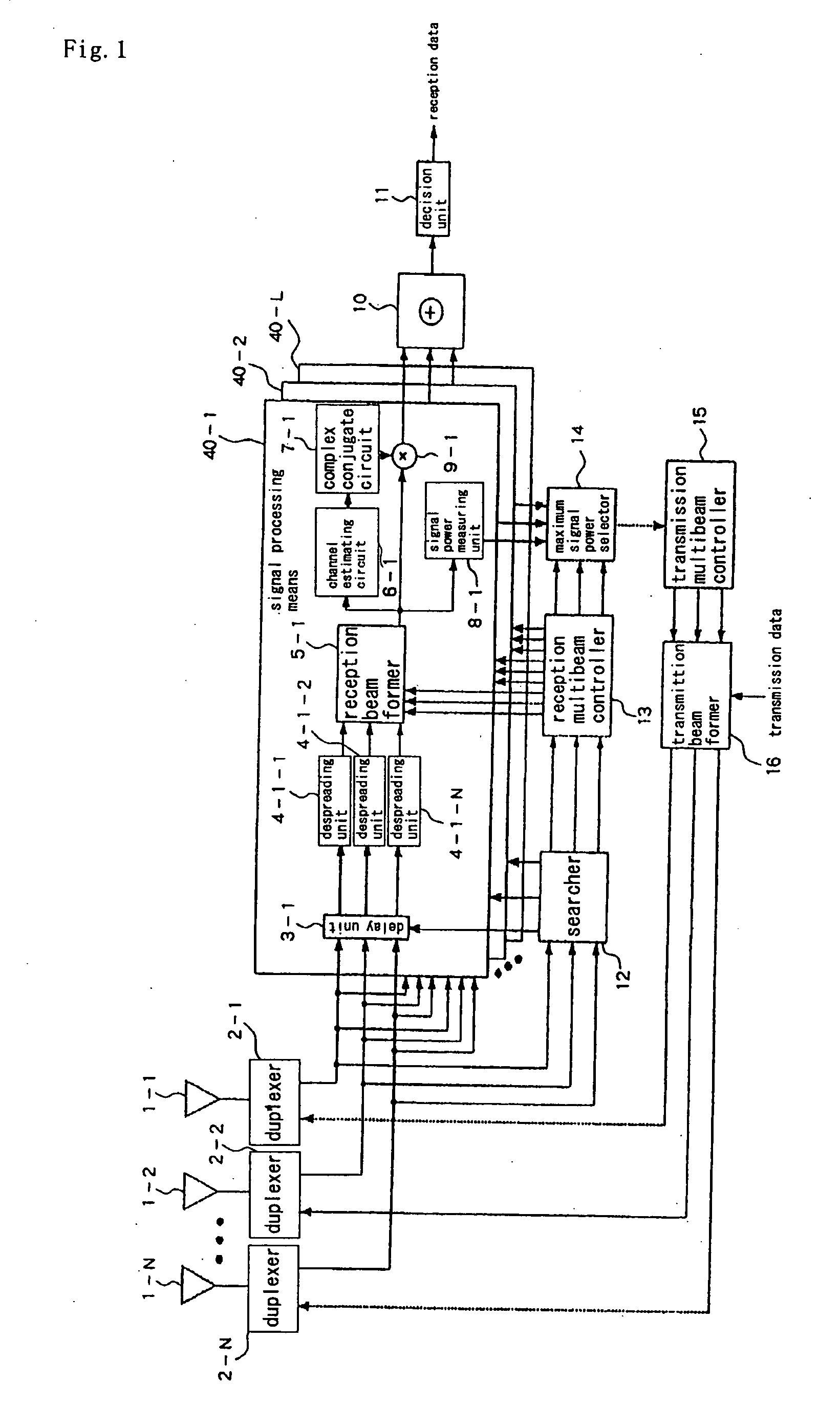

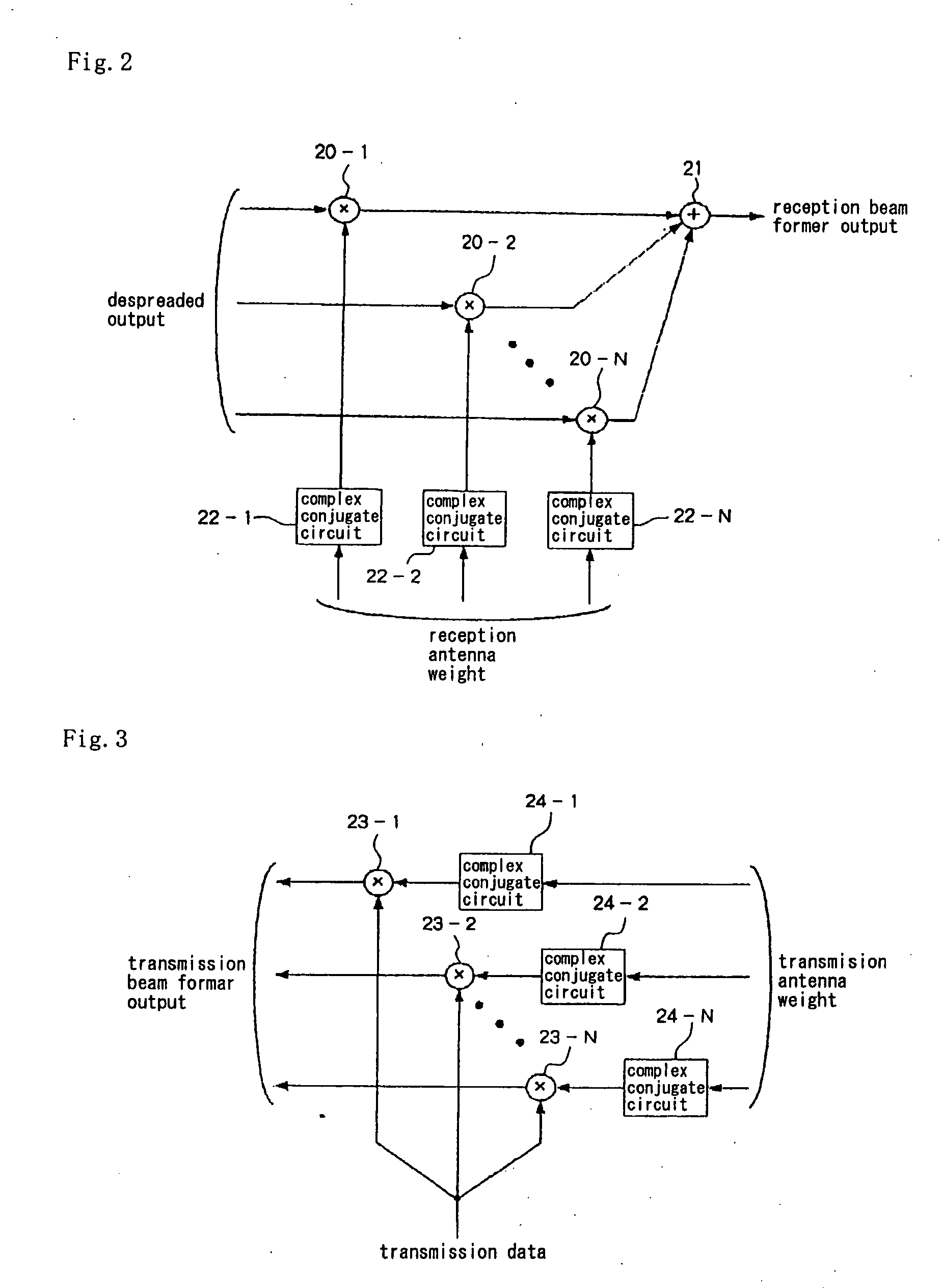

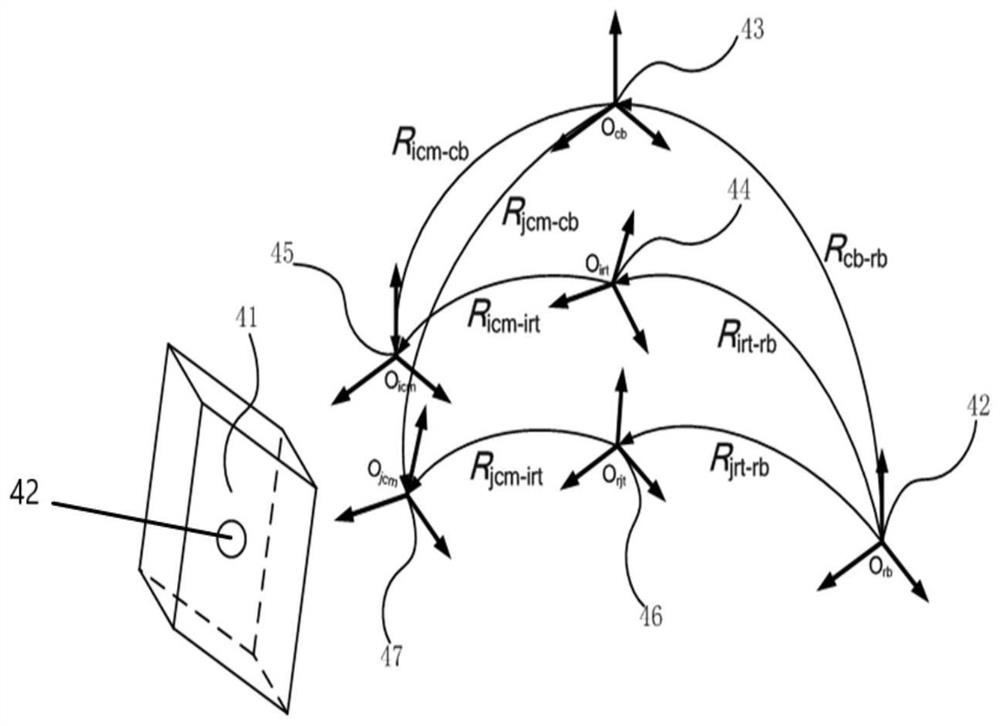

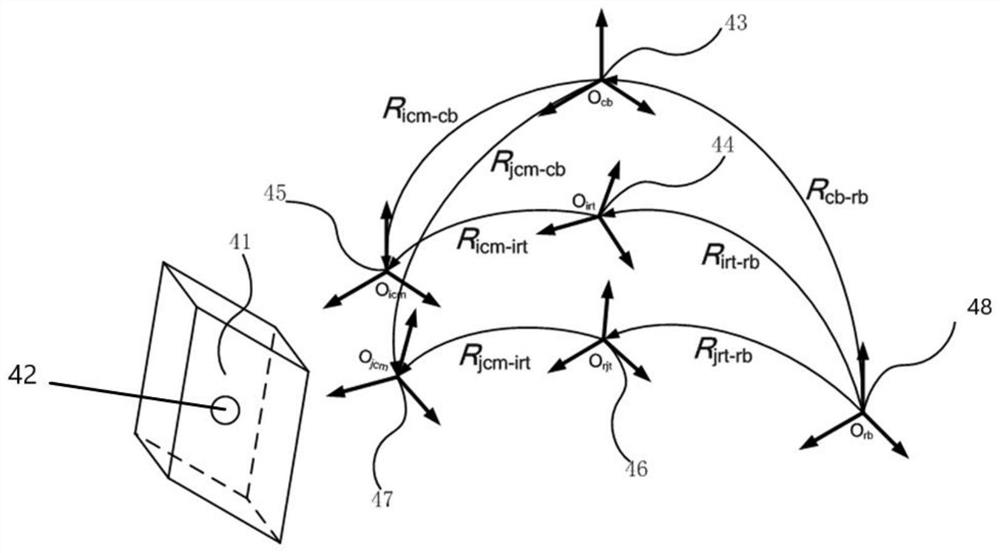

Multi-beam transmitting/receiving apparatus and transmitting/receiving method

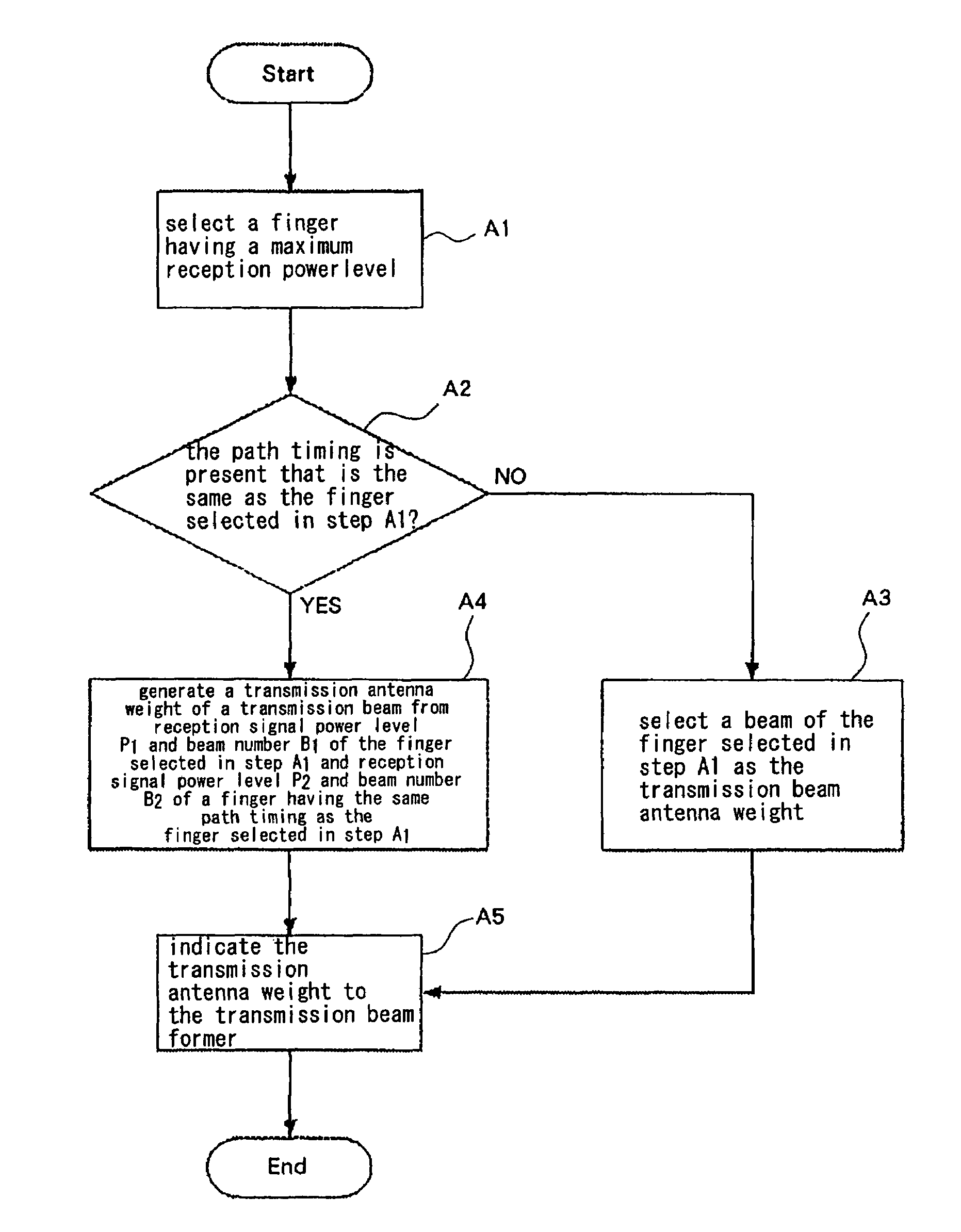

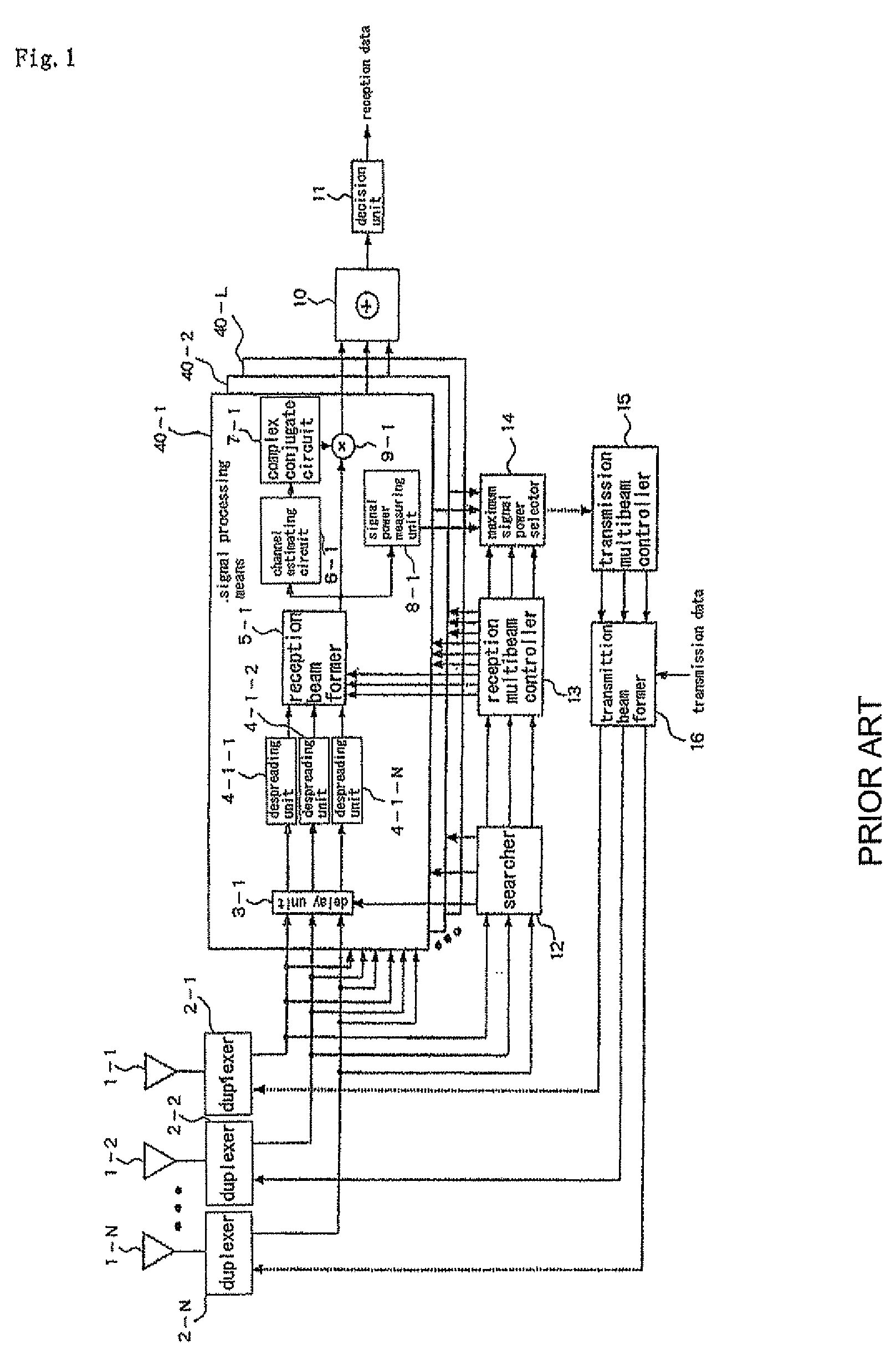

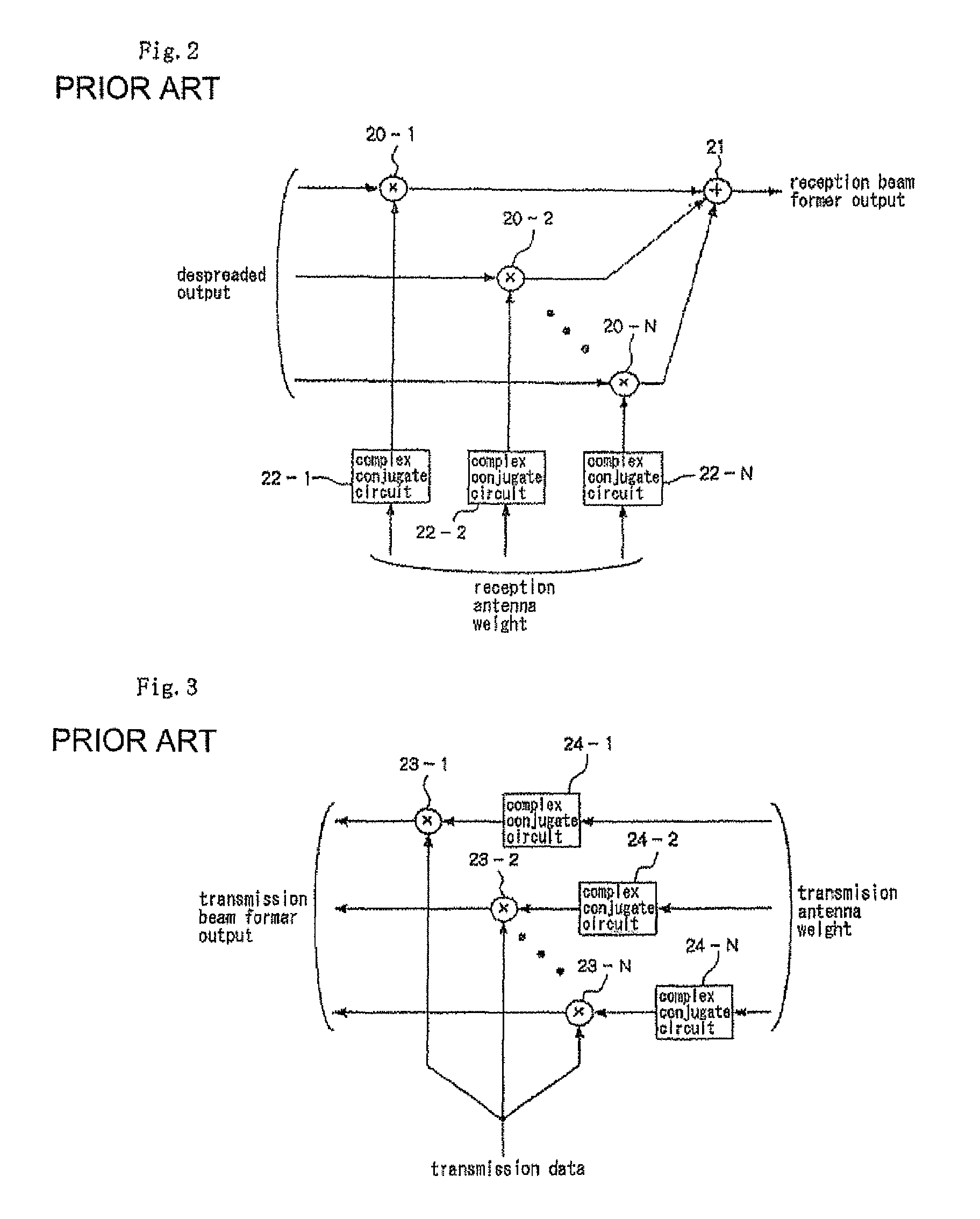

InactiveUS7482975B2Improve direction accuracyConvenient ArrangementSpatial transmit diversityMultiplex communicationSignal processingPower measure

A multibeam transmitting / receiving apparatus is provided that is capable of increasing the accuracy of a direction in which a transmission beam is to be transmitted, with a simple arrangement. Signal power measuring units (8-1 through 8-L) of signal processing means (40-1 through 40-L) measure reception signal power levels averaged over a given time, using outputs from reception beam formers (5-1 through 5-L), and indicate the measured reception signal power levels to transmission antenna weight generator (30). Transmission antenna weight generator (30) generates transmission antenna weights, which has been weighted by a reception signal level, from a transmission antenna weight corresponding to reception signal power level P1 and a beam number B1 of a finger having a maximum reception signal power level, and a transmission antenna weight corresponding to reception signal power level P2 and a beam number B2 of a finger having the same path timing as the finger having the maximum reception signal power level. The generated transmission antenna weights are used in transmission beam former (16).

Owner:NEC CORP

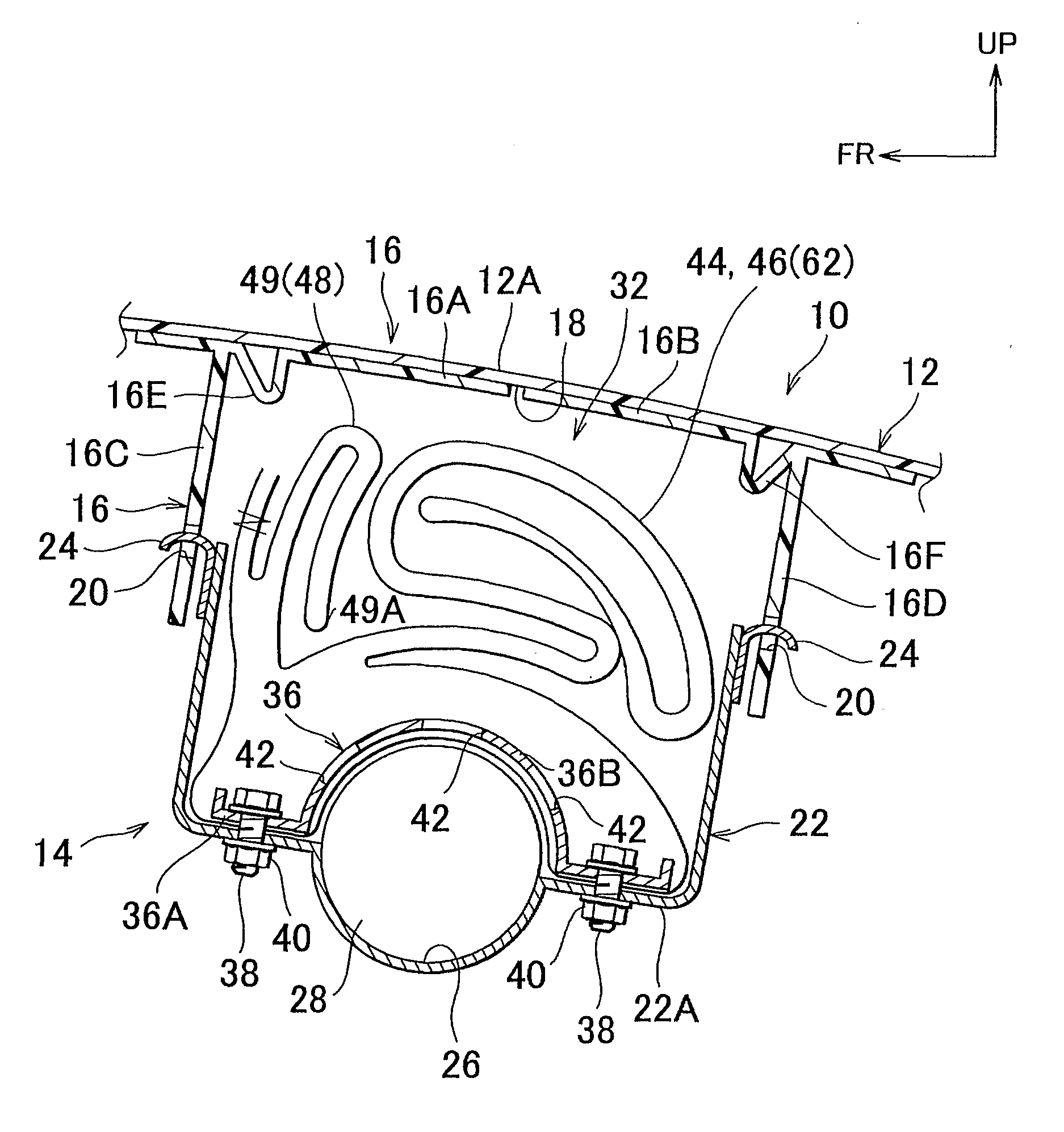

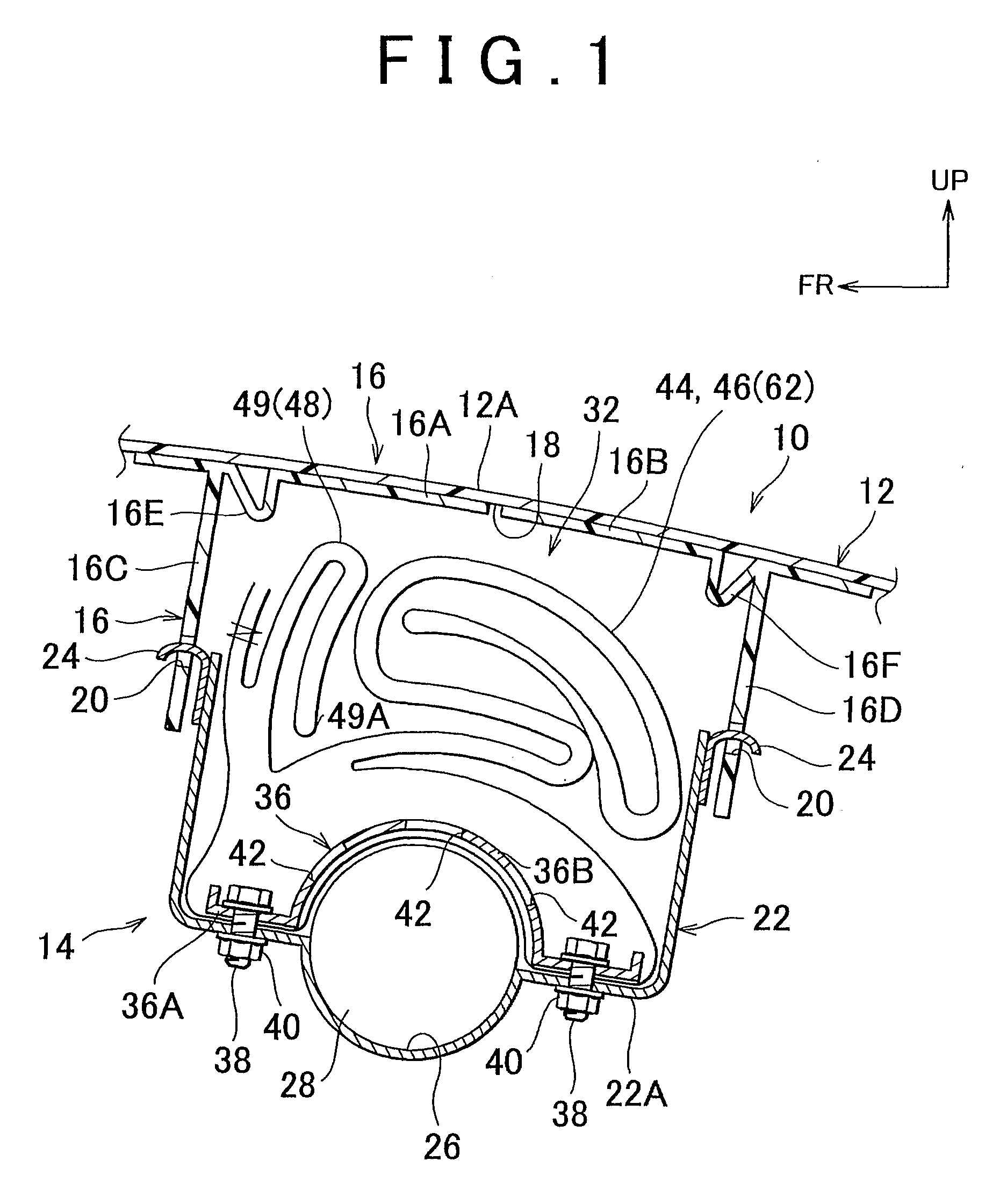

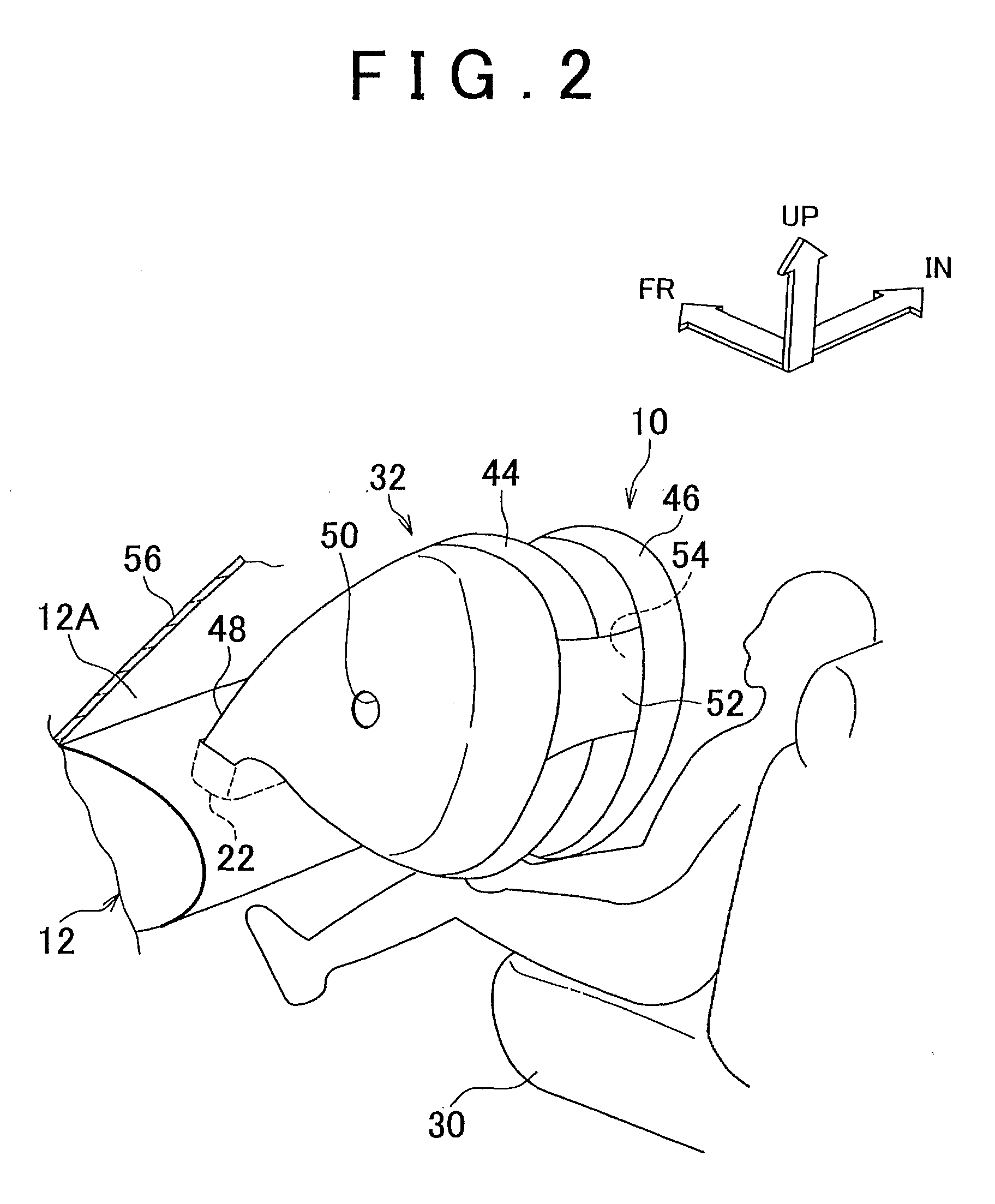

Method of folding passenger-seat airbag

InactiveUS7793975B2Improve direction accuracyPedestrian/occupant safety arrangementEngineeringAirbag

Owner:TOYOTA MOTOR EAST JAPAN +1

Multi-beam transmitting/receiving apparatus and transmitting/receiving method

InactiveUS20070109183A1Improve direction accuracyConvenient ArrangementSpatial transmit diversityMultiplex communicationEngineeringMulti beam

A multibeam transmitting / receiving apparatus is provided that is capable of increasing the accuracy of a direction in which a transmission beam is to be transmitted, with a simple arrangement. Signal power measuring units (8-1 through 8-L) of signal processing means (40-1 through 40-L) measure reception signal power levels averaged over a given time, using outputs from reception beam formers (5-1 through 5-L), and indicate the measured reception signal power levels to transmission antenna weight generator (30). Transmission antenna weight generator (30) generates transmission antenna weights, which has been weighted by a reception signal level, from a transmission antenna weight corresponding to reception signal power level P1 and a beam number B1 of a finger having a maximum reception signal power level, and a transmission antenna weight corresponding to reception signal power level P2 and a beam number B2 of a finger having the same path timing as the finger having the maximum reception signal power level. The generated transmission antenna weights are used in transmission beam former (16).

Owner:NEC CORP

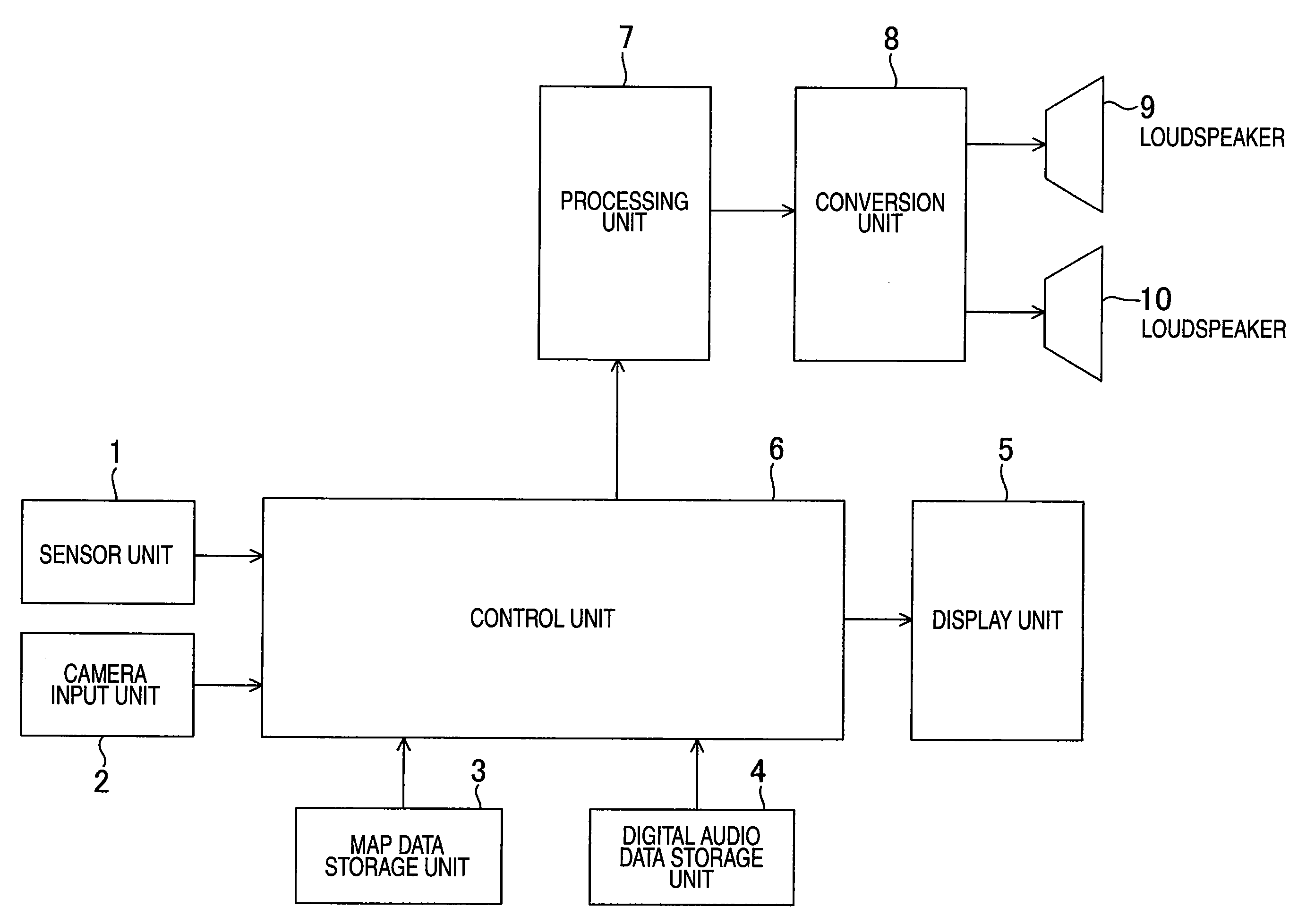

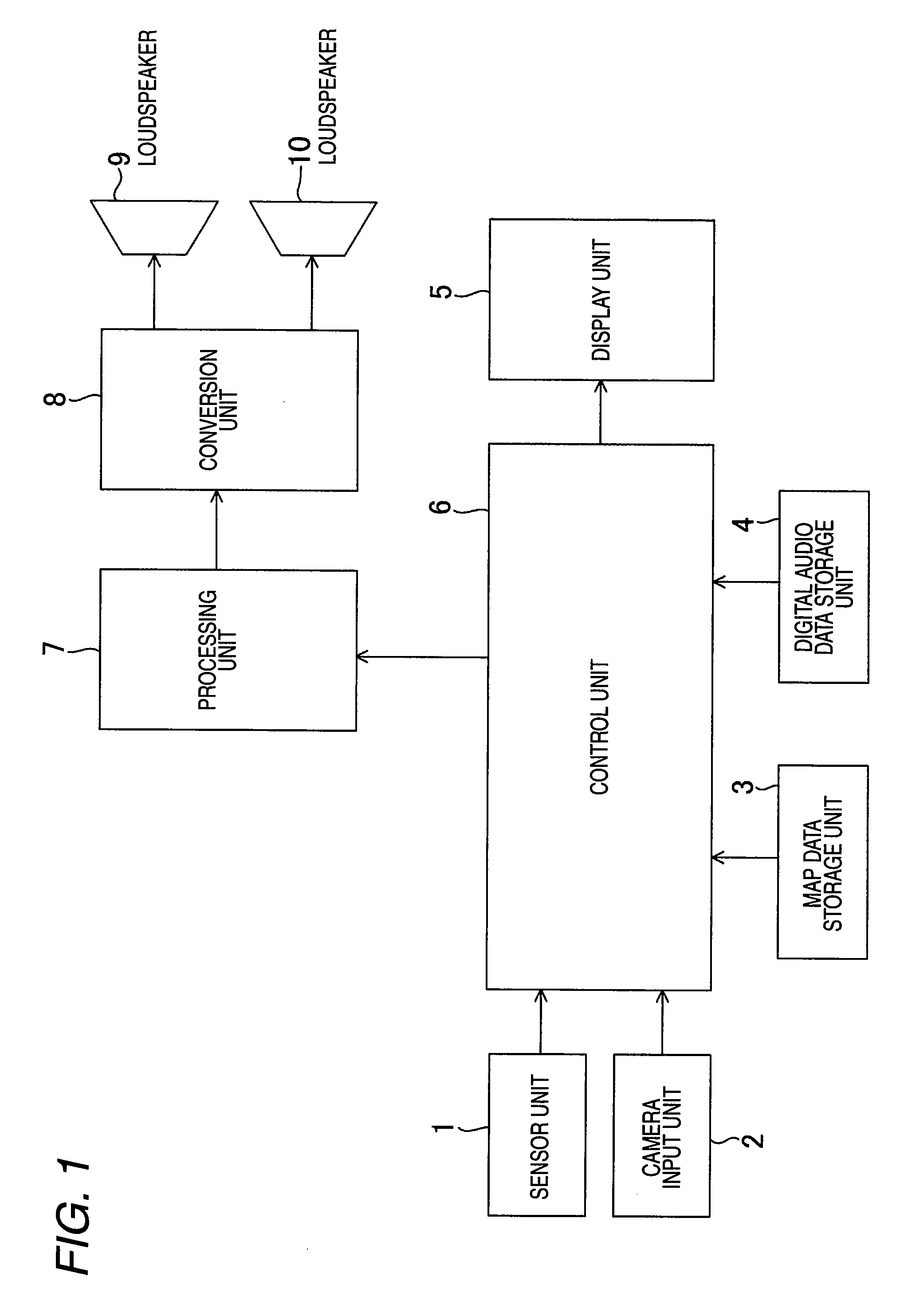

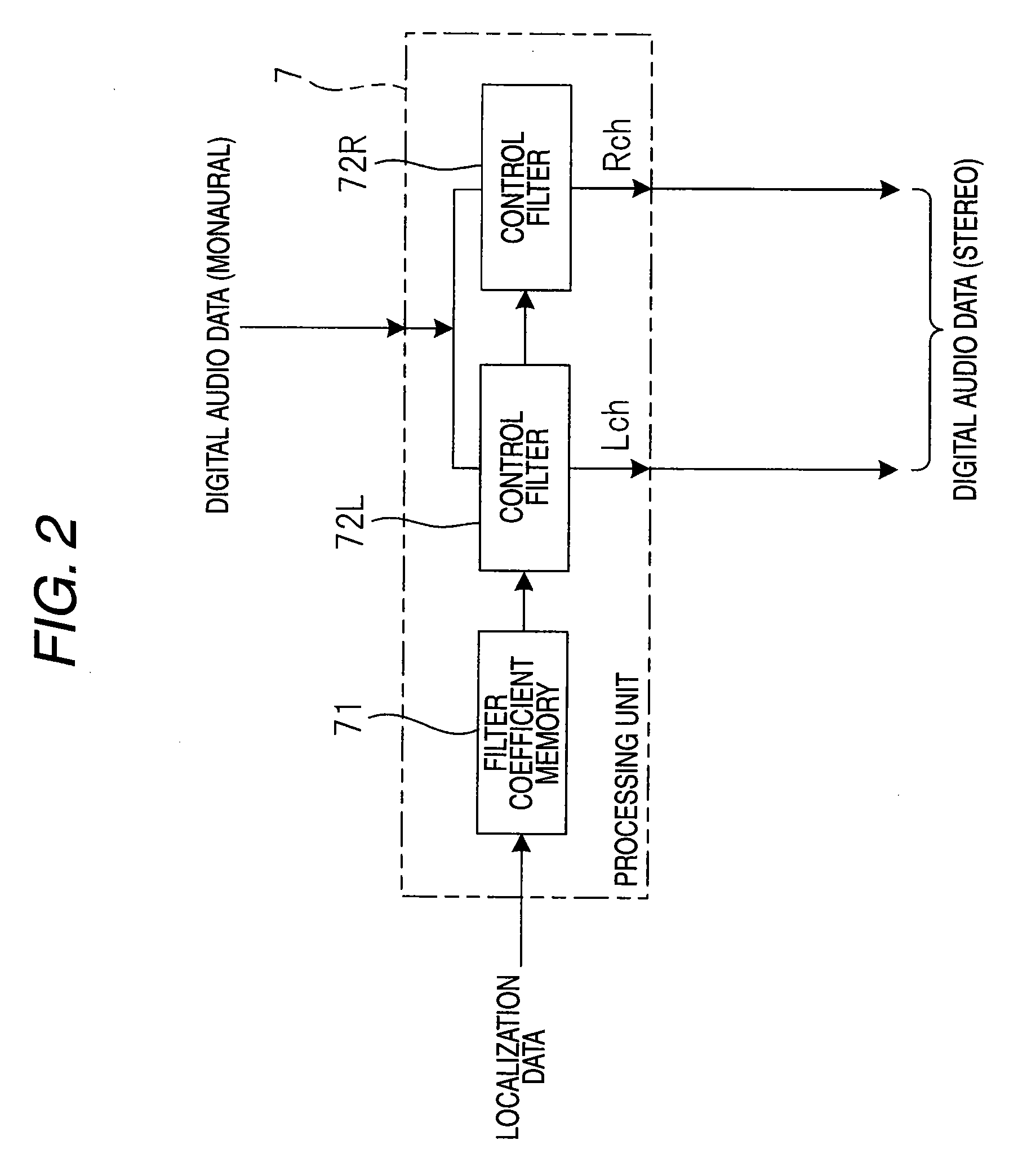

Stereophonic sound control apparatus and stereophonic sound control method

InactiveUS20080118074A1Improve direction accuracyImprove accuracySatellite radio beaconingTwo-channel systemsLoudspeakerComputer science

A control unit 6 obtains position data from a sensor unit 1 to specify the position of the main body of an apparatus, and also obtains acceleration data from the sensor unit 1 to specify the azimuth along which the main body faces forward. Then, the control unit employs the azimuth data and the position data to calculate distance data and directional data relative to a predesignated or given position, and outputs these data as sound localization data. Based on the sound localization data, a processing unit 7 performs a stereophonic sound process for digital audio data, and generates digital audio data having directivity. A conversion unit 8 converts the digital audio data into analog audio data, and drives loudspeakers 9 and 10 to release stereophonic speech. As a result, using a speech form that is easily understood simply by listening, a direction instruction can be provided for a listener.

Owner:PANASONIC CORP

Golf putter with compensation for stroking errors

InactiveUS20070259734A1Improve direction accuracyReduce frictionGolf clubsEnergy transferEngineering

The putter disclosed herein has an aiming mark at an oblique angle that compensates for a player's misalignment of the putter with the aimline or for putter twisting during the stroke. The face has friction and energy transfer characteristics that correct for errors in club face orientation or for directional errors in stroking the putter. The putter can be configured with a weight distribution that causes the compensations to vary with stroking force. The aiming mark, the face characteristics and the weight distribution compensations may be combined in different proportions depending on a player's stroking errors.

Owner:POLLMAN FREDERIC W

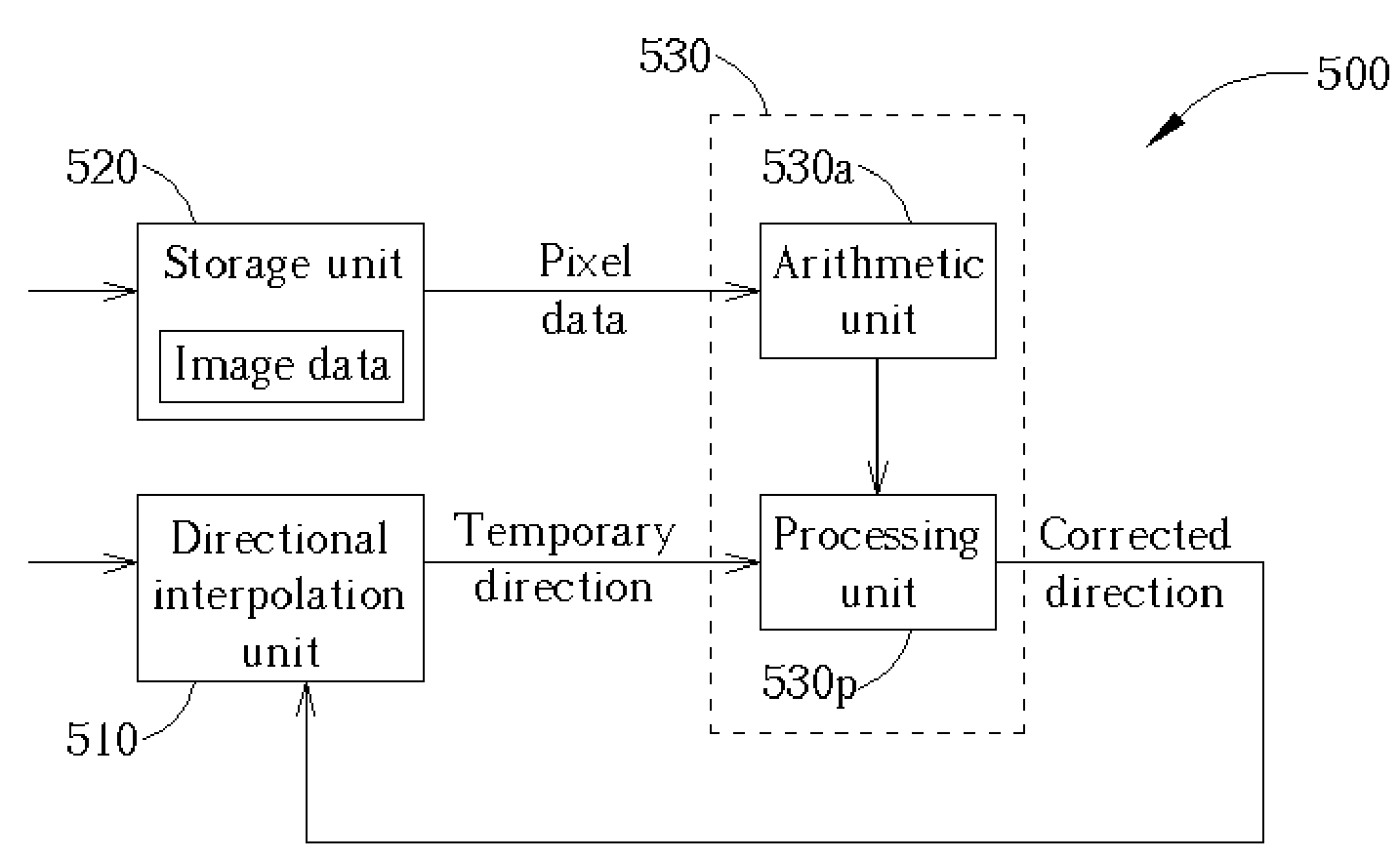

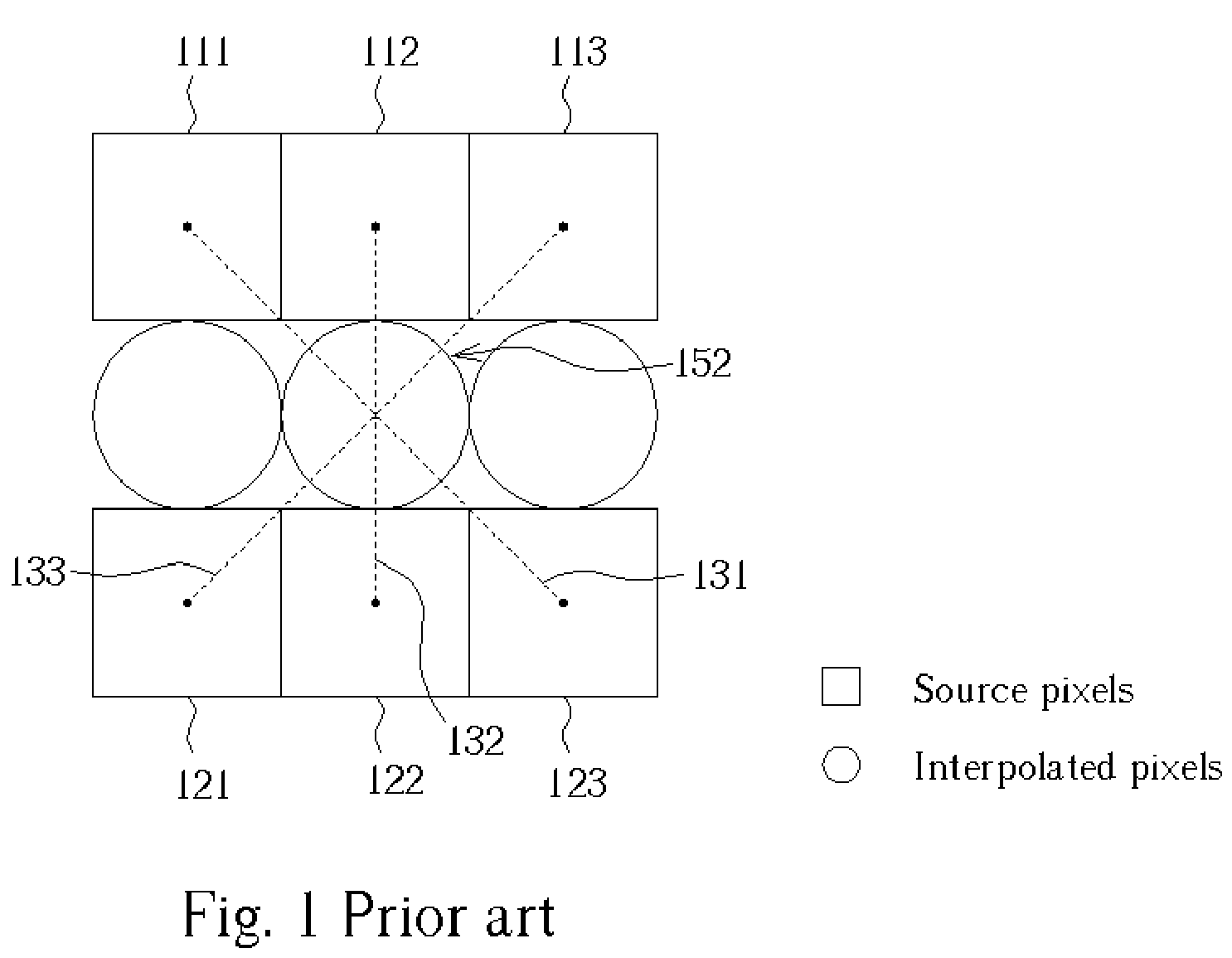

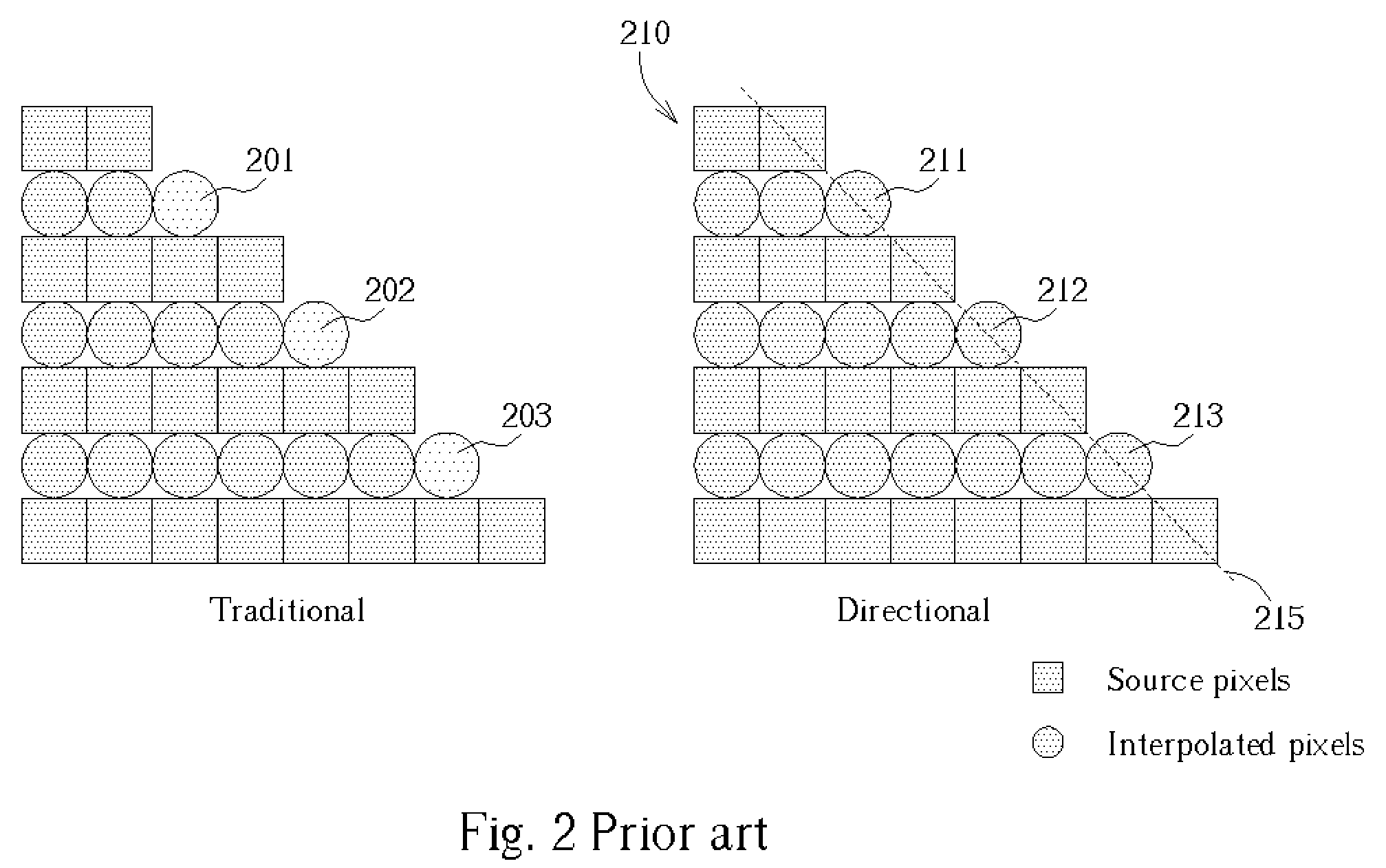

Method for controlling interpolation direction and related device

InactiveUS7397973B2Improve direction accuracyImprove accuracyTelevision system detailsGeometric image transformationComputer graphics (images)Pixel value difference

Owner:MEDIATEK INC

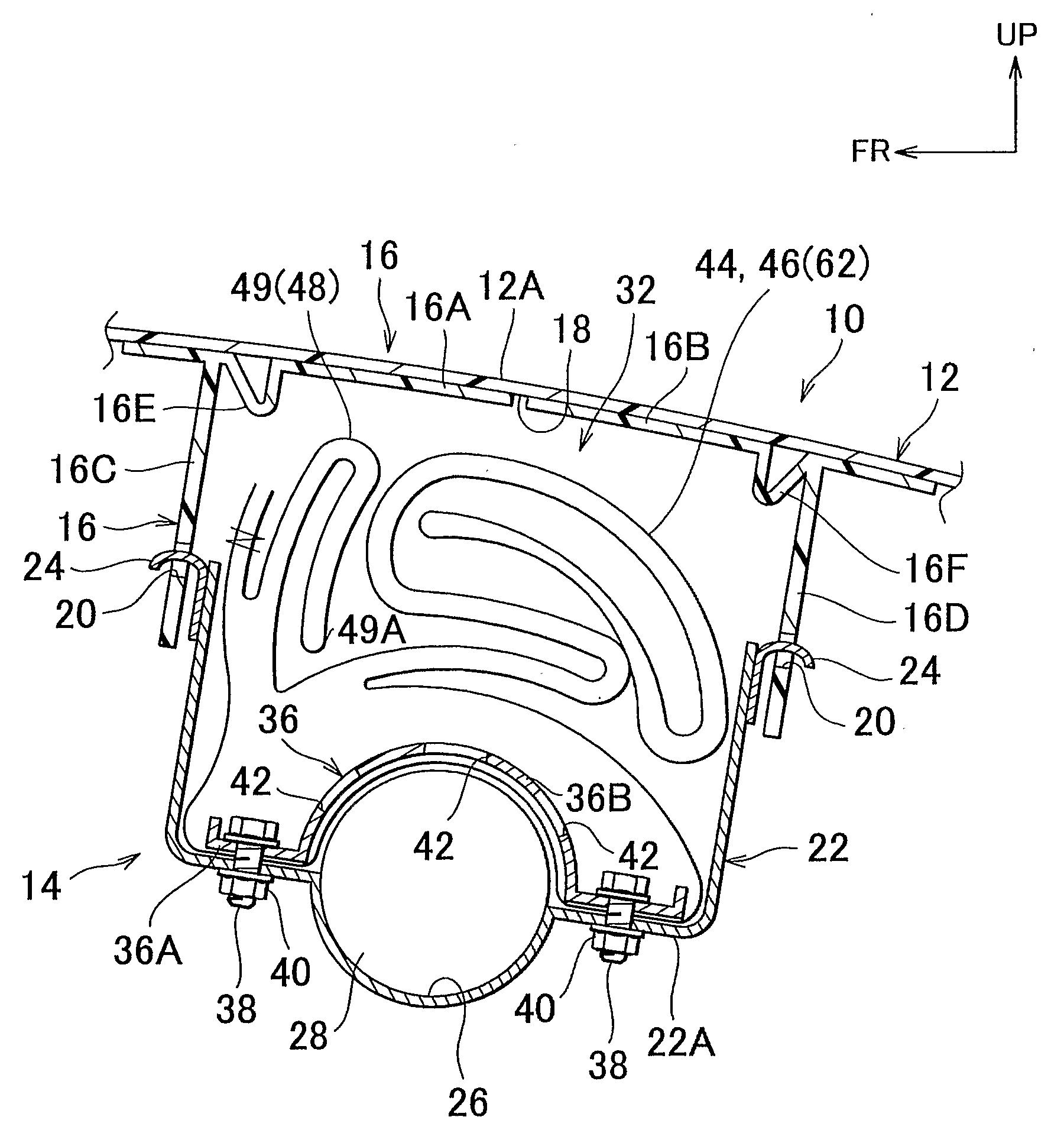

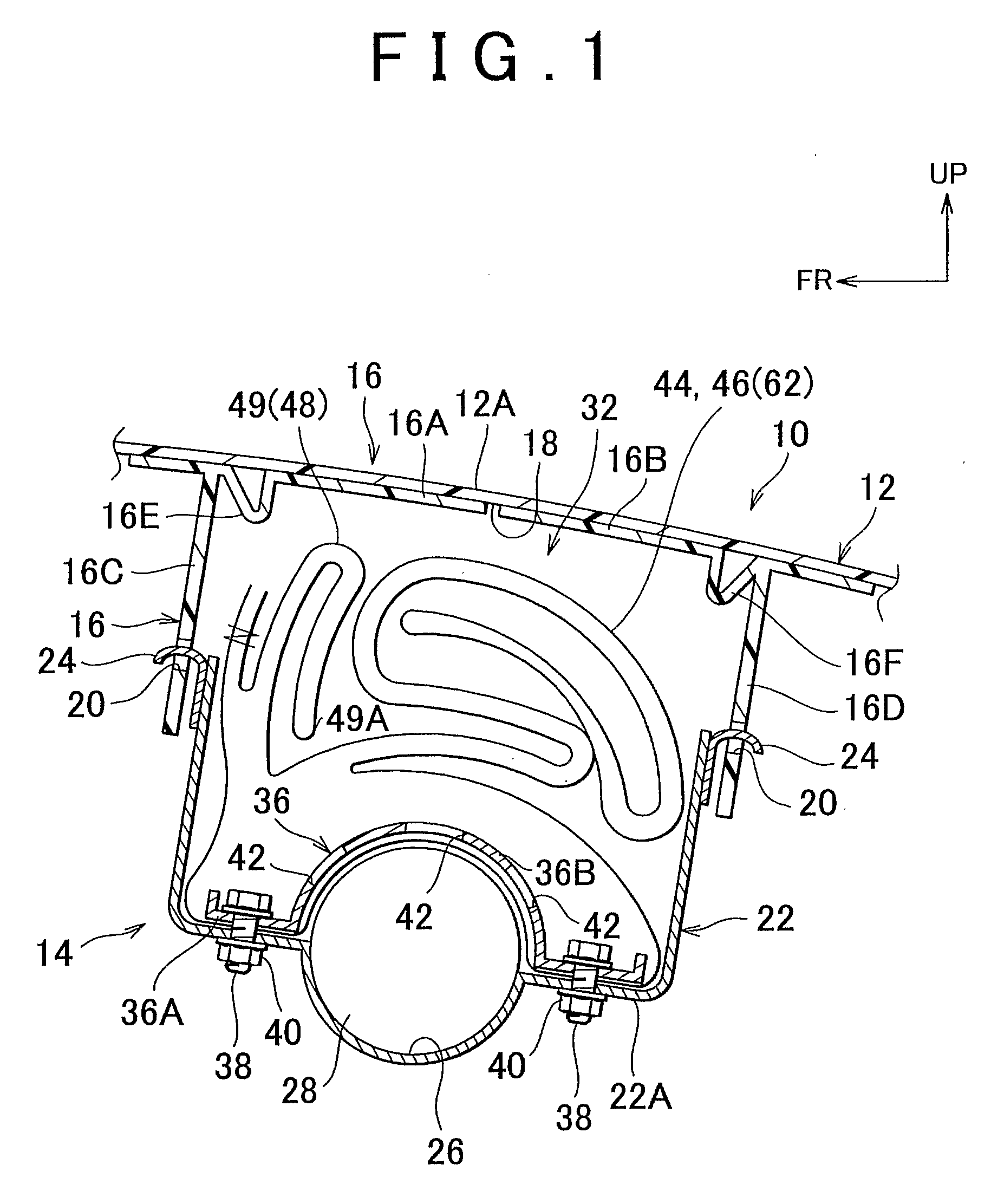

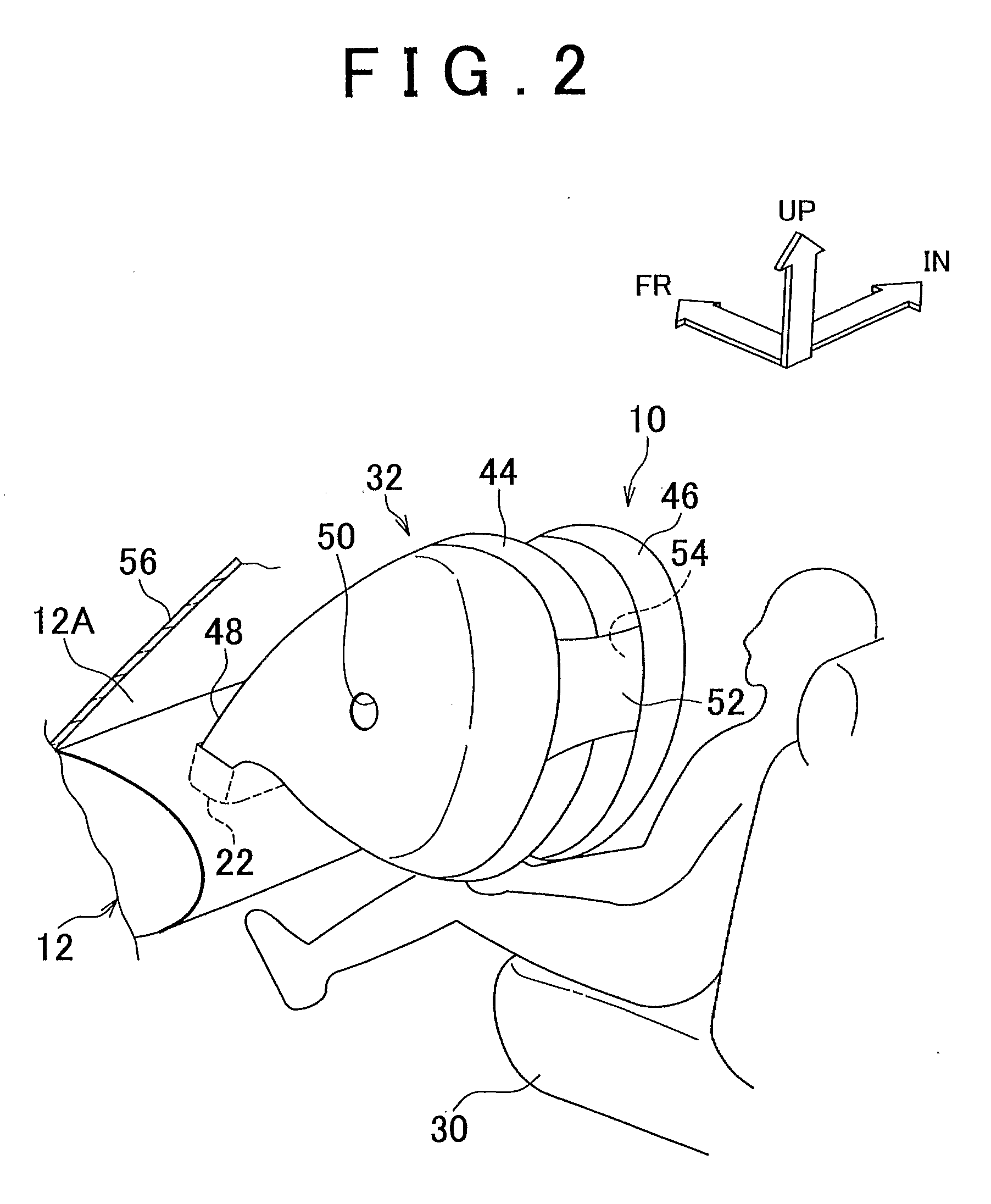

Method of Folding Passenger-Seat Airbag

InactiveUS20080122208A1Improve direction accuracyPedestrian/occupant safety arrangementEngineeringAirbag

A passenger-seat airbag (32) includes a pair of left and right airbags (44, 46), and a root portion (48) that is connected to both of the left and right airbags (44, 46). When the passenger-seat airbag (32) is provided in a vehicle, an airbag folded portion (62) that forms the left and right airbags (44, 46) is positioned closer to the rear of the vehicle than the root portion (48) is, and a slack portion (49) that forms the root portion (48) is made upright along the airbag folded portion (62), and is positioned closer to the front of the vehicle than the airbag folded portion (62) is. Thus, the slack portion (49) is expanded and deployed toward a windshield earlier to form “a wall”. Then, the left and right airbags (44, 46) are stably deployed toward a passenger seat (toward the rear of the vehicle).

Owner:TOYOTA MOTOR EAST JAPAN +1

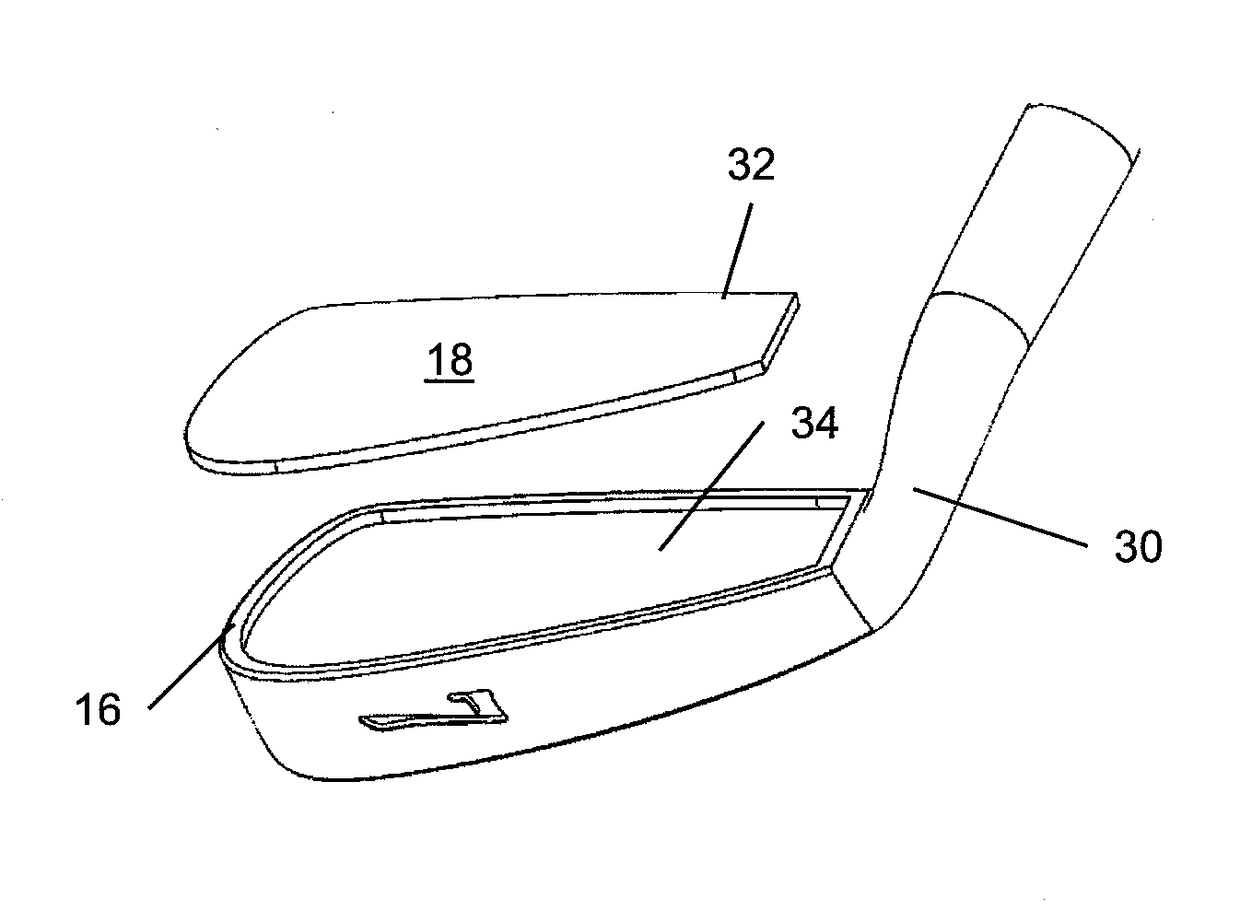

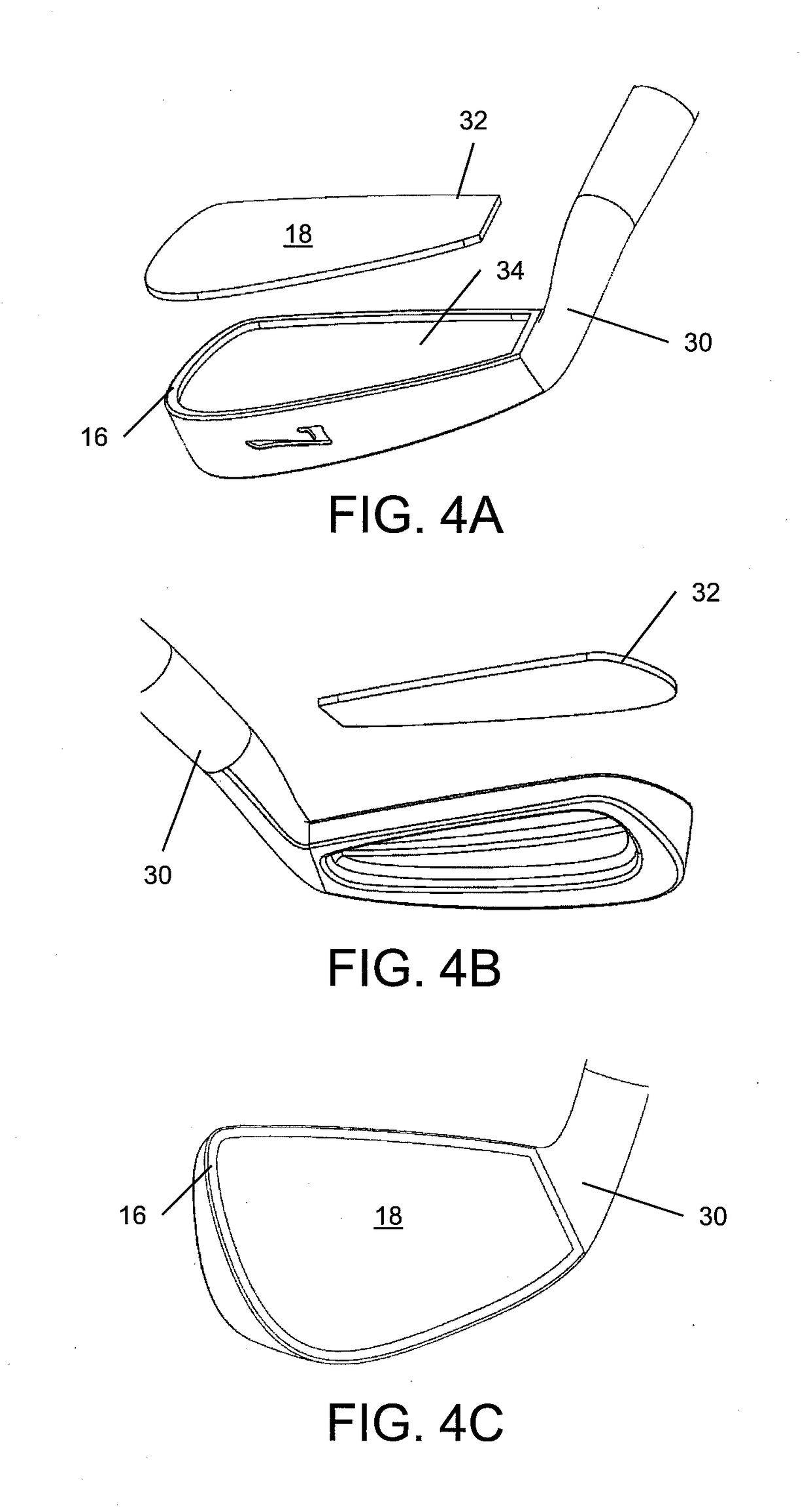

Method and apparatus for optimizing launch characteristics of a golf club

InactiveUS20180036606A1Improved launch angleGreat carry distanceGolf clubsRacket sportsBiomedical engineeringGolf club

Owner:GAME CHANGER IND LLC

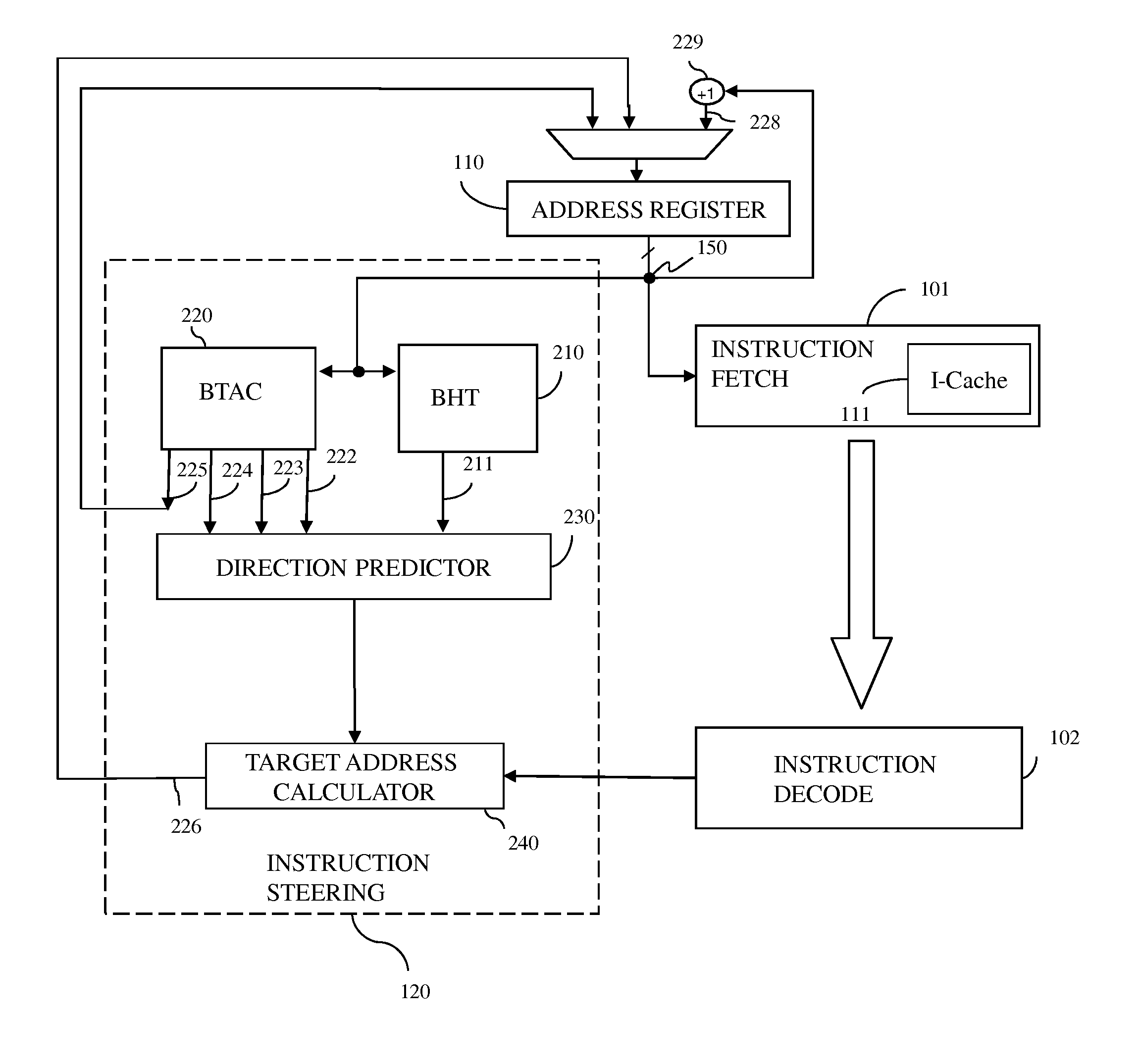

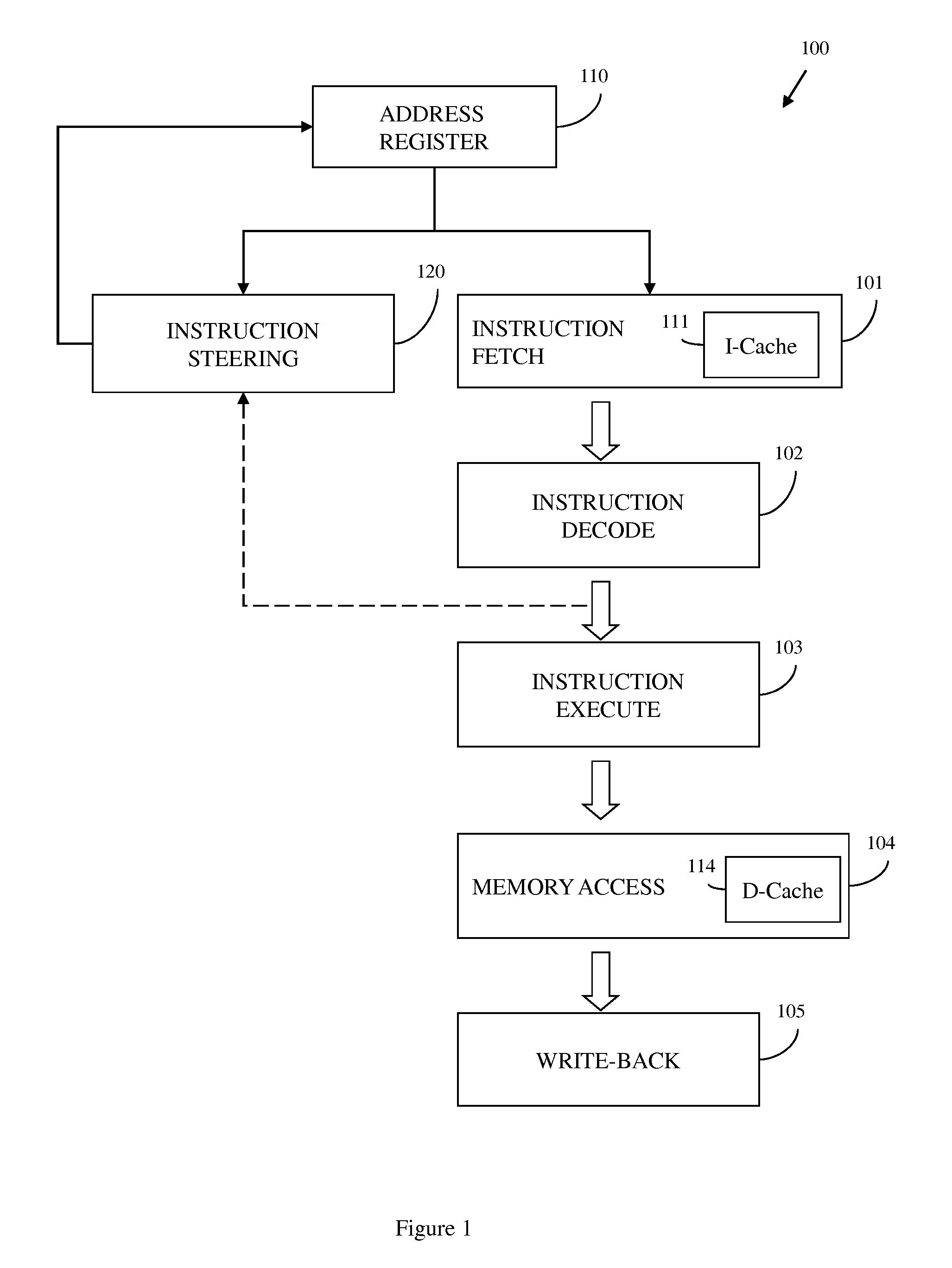

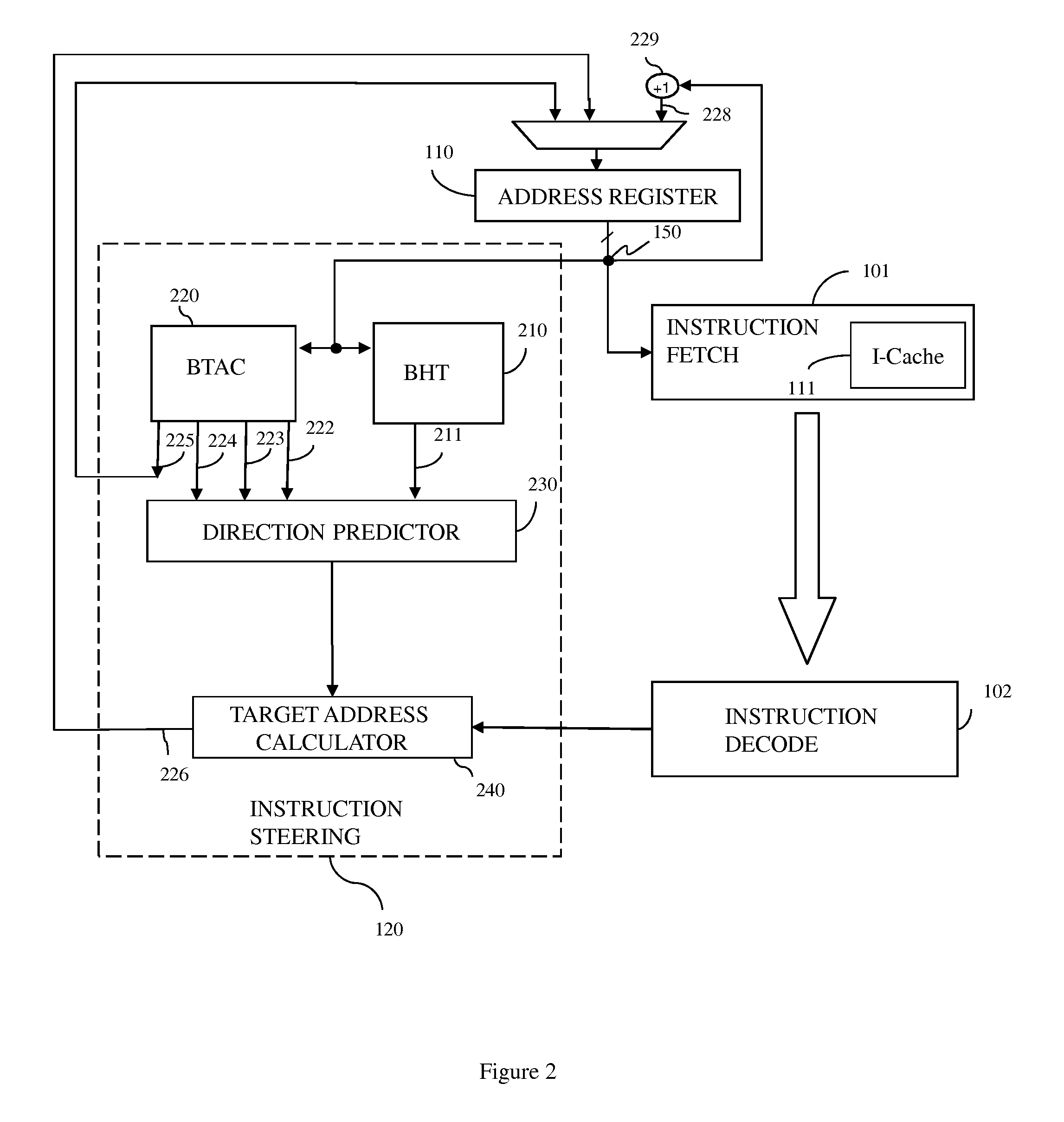

Processor and data processing method incorporating an instruction pipeline with conditional branch direction prediction for fast access to branch target instructions

ActiveUS9201654B2Delay minimizationEasy accessDigital computer detailsConcurrent instruction executionRapid accessInstruction pipeline

Disclosed are a processor and a processing method incorporating an instruction pipeline with direction prediction (i.e., taken or not taken) for conditional branch instructions. In the embodiments, reading of a branch instruction history table (BHT) and a branch instruction target address cache (BTAC) for branch direction prediction occurs in parallel with the current instruction fetch in order to minimize delay in the next instruction fetch. Additionally, direction prediction is performed in the very next clock cycle based either on an initial direction prediction for the specific instruction, as stored in the BHT, or, if applicable, on a prior entry for the specific instruction in the BTAC. An override bit associated with each entry in the BTAC is the determining factor for whether or the BTAC or BHT is controlling. Override bits in the BTAC can be pre-established based on the branch instruction type in order to ensure prediction accuracy.

Owner:IBM CORP

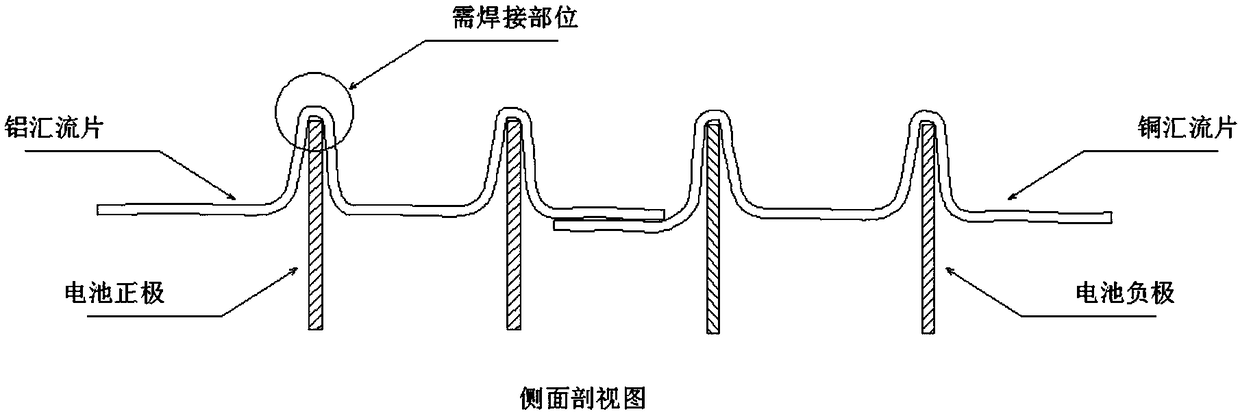

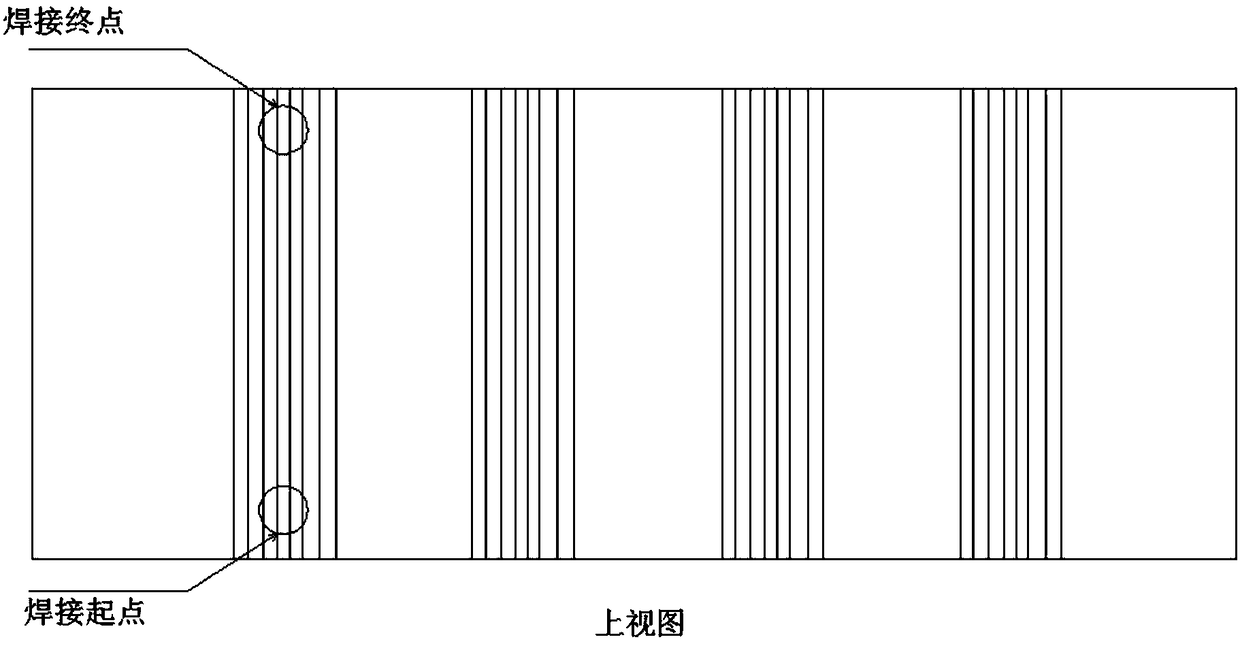

Battery module welding method and system

InactiveCN108480871ASave the link of height measurementImprove welding pass rateWelding/cutting auxillary devicesAuxillary welding devicesControl systemOverall efficiency

The invention provides a battery module welding method and system. The battery module welding method comprises the following steps that 1, an initial X coordinate and an initial Z coordinate of any welding point of the battery module are detected by a 2D scanner; 2, an adjusted X coordinate and an adjusted Z coordinate of the welding point are acquired according to the initial X coordinate, the initial Z coordinate and a preset deviation value of the welding point; and 3, welding is carried out on the welding point through a PLC welding system according to the adjusted X coordinate, the adjusted Z coordinate and a preset Y coordinate of the welding point. According to the battery module welding method and system, the 2D scanner adopts laser detection and is not limited by the glossiness ofa metal surface, and therefore the welding point is basically detected, the X coordinate and the Z coordinate of the welding point can be detected, height measurement is omitted, the accuracy is improved, the welding percent of pass is high, and the welding speed is greatly improved; and meanwhile, all the welding points of the battery module can be detected only by one step by the 2D scanner, and therefore the overall efficiency of the machine is improved.

Owner:WUHAN YIFI LASER EQUIP CO LTD

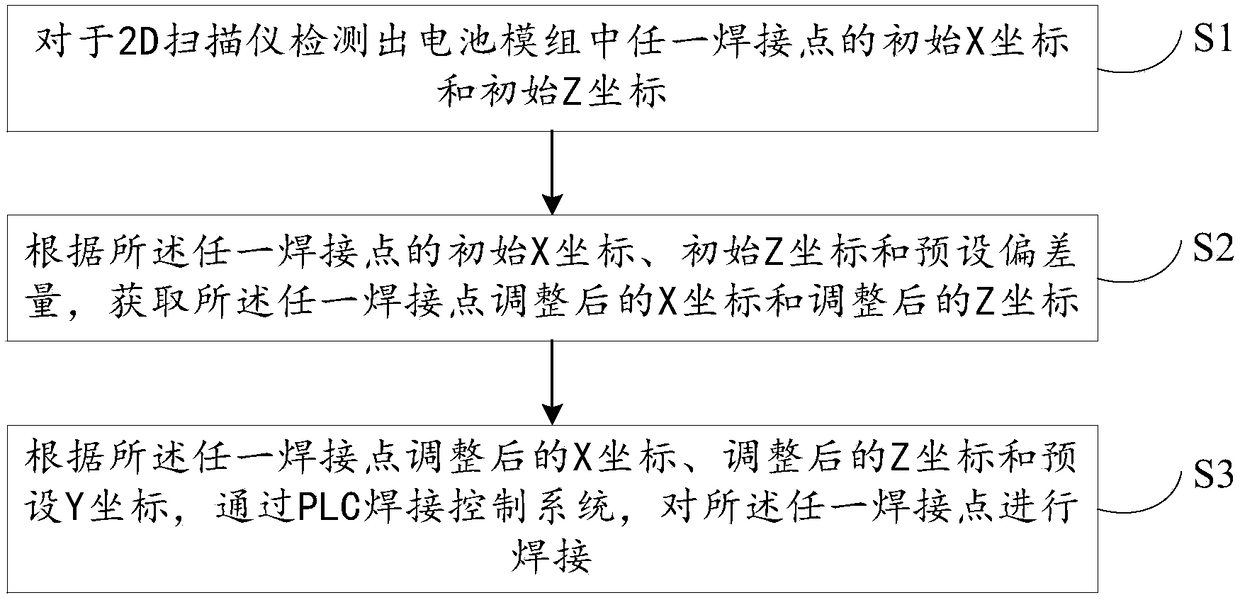

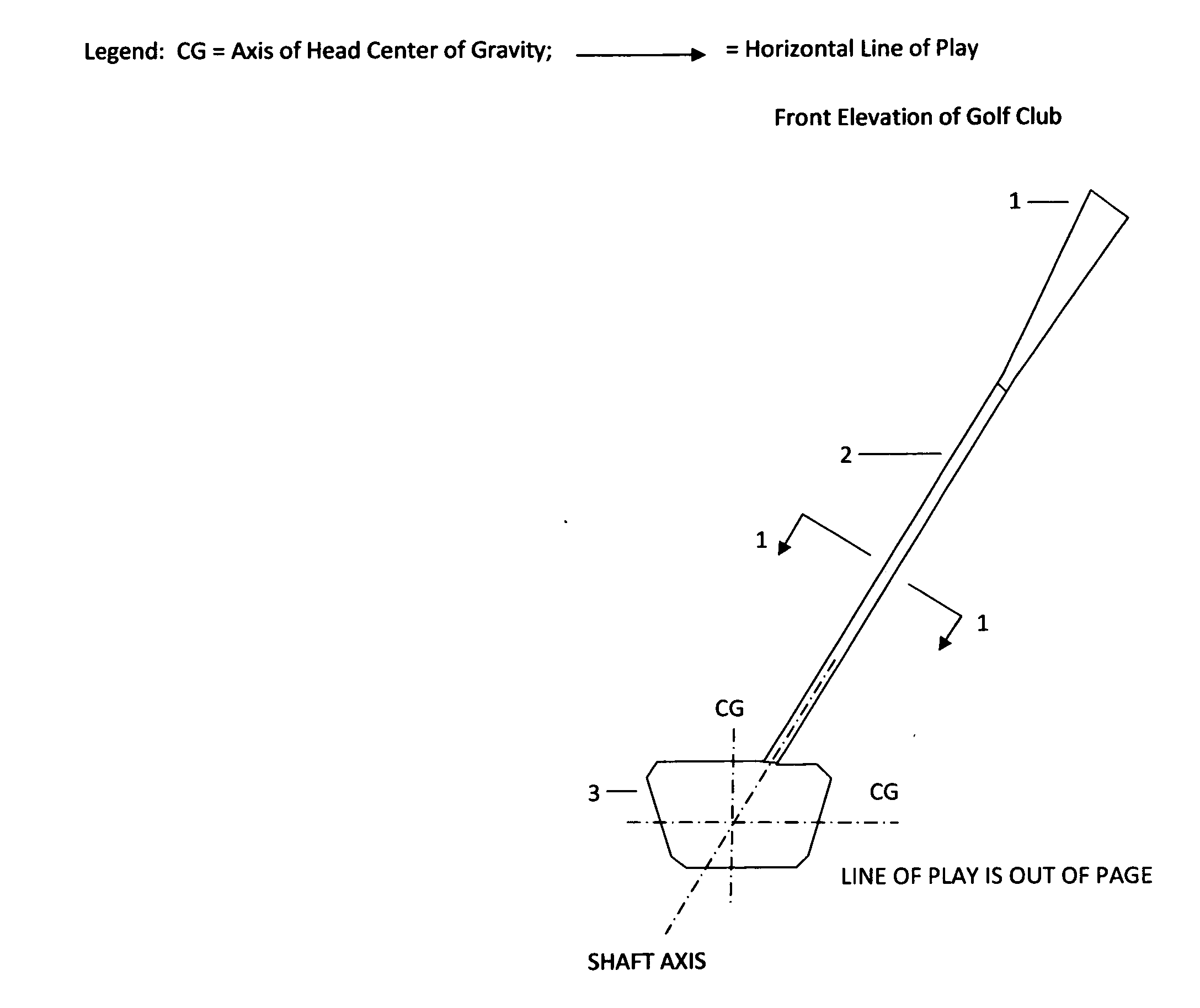

Aerodynamic balanced wood form and/or iron form golf club

InactiveUS20120015756A1Reduce widthLess aerodynamic dragGolf clubsRacket sportsHigh momentumMomentum transfer

The wood or iron golf club has a reduced shaft width transverse to the direction of motion and a greater shaft depth parallel to the direction of motion, therefore, has a reduced frontal area that creates less aerodynamic drag and a higher resistance to bending opposite the direction of motion, respectively. The low drag rigid shaft allows higher head velocity, higher momentum transfer to the ball, higher ball velocity, and longer more accurate drives then current clubs with elongated cone shaped symmetrical shafts.The wood or iron gulf club shaft-head configuration has the shaft axis intersecting the common axis of the horizontal component of the line of play and the head center of gravity. The club therefore does not create a torque about the shaft axis during the swing motion or ball impact and facilitates greater accuracy and consistency in hitting the optimum point on the ball with the optimum point on the club head.

Owner:MELLON MILTON THOMAS

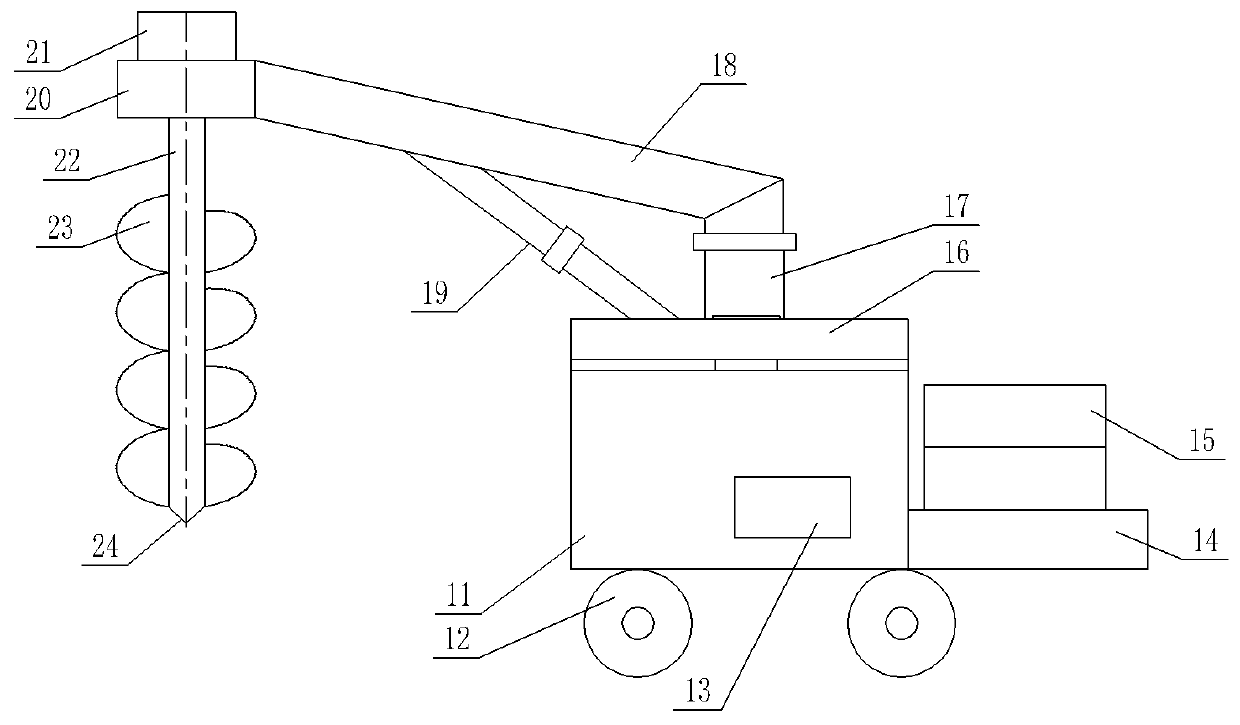

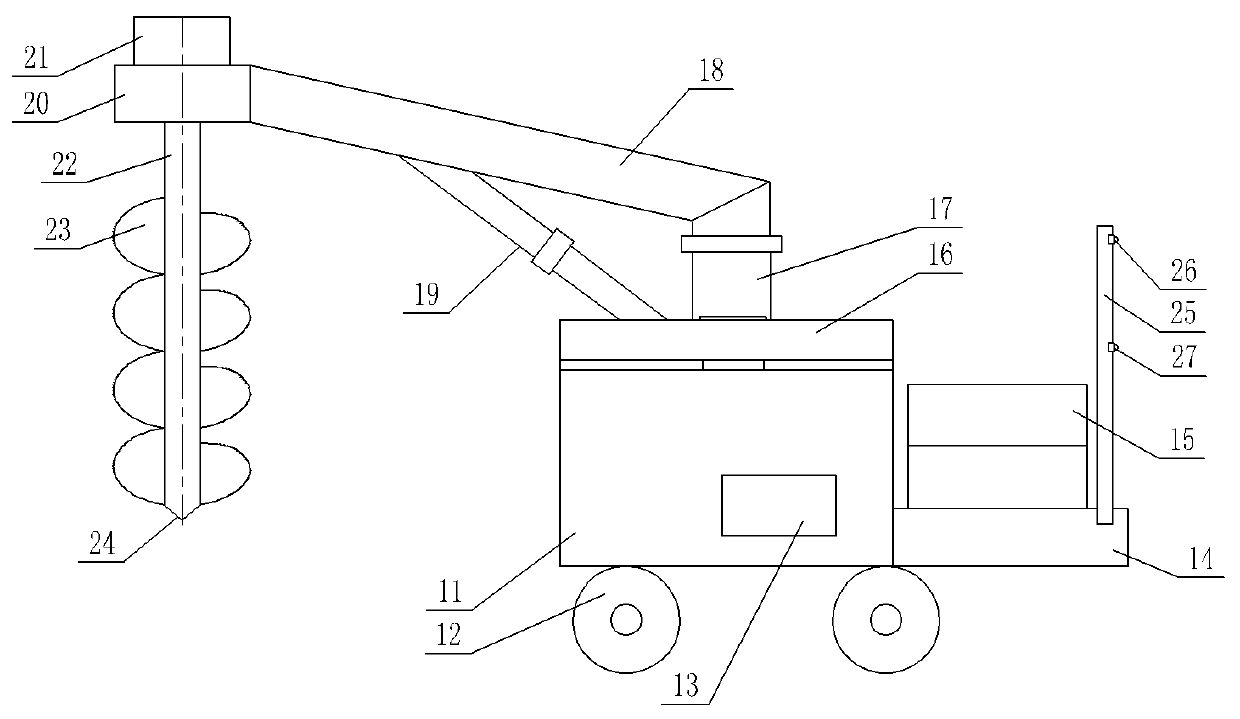

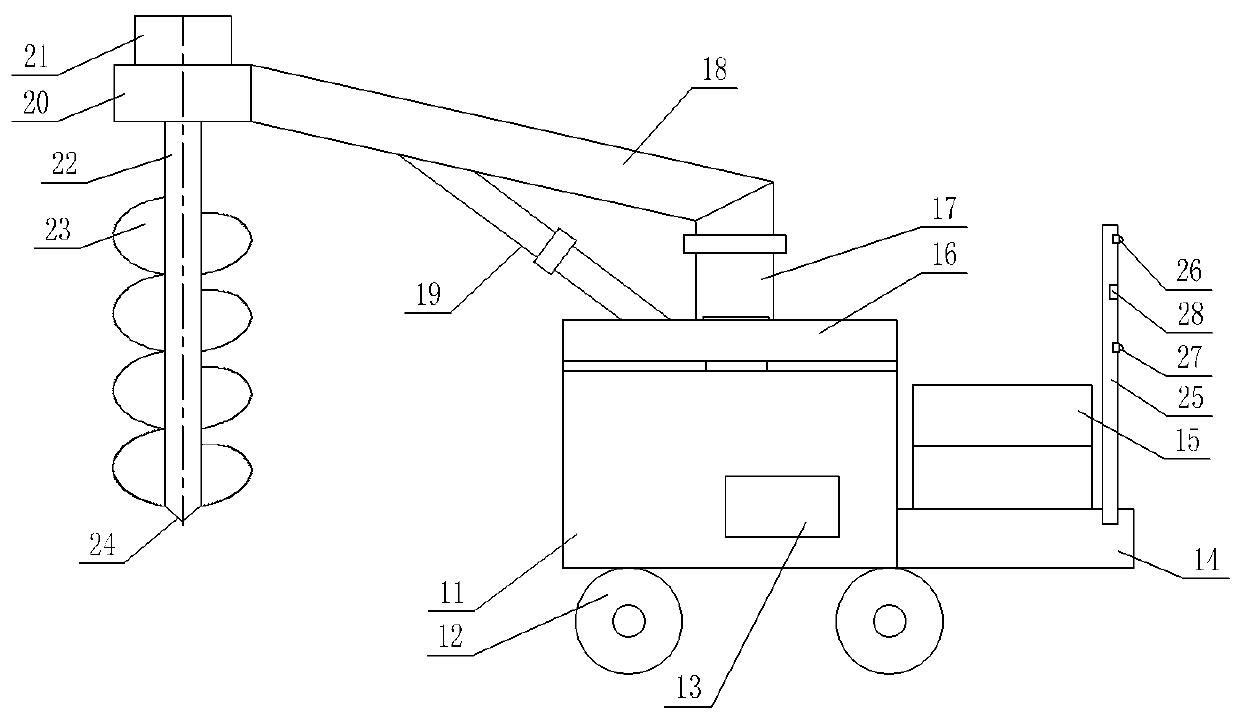

Electric pole pit groove digging device

InactiveCN110700342AImprove stability and consistencyThe depth is easy to controlSoil-shifting machines/dredgersStructural engineeringDistance sensors

The invention discloses an electric pole pit groove digging device. The electric pole pit groove digging device comprises a frame, a rotating disc rotatably connected to the frame, a lifting mechanismconnected to the rotating disc, a digging knife assembly connected to the lifting mechanism for digging a pit groove, a counterweight assembly fixedly arranged at the rear portion of the frame and used for balancing the weight of the lifting mechanism, and a travelling mechanism arranged below the frame. According to the electric pole pit groove digging device, a pole carrying pit is excavated through mechanical automation, time and labor are saved, the construction efficiency is high, the depth of the pit groove is convenient to control, the stability consistence of carried poles is high, aposition sensor is used for aligning the front electric pole and the rear electric pole, the carried poles are guaranteed to be in a straight line, and the interval distance among the electric poles is measured and adjusted through an infrared distance sensor, so that the direction accuracy of a power transmission line is improved, and the running stability of the power transmission line is guaranteed.

Owner:STATE GRID CORP OF CHINA +1

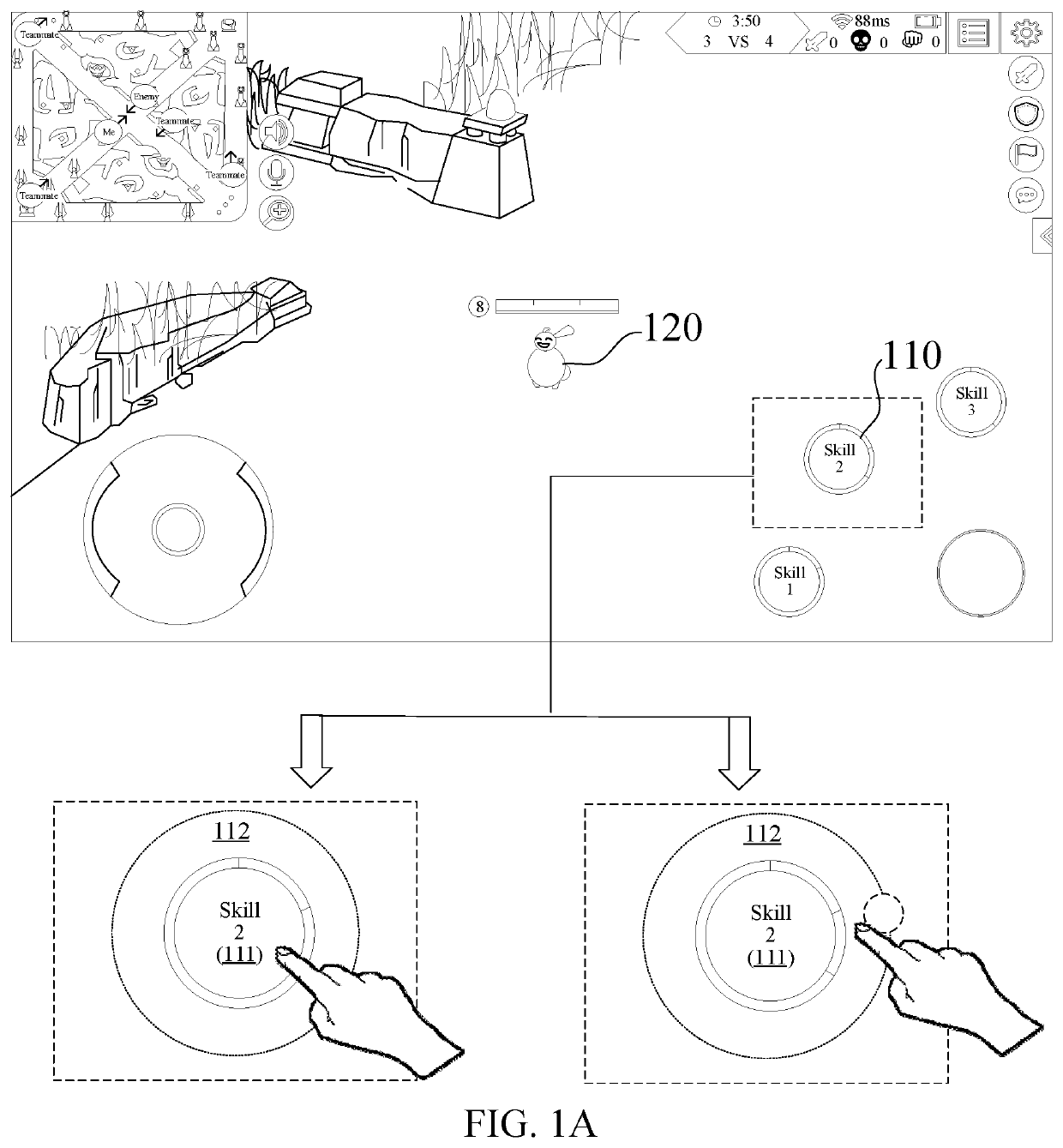

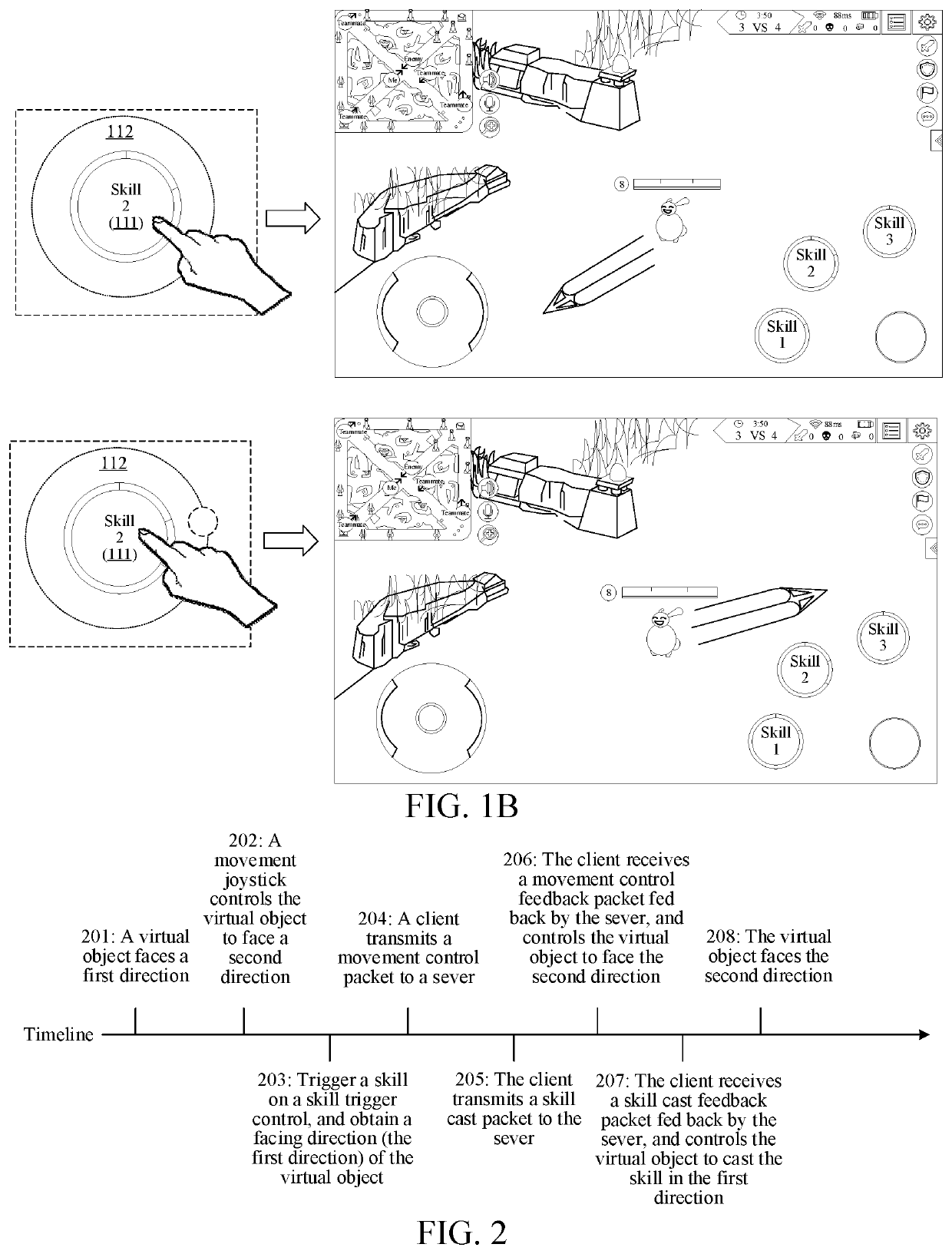

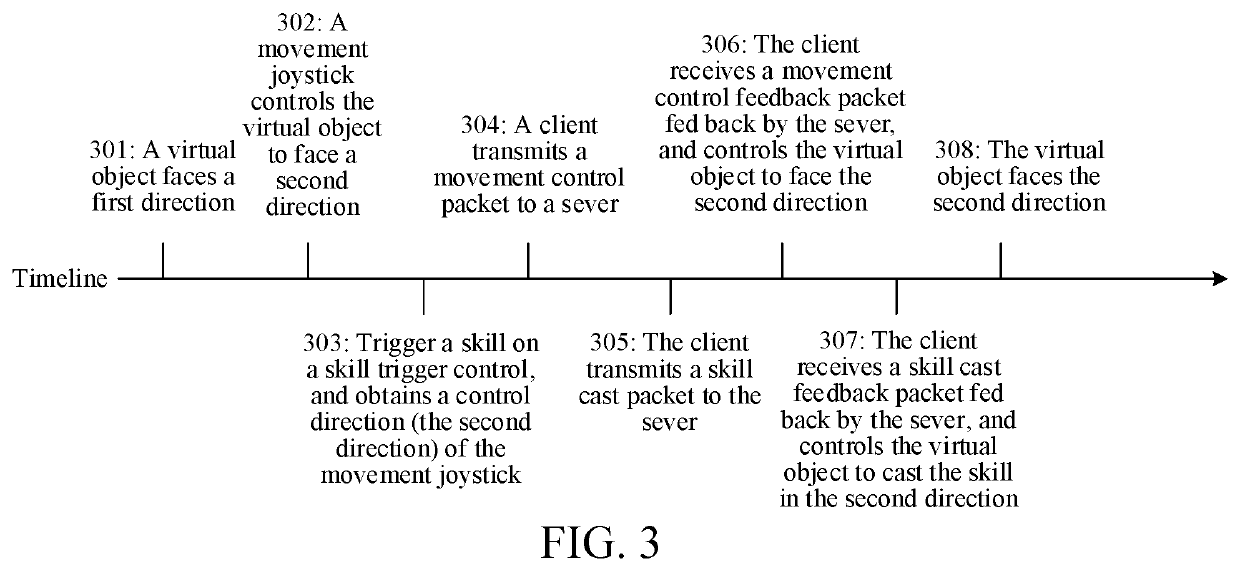

Virtual character control method and apparatus, device, and storage medium

A virtual character control method includes: displaying a virtual environment interface; receiving a skill cast operation and a movement control operation, the skill cast operation being used for casting a directional skill in a first direction, and the movement control operation being used for controlling a main control virtual character to move in a second direction, the first direction and the second direction being independent of each other; and controlling the main control virtual character to cast the directional skill in the second direction. When the directional skill is cast, the second direction is determined according to the received movement control operation, and the main control virtual character is controlled to cast the directional skill in the second direction.

Owner:TENCENT TECH (SHENZHEN) CO LTD

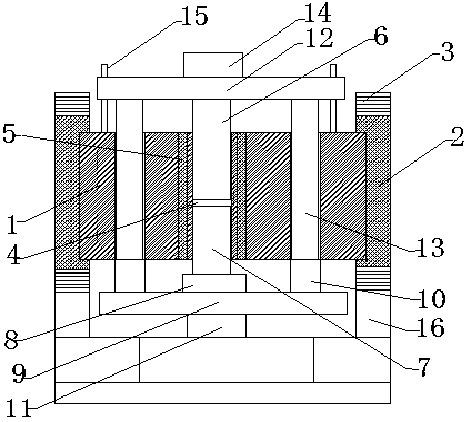

A kind of powder forming device and forming method thereof

The invention discloses a powder molding device and a molding method thereof. The device comprises a mold, a pair of yokes meshed on the outer side of the mold, coils wound on the outer sides of the yokes, a mold cavity formed in the middle portion of the mold, straight strip yokes vertically embedded on the outer side of the mold cavity, an upper mold movably embedded on the upper side of the mold cavity, a lower mold movably embedded on the lower side of the mold cavity and a vibration mechanism mounted in cooperation with the bottom of the lower mold; the vibration mechanism is mounted on the top plate; hollow sliding rods are further mounted on the top plate, and the hollow sliding rods and the mold are movably embedded; and a pressing plate is mounted on the top of the upper mold in a matched manner. The molding method of the powder molding device comprises the following steps of firstly, operation before filling, secondly, preliminary material filling, thirdly, material filling again, fourthly, mold assembly direction selection, fifthly, molding and sixthly, mold stripping. According to the powder molding device and the molding method of the device, the direction selection precision can be improved, and the yield and the product quality are improved.

Owner:ZHUZHOU RUIDEER METALLURGICAL EQUIP MFG CO LTD

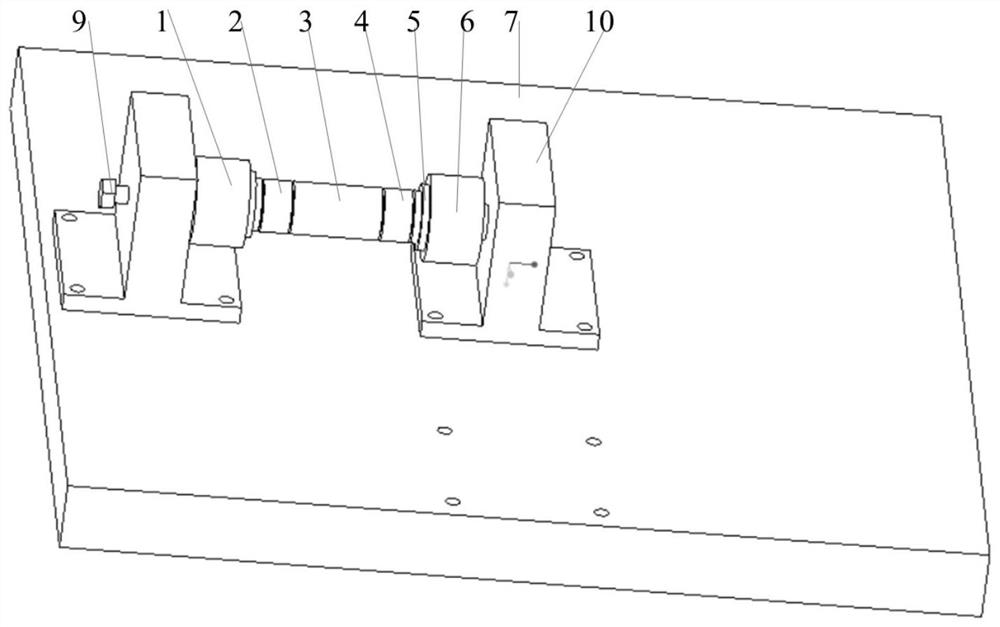

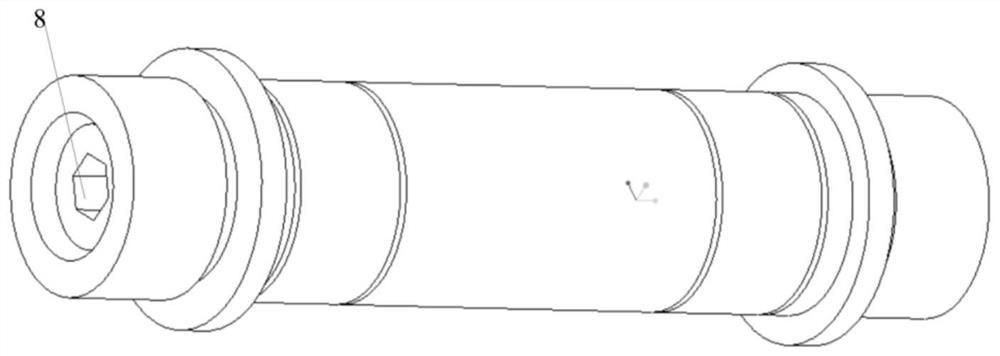

Sensing Actuator Based on Direct and Inverse Piezoelectric Effect

ActiveCN110426142BGuaranteed reliabilityImprove direction accuracyForce measurement using piezo-electric devicesPiezoelectric actuatorsEngineering

The invention belongs to the technical field of sensing and measurement and control, and provides a sensing actuator based on forward and reverse piezoelectric effects. The present invention realizes the requirement of generating a one-dimensional force with controllable size, direction and action point by combining the piezoelectric actuator and the piezoelectric sensor, which is of great significance to the improvement of the precision of the whole calibration experiment result. The device of the invention is composed of a piezoelectric actuator, a piezoelectric sensor, a loading base, a loading bottom plate, an inner sleeve, an intermediate shaft and the like. The device has compact structure design, reliable working principle and strong adaptability. It is a high-precision force generating device, which broadens the design thinking of force generating and detecting devices.

Owner:DALIAN UNIV OF TECH

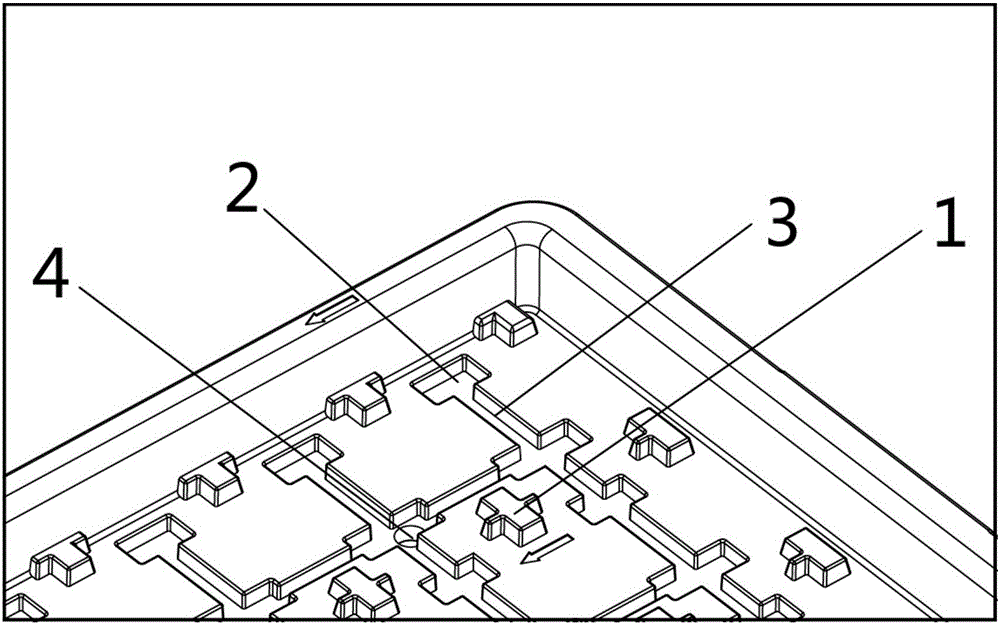

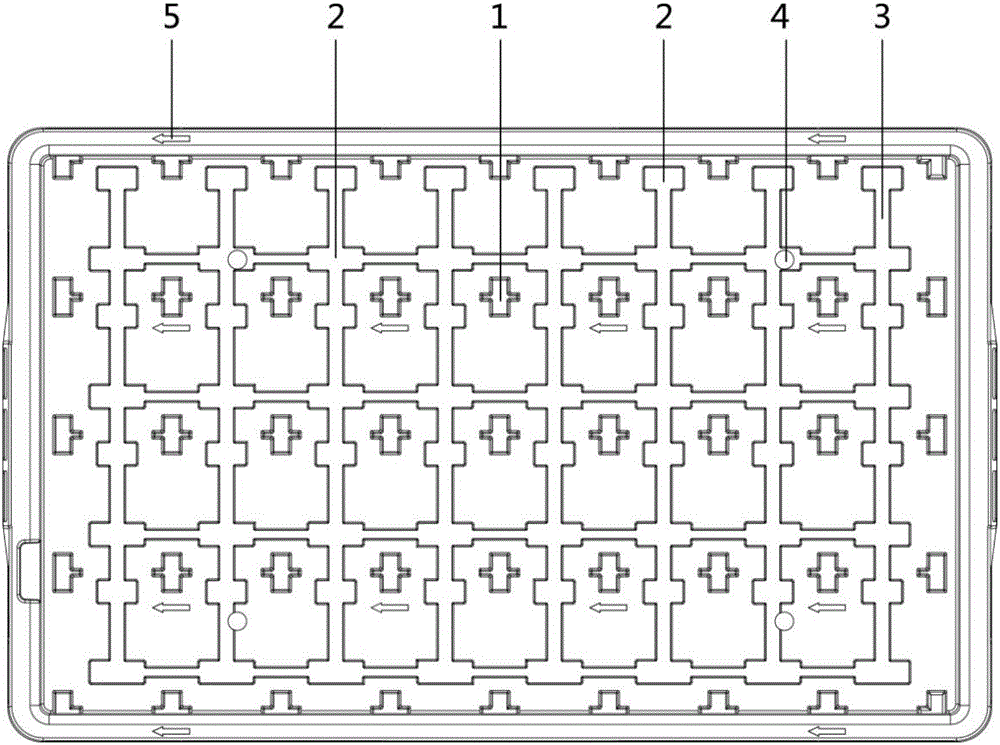

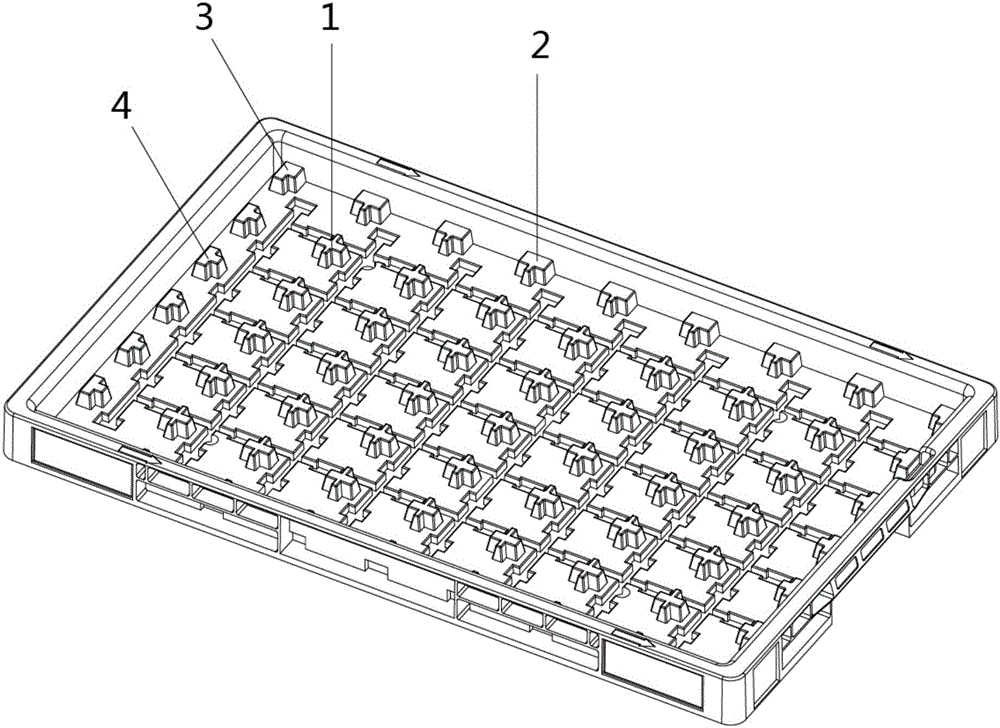

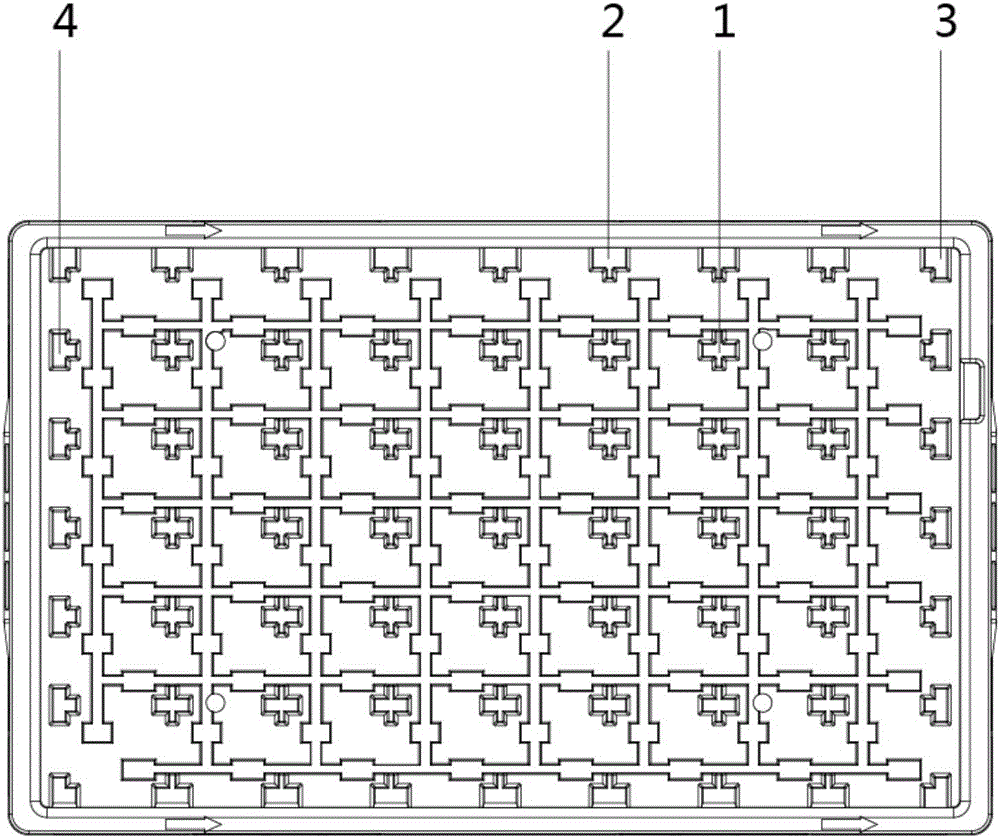

Three-phase module box circulating box

A three-phase module box circulating box is a box body with an upper opening. A plurality of interval ribs are arranged in the box body in an array shape and partition the bottom of the box body to form a plurality of module containing areas used for containing module boxes; an ultrasonic welding process is adopted for the containing areas at the positions of module box joints, water guiding grooves, water guiding holes, a guiding mark, a box frame and a box base; and in use, the module boxes are placed in the containing areas which are partitioned and positioned by the interval ribs according to the direction of a guiding arrow in the box body, the box body is sequentially filled with the module boxes, box bodies can be sequentially stacked together according to positioning structures at the positions of the bottom faces and openings of the box bodies, the accuracy is improved when workers place products and the products are conveyed, the number and stability of multi-layer stacking are achieved, and the machining and producing efficiency is improved.

Owner:STATE GRID HUNAN POWER SUPPLY SERVICE CENT (METROLOGY CENT) +1

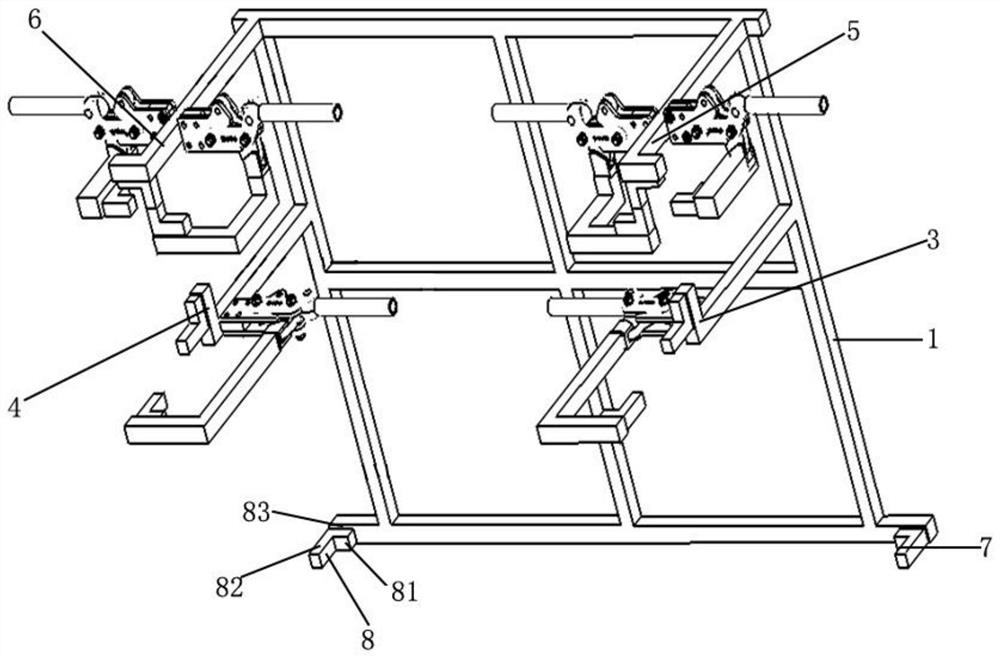

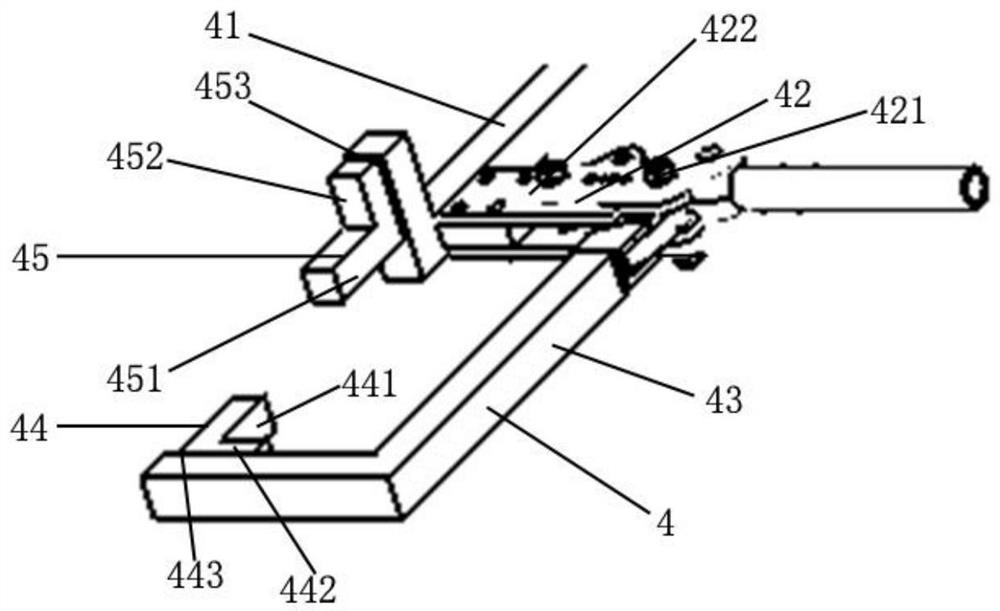

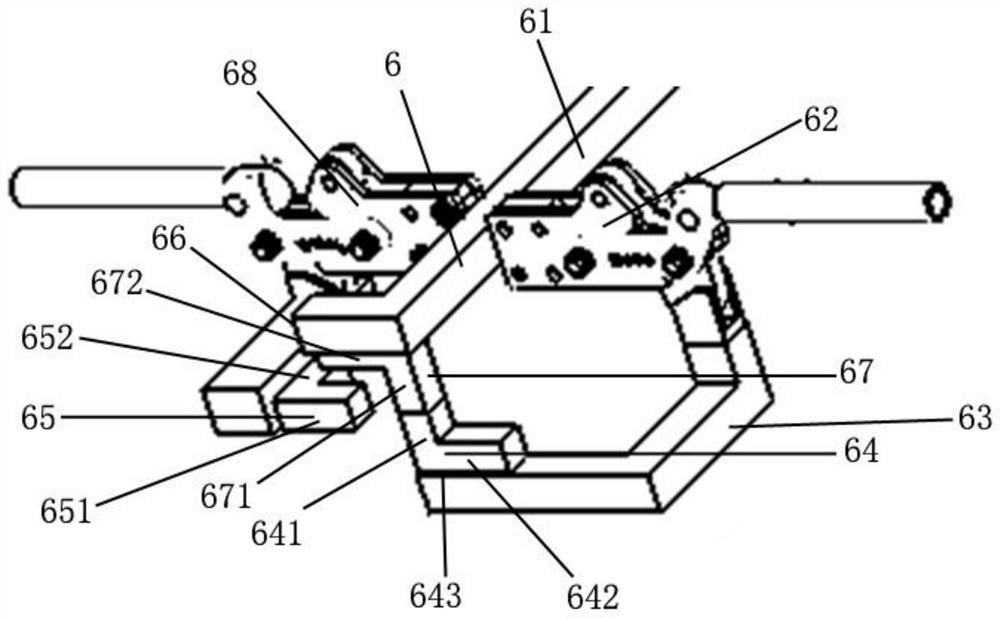

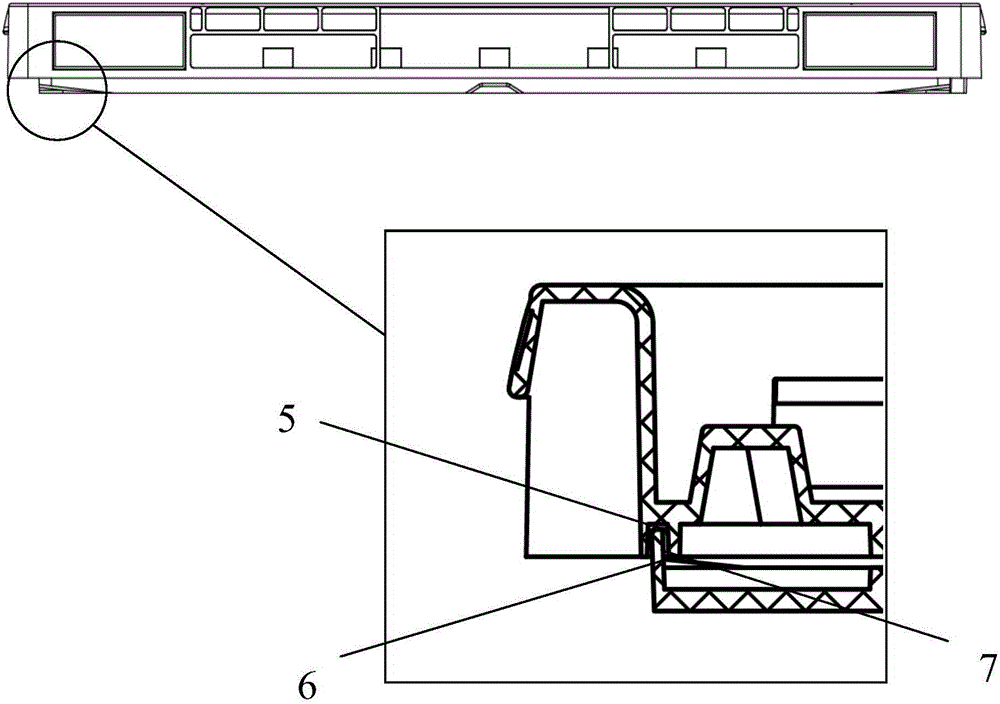

Centering machine cover assembling tool structure

PendingCN113830204ALittle difference between left and right clearanceSize link shortVehiclesMachineMachining process

The invention discloses a centering machine cover assembling tool structure comprising tool frames which are arranged in a bilateral symmetry mode, and the left side and the right side of the front portion of each tool frame are provided with a left side Z-direction positioning supporting block and a right side Z-direction positioning supporting block in a downward vertical protruding and extending mode correspondingly; a left Z-direction positioning mechanism and a right Z-direction positioning mechanism are arranged on the left side and the right side of the middle of the tool frame in a vertically downward protruding and extending mode correspondingly. A left side XY direction positioning mechanism and a right side XY direction positioning mechanism are arranged on the left side and the right side of the rear portion of the tool frame in a downward vertical protruding and extending mode correspondingly. By the adoption of the centering machine cover assembling tool structure, the difference between the left gap and the right gap is small after a machine cover is installed, and the centering performance of machine cover assembling is guaranteed; meanwhile, the size chain ring can be short, the precision in the Y direction is high, the influence of the machining process is small, and the adjustment workload is reduced; in addition, the quality cultivation process is convenient to debug, low in reworking cost, high in debugging efficiency and wide in applicability.

Owner:IAT AUTOMOBILE TECH

Method for determining and optimizing power parameters in manufacturing process of plasma display screen

ActiveCN103236385ASave time and resource costsImprove direction accuracyTube/lamp screens manufactureSingle processProcess engineering

The invention discloses a method for determining and optimizing power parameters in the manufacturing process of a plasma display screen. A regression relation model of the important power parameters and yield in the manufacturing process of the plasma display screen is established by utilizing the historical data of the manufacturing process and the importance degree influencing the quality of a plasma display screen product is reflected by utilizing a regression coefficient, so that important power parameter items which need to be subjected to management and control reinforcement with emphasis are determined and a power parameter control strategy for promoting the total yield or the single-process yield is found. The method has the active effects that time and resource cost which are consumed in a manner of repeatedly carrying out testing design and verification are saved and direction accuracy on the aspects of power parameter control items and the control range is promoted; and moreover, the aim of continuously and spirally promoting the yield of the plasma display screen can be fulfilled and the rejection rate in the manufacturing process is indirectly reduced. Meanwhile, the method disclosed by the invention cannot be related to the interruption of production of a production line, so that online dynamic determination and regulation management of the power parameters of the manufacturing process are implemented.

Owner:江苏鼎峯云计算有限公司

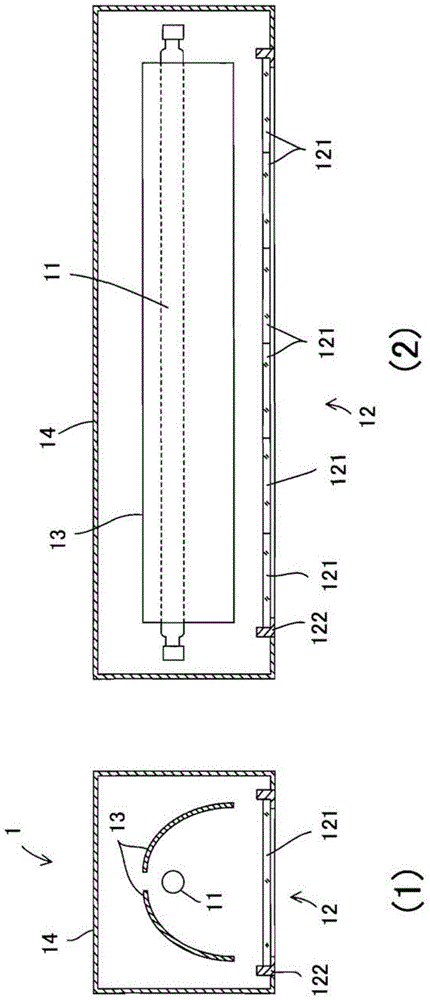

Polarized light irradiation device for photo-alignment and polarized-light irradiation method for photo-alignment

ActiveCN104296874BImprove detection accuracyHigh precisionPhotomechanical exposure apparatusLight polarisation measurementLight irradiationOptical polarization

The invention provides a polarized light irradiation apparatus and method for photo-alignment, which is capable of detecting the direction of a polarization axis of irradiated polarized light in high precision and performing photo-alignment treatment in high quality in the aspect of direction precision. A workpiece (W) is arranged on an irradiation surface (R). When the workpiece (W) is irradiated by the polarized light by virtue of irradiating the irradiation surface (R) through a polarized element (121), a polarization direction detector (40) is arranged on the irradiation surface (R) and detects the direction of the polarization axis of the polarized light. A polarization analyzer arranged in the polarization direction detector (40) is located in advance by a polarization analyzer calibrator, and a rotary original point is at a specified angle with respect to the reference direction of the apparatus. Based on the polarization direction detected by the polarization direction detector (40), the deviation of the polarization axis can be obtained and by using a polarized element adjusting mechanism (7) to adjust the posture of the polarized element (121), the deviation can be eliminated.

Owner:USHIO DENKI KK

Method for drilling on curved surface structure

The invention relates to a method for drilling on a curved surface structure. Drilling equipment is used for drilling on the curved surface structure of an object to be drilled, the drilling equipment comprises a motion platform with multiple degrees of freedom and a drilling assembly connected with the motion platform, and the drilling assembly comprises a machine base unit, a drilling unit and a visual detection unit; the machine base unit is installed on the motion platform; the drilling unit is arranged on the machine base unit in a sliding mode and the visual detection unit is fixedly connected to the machine base unit. The method comprises the following steps that firstly, the visual detection unit is aligned with a drilling area of the object to be drilled, and a normal direction of a position to be drilled in the drilling area is calculated; secondly, the position of the drilling unit is adjusted, and the axis of a drilling main shaft arranged on the drilling unit coincides with the normal direction; and thirdly, the drilling main shaft is driven to rotate and move forwards at a high speed, and a target hole is obtained after drilling is completed. The normal direction of the drilling position is obtained through visual detection technology and coincides with the axis of the drilling unit, and the drilling direction precision of the curved surface structure can be improved.

Owner:AVIC BEIJING AERONAUTICAL MFG TECH RES INST

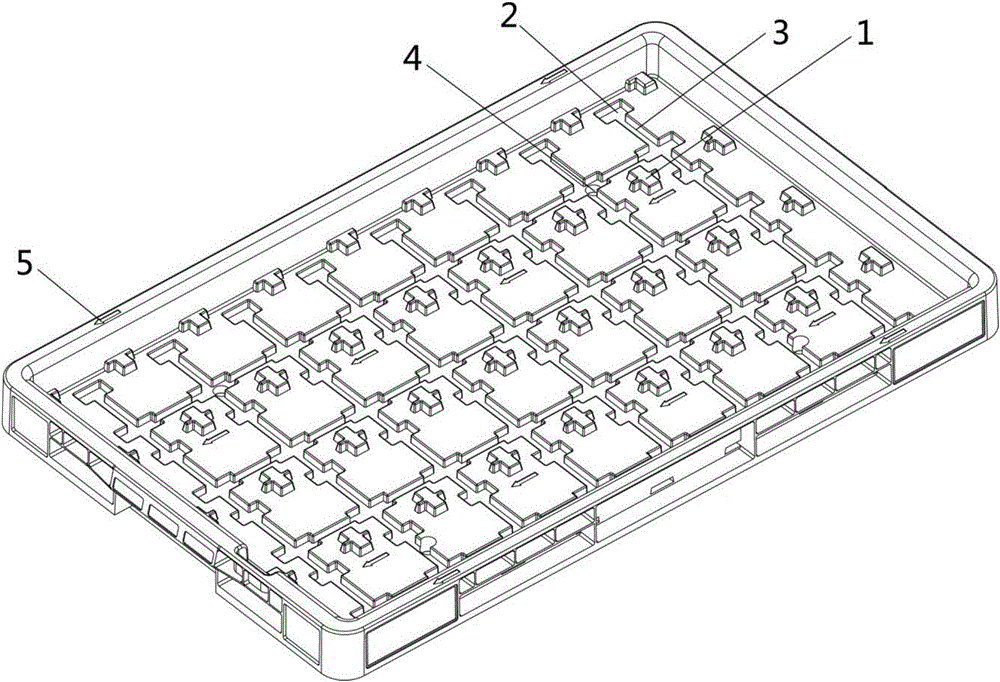

Single-phase module box transfer box

InactiveCN105922216AIncreased direction accuracyAchieving Quantity and StabilityWork tools storageSingle phaseEngineering

The invention provides a single-phase module box transfer box. The single-phase module box transfer box is provided with an upper opening. A plurality of partition ribs are arrayed in the box. The partition ribs divide the bottom of the box into a plurality of module containing areas for containing module boxes. A box frame and a box base are bonded together through super glue. During using, the module boxes are placed in the containing areas partitioned and defined by the partition ribs, the boxes are filled with the module boxes in sequence, locating structures at the bottom faces of the boxes and locating structures at the openings of the boxes can be sequentially stacked, the direction accuracy of placement and conveying of products by workers is improved, the number of multi-layer stacked boxes is increased, and the multi-layer stacking stability and the processing and production efficiency are improved.

Owner:STATE GRID HUNAN POWER SUPPLY SERVICE CENT (METROLOGY CENT) +1

Determination and Optimization Method of Dynamic Parameters in the Manufacturing Process of Plasma Display

ActiveCN103236385BImprove yield rateDoes not involve interruption of productionTube/lamp screens manufactureProduction lineSingle process

The invention discloses a method for determining and optimizing power parameters in the manufacturing process of a plasma display screen. A regression relation model of the important power parameters and yield in the manufacturing process of the plasma display screen is established by utilizing the historical data of the manufacturing process and the importance degree influencing the quality of a plasma display screen product is reflected by utilizing a regression coefficient, so that important power parameter items which need to be subjected to management and control reinforcement with emphasis are determined and a power parameter control strategy for promoting the total yield or the single-process yield is found. The method has the active effects that time and resource cost which are consumed in a manner of repeatedly carrying out testing design and verification are saved and direction accuracy on the aspects of power parameter control items and the control range is promoted; and moreover, the aim of continuously and spirally promoting the yield of the plasma display screen can be fulfilled and the rejection rate in the manufacturing process is indirectly reduced. Meanwhile, the method disclosed by the invention cannot be related to the interruption of production of a production line, so that online dynamic determination and regulation management of the power parameters of the manufacturing process are implemented.

Owner:江苏鼎峯云计算有限公司

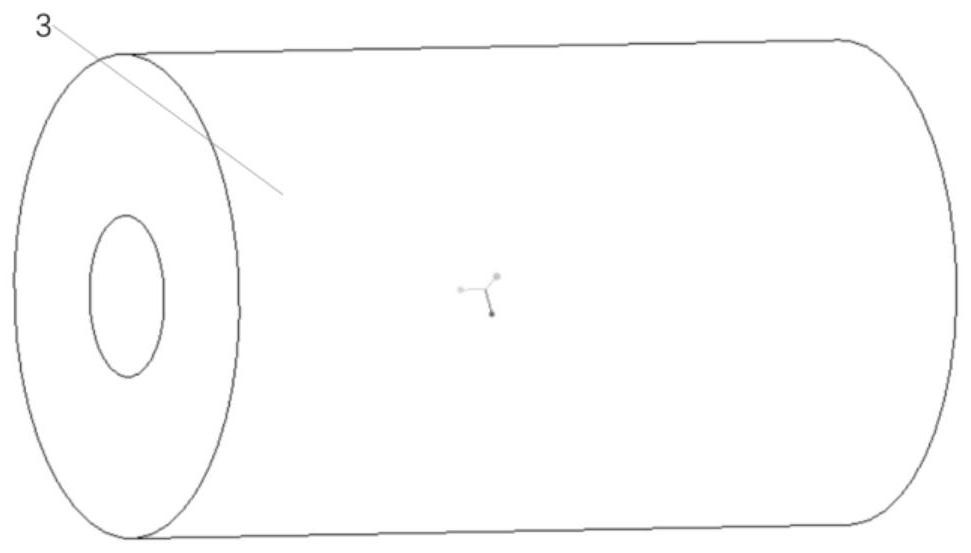

Exercise machine

ActiveUS10617904B2Improve direction accuracyQuick changeMuscle exercising devicesRotational axisClassical mechanics

Machine for gymnastic exercises comprising a sliding rail (3), a carriage (4) installed in a sliding manner on the sliding rail (3), a first pulley (21) and a second pulley (22) installed on the carriage (4) and rotatable in an idle manner around respective axes of rotation, a gripping element (6), cable traction means (16) comprising a first cable branch (a) and a second cable branch (b) provided with respective and separate connection ends (17) attached to the gripping element (6). The first cable branch (a) and the second cable branch (b) wind at least partly around the first pulley (21) and respectively the second pulley (22) to define first return segments (23) comprised between the gripping element (6) and respectively the first pulley (21) and second pulley (22), and second return segments (24) that extend one on a first side (25) and the other on a second side (26), opposite the first side (25), of the carriage (4) and substantially parallel to the sliding rail (3).

Owner:AKUIS SRL

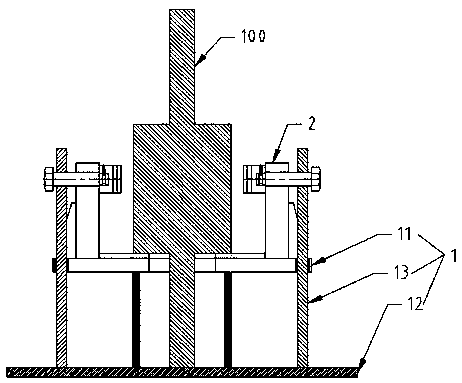

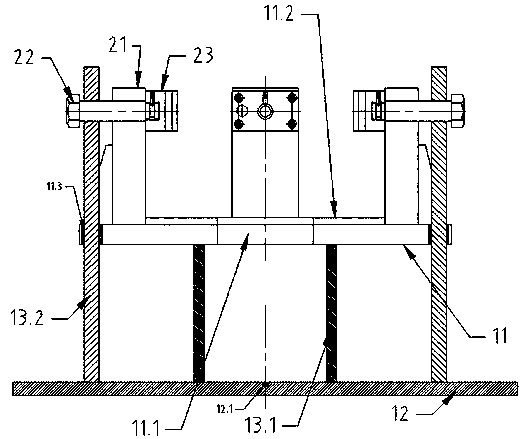

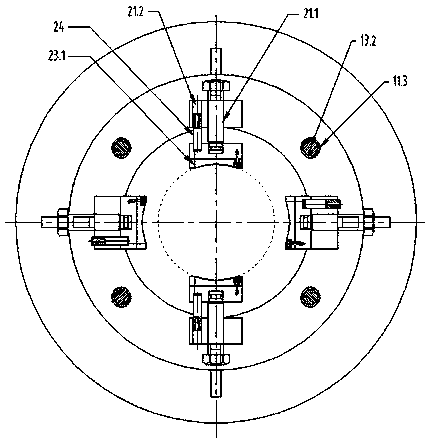

Rotor vertical fixing device and rotor vertical fixing method

Provided is a vertical fixing device for a rotor. The device includes a support table and a clamping assembly arranged on the support table, the rotor is vertically placed on the support table, the clamping assembly clamps the rotor, the device is characterized in that the support table includes an upper support plate for supporting the weight of the rotor, a bottom plate which is positioned underthe upper support plate and is larger than the upper support plate, and a support adjustment assembly capable of driving the upper support plate to move up and down, the support adjustment assembly is fixed on the bottom plate and used for supporting the upper support plate, a through hole with the diameter smaller than the maximum diameter of the rotor is formed in the center of the upper support plate, a rotating shaft of the rotor penetrates the through hole, the end face of the rotating shaft is in contact with the center of the bottom plate, and the upper support plate is provided with arubber gasket in contact with the rotor. The device is used for vertically fixing the rotor and is simple in structure and high in universality, the vertical placing direction of the rotor is high inprecision, and the reliability and accuracy of vertical processing of the rotor are improved. The invention further provides a vertical fixing method for the rotor.

Owner:CSR ZHUZHOU ELECTRIC CO LTD

Multi-beam measuring device with high directional stability for 3D scanning of an environment

PendingUS20210141064A1Improve direction accuracyImprove positioningElectromagnetic wave reradiationBeam directionMeasurement device

A measuring device comprises a base, a case, and a rotating member rotatable about the axis of rotation. The rotating member comprises a transmission unit configured to emit transmission beams to different beam directions. The rotating member further comprises a receiver unit configured to receive returning transmission beams. A longitudinal member is fixed to the base and extends in a central area of the rotating member along the axis of rotation over a range including the transmission unit and the receiver unit. Two bearing members are arranged on the longitudinal member and on the rotating member. In the direction of the axis of rotation, the transmission unit and the receiver unit are located in a range between the two bearing members. The measuring device has a high aiming accuracy and low hysteresis of the turning transmission beams.

Owner:HEXAGON TECH CENT GMBH

A method for drilling holes in curved surface structures

Owner:AVIC BEIJING AERONAUTICAL MFG TECH RES INST

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com