Centering machine cover assembling tool structure

A canopy, neutral technology, applied in the field of neutral canopy attachment structure, can solve the problems of uneven gap between the canopy and the fender, affecting consumer evaluation, large cumulative error, etc., achieving high debugging efficiency, The effect of convenient debugging and high precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] The present invention will be further described in detail below in conjunction with the accompanying drawings, so that those skilled in the art can implement it with reference to the description.

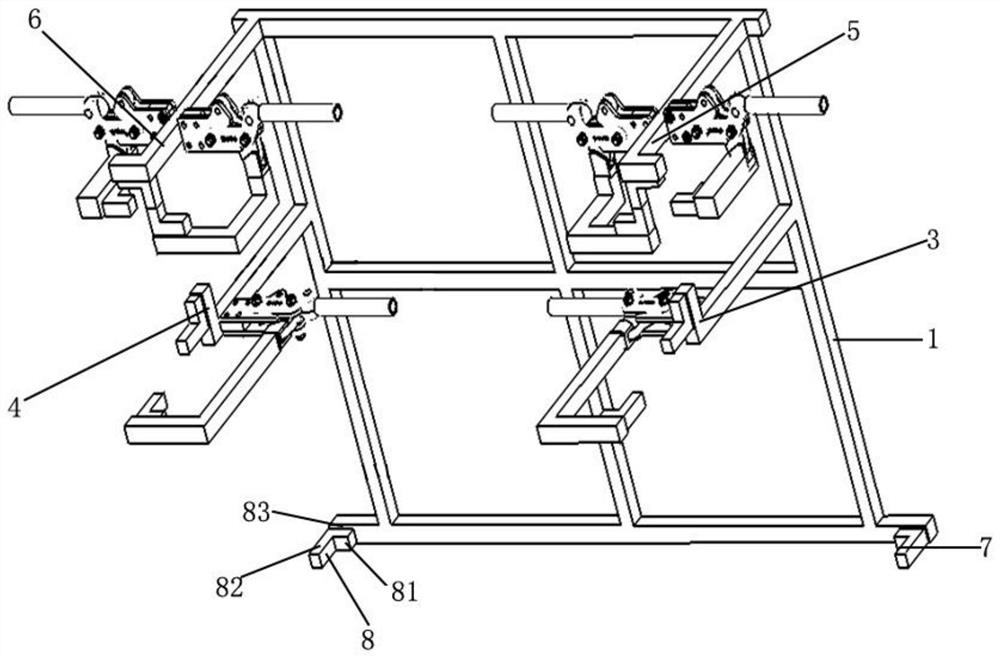

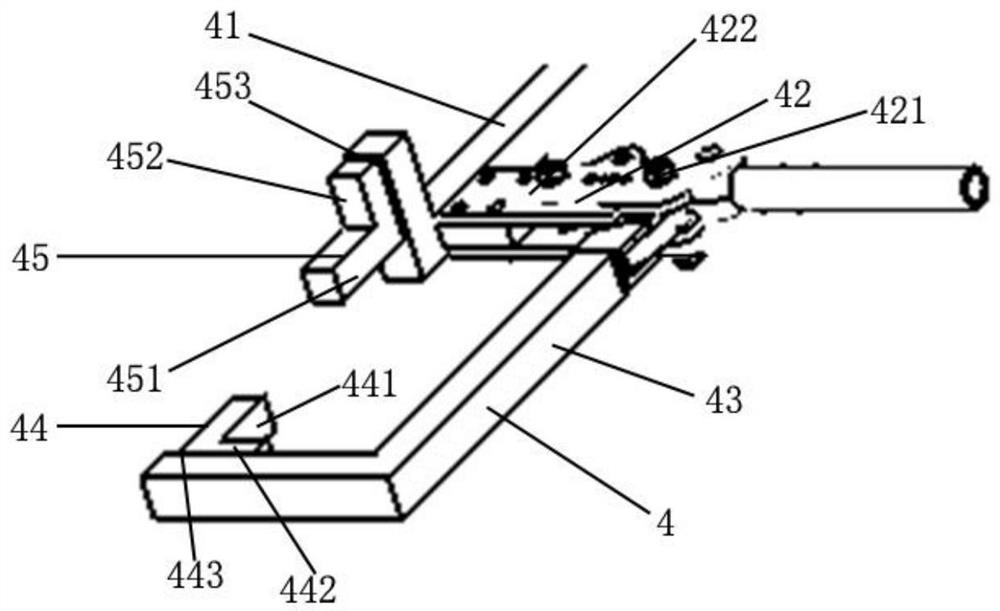

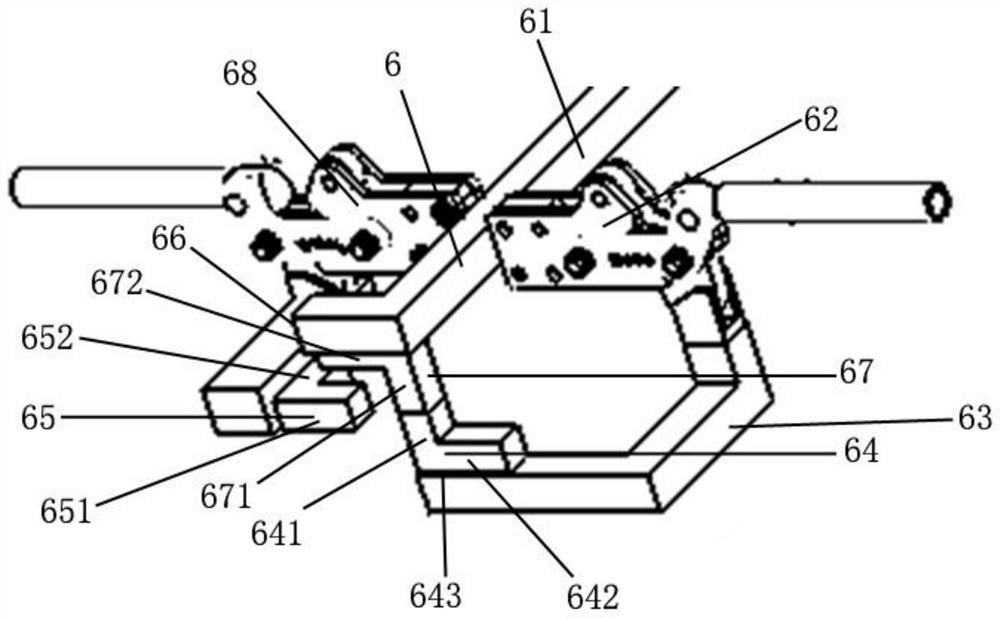

[0041] Such as figure 1 , figure 2 , image 3 As shown, the neutral machine cover fitting structure of the present invention includes a tooling frame 1 arranged symmetrically on the left and right. Z direction positioning support block 8 and right side Z direction positioning support block 7. The left side and the right side of the middle part of the tooling frame 1 are provided with a left side Z-direction positioning mechanism 4 and a right side Z-direction positioning mechanism 3 protruding vertically downward respectively. The left side and the right side of the rear part of the tooling frame are provided with a left XY positioning mechanism 6 and a right XY positioning mechanism 5 protruding vertically downward respectively.

[0042] Specifically, the left side Z-di...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com