Three-phase module box circulating box

A module box and turnover box technology, applied in the direction of manufacturing tools, tool storage devices, etc., can solve the problems of waste efficiency, processing errors, no module boxes, etc., to increase direction accuracy, improve processing production efficiency, and achieve quantity and stability sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] Below in conjunction with specific embodiment and accompanying drawing, the present invention is described in further detail:

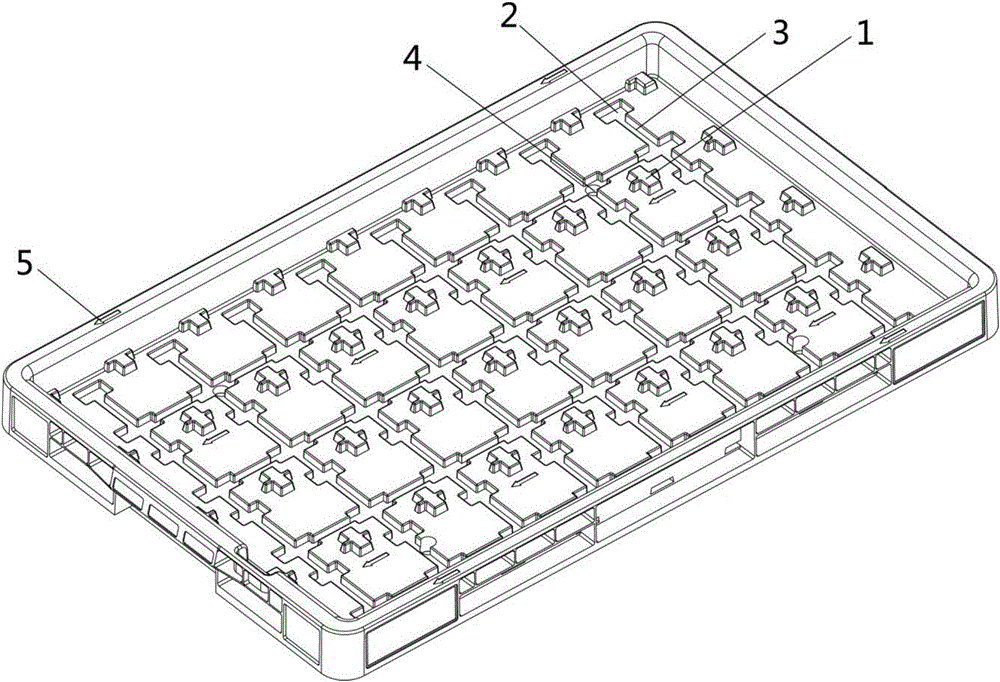

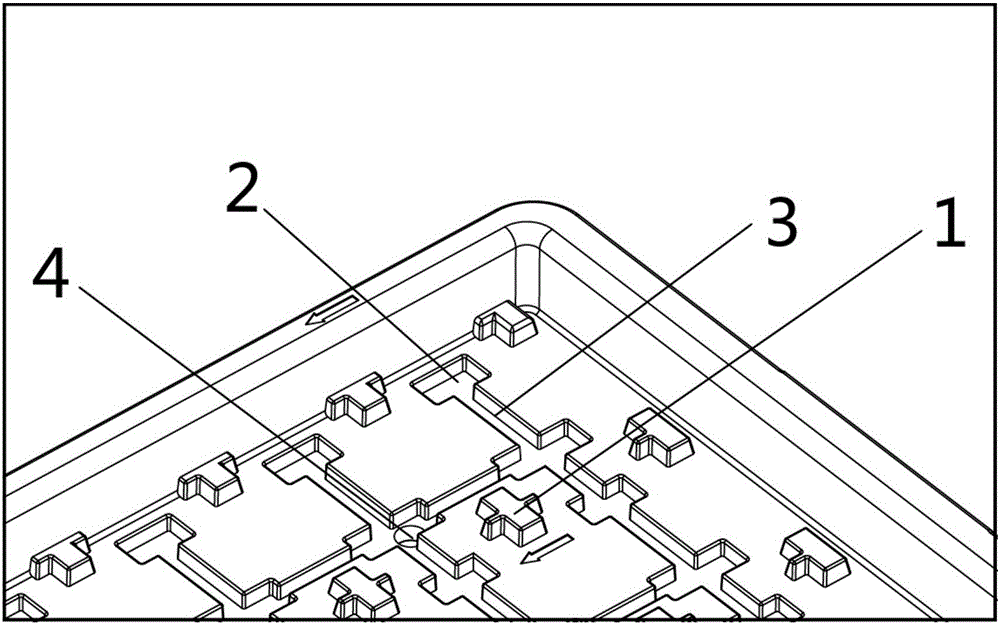

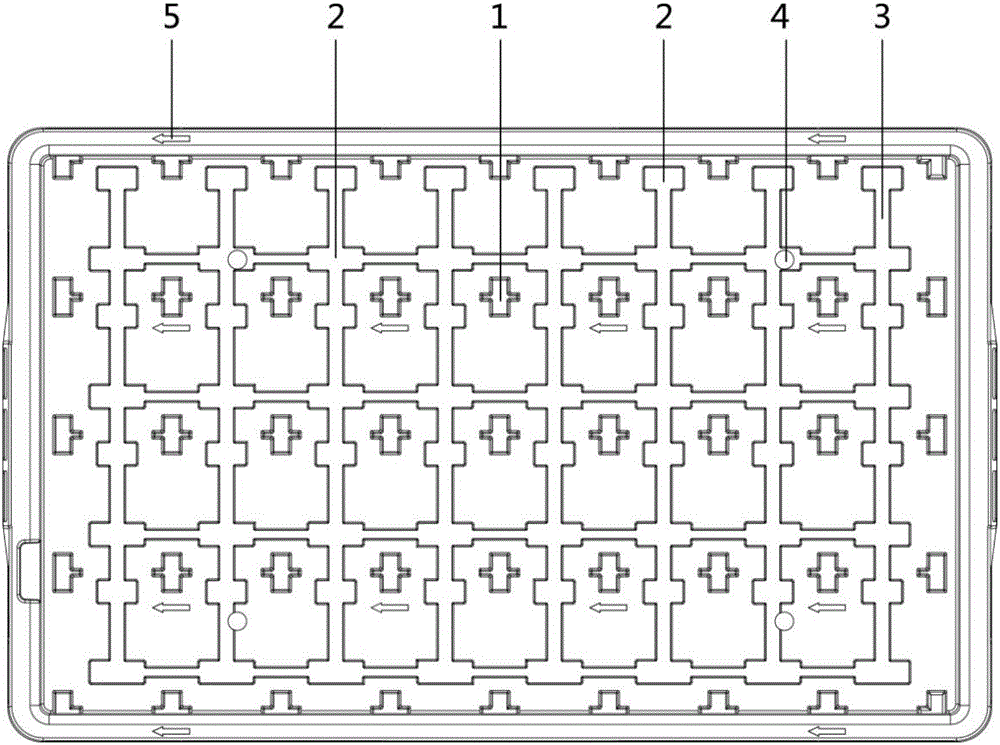

[0019] Such as image 3 and Figure 4 As shown in the figure, firstly put the pins of the module box towards the box body, insert the pins of the module box into the accommodation area (2) where the pins of the module box are located, and use the spacer ribs (1) to fix and position the module box. When the module box fills the entire box body, it can be used as one layer. When it is multi-layered, it can be placed together in a multi-layered manner, and used according to the direction indication of the guide mark (5).

[0020] The above is only an embodiment of the present invention, and does not limit the patent scope of the present invention. Any equivalent structure or equivalent process transformation made by using the description of the present invention and the contents of the accompanying drawings, or directly or indirectly used in othe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com