Electric pole pit groove digging device

A technology for excavating devices and pits, which is applied to earth movers/shovels, construction, etc. It can solve the problems of slow construction efficiency, affecting the quality of planting poles, time-consuming and labor-intensive problems, and achieves easy depth of pits and high construction efficiency. Stable and consistent effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

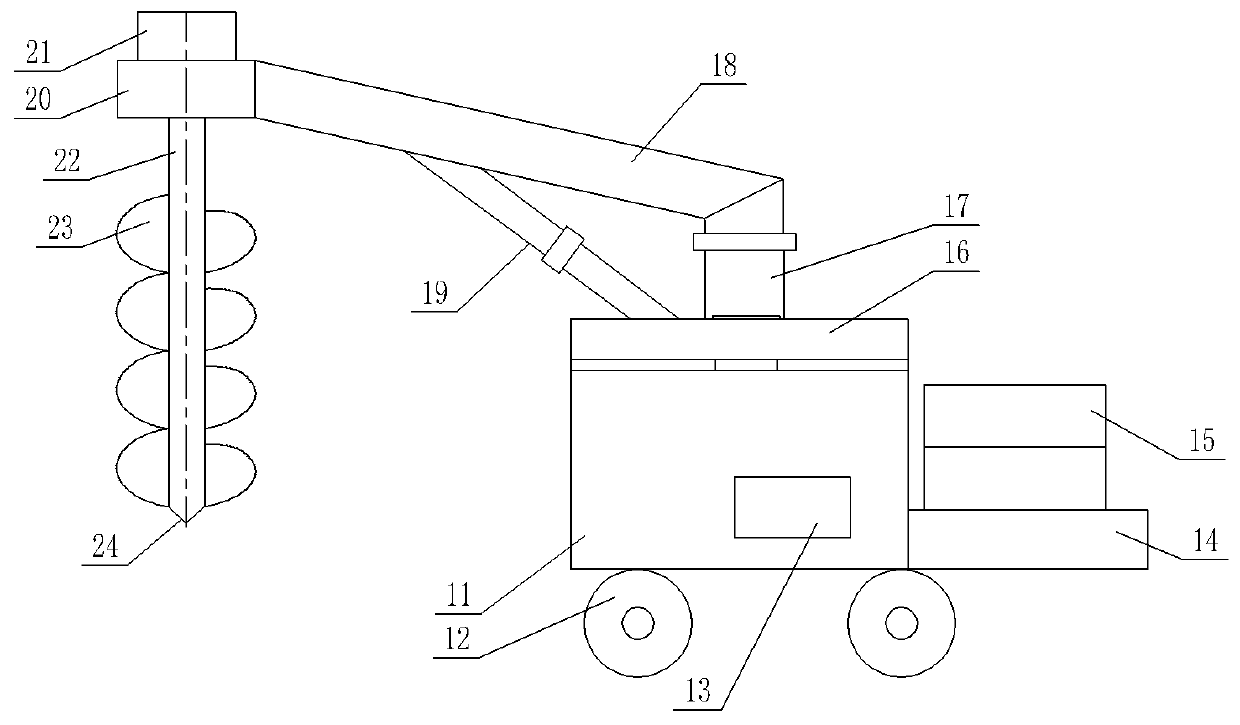

[0037] as attached figure 1 with 7 shown;

[0038] An electric pole pit digging device, comprising a vehicle frame 11, a turntable 16 rotatably connected to the vehicle frame 11, a lifting mechanism connected to the turntable 16, an excavating knife assembly connected to the lifting mechanism for digging pits, a fixed A counterweight assembly arranged at the rear of the vehicle frame 11 to balance the weight of the lifting mechanism and a running mechanism arranged at the bottom of the vehicle frame 11 .

[0039] Further, the lifting mechanism includes a fixed column 17 fixedly connected to the turntable 16, a boom 18 whose lower end is hinged on the fixed column 17, a telescopic cylinder 19 whose two ends are respectively hinged to the middle of the turntable 16 and the boom 18, and fixedly connected Horizontal mount 20 at the end of boom 18 .

[0040] Further, a central hole is provided in the middle of the turntable 16, and a center column 30 fixed on the frame 11 is arr...

Embodiment 2

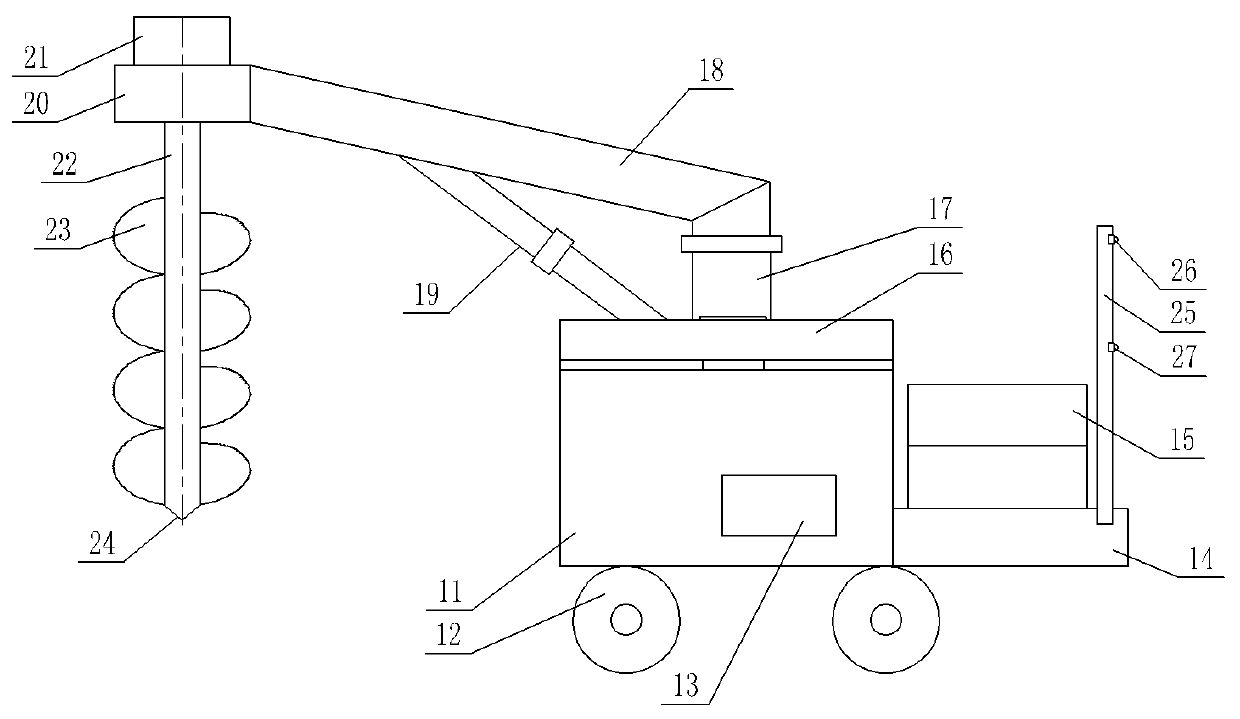

[0048] as attached figure 2 and 7 shown;

[0049] On the basis of the first embodiment, further, an alignment rod is fixedly installed on the counterweight platform 14 .

[0050] The alignment rod includes a vertical rod body 25 whose lower end is fixed on the counterweight platform 14 and a first position sensor 26 and a second position sensor 27 fixedly arranged on the vertical rod body 25 at intervals;

[0051] The detection directions of the first position sensor 26 and the second position sensor 27 are the same, and are used to detect the position of the electric pole at the front or the rear.

[0052] This embodiment realizes automatic mechanical excavation of pole-loading pits, saving time and effort, high construction efficiency, and high stability and consistency of planting poles. Position sensors are used to align the front and rear poles to ensure that the poles are planted on a straight line, thereby improving the direction of the transmission line. Accuracy a...

Embodiment 3

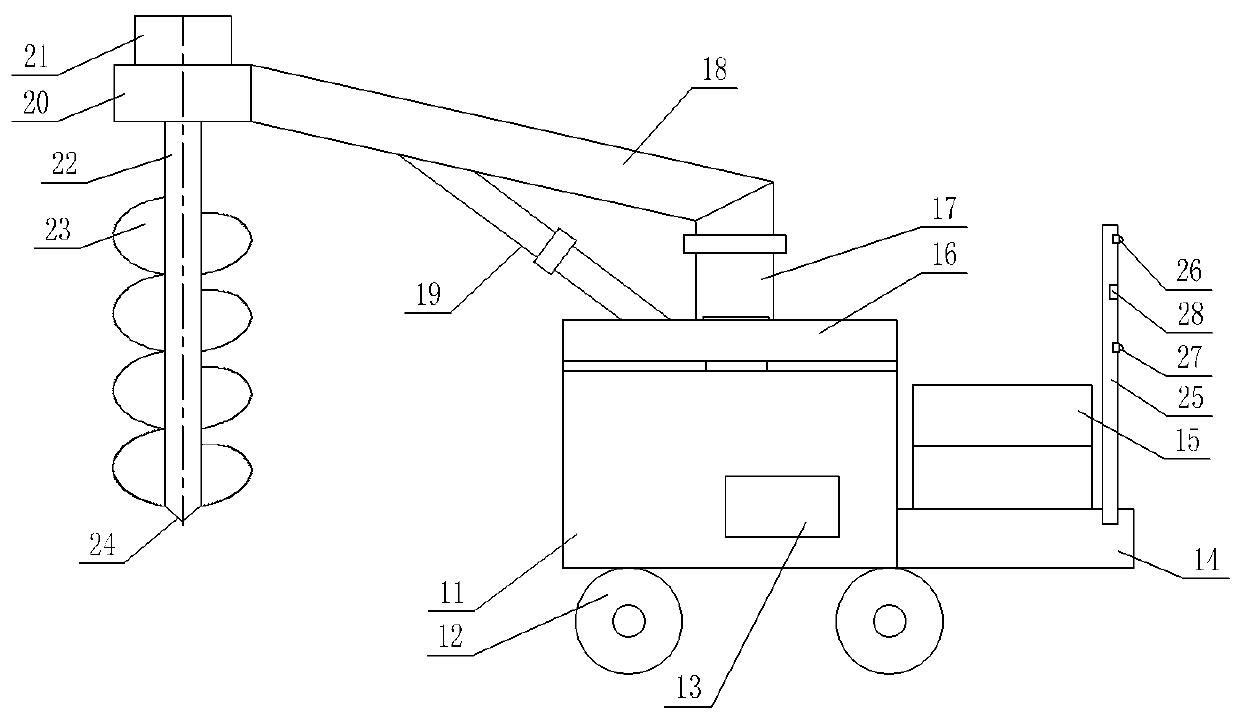

[0054] as attached image 3 , 6 and 7 as shown;

[0055] On the basis of the second embodiment, further, the vertical rod body 25 is also fixedly provided with an infrared distance sensor 28, the infrared light emission direction of the infrared distance sensor 28 is the same as the detection direction of the first position sensor 26, for Measure the separation distance from the front or rear poles.

[0056] Realize mechanical automatic digging of pole pits, saving time and labor, high construction efficiency, high stability and consistency of planting poles, using position sensors to align front and rear poles to ensure that poles are planted in a straight line, and measuring and adjusting electric poles through infrared distance sensors The distance between the poles can be adjusted to improve the direction accuracy of the transmission line and ensure the stability of the transmission line operation.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com