Refrigeration chip type heat pipe performance testing device

A cooling chip and testing equipment technology, which is applied in the field of cooling chip heat pipe performance testing equipment, can solve the problems of large temperature fluctuations of the cold plate, low production efficiency, and long testing time, and achieve high testing efficiency and cost savings and energy, the effect of short test time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

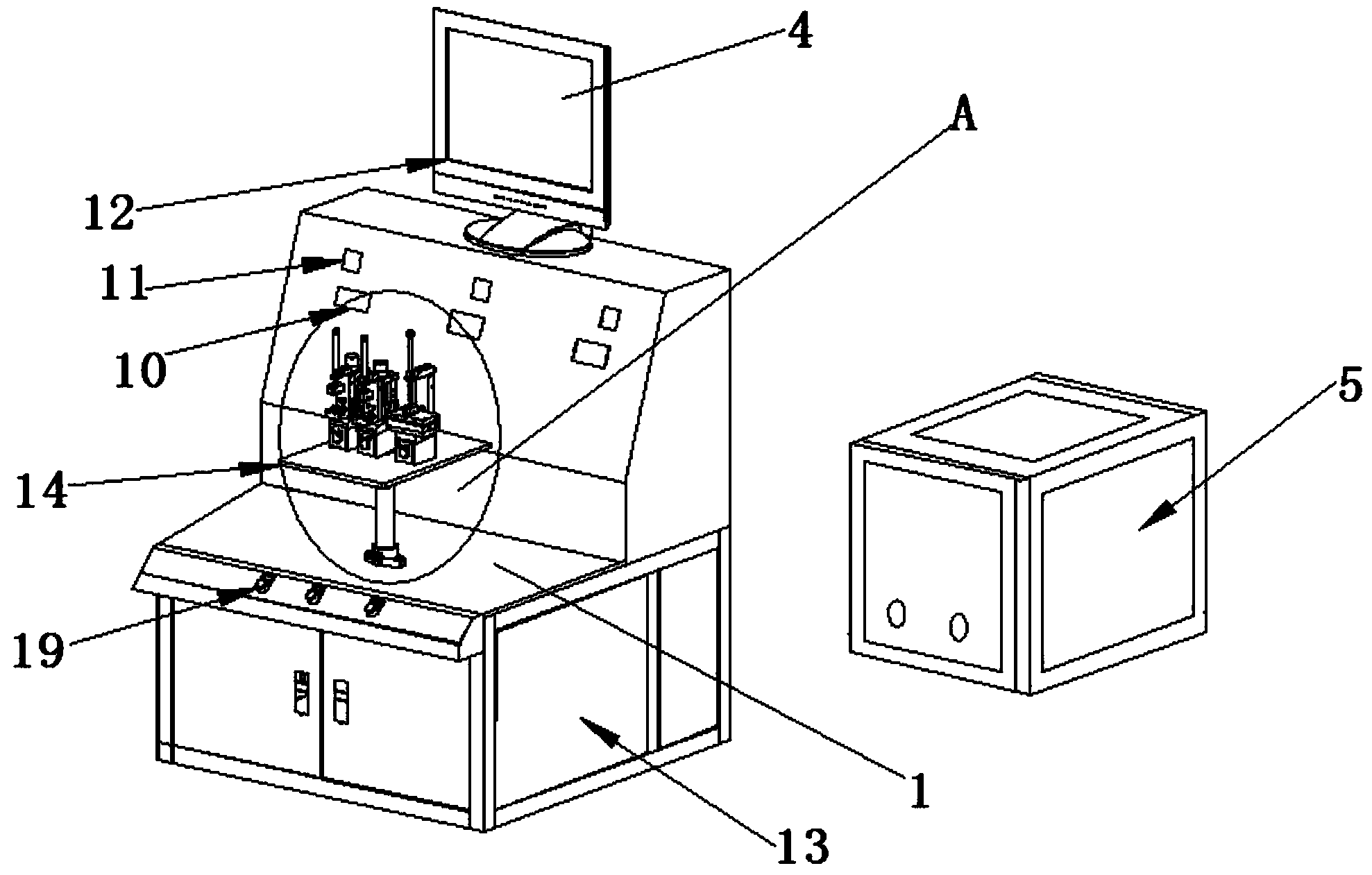

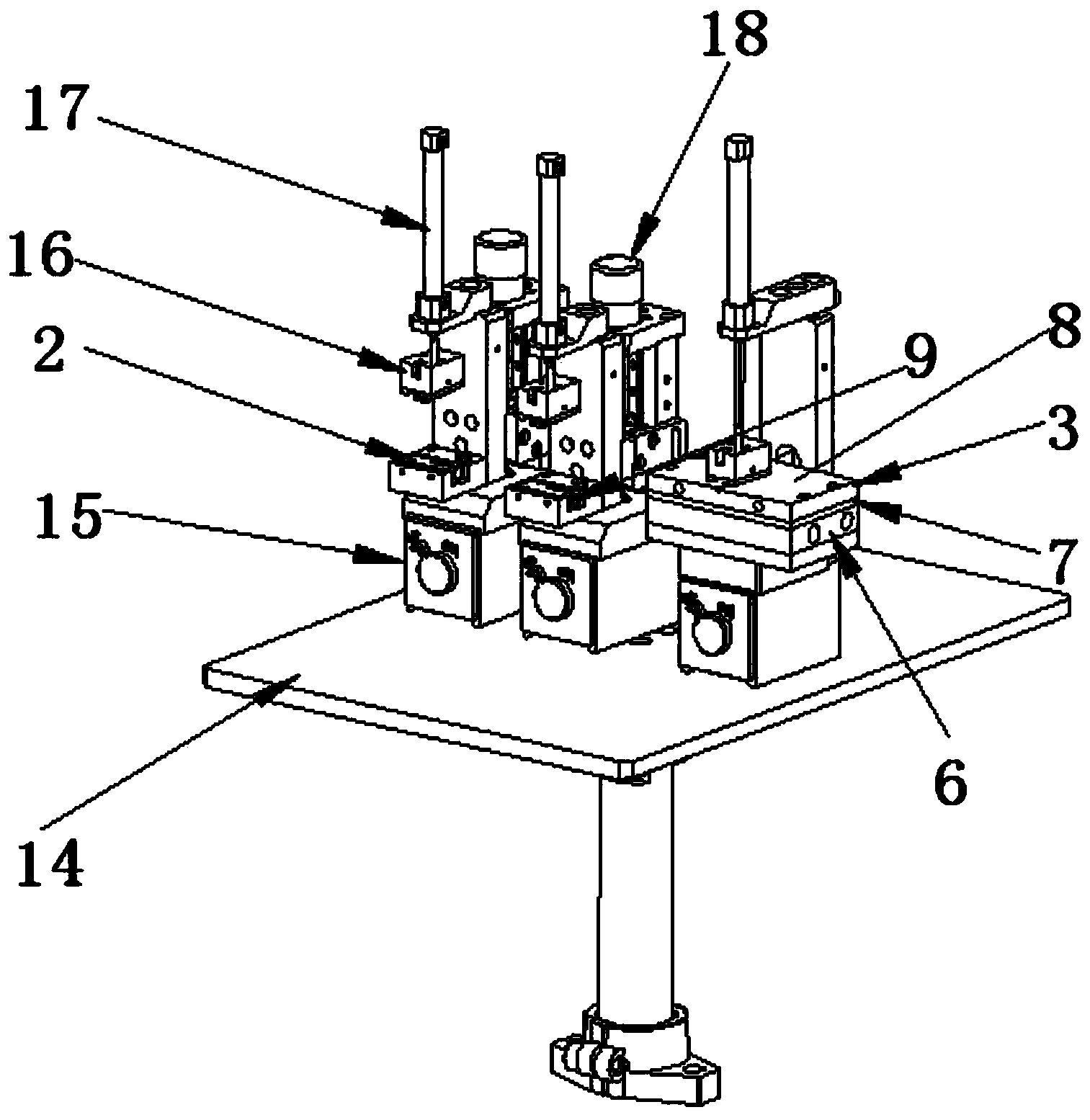

[0028] The present invention will be further described below in conjunction with the accompanying drawings.

[0029] Such as Figure 1-2 As shown, a cooling chip type heat pipe performance testing equipment is characterized in that it includes: a heating device 2, a cooling device 3 and a control device 4 arranged on the operating table 1, and the cooling device 3 is externally connected to two refrigerators 5 , the cooling device 3 includes a cold plate 6 for communicating with the refrigerator 5, a cooling chip 7 and a cooling copper block 8 for placing the cooling end of the heat pipe to be measured, and the cooling chip 7 is arranged on the Between the cooling copper block 8 and the cold plate 6.

[0030] The cold plate 6 is an internal circulation structure with a liquid inlet and a liquid outlet, and the cold plate 6 and the refrigerator 5 are filled with cooling circulating liquid.

[0031] The cooling circulating liquid includes water, alcohol or cooling liquid.

[...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Flip angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com