Patents

Literature

30results about How to "Improve stability and consistency" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Power transmission line unmanned aerial vehicle autonomous inspection system and working method thereof

InactiveCN110113570AImprove stability and consistencyAddress technology dependenciesChecking time patrolsClosed circuit television systemsInstabilityAerospace engineering

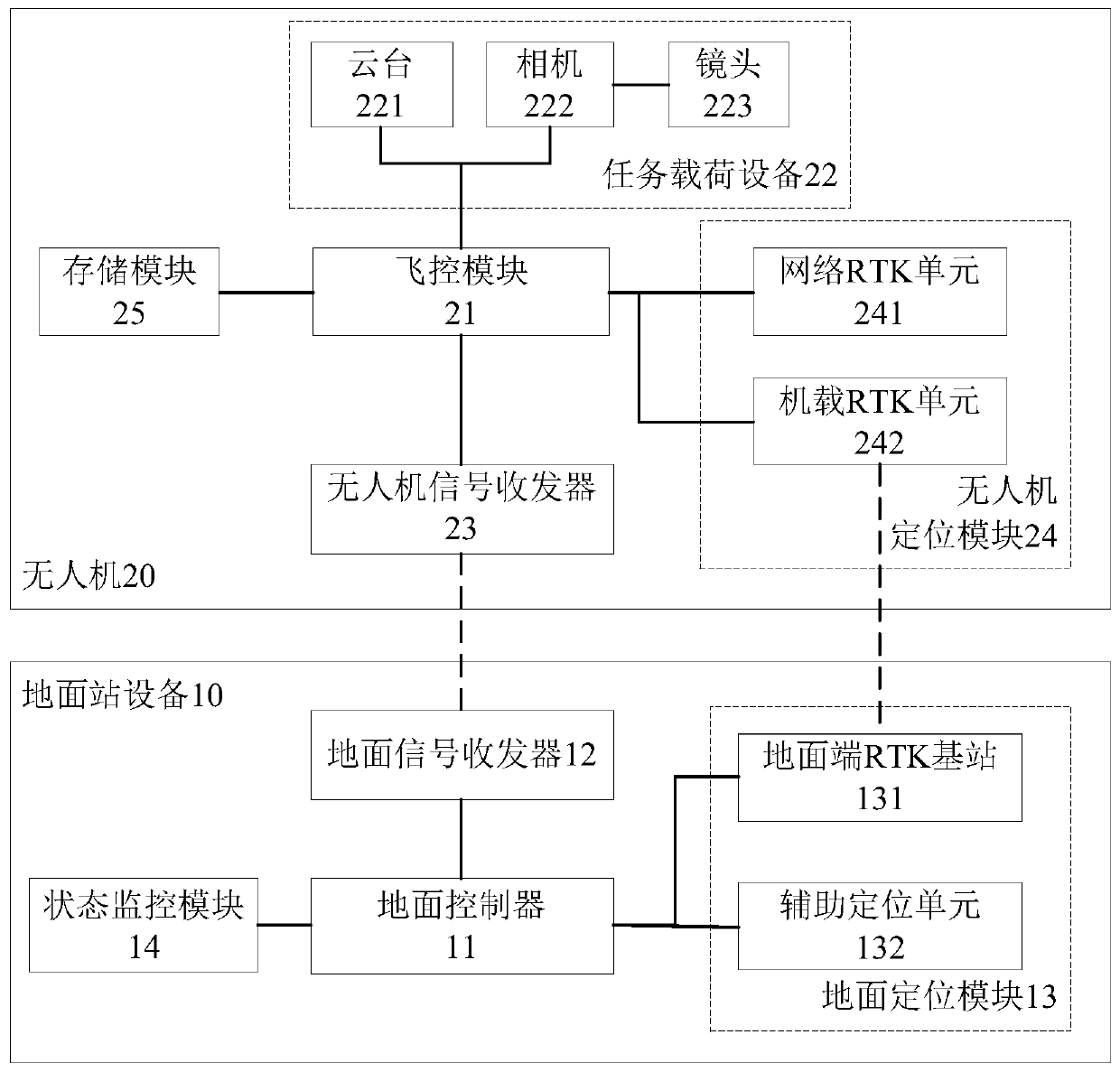

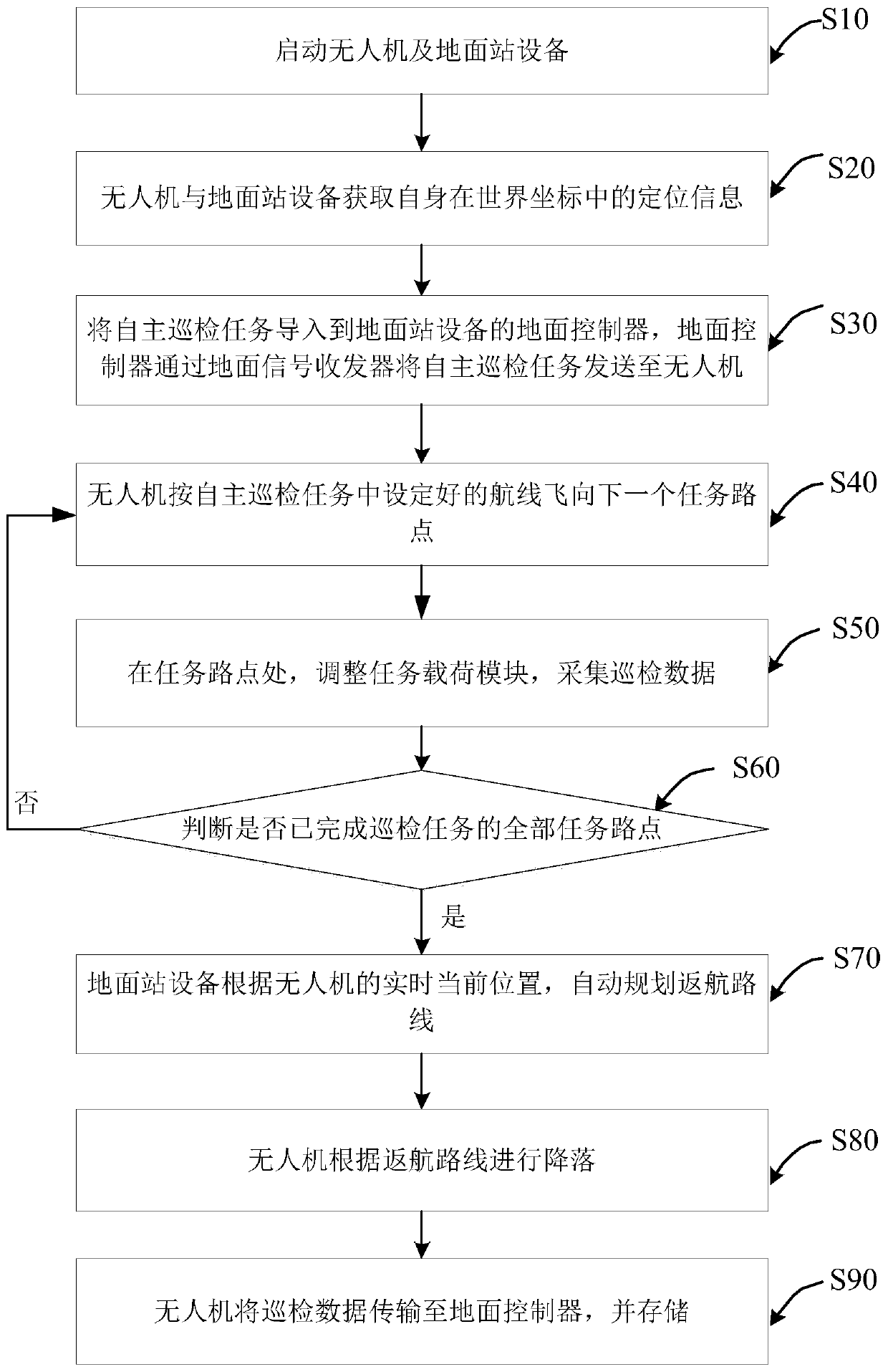

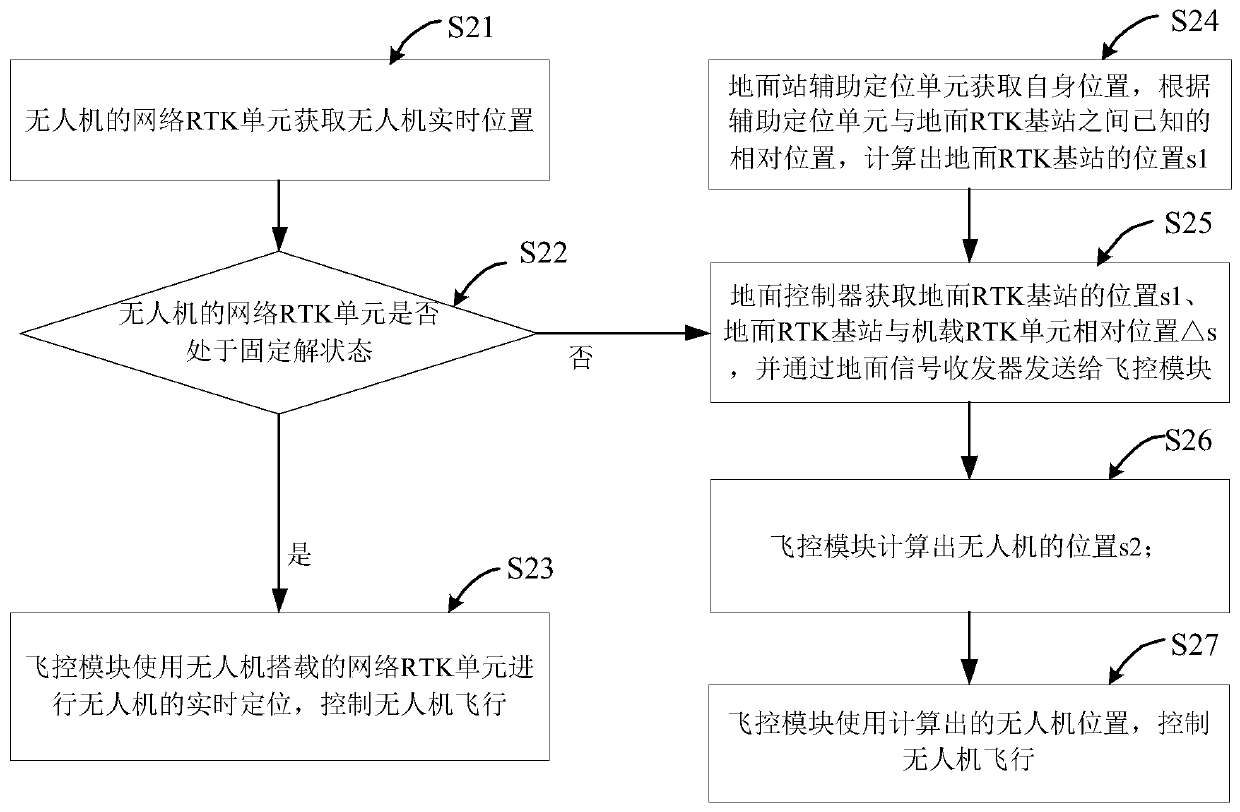

The invention discloses a power transmission line unmanned aerial vehicle autonomous inspection system. The system comprises ground station equipment, an unmanned aerial vehicle and an unmanned aerialvehicle positioning module, an autonomous inspection task is sent to the unmanned aerial vehicle through the ground station equipment, a flight control module of the unmanned aerial vehicle autonomously controls the unmanned aerial vehicle to execute the inspection task, and collected inspection data is sent to the ground station equipment to be stored. According to the invention, manual intervention can be reduced; the unmanned aerial vehicle can automatically collect and store the inspection data, reduce dependence of the unmanned aerial vehicle on people in the power transmission line inspection application, avoid instability caused by other factors such as operation habits and physical conditions of operators, realize automation of the unmanned aerial vehicle in the power transmissionline inspection application, reduce labor cost, and improve consistency and reliability of the inspection data; the two sets of unmanned aerial vehicle positioning modules are used for positioning the unmanned aerial vehicle, so that the position acquisition stability of the unmanned aerial vehicle is ensured.

Owner:JIANGSU FRONTIER ELECTRIC TECH +3

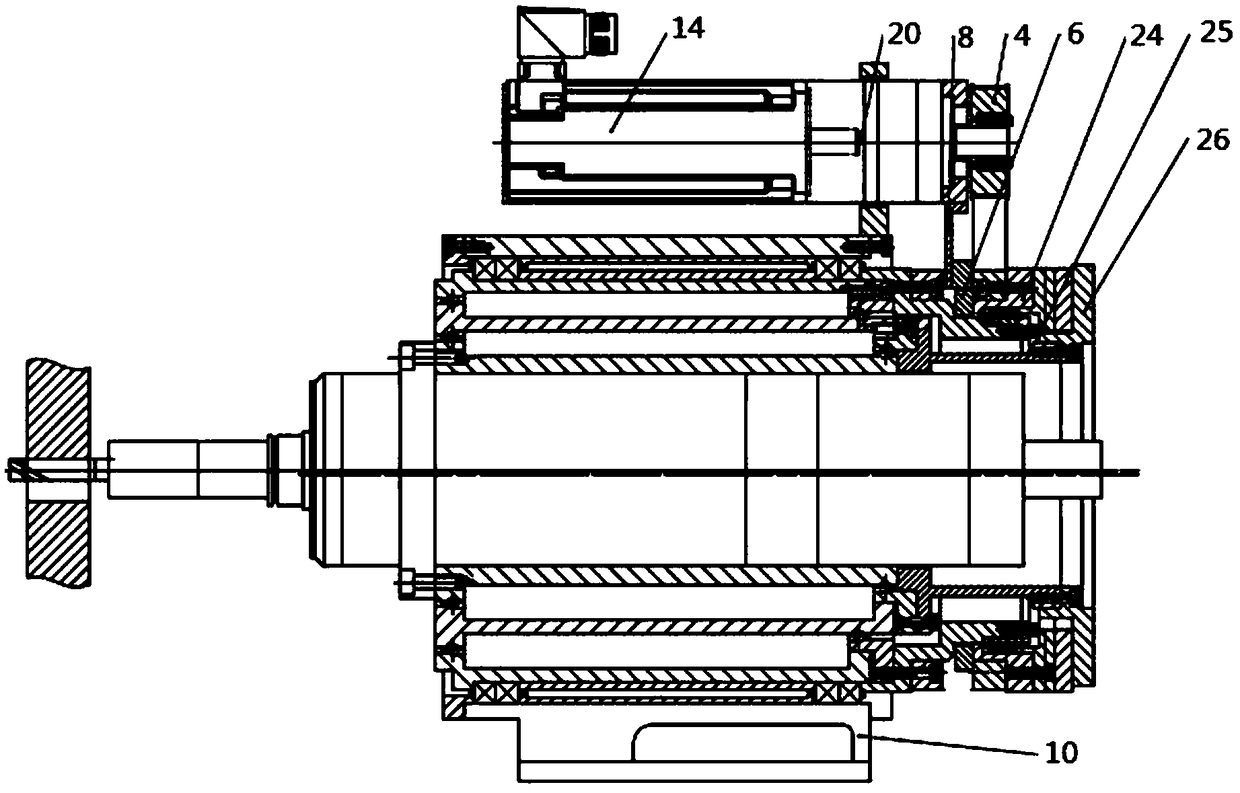

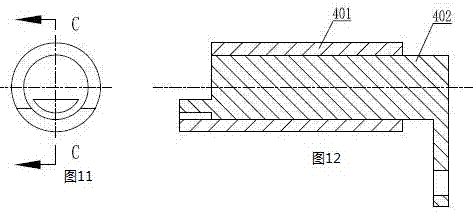

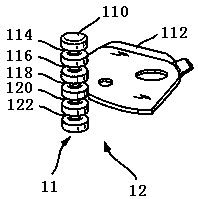

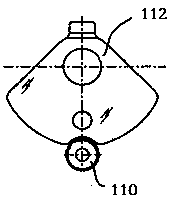

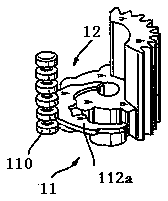

Helical milling device and helical milling method

PendingCN108927557AImprove stability and consistencyReduce rotation accuracy errorMilling equipment detailsAgricultural engineeringMachine tool

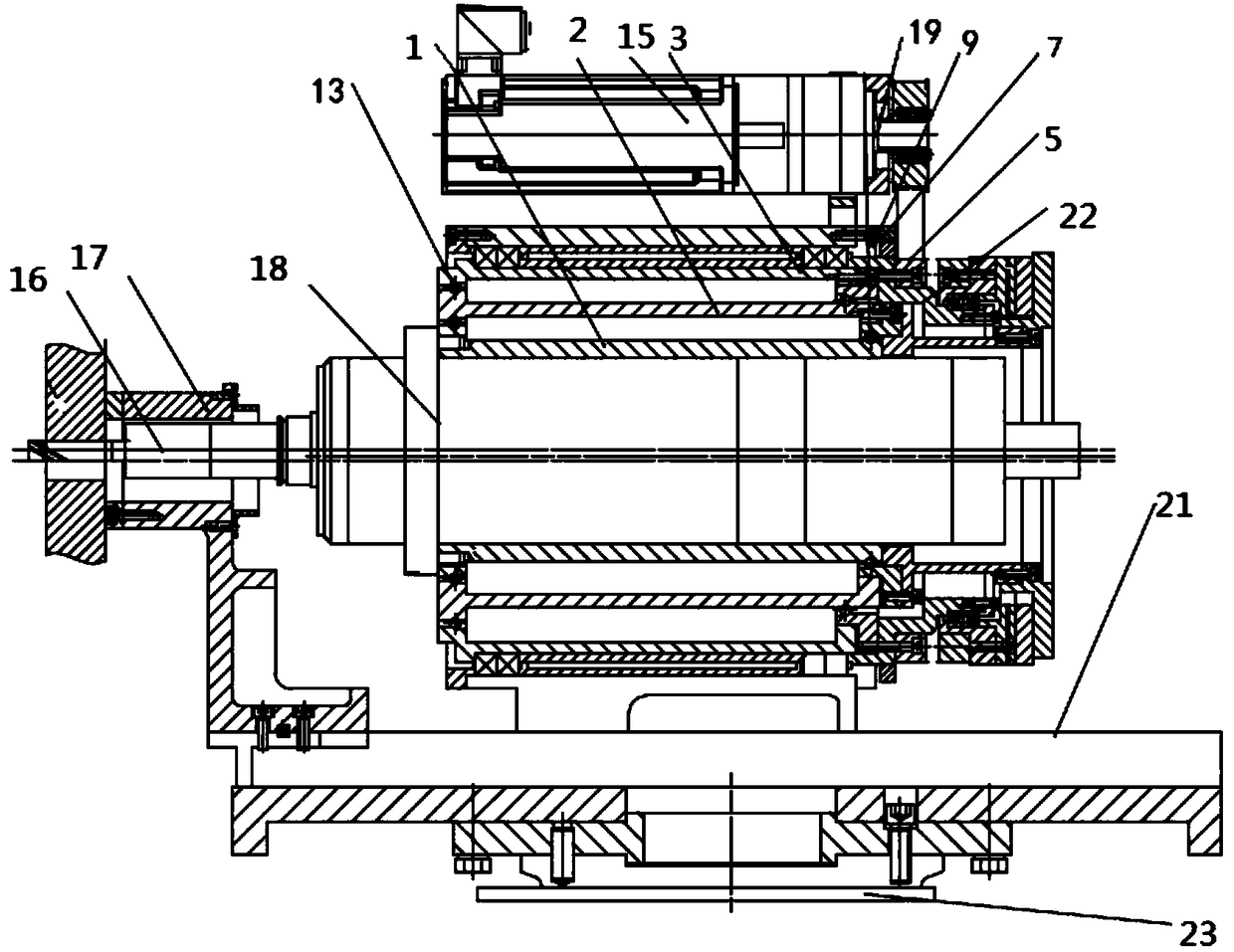

The invention belongs to the technical field of automatic hole production, and concretely relates to a helical milling device and a helical milling method. The helical milling device comprises an autorotation shaft, an eccentric adjusting shaft, a revolution shaft, a revolution belt pulley, an adjusting belt pulley and a control system, and further comprises an adjusting shaft detection grating ruler and a revolution shaft detection grating ruler, and full-closed loop detection is performed on the rotation angle of the eccentric adjusting shaft and the synchronization of the revolution shaft and the eccentric shaft. The revolution shaft, the eccentric adjusting shaft and the autorotation shaft of the device are provided with raceways, rolling elements are clamped in the raceways, and the self race ways and the rolling elements are adopted to substitute standard bearings, so problems of low rotating angle adjusting precision of existing helical milling devices and poor rotating consistence of the eccentric adjusting shaft and the autorotation shaft, and problems of overlarge use load of a hinged arm robot and a machine tool end and error accumulation caused by nesting of multilayerstandard bearings, caused by large size and large mass of the device are solved.

Owner:NAT INST CORP OF ADDITIVE MFG XIAN

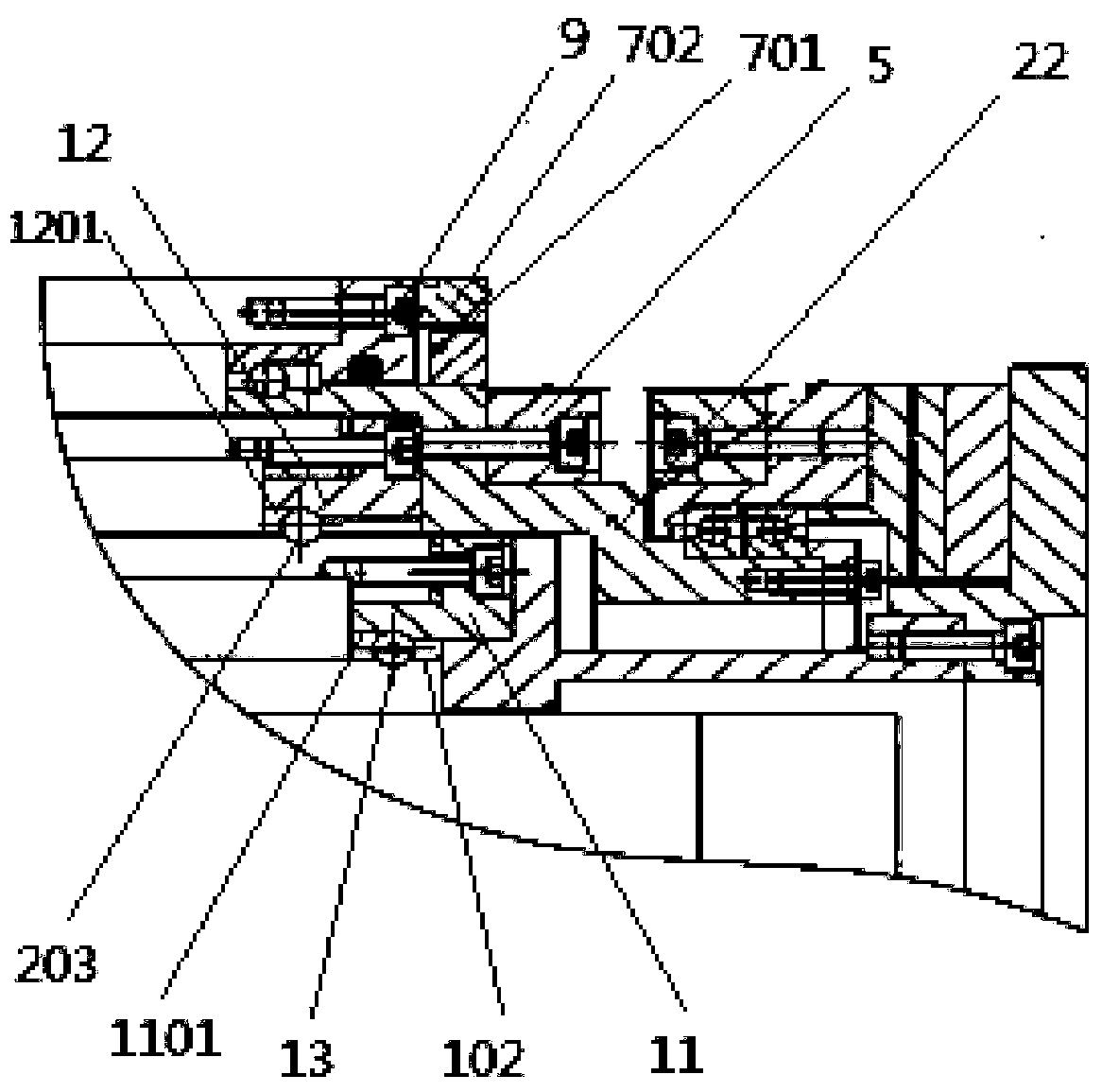

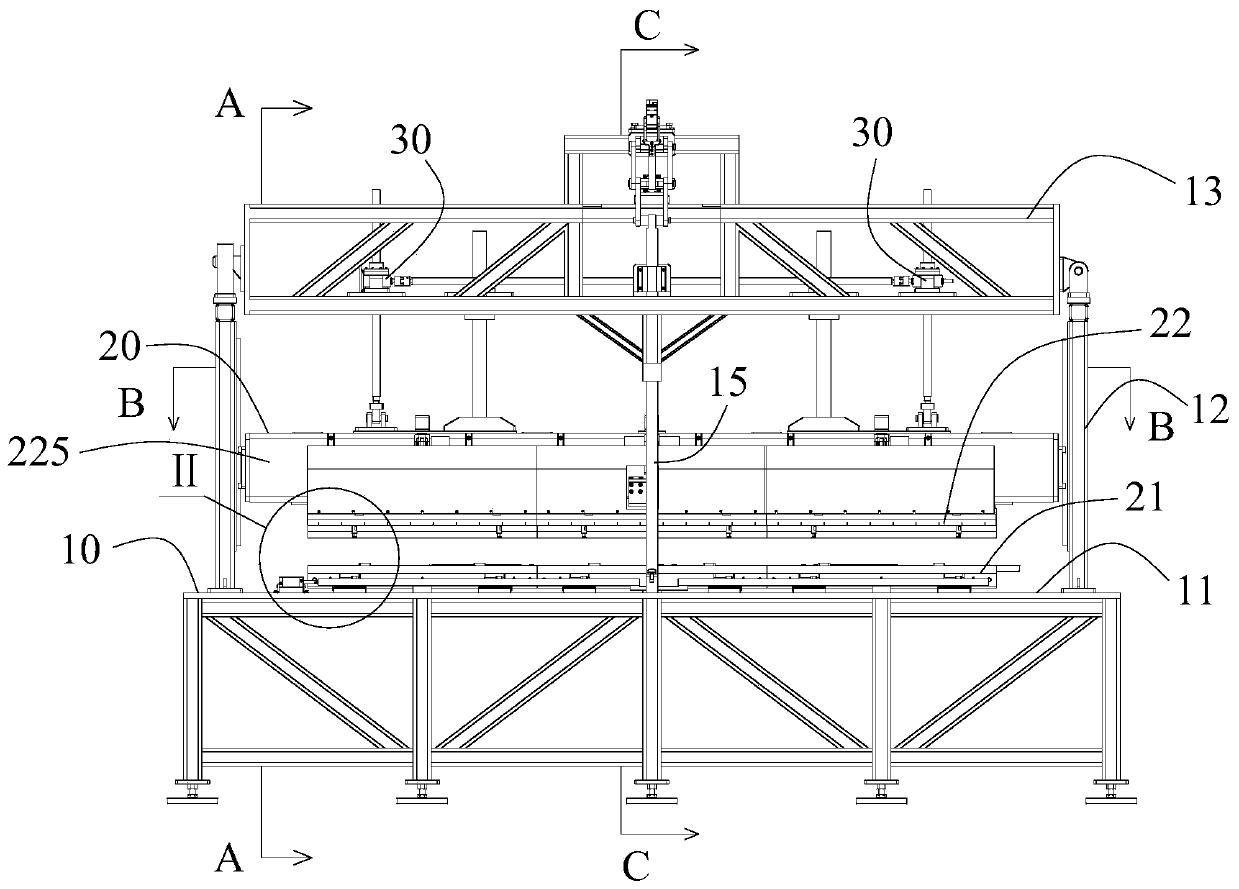

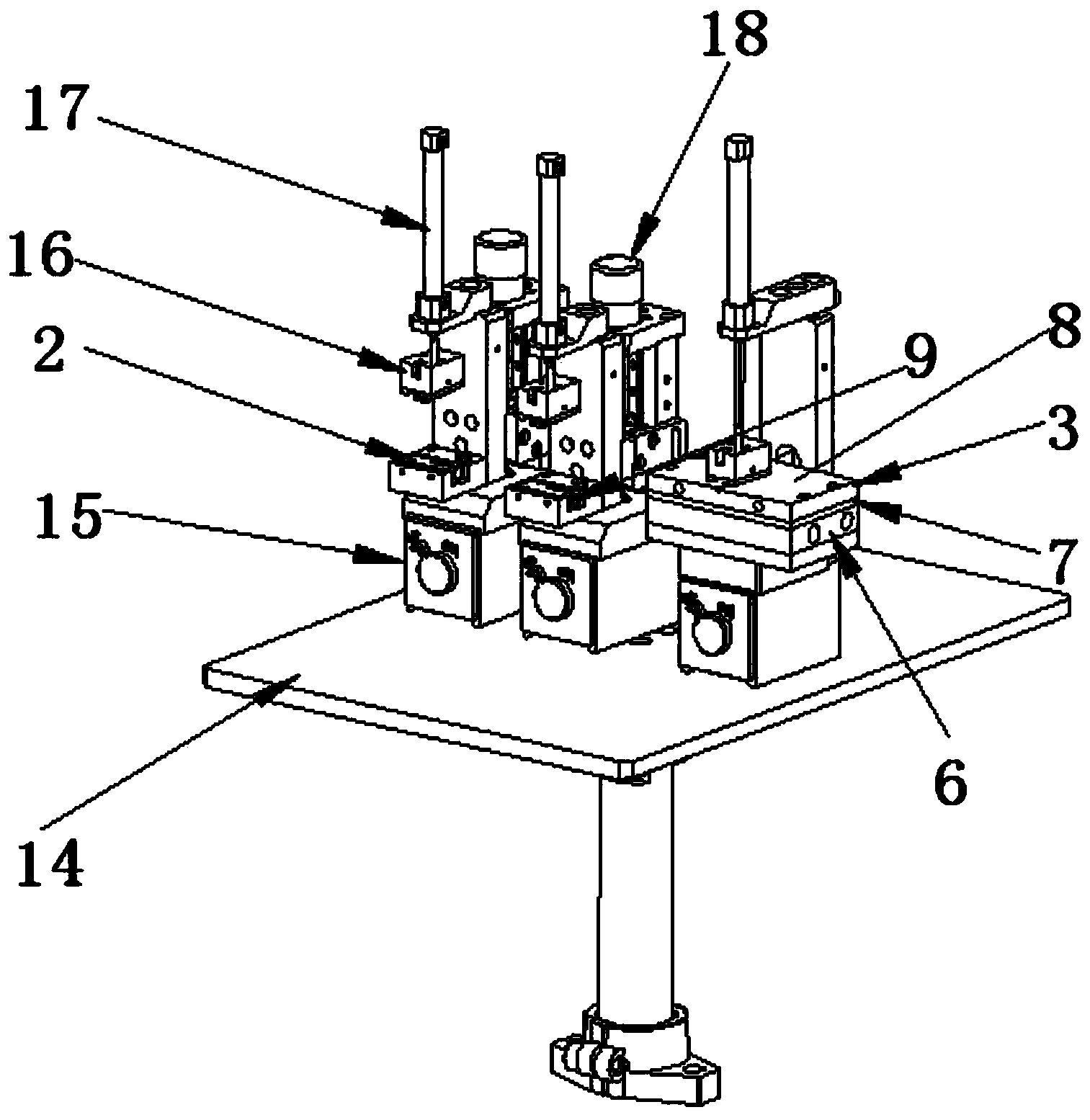

Platform special for flexible welding of explosion-proof cabinet

PendingCN110076512AImprove splicing and welding efficiencyImprove stability and consistencyWelding/cutting auxillary devicesAuxillary welding devicesEngineeringWelding

The invention provides a platform special for flexible welding of an explosion-proof cabinet. The platform is characterized in that a transverse fixed plate and a longitudinal fixed plate are fixedlyarranged on a bottom plate, wherein the transverse fixed plate and the longitudinal fixed plate are perpendicular to each other, one end of the transverse fixed plate and one end of the longitudinal fixed plate are connected, a transverse movable plate is arranged at the position, opposite to the transverse fixed plate, of the bottom plate, the transverse movable plate can be close to or far awayfrom the transverse fixed plate along longitudinal sliding holes formed in the bottom plate, a longitudinal movable plate is arranged at the position, opposite to the longitudinal fixed plate, of thebottom plate, and the longitudinal movable plate can be close to or far away from the longitudinal fixed plate along transverse sliding holes formed in the bottom plate. According to the platform, theautomation of the whole process of box body splicing, clamp actions and welding can be realized, the cabinets with different sizes can be manufactured, the splicing and welding efficiency of the cabinet is remarkably improved, the quality requirement of the cabinet is ensured, and the manufacturing cost of tooling clamps can be greatly reduced.

Owner:NANYANG YITONG EXPLOSION-PROOF ELECTRIC CO LTD

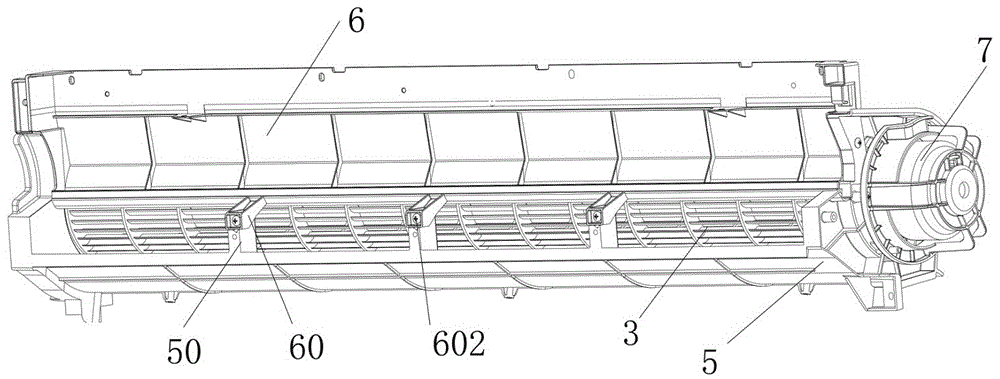

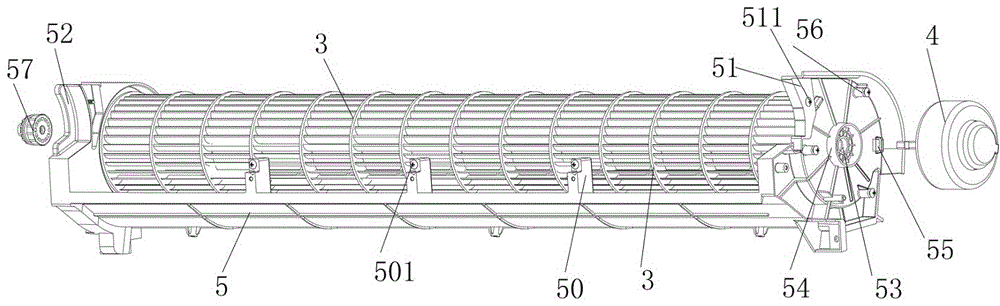

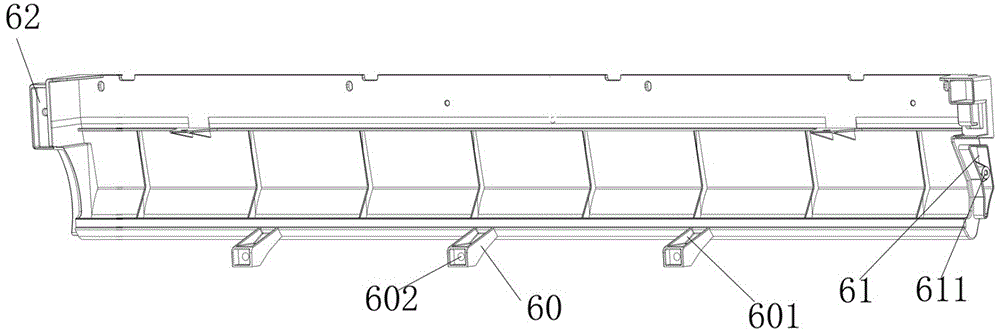

Cross-flow air flue device and vertical air conditioner thereof

ActiveCN106369781AReduce the cost of the whole machineImprove stability and consistencyDucting arrangementsLighting and heating apparatusFlueDrive motor

The invention discloses a cross-flow air flue device and a vertical air conditioner of the cross-flow air flue device. The cross-flow air flue device comprises a front panel with an air outlet, a front air flue assembly, a rear air flue assembly, a volute, a volute tongue and a motor pressing plate, wherein the front air flue assembly is composed of wind sweeping blades, a sliding door and a driving motor, the rear air flue assembly is composed of a cross-flow fan and a motor, the volute is used for containing the cross-flow fan, the volute tongue is connected with the volute and used for lowering air exhaust noise, and the motor pressing plate is used for fixing the motor to the top of the volute. The front air flue assembly is arranged on an air outlet of the front panel. The front air flue assembly is directly arranged on the front panel rather than being connected with the front panel through a front air flue, and the problem that a matching gap is produced between the front air flue and the front panel is avoided. The motor and the cross-flow fan with the heavy weight are fixedly connected through the volute. The cross-flow fan and the motor are combined into a whole through the volute used as a middle connecting piece and then installed on a rear shell, the problem that a matching gap and air flue noise are produced when the motor and the cross-flow fan are respectively and independently arranged on the rear shell is avoided, and the coaxiality between the motor and the cross-flow fan is ensured.

Owner:SHENZHEN SKYWORTH AIR CONDITIONING TECH CO LTD

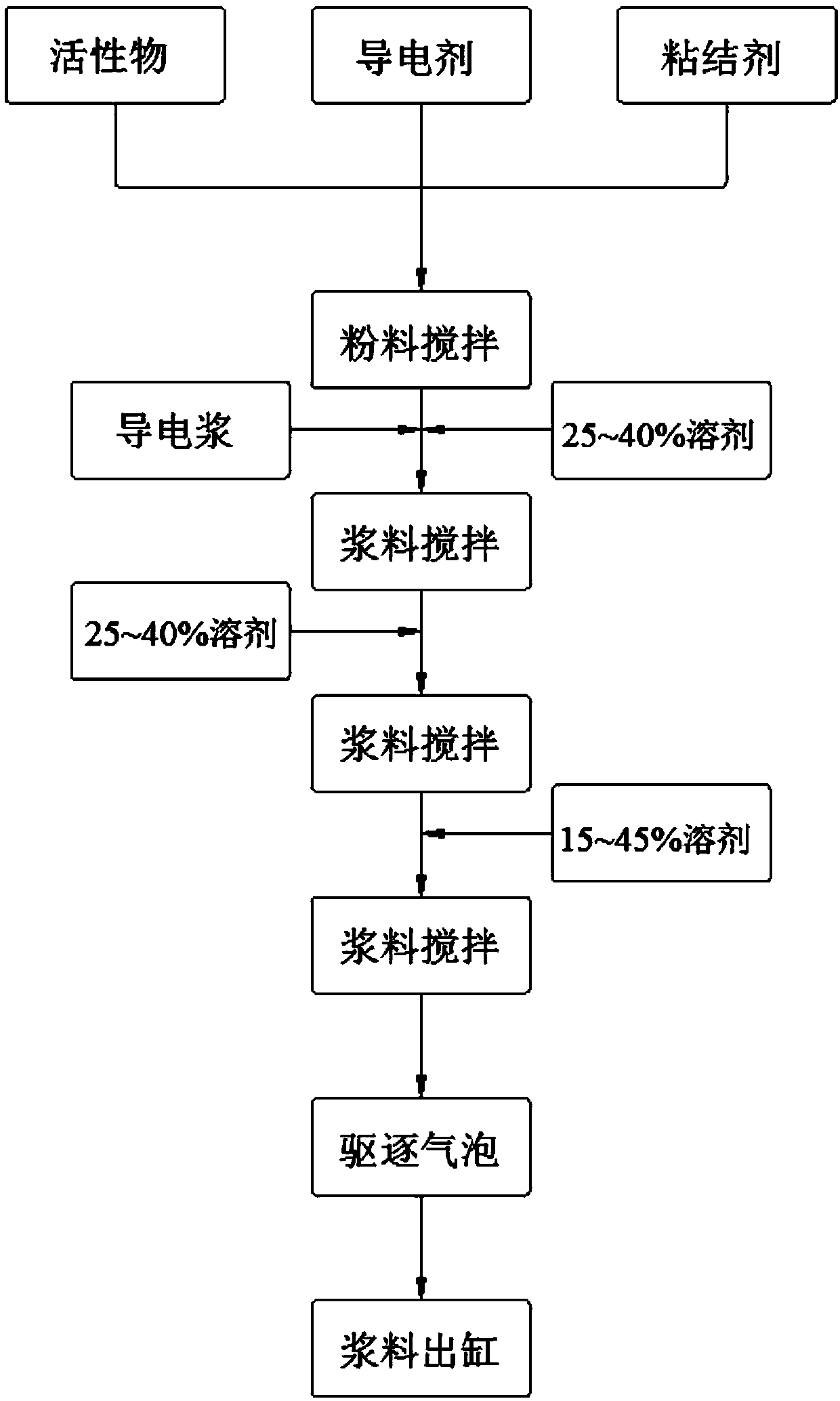

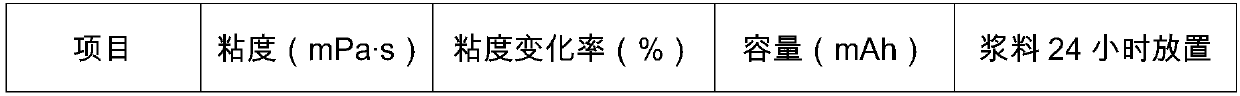

Preparation process of lithium ion oil slurry without glue and oily electrode slurry

InactiveCN109546074AImprove stability and consistencyImprove consistency and safety and cycle lifeElectrode manufacturing processesSolventLithium

The invention relates to the technical field of a lithium ion cell and particularly relates to a preparation process of the lithium ion oil slurry without glue and an oily electrode slurry. The methodcomprises steps that an active material, a conductive agent and a binder are dry-mixed and stirred to form a mixed powder having the solid content of 90-80%; a conductive slurry and a solvent are added to the mixed powder and then stirred to obtain the slurry having the solid content of 80-70%; after a solvent is added to the mixed powder, the slurry having the solid content of 70-60% is obtainedafter stirring; a solvent is further added to the slurry and is then stirred; a revolutionary paddle is made to rotate in reverse to remove all the bubbles to the surface of the slurry; the slurry isfiltered and discharged. The method is advantaged in that operation is simple, the method is suitable for an automatic feeding system, the whole mixing time can be controlled within 3.5-7 hours according to difference of main materials, the utilization rate of equipment is improved, and performance of the slurry is made to be more uniform and more stable.

Owner:福建冠城瑞闽新能源科技有限公司

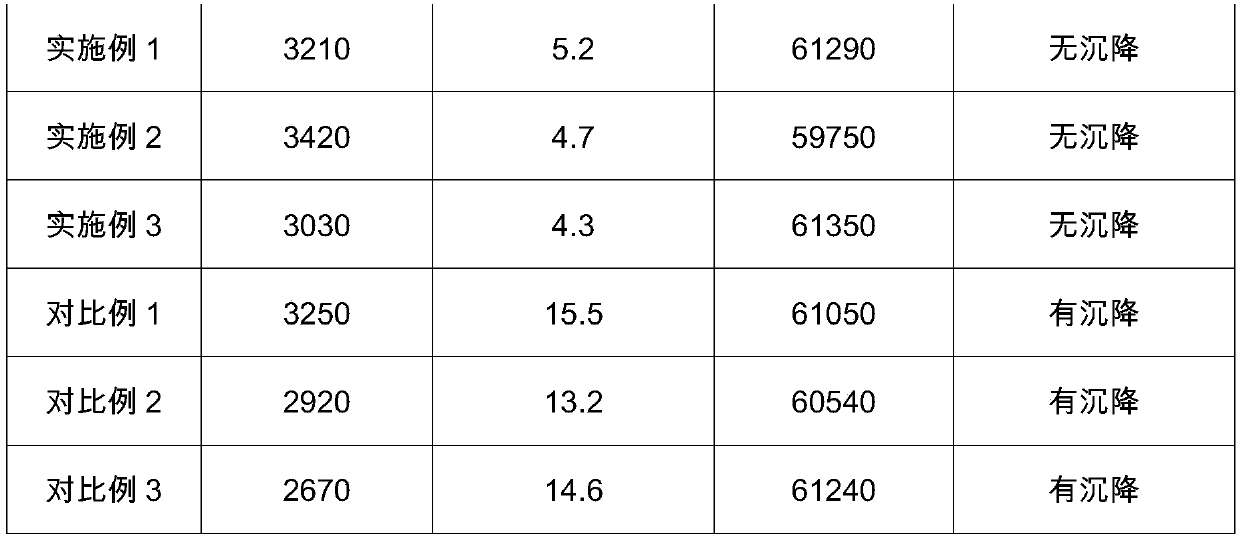

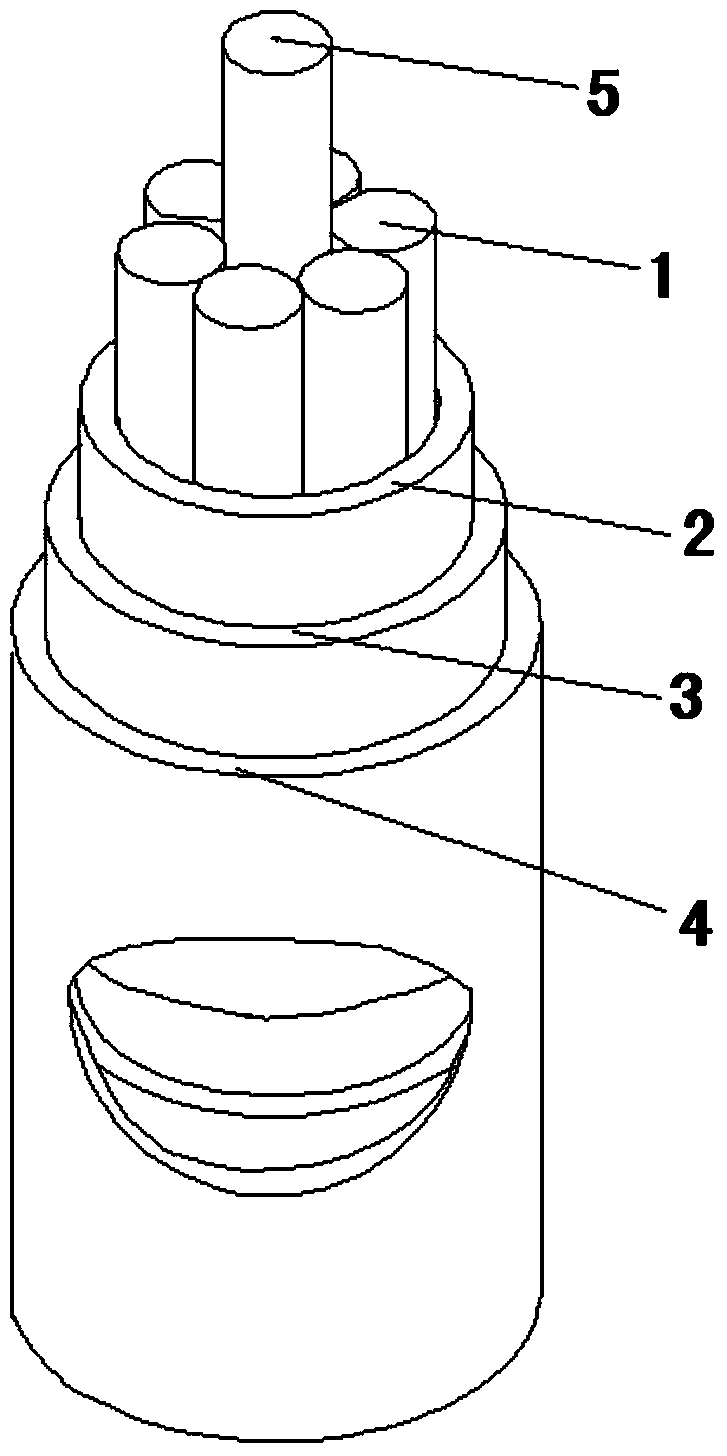

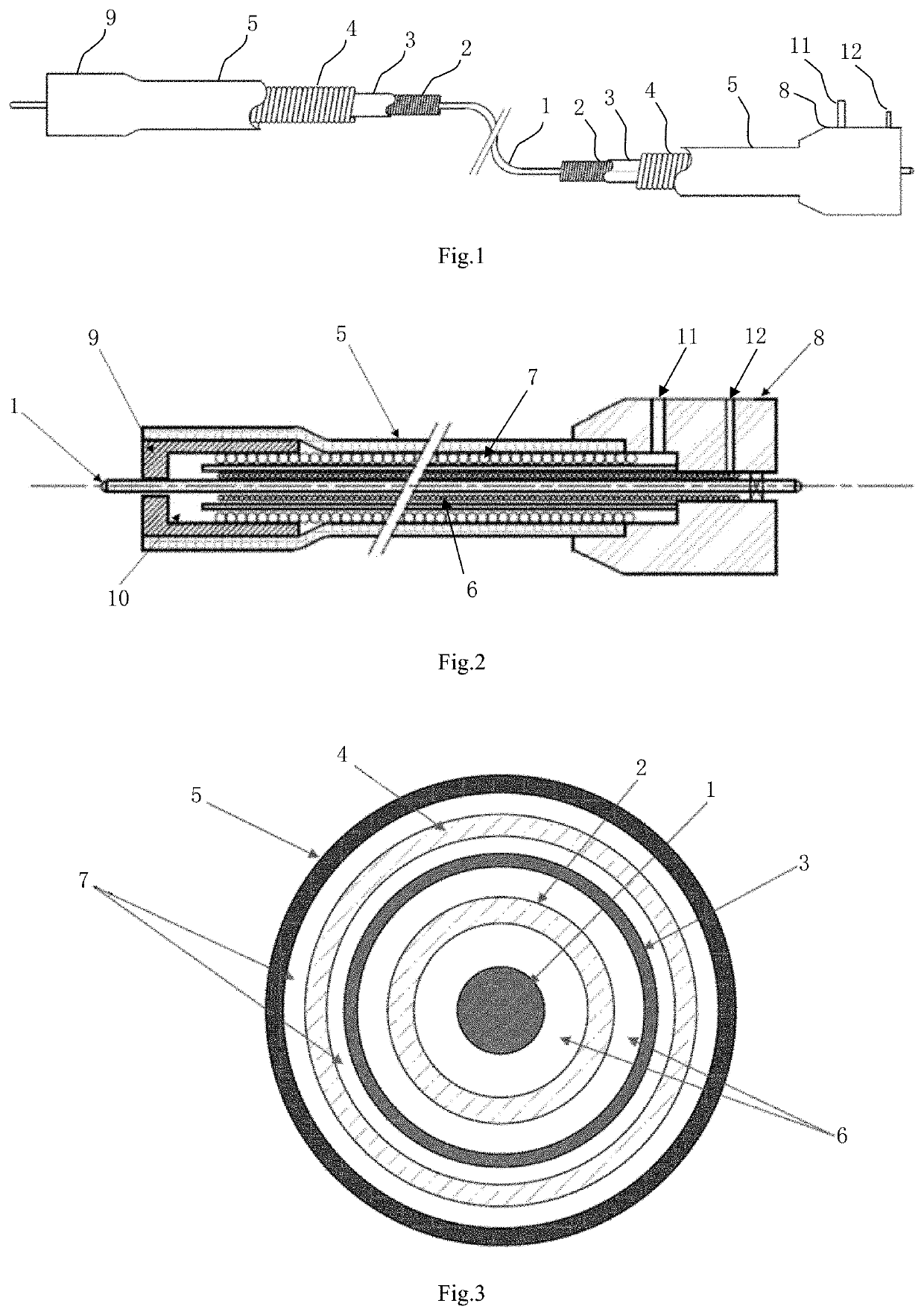

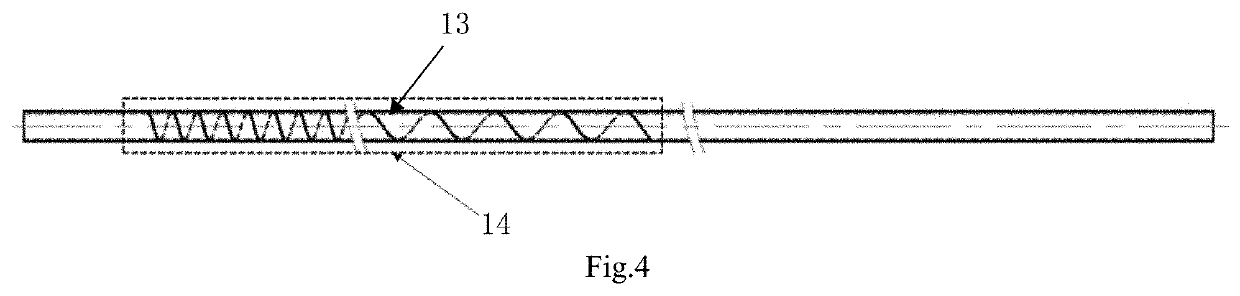

Multi-section cable type measuring electrode of admittance or capacitance level meter

InactiveCN103542910AImprove stability and consistencyHigh measurement accuracyLevel indicators by physical variable measurementCapacitanceMeasurement precision

The invention relates to a multi-section cable type measuring electrode of an admittance or capacitance level meter. The multi-section cable type measuring electrode of the admittance or capacitance level meter comprises a plurality of shielded conductors, a first insulating layer arranged on the periphery of the shielded conductors, a metal shielding layer arranged on the periphery of the first insulating layer, and a second insulating layer arranged on the periphery of the metal shielding layer, wherein the metal shielding layer is of a sectioned structure, the sections of the metal shielding layer correspond to the shielded conductors in a one-to-one mode, and each section of the metal shielding layer serves as an independent measuring electrode and is electrically connected with the corresponding shielded conductor. The multi-section cable type measuring electrode of the admittance or capacitance level meter has the advantages that as a flexible structure is adopted to replace a rigid structure, the weight of a sensor is reduced; the multi-section cable type measuring electrode of the admittance or capacitance level meter is suitable for measuring the material level of liquid and slurry materials, and can be suitable for measuring the material level of solid materials after a flexible protective device is additionally arranged on the periphery of the electrode; the multi-section cable type measuring electrode is used in cooperation with an intelligent multi-channel admittance (capacitance) transducer so that the changes of physical properties of the materials can be automatically tracked, and automatic calibration can be achieved; the performance of external environment interference resistance and high measurement precision are improved.

Owner:于浩业 +1

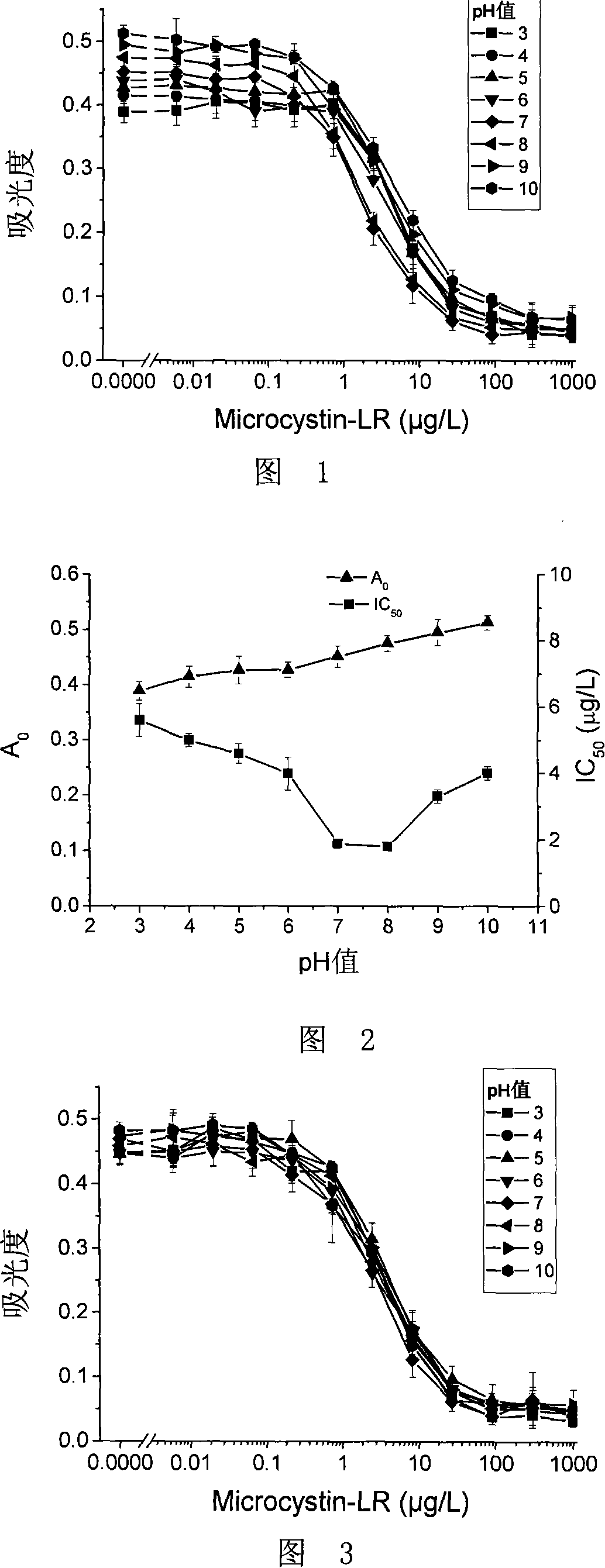

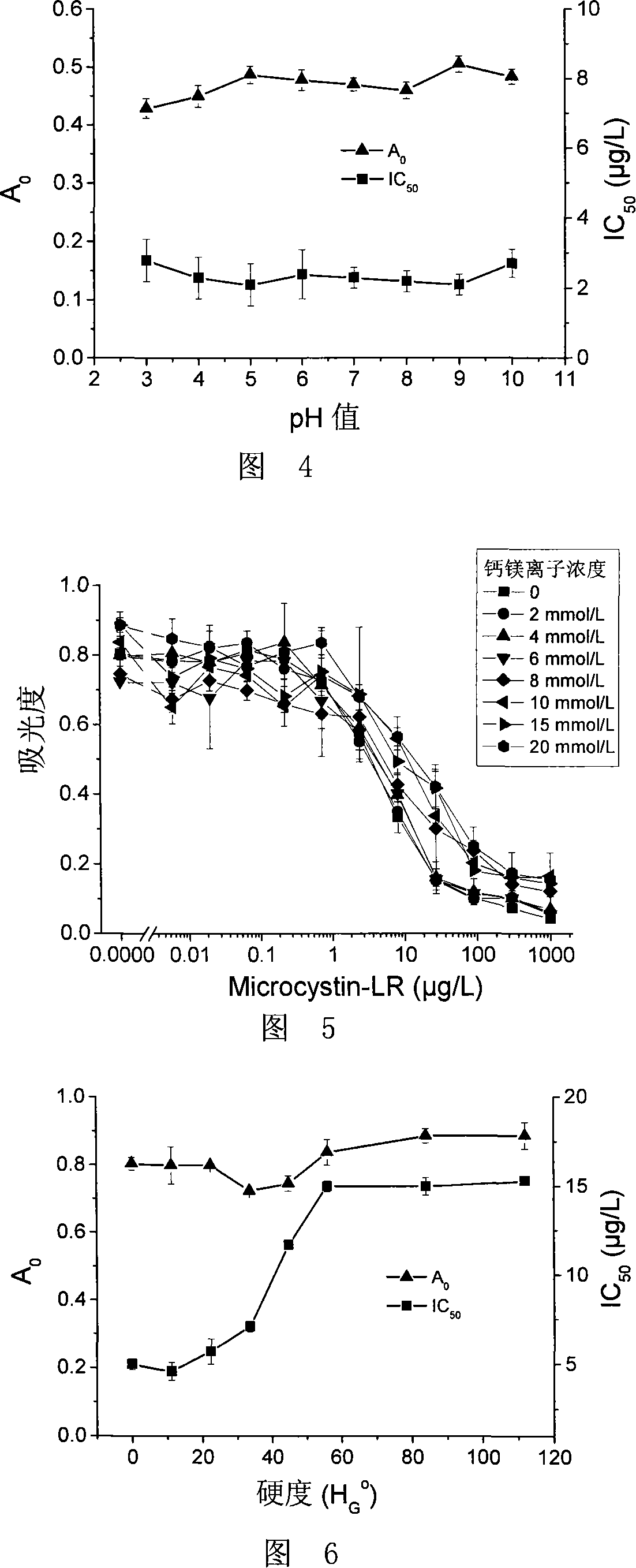

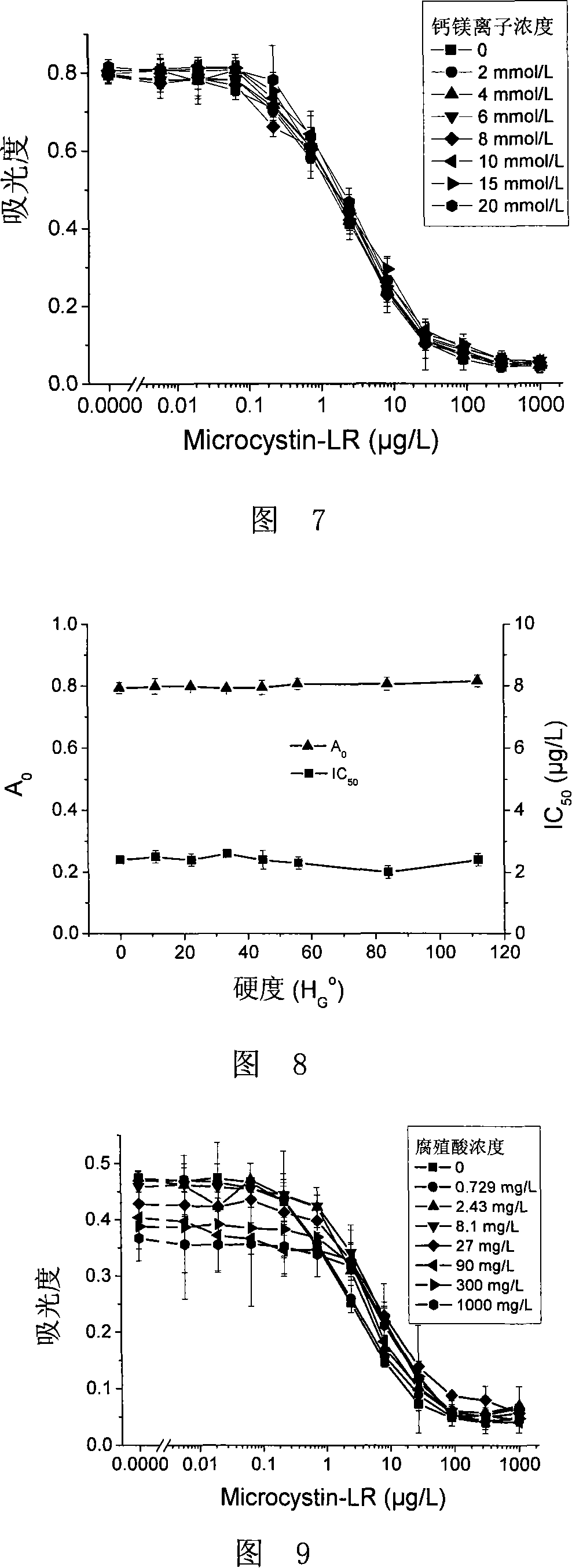

Method for increasing anti matrix effect in immunity detection for environmental sample, and dedicated buffer solution

ActiveCN101093223AImprove stabilityImprove stability and consistencyPreparing sample for investigationBiological testingComplexonsEnvironmental chemistry

A special buffer solution of raising anti-substrate effect of environment sample immune-detection is prepared for adding NaCI as making its final concentration be 10-100g / L and adding inert protein as making its final concentration be 2-20g / L as well as adding complexon III as making its final concentration be 2-20g / L into existed buffer solution with concentration of 0.05-0.12mol / L and pH value of 7.0-8.0.

Owner:TSINGHUA UNIV

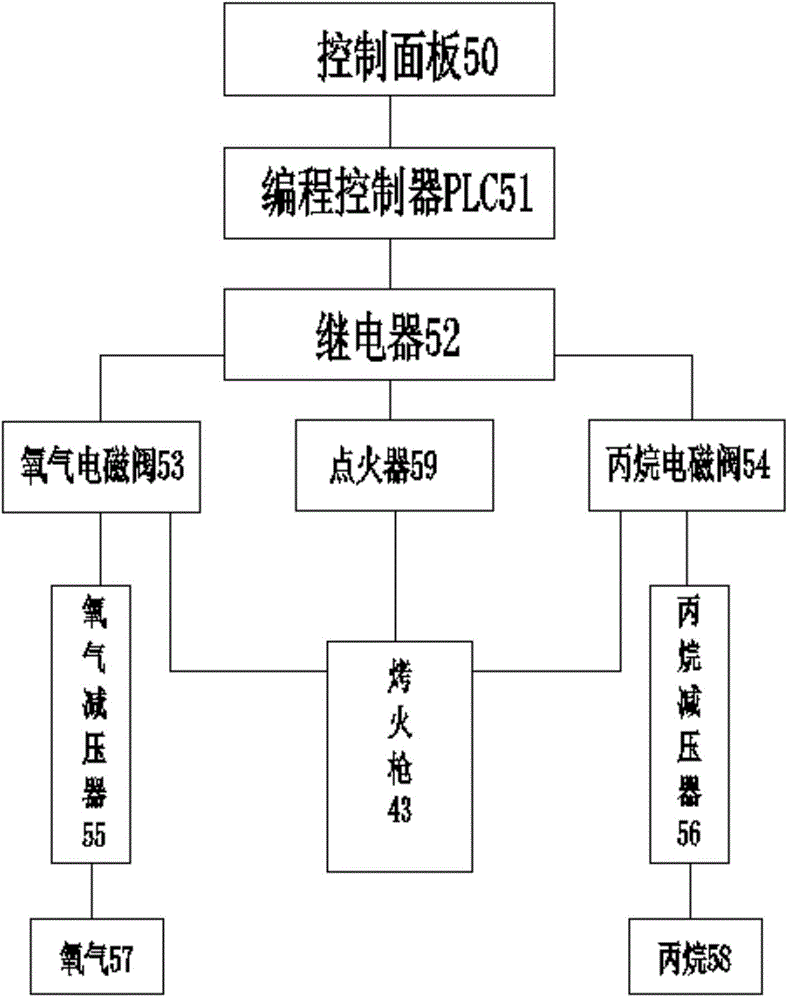

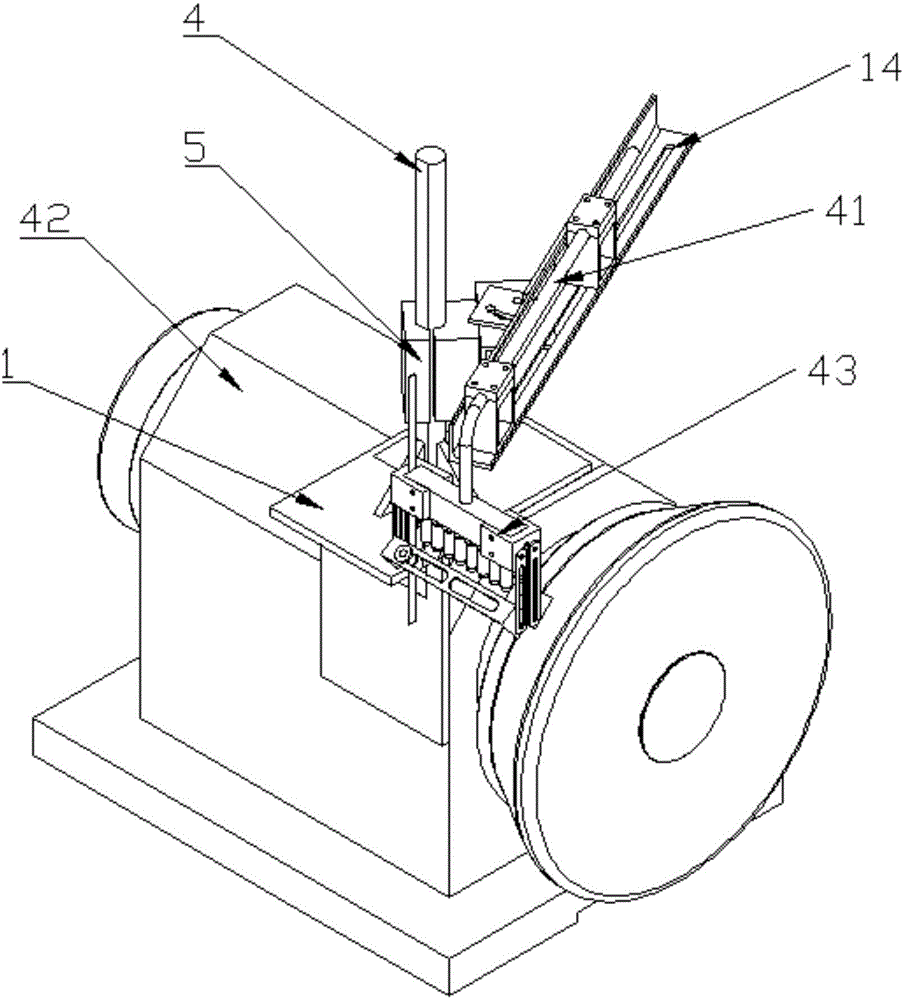

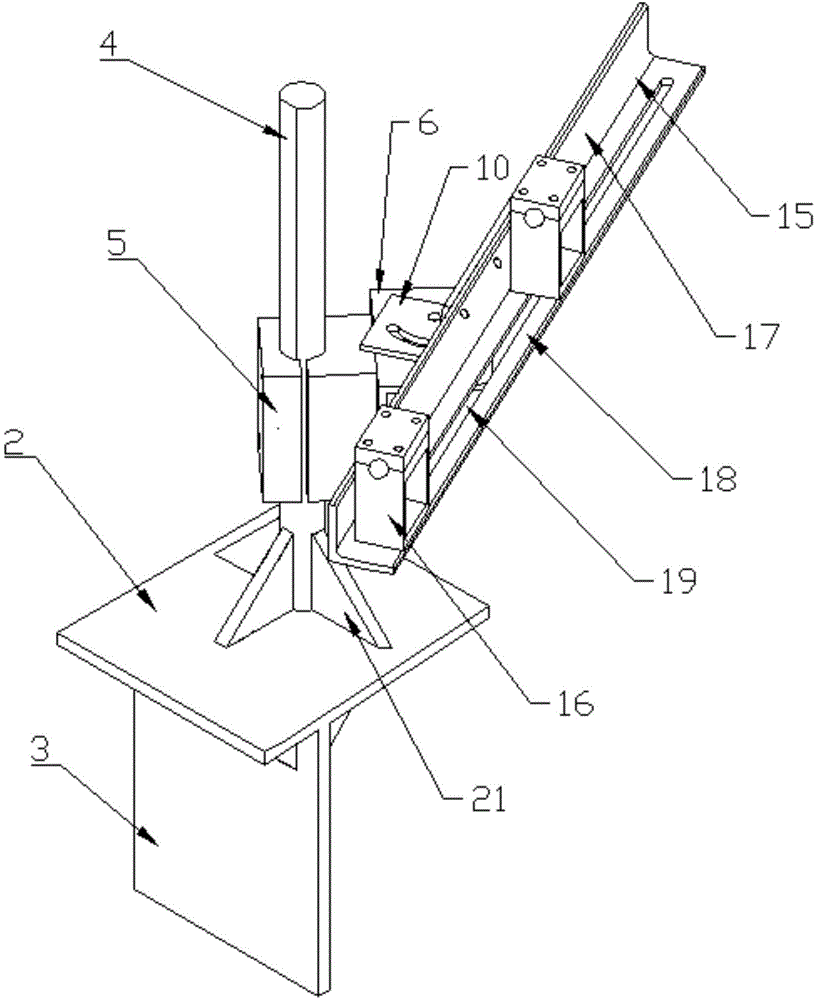

Automatic firing system for spinning hot necking machine

ActiveCN104525764AImprove stability and consistencyGuaranteed stabilityMake-and-break ignitionHollow articlesSpray nozzleGas pipeline

The invention relates to an automatic firing system for a spinning hot necking machine. The automatic firing system comprises a supporting device arranged on the necking machine, a firing gun mounted on the supporting device and a firing control system connected with the firing gun. The firing gun comprises a gun head base, a spray nozzle arranged on the gun head base, an ignition rack located on the side edge of the gun head base, an ignition electrode arranged on the ignition rack, and a gas pipeline connected with the gun head base. The firing control system comprises a control panel, a PLC connected with the control panel through a wire, a relay connected with the PLC through a wire, a gas electromagnetic valve and an igniter, wherein the gas electromagnetic valve and the igniter are both connected with the relay through wires. The gas electromagnetic valve is connected with a gas pipeline placed on the top of the gun head base and a gas cylinder pipeline containing gas, and the igniter is connected with the ignition electrode through a wire. The automatic firing system can guarantee the personal safety of technical personnel, further lower the labor intensity of the technical personnel, and improve the production rate, the product quality and the processing precision.

Owner:SHENYANG OUSHIDUN NEW MATERIAL TECH

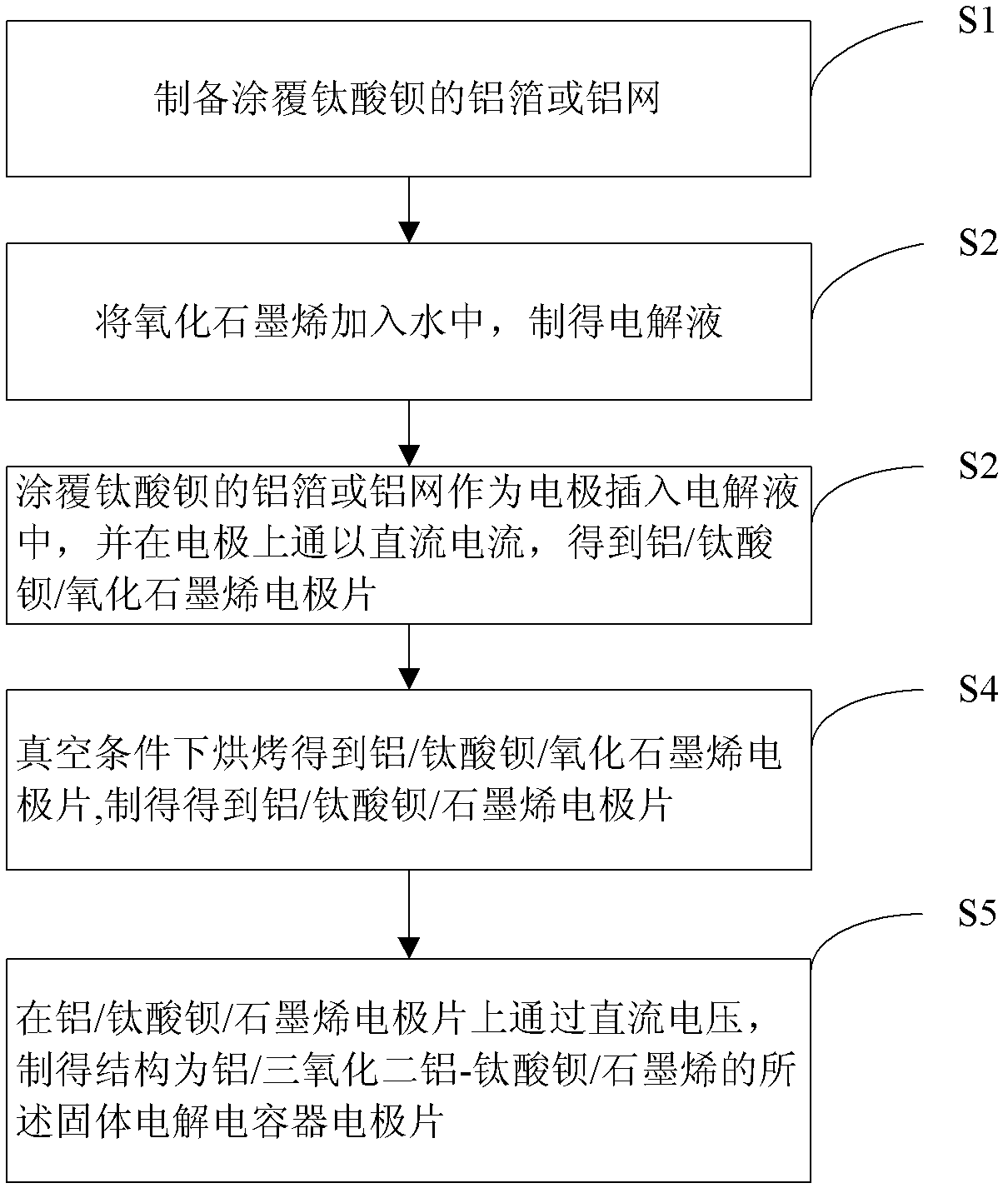

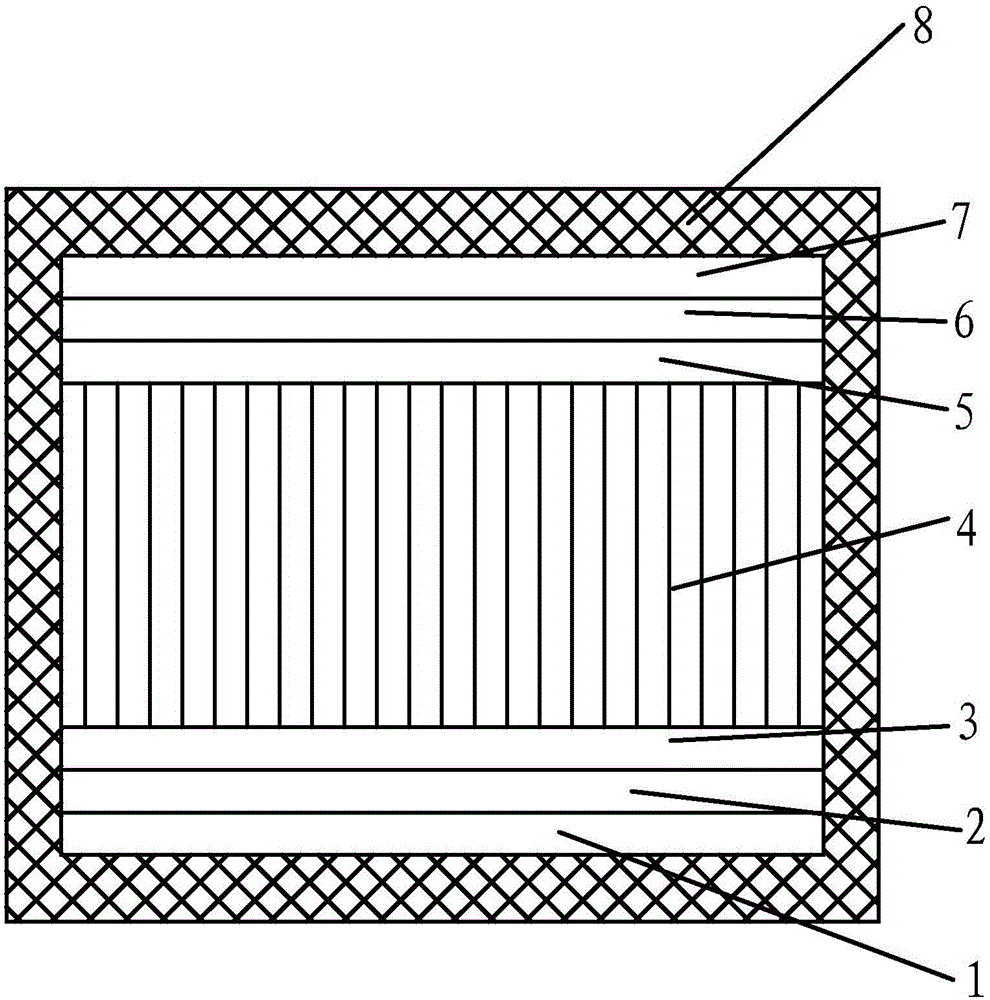

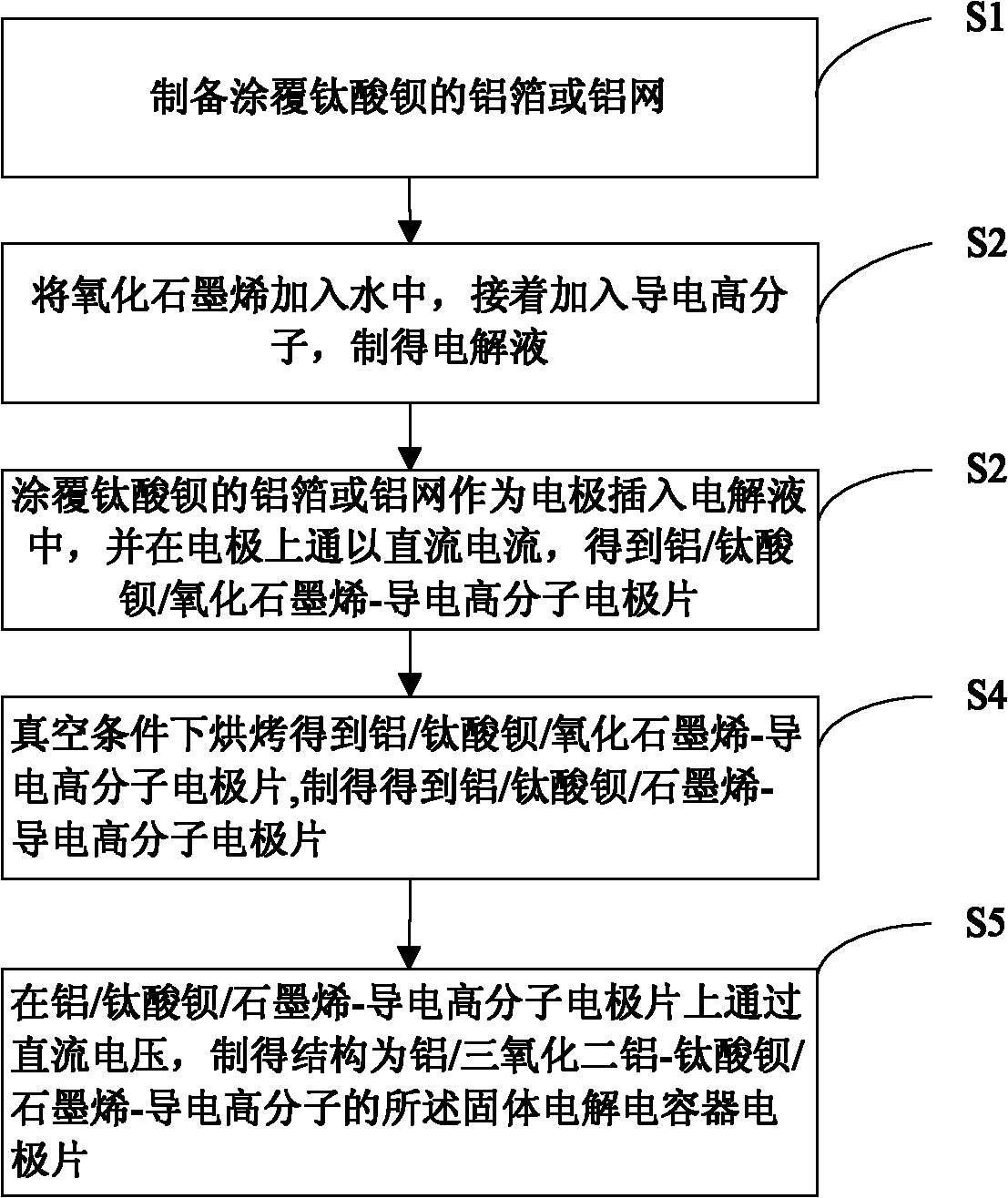

Composite type solid electrolytic capacitor electrode slice and preparation method thereof

ActiveCN102810401AImprove stability and consistencySimple preparation processSolid electrolytic capacitorsCapacitor electrodesAluminiumGraphene

The invention discloses a composite type solid electrolytic capacitor electrode slice and a preparation method thereof, belonging to the field of capacitor electrodes. The composite solid electrolytic capacitor electrode slice is structurally made of aluminum / aluminum oxide-barium titanate / graphene. As the graphene is used for taking the place of a conductive macromolecule electrolyte material, the composite solid electrolytic capacitor electrode slice provided by the invention has excellent stability and consistency; and moreover the electrode slice is simple in preparation process, low in cost and is applicable to industrial production.

Owner:OCEANS KING LIGHTING SCI&TECH CO LTD +1

Machine-woven wire-drawn air cushion and production method therefor

ActiveCN106393832AImprove stability and consistencyGood mechanical strengthSynthetic resin layered productsLaminationHoneycombWoven fabric

The invention provides a machine-woven wire-drawn air cushion and a production method therefor. The machine-woven wire-drawn air cushion comprises an air cushion body, wherein the air cushion body comprises a first PVC (Polyvinyl Chloride) film, a first gridding fabric, a first machine-woven fabric, a wire-drawn fabric, a second machine-woven fabric, a second gridding fabric and a second PVC film sequentially from bottom to top; the first PVC film is connected with the first gridding fabric through binding, the first gridding fabric is connected with the first machine-woven fabric through weaving, the first machine-woven fabric is connected with the wire-drawn fabric through weaving, the wire-drawn fabric is connected with the second machine-woven fabric through weaving, the second machine-woven fabric is connected with the second gridding fabric through weaving, and the second gridding fabric is connected with the second PVC film through binding; and the periphery is wrapped with a buffer layer, honeycomb pores are formed in the buffer layer, the pore size of each honeycomb pore gradually increases from outer side to inner side, the sidewall of each honeycomb pore is an elastic support wall, through pores are formed in the elastic support walls, and the pore size of the through pores is smaller than that of the honeycomb pores. According to the machine-woven wire-drawn air cushion and the production method therefor, the rising stability and consistency of stress are improved.

Owner:浙江华生科技股份有限公司

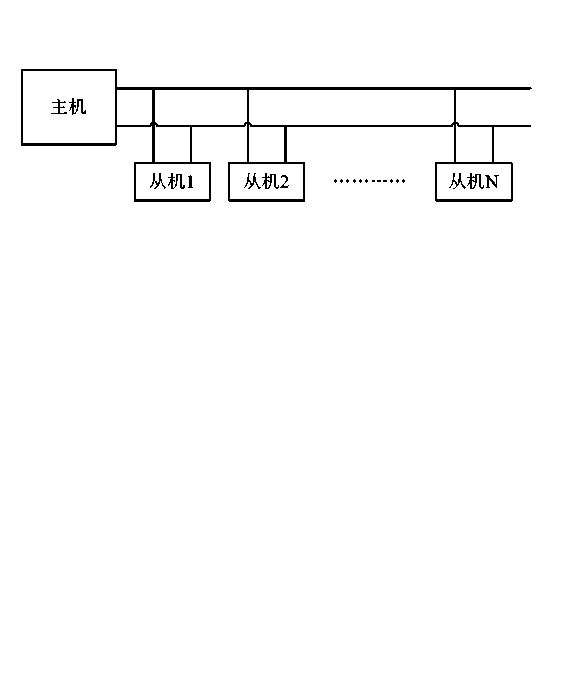

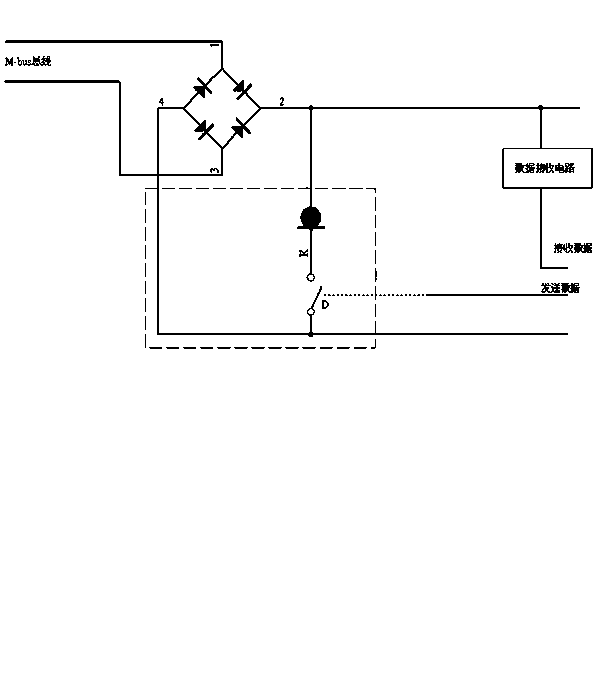

Current regulative diode circuit of meter bus slave interface

ActiveCN103728951ACommissioning production indirect fastImprove stability and consistencyTotal factory controlProgramme total factory controlTransmission lineControl switch

The invention discloses a current regulative diode circuit of a meter bus slave interface. The current regulative diode circuit of the meter bus slave interface comprises a bridge rectifier circuit, a constant current circuit, a data receiving circuit and a data sending circuit. The two input ends of the bridge rectifier circuit are used for being connected with two transmission lines of a meter bus respectively. The first output end of the bridge rectifier circuit is respectively connected with the input end of the constant current circuit and the data receiving circuit. The constant current circuit comprises at least one current regulative diode. The output end of the constant current circuit is connected to the second output end of the bridge rectifier circuit through a switch circuit. The data receiving circuit is provided with a data receiving port and is used for receiving data. The data sending circuit is provided with a data sending port and is used for sending data. The control end of the switch circuit is connected with the data sending circuit and is used for controlling switching-on and switching-off of the switch circuit according to the data sent by the data sending circuit.

Owner:深圳市源啓智能科技有限公司

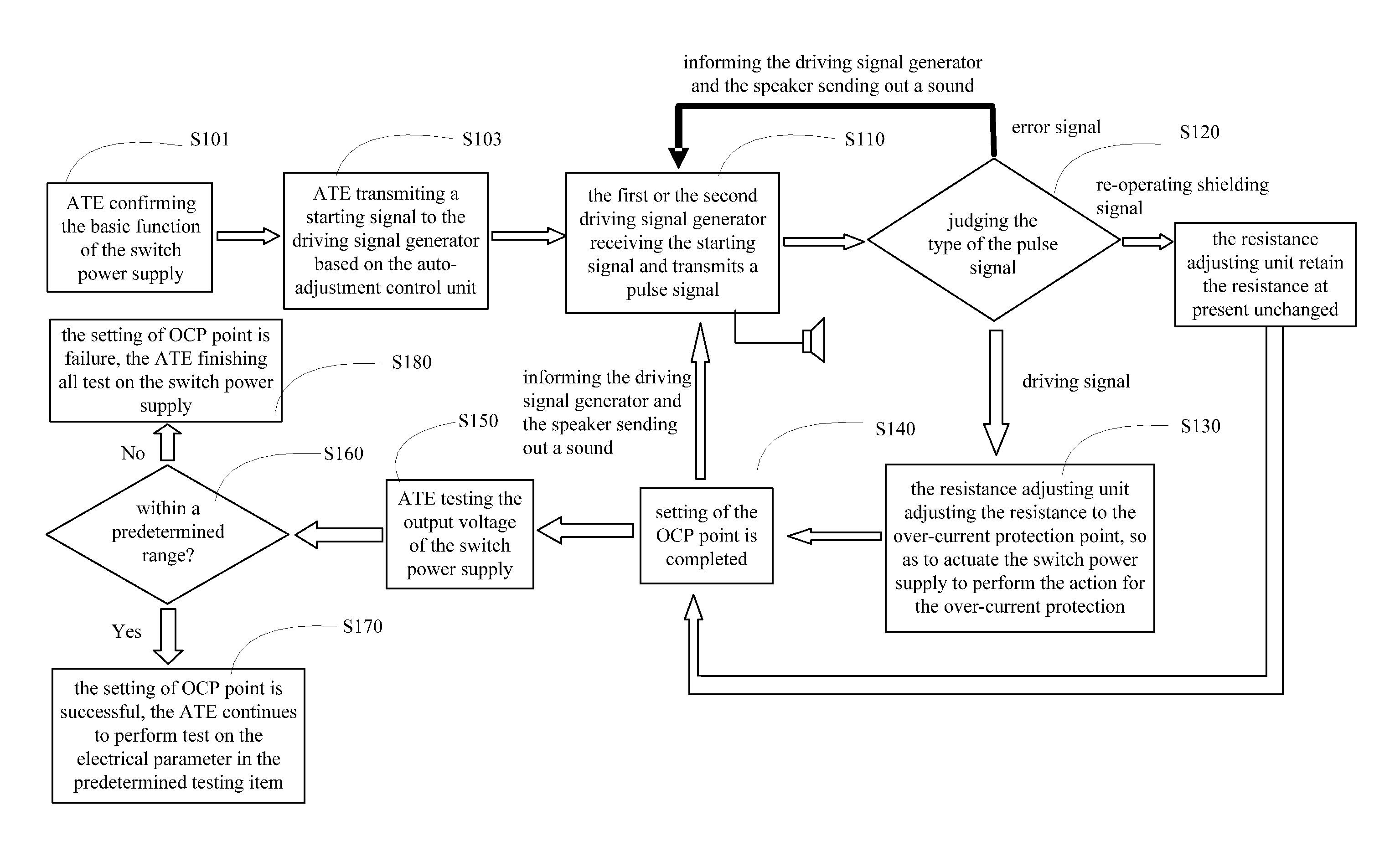

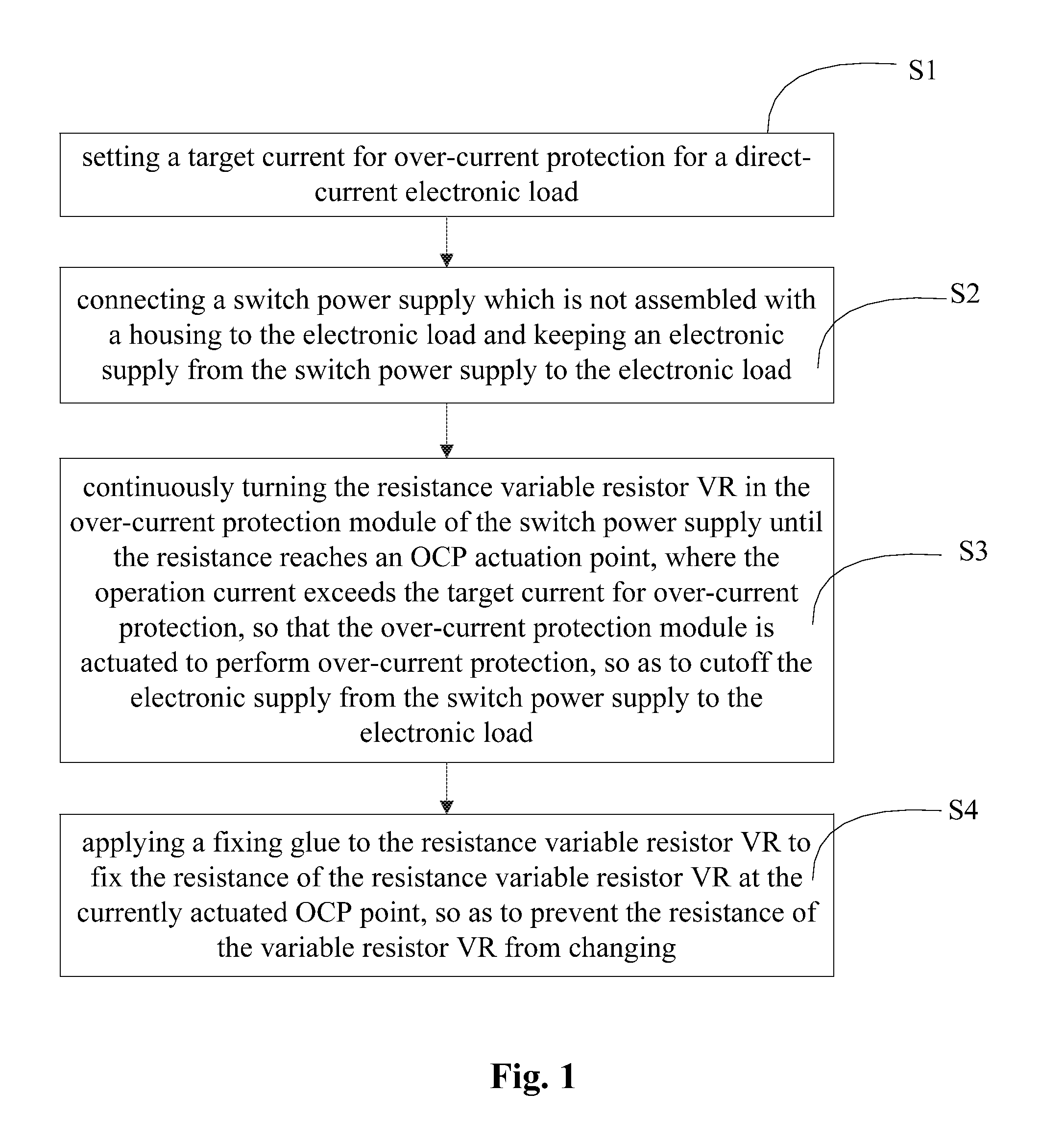

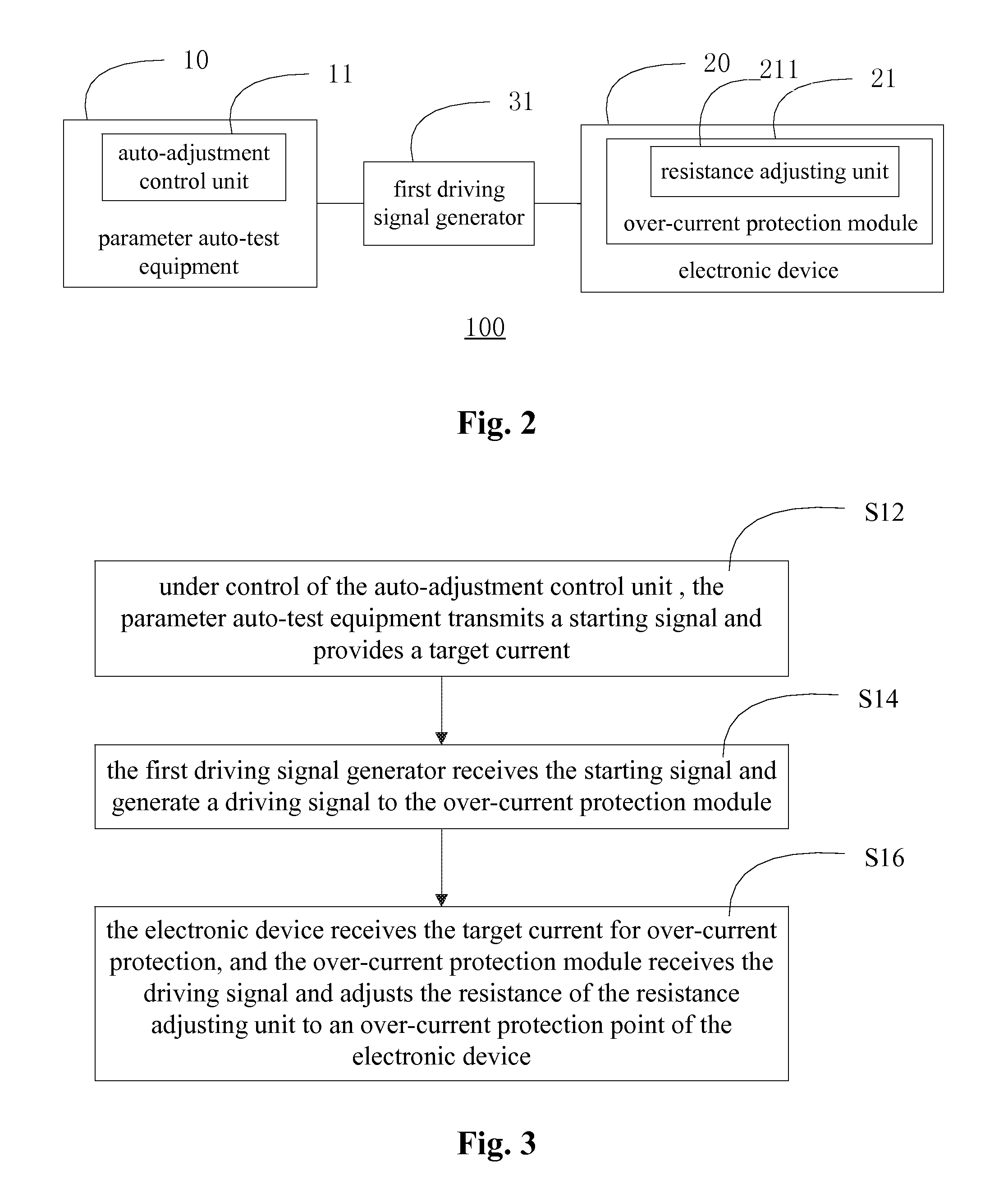

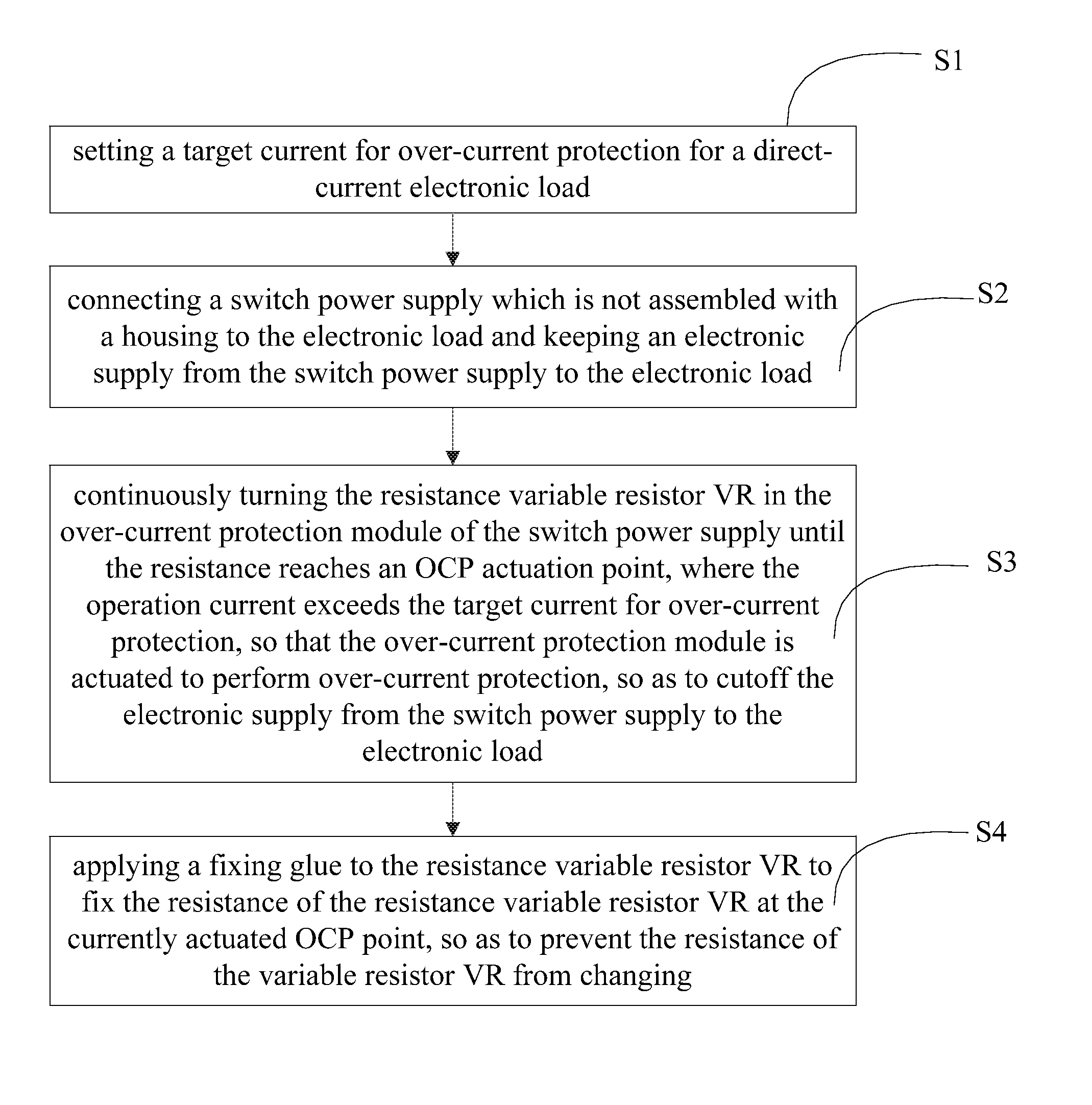

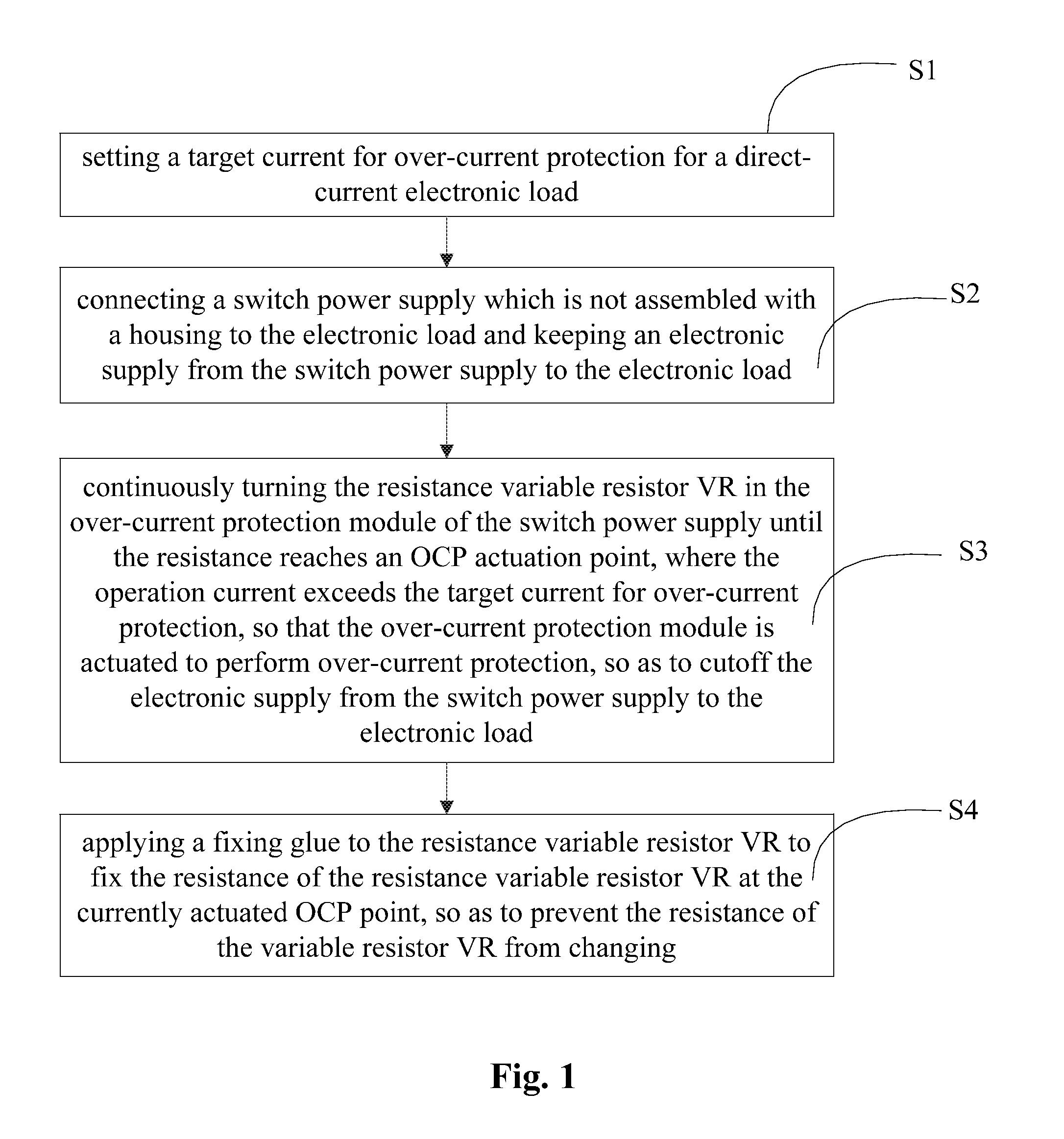

Method, system, and control apparatus for setting over-current protection point of electronic device

InactiveUS20140002119A1Save labor costImprove stability and consistencyParameter calibration/settingElectrical testingStart signalEngineering

The invention discloses a method, a system, and a control apparatus for setting an over-current protection point of an electronic device. The method comprises: step 1, the parameter auto-test equipment transmitting a starting signal and outputting a target current for over-current protection based on the auto-adjustment control unit; step 2, the first driving signal generator receiving the starting signal and transmitting a driving signal to the over-current protection module; and step 3, the electronic device receiving the target current for over-current protection, and the over-current protection module receiving the driving signal and adjusting a resistance of the resistance adjusting unit to the over-current protection point of the electronic device. The invention attains fully automatic operation on the over-current protection point of the electronic device, improves stability and consistency of setting the over-current protection point, and saves labor cost at the same time.

Owner:DELTA ELECTRONICS SHANGHAI CO LTD

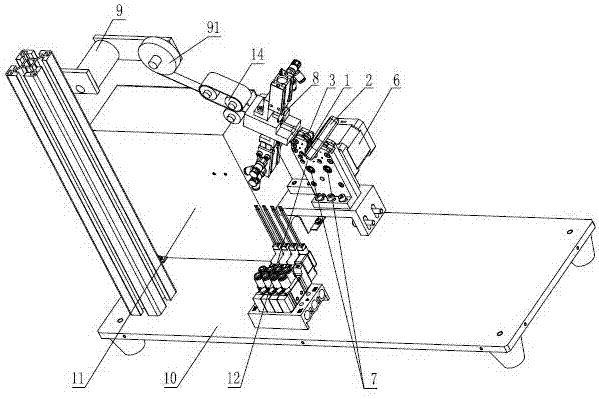

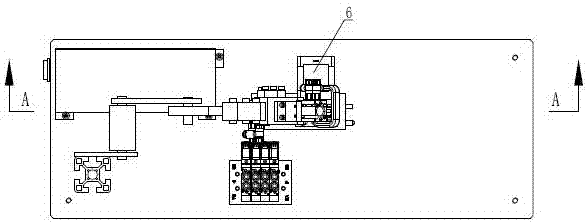

Automatic tape coating machine

InactiveCN106981959AImprove stability and consistencyReduce labor intensityApplying solid insulationElectrical and Electronics engineeringAdhesive belt

The invention provides an automatic tape coating machine. The automatic tape coating machine comprises a frame, a protection board, a power producer, a transmission mechanism, a center winding wheel, a winding wheel centering mechanism, a tape cutting mechanism, a roller tape conveying mechanism, an electric control system, a tape support and a tape, wherein the roller tape conveying mechanism is used for conveying the tape to a notch of a radial slot of the center winding wheel, one end of the tape is pushed by a motor coil into the radial slot of the center winding wheel, the tape is cut by the tape cutting mechanism, the center winding wheel is made to rotate by the power producer through the transmission mechanism, the tape is driven to wind around the motor coil through rotation of the center winding wheel, the center winding wheel is supported by the winding wheel centering mechanism, and the roller tape conveying mechanism can be replaced by combination of a tape clamping mechanism and a tape drawing mechanism. The automatic tape coating machine is advantaged in that an automatic solution scheme is provided for tape coating work of the motor coil for replacing manual work of tape coating of the motor coil in the prior art.

Owner:SHENZHEN SWIFT AUTOMATION TECH CO LTD

Composite material cap-type stringer forming device

ActiveCN110561788APrevent folds from overlappingImprove stability and consistencyMoulding deviceLinear drive

The invention relates to the technical field of hot die pressing forming, in particular to a composite material cap-type stringer forming device. The composite material cap-type stringer forming device comprises a lower die and an upper die, wherein the upper die comprises a cap top upper die and a side upper die, and the side upper die is connected with the cap top upper die through a second linear driving part; a limiting equal-height column is fixed on the lower surface of the side upper die; a guide hole corresponding to the limiting equal-height column is formed in the lower die; a sliding cavity communicates with the lower portion of the guide hole; a heightening plate is arranged in the sliding cavity; the heightening plate is connected with a transverse driving piece fixed on a lower base frame; and the transverse driving piece drives the heightening plate to move in the sliding cavity. According to the composite material cap-type stringer forming device, the limiting equal-height column and the heightening plate are arranged on the side upper die, so that the distance between the upper die and the lower die when the upper die is pressed down is changed, prepregs on two sides of a cap top are uniformly and smoothly shrunk towards the middle under the action of friction force between the upper die and the lower die when the cap top is pressed down, and the consistency and stability of product molding are improved.

Owner:常州新创航空科技有限公司

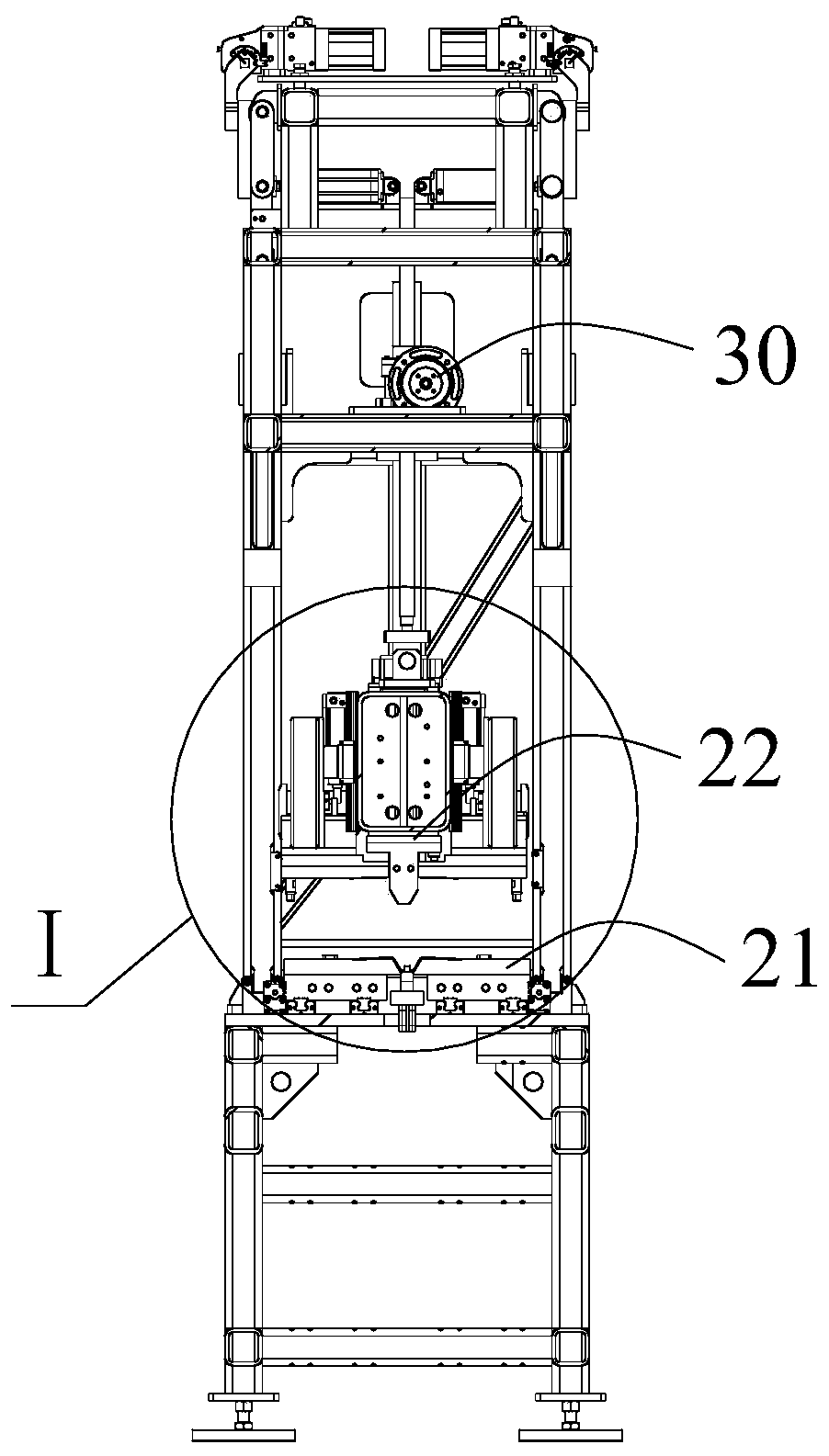

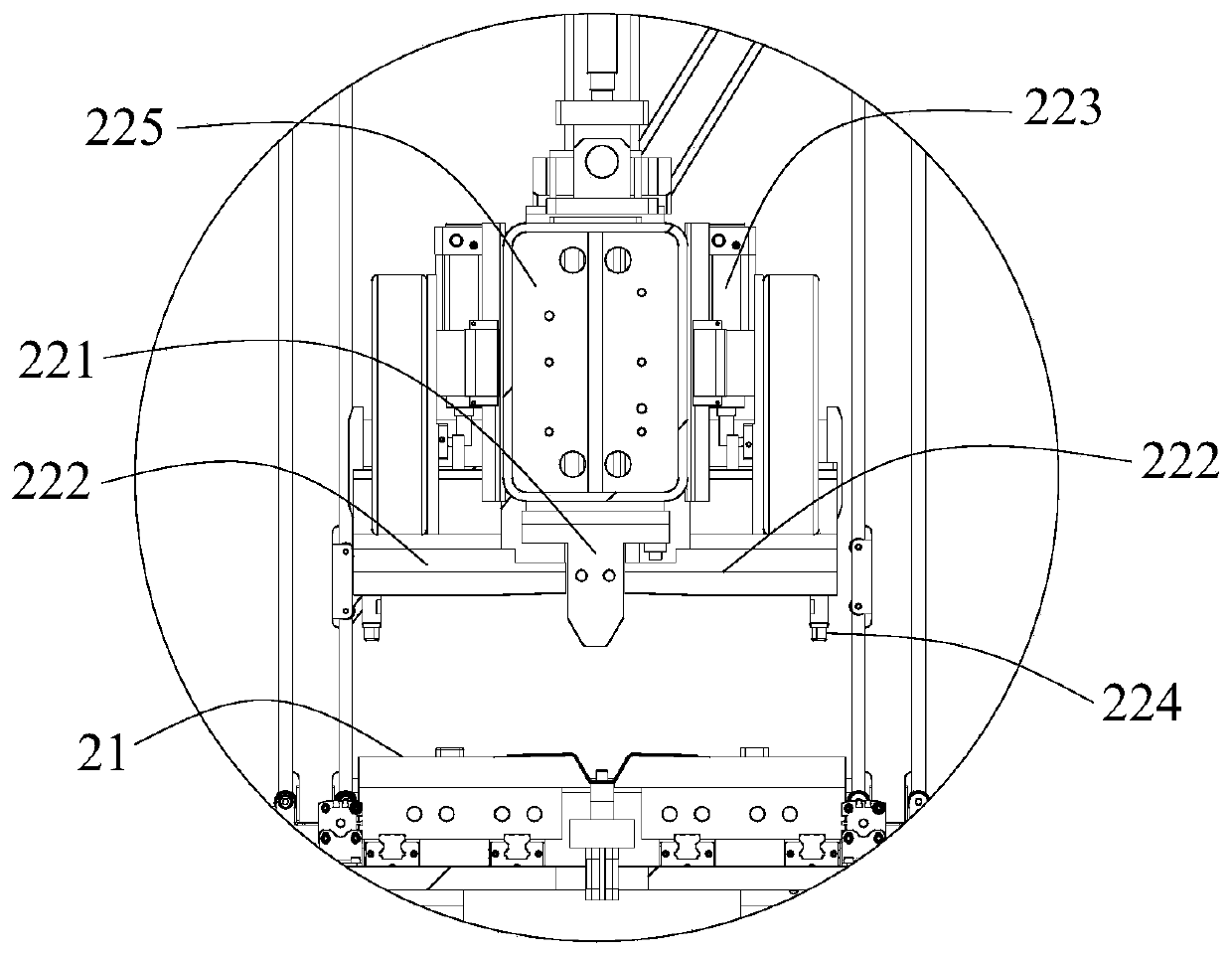

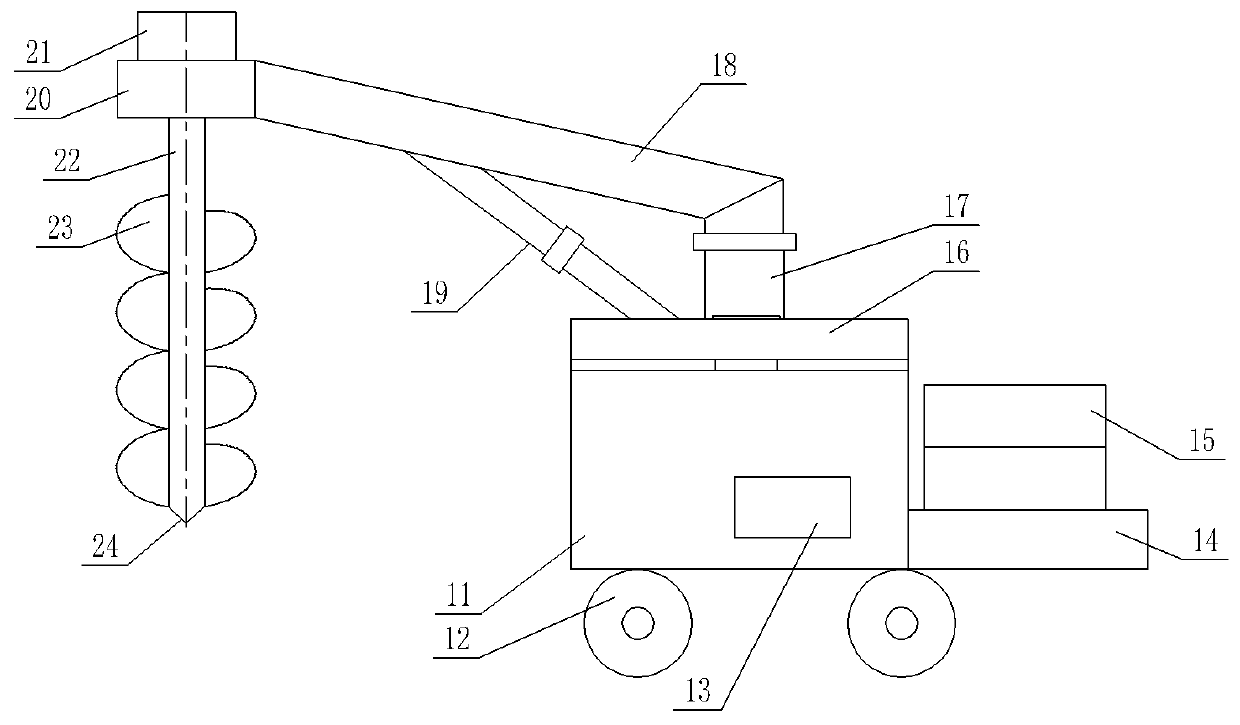

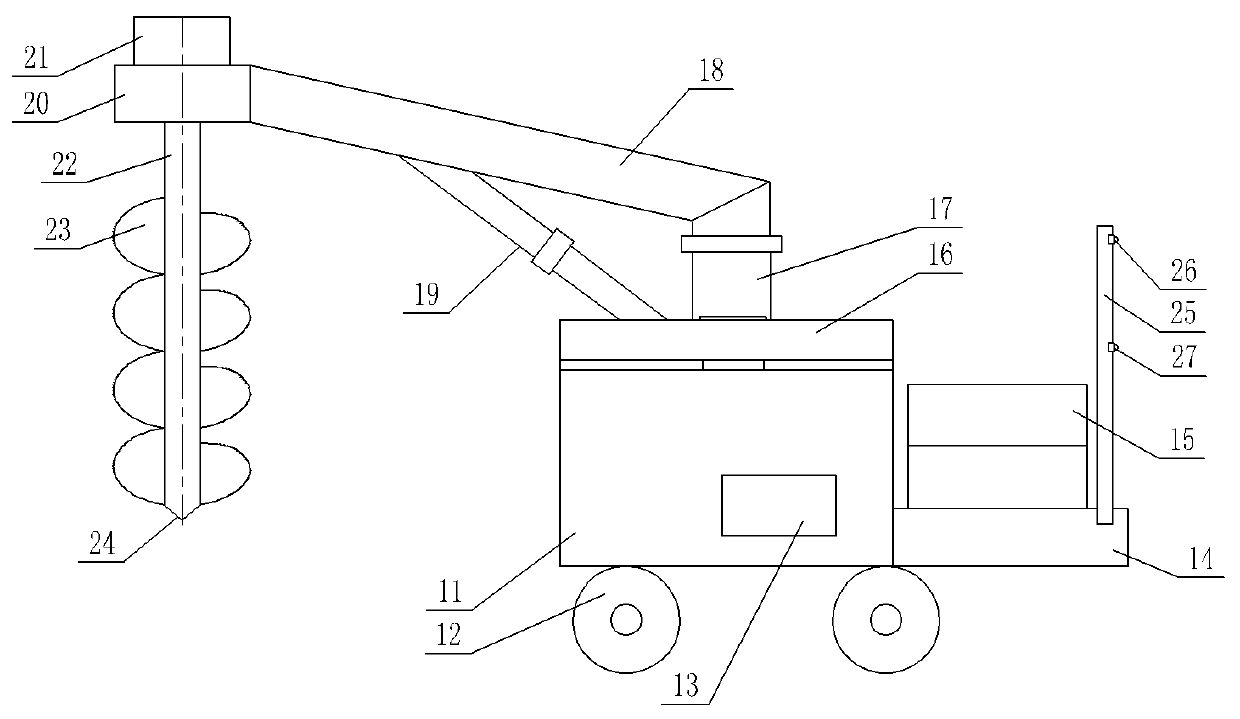

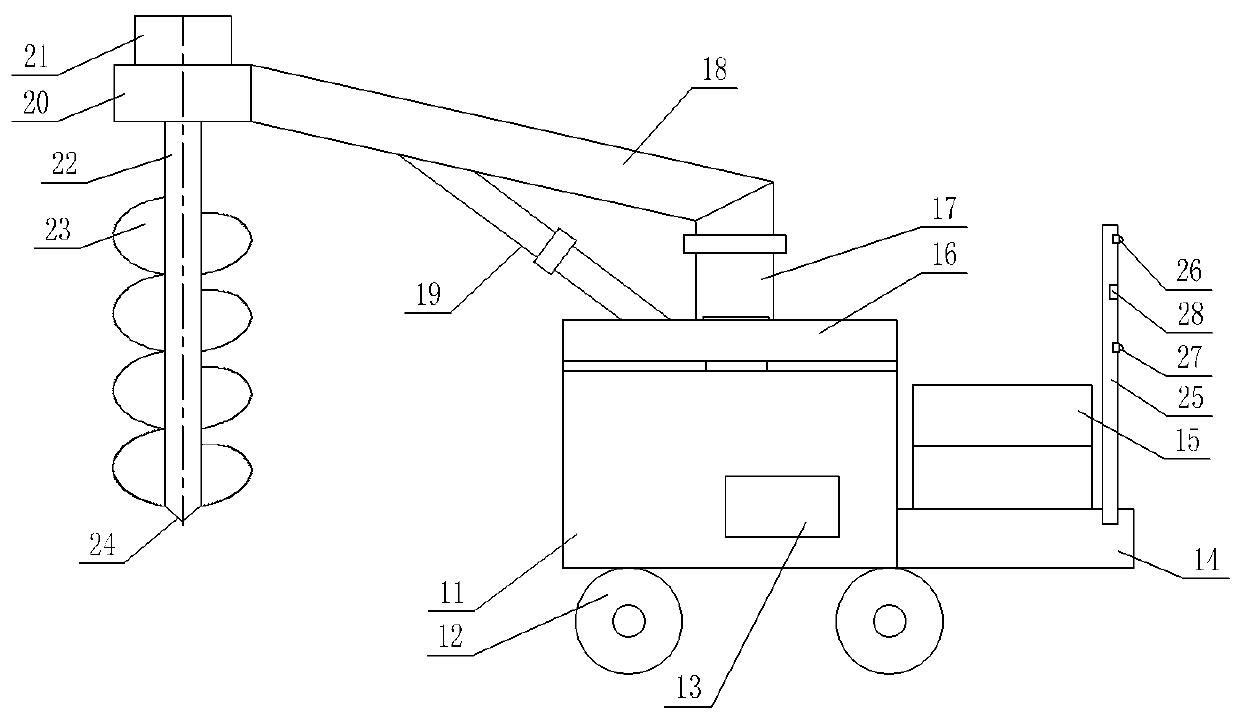

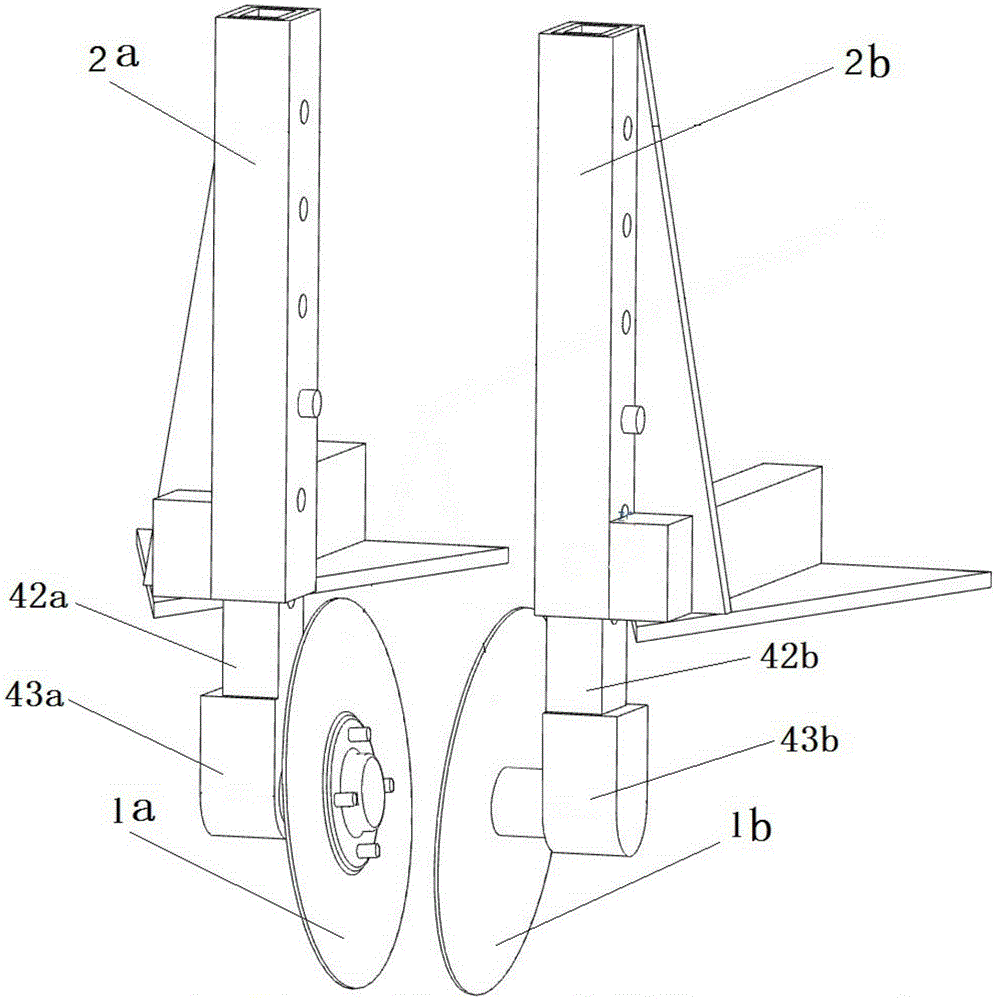

Electric pole pit groove digging device

InactiveCN110700342AImprove stability and consistencyThe depth is easy to controlSoil-shifting machines/dredgersStructural engineeringDistance sensors

The invention discloses an electric pole pit groove digging device. The electric pole pit groove digging device comprises a frame, a rotating disc rotatably connected to the frame, a lifting mechanismconnected to the rotating disc, a digging knife assembly connected to the lifting mechanism for digging a pit groove, a counterweight assembly fixedly arranged at the rear portion of the frame and used for balancing the weight of the lifting mechanism, and a travelling mechanism arranged below the frame. According to the electric pole pit groove digging device, a pole carrying pit is excavated through mechanical automation, time and labor are saved, the construction efficiency is high, the depth of the pit groove is convenient to control, the stability consistence of carried poles is high, aposition sensor is used for aligning the front electric pole and the rear electric pole, the carried poles are guaranteed to be in a straight line, and the interval distance among the electric poles is measured and adjusted through an infrared distance sensor, so that the direction accuracy of a power transmission line is improved, and the running stability of the power transmission line is guaranteed.

Owner:STATE GRID CORP OF CHINA +1

Gear selecting and shifting positioning mechanism for gear selecting and shifting actuator

PendingCN111577887AIncreased Strength and RigidityImprove stability and consistencyControlled membersGearing controlStructural engineeringControl engineering

The invention relates to a gear selecting and shifting positioning mechanism for a gear selecting and shifting actuator. The gear selecting and shifting positioning mechanism comprises a gear selecting and shifting shaft, a gear selecting door, a limiting pin and a limiting pin mounting part. The limiting pin is arranged on the limiting pin mounting part. The gear selecting door is fixedly arranged on the gear selecting and shifting shaft, and the outer surface of the gear selecting door is provided with an open slot and a plurality of limiting grooves; and the plurality of limiting grooves are arranged at intervals in the axial direction parallel to the axis of the gear selecting and shifting shaft, and the open slot extends in the axial direction parallel to the axis of the gear selecting and shifting shaft and is vertically intersected with the plurality of limiting grooves. When the gear selecting door moves axially, the limiting pin extending into the open slot is enabled to be selectively aligned with one limiting groove; and when the gear selecting door rotates in the circumferential direction, the limiting pin extending into the open slot is enabled to enter the limiting groove aligned with the limiting pin, or the limiting pin extending into the limiting groove is enabled to enter the open slot. According to the gear selecting and shifting positioning mechanism in theinvention, the strength and rigidity of the product are increased without increasing the volume of the product, and the friction force in the gear selecting and shifting process can be reduced.

Owner:ZHEJIANG KEBODA IND

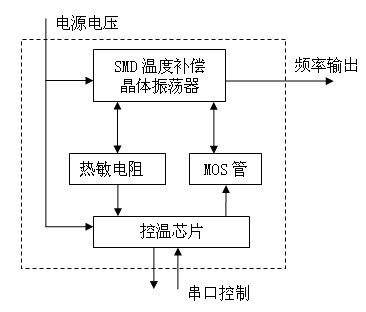

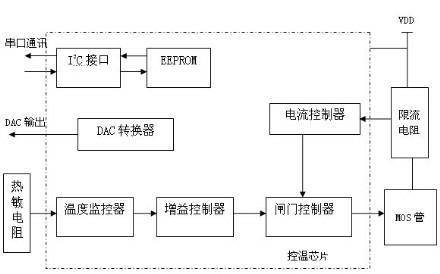

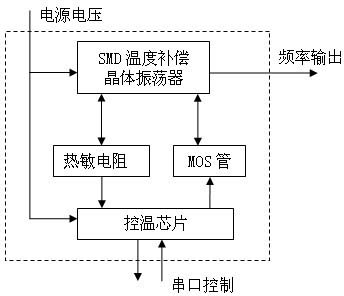

SMD (Surface Mounted Device) micro constant-temperature crystal oscillator

InactiveCN102437817AImprove stability and consistencyHighly integratedOscillations generatorsOxide semiconductorBatch production

The invention discloses an SMD (Surface Mounted Device) micro constant-temperature crystal oscillator which comprises a temperature control circuit and an SMD temperature compensation crystal oscillator connected with the temperature control circuit. The SMD micro constant-temperature crystal oscillator is characterized in that the temperature control circuit comprises a temperature control chip, a thermistor, an MOS (Metal Oxide Semiconductor) transistor and a current-limiting resistor, wherein the thermistor, the MOS transistor and the current-limiting resistor are connected with the temperature control chip respectively and the thermistor and the MOS transistor are connected with the SMD temperature compensation crystal oscillator respectively. By using the crystal oscillator, high-precision temperature control of the constant-temperature crystal oscillator in a small volume, the better uniformity and stability of the crystal oscillator and the high integration and automatic debugging of the temperature control circuit are realized, therefore the crystal oscillator has a relatively high digitalization level and the batch production of the constant-temperature crystal oscillator can be realized easily; and the crystal oscillator has the advantages of small size, low power consumption and low manufacturing cost.

Owner:CHENGDUSCEON ELECTRONICS

Technology for preparing permanent-magnet material

InactiveCN1152393CIncrease vacuumImprove stability and consistencyInorganic material magnetismRare earthSintering atmosphere

A technology for making high-performance permanent-magnet Nd-Fe-B-Cl material features that the raw blank is sintered in heat treating furnace containing gas sucking agent prepared from Zr84Al16 powder and mixed rare-earth powder through three treating stages and then cooled from 1000 to 90 deg.C at speed of 0.2-0.5 deg.C / min. Its advantages include high stability, magnetic performance and uniformity.

Owner:潘树明

Flexible Shaft Structure Insulating Wear Particles by Perfusion

PendingUS20210113752A1Reduce noiseReduce vibrationBlood pumpsMedical devicesInsulation layerWear particle

The present invention discloses a flexible shaft structure insulating wear particles by perfusion, which includes a flexible transmission shaft, a proximal holder is provided at one end of the flexible transmission shaft, a distal holder is provided at the other end of the flexible transmission shaft, a constraint insulator and an outer sheath tube are provided outside the flexible transmission shaft, and the constraint insulator sequentially includes an inner constraint layer, an insulation layer and an outer constraint layer from inside to outside; a perfusion inflow annular cavity is formed between the outer constraint layer and the outer sheath tube and between the outer constraint layer and the insulation layer, respectively, and a static sealed inner cavity is formed between the inner constraint layer and the insulation layer and between the inner constraint layer and the flexible transmission shaft, respectively; the proximal holder is provided with a perfusion inlet pipeline communicated with the perfusion inflow annular cavity and a perfusion exhaust pipeline communicated with the static sealed inner cavity; and the distal holder is provided with a perfusion insulation cavity. According to the present invention, the generated wear particles can be effectively insulated, the stability and consistency of perfusion flow of the product are improved, and the problems of vibration and noise of the flexible shaft under high-speed rotation are solved.

Owner:FENGKAI MEDICAL INSTR (SHANGHAI) CO LTD

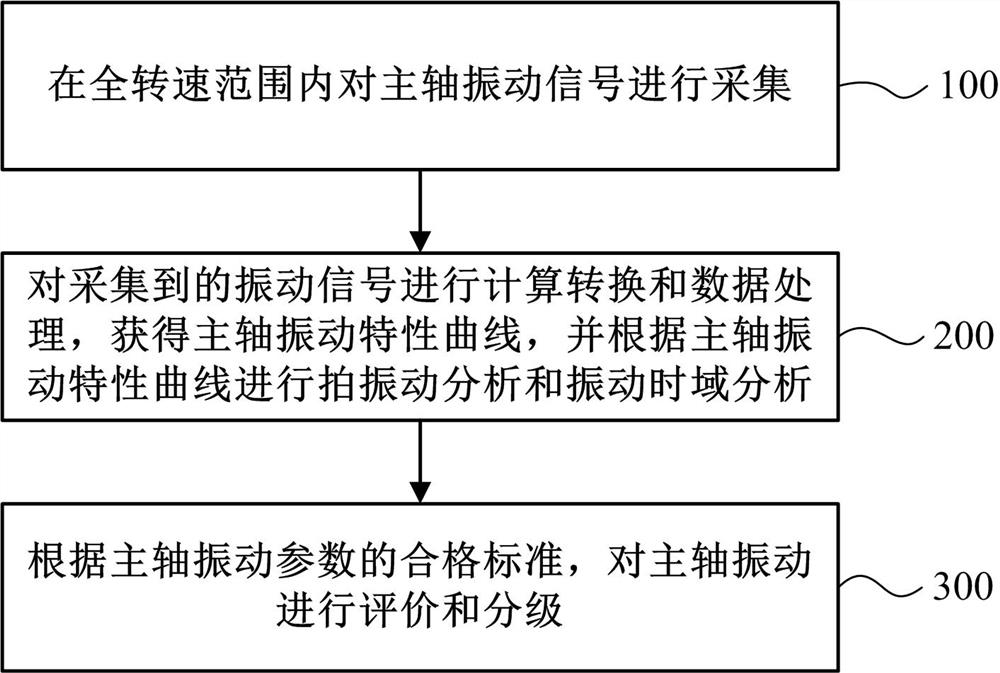

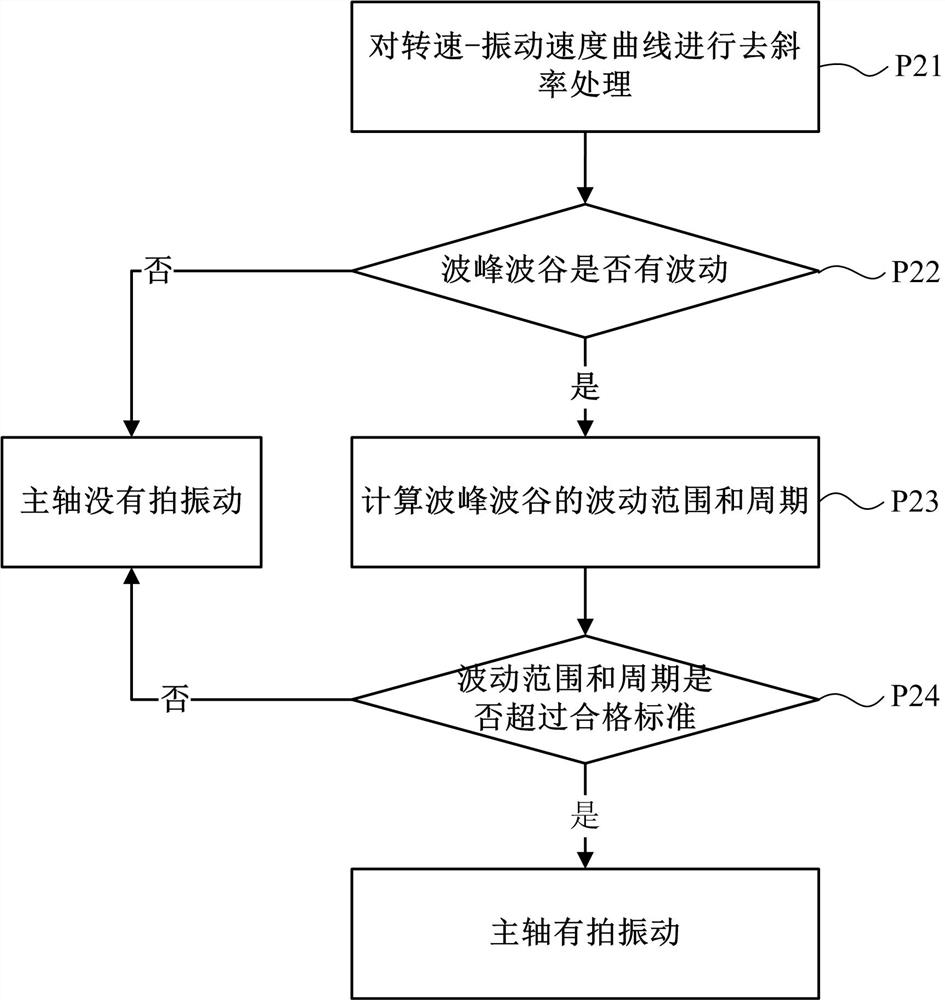

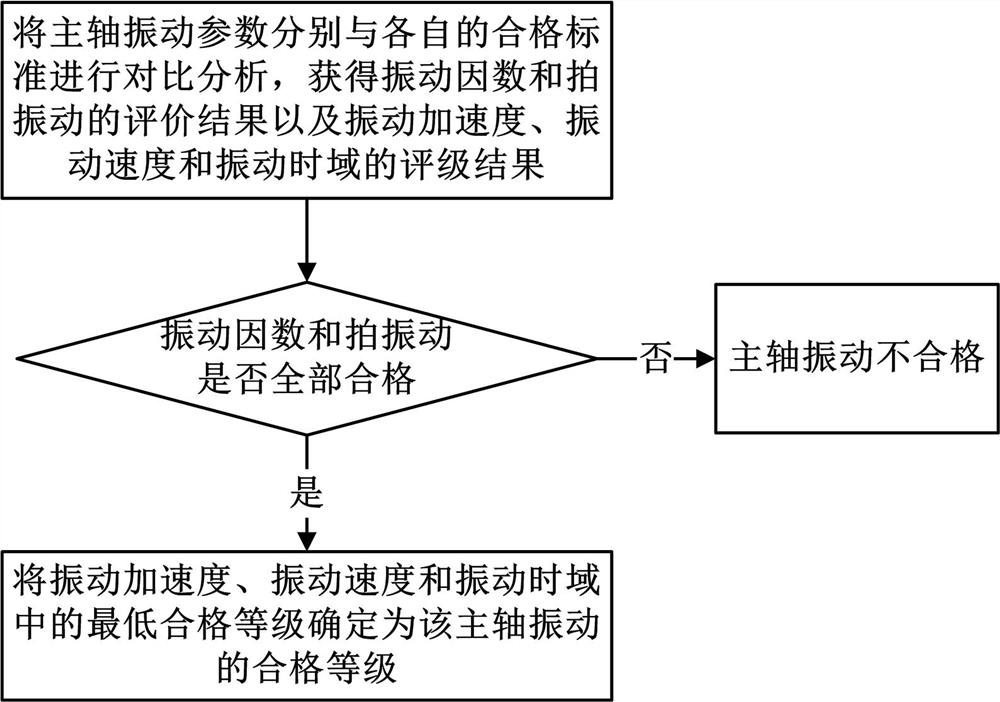

Method and system for evaluating vibration of main shaft

PendingCN114812797ALower skill requirementsImprove stability and consistencyMachine part testingSubsonic/sonic/ultrasonic wave measurementVibration accelerationStructural engineering

The invention belongs to the field of mechanical performance detection, and particularly relates to a main shaft vibration evaluation method and system. Main shaft vibration parameters including vibration acceleration, vibration speed, vibration factors, beat vibration and vibration time domain are obtained by detecting and analyzing main shaft vibration in a full rotation speed range; and respectively and automatically comparing and analyzing with respective qualified standards to obtain an evaluation or rating result of the vibration parameters of each main shaft. And automatically judging the vibration grade of the main shaft according to the evaluation or rating result of each main shaft vibration parameter. According to the invention, not only can automatic detection and analysis of spindle vibration be realized, but also automatic evaluation and grading can be carried out according to the detection and analysis result, no human participation is needed, the operation is simple, the analysis is comprehensive, and the reliability is high.

Owner:北京精雕精密机械制造有限公司

Method, system, and control apparatus for setting over-current protection point of electronic device

InactiveUS9341696B2Improve stability and consistencyReduce labor costsParameter calibration/settingElectrical measurementsEngineeringFully automatic

A method, a system, and a control apparatus for setting an over-current protection point of an electronic device are provided. The method comprises: step 1, the parameter auto-test equipment transmitting a starting signal and outputting a target current for over-current protection based on the auto-adjustment control unit; step 2, the first driving signal generator receiving the starting signal and transmitting a driving signal to the over-current protection module; and step 3, the electronic device receiving the target current for over-current protection, and the over-current protection module receiving the driving signal and adjusting a resistance of the resistance adjusting unit to the over-current protection point of the electronic device. The invention attains fully automatic operation on the over-current protection point of the electronic device, improves stability and consistency of setting the over-current protection point, and saves labor cost at the same time.

Owner:DELTA ELECTRONICS (SHANGHAI) CO LTD

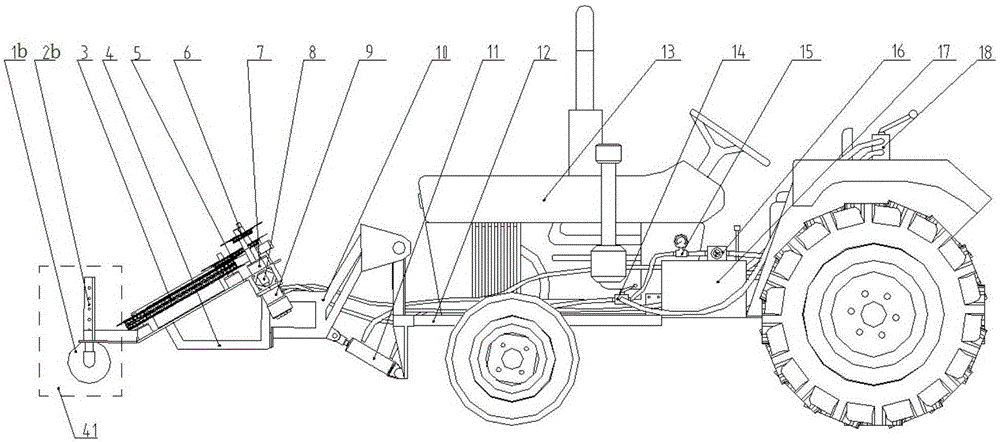

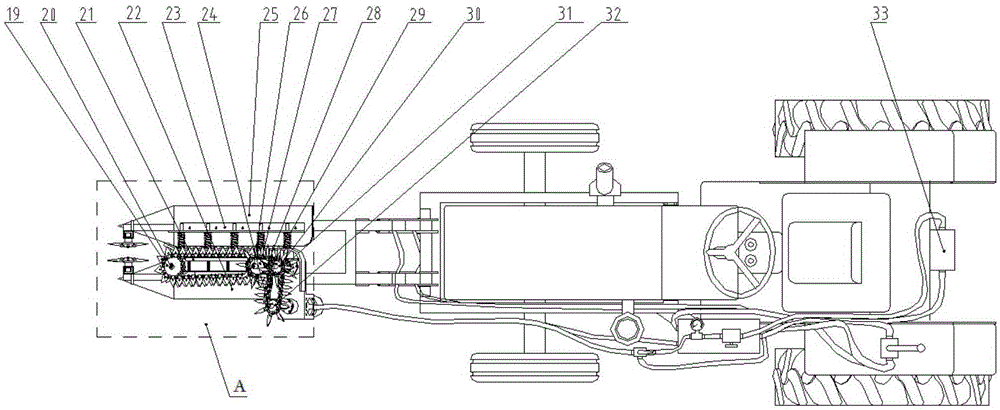

A sprocket type cotton stalk pulling mechanism

The invention discloses a sprocket type cotton stalk pulling mechanism. By the adoption of a device in which a pulling sprocket and a floating pressure chain are matched, cotton stalks with different diameters are pulled. A disc type grain seedling dividing and soil crushing device is used for conducting grain seedling division and soil crushing on the cotton stalks, the soil structure is damaged, binding force between cotton stalk root systems and soil is effectively reduced, and the purposes of grain seedling guidance and pulling drag reduction are achieved. A hydraulic system is adopted for power drive, field pulling vibration can be effectively lowered, and stable continuity of power output of a whole machine is improved. The mechanism is simple in structure and safe in operation, the cotton stalks can be uprooted quickly, the pulling effect is good, hand labor intensity can be greatly relieved, and labor intensity of farmers is remarkably relieved. The mechanism can also be used for pulling stalks of tobacco, hemp and other crops.

Owner:HUAZHONG AGRI UNIV

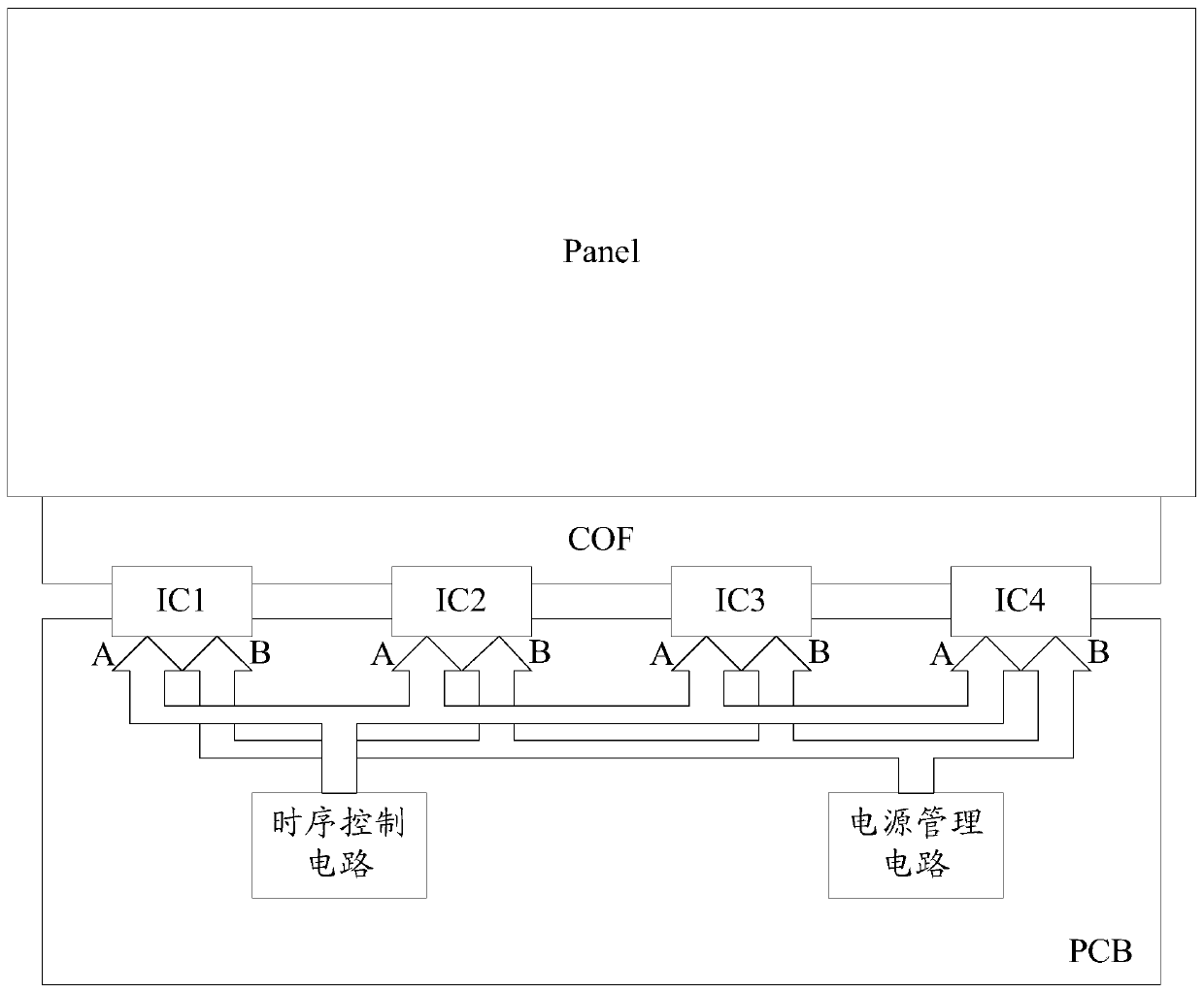

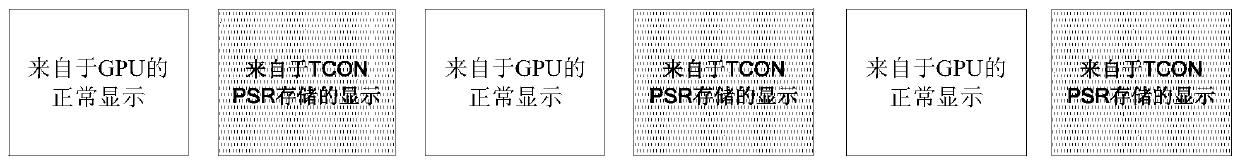

A display driving circuit board, its driving method and display device

ActiveCN107039013BImprove stability and consistencyEnhance experience tasteStatic indicating devicesAdvertisingDriver circuitHemt circuits

A display drive circuit board, its driving method and a display device provided by embodiments of the present invention adopt a method of adding a display refresh frequency detection unit and a common voltage pre-storage compensation unit to the display drive circuit board; through the display refresh frequency detection unit Detect the display refresh frequency of the frame start signal output by the timing control circuit, and then the common voltage pre-stored compensation unit determines the display refresh frequency output by the display refresh frequency detection unit based on the pre-stored correspondence between each display refresh frequency and each common voltage. corresponding public voltage, and controls the power management circuit to output a public voltage corresponding to the display refresh frequency, so that the display driver circuit board can adjust the output public voltage in real time to the best common voltage that matches the display refresh frequency according to changes in the display refresh frequency. The voltage is conducive to improving the stability and consistency of the display panel, and can alleviate the flicker problem, thereby improving the display quality of the display panel.

Owner:SHANGHAI AVIC OPTOELECTRONICS

Solid electrolytic capacitor electrode slice and preparation method thereof

ActiveCN102810403AImprove stability and consistencySimple preparation processSolid electrolytic capacitorsCapacitor electrodesAluminiumGraphene

The invention discloses a solid electrolytic capacitor electrode slice and a preparation method thereof, belonging to the field of capacitor electrode. The solid electrolytic capacitor electrode slice is structurally made of aluminum / aluminum oxide-barium titanate / graphene-conductive macromolecule. As the graphene is used for taking the place of a conductive macromolecule electrolyte material, the solid electrolytic capacitor electrode slice provided by the invention has excellent stability and consistency; and moreover the electrode slice is simple in preparation process, low in cost and is applicable to industrial production.

Owner:OCEANS KING LIGHTING SCI&TECH CO LTD +1

Cap assembly and secondary battery

InactiveUS20190267582A1High strengthReduce distortionVent arrangementsSecondary cells manufactureMechanical engineeringPressure increase

The present disclosure provides a cap assembly and a secondary battery. The cap assembly comprises a cap plate, a reinforcement structure and a vent piece. The cap plate is provided with a through-hole; the vent piece is fixed with the cap plate and covers the through-hole from above. The reinforcement structure is provided in the through-hole and fixed with an inner wall of the through-hole, and the reinforcement structure partially blocks the through-hole. The secondary battery comprises: a case having an opening in a top thereof, an electrode assembly received in the case, and the cap assembly according to the first aspect of the present disclosure fixed with the case in the top. When the secondary battery works normally, a certain amount of gas will be generated inside the secondary battery, thereby leading to a pressure inside the secondary battery increasing. By providing the reinforcement structure in the through-hole, it can increase the strength of the cap plate, thereby reducing deformation of the cap plate when the pressure inside the secondary battery increases, especially deformation of the cap plate at the through-hole, and in turn ensuring the connecting strength between the vent piece and the cap plate, improving the stability and the consistency of vent function of the cap assembly, and promoting the safety performance of the secondary battery.

Owner:CONTEMPORARY AMPEREX TECH CO

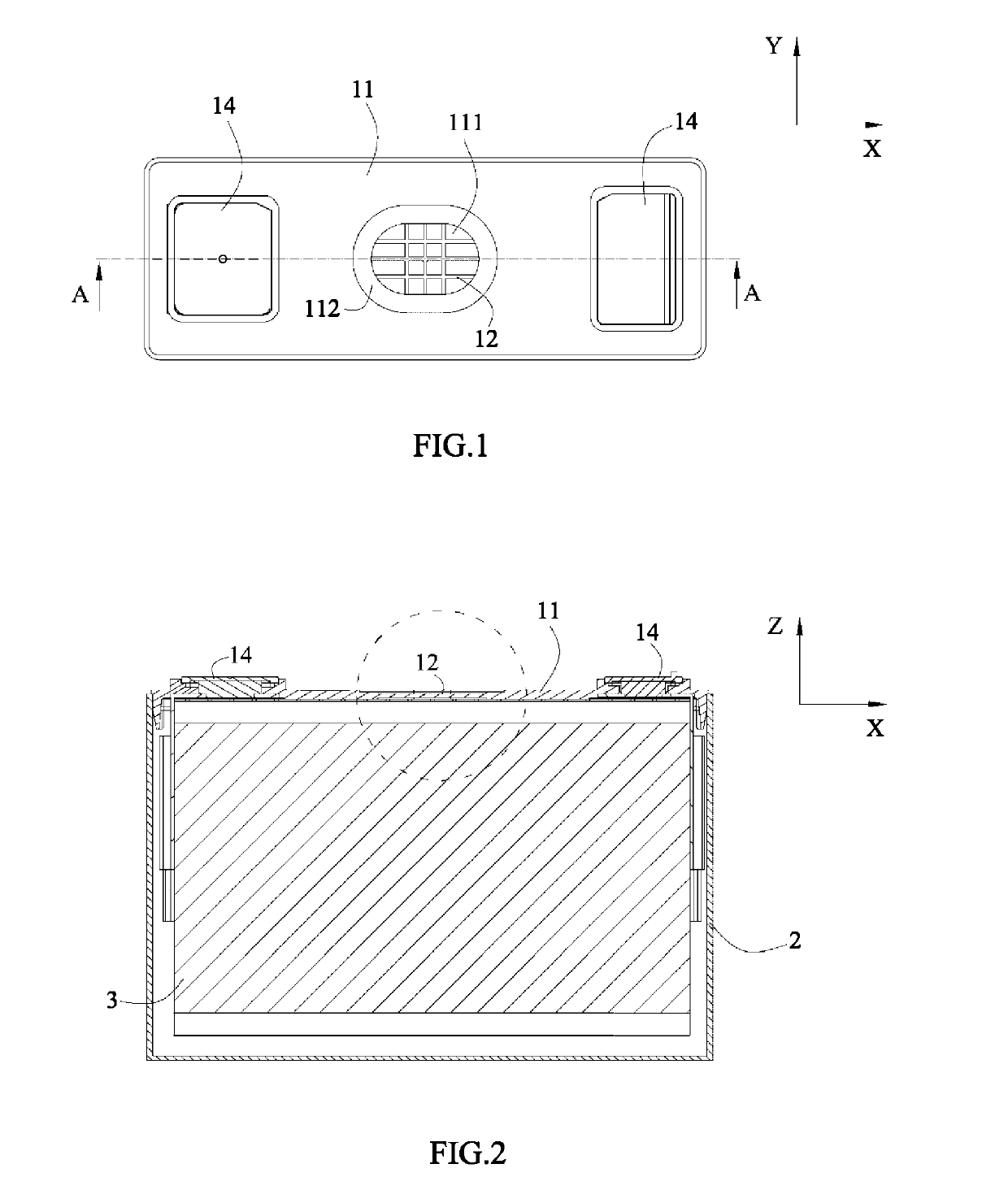

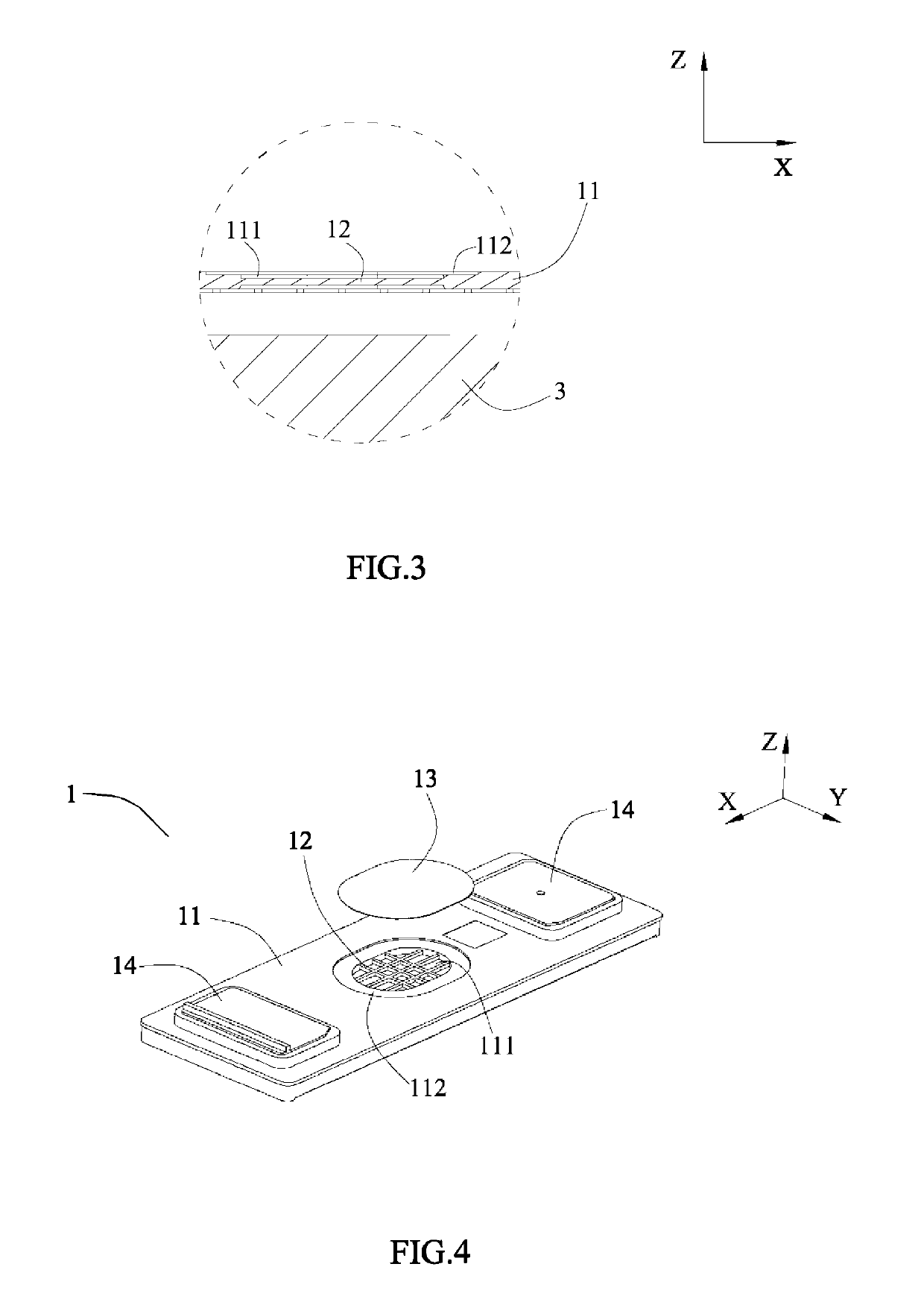

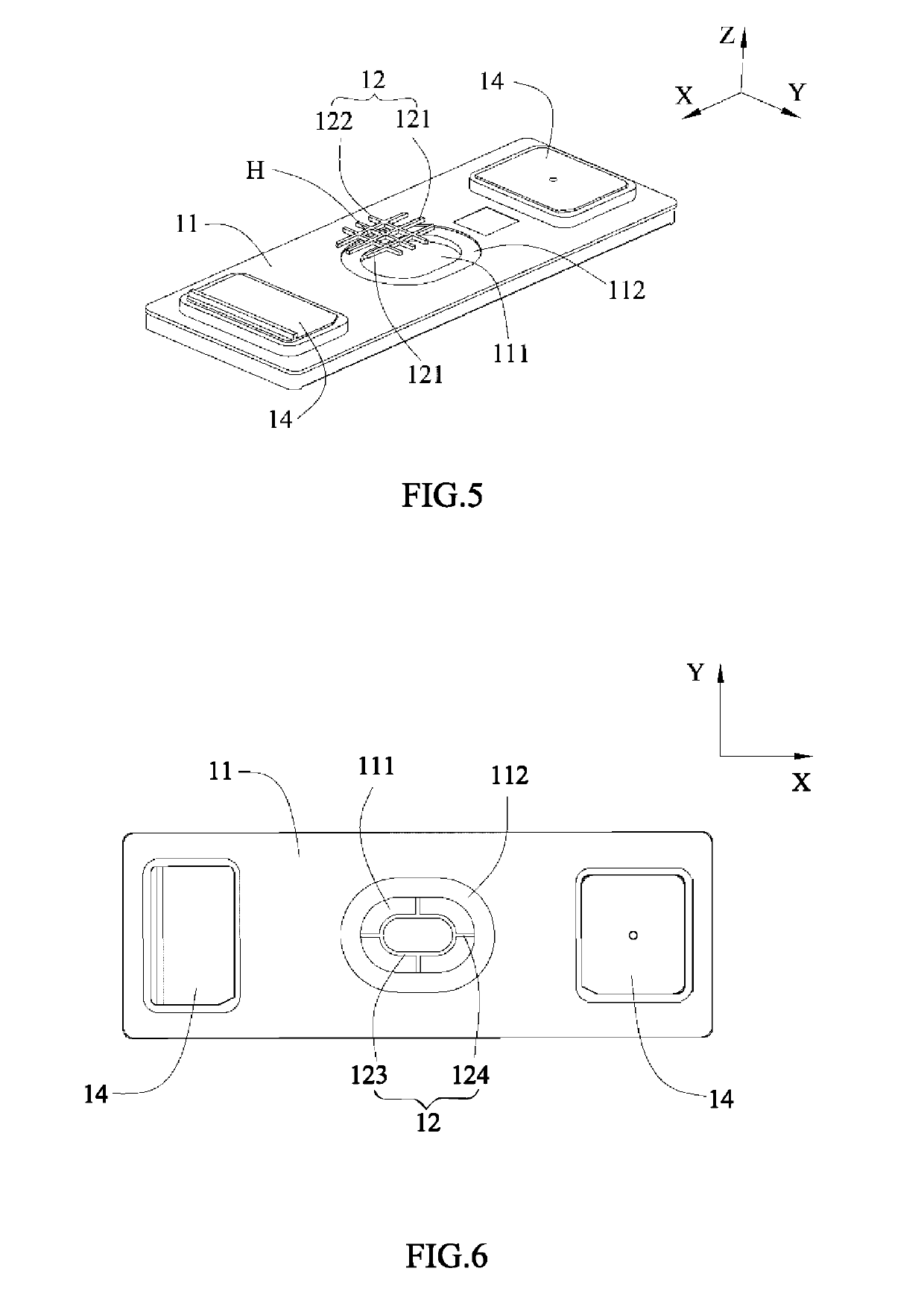

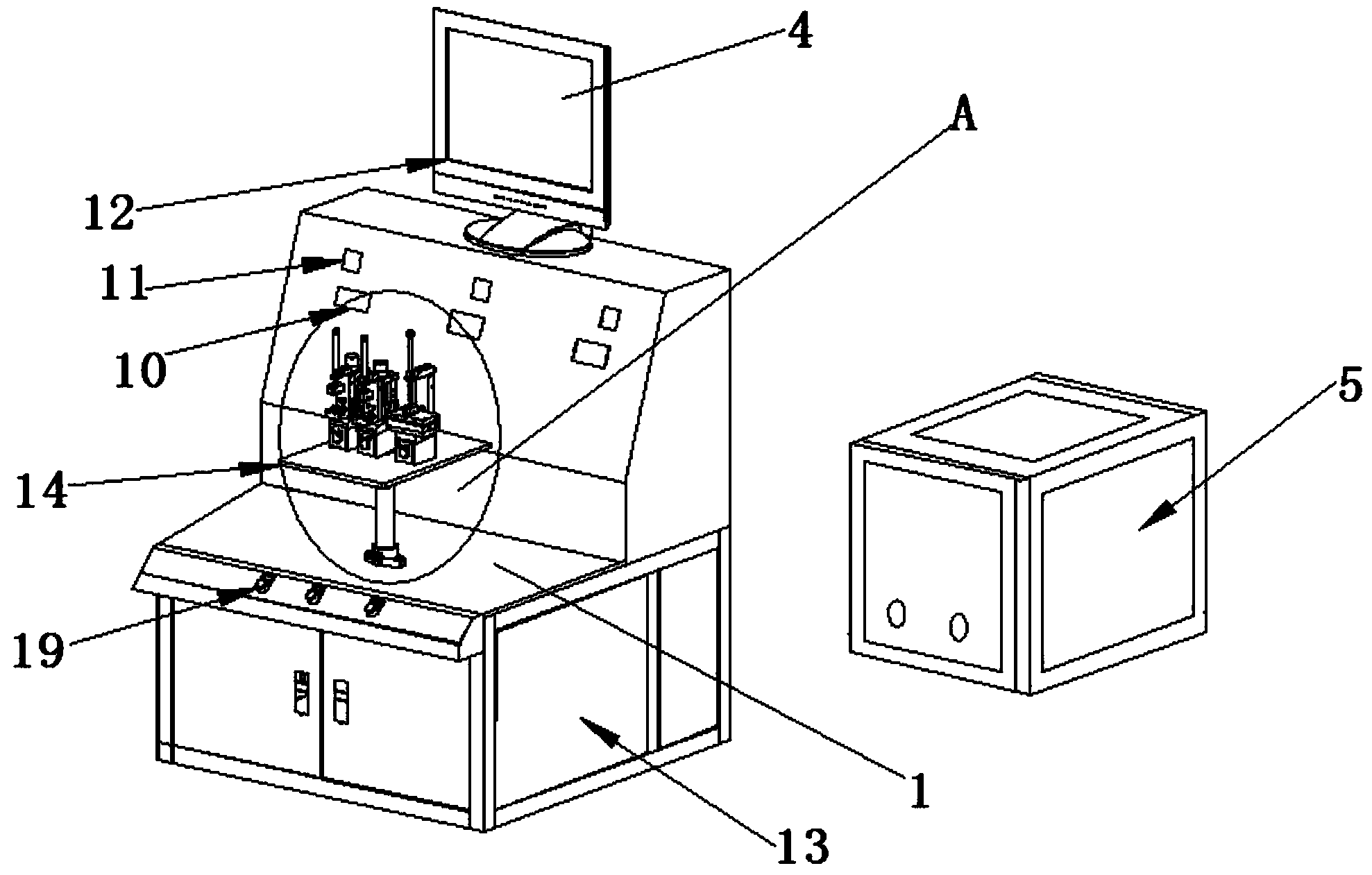

Refrigeration chip type heat pipe performance testing device

ActiveCN104330277ASmall temperature fluctuationsImprove stability and consistencyStructural/machines measurementEngineeringTest facility

The invention discloses a refrigeration chip type heat pipe performance testing device which is characterized by comprising a heating device (2), a cooling device (3) and a control device (4), wherein the heating device (2), the cooling device (3) and the control device (4) are arranged on an operation platform (1). The cooling device (3) is externally connected with two refrigerators (5), and comprises a cooling plate (6), a refrigeration chip (7) and a cooling copper block (8), wherein the cooling plate (6) is used for being communicated with the refrigerators (5), the cooling copper block (8) is used for placing the cooling end of a heat pipe to be tested, and the refrigeration chip (7) is arranged between the cooling copper block (8) and the cooling plate (6). The refrigeration chip type heat pipe performance testing device has the advantages of high temperature control accuracy and testing efficiency, energy conservation and environment protection, and good stability, and is suitable for popularization and application.

Owner:KUNSHAN HYB RADIATOR

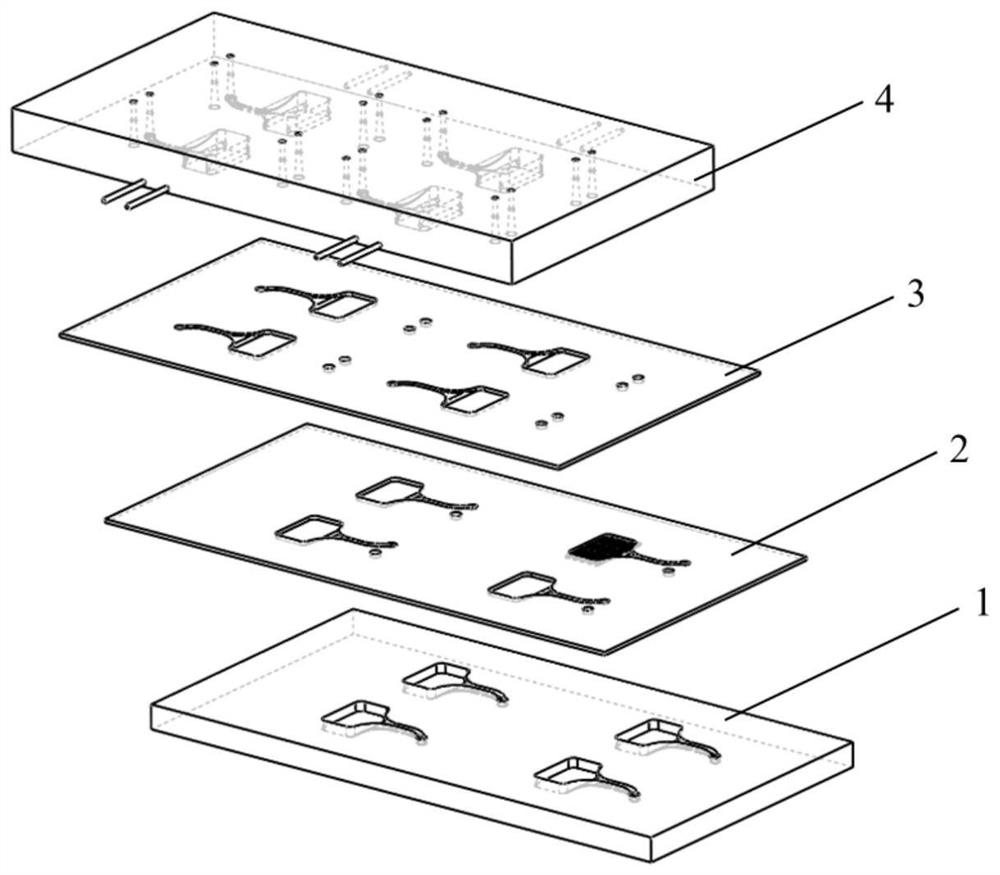

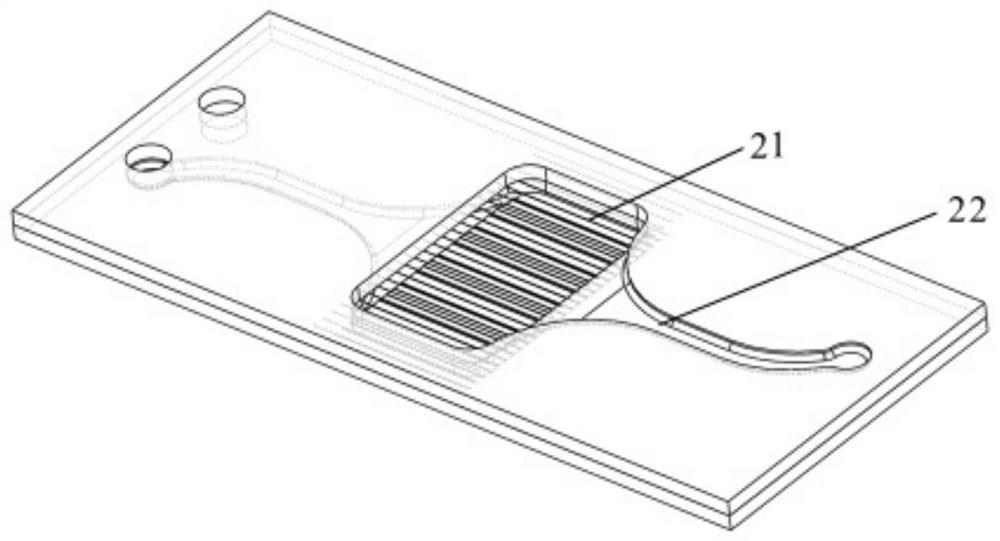

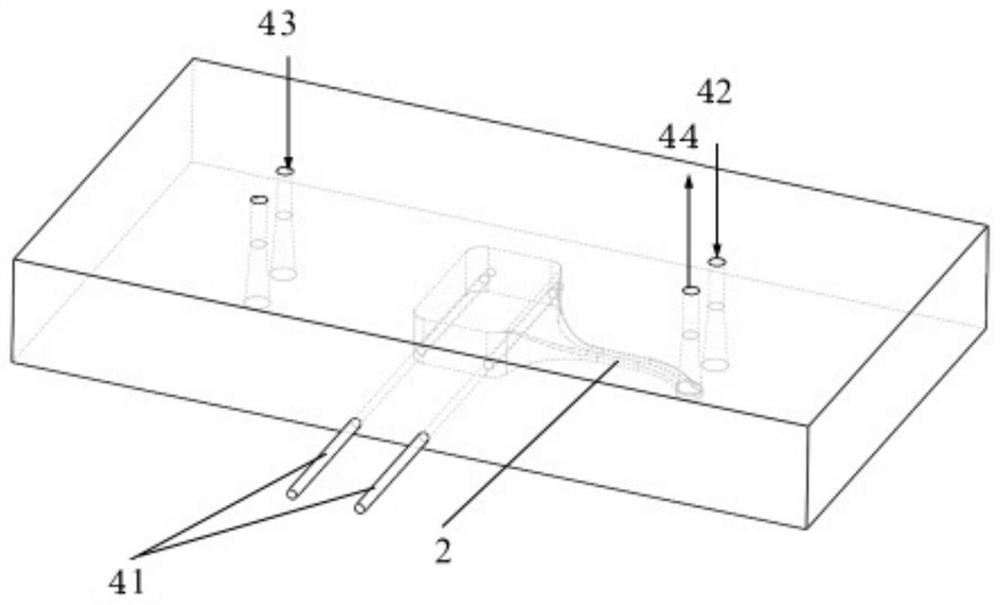

Organ chip, integrated module and system thereof, preparation method and application

PendingCN114832874APromote orderly arrangementImprove stability and consistencyTelevision system detailsBioreactor/fermenter combinationsThin membraneElectrical stimulator

The invention discloses an organ chip, an integrated module and system thereof, a preparation method and application. The organ chip comprises a bottom cover, a PDMS thin film and a top cover, cavities are formed in the bottom cover and the top cover, and an ordered fiber support is arranged in the PDMS thin film; the bottom cover, the PDMS thin film and the top cover are sequentially arranged in a stacked mode, a cell culture chamber is defined by cavities of the bottom cover and the top cover, the ordered fiber support is located in the cell culture chamber, and an electric excitation element is further integrated in the top cover. A module integrating a multi-channel electrical stimulator and an automatic perfusion system is connected with an arrayed organ chip, synchronous electrical stimulation and continuous fluid stimulation are applied to on-chip tissues, and the organ chip can be used for cell culture of high-throughput drug detection.

Owner:XIAMEN UNIV

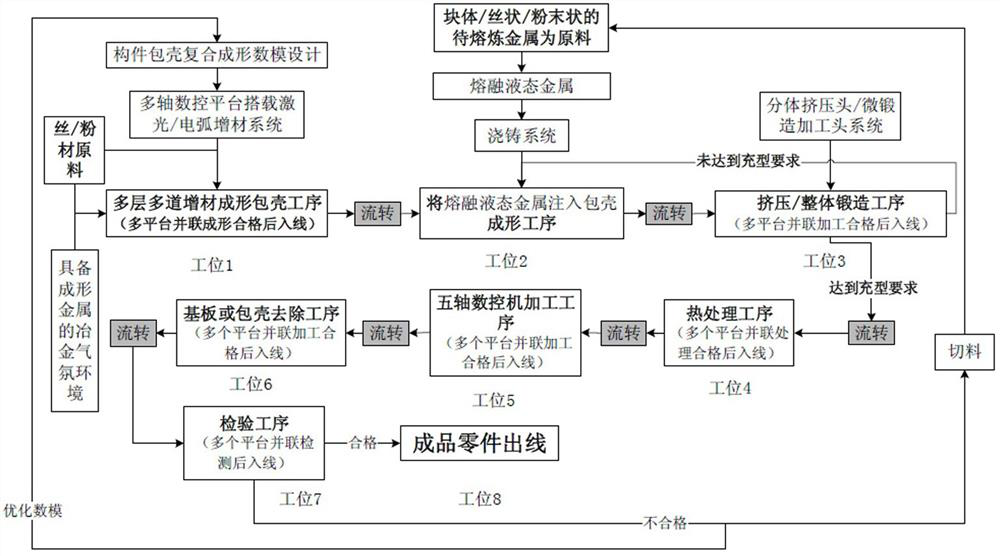

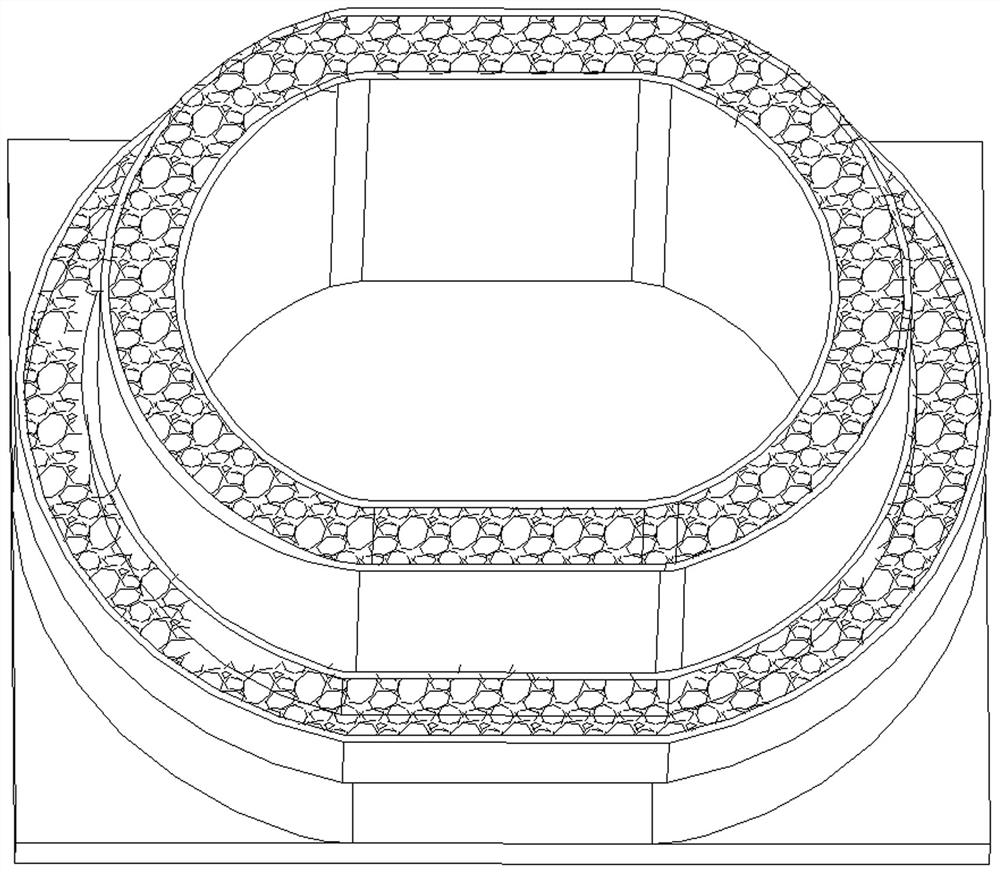

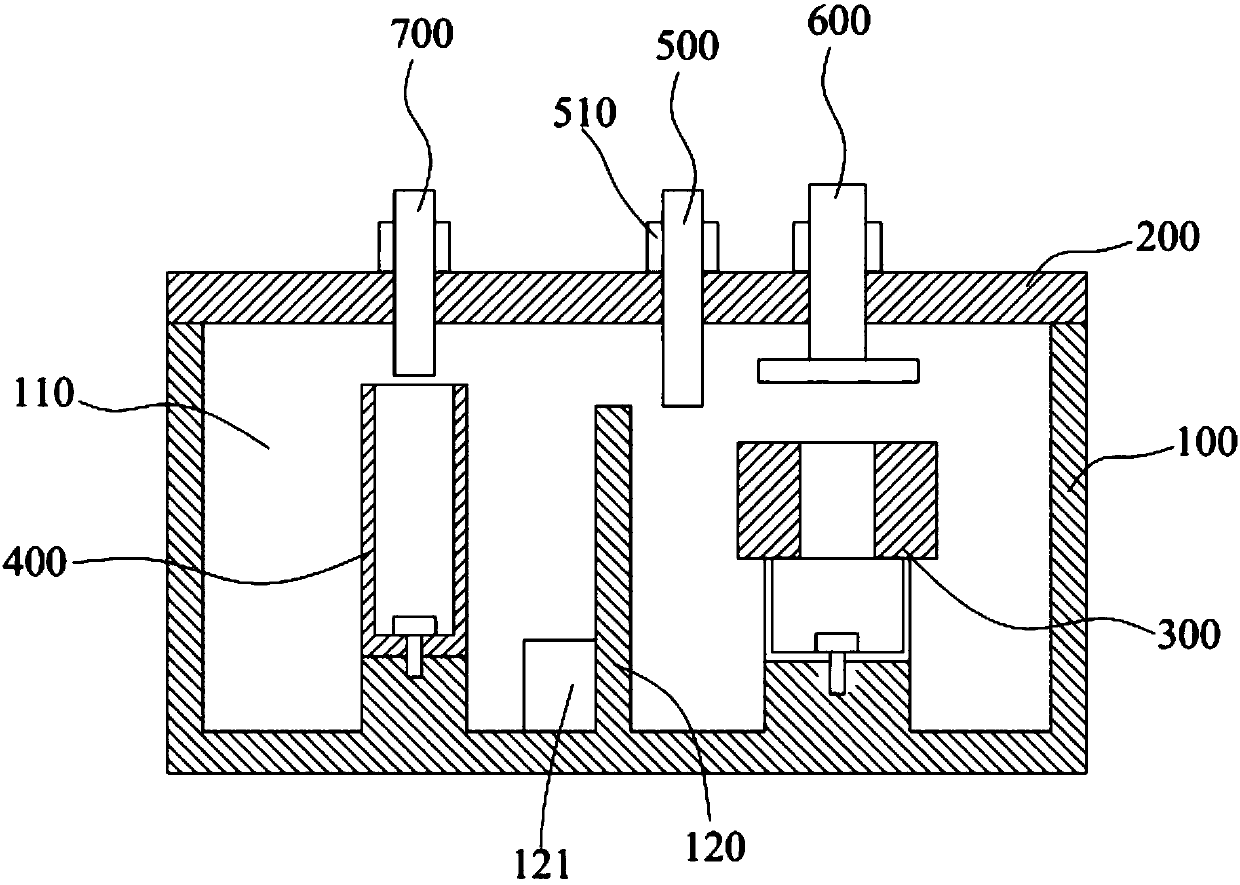

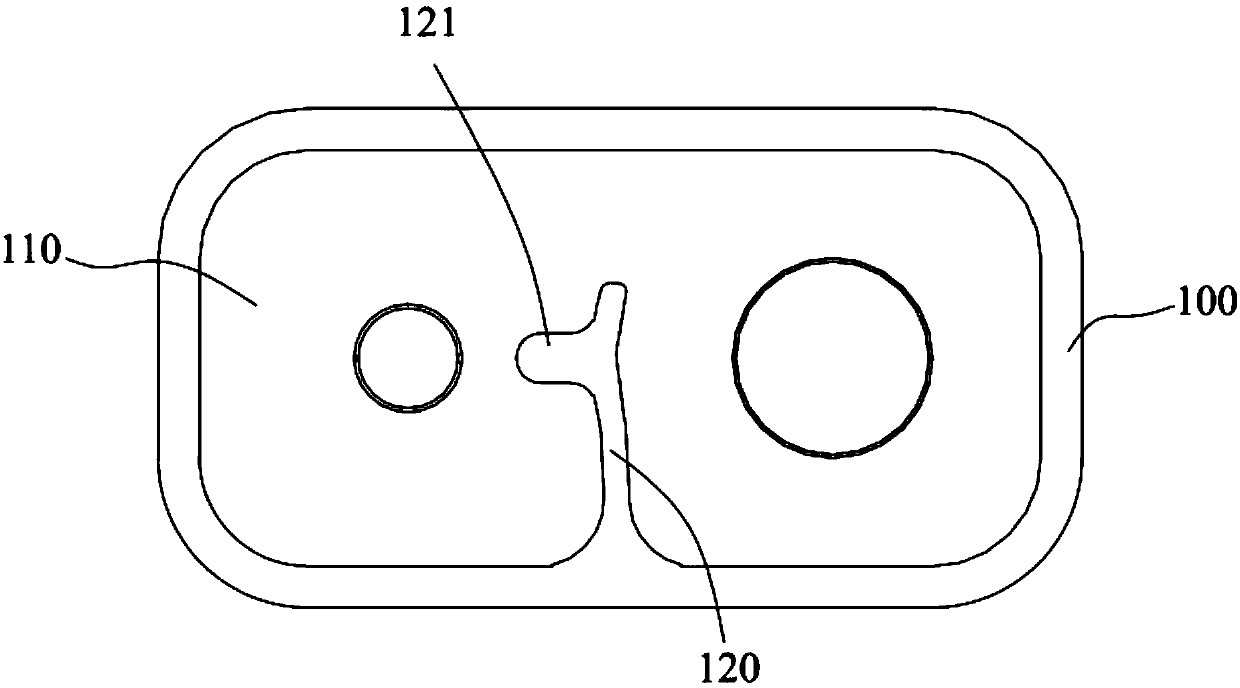

A kind of cladding type composite additive production line manufacturing method

ActiveCN112974835BImprove stability and consistencyImprove stabilityAdditive manufacturing apparatusFoundry mouldsNumerical controlLiquid metal

The present invention relates to a manufacturing method of cladding composite additive production line, including the following steps: S1, parallel multi-station, according to the data model, process silk / powder material raw materials through multi-axis numerical control platform equipped with laser and arc additive system forming a cladding; S2, pouring the molten liquid metal into the cladding, and then casting the molten liquid metal into shape; S3, connecting multiple stations in parallel, forming a cast solidified structure when the molten liquid metal is cooled to a semi-solid or forging extrusion temperature, Then extrude or forge the solidified structure of the casting; S4, parallel multi-station, heat-treat the composite formed blank; S5, parallel multi-station, machine the blank into parts; S6, parallel multi-station Station, remove the substrate or cladding; S7, parallel multi-station, inspect the parts; S8, parallel multi-station, after passing the inspection, the finished parts go out of the line and packaged. The invention belongs to the technical field of composite material additive manufacturing.

Owner:AVIC BEIJING AERONAUTICAL MFG TECH RES INST

Dielectric filter with adjustable coupling and dielectric resonator mixed and matched with metal resonator

InactiveCN107611537AImprove stability and consistencyImprove work efficiencyWaveguide type devicesPhysicsHelical resonator

The invention discloses a dielectric filter with adjustable coupling and a dielectric resonator mixed and matched with a metal resonator. The dielectric filter comprises a shell, a cover board, the dielectric resonator and the metal resonator, an open cavity is formed in the top of the shell in a concave mode, the cover board is detachably fixed to the open end of the cavity, the dielectric resonator and the metal resonator are arranged in the cavity in parallel, a coupling block is arranged on the inner wall of the cavity in an inward protruding and extending mode, the side, close to the metal resonator, of the coupling block protrudes and extends to a boss, the coupling block is arranged between the dielectric resonator and the metal resonator, and the side, close to the coupling block,of the dielectric resonator is provided with an adjustable threaded rod. According to the filter, a traditional coupling and transformation piece is replaced by the coupling block, and the coupling block and the shell can be integrated, so that the consistency and the stability of the coupling block are improved; by arranging the adjustable threaded rod, adjustable production is achieved, and theworking efficiency is improved.

Owner:苏州灿勤通讯技术有限公司

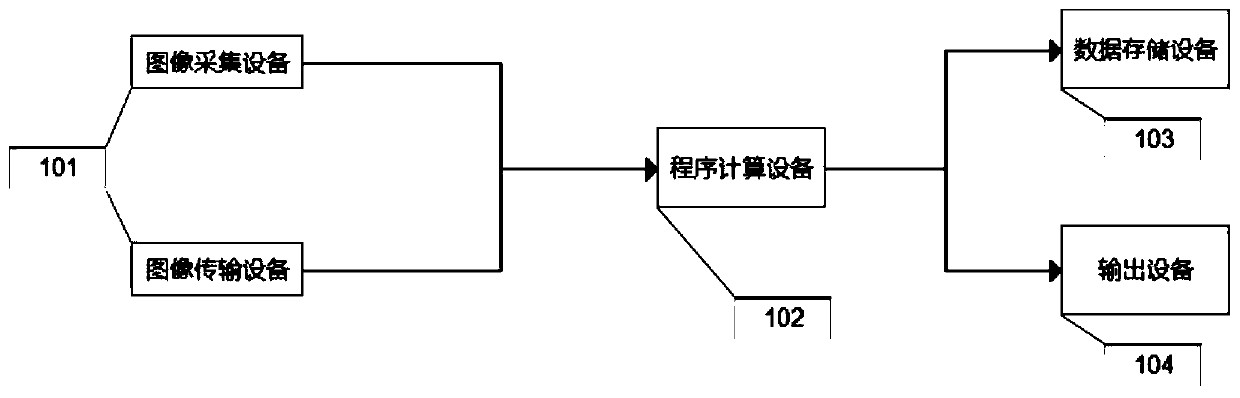

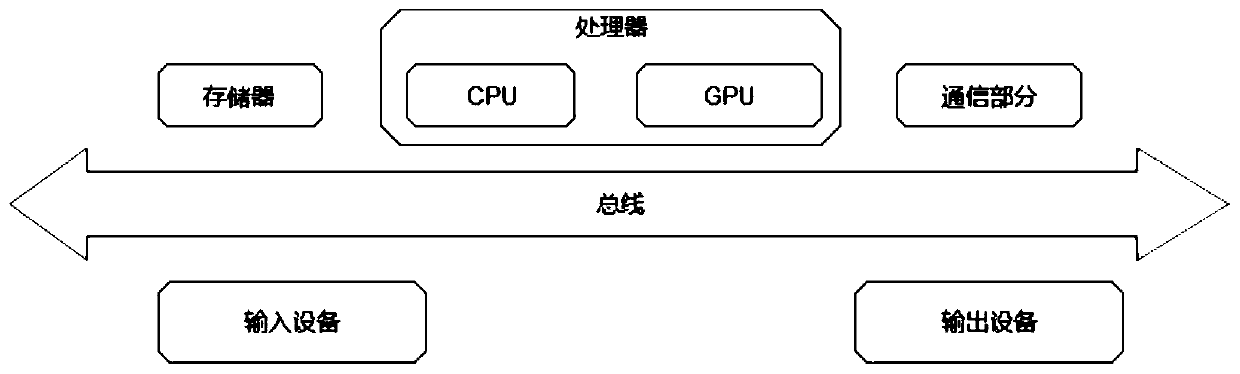

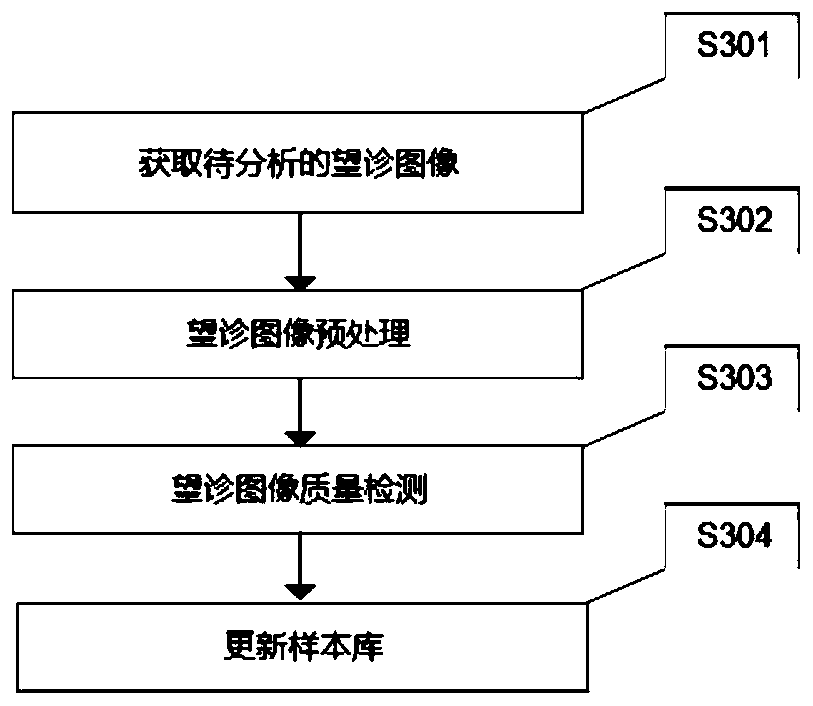

Inspection image quality evaluation method, device and equipment and storage medium

PendingCN110874840AImprove stability and consistencyGuaranteed Accuracy and ReliabilityImage enhancementImage analysisSample classificationEngineering

The invention discloses an inspection image quality evaluation method. The method comprises the following specific steps: A, acquiring an inspection image to be analyzed; B, preprocessing the inspection image according to the actual scene to enable the inspection image to accord with subsequent processing; C, performing quality detection on the inspection image by adopting an image algorithm basedon a neural network; obtaining a total score of the inspection image quality and various index values influencing the total score; and D, classifying the samples into a sample library according to aquality detection result to realize standardized management of inspection image data, so that quality evaluation can be performed on the inspection image or a certain target or a certain type of target on the image, the inspection image with unqualified quality is filtered out, and meanwhile, unqualified indexes and quantitative parameters are given. The problem that objective comparison is difficult to carry out between different data sets and between different auxiliary diagnosis algorithms is solved, so that the stability and consistency of doctors and an auxiliary diagnosis and treatment system are improved, the reliability and accuracy of diagnosis results are ensured, and misdiagnosis and missed diagnosis are reduced.

Owner:上海国民集团健康科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com