Composite type solid electrolytic capacitor electrode slice and preparation method thereof

A capacitor electrode and solid electrolysis technology, applied in the field of electrode sheets, can solve the problems of easy combustion, high production cost, limited environmental protection and future market, and achieve the effects of improving stability and consistency, simple preparation process and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

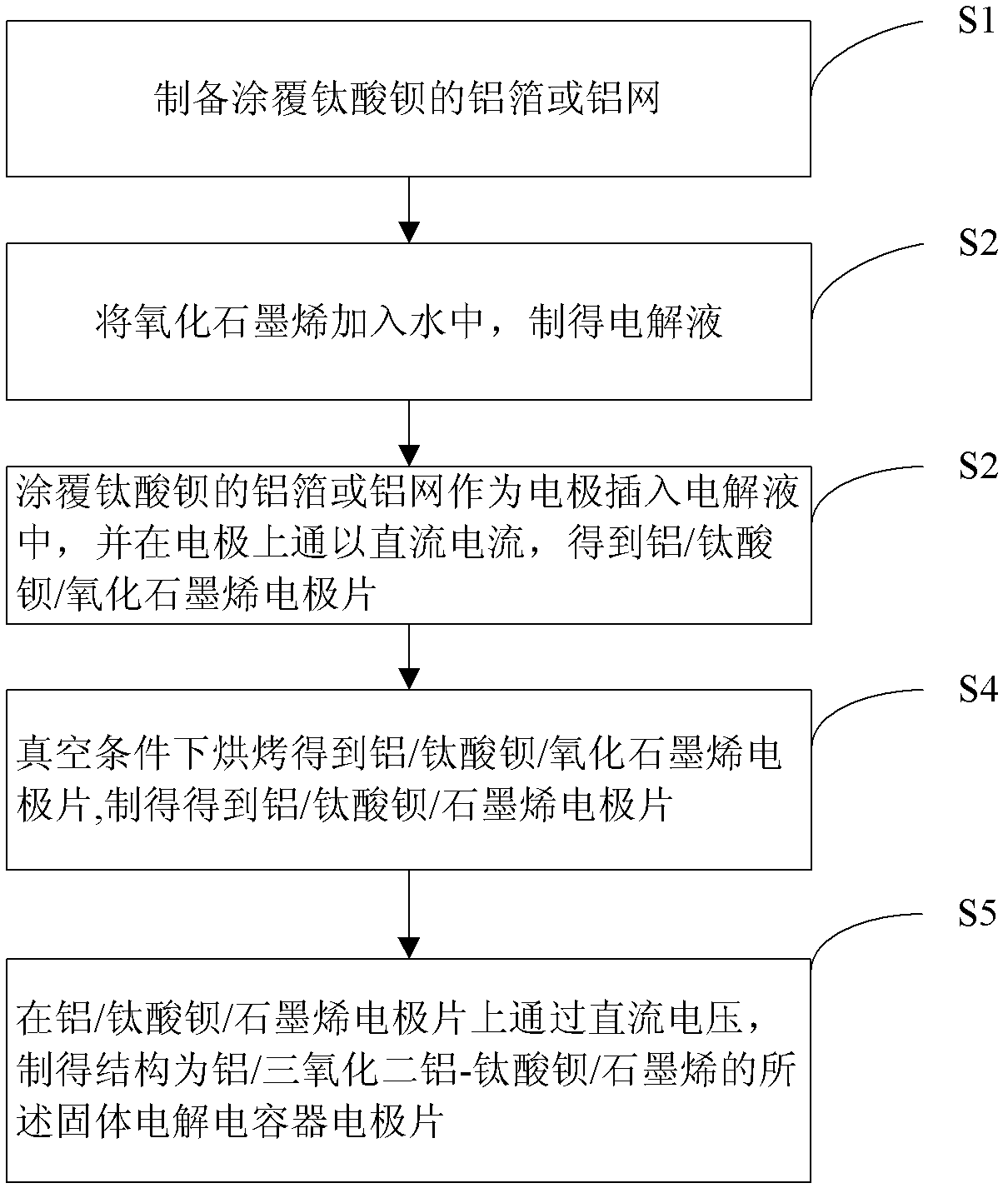

[0022] The preparation method of above-mentioned compound type solid electrolytic capacitor electrode sheet provided by the present invention, its steps are as follows:

[0023] S1. Dip aluminum foil or aluminum mesh into a container containing a suspension of barium titanate nanopowder, and then heat-treat at 500-700° C. for 0.5-12 hours in a vacuum atmosphere to obtain an aluminum foil or aluminum mesh coated with barium titanate;

[0024] S2, dissolving graphene oxide in an aqueous solution to prepare an electrolyte; wherein, the molar concentration of graphene oxide is 1 to 3 mol / L;

[0025] S3. Insert the aluminum foil or aluminum mesh coated with barium titanate prepared in step S1 into the electrolyte solution prepared in step S2 as an electrode, and pass a direct current of 1 to 10 mA on the electrode for 1 to 24 hours. Obtain aluminum / barium titanate / graphene oxide electrode sheet;

[0026] S4. Place the aluminum / barium titanate / graphene oxide electrode sheet prepare...

Embodiment 1

[0034] The preparation method of composite solid electrolytic capacitor electrode sheet is as follows:

[0035] (1) Graphite oxide: add 20 g of 50-mesh graphite powder with a purity of 99.5%, 10 g of potassium persulfate and 10 g of phosphorus pentoxide into concentrated sulfuric acid at 80° C., stir evenly, cool for more than 6 hours, wash until neutral, and dry; Add the dried sample to 230mL of concentrated sulfuric acid at 0°C, then add 60g of potassium permanganate, keep the temperature of the mixture below 20°C, then keep it in an oil bath at 35°C for 2h, then slowly add 920mL of deionized water After 15 minutes, add 2.8L of deionized water and 50mL of 30% hydrogen peroxide successively, after which the color of the mixture turns bright yellow, suction filter while it is hot, and then wash with 5L of 10% hydrochloric acid, suction filter, Graphite oxide was obtained by vacuum drying at 60°C for 48 hours;

[0036] (2) immersing the aluminum foil in a container filled with...

Embodiment 2

[0043] The preparation method of composite solid electrolytic capacitor electrode sheet is as follows:

[0044](1) Graphite oxide: add 20 g of 50-mesh graphite powder with a purity of 99.5%, 10 g of potassium persulfate and 10 g of phosphorus pentoxide into concentrated sulfuric acid at 80° C., stir evenly, cool for more than 6 hours, wash until neutral, and dry; Add the dried sample to 230mL of concentrated sulfuric acid at 0°C, then add 60g of potassium permanganate, keep the temperature of the mixture below 20°C, then keep it in an oil bath at 35°C for 2h, then slowly add 920mL of deionized water After 15 minutes, add 2.8L of deionized water and 50mL of 30% hydrogen peroxide successively, after which the color of the mixture turns bright yellow, suction filter while it is hot, and then wash with 5L of 10% hydrochloric acid, suction filter, Graphite oxide was obtained by vacuum drying at 60°C for 48 hours;

[0045] (2) immersing the aluminum foil in a container containing a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Conductivity | aaaaa | aaaaa |

| Conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com