Patents

Literature

45results about How to "Promote orderly arrangement" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Polycarbonate composite material and preparation method thereof and method for manufacturing LED (Light Emitting Diode) lamp housing

ActiveCN102250462AImprove interfacial adhesionReduced solvent stress cracking resistancePoint-like light sourceGlobesEpoxyProcedure Agents

The invention discloses a polycarbonate (PC) composite material and a preparation method thereof and a method for manufacturing an LED (Light Emitting Diode) lamp housing. The composite material is prepared from the following components in percentage by weight: 84-98.59 percent of polycarbonate resin, 0.01-8 percent of light diffusant, 1-5 percent of silicone resin, 0.1-1 percent of processing agent, 0.1-1 percent of thermal stabilizer, 0.1-1 percent of light stabilizer and 0.1-1 percent of processing aid. In the invention, the light diffusant is processed by using epoxy resin, so that the interfacial bond of the light diffusant and polycarbonate is improved, and the solvent-stress-resistant cracking performance of the PC composite material is decreased. Ordered arrangement of polycarbonate molecules is increased and the internal stress is reduced under optimized injection mould temperature; and the minimum influence of a toughening component on the transparency of a final lamp housing product is guaranteed by adding the silicone resin with refractive index of 1.587 and toughening effect. The reduction in impact strength of the lamp housing product brought by higher mould temperature during injection molding can be compensated by adding the silicone resin. The light diffusion PC material with a balance among light transmittance, haze and diffusion angle is obtained by adding the light diffusant, so that an LED lamp emits non-dazzling, soft and pleasant light.

Owner:GUANGZHOU SUPER DRAGON ENG PLASTICS

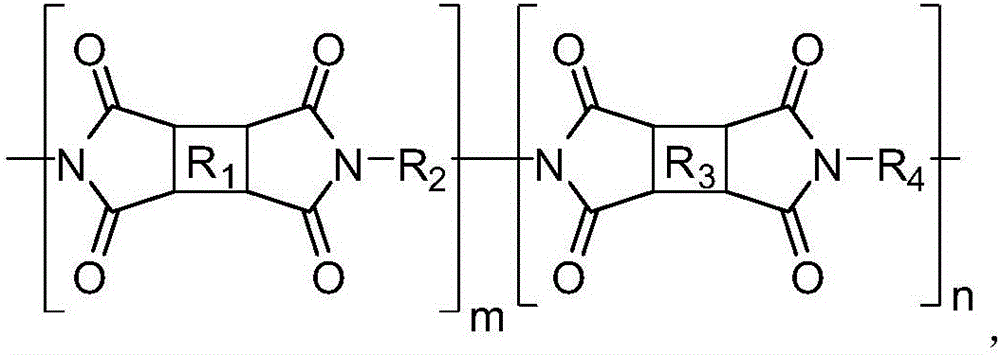

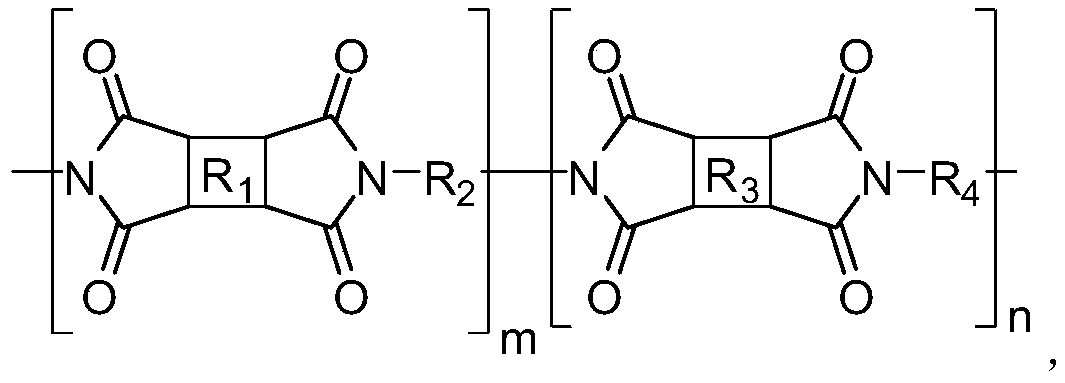

Polyimide film with low thermal expansion coefficient and preparation method of polyimide film

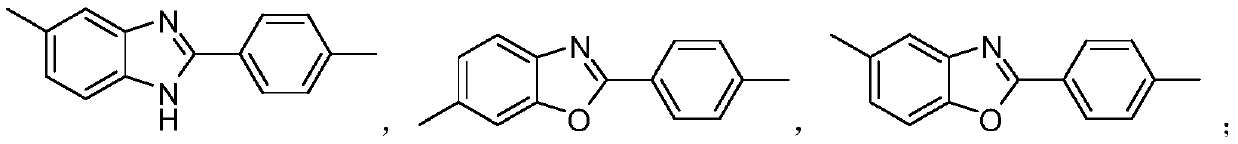

ActiveCN106543720ASmall coefficient of thermal expansionEnhanced interactionThermal expansionStructural formula

The invention belongs to the field of high polymer materials and particularly relates to a polyimide film with a low thermal expansion coefficient and a preparation method of the polyimide film. The polyimide film has the following structural formula shown in the specification, wherein R1 and R3 are residues of two different tetracarboxylic acid dianhydride monomers, and R2 and R4 are residues of two different di-primary amine monomers. The preparation method is a multi-step polymerization method, firstly, two polyimide acid solutions with different structure units are obtained through polymerization respectively, then the solutions are mixed and then polymerized, finally, heating drying is carried out, and the polyimide film with the low thermal expansion coefficient is obtained. Compared with the prior art, the polyimide film with the low thermal expansion coefficient introduces ester bonds / amide, imidazole / oxazole and other structure units into molecular structure design at the same time, the interaction force among molecules is improved, the thermal expansion coefficient of the polyimide film is effectively reduced, meanwhile, the thermal expansion coefficient of the polyimide film can be adjusted and controlled by adopting different formulas, and the matching problem among different substrate materials is solved.

Owner:株洲天颐莱新材料技术有限公司

Method for preparing mesophase pitch through hydrogenation upgrading and co-carbonization of FCC (Fluid Catalytic Cracking) decant oil

InactiveCN107312561AImprove spin performanceReduce usageWorking-up pitch/asphalt/bitumen by chemical meansFiberCarbon fibers

The invention provides a method for preparing a petroleum-based mesophase pitch with high anisotropic structure content and low softening point. The method comprises the following steps: conducting reduced pressure distillation on an FCC (Fluid Catalytic Cracking) decant oil of a naphthenic crude, taking a cut fraction with the boiling point of 400-540 DEG C as a raw material, and reacting for 1-8 hours at the temperature of 400-460 DEG C and under the pressure of 4 MPa to obtain a petroleum pitch; then adding a hydrogen donor, reacting under condition of the self-generated pressure at the temperature of 380-450 DEG C at the initial nitrogen pressure of 5 MPa, then reducing the pressure to the normal pressure, cooling to 340 DEG C, and blowing with high-purity nitrogen for 0.5 hour to obtain a hydrogenated pitch; finally adding a co-carbonization additive, and reacting for 2-16 hours at the temperature of 400-480 DEG C at the pressure of 4MPa to obtain the high-quality mesophase pitch. The preparation process is simple, the production cost is low, the anisotropic structure content (more than 98%) of the prepared mesophase pitch is high, the softening point (230-270 DEG C) is low, the spinning property is good, and the mesophase pitch is an excellent precursor for preparing a high-modulus carbon fiber.

Owner:QINGDAO UNIV OF SCI & TECH

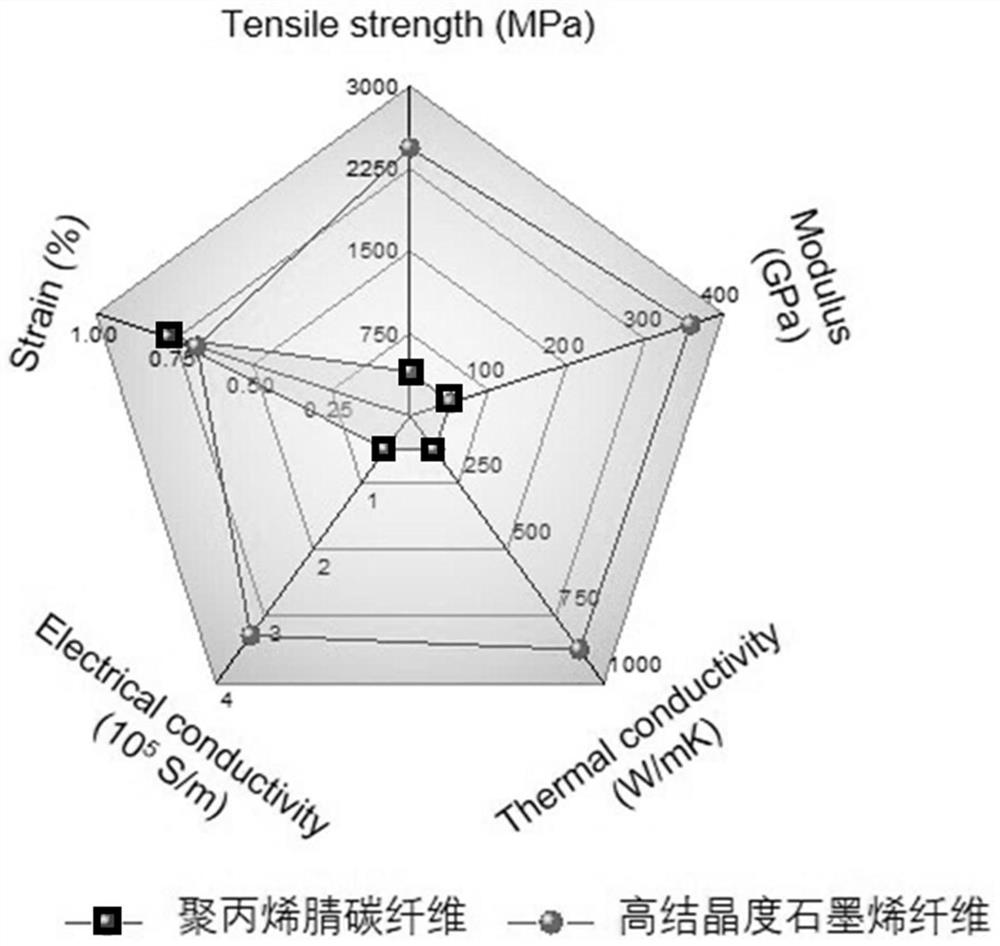

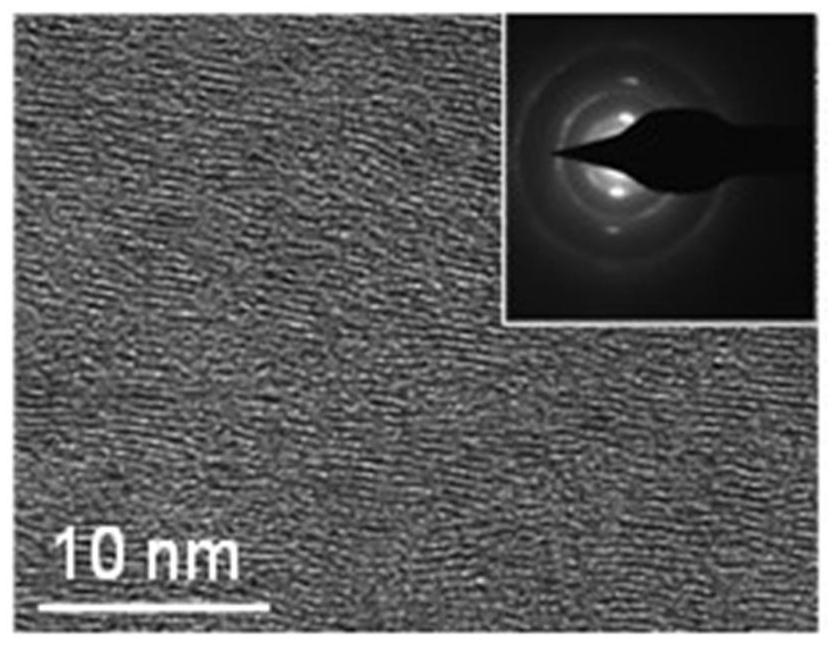

Preparation method of carbon-based nano fiber

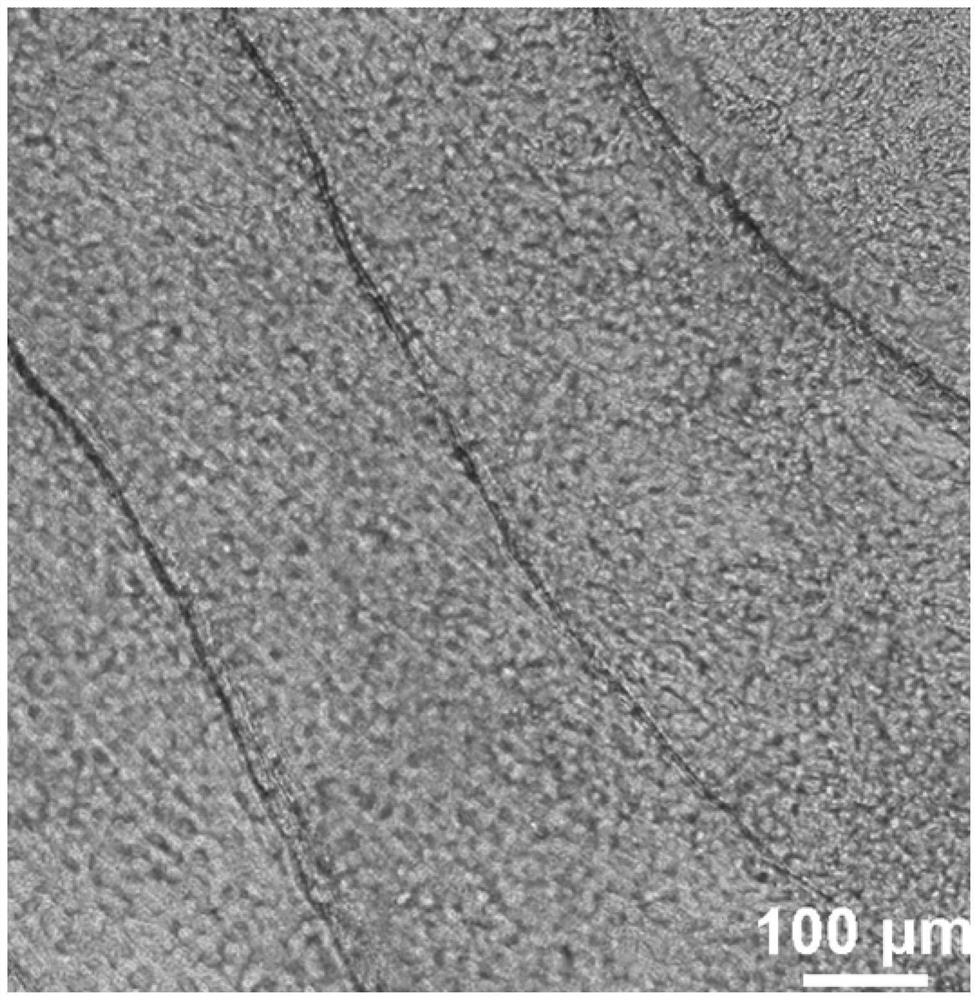

InactiveCN103628182AConvenient ArrangementPromote orderly arrangementFilament/thread formingFibre chemical featuresFiber bundleElectrospinning

The invention relates to a preparation method of carbon-based nano fiber. The method comprises the steps of firstly, preparing graphene oxide into nematic phase solution, and then preparing the nematic phase solution into a carbon-based nano-fiber film or a carbon-based nano-fiber bundle by an electrospinning technique. The method adopts the nematic phase graphene oxide solution as raw material, and the carbon-based nano-fiber can be prepared by the electrospinning technique; the nematic phase solution can be easily arranged in order in the preparation process of the nano fiber, so that the defects of performances in the aspects of mechanical strength, electric conduction, heat conduction and the like caused by the low orderly arrangement degree of the fiber since the electrospinning material is not sufficiently stretched in the electrospinning technique can be well overcome; therefore, the graphene oxide and the carbon-based nano fiber can be well further popularized and applied.

Owner:SOUTHEAST UNIV

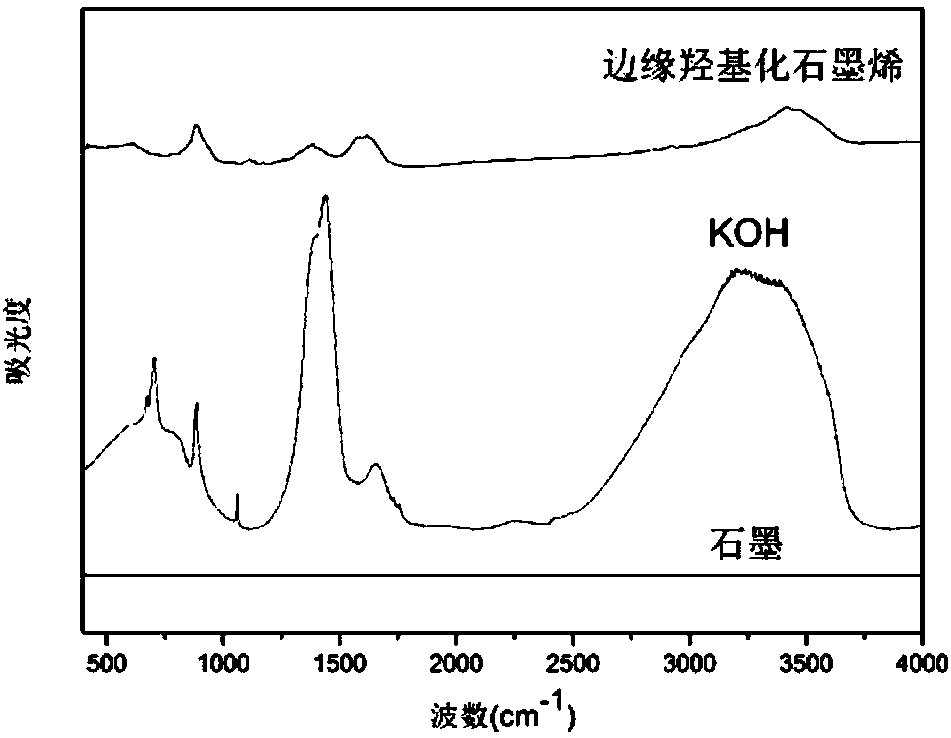

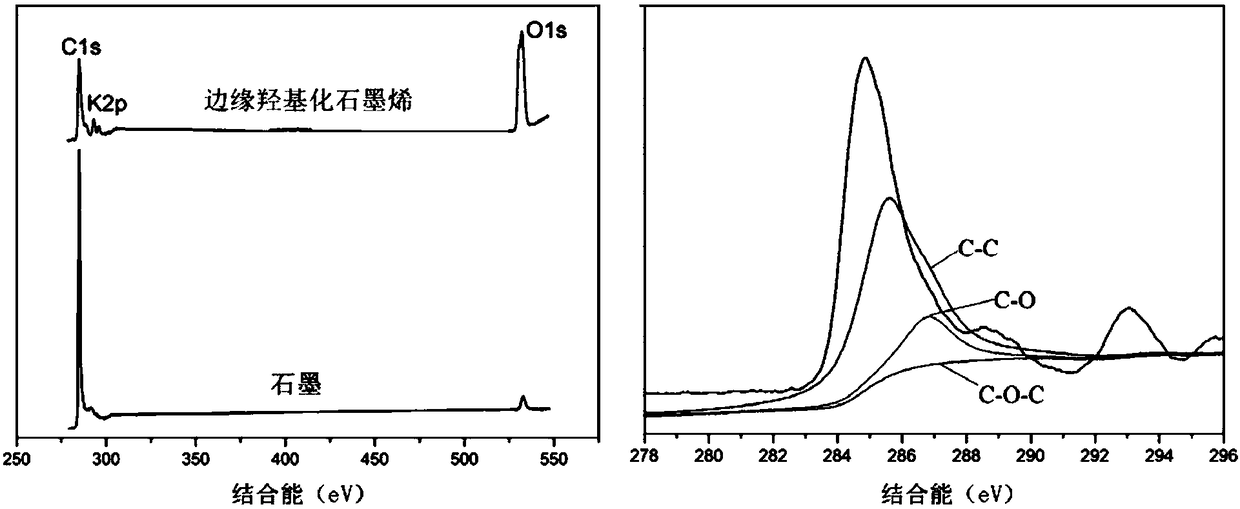

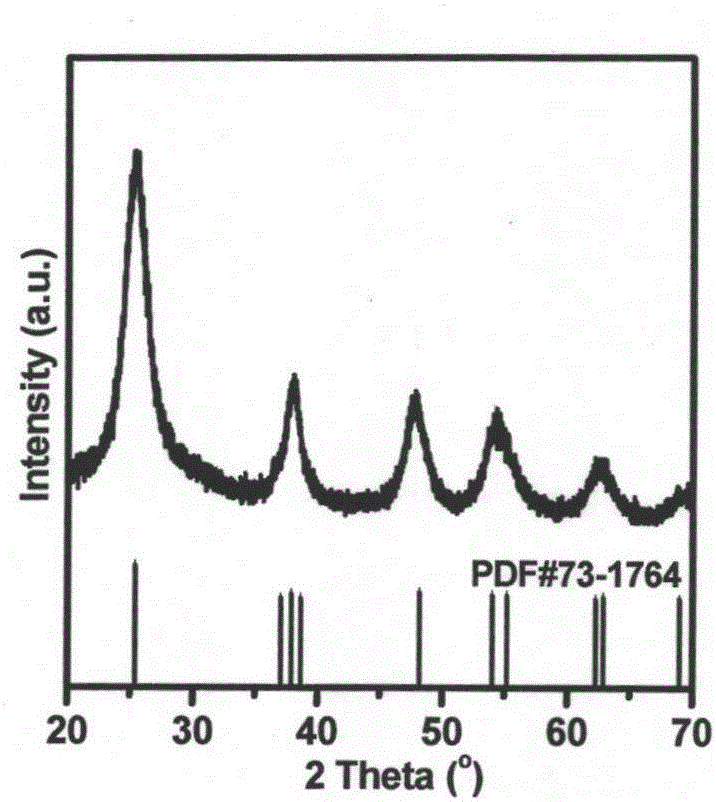

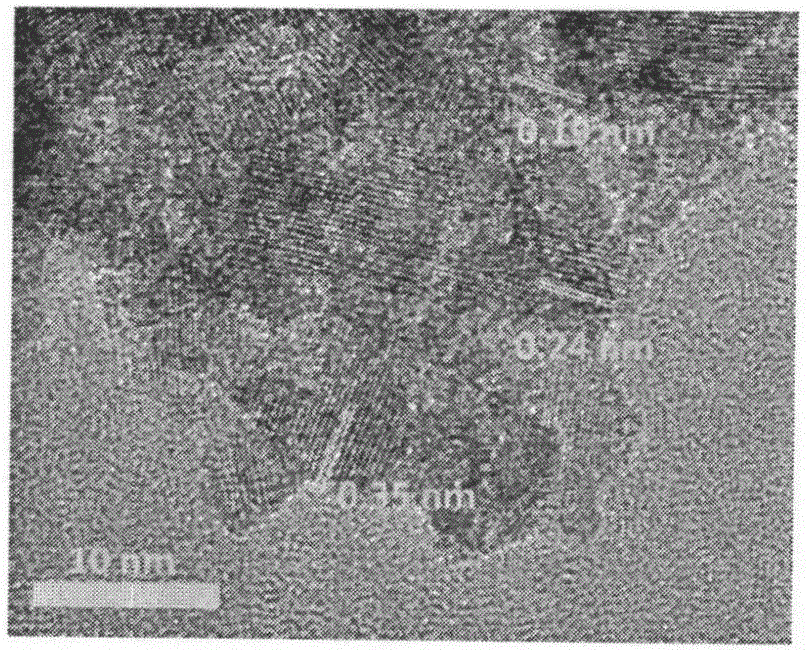

Graphitized film and preparation method and application thereof

InactiveCN108314033AHigh thermal conductivityProtect thermal conductivityCarbon compoundsComposite filmIn situ polymerization

The invention relates to the technical field of functional film materials, and in particular relates to a graphitized film and a preparation method and application thereof. The preparation method of the graphitized film comprises: (1) low temperature in-situ polymerization of a diamine monomer and a dianhydride monomer; (2) film casting of an obtained mixed solution; (3) in-sequence drawing treatment and heating imidization of an obtained graphene / polyamic acid composite film; (4) and in-sequence heating carbonization and heating graphitization of an obtained graphene / polyimide composite film.Edge-functionalized graphene is used as a filler, and the graphene / polyamic acid composite film is appropriately drawn to improve the orientation and regularity of the composite film, and so that theobtained graphitized film has high directivity, high conductivity and high thermal conductivity, and is expected to be better applied in microelectronic packaging, electromagnetic shielding, heat dissipating materials, electrode materials and other aspects.

Owner:BEIJING UNIV OF CHEM TECH

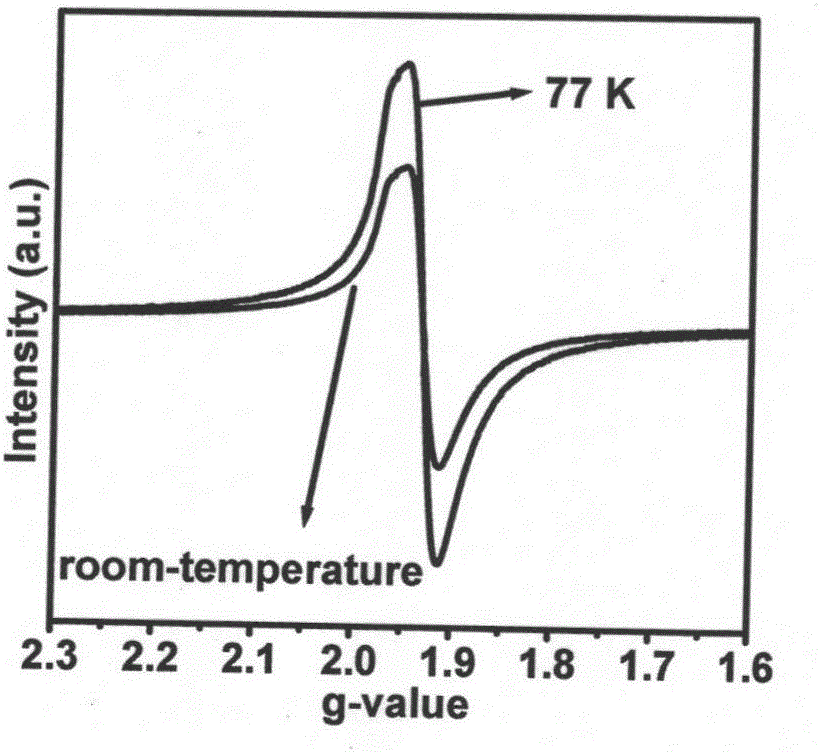

Porous reducing state titanium dioxide crystal material and preparation method thereof

InactiveCN106319626AAchieve crystallizationRealize build flawsPolycrystalline material growthSingle crystal growth detailsHigh energySynthesis methods

The invention provides a porous reducing state titanium dioxide crystal material and a preparation method thereof. The porous reducing state titanium dioxide crystal material has the anatase crystal phase; the specific surface area is 463 to 736 m<2> / g; the pore diameter is 1 to 4nm; the doping quantity of the surface Ti<3+> irons is 5.1 percent to 9.4 percent; the light absorption interval covers ultraviolet light and visible light intervals. Through an optoelectronic storage technology under the room temperature condition, the porous reducing state titanium dioxide crystal material with the large specific surface area is synthesized for the first time. The preparation method is different from a conventional synthesis method; a mild room temperature processing process is used for replacing a conventional high-energy processing process to realize the material crystallization and to overcome building defects. The porous reducing state titanium dioxide crystal material and the preparation method have the advantages that the synthesis technology is simple and green, and is suitable for large-scale production.

Owner:SHANGHAI TECH UNIV

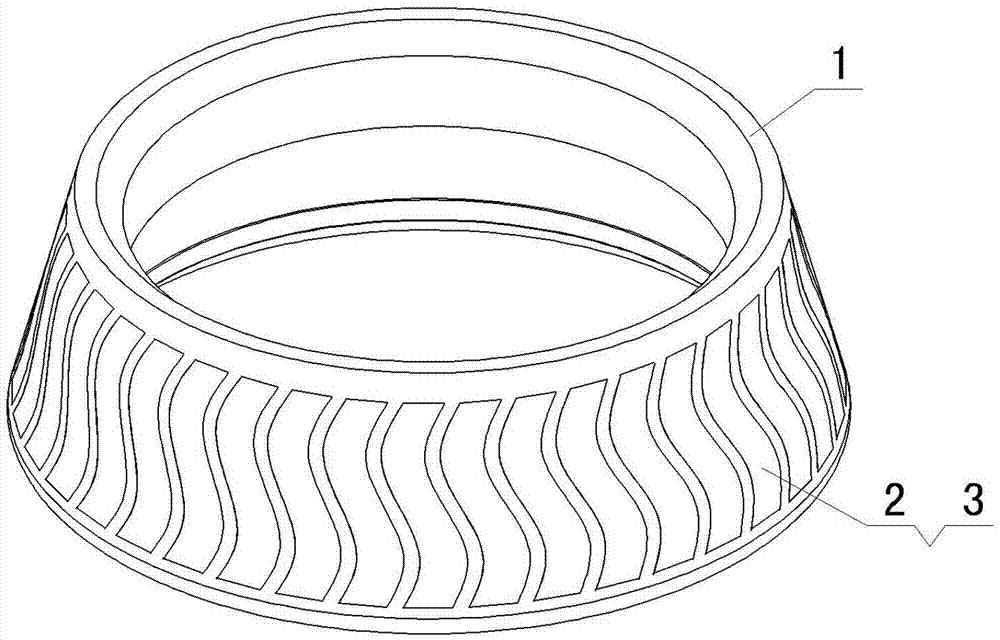

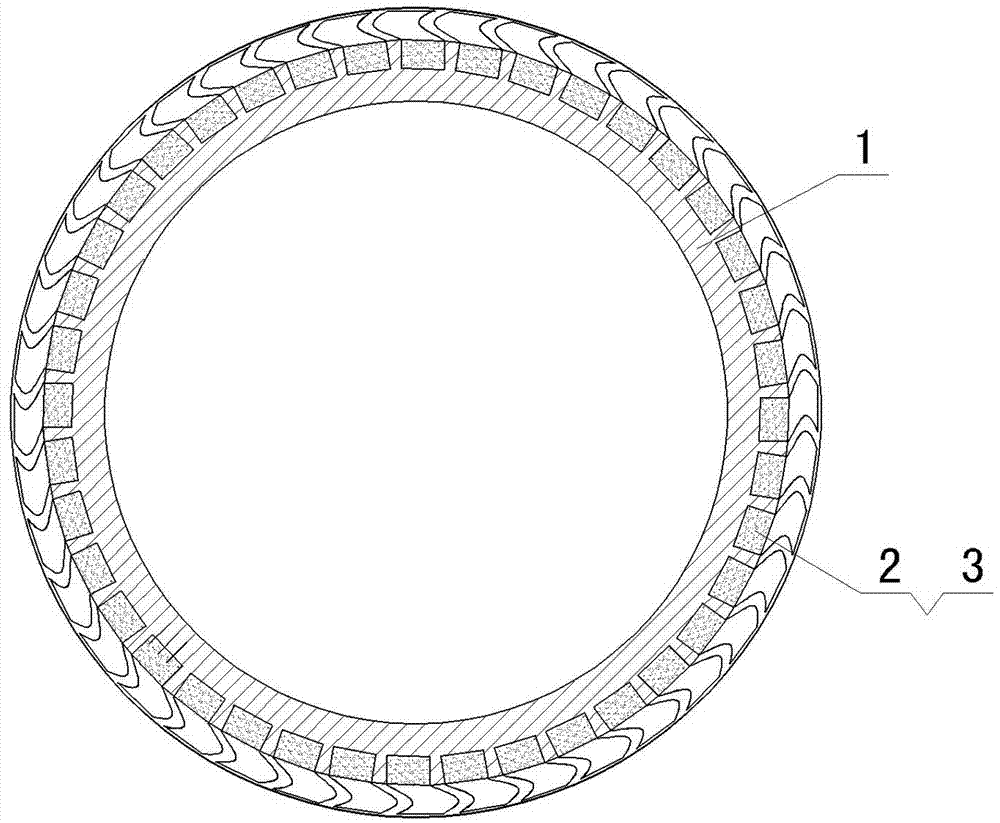

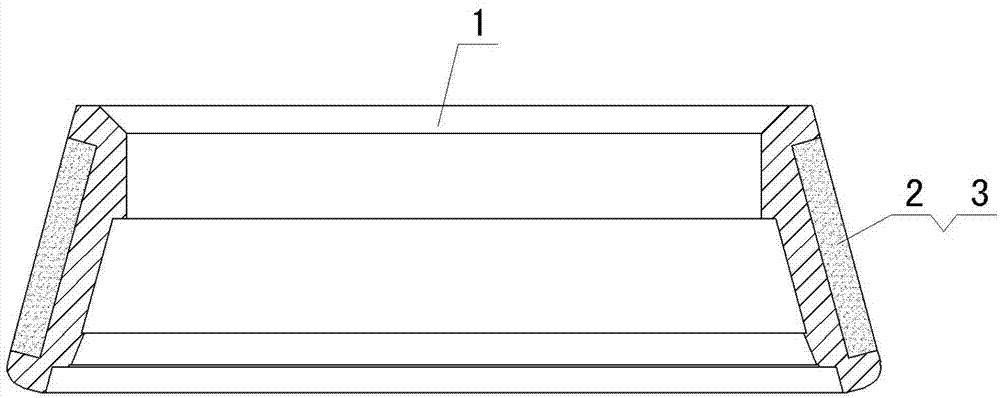

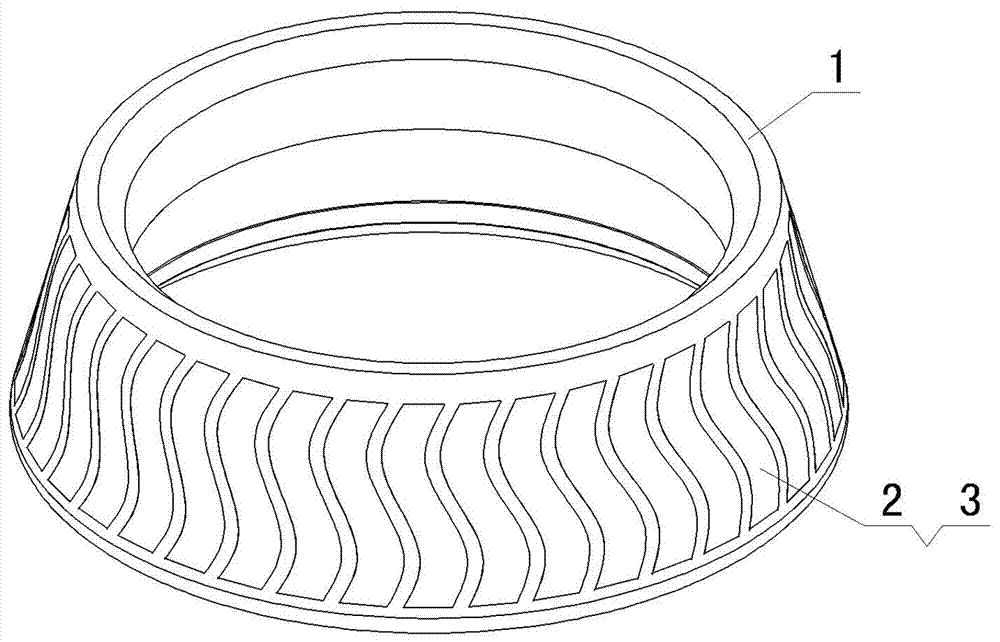

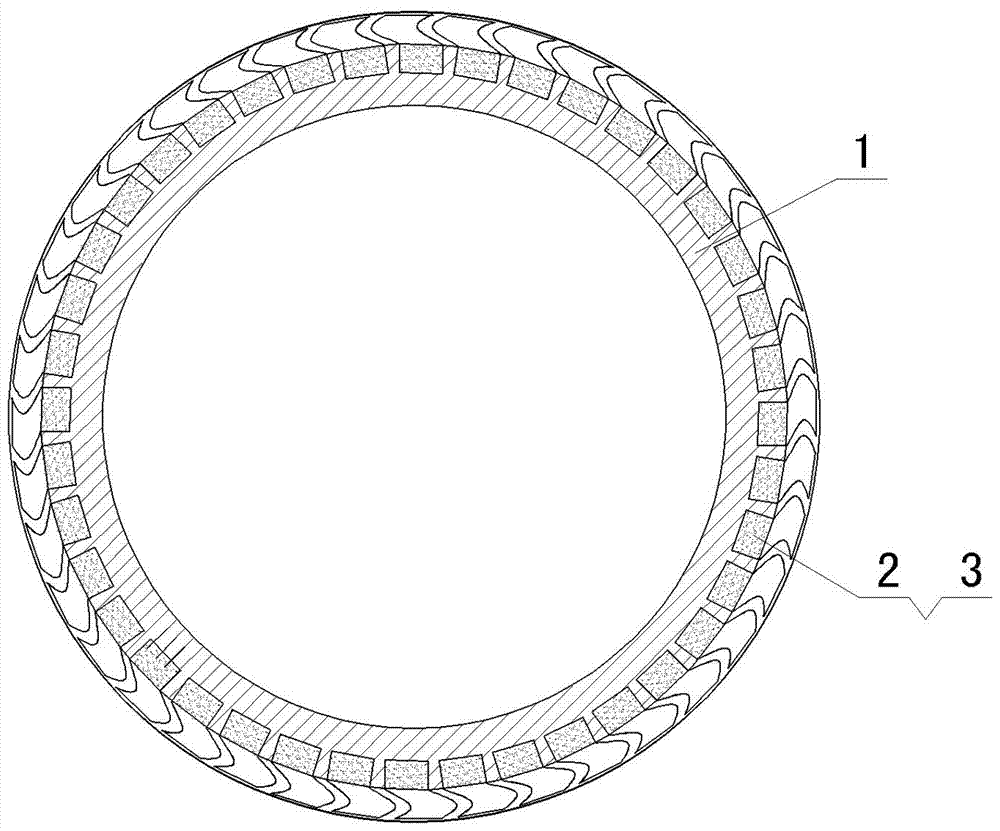

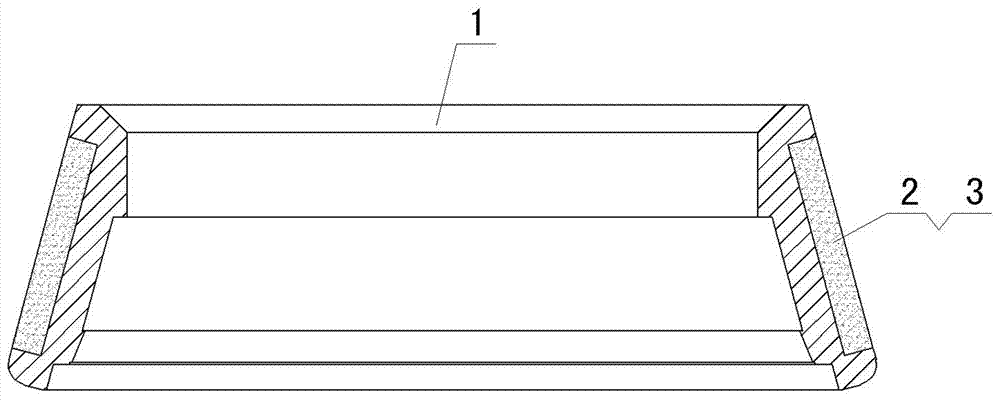

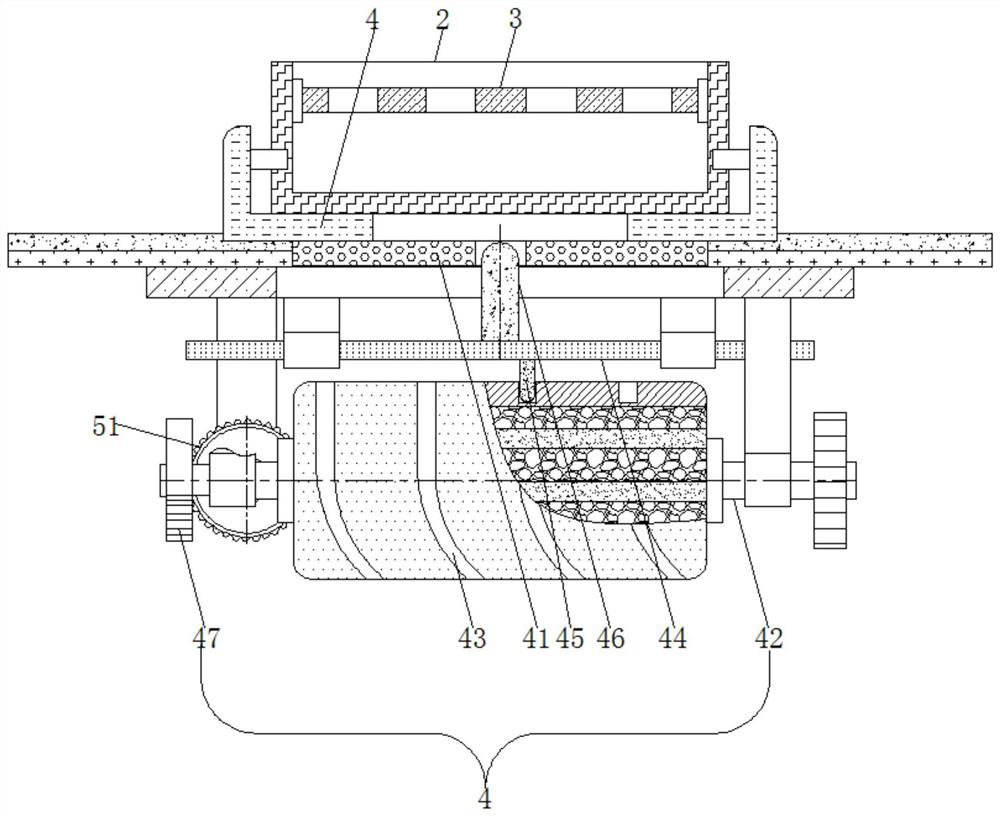

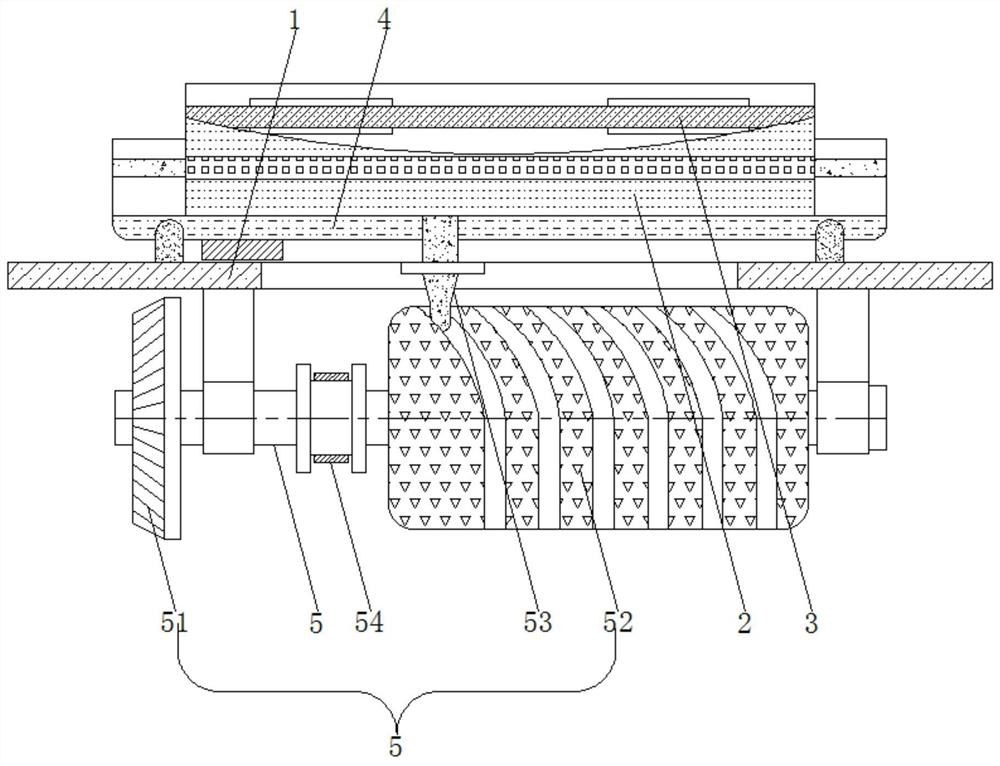

Composite material grinding roller and manufacturing method thereof

The invention relates to a composite material grinding roller and a manufacturing method thereof. The composite material grinding roller comprises a metal roller body and a plurality of wave-shaped composite bodies, wherein the wave-shaped composite bodies are embedded into a working plane of the metal roller body at equal intervals, are integrated with the metal roller body and are wave-shaped ceramic reinforcements or wave-shaped structural bodies composited from wave-shaped ceramic reinforcements and a metal substrate; the wave-shaped ceramic reinforcements are prepared by curing ceramic particles. The manufacturing method of the composite material grinding roller comprises the following steps: firstly designing and manufacturing the wave-shaped composite bodies of required sizes; then carrying out casting forming; and finally, cooling and processing, so as to obtain the composite material grinding roller. By virtue of design of the wave-shaped ceramic reinforcements, the composite material grinding roller has the structural characteristics that the ceramic reinforcements are easily and orderly arrayed in a mold cavity and are applicable to mechanical operation; the displacement and the malposition of each individual ceramic reinforcement in a casting process are effectively avoided; the whole displacement of the ceramic reinforcements in a working condition use process is avoided, and particularly, the composite material grinding roller is a secondarily poured large-sized composite material grinding roller.

Owner:GUANGDONG INST OF NEW MATERIALS

Application of compound SS-31 to prepare medicine for treating Friedreich's ataxia and related diseases

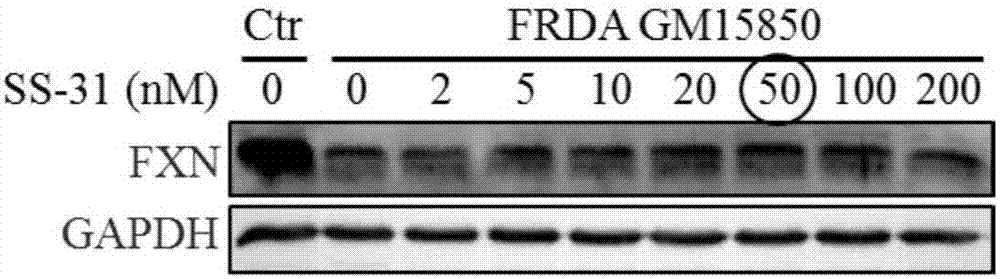

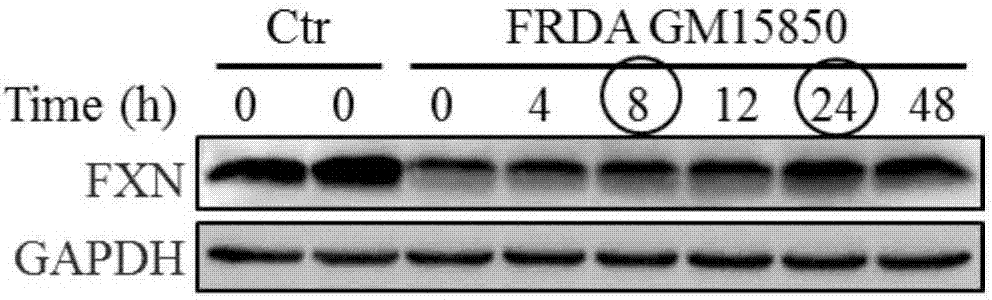

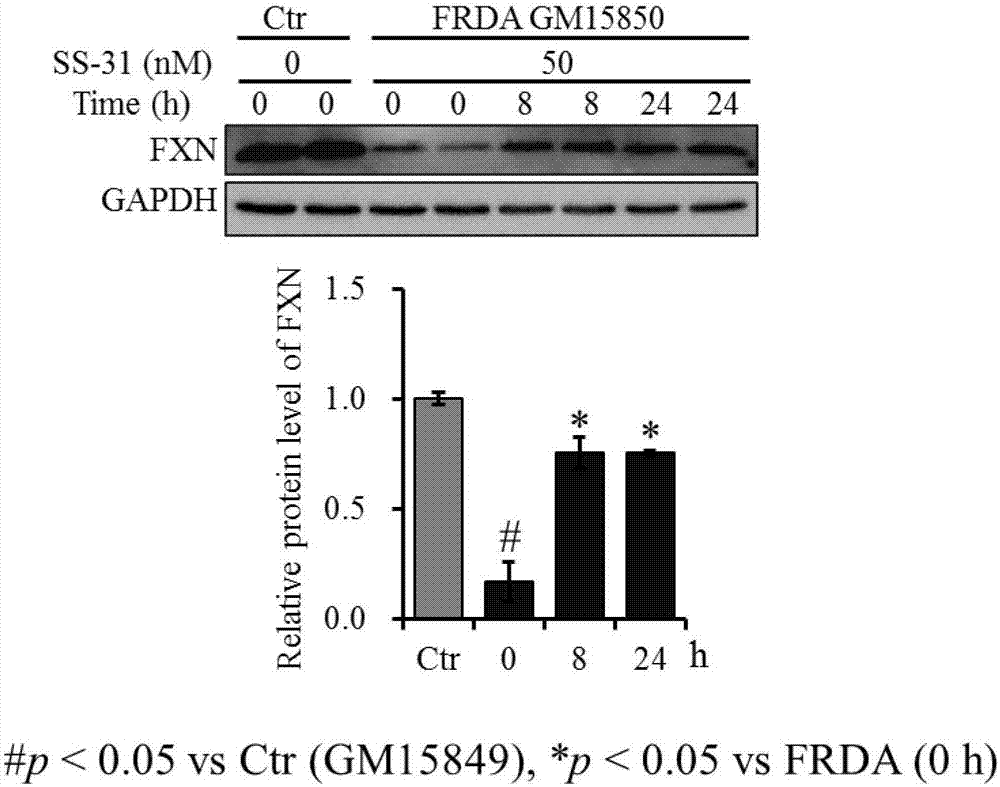

InactiveCN107320711AHuge market valueHuge social benefitsNervous disorderTetrapeptide ingredientsDiseaseMitophagy

The invention discloses an application of a compound Szeto-Schiller-31 (SS-31) to prepare a medicine for treating Friedreich's ataxia (FRDA) and related diseases. The invention belongs to the field of a medicine, and specifically relates to an application of SS-31 to treat FRDA diseases. It is found from experiments that SS-31 can up-regulate expression of frataxin (FXN) in FRDA patient's cells in a translational level, adjust iron metabolism in FRDA patient's cells, promote synthesis of iron-sulfur clusters in mitochondria, improve the function of mitochondria, reduce generation of ROS in patient's cells, and improve anti-oxidative stress performance of cells. The result shows that SS-31 has the potential value of treating FRDA.

Owner:NANJING UNIV

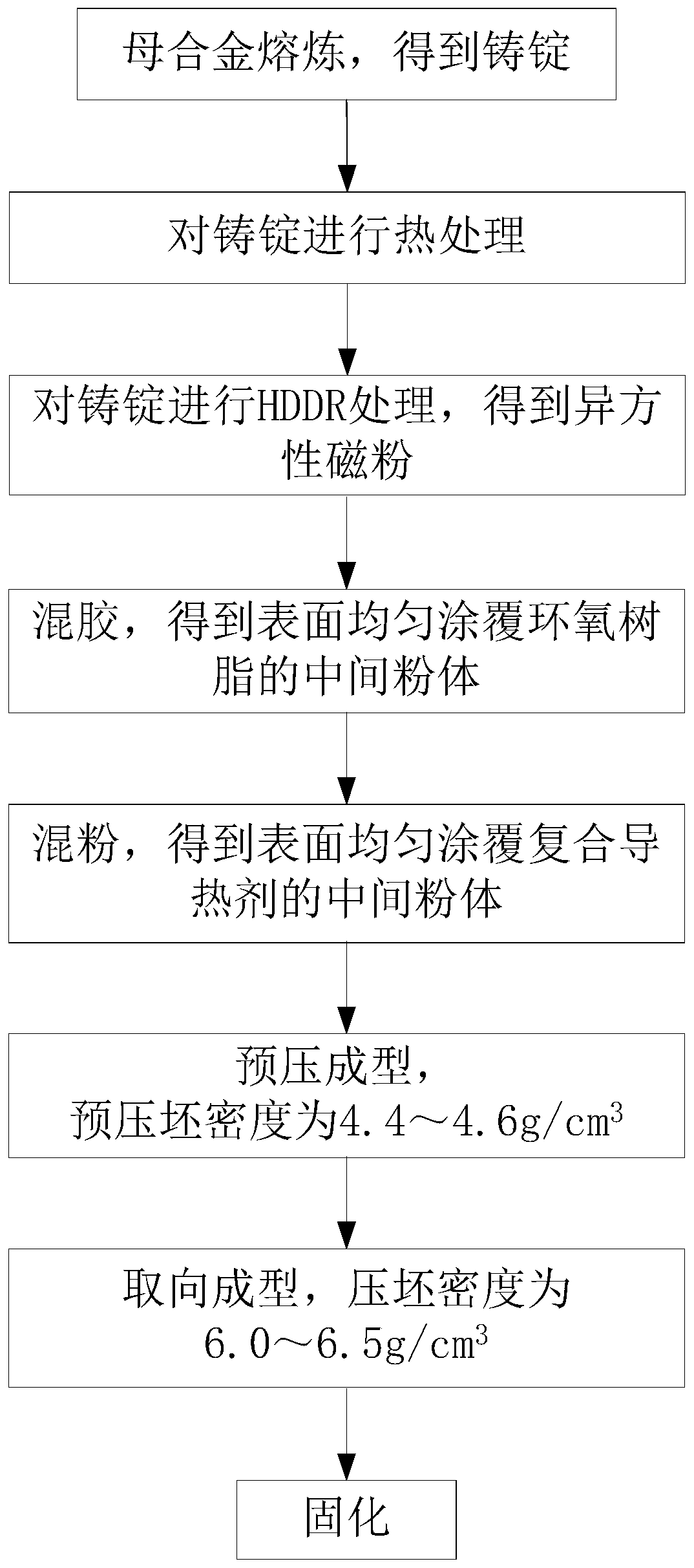

Warm-press molded bonded magnet and preparation method thereof

ActiveCN110767403AImprove compactnessImprove uniformityInductances/transformers/magnets manufactureMagnetic materialsEpoxyPhysical chemistry

The invention discloses a warm-press molded bonded magnet and a preparation method thereof. The warm-press molded bonded magnet comprises anisotropic neodymium iron boron magnetic powder, an adhesiveand a composite heat conduction agent. The preparation method comprises the steps of: master alloy smelting, heat treatment, HDDR treatment, glue mixing, powder mixing, pre-pressing forming, orientation forming, curing and the like. By adding a composite heat conduction agent, the heat conduction capability of a pre-pressed blank is enhanced to reach the Tf conversion temperature of added epoxy resin in an extremely short time, so that the powder is positioned in the uniform viscous epoxy resin, powder particles are conveniently arranged in order during orientation, the orientation is more complete, the effect is more remarkable, the density and the overall uniformity of the magnetic ring are improved during pressing, the conditions of layering, incomplete cementation and the like during orientation pressing are avoided, and the homogenization degree of the oriented magnetic ring is higher; and moreover, the composite heat conduction agent can replace traditional lubricants such as zinc stearate and magnesium stearate, so that the flowability of the magnetic powder is improved.

Owner:GRIREM ADVANCED MATERIALS CO LTD +1

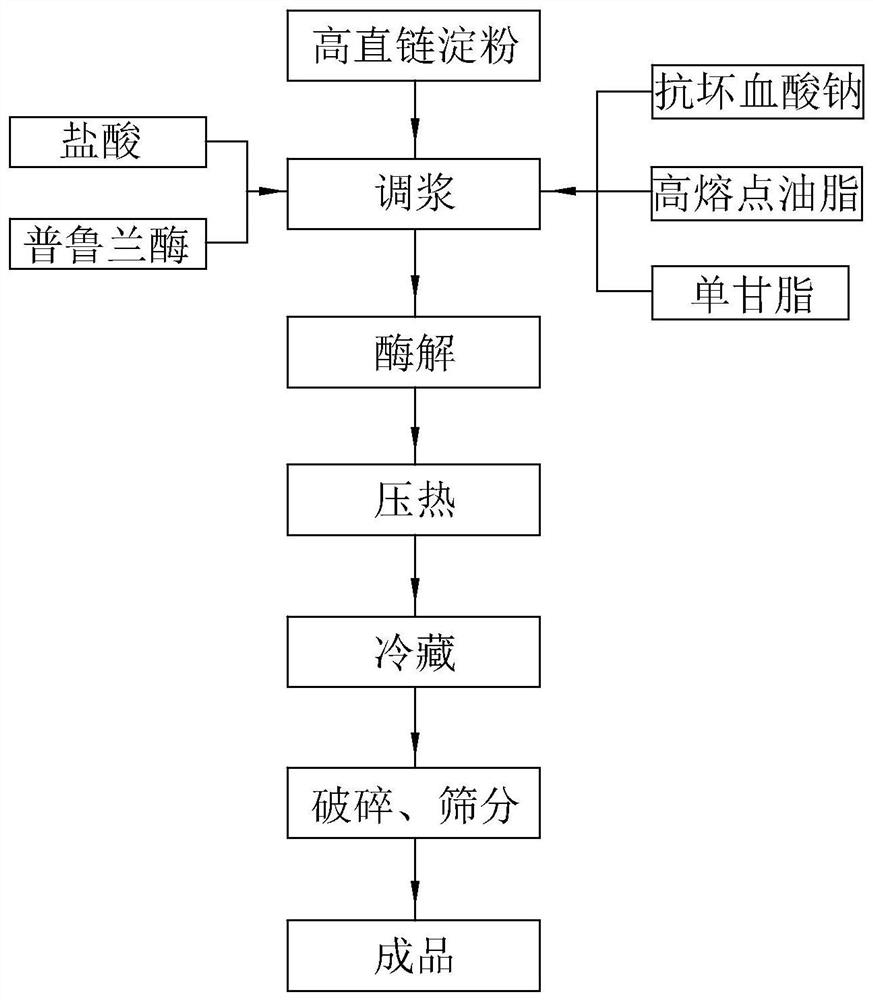

Method for preparing resistant starch RS3 from high-amylose corn starch

PendingCN113789356AIncrease contentPromote orderly arrangementFermentationBiotechnologyResistant starch

The invention discloses a method for preparing resistant starch RS3 from high-amylose corn starch. The method comprises the following steps: slurrying the high-amylose corn starch, then, adding an antioxidant, high-melting-point grease and a debranching enzyme, carrying out uniform mixing, then, carrying out refrigerating treatment at high temperature and high pressure and low temperature, and carrying out crushing and sieving, thereby obtaining the resistant starch RS3. According to the resistant starch RS3 produced by the method, the defect of 'sand grain feeling' of the existing products is overcome, and the product has the advantages of smooth taste, high resistant starch content, good heat resistance and high enzymolysis resistance.

Owner:WEIFANG SHENGTAI PHARM CO LTD

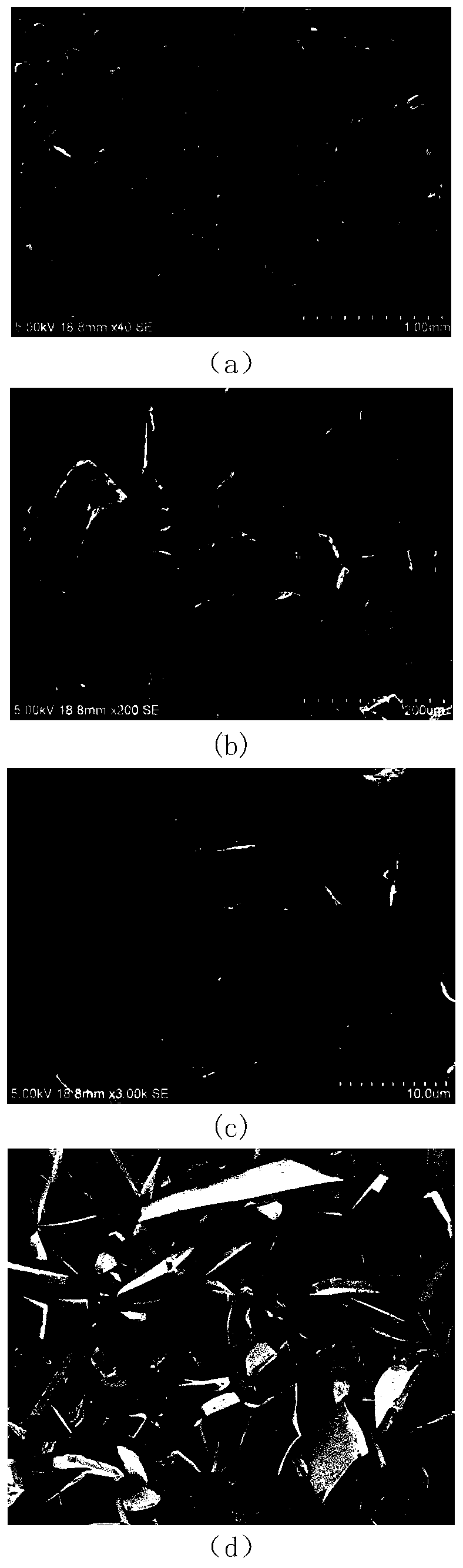

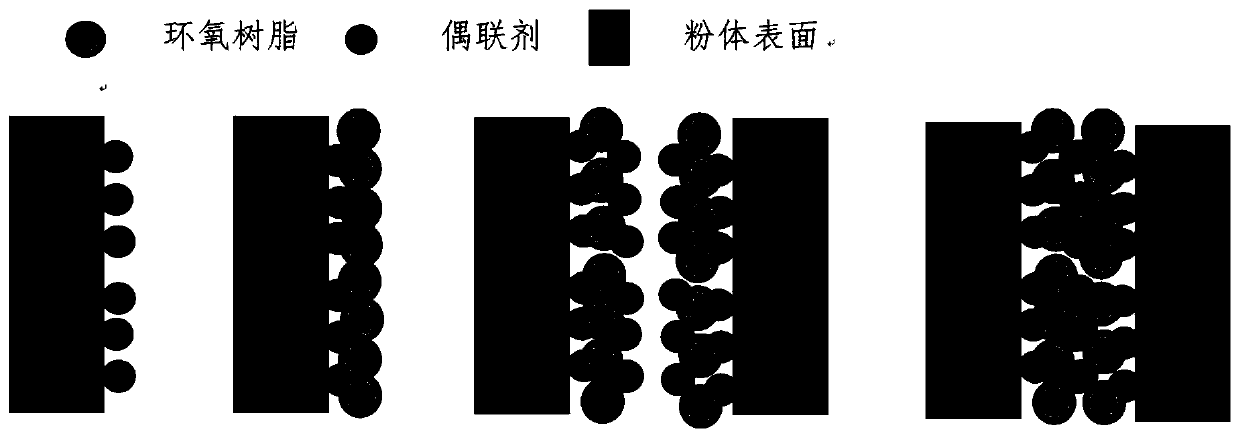

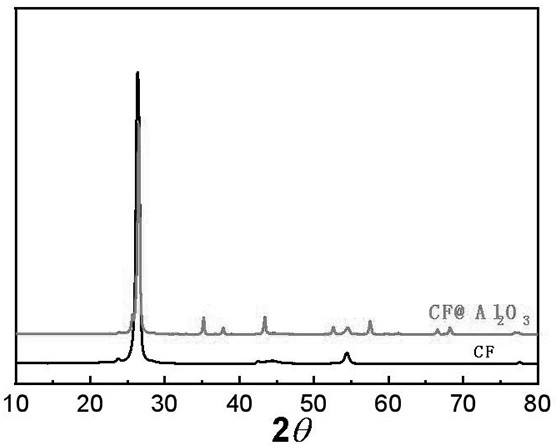

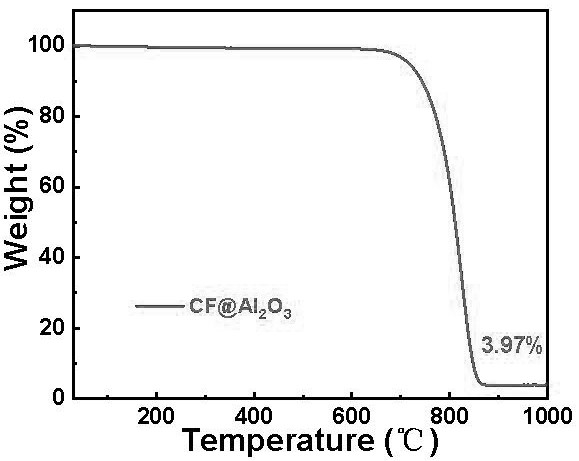

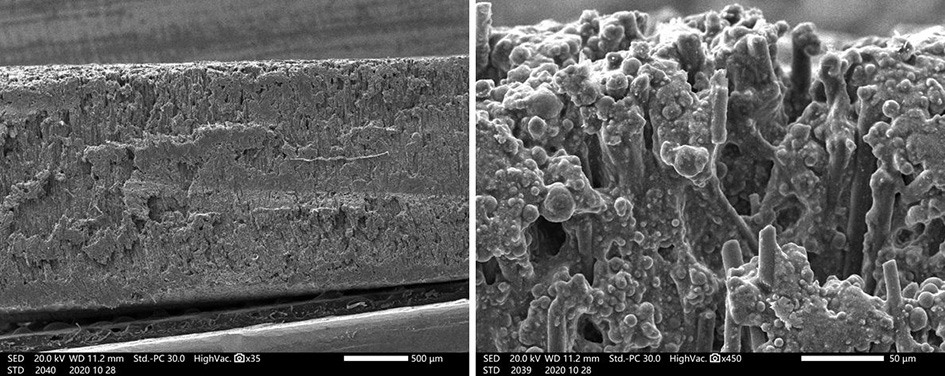

High-thermal-conductivity insulating spacer and preparation method thereof

ActiveCN112712944AImprove thermal conductivityLow conductivityMetallic oxidesHeat-exchange elementsFiberCarbon fibers

The invention discloses a high-thermal-conductivity insulating spacer and a preparation method thereof. The high-thermal-conductivity insulating spacer is composed of an insulator and a functional filler, wherein the functional filler is alumina-coated carbon fiber; according to the high-thermal-conductivity insulating spacer, the aluminum oxide coated carbon fibers are used as the high-thermal-conductivity filler, so high thermal conductivity of the carbon fibers is maintained, and electrical conductivity of the carbon fibers is weakened; and then the prepared high-thermal-conductivity filler is orderly arranged in an insulator by utilizing a mechanical extrusion orientation technology, so a thermal-conductive gasket prepared on the basis of the alumina-coated carbon fiber has high thermal conductivity and high insulativity, and requirements of practical application are met.

Owner:武汉肯达科讯科技有限公司

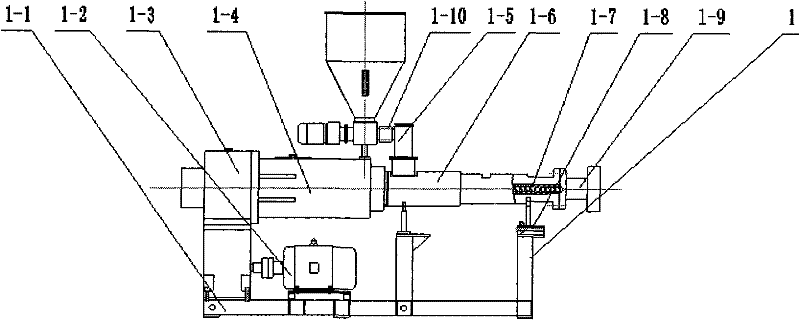

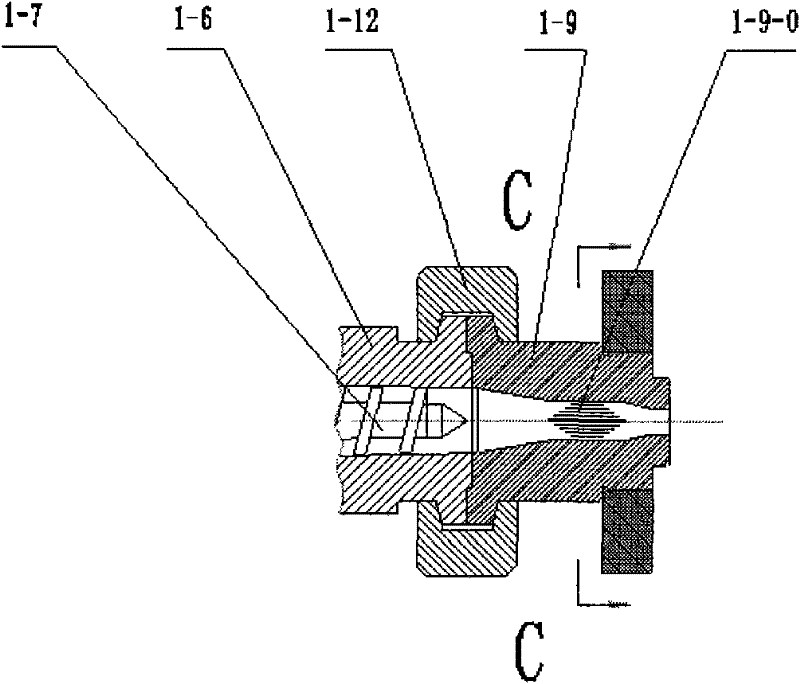

Merging core for extrusion moulding machine

InactiveCN101746039AReduce stressReduce problems such as stratificationEngineeringMechanical engineering

The invention discloses a merging core for extrusion moulding machine, characterized in that the merging core is provided with a guide pore, the cavity of which is provided with a guide device which can either be straight grid tray or broken line gird plate, and which can also be vertical tooth-staggered grid tray; the guide pore can also be conic, and the width of inlet ends of grid pores between the straight grid trays is larger than the width of outlet ends. As a component for wood-plastic composite extrusion moulding equipment, the merging core can enhance the quality of articles and is suitable for the extrusion moulding of wood-plastic composite extrusion moulding machine.

Owner:QINGDAO HUASHENG HIGH TECH DEV

A kind of manufacturing method of composite material grinding roller

ActiveCN104741173BAvoid displacementPromote orderly arrangementGrain treatmentsWave shapeMetal substrate

The invention relates to a composite material grinding roller and a manufacturing method thereof. The composite material grinding roller comprises a metal roller body and a plurality of wave-shaped composite bodies, wherein the wave-shaped composite bodies are embedded into a working plane of the metal roller body at equal intervals, are integrated with the metal roller body and are wave-shaped ceramic reinforcements or wave-shaped structural bodies composited from wave-shaped ceramic reinforcements and a metal substrate; the wave-shaped ceramic reinforcements are prepared by curing ceramic particles. The manufacturing method of the composite material grinding roller comprises the following steps: firstly designing and manufacturing the wave-shaped composite bodies of required sizes; then carrying out casting forming; and finally, cooling and processing, so as to obtain the composite material grinding roller. By virtue of design of the wave-shaped ceramic reinforcements, the composite material grinding roller has the structural characteristics that the ceramic reinforcements are easily and orderly arrayed in a mold cavity and are applicable to mechanical operation; the displacement and the malposition of each individual ceramic reinforcement in a casting process are effectively avoided; the whole displacement of the ceramic reinforcements in a working condition use process is avoided, and particularly, the composite material grinding roller is a secondarily poured large-sized composite material grinding roller.

Owner:GUANGDONG INST OF NEW MATERIALS

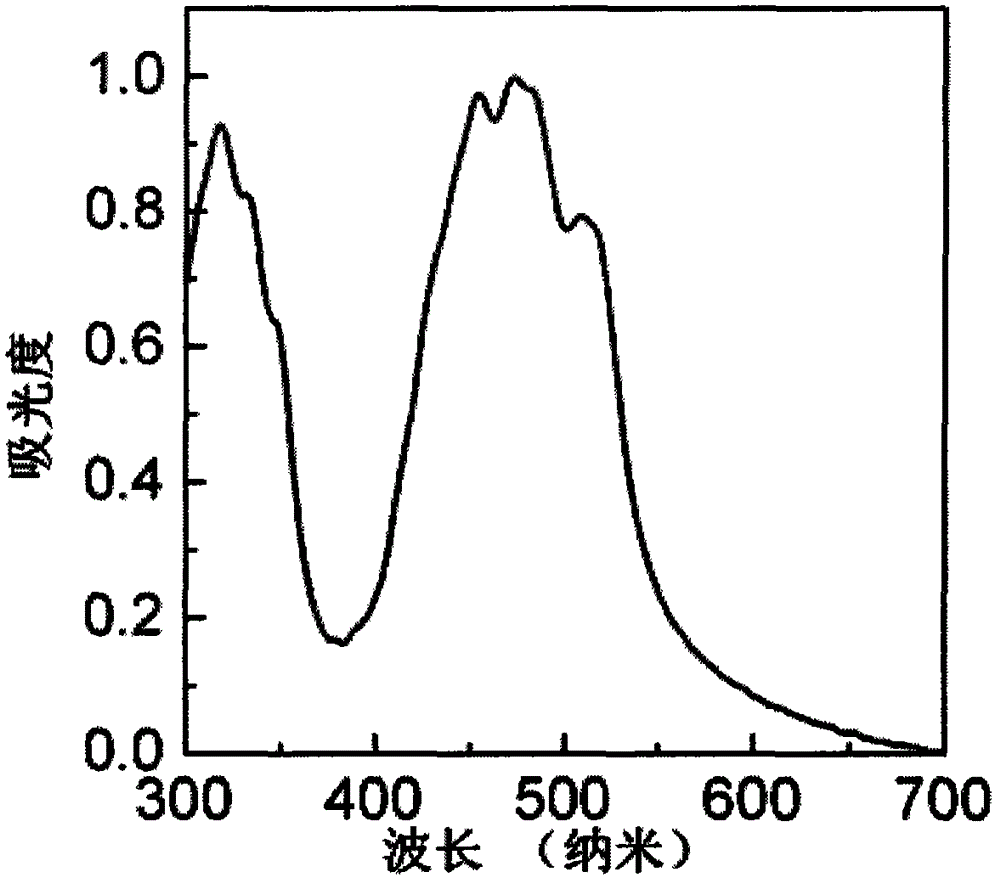

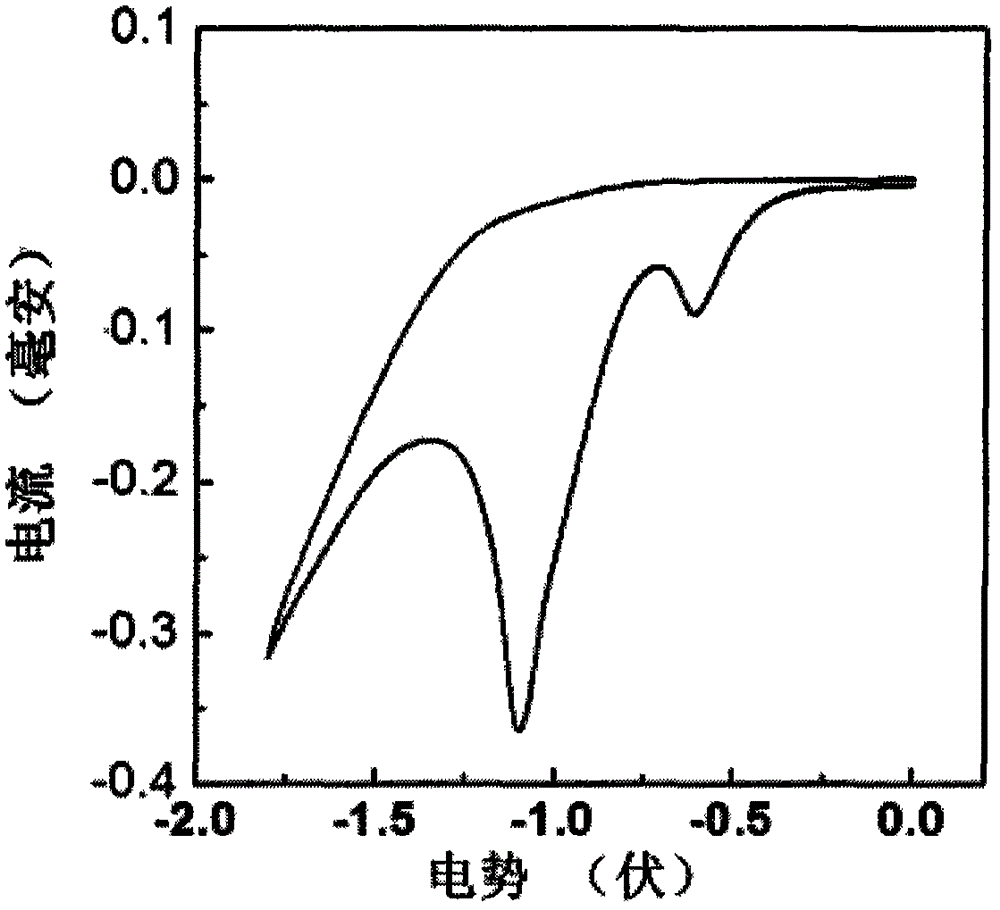

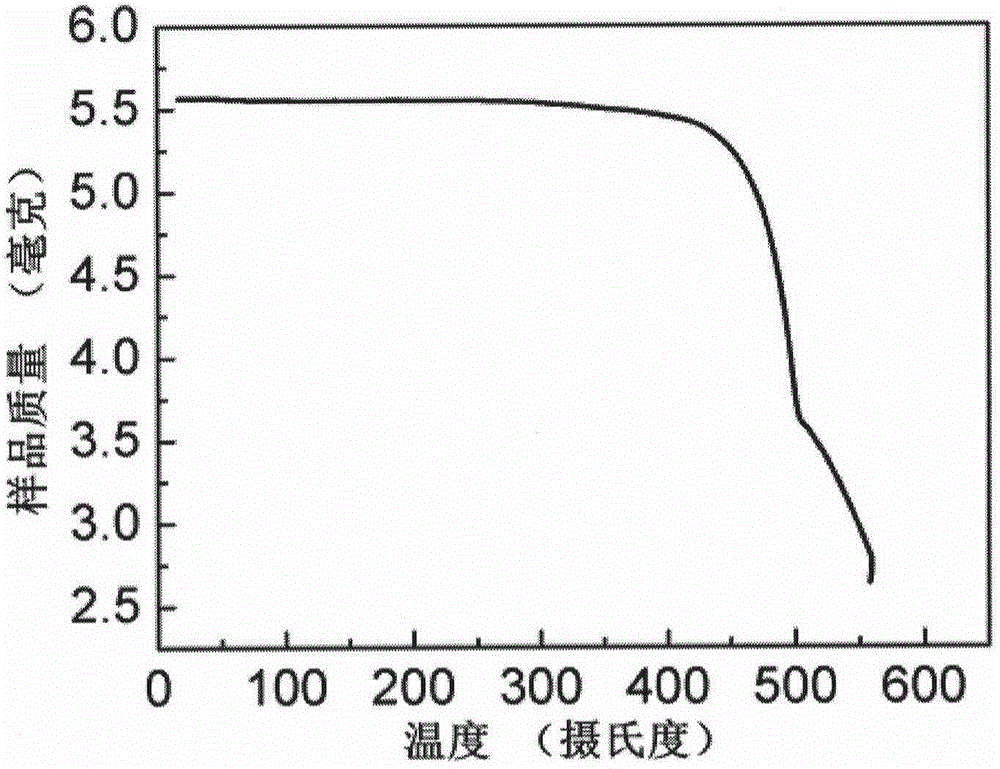

Preparation method and application of organic conjugated micro-molecules rich in nitrogen and sulfur

InactiveCN105884794AUniversalImprove stabilityOrganic chemistrySolid-state devicesQuinoxalinePyrazine

The invention discloses organic conjugated micro-molecules rich in nitrogen and sulfur, and a preparation method and application thereof. The organic conjugated micro-molecules rich in nitrogen and sulfur have a structure shown by formula (I), wherein R is hydrogen, alkyl or aryl. The invention also provides a preparation method of the compound of formula (I). The synthetic route of the organic conjugated micro-molecules is simple and effective; raw materials are commercial cheap products, and the synthesis cost is low; and a synthetic method has universality, and can be popularized and applied to synthesis of other various substituent substituted tetrathiophene derivatives. OFETs (organic field-effect transistors) prepared by taking 5,11-dihydro-2,2'-([1,3]) dithiol [4,5-e] pyrazine [2,3-g][1,3] dithiol [4,5-b] quinoxaline-2,8-diidene) di-malononitrile compound (DTYM), synthesized by the method disclosed by the invention, as an organic semiconductor layer are relatively high in mobility and on / off ratio, the highest electron mobility is 0.005cm<2>V<-1>s<-1>, the on / off ratio is greater than 10<3>, and the organic conjugated micro-molecules have a good application prospect in n-type OFET devices.

Owner:INST OF CHEM CHINESE ACAD OF SCI

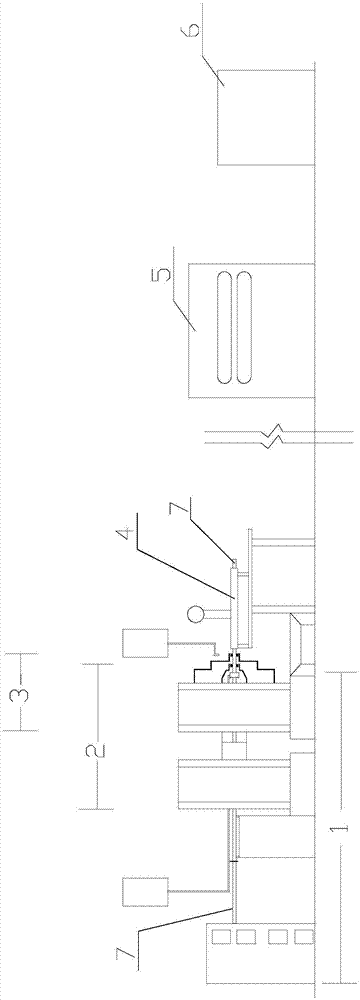

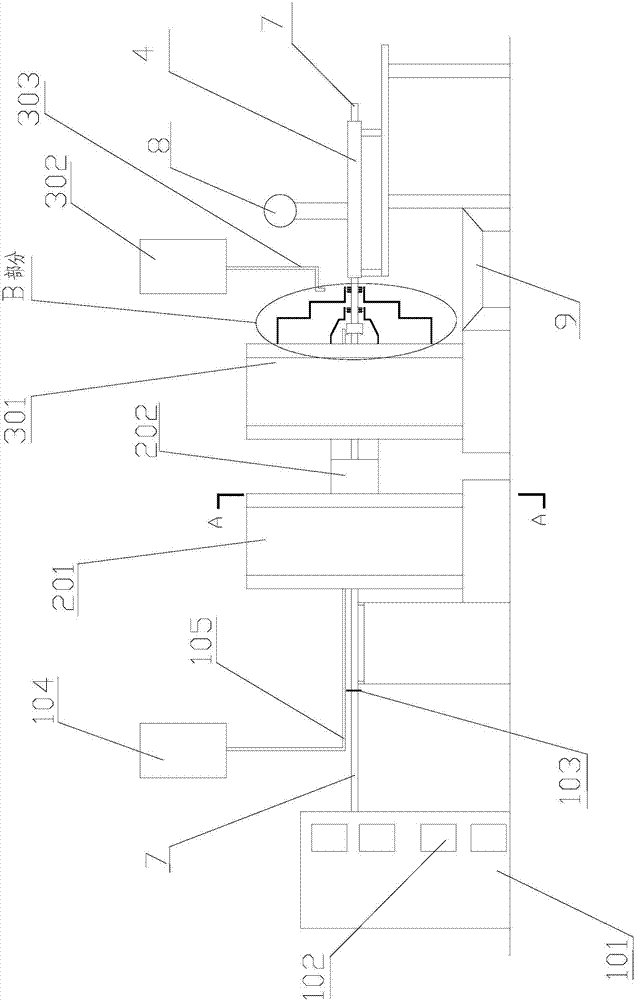

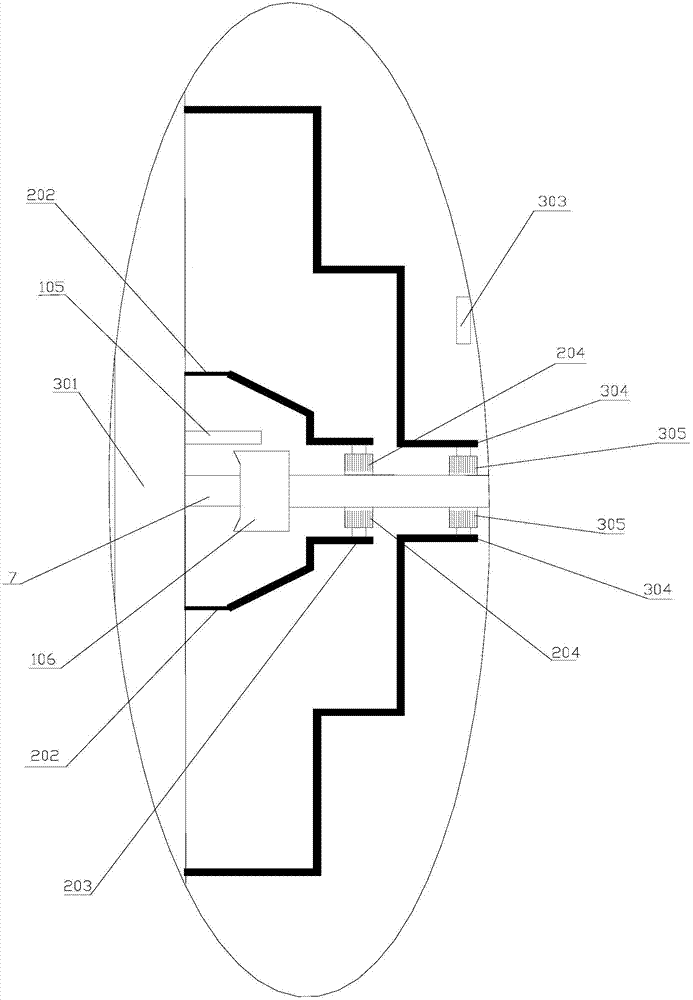

Production device for direct-pull winding composite glass reinforced plastic pipe

PendingCN107336448AImprove composite qualityReduced pull resistanceTubular articlesTraction unitMechanical engineering

The invention discloses a production device for a direct-pull winding composite glass reinforced plastic pipe. The production device comprises a direct-pull layer unit, a front winding layer unit and a reverse winding layer unit which are sequentially distributed front and back along an inner mold. An outer mold disposed on the inner mold in a sleeving mode is arranged at the rear side of the reverse winding layer unit. The outer mold is provided with a heating mechanism. A traction unit and a cutting unit are sequentially distributed at the rear side of the outer mold. A direct-pull gluing point, a first winding point and a second winding point are all arranged in an area between a reverse winding roller and an outer mold inlet in a concentrated mode, and the area is called a processing section. The direct-pull gluing point, the first winding point and the second winding point are sequentially distributed in the processing section in a front-back approaching mode. The second winding point gets close to the outer mold inlet. By the adoption of the production device, the composite quality of the glass reinforced plastic pipe is greatly improved; and meanwhile, drawing resistance of a composite layer is greatly reduced, production can be better completed smoothly and power consumption is reduced.

Owner:黄明发

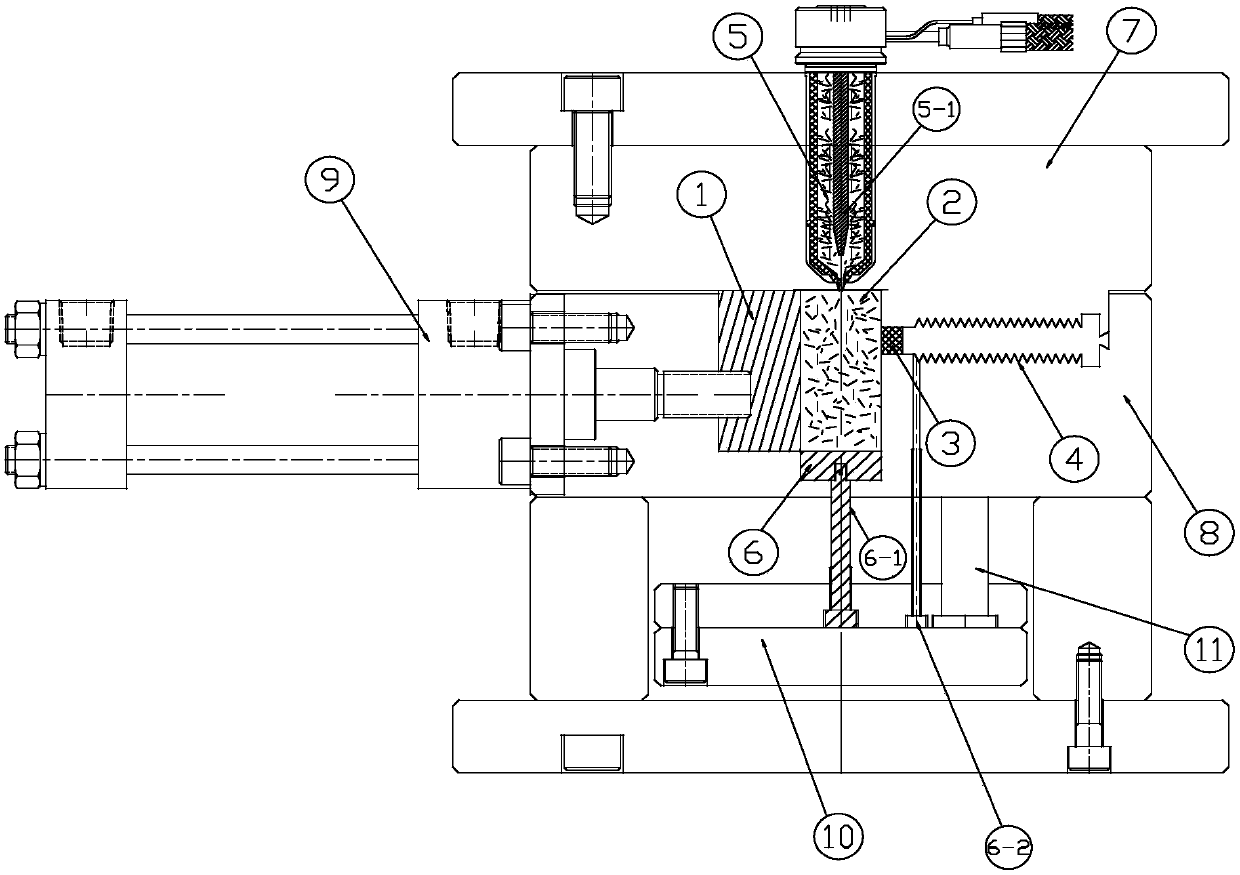

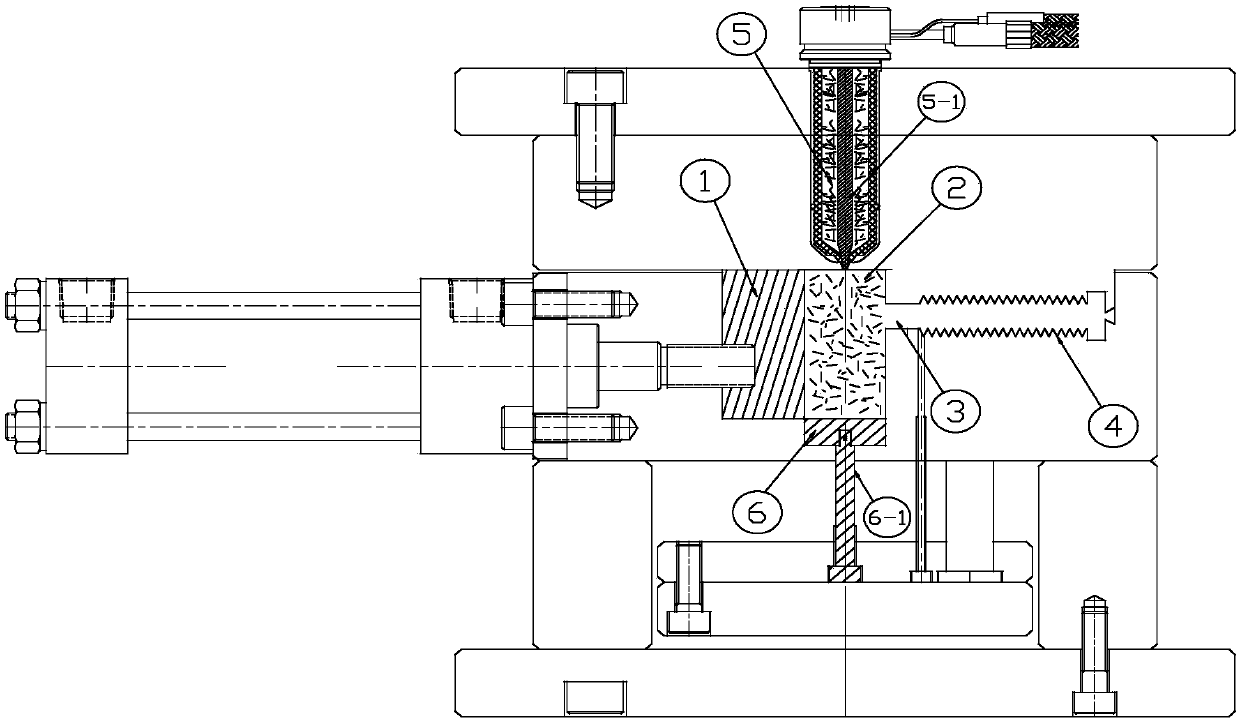

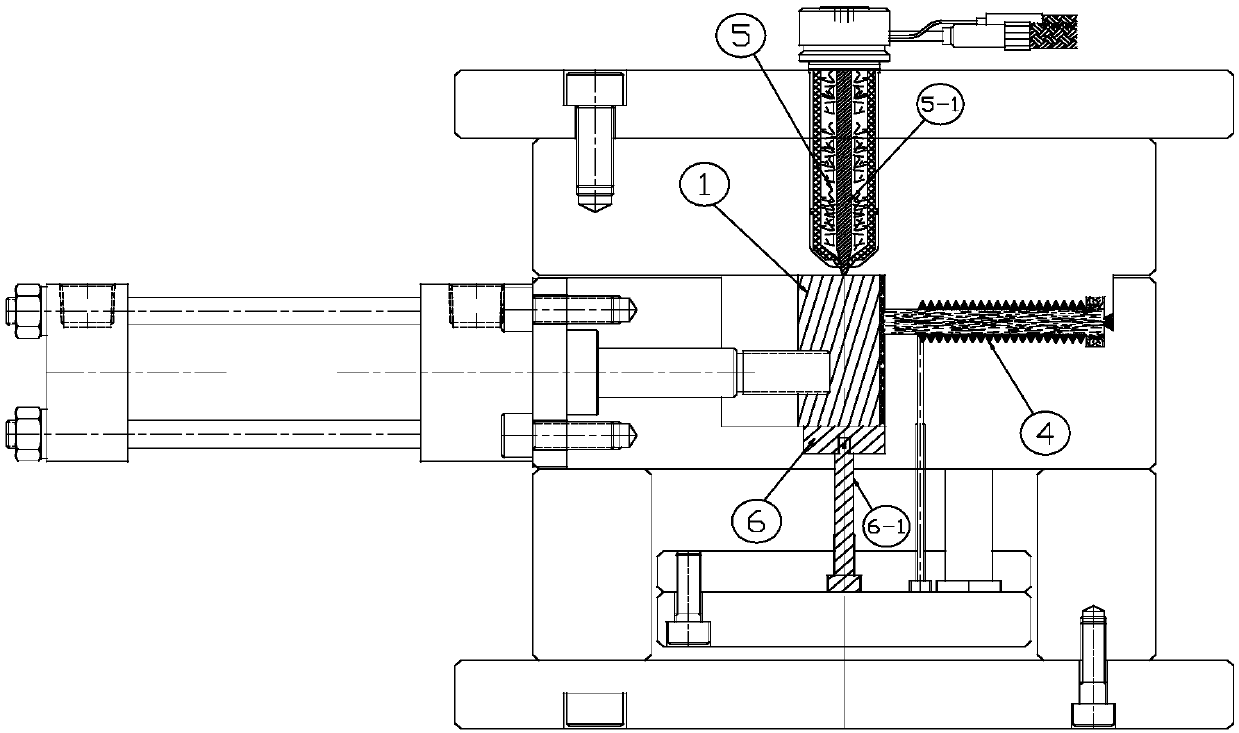

Crystalline material injection molding self-reinforcement process and equipment

The invention discloses a crystalline material injection molding self-reinforcement process. The process includes the steps of: 1, injection molding mould pressing shear induced crystallization treatment: subjecting an injection molding raw material in a heated molten state to injection moulding, then conducting mould pressing extrusion on a semisolid injection molded blank material into a moldingcavity; and 2, stable molding treatment: heating the molding cavity to complete thermal stability treatment of a molded part. The process provided by the invention combines injection molding and mould pressing, carries out second mould pressing extrusion at a crystallization temperature in the injection moulding process of a thermoplastic material, and controls different compression ratios to promote rapid crystallization orientation and utilizes later heat treatment to fix the orientation state and release internal stress, and the product can satisfy the requirements of surgical implantationcrystalline thermoplastic material medical irregular precision injection molded parts for mechanical properties and stability, and has a wide range of application.

Owner:CHENGDU MEDART MEDICAL SCI CO LTD

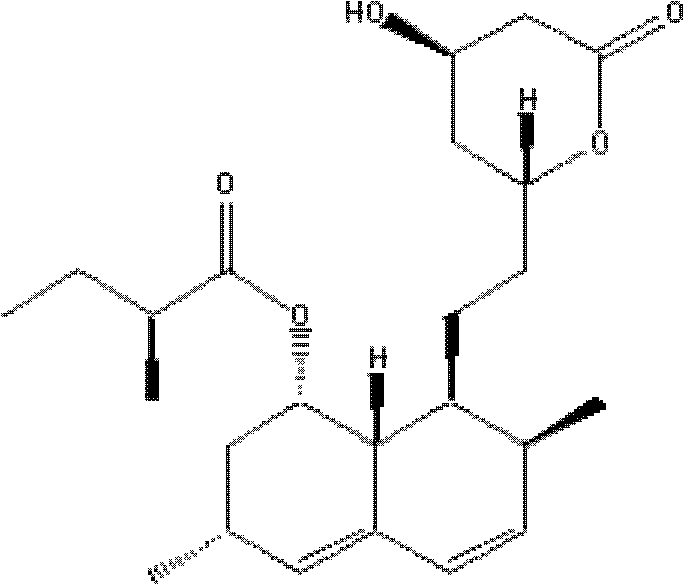

Lovastatin purification method combining auxiliary magnetic crystallization

ActiveCN103172604APromote orderly arrangementHigh purityOrganic chemistryOrganic solventPurification methods

The invention discloses a lovastatin purification method combining auxiliary magnetic crystallization, which comprises the following steps: dissolving a lovastatin crude product in organic solvent, and then gradually cooling the lovastatin solution; and applying a magnetic field to the solution until crystals are precipitated, and separating and drying the crystals to obtain a lovastatin product. In the crystallization process, the ordered arrangement of lovastatin molecules is increased through auxiliary magnetic treatment, thereby increasing the quality and quantity of high-purity crystal nuclei, improving the crystallization conditions, obtaining the crystals which are high in purity and easy to separate and enhancing the product quality.

Owner:NEW FOUNDER HLDG DEV LLC +2

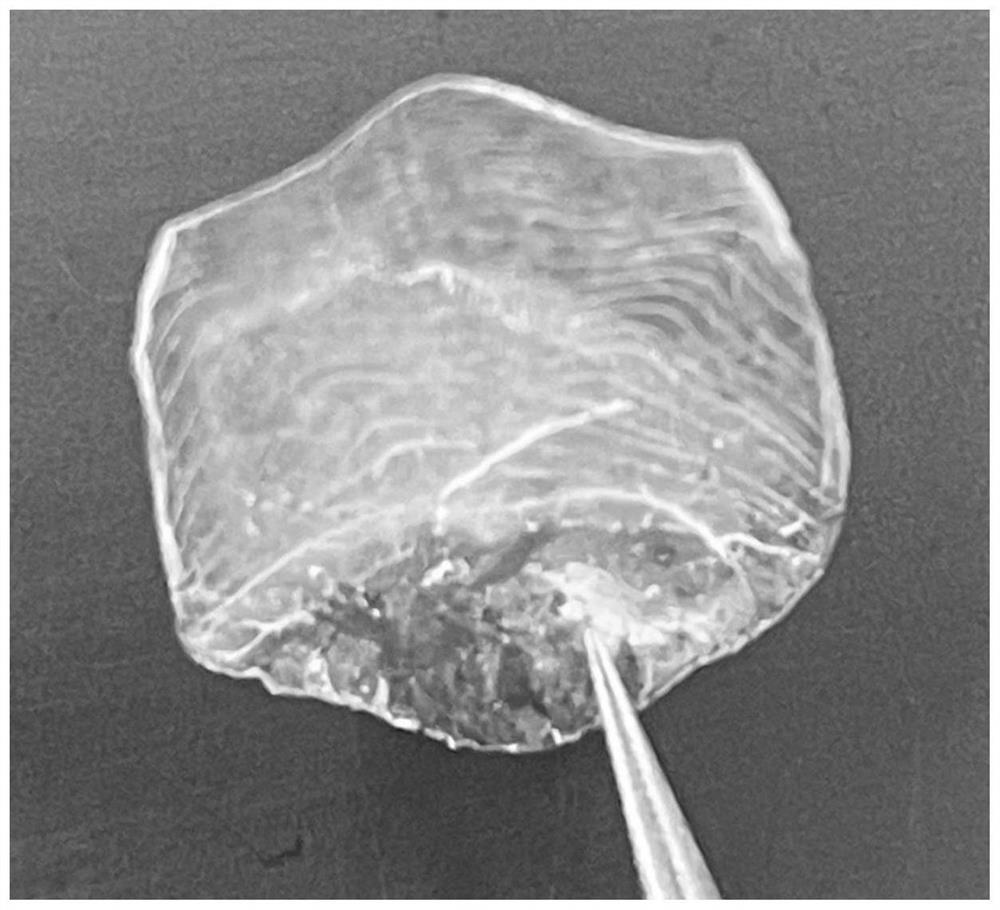

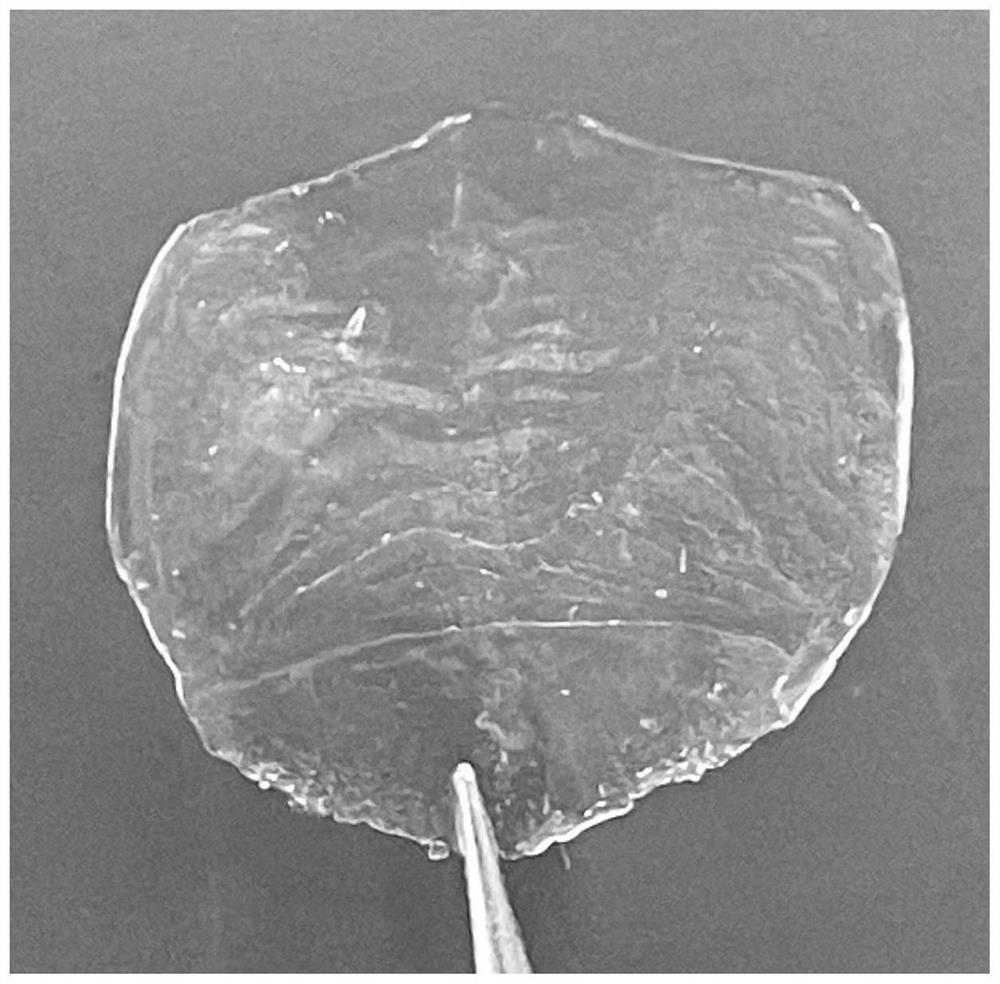

Method for constructing engineered intelligent myocardial tissue based on fish scale substrate

PendingCN114540286ARealize comprehensive utilizationAbundant fresh water resourcesCulture processArtificial cell constructsFresh fishEngineering

The invention discloses a method for constructing an engineered intelligent myocardial tissue based on a fish scale substrate. The method comprises the following steps: cleaning fresh fish scales, removing pigments by adopting an alkaline solution, and then carrying out decalcification treatment on the fish scales; a layer of thermally induced deformation film is adhered to the bottom of the fish scale; the treated fish scales are subjected to sterilization and surface modification, and then myocardial cells and other supporting cells are inoculated for co-culture; under the driving of near-infrared laser, the fish scales of the compound cells simulate cardiac contraction to autonomously deform so as to construct intelligent cardiac muscle tissues. According to the method disclosed by the invention, the engineered myocardial tissue with space-time intelligent response can be obtained, the structure and function maturation of the engineered myocardial tissue can be promoted by fully combining directional cell assembly and simulating non-contact mechanical stimulation of an in-vivo physiological environment, and the method is applied to the research of myocardial repair, in-vitro cardiovascular disease model construction and cardiac toxicity screening.

Owner:SUZHOU FISHSEEDS BIOLOGICAL TECH CO LTD

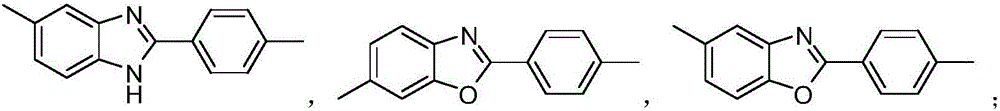

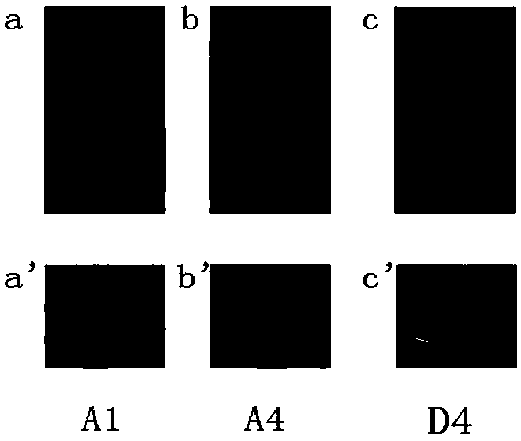

Low thermal expansion coefficient silicon dioxide/polyimide composite film and preparation method thereof

PendingCN110372895AThermal Expansion Coefficient ControlImprove thermal stabilityBenzoxazoleComposite film

The invention discloses a low thermal expansion coefficient SiO2 / polyimide composite film and preparation method thereof. The composite film is prepared from a basis material of rigidity polyimide andSiO2 through in-situ composite, and the basis polyimide is prepared from 1,2,4,5-Bbenzenetetracarboxylic anhydride (PMDA) and 2-(4-aminophenyl)-5-amidogen-benzoxazole (BOA) through polycondensation.According to the low thermal expansion coefficient SiO2 / polyimide composite film and the preparation method thereof, the preparation technology is simple, and SiO2 is well dispersed in the basis material. Compared with the prior art, according to the SiO2 / polyimide composite film, the rigidity PMDA and the BOA structural units are introduced in the molecular structure of the basis material, and meanwhile the high thermostability and the low thermal expansion coefficient of the prepared SiO2 / polyimide composite film are presented through the high heat resistance of the BOA. The requirements ofheating matching of silicon-based materials in the aspect of integrated circuit and chip package technology can be well met, the low thermal expansion coefficient SiO2 / polyimide composite film can beused in the microelectronics industry, for example, insulating layers in multilevel-multilayer metallization of the electronic packaging field; and the low thermal expansion coefficient SiO2 / polyimidecomposite film can also be used for insulating layers in solar cells. Thus, the low thermal expansion coefficient SiO2 / polyimide composite film has wide application prospects.

Owner:CHONGQING UNIV OF ARTS & SCI

Polycarbonate composite material and preparation method thereof and method for manufacturing LED (Light Emitting Diode) lamp housing

ActiveCN102250462BImprove interfacial adhesionReduced solvent stress cracking resistancePoint-like light sourceGlobesEpoxyProcedure Agents

The invention discloses a polycarbonate (PC) composite material and a preparation method thereof and a method for manufacturing an LED (Light Emitting Diode) lamp housing. The composite material is prepared from the following components in percentage by weight: 84-98.59 percent of polycarbonate resin, 0.01-8 percent of light diffusant, 1-5 percent of silicone resin, 0.1-1 percent of processing agent, 0.1-1 percent of thermal stabilizer, 0.1-1 percent of light stabilizer and 0.1-1 percent of processing aid. In the invention, the light diffusant is processed by using epoxy resin, so that the interfacial bond of the light diffusant and polycarbonate is improved, and the solvent-stress-resistant cracking performance of the PC composite material is decreased. Ordered arrangement of polycarbonate molecules is increased and the internal stress is reduced under optimized injection mould temperature; and the minimum influence of a toughening component on the transparency of a final lamp housing product is guaranteed by adding the silicone resin with refractive index of 1.587 and toughening effect. The reduction in impact strength of the lamp housing product brought by higher mould temperature during injection molding can be compensated by adding the silicone resin. The light diffusion PC material with a balance among light transmittance, haze and diffusion angle is obtained by adding the light diffusant, so that an LED lamp emits non-dazzling, soft and pleasant light.

Owner:GUANGZHOU SUPER DRAGON ENG PLASTICS

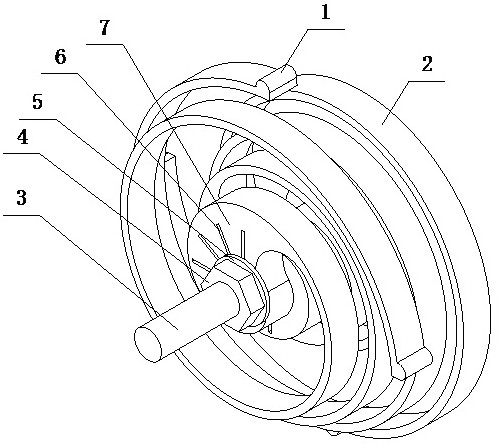

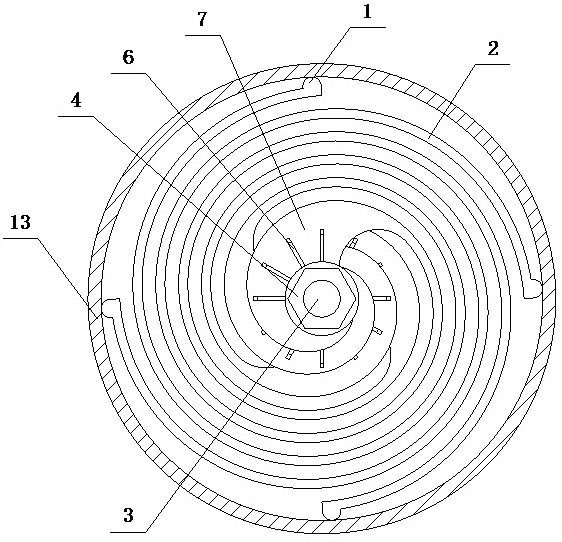

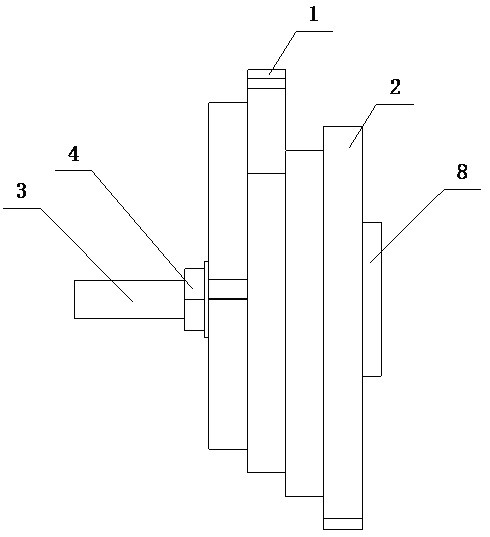

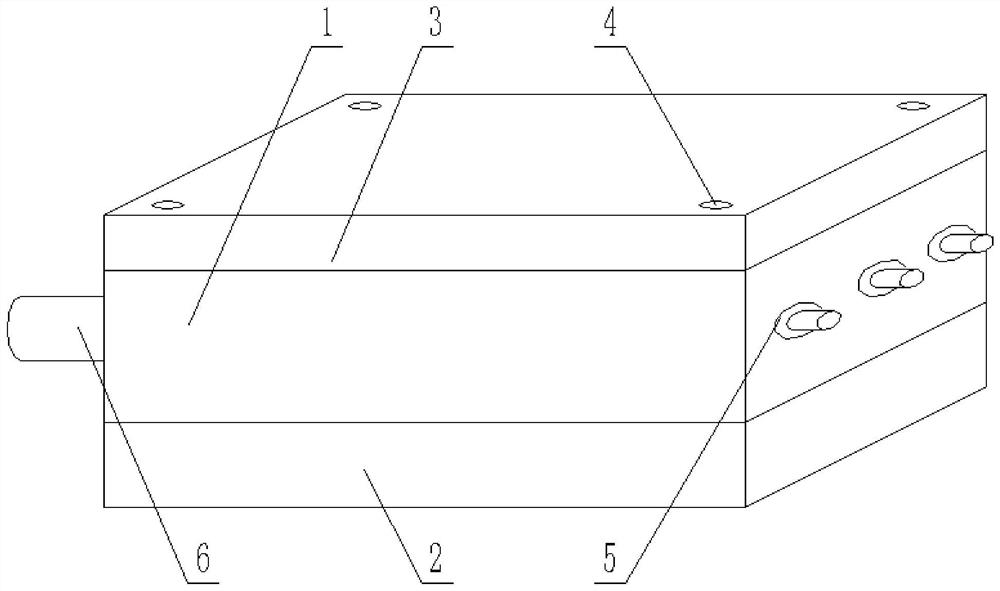

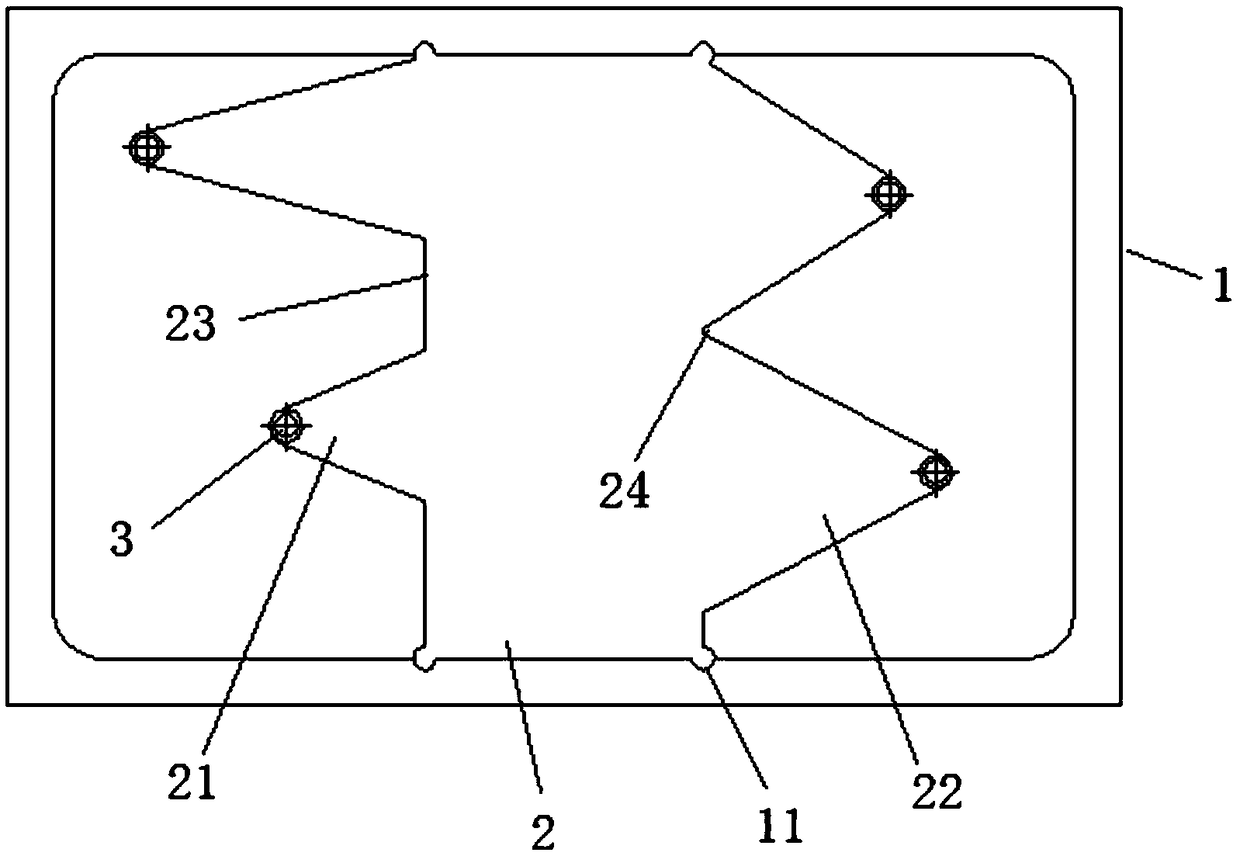

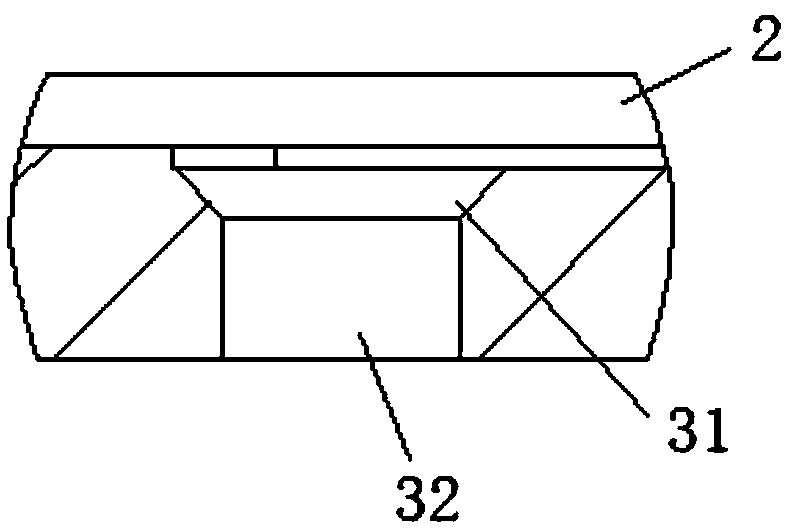

Cable core shaping device

ActiveCN112002495APromote orderly arrangementAvoid Offset MisalignmentCable/conductor manufactureStructural engineeringElectric cables

The invention relates to a cable core shaping device, and discloses a shaping device which can ensure the arrangement compactness while arranging cable cores orderly and can prevent the interior of the cable from deviating and displacing. The device is characterized in that the limiting block is a circular block; a fixing slot is formed in the limiting block in the radial direction; a protective pad is arranged on a centering column in a sleeving manner; a fixing screw cap is screwed with the centering column; the fixing device is composed of an anti-skid protruding pad, a vortex plate, angleinserting grooves, a middle solid plate, a penetrating hole, an inserting block and a threading groove; one end of the vortex plate is connected with the middle solid plate; the other end of the vortex plate extends in a vortex mode in the direction away from the middle solid plate to form the threading groove; the anti-skid protruding pad is arranged at the other end of the vortex plate; the penetrating hole corresponding to the centering column is formed in the middle solid plate; the four angle inserting grooves are formed in one side of the middle solid plate in the circumferential direction around the center of the penetrating hole, and the included angle between every two adjacent angle inserting grooves is 30 degrees; and the inserting block corresponding to the fixing inserting groove is arranged on the other side of the middle solid plate.

Owner:黄山万泰电缆有限公司

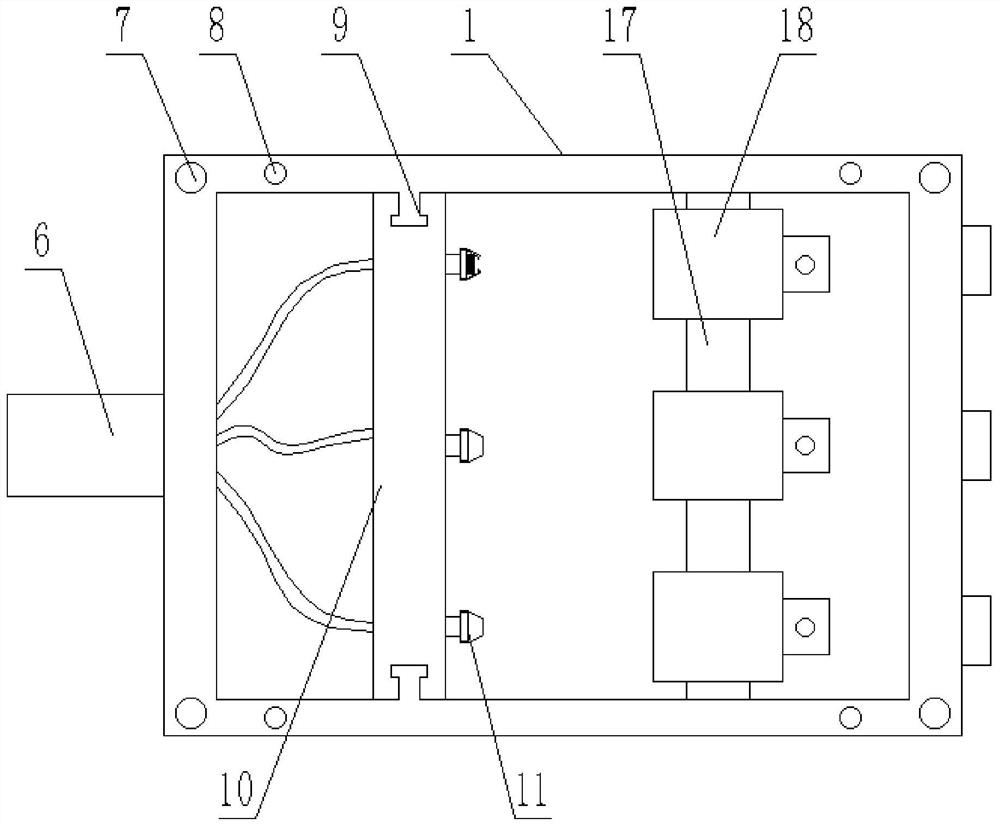

A kind of anti-violence plugging and unplugging electrical equipment junction box

ActiveCN109412096BPromote orderly arrangementAvoid damageElectrical apparatusStructural engineeringElectric equipment

The invention discloses an electrical equipment wiring box capable of preventing violent plugging and pulling. The electrical equipment wiring box comprises a sealing bottom box, an opening box and acover plate which are sequentially overlapped and arranged, wherein the upper side and the lower side of the opening box are of an opening structure, and the two sides of the opening box are providedwith a lead-in wire outlet and at least one lead-out wire outlet hole respectively, and the number of the lead-out line holes is set according to actual use conditions; two symmetric sliding rods arearranged on the inner wall of the length direction of the opening box, and a wiring board which is in sliding connection with the two sliding rods is arranged between the two sliding rods; the wiringboard which is connected with the opening box is arranged in a sliding mode, so that the ordered arrangement of the multi-strand combined wire harnesses in the device is facilitated, and meanwhile, awire binding device with an elastic sheet is arranged on the wiring board, and after the installation is completed, the elastic sheet is in contact with a wire harness pipe; and when violent pulling occurs, the wire harness can be quickly inserted into the wire harness tube, and continuous outward pulling of the wire harness can be stopped immediately, so that damage caused by violent pulling is avoided, and loss caused by instantaneous power failure can be avoided to a certain extent when violent events occur.

Owner:HANGZHOU FEISILITE TECH

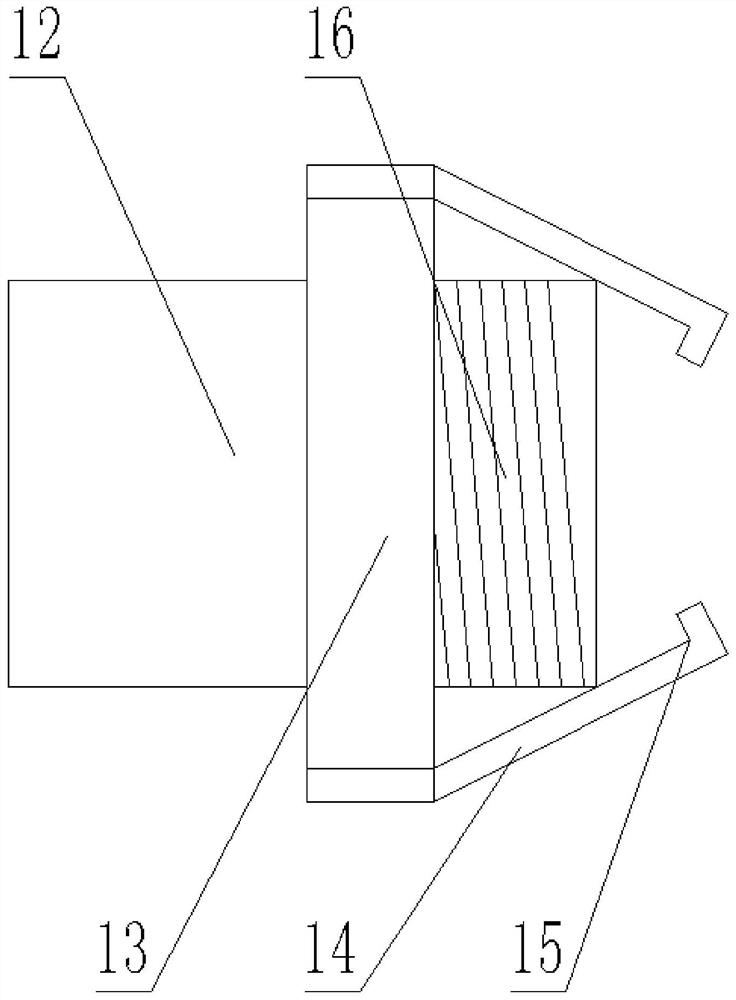

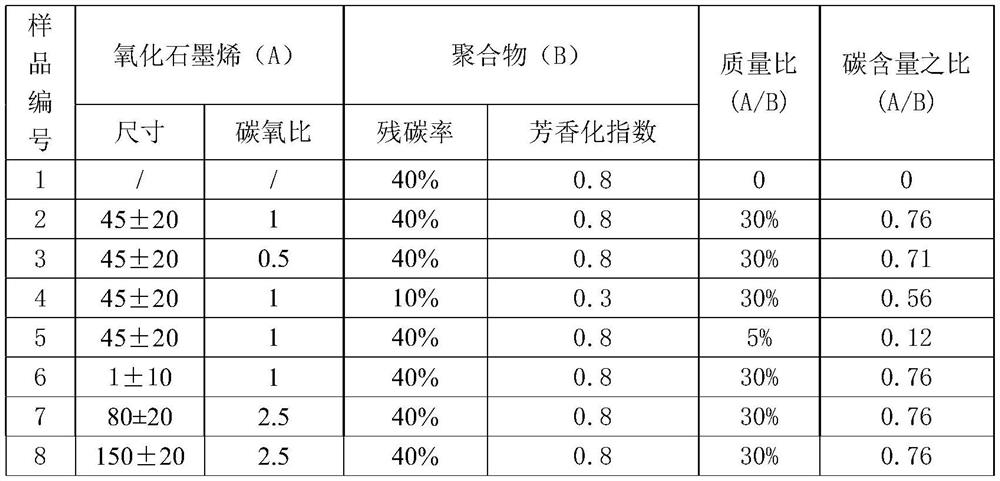

Preparation method of graphene fiber with high graphite crystallinity

ActiveCN114481369AHigh carbon residue rateImprove the degree of graphitizationElectroconductive/antistatic filament manufactureGrapheneCatalytic pyrolysisFiber

The invention discloses a preparation method of a graphene fiber with high graphite crystallinity, which mainly adopts a wet spinning mode to perform liquid-phase composite assembly on graphene oxide and other polymer materials, and two-dimensional graphene oxide sheets perform'template orientation 'on polymer molecules to obtain the graphene fiber with high graphite crystallinity. The polymer molecules are directionally crystallized on the two-dimensional graphene oxide sheet, so that the composite precursor with high orientation degree and crystallinity is prepared. The preparation method comprises the following steps: performing high-temperature treatment on a graphene sheet with a two-dimensional topological structure, performing catalytic pyrolysis on molecules through an induced graphitization effect, and directionally generating a graphene-like carbon layer by taking a single-layer graphene sheet as a template, so that the stacking behavior of the graphene sheet layer is promoted, and the composite carbon fiber with an optimal graphite crystal structure is prepared. The graphene fiber material prepared by the method has the characteristics of low cost, high crystallinity and high performance, and can be applied to the field of light high-strength structural materials. The invention relates to a high-crystallinity graphene fiber material with a two-dimensional induction effect and a preparation method of the high-crystallinity graphene fiber material.

Owner:ZHEJIANG UNIV

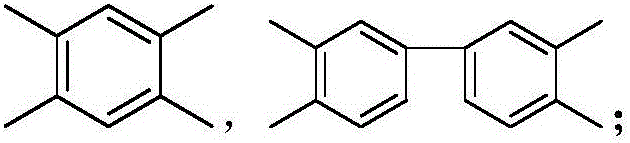

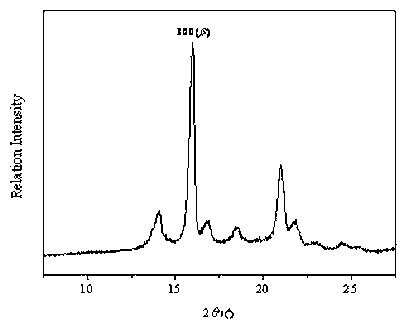

Liquid-crystal poly(methyl)acrylate beta-crystal-form polypropylene nucleating agent and preparation method thereof

InactiveCN102153687BFast crystallizationGood dispersionLiquid crystal compositionsPolymer scienceMeth-

The invention relates to the technical field of nucleating agents, and particularly relates to a liquid-crystal poly(methyl)acrylate beta-crystal-form polypropylene nucleating agent and a preparation method thereof. The liquid-crystal poly(methyl)acrylate beta-crystal-form polypropylene nucleating agent provided by the invention uses a poly(methyl)acrylate chain as the macromolecule frame, and uses a mesogenic unit as a side chain, wherein the mesogenic unit comprises a flexible space group, a liquid-crystal nucleus, and an alkyl or alkoxy group. The preparation method of the liquid-crystal poly(methyl)acrylate beta-crystal-form polypropylene nucleating agent comprises the following steps: synthesizing a double-bond-containing liquid-crystal monomer; dissolving 2-5g of the liquid-crystal monomer in 50-100 ml of solvent, and adding 0.02-0.005g of azodiisobutyronitrile at 60 DEG C to react for 12-24 hours; and pouring the reactant in methanol, precipitating, filtering, washing with ethanol three times, and drying to obtain the final product.

Owner:NORTHEASTERN UNIV LIAONING

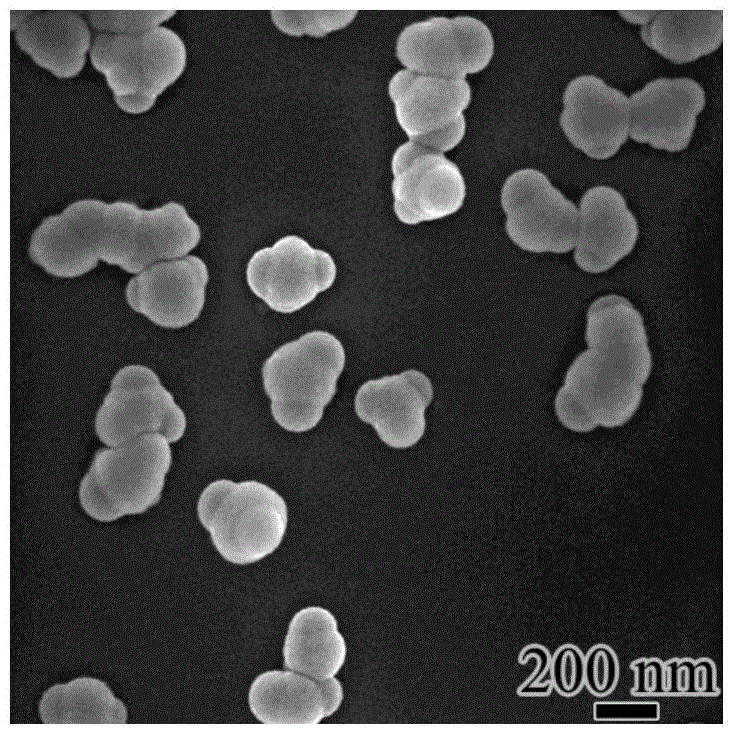

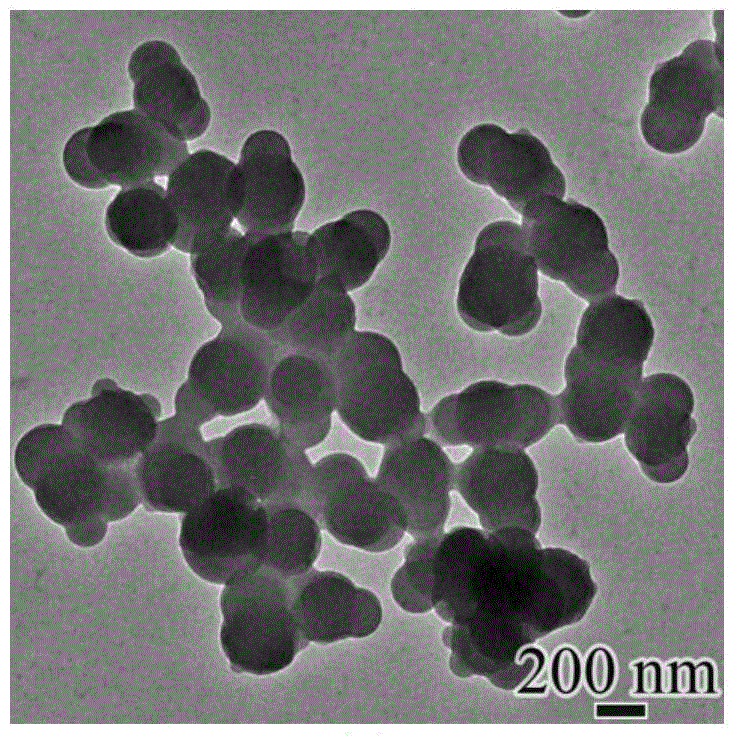

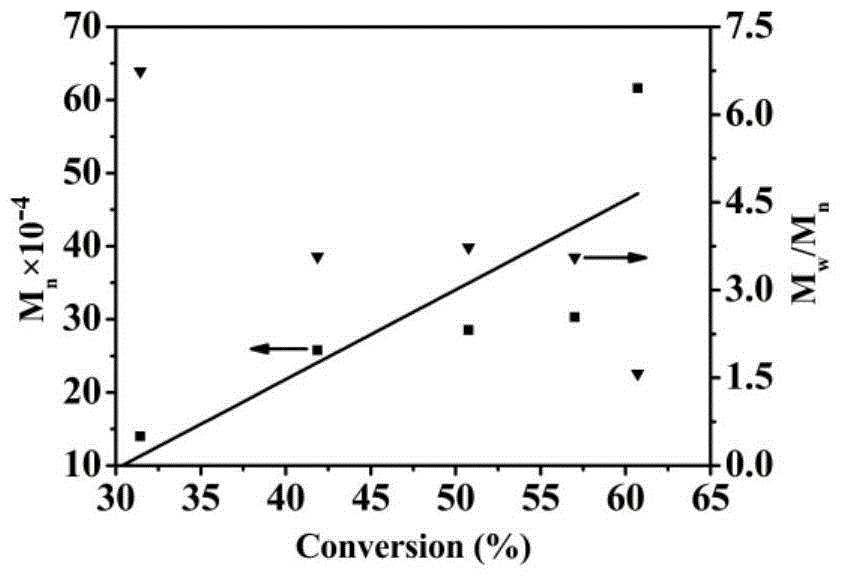

A preparation method of anisotropic asymmetric latex particles with adjustable morphology

Owner:HEBEI UNIV OF TECH

A kind of polyimide film with low thermal expansion coefficient and preparation method thereof

ActiveCN106543720BSmall coefficient of thermal expansionEnhanced interactionThermal dilatationPolymer science

The invention belongs to the field of high polymer materials and particularly relates to a polyimide film with a low thermal expansion coefficient and a preparation method of the polyimide film. The polyimide film has the following structural formula shown in the specification, wherein R1 and R3 are residues of two different tetracarboxylic acid dianhydride monomers, and R2 and R4 are residues of two different di-primary amine monomers. The preparation method is a multi-step polymerization method, firstly, two polyimide acid solutions with different structure units are obtained through polymerization respectively, then the solutions are mixed and then polymerized, finally, heating drying is carried out, and the polyimide film with the low thermal expansion coefficient is obtained. Compared with the prior art, the polyimide film with the low thermal expansion coefficient introduces ester bonds / amide, imidazole / oxazole and other structure units into molecular structure design at the same time, the interaction force among molecules is improved, the thermal expansion coefficient of the polyimide film is effectively reduced, meanwhile, the thermal expansion coefficient of the polyimide film can be adjusted and controlled by adopting different formulas, and the matching problem among different substrate materials is solved.

Owner:株洲天颐莱新材料技术有限公司

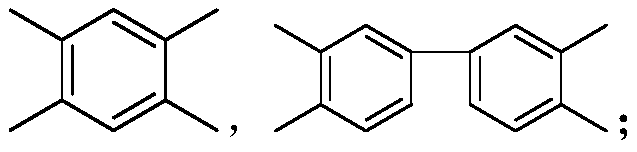

Composition containing plant extracts for regulating scalp grease secretion and brightening and smoothening hair and shampoo containing composition

ActiveCN114224754AImprove itchingCracked improvementCosmetic preparationsHair cosmeticsHair rootsCamellia oleifera

The invention discloses a plant extract-containing composition for regulating scalp grease secretion and brightening and smoothening hair. The plant extract-containing composition is prepared from hydrolyzed keratin, camellia oleifera seeds, cacumen biotae, semen cassiae, porous starch and nano antibacterial particles. The plant extract-containing composition for regulating scalp grease secretion, brightening and smoothening hair contains various plant extracts, and can improve the ordered arrangement of hair scales, inhibit the breeding of bacteria and fungi, regulate the water-oil balance of head skin, clean and remove dandruff by utilizing the effects of camellia oleosa seed oil, other plant extracts and hydrolyzed keratin; the shampoo can supplement nutrition and moisture required by hair and scalp, reduce scalp itching, prevent hair loss and furcation, improve scalp blood circulation, promote metabolism, make hair roots strong, make hair dense and soft, and make hair healthy. The composition and a silicone-oil-free shampoo matrix can effectively avoid scalp problems caused by accumulation of silicone oil, so that washed hair is fluffy and natural, and is really bright, smooth, soft and glossy.

Owner:广西和桂集团有限公司

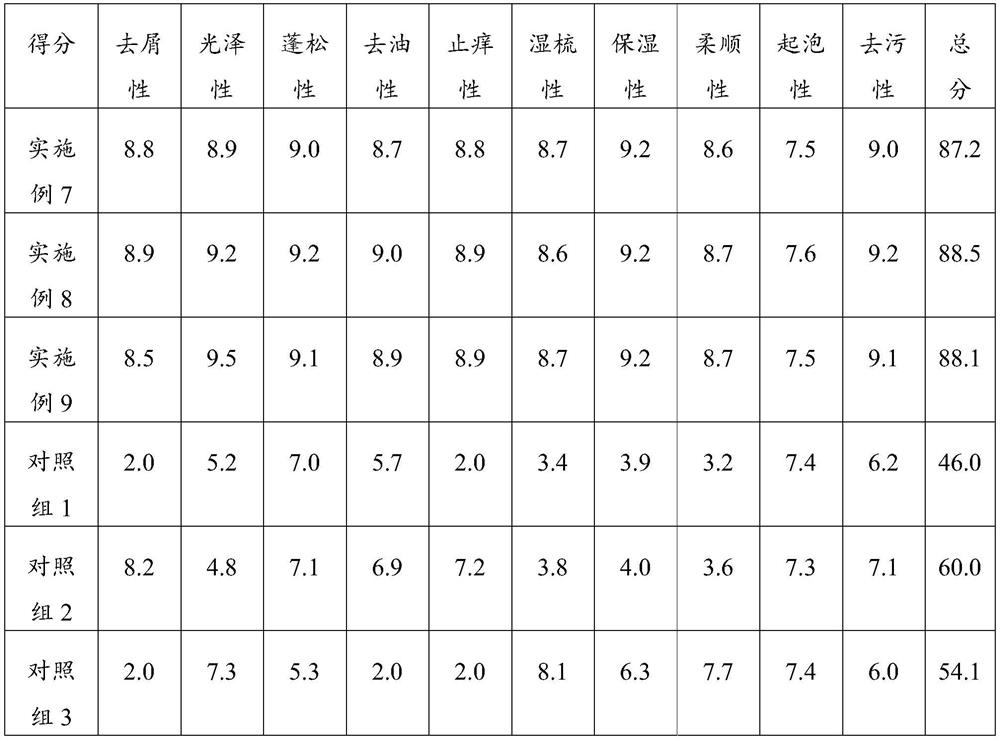

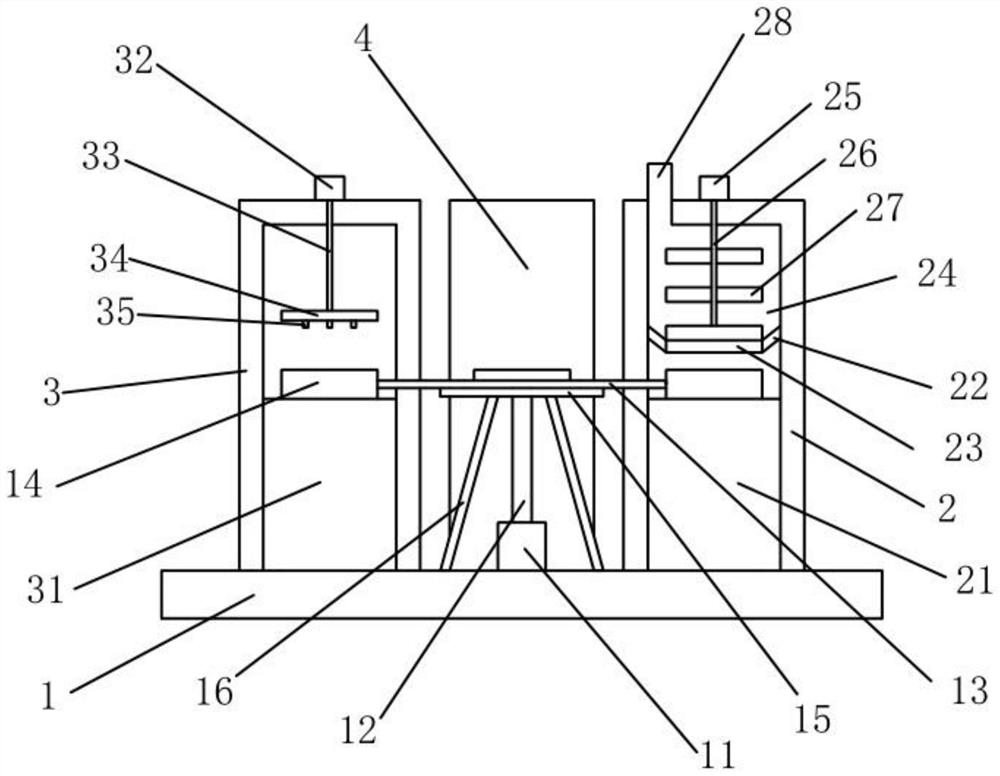

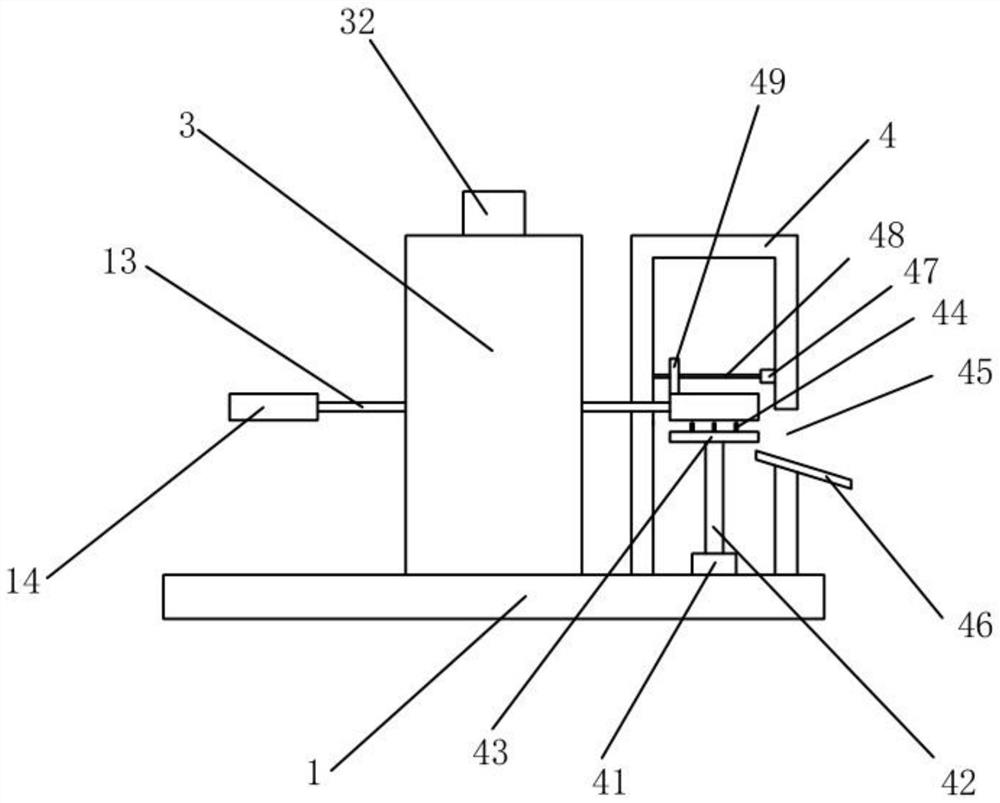

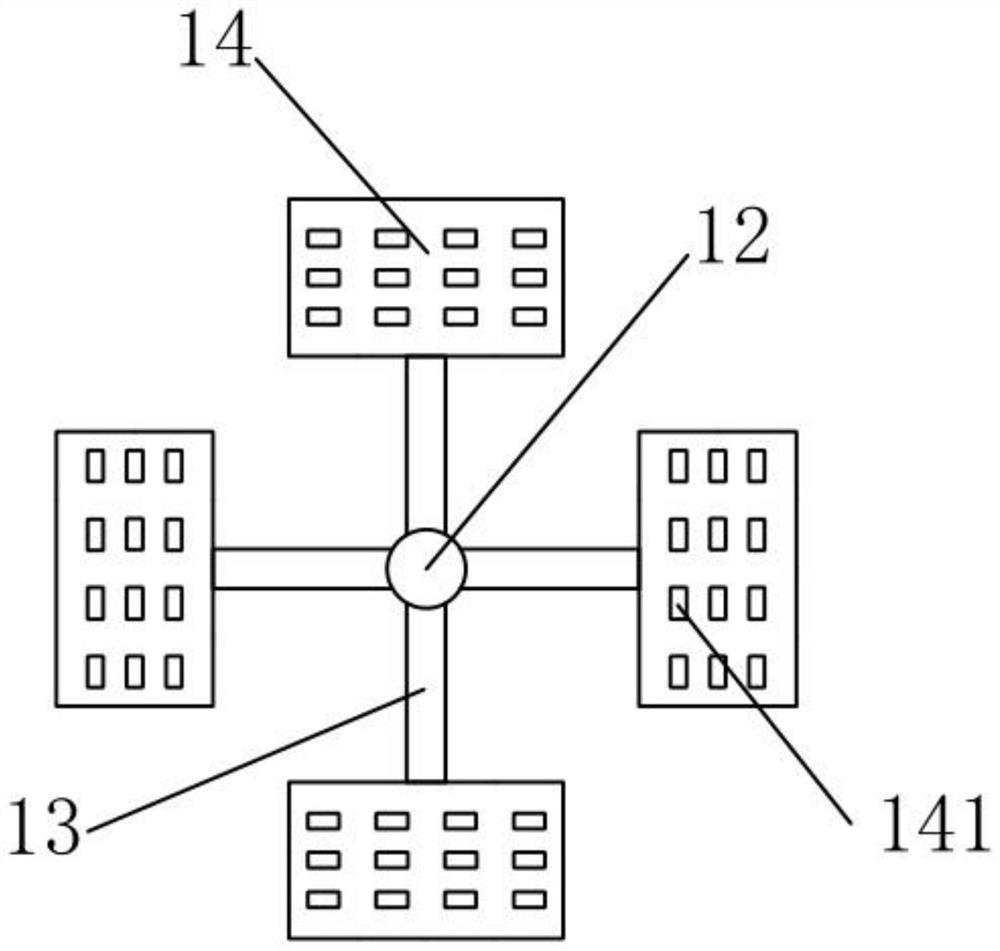

Light-emitting semiconductor automatic arrangement device for rectangular lighting lamp panel

InactiveCN113316283AConvenient ArrangementEasy to arrange and operateElectrical apparatusElectroluminescent light sourcesStructural engineeringMechanical engineering

The invention relates to the technical field of semiconductor lighting device manufacturing, and discloses a light-emitting semiconductor automatic arrangement device for a rectangular lighting lamp panel. The device comprises a base, a mounting plate is arranged at the upper part of the base, and a lamp panel is arranged in the mounting plate; a transverse sliding plate assembly is slidably connected to the upper surface of the base, a longitudinal transmission assembly is arranged at the lower portion of the base, agroove plate is arranged on the lower surface of the transverse sliding plate assembly, and a transmission shaft is arranged at the lower portion of the transverse sliding plate assembly. According to the light-emitting semiconductor automatic arrangement device for the rectangular lighting lamp panel, thetransmission shaft and a first driving roller are used in cooperation, and a groove column and a sliding rod are used in cooperation, a push column and the groove plate are used in cooperation, and the transverse sliding plate assembly and the mounting plate are used in cooperation, so that the lamp panel can move at equal intervals in the transverse direction, semiconductor unit devices can be conveniently and orderly arranged on the surface of the lamp panel, the arrangement operation of the semiconductor unit devices is convenient, and the arrangement effect is good.

Owner:雅佳(广州)电子科技有限公司

A preparation process of composite wear-resistant material for brake pads

The invention discloses a preparation process of a composite wear-resistant material for brake pads. The composite wear-resistant material is made of the following raw materials in parts by weight: 15-25 parts of modified phenolic resin, 10-25 parts of carbon fiber, and 10 parts of sepiolite fiber ‑25 parts, coke powder 10‑20 parts, mica powder 10‑20 parts, tire powder 10‑20 parts, stearic acid 1.5‑3 parts, silane coupling agent 0.5‑2 parts, flame retardant 0.5‑2 parts; The modified phenolic resin contains B-O bonds in the molecule, and the B-O bonds have high bond energy and great flexibility, which effectively improves its own heat resistance. At the same time, the linear carbon chain and carbon-carbon double bond are flexible groups, changing the resin The distance between molecules and the movement direction and plasticity between molecules effectively promote the orderly arrangement of resin molecules during curing, thereby improving the heat resistance and toughness of phenolic resin. The improvement of toughness makes the composite wear-resistant material wear-resistant Better performance and higher impact resistance, which in turn increases the service life of the brake pads.

Owner:HENGSHUI ZHONGCHENG FRICTION MATERIAL

Rapid and automatic mica plate splitting and feeding jig

PendingCN108910464AEasy separation and aggregationGood for alignmentConveyorsConveyor partsAcute angleMechanical engineering

The invention discloses a rapid and automatic mica plate splitting and feeding jig. The jig comprises a board body jig, a groove formed in the board body jig and multiple blanking holes formed in thegroove; the groove comprises multiple first acute angle grooves which are formed in one side of the board body jig and protrude toward the outer side and multiple second acute angle grooves which areformed in the other side of the board body jig and protrude towards the outer side, a connecting part parallel to the side of the board body jig is arranged between the first acute angle grooves, an acute angle part which is in opposite reverse extension connection with the second acute angle grooves is formed between the second acute angle grooves, the blanking holes are formed in the top cornerpositions of the first acute angle grooves and the second acute angle grooves, and vertically penetrate the board body jig, and the blanking holes comprise inverted-conical first hole positions, and columnar second hole positions arranged on the bottoms of the first hole positions. Stable and continuous automatic feeding of mica plates is achieved.

Owner:苏州睿立汇自动化科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com