Polyimide film with low thermal expansion coefficient and preparation method of polyimide film

A technology of polyimide film and low thermal expansion coefficient, which is applied in the field of polyimide film with low thermal expansion coefficient and its preparation, can solve the problems of thermal expansion coefficient difference, material or device failure, delamination, etc., and achieve the reduction of thermal expansion coefficient , improve the interaction force, and improve the effect of orderly arrangement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

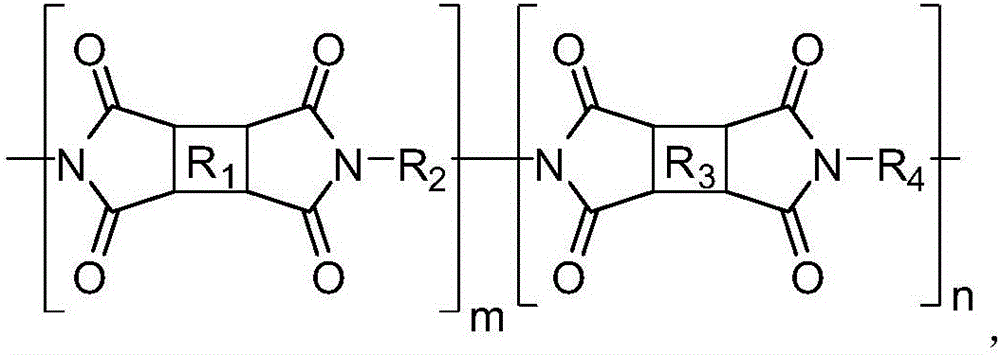

[0034] In this embodiment, the polyimide resin material has the following structural formula:

[0035]

[0036] The specific preparation method is:

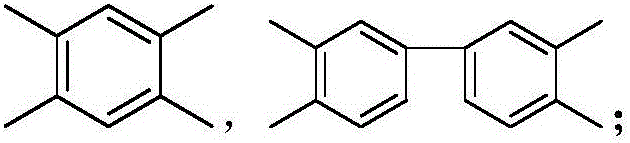

[0037] (1), under nitrogen protection, 4.0mmol of 3,3',4,4'-biphenyltetracarboxylic dianhydride, 4.0mmol of 4,4'-diaminobiphenyl, 15ml of N-methylpyrrolidone Add it into the reaction bottle, stir at room temperature for 8 hours, and prepare a viscous polyamic acid solution A;

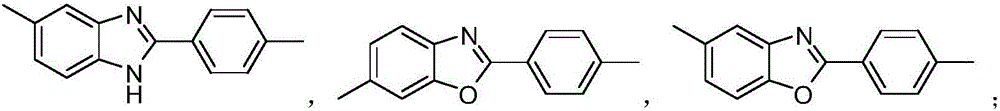

[0038] (2), under the protection of nitrogen, add 4.0mmol of terephthalamide dianhydride, 4.0mmol of 2-(4-aminophenyl)-6-aminobenzimidazole, and 15ml of N-methylpyrrolidone into the reaction flask , stirring at room temperature for 8 hours to prepare a viscous polyamic acid solution B;

[0039] (3), polyamic acid solution A and polyamic acid solution B were mixed together, and stirred at room temperature for 8 hours to prepare the final polyamic acid solution;

[0040] (4), the prepared polyamic acid solution is configured into a solution with a conc...

Embodiment 2

[0043] In this embodiment, the polyimide resin material has the following structural formula:

[0044]

[0045] The specific preparation method is:

[0046] (1), under nitrogen protection, 2.0mmol of 3,3',4,4'-biphenyltetracarboxylic dianhydride, 4.0mmol of 4,4'-diaminobiphenyl, 15ml of N-methylpyrrolidone Add it into the reaction bottle, stir at room temperature for 8 hours, and prepare a viscous polyamic acid solution A;

[0047] (2), under the protection of nitrogen, add 6.0mmol of terephthalamide dianhydride, 4.0mmol of 2-(4-aminophenyl)-6-aminobenzimidazole, and 15ml of N-methylpyrrolidone into the reaction flask , stirring at room temperature for 8 hours to prepare a viscous polyamic acid solution B;

[0048] (3), polyamic acid solution A and polyamic acid solution B were mixed together, and stirred at room temperature for 8 hours to prepare the final polyamic acid solution;

[0049] (4) Obtain a polyimide film according to the film drying treatment method in Examp...

Embodiment 3

[0052] In this embodiment, the polyimide resin material has the following structural formula:

[0053]

[0054] The specific preparation method is:

[0055] (1) Under nitrogen protection, 1.0 mmol of 3,3',4,4'-biphenyltetracarboxylic dianhydride, 3.0 mmol of 4,4'-diaminobiphenyl, 10 ml of N,N-diphenyl Methylacetamide was added to the reaction flask, and stirred at room temperature for 8 hours to prepare a viscous polyamic acid solution A;

[0056] (2), under nitrogen protection, mix 7.0mmol of terephthalamide dianhydride, 5.0mmol of 2-(4-aminophenyl)-6-aminobenzimidazole, 20ml of N,N-dimethylacetamide Add it into the reaction bottle, stir at room temperature for 8 hours, and prepare a viscous polyamic acid solution B;

[0057] (3), polyamic acid solution A and polyamic acid solution B were mixed together, and stirred at room temperature for 8 hours to prepare the final polyamic acid solution;

[0058] (4), the prepared polyamic acid solution is configured into a solution...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

| thermal decomposition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com