High-thermal-conductivity insulating spacer and preparation method thereof

An insulating gasket and high thermal conductivity technology, applied in the direction of insulators, insulators, inorganic insulators, etc., can solve the problems of poor thermal conductivity, poor insulation, and poor thermal conductivity of thermally conductive insulating gaskets

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] Embodiment 1: A high thermal conductivity insulating gasket, the high thermal conductivity insulating gasket is composed of insulators and functional fillers, and the functional fillers are carbon fibers coated with alumina, wherein the alumina is α-alumina, the carbon fibers are short carbon fibers, and the insulator is silica gel.

Embodiment 2

[0029] Embodiment 2: a kind of preparation method of high thermal conductivity insulating pad, it comprises the following steps:

[0030] S1. Preparation of dispersion liquid: Mix 10 g of short carbon fibers and 1 mL of dispersant with 100 mL of n-hexane, stir until uniformly dispersed, and maintain at 40° C. for 0.5 h; wherein, the dispersant is sorbitan fatty acid ester;

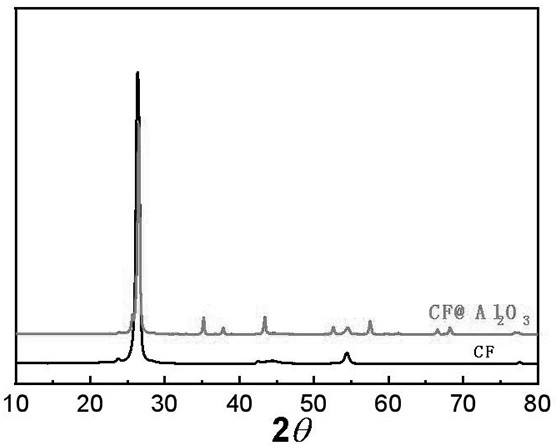

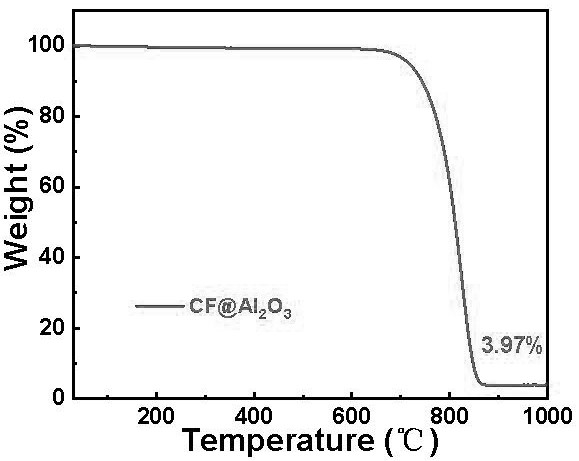

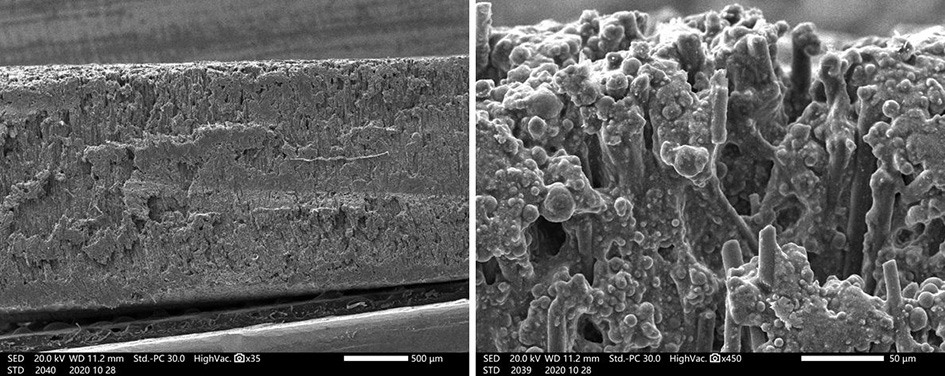

[0031] S2. Coated carbon fiber: 5g of aluminum sol aqueous solution with a solid content of 10wt% was mixed with the carbon fiber dispersion prepared in step S1 for reaction, and after 1 hour of reaction, it was dried at 60°C to constant weight to obtain the alumina-coated carbon fiber material ,Such as figure 1 As shown in the X-ray diffraction diagram, it can be seen that the cladding layer Al 2 o 3 It is α-type crystal, after coating, CF@Al 2 o 3 still contains the original crystal structure of CF; for CF@Al 2 o 3 The thermogravimetric analysis diagram obtained by performing thermogravimetric ana...

Embodiment 3

[0034] Embodiment 3: a kind of preparation method of high thermal conductivity insulating pad, it comprises the following steps:

[0035] S1. Preparation of dispersion: mix 20g of short carbon fibers and 3mL of dispersant with 200mL of petroleum ether, stir until uniformly dispersed, and maintain at 60°C for 1.5h; wherein, the dispersant is sorbitan fatty acid ester ;

[0036] S2. Coated carbon fiber: Mix 0.2 g of an aluminum sol aqueous solution with a solid content of 30 wt% and the carbon fiber dispersion prepared in step S1 for reaction, and then dry at 80°C to constant weight after 2 hours of reaction to obtain the alumina-coated carbon fiber materials such as figure 1 As shown in the X-ray diffraction diagram, it can be seen that the cladding layer Al 2 o 3 It is α-type crystal, after coating, CF@Al 2 o 3 still contains the original crystal structure of CF; for CF@Al 2 o 3 The thermogravimetric analysis diagram obtained by performing thermogravimetric analysis und...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com