Merging core for extrusion moulding machine

A technology for extrusion molding machines and confluence cores, which is applied in the field of confluence cores for extrusion molding machines, can solve problems such as turbulent flow accumulation or delamination, and affect product quality, so as to reduce turbulent flow, increase product size stability, and improve efficiency. Effects of Ordination and Orientation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

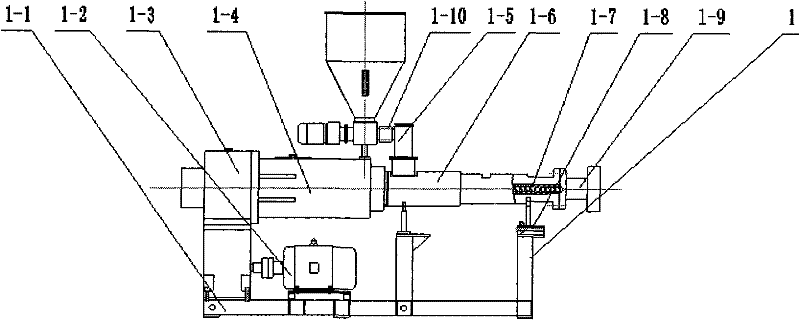

[0022] figure 1 It is a schematic diagram of a twin-screw extruder 1 equipped with a confluence core of the present invention, including a motor 1-2, a reduction gear box 1-3, a distribution gear box 1-4, a feeding device 1-5, a machine barrel 1-6, Extrusion screw 1-7, confluence core 1-9, preheating device 1-10. The motor 1-2 drives the extrusion screw 1-7 through the reduction box 1-3 and the distribution box 1-4; the outlet of the feeding device 1-5 is connected to the feed port of the barrel 1-6, and the For feeding, the extrusion screw 1-7 is installed in the machine barrel 1-6, and the material is extruded from the confluence core 1-9 through the extrusion of the extrusion screw 1-7.

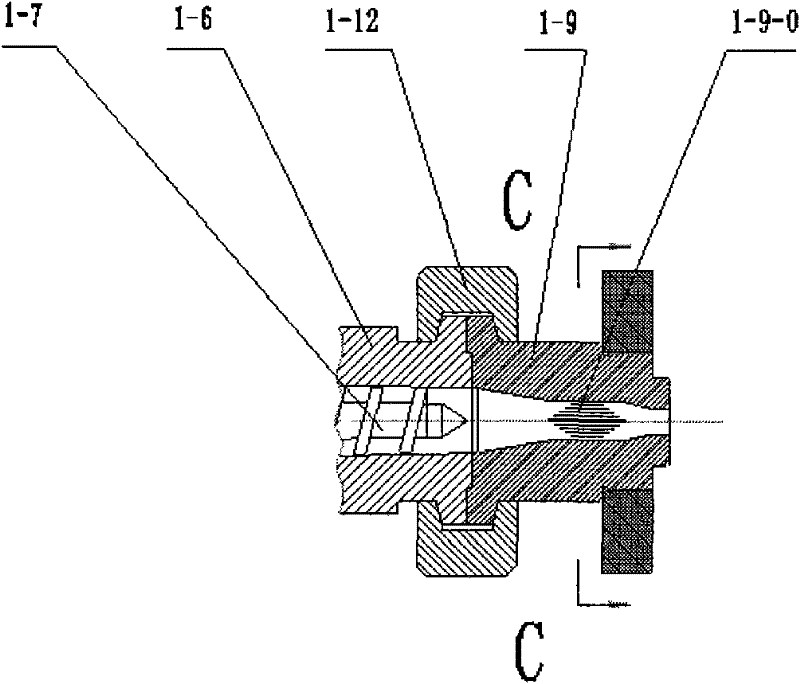

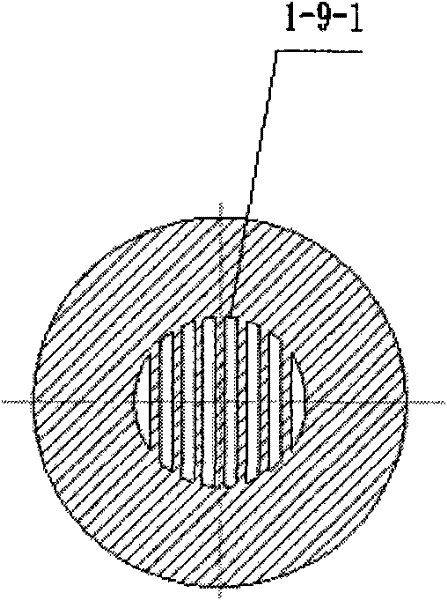

[0023] figure 2 for figure 1 The enlarged view of the axial section of the confluence core 1-9 and the barrel 1-6 in the figure shows the structure of the confluence core 1-9, and the confluence core 1-9 is located at the discharge port of the barrel 1-6, Install it on one end of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com