Warm-press molded bonded magnet and preparation method thereof

A technology of bonded magnets and warm pressing molding, which is applied in the direction of inductance/transformer/magnet manufacturing, magnetic objects, magnetic materials, etc., and can solve problems such as poor orientation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

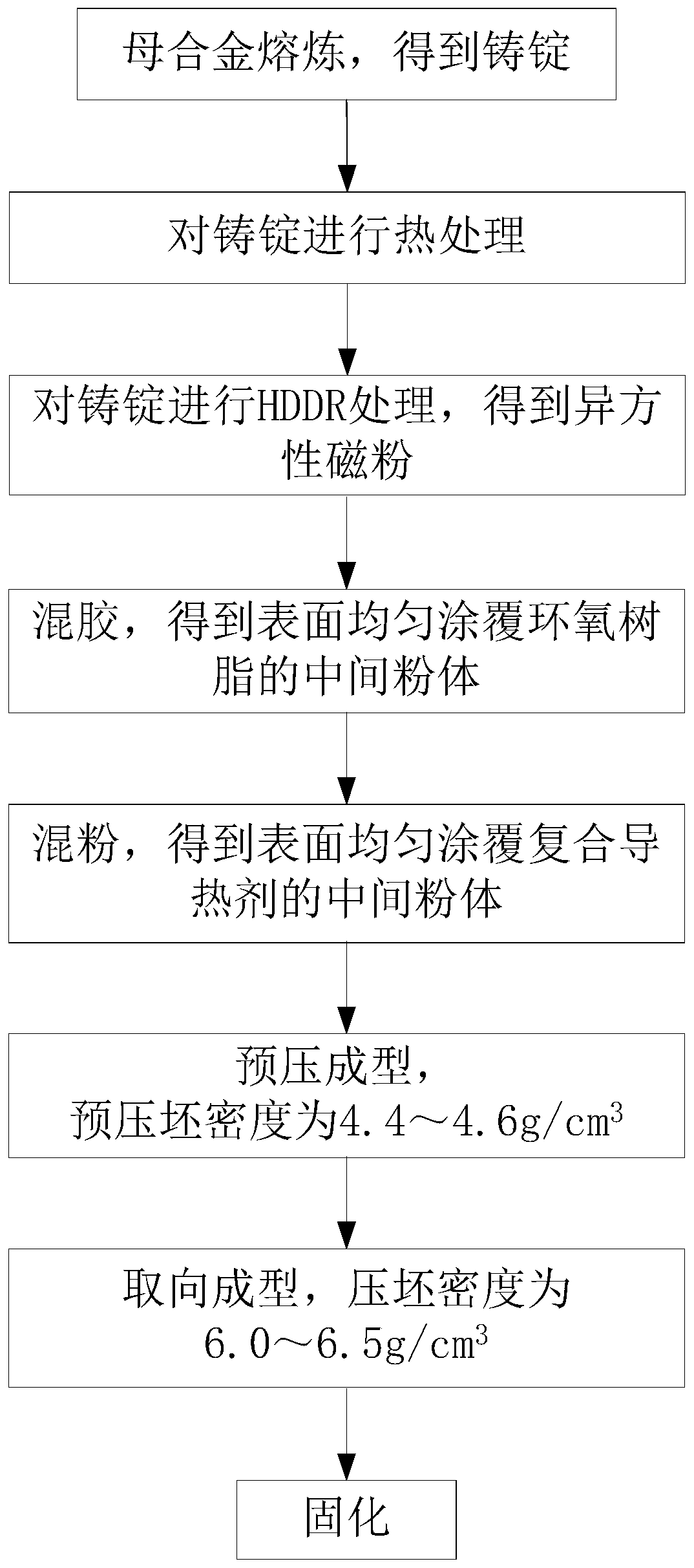

[0048] The second aspect of the present invention provides a method for preparing a warm-pressed bonded magnet, such as figure 1 shown, including the following steps:

[0049] Step 1. Master alloy smelting: Proportion all raw materials according to the mass percentage of the above-mentioned anisotropic NdFeB magnetic powder, heat the prepared raw materials by medium frequency induction into molten metal by vacuum smelting method, and then pour them into double-sided water-cooled fixed molds , get an ingot. Specifically, the cast ingot is a plate-like rapidly quenched NdFeB alloy with a columnar crystal structure, and the thickness is 15-30 mm.

[0050] Step 2. Heat treatment: put the ingot into a vacuum heat treatment furnace, vacuumize and heat to 1100°C-1200°C, fill with argon gas to a certain pressure, keep the furnace at a constant temperature for a period of time, and then lower the temperature step by step and keep it for a period of time. Time, and finally air-cooled ...

Embodiment 1

[0073] (1) Ingredients: 50kg of raw materials are formulated according to the formula, and the surface of the iron rod is derusted and cleaned. Rare earth materials are required to be free from moisture, oil and rust.

[0074] (2) Ingot casting: the prepared raw material is heated by intermediate frequency induction into molten metal by vacuum smelting method, and then poured into a double-sided water-cooled fixed mold to finally obtain a plate-shaped fast-quenching Nd-Fe-B alloy with a columnar crystal structure, cast The proportion of ingot columnar crystals is between 70% and 90%, and the thickness is 15-30mm.

[0075] (3) Heat treatment: Put the ingot into a vacuum heat treatment furnace, vacuumize and heat to 1150°C, fill with argon to -0.08MPa, keep the furnace at a constant temperature for 20h, then start filling with argon to -0.04MPa, and cool down Operation, after 13 minutes, the temperature in the furnace is reduced to 900°C and kept at a constant temperature for 2 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Bulk density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com