Patents

Literature

109 results about "Melt quenching" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Cs3LaCl6 nanocrystalline-containing transparent chalcohalide glass ceramic and its preparation

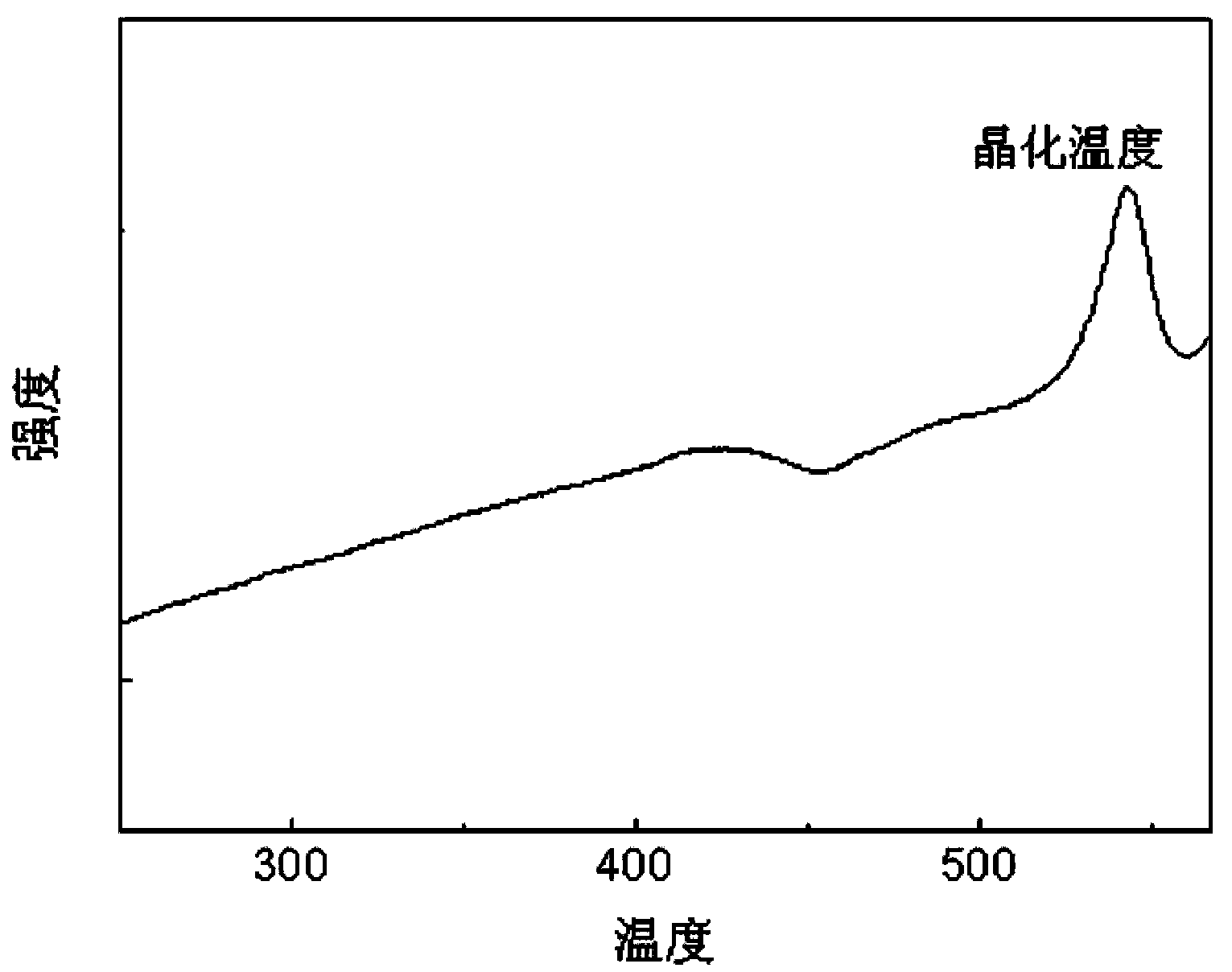

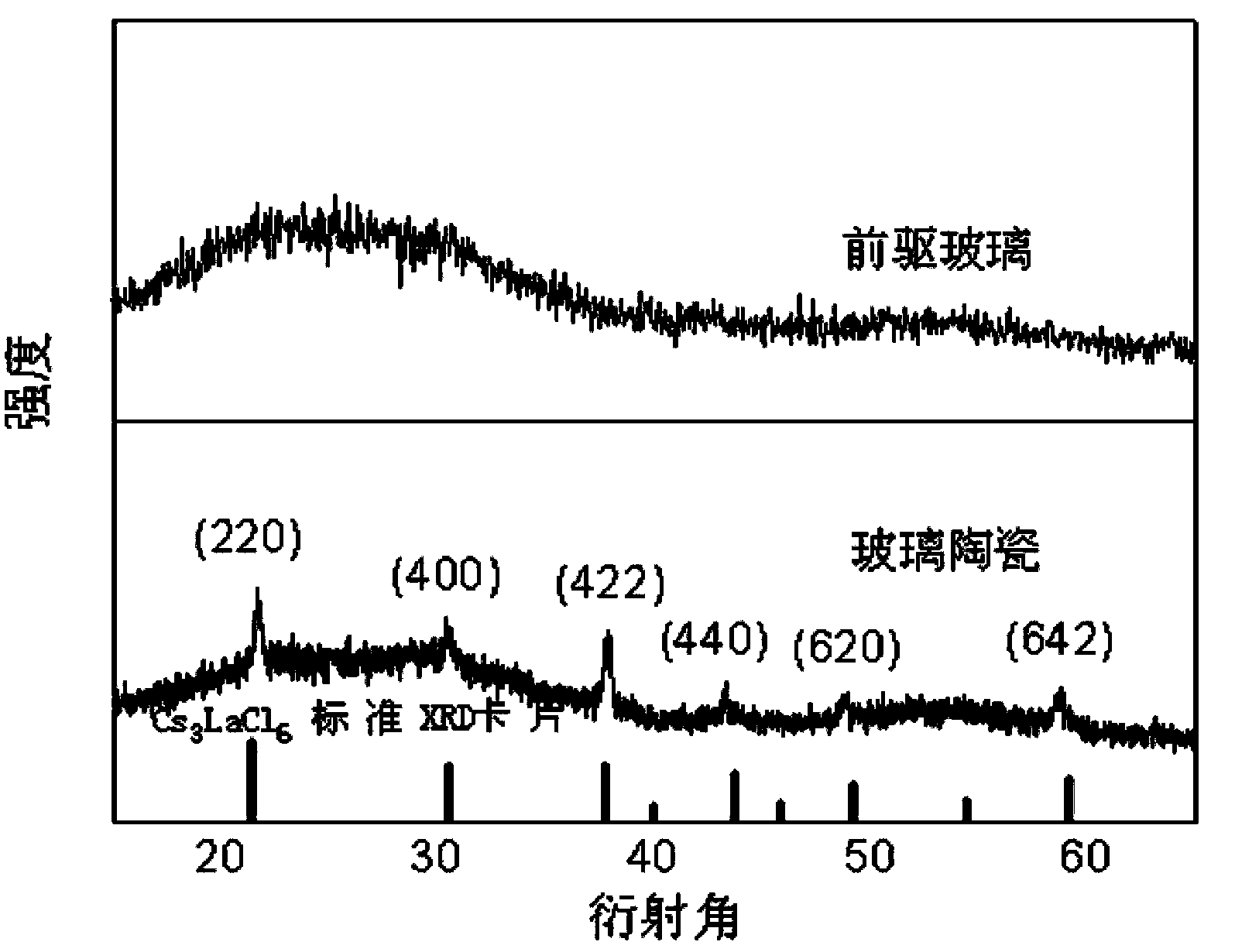

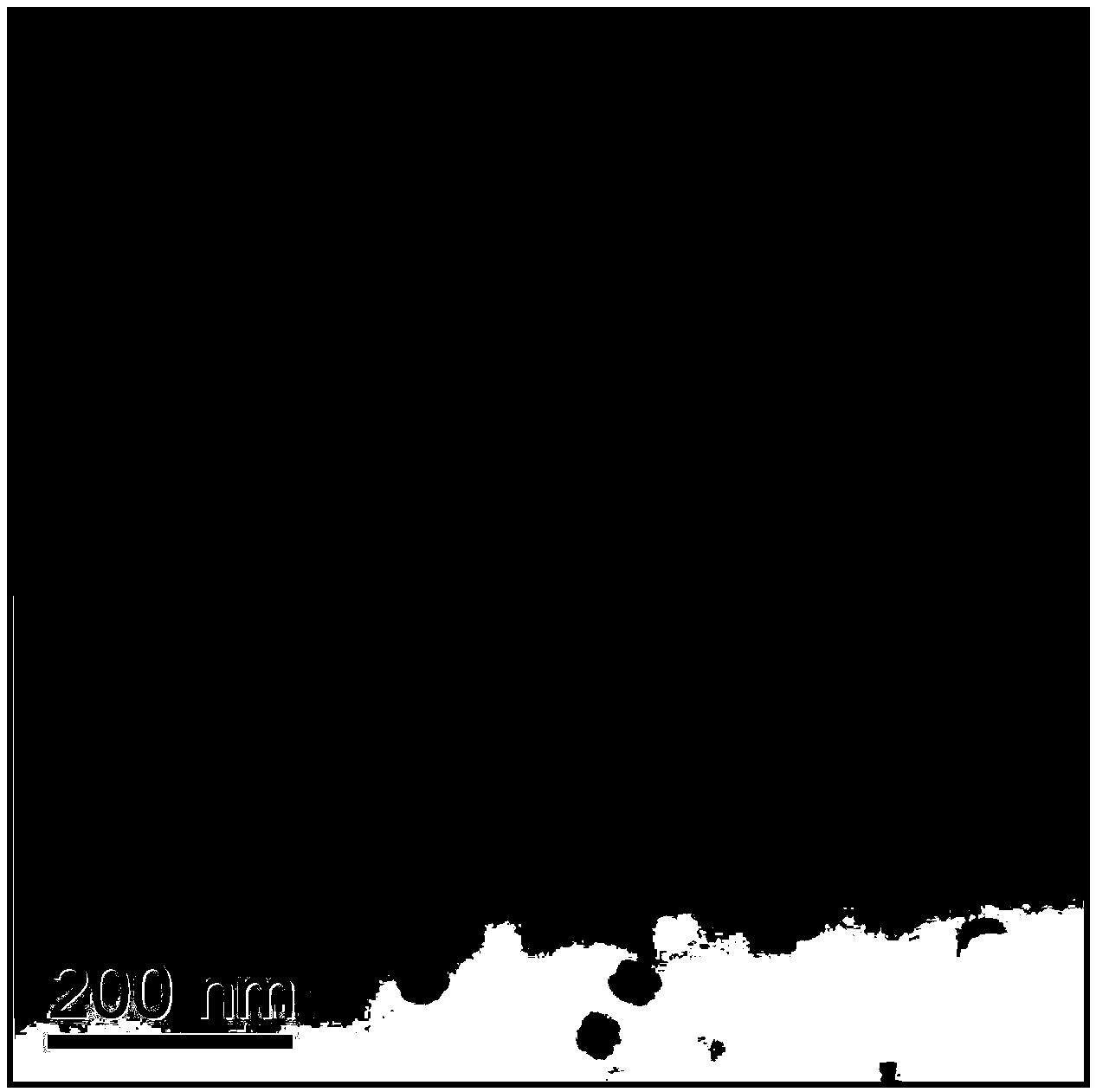

The invention discloses a Cs3LaCl6 nanocrystalline-containing transparent chalcohalide glass ceramic and its preparation. The glass ceramic comprises: 40-60 mol% of GeS2; 25-35 mol% of Ga2S3; 2-8 mol% of La2S3; 2-8 mol% of LaCl3; 10-20 mol% of CsCl; and 0.01-0.2 mol% of Re2S3, wherein Re represents a rare earth ion (such as Nd, Er). The preparation process of the glass ceramic consists of melt quenching preparation of precursor glass and subsequent crystallization heat treatment of the precursor glass. By component exploration, the transparent chalcohalide glass ceramic containing the single Cs3LaCl6 nanocrystalline can be prepared. The nanocomposite material has excellent properties of under near-infrared transfer and visible up-conversion luminescence, and has potential application in near infrared lasers, optical fiber amplifiers, three-dimensional solid-state display and other fields.

Owner:FUJIAN INST OF RES ON THE STRUCTURE OF MATTER CHINESE ACAD OF SCI

Iron-based permanent magnets and their fabrication as well as iron-based permanent magnet alloy powders for permanent bonded magnets and iron-based bonded magnets

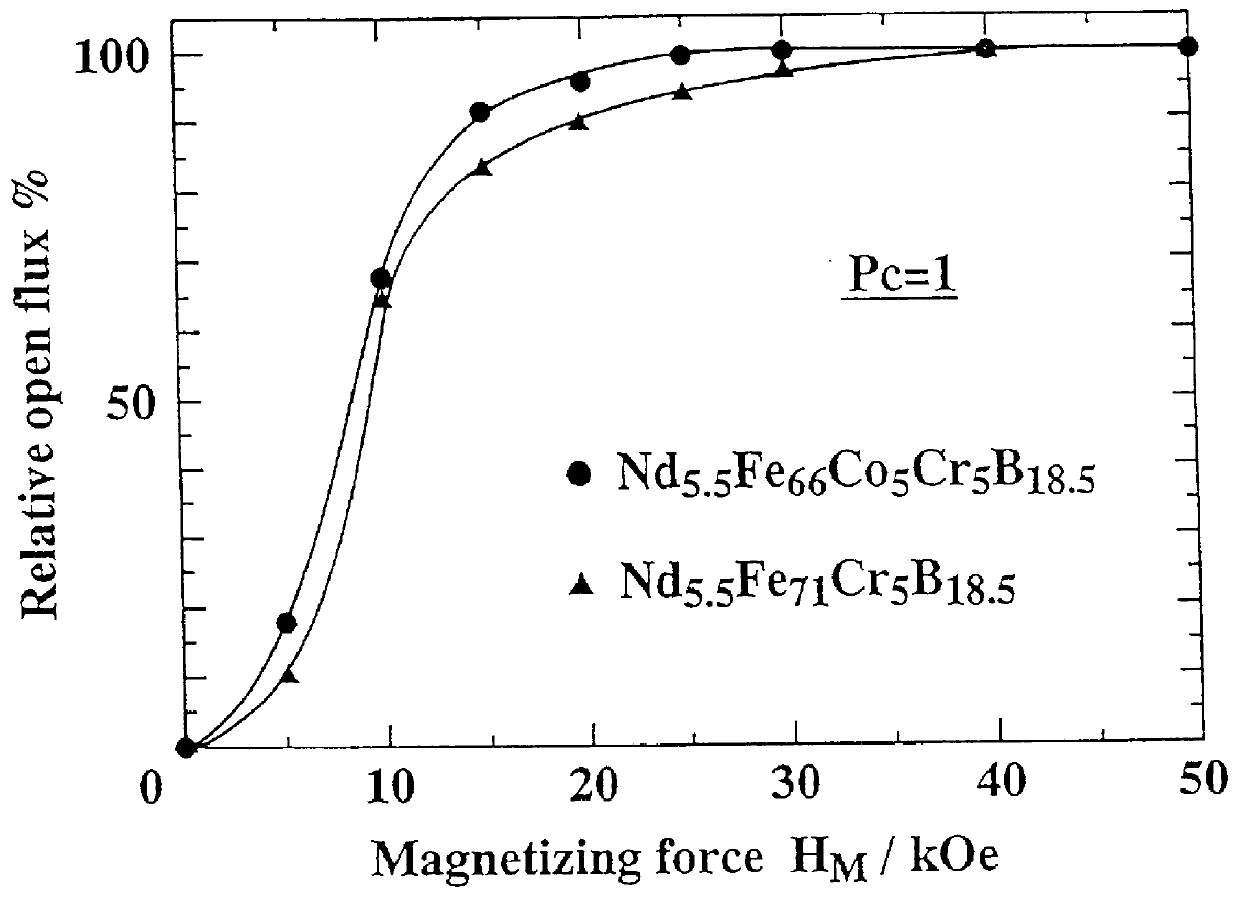

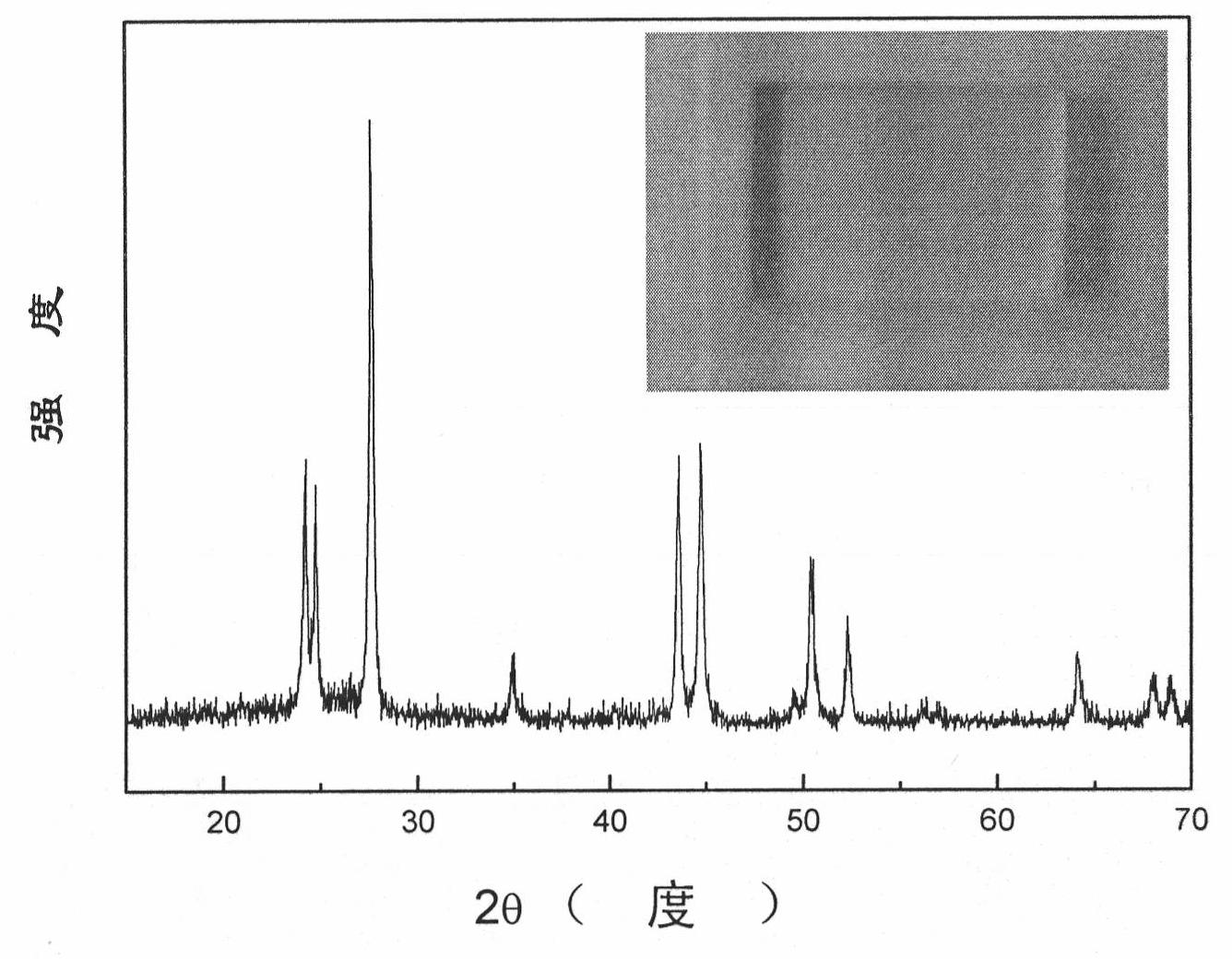

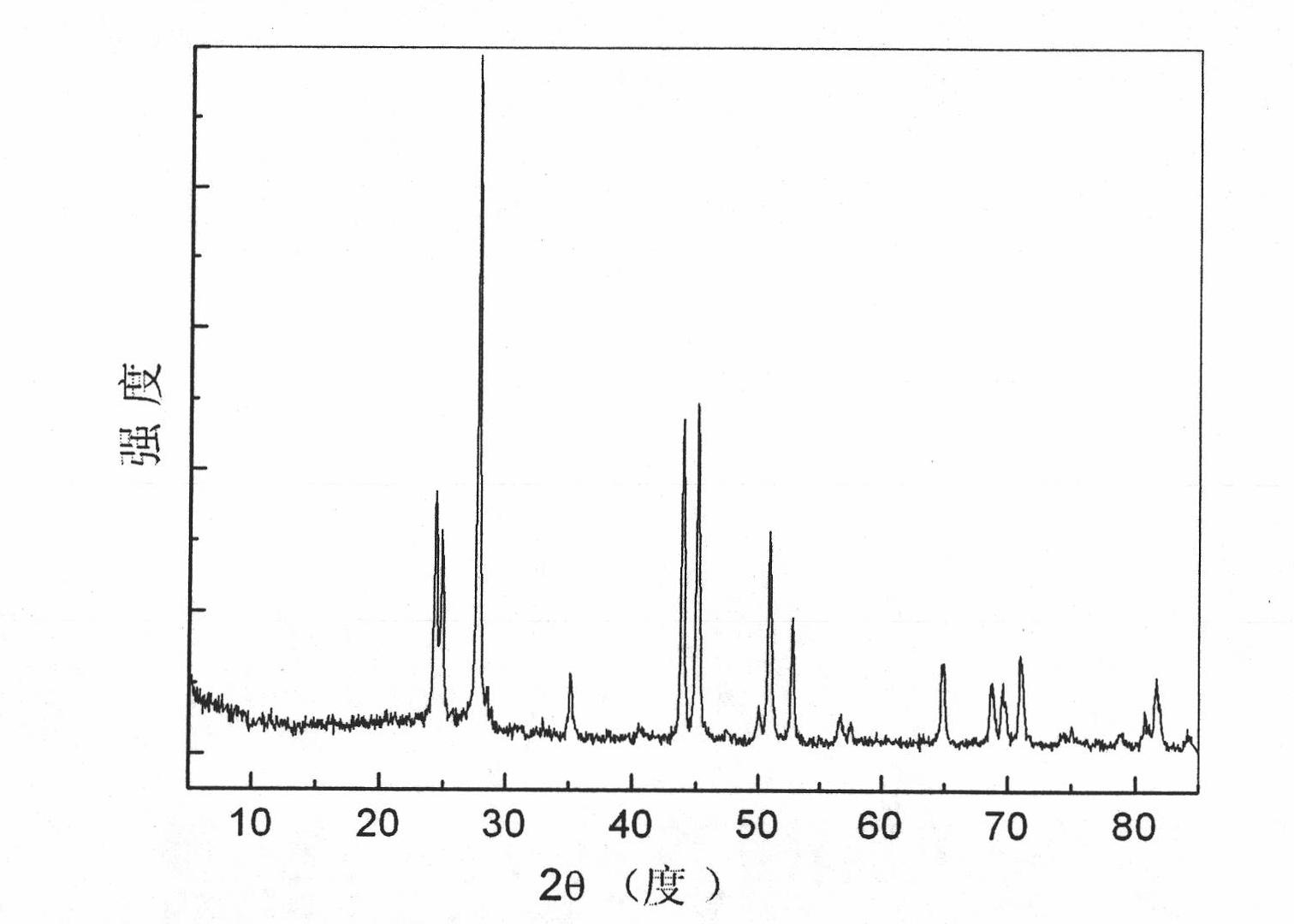

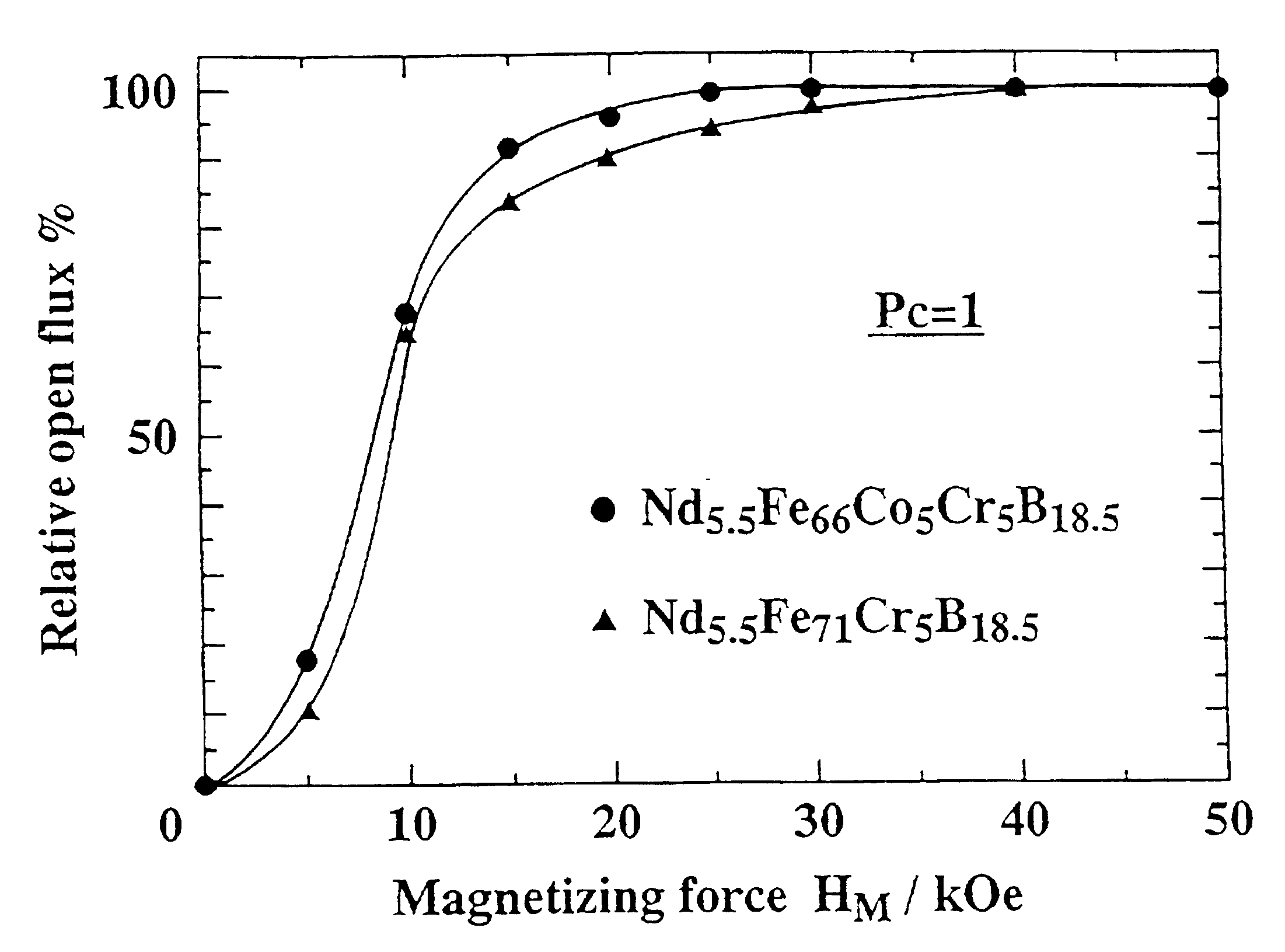

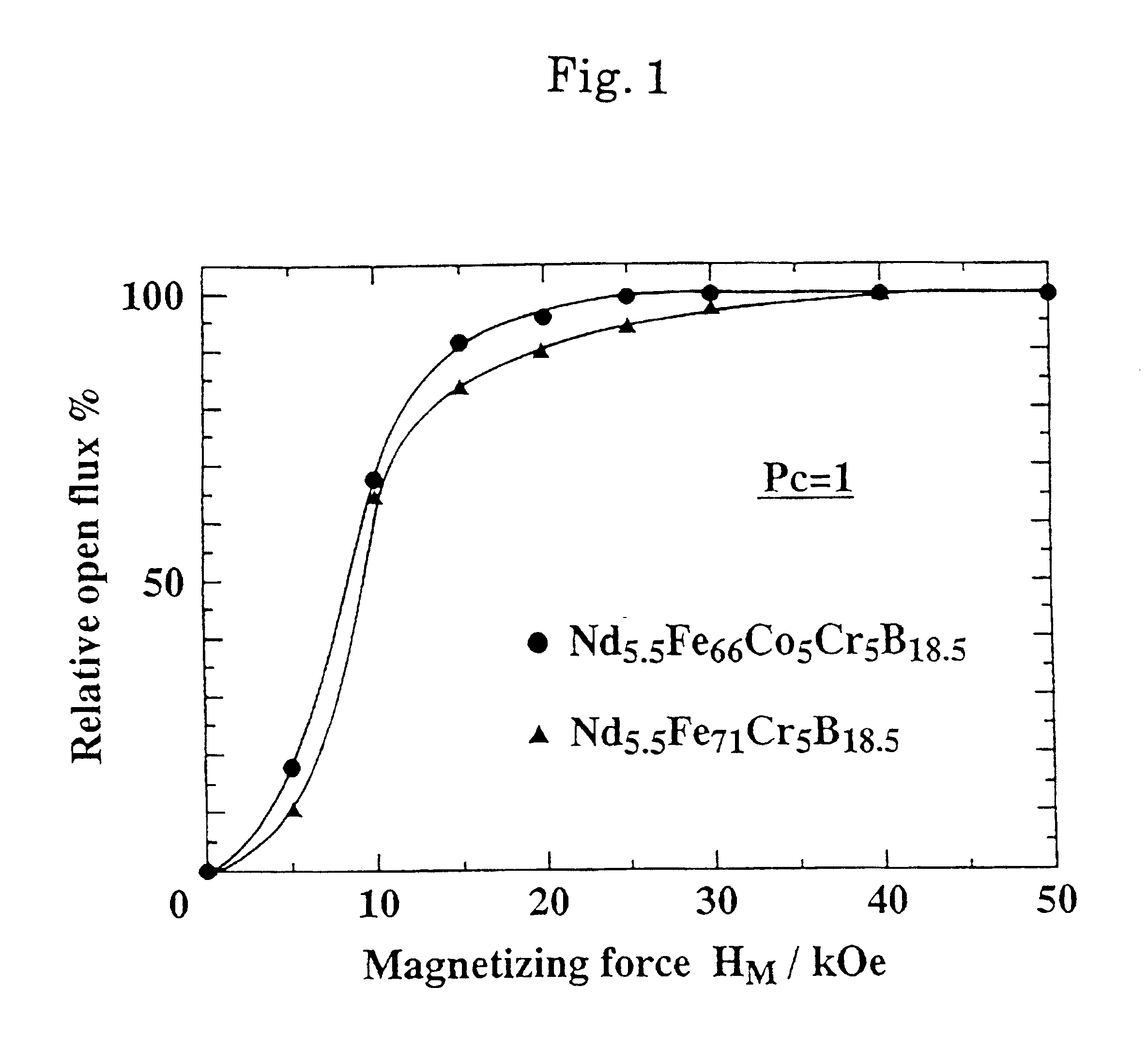

With the intention of establishing fabrication methods for cheaply produced (Fe,Co)-Cr-B-R-type bonded magnets or (Fe,Co)-Cr-B-R-M-type bonded magnets containing few rare earth elements and having a coercive force iHc above 5 kOe and a residual magnetic flux density Br above 5.5 kG matching the cost performance of hard ferrite magnets, we have obtained iron-based permanent magnets consisting of microcrystal clusters where the average crystal size of each component phase is in the range 1 nm DIFFERENCE 30 nm and where both a soft magnetic phase consisting of a ferromagnetic alloy whose main components are alpha -Fe and a ferromagnetic alloy having iron, and a hard magnetic phase having a Nd2Fe14B-type crystal structure coexist within the same powder particles, by melt-quenching of a (Fe,Co)-Cr-B-R(Pr,Nd)-type molten alloy or a (Fe,Co)-Cr-B-R-M (M=Al,Si,S,Ni, Cu,Zn,Ga,Ag,Pt,Au,Pb)-type molten alloy of a particular composition containing few rare earth elements, to obtain an essentially amorphous structure or a structure both amorphous and with small amounts of fine crystals, and by applying a crystallization heat treatment under specific conditions. By grinding this iron-based permanent magnet to an average powder particle size of 3 mu m DIFFERENCE 500 mu m and combining the resultant iron-based permanent magnet alloy powder with a resin, we can obtain an iron-based bonded magnet with good thermal and magnetic properties and with the magnetic characteristics iHc> / =5 kOe, Br> / =5.5 kG and (BH)max> / =6 MGOe.

Owner:SUMITOMO SPECIAL METAL CO LTD

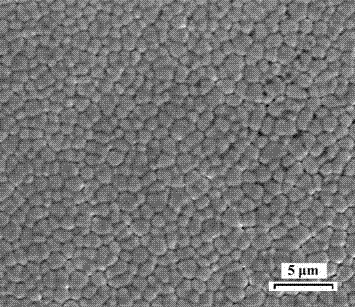

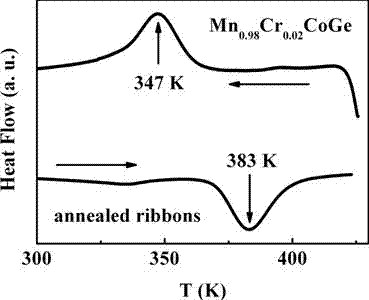

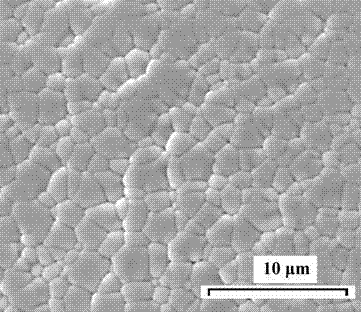

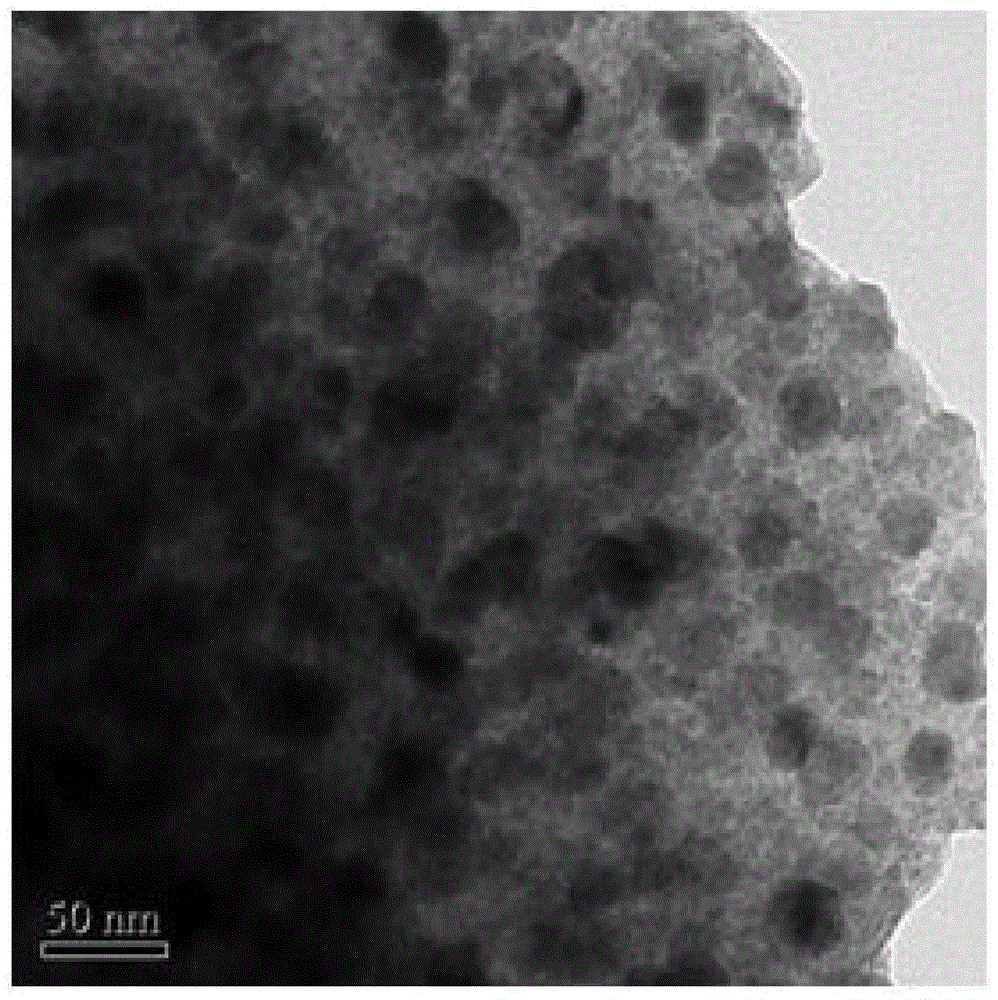

Method for manufacturing Mn-Co(Ni)-Ge-based alloy ribbon through electric arc melting and quick melt quenching

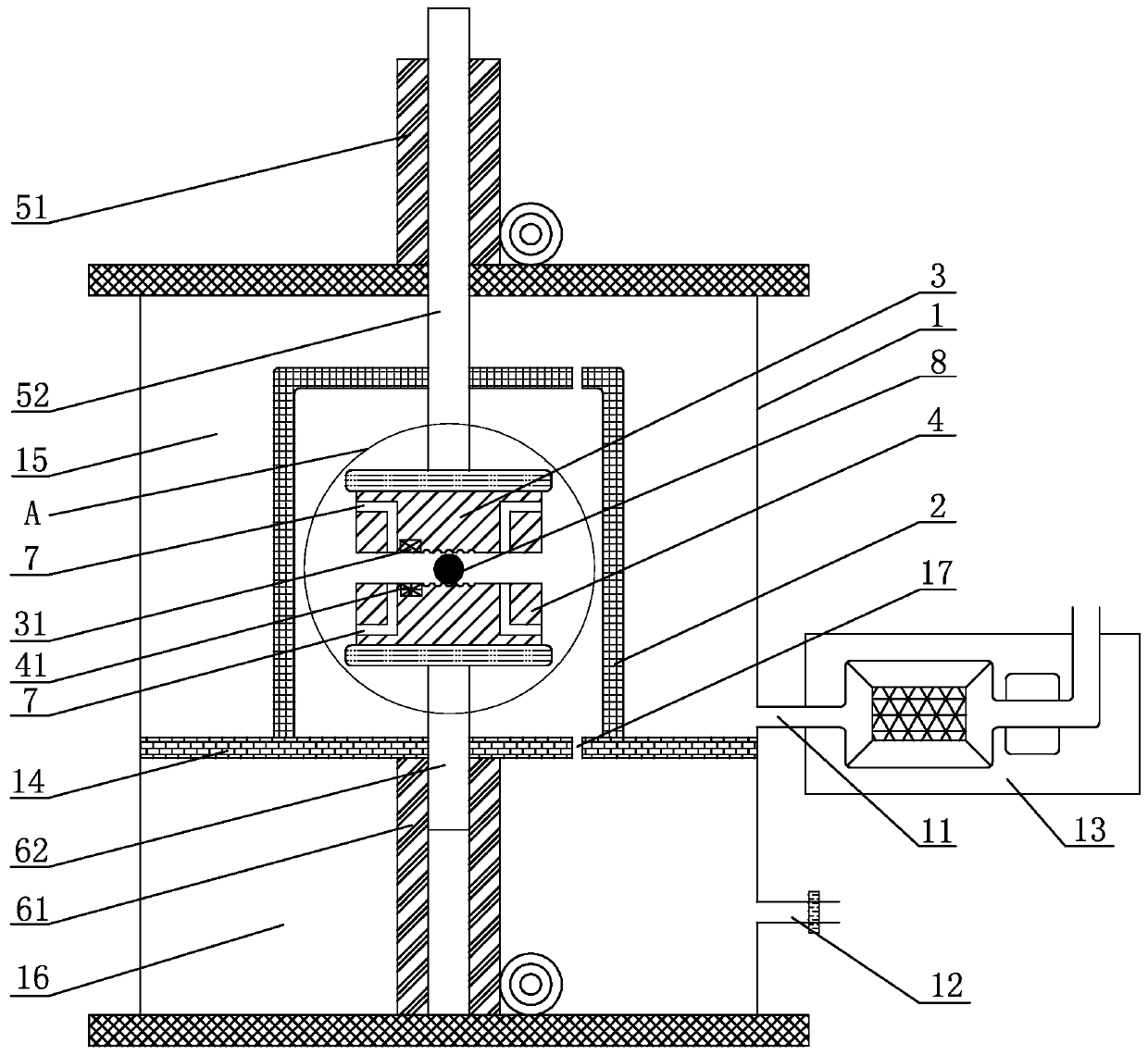

Provided is a method for manufacturing a Mn-Co(Ni)-Ge-based alloy ribbon through electric arc melting and quick melt quenching. The method comprises the steps that (1), dosing is carried out, wherein the mass of needed metal elements such as Mn, Co(Ni), and Ge is calculated according to the stoichiometric ratio and then dosing is carried out; (2), electric arc melting is carried out, wherein well prepared raw materials are put into a water-cooled copper crucible electric arc furnace, the vacuum is pumped to below 3-10Pa, the furnace is filled with argon, then electric arc melting is carried out, and the process is carried out 3-4 times; (3), rapid melt quenching is carried out, wherein a Mn-Co(Ni)-Ge-based alloy cast ingot is installed into a quartz tube of the inner diameter being 10mm and then is placed into a rapid quenching furnace chamber, the vacuum inside the furnace chamber is pumped to be 4-10Pa, then argon is introduced, the cast ingot is melted to be in a liquid state in a high-frequency induction heating mode, then the liquid is sprayed to a copper roller through small holes in the bottom of the quartz tube, the copper roller rotates at a high speed, and then a rapidly quenched ribbon is obtained; (4), homogenizing treatment is carried out, wherein a ribbon sample is sealed in the quartz tube, annealing thermal treatment is carried out inside a high temperature furnace, and then the ribbon sample is placed into cold water and is quenched. The manufacturing method is simple and convenient to implement. By means of the method, the annealing processing time is greatly shortened or even avoided, the manufacturing cost is lowered, and the consumption of energy sources is reduced.

Owner:NANCHANG HANGKONG UNIVERSITY

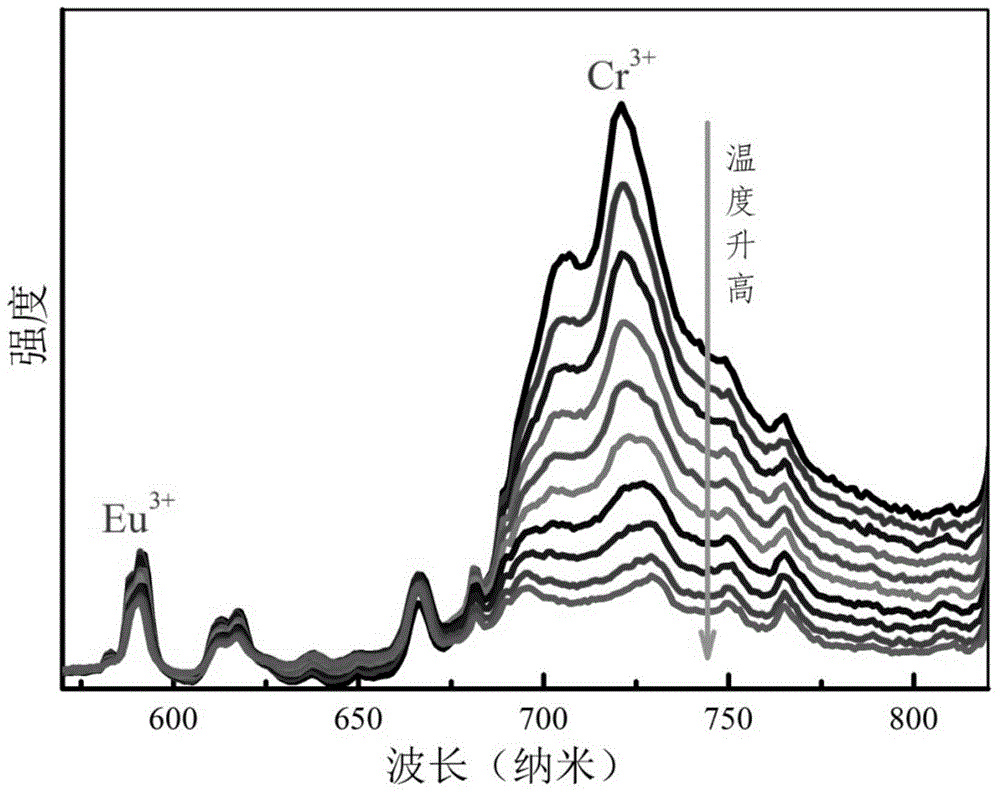

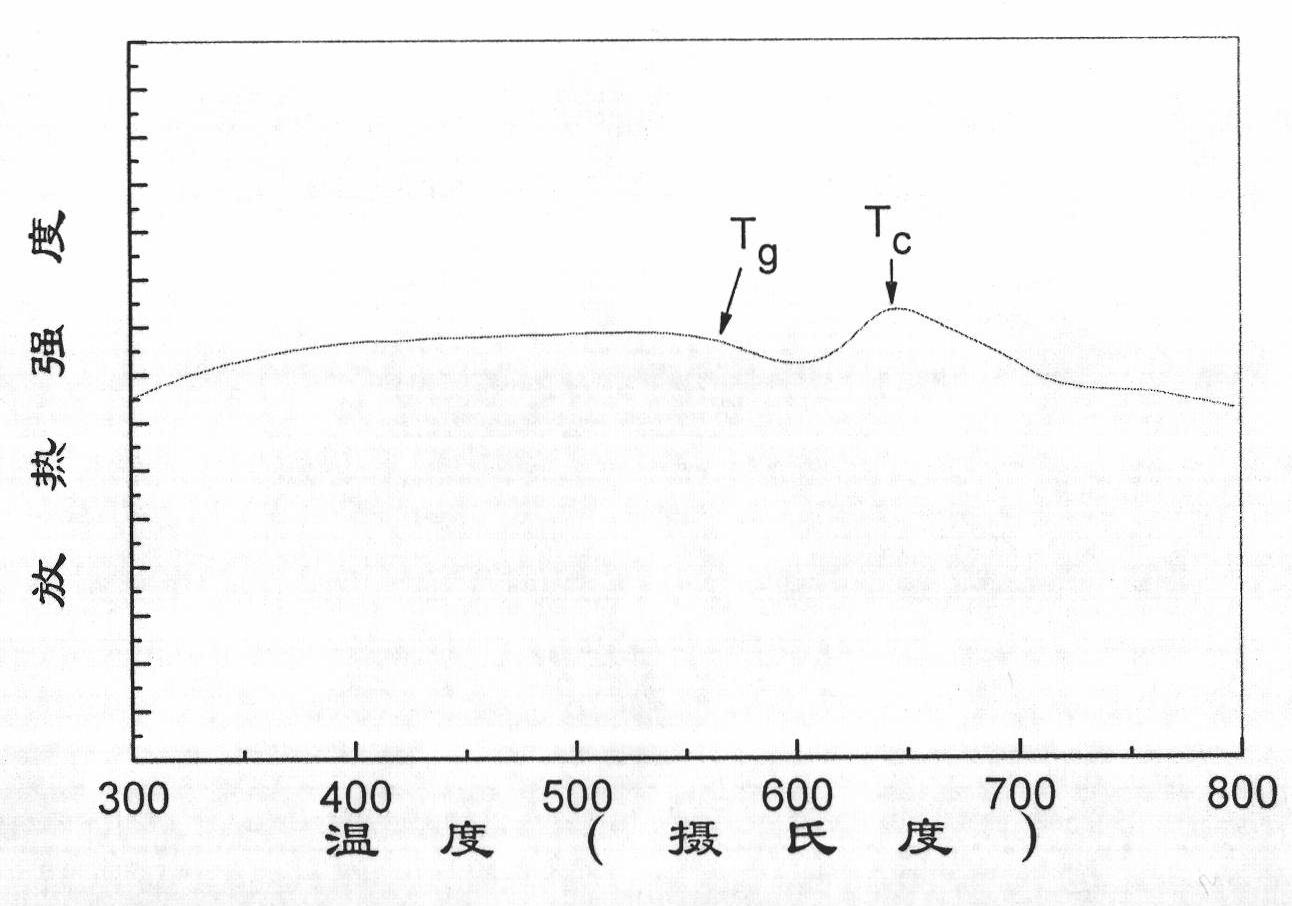

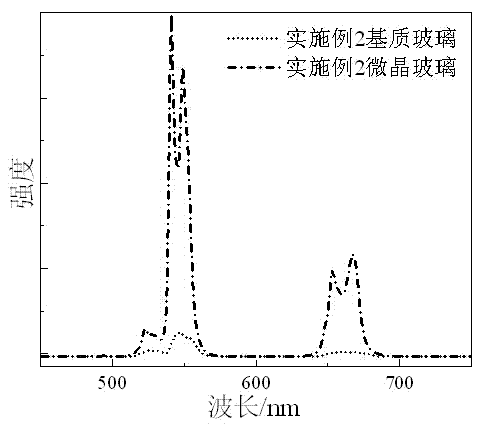

Double active ion doped bicrystal glass ceramic fluorescence temperature probe materials and preparation method thereof

The invention discloses double active ion doped bicrystal glass ceramic fluorescence temperature probe materials and a preparation method thereof. The glass ceramic comprise components as follows: 30 mol%-50 mol% of SiO2,15 mol%-30 mol% of Al2O3, 0-20 mol% of NaF, 0-20 mol% of LiF, 0-15 mol% of ZnO, 5 mol%-15 mol% of ReF3, 5 mol%-20 mol% of Ga2O3, 0.001 mol%-2 mol% of LnF3 and 0.001 mol%-2 mol% of TM compounds, wherein Ln is the rare earth ion luminescence center; TM is the transition metal ion luminescence center. The glass ceramic is prepared with a melt quenching method and through follow-up crystallization and heat treatment. The glass ceramic has strong temperature-dependent emission intensity and can be taken as a self-correcting fluorescence temperature detecting material, and the sensitivity at the highest temperature can reach 8% K<-1>.

Owner:HANGZHOU DIANZI UNIV

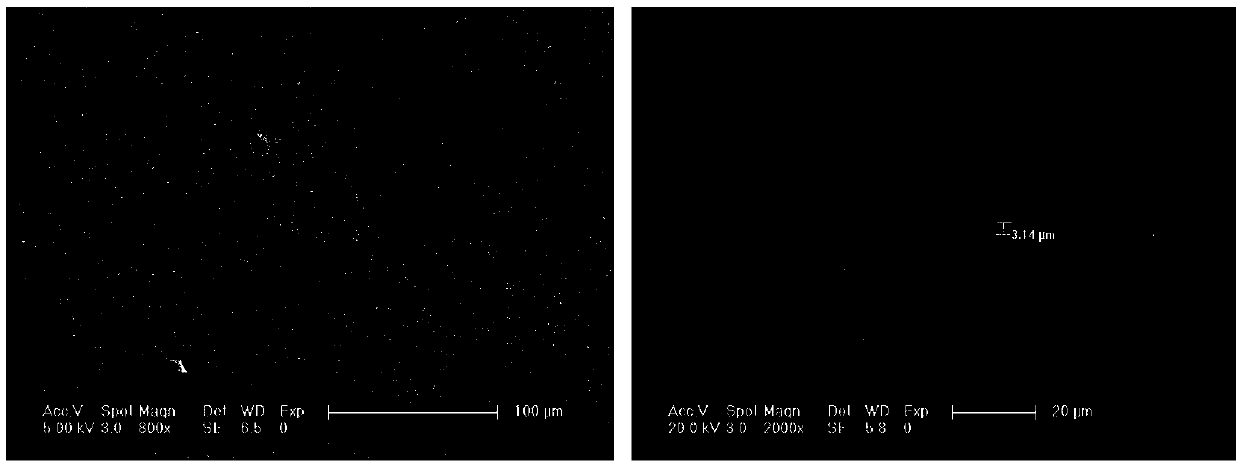

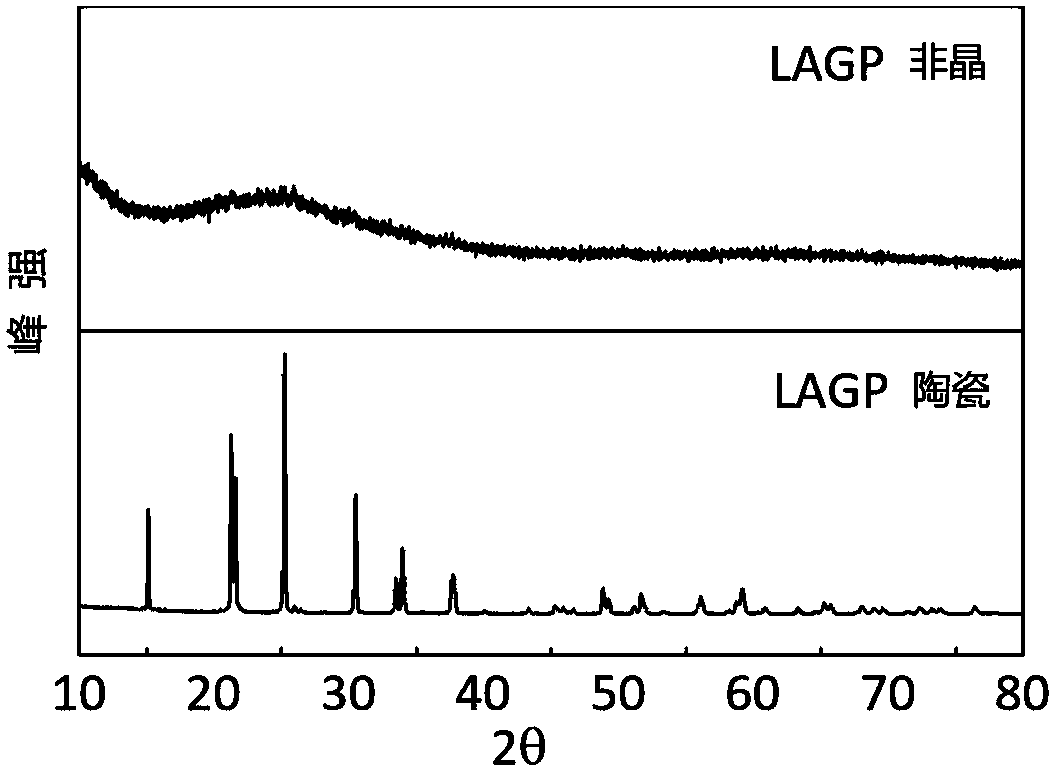

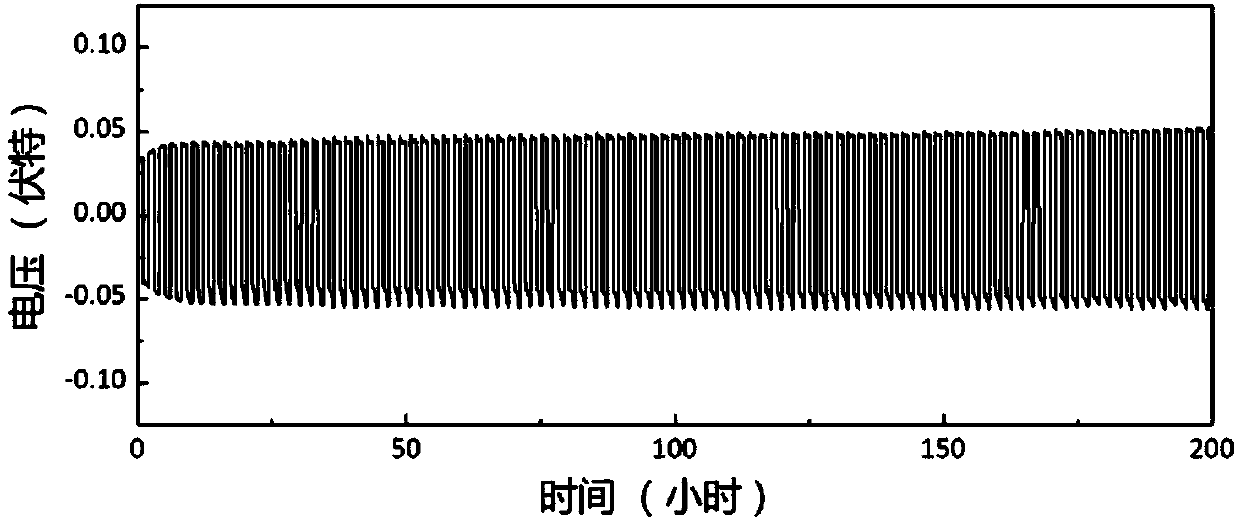

Inorganic solid electrolyte with surface made of amorphous substance and preparation method thereof

ActiveCN107611476ALower impedanceImprove stabilitySecondary cellsSolid state electrolyteChemical composition

The invention provides a preparation method of an inorganic solid electrolyte with a surface made of an amorphous substance. The preparation method comprises the following steps: A) preparing an amorphous substance having the same chemical composition as a solid electrolyte substrate material by a melting-quenching method or a high-energy ball milling method; B) mixing the amorphous substance, a binder and a solvent to obtain composite material slurry; and C) coating the surface of the solid electrolyte substrate material with the composite material slurry, removing the solvent and the binder,and softening the amorphous substance to obtain the inorganic solid electrolyte with the surface made of the amorphous substance.

Owner:ZHEJIANG FUNLITHIUM NEW ENERGY TECH CO LTD

3 mu m rare earth ion doped bismuth-germinate laser glass and preparation method thereof

InactiveCN102674690ANo devitrificationUniform physical and chemical propertiesFluorescenceRare earth ions

The invention discloses 3 mu m rare earth ion doped bismuth-germinate laser glass and a preparation method thereof. The glass comprises 32-41mol% of Bi2O3, 40-55mol% of GeO2, 9.25-15.5mol% of R12O (R1 refers to one alkali metal of Li, Na and K) and 3-6mol% of R2F3 (R2 refers to one kind or two kinds of rare earth ions such as Er, Pr, Tm, Nd and Yb). The glass prepared by a melt-quenching method is brilliant yellow in color and uniform in physicochemical property. The glass is stable in thermodynamic property, high in crystallization resistant ability and high in transmissivity at a wave band of 3 mu m. The glass has high 3 mu m fluorescence under a laser diode pump with the wavelength of 980nm and is applicable to preparation and application of optical fiber materials of the 3 mu m rare earth ion doped bismuth-germinate laser glass.

Owner:SHANGHAI INST OF OPTICS & FINE MECHANICS CHINESE ACAD OF SCI

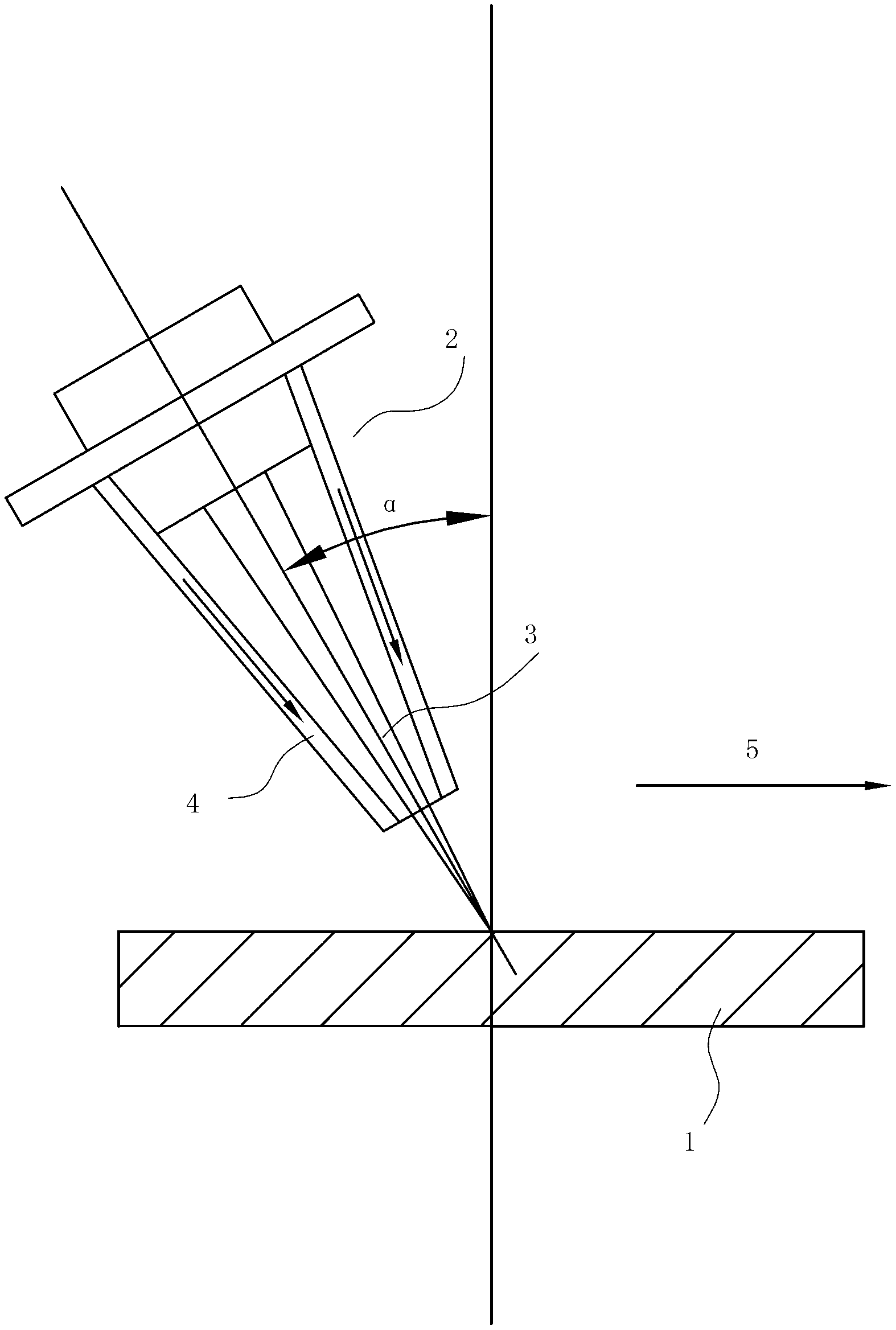

Laser melting quenching process capable of greatly increasing RuT300 surface hardness

The invention relates to a laser melting quenching process capable of greatly increasing the RuT300 surface hardness. The laser melting quenching process is characterized by comprising the following steps of carrying out flattening treatment and surface pretreatment on the surface of a to-be-treated RuT300 workpiece, setting the included angle of the transmitting direction of a laser beam and the normal of the treated surface of the workpiece at 0-45 DEG, carrying out laser melting quenching and carrying out liquid penetrant test immediately after the workpiece is cooled to the room temperature after the laser melting quenching. Compared with the prior art, the process disclosed by the invention has advantages that the operation is simple, the efficiency is high and the corresponding surface blackening treatment is not needed, so that the processing efficiency is increased; the workpiece deformation is little, so that the application of high-precision parts or dies can be satisfied; and the repeatability is good, the crater crack problem is well solved and a laser quenching zone with no crack or air hole on the surface is obtained, so that the surface fatigue resistance of the parts can be greatly increased and the service life of the parts is prolonged.

Owner:北方材料科学与工程研究院有限公司 +1

Cryogenic treatment method of nano permanent magnetic RE crystal material

InactiveCN1487535AImprove magnetismInductances/transformers/magnets manufactureMagnetic materialsMelt quenchingRare earth

The present invention provides one cryogenic treatment method of nano permanent magnetic RE crystal material. The treated nano permanent magnetic RE crystal alloy series include single-phase R2Fe14B one, Fe3 / R2Fe14B one, R2Fe14B / alpha-Fe one and Sm2Fe17Nx / alpha-Fe one. The preparation process includes smelting alloy; quick melt quenching to obtain non-crystalline and / or nano crystalline quenched alloy; crystallizing treatment of the quenched alloy; cryogenic treatment of alloy at -199~-135 deg.c for 1-20 hr before and / or after crystallizing treatment of the quenched alloy; and temperature raising in the rate of 10-100 deg.c / min. The said process can refine crystal in 10-50 nm and raise magnetic performance obviously.

Owner:UNIV OF SCI & TECH BEIJING

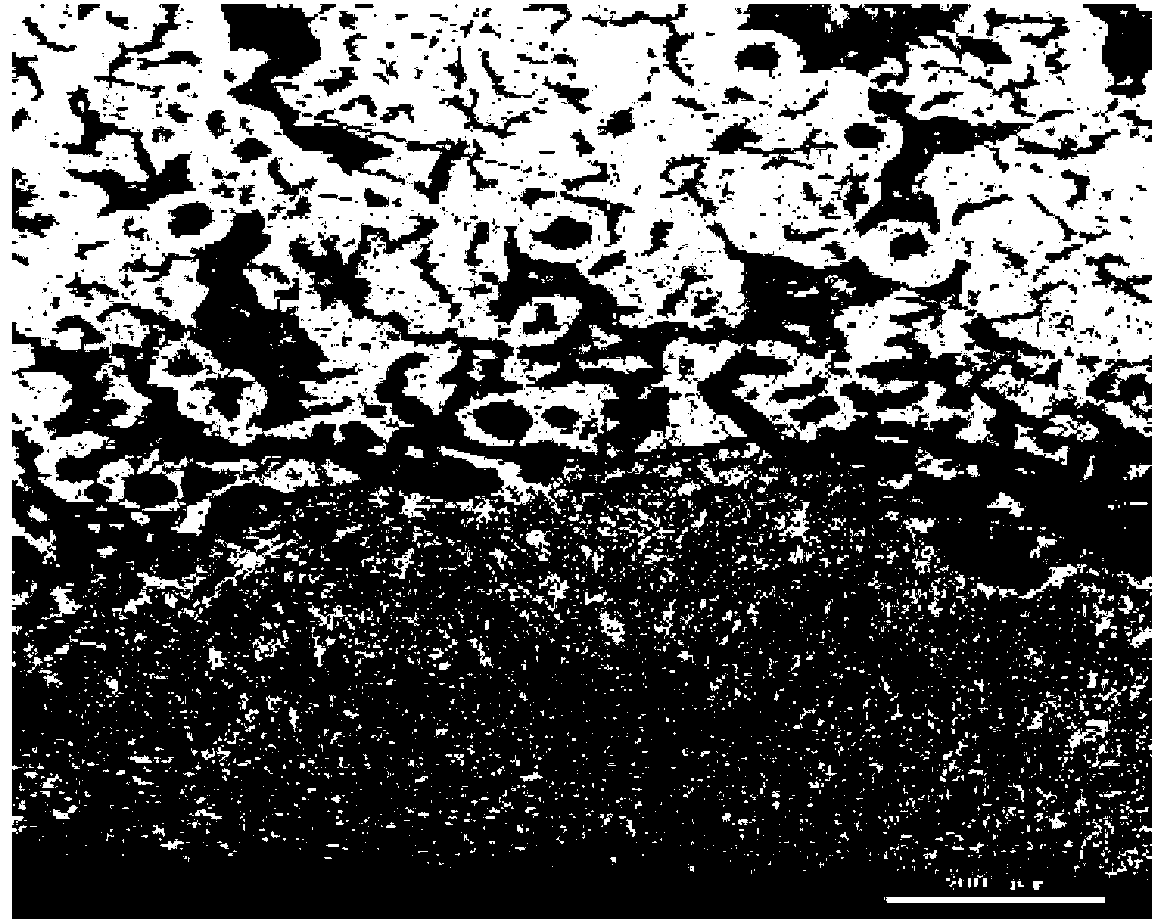

Transparent glass ceramic with tunable light emitting colors and preparation technique thereof

The invention discloses a transparent glass ceramic with tunable light emitting colors and a preparation technique thereof. The glass ceramic comprises the following components: 40 to 60mol% of SiO2, 10 to 30mol% of Al2O3, 5 to 25mol% of NaF, 8 to 15mol% of LaF3, 0.005 to 1mol% of EuF3, less than 0.02% of MSO4 and less than 0.02% of Fe, wherein M represents Mg or Ca or Ba or Sr. The preparation technique for the glass ceramic comprises two steps of melt quenching preparation of precursor glass and subsequent crystallization treatment of the precursor glass. By regulating the components of the glass ceramic and controlling the crystallization behaviors of LaFe nano crystal, the glass ceramic can emit color tunable visible light comprising white light under the excitation of ultraviolet. The material is expected to replace the conventional fluorescent powder to construct a novel white light emitting diode (LED) device with stable light color and long service life, or developed into novel solid three-dimensional light display and backlight materials.

Owner:FUJIAN INST OF RES ON THE STRUCTURE OF MATTER CHINESE ACAD OF SCI

Amorphous nanocrystalline alloy thin strip and preparation method thereof

The invention provides an amorphous nanocrystalline alloy thin strip and a preparation method thereof. The expression formula of composition of alloy is Fe73.2Cu1Mo(3-x)VxSi12B10.5P0.3, wherein x is greater than 0 and is not greater than 2.5. The method comprises the steps: smelting raw materials which are proportioned according to the ratio of all elements in the alloy, and casting, so as to form an alloy ingot; carrying out strip-spinning by using a single-roller melt-quenching method, so as to prepare an amorphous thin strip; finally, carrying out crystallization heat treatment, thereby obtaining the amorphous nanocrystalline alloy thin strip. According to the alloy thin strip prepared by the technical scheme of the invention, the saturated magnetic induction intensity is not lower than 1.4T, the preparation process is simple, the cost of the alloy is low, and the prepared amorphous nanocrystalline alloy thin strip has the performance characteristics of high-frequency low iron loss, high magnetic permeability and good stability.

Owner:GLOBAL ENERGY INTERCONNECTION RES INST CO LTD +1

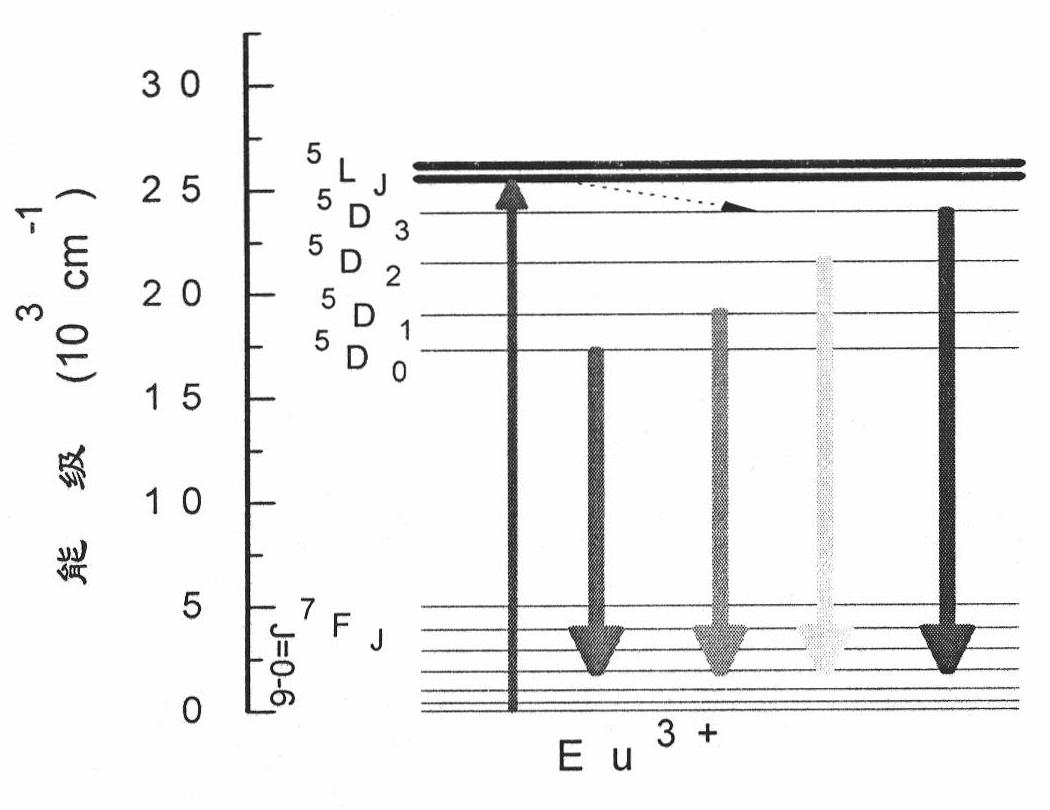

Transparent glass ceramic material for ultraviolet excited white LED and preparation technique thereof

InactiveCN102092951AIntense multicolor (including white) tunable luminescenceIntensely Tunable LuminescenceRare earth ionsUltraviolet

The invention discloses a transparent glass ceramic material for an ultraviolet excited white light emitting diode (LED) and a preparation technique thereof. The glass ceramic comprises the following components: 40 to 60mol% of SiO2, 10 to 30mol% of Al2O3, 5 to 25mol% of CeF3, 0 to 15mol% of NaF, 0 to 15mol% of LiF, 0.01 to 5mol% of ReF3, less than 0.5% of MSO4 and less than 0.02% of Fe. Re represents rare-earth ions (such as Eu, Tb, Dy or the like); M represents Mg or Ca or Ba or Sr; and the content of the NaF and the content of the LiF are not 0 at the same time. The preparation technique for the glass ceramic comprises two steps of melt quenching preparation of precursor glass and subsequent crystallization treatment of the precursor glass. By changing rare-earth doping, the glass ceramic can generate intense multi-color (comprising white color) tunable light emission under the excitation of ultraviolet, and is expected to be developed and applied to a novel white LED device excited by an ultraviolet chip.

Owner:FUJIAN INST OF RES ON THE STRUCTURE OF MATTER CHINESE ACAD OF SCI

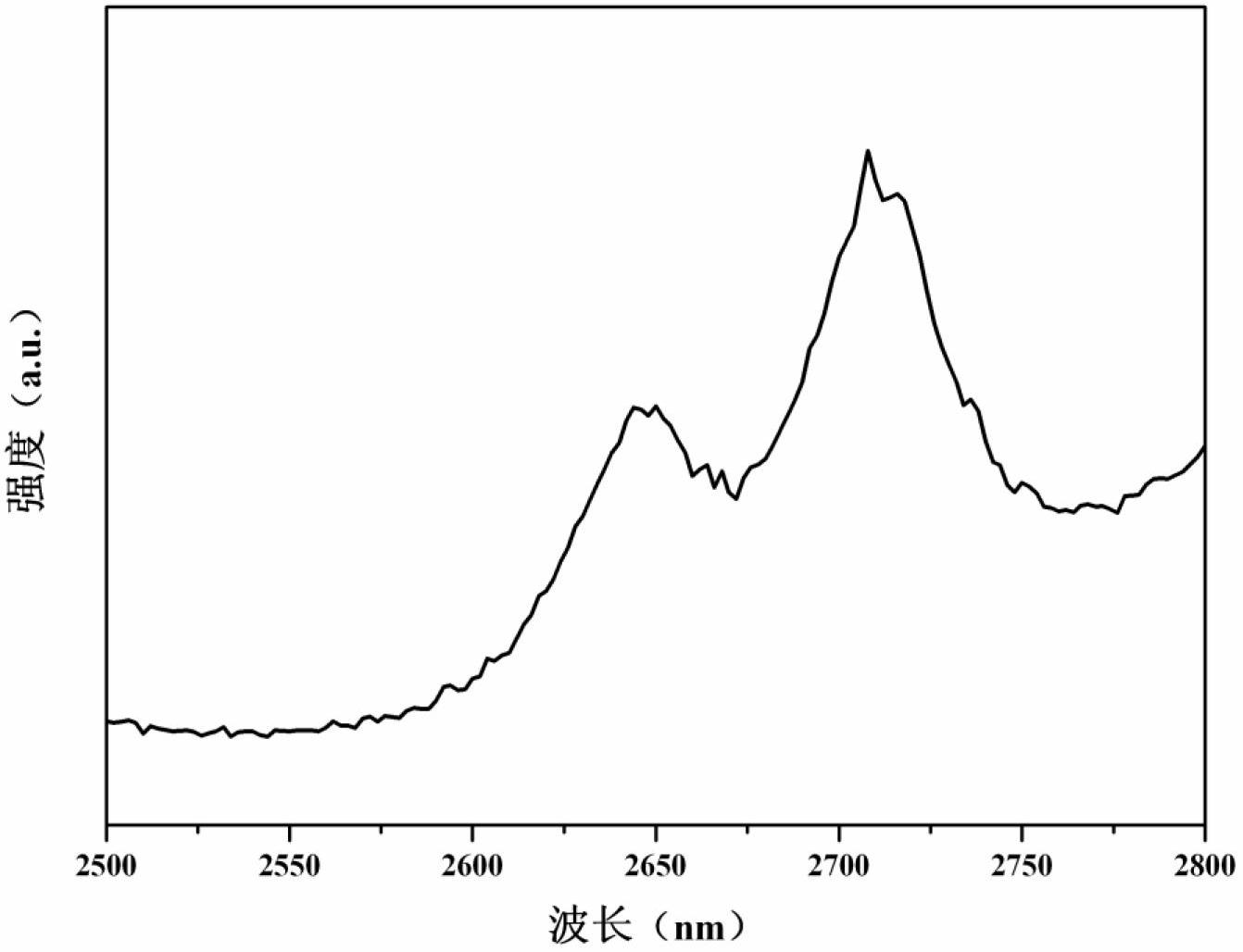

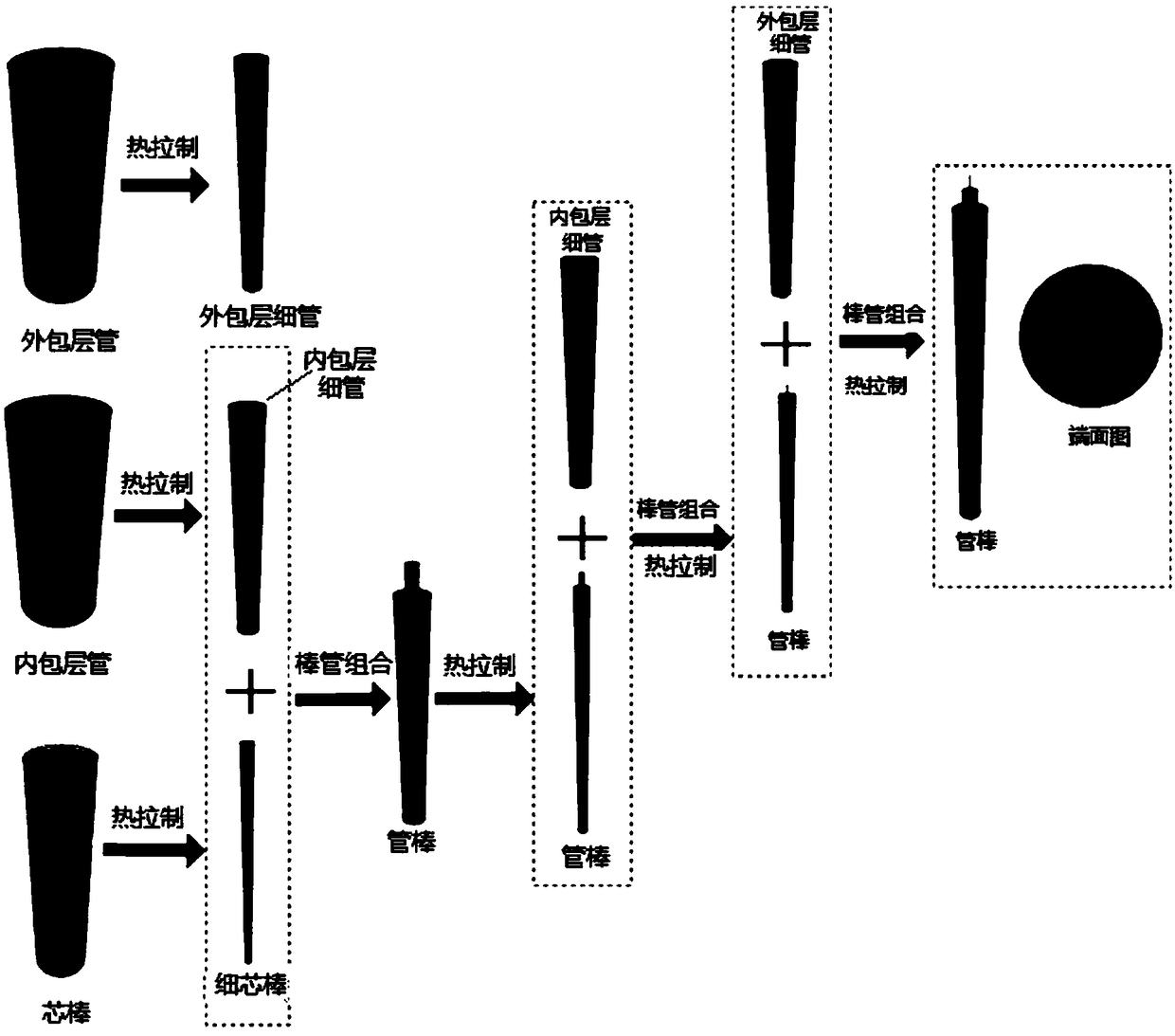

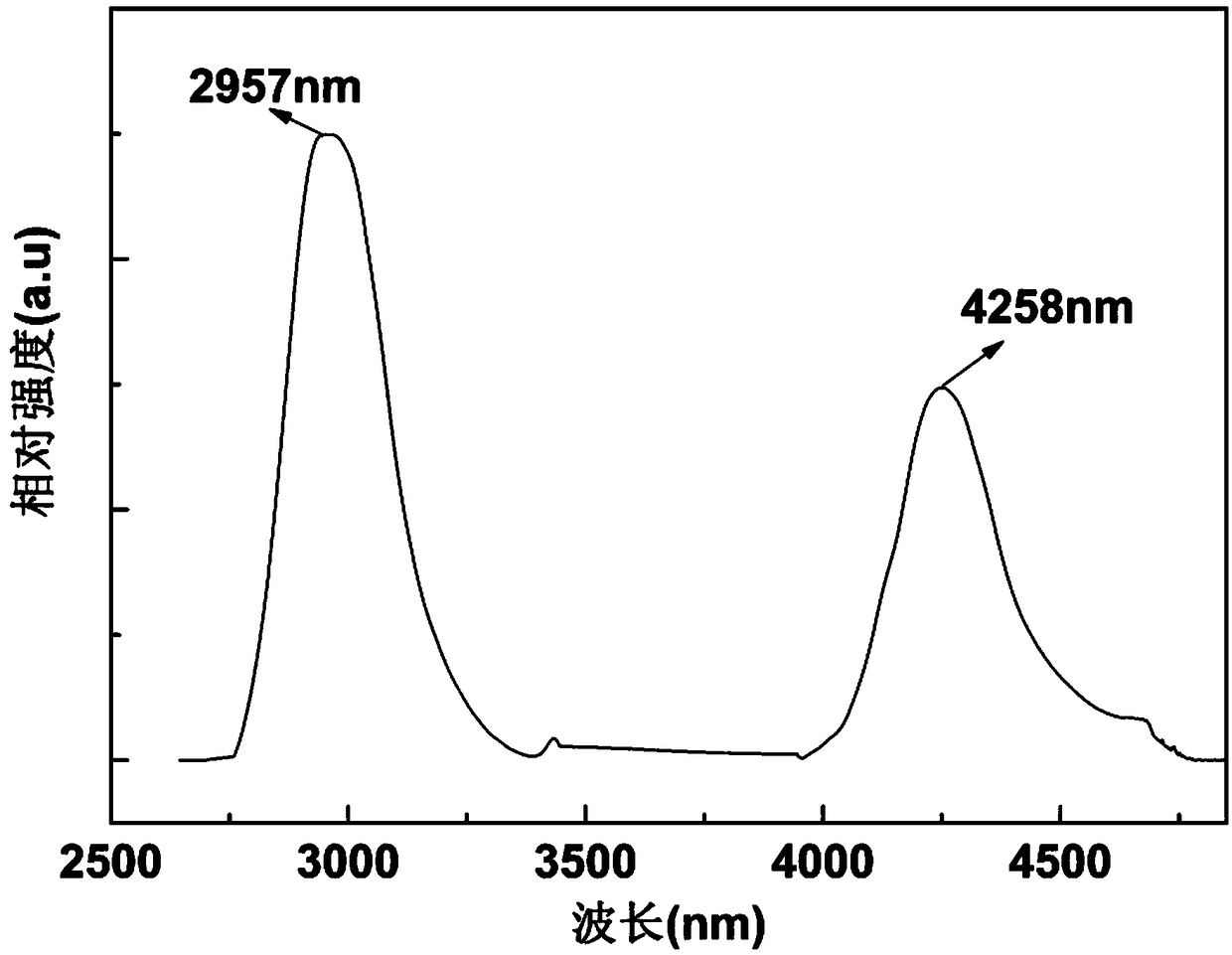

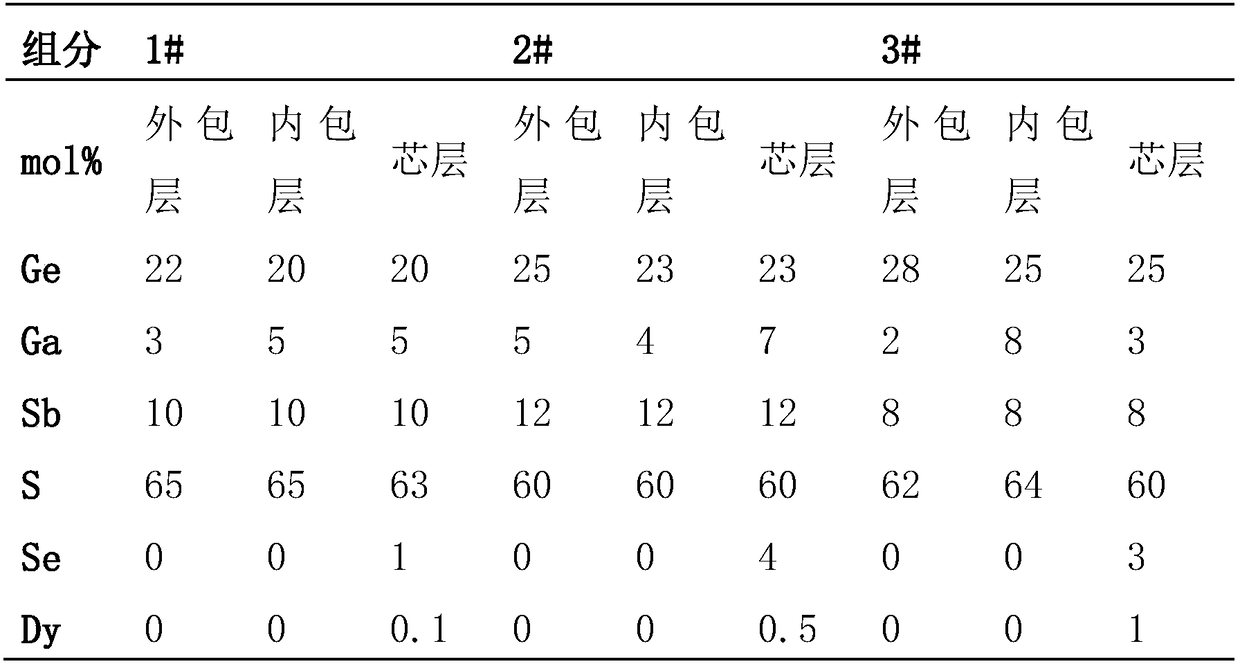

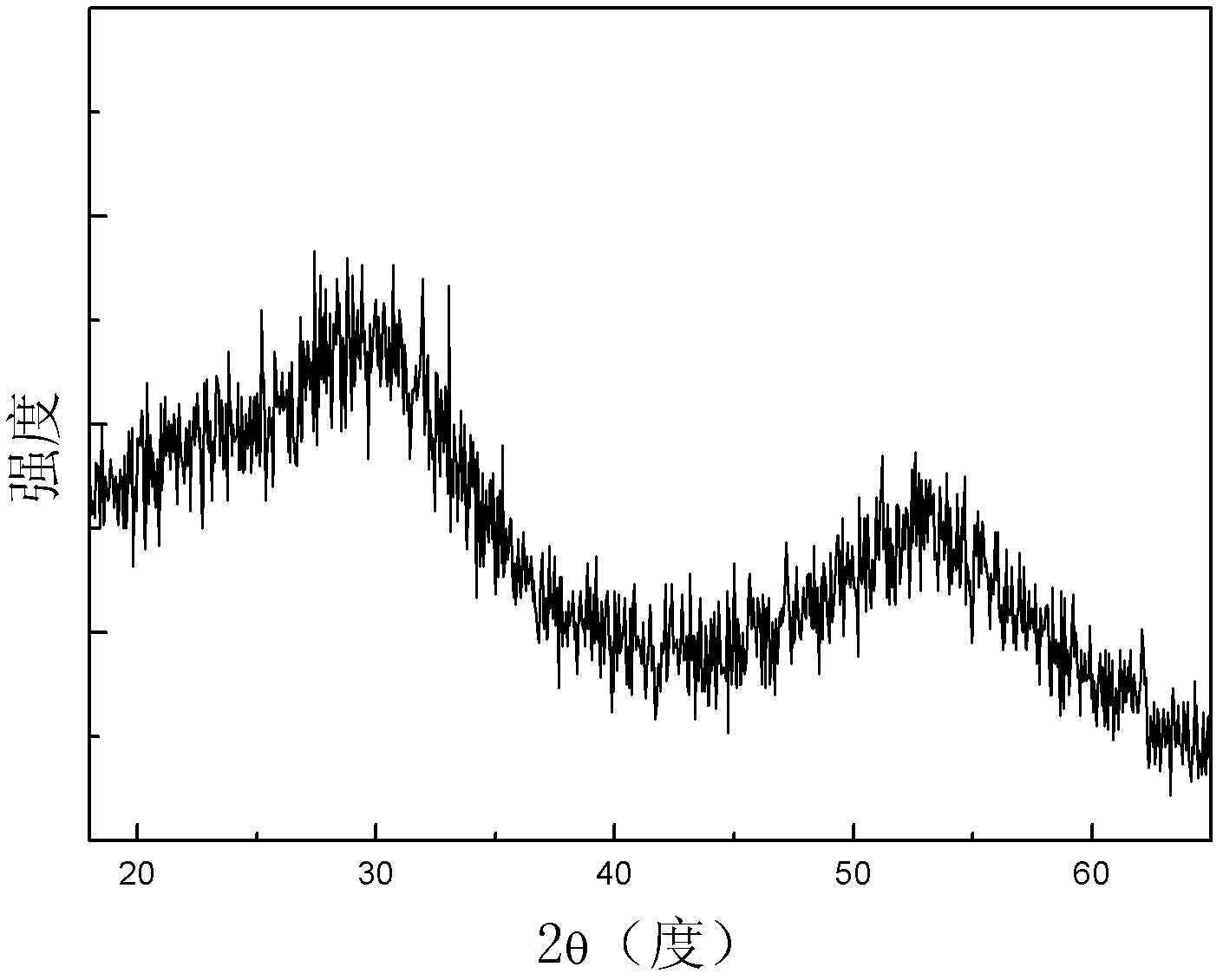

Single-mode double-cladding dysprosium-doped chalcogenide glass optical fiber and preparation method thereof

ActiveCN108732680AEasy to operateIncrease success rateGlass optical fibreGlass making apparatusFluorescence spectraMelt quenching

The invention provides a single-mode double-cladding dysprosium-doped chalcogenide glass optical fiber and a preparation method thereof. The single-mode double-cladding dysprosium-doped chalcogenide glass optical fiber is composed of an outer cladding, an inner cladding and a fiber core. An outer cladding tube and an inner cladding tube are prepared by adopting a high-speed tube rotating method, acore rod is prepared by adopting a melt quenching method, the single-mode double-cladding dysprosium-doped chalcogenide glass optical fiber with small core cladding eccentricity, tight interface adherence, smooth surface and good roundness is prepared by combining with a repeated rod-in-tube method, intermediate infrared optical fiber fluorescence spectra with wavelengths of 2957 and 4258 nm respectively are obtained in later tests, and the optical fiber provided by the invention can be expected to be an ideal intermediate infrared active optical fiber material. The optical fiber preparationmethod solves the problems that the core cladding is prone to be eccentric, the size of the core cladding is not easy to be control quantitatively and the core cladding junction surface is not tightlyattached in the preparation of the existing chalcogenide glass optical fiber.

Owner:XI'AN INST OF OPTICS & FINE MECHANICS - CHINESE ACAD OF SCI

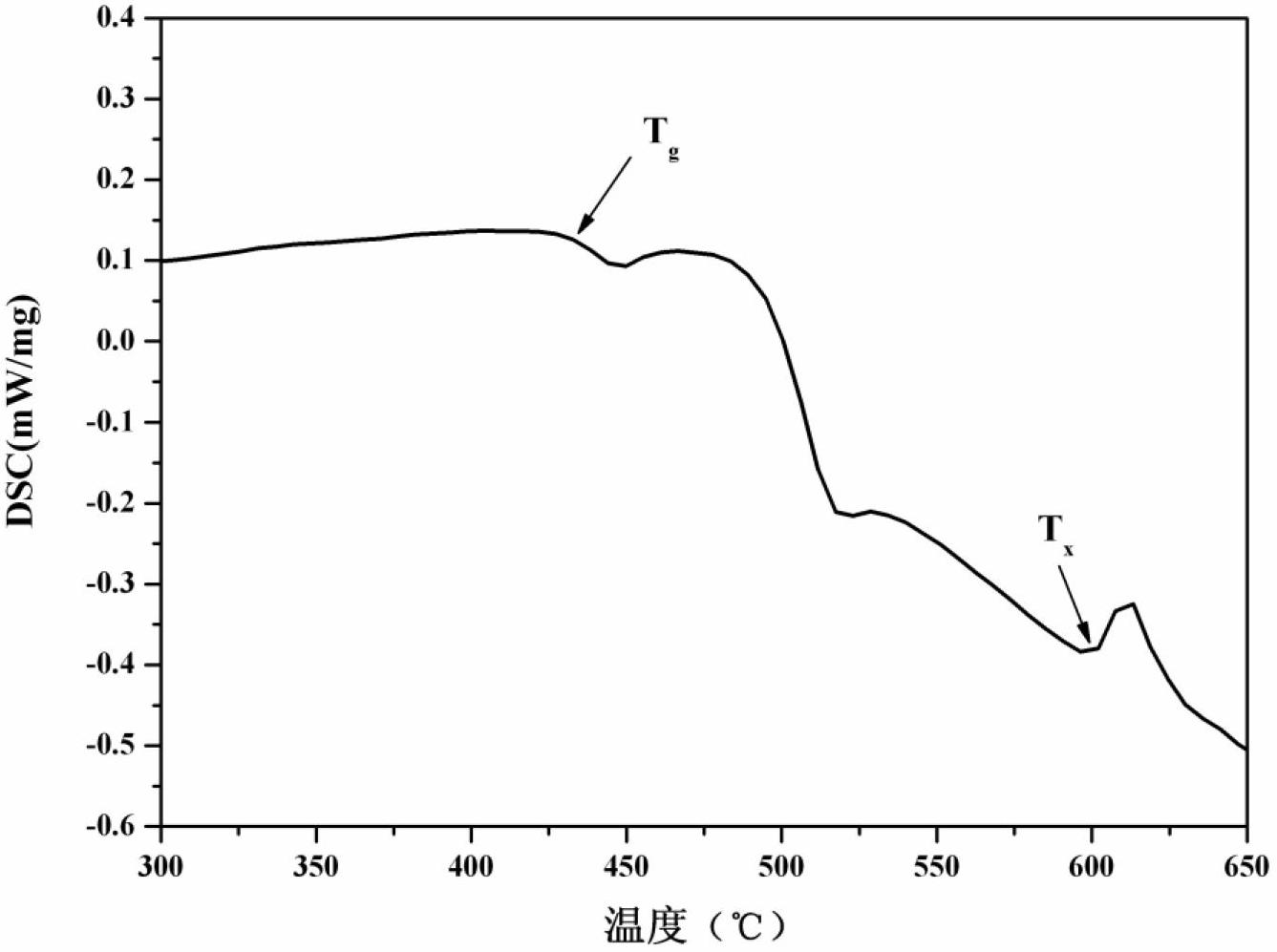

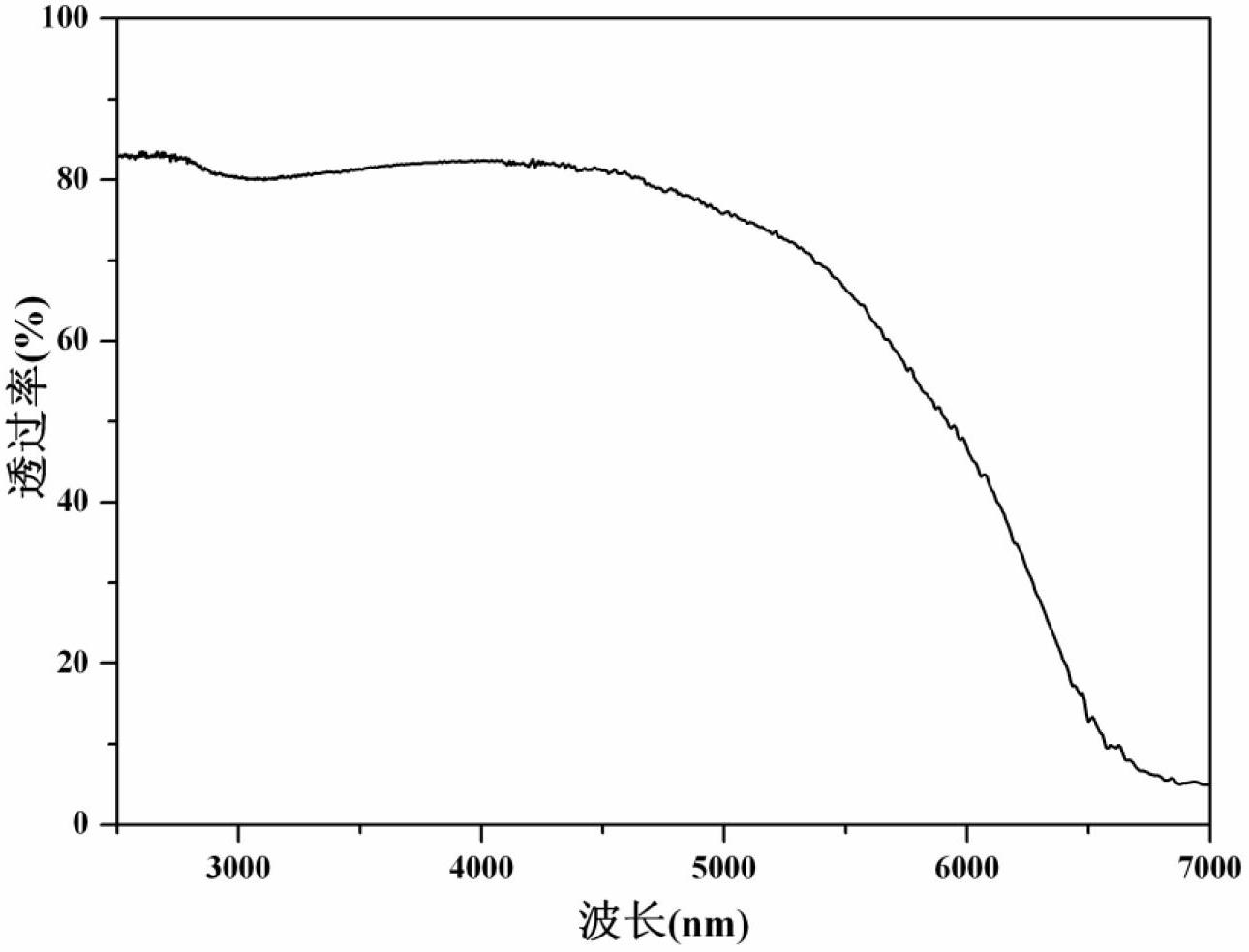

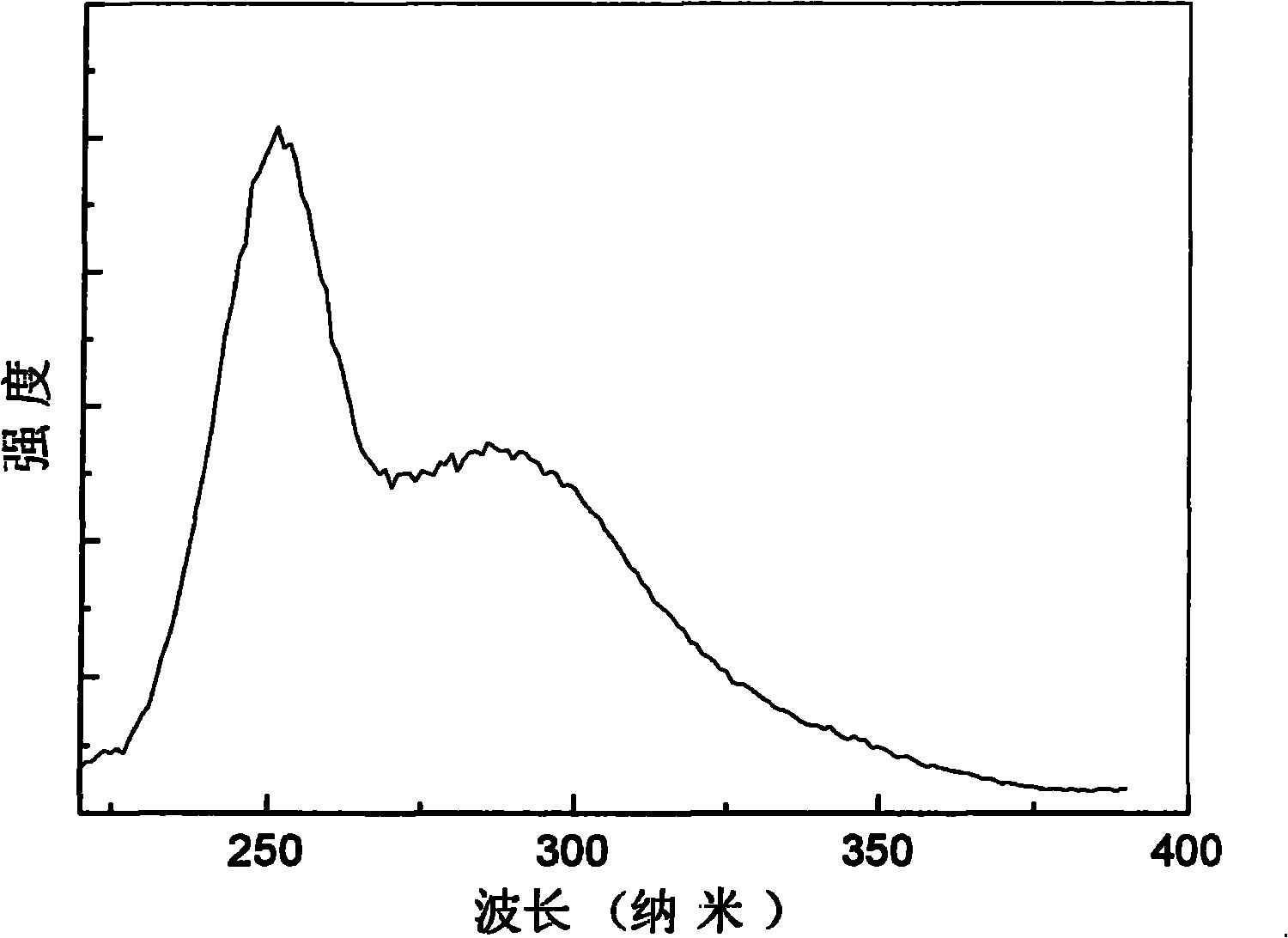

Mid-infrared luminescent chalcohalide glass and preparation technology thereof

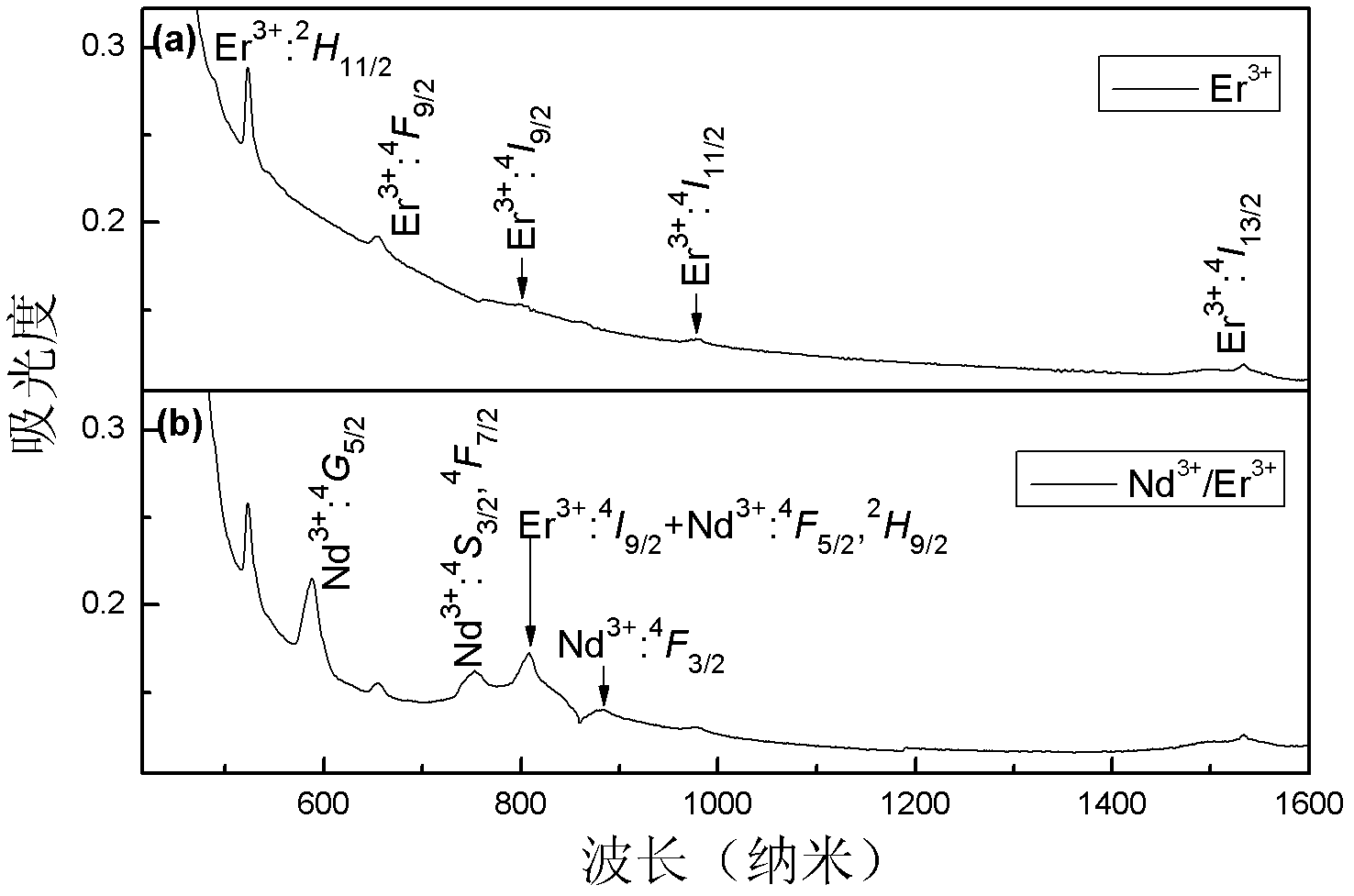

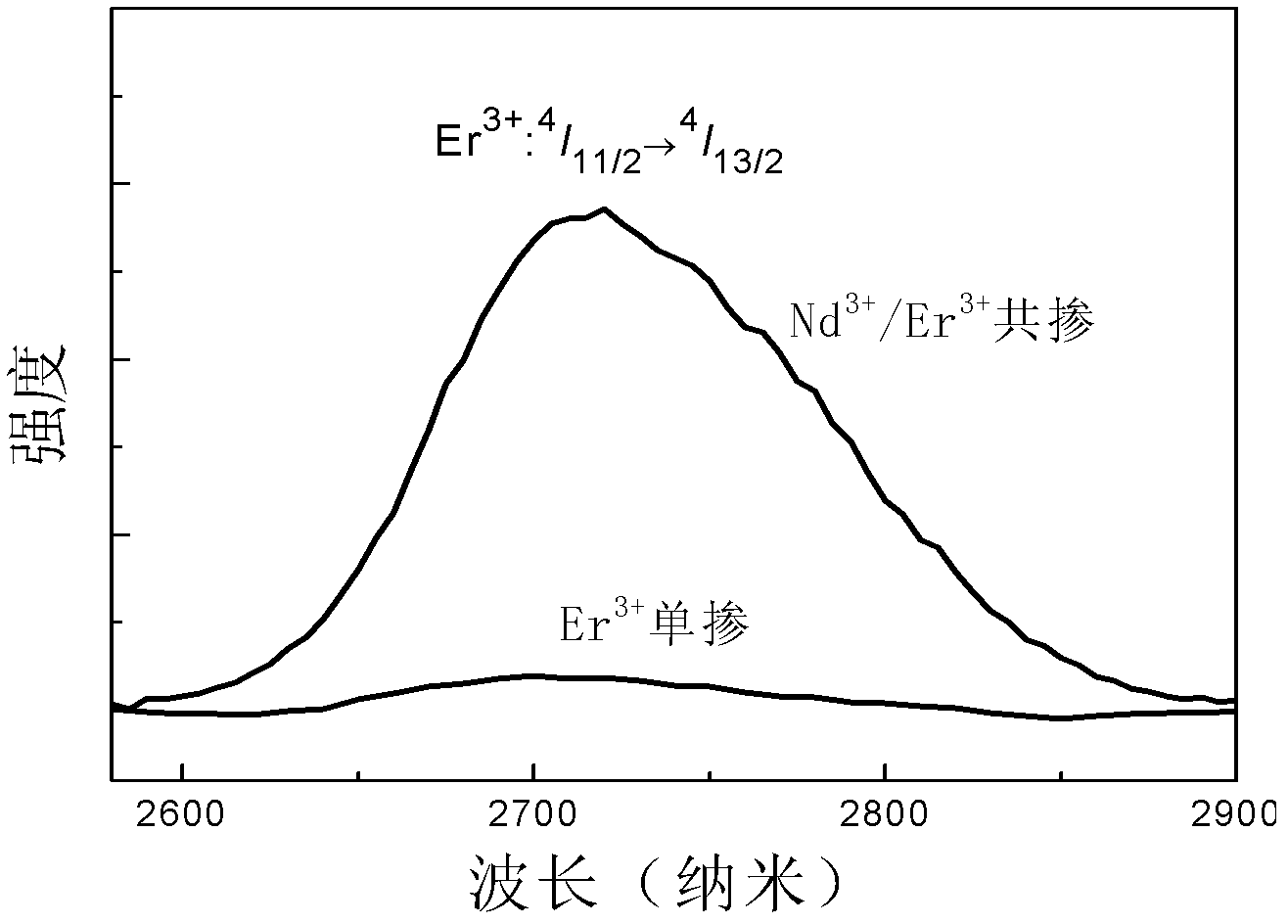

The invention discloses a 2.7 mu m mid-infrared luminescent chalcohalide glass and a preparation technology thereof. The glass is prepared by using a melt quenching method and comprises the following components expressed in mole percent: 50 to 70 mol% of GeS2, 15 to 35 mol% of Ga2S3, 5 to 15 mol% of CsCl, 0.1 to 0.5 mol% of Er2S3 and 0 to 0.15 mol% of Nd2S3 (wherein the total content of all the components is 100 mol%). Since the mid-infrared luminescent chalcohalide glass has extraordinary infrared transmittance and good thermal and mechanical performances, the mid-infrared luminescent chalcohalide glass is expected to be applied in fabrication of 2.7 mu m mid-infrared lasers.

Owner:FUJIAN INST OF RES ON THE STRUCTURE OF MATTER CHINESE ACAD OF SCI

Glass with mid-infrared luminescent property, and preparation method and application thereof

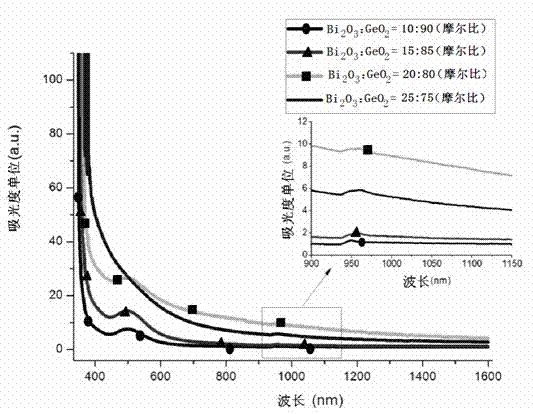

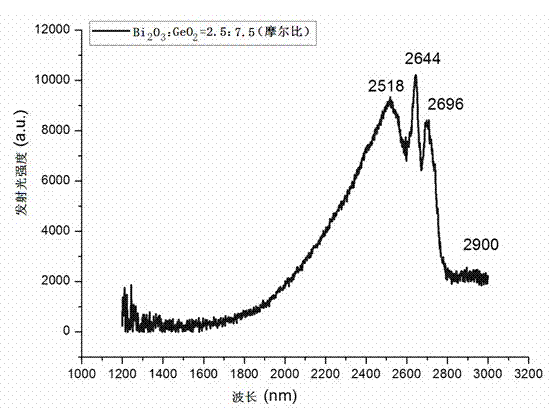

The present invention provides glass with a mid-infrared luminescent property. The glass is composed of a binary system of Bi2O3 and GeO2, wherein the purity of Bi2O3 and GeO2 is greater than 99.9%, and the mole percent of Bi2O3 is 1-40%. A preparation method includes: mixing Bi2O3 and GeO2 sufficiently, and compressing into blocks, wherein the mole percent of Bi2O3 is 1-40%. The glass is prepared by a melt quenching method. The glass with the mid-infrared luminescent property includes Bi ions, can produce a mid-infrared emission band of ultra-wideband, is stable in physical and chemical properties, easy in material processing, can also be drawn into optical fibers as needed, has good compatibility with other optical system, is simple in excitation conditions, is suitable for laser diode pumping, and can make good use of maturely-developed diode laser as a pumping source, resulting in a compact, high-efficiency and low-cost commercial laser.

Owner:SHANGHAI INST OF CERAMIC CHEM & TECH CHINESE ACAD OF SCI

Iron-based permanent magnets and their fabrication as well as iron-based permanent magnet alloy powders for permanent bonded magnets and iron-based bonded magnets

InactiveUSRE37666E1Cheap and stable processNanomagnetismInorganic material magnetismRare-earth elementMagnetic phase

With the invention of establishing fabrication methods for cheaply produced (Fe,Co)-Cr-B-R-type bonded magnets or (Fe,Co)-Cr-B-R-M-type bonded magnets containing few rare earth elements having a coercive force iHc above 5 kOe and a residual magnetic flux density Br above 5.5 kG matching the cost performance of hard ferrite magnets, we have obtained iron-based permanent magnets consisting of microcrystal clusters where the average crystal size of each component phase is in the range 1 nm ~30 nm and where both a soft magnetic phase consisting of a ferromagnetic alloy whose main components are alpha-Fe and a ferromagnetic alloy having iron, and a hard magnetic phase having a Nd2Fe14B-type crystal structure coexist within the same powder particles, by melt-quenching of a (Fe,Co)-Cr-B-R(Pr,Nd)-type molten alloy or a (Fe,Co)-Cr-B-R-M (M=Al,Si,S,Ni, Cu,Zn,Ga,Ag,Pt,Au,Pb)-type molten alloy of a particular composition containing few rare earth elements, to obtain an essentially amorphous structure or a structure both amorphous and with small amounts of fine crystals, and by applying a crystallization heat treatment under specific conditions. By grinding this iron-based permanent magnet to an average powder particle size of 3 mum~500 mum and combining the resultant iron-based permanent magnet alloy powder with a resin, we can obtain an iron-based bonded magnetic with good thermal and magnetic properties and with the magnetic characteristics iHc>=5 kOe, Br>=5.5 kG and (BH)max>=6 MGOe.

Owner:SUMITOMO SPECIAL METAL CO LTD

Rare earth-doped oxyfluoride germanate microcrystalline glass and preparation method thereof

InactiveCN104743885AImprove luminosityIncrease the intensity of upconversion luminescenceRare-earth elementUp conversion

The invention discloses rare earth-doped oxyfluoride germanate microcrystalline glass and a preparation method thereof, and belongs to the technical field of luminescent materials. The microcrystalline glass comprises the following components in percentage by mole: 39-55% of GeO2, 5-15% of ZnO, 5-15% of AlF3, 10-25% of BaF2, 1-10% of Na2O, 1-20% of NaF and 0.5-5% of RF2 (R is rare earth elements). The preparation method comprises the following steps: firstly preparing oxyfluoride germanate glass by using a melt quenching method; and then, carrying out micro-crystallization on matrix glass by virtue of a thermal treatment process to obtain transparent oxyfluoride germanate microcrystalline glass, wherein the prepared oxyfluoride germanate microcrystalline glass has good transmission of light in a range from near-infrared rays to visible light, and the up-conversion luminescence of rare earth ions is remarkably enhanced. The prepared rare earth-doped oxyfluoride germanate microcrystalline glass containing NaBaAlF6 nano-crystals is simple in preparation method, high in environmental-friendly safety and relatively low in production cost.

Owner:KUNMING UNIV OF SCI & TECH

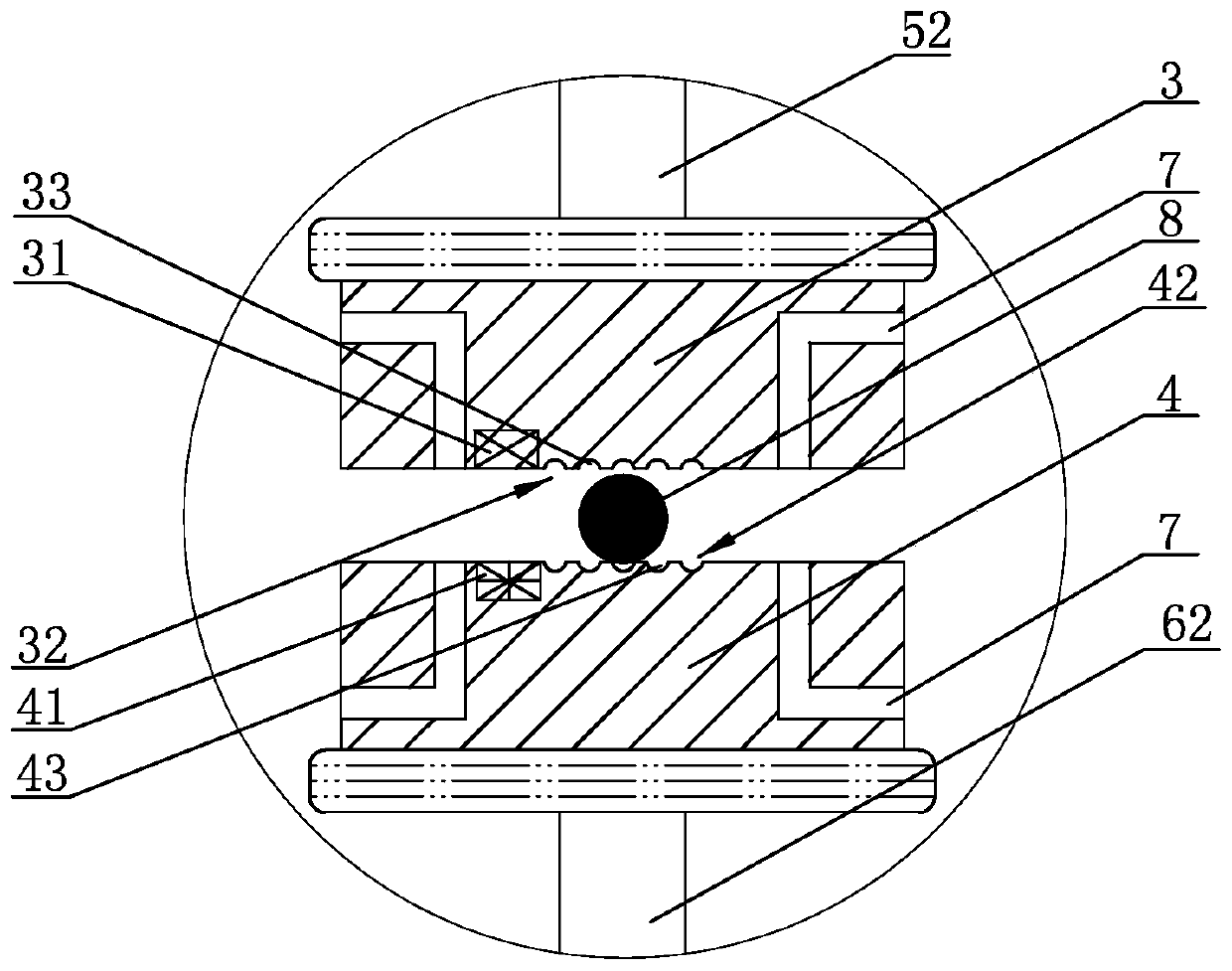

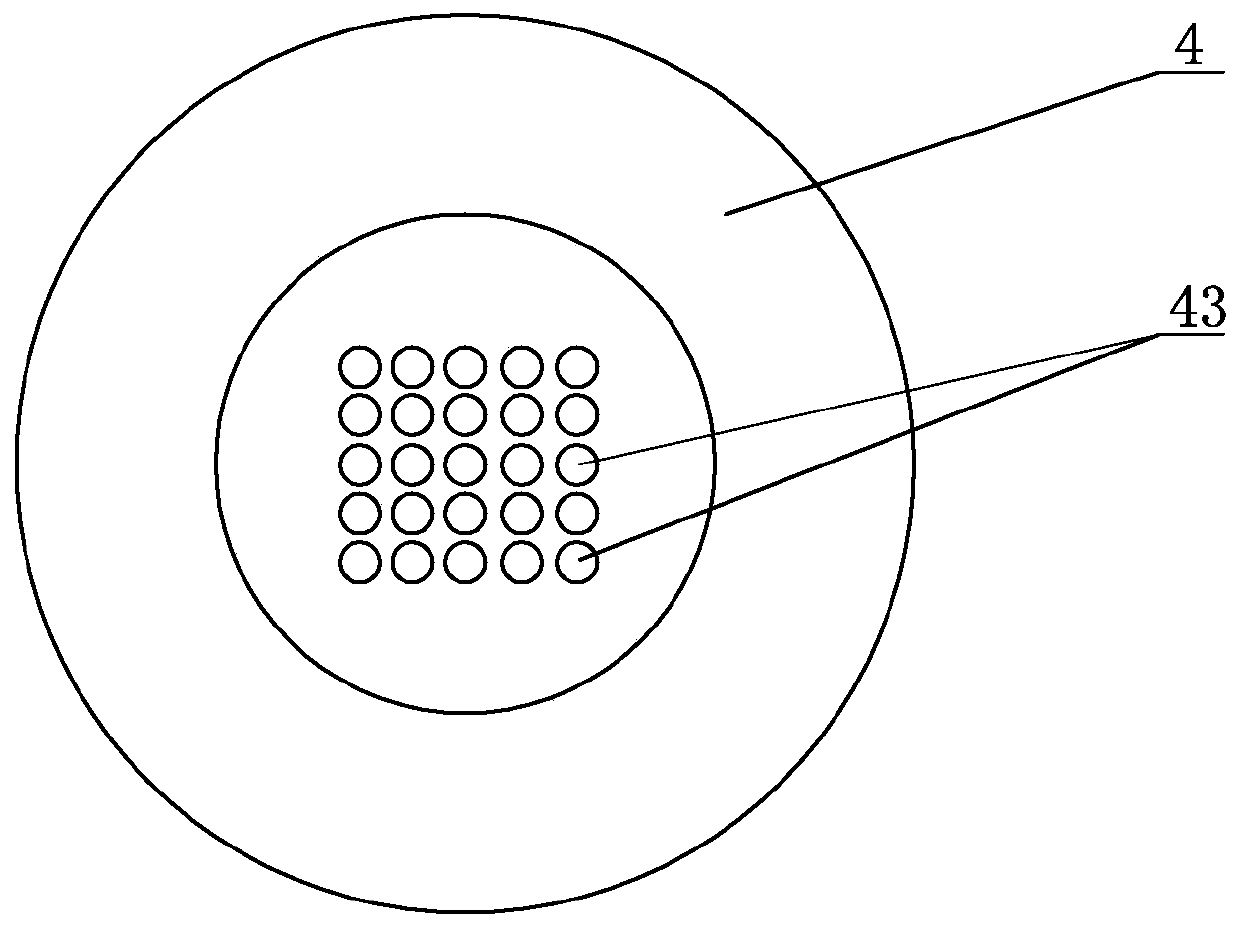

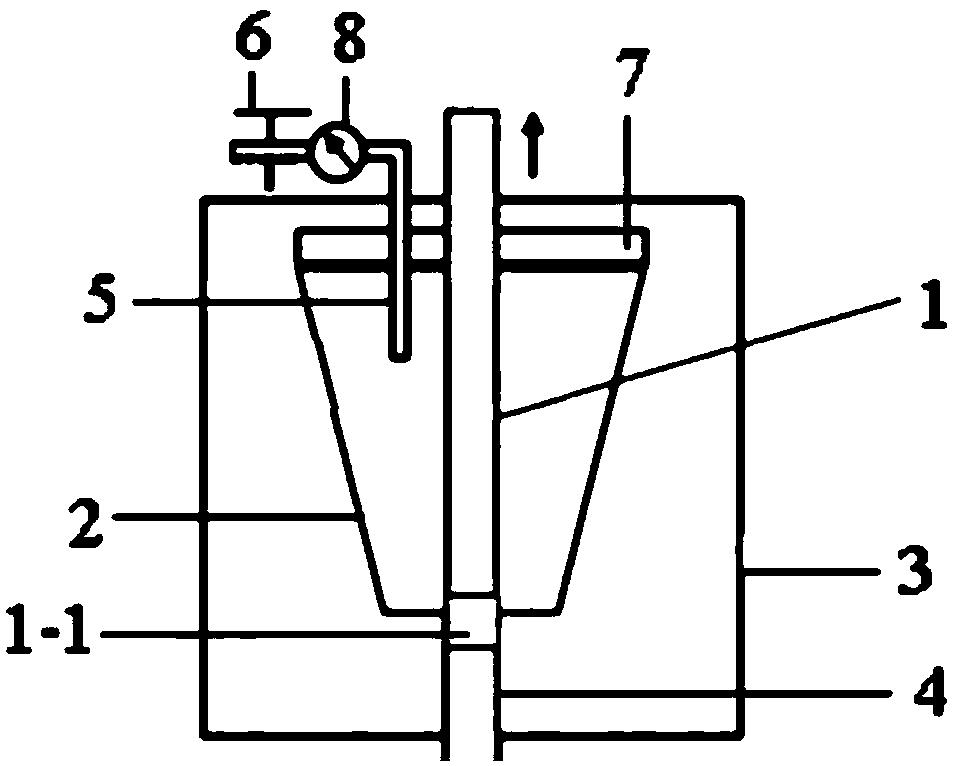

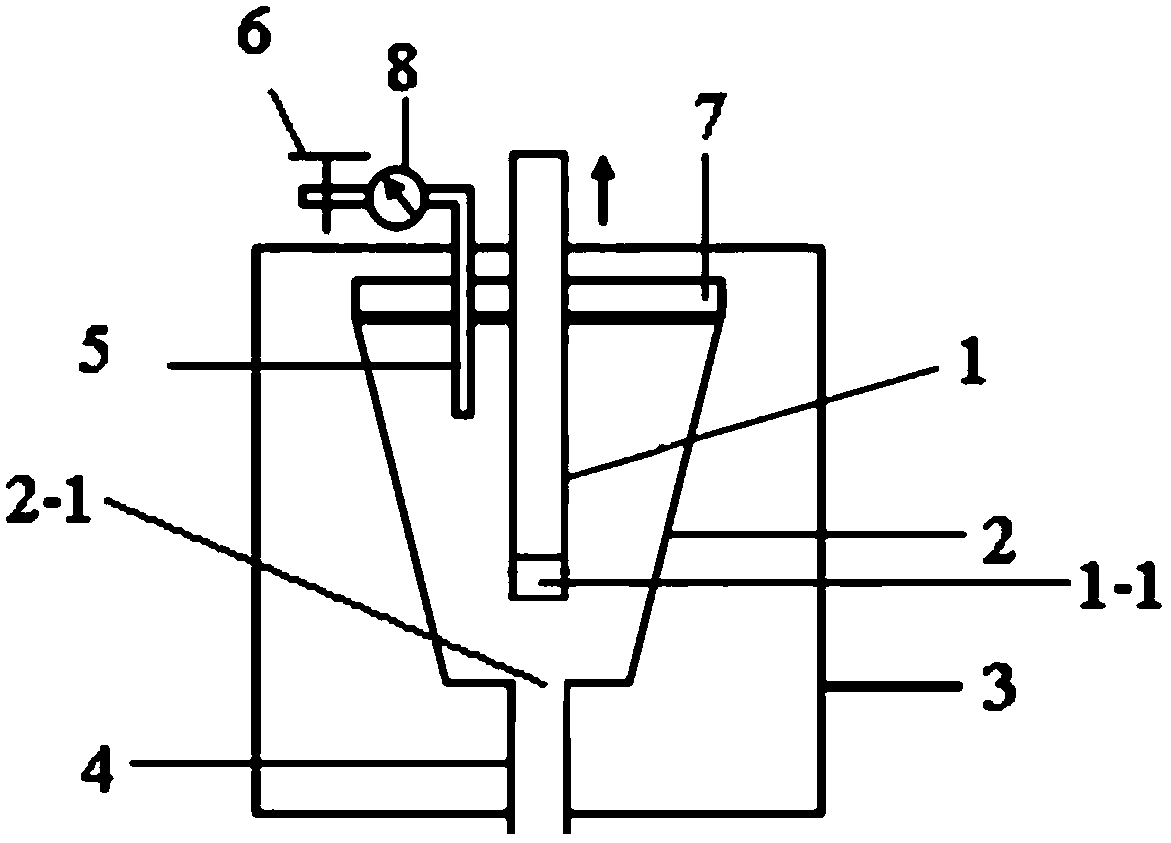

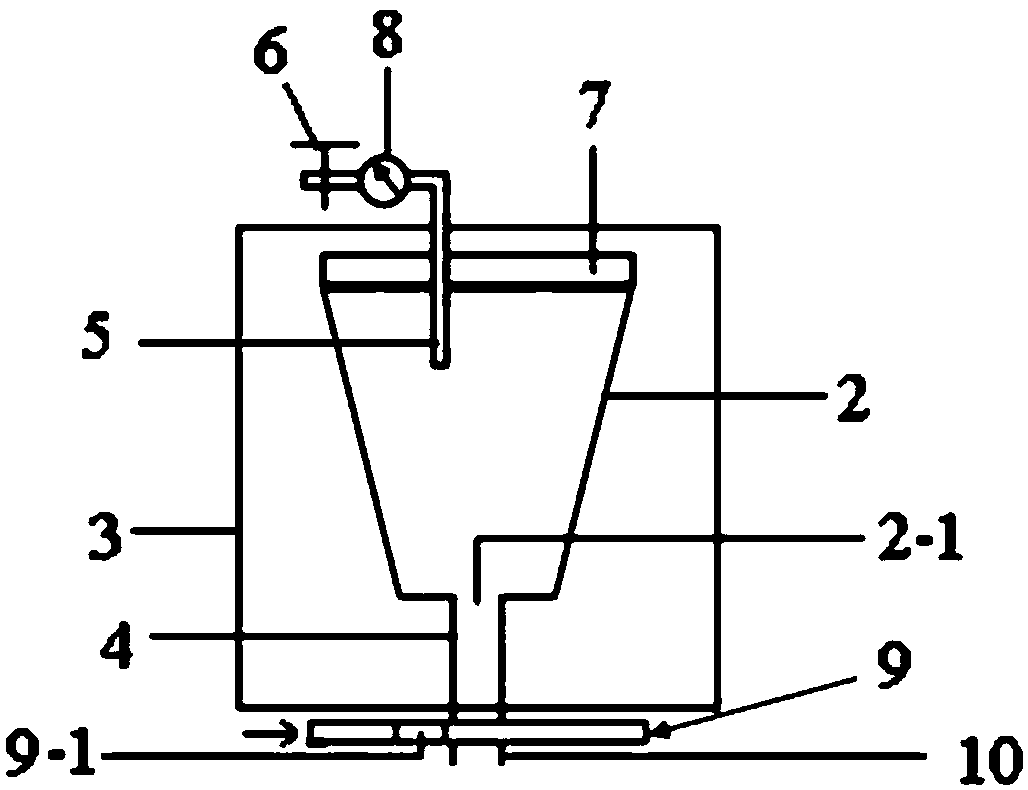

Hot-press forming preparation method of chalcogenide glass microlens

ActiveCN110698042AReduce manufacturing costImprove consistencyGlass pressing apparatusNight visionHigh volume manufacturing

The invention discloses a hot-press forming preparation method of chalcogenide glass microlens. A chalcogenide glass block prepared by a melt quenching method is used as a preform, and the chalcogenide glass microlens is prepared by using a specific hot-press forming device through a specific mold and process. According to the hot-press forming preparation method for preparing chalcogenide glass microlens, a plurality of small-caliber chalcogenide glass microlenses can be fabricated by molding at one time, and small-caliber chalcogenide glass aspheric microlens lenses can be produced in a large scale. Production efficiency is high, and consistency and uniformity in shape, size and quality of the produced microlens lenses are high. In addition, according to the preparation method provided by the invention, the perform is used as a molding object, operation is simple, and raw materials can be fully utilized, so that production cost of the microlens can be greatly reduced. The chalcogenide glass microlens prepared by the preparation method can be widely applied to various small-caliber infrared imaging lenses required by vehicle-mounted night vision, hand-held industrial monitoring, infrared mobile phones and the like.

Owner:NINGBO UNIV

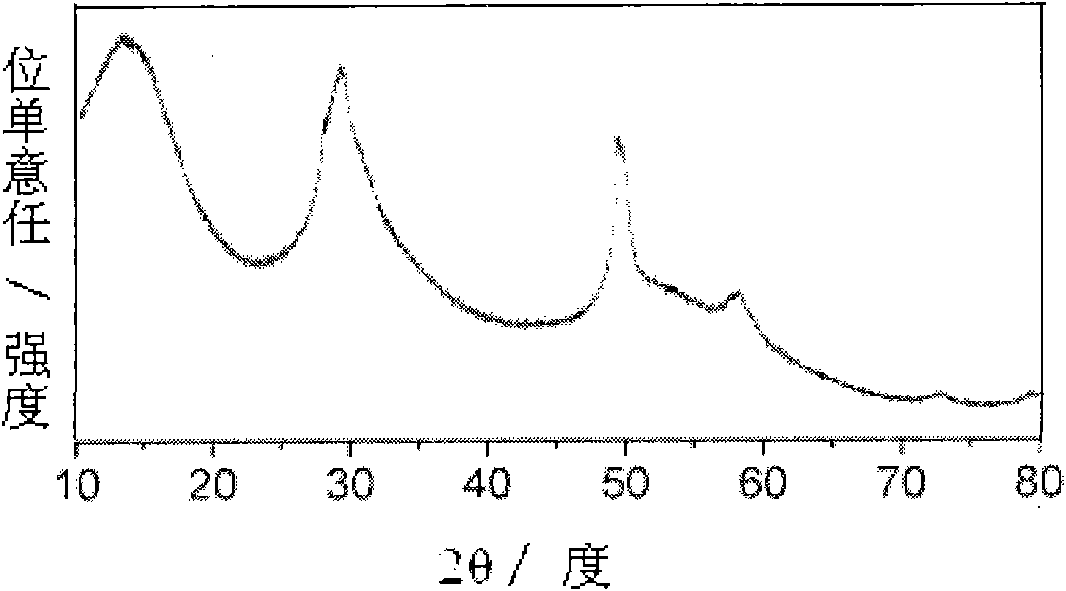

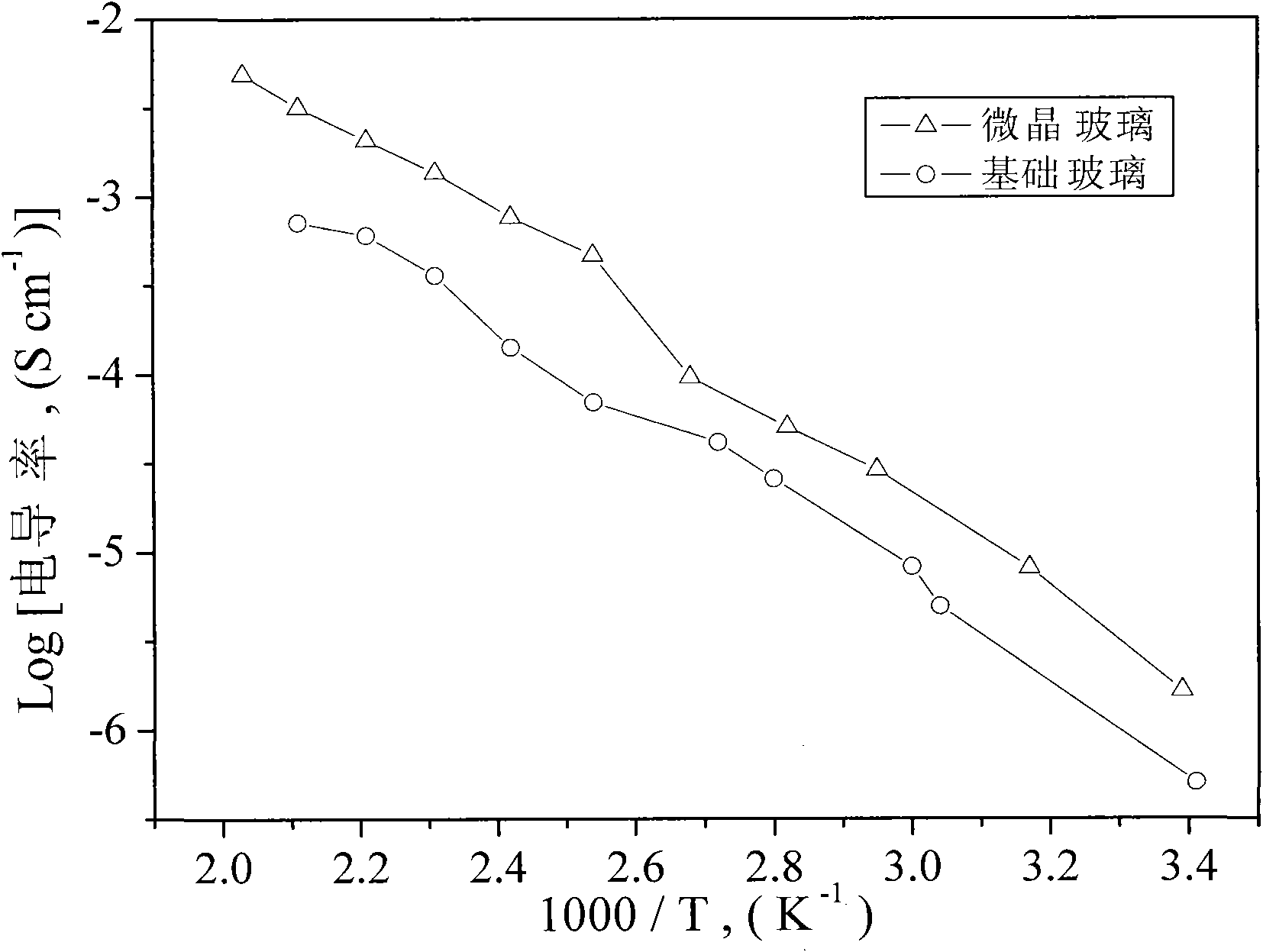

Chalcogenide microcrystalline glass material with function of lithium ion conductor and preparation method thereof

InactiveCN101811829AHigh electrical conductivityImproved resistance to atmospheric erosionElectrical conductorChalcogenide glass

The invention provides a chalcogenide microcrystalline glass material with the function of an ion conductor, which is characterized in that the molar composition of the material has the chemical formula of (100-x-y) GeS2. xGa2S3. yLiI, wherein x=20-25, and y=10-20. A preparation method of the chalcogenide microcrystalline glass material comprises the steps of: first, preparing chalcogenide glass by using a melt quenching method, and obtaining the chalcogenide microcrystalline glass with the function of the ion conductor by precise heat treatment and controllable micritization of base glass. Compared with base chalcogenide glass, the chalcogenide microcrystalline glass with the solid electrolyte function of the ion conductor obviously improves the conductivity, and improves the atmospheric corrosion resistance and thermodynamic stability.

Owner:WUHAN UNIV OF TECH

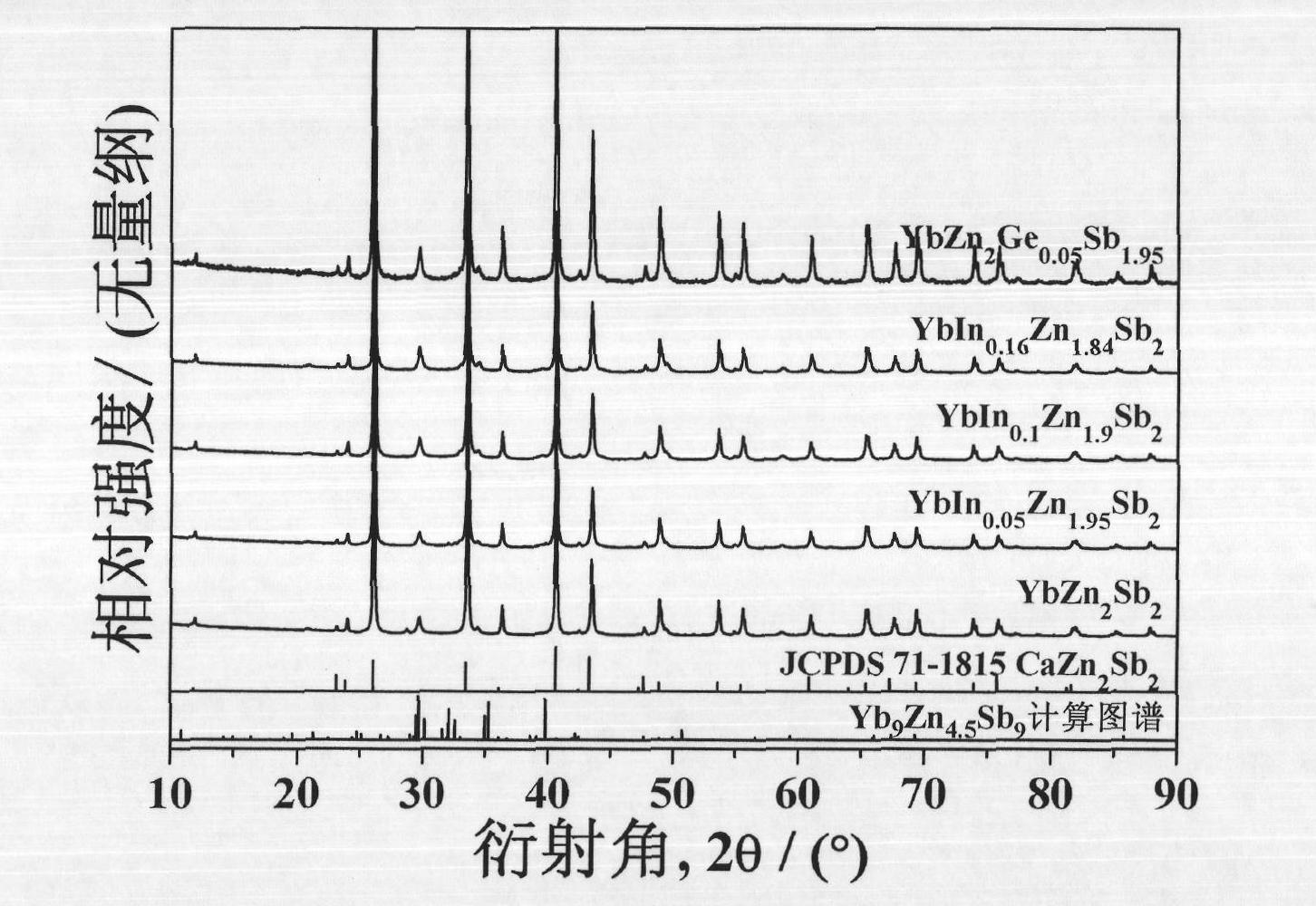

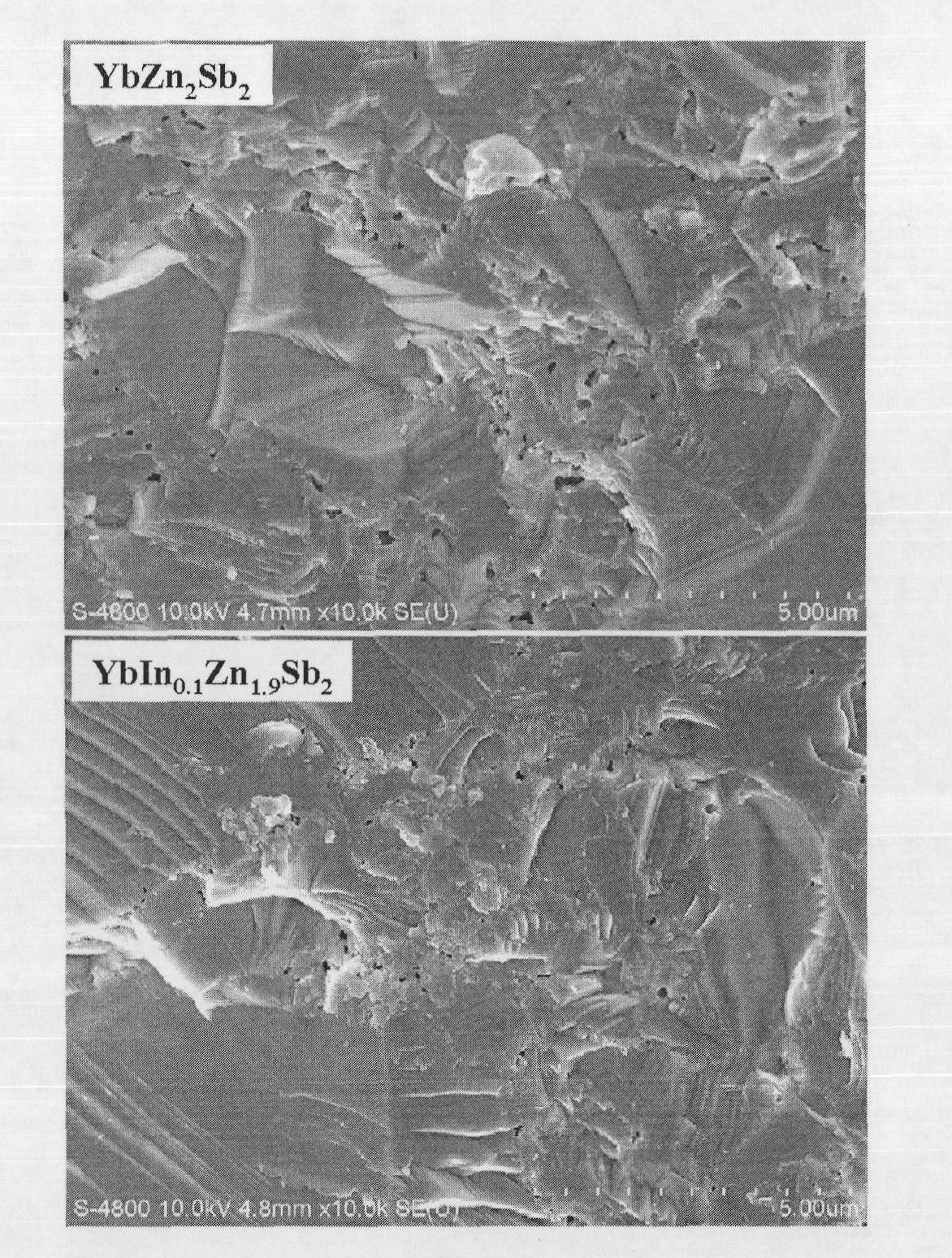

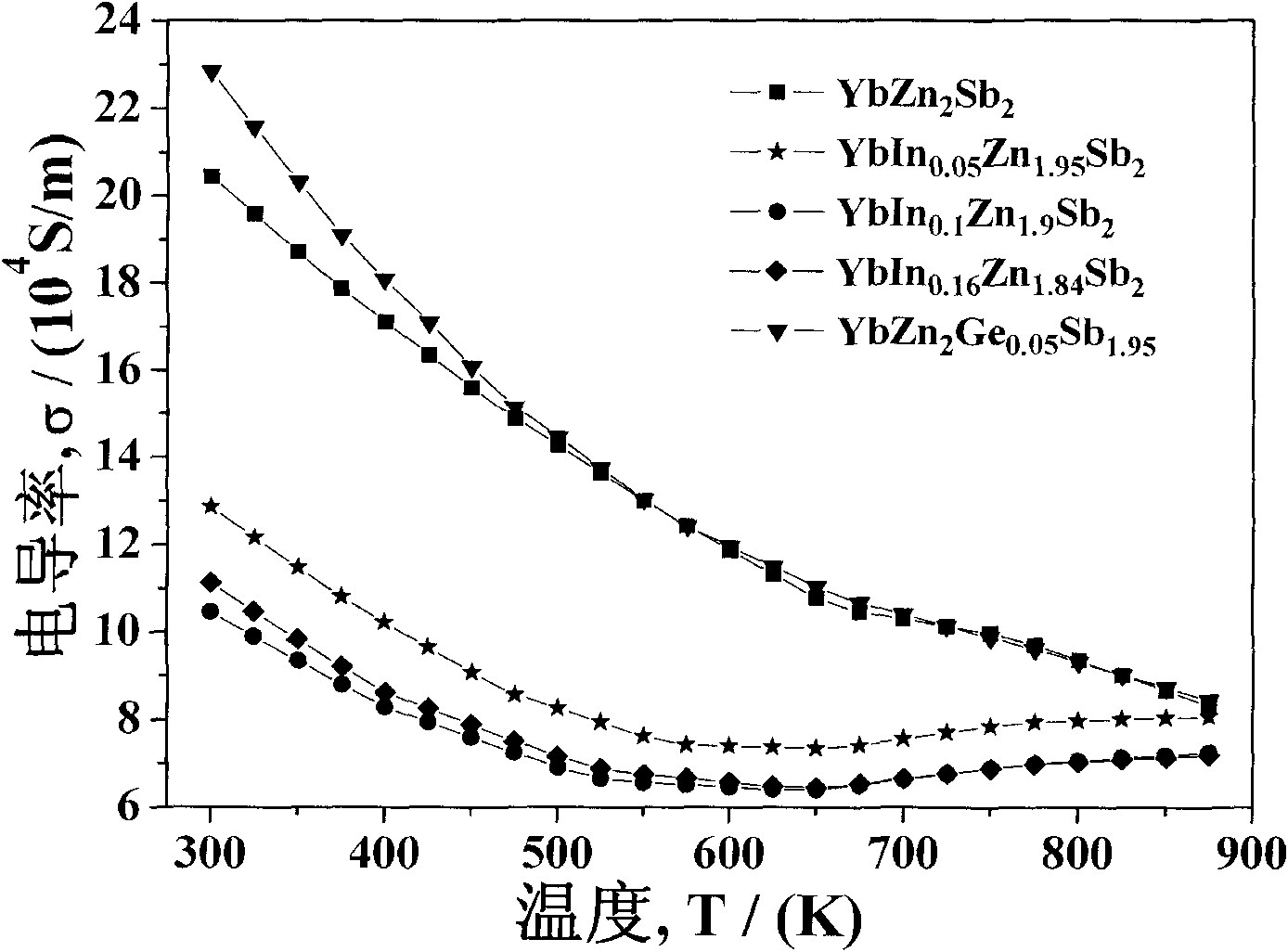

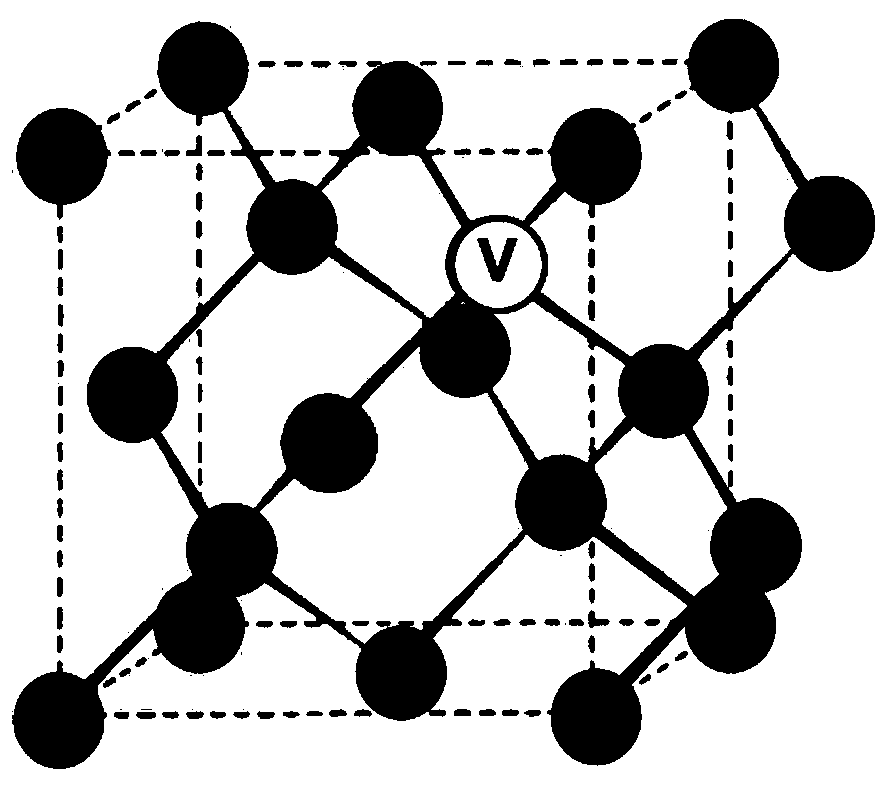

Zinc antimony based porous p-type thermoelectric material and preparation method thereof

InactiveCN101857929AShort manufacturing cycleConducive to large-scale industrial productionThermoelectric materialsMelt quenching

The invention relates to a zinc antimony based porous p-type thermoelectric material and a preparation method thereof. The general chemical formula of the material is R (Zn2-xTx) 2 (Sb2-yMy) 2, wherein R denotes an element Yb, Eu or Ca; T denotes In, Mn or Cd, x denotes T doping stoichiometric ratio, and x is more than or equal to zero and is less than or equal to 2; and M denotes Si, Ge or As, y denotes M doping stoichiometric ratio, and y is more than or equal to zero and is less than or equal to 2. The method adopts a technology of mother alloy high-temperature fusion in vacuum or under the protection of inert gas, a melt-quenching technology and a discharge plasma mother alloy sintering and quenching technology to prepare the zinc antimony based porous p-type thermoelectric material with aperture of 20-200nm. The ZT value of the material not doped with YbZn2Sb2 material can reach 0.59, the ZT value of the doped material can be further improved and the material can be used in the thermoelectric conversion power generation or refrigeration field. The invention has the advantages that the technology is simple, the preparation cycle is short, the energy consumption is low and the industrialized production can be realized.

Owner:WUHAN UNIV OF TECH

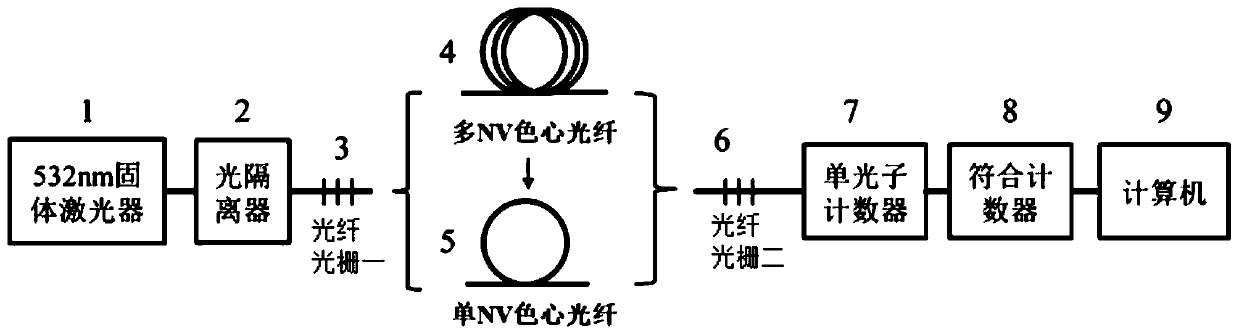

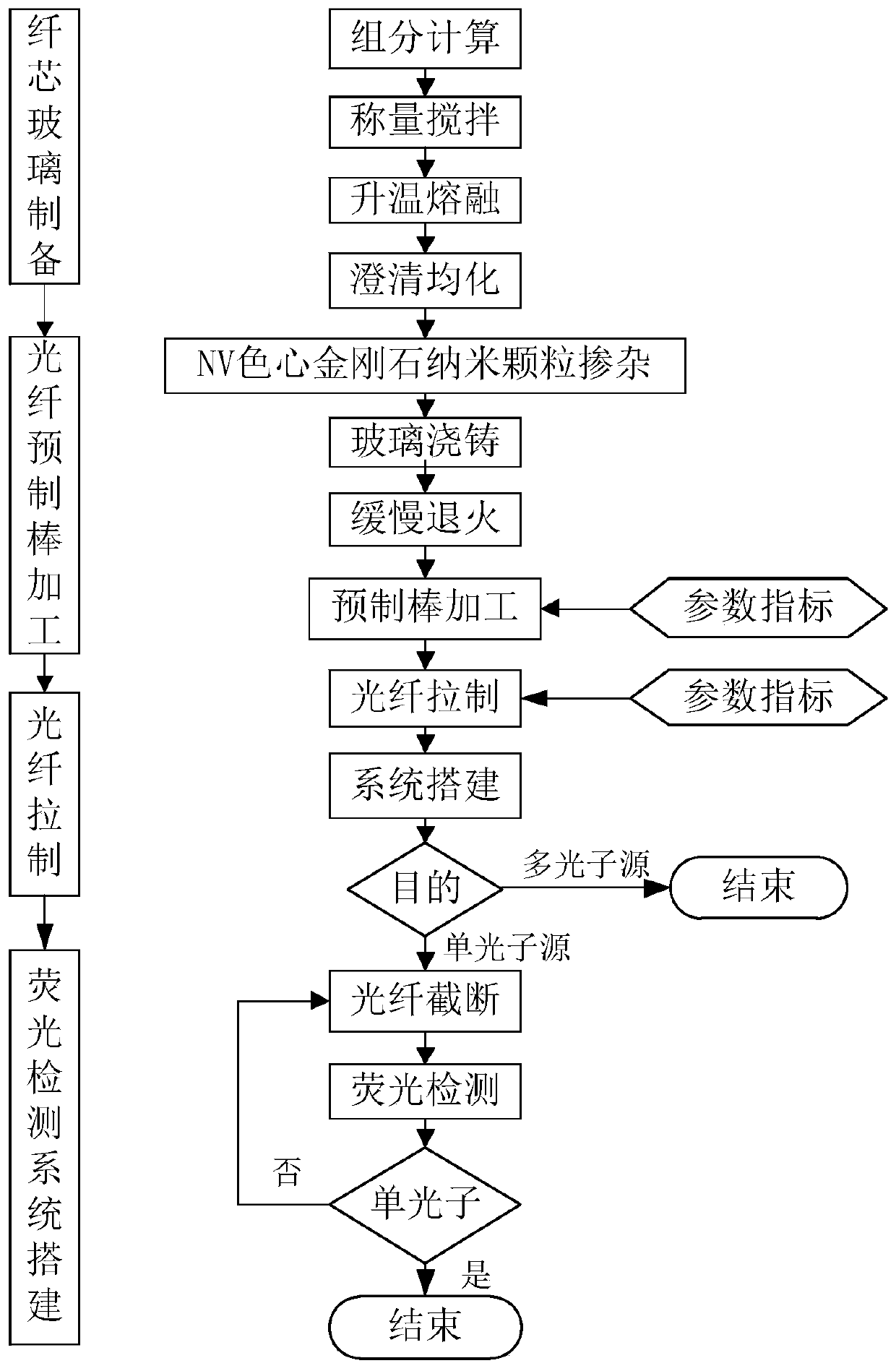

Preparation method of optical fiber NV color center single/multi-photon source

InactiveCN110510885AHigh transplantabilityReduce manufacturing costGlass making apparatusOptical elementsFiberColour centre

The invention discloses a preparation method of an optical fiber type NV color center single / multiphoton source. Diamond nanoparticles containing a NV color center are used as a luminescent medium, tellurite glass is prepared by a melt quenching method, the trace diamond nanoparticles are injected into glass liquid, fiber core glass is prepared, an optical fiber doped with NV color center diamondnanoparticles is drawn, and the NV color center is excited by a 532 nm solid laser to prepare the optical fiber type NV color center multiphoton source. On this basis, the multiphoton fiber with multiple color centers can be repeatedly cut in half and detected to prepare the optical fiber NV color center single photon source. The preparation method has low preparation cost, strong reliability andhigh portability.

Owner:LASER RES INST OF SHANDONG ACAD OF SCI

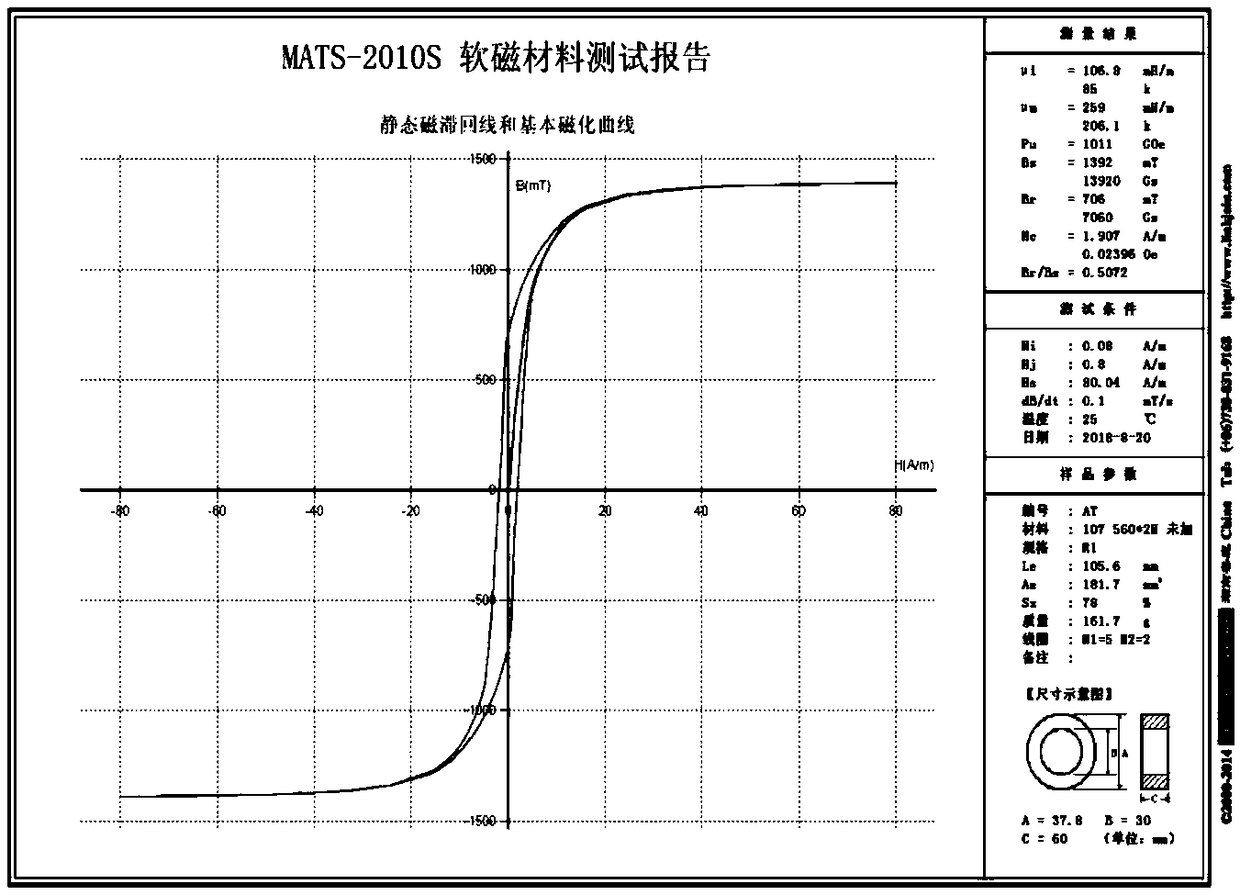

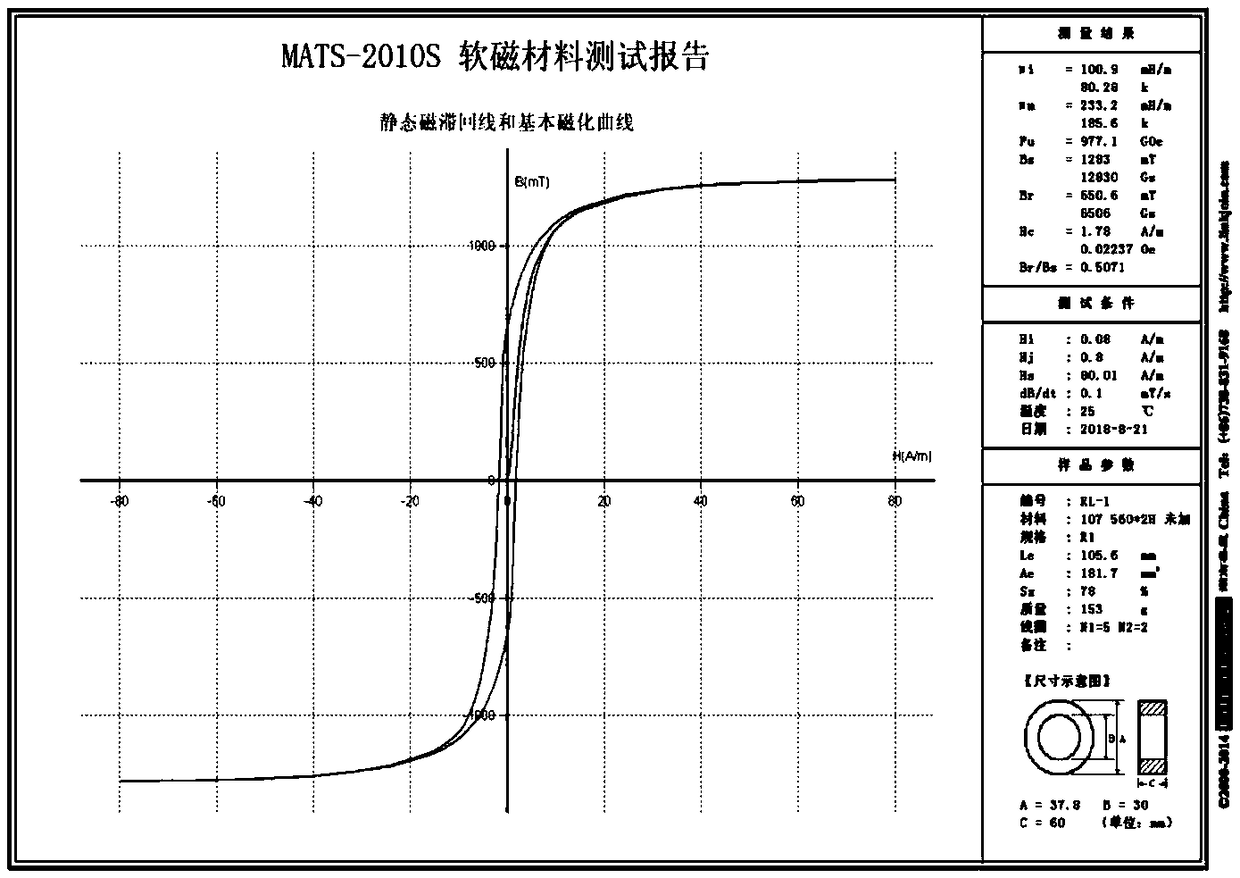

Low-loss nanocrystalline alloy soft magnetic material and preparation method thereof

The invention provides a low-loss nanocrystalline alloy soft magnetic material and a preparation method thereof. The alloy formula design is optimized, and V, N and a small quantity of rare earth element M are added on the basis of a national standard alloy component 1K107. A FeCuNbVSiBNM iron-based nanocrystalline alloy strip is prepared through proportioning, mother alloy preparation through steelmaking and secondary remelting by means of a single-roller melt quenching method. The low-loss nanocrystalline alloy soft magnetic material has the characteristics of high resistivity, low loss, high Bs value, high permeability, good flatness and the like.

Owner:DAYOU SCIENTFIC & TECHNICAL CO LTD

Method for preparing mixture of alumina based amorphous and solid solution ceramic micron powder by high temperature melt quenching method

The invention relates to a method for preparing a mixture of alumina based amorphous and solid solution ceramic micron powder by a high-temperature melt quenching method. The method solves the problems of low conversion rate of ceramic, long time, low output, high cost of ceramic amorphous object and non industrial production in the prior art can be solved; Al2O3 powder and diluent powder are uniformly mixed, the Al2O3 composite powder are fusion by high-temperature heating equipment, after insulation for a while, a quenching apparatus is used for cooling Al2O3 melt, and the Al2O3 melt is crushed to the mixture of alumina based amorphous and solid solution ceramic micron powder. The method has the advantages of simple process and large output, which belongs to the field of ceramic micron powder preparation.

Owner:HARBIN INST OF TECH

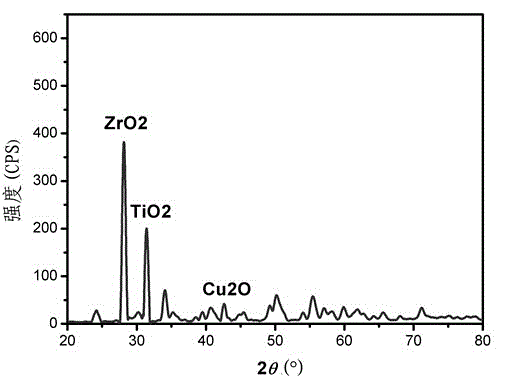

Preparation method of copper-containing metal composite oxide photocatalytic material

ActiveCN104445356ADoes not involve emissionsReduce usageCopper oxides/halidesElectric arc furnaceOxygen

The invention discloses a preparation method of a copper-containing metal composite oxide photocatalytic material. The preparation method comprises the following steps: putting copper and zirconium into a vacuum electric arc furnace, performing vacuum pumping, then charging argon, starting smelting, keeping for 60-90 seconds after copper and zirconium are smelted, cooling to obtain an alloy molten ingot, turning over, repeating for 4 to 6 times, putting the alloy molten ingot into rapid melt quenching and melt spinning equipment, performing vacuum pumping, then charging argon, performing smelting by adopting a magnetic induction heating mode to form a melt after completely melting, opening an air pressure valve, spraying the melt on the surface of a copper roller which rapidly rotates to obtain a continuous amorphous alloy ribbon, and putting the amorphous alloy ribbon into a ceramic cup, wherein the ceramic cup comprises a ceramic base, the ceramic base is connected with a ceramic cup cover, the ceramic cup cover is provided with an air inlet hole, an observation view window and a graphite electrode, and the ceramic base is in sliding connection with an ignition graphite electrode; and connecting one end of the amorphous alloy ribbon with the graphite electrode, charging oxygen, then pushing the ignition graphite electrode to the amorphous alloy ribbon, and enabling the ignition graphite electrode to be in contact with the amorphous alloy ribbon to generate electric sparks for igniting an alloy strip material.

Owner:SOUTHEAST UNIV

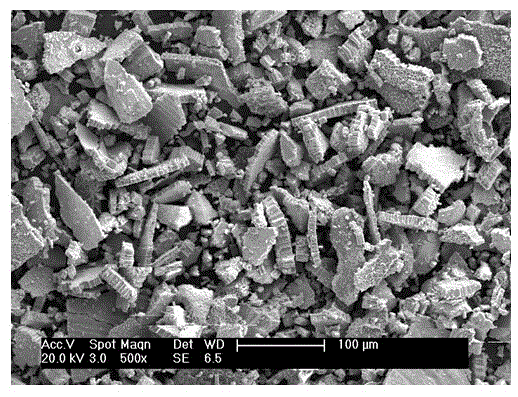

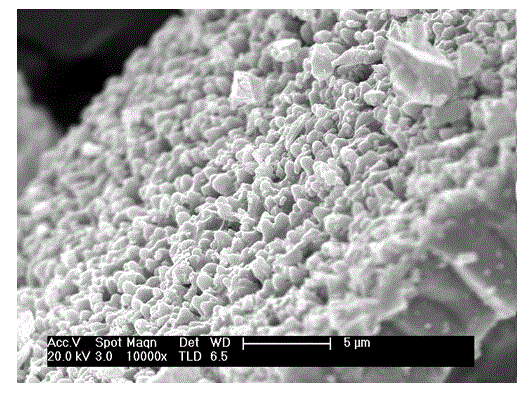

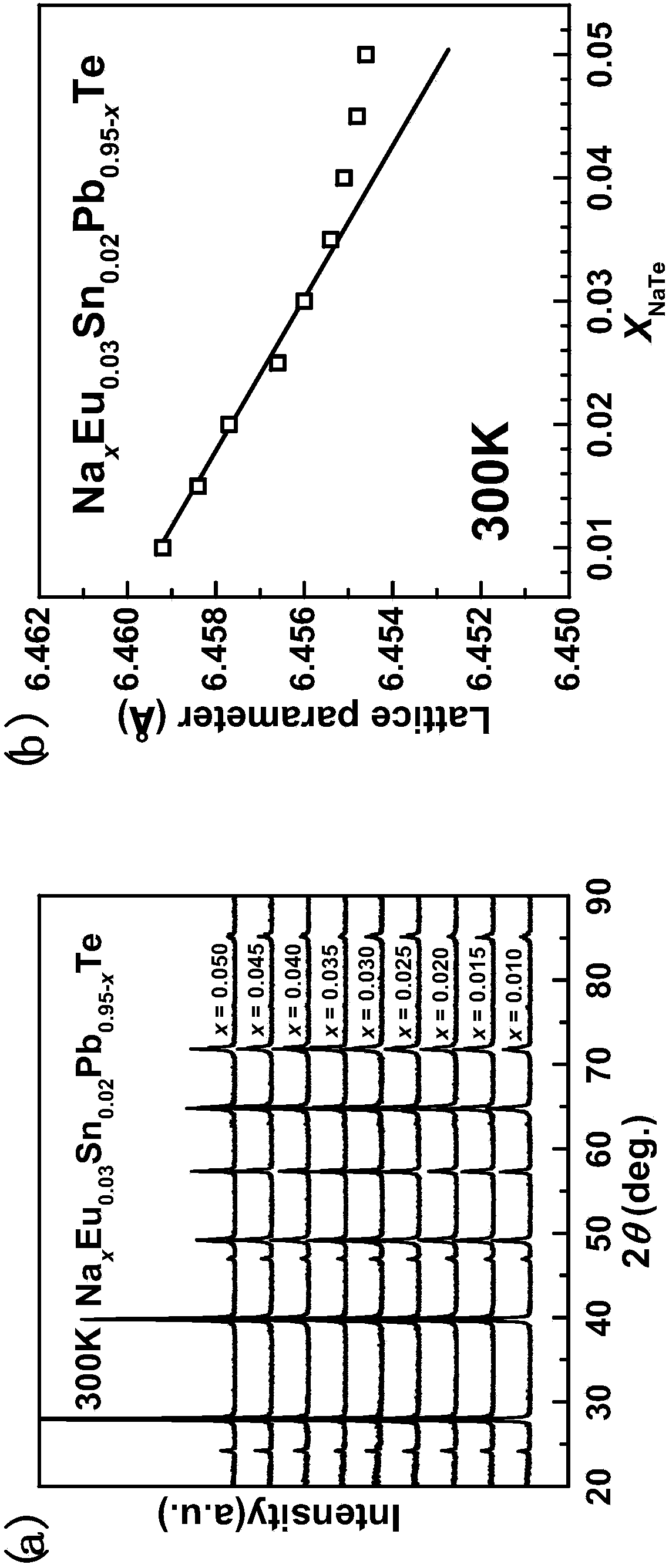

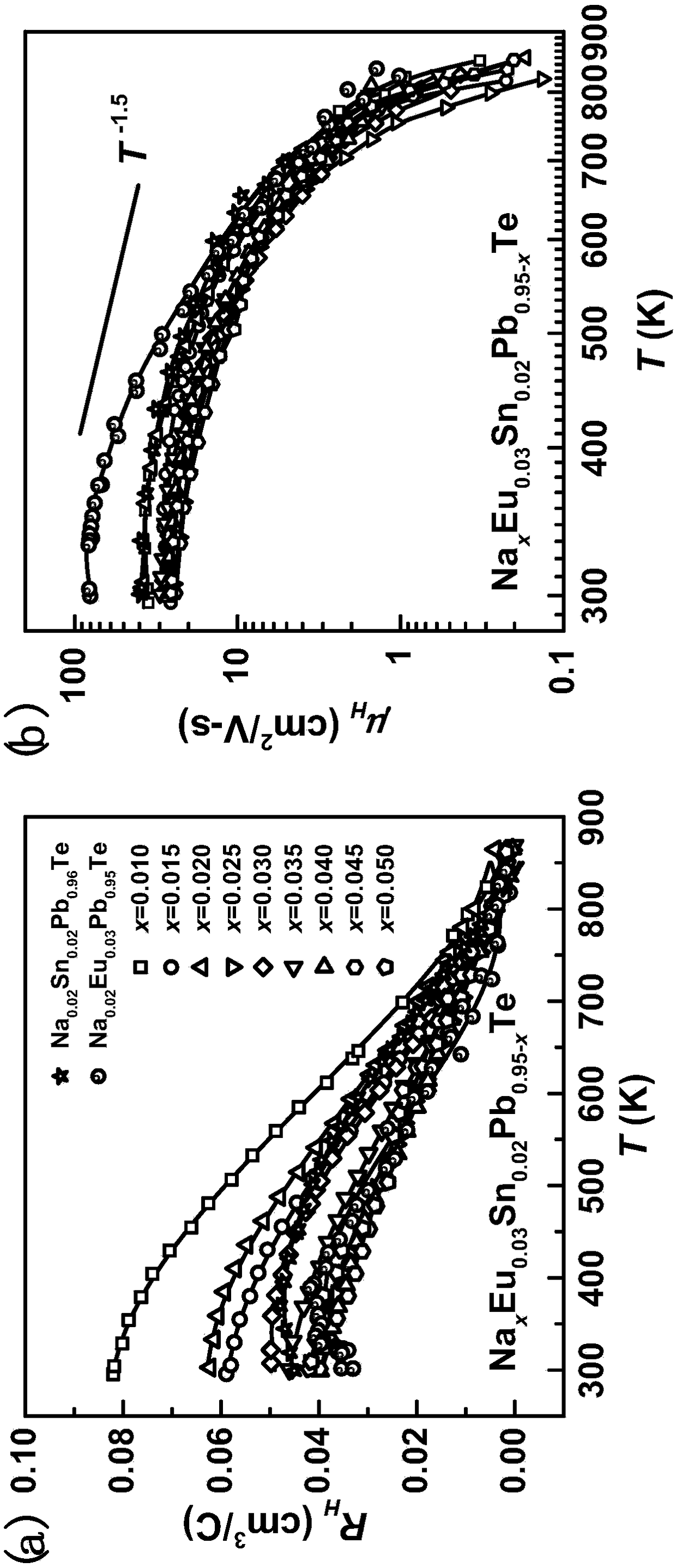

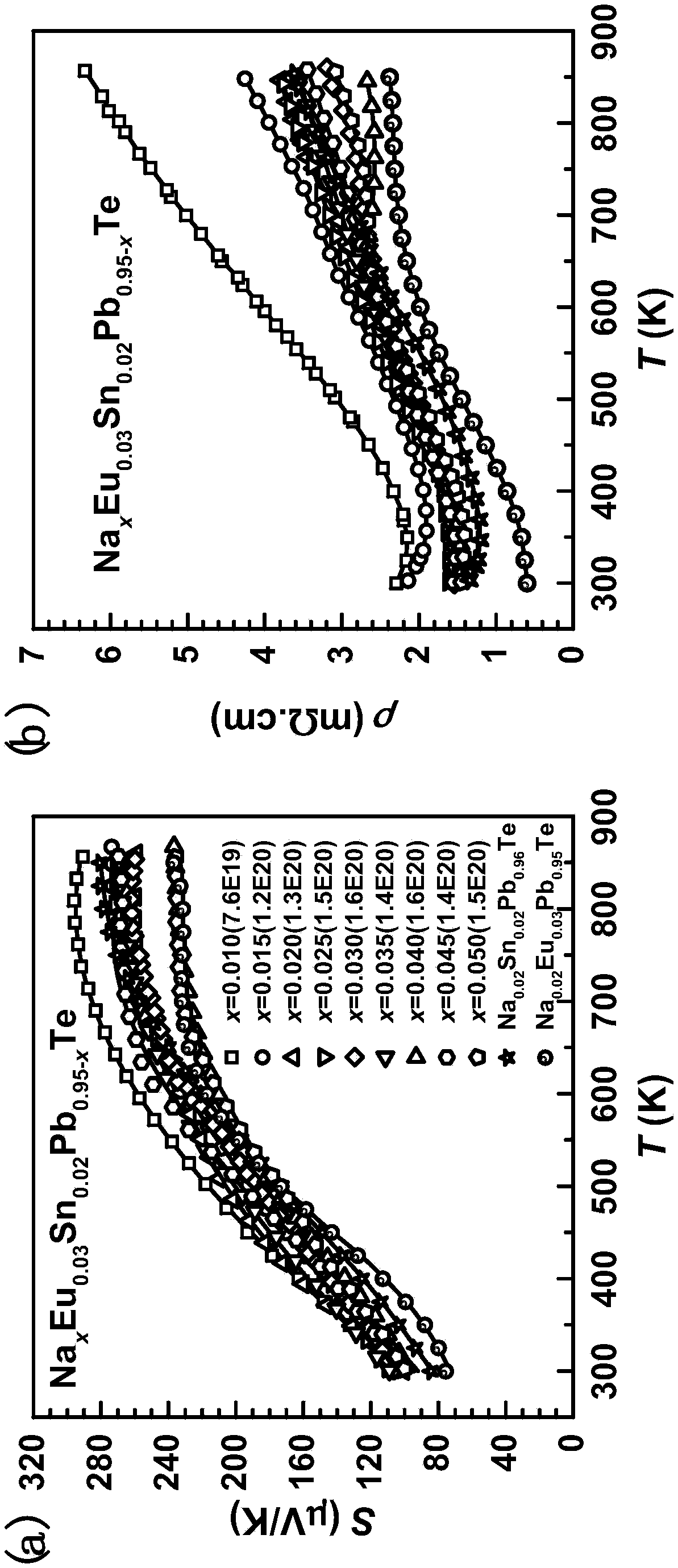

High-performance PbTe-based solid solution thermalelectric material and preparation method thereof

ActiveCN108516526ALow thermal conductivityHigh densityMetal selenides/telluridesBinary selenium/tellurium compoundsThermoelectric materialsHigh density

The invention relates to a high-performance PbTe-based solid solution thermalelectric material and a preparation method thereof. The chemical formula of the thermalelectric material is NaxEu0.03Sn0.02Pb0.95-xTe, wherein x is equal to 0.01-0.05, during preparation, simple substance raw materials Na, Eu, Sn, Pb and Te are weighed according to the stoichiometric proportion and subjected to vacuum encapsulation, then primary melt quenching and secondary heat treatment quenching are sequentially conducted, and finally, a target product is obtained through a hot pressed sintering method. Compared with the prior art, the low-thermal conductivity high-performance thermalelectric material is prepared, the method for preparing the thermalelectric material with high density, high mechanical strengthand high thermalelectric property is explored, and the thermalelectric peak value zT of the thermalelectric material at the temperature of 850 K reaches 2.6, so that the thermalelectric material is ahigh-performance thermalelectric material with a tremendous potential.

Owner:TONGJI UNIV

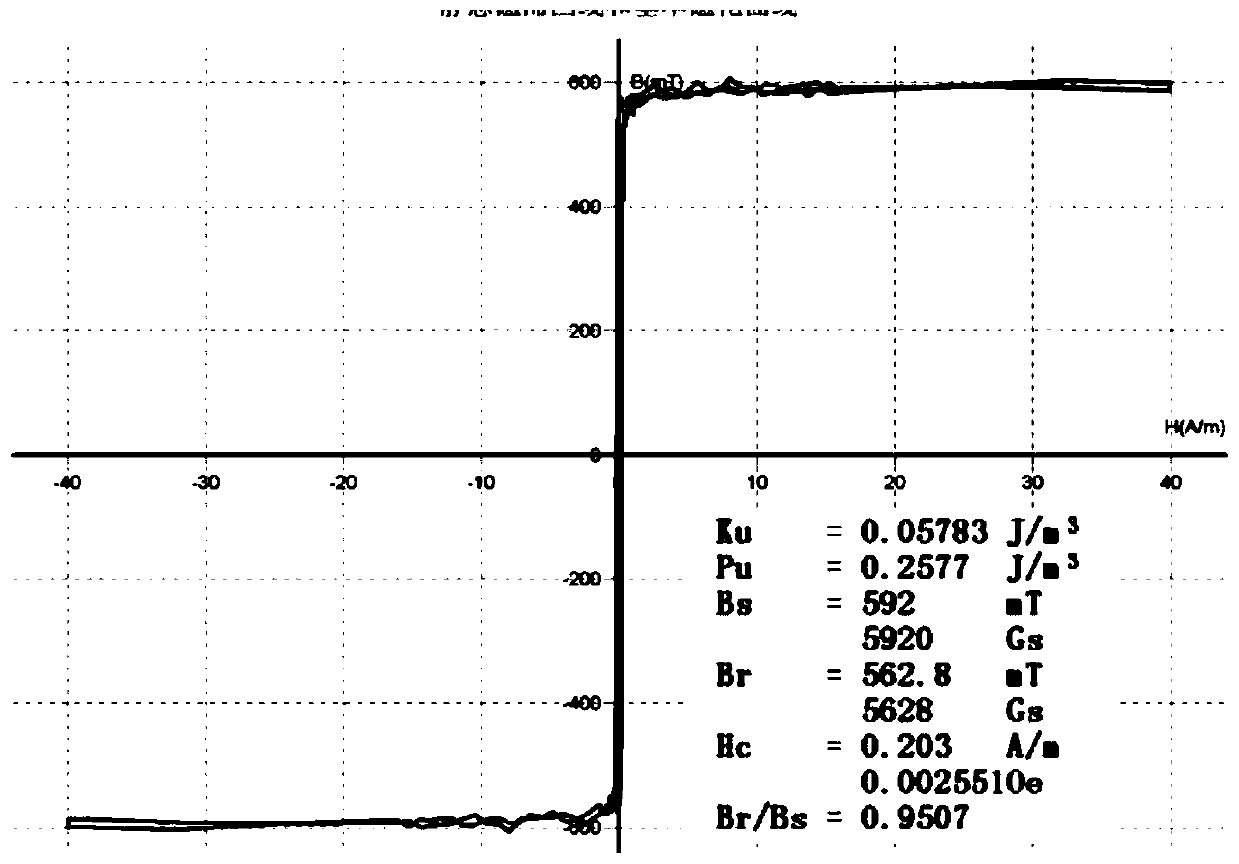

High-squareness cobalt-based amorphous alloy iron core and preparation method thereof

ActiveCN110400670AHigh saturation magnetic inductionReduce lossMagnetic materialsMagnetic core manufactureRare-earth elementSteelmaking

The invention discloses a high-squareness cobalt-based amorphous alloy iron core and a preparation method thereof. The high-squareness cobalt-based amorphous alloy iron core comprises the following components: by atomic mass percentage, 2 to 4% of Fe, 1 to 2% of Mn, 2 to 4% of Mo, 10 to 13% of Si, 11 to 13% of B, 0 to 0.5% of W and the rest being Co, wherein W is Tb or La or a mixture of Tb and La. By optimizing the alloy formulation design, by adding a small amount of rare earth element W, master alloy is prepared through batching and steelmaking, a single-roller melt quenching method is usedafter secondary remelting to prepare a cobalt-based amorphous alloy magnetic core, the high squareness is kept to be Br / Bs no smaller than 90, the low coercive force Hc is smaller than 0.3A / m, the temperature stability is high, and high Bs value and high magnetic permeability are achieved.

Owner:DAYOU SCIENTFIC & TECHNICAL CO LTD

Rare earth doped porous oxyfluoride silicate glass ceramic and preparation method thereof

InactiveCN105152537AChange photoluminescent colorEasy to preparePhotoluminescenceFrequency conversion

The invention relates to rare earth doped porous oxyfluoride silicate glass ceramic and a preparation method thereof and belongs to the technical field of photoluminescence. A rare earth doped glass frequency conversion luminescent material is prepared from raw materials in mole percentage as follows: 30%-55% of SiO2, 5%-30% of Al2O3, 10%-30% of BaF2, 10%-30% of Na2O, 0%-3% of YbF3, 0%-3% of Yb2O3, 0%-0.8% of Tb2O3, 0%-0.8% of TbF3, 0%-0.6% of Ho2O3 and 0%-0.6% of HoF3. According to the preparation method, porous oxyfluoride silicate glass is prepared firstly with a melt quenching method, porous matrix glass is subjected to thermal treatment, and the porous oxyfluoride silicate glass ceramic is obtained. The prepared rare earth doped porous oxyfluoride silicate glass ceramic has the characteristics of local microcrystalization or crystallization to change the photoluminescence color of a microcrystalization or crystallization area, that is, dark red of the matrix glass is turned to bright green after crystallization for up-conversion luminescence; the preparation method for preparing the rare earth doped porous oxyfluoride silicate glass ceramic is simple, and the production cost is lower.

Owner:KUNMING UNIV OF SCI & TECH

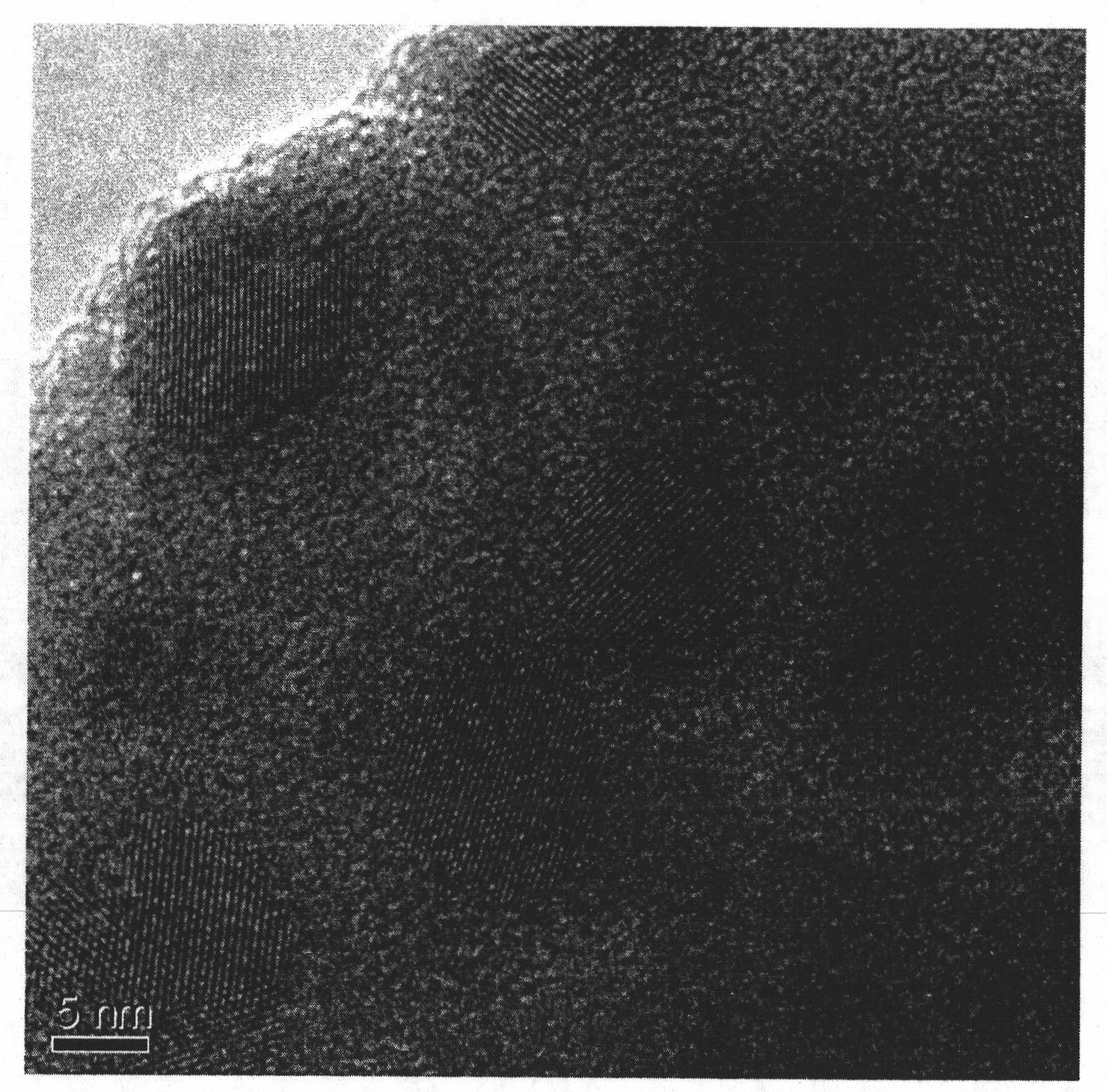

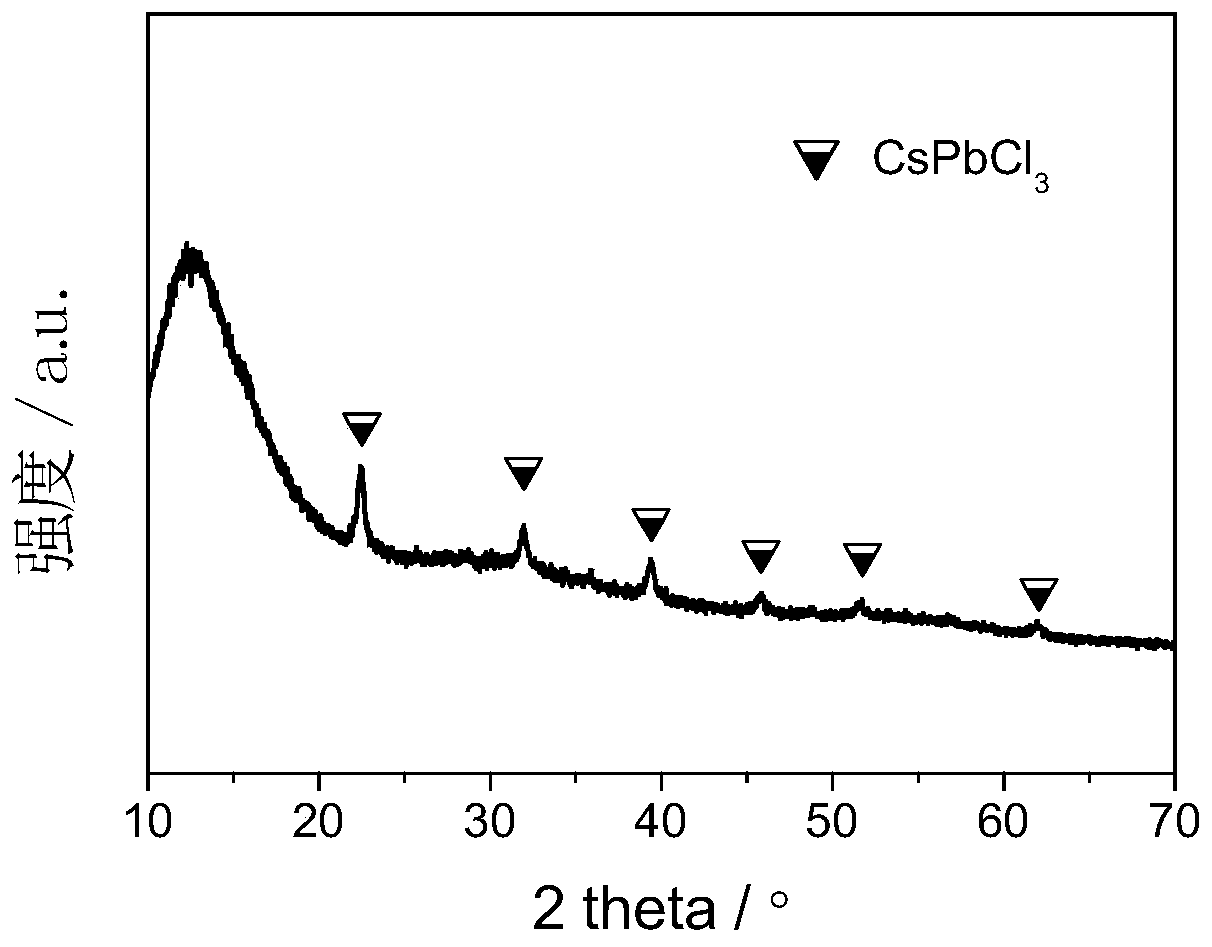

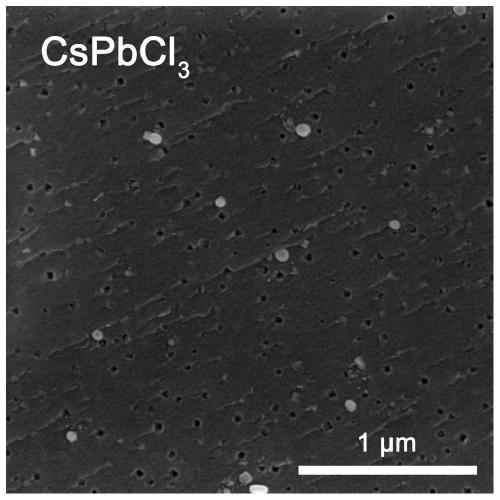

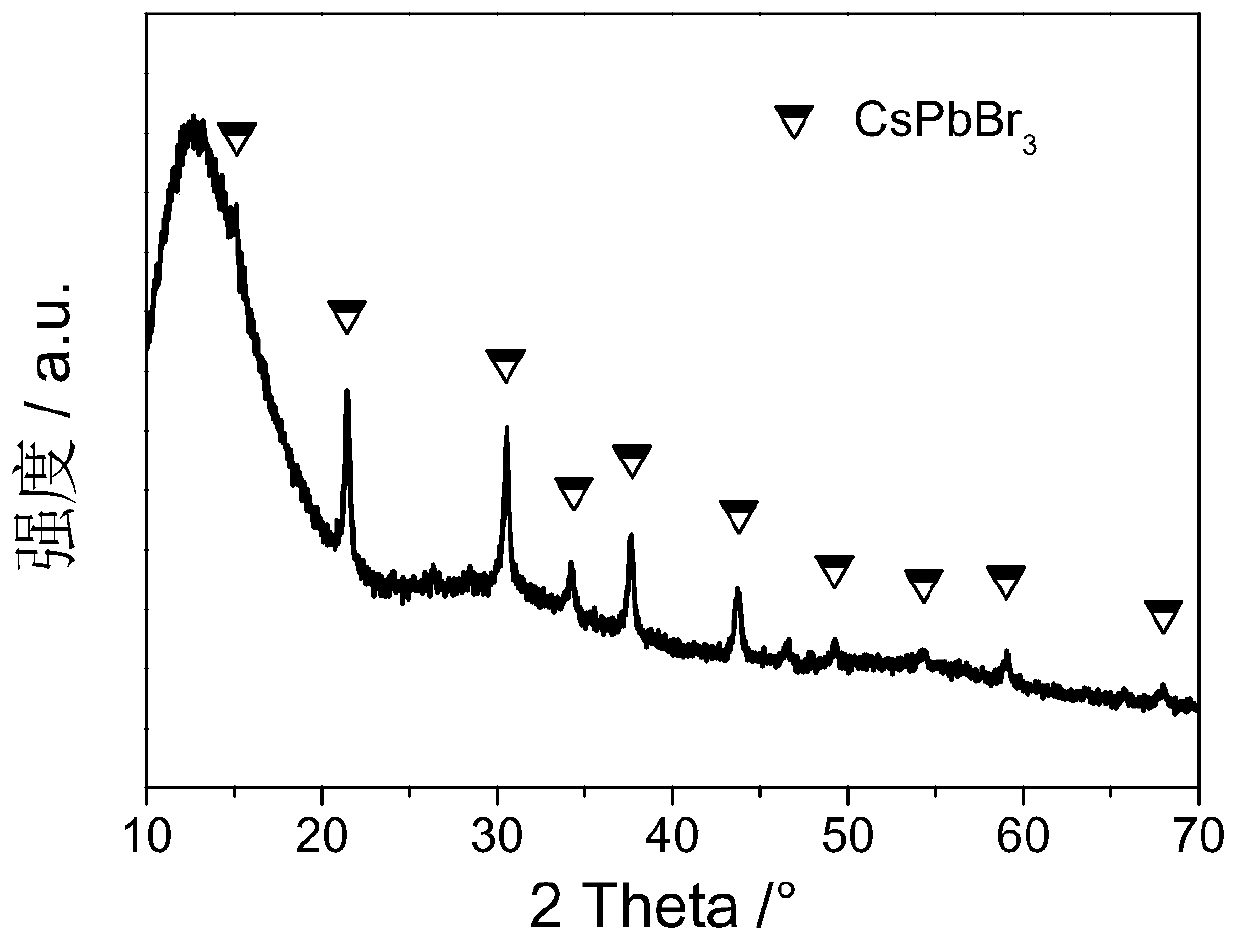

Inorganic lead-cesium halide nanocrystalline composite chalcogenide glass ceramic material and preparation method thereof

ActiveCN109928640AHigh thermodynamic stabilityImprove impact performanceGlass furnace apparatusChalcogenide glassQuenching

The molar composition of the inorganic lead-cesium halide nanocrystalline composite chalcogenide glass ceramic material disclosed by the invention is shown as a chemical formula, (1-x-y-z)GeS2.XSb2S3.YGa2S3.ZCsPbX3, wherein x = 0.15-0.75, y = 0.05-0.2, z = 0.05-0.1, and X is Cl, Br or I; and CsPbX3 is compounded in the chalcogenide glass ceramic material in the form of separated nanocrystalline. The material is transparent in a spectral range of 2-10 micrometers and has good thermal and chemical stability and good fracture toughness, so that the material is suitable for rare earth ion doping to research and develop novel mid-infrared light-emitting or laser materials and related quantum dot light-emitting materials. The preparation method of the material comprises the following steps: by taking GeS2-Sb2S3-Ga2S3 as a glass matrix, adding a CsPbX3 component which is nearly saturated; preparing basic chalcogenide glass by a melting quenching method; and performing crystallization heat treatment so that CsPbX3 nanocrystals are controllably separated out. According to the preparation method of the material, proper glass composition can be designed and selected according to functional requirements, so that the size and distribution of precipitated CsPbX3 crystal grains are controlled.

Owner:NINGBO UNIV

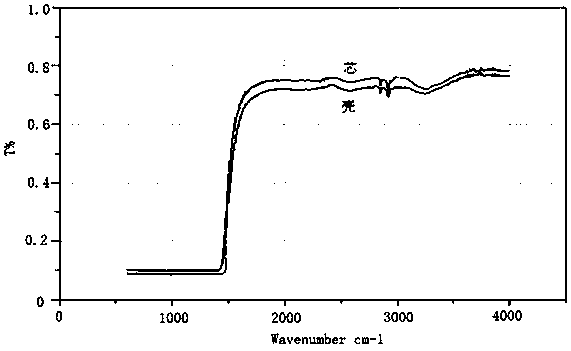

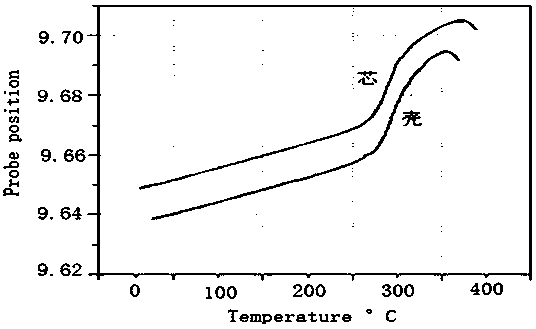

Anti-magnetic glass system for preparation of single-mode magneto-optic glass fiber

The invention discloses an anti-magnetic glass system for the preparation of a single-mode magneto-optic glass fiber. The system is based on a TeO2 and PbO glass network body, and through the stable B2O3 and SiO2 glass structure, the glass performance parameter is improved. The glass components of a core and a shell refer to (58.8-60 mol%)TeO2-(39.2-40 mol%)PbO-(0-2 mol%)B2O3 and (56-57 mol%)TeO2-(36-38 mol%)PbO-(0-4 mol%)B2O3-(0-3 mol%)SiO2. The glass is prepared through a melt quenching process at 900-1000 DEG C. The Faraday coefficient (0.2-0.25min / Oe.cm) of the system is large, the systemhas no temperature dependence, visible light and infrared light transmittance is larger than 70%, the thermal stability is larger than 100 DEG C, and the system meets the matching requirements of magneto-optic glass fiber cores and shell glass for the linear thermal expansion coefficient, the refractive index and the glass transition temperature.

Owner:HENAN UNIVERSITY OF TECHNOLOGY

Synthetic ceramic tile and method for producing the same

InactiveUS20090291276A1Improve the decorative effectImprove performancePretreated surfacesCeramic layered productsMelt quenchingTitanium

A method for producing synthetic ceramic tile, including at least providing a ceramic tile, coating a coating on the ceramic tile, the coating containing at least an aluminum pigment and / or at least a titanium-mica pearlescent pigment, and drying a liquid coating deposited on the ceramic tile, or melt-quenching or melt-curing a powder coating deposited on the ceramic tile. The synthetic ceramic tile has a metallic or pearl color, which improves its decorative effect.

Owner:FENG JIANSHENG

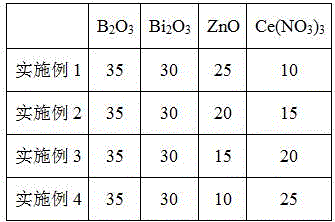

Ce-containing low-temperature sealing glass as well as preparation and application method of Ce-containing low-temperature sealing glass

The invention discloses Ce-containing low-temperature sealing glass as well as preparation and application method of the Ce-containing low-temperature sealing glass. The Ce-containing low-temperature sealing glass consists of the following raw materials: B2O3, Bi2O3, ZnO and Ce(NO3)3 in a molar ratio of (10-50):(20-40):(5-30):(0-30). Through the coordination between high-concentration Bi2O3 and B2O3, the softening temperature of glass is lowered, so that low-temperature sealing is realized; Ce<3+> in a glass network prepared by melting quenching is transformed into Ce<4+>, the transformation of Bi<3+> in glass into Bi<5+> is prevented, and the refractive index of glass is stabilized; and Ce not only can further lower the softening temperature of the sealing glass, but also can adjust the expansion factor of the glass so as to remarkably improve the sealing property of the sealing glass. Moreover, Ce remarkably reduces the surface tension of the glass, improves the interface bonding property between the sealing glass and an alloy connector and is applicable to the field of photoelectric materials and other low-temperature precise sealing. According to the invention, the preparation raw materials are simple and easily available, the cost is low, the technology is simple and feasible, and the prepared low-temperature sealing glass has good performance and stable refractive index and meets the conditions of practical utilization and industrialization.

Owner:FUZHOU UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com