Chalcogenide microcrystalline glass material with function of lithium ion conductor and preparation method thereof

A technology of glass-ceramic and ion conductor, applied in the field of chalcogenide glass-ceramic and its preparation, can solve unseen problems, achieve high lithium ion conductivity, improve atmospheric erosion resistance and thermodynamic performance, and improve atmospheric erosion resistance effect of ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

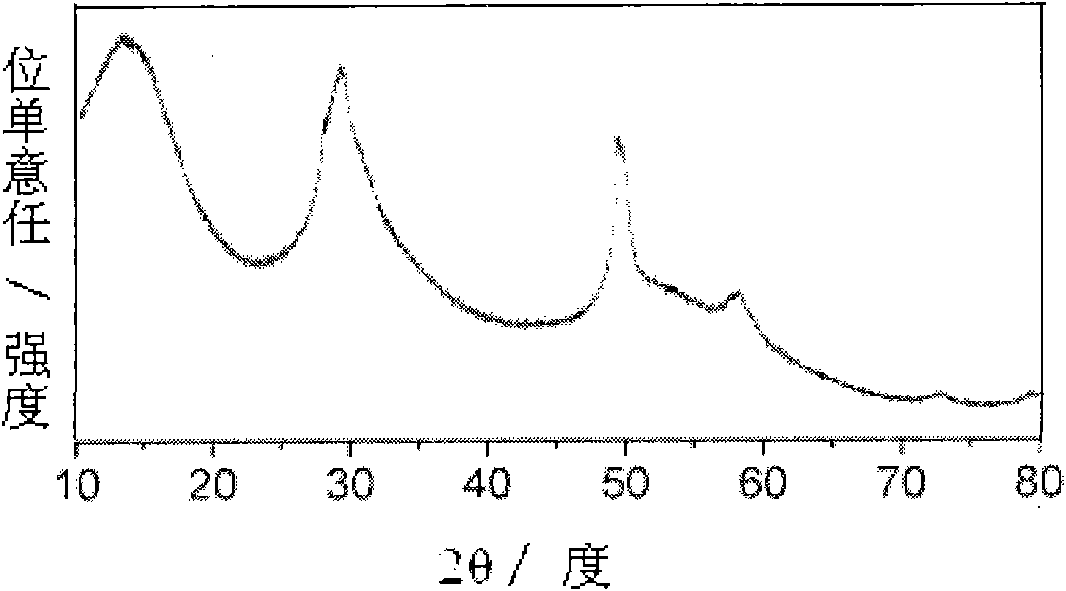

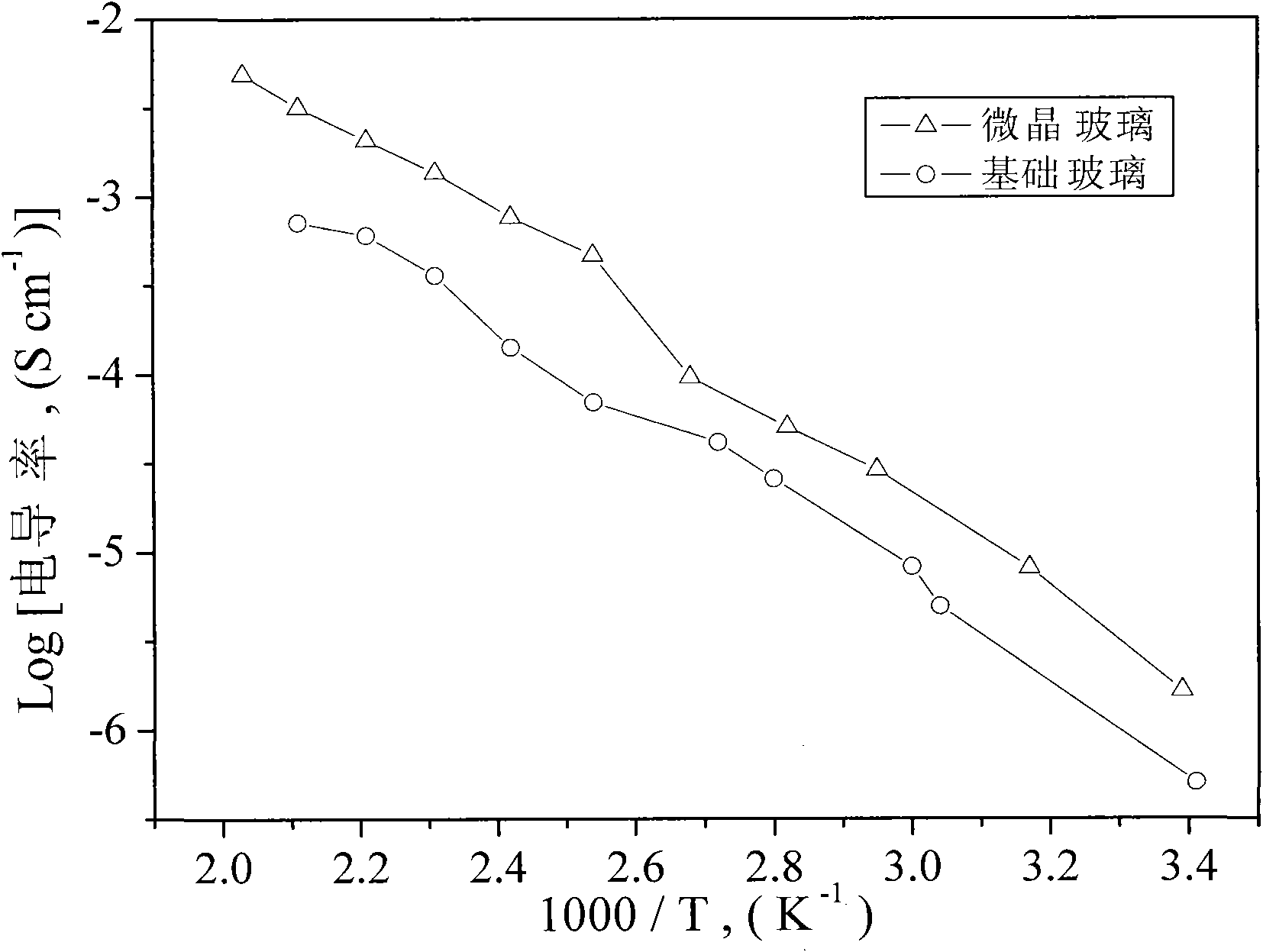

[0024] A chalcogenide glass-ceramic material with the function of lithium ion conductor, its molar composition is expressed as: 56GeS 2 24Ga 2 S 3 · 20LiI.

[0025] The specific preparation method is as follows:

[0026] 1). Select raw materials: according to 56GeS 2 24Ga 2 S 3 20LiI selects elemental Ge, Ga, S and compound LiI raw materials, the purity of elemental Ge, Ga, S and compound LiI are respectively ≥ 99.999%, and it is used for later use;

[0027] 2).In an environment full of inert gas, mix Ge, Ga, S and compound LiI raw materials, after grinding and mixing to make batches, put them in a container and vacuumize, the vacuum degree is 10 -3 ~10 -6 Pa, then seal the container and place it in a heating device;

[0028] 3). Preparation of the basic glass: heat the container containing the batch material in step 2), first slowly raise the temperature to 595°C-605°C at a rate of less than 3°C / min, and keep it at this temperature for 3-5 hours, Then heat up to 900-...

Embodiment 2

[0036] A chalcogenide glass-ceramic material with the function of lithium ion conductor, its molar composition is expressed as: 65GeS 2 25Ga 2 S 3 · 10LiI.

[0037] The specific preparation method is as follows:

[0038] 1). Select raw materials: according to 65GeS 2 25Ga 2 S 3 10LiI, select elemental Ge, Ga, S and compound LiI raw materials, the purity of elemental Ge, Ga, S and compound LiI are respectively ≥ 99.999% (mass), and set aside;

[0039] 2). Carry out according to embodiment 1 of 2).

[0040] 3). Carry out according to embodiment 1 of 3).

[0041] 4). Carry out according to embodiment 1 of 4).

[0042] 65 GeS 2 25Ga 2 S 3 Determination of the glass transition temperature of 10LiI base glass: Obtain the differential thermal curve at a heating rate of 10°C / min through a differential calorimeter, and then find out the start temperature of the glass transition of 402°C and the end temperature of 418°C by extrapolating the tangent method , and the midpoint ...

Embodiment 3

[0048] A chalcogenide glass-ceramic material with the function of lithium ion conductor, its molar composition is expressed as: 65GeS 2 20Ga 2 S 3 · 15LiI.

[0049] The specific preparation method is as follows:

[0050] 1). Select raw materials: according to 65GeS 2 20Ga 2 S 3 15LiI, select elemental Ge, Ga, S and compound LiI raw materials, the purity of elemental Ge, Ga, S and compound LiI are respectively ≥ 99.999% (mass), and set aside;

[0051] 3). Carry out according to embodiment 1 of 3).

[0052] 4). Carry out according to embodiment 1 of 4).

[0053] 65 GeS 2 20Ga 2 S 3 Determination of the glass transition temperature of 15LiI base glass: Obtain the differential thermal curve at a heating rate of 10°C / min through a differential calorimeter, and then use the extrapolation tangent method to find the glass transition start temperature of 371°C and end temperature of 389°C , and take the midpoint temperature of 380°C between the start temperature and the end ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Coefficient of expansion | aaaaa | aaaaa |

| Coefficient of expansion | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com